Manufacturing method of salt bridge used in low temperature environment

A low-temperature environment and production method technology, applied in the direction of electrochemical variables of materials, can solve the problems of residual bubbles, easy solidification, and non-gelation, etc., and achieve the effects of moderate gelation speed, stable chemical properties, and good fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

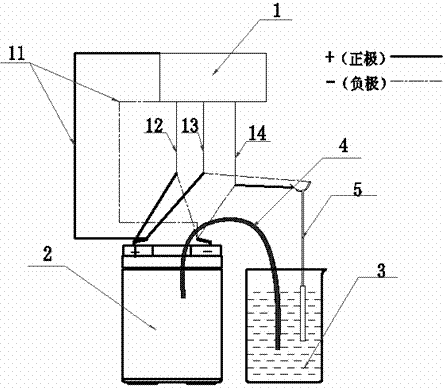

Method used

Image

Examples

Embodiment 1

[0029] The salt bridge used under the low temperature environment has the ratio of raw materials in parts by weight, saturated potassium nitrate solution: soluble starch: density of 1.34g / cm 3 The ratio of dilute sulfuric acid is 8:7:4.

[0030] 1. First measure 8 grams of saturated KNO 3 The solution is placed in a 30mL small beaker, and the density is 1.34g / cm 3 Slowly pour 4 grams of dilute sulfuric acid into the saturated KNO 3 In a small beaker of the solution, stir well with a glass rod. Then measure 7 grams of soluble starch, pour into the saturated KNO 3 In a small beaker of the solution, stir it with a glass rod for a few seconds until it is uniform and presents a cloudy floating state.

[0031] 2. Make sure that the bottom of the beaker is dry and put it on the preheated muffle furnace, and then stir it with a glass rod for 1-2 minutes, so that the turbid floating starch is heated to a translucent beige paste, stop stirring, and turn off the power of the muffle f...

Embodiment 2

[0036] The salt bridge used under the low temperature environment has the ratio of raw materials in parts by weight, saturated potassium nitrate solution: soluble starch: density of 1.34g / cm 3 The ratio of dilute sulfuric acid is 10:10:2.

[0037] The preparation steps are as in Example 1.

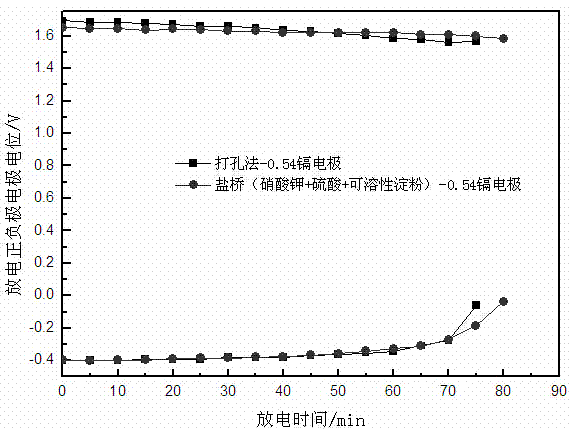

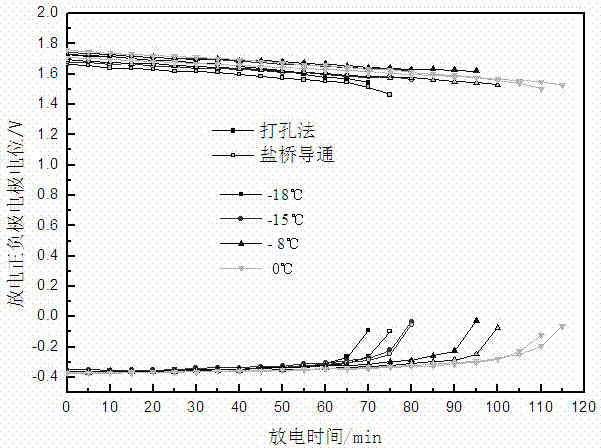

[0038] Cut the prepared salt bridge to a length of 100mm as required, press figure 1 The connection method is connected, and placed in different environments at 0 ° C ~ -18 ° C for 12 hours, according to the process, the current 6A is discharged to 1.75V / single cell, and then 0.18C 2 A limited voltage 2.5V / single cell constant current and constant voltage charging for 12 hours. Process the measured positive and negative electrode potentials, and compare them with the previous punching method, such as image 3 shown.

[0039] From Example 2, image 3The results of the test show that the test results of the salt bridge prepared by this method are basically consistent with the discharge ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com