Oil slag separation and re-squeezing device for middle and small-sized oil squeezing machine

A technology of oil residue separation and oil press machine, which is applied in the direction of fat oil/fat production, fat oil/fat refining, fat generation, etc. It can solve the problems of unsuitable small and medium-sized oil presses for processing oil residue, high labor intensity, and large space required. problem, to achieve the effects of high oil residue separation efficiency, high automation, and small equipment footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described in detail below in conjunction with the accompanying drawings to facilitate a clearer understanding of the present invention, but they do not limit the present invention.

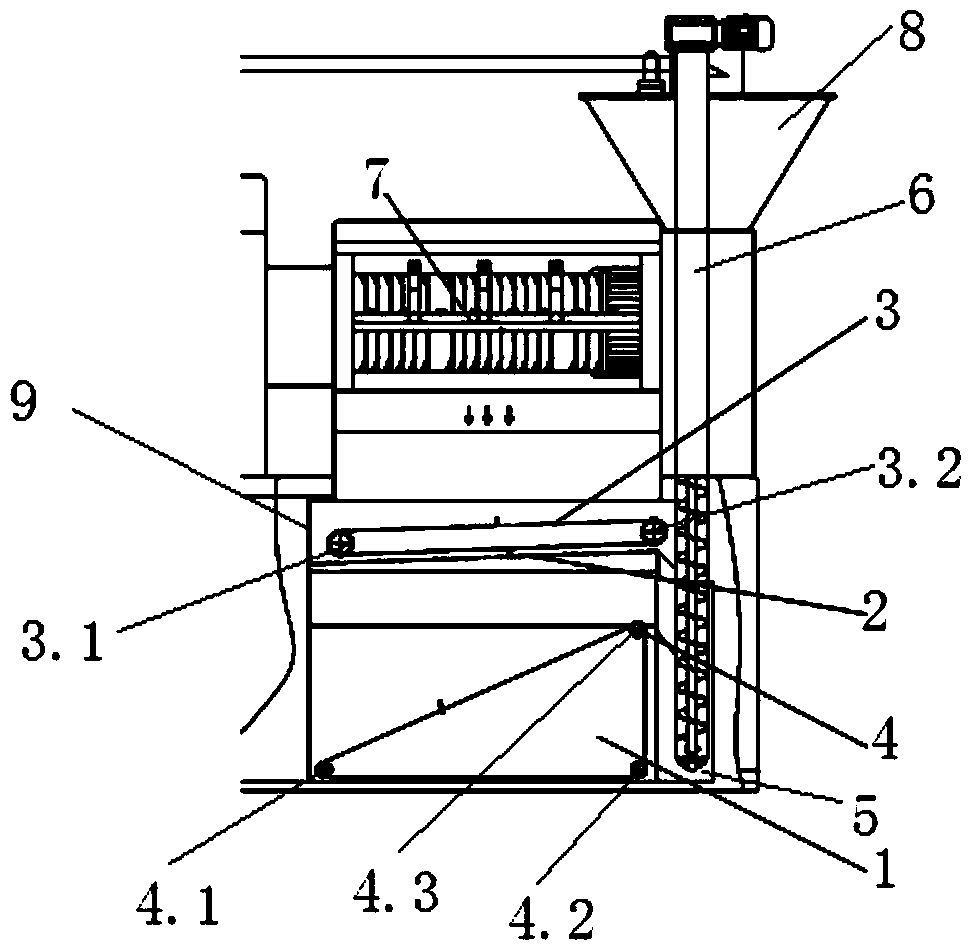

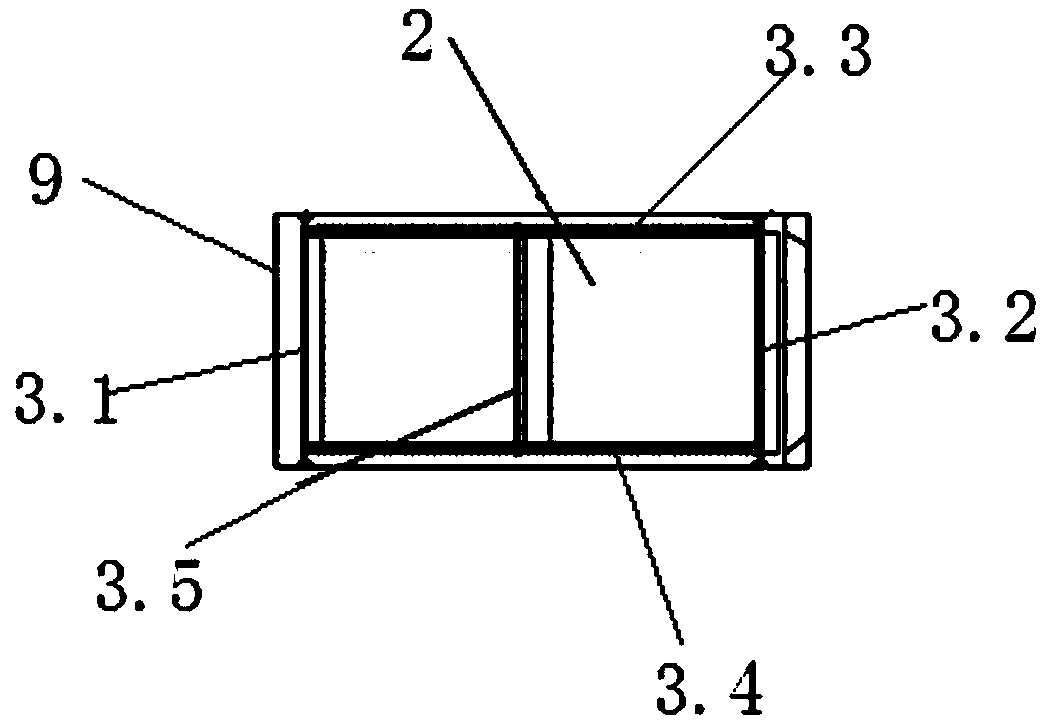

