Patents

Literature

38results about How to "With speed control function" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Unmanned aerial vehicle type automatic sampling system at fixed points of water surface

InactiveCN104458329ASimple structureLow manufacturing costWithdrawing sample devicesElectric machinerySelf locking

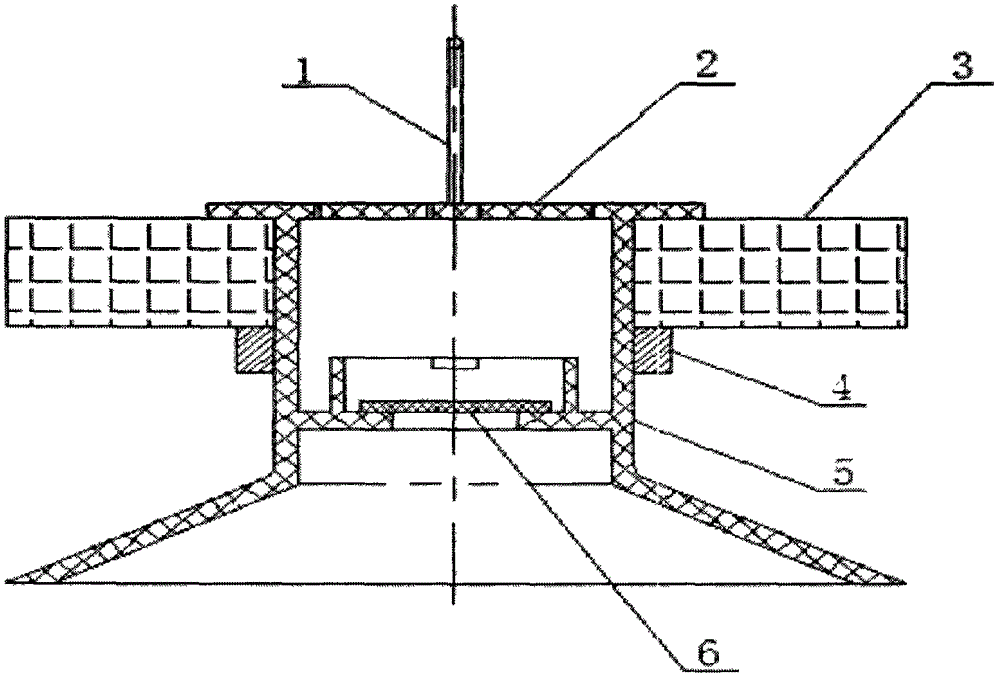

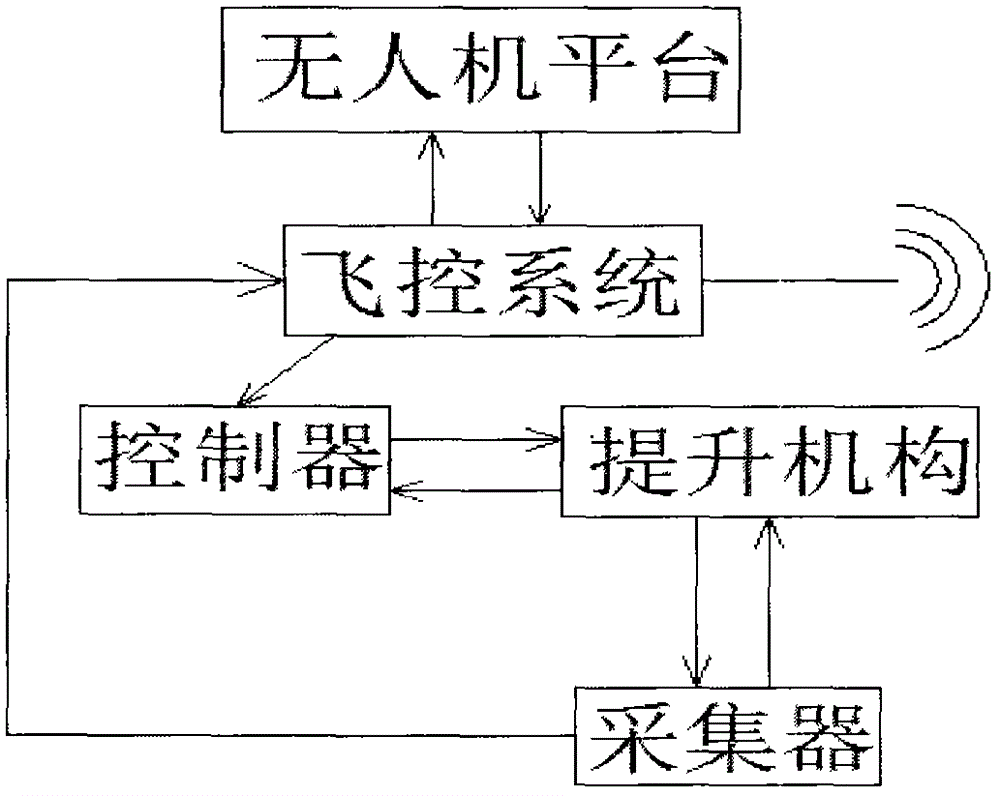

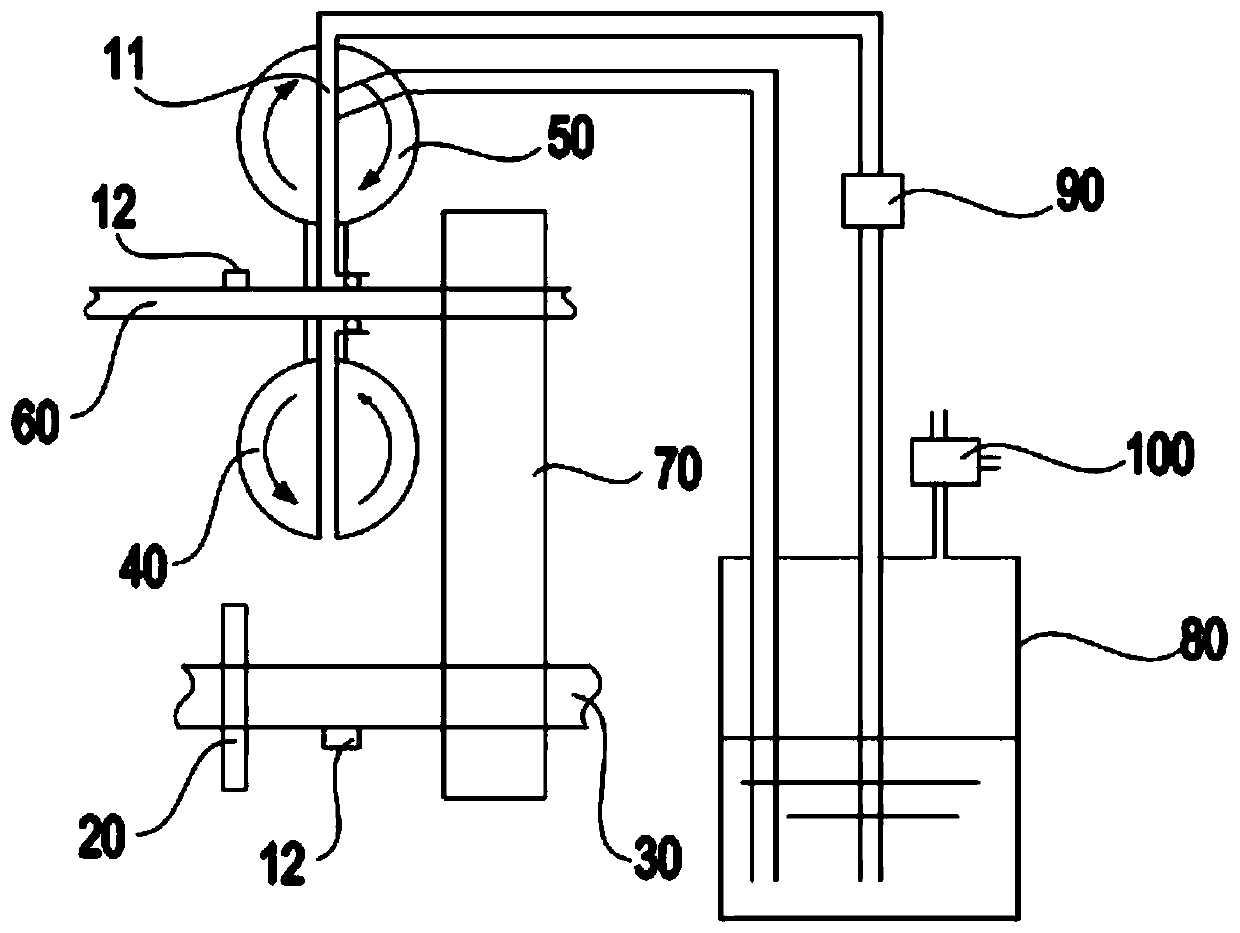

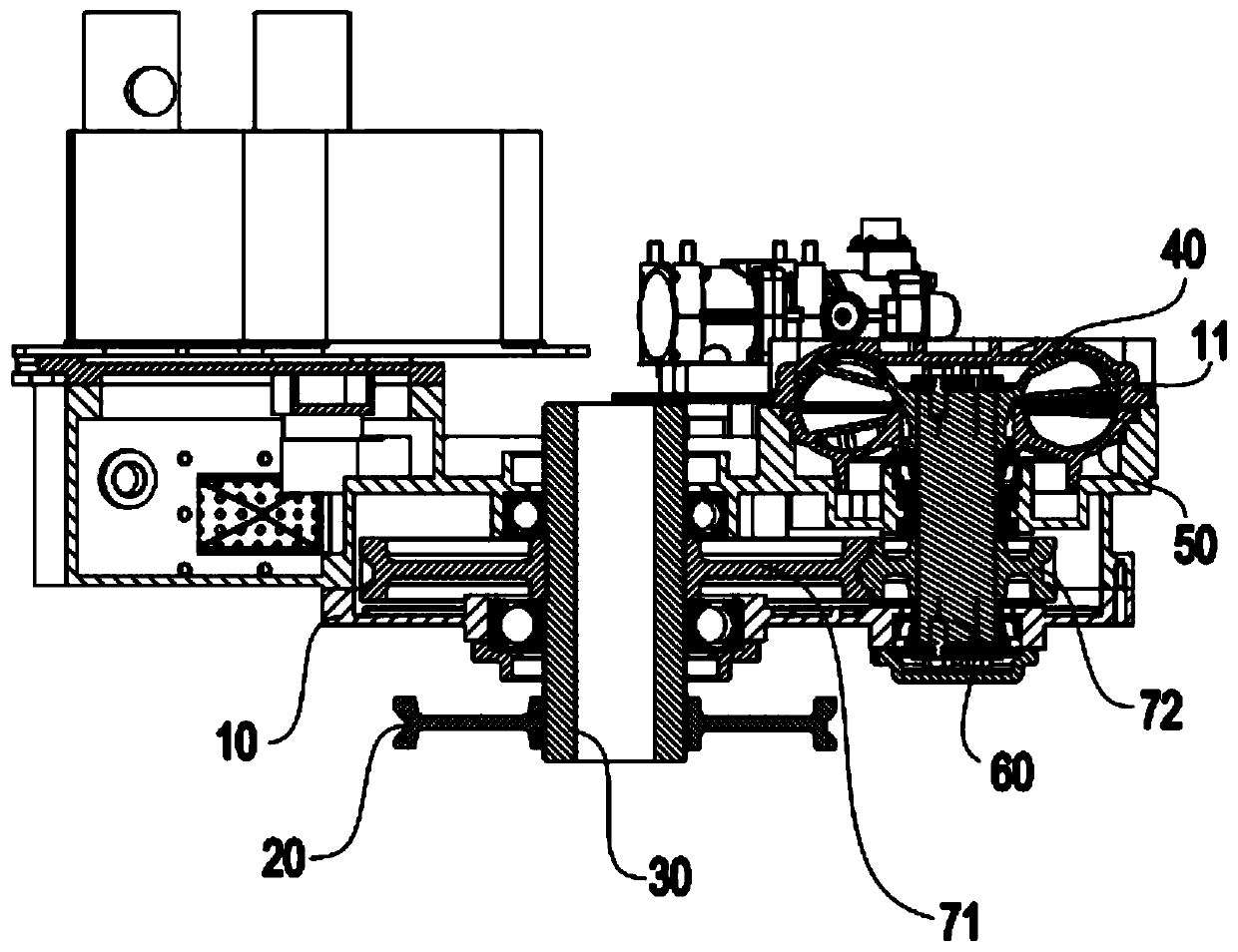

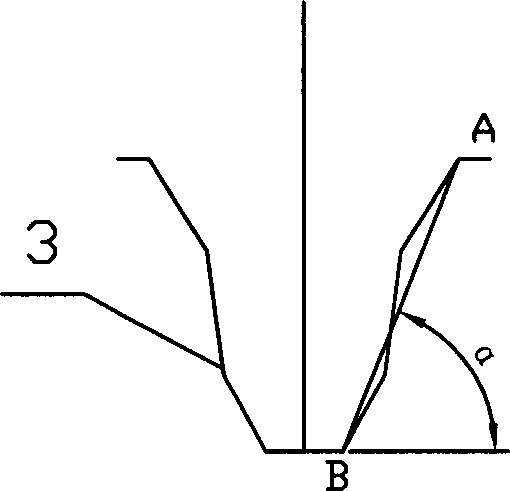

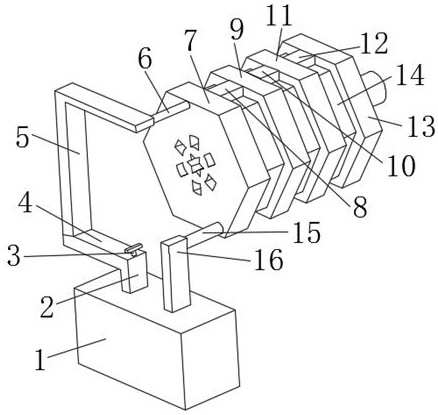

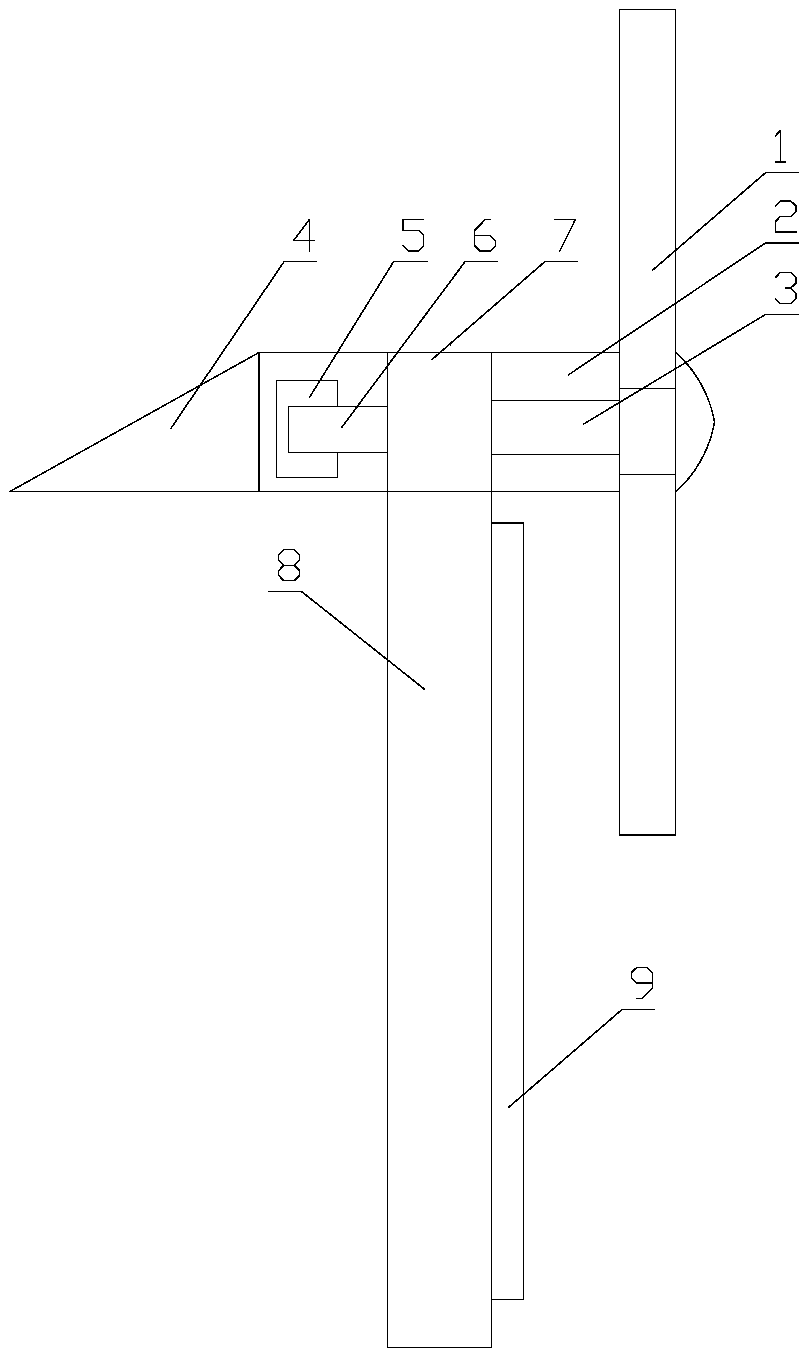

The invention relates to an unmanned aerial vehicle type automatic sampling system at fixed points of the water surface. The unmanned aerial vehicle type automatic sampling system comprises a water sampler, a lifting mechanism and a control circuit, wherein the water sampler comprises a barrel body and a periphery component, a large conical horn mouth is designed at the lower end of the barrel body, and an end cover exhaust device is arranged at the upper end of the barrel body; a buoyancy ring and a heavy ring are arranged at the outer side of the barrel body, the buoyancy ring is arranged at the lower end of an end cover, and the heavy ring is arranged at the lower end of the buoyancy ring; and a valve cover is arranged at the bottom of the inner side of the barrel body; the integrity is connected by a flying ring, the lifting mechanism is connected at the upper part of the flying ring, and is controlled by the control circuit. The lifting mechanism adopts a winding and distributing mechanism, the winding mechanism is composed of a power motor, a worm-gear speed reducer and a speed ratio guide wire wheel set, the speed ratio guide wire wheel set is connected with the flying ring by a connecting wire, the speed ratio guide wire wheel set is connected with the worm-gear speed reducer which is connected with the power motor; while the twisting force is increased, self locking can be achieved; and the system adopts the unmanned aerial vehicle system to realize sampling, the traditional manual sampling mode can be replaced completely, and rapid, intelligent and high-efficiency water sampling can be achieved.

