Patents

Literature

86results about How to "Moderate speed" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

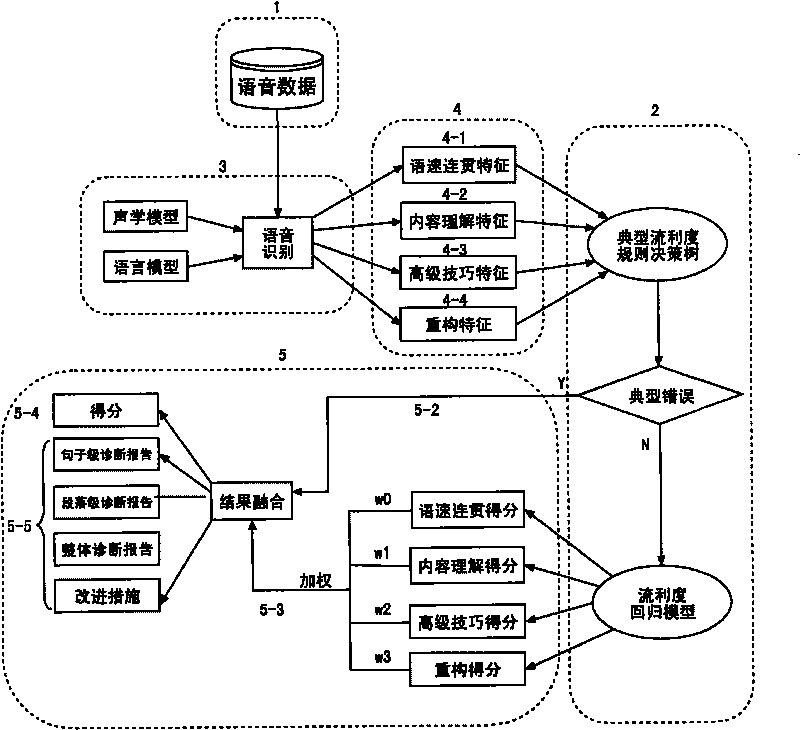

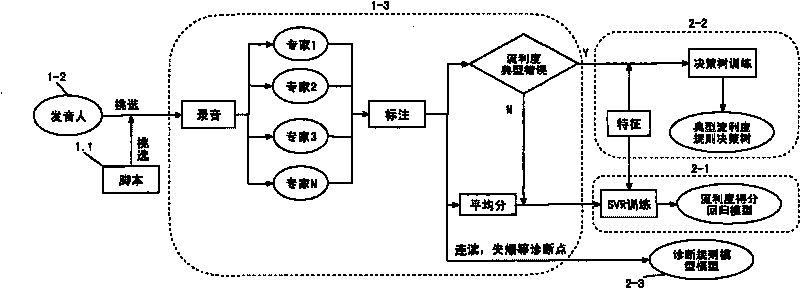

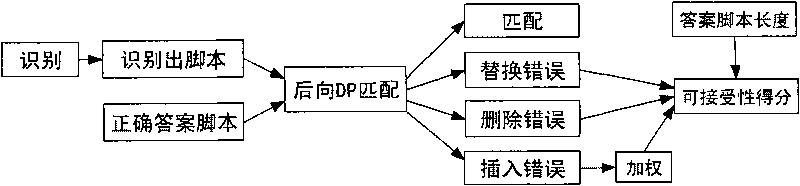

Method for automatic evaluation based on generalized fluent spoken language fluency

ActiveCN101740024ATroubleshoot automated assessment issuesFast scoringSpeech recognitionData dredgingSpoken language

The invention relates to a method for automatic evaluation based on generalized fluent spoken language fluency, which comprises the following steps of: acquiring speech data according to different ages and spoken language levels by using a speech input device; adopting an evaluating model based on characteristics of the generalized fluency and the machine learning training fluency; configuring a speech recognition system with corresponding parameters according to scripts of different subjects and genders of enunciators in the speech data; performing quantification on speech speed coherence, content understanding, advanced skills and reconstruction standard characteristics in the speech data to comprehensively extract the characteristics of the fluency from the speech data from the angle of expert assessment and evaluation; and adopting a decision tree method in regression fitting analysis and data mining to detect faults of abnormal fluency and grade and diagnose the fluency. The acquired score of the machine fluency can reach the level close to that of grading experts, and the relativity index exceeds that of 2 to 3 of general 5 experts; besides, the method has a high speed, and can be embedded into a spoken language automatic evaluation system to serve as an important module to evaluate fluency indexes in pronunciation quality.

Owner:IFLYTEK CO LTD

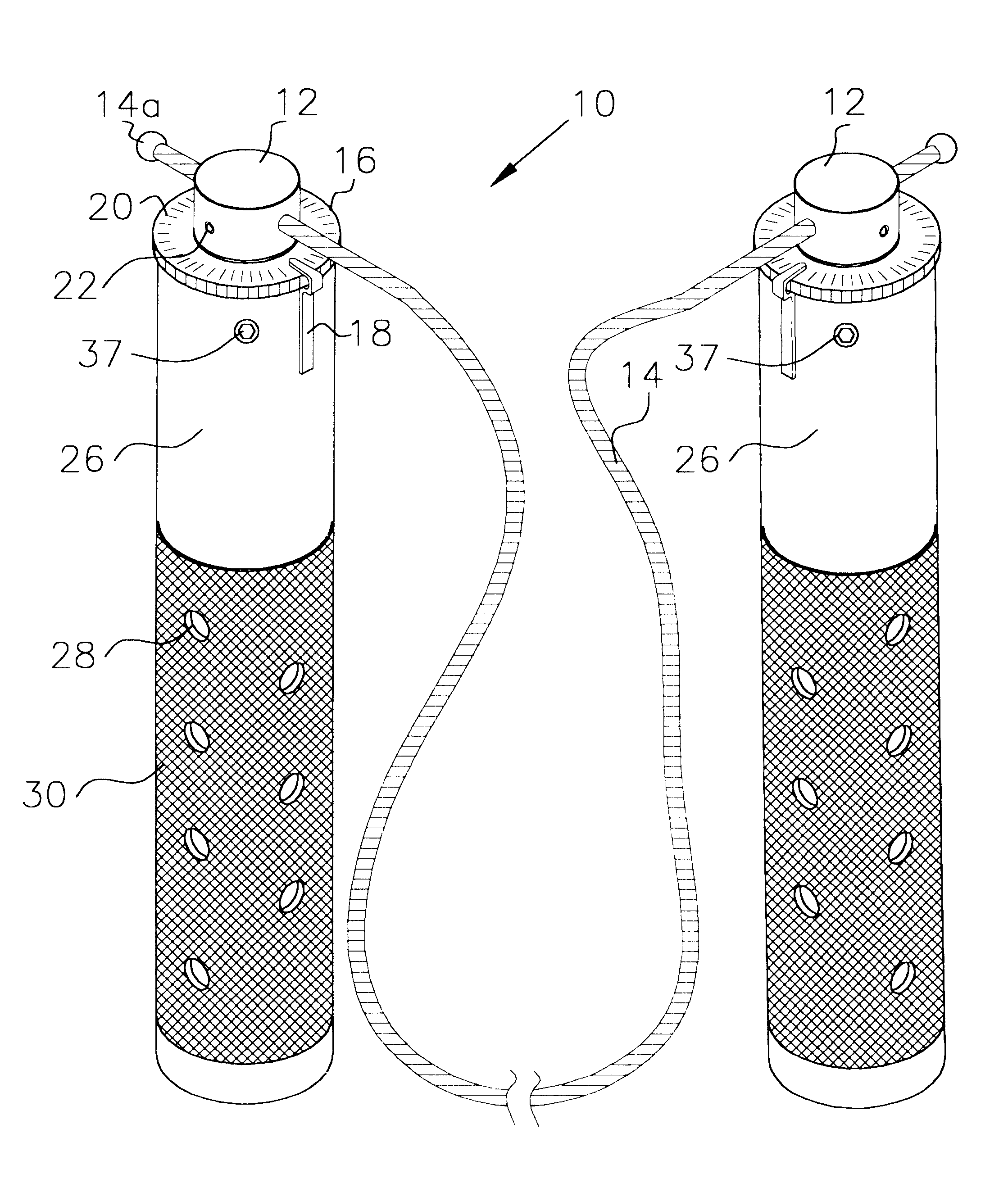

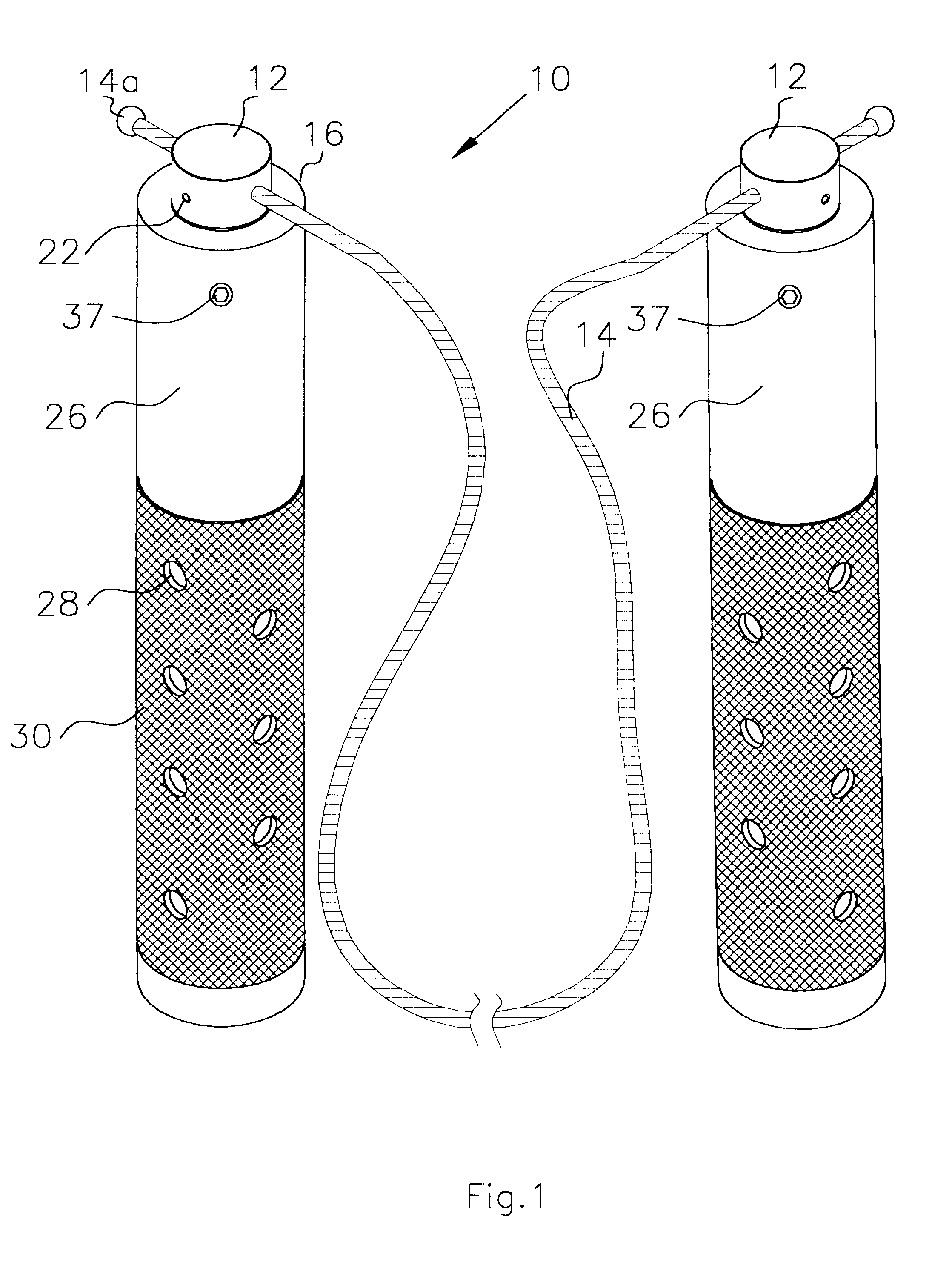

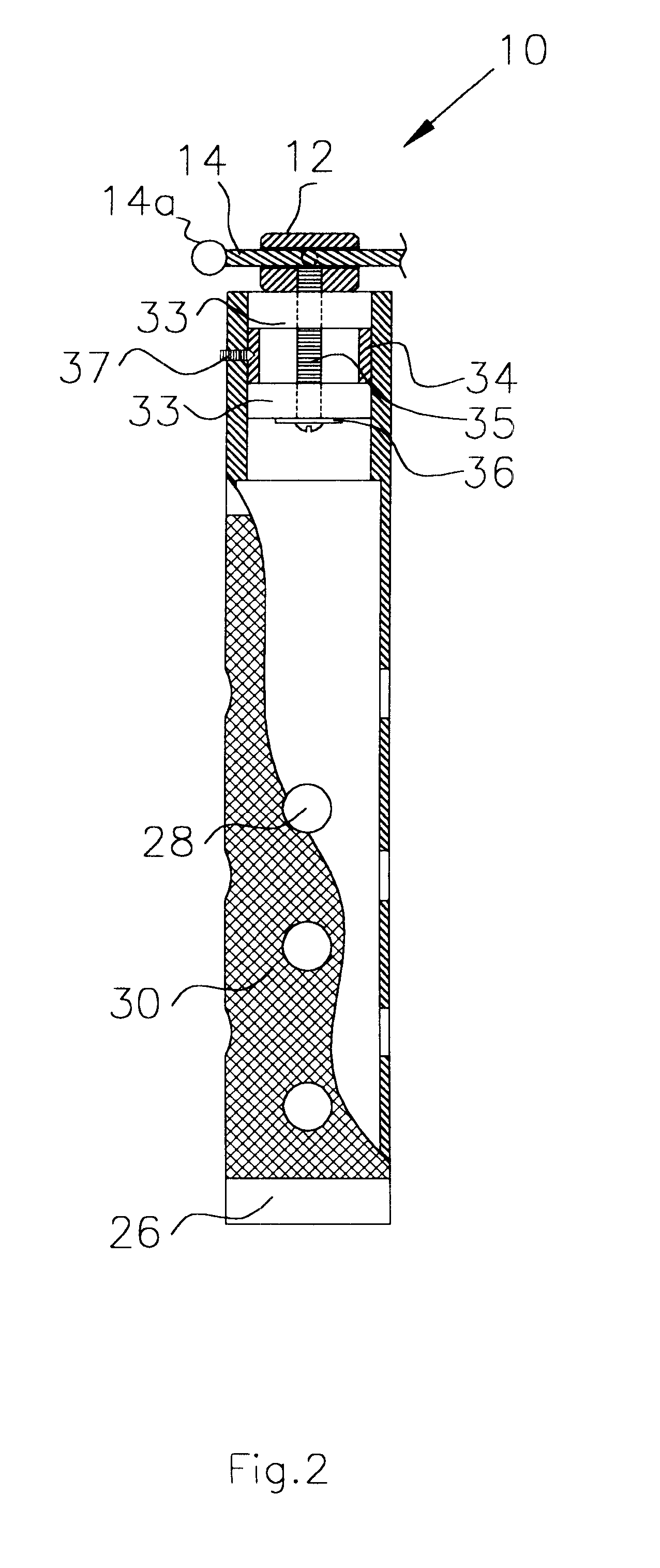

Adjustable speed ball bearing jump rope

InactiveUS6551222B1Simple and efficient designEffectively and inexpensively cures deficiencySkipping-ropesJumping ropeBall bearing

A speed ball bearing jump rope construction with an adjustable rope length, the invention consisting of a pair of hollow handles having external grip surfaces, vent holes and a bearing assembly at one end of each handle fastened with a screw threaded into the handles. Screws mounted within each of the tops of the bearing assemblies permit the rope to slide to shorten the length.

Owner:BEAVER TERRY L

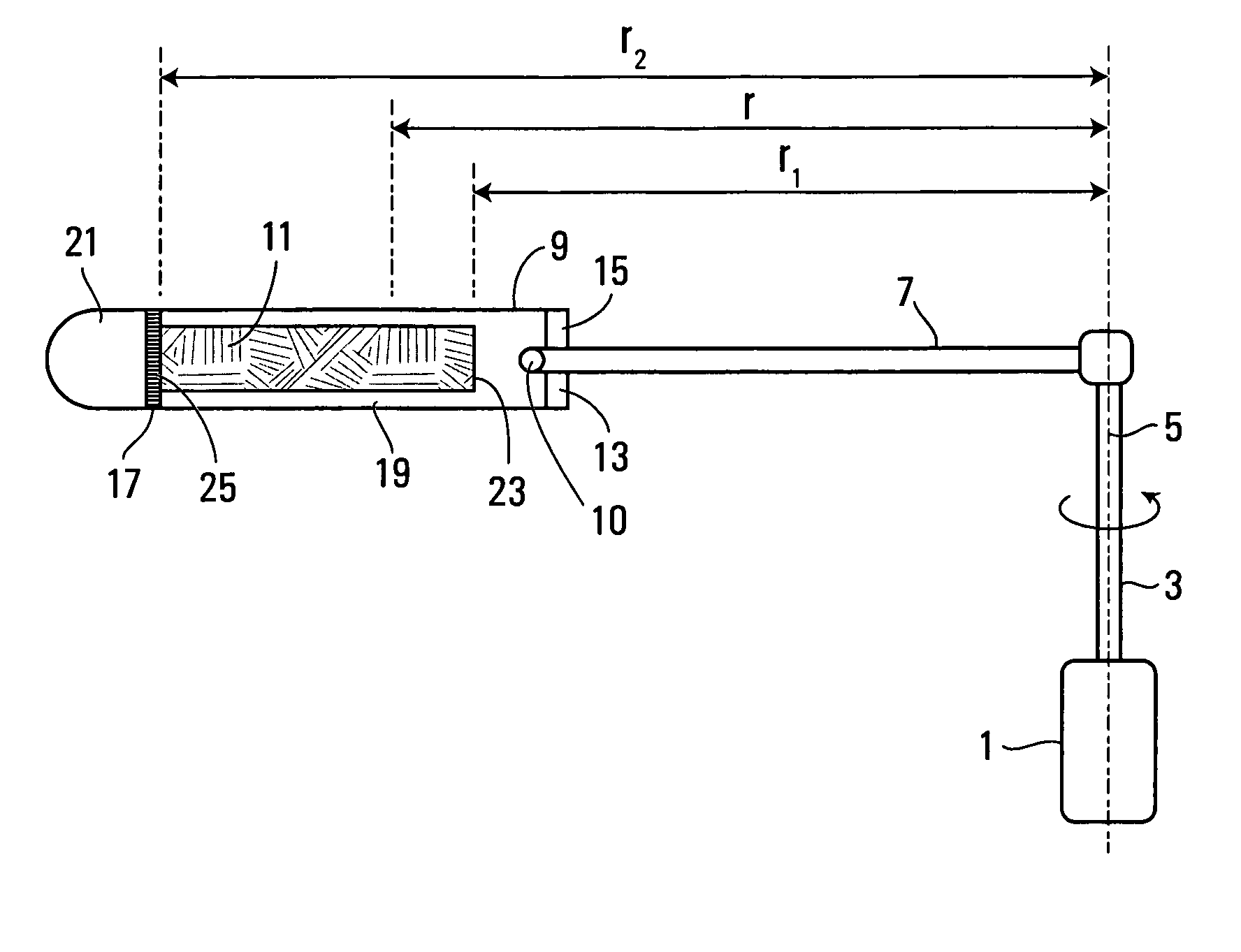

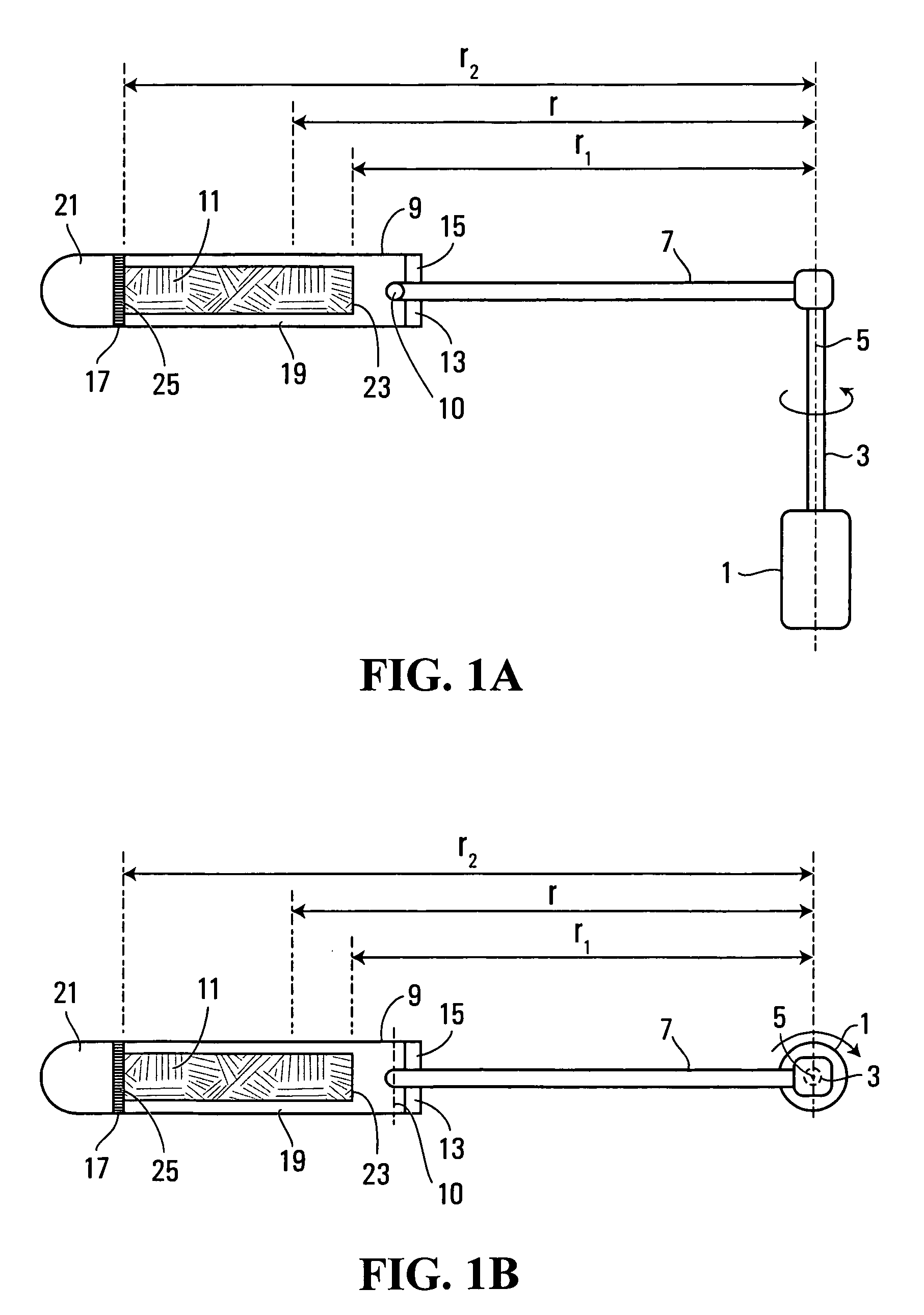

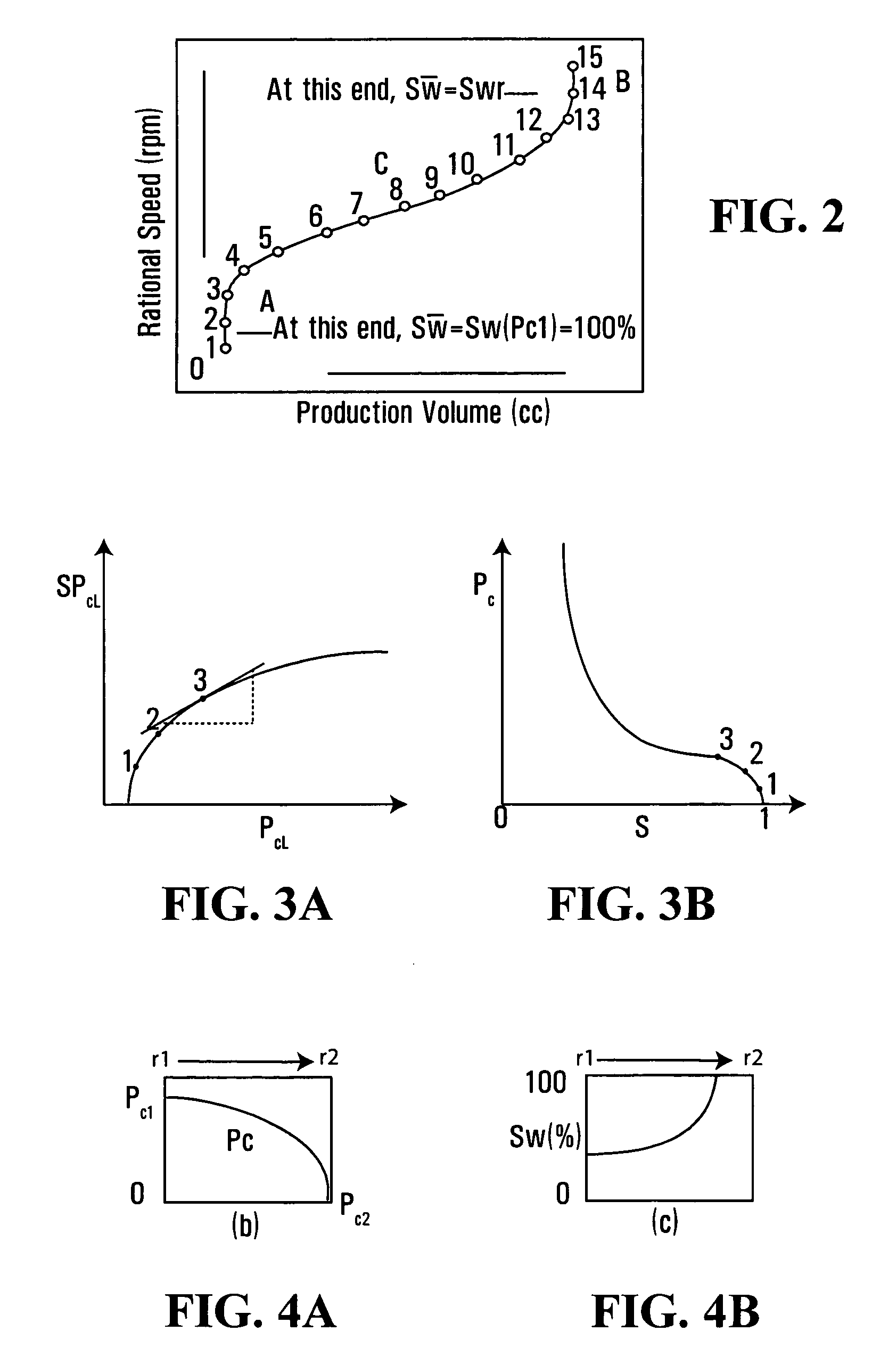

Methods and apparatus for measuring capillary pressure in a sample

ActiveUS20060116828A1Improve signal-to-noise ratioEliminate the effects ofAnalysis using nuclear magnetic resonanceMeasurements using NMR imaging systemsCapillary pressureCapillary Tubing

A method and apparatus are provided for measuring a parameter such as capillary pressure in porous media such as rock samples. The method comprises mounting a sample in a centrifuge such that different portions of the sample are spaced at different distances from the centrifuge axis, rotating the sample about the axis, measuring a first parameter in the different portions of the sample, and determining the value of a second parameter related to the force to which each portion is subjected due to rotation of the sample. In one embodiment, the first parameter is relative saturation of the sample as measured by MRI techniques, and the second parameter is capillary pressure.

