DC motor with commutator and its driven washing machine

A technology of DC motors and commutators, applied in the field of washing machines, can solve problems such as unavoidable overvoltage, complicated reliability and cost of brush machinery and circuit structures, and inability to meet the freewheeling time, etc., and achieve a firm mechanical and circuit structure Simple, excellent speed regulation characteristics, and the effect of improving life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

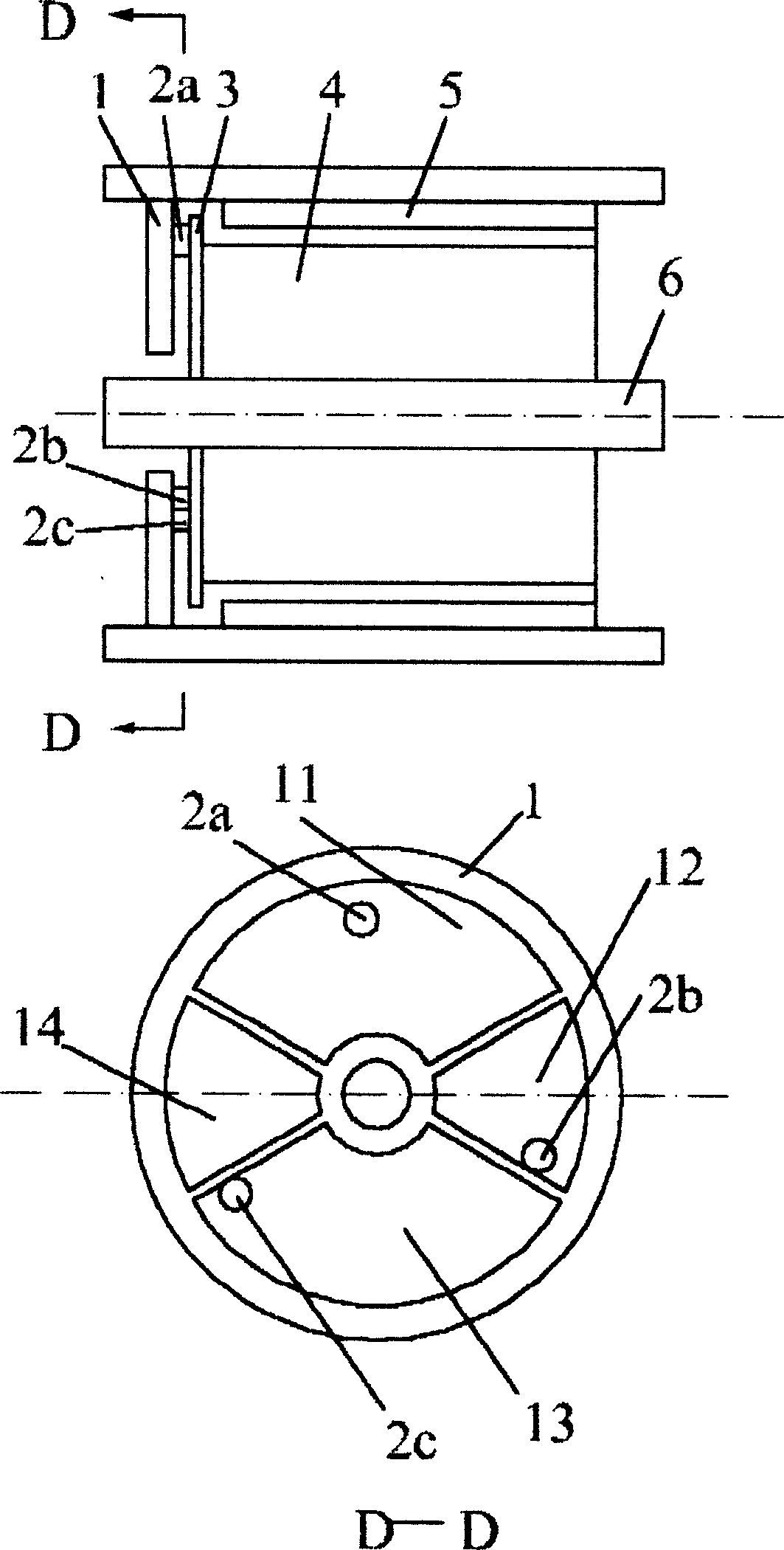

