Patents

Literature

165results about How to "Avoid air bubbles" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

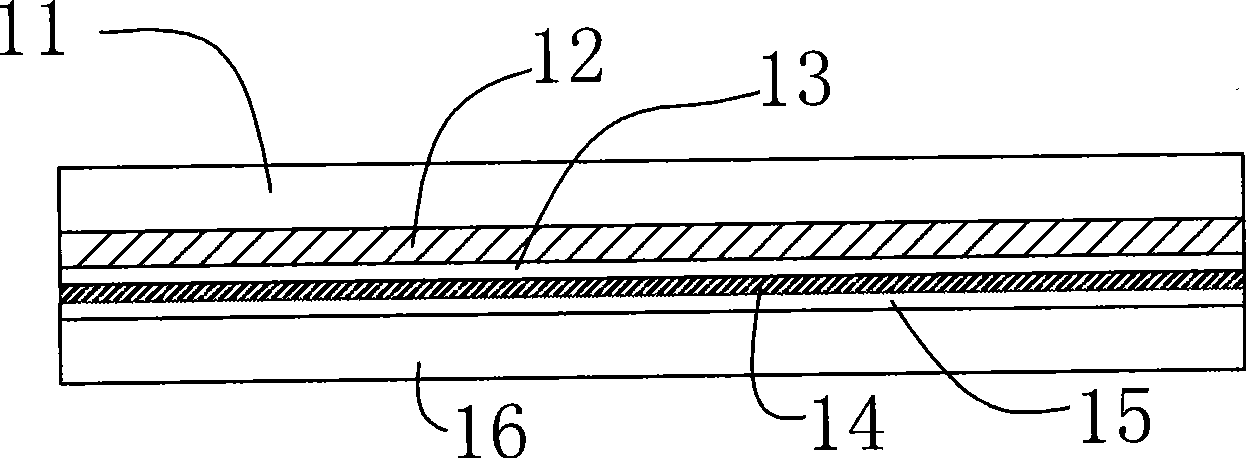

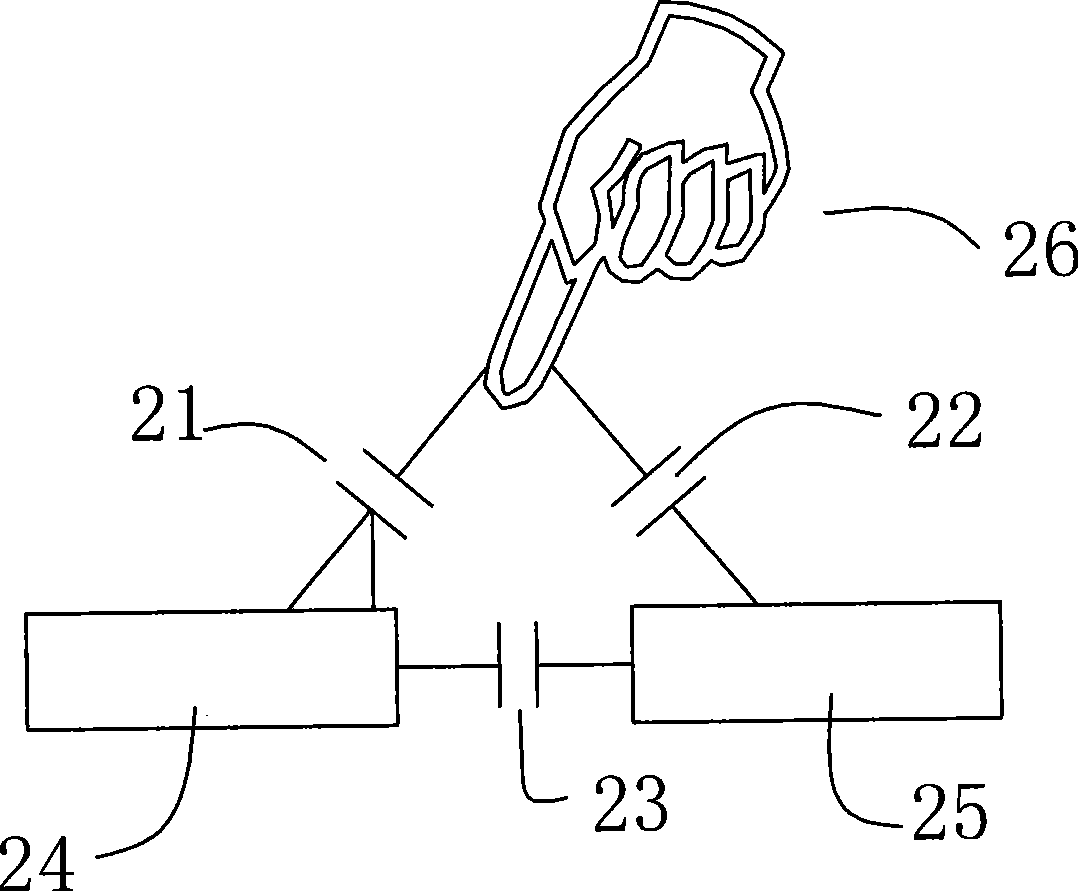

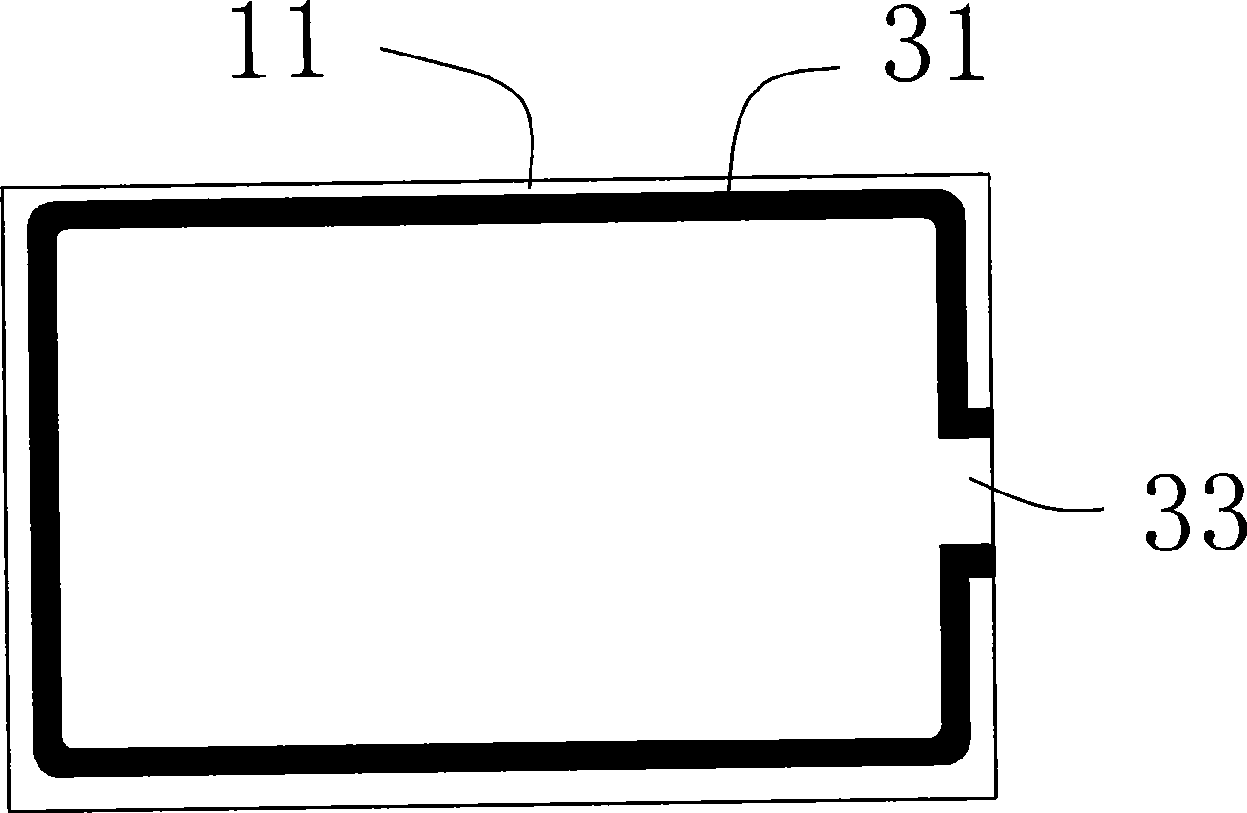

Condenser type touch screen substrate attaching method

InactiveCN101482786AAvoid air bubblesOvercome glue overflowInput/output processes for data processingVacuum pumpingLiquid state