Owner:QINGDAO OUSEN SYST TECH

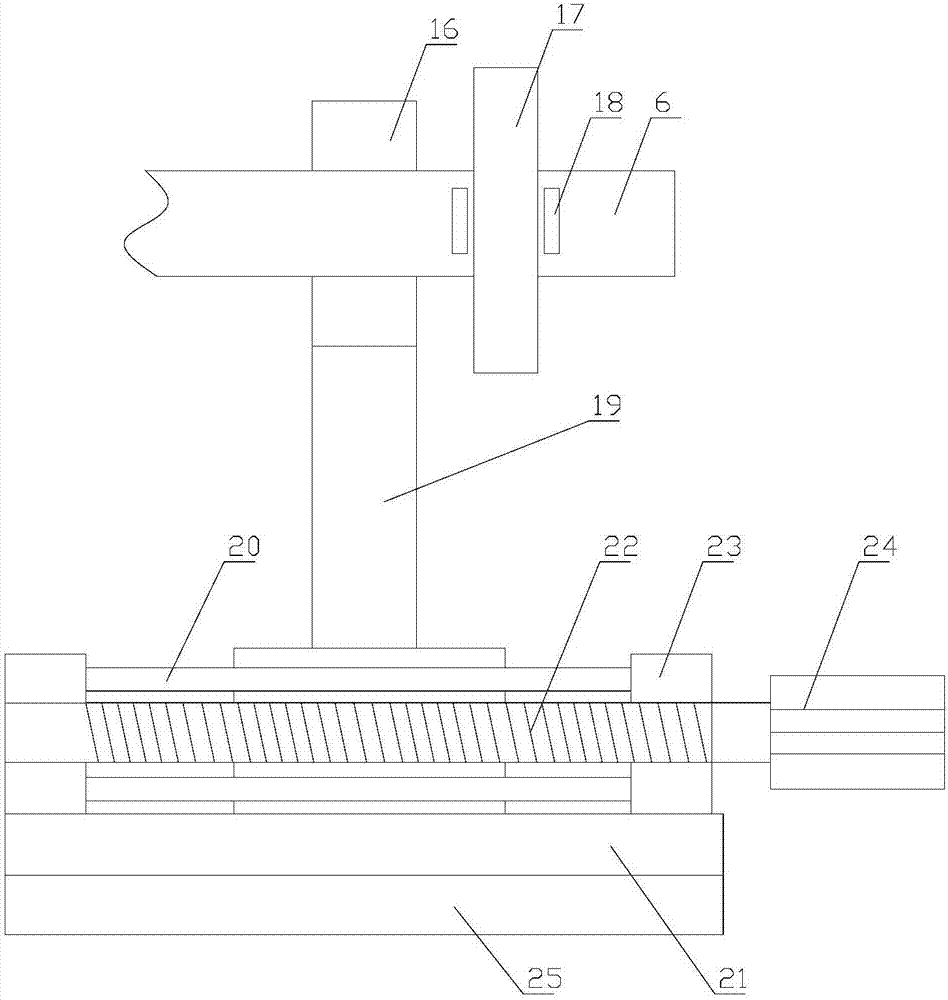

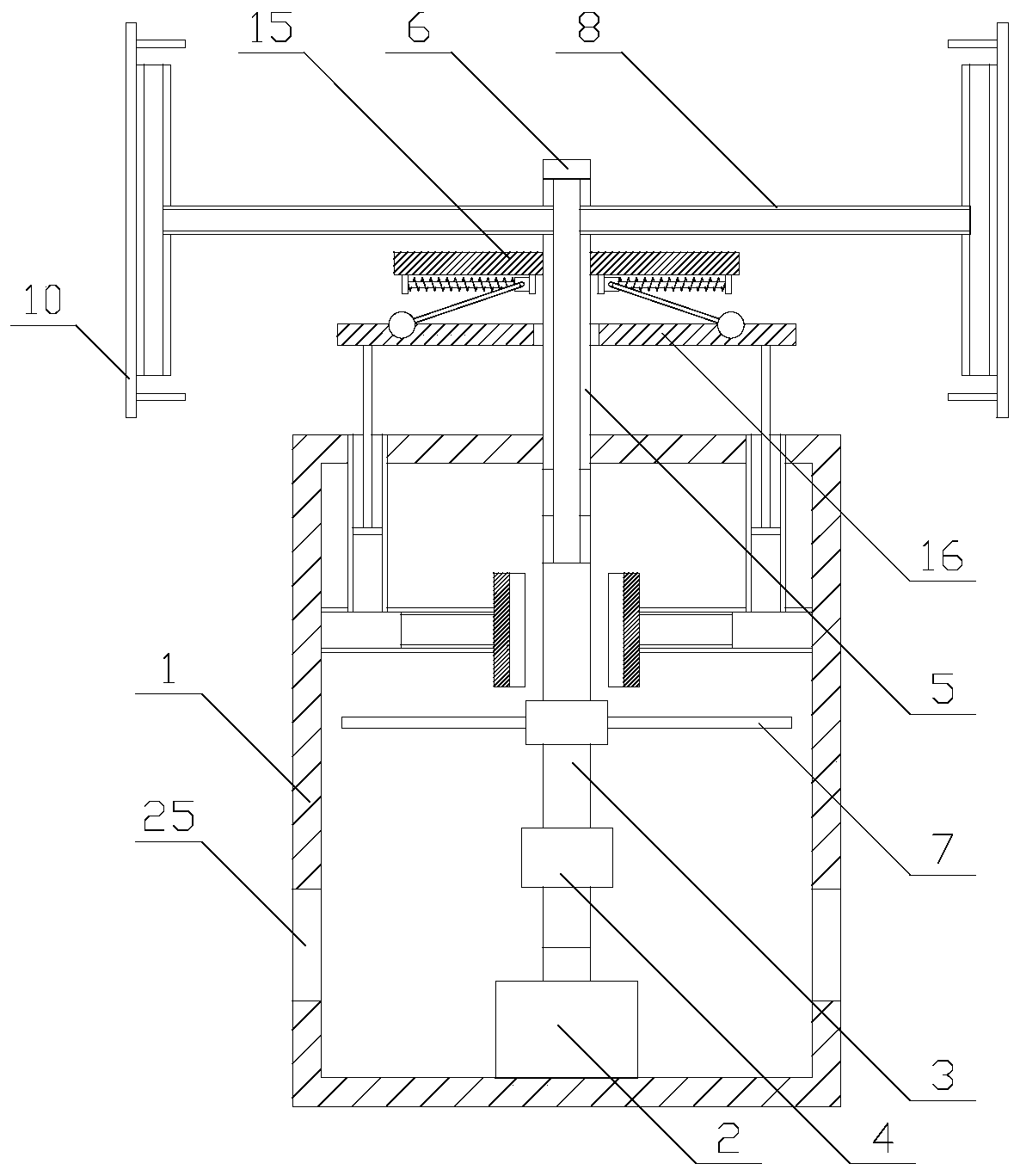

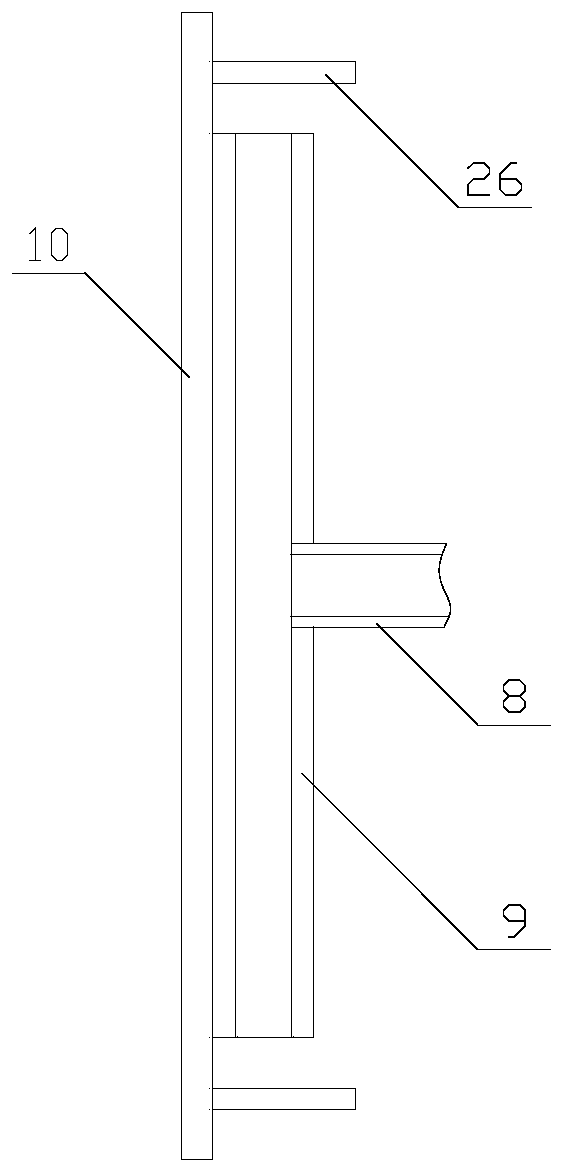

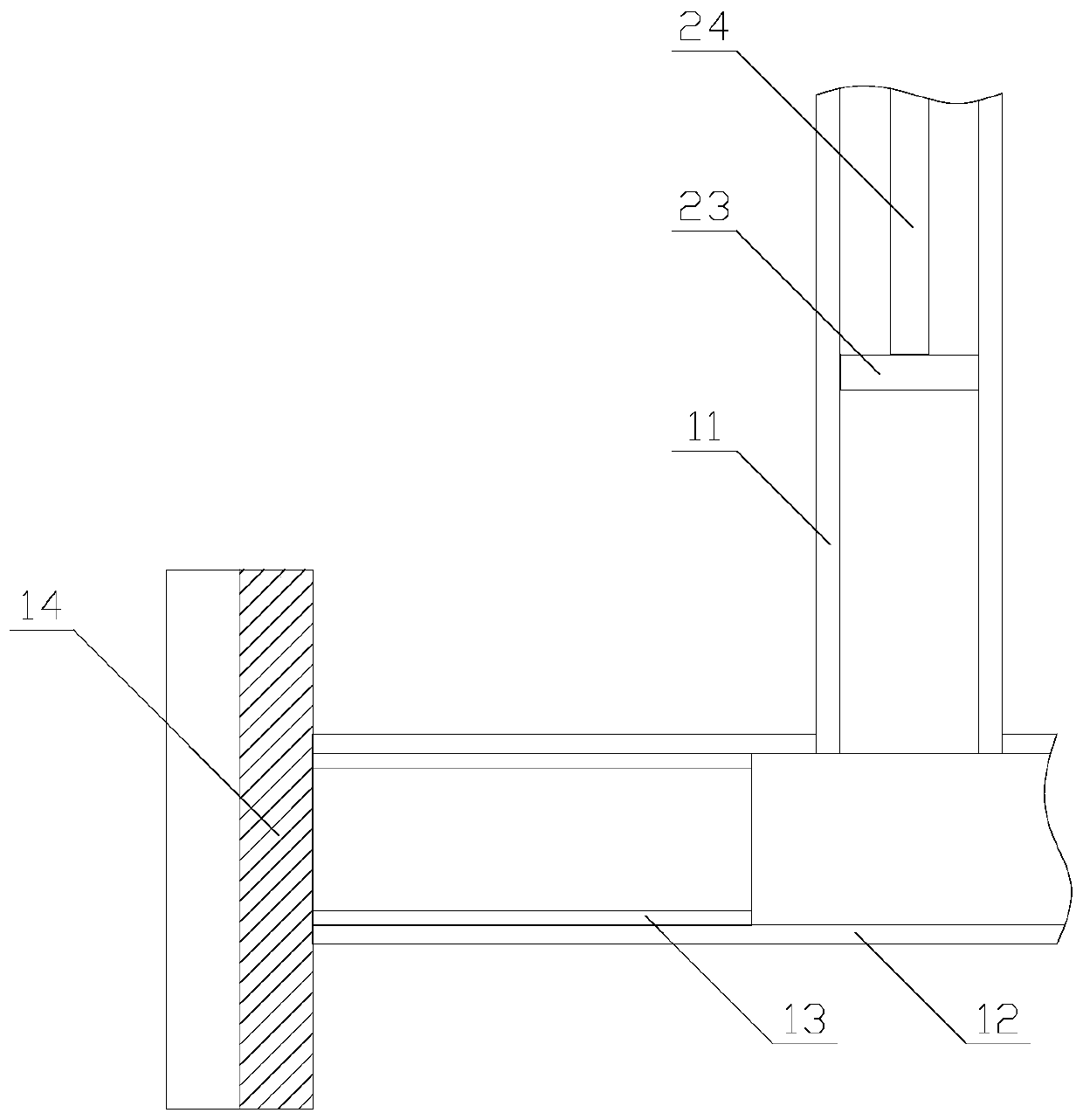

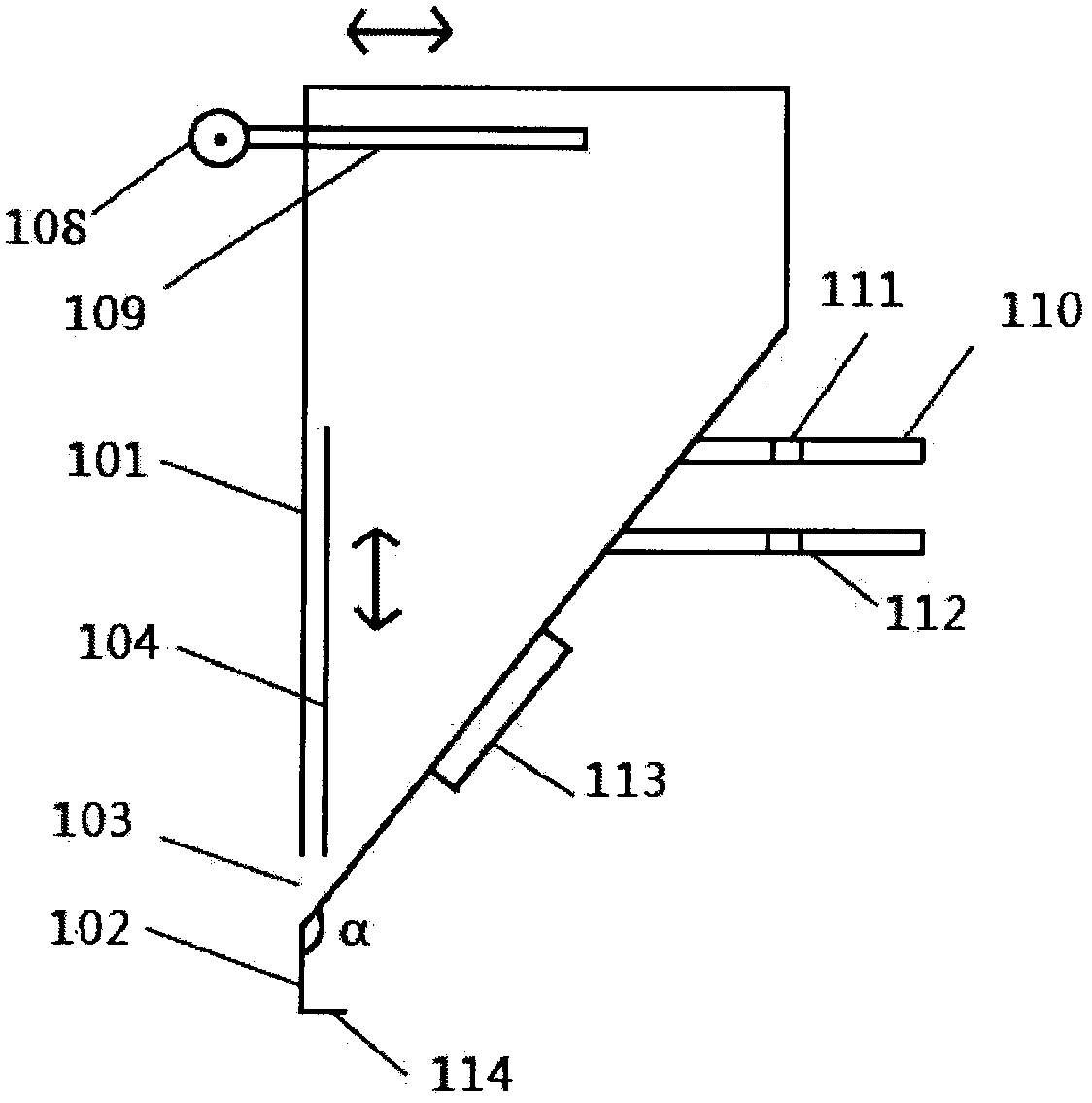

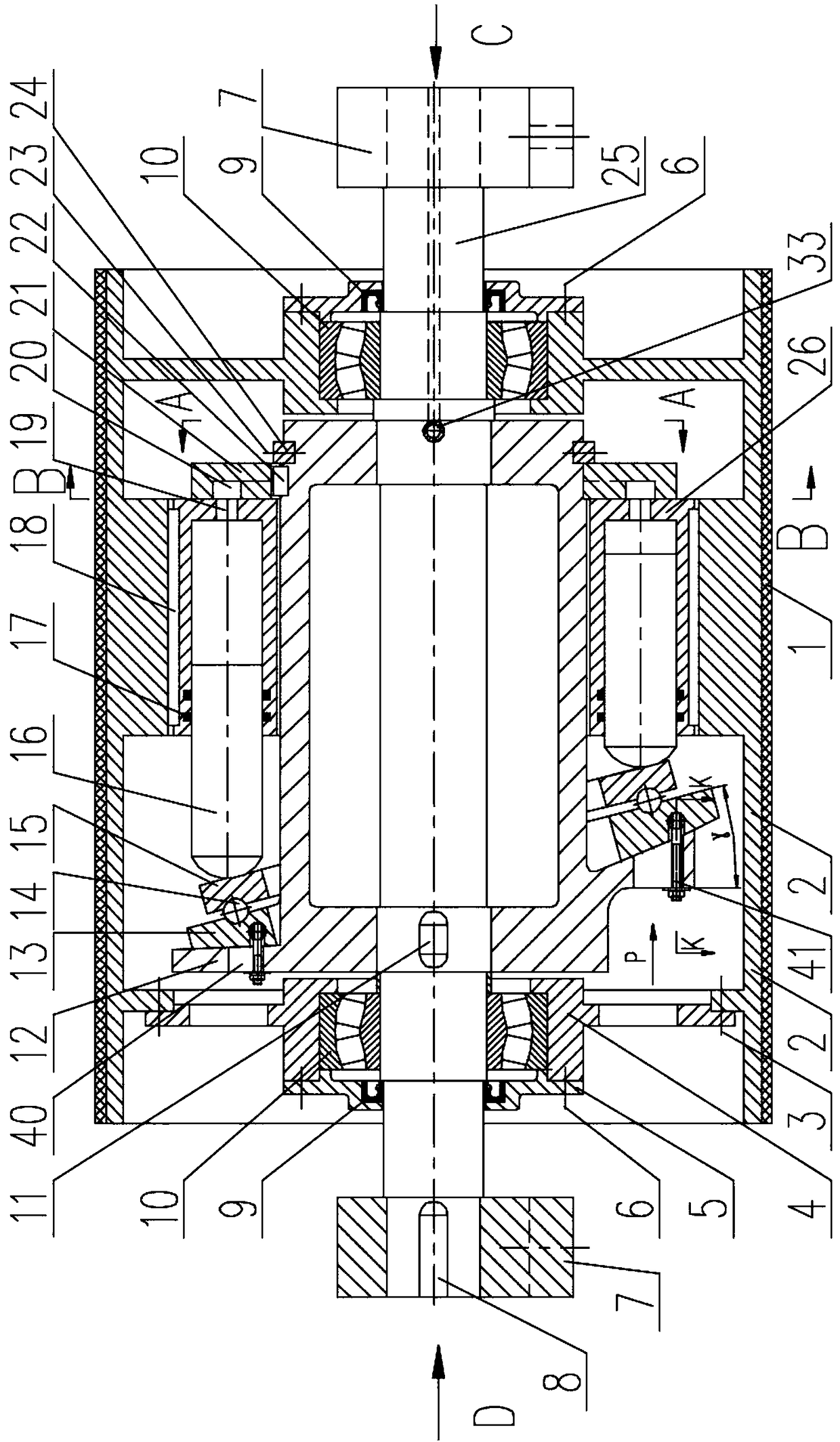

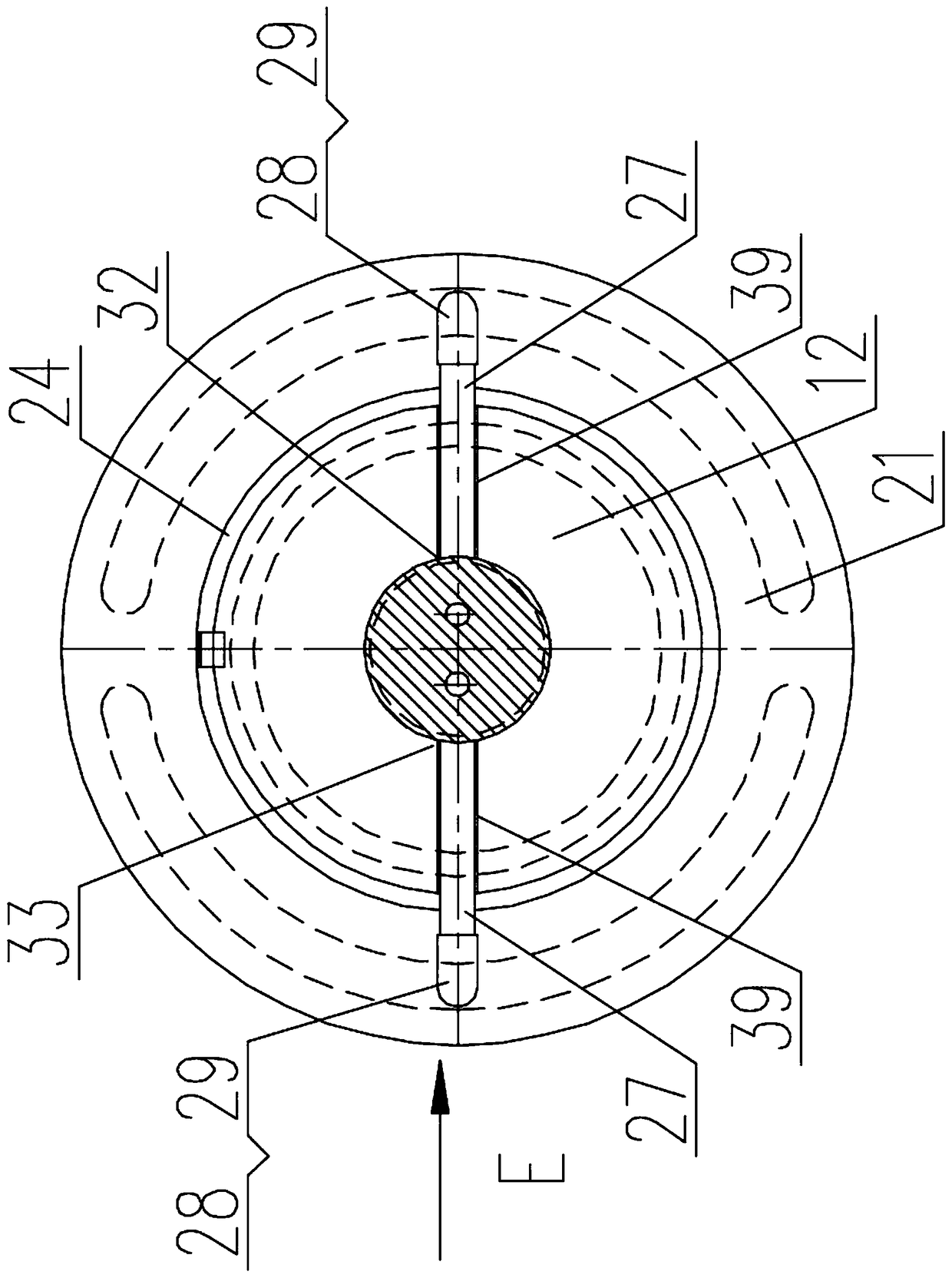

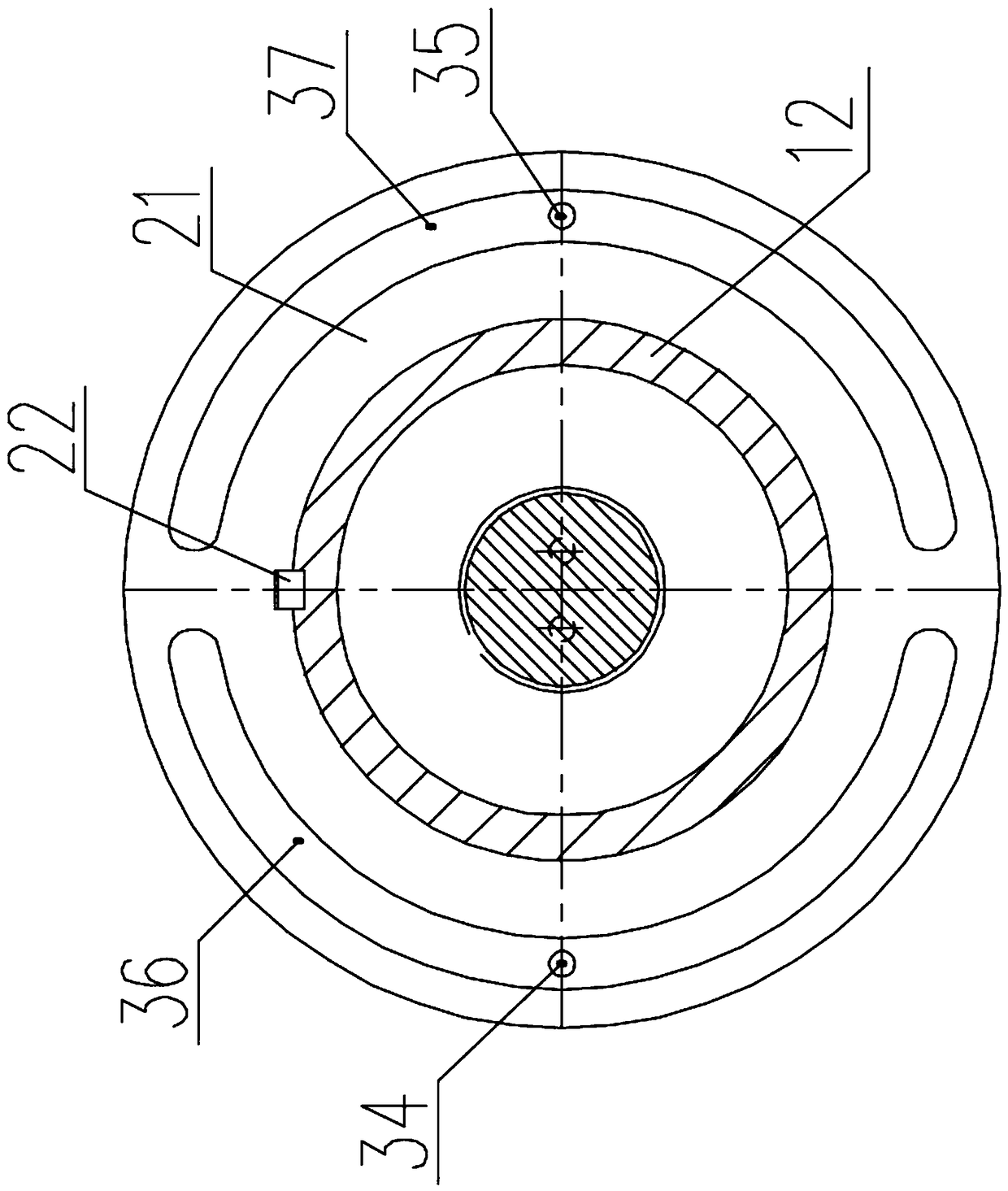

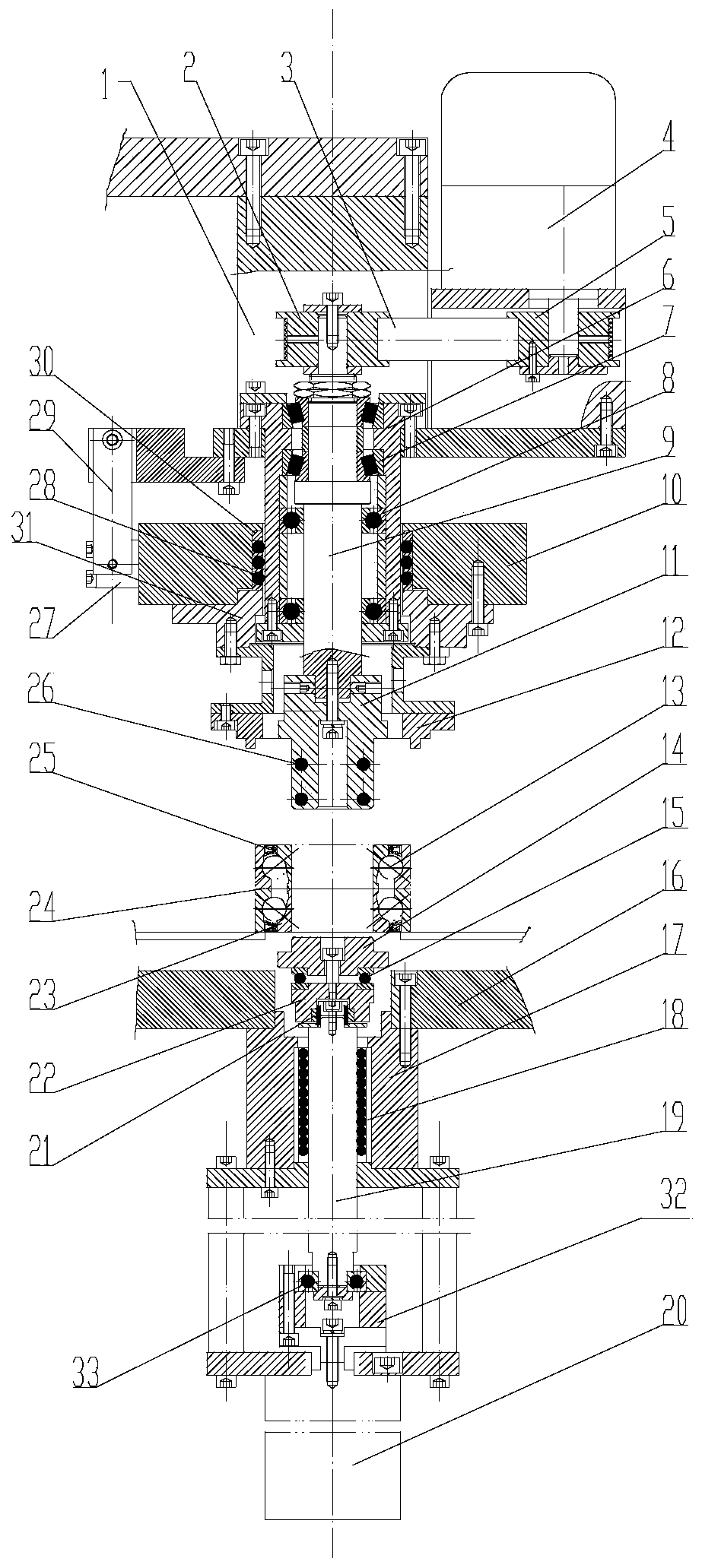

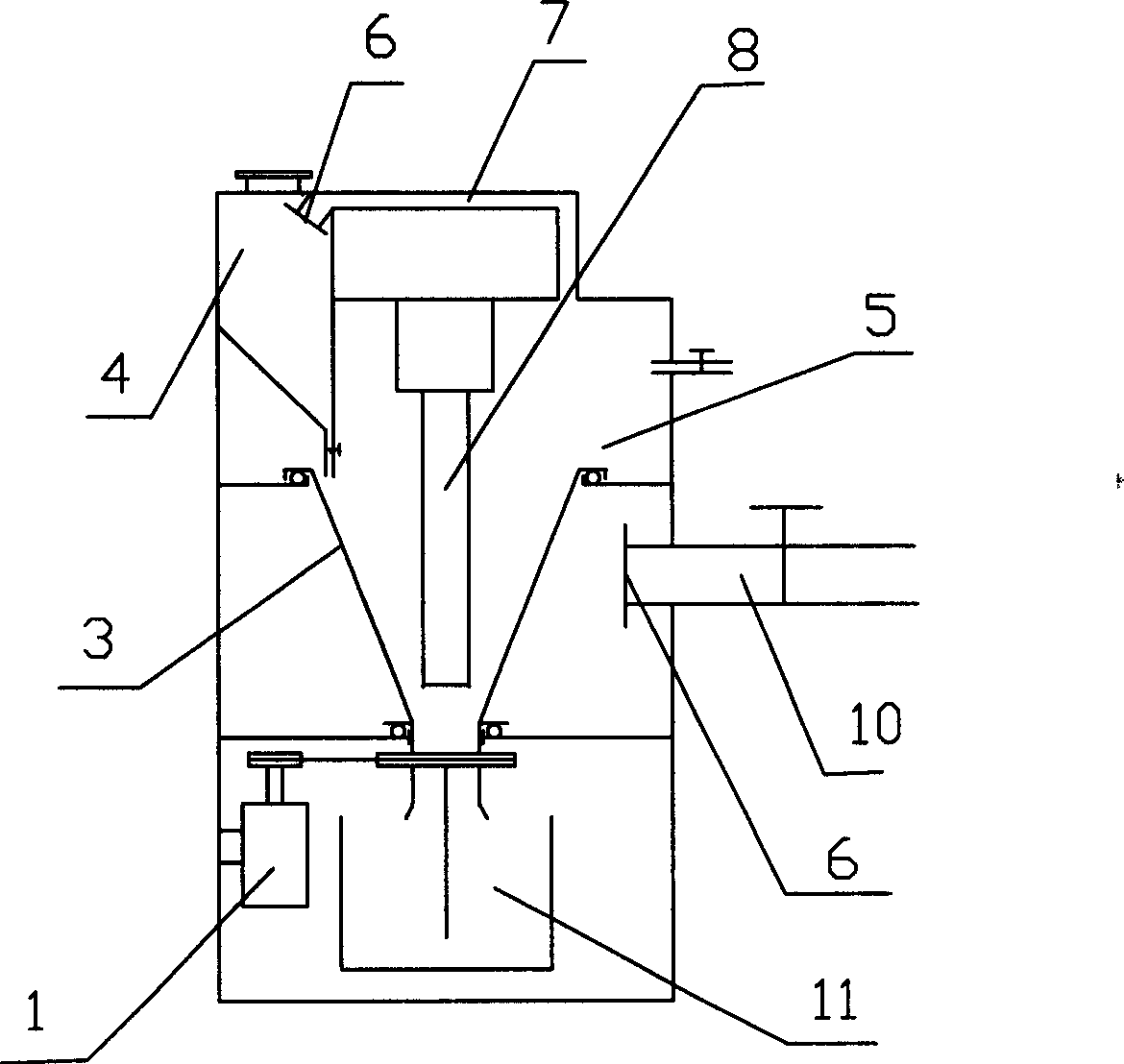

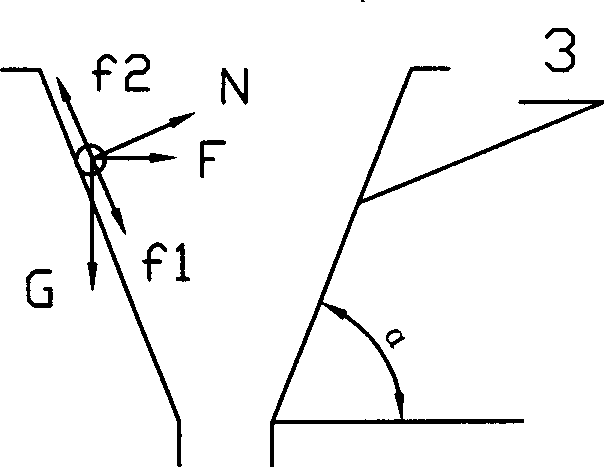

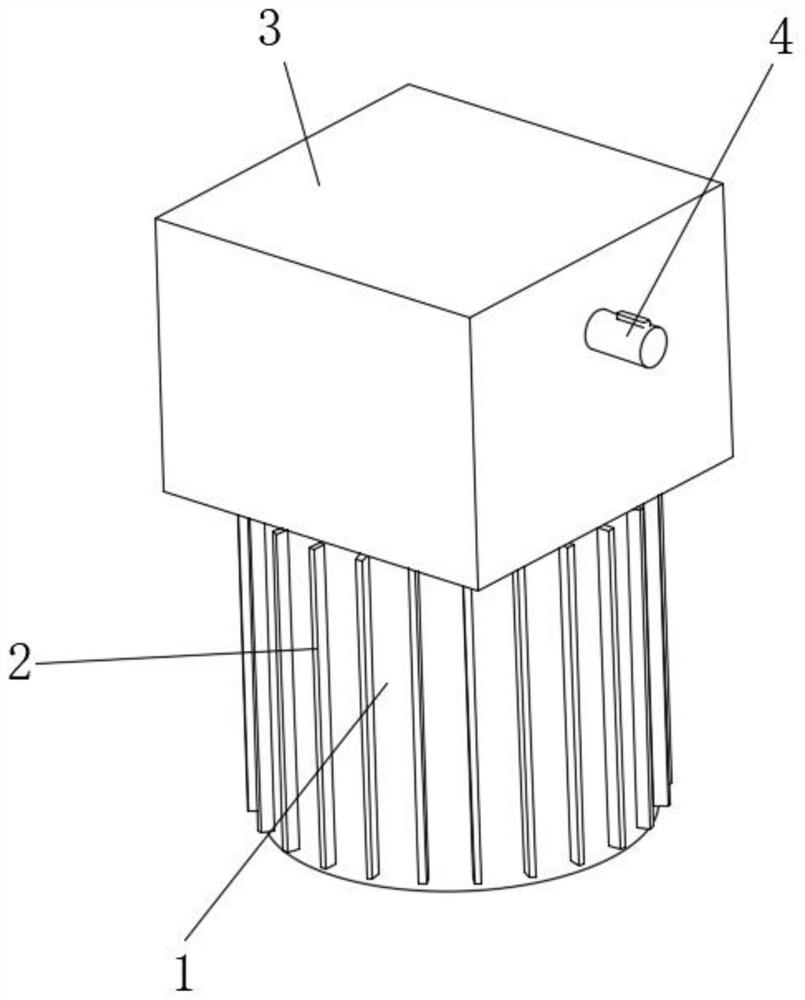

Technique for film plating on powder surface and equipment thereof

InactiveCN101082120AEasy flipWith speed control functionVacuum evaporation coatingSputtering coatingVacuum pumpingMetallurgy