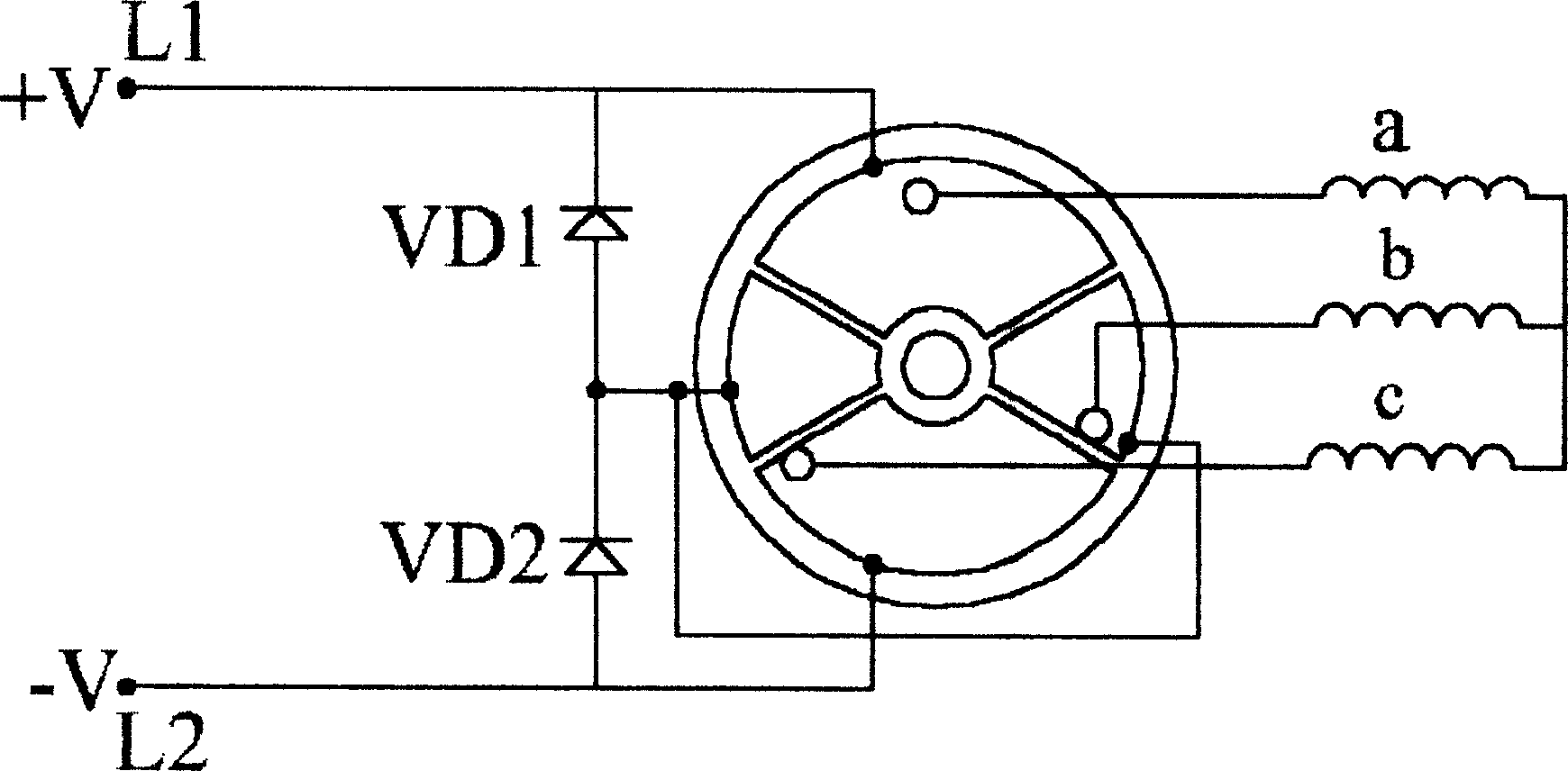

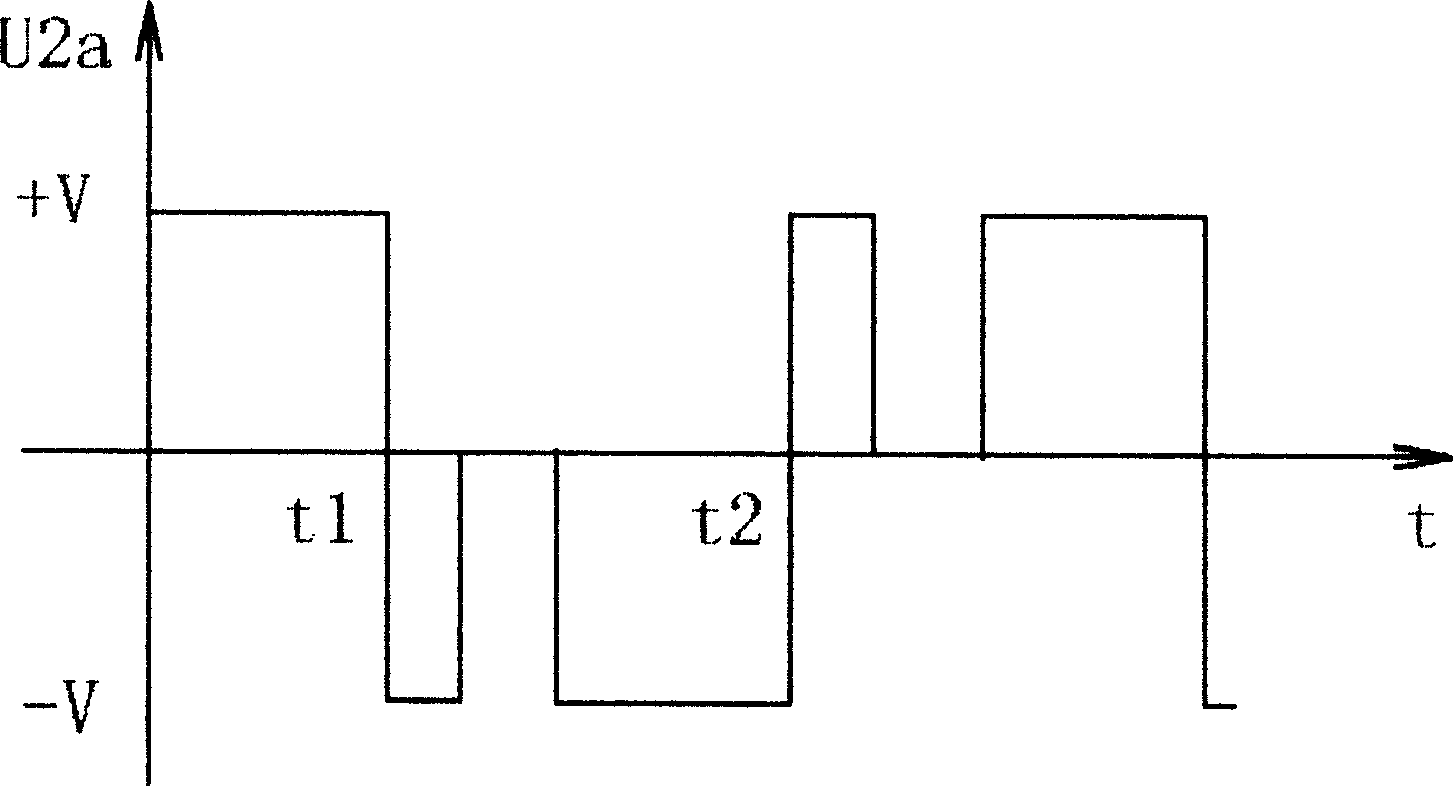

[0037] The working process of the embodiment DC motor can refer to image 3 The waveform of the potential U2a of the brush 2a shown:

[0038] The rotor drives the brush plate 3 to rotate clockwise, the brush 2a first contacts the positive pole commutator piece 11, U2a is the potential +V of the positive pole L1 of the power supply device; at the time t=t1, it rotates until it contacts the freewheeling commutator piece 12, maintaining The induced electromotive force in the original current direction makes the semiconductor diode VD2 conduct, and U2a changes to the potential -V of the negative pole L2 of the power supply device, until the freewheeling is completed to 0; it continues to rotate until it contacts the negative commutator piece 13, and U2a is the negative pole L2 of the power supply device. At the moment t=t2, it rotates to contact the freewheeling commutator 14, the induced electromotive force makes the semiconductor diode VD1 conduct, and U2a changes from -V to +V ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com