Variable-speed three-phase asynchronous motor

A three-phase asynchronous motor technology, applied to asynchronous induction motors, electrical components, electromechanical devices, etc., can solve the problems of reducing the power factor of the input circuit of the frequency converter, grid pollution, and easy failures, to overcome the increase in operating costs, Wide range of speed regulation, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

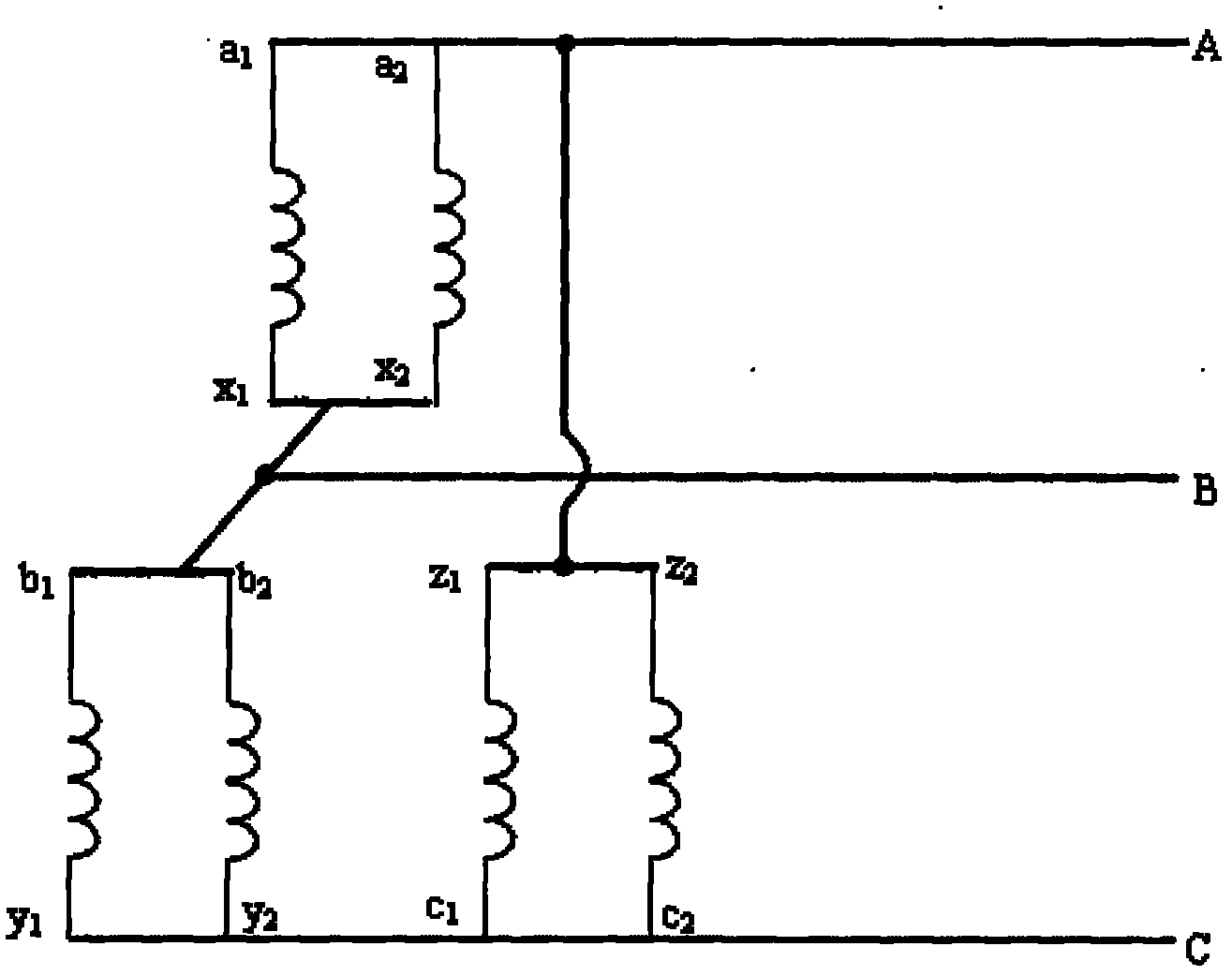

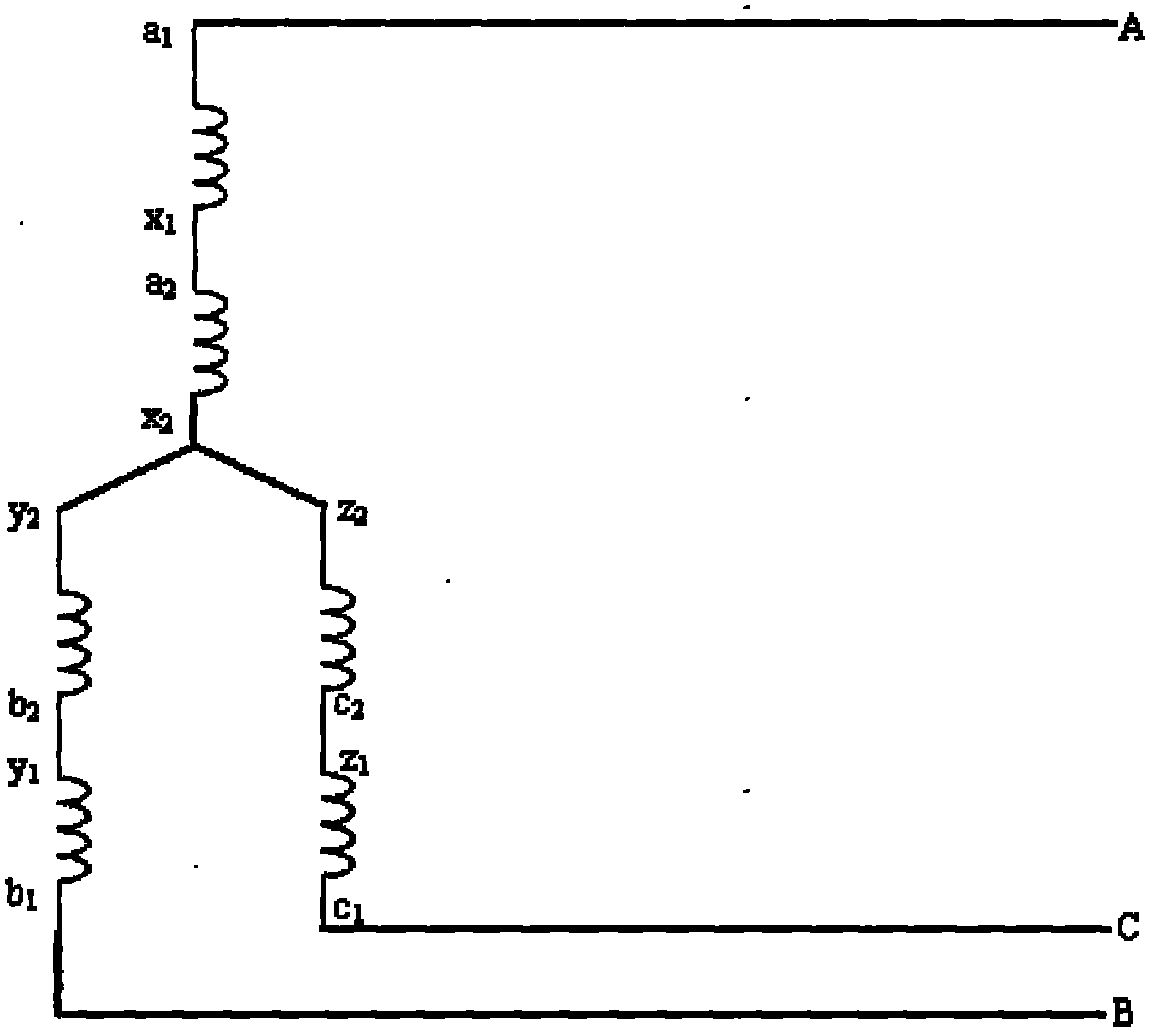

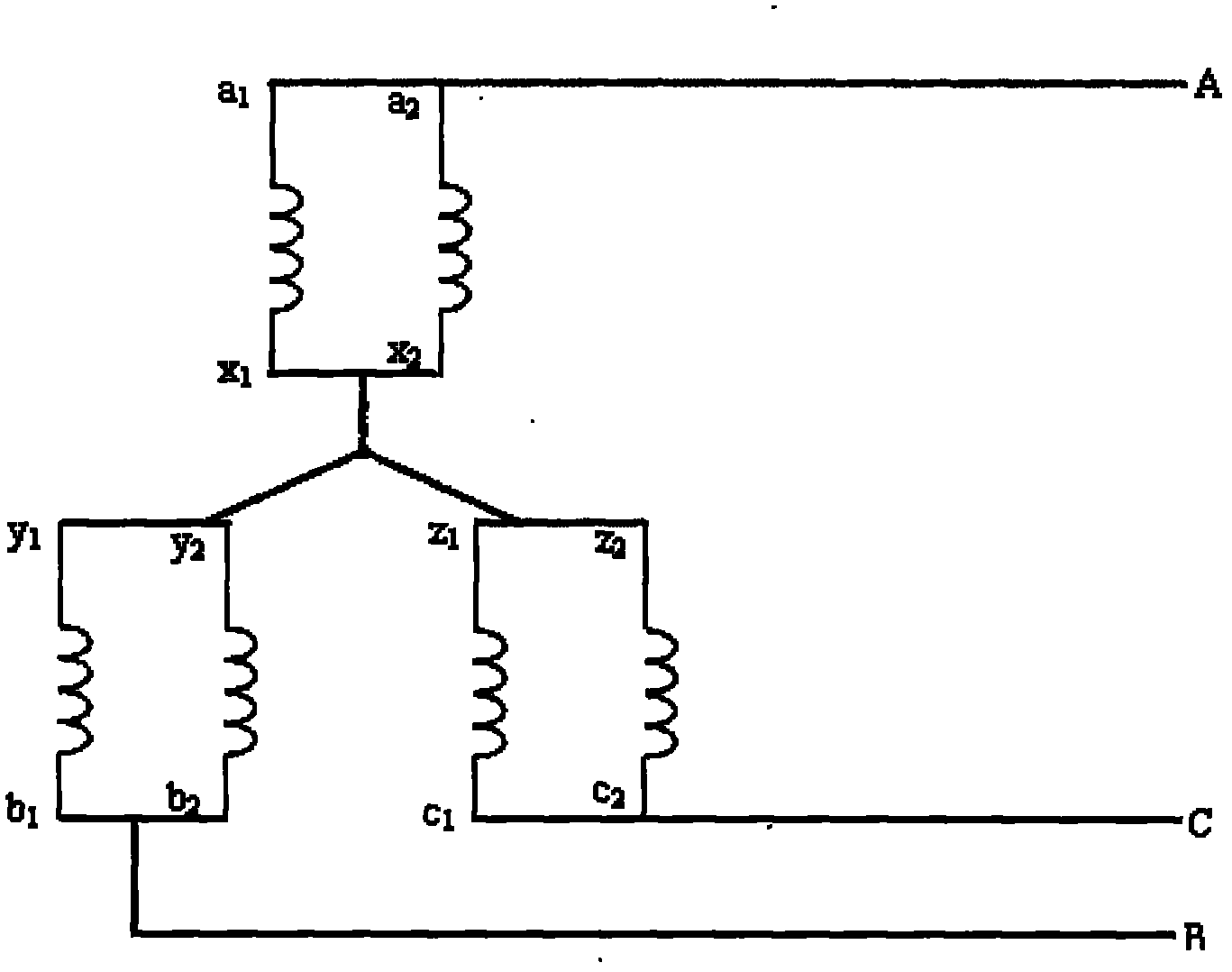

[0033] Implementing a multi-speed three-phase asynchronous motor described in the present invention is based on the existing three-phase asynchronous motor, by changing the connection method of the three-phase stator winding and the connection method of the phase winding group winding to realize the three-phase asynchronous motor Multi-speed operation, now take the four-speed motor as an example to explain as follows:

[0034] The four-speed motor of the present invention is high-speed, sub-high speed, sub-low speed and low speed, and its specific implementation method is: the stator winding of the motor is composed of two sub-windings, and the wire diameters, turns and distribution rules of the two sub-windings are the same, The distribution pattern, number of poles, and pitch of the windings are the same as those of the general series of three-phase asynchronous motors, and no special design is required. The drive equipment requirements are determined.

[0035] Such as fig...

specific Embodiment approach 2

[0048] Implementation of single-winding 8-speed three-phase asynchronous motor: stator slot number 36, 6 poles, 3 phases, capacity 1.1kW, rotor slot number 42, cast aluminum rotor, stator each phase has three sub-windings 1, 2, 3, 1 138 conductors per slot for No. 2 winding, 0.45mm wire diameter, single-layer chain winding; 50 conductors per slot for No. 3 winding, 0.45mm wire diameter. The outlet box is equipped with a terminal block, and each phase has 6 outlet terminals, each of which is represented as the first and last ends of windings 1, 2, and 3, and the first and last ends of the sub-windings are connected in parallel. The first end is used as the first end of the phase winding, and the first end is used as the end of the phase winding. When sub-windings 1 and 2 are connected in series, the end of sub-winding No. 1 is connected to the head of sub-winding No. 2, the head of sub-winding No. 1 is used as the first end of phase winding, and the end of sub-winding No. 2 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com