Owner:GREEN IMAGING TECH

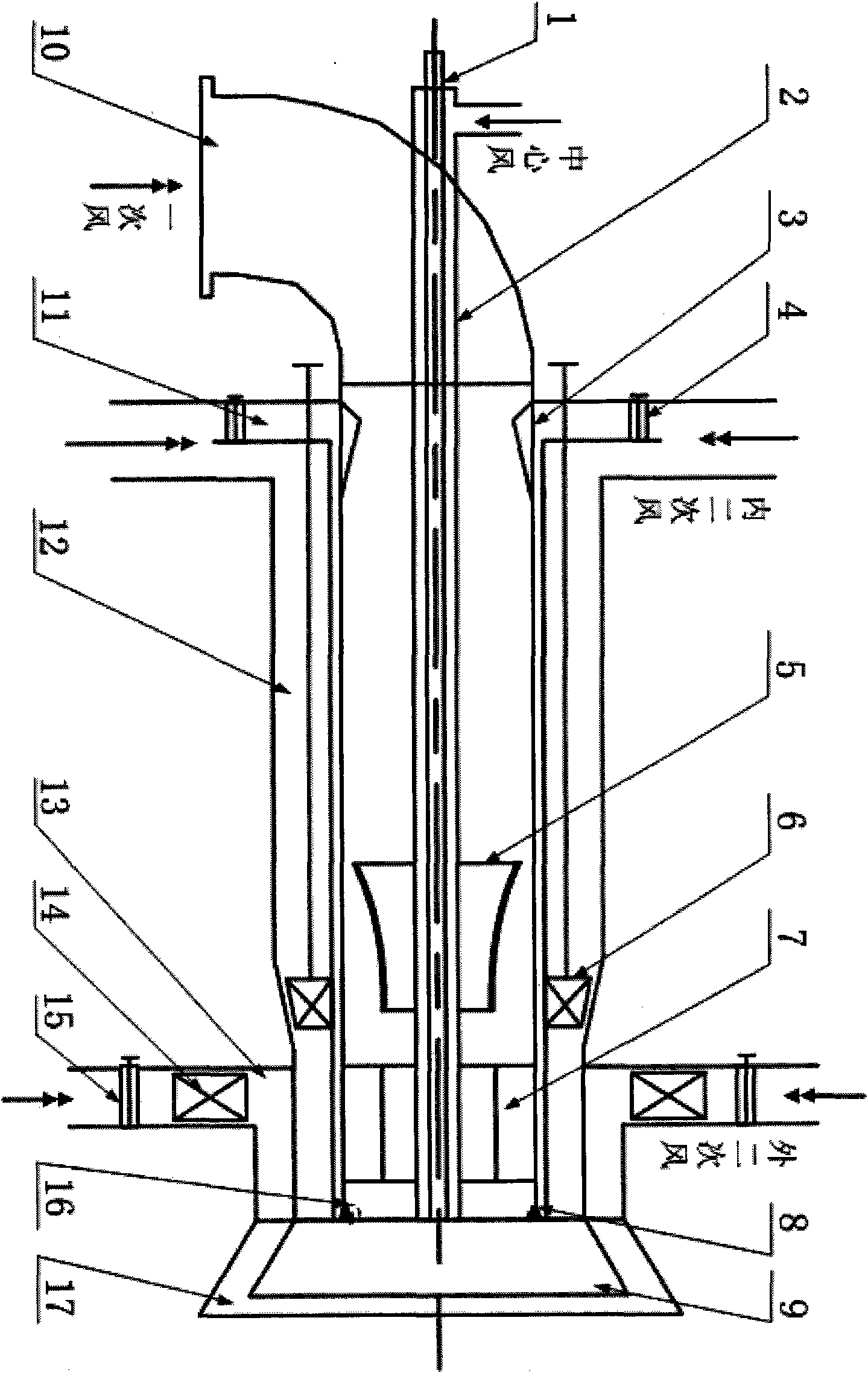

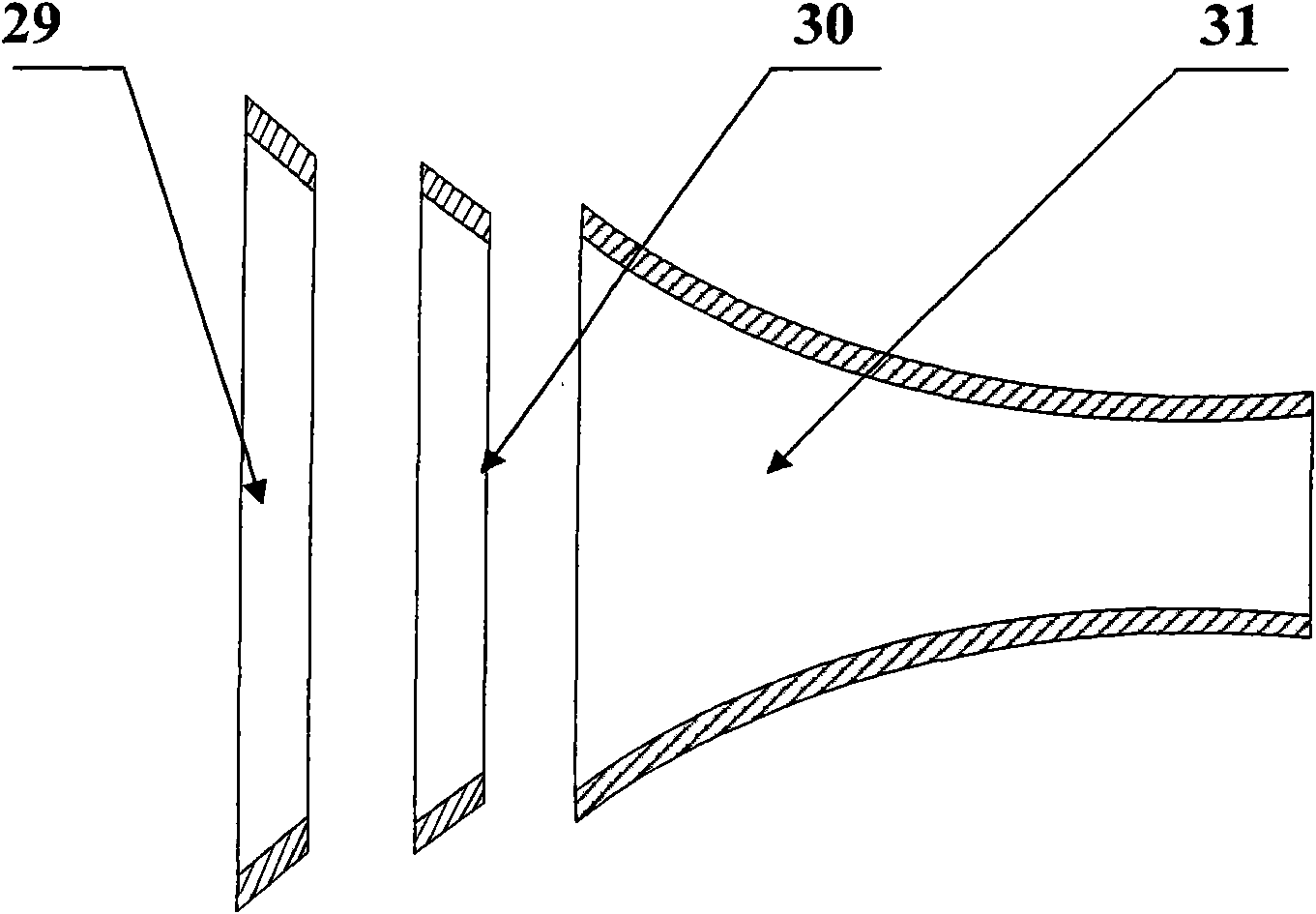

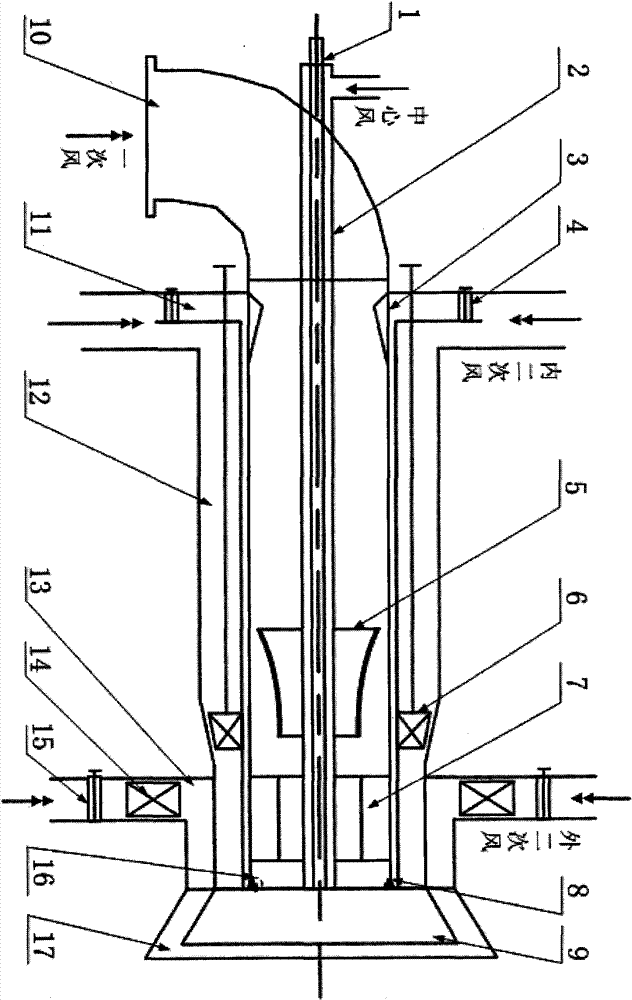

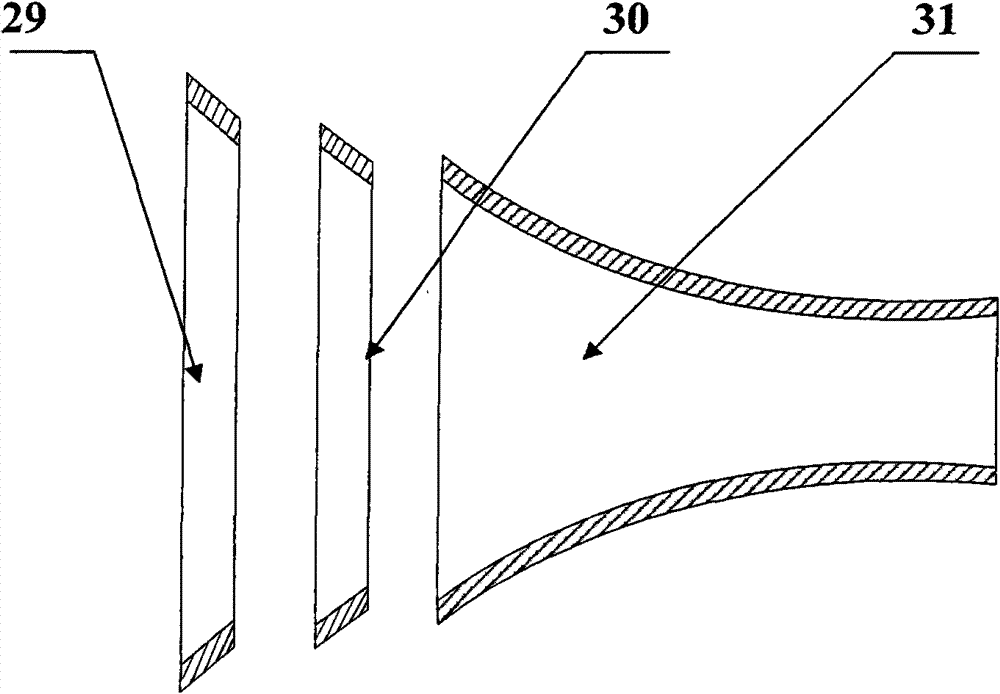

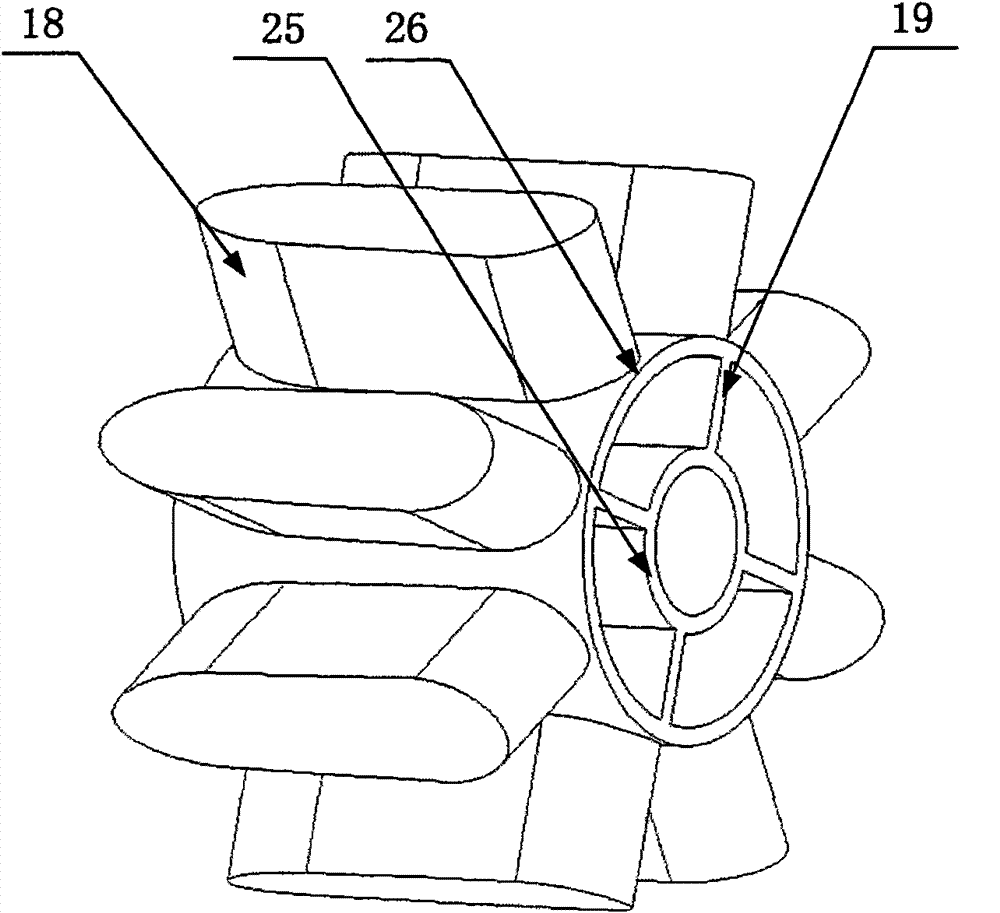

Composite concentration triple-wind-regulating low-NOx cyclone pulverized-coal burner

ActiveCN102062396AFire stableExtended service lifePulverulent fuel combustion burnersIndirect carbon-dioxide mitigationCycloneConvex structure

The invention relates to a composite concentration triple-wind-regulating low-NOx cyclone pulverized-coal burner which comprises a central wind passage, wherein a primary wind passage, an internal direct-flow secondary wind passage, an internal rotational-flow secondary wind passage and an external rotational-flow secondary wind passage are sequentially and concentrically arranged at the outer side of the central wind passage from inside to outside, a conical pulverized-coal concentrating device and a star-shaped pulverized-coal concentrating device are arranged in the primary wind passage, and a reversed V-shaped expanded opening and a zigzag axial and radial double concave-convex structured burning-stabilizing device are arranged at the outlet of the primary wind passage; and after primary wind passes through the pulverized-coal concentrating device, an intense standing-vortex burning-stabilizing firing area with obvious circumferential and radial pulverized-coal concentration distribution is formed at the outlet of the burner, and the burning conditions of high-temperature reflow smoke gas and oxygen-deficient rich fuel are generated. The burner has extremely strong firing-stabilizing performance and good coal adaptability and effectively reduces the concentration of nitrogen oxides.

Owner:XI AN JIAOTONG UNIV

High insulating anticorrosive paint

The invention discloses a high insulating anticorrosive paint, which is designed for solving the technical problem that the comprehensive indexes of temperature resistance, flame resistance, heat insulation, adhesive force, density and the like of the conventional insulating patient are difficult to meet the harsh requirements of the high-speed train field. The paint comprises the following components in percentage by mass: 50 to 70 percent of epoxy modified organic silicon resin, 10 to 20 percent of hollow microspheres, 10 to 15 percent of composite flame retardant, 5 to 15 percent of hydrotalcite, 3 to 8 percent of titanium dioxide and 1 to 3 percent of auxiliary agent. The paint is prepared according to the proportion and requirements. The paint has the advantages that: the preparation process is simple, reasonable and easy to implement; the paint has good heat resistance, heat insulation, anticorrosive performance and heat preservation performance; and the paint is particularly suitable to be applied on high-speed trains and various aviation aircrafts with high comprehensive performance requirements.

Owner:法库县矿产资源研究发展中心

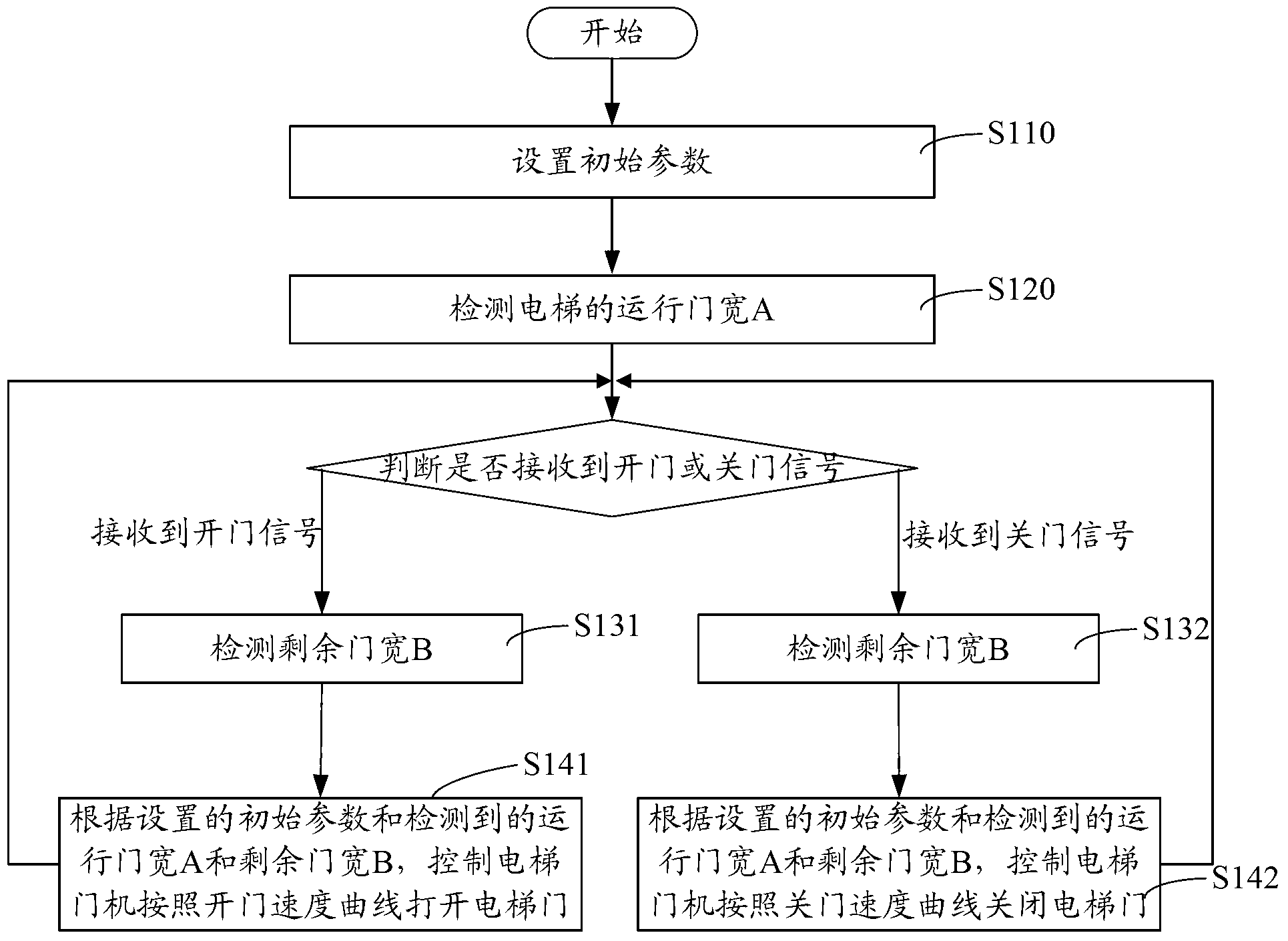

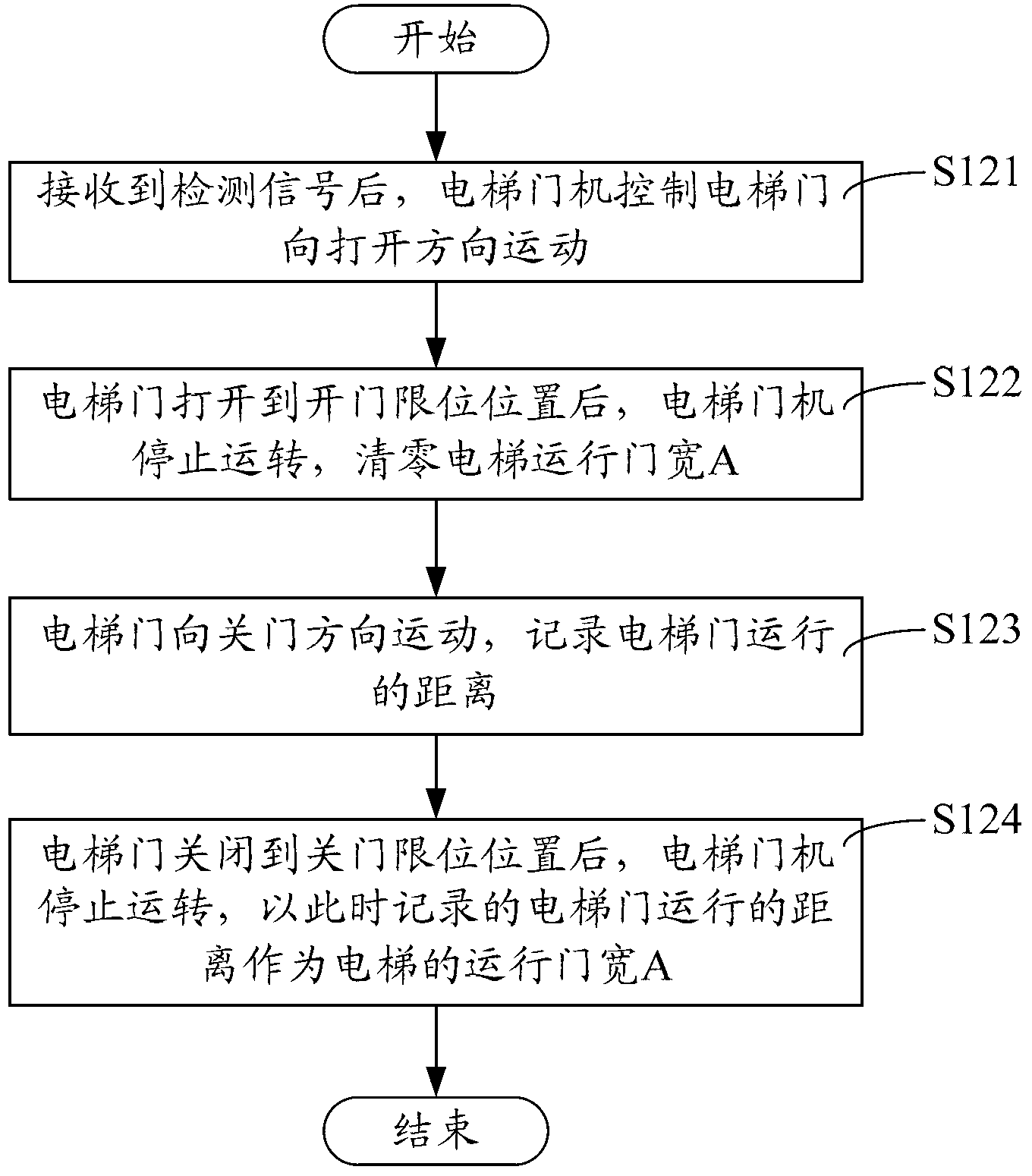

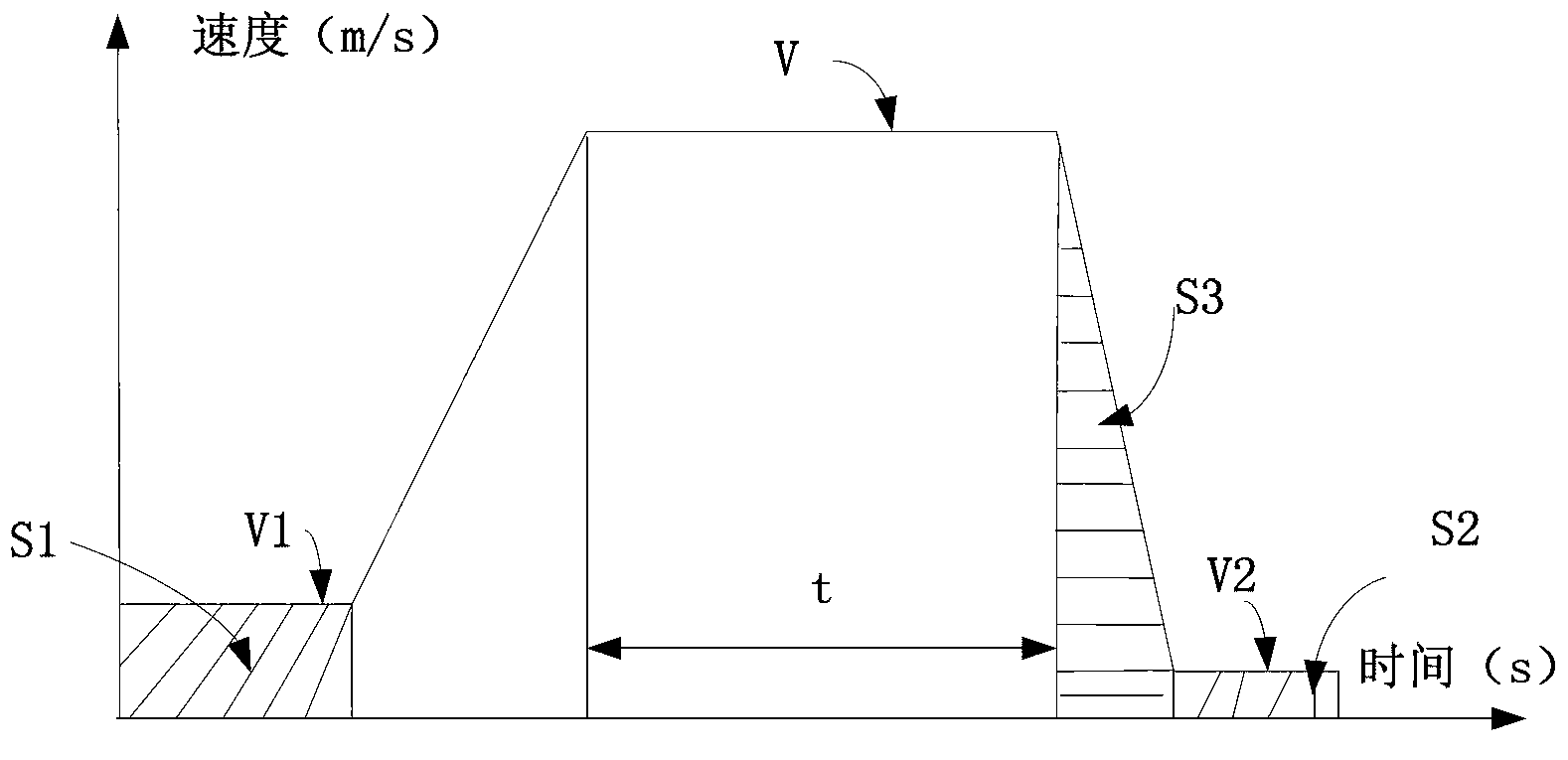

Elevator door motor control system and elevator door motor control method

An elevator door motor control system and an elevator door motor control method control opening and closing of an elevator door by controlling running of an elevator door motor. The elevator door motor control method includes the steps: setting initial parameters, detecting a running door width A of an elevator, detecting a residual door width B, and according to the set initial parameters, the detected running door width A and the detected residual door width B, controlling the elevator door motor to open or close the elevator door according to a door opening speed curve or a door closing speed curve after a door opening command or a door closing command is received. The elevator door motor control method has the advantages that by optimizing the door opening and door closing speed curves, the method enables the elevator door to be proper in speed when the elevator door is opened and closed, and speed is low in starting and ending stages while speed in an intermediate stage is high, so that door opening and closing efficiency is improved, and comfort level is good during opening and closing of the elevator door.