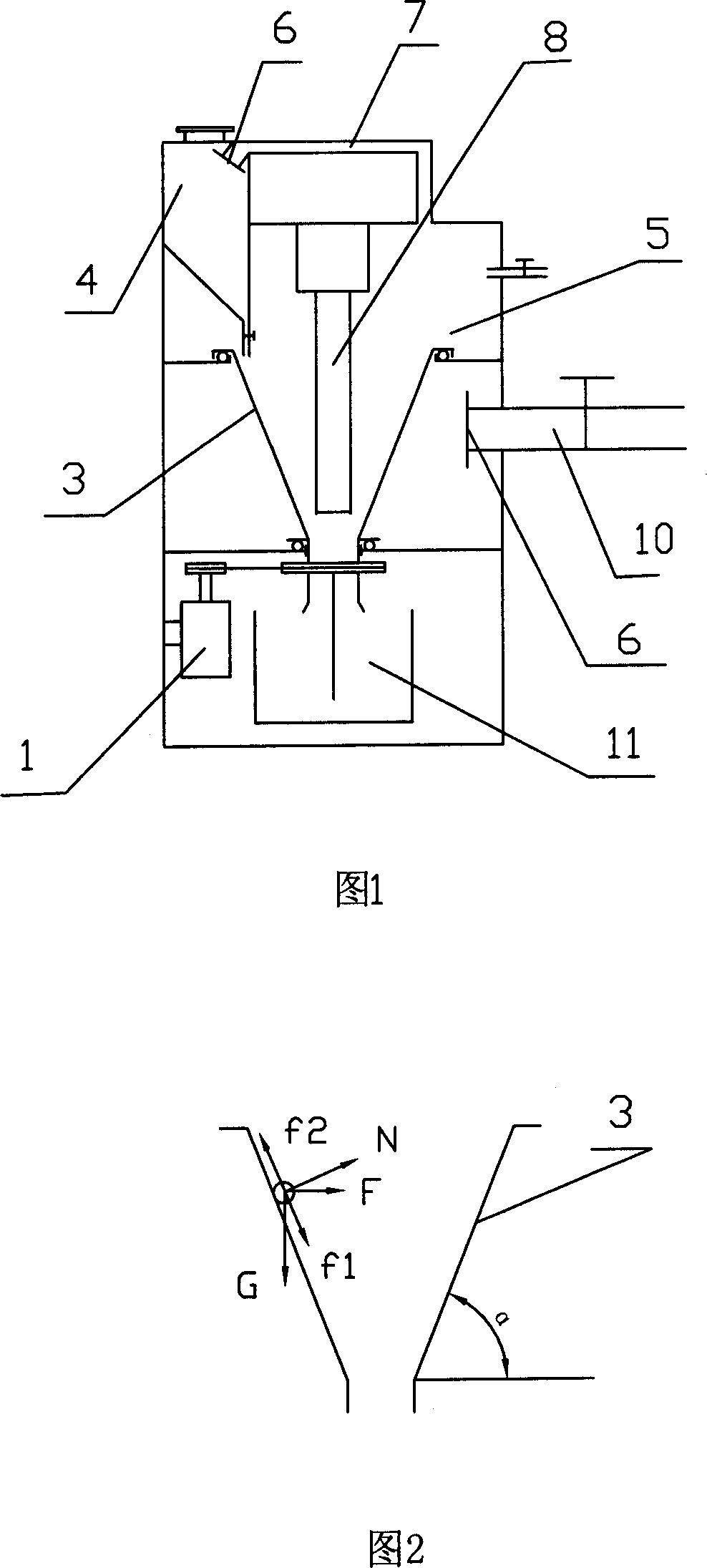

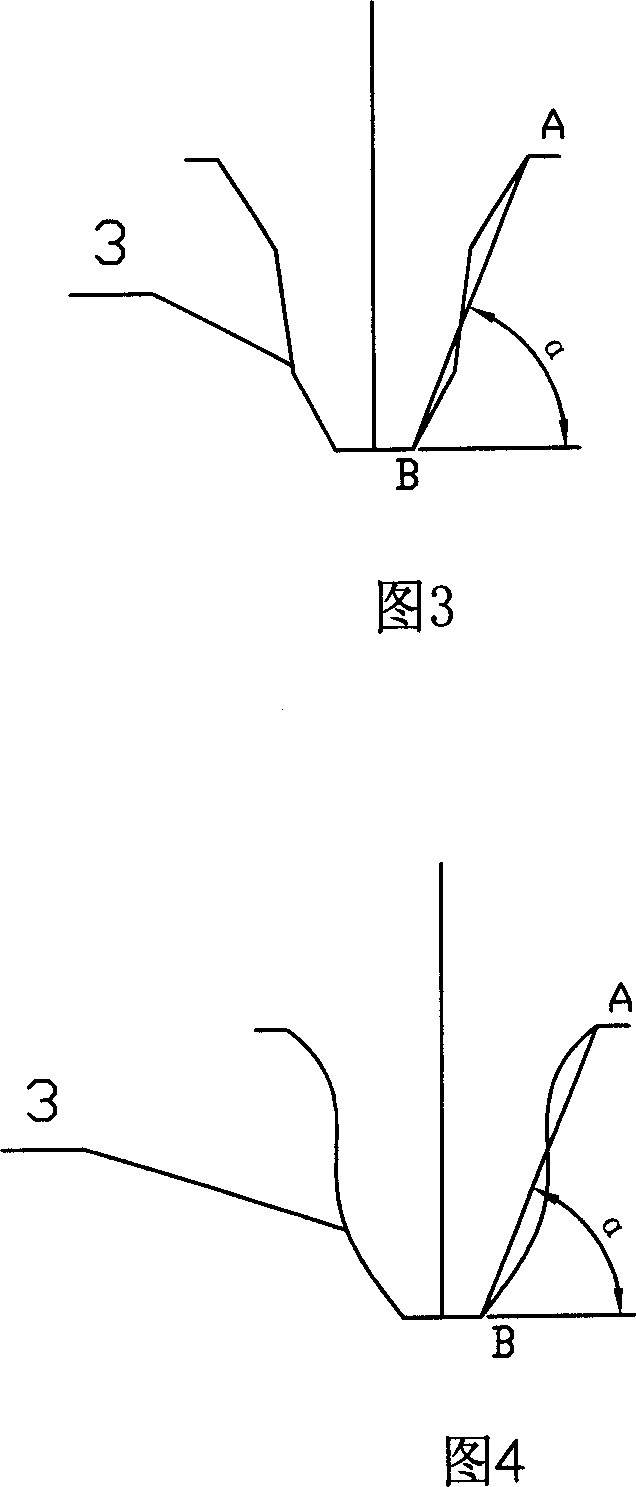

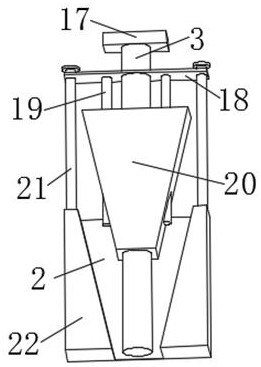

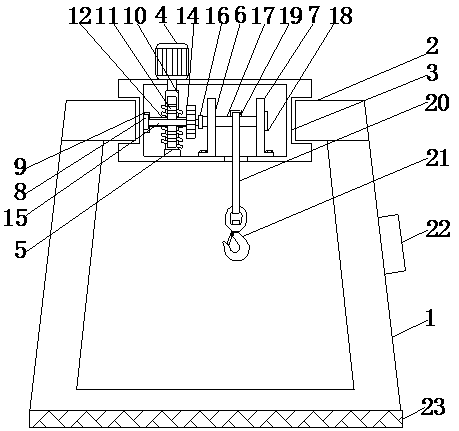

The present invention is powder surface coating process and apparatus. During coating powder, the powder is made to fall spirally in a vacuum environment and a homogeneous cladding is formed on the surface of the powder. The apparatus for coating powder includes one vacuum chamber, a vacuum film coating source, and a vacuumizing system. Inside the vacuum chamber, there are one turned conic rotary hopper, one feeding chamber connected to the upper end of the hopper, and collecting chamber connected to its lower end. The vacuum film coating source mounted in the middle part inside the hopper has one speed adjustable motor for rotating the hopper. The present invention has great coating capacity and low running cost.

Owner:BYD CO LTD

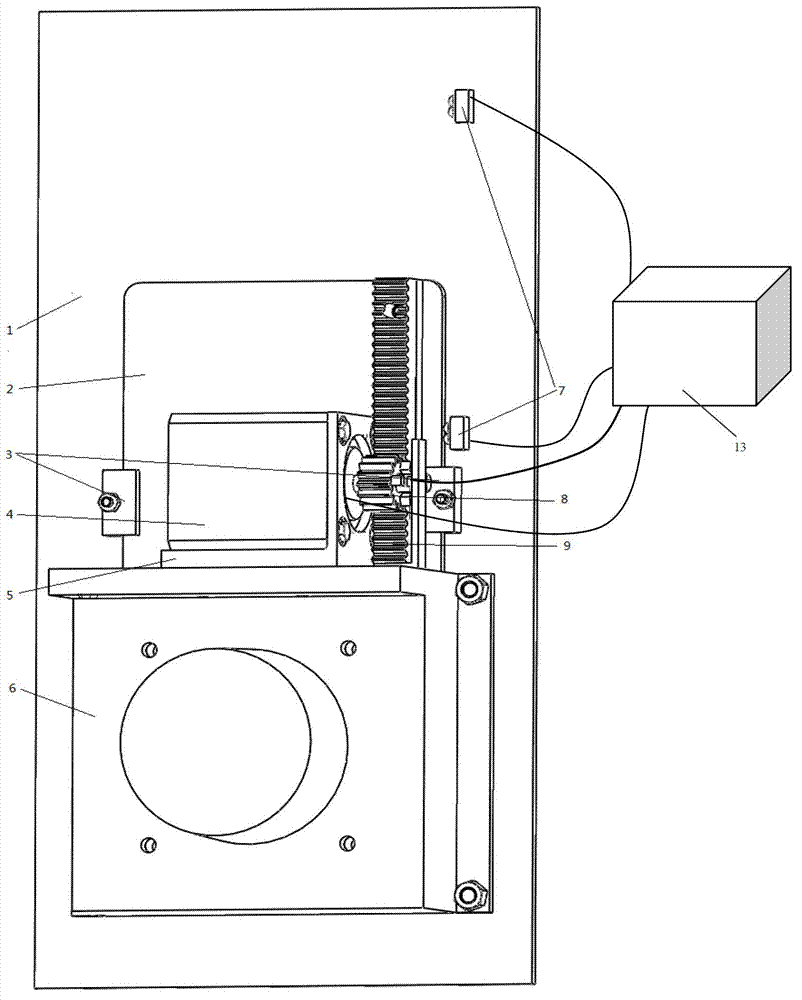

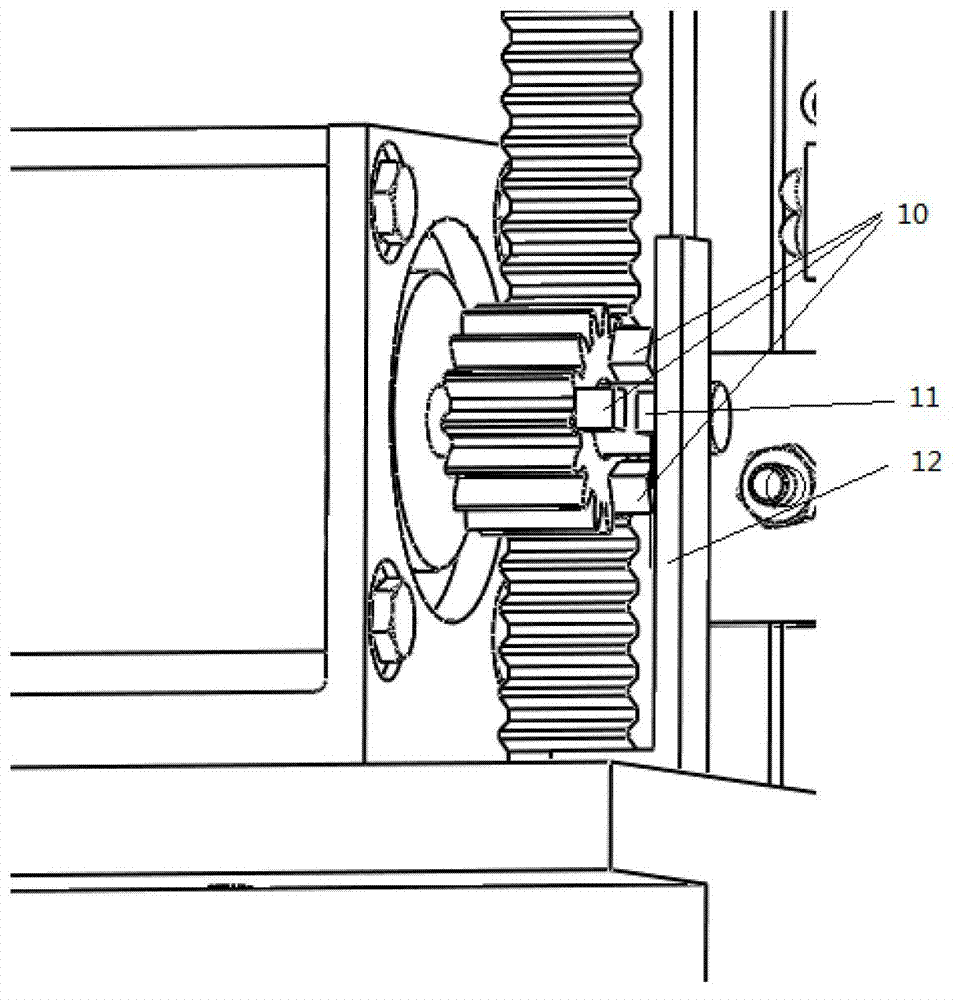

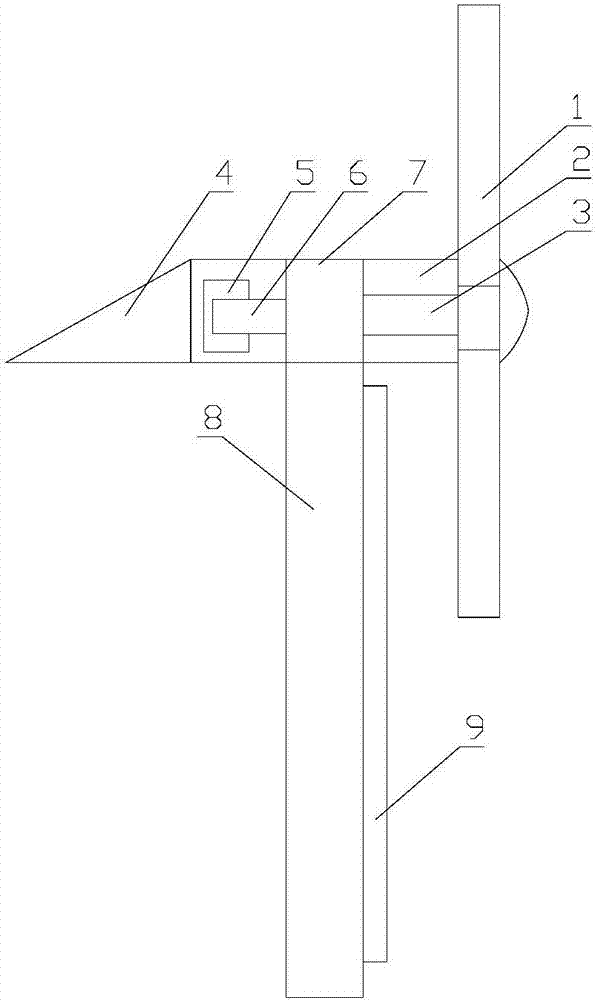

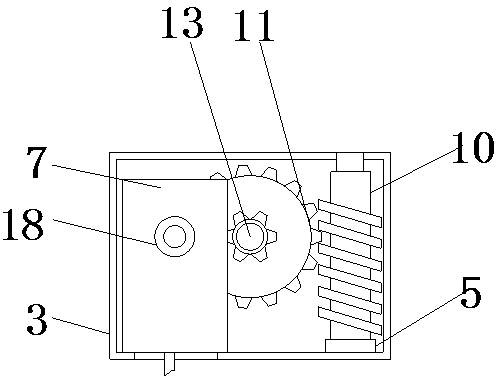

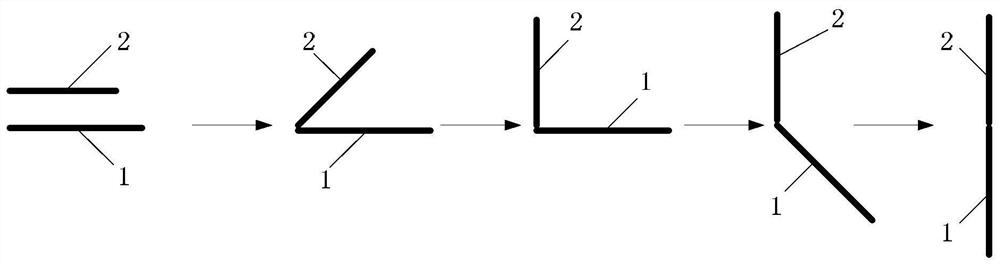

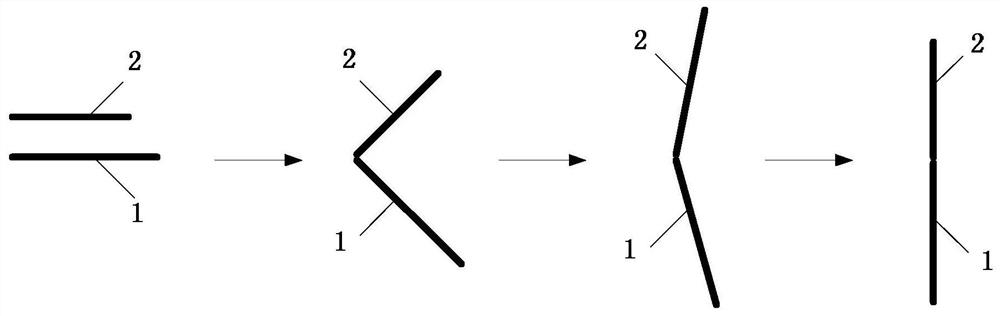

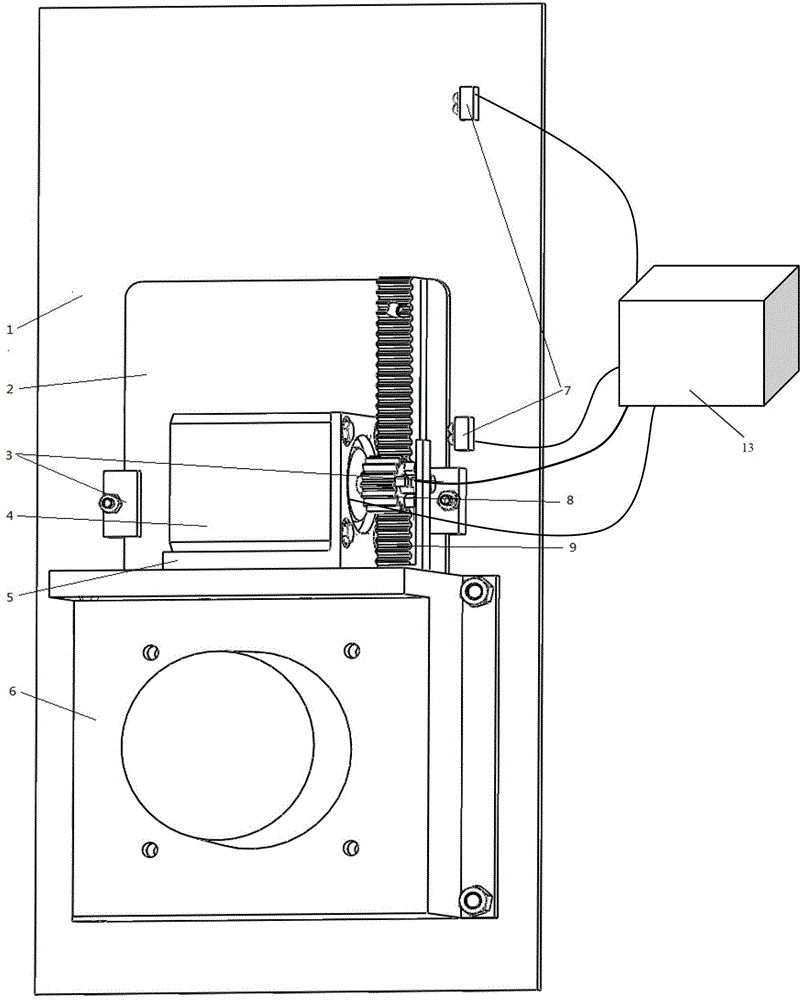

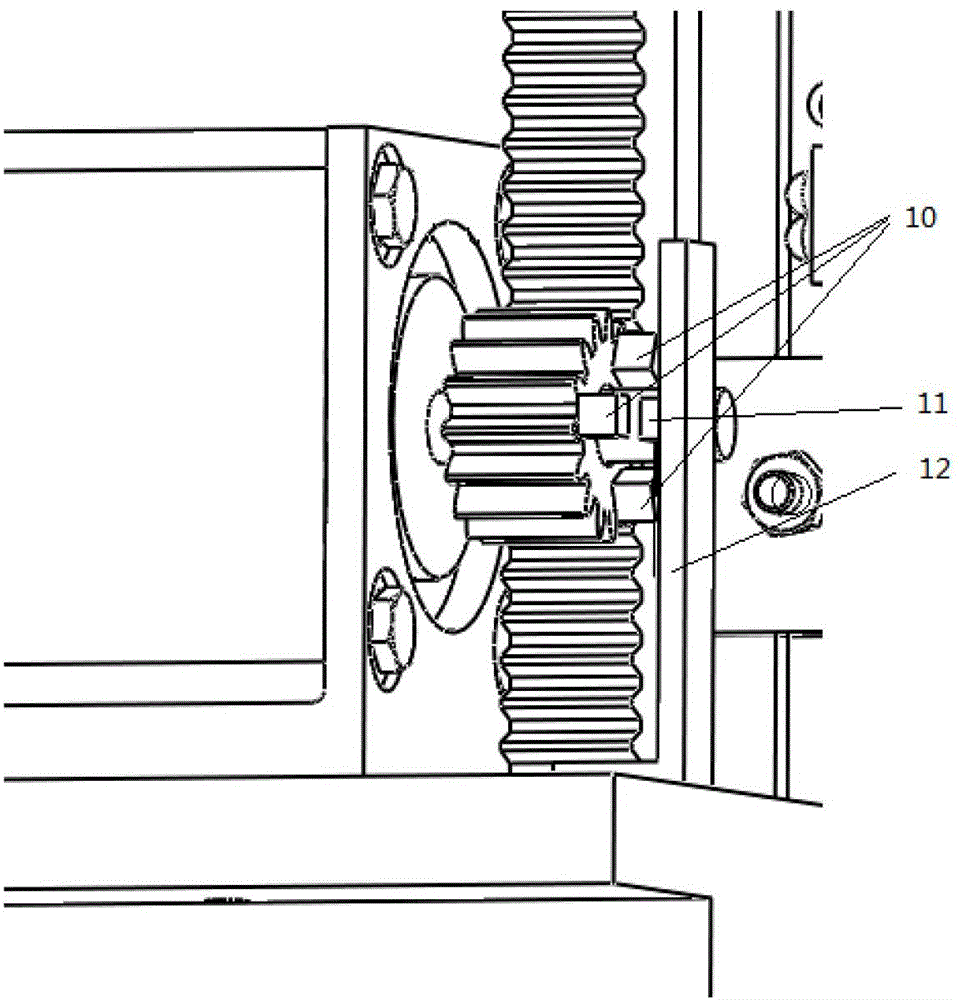

Safeguard device for charging port of electric automobile charging pile

InactiveCN103163805AReduce energy consumptionModerate speedProgramme controlComputer controlMicrocontrollerControl circuit

The invention discloses a safeguard device for a charging port of an electric automobile charging pile. The safeguard device comprises a shell, a step motor, a bin gate, a gear, a rack, guide sheets, infrared reflective proximity switch sensors, Hall sensors, magnets and a singlechip control circuit; the shell and the guide sheets are fixed on the inner wall of the charging pile, the shell is provided with a straight opening matched with the guide sheets to form a guide mechanism, and the bin gate is arranged in the guide mechanism; the gear is arranged on a shaft of the step motor, and the rack matched with the gear is arranged on the bin gate; the two infrared reflective proximity switch sensors are arranged on the inner wall of the charging pile and used for detecting complete opening and complete closure of the bin gate respectively; the magnets are arranged at the edge of the outer end face of the gear, and the Hall sensors are arranged at the corresponding positions; and the infrared reflective proximity switch sensors, the Hall sensors and the step motor are connected with corresponding ports of the singlechip control circuit respectively. The safeguard device is safe, reliable, low in energy consumption, simple in structure and convenient to operate.

Owner:NANJING UNIV OF SCI & TECH

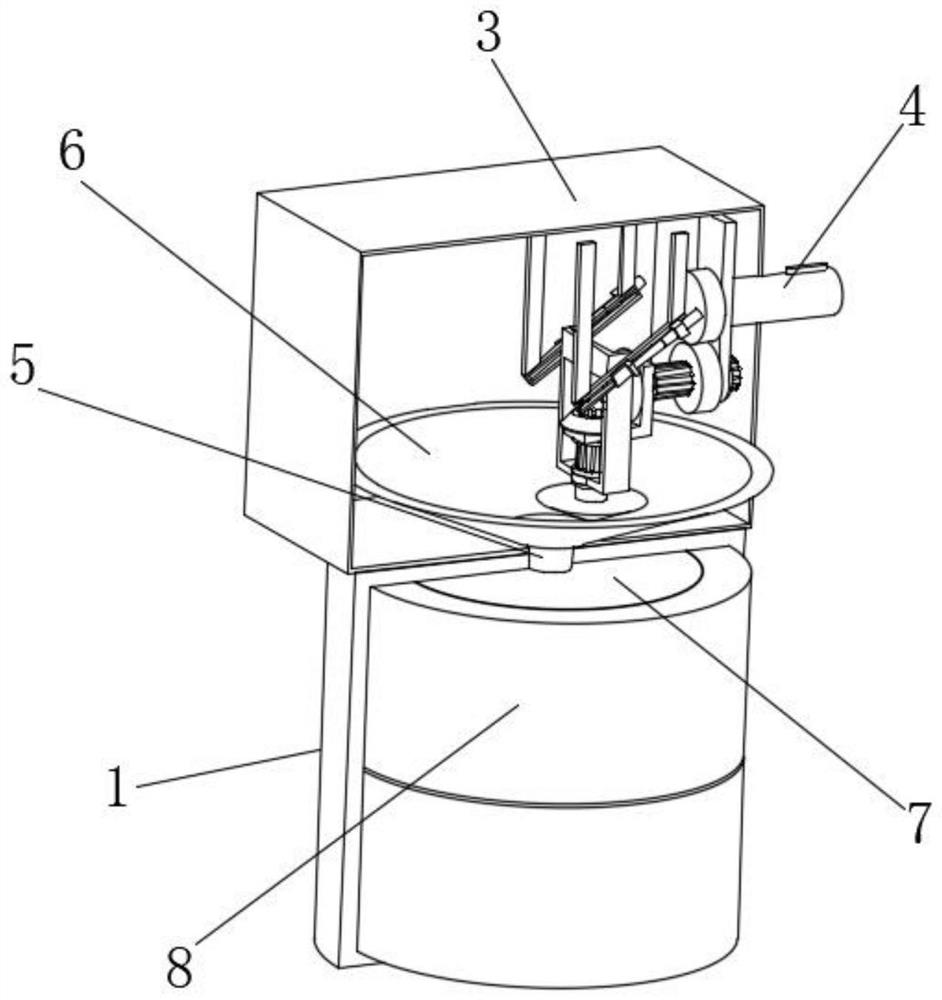

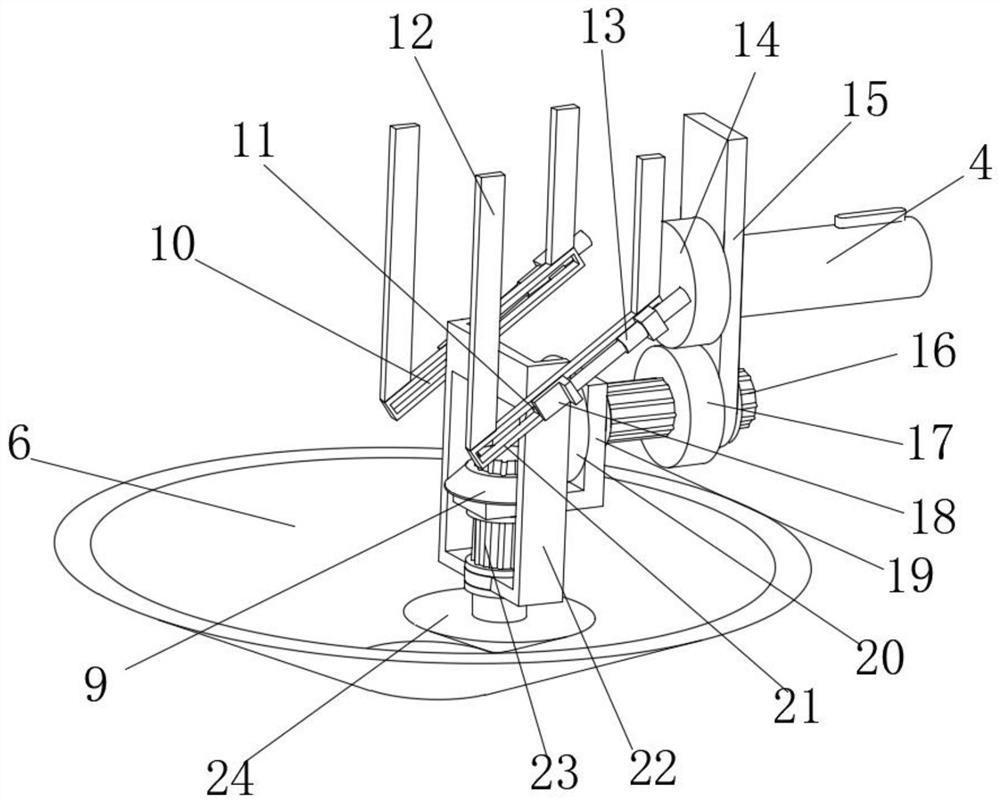

Wind driven generator having speed adjusting function

ActiveCN106949015AWith speed control functionIngenious structural designWind motor controlWind motor supports/mountsWind drivenTower

The invention relates to a wind driven generator having a speed adjusting function. The wind driven generator having the speed adjusting function comprises a tower body, a shell, a fan mechanism, a gearbox and a power generation mechanism. The gearbox comprises a variable-speed gear assembly, a leftward and rightward adjusting assembly, a PLC and a frontward and backward adjusting assembly. The variable-speed gear assembly comprises a variable-speed rotating shaft, a first variable-speed gear and an infrared receiver. The leftward and rightward adjusting assembly comprises an infrared transmitter, a bearing, a sliding block, a lead screw, fixed blocks, a first motor, a shifting block and a base. The frontward and backward adjusting assembly comprises a second motor, a round gear and a strip gear. According to the wind driven generator having the speed adjusting function, a power generation system in the power generation mechanism sends an instruction to the PLC, the PLC can move a high-speed gear in the power generation mechanism to be meshed with an appropriate variable-speed gear through a frontward and backward adjusting mechanism and a leftward and rightward adjusting structure, and it is guaranteed that the power generation mechanism is in the most stable power generation state; and, when wind force is large, the wind driven generator having the speed adjusting function can be protected.

Owner:新昌县羽林街道维新机械厂

New energy equipment with speed regulation function

InactiveCN111502911AReduce runoutImprove stabilityWind motor controlVariable speed operation controlNew energyDrive shaft

The invention relates to new energy equipment with a speed regulation function. The equipment comprises a power generation box, a power generator, a transmission shaft and a bearing, wherein the powergeneration box is in a cuboid shape, the transmission shaft is vertically arranged, the power generator, the transmission shaft and the bearing are all arranged in the power generation box, the powergenerator is installed at the bottom end of the transmission shaft and fixed to the bottom in the power generation box, an inner ring of the bearing is installed on the transmission shaft, an outer ring of the bearing is fixed to the inner wall of the power generation box, a power mechanism and a speed regulating mechanism are arranged on the power generation box, and the power mechanism comprises a rotating pipe, a sealing block, fan blades and at least two power assemblies. According to the new energy equipment with the speed regulation function, a power generation function is achieved through the power mechanism, in addition, a function of regulating the rotating speed of the transmission shaft is achieved through the speed regulating mechanism, and damage to the power generator due tooverheating caused by too high rotating speed of the transmission shaft is prevented.

