Cross-linked polymer microsphere as well as preparation method and application thereof

A technology of cross-linked polymers and polymers, applied in the direction of drilling compositions, chemical instruments and methods, etc., can solve the problems of weak shear resistance and poor deep plugging performance, and achieve enhanced plugging performance and improved Moderate effect of shear resistance and water expansion ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] Embodiment 1, preparation cross-linked polymer microsphere

[0049] Step 1: At room temperature, add 12 parts of acrylamide, 5 parts of 2-acrylamide-2-methallyl sulfonic acid and 3 parts of stearyl acrylate to 40 parts of deionized water, and stir at 300r / min for 15min Until it is uniform, then add 0.1 part of bisphenol propane and 0.05 part of formaldehyde, stir at 300r / min for 15min until uniform, then add 0.4 part of potassium persulfate, stir for 15min at 300r / min until uniform, and obtain the water phase .

[0050] Step 2: Add 14 parts of Span80 to 80 parts of 10# white oil, raise the temperature to 50°C, stir for 45min, then cool down to 30°C to obtain the oil phase.

[0051] Step 3: Add the oil phase in step 2 into a three-necked flask, connect the reflux condensing device, pass nitrogen for 30 minutes, set the temperature of the water bath at 30°C, and stir at a speed of 450r / min, then add the water phase in step 1 dropwise with a constant pressure separating f...

Embodiment 2

[0054] Embodiment 2, preparation cross-linked polymer microsphere

[0055] Step 1: At room temperature, add 12 parts of acrylamide, 5 parts of 2-acrylamide-2-methallyl sulfonic acid and 3 parts of stearyl acrylate to 40 parts of deionized water, and stir at 300r / min for 15min until Uniform, then add 0.1 part of bisphenol propane and 0.05 part of formaldehyde, stir at 300r / min for 15min until uniform, then add 0.4 part of azobisisobutyronitrile, stir at 300r / min for 15min until uniform, get water box;

[0056] Step 2: Add 14 parts of Span60 to 80 parts of 10# white oil, raise the temperature to 50°C, stir for 45 minutes, then cool down to 30°C to obtain the oil phase;

[0057] Step 3: Add the oil phase in step 2 into a three-necked flask, connect the reflux condensing device, pass nitrogen for 30 minutes, set the temperature of the water bath at 30°C, and stir at a speed of 450r / min, then add the water phase in step 1 dropwise with a constant pressure separatory funnel , emul...