Owner:SHENZHEN HPMONT TECH

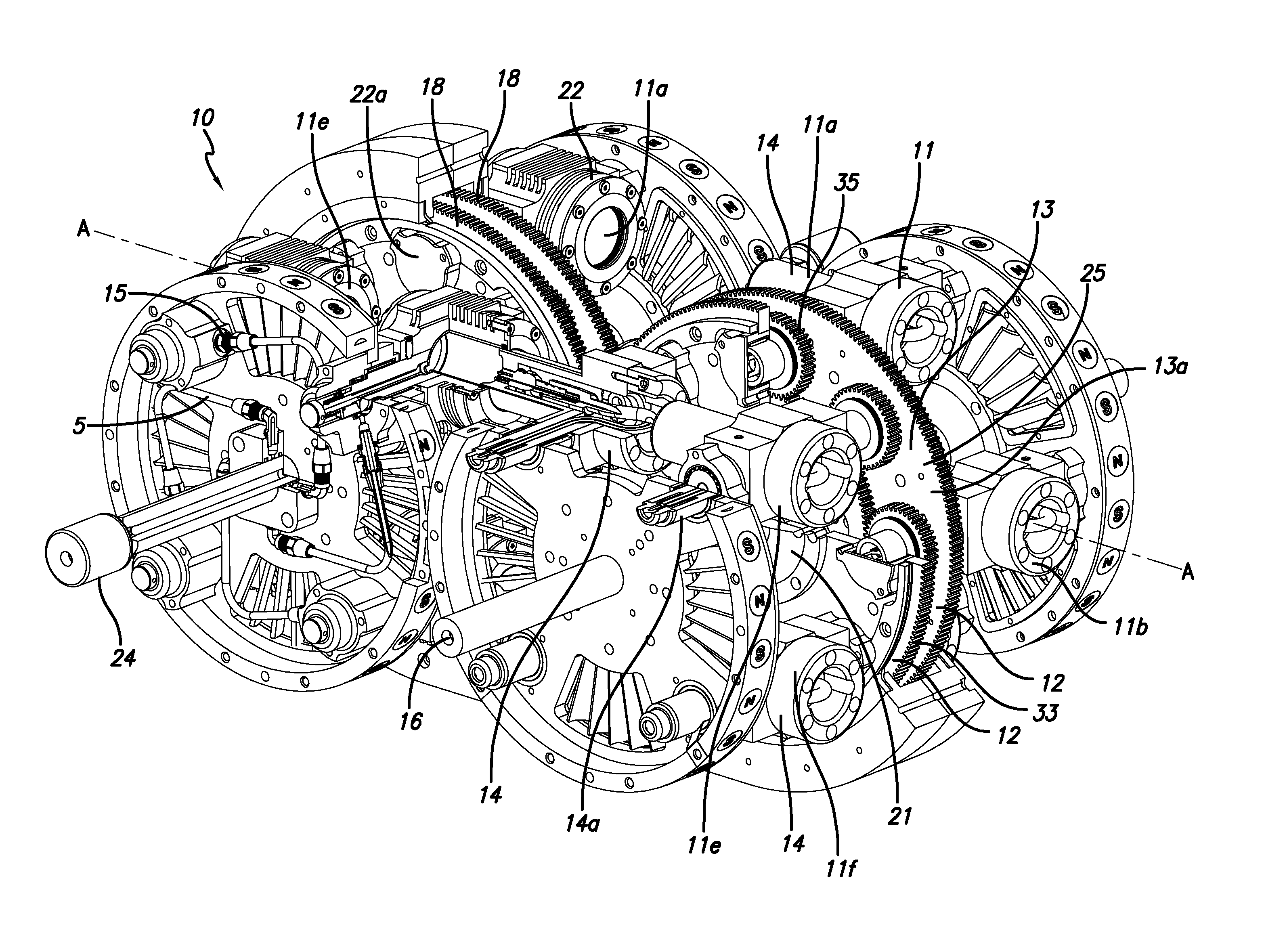

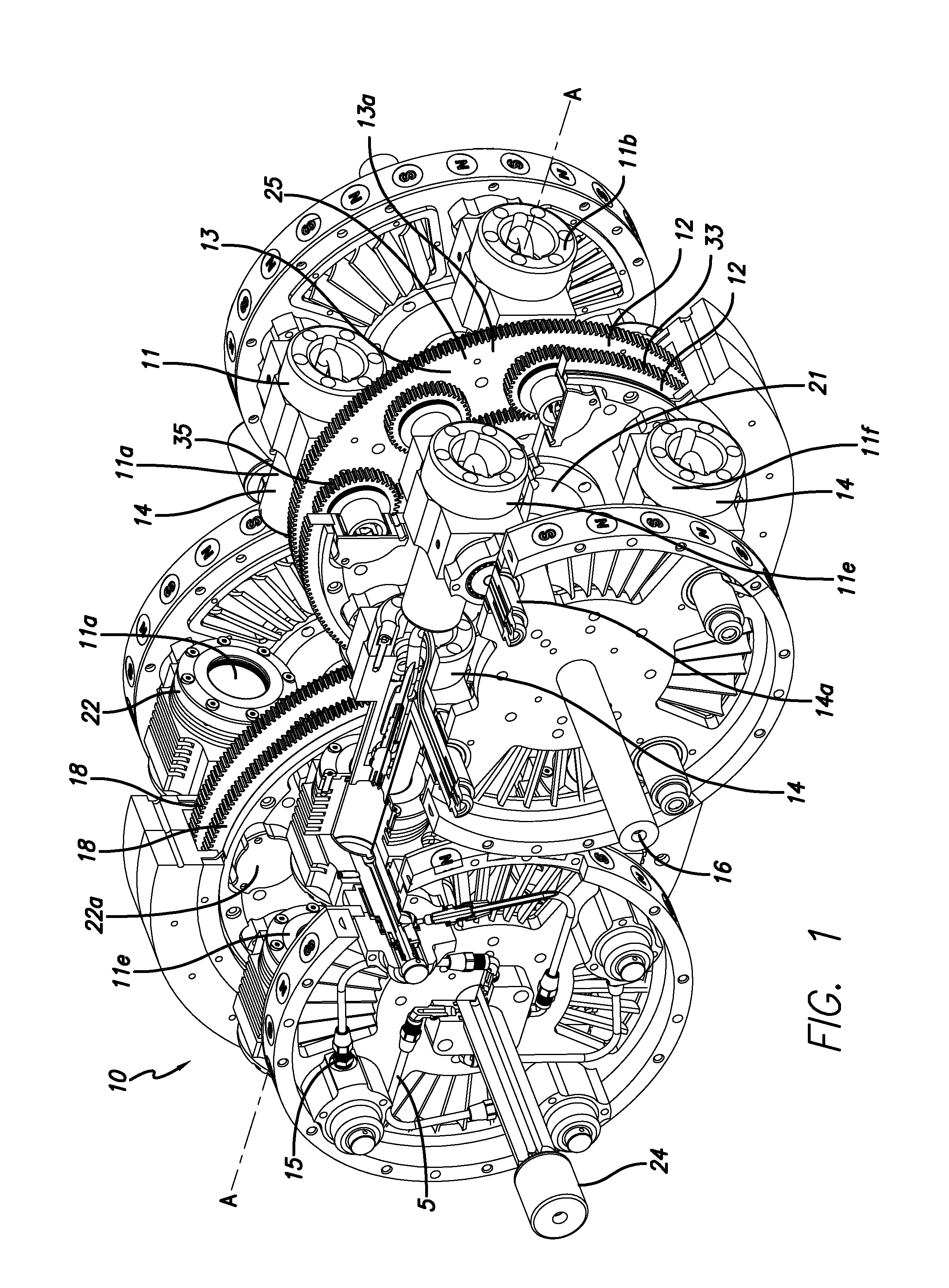

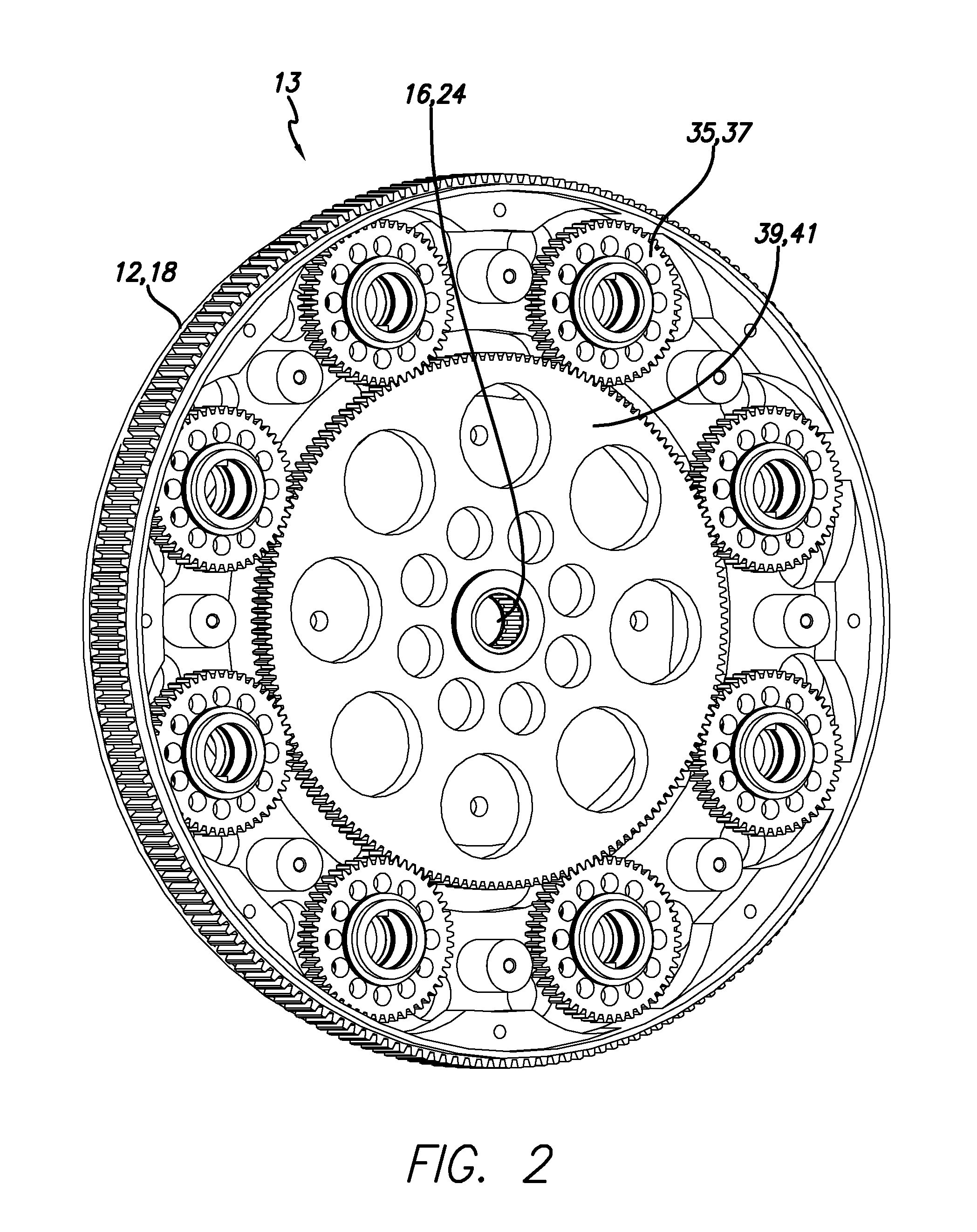

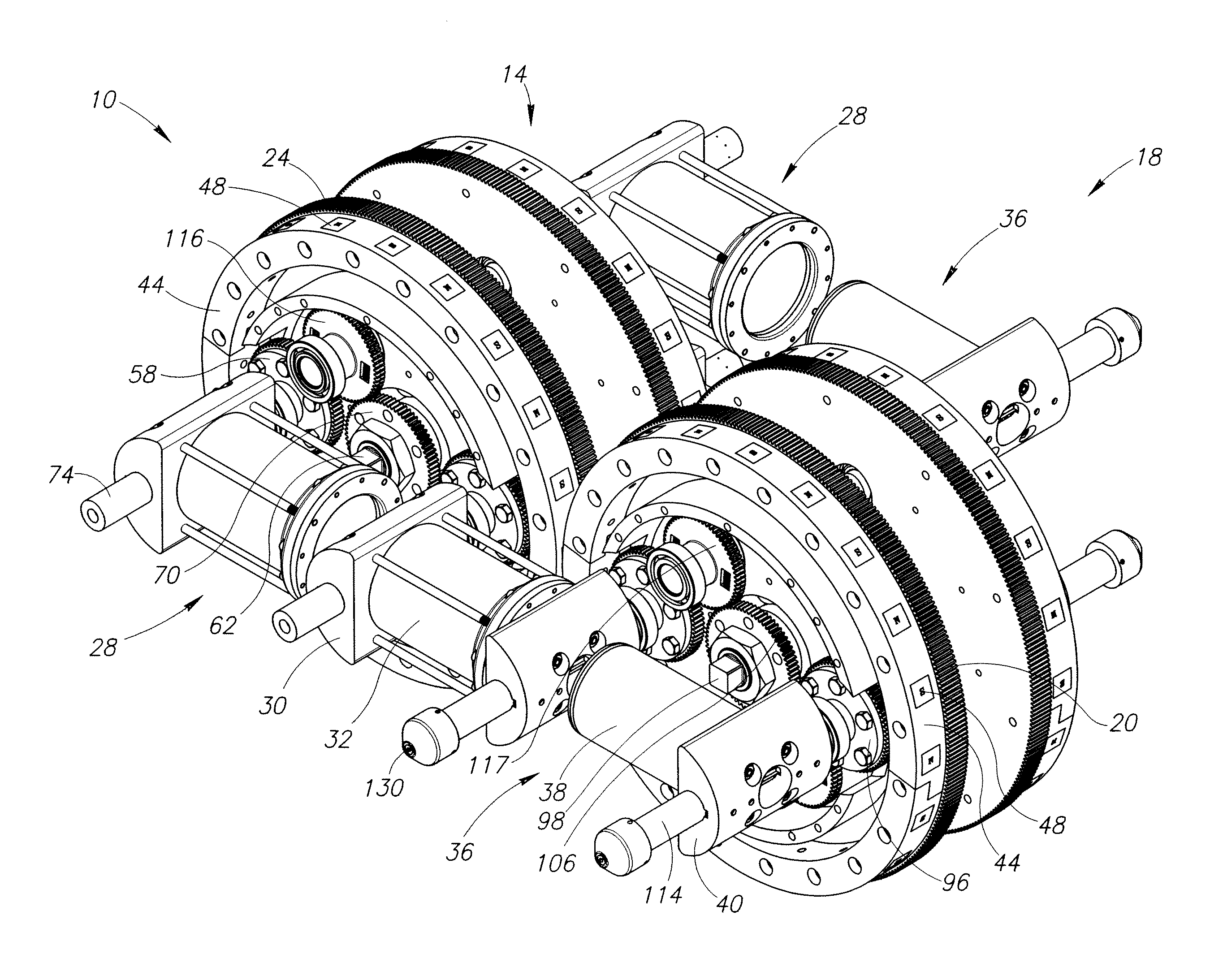

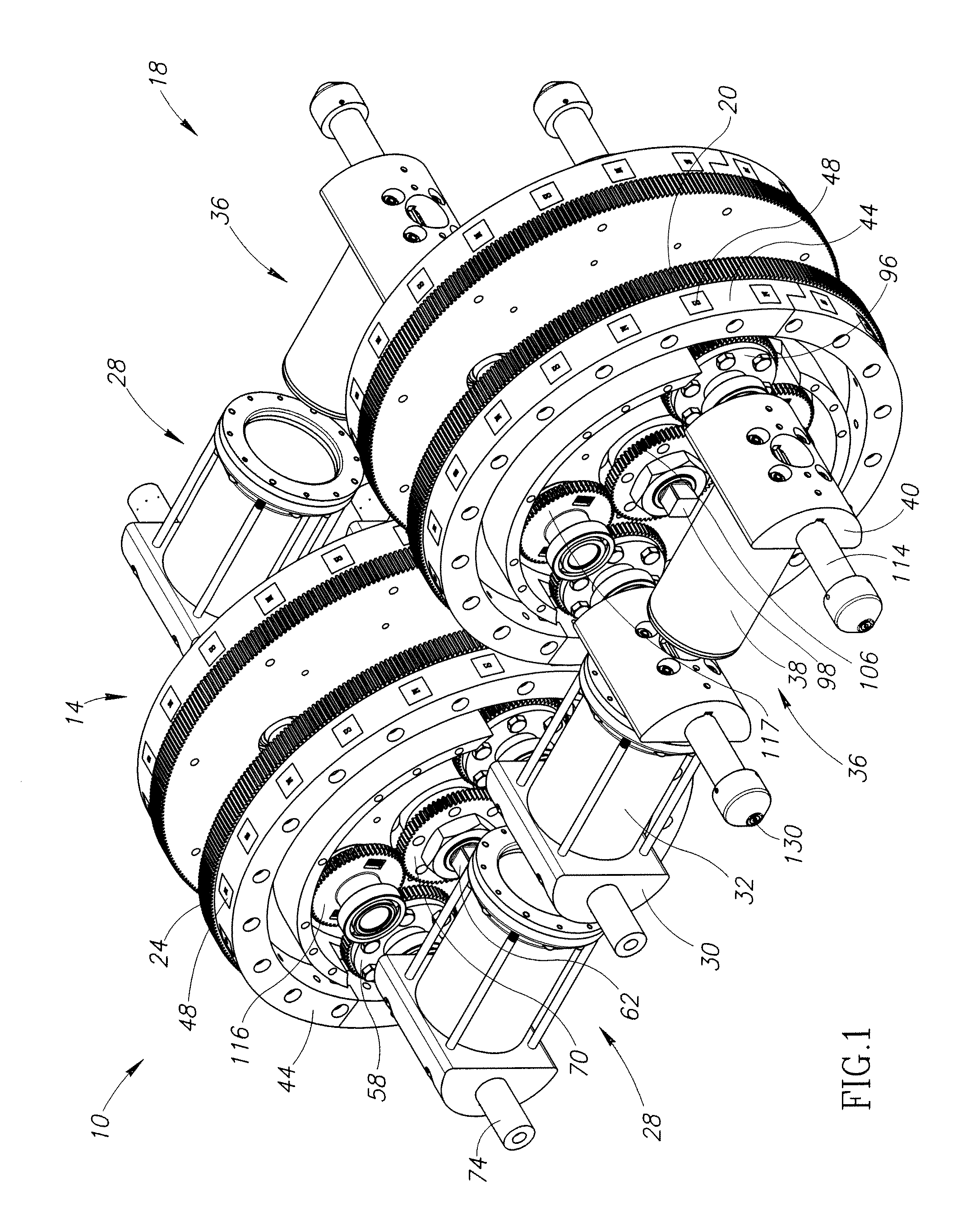

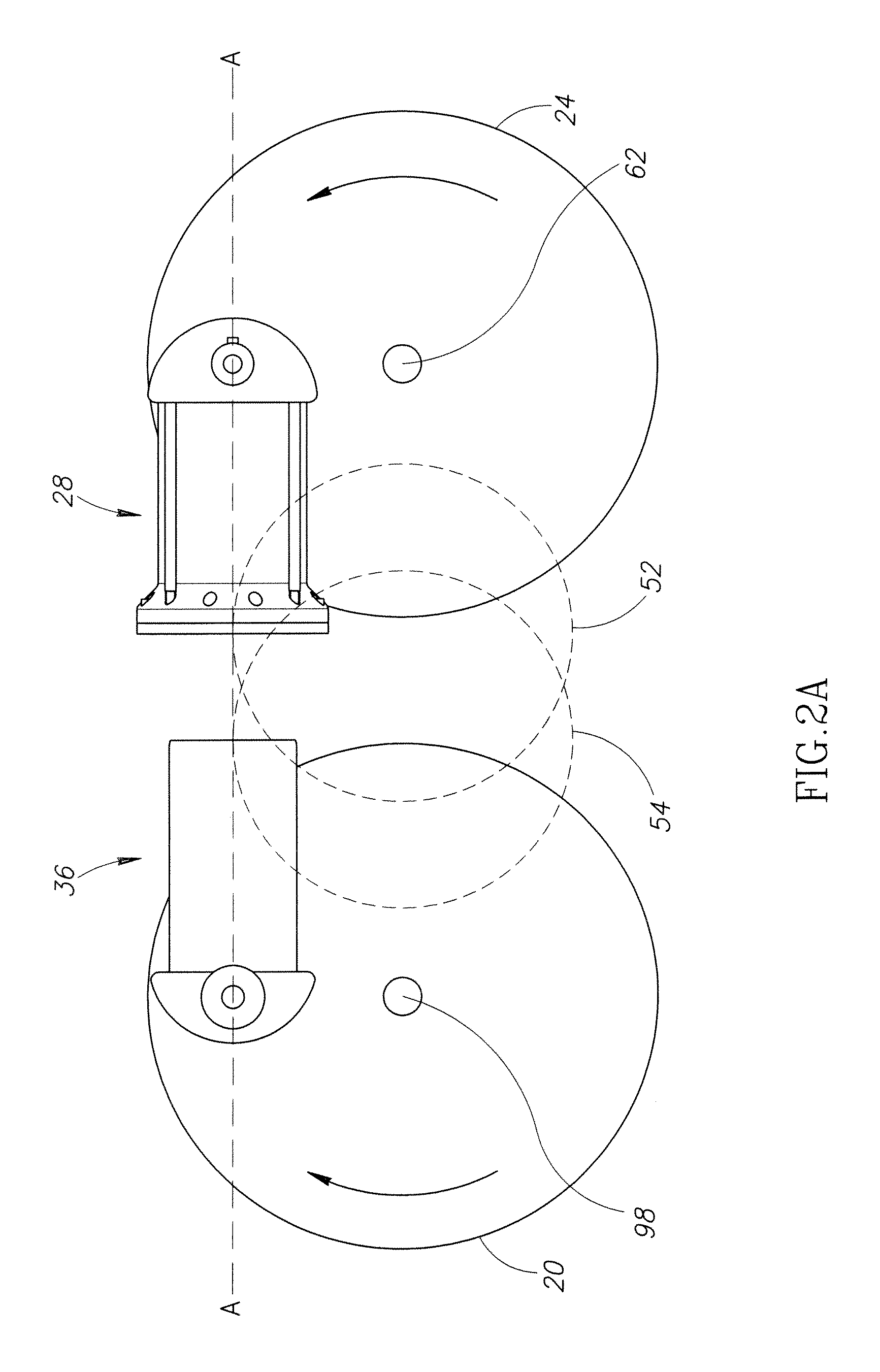

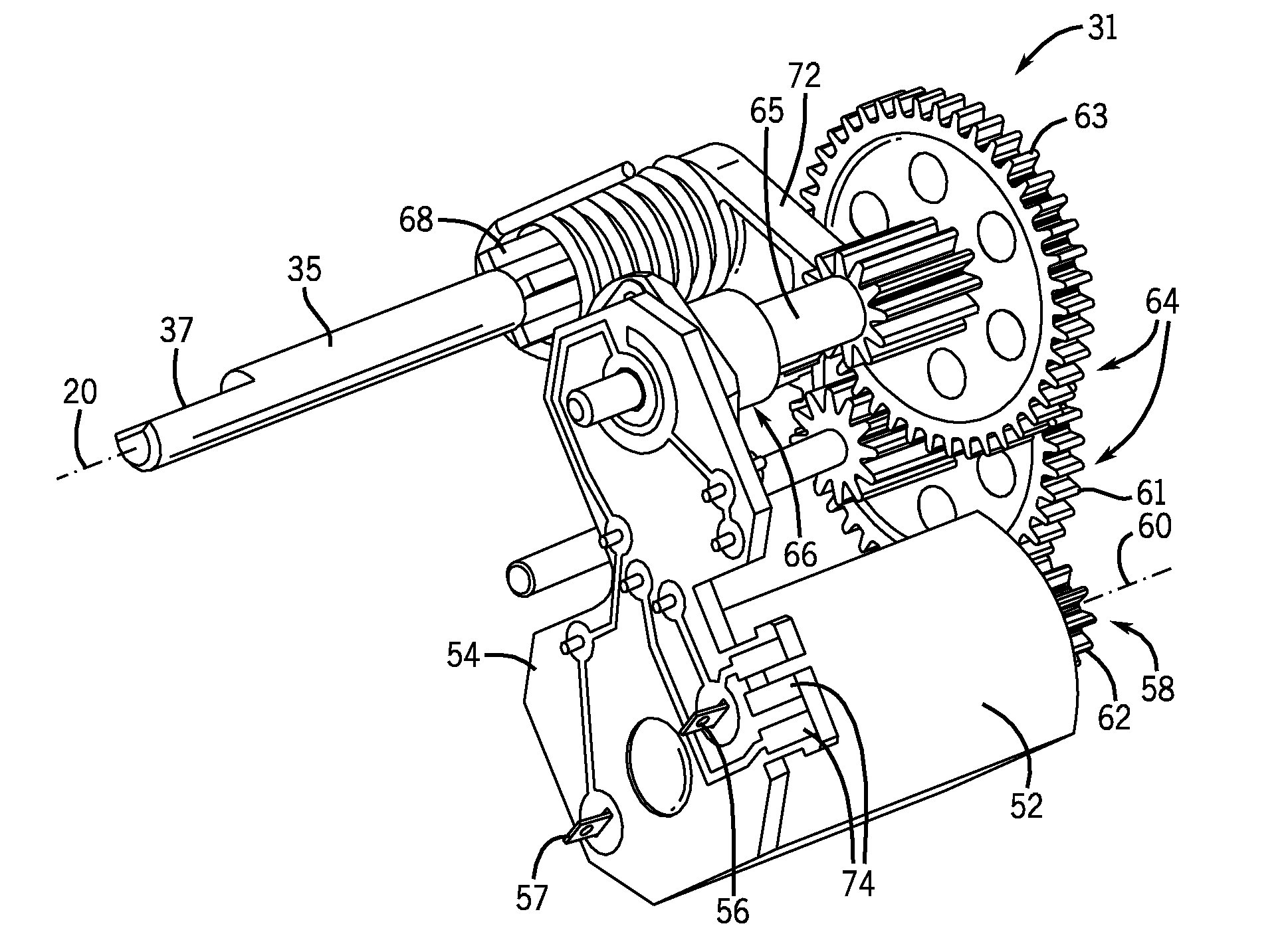

Orbital, non-reciprocating, internal combustion engine

ActiveUS8161924B1Reduce coolingLow in smog producing emissionInternal combustion piston enginesEngines with rotating cylindersPistonInternal combustion engine