The present invention provides a capacitor type touch screen substrate adhibiting method which comprises the following main steps: firstly, preparing a strip of frame adhesive with an opening by adhesive on the perimeter of abutted surface of substrate of one prepared substrate; after attaching the upper substrate and the lower substrate together, forming a cavity between two abutted surfaces of substrate; executing vacuum pumping to the cavity through an opening; after contacting the opening with the liquid adhesive, pressurizing the periphery of adhesive so that the adhesive is injected into the cavity depending on the vacuum differential pressure or capillarity; and finally solidifying the adhesive injected into the cavity thereby obtaining the finished product of capacitor type touch screen. The invention can reduce or avoid the air bubble generated in attaching the upper substrate and the lower substrate and has the advantages of increased product quality, increased finished product rate, increased production efficiency, etc.

Owner:深圳市中显微电子有限公司

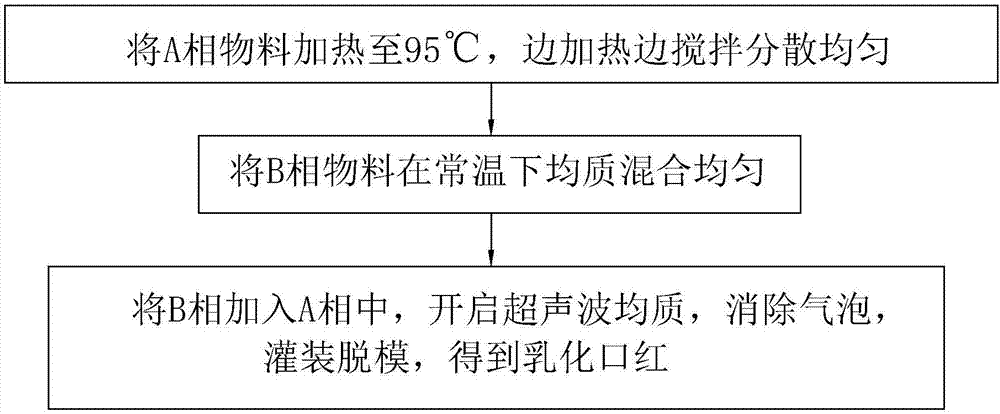

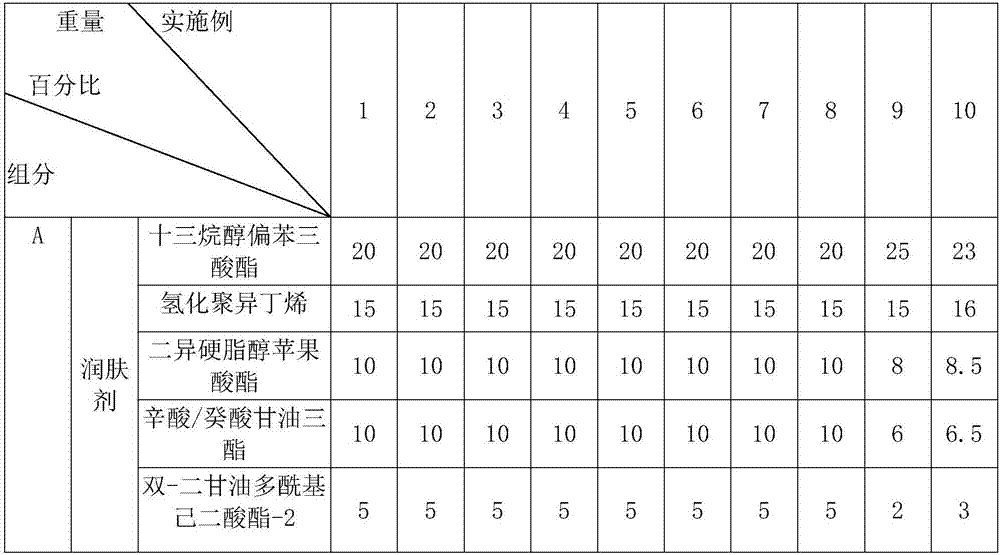

Emulsified lipstick and preparation method thereof

InactiveCN107496201AAvoid air bubblesImprove yieldCosmetic preparationsMake-upChemistryWater soluble

The invention discloses an emulsified lipstick and a preparation method thereof, and belongs to the technical field of cosmetics. The emulsified lipstick is prepared from the following components in percentage by weight: 51 to 71% of skin moisturizer, 13 to 17% of hardener, 4 to 10% of brightener, 2 to 3% of polyglycerol-2 triisostearate, 0.5 to 1% of dipoly-pentaerythritol tri-polyhydroxyl stearate, 2 to 5% of phytosterol / octyl dodecyl lauryl glutamate, 2 to 5% of water, 2.01 to 4.02% of water-soluble moisturizer, and 0.5 to 2.5% of water-soluble plant extract. The emulsified lipstick has the advantages that by adopting two types of emulsifiers, and matching with the ultrasonic demulsifying technology, the production of air bubbles due to evaporation of water phase is avoided, and the finished rate is improved; the moisturizer, cornflower flower extract, ginko leaf extract and golden chamomile flower extract can be added into the lipstick, so that the lip wrinkles can be lightened, the skin elasticity is improved, the toxicity is effectively removed, the circulation of micro-blood vessels is stimulated, the skins are nourished, and the functions of the lipstick are widened; under the synergistic function of glycerin, hyaluronic acid and polyquaternium-51, the natural skin bionic moisturizing film is formed, and the lip skin is moisturized and smooth.