Owner:南京振轩新能源科技有限公司

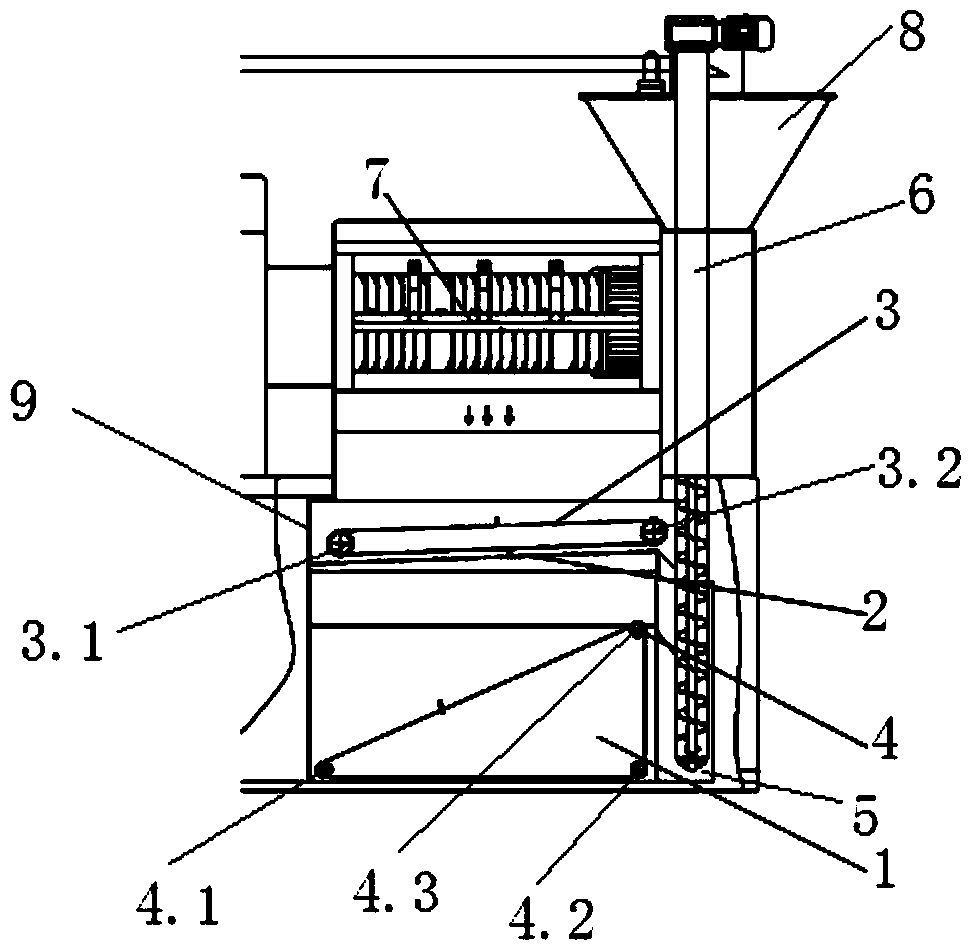

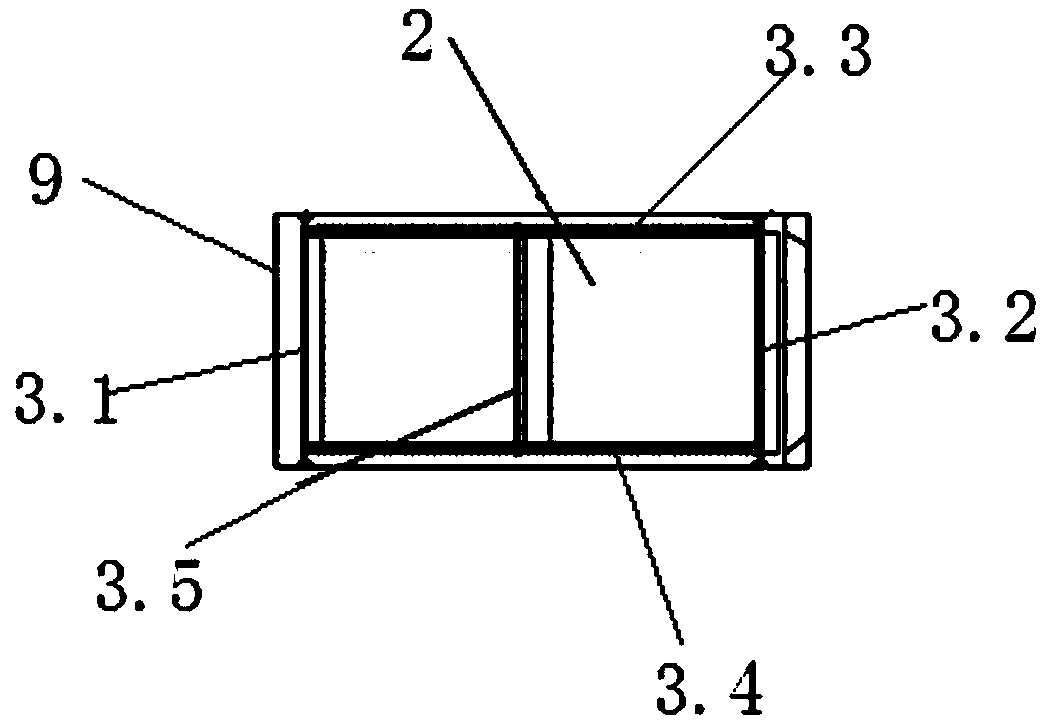

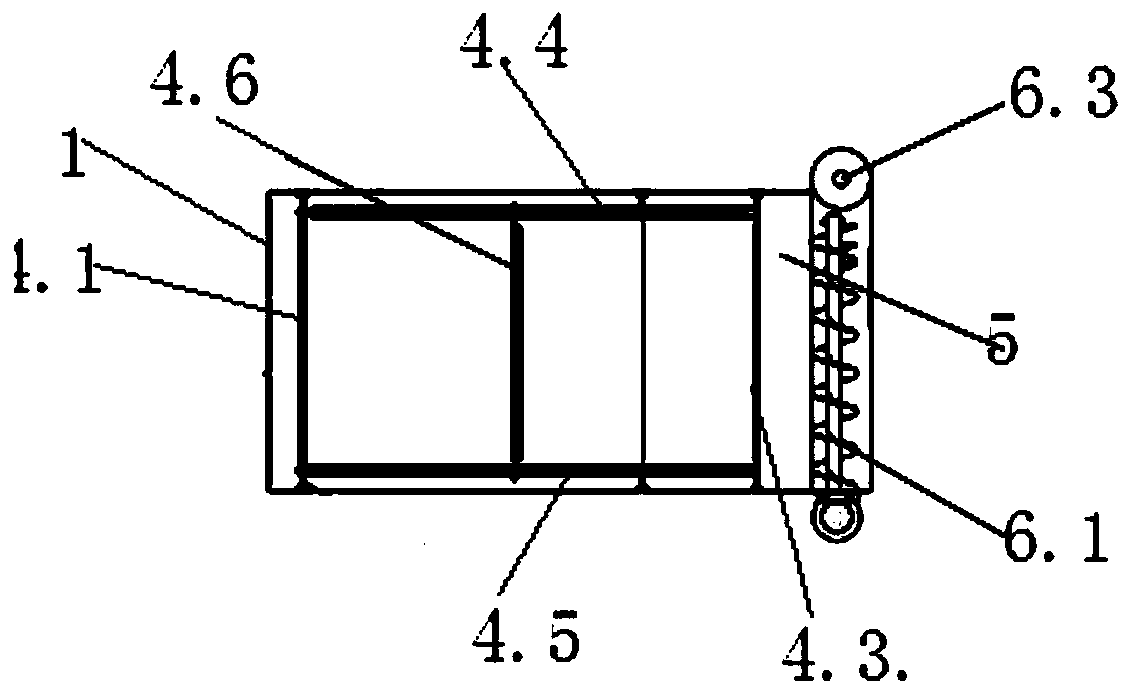

Oil slag separation and re-squeezing device for middle and small-sized oil squeezing machine

PendingCN108690712AEasy to separateImprove separation efficiencyFatty-oils/fats refiningFatty-oils/fats productionSlagFuel tank

The invention discloses an oil slag separation and re-squeezing device for a middle and small-sized oil squeezing machine. The oil slag separation and re-squeezing device comprises a crude oil box arranged under a crude oil outlet of the oil squeezing machine; the crude oil box is arranged on a machine frame of the oil squeezing machine; a crude oil filtering screen is arranged above the crude oilbox; a first skimmer is arranged above the crude oil filtering screen; a second skimmer is arranged at the inner bottom of the crude oil box; one side of the crude oil box is provided with a slag collecting groove; the slag discharging ends of the first skimmer and the second skimmer are respectively communicated with the slag collecting groove; an oil slag lifting mechanism is arranged in the slag collecting groove; the slag discharging end of the oil slag lifting mechanism is communicated with the feeding end of the oil squeezing machine. The twice oil slag separation is realized through the filtering by the crude oil filtering screen and the clarification of the crude oil box; the oil slag in the crude oil is separated to the maximum degree; the oil slag separation effect is good; theoil slag separation efficiency is high; the equipment occupied area is small; the automation degree is high; the work intensity of workers is greatly reduced.

Owner:INST OF OIL CROPS RES CHINESE ACAD OF AGRI SCI

Intelligent aluminum alloy hub low-pressure casting device with speed regulation function

The invention relates to an intelligent aluminum alloy hub low-pressure casting device with a speed regulation function. The intelligent aluminum alloy hub low-pressure casting device comprises an airinlet pipe, a crucible, a lifting mechanism, a casting mechanism and a liquid lifting pipe; a plurality of speed regulation mechanisms are arranged in the gas inlet pipe; the speed regulation mechanism comprises a translation assembly, a translation block, a speed regulation plate and a speed regulation assembly; the speed regulation assembly comprises a pressure plate, a spring, a speed regulation rod and two limiting units, the casting mechanism comprises a first motor, a first driving shaft, an upper mold, a lower mold and at least two connecting assemblies, the intelligent aluminum alloyhub low-pressure casting device with the speed regulation function is used for controlling the flow speed of air through the speed regulation mechanism, and then the flow of the air is adjusted, so that the air pressure in the crucible is stably increased, the use amount of the molten aluminum is conveniently controlled accurately, and the quality of the hub forming is improved, moreover, the upper die and the lower die are driven to rotate through a casting mechanism, so that the flowing of molten aluminum is enhanced, so that the molten aluminum is uniformly distributed between the upper mold and the lower mold, and the quality of hub forming and the practicability of device are further improved.

Owner:南京卓茨机电科技有限公司

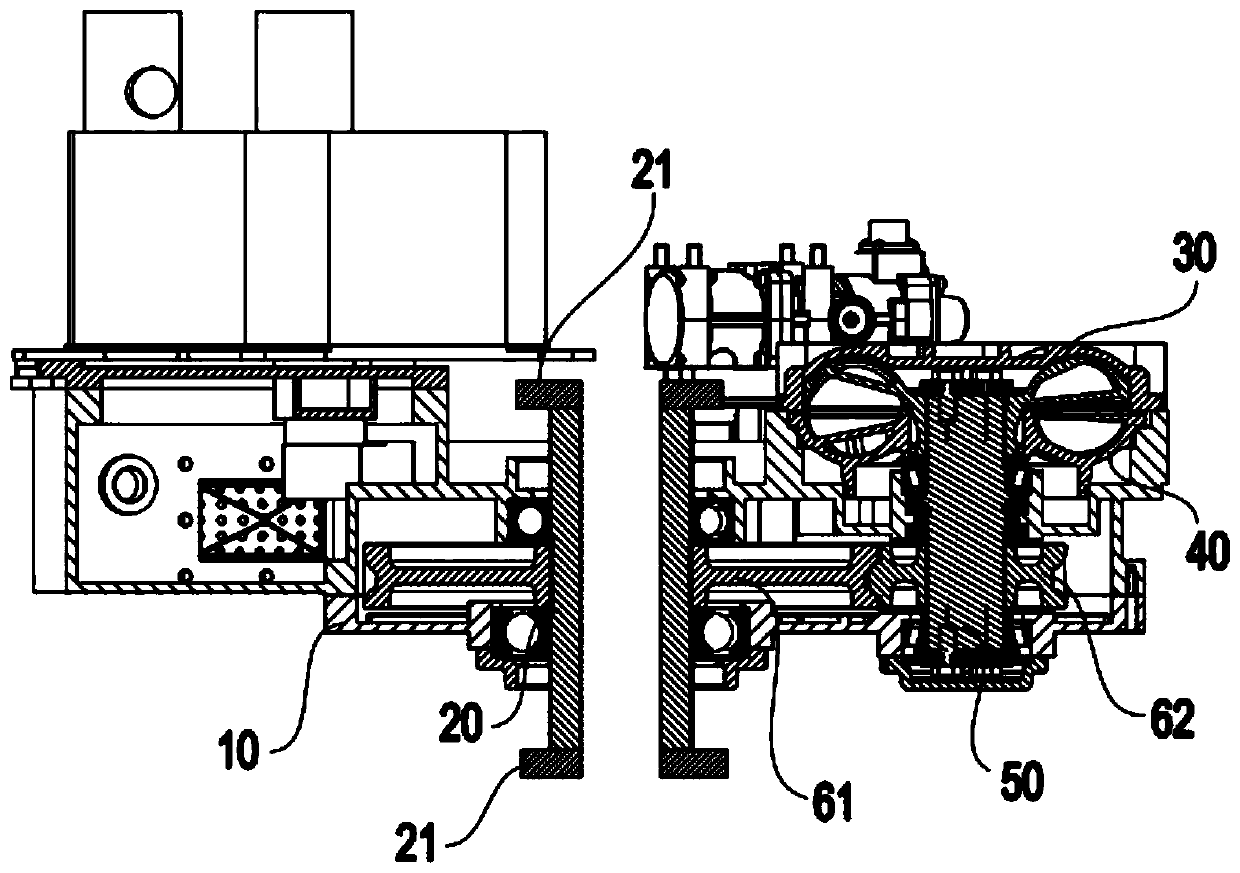

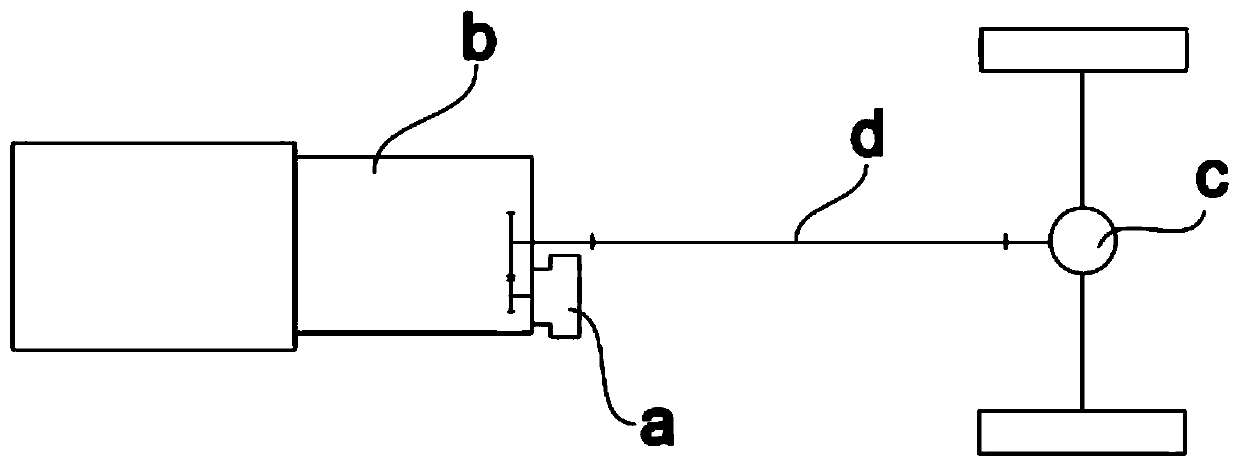

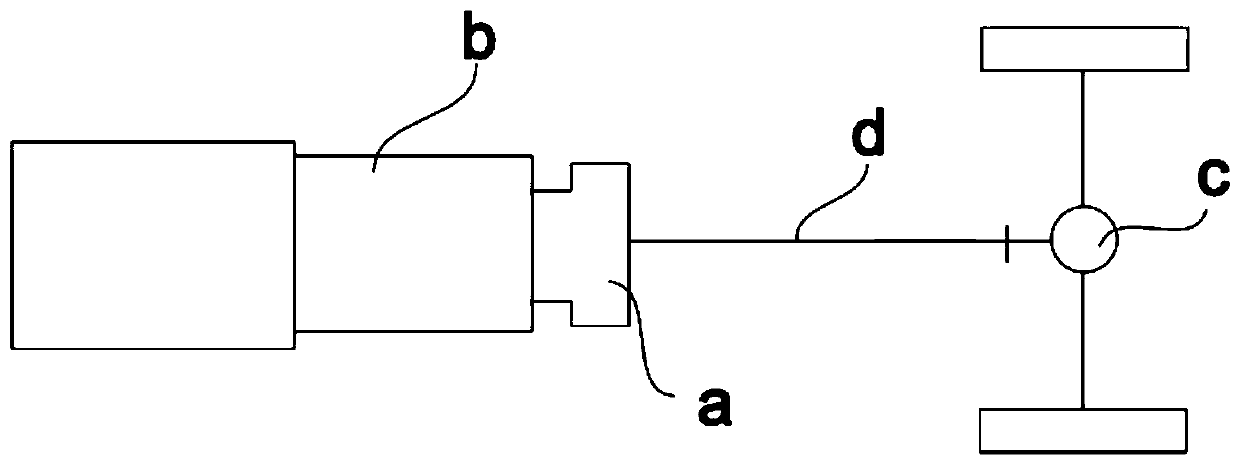

Hydraulic speed reducing device

PendingCN110081098AFlexible installationWide range of applicationsLiquid resistance brakesToothed gearingsImpellerStator

The invention discloses a hydraulic speed reducing device. The hydraulic speed reducing device comprises a shell, a first rotating shaft, and a rotor impeller, a stator impeller, a second rotating shaft and a speed adjusting mechanism integrated in the shell; a working cavity is formed between the rotor impeller and the stator impeller; the second rotating shaft is connected with the rotor impeller; the first rotating shaft is connected with the second rotating shaft through the speed adjusting mechanism; one end of the first rotating shaft is connected with an output shaft of a vehicle gearbox, and the opposite end is connected with an input shaft of a vehicle drive axle; or one end of the first rotating shaft is directly connected with the input shaft of the vehicle drive axle. The speedadjusting mechanism is integrated in the shell of the hydraulic speed reducing device to achieve the speed adjusting function; and meanwhile, through change of the mounting mode, the speed adjustingmechanism can be independently mounted on a vehicle girder without improving the structure of the vehicle gearbox to achieve the advantage of flexible installation.

Owner:SUZHOU TESUAN ELECTROMECHANICAL TECH CO LTD

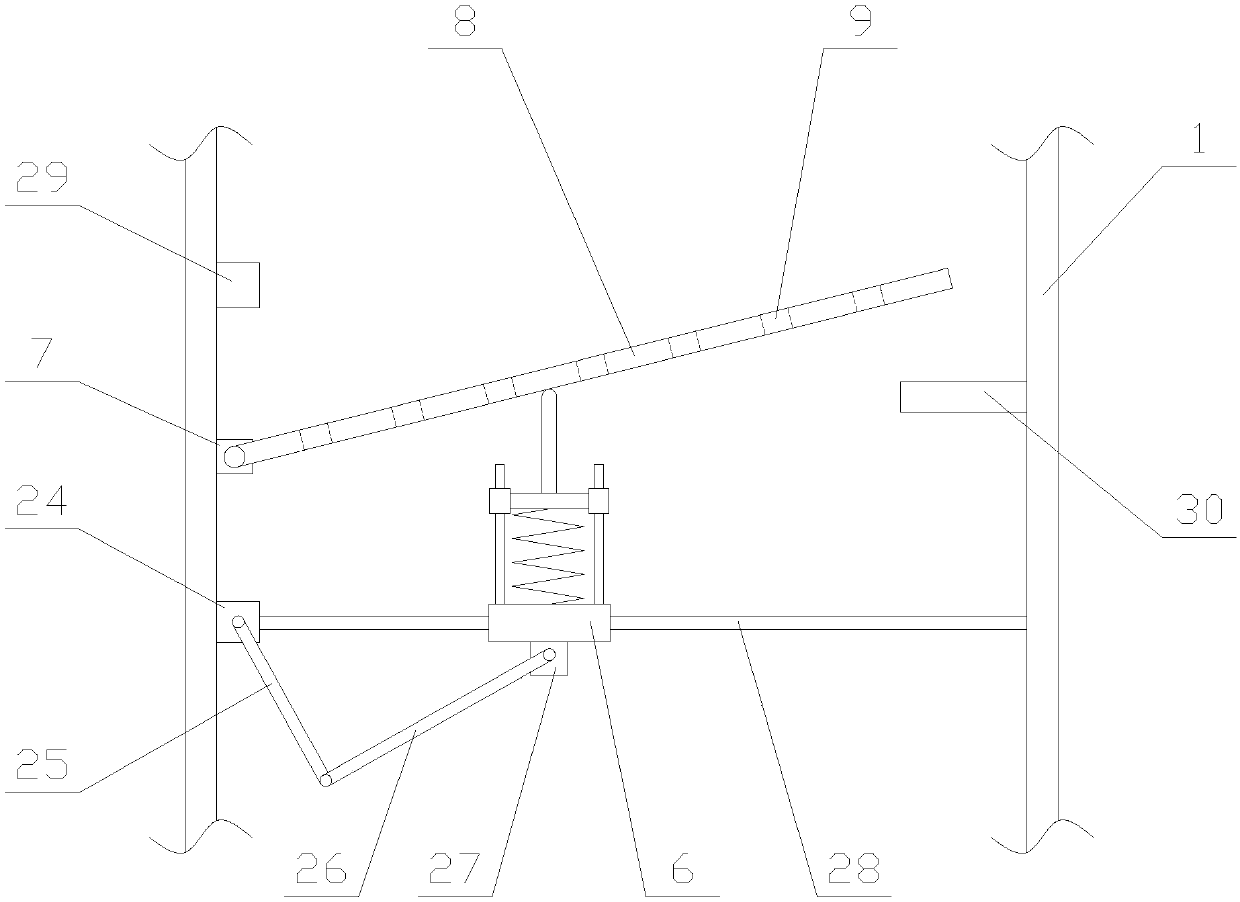

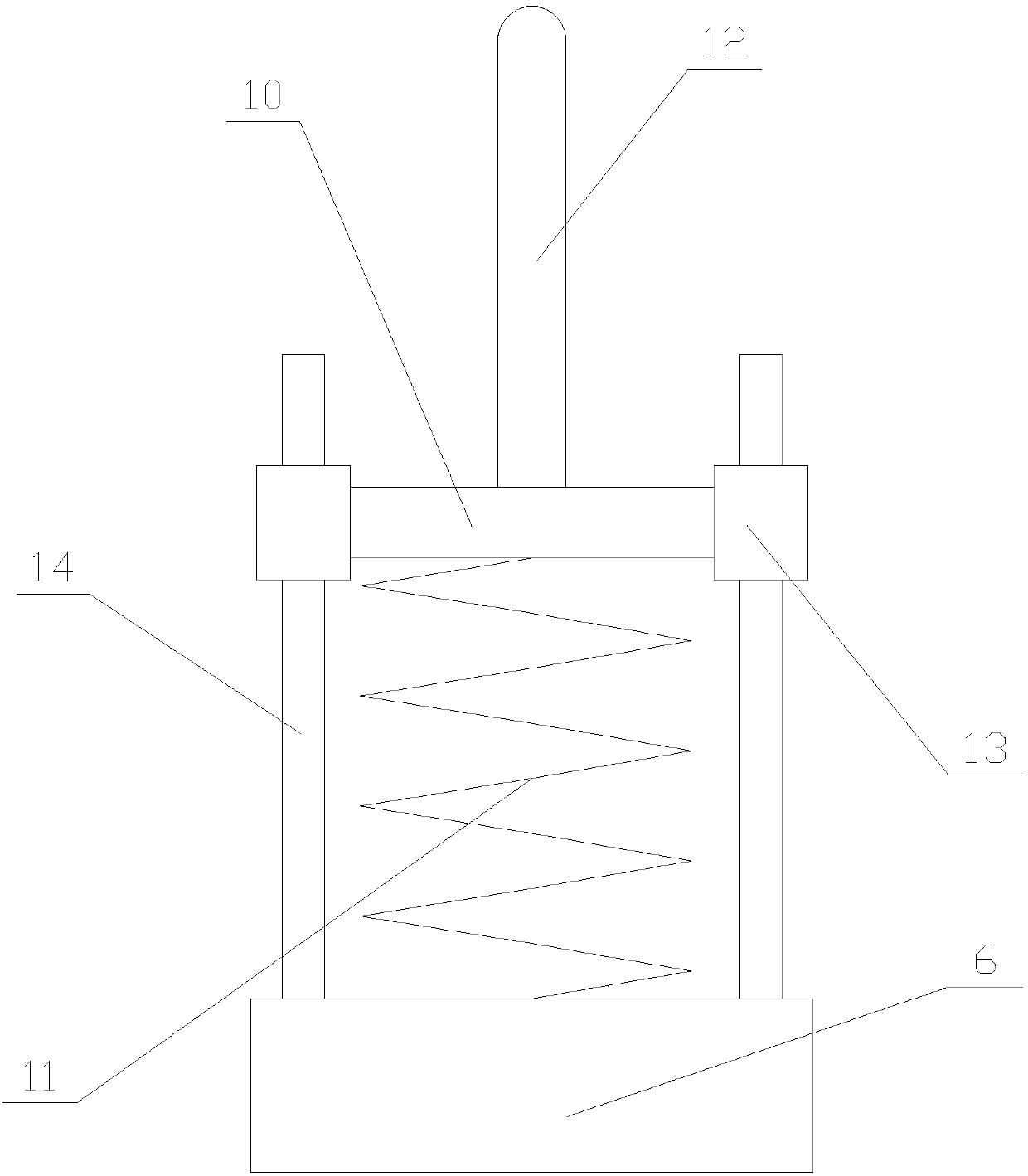

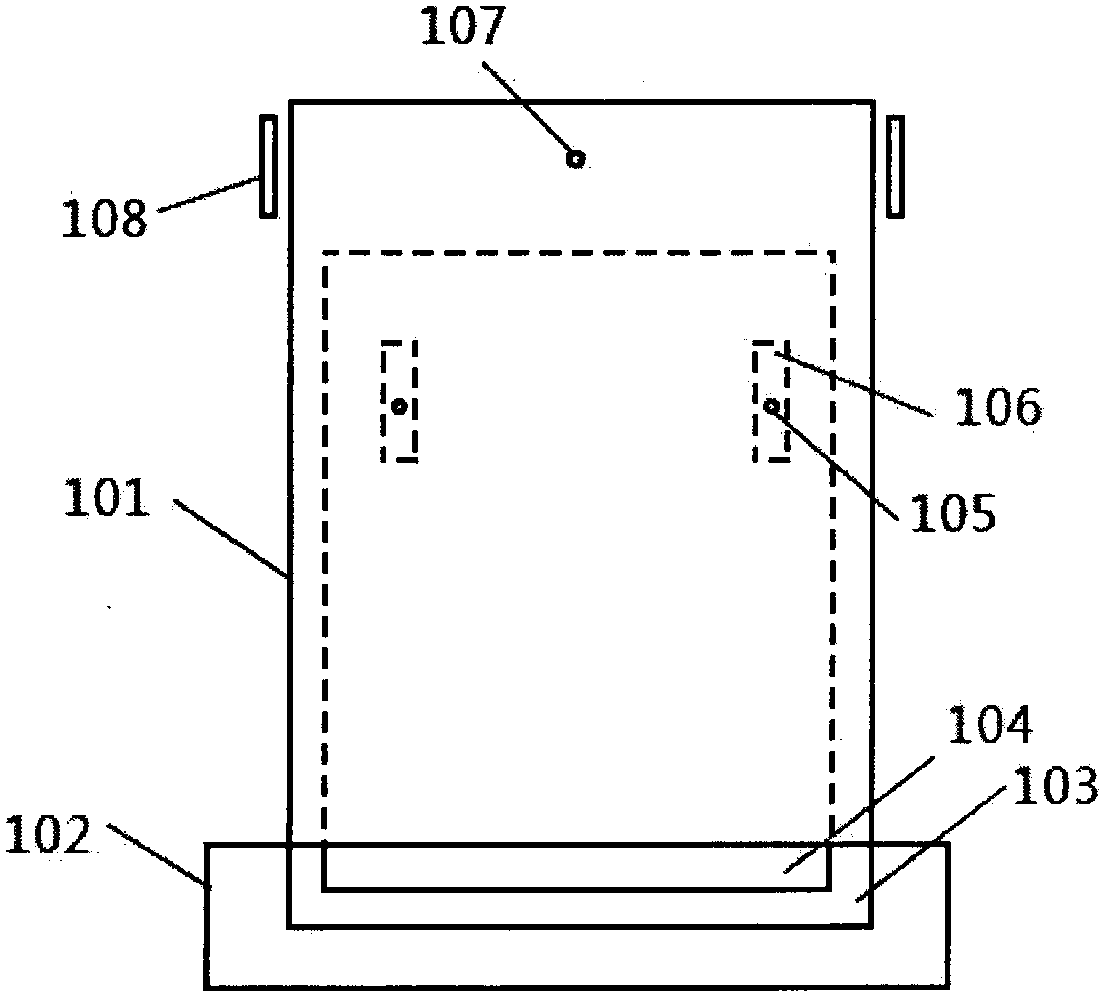

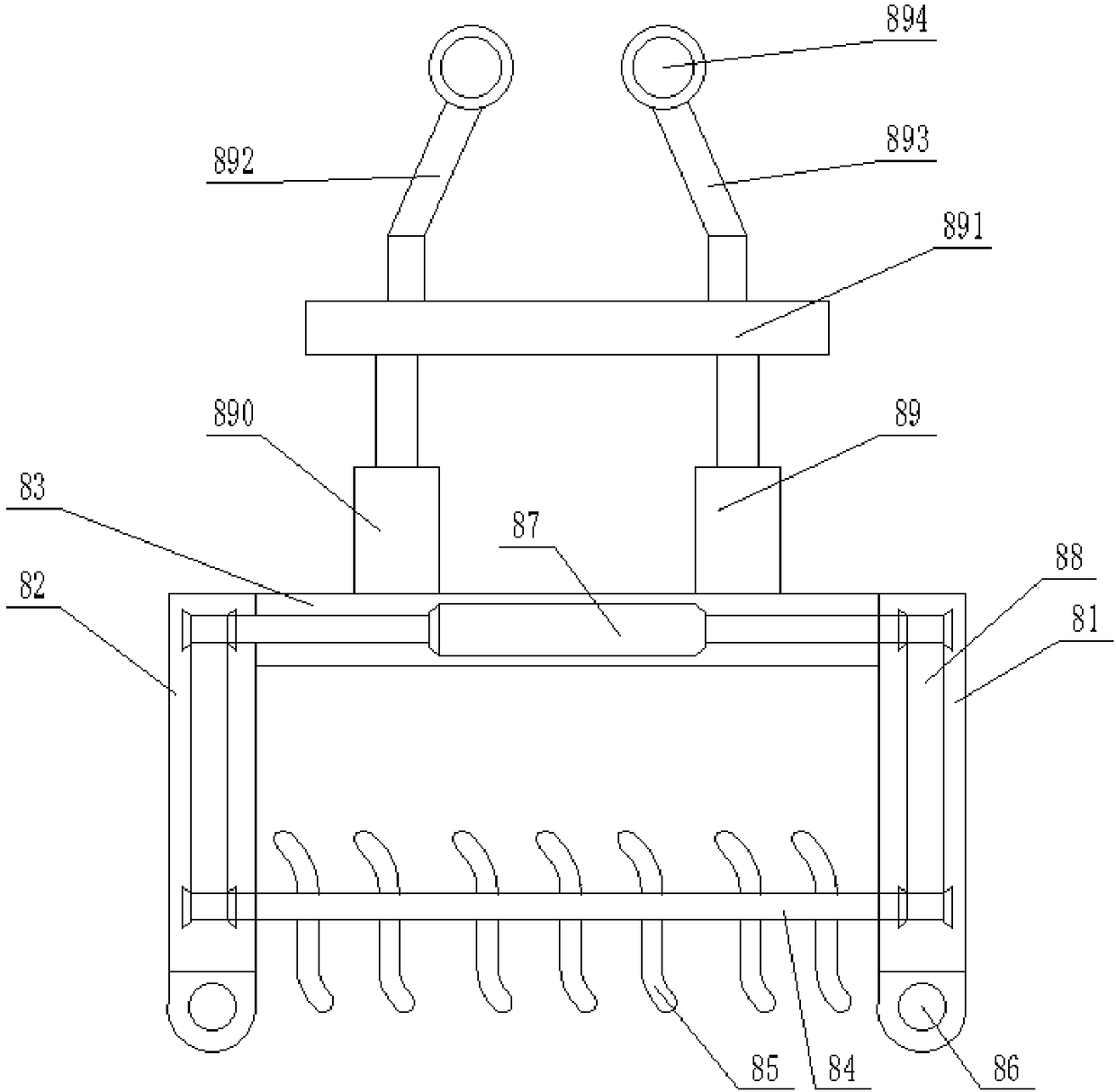

Hanging-type handheld vibrating plastering machine

PendingCN108505731AWith speed control functionReduced vibration dampingBuilding constructionsEngineeringWinch

The invention discloses a hanging-type handheld vibrating plastering machine, and relates to a building plastering machine. The hanging-type handheld vibrating plastering machine is composed of a handheld vibrating plastering device, a sling, a hanging bracket and an electric winch. The handheld vibrating plastering device is connected with the hanging bracket and the electric winch through the sling. A high-frequency vibrator, a control handle and a controller are arranged on a machine body of the handheld vibrating plastering device. The handheld vibrating plastering device is connected withthe hanging bracket only through the sling to be hung on the lower portion of one end of a hanging arm of the hanging bracket. A constructor operates the handheld vibrating plastering machine throughthe control handle with the controller to make back and forth movement from bottom to top for construction. The electric winch is arranged on the hanging bracket constituted by a base, a vertical column and the hanging arm, and the hanging arm can rotate in the horizontal direction. The hanging-type handheld vibrating plastering machine has the characteristics of simple structure, flexible operation and high practicability.