A combustible fluid operated orbital engine has plural sets of cooperating cylinder and piston members with respective parallel axes of rotation, respective cylinder and piston carrier wheels with respective axes of rotation parallel to the members' axes of rotation carrying said members circularly and orbitally and at all times in opposed relation on a common longitudinal axis along intersecting counter paths. Respective gearing structures supported by the cylinder and piston carrier wheels rotate the members counter to their circular motion direction to maintain their opposed relation for their periodic interfittment when their respective paths intersect. A combustible fluid supply is provided to the cylinder member for combustion coincident with the periodic interfittment in engine operating relation. The common longitudinal axes of the cylinder / piston sets are at all times parallel with each other.

Owner:LOCKSHAW JAMES +1

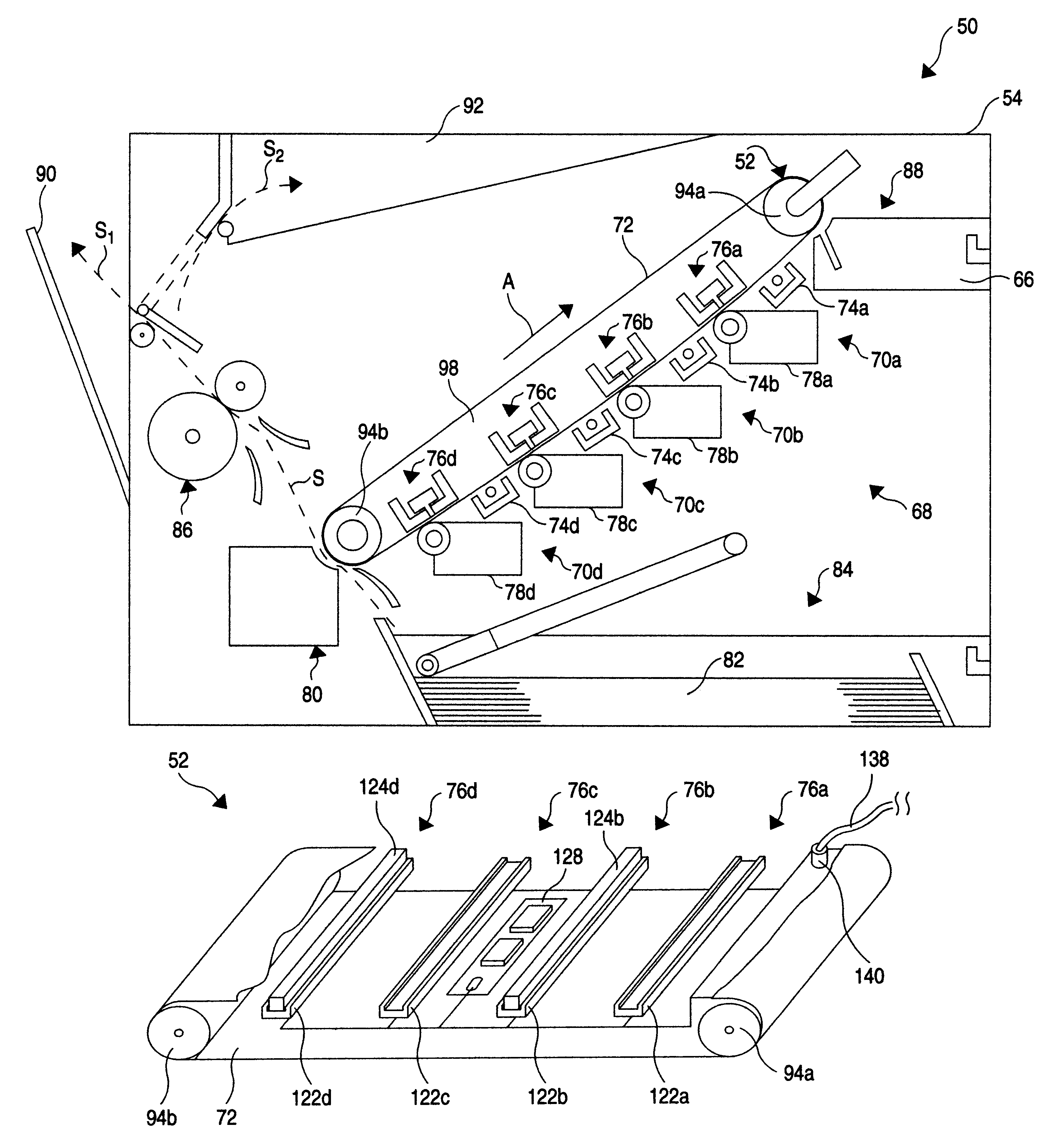

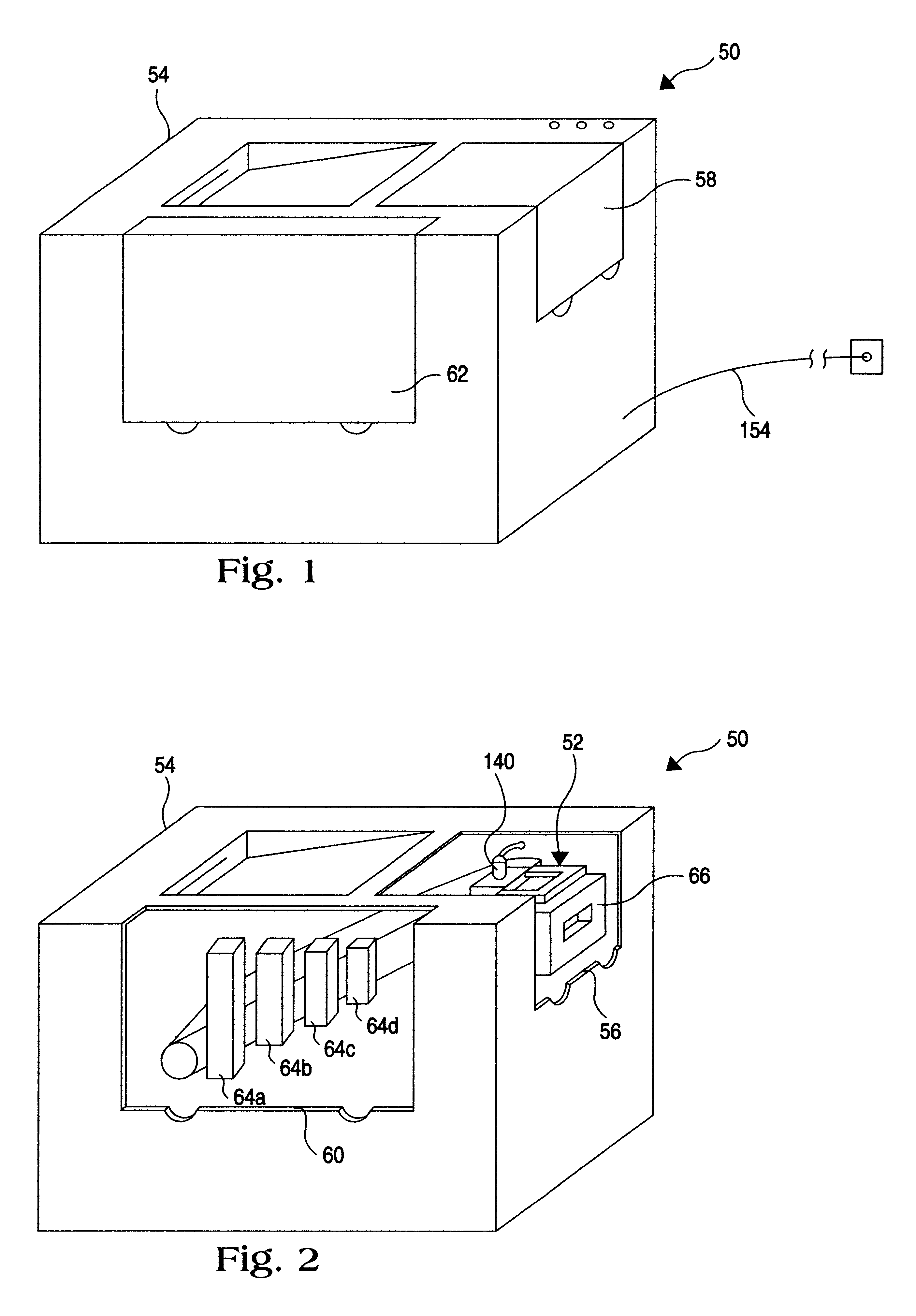

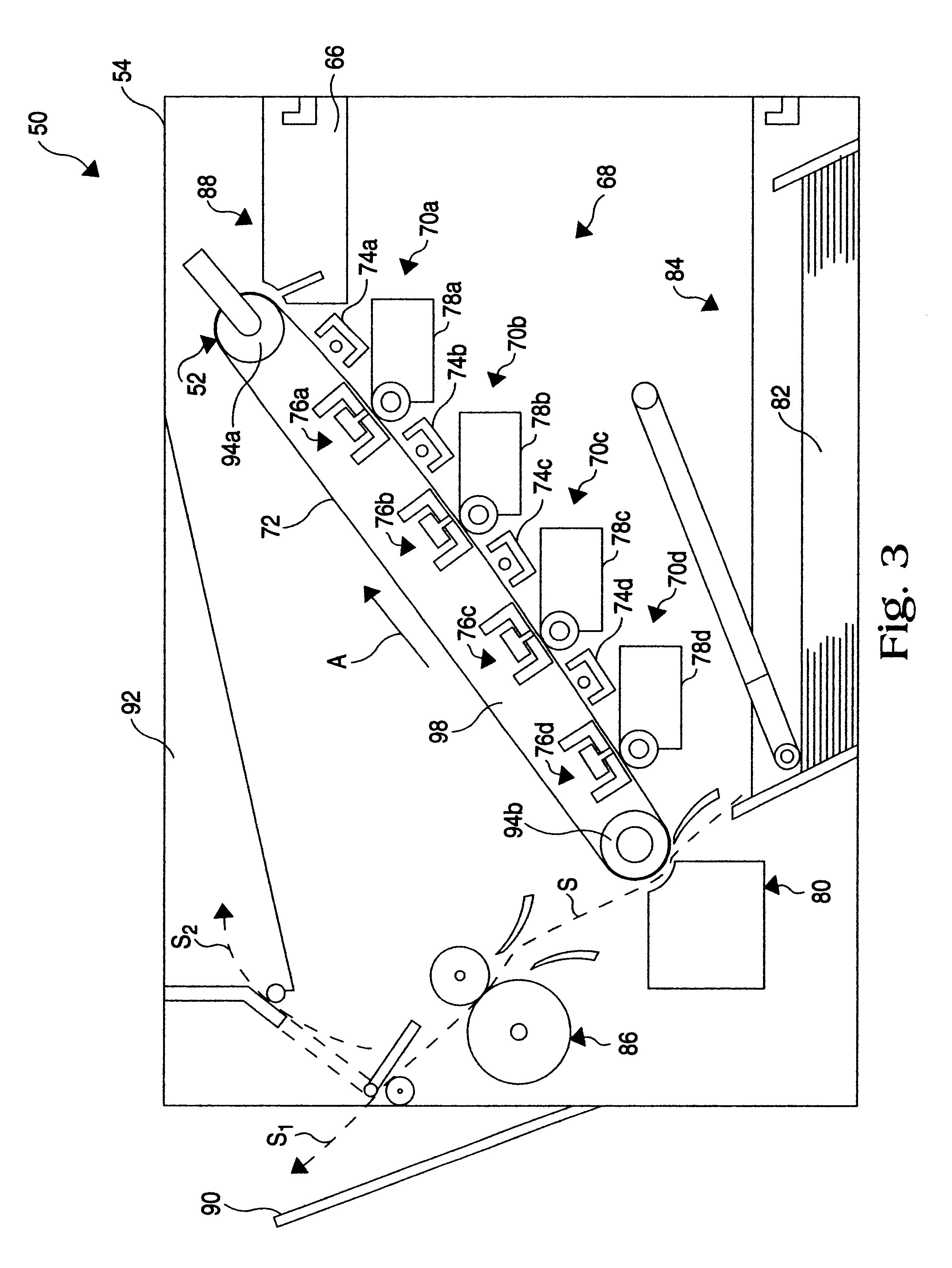

Upgradeable imaging systems with configurable printing routines

InactiveUS6487376B1Price can be changedModerate speedElectrographic process apparatusInterior spaceEngineering

An upgradeable imaging system includes a housing with an opening. A support structure and a plurality of imaging stations are disposed within the housing. Each imaging station includes a charging unit and a developing unit. The imaging system also includes a removable module with a photoreceptive substrate. The removable module has an interior space defined within the photoreceptive substrate and at least one exposing unit disposed within the interior space. The removable module is configured to be engageable with the support structure and passable through the opening of the housing. When the removable module is engaged with the support structure, the photoreceptive substrate is disposed operatively adjacent to the imaging stations. Accordingly, the removable module may be removed from the imaging system and replaced with another module. The imaging system includes circuitry for configuring the imaging stations to operate according to a printing routine depending upon the number of exposing units.

Owner:AETAS TECH

A kind of acetic acid series ITO etchant and preparation technology

ActiveCN102286288AModerate speedStrong singlenessSurface treatment compositionsIon-exchange resinIon

The invention discloses an acetic acid ITO (Indium Tin Oxide) etching liquid and a preparation process thereof. The acetic acid ITO etching liquid is prepared by uniformly mixing hydrochloric acid, acetic acid, inorganic salt chloride and pure water. The ITO etching liquid preparation process comprises the following steps of : under the normal pressure and temperature, controlling or removing foreign ions in the hydrochloric acid and the acetic acid by strong acidic ion-exchanging resin; maintaining the rotation speed of the mixer of a dosing tank; sequentially adding part of the pure water, acetic acid, hydrochloric acid, inorganic salt chloride and the rest of the pure water in the dosing tank; and fully mixing, filtering the mixture by a filter, and finally preparing the acetic acid ITO etching liquid. In the invention, the acetic acid ITO etching liquid has small granularity, high purity, strong etching monotony, can control the etching angle of the transparent conducting film of an ITO semi-conductor and the etching mount of different metal layers, and has no influences to client terminal equipment and personnel.

Owner:JIANGYIN RUNMA ELECTRONICS MATERIAL

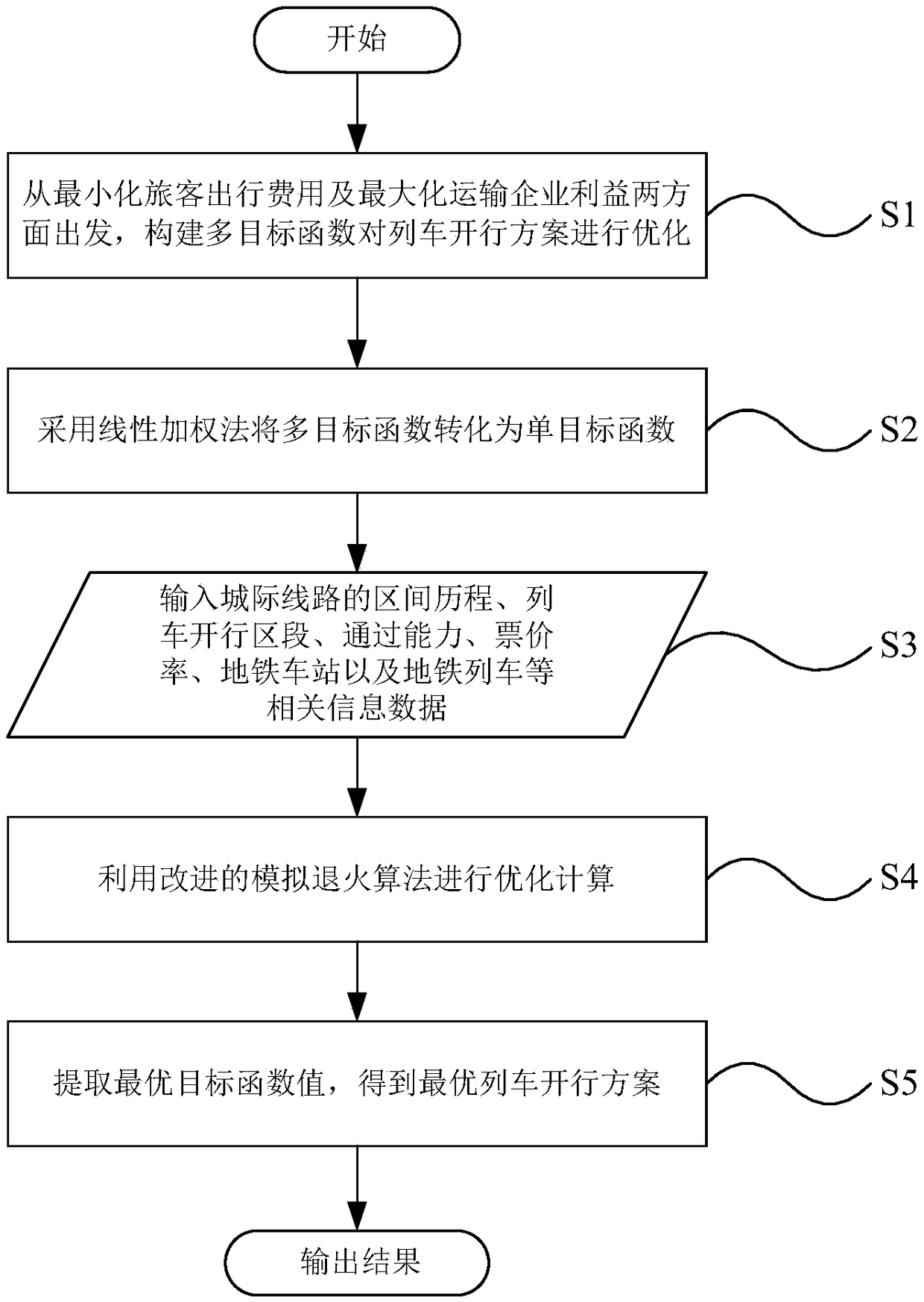

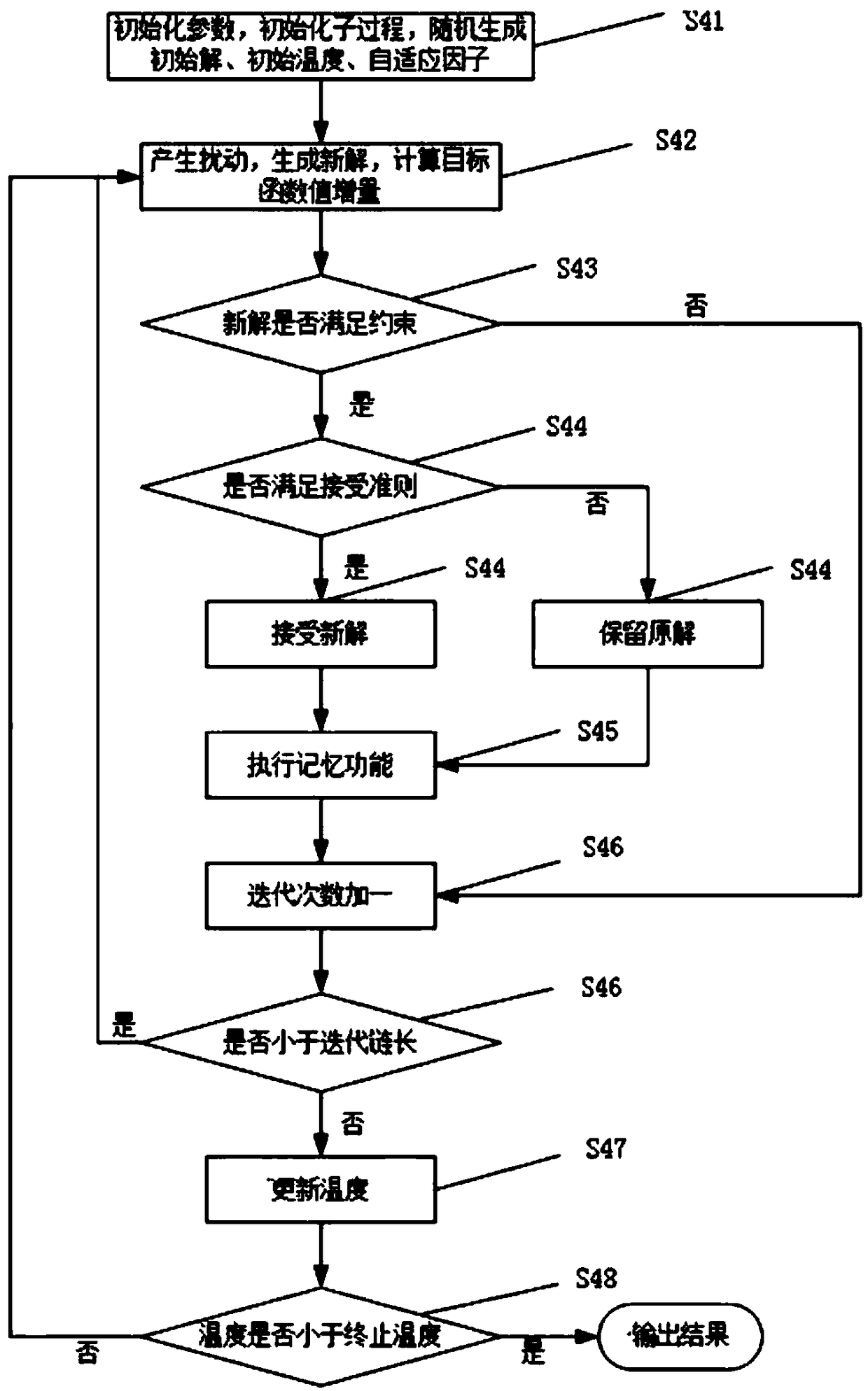

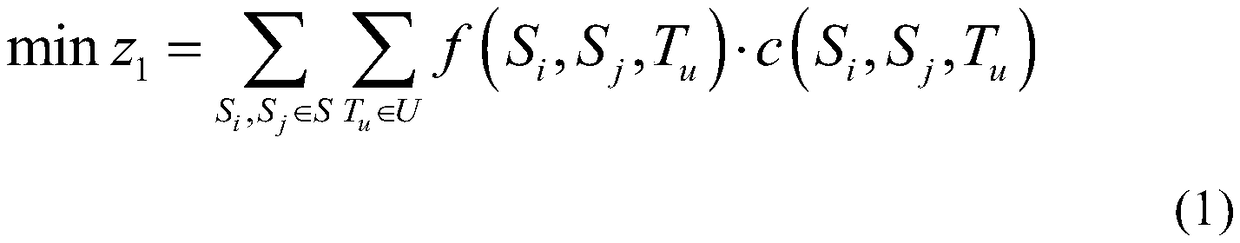

An optimization method of an inter-city train operation scheme based on an improved simulated annealing algorithm

InactiveCN108985500ASolve processing problemsAdaptableForecastingInfluence factorSimulated annealing

The invention discloses an optimization method of an inter-city train operation scheme based on an improved simulated annealing algorithm. The method mainly comprises the following steps: step S1, constructing a multi-objective function and establishing an operation scheme optimization model; step S2, converting a multi-objective function into a single objective function by adopting a linear weight method; step S3, confirming relevant influence factors of inter-city train operation; step S4, optimizing the train operation scheme by using the improved simulated annealing algorithm; step S5, extracting that optimal objective function value according to the calculation result. The invention relates to an intercity train operation scheme optimization method based on an improved simulated annealing algorithm to provide a new method for the optimization of inter-city train operation scheme. Meanwhile, the problems of a conventional simulated annealing algorithm that the solving time is too long, the initial temperature is difficult to determine and the current optimal solution is lost due to the probability acceptance criteria in the search process are solved, the advantages of the global optimal solution can be found more easily.

