Piezo-electricity ultrasound and electromagnet integration driven electric motor

An integrated piezoelectric and electromagnetic hybrid technology, applied in the direction of piezoelectric effect/electrostrictive or magnetostrictive motors, generators/motors, electrical components, etc. , difficulty in speed regulation, etc., to achieve the effect of compact structure, wide speed regulation range and small electrical time constant

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

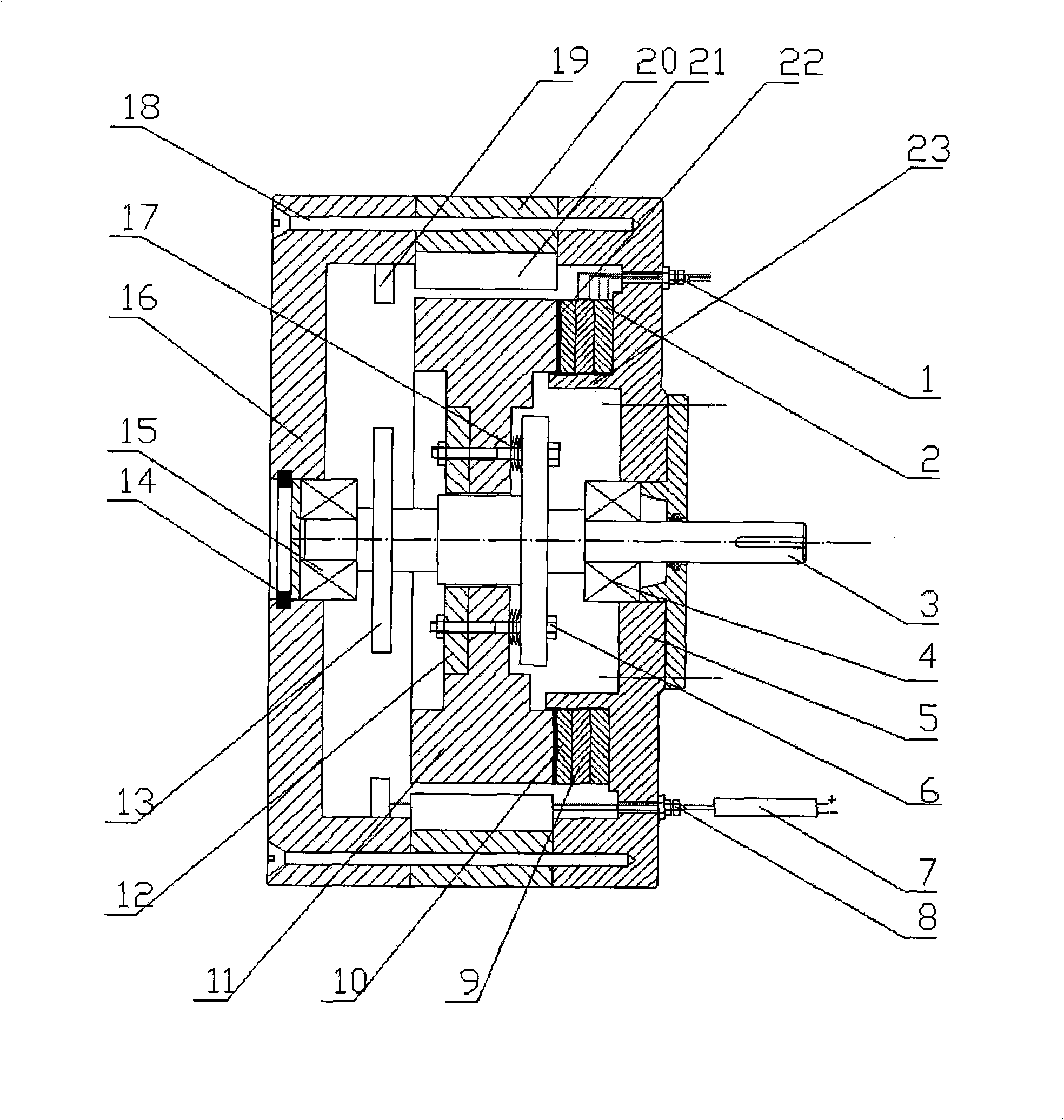

[0018] A motor driven by an integrated piezoelectric ultrasonic and electromagnetic hybrid as shown in the attached figure.

[0019] One end of the output shaft 3 is supported on the rear end cover bearing 15 of the motor rear end cover 16, positioned with the shaft end retaining ring 14, and the other end of the output shaft 3 is supported on the front cover bearing 4 of the motor front end cover 5, and the two end covers Silicon steel sheets 20 are installed in between and connected into a whole with connecting screws 18 to constitute the installation space of the entire motor; electromagnetic stator windings 21 are wound on the silicon steel sheets 20, and the multiplexed rotor is installed on the output shaft 3 collar facing the electromagnetic stator windings 21 11. The electromagnetic drive coil terminal 8 is installed on the front end cover 5 of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com