Method and device for removing hydrogen sulfide through steel slag

A technology of hydrogen sulfide and steel slag, which is applied in the field of hydrogen sulfide removal and hydrogen sulfide removal by using steel slag, which can solve the problems of complexity, pollution of the environment, and many device control units, and achieve the effects of high annual output, uniform contact, and complete reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

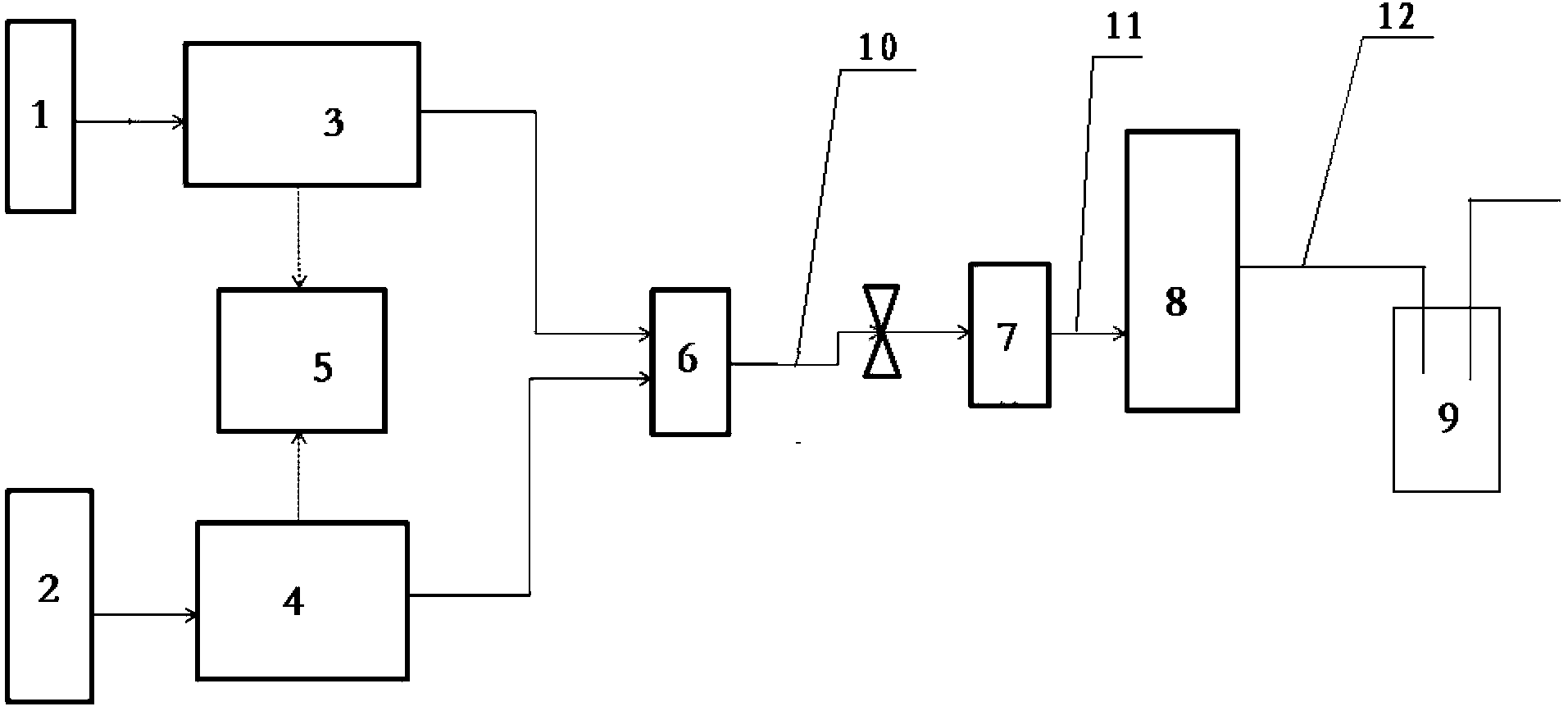

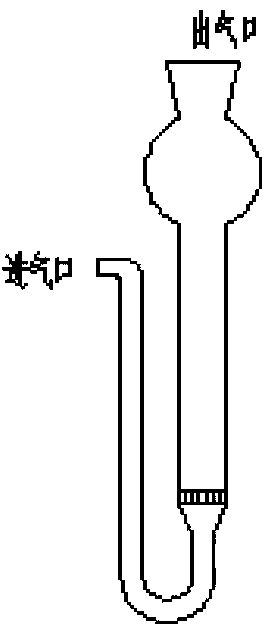

[0046] A device for removing hydrogen sulfide from steel slag, the structure of which is as follows figure 1 As shown, it includes a nitrogen storage tank, a gas storage tank 2 to be treated, a reaction bed, a flue gas analyzer 8 and a mixed gas temporary storage tank 6, and hydrogen sulfide gas or gas containing hydrogen sulfide is housed in the gas storage tank to be treated. The nitrogen storage tank 1 and the gas storage tank 2 to be treated are all communicated with the mixed gas temporary storage tank 6 through pipelines, and the mixed gas temporary storage tank 6 is communicated with the reaction bed through the connecting pipe 10, and the reaction bed is sand The core funnel 7, the connecting pipe 10 is connected to the bottom of the sand core funnel 7, the bottom of the sand core funnel 7 is provided with a water bath for heating the sand core funnel 7, and the top of the sand core funnel 7 is provided with a seal for sealing the sand core funnel Rubber plug, a connec...

Embodiment 2

[0049] Utilize the device described in embodiment 1 to carry out the method for removing hydrogen sulfide, comprise steps as follows:

[0050] 1. Dry the steel slag so that the water content of the steel slag is controlled at 0wt%, then pulverize and pass through a 20-mesh sieve to make steel slag powder. Take 0.5g of steel slag powder and place it evenly on the sand core filter plate of the sand core funnel. The steel slag powder The tile thickness is 2cm;

[0051] 2. Heat the reaction bed to 30°C in a water bath and keep it at a constant temperature;

[0052] 3. At the same time, open the control valve between the nitrogen storage tank and the mixed gas temporary storage tank and the control valve between the gas storage tank to be treated and the mixed gas temporary storage tank to control the gas flow rate, observe the flow display instrument, adjust the flow rate, hydrogen sulfide The gas and nitrogen are passed into the mixed gas temporary storage tank 6, and mixed even...

Embodiment 3

[0059] Utilize the device described in embodiment 1 to carry out the method for removing hydrogen sulfide, comprise steps as follows:

[0060] 1. The steel slag is dried so that the water content of the steel slag is controlled at 5wt%, then pulverized and passed through a 40-mesh sieve to make a steel slag powder. Take 1g of the steel slag powder and place it evenly on the sand core filter plate of the sand core funnel. The paving thickness is 3cm;

[0061] 2. Heat the reaction bed to 40°C in a water bath and keep it at a constant temperature;

[0062] 3. At the same time, open the control valve between the nitrogen storage tank and the mixed gas temporary storage tank and the control valve between the gas storage tank to be treated and the mixed gas temporary storage tank to control the gas flow rate, observe the flow display instrument, adjust the flow rate, hydrogen sulfide The gas and nitrogen are passed into the mixed gas temporary storage tank 6, and mixed evenly in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com