Owner:吴奉军

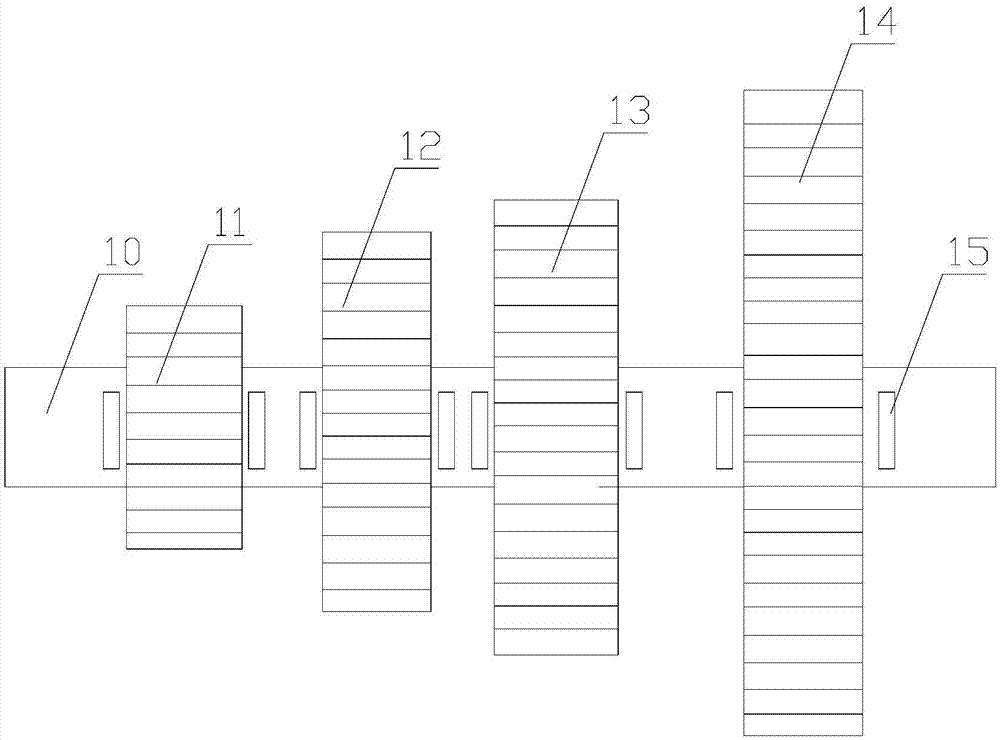

Speed regulating mechanism of electric bench grinder

InactiveCN104191364AWith speed control functionEasy to useGrinding drivesAutomatic grinding controlElectric machineryBench grinder

The invention discloses a speed regulating mechanism of an electric bench grinder. The speed regulating mechanism of the electric bench grinder has the speed regulating function and comprises a motor end cover and a motor shaft, wherein a photosensitive piece is arranged on the motor shaft, a plurality of photosensitive holes are formed in the photosensitive piece, a photoreceptor which is matched with the photosensitive piece is arranged on the motor end cover, and the photoreceptor is connected with a control panel through a circuit board. The speed regulating mechanism of the electric bench grinder has the advantages that the speed regulating function is achieved, and using is extremely convenient.

Owner:陈新中

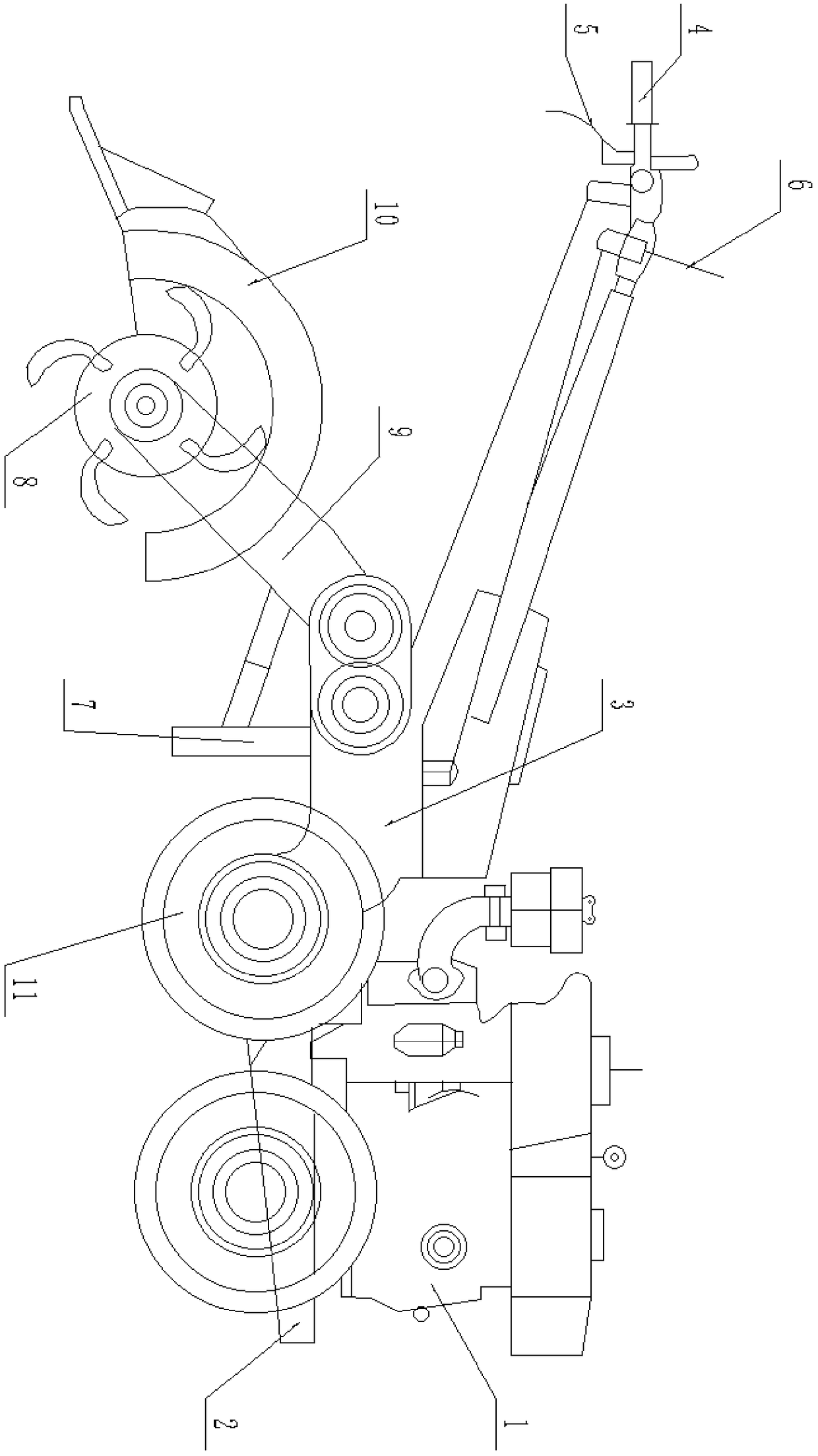

Four-wheel drive rotary cultivator

The invention provides a four-wheel drive rotary cultivator, and solves the problems that the height of a prior rotary cultivator is fixed and cannot be adjusted, the rotary cultivator is driven by two wheels, the climbing capacity is not enough at pot hole places, the rotary cultivator falls into the pot holes easily, and the prior used blades are generally integrated. When the four-wheel drive rotary cultivator provided by the invention is in use, a front walking shaft and a rear walking shaft are connected together by chains, so that four-wheel drive is realized, and the phenomena that theclimbing capacity is not enough at pot hole places and the rotary cultivator slips easily can be avoided; two ends of a rotary cultivator shaft are directly driven by a double-output-shaft gasoline engine, and the two ends of the rotary cultivator shaft are directly connected by adopting double output shafts, so that enough power is ensured, a speed adjusting function is achieved, and the speed adjustment is convenient; when the height needs to be adjusted, the height is directly adjusted by a first lifting column and a second lifting column; a rotary cultivator is connected with a connectingseat through fixing bolts, so that convenience for later disassembly and maintenance is provided; and blades are designed by adopting a split type, so that when the rotary blades are required to be sharpened, the rotary cultivator blades can be removed through fixing pieces, sharpening is carried out separately, and great convenience is provided to sharpening operators.

Owner:咸阳恒佳机械有限公司

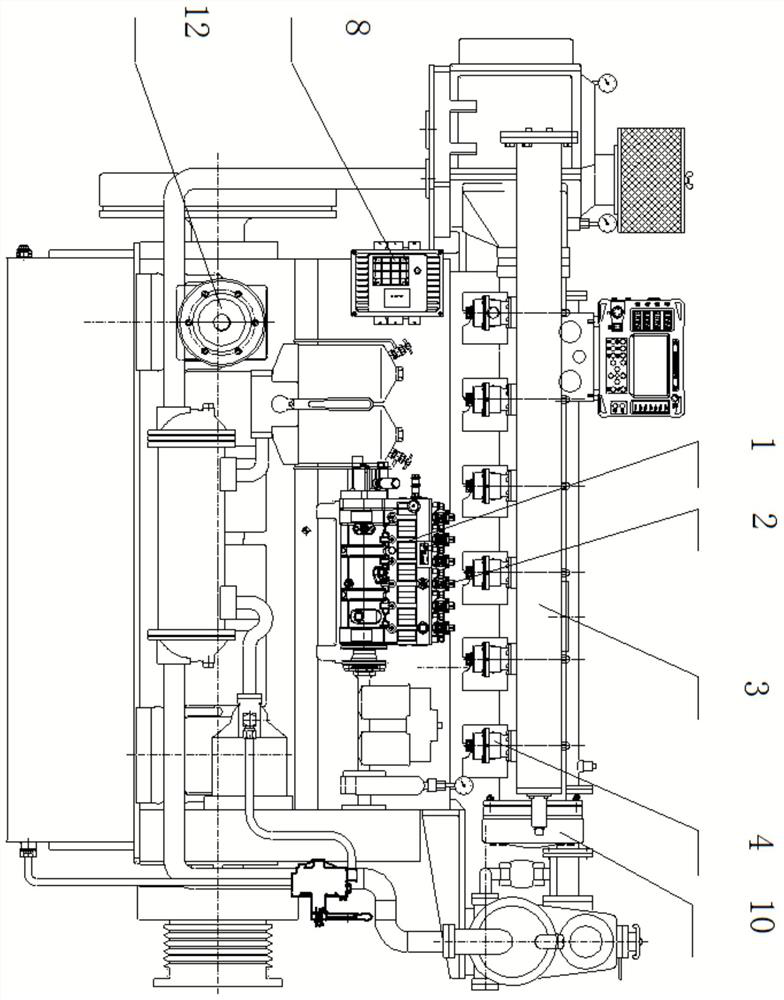

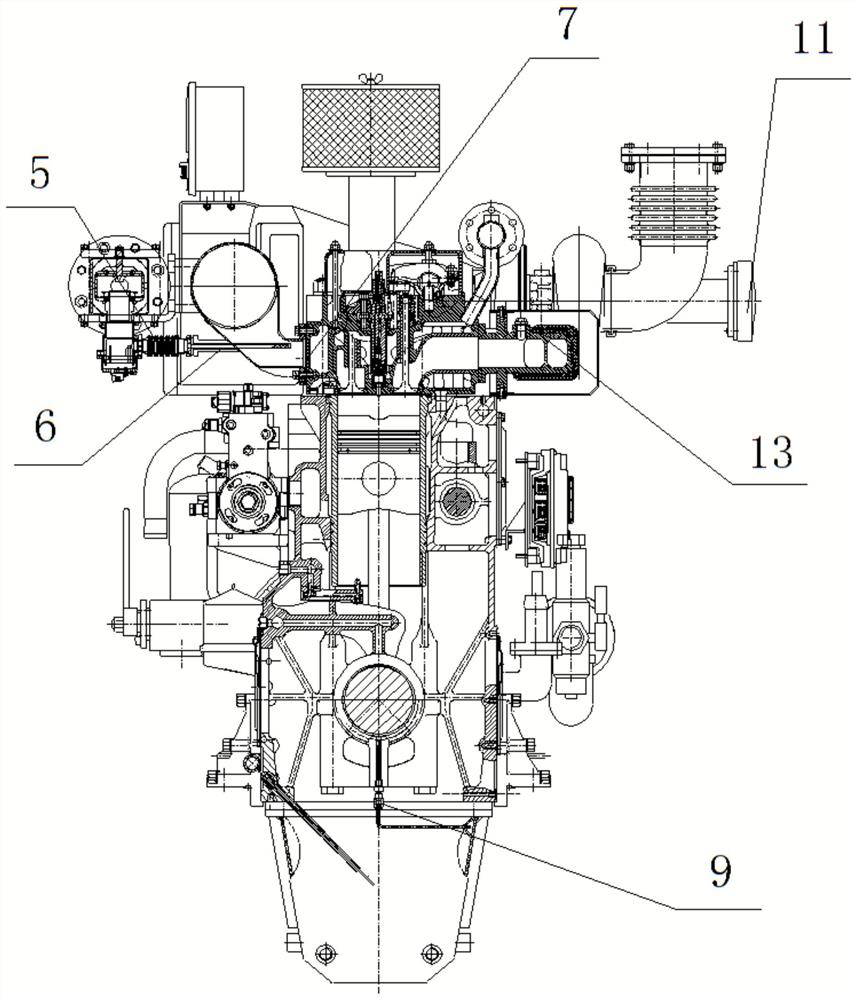

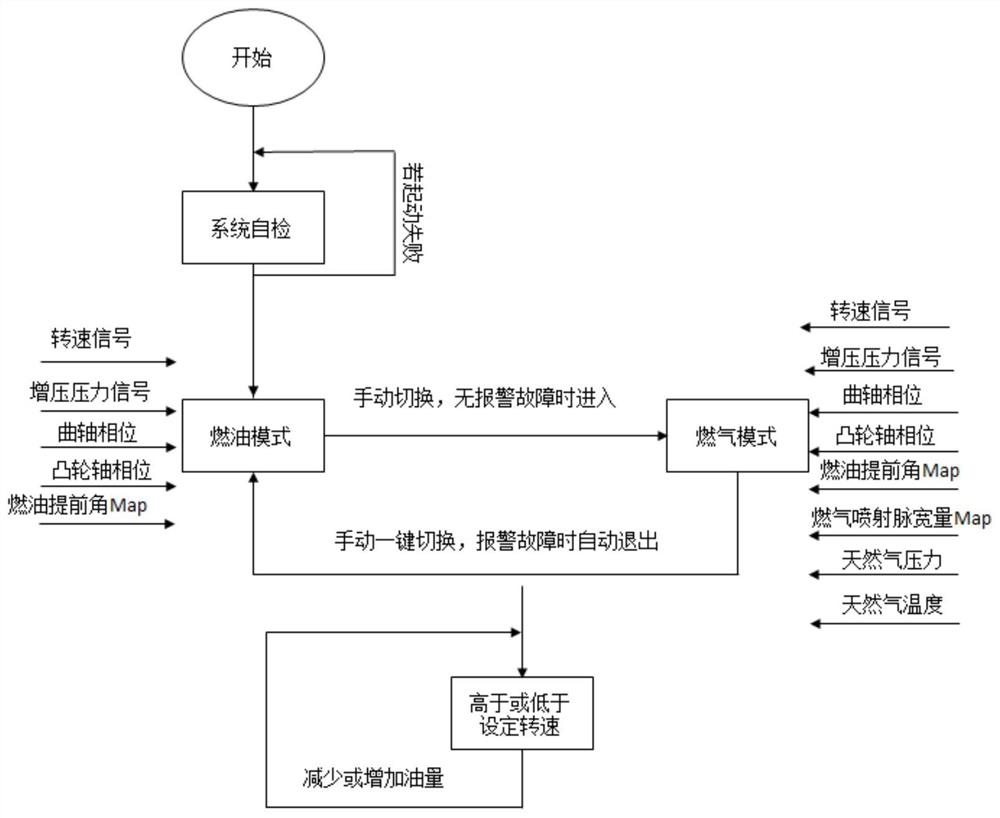

Marine medium-and-high-speed oil-gas double-electric-control dual-fuel engine

PendingCN113217206ARealize speed adjustment functionGuaranteed operational safetyElectrical controlMachines/enginesMarine engineeringCommon rail

The invention relates to a marine medium-high-speed oil-gas dual-electronic-control dual-fuel engine. The marine medium-high-speed oil-gas dual-electronic-control dual-fuel engine comprises a fuel high-pressure injection electronic-control combined pump, fuel injection electromagnetic valves and a natural gas injection system common rail pipe, wherein the fuel injection electromagnetic valves are arranged at the fuel outlet positions of plungers of all cylinders; the fuel injection time and the fuel quantity are controlled through a fuel control part in an oil-gas double-control ECU; each cylinder of the natural gas injection system common rail pipe is provided with a fuel gas injection electromagnetic valve respectively; opening and closing of the fuel gas injection electromagnetic valves are controlled through a fuel gas part in the oil-gas double-control ECU; and fuel gas is directly injected to a gas inlet of a cylinder cover through a corrugated pipe and a fuel gas injection pipe. Meanwhile, the invention discloses a working method of the marine medium-high-speed oil-gas dual-electronic-control dual-fuel engine. According to the working method, parameters such as required injection oil quantity and pulse width are automatically calculated according to hardware parameters of an electronic control pump hardware parameter ECU, and oil quantity correction is carried out based on the rotating speed and exhaust temperature difference, so that the rotating speed adjusting function of the engine is achieved.