Owner:LANZHOU JIAOTONG UNIV

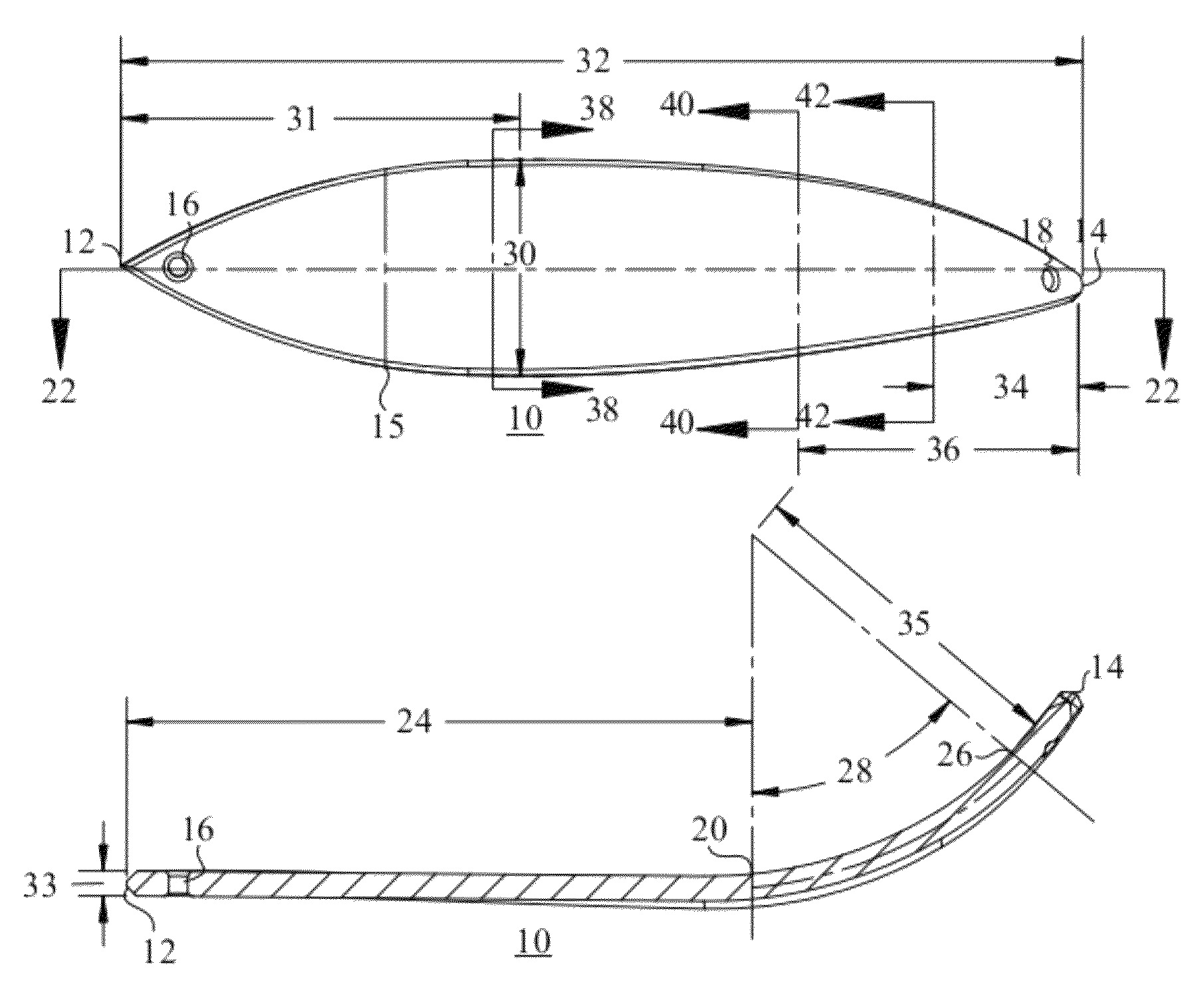

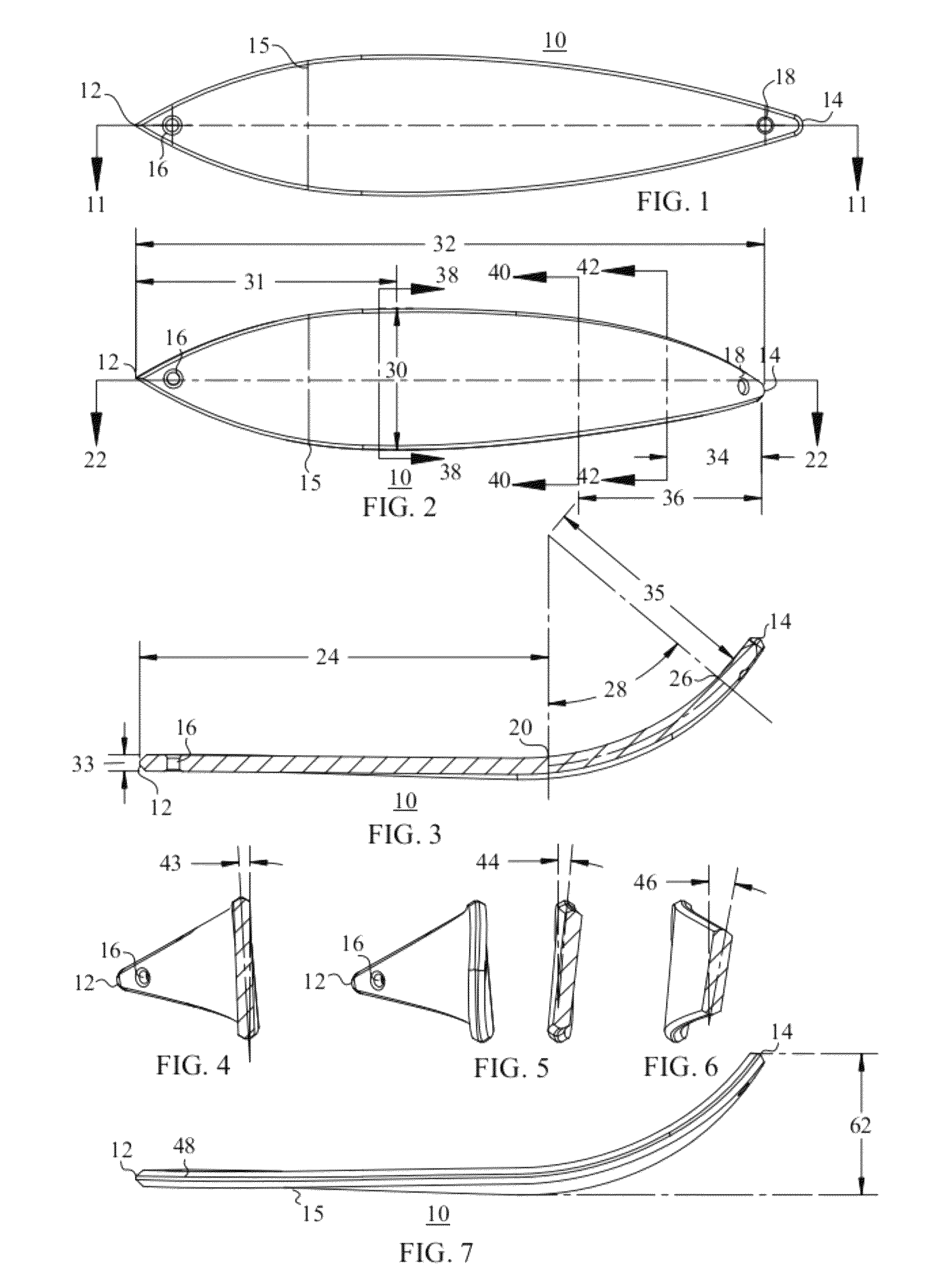

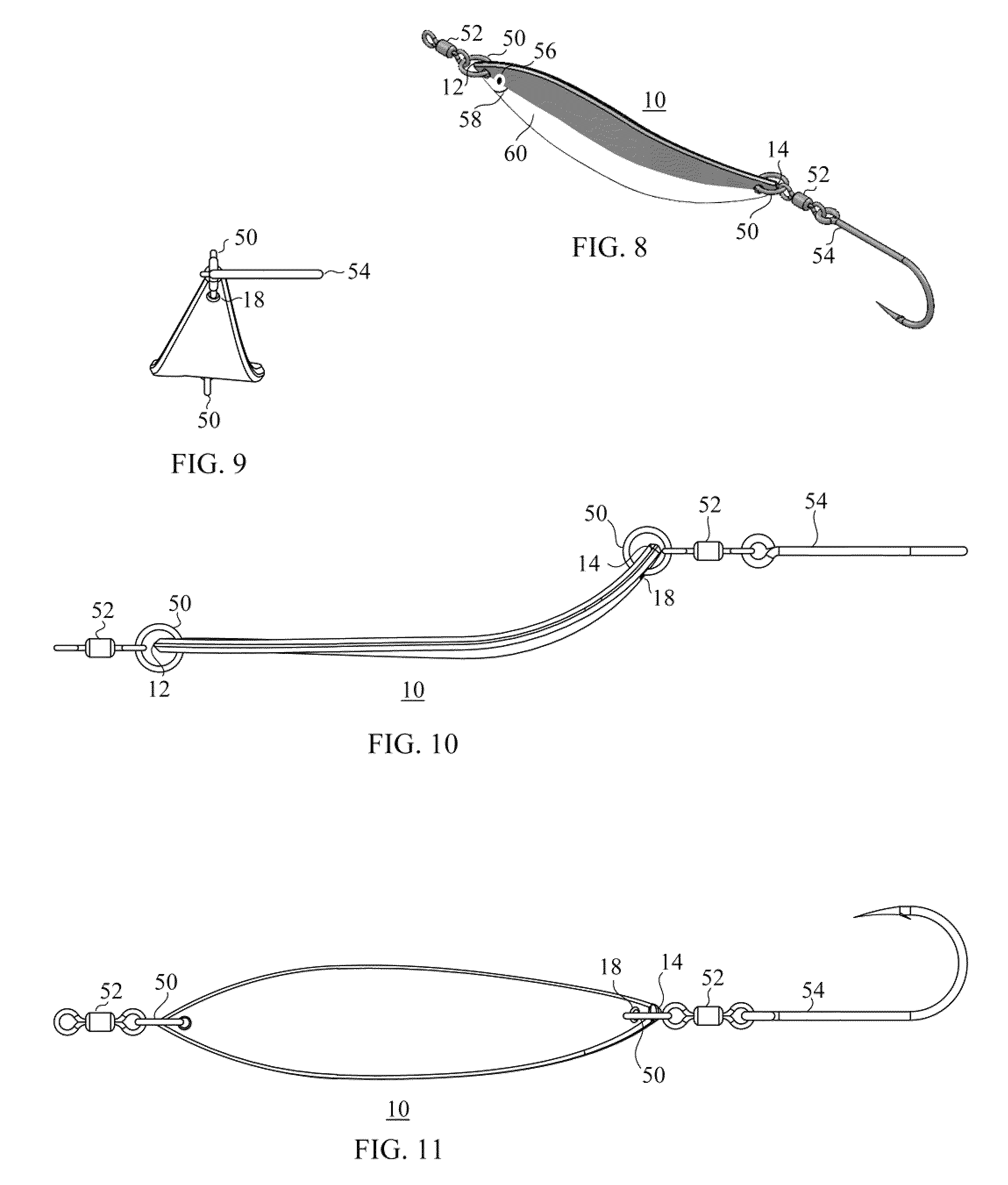

Fishing lure

Owner:JONES CHARLES FREDERICK

Special continuous casting crystallizer protection slag for bloom type easy-cutting steel and preparation method thereof as well as bloom type easy-cutting steel continuous casting method

The invention relates to the technical field of steelmaking, and provides a special continuous casting crystallizer protection slag for bloom type easy-cutting steel. The protection slag comprises thefollowing components of, by weight, 27%-32% of CaO, 40%-43% of SiO2, 1%-4% of MgO, 3.5%-6% of Al2O3, 1%-4% of Na2O, 0.77%-4% of F-, 0.19%-1% of Li2O, 0.25%-1.47% of B2O3 and 8%-14% of C. The protection slag can solve the problems that the molten steel surface is prone to generate large slag strips, and the surface of a casting blank is not smooth in the continuous casting process of the easy-cutting steel. The invention further provides a method for preparing the protection slag by taking wollastonite, carbon-free soot, glass powder, fluorite, clinker, white alkali, carbon black, amorphous graphite, clay, lithium carbonate, borax, calcite, magnesia and bauxite as raw materials. The invention further provides a bloom type easy-cutting steel continuous casting method using the protection slag in the continuous casting process. The casting blank prepared by using the method is good in quality.

Owner:XIXIA LONGCHENG METALLURGICAL MATERIALS CO LTD

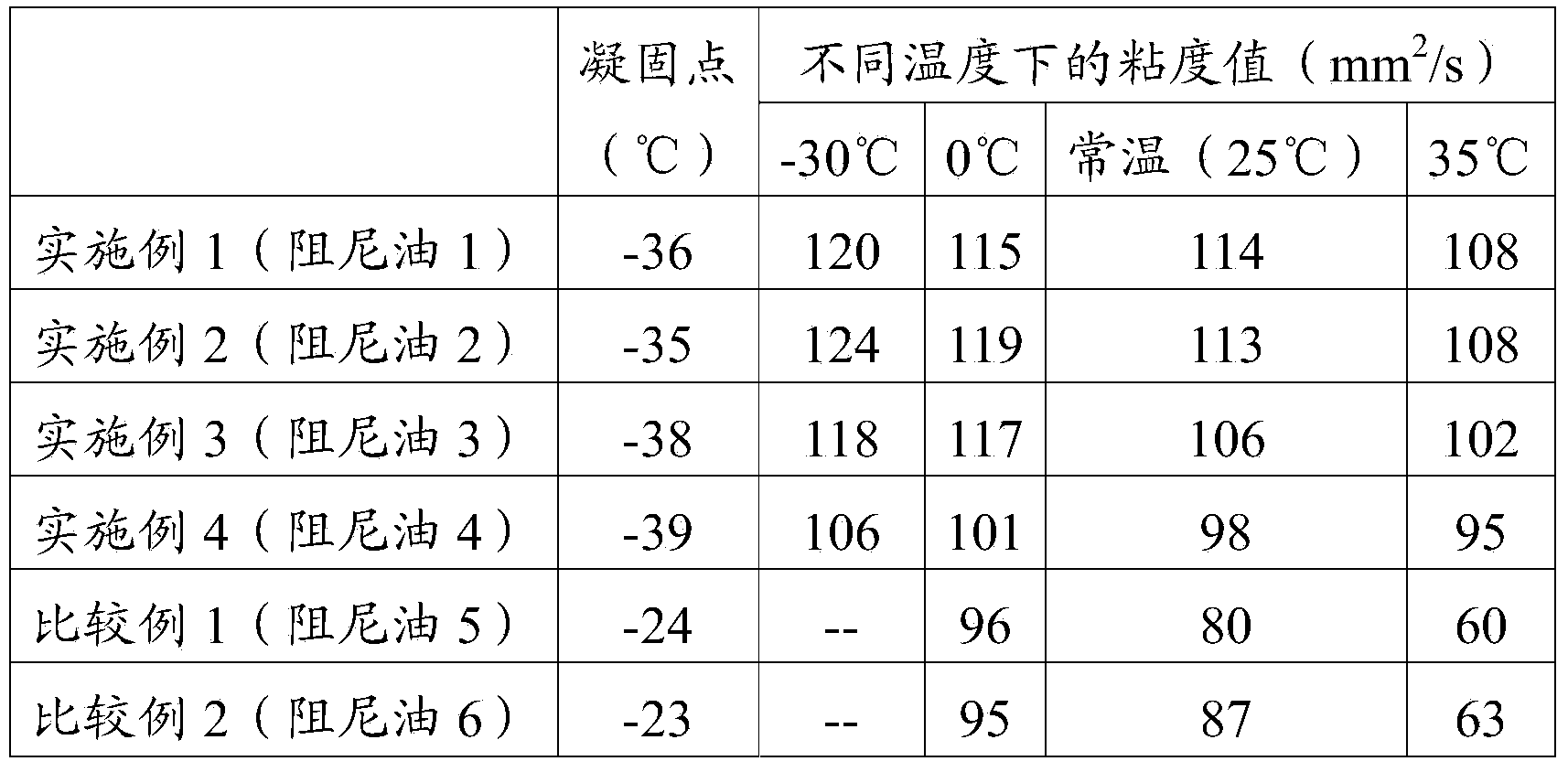

Damping oil composition for damper as well as preparation method thereof

ActiveCN103484221ALow freezing pointSuitable for a wide temperature rangeLubricant compositionChemical compositionLiquid hydrocarbons

The invention relates to a damping oil composition for a damper as well as a preparation method of the damping oil composition. The damping oil composition consists of (A) silicone oil, (B) polyisobutene, (C) a liquid hydrocarbon mixture and (D) hydrogenated rosin. The preparation method of the damping oil composition for the damper comprises the following steps: (a) heating polyisobutene to 70-100 DEG C, and then mixing with silicone oil to obtain mixed liquor; (b) adding the liquid hydrocarbon mixture into the mixed liquor, and uniformly stirring and mixing; and (c) adding the hydrogenated rosin into the liquor obtained in the step (b), and uniformly mixing and stirring to prepare the damping oil composition. The damping oil prepared by the method provided by the invention is wide in applicable temperature range, simple and convenient and feasible in production process, and applicable to batch production on a large scale.

Owner:BAIC MOTOR CORP LTD

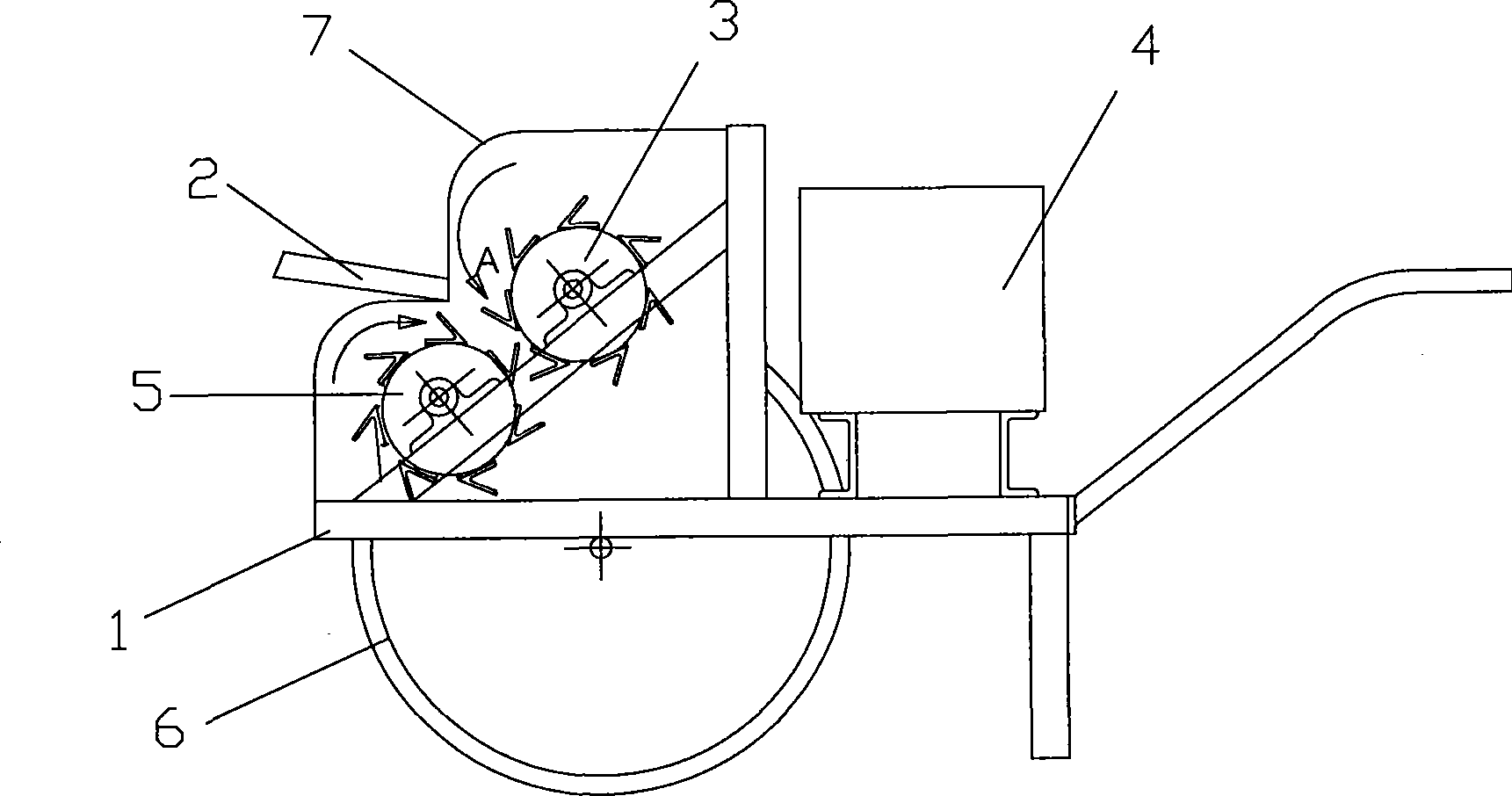

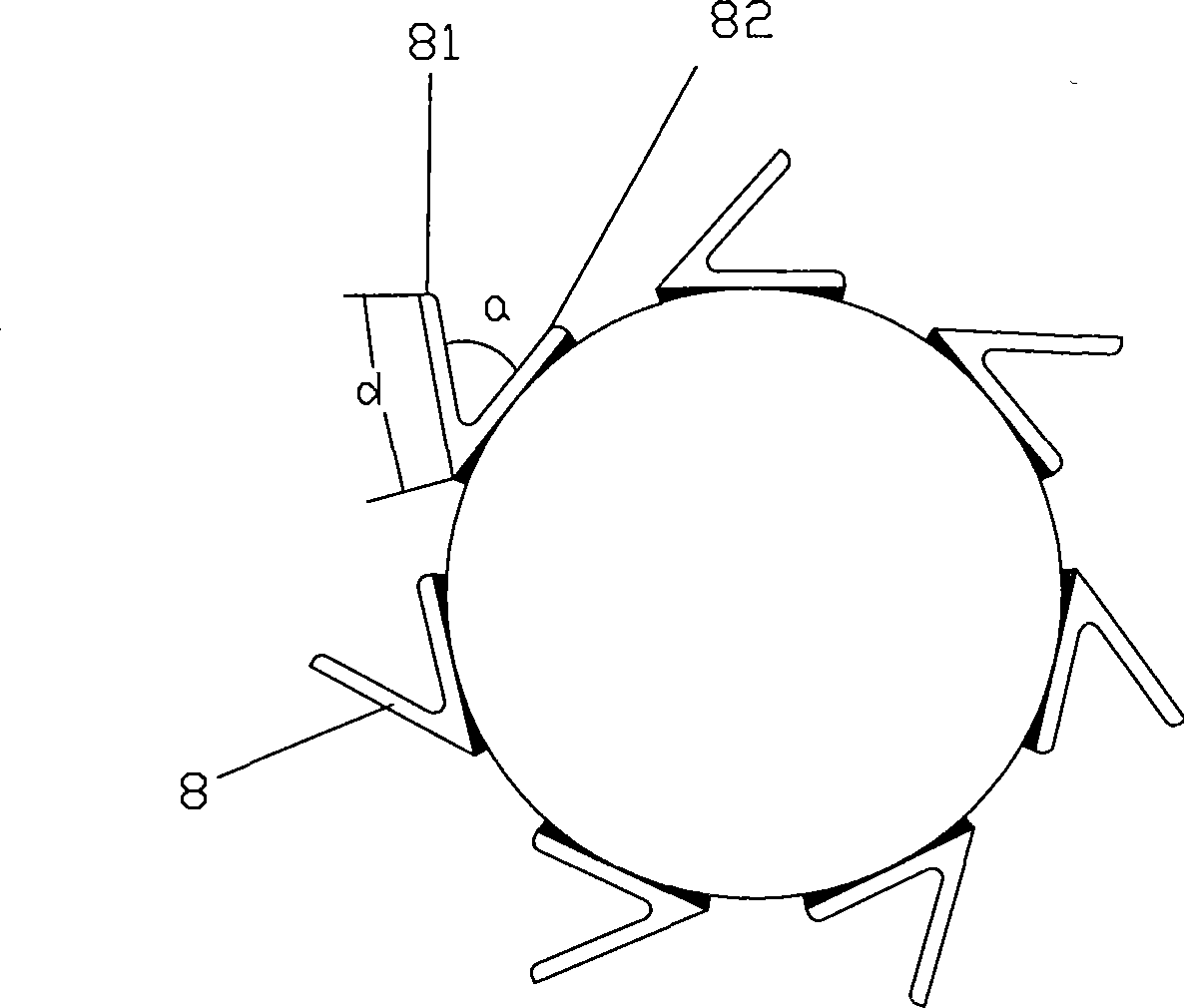

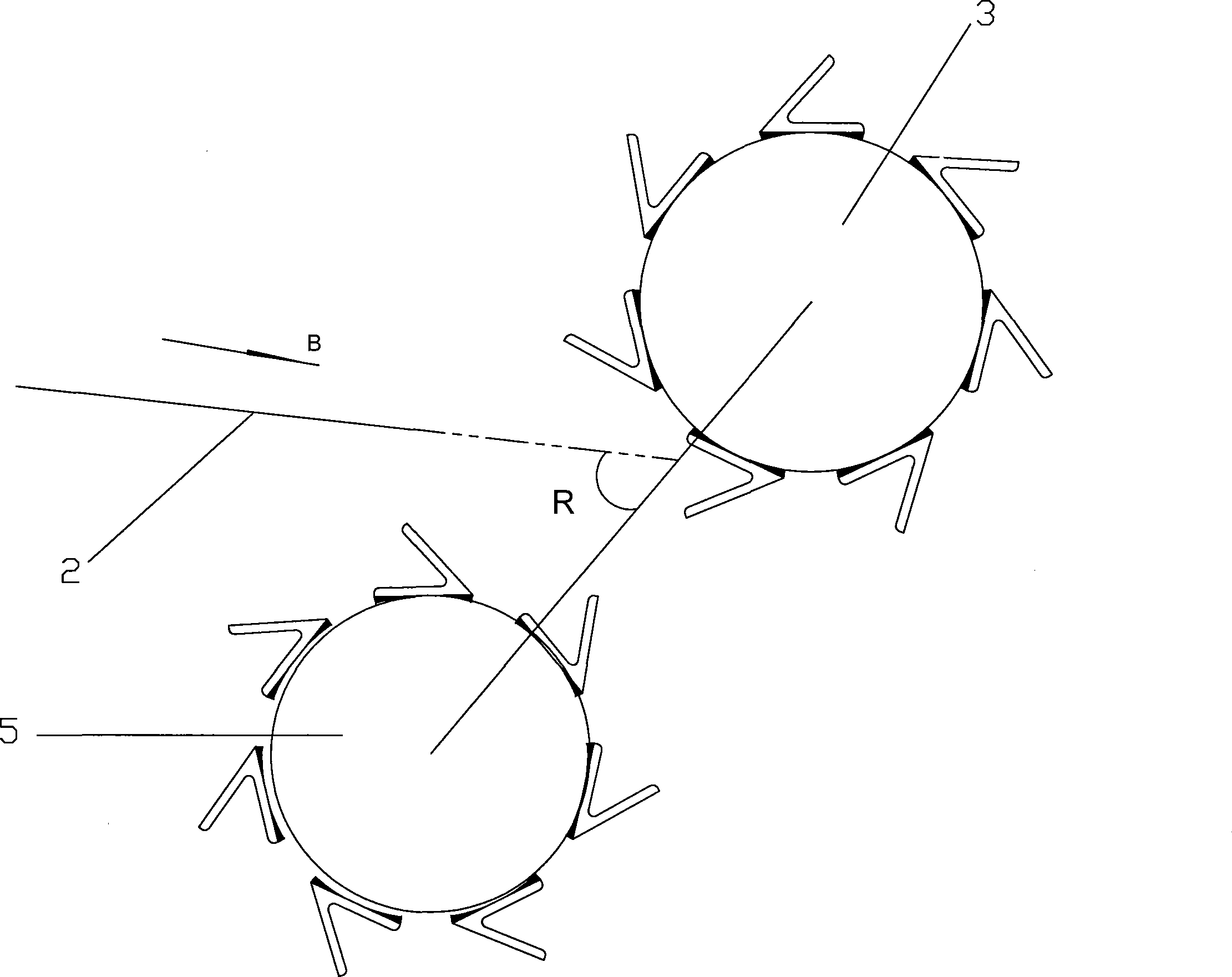

Return pull-type decorticating machine

InactiveCN101250755AModerate speedShort stayMechanical fibre separationEngineeringMechanical engineering

A reverse drawing type decorticating machine comprises a frame, a hemp feeding channel, a decorticating roller which are installed on the frame and a power arrangement which is used for driving the decorticating roller, the reverse-drawing decorticating machine is characterized in that the decorticating roller comprises a drive decorticating roller and a driven decorticating roller, wherein the angle R between the connecting wire of the axial center which belongs to the drive decorticating roller and the driven decorticating roller and the hemp feeding channel is 30DEG C-60DEG C. The reverse drawing type decorticating machine of the invention has the advantages of ensuring safety in production, clean hemp decorticating, high efficiency, and no damage to hemp fiber.