Owner:上海禾雅化妆品有限公司

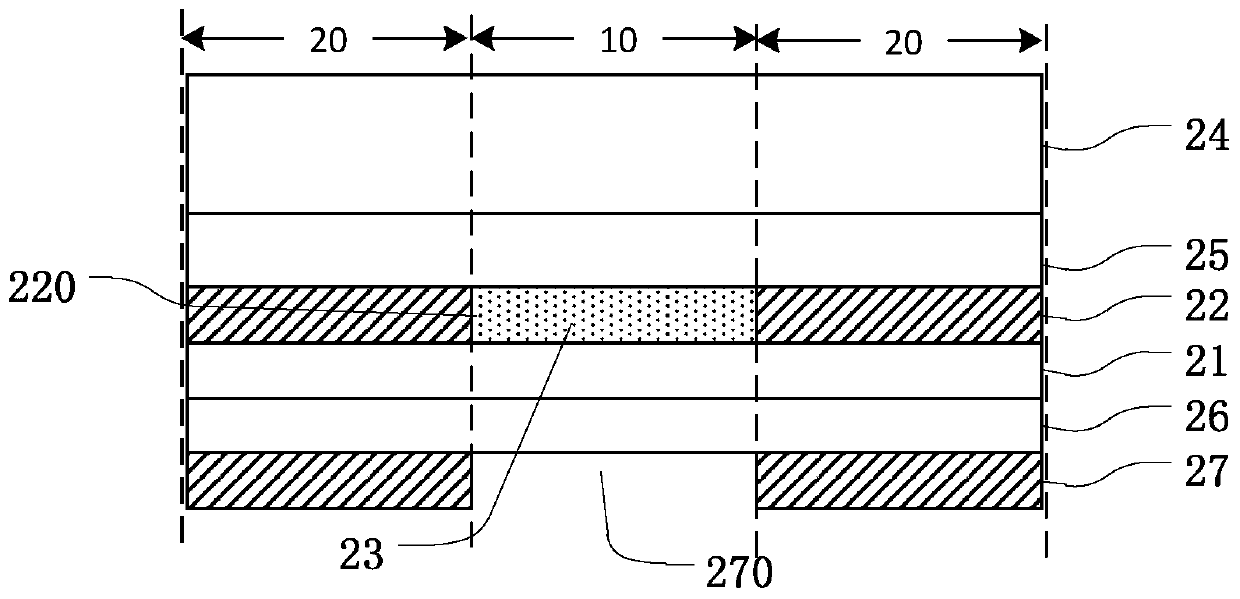

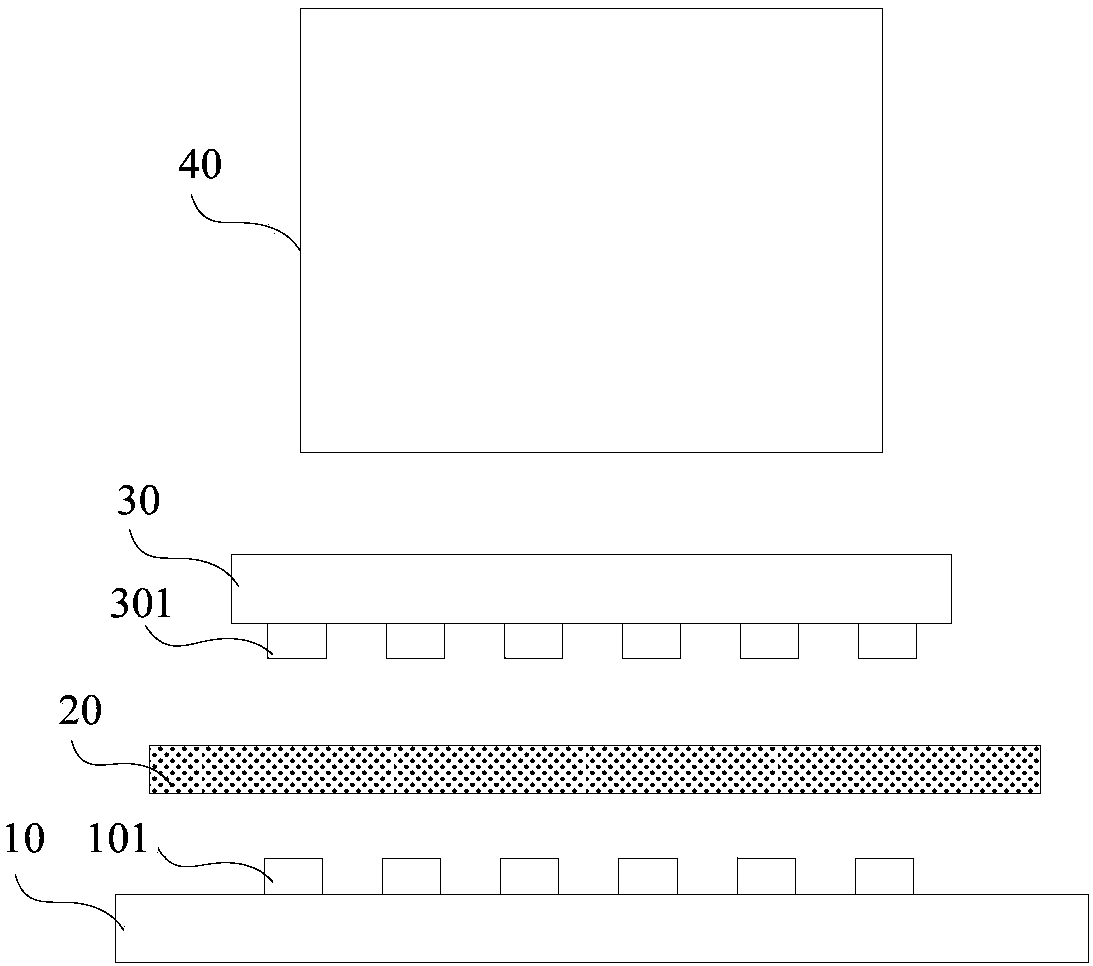

Display screen and preparation method of display screen

InactiveCN106406626AEliminate the gapAvoid air bubblesInput/output processes for data processingEngineering