Owner:淄柴机器有限公司

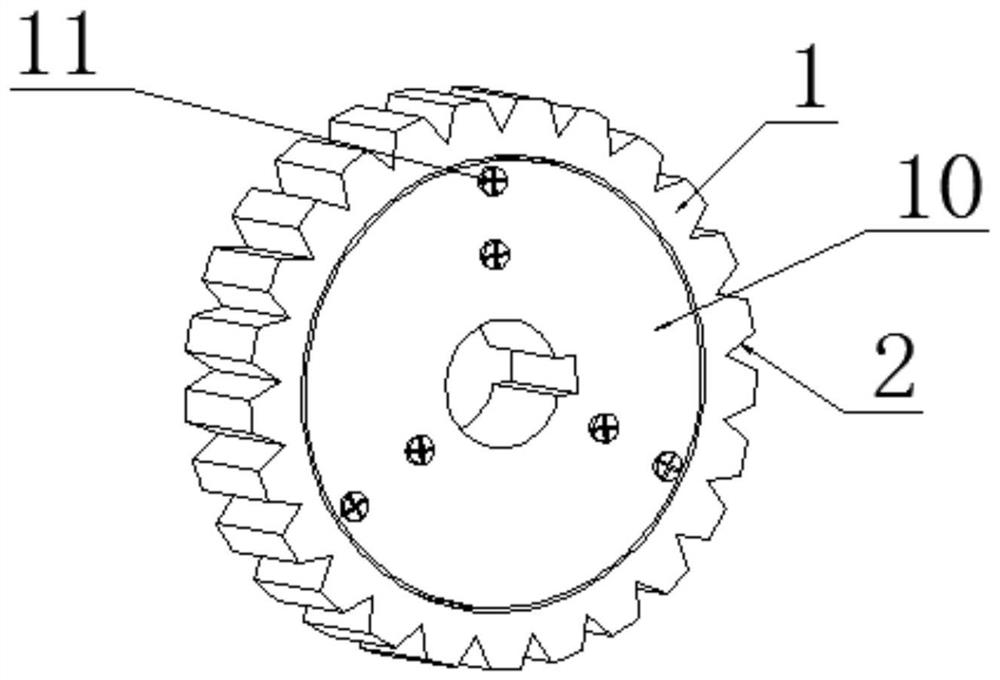

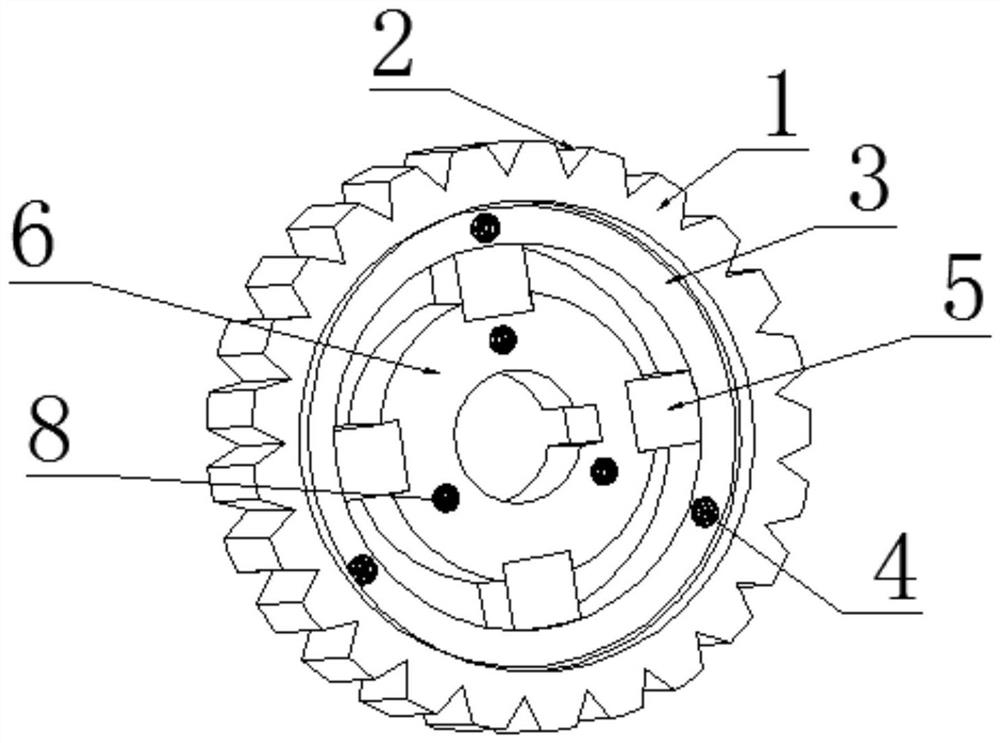

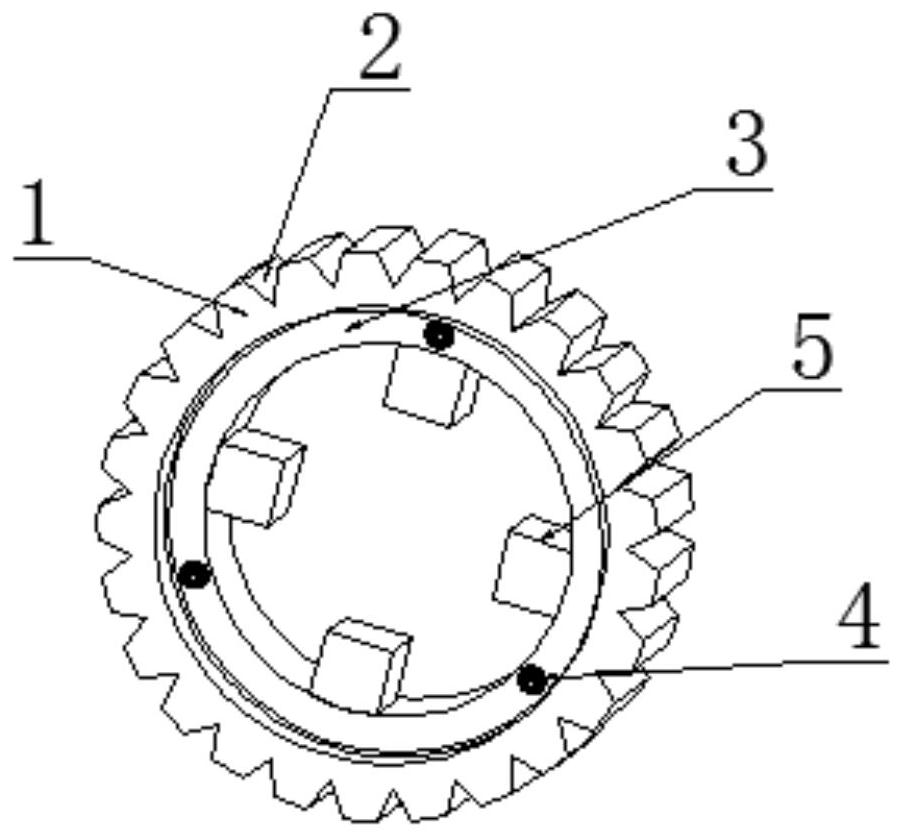

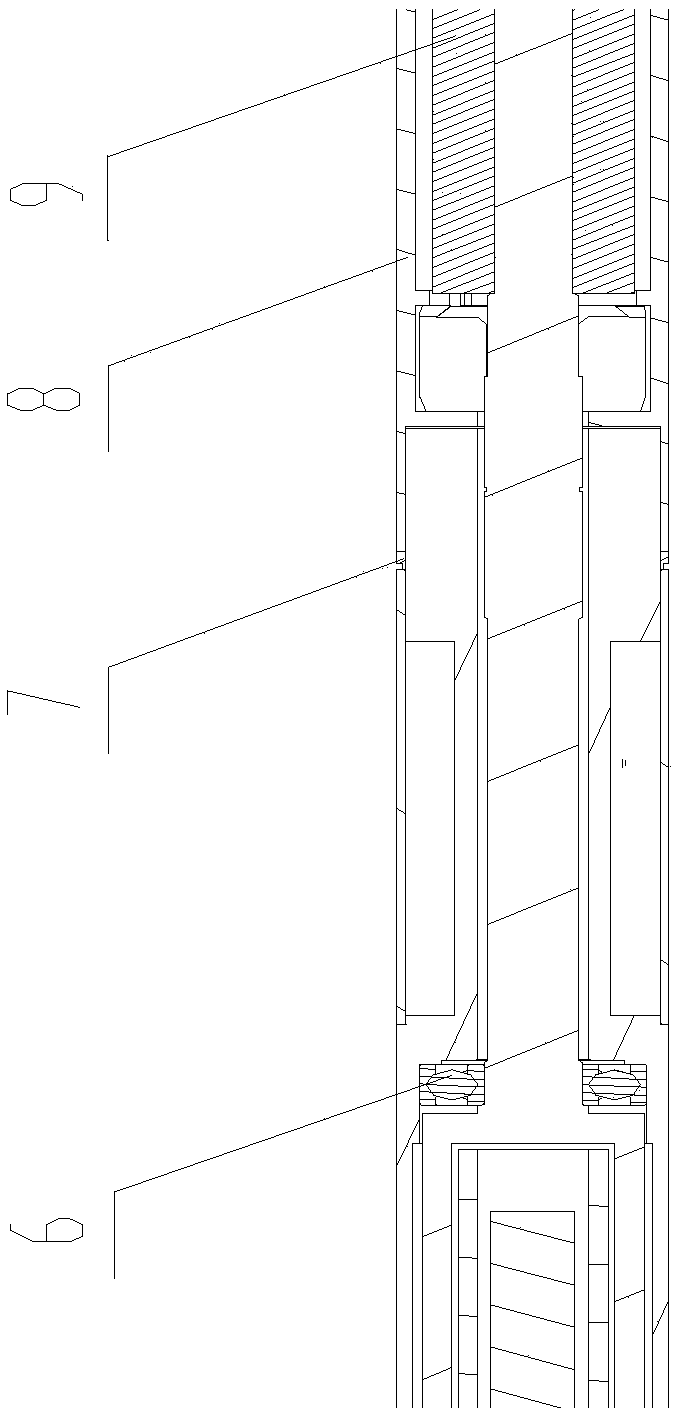

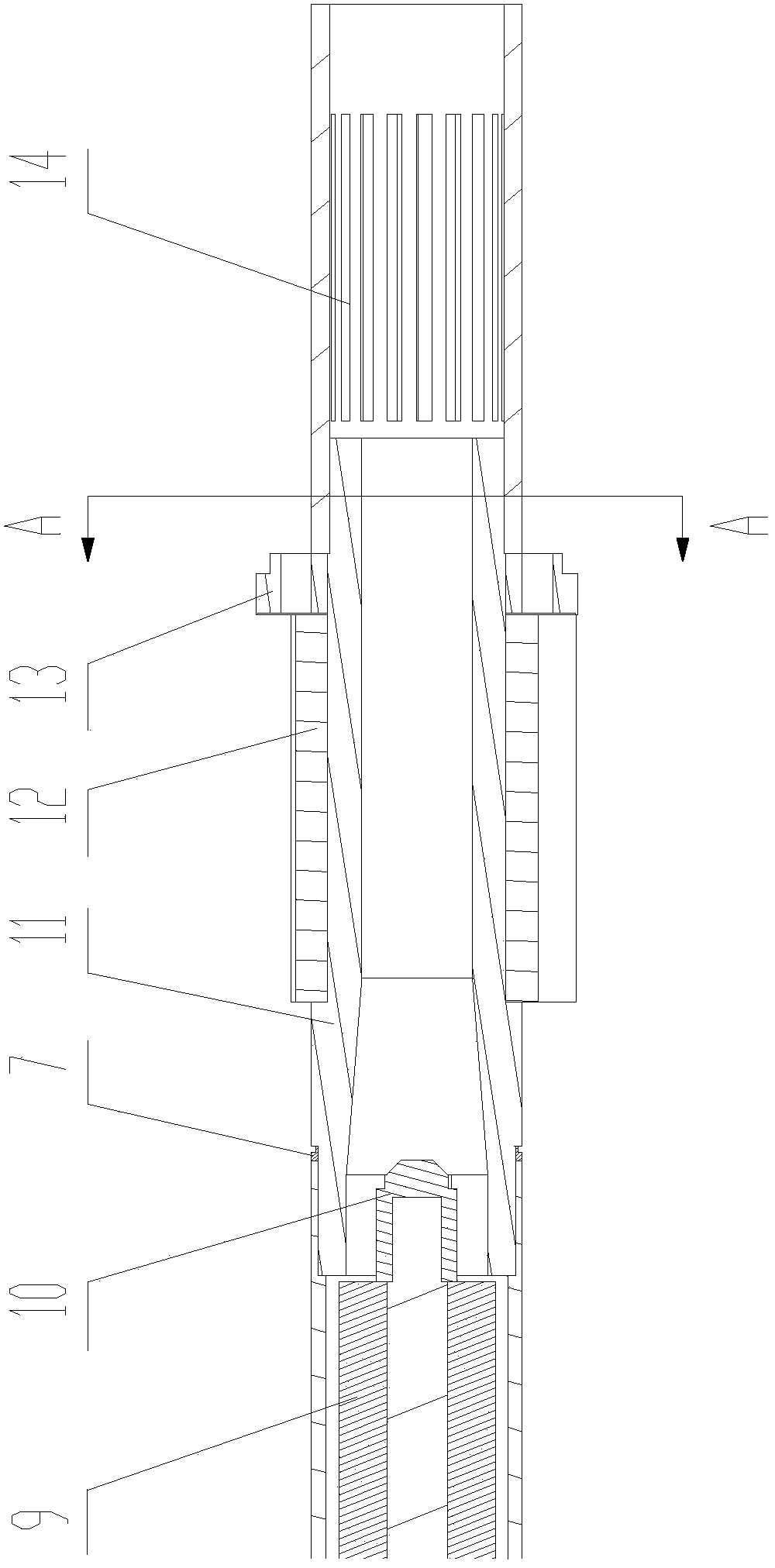

Annular gear with speed regulating function

InactiveCN111664240AWith speed control functionSimple speed regulationEngine sealsPortable liftingGear wheelEngineering

Owner:黄华

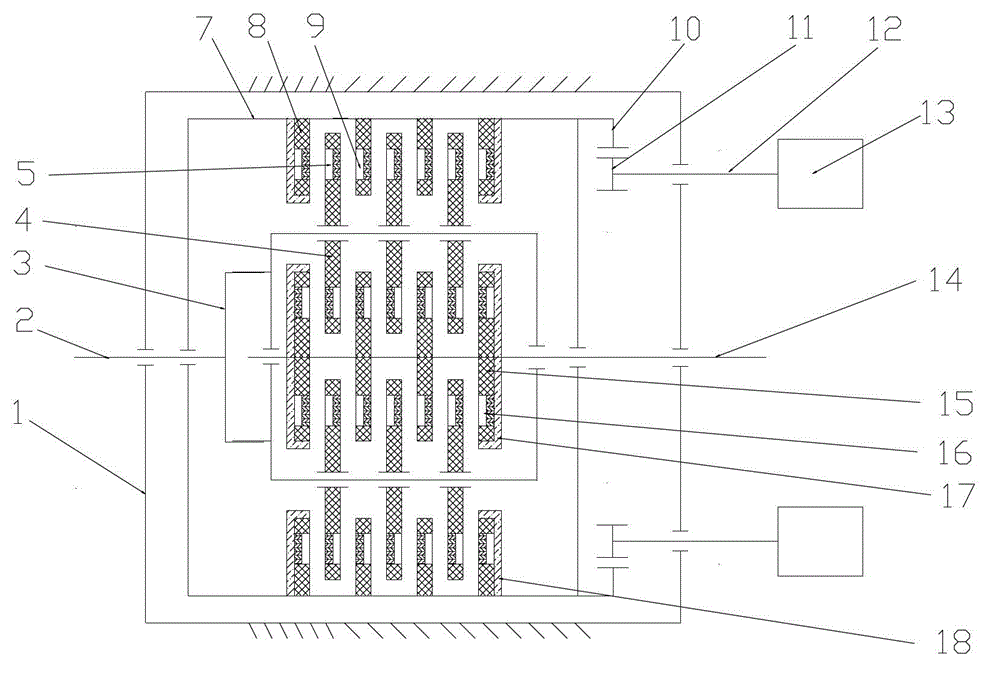

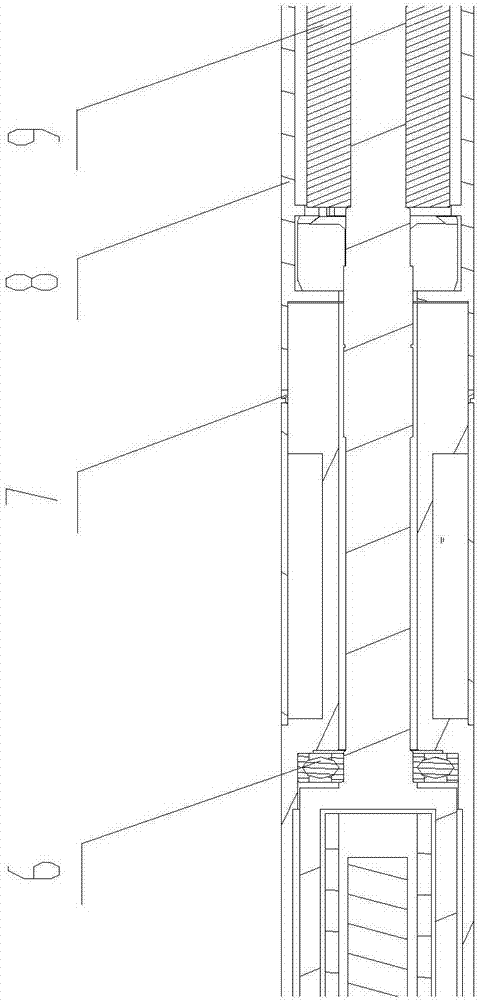

Measurement while drilling mud generator with speed regulation function

ActiveCN104675612AWith speed control functionExcellent output power qualityHydro energy generationReaction enginesImpellerPower quality

The invention discloses a measurement while drilling mud generator with a speed regulation function. The mud generator comprises a mud impeller, a magnetic coupling transmission device, a generator shell, a generator stator, a generator rotating shaft, a speed regulating motor stator, a speed regulating circuit and a speed measuring sensor. One end of the magnetic coupling transmission device is fixedly connected with the mud impeller while the other end is fixedly connected with the generator rotating shaft, the magnetic coupling transmission device is arranged in the generator shell, and the generator stator and the speed regulating motor stator are fixed to the inner wall of the generator shell. The input end of the speed regulating circuit is connected with the output end of the speed measuring sensor, and the rotating speed of a motor is regulated according to an induction value of the speed measuring sensor. The rotating speed of the motor is more stable, output voltage is smoother, output electric energy is higher in quality, motor efficiency is improved while service life is prolonged by the aid of the stable rotating speed, and performance of the motor is better.

Owner:BEIJING RES INST OF PRECISE MECHATRONICS CONTROLS

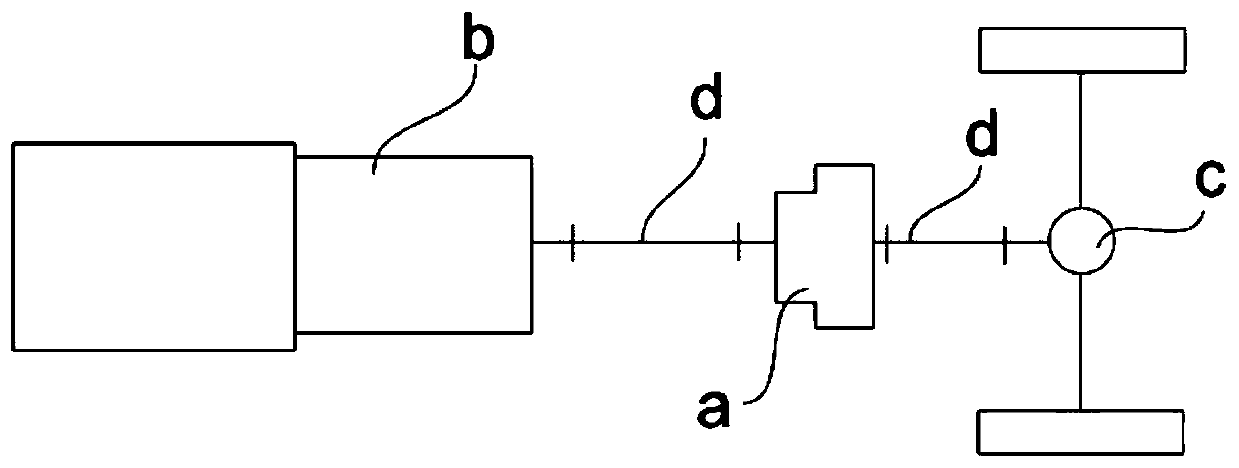

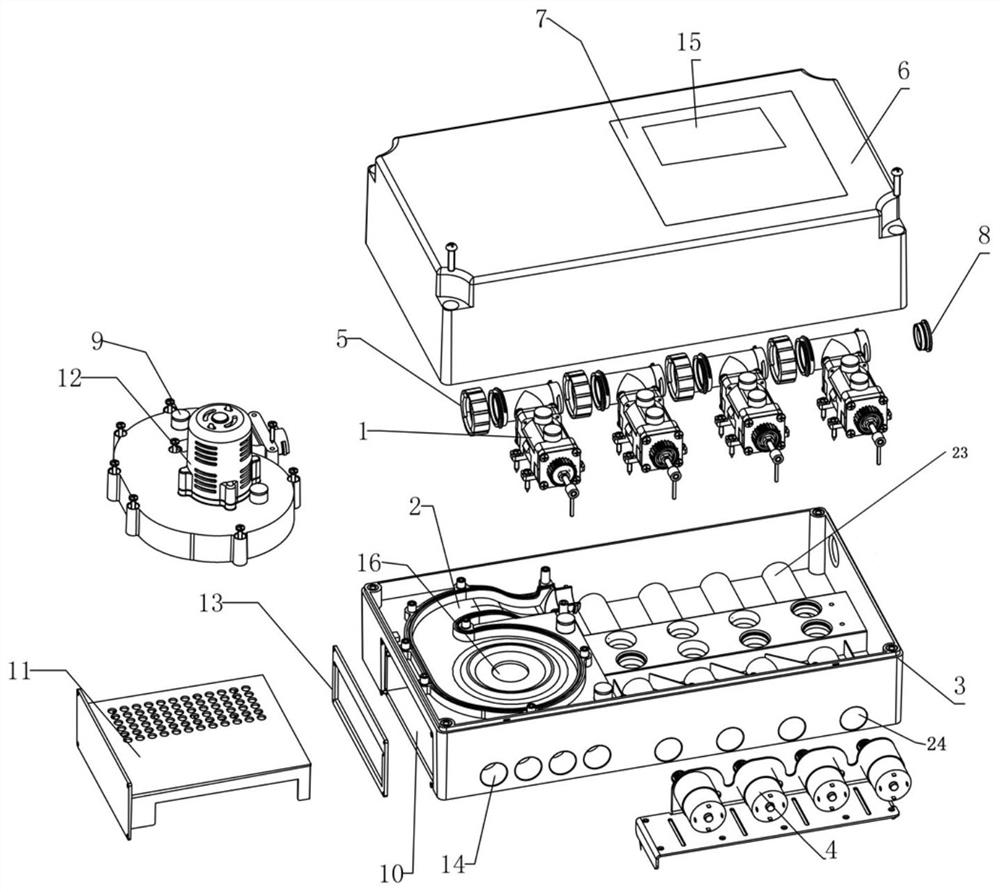

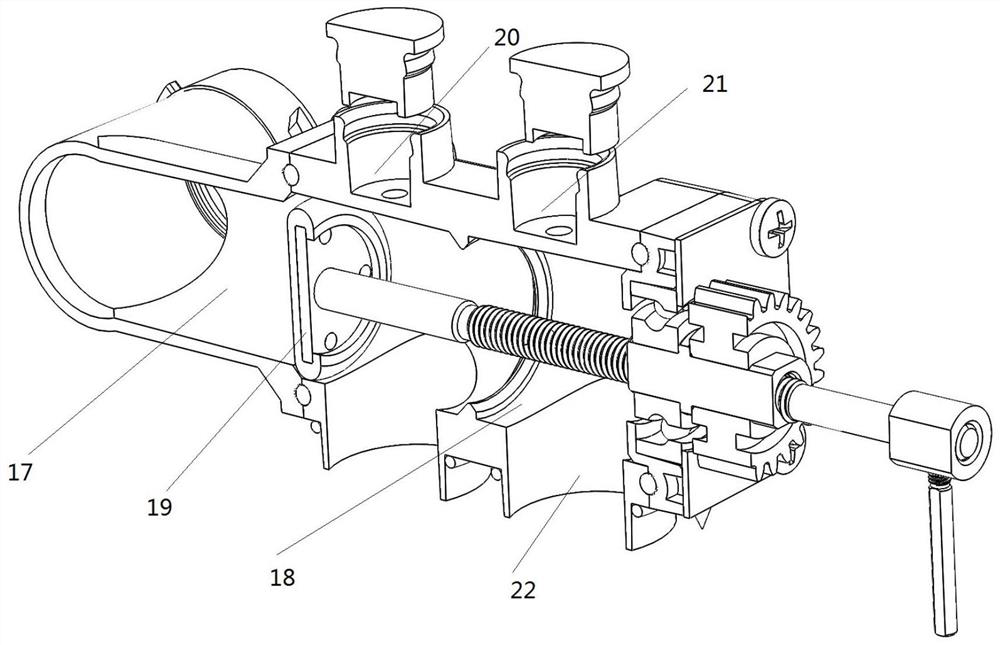

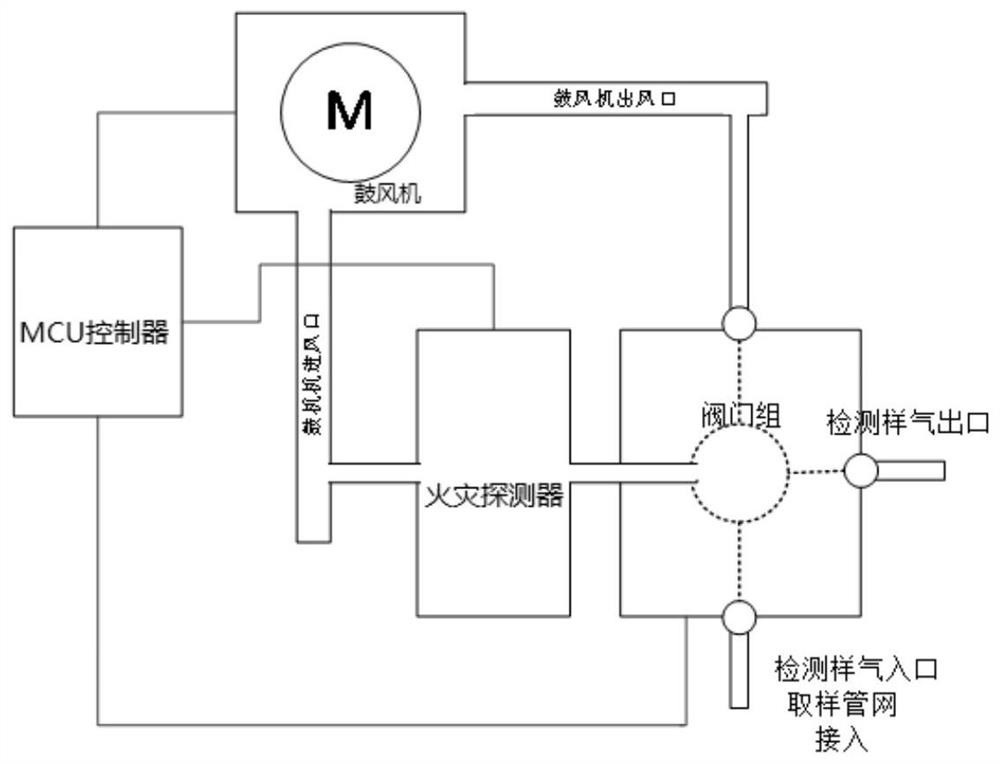

Self-cleaning air sampling alarm device and working method thereof

PendingCN112309072AEasy accessDoes not affect power supplyHollow article cleaningParticle suspension analysisFire detectorAutomatic control

The invention discloses a self-cleaning air sampling alarm device which comprises a valve assembly, a fan assembly, a base, a driving motor, a valve group coupler and an MCU controller integrated on aPCB, the fan assembly is communicated with one end of the valve assembly through the valve group coupler, and the other end of the valve assembly is provided with a plug. The fan assembly is used forproviding sample gas flow with stable wind pressure, the valve assembly is used for realizing multipath sampling detection feedback results, and the MCU controller is used for receiving and feeding back instructions to realize automatic control. The device has the beneficial effects that the structure is simple, the wind speed loss is good, pipe network cleaning and pressurizing functions can beswitched, during normal work, a high-pressure air inlet of the air blower is cut off, and the air suction type fire detector on the pipe network is prevented from being damaged; during cleaning, the air blower sucks air through the air filter and outputs high-pressure clean air; and during pressurization work, the sensitivity of the air-breathing fire detector can be improved.

Owner:YUNNAN HUOFENGHUANG FIRE TECH

Hydraulic axial plunger type transmission roller capable of adjusting speed

The invention discloses a hydraulic axial plunger type transmission roller capable of adjusting speed. The hydraulic axial plunger type transmission roller capable of adjusting speed comprises a roller driving device arranged between two radial plates, the roller driving device comprises a supporting body, a steel ball, an inclined disc, a rotary table, a plunger, a cylinder body and an oil distribution disc, and a shaft oil inlet and a shaft oil outlet are formed in the front end surface of a roller shaft. According to the hydraulic axial plunger type transmission roller capable of adjustingspeed, rotary torque is generated on the rotary table by using radial component force of the rotary table generating counter-acting force on the plunger under the extrusion of the plunger, the rotarytorque pushes the barrel body to rotate through cylinder bodies mounted on the inner surface of barrel body in a uniform distribution mode in the circumferential direction, on the one hand, the innerspace of the barrel body can be fully used, on the other hand, a mode of roller axial inlet and outlet pressure oil is adopted, therefore, additional transmission device installation space does not need to be arranged, installation and maintenance are facilitated, the production cost and the maintenance cost of auxiliary facility can be reduced, and the hydraulic axial plunger type transmission roller capable of adjusting speed is especially suitable for high gas mines or belt conveyors with no space arranged in a transmission device.

Owner:XUZHOU UNIV OF TECH

Hydraulic speed reduction device

PendingCN110081096AWith speed control functionChange braking torqueLiquid resistance brakesToothed gearingsImpellerStator

The invention discloses a hydraulic speed reduction device. The hydraulic speed reduction device is installed and attached to a vehicle speed changing box and is connected with an output shaft or a transmission shaft of the vehicle speed changing box in parallel. The hydraulic speed reduction device comprises a shell, a driven gear and a first rotation shaft and further comprises a rotor impeller,a stator impeller, a second rotation shaft and a speed adjusting mechanism which are integrated in the shell. A work cavity is formed between the rotor impeller and the stator impeller. The second rotation shaft is connected with the rotor impeller. The first rotation shaft stretches into the shell and is connected with the second rotation shaft through the speed adjusting mechanism. The driven gear is in shaft connection to the first rotation shaft and is engaged with a drive gear on the output shaft of the vehicle speed changing box. The speed adjusting mechanism is integrated in the shellof the hydraulic speed reduction device, the hydraulic speed reduction device has the function of speed adjusting, meanwhile, the installing manner of the hydraulic speed reduction device is changed,the hydraulic speed reduction device is connected with the vehicle speed changing box in parallel, the structure of the hydraulic speed reduction device can be more compact, and the production cost isreduced.