Owner:JIANGSU REDBUD DYEING TECH CO LTD

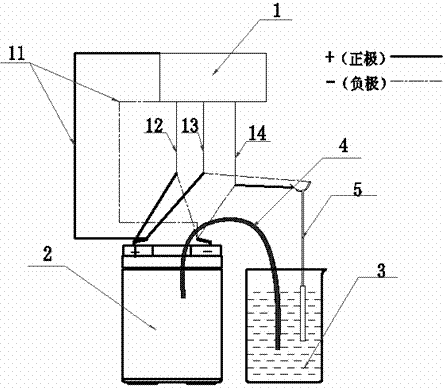

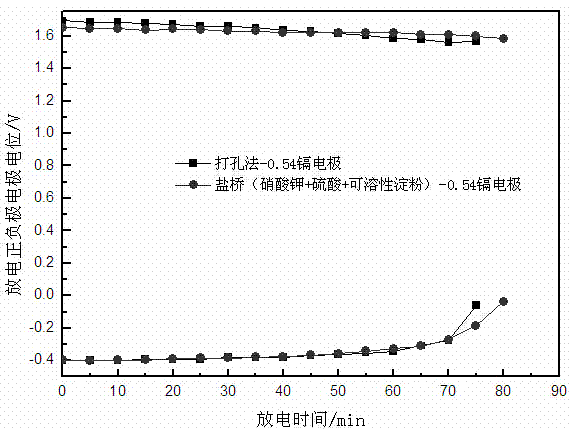

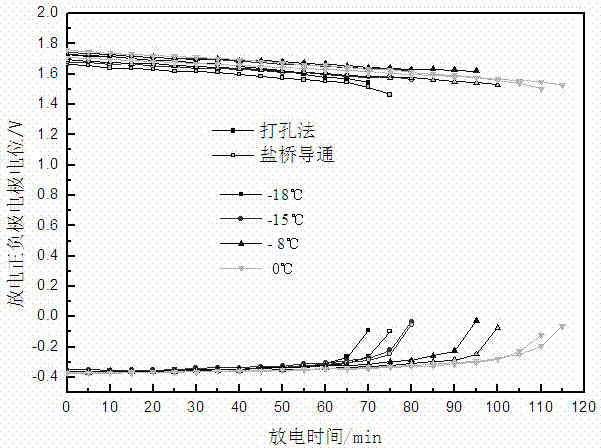

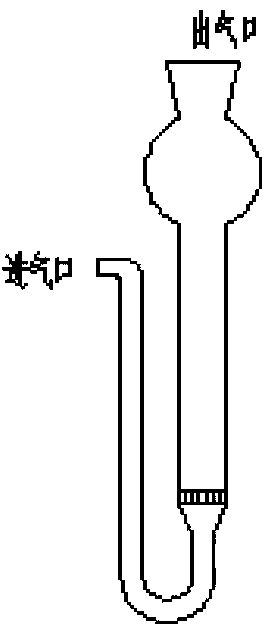

Manufacturing method of salt bridge used in low temperature environment

ActiveCN104330451AGood solubilityChemically stableMaterial electrochemical variablesSalt bridgeSolubility

The invention discloses a manufacturing method of a salt bridge used in low temperature environment. The mixture in the salt bridge is composed of the following components: a saturated potassium nitrate solution, soluble starch, and diluted sulfuric acid with a density of 1.2 to 1.35 g / cm3 according to a weight ratio of 5-11:4-10:1-5. The salt bridge is made of plastic soft pipe. The manufacture of the salt bridge is simple, the raw material consumption is little, the length of the salt bridge can be adjusted at will, and the soluble starch has good solubility. The salt bridge has the advantages of stable chemical property, strong absorbing force, good fluidity, and proper gelation speed, and can be used in low temperature environment with a temperature of -20 to 0 DEG C, and the test results are precise and stable. Moreover the shortages of conventional salt bridges are overcome.

Owner:TIANNENG GRP JIANGSU TECH

Nickel-plating solution for preparing semiconductor silicon wafers

ActiveCN105316663AGood stabilityModerate speedLiquid/solution decomposition chemical coatingSal ammoniacNickel salt

Owner:JIANGYIN JIANGHUA MICROELECTRONICS MATERIAL

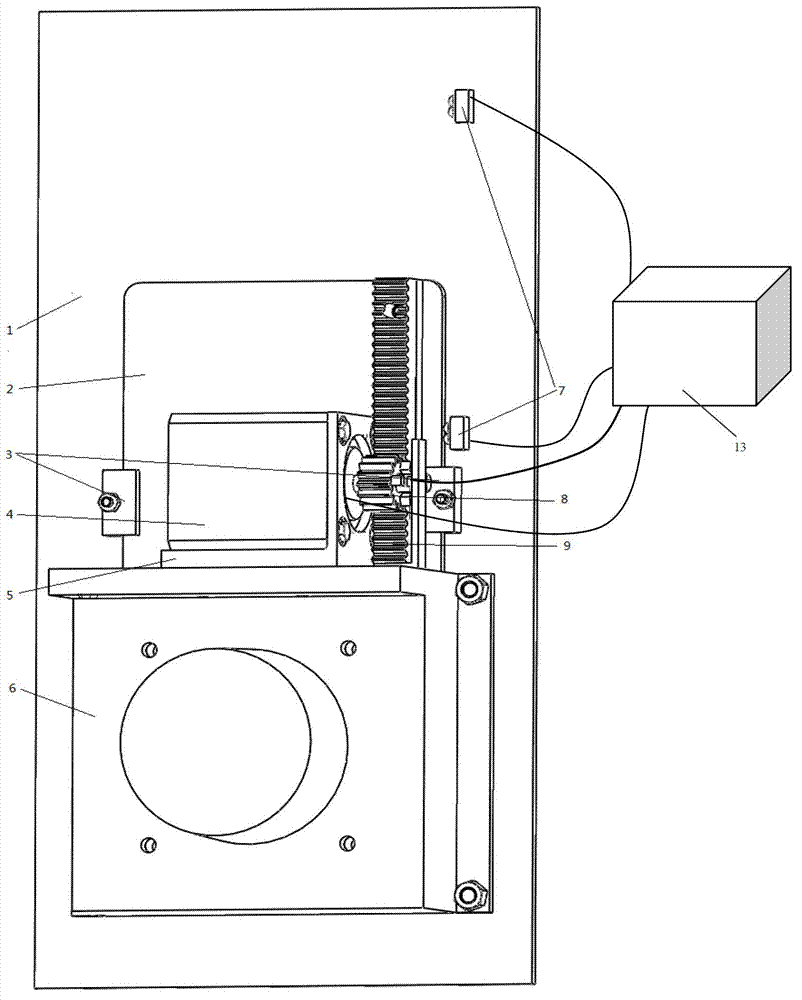

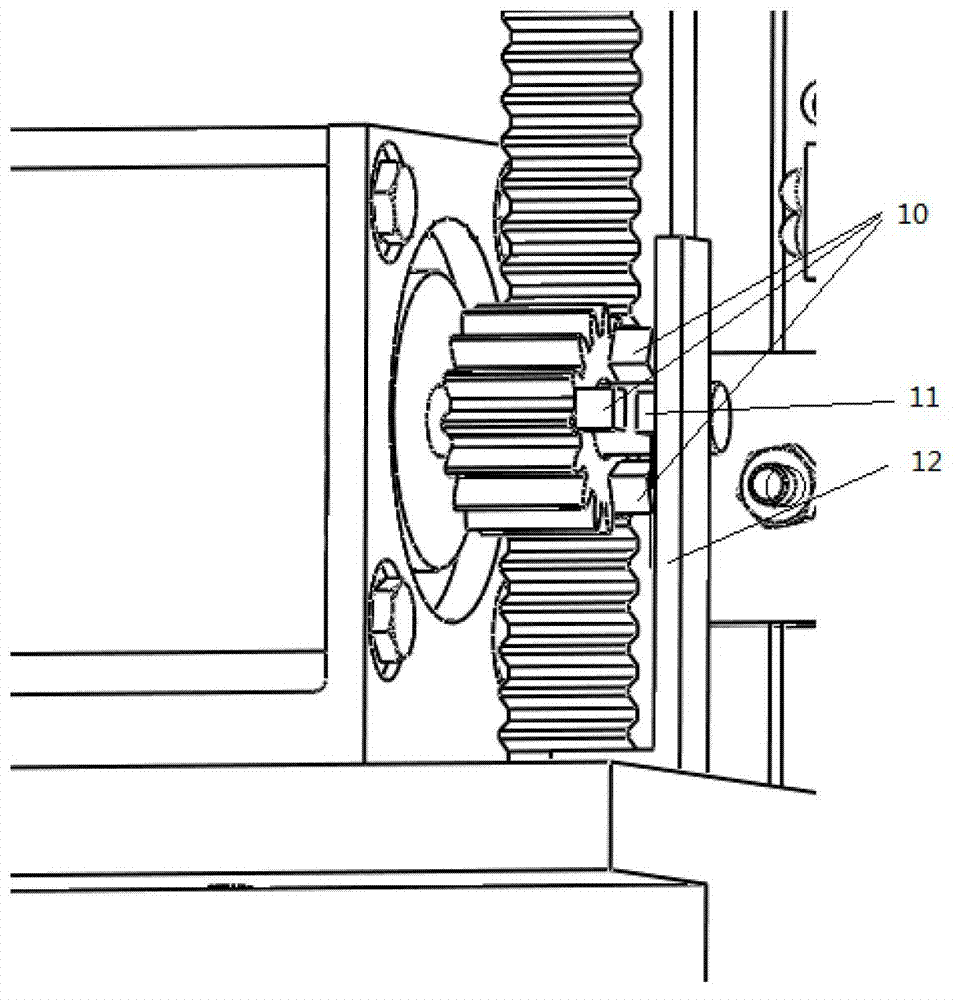

Safeguard device for charging port of electric automobile charging pile

InactiveCN103163805AReduce energy consumptionModerate speedProgramme controlComputer controlMicrocontrollerControl circuit

The invention discloses a safeguard device for a charging port of an electric automobile charging pile. The safeguard device comprises a shell, a step motor, a bin gate, a gear, a rack, guide sheets, infrared reflective proximity switch sensors, Hall sensors, magnets and a singlechip control circuit; the shell and the guide sheets are fixed on the inner wall of the charging pile, the shell is provided with a straight opening matched with the guide sheets to form a guide mechanism, and the bin gate is arranged in the guide mechanism; the gear is arranged on a shaft of the step motor, and the rack matched with the gear is arranged on the bin gate; the two infrared reflective proximity switch sensors are arranged on the inner wall of the charging pile and used for detecting complete opening and complete closure of the bin gate respectively; the magnets are arranged at the edge of the outer end face of the gear, and the Hall sensors are arranged at the corresponding positions; and the infrared reflective proximity switch sensors, the Hall sensors and the step motor are connected with corresponding ports of the singlechip control circuit respectively. The safeguard device is safe, reliable, low in energy consumption, simple in structure and convenient to operate.

Owner:NANJING UNIV OF SCI & TECH

Method and device for removing hydrogen sulfide through steel slag

The invention relates to a method for removing hydrogen sulfide through steel slag. The method includes that steel slag is dried and crushed and then is filled in a reaction bed, the reaction bed is heated to be at 30-50 DEG C and then is kept at constant temperature; mixed gases are filled from the bottom of the reaction bed at 80-100 SCCM constant speed, tail gases generated after reaction are discharged from the top of the reaction bed and filled into a flue gas analyzer; when the flue gas analyzer detects that the tail gases contain hydrogen sulfide, the tail gases discharged from a gas outlet of the flue gas analyzer are filled into alkaline liquor, and when the flue gas analyzer detects that concentration of hydrogen sulfide reaches 10-20mg / m<3>, filling of mixed gases is stopped. According to the method, waste steel slag serves as treating agents, the two reactants are wide in sources and large in harm, and reactions of the two reactants can remove stink and solve the problem of environment pollution caused by steel slag; the hydrogen sulfide removing efficiency is high, the industrial wastes, namely steel slag, can be recycled, and the bidirectional effect of using waste to treat waste is achieved; the treated steel slag can be used as building materials and ecological risks and secondary pollution are avoided.

Owner:SHANDONG UNIV

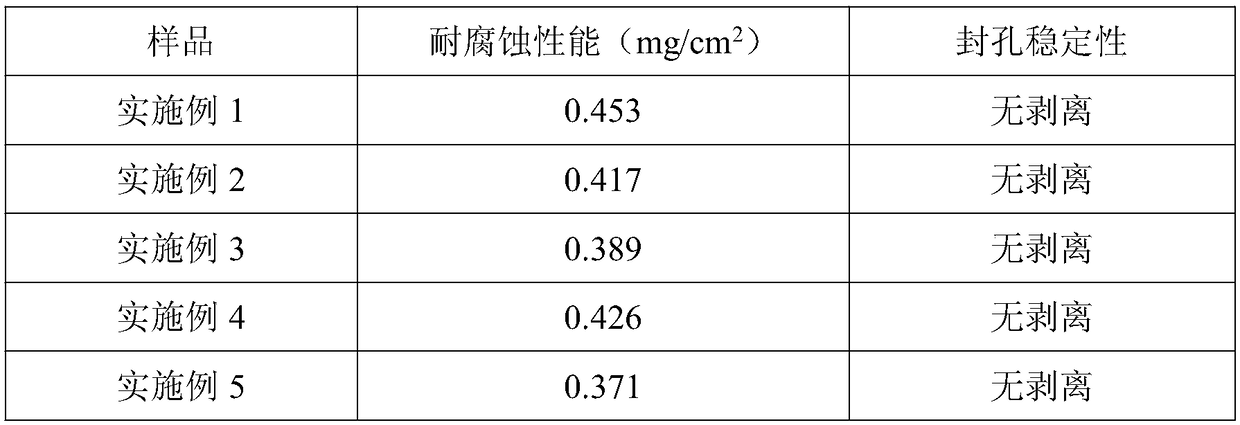

Hole sealing process for magnesium-aluminum alloy

InactiveCN108441923AGood adhesionImprove compactnessSurface reaction electrolytic coatingStearic acidMaterials science

The invention discloses a hole sealing process for magnesium-aluminum alloy. The hole sealing process comprises the following steps of: washing the magnesium-aluminum alloy by using water; degreasingthe magnesium-aluminum alloy by using alkaline liquid; polishing the magnesium-aluminum alloy by using an electrolyte and subsequently carrying out anodic oxidation; washing the magnesium-aluminum alloy by using deionized water and drying the magnesium-aluminum alloy by cold air to obtain film-coated magnesium-aluminum alloy for later use; by weight, adding 10-13 parts of tetraethoxysilane into 40parts of ethanol; subsequently adding acetic acid to regulate the pH value to be 4.6 to 5.3; continuously mixing for 30 min to 40 min to obtain sol A; adding 5-7 parts of butyl titanate into 60 partsof ethanol; mixing the butyl titanate with the ethanol uniformly; afterwards slowly adding the acetic acid to regulate the pH value to 3.5 to 4; continuously mixing for 30 min to 40 min to obtain solB; dissolving stearic acid by using isopropanol; adding the sol A and the soil B into the isopropanol to obtain hole sealing liquid; and carrying out hole sealing on the magnesium-aluminum alloy by using the hole sealing liquid. The hole sealing process disclosed by the invention has the characteristics of being free of fluorine, free of heavy metal pollution, stable in hole sealing effect and low in energy consumption.

Owner:长沙小新新能源科技有限公司

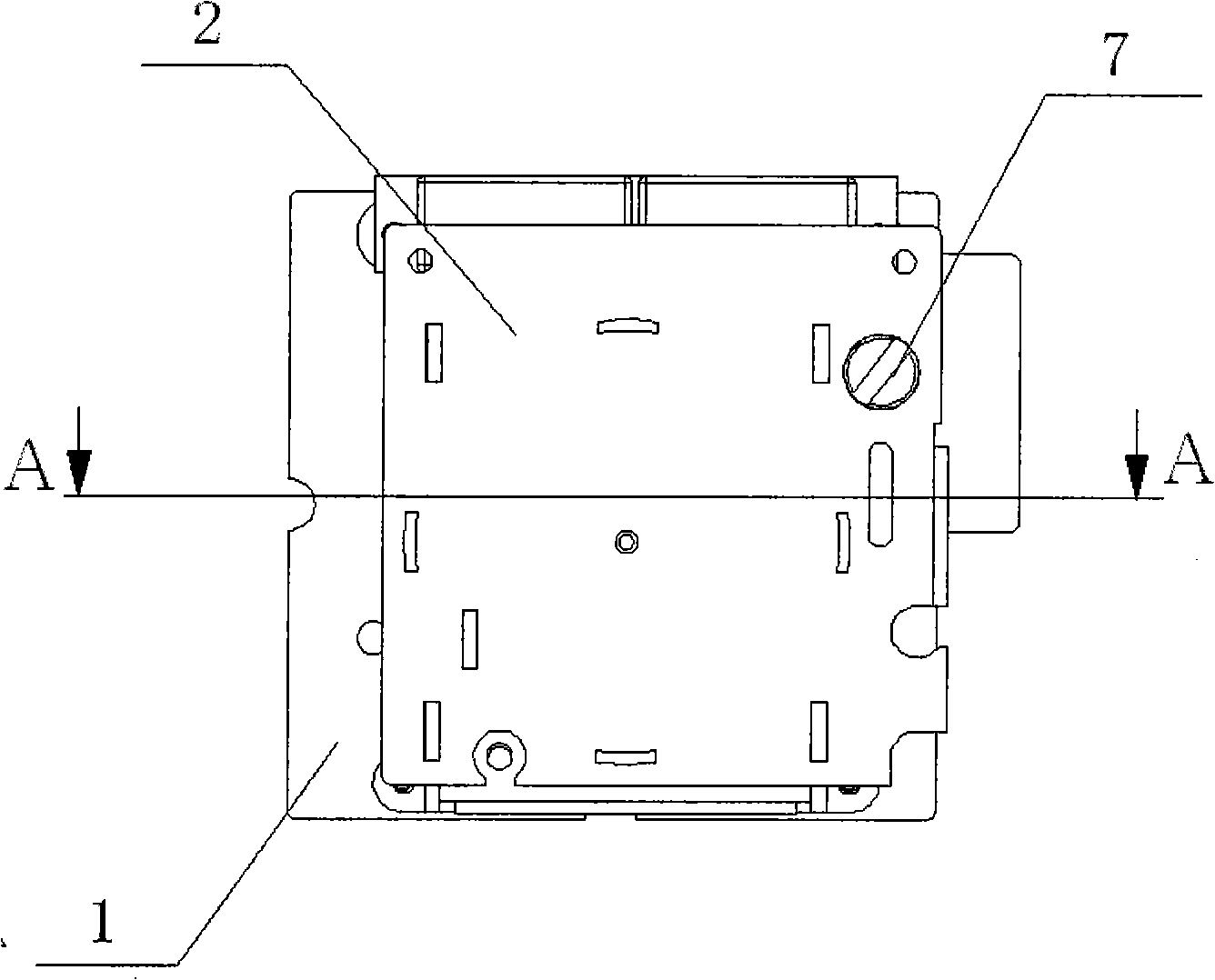

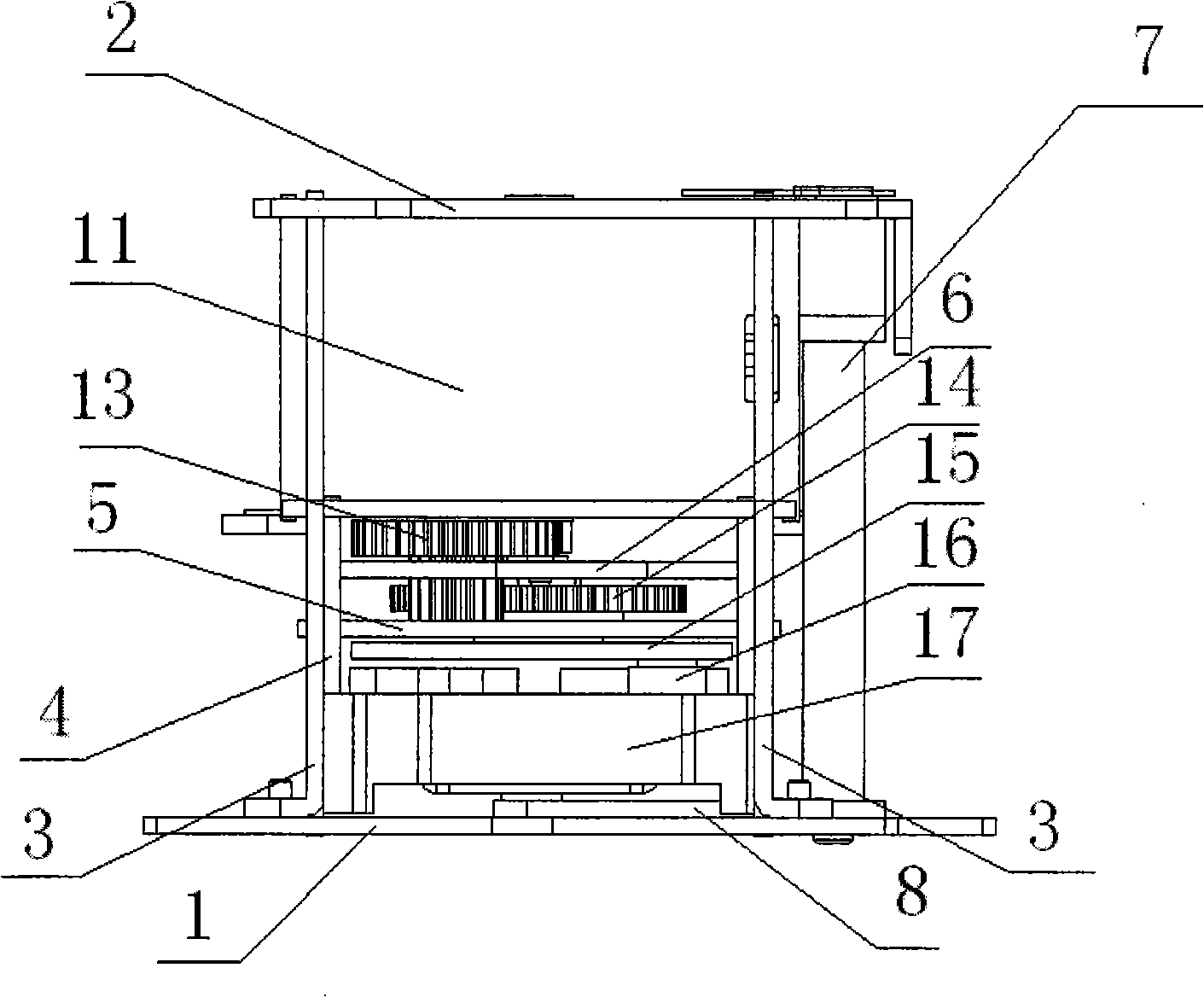

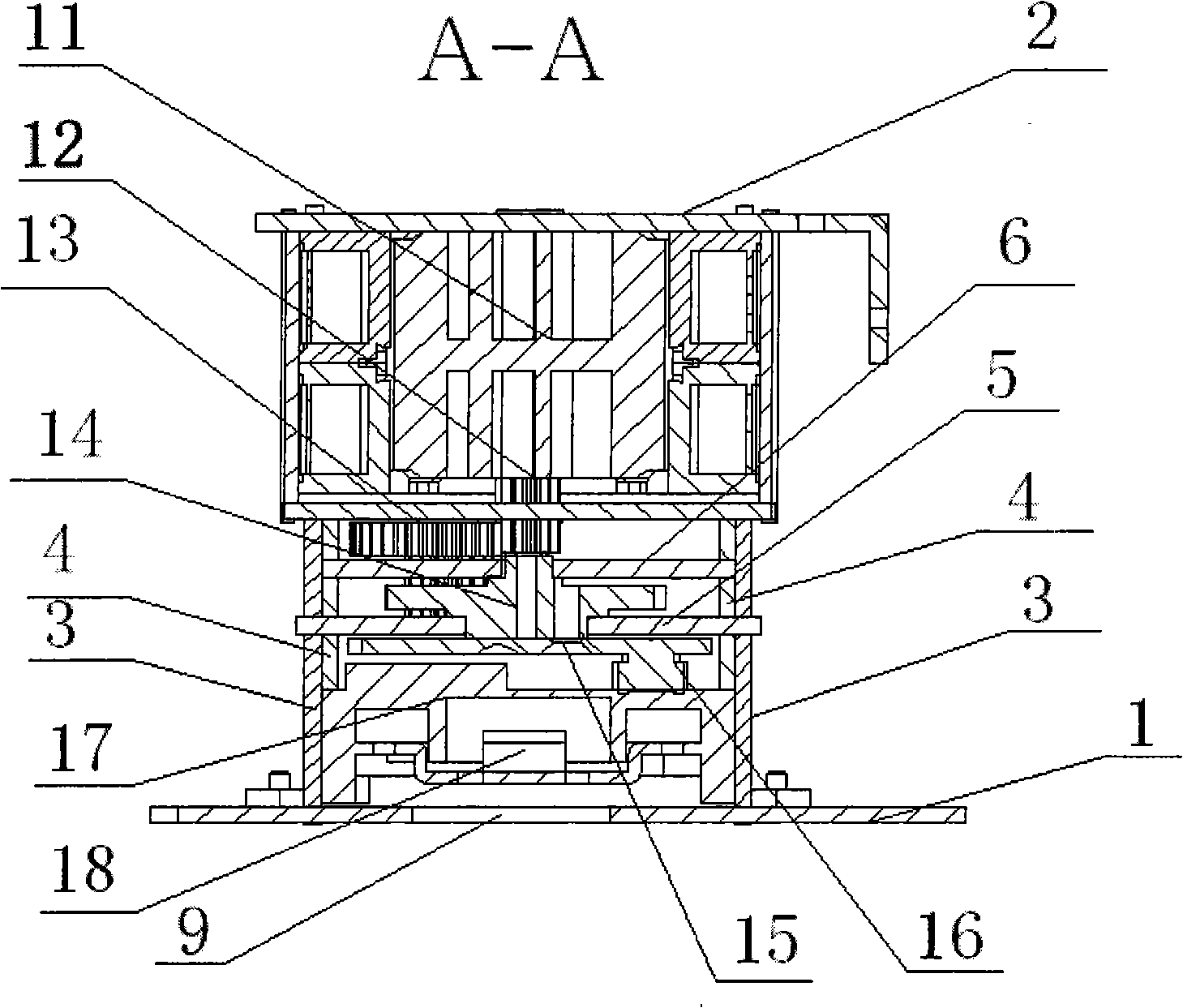

Electrically-operated mechanism

InactiveCN101295589AAvoid safety accidentsSimple organizationSwitch power arrangementsProtective switch operating/release mechanismsSynchronous motorEngineering