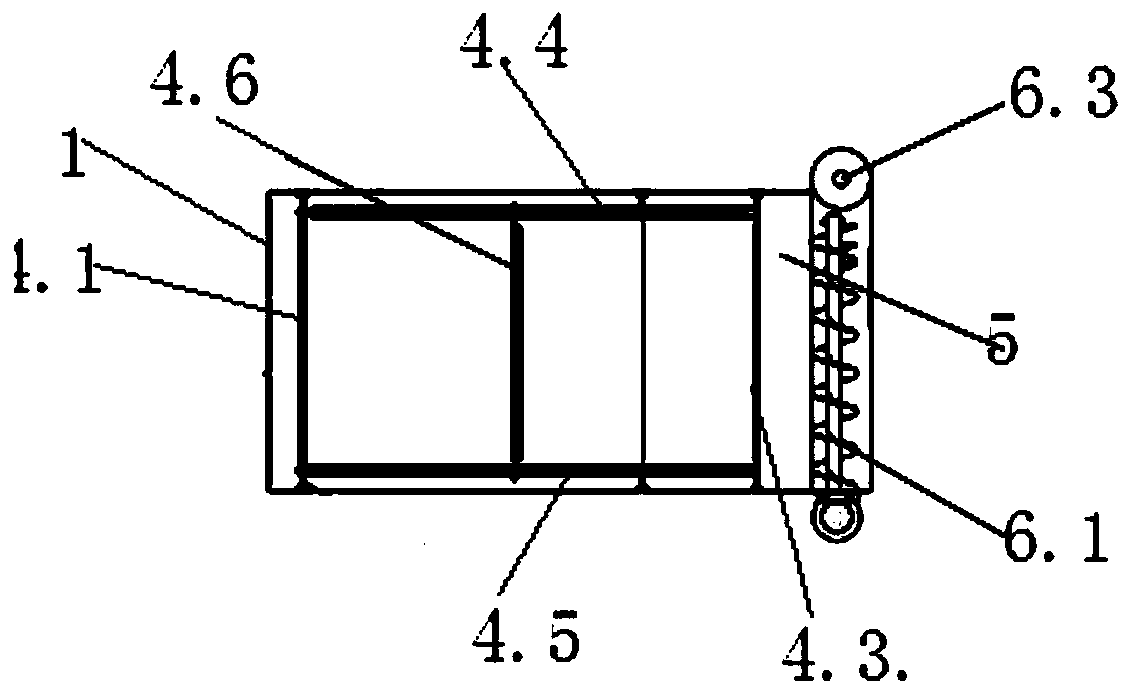

[0023] Such as figure 1 The shown oil residue separation and return device for small and medium-sized oil presses includes a crude oil tank 1 located directly below the crude oil outlet of the press cage 7 of the oil press. The angle is 30-65°, the crude oil tank 1 is assembled on the frame 9 of the oil press, and the crude oil filter 2 is arranged above the crude oil tank 1, and the crude oil filter 2 is a detachable screen with a sieve aperture of 0.2- 2.5 mm, the top of the crude oil filter 2 is provided with a first slag remover 3 , and the first slag remover 3 and the crude oil filter 2 are assembled on the frame 9 of the oil press. The bottom of the crude oil tank 1 is provided with a second slag remover 4, and one side of the crude oil tank 1 is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com