Owner:SUZHOU TESUAN ELECTROMECHANICAL TECH CO LTD

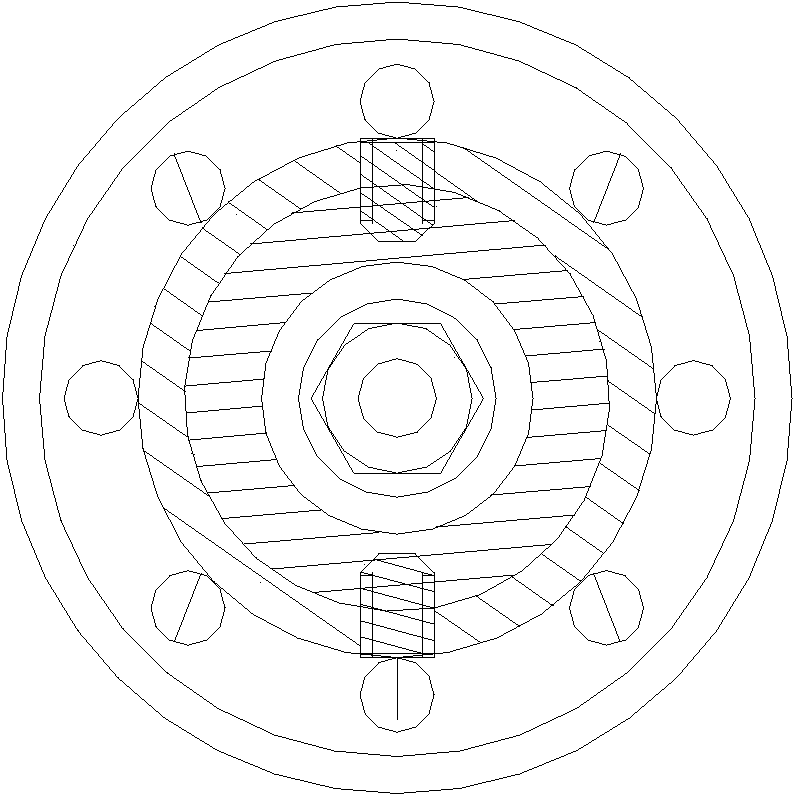

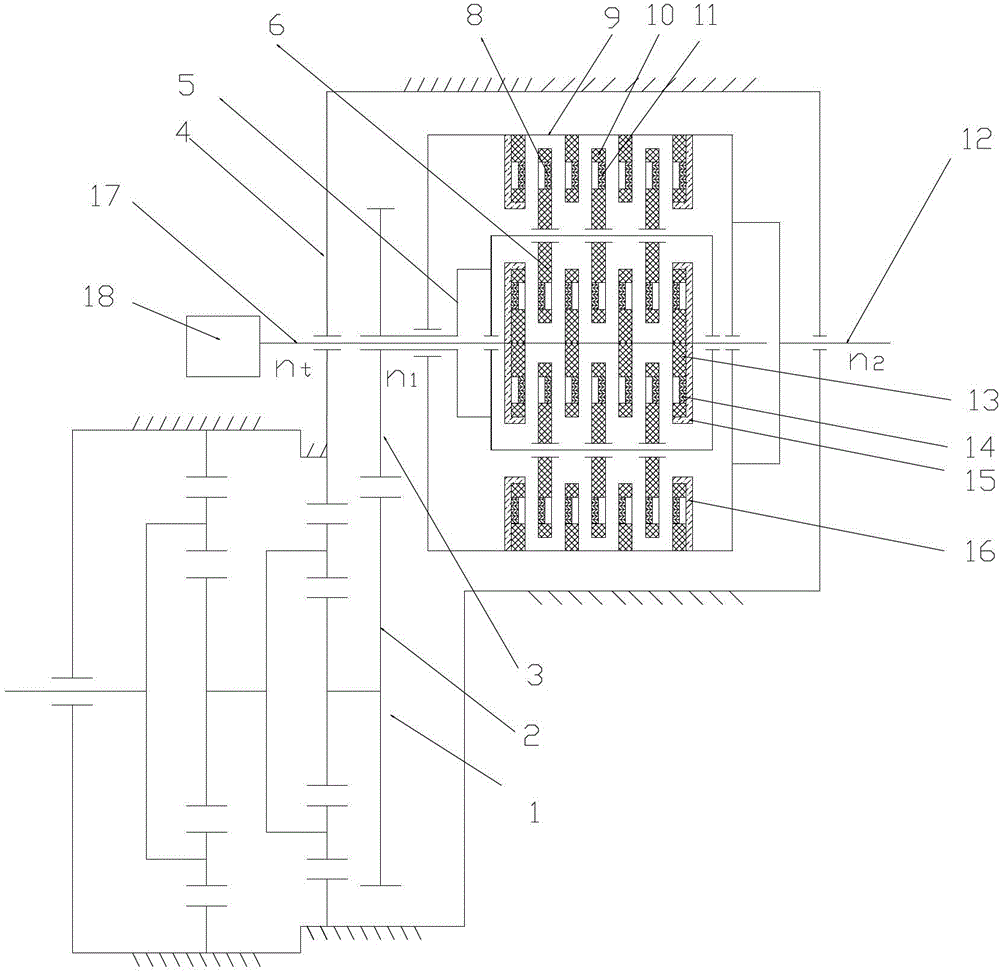

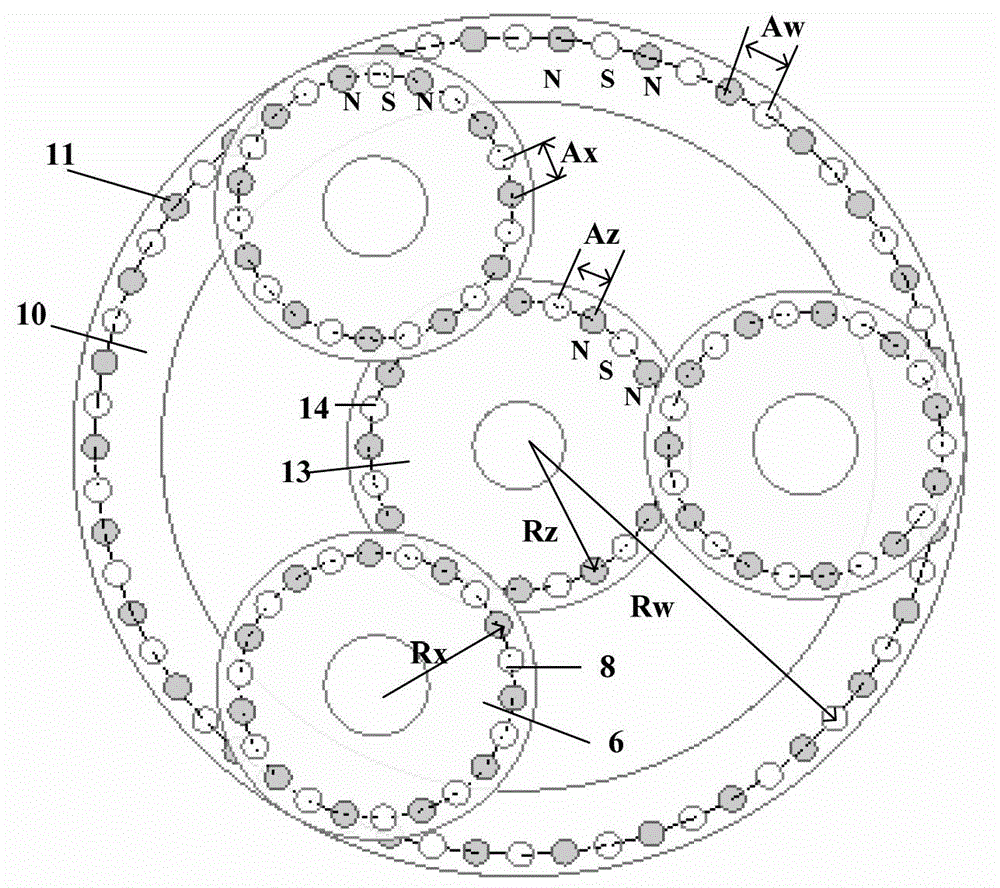

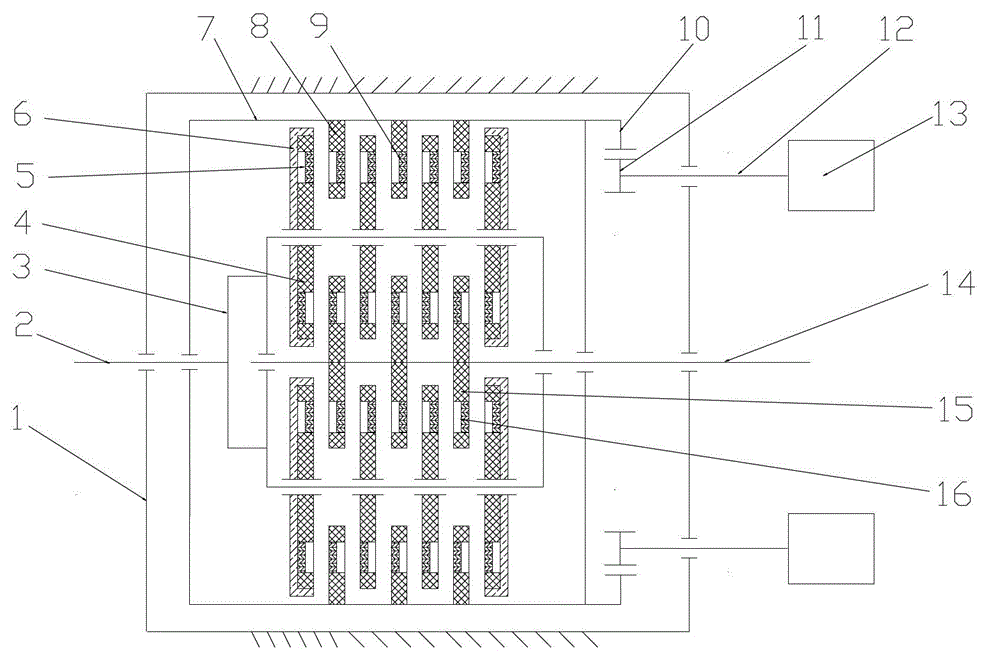

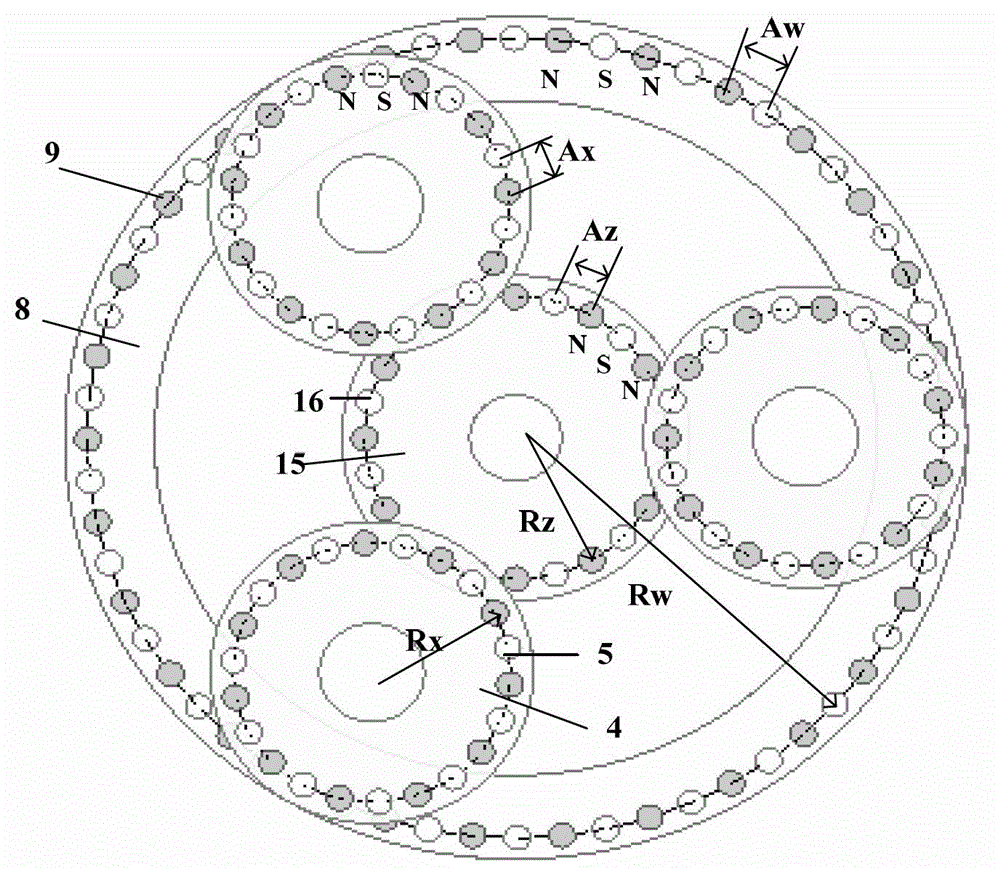

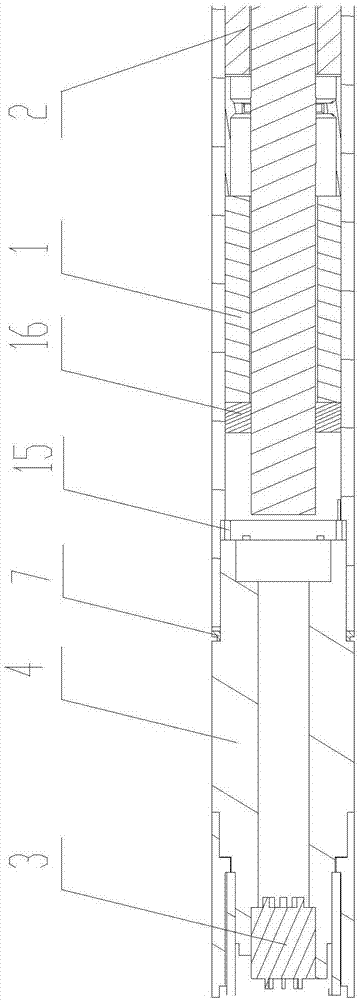

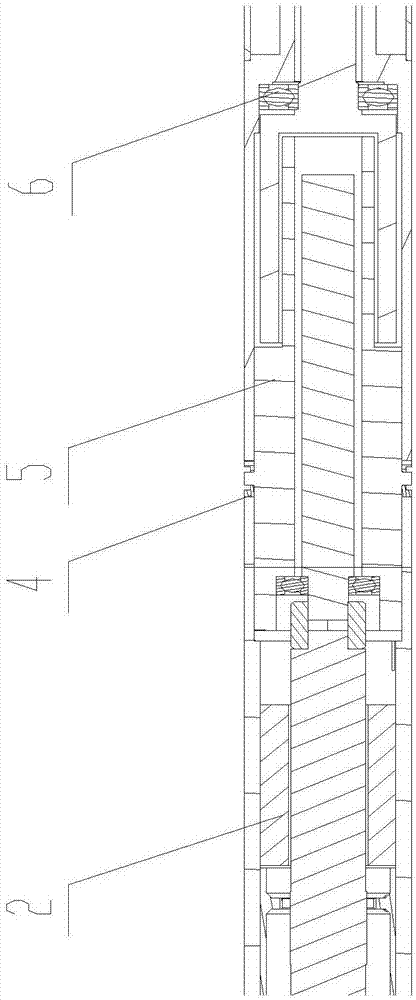

Planetary magnetic meshing flexible speed-regulating transmission device

InactiveCN102720822AWith speed control functionSpeed regulation power is smallGearingEngineeringMagnet

The invention relates to a planetary magnetic meshing flexible speed-regulating transmission device. The transmission device comprises a housing, a planetary magnet wheel assembly, an outer magnetosphere assembly, a central magnet wheel assembly, a speed-regulating motor and a front gear case, wherein the planetary magnet wheel assembly, the outer magnetosphere assembly and the central magnet wheel assembly are arranged inside the housing, the speed-regulating motor is connected with the central magnet wheel assembly and is arranged outside the housing, the front gear case is connected with the planetary magnet wheel assembly and is arranged outside the housing, corresponding bearings are arranged among the planetary magnet wheel assembly, the outer magnetosphere assembly and the central magnet wheel assembly, the planetary magnet wheel assembly, the outer magnetosphere assembly and the central magnet wheel assembly can rotate, and three concentric rotating axes are formed. Compared with the prior art, the transmission device has the advantages that the rotation-speed relation of an input shaft and an output shaft can be regulated continuously, the loss and the noise are low, and a torsion limiting function is achieved.

Owner:SHANGHAI UNIVERSITY OF ELECTRIC POWER

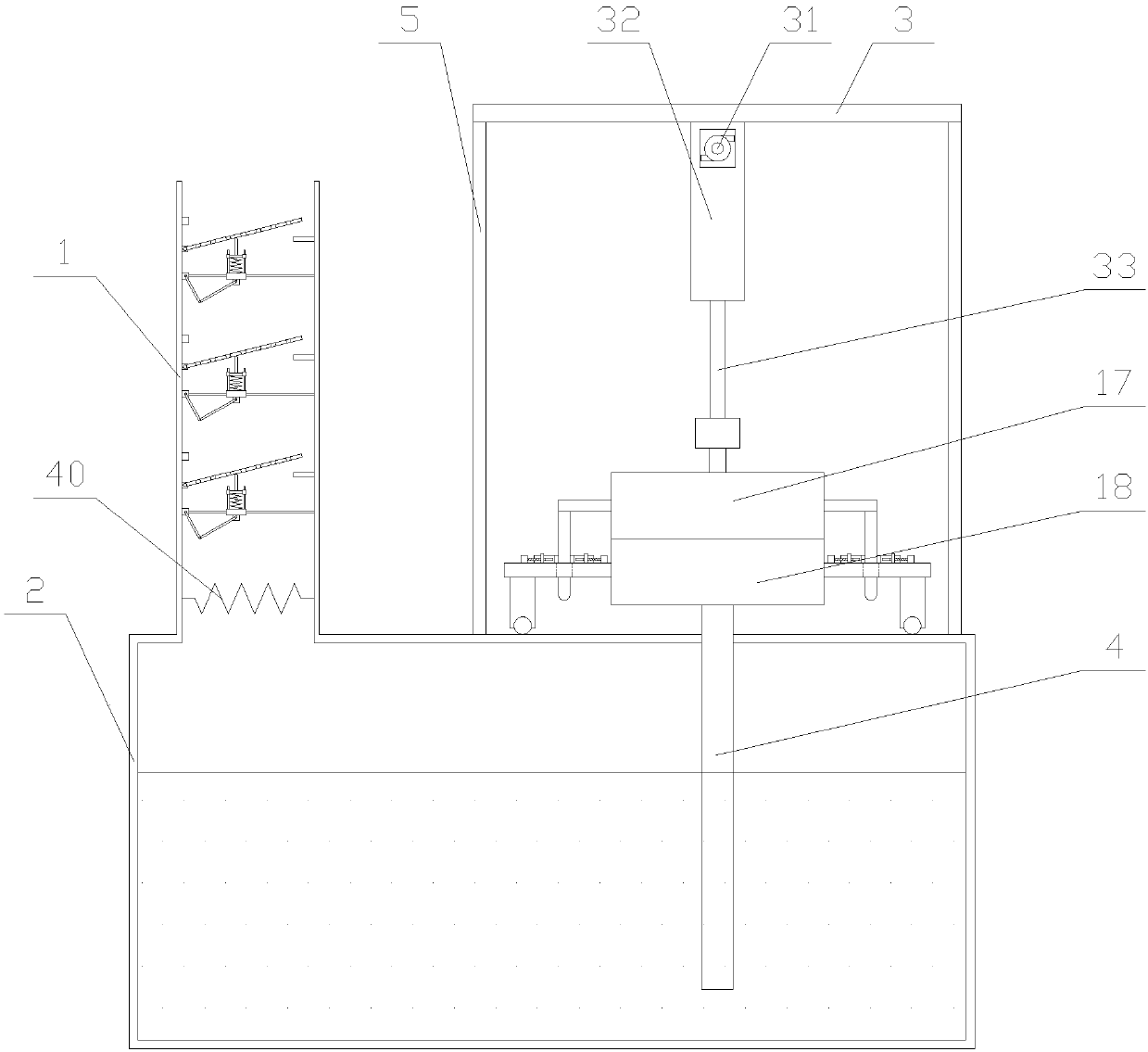

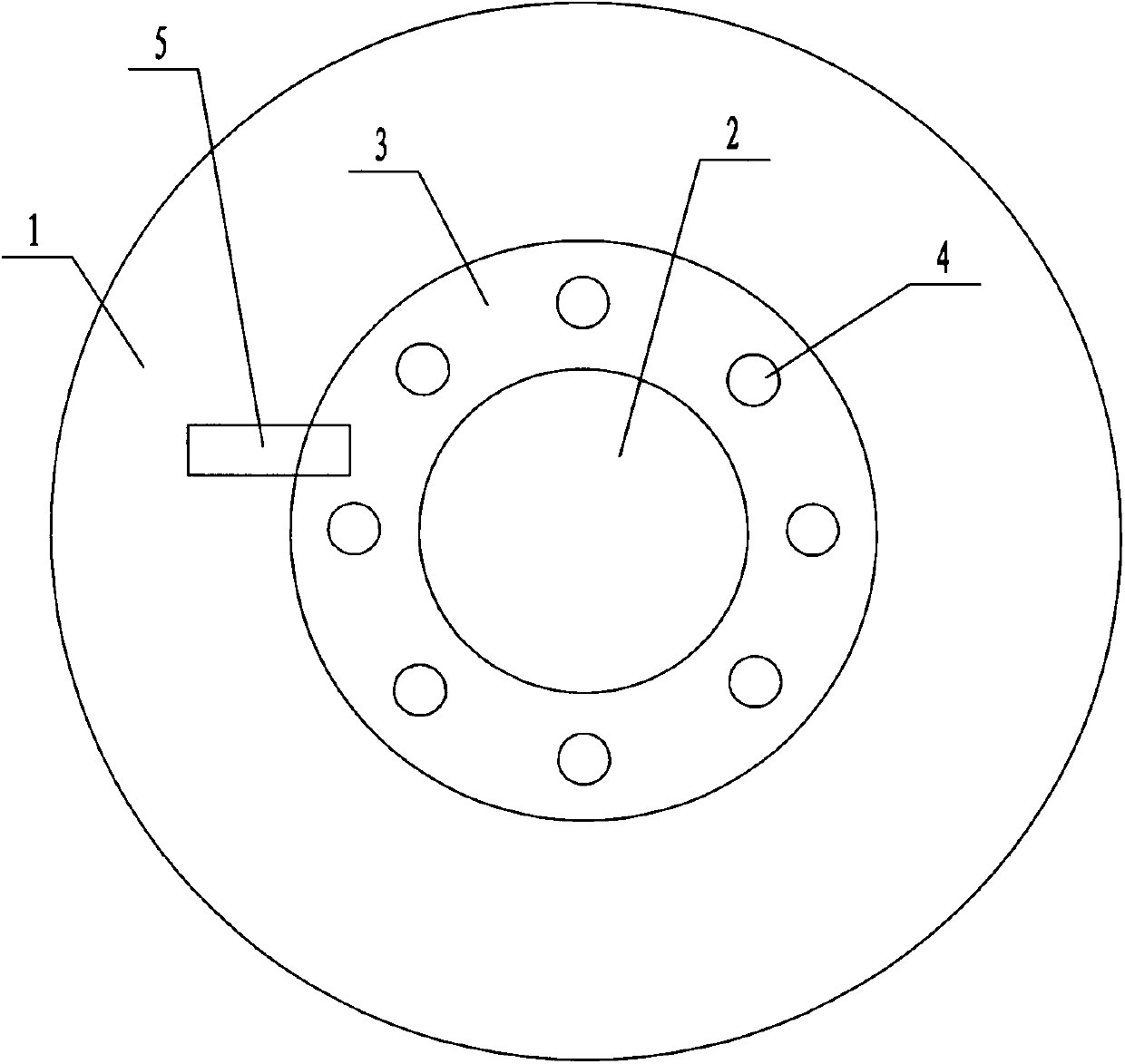

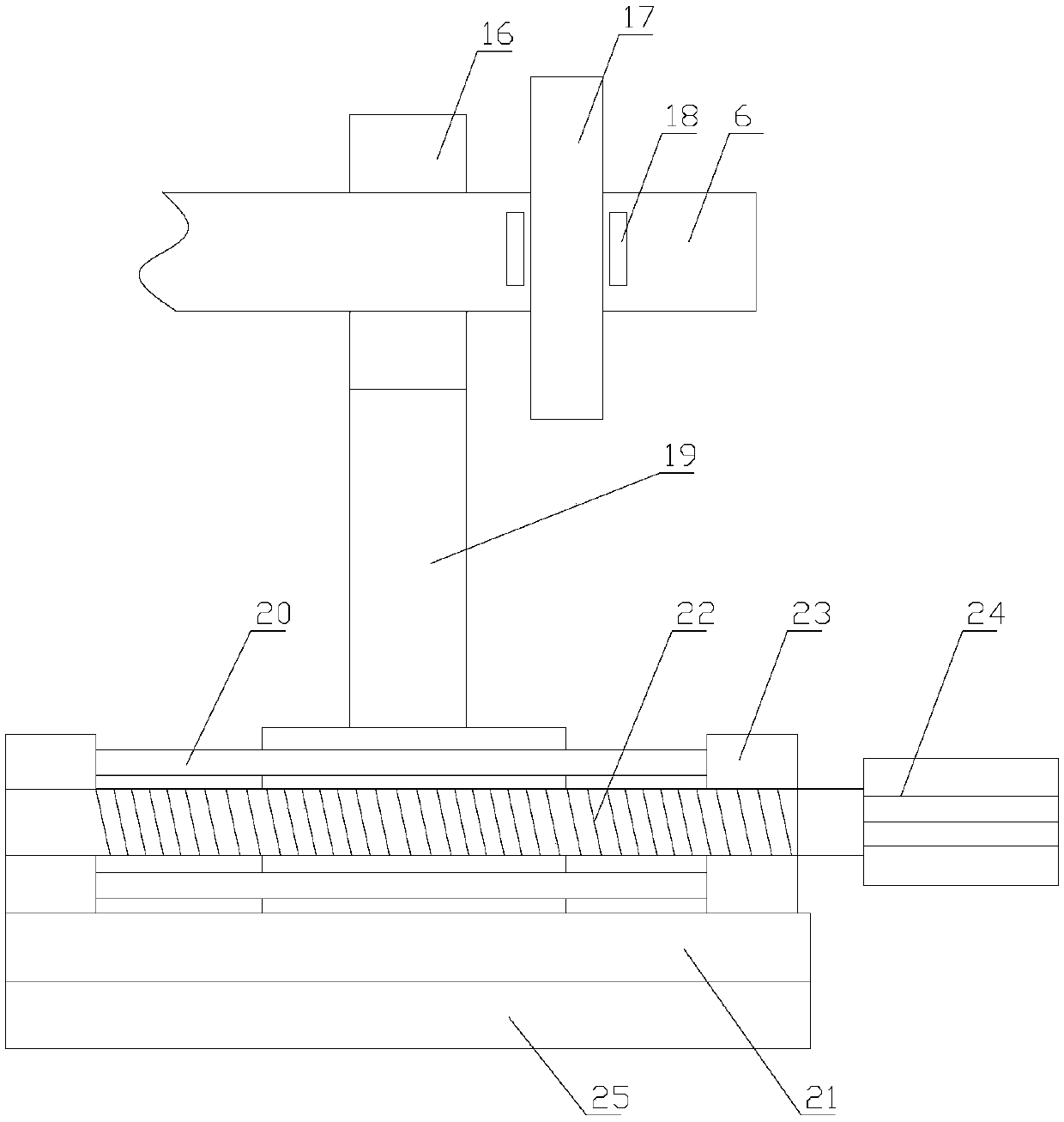

Torque detection device for hub bearing

PendingCN110261106ASimple structureImprove overall quality stabilityMachine part testingWork measurementTorque sensorEngineering

The invention discloses a torque detection device for a hub bearing. The hub bearing is arranged in a torque detection position; the hub bearing moves upwards under the action of a feeding device; a motor drives a driving shaft and a positioning mandrel to synchronously rotate, so that the positioning mandrel drives the inner ring of the automobile hub bearing to rotate; seals on the inner ring and outer ring of the automobile hub bearing rub each other, so that a torque is generated to drive the outer ring to rotate; under the action of the torque of a friction force between the outer ring and a torque pressing plate, the torque pressing plate and a torque weight-balancing plate rotate; and the torque weight-balancing plate rotates to generate a twisting force; the twisting force acts on a torque sensor; the torque sensor outputs a torque; and therefore, the rotating torque of the automobile hub bearing can be measured.

Owner:CHONGQING CHANGJIANG BEARING

Technique for film plating on powder surface and equipment thereof

InactiveCN101082120BEasy flipWith speed control functionVacuum evaporation coatingSputtering coatingVacuum pumpingMetallurgy

The present invention is powder surface coating process and apparatus. During coating powder, the powder is made to fall spirally in a vacuum environment and a homogeneous cladding is formed on the surface of the powder. The apparatus for coating powder includes one vacuum chamber, a vacuum film coating source, and a vacuumizing system. Inside the vacuum chamber, there are one turned conic rotaryhopper, one feeding chamber connected to the upper end of the hopper, and collecting chamber connected to its lower end. The vacuum film coating source mounted in the middle part inside the hopper has one speed adjustable motor for rotating the hopper. The present invention has great coating capacity and low running cost.

Owner:BYD CO LTD

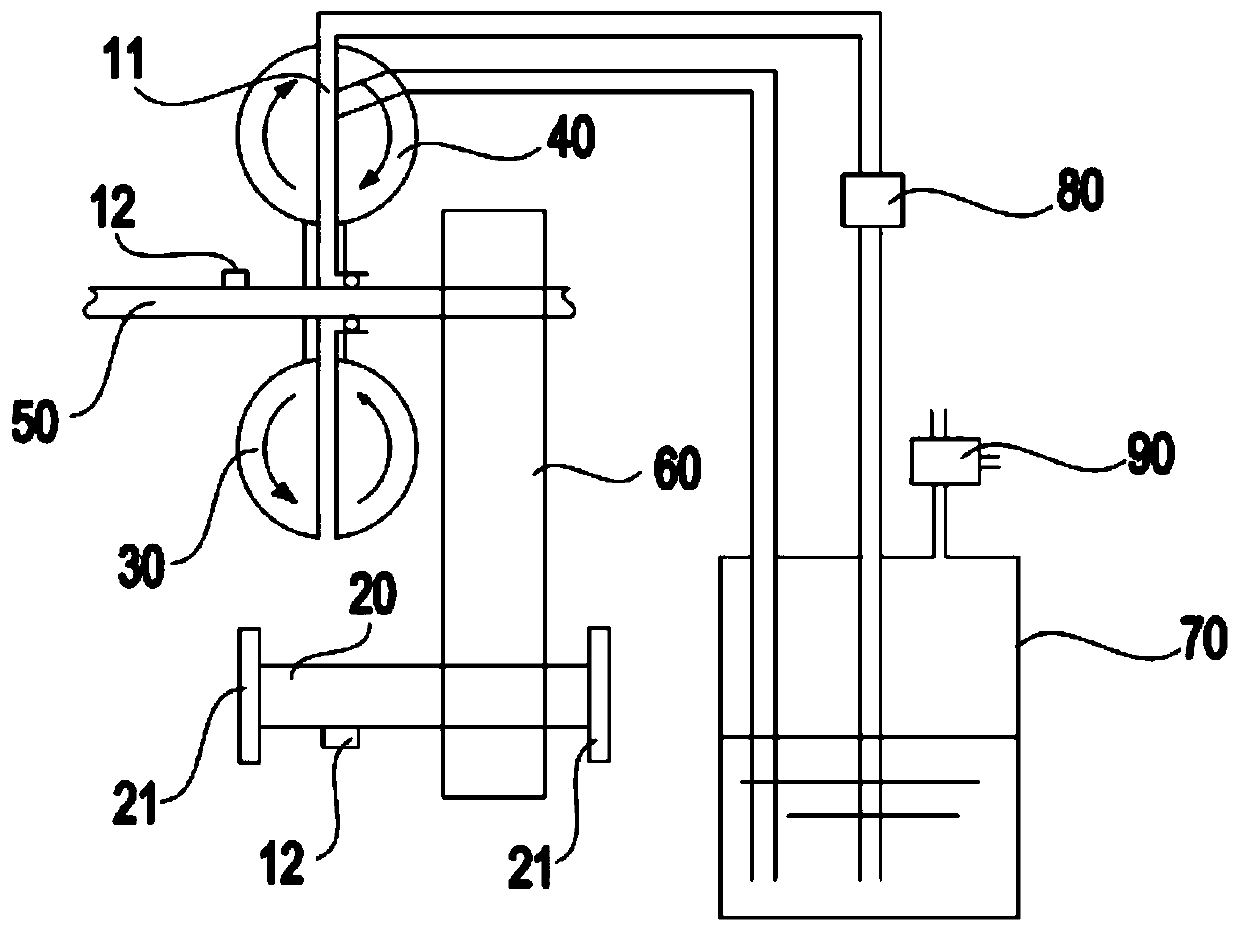

Oil cooling speed regulation type cooling system

InactiveCN111711321AAvoid accumulationImprove cooling efficiencyCooling/ventillation arrangementSupports/enclosures/casingsThermodynamicsOil cooling

The invention discloses an oil cooling speed regulation type cooling system which solves the problems of the cooling system that the temperature accumulation happens, the local hotspots are formed, aheat source needs to be directly cooled to improve the cooling efficiency, and a speed regulation function does not exists. The cooling system comprises an oil tank, a first connecting pipe is mountedat one side of the top end of the oil tank, and the top of the first connecting pipe is connected with a second connecting pipe. A guide plate is fixed at the bottom of the first connecting pipe, a screw is mounted at the top end of the guide plate, and a top plate is connected to top of the screw. A guide rod is fixed at one side of the top plate, a rotating shaft sleeves the middle of the top plate, and a rotating rod is fixed at the top of the rotating shaft. The middle of the rotating shaft is sleeved with a trapezoidal block, a third connecting pipe is connected to one side of the top ofthe second connecting pipe, an oil inlet pipe is fixed to the top of the third connecting pipe, and a base is mounted at one end of the oil inlet pipe away from the third connecting pipe. According to the invention, the temperature accumulation is avoided, the local hotspots are not formed, the heat source does not need to be directly cooled to improve the cooling efficiency, the structure is simple, and the cooling system has the speed regulation function and is convenient to use.

Owner:NANJING MAGNET INTELLIGENCE TECH CO LTD

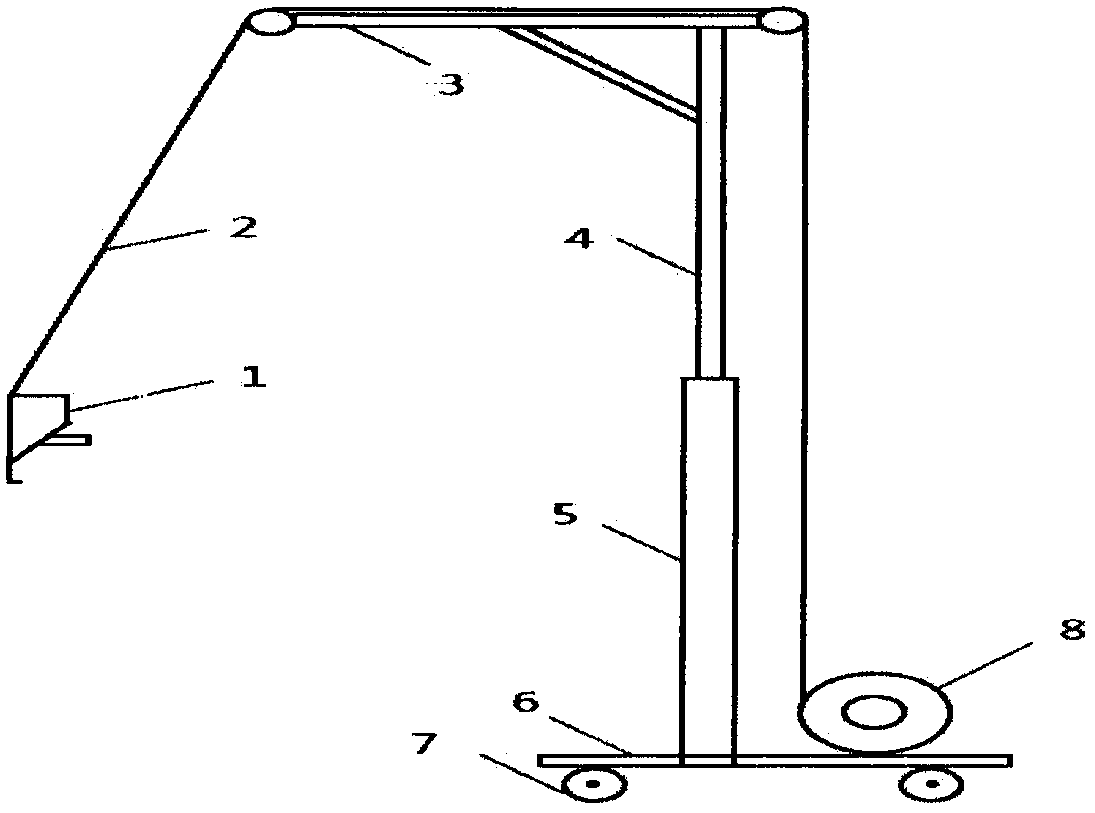

A hoisting frame with speed regulating function

ActiveCN106315409BWith speed control functionSave labor timeTrolley cranesLoad-engaging elementsGear wheelEngineering

Owner:重庆进取起重设备租赁有限公司

Permanent magnet synchronous motor

InactiveCN113904495AWith speed control functionCompact structureMechanical energy handlingSupports/enclosures/casingsSynchronous motorClassical mechanics

The invention belongs to the technical field of motors, and particularly discloses a permanent magnet synchronous motor which comprises a shell, wherein the shell is internally provided with a stator, a rotor is rotationally matched in the stator, the rotor is fixedly connected with a rotating shaft, the upper part of the shell is fixedly connected with a mounting box, the end of the rotating shaft is coaxially connected with a conical cover, the conical cover is located in the shell, the inner surface of the conical cover is in friction fit with a conical friction wheel, the taper of the friction wheel is the same as that of the conical cover, the friction wheel is coaxially connected with one end of a second connecting shaft, the second connecting shaft is rotationally installed on a mounting frame, the other end of the second connecting shaft is coaxially connected with a second spline shaft, and the second spline shaft penetrates through a first spline hole which is formed in the middle of the first bevel gear and is in sliding fit with the first bevel gear. The permanent magnet synchronous motor has a stepless speed change function.