The invention relates to an electric operation mechanism which includes a bracket, a motor, a reducing mechanism and an operation mechanism. The invention is characterized in that the motor is an AC synchronous motor; the AC synchronous motor is connected with the reducing mechanism through a motor output shaft; the reducing mechanism is connected with the operation mechanism; the invention uses the AC synchronous motor to replace a traditional DC magnetoelectric machine and a traditional AC series excited machine; the AC synchronous motor has the advantages of simple mechanism, smaller size as well as proper rotating speed and power; therefore, the structure of the reducing mechanism connected with the AC synchronous motor is simple; both the AC synchronous motor and the reducing mechanism greatly save the size of electric operation and save the manufacture cost.

Owner:崔剑忠

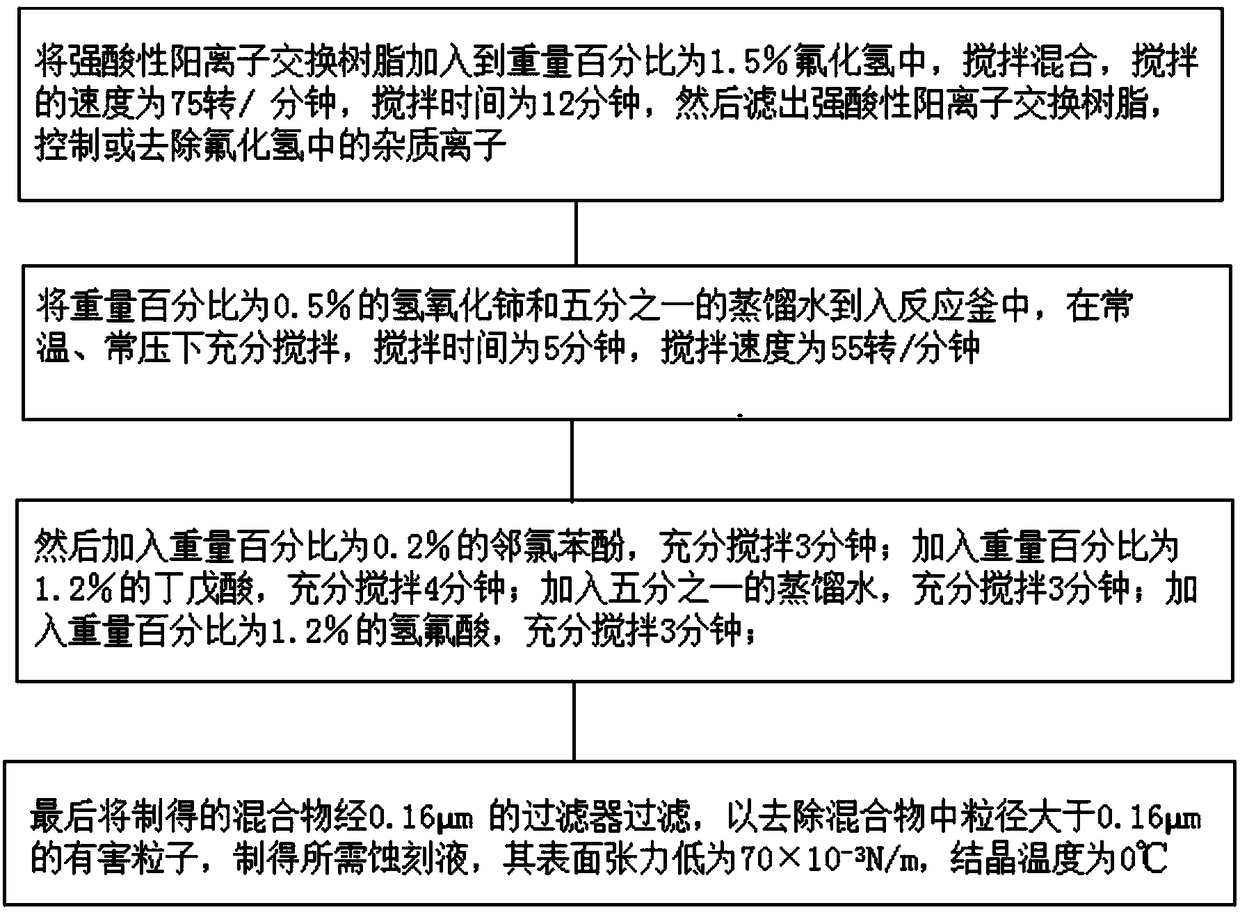

Preparation method for etching liquid for thin film transistor

The invention discloses a preparation method for etching liquid for a thin film transistor. The etching liquid comprises the following compositions in percentage by weight: 0.5%-2.3% of cerium hydroxide, 0.2%-1.8% of o-chlorophenol, 1.2%-2.6% of isobutylglutaric acid, 1.2%-2.6% of hydrofluoric acid, 1.5%-2.3% of hydrogen fluoride, 2.5%-3.3% of a nonionic surfactant, 1.5%-2.6% of a de-foaming agentand the balance of distilled water. Cerium hydroxide, o-chlorophenol, isobutylglutaric acid, hydrofluoric acid and hydrogen fluoride are added on the basis of the original process, so that etching can be performed when penetration of an anti-corrosion coating does not occur, and etching speed of a chromium metal film is remarkably increased, and therefore, the preparation method has controllableetching speed, effectively inhibits degradation of an anti-corrosion protective layer, obtains a chromium metal film assembly line with a flat and smooth surface, and has an important application value.

Owner:佛山杰致信息科技有限公司

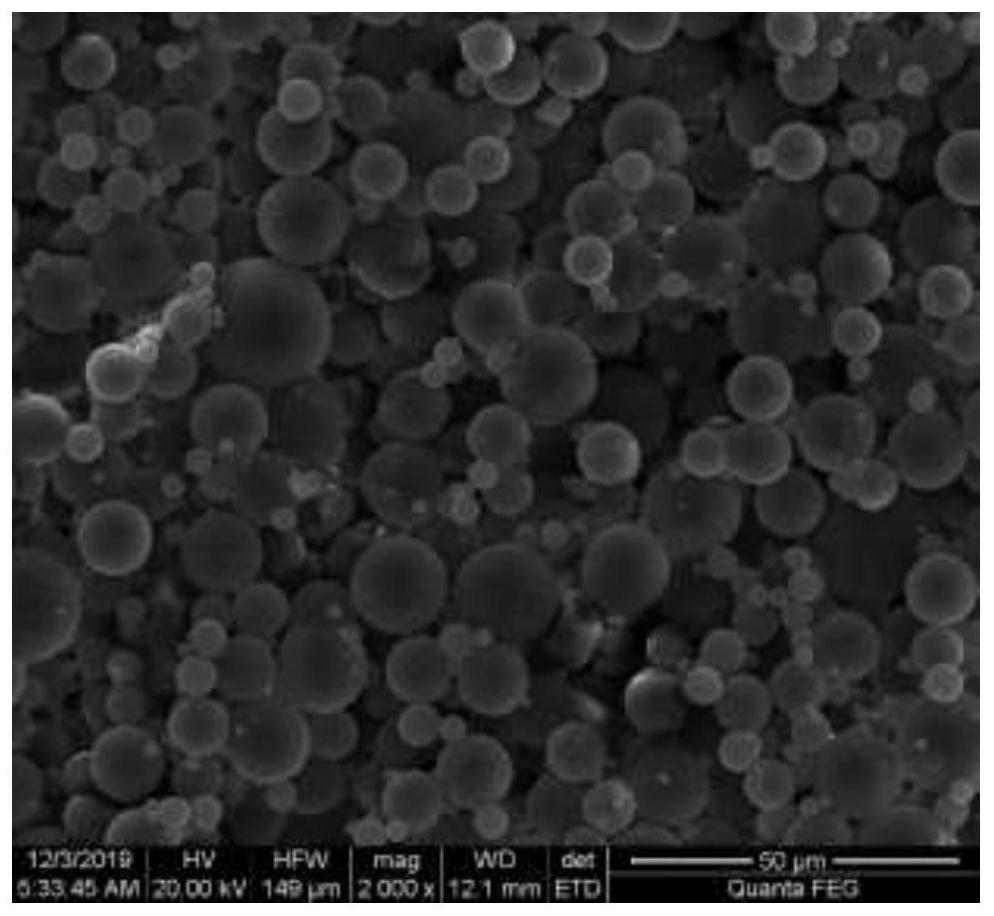

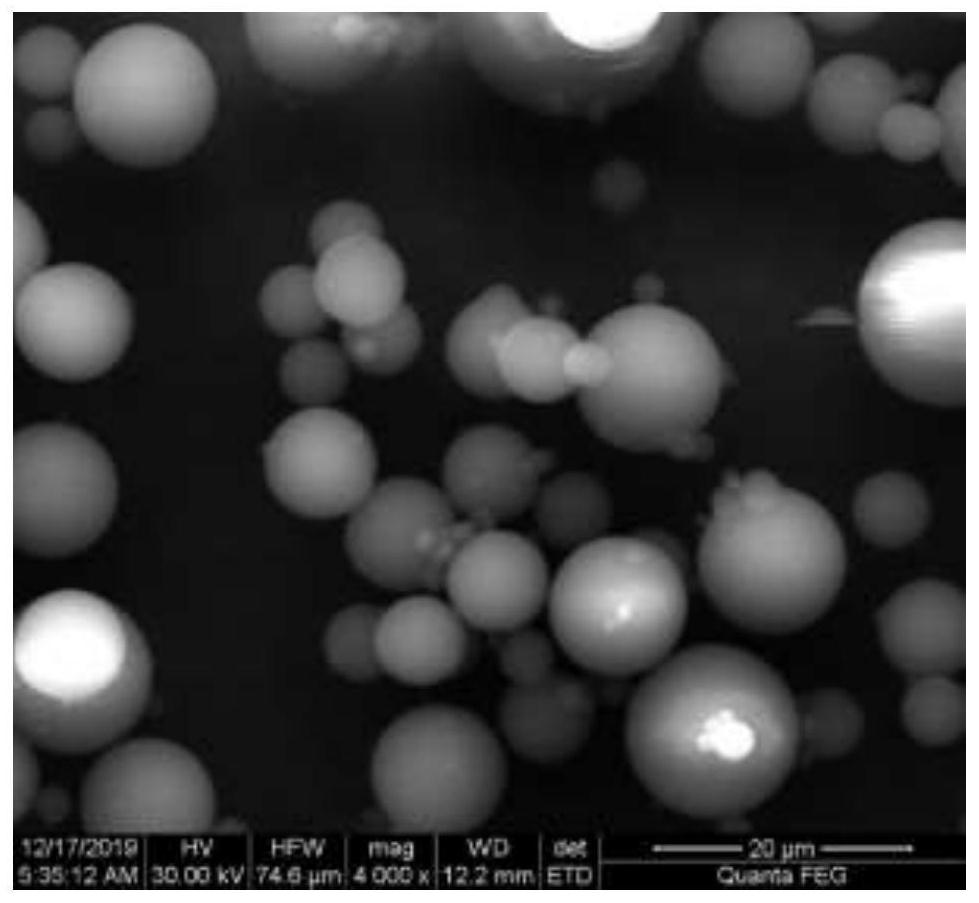

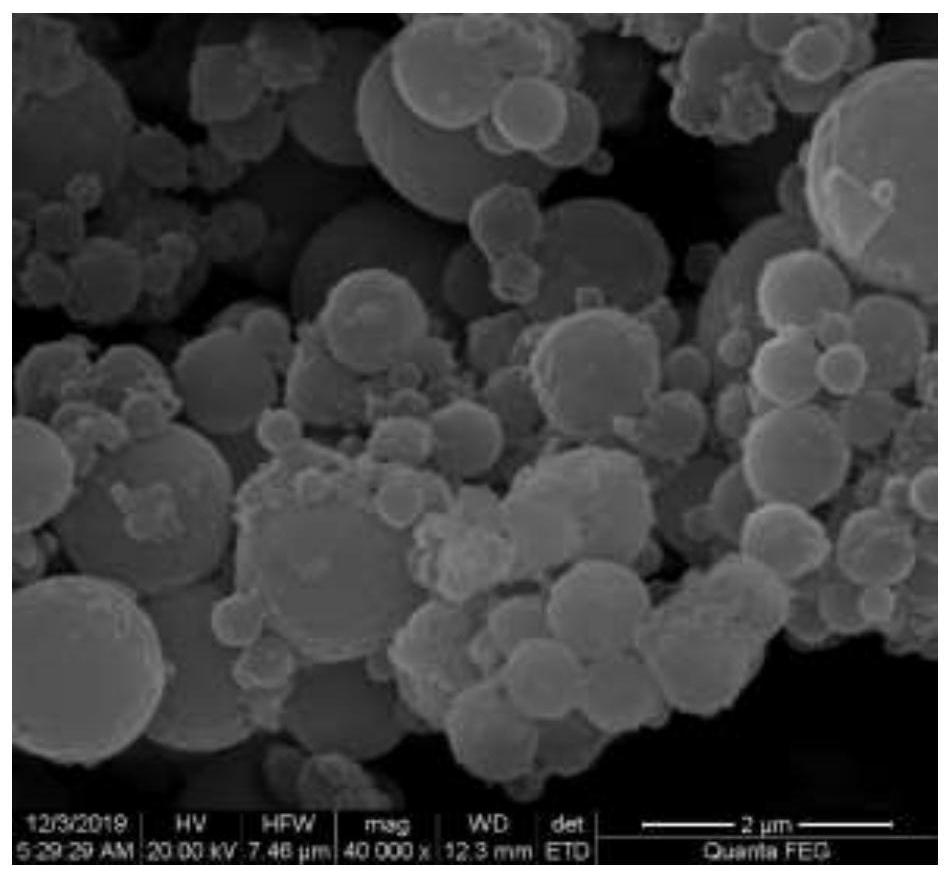

Cross-linked polymer microsphere as well as preparation method and application thereof

ActiveCN112062899AImprove shear resistanceImprove resistance to shear damageDrilling compositionPolymer scienceMeth-

The invention discloses a cross-linked polymer microsphere as well as a preparation method thereof. The cross-linked polymer microsphere is prepared by adopting an inverse emulsion method, and the preparation method comprises the following steps: by taking an aqueous solution of a polymer monomer, an initiator and a cross-linking agent as an aqueous phase, adding an oil phase containing an emulsifier into the aqueous phase, stirring to form an emulsion taking oil as an external phase, and reacting to obtain the cross-linked polymer microsphere. The polymer monomer is a mixture of acrylamide, 2-acrylamide-2-methyl propanesulfonic acid and octadecyl acrylate in a mass ratio of 6:(0-3):(1-2), and the cross-linking agent is bisphenol propane and formaldehyde in a mass ratio of (1.5-2):1, and the mass fraction of the cross-linking agent in the water phase is 0.1%-1.5%. The cross-linked polymer microsphere has the advantages that the cross-linked polymer microsphere is good in shear resistance and other stability, the defects that an existing polymer microsphere is high in water absorption expansion rate, large in water absorption expansion multiple and poor in shear resistance are overcome, and the cross-linked polymer microsphere has wide application prospects in the field of deep profile control of oil reservoirs.

Owner:CHINA UNIV OF PETROLEUM (BEIJING) +1

Orbital, non-reciprocating, internal combustion engine

ActiveUS20130092121A1Improve engine efficiencyImprove simplicityInternal combustion piston enginesPistonsRotational axisCombustion

A combustible fluid-operated orbital engine having sets of cooperating cylinder and piston members with respective parallel axes of rotation. Respective cylinder and piston carrier wheels with respective axes of rotation parallel to the piston / cylinder axes of rotation carrying the pistons / cylinders circularly and orbitally and at all times in opposed relation on a common longitudinal axis along intersecting counter paths. Respective gearing structures or belts / sprockets supported by the cylinder and piston carrier wheels rotate the pistons / cylinders counter to their circular motion direction to maintain their opposed relation for their periodic interfittment when their respective paths intersect. A combustible fluid supply is provided to the cylinder member for combustion coincident with the periodic interfittment in engine operating relation. The pistons / cylinders may include ceramic material. The compression sealing system is located in the entry of each cylinder rather than being connected to the piston.

Owner:LOCKSHAW JAMES +1

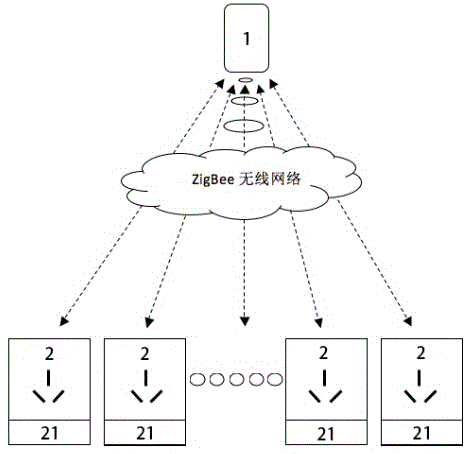

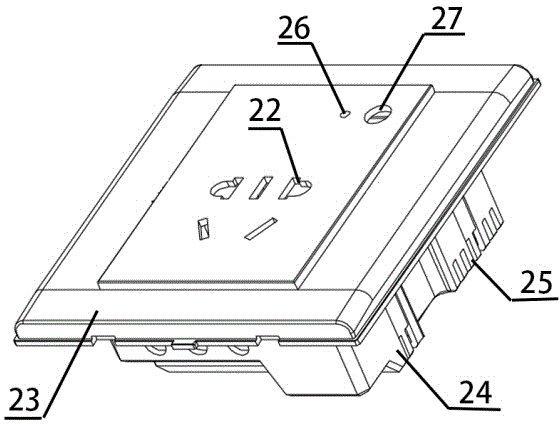

Socket based on ZIGBEE wireless communication and compact socket

InactiveCN104577538AImprove reliabilityImprove stabilityCoupling device detailsElectricityComputer module

The invention discloses a socket based on ZIGBEE wireless communication. A ZIGBEE application protocol is controlled by user equipment. The socket comprises a main body, wherein an electricity-getting slot of indoor user equipment is formed in one end of the main body, and a commercial power line is connected to the other end of the main body; an electricity metering module used for acquiring electricity utilization information of the indoor user equipment getting electricity through the socket, a ZIGBEE communication module used for bearing the ZIGBEE application protocol and wirelessly connected with the user equipment, a relay switch connected with the ZIGBEE communication module and used for switching on or off the socket according to received user signals, and a power supply for converting an AC (alternating-current) 220V commercial power supply into a working power supply for the ZIGBEE communication module and the electricity metering module are arranged in the main body.