Embodiment 3

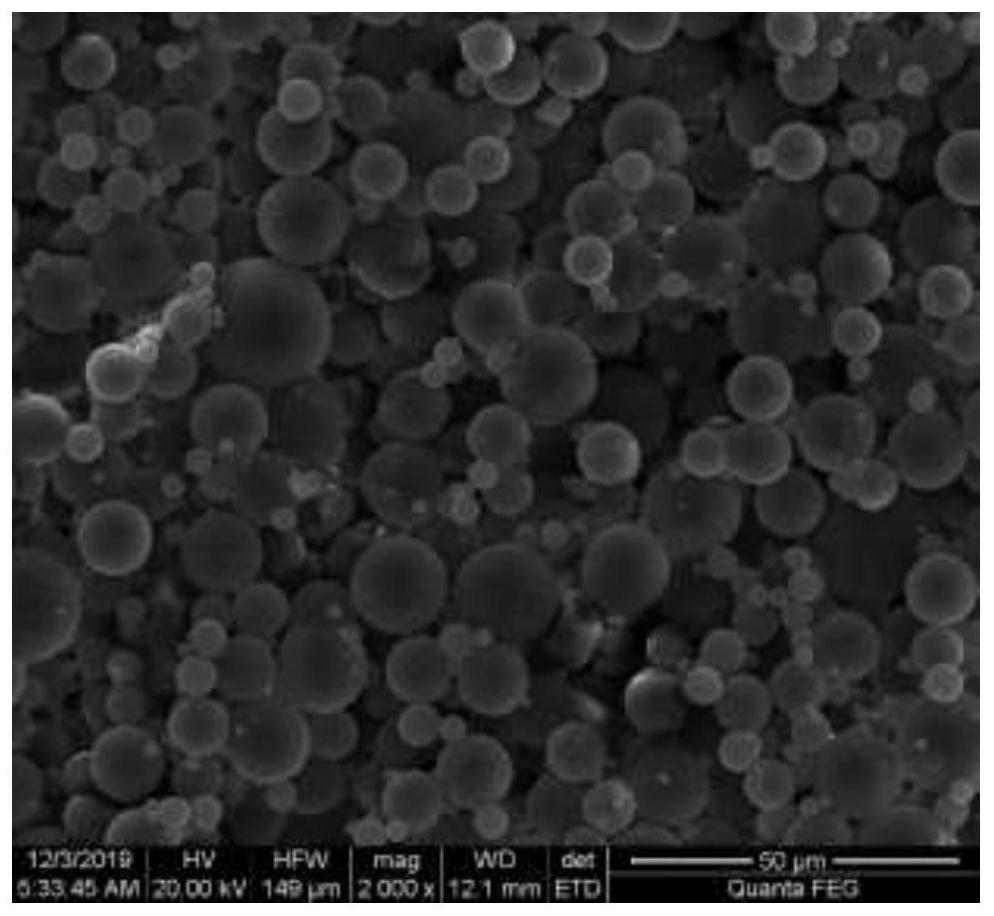

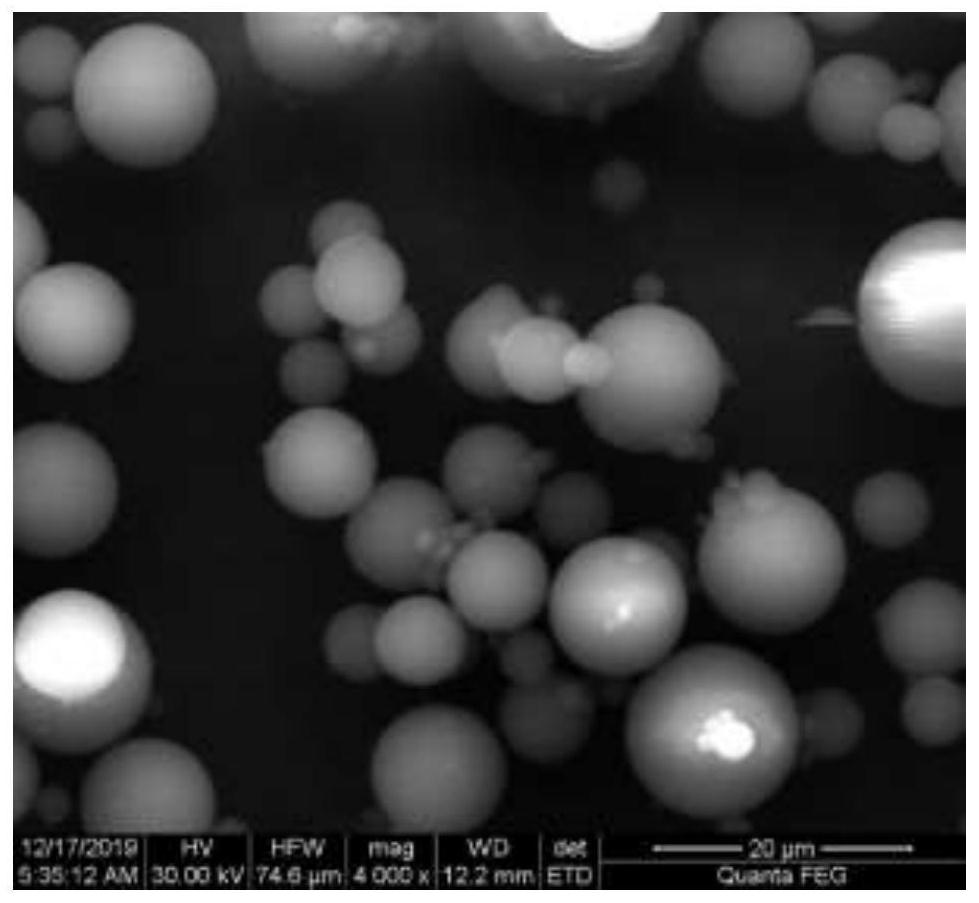

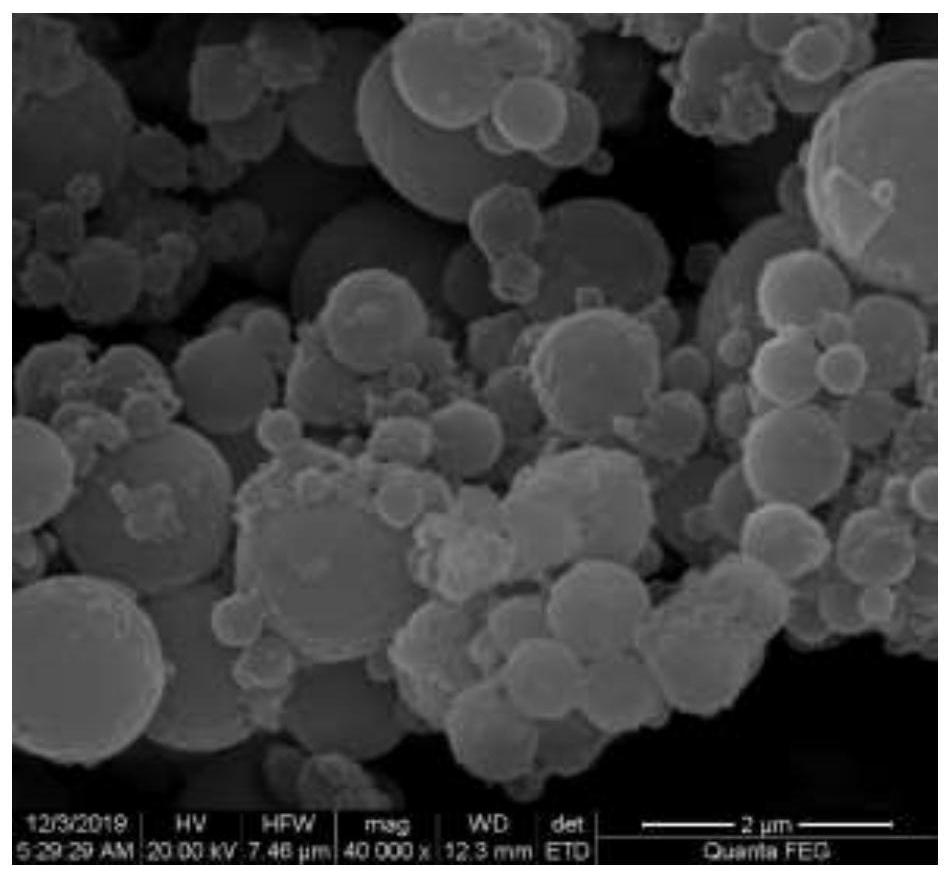

[0067] 1. Microsphere water swelling experiment

[0068] Take PAM microspheres and the dry powder of cross-linked polymer microspheres in Example 1 or 2 to prepare 3000mg / L deionized aqueous solution, pour them into 20mL sealed glass bottles, place them in a constant temperature oven at 55°C, and take them out after swelling for 5 days , the diameter of the microspheres before and after swelling was measured by SEM to calculate the swelling ratio of the microspheres.

[0069] 2. Microsphere shear performance experiment

[0070] Take PAM microspheres and the dry powder of cross-linked polymer microspheres in Example 1 or 2 to prepare 3000mg / L deionized aqueous solution. At room temperature, they are respectively injected at a rate of 1mL / min to carry out long core displacement experiments. The core penetration The ratio is 2500-3000mD, and the morphology changes before and after the microsphere displacement are measured by SEM.

[0071] 3. Results and discussion

[0072] fi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com