Owner:李爱香

A wind power generator with speed regulation function

ActiveCN106949015BWith speed control functionIngenious structural designWind motor controlWind motor supports/mountsWind drivenGear wheel

The invention relates to a wind driven generator having a speed adjusting function. The wind driven generator having the speed adjusting function comprises a tower body, a shell, a fan mechanism, a gearbox and a power generation mechanism. The gearbox comprises a variable-speed gear assembly, a leftward and rightward adjusting assembly, a PLC and a frontward and backward adjusting assembly. The variable-speed gear assembly comprises a variable-speed rotating shaft, a first variable-speed gear and an infrared receiver. The leftward and rightward adjusting assembly comprises an infrared transmitter, a bearing, a sliding block, a lead screw, fixed blocks, a first motor, a shifting block and a base. The frontward and backward adjusting assembly comprises a second motor, a round gear and a strip gear. According to the wind driven generator having the speed adjusting function, a power generation system in the power generation mechanism sends an instruction to the PLC, the PLC can move a high-speed gear in the power generation mechanism to be meshed with an appropriate variable-speed gear through a frontward and backward adjusting mechanism and a leftward and rightward adjusting structure, and it is guaranteed that the power generation mechanism is in the most stable power generation state; and, when wind force is large, the wind driven generator having the speed adjusting function can be protected.

Owner:新昌县羽林街道维新机械厂

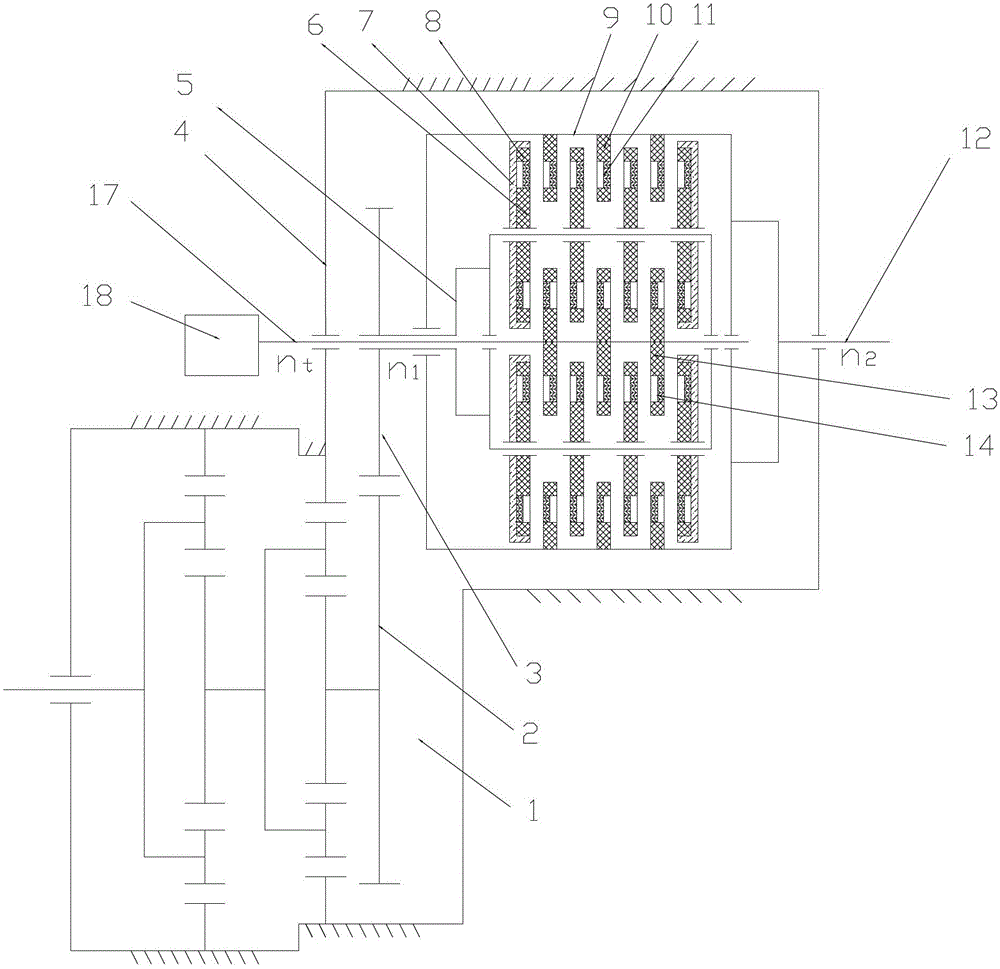

Speed-adjustable planetary magnetic meshing flexible transmission device

InactiveCN102720823AWith speed control functionSpeed regulation power is smallGearingLow noiseEngineering

The invention relates to a speed-adjustable planetary magnetic meshing flexible transmission device which comprises a shell, a planetary magnetic wheel component, an outer magnetic ring component, a central magnetic wheel component and an outer ring speed adjusting component, wherein the planetary magnetic wheel component, the outer magnetic ring component and the central magnetic wheel component are arranged in the shell, the outer ring speed adjusting component is connected with the outer magnetic ring component, and corresponding bearings are arranged among the planetary magnetic wheel component, the outer magnetic ring component and the central magnetic wheel component, so that the planetary magnetic wheel component, the central magnetic wheel component and the outer magnetic ring component can rotate so as to form three concentric rotating shafts. Compared with the prior art, the device provided by the invention has the advantages of capability of continuously adjusting the relation between the rotating speeds of an input shaft and an output shaft, low loss, low noise, twisting prevention and the like.

Owner:SHANGHAI UNIVERSITY OF ELECTRIC POWER

Mud generator with speed regulation function for measurement while drilling

ActiveCN104675612BWith speed control functionExcellent output power qualityHydro energy generationReaction enginesPower qualityImpeller

The invention discloses a measurement while drilling mud generator with a speed regulation function. The mud generator comprises a mud impeller, a magnetic coupling transmission device, a generator shell, a generator stator, a generator rotating shaft, a speed regulating motor stator, a speed regulating circuit and a speed measuring sensor. One end of the magnetic coupling transmission device is fixedly connected with the mud impeller while the other end is fixedly connected with the generator rotating shaft, the magnetic coupling transmission device is arranged in the generator shell, and the generator stator and the speed regulating motor stator are fixed to the inner wall of the generator shell. The input end of the speed regulating circuit is connected with the output end of the speed measuring sensor, and the rotating speed of a motor is regulated according to an induction value of the speed measuring sensor. The rotating speed of the motor is more stable, output voltage is smoother, output electric energy is higher in quality, motor efficiency is improved while service life is prolonged by the aid of the stable rotating speed, and performance of the motor is better.

Owner:BEIJING RES INST OF PRECISE MECHATRONICS CONTROLS

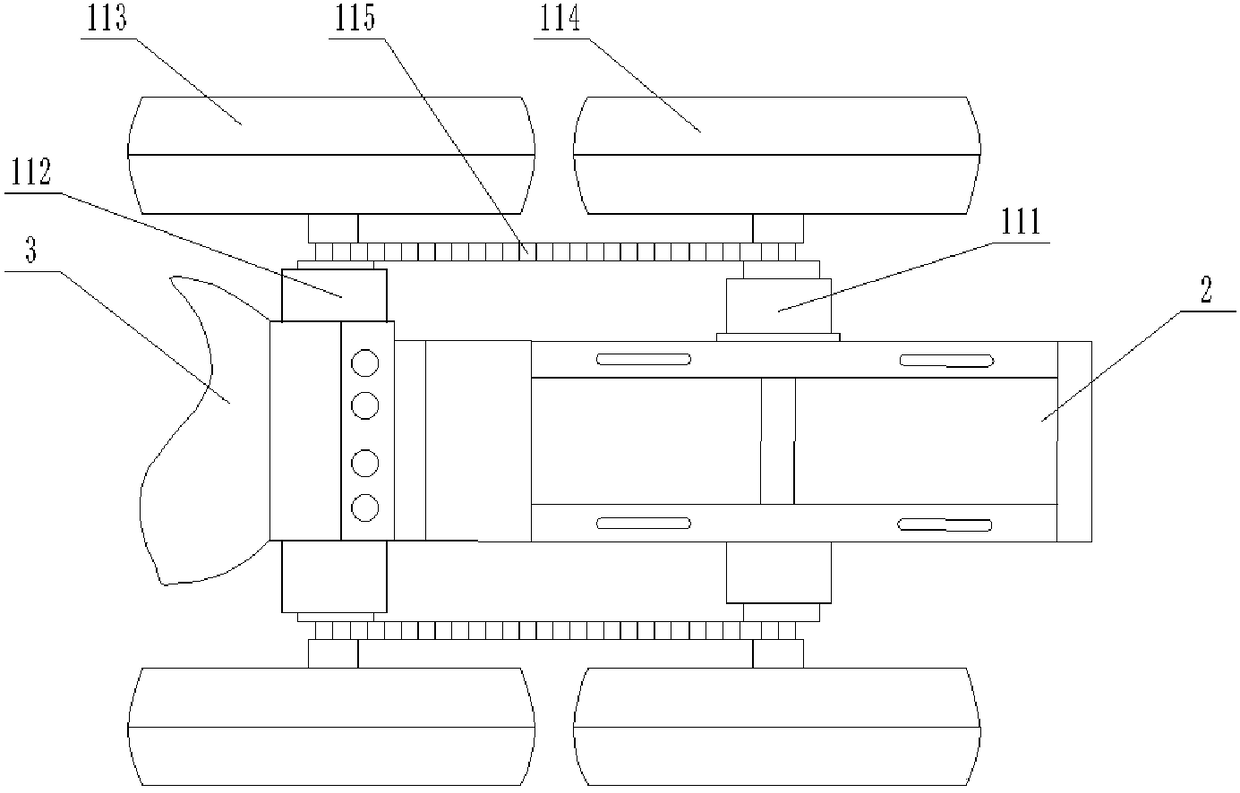

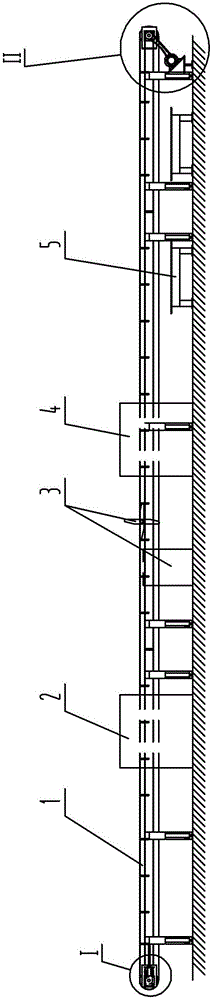

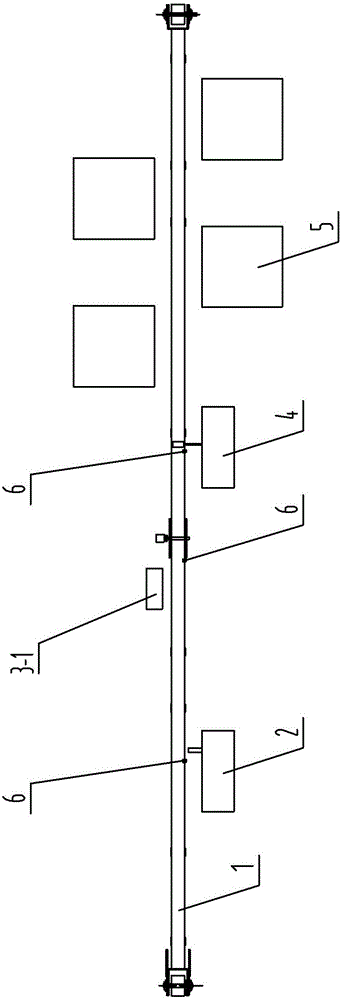

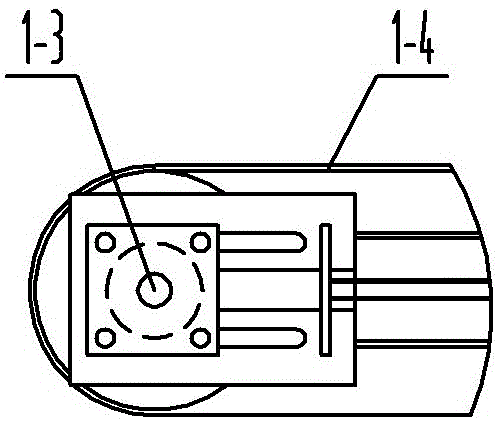

Finished brick automatic sorting production line

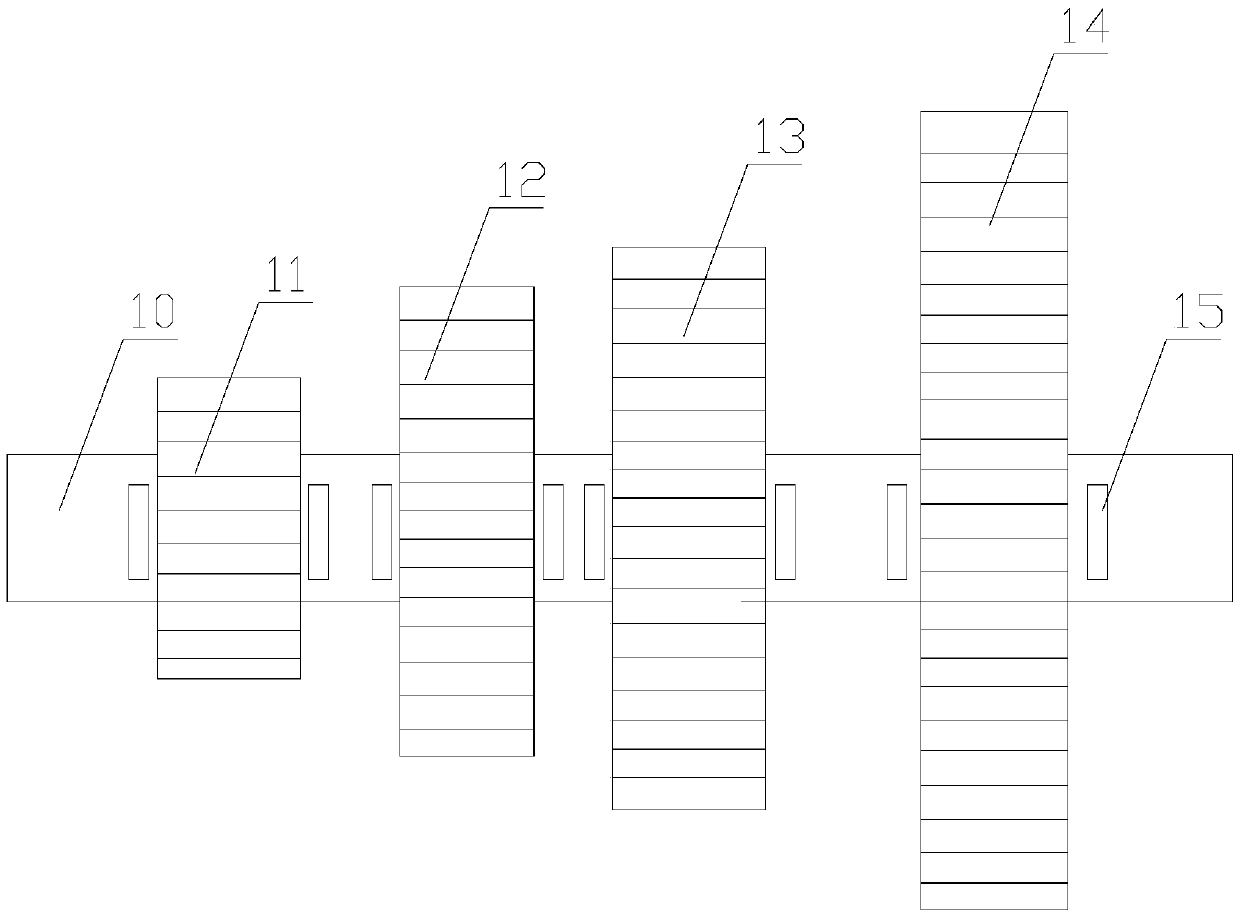

ActiveCN103332430BReduce labor intensitySimple structureLiquid surface applicatorsConveyorsProduction lineBrick

The invention belongs to the technical field of cement kiln brick sorting, and particularly relates to an automatic sorting production line of a finished brick. The production line comprises a conveying line, wherein a code spraying mechanism, a turnover mechanism and a glue spraying mechanism are sequentially mounted on the conveying line and in a conveying direction of the conveying line from front to back; the code spraying mechanism and the glue spraying mechanism are placed on one side of the conveying line; brick placing platforms are arranged on the two sides of the rear part of the conveying line respectively; optoelectronic switches are mounted on the conveying line on one side of each of the code spraying mechanism, the turnover mechanism and the glue spraying mechanism; the conveying line comprises a rack; a driving roller and a driven roller are arranged at the two ends of the rack respectively; the driving roller is in transmission connection with the driven roller by a rounding synchronous belt; and a chain wheel at a shaft end of the driving roller is in transmission connection with a chain wheel at an output shaft end of a motor reducing gear. The production line is simple in structure, significant in economic benefit and convenient to popularize and implement, integrates conveying, code spraying, turnover and glue spraying, reduces the labor intensity of a worker, improves the production efficiency, increases a product qualification rate, saves manpower, and increases the shift yield.

Owner:TONGDA REFRACTORY TECH CO LTD +1

Hydraulic speed reduction device

PendingCN110081099AWith speed control functionChange braking torqueLiquid resistance brakesToothed gearingsImpellerEngineering

The invention discloses a hydraulic speed reduction device. The hydraulic speed reduction device is installed and attached to a vehicle speed changing box and is connected with the vehicle speed changing box in series. The hydraulic speed reduction device comprises a shell and a first rotation shaft and further comprises a rotor impeller, a stator impeller, a second rotation shaft and a speed adjusting mechanism which are integrated in the shell. A work cavity is formed between the rotor impeller and the stator impeller. The second rotation shaft is connected with the rotor impeller. The firstrotation shaft stretches into the shell and is connected with the second rotation shaft through the speed adjusting mechanism. One end of the first rotation shaft is connected with an output shaft ofthe vehicle speed changing box, and the opposite end is connected with a drive axle. The speed adjusting mechanism is integrated in the shell of the hydraulic speed reduction device, the hydraulic speed reduction device has the function of speed adjusting, meanwhile, the installing manner of the hydraulic speed reduction device is changed, the hydraulic speed reduction device is installed and attached to the vehicle speed changing box and is connected with the vehicle speed changing box in series, and the axial installing size is effectively reduced.

Owner:SUZHOU TESUAN ELECTROMECHANICAL TECH CO LTD

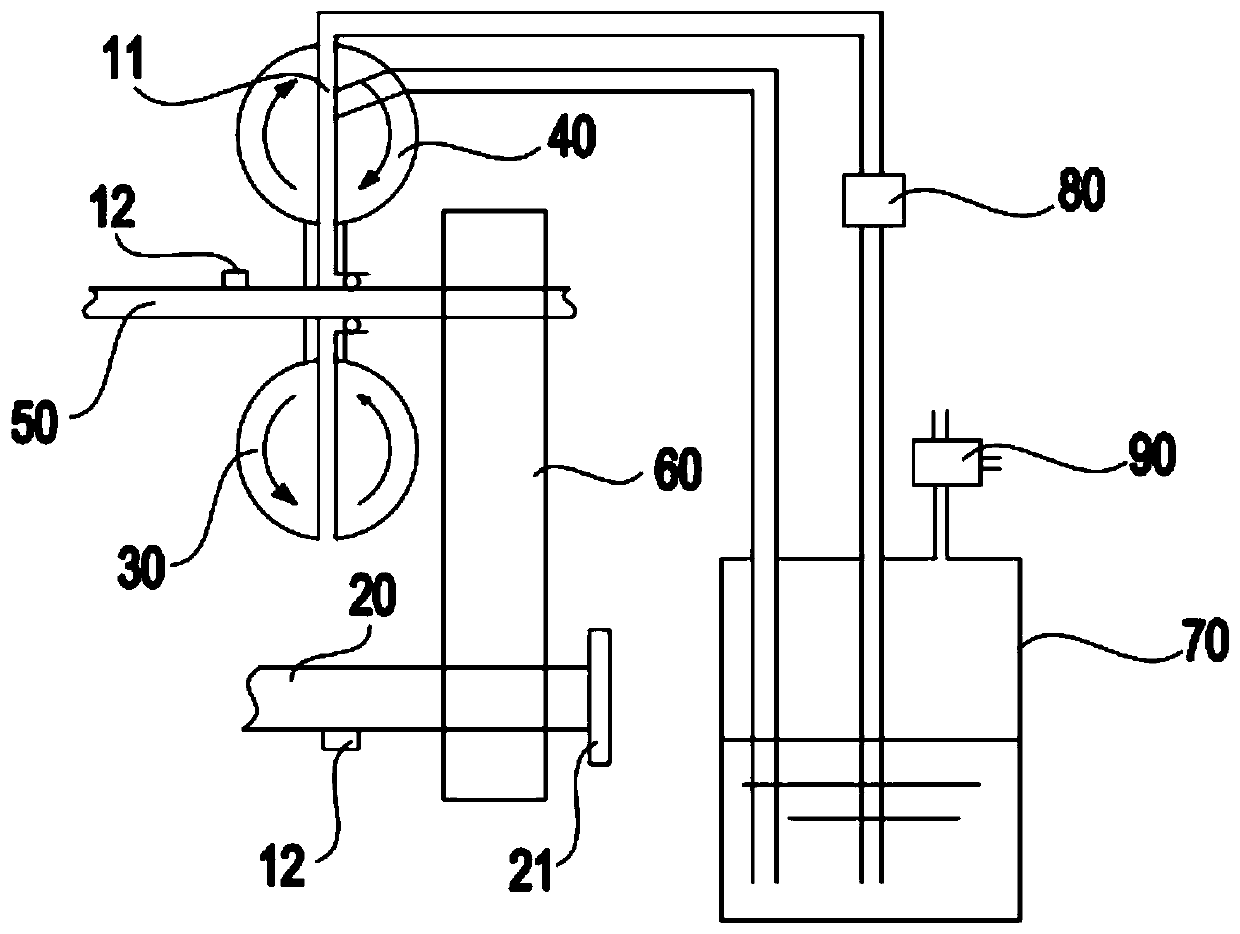

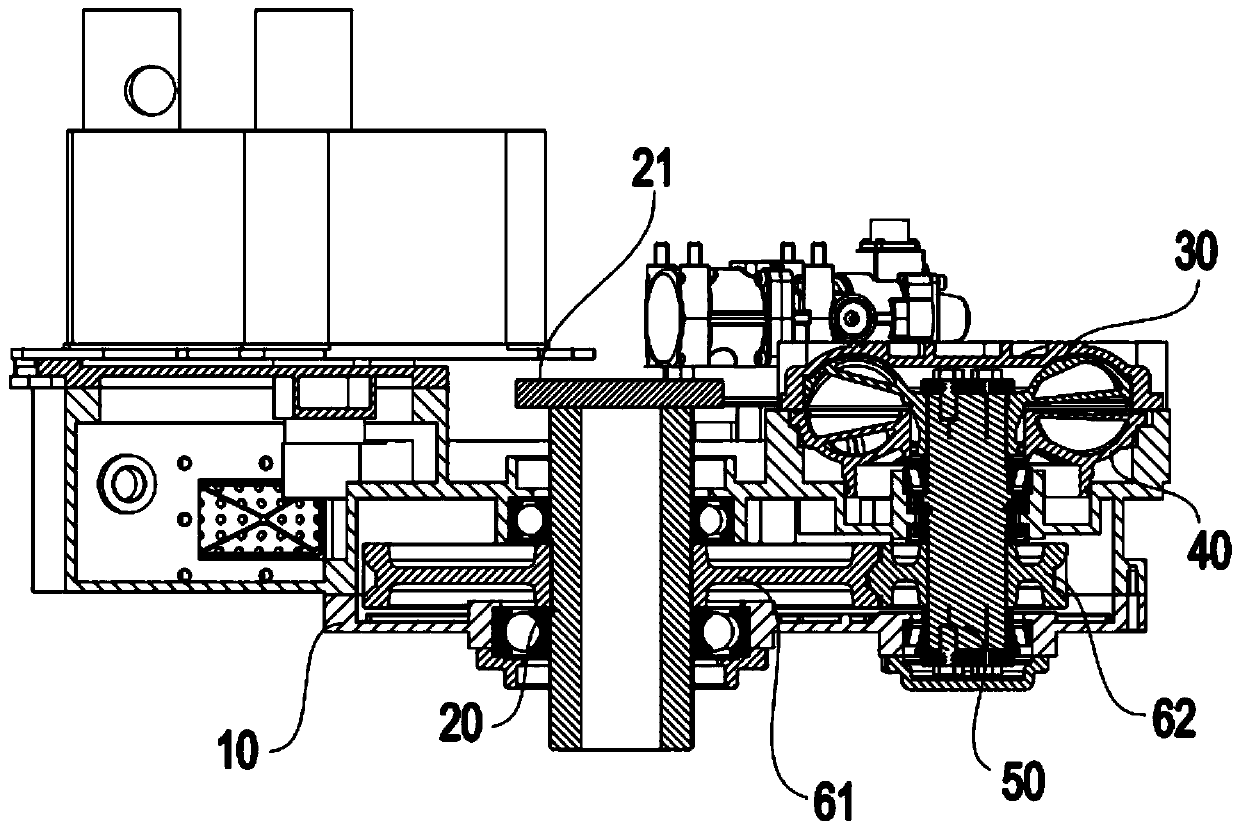

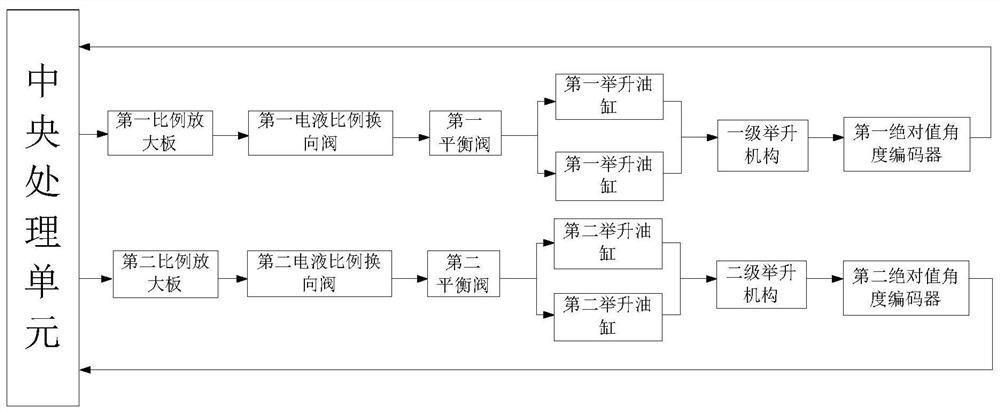

Large-array antenna stacking lift control system and method

ActiveCN110714956BSolve the problem of difficult lifting heightShorten the erection timeServomotor componentsAntenna supports/mountingsControl systemControl engineering

The invention discloses a large-array antenna superimposed lifting control system, which includes a central processing unit and two-stage lifting control systems. The input and output ends of each lifting control system are connected to the central processing unit; each stage The lifting control system includes a sequentially connected proportional amplifying board, an electro-hydraulic proportional directional valve, a balance valve, a lifting cylinder, a lifting mechanism, and an absolute value angle encoder; In the control method, the absolute value angle encoder detects the lifting angle of each level of lifting mechanism and feeds it back to the central processing unit for comparison operation, and then the central processing unit provides compensation signals through the proportional amplification board, electro-hydraulic proportional reversing valve, The balance valve and the lifting cylinder control the lifting action of the two-stage lifting mechanism to maintain synchronization. The present invention not only can lift the antenna to the height of 16 meters smoothly, but also shortens the erection time of the antenna and wins precious time for the special equipment to perform tasks.

Owner:ANHUI BOWEI CHANGAN ELECTRONICS

Safeguard device for charging port of electric automobile charging pile

InactiveCN103163805BReduce energy consumptionModerate speedProgramme controlComputer controlMicrocontrollerControl circuit

The invention discloses a safeguard device for a charging port of an electric automobile charging pile. The safeguard device comprises a shell, a step motor, a bin gate, a gear, a rack, guide sheets, infrared reflective proximity switch sensors, Hall sensors, magnets and a singlechip control circuit; the shell and the guide sheets are fixed on the inner wall of the charging pile, the shell is provided with a straight opening matched with the guide sheets to form a guide mechanism, and the bin gate is arranged in the guide mechanism; the gear is arranged on a shaft of the step motor, and the rack matched with the gear is arranged on the bin gate; the two infrared reflective proximity switch sensors are arranged on the inner wall of the charging pile and used for detecting complete opening and complete closure of the bin gate respectively; the magnets are arranged at the edge of the outer end face of the gear, and the Hall sensors are arranged at the corresponding positions; and the infrared reflective proximity switch sensors, the Hall sensors and the step motor are connected with corresponding ports of the singlechip control circuit respectively. The safeguard device is safe, reliable, low in energy consumption, simple in structure and convenient to operate.

Owner:NANJING UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com