Owner:WUHAN CHINA STAR OPTOELECTRONICS TECH CO LTD

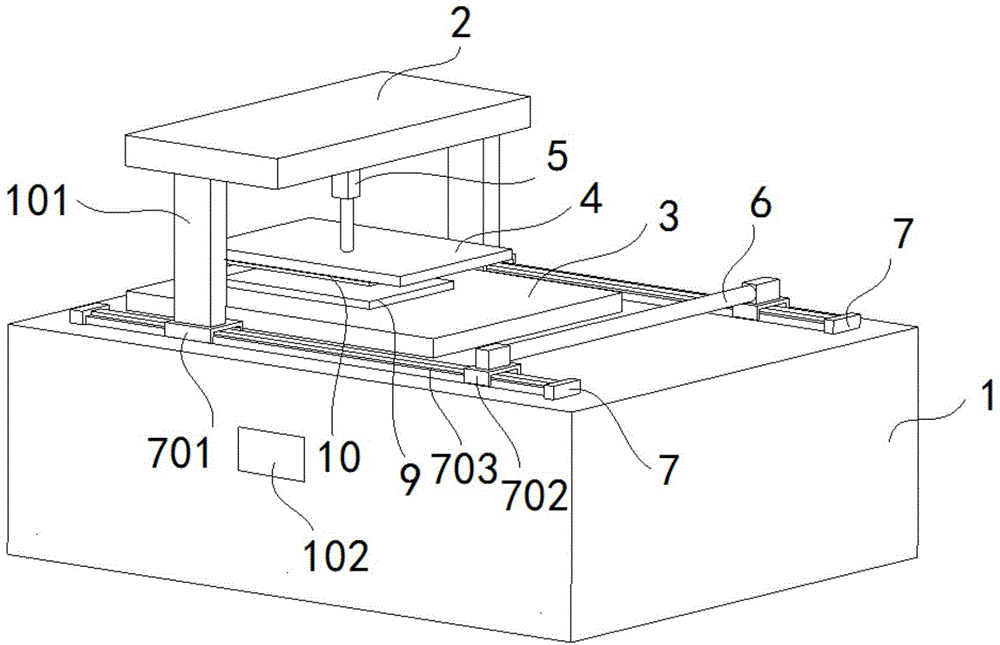

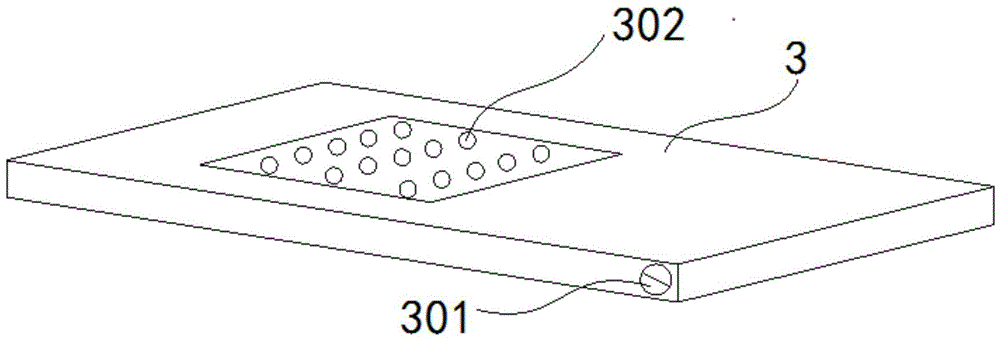

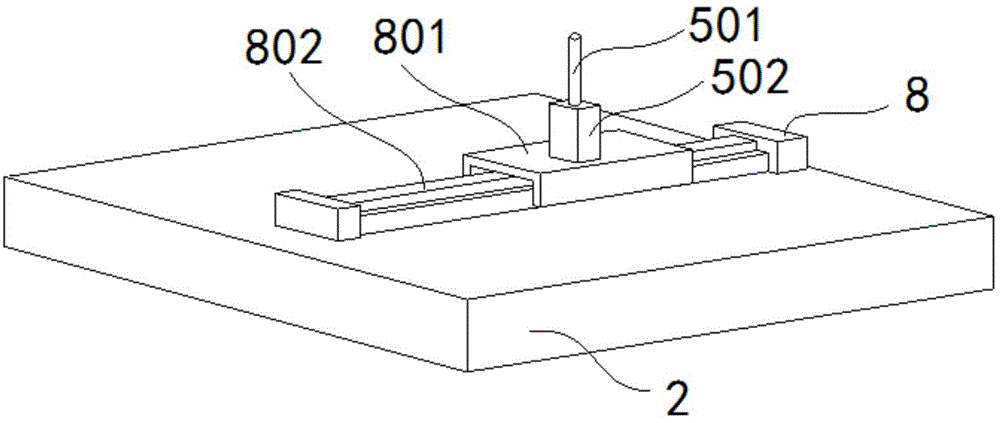

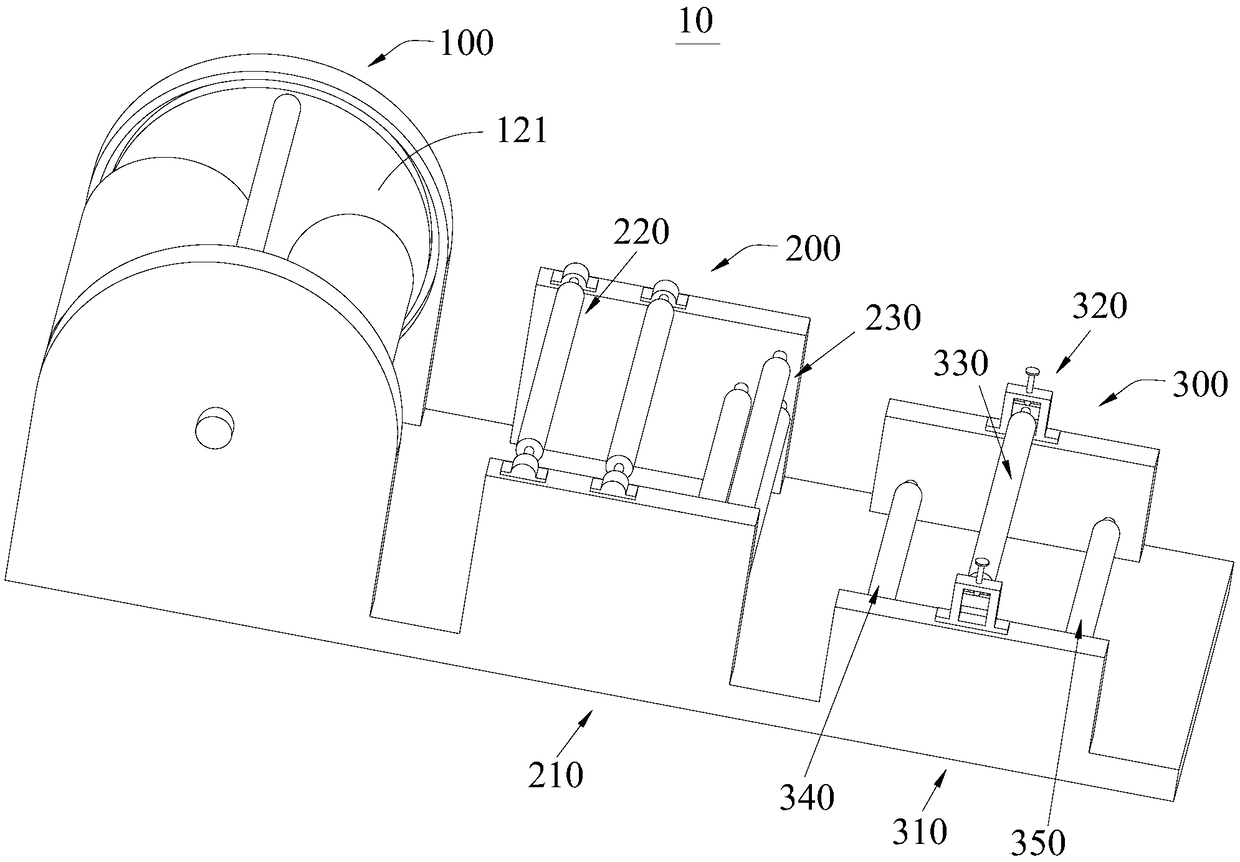

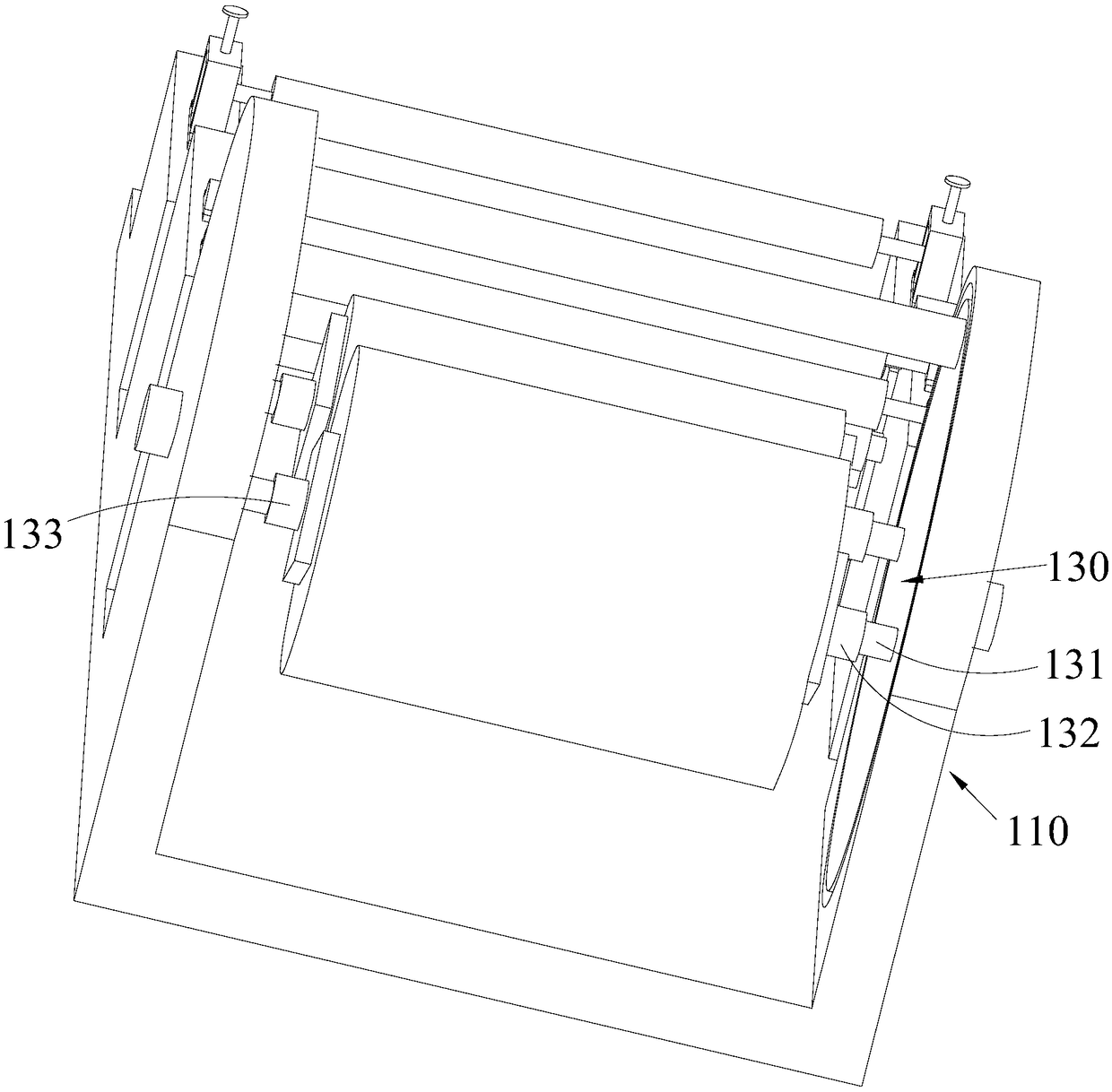

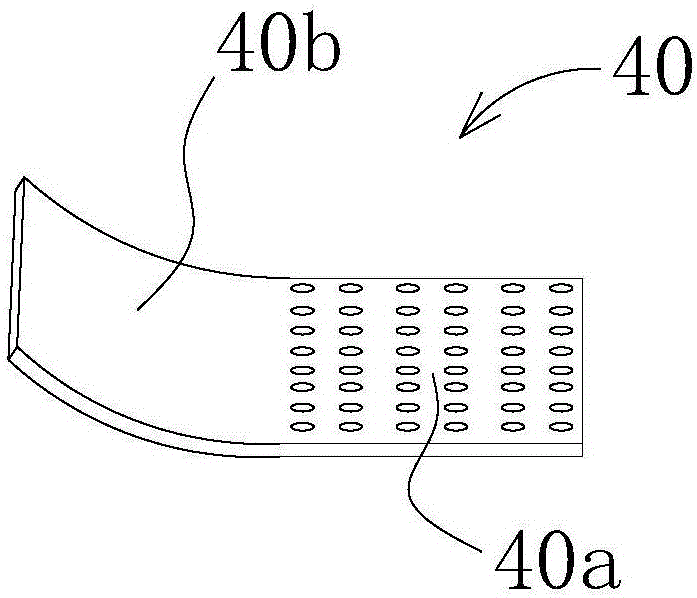

Polarizer attaching device for liquid crystal display

ActiveCN104808364AAvoid air bubblesGood attachment effectNon-linear opticsPolarizerLiquid-crystal display

The invention discloses a polarizer attaching device for a liquid crystal display. The polarizer attaching device comprises a base, an attaching platform, an adsorption plate and a compression roller, wherein a first vacuum adsorption hole, a second vacuum adsorption hole and a third vacuum adsorption hole are formed in the adsorption plate; the compression roller is arranged on the base; polarizers can fall in sequence to cover a glass substrate, and the compression roller is utilized for laminating the polarizers with the glass substrate, so that the generation of bubbles is effectively avoided; position sensors are arranged in the adsorption plate and the attaching platform, so that the position information of the adsorption plate and the attaching platform can be obtained; the transverse motion of the adsorption plate is realized by controlling a sliding support to slide on a first driving device, the longitudinal motion of the adsorption plate is realized by controlling a cylinder to slide on a second driving device, and the up-and-down motion of the adsorption plate is realized by controlling the piston rod of the cylinder, so that accurate positioning between the adsorption plate and the attaching platform realizes correct attaching of the polarizers and the glass substrate; the device is simple in structure, good in patch quality and high in positioning accuracy.