Owner:WAHLAP TECH CO LTD +1

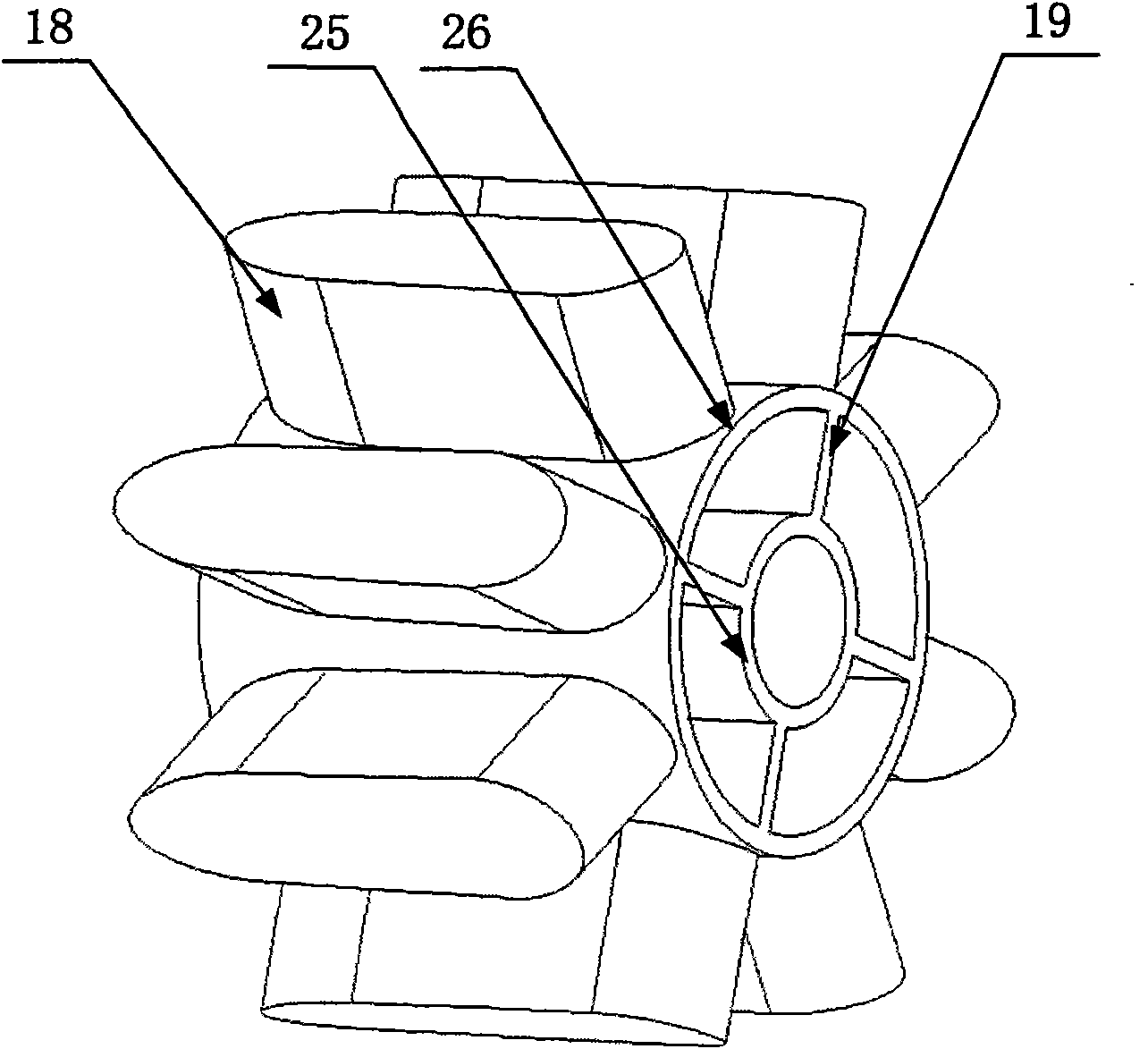

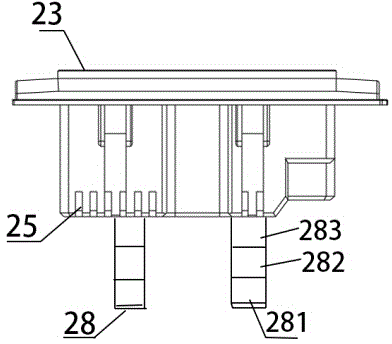

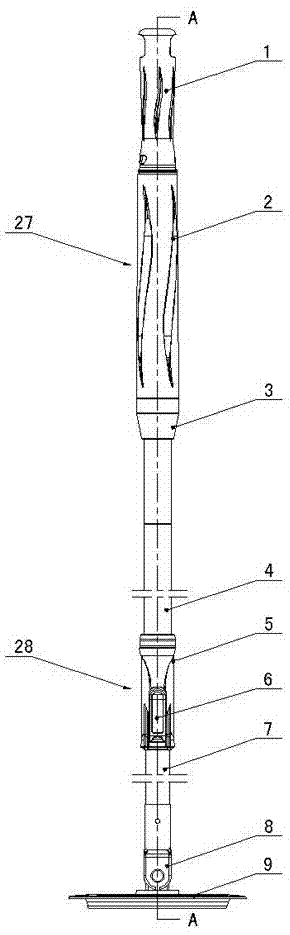

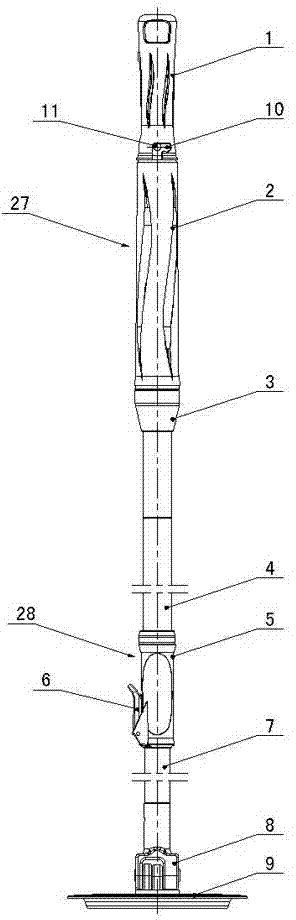

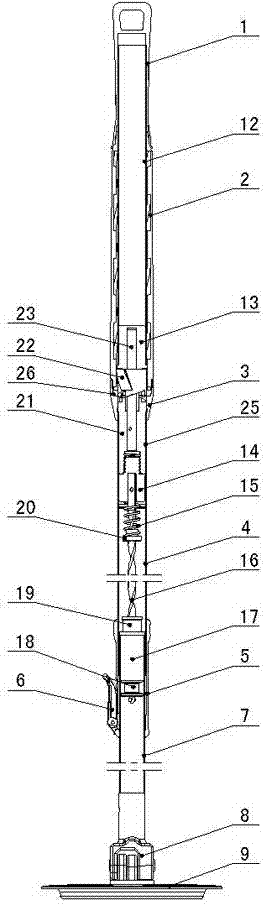

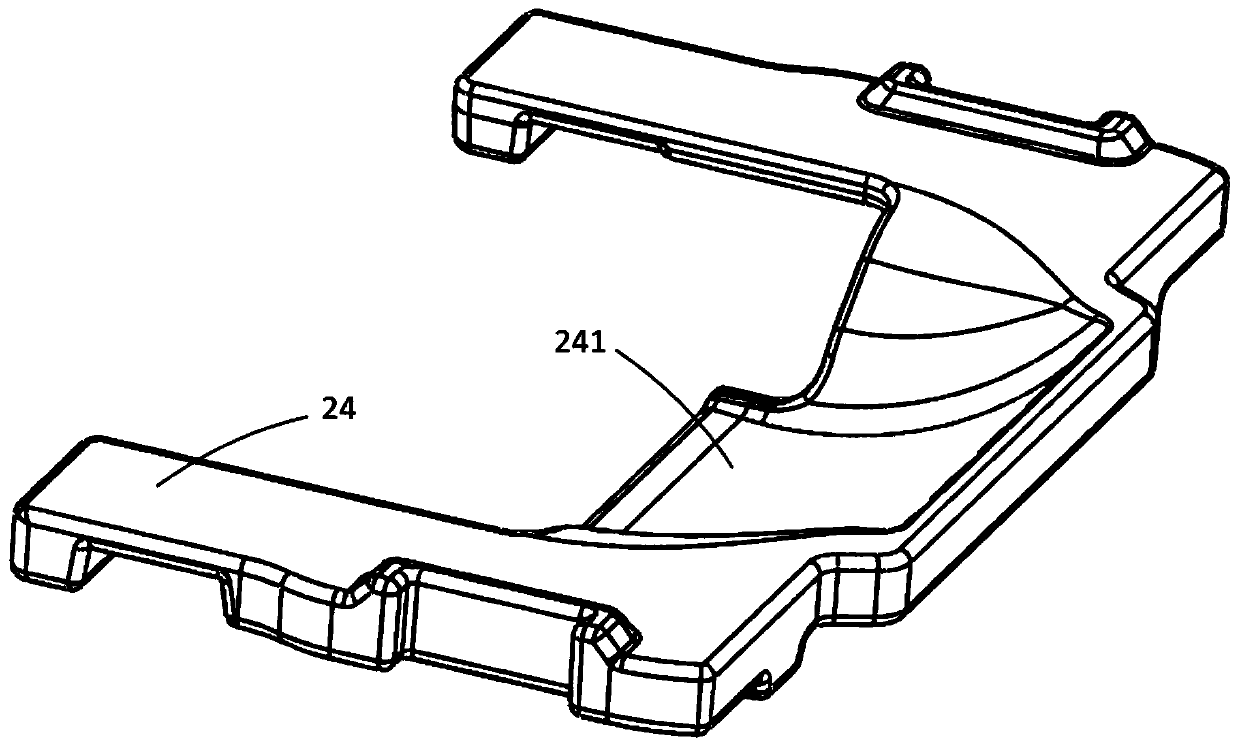

Hand-pressing type two-speed rotating mop

The invention discloses a hand-pressing type two-speed rotating mop which comprises a handle (1), an upper rod (12), a middle rod (4), a first-speed driving mechanism (28), a lower rod (7) and a mop assembly (9). The handle (1) is fixed to the upper rod (12), and the first-speed driving mechanism (28) is connected between the middle rod (4) and the lower rod (7). When the handle (1) is pressed down, the first-speed driving mechanism (28) drives the mop assembly (9) to rotate at first speed. A second-speed driving mechanism (27) is connected between the upper rod (12) and the middle rod (4). When the first-speed driving mechanism (28) and the lower rod (7) are locked, the handle (1), the upper rod (12), the middle rod (4), the first-speed driving mechanism (28) and the lower rod (7) are connected into a whole. When the second-speed driving mechanism (27) is pressed down, the mop assembly (9) is driven to rotate at second speed. By the adoption of the structure, the hand-pressing type two-speed rotating mop has the advantages of being simple and reasonable in structure, light and convenient to operate and use, good in cleaning and dehydrating effect, low in production cost and long in service life, rotating at different speeds during cleaning and dehydrating, and the like.

Owner:周高扬

Composite concentration triple-wind-regulating low-NOx cyclone pulverized-coal burner

ActiveCN102062396BFire stableExtended service lifePulverulent fuel combustion burnersIndirect carbon-dioxide mitigationConvex structureCyclone

The invention relates to a composite concentration triple-wind-regulating low-NOx cyclone pulverized-coal burner which comprises a central wind passage, wherein a primary wind passage, an internal direct-flow secondary wind passage, an internal rotational-flow secondary wind passage and an external rotational-flow secondary wind passage are sequentially and concentrically arranged at the outer side of the central wind passage from inside to outside, a conical pulverized-coal concentrating device and a star-shaped pulverized-coal concentrating device are arranged in the primary wind passage, and a reversed V-shaped expanded opening and a zigzag axial and radial double concave-convex structured burning-stabilizing device are arranged at the outlet of the primary wind passage; and after primary wind passes through the pulverized-coal concentrating device, an intense standing-vortex burning-stabilizing firing area with obvious circumferential and radial pulverized-coal concentration distribution is formed at the outlet of the burner, and the burning conditions of high-temperature reflow smoke gas and oxygen-deficient rich fuel are generated. The burner has extremely strong firing-stabilizing performance and good coal adaptability and effectively reduces the concentration of nitrogen oxides.

Owner:XI AN JIAOTONG UNIV

Nanometer-titania-based preparing method for etching liquid for circuit board

InactiveCN105525292AEtching speed is fastControllable etching speedSurface-active agentsControllability

The invention discloses a nanometer-titania-based preparing method for etching liquid for a circuit board. The etching liquid includes, by weight percentage, 3.5%-6.5% of nanometer titania, 0.5%-1.2% of ferric trichloride, 0.5%-1.6% of nitric acid, 2.5%-3.3% of organic hydrochloric acid, 1.5%-2.3% of a non-ionic surface active agent, 0.5%-1.5% of a stabilizer, 3.5%-5.6% of a defoamer and the balance distilled water. According to the method, the nanometer titania is newly added on the basis of an original process, etching can be carried out under the condition that etch-resistant coating permeation does not occur, the etching speed of a chromium metal film is obviously increased, the controllability of the etching speed is achieved, degradation of the anti-corrosion protective layer is effectively restrained, chromium metal film wires with smooth surfaces are obtained, and the important application value is achieved.

Owner:WUXI JIJIN ENVIRONMENTAL PROTECTION TECH CO LTD

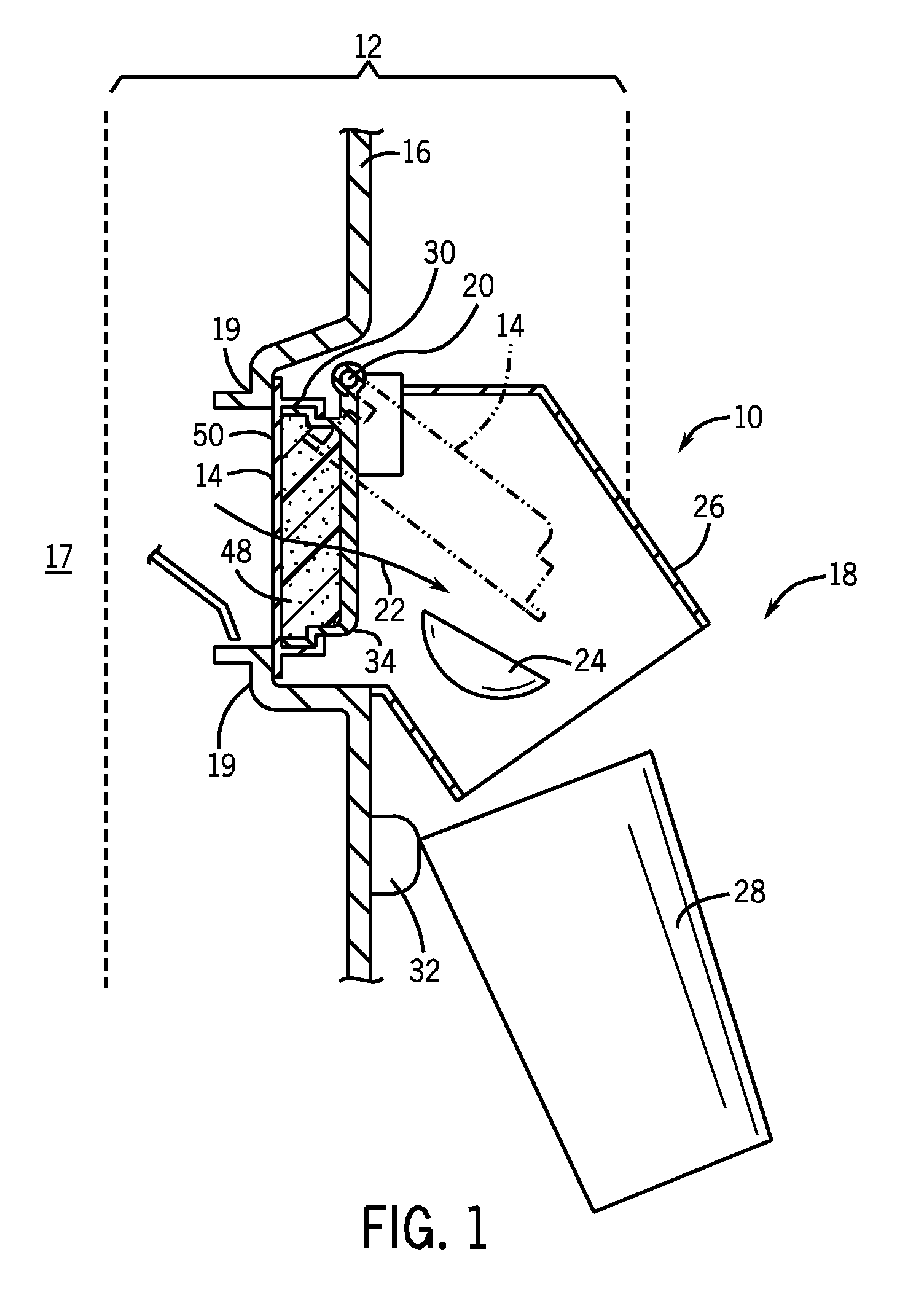

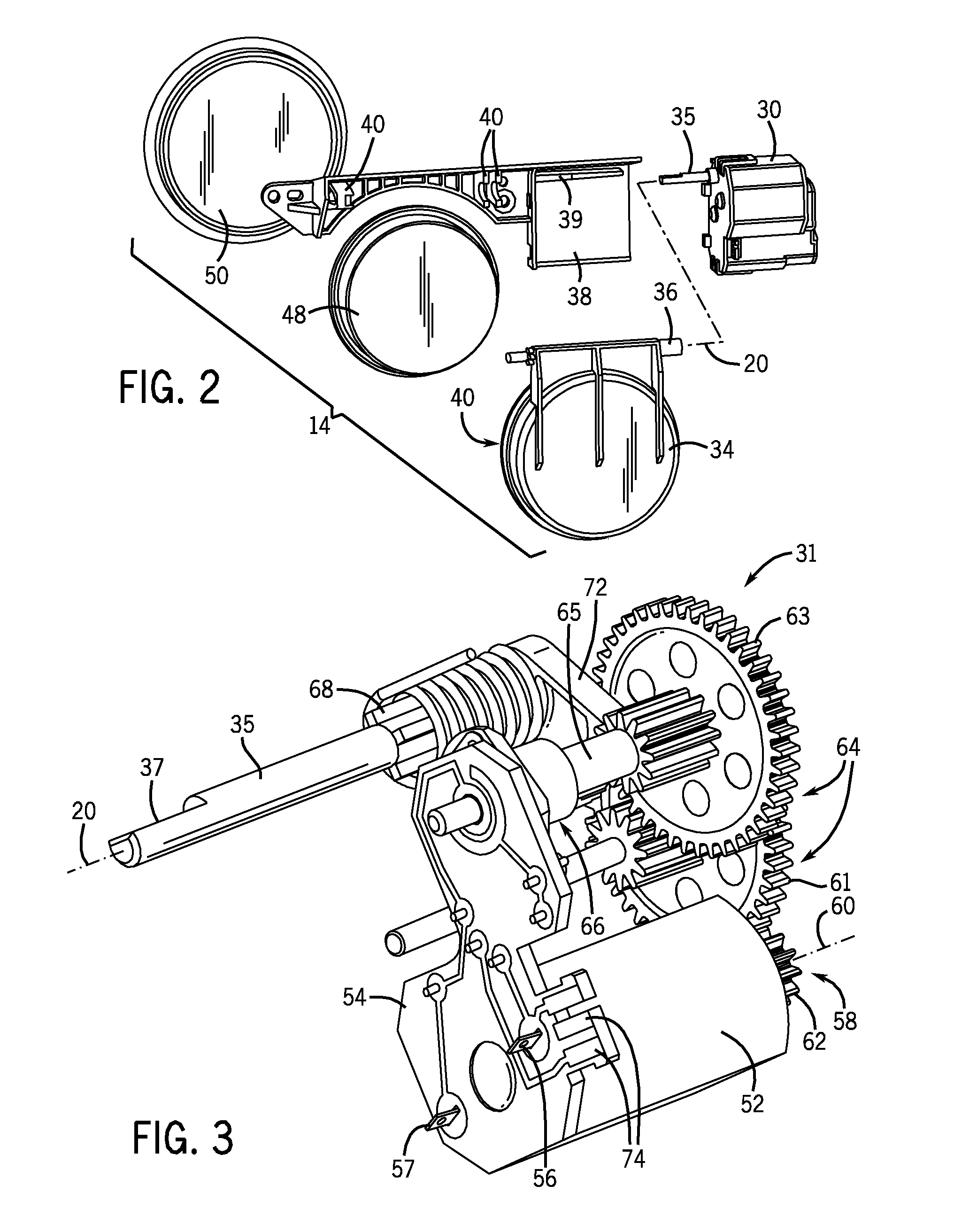

Rotary actuator for energy efficient ice cube dispenser door system

ActiveUS9033192B2Moderate speedSlow down the closing speedAssociation with control/drive circuitsOperating means/releasing devices for valvesPermanent magnet motorGear train

A rotary actuator suitable for use in a refrigerator ice-dispensing door provides a rotating shaft driven by a DC permanent magnet motor through a gear train and subject to a returning force of an internal spring. The gear train communicates with a switch to reduce current to the motor when a limit of travel is reached and a shunting path is provided around the motor to produce generative braking when power is removed from the motor and the actuator rotates backward to its initial position.

Owner:ILLINOIS TOOL WORKS INC

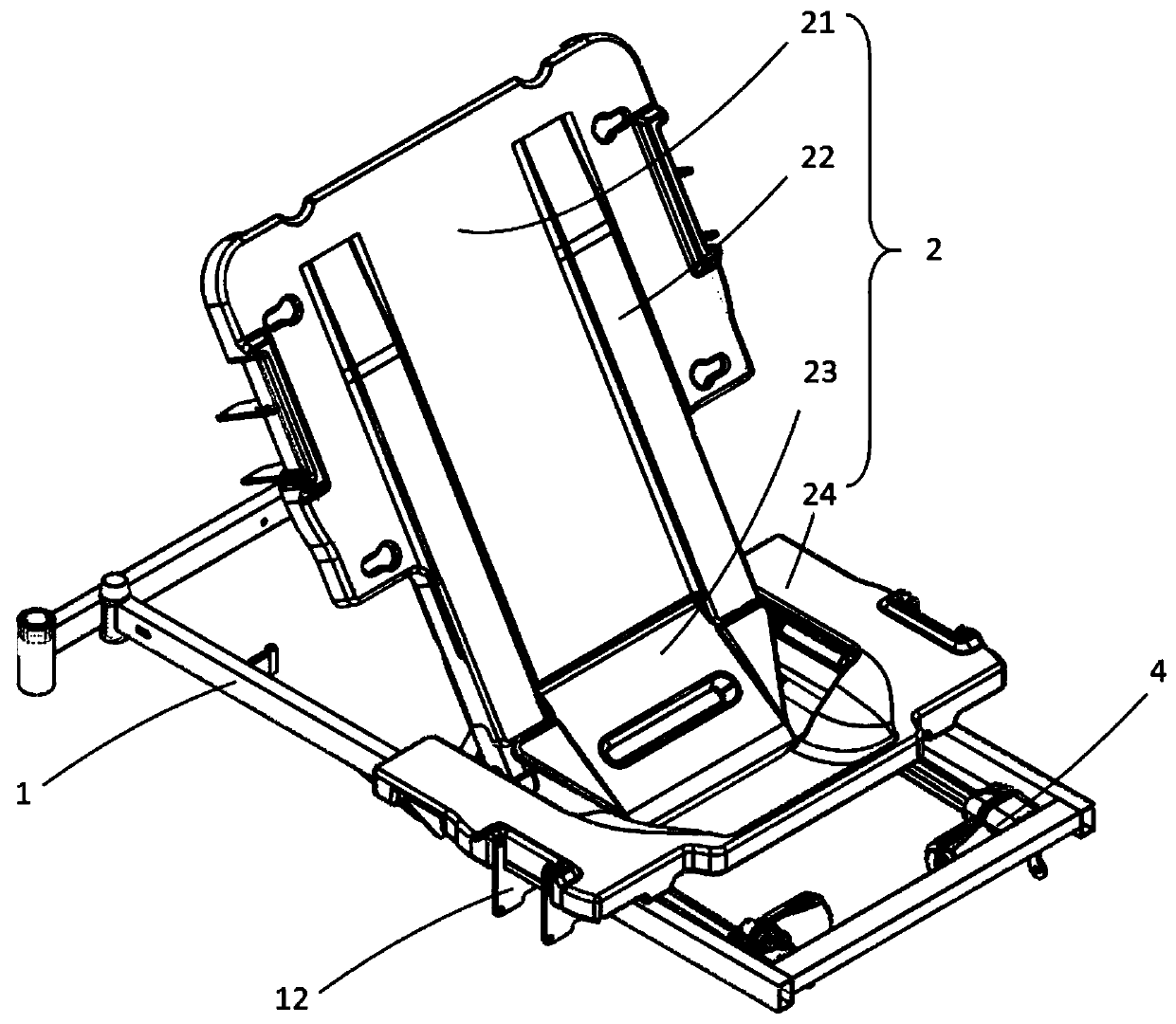

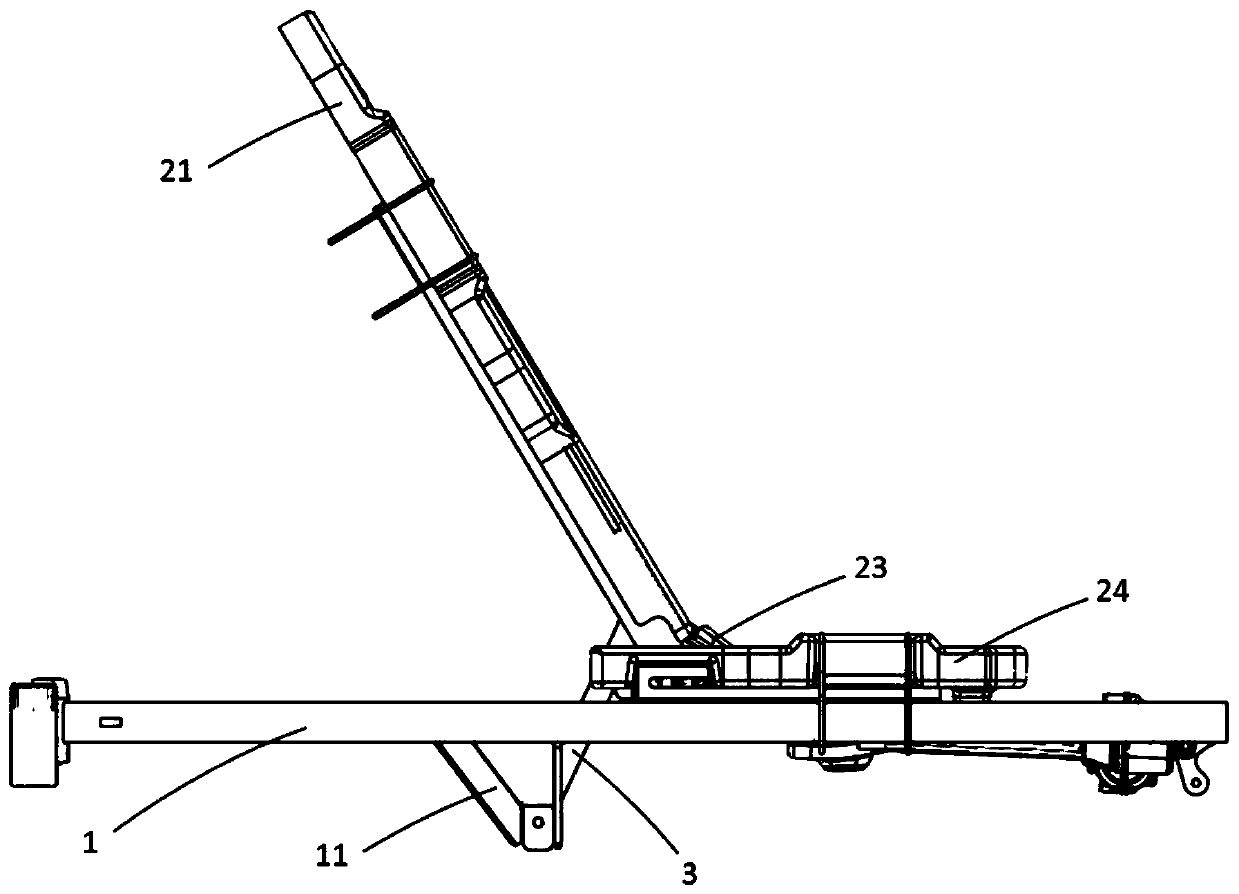

Multi-angle adjusting structure of bed board

PendingCN110680638AComfortable sitting and lyingRealize linkageNursing bedsAmbulance servicePhysical medicine and rehabilitationNursing care

The invention discloses a multi-angle adjusting structure of a bed board, which comprises a bed body support, the bed board, a rack plate and a driving mechanism. The bed board further comprises a connecting back plate, a supporting frame, a hip supporting plate and a fixing plate. The lower supporting connecting pieces are symmetrically fixed to the two sides of the bed body support, the lower support connecting piece is coupled with one end of the rack plate; two groups of driving mechanisms are arranged on the left and right sides, and each group consists of a push rod and a motor; the tailend of the push rod is coupled with a back motor base; and the motor is fixedly installed on the two sides of the bed body support. According to the adjusting structure disclosed by the invention, the height and angle of the back can be adjusted according to the needs of a patient, and meanwhile, due to the unique hip supporting plate design of the structure, the situations of unstable sitting posture and forward sliding during back adjustment can be avoided, and the rest and nursing requirements of the patient are met.

Owner:HEBEI VANRY MEDICAL DEVICES CO LTD

Indium tin oxide (ITO) etching solution for high-generation panel

InactiveCN110564420AModerate speedStrong singlenessSurface treatment compositionsAcetic acidPotassium

The invention discloses an indium tin oxide (ITO) etching solution for a high-generation panel. The ITO etching solution is prepared by mixing raw materials comprising hydrochloric acid, acetic acid,a metal salt, a surfactant, a defoaming agent and water according to a certain ratio. The weight proportions of the raw materials are as the follows: 10-30% of hydrochloric acid, 1-10% of acetic acid,0.1-1% of the metal salt, 0.05-0.5% of the surfactant, 0.1-1% of the defoaming agent and the balance of water; and preferably the weight proportions of the raw materials are as the follows: 22% of hydrochloric acid, 7% of acetic acid, 0.5% of the metal salt, 0.2% of the surfactant, 0.07% of the defoaming agent and the balance of water. The metal salt is alkaline metal salt, wherein the alkali metal salt is potassium hydrochloride; the water is pure water, wherein the concentration of impurity ions in the water is not higher than 100 ppm; the concentration of the hydrochloric acid is 35%, theconcentration of the acetic acid is 90%, and purity of the potassium hydrochloride is 98%. According to the invention, no etching residues are generated in an etching process of the ITO etching solution; foaming is effectively inhibited and generation of a large amount of foam is avoided; an amorphous ITO film can be etched with high efficiency and high precision under mild working conditions; andthe process is very convenient to operate and is easy to control.

Owner:合肥中聚和成电子材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com