Owner:深圳市宇创显示科技有限公司

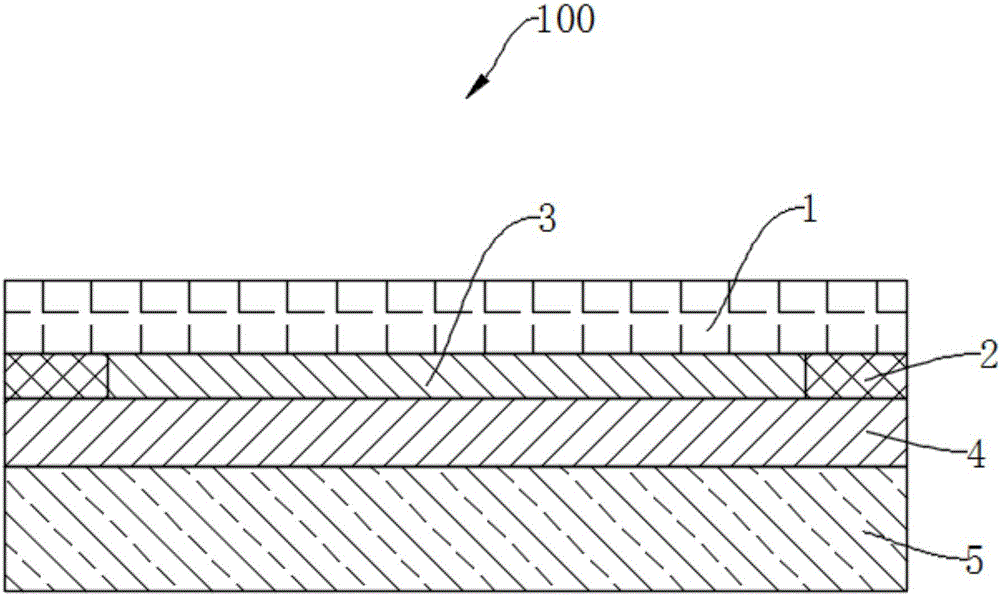

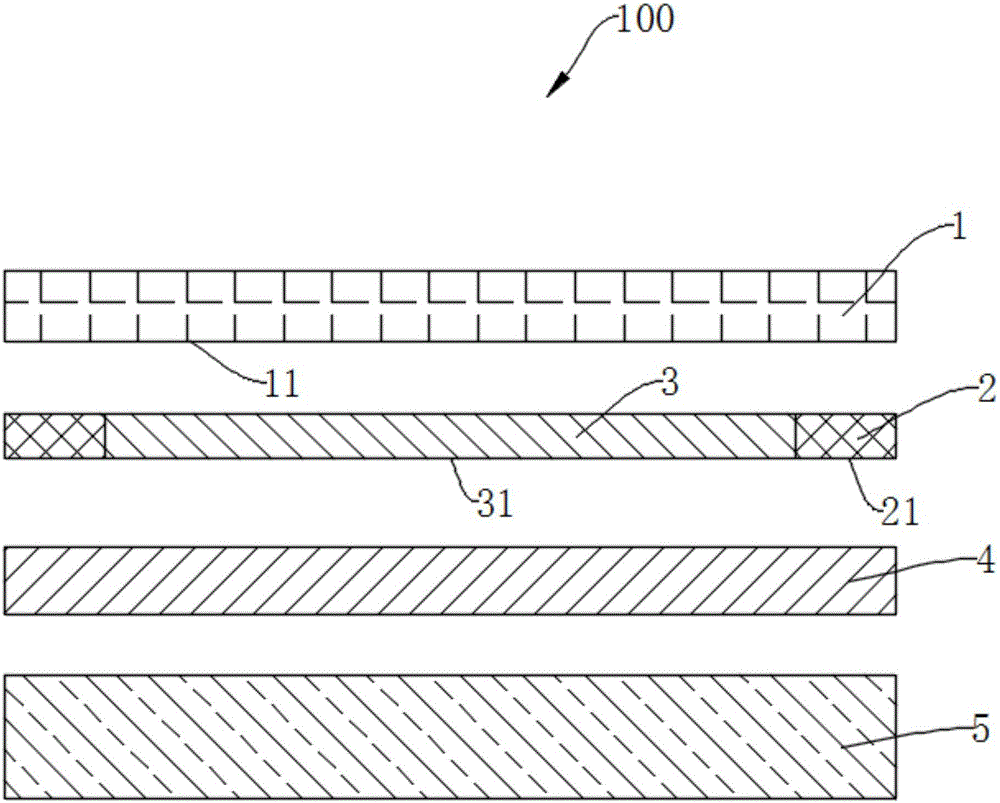

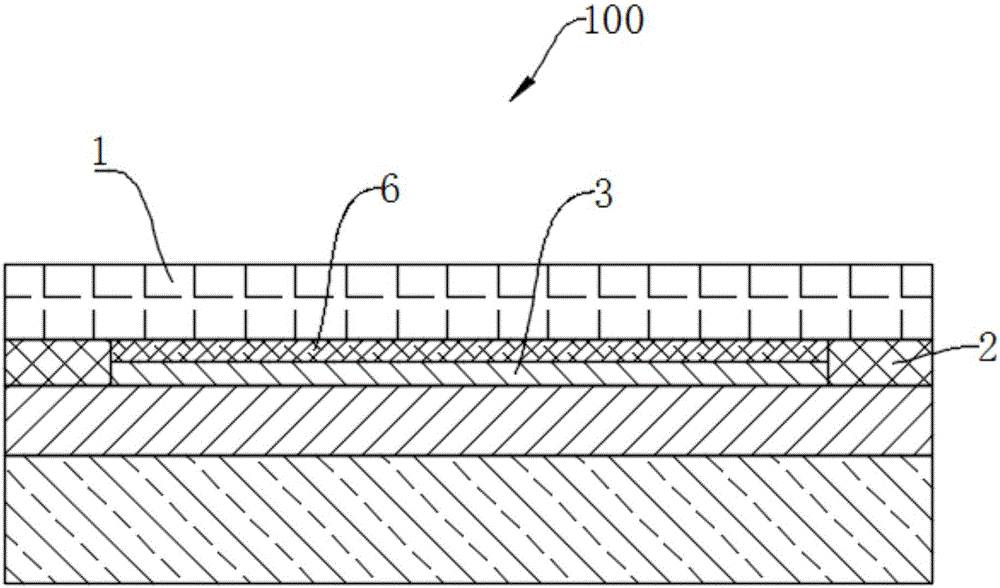

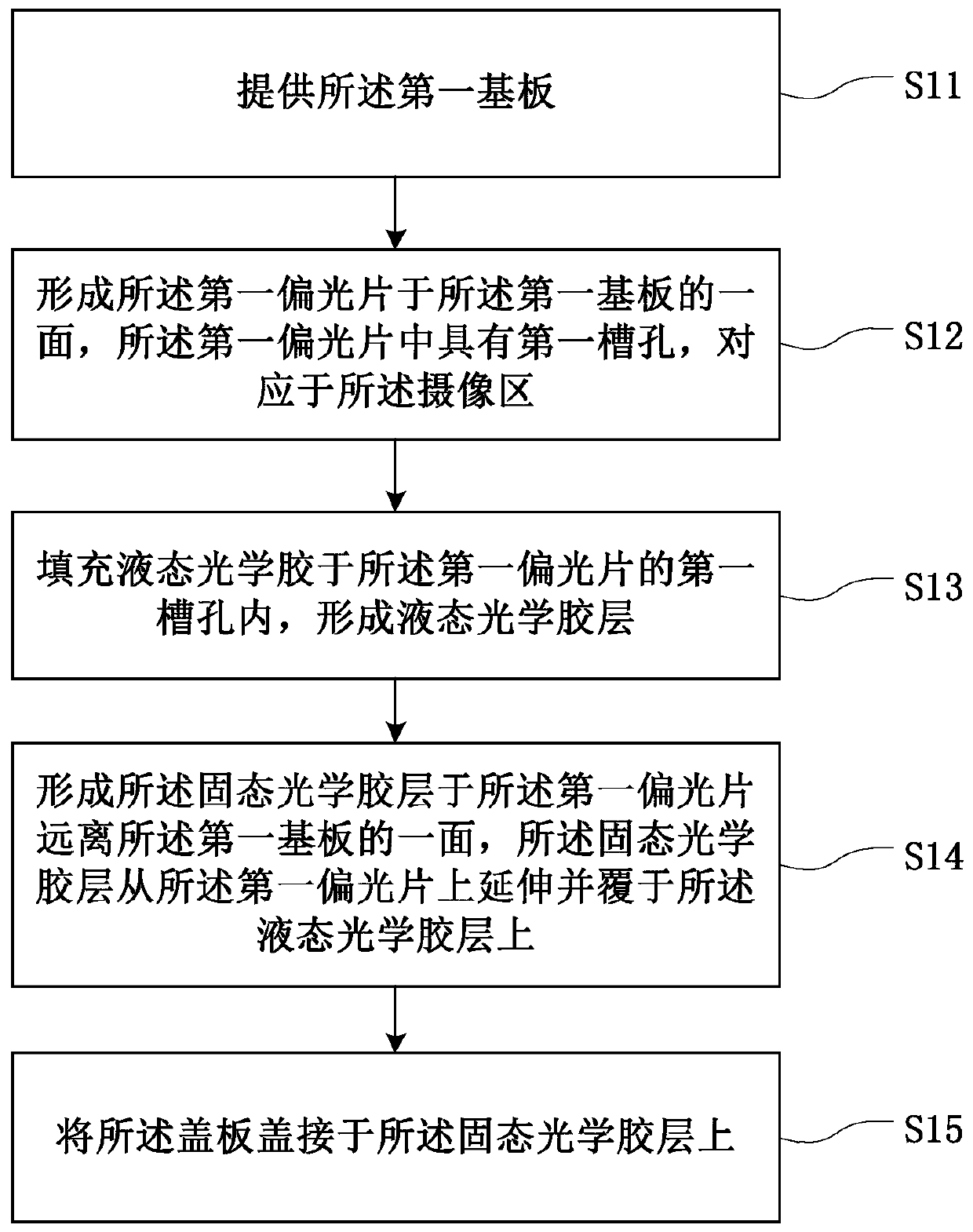

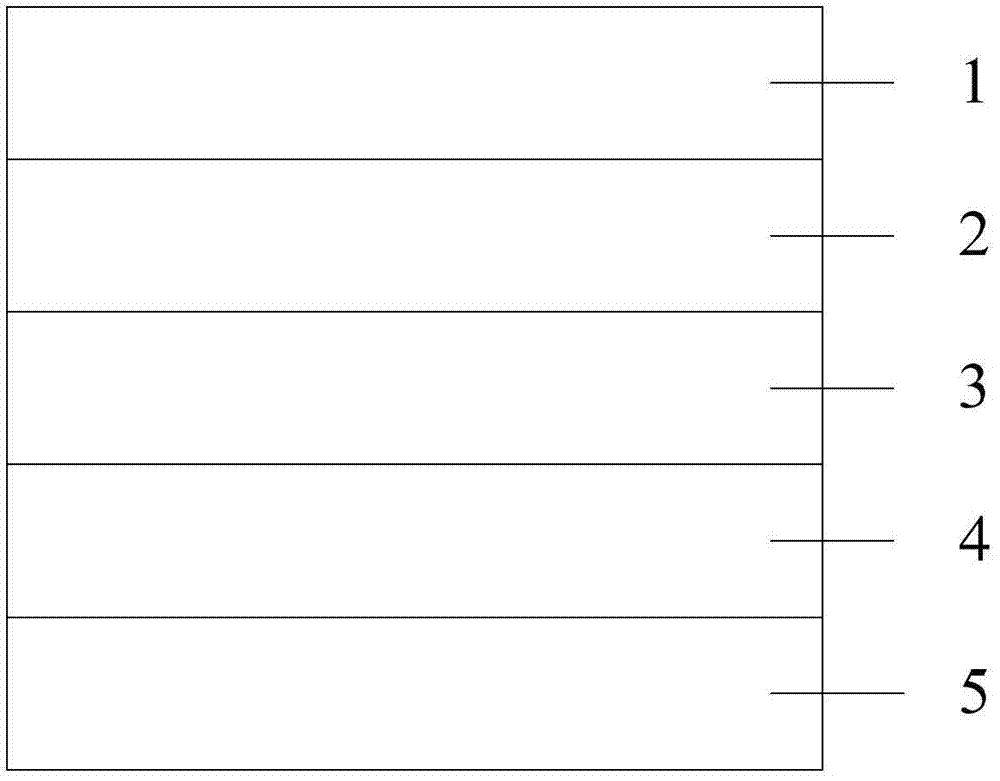

Display panel and preparation method thereof

InactiveCN110908163AImprove qualityIncrease absorbanceTelevision system detailsColor television detailsTransmittanceEngineering

The invention provides a display panel and a preparation method thereof. The display panel comprises a camera shooting area, a display area surrounding the camera shooting area, a first substrate, a first polarizer, a liquid optical adhesive layer, a cover plate and a solid optical adhesive layer. The first polaroid is arranged on one surface of the first substrate; the first polaroid is providedwith a first slotted hole corresponding to the camera shooting area; the first slotted hole is filled with the liquid optical adhesive layer; the cover plate is connected to the face, away from the first substrate, of the first polaroid in a covering mode. The solid optical adhesive layer is at least arranged between the cover plate and the first polaroid. The invention has the technical effects;according to the display panel and the preparation method thereof provided by the invention, the liquid optical adhesive is used for replacing the solid optical adhesive to fill the slotted hole of the corresponding camera shooting area, so that the phenomenon of bubbles when the slotted hole is filled with the solid optical adhesive is avoided, the laminating yield is improved, the light absorption rate of the optical adhesive at the slotted hole is improved, the light transmittance of the camera shooting area is improved, and the quality of the display panel is further improved.

Owner:WUHAN CHINA STAR OPTOELECTRONICS TECH CO LTD

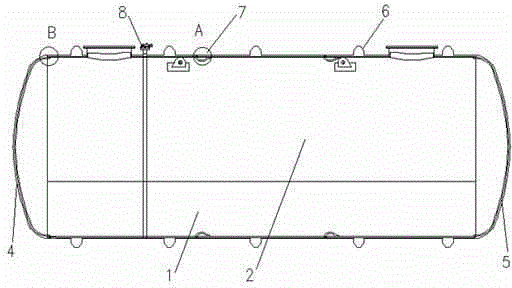

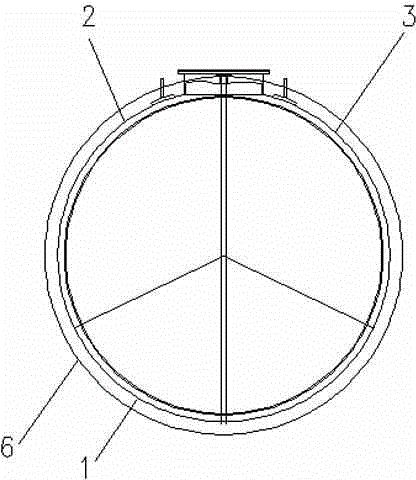

Glass fiber reinforced plastic double-deck oil tank and manufacture technology thereof

ActiveCN104816897AReduce difficultyImprove work efficiencyLarge containersSteel platesVacuum pressure

The invention relates to a glass fiber reinforced plastic double-deck oil tank which comprises an oil tank main body, a leakage detector and a transportation and installation annular support structure, wherein an oil inlet is formed in the top of the oil tank main body; the oil tank main body comprises a steel tank body at the inner layer, the steel tank body comprises a middle steel plate, side steel plates and a seal steel plate, and the middle steel plate, side steel plates and seal steel plate are fixedly connected for forming a closed cavity; a middle interlayer is covered at the periphery of the steel tank body, a glass fiber reinforced plastic outsourcing layer is arranged at the periphery of the middle interlayer, and the glass fiber reinforced plastic outsourcing layer comprises a first RTM region, a second RTM region, a third RTM region, a fourth RTM region and a fifth RTM region. The steel tank body adopts socket type, overlap joint type for connecting tank body steel plates, double-deck welding ensures connection reliability and airtightness, and the operation is convenient and fast; a vacuum pressure detection method is sensitive and timely; the glass fiber reinforced plastic outsourcing layer adopts RTM manufacture technology, the strengthening rib is integrated with the tank body for avoiding bubble residue of outer shell of the tank body and ensuring structure strength and stability.

Owner:保定长空石油工业股份有限公司

Mobile phone cover glass main printing technology

The invention relates to the technical field of mobile phone cover glass printing, in particular to a mobile phone cover glass main printing technology. The mobile phone cover glass main printing technology comprises the steps of (1) primary mirror-like silver printing, wherein a mirror-like silver layer is printed on the lower surface of clear glass in a blade coating mode by means of the screen printing technique; (2) secondary bluish violet printing, wherein a second bluish violet layer is printed on the lower surface of the clear glass in a blade coating mode by means of the screen printing technique; (3) tertiary pearl white printing, wherein a pearl white layer is printed on the lower surface of the clear glass in a blade coating mode by means of the screen printing technique. According to the mobile phone cover glass main printing technology, by means of the composite printing technology conducted on the clear glass and combining the primary mirror-like silver printing, the secondary bluish violet printing and the tertiary pearl white printing, printed patterns are stereoscopic, and natural transition is achieved between different ink layers. The mobile phone cover glass main printing technology has the advantages that operation is simple and convenient to control, quality is stable, production efficiency is high, and large-scale industrial production can be achieved.

Owner:广东星弛光电科技有限公司

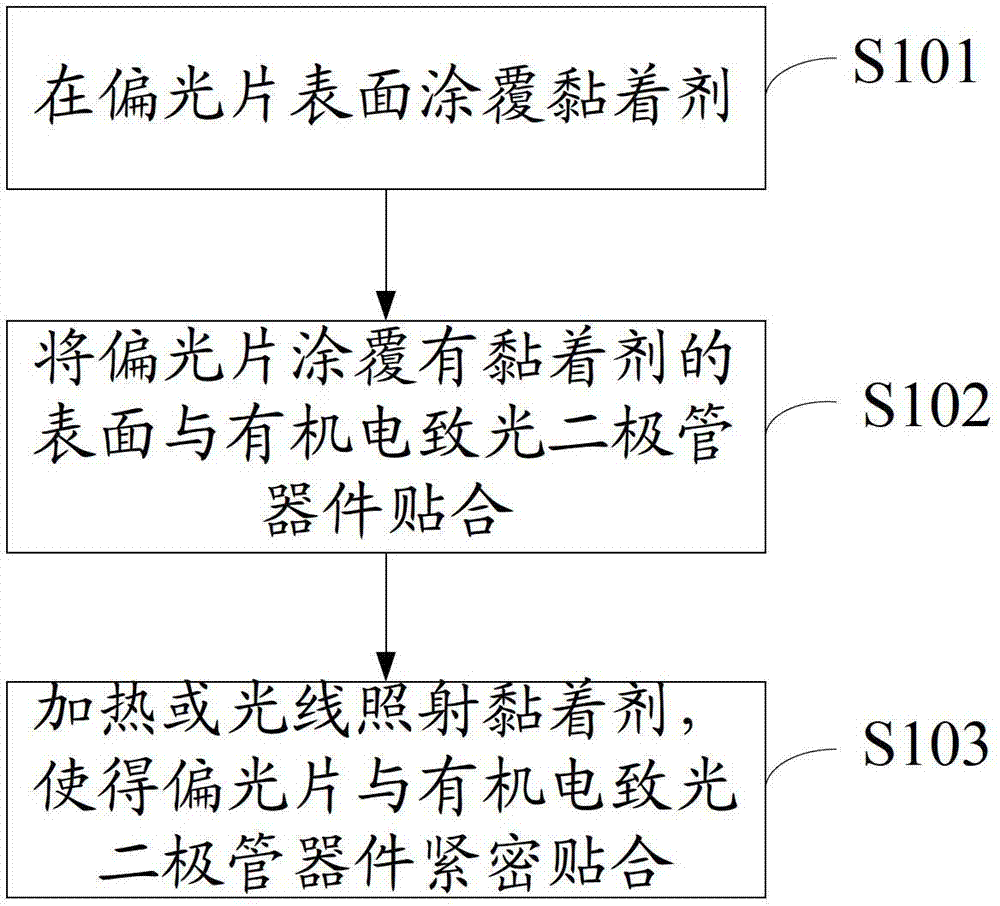

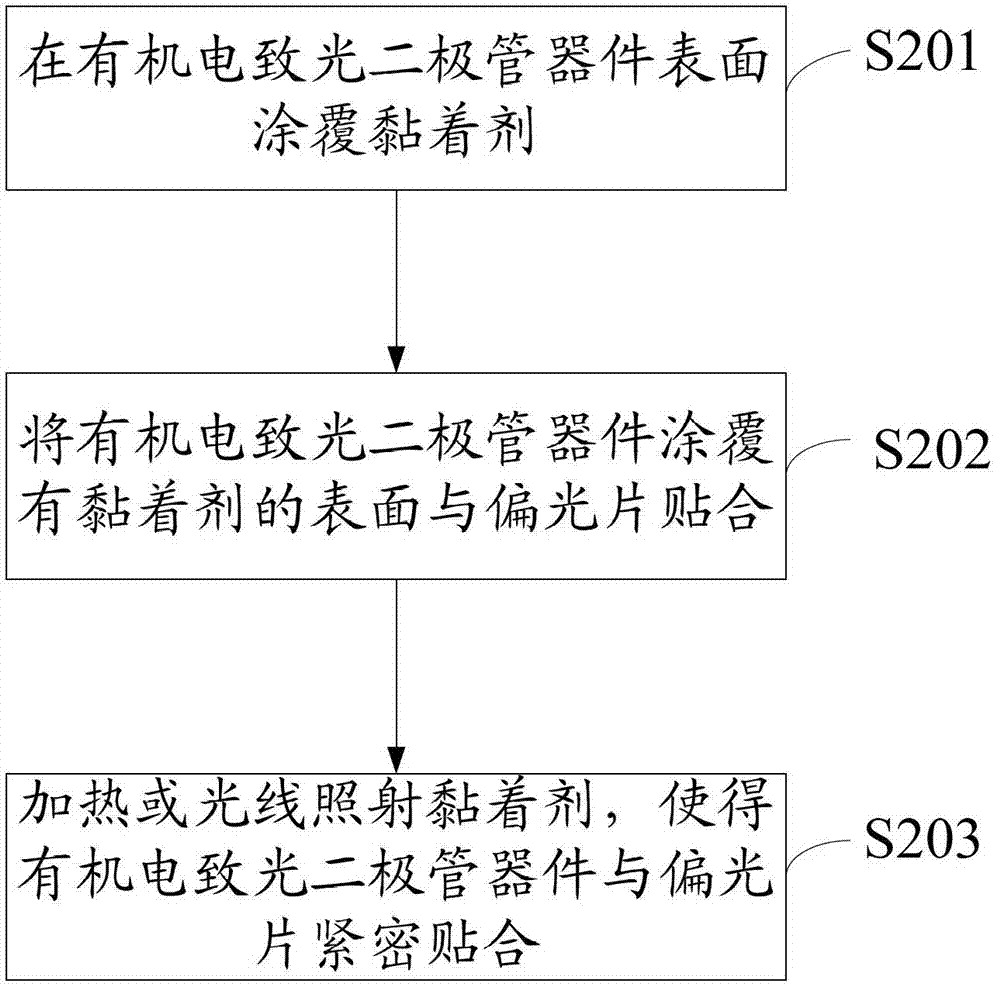

Organic light-emitting diode (OLED) display and method for coating polarizing film of OLED display

ActiveCN102903735AAvoid air bubblesImprove yieldLayered productsSolid-state devicesChemistryFilm coating

The embodiment of the invention discloses a method for coating a polarizing film of an organic light-emitting diode (OLED) display. The OLED display comprises an OLED device. The method mainly comprises the following steps of: coating an adhesive on the surface of the polarizing film; attaching the surface of the polarizing film, on which the adhesive is coated, to the OLED device; and heating or irradiating the adhesive, so the polarizing film is tightly attached to the OLED device. The embodiment of the invention also discloses the OLED display. The method and the OLED display have the advantages that bubbles can be prevented from being generated in a polarizing film coating process, and the yield of the polarizing film coating process is improved.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

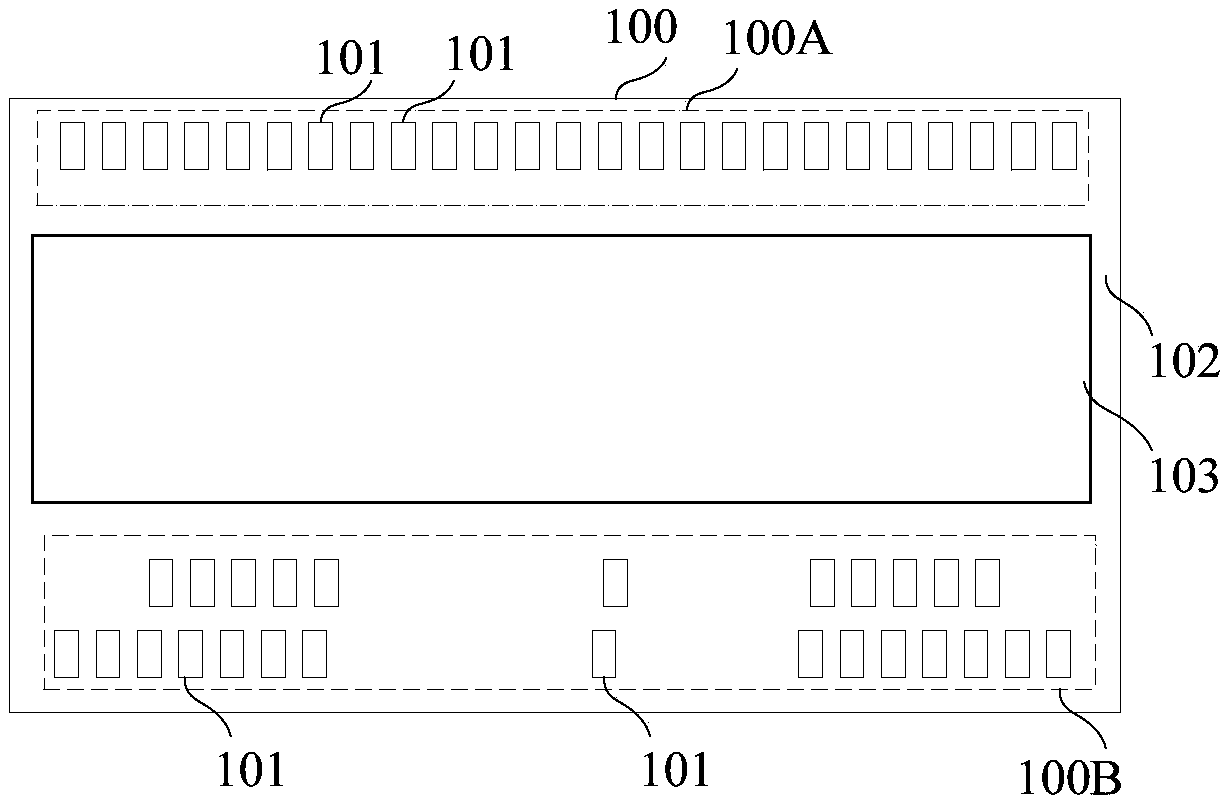

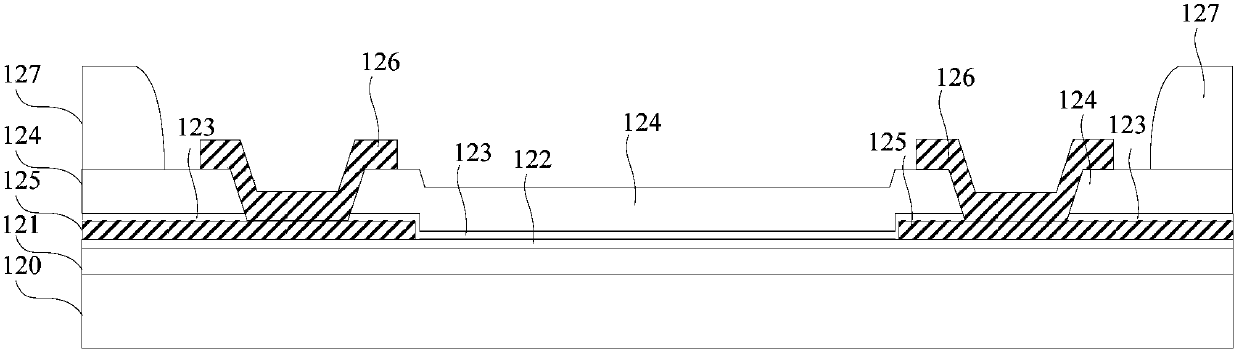

Display substrate and manufacturing method thereof, display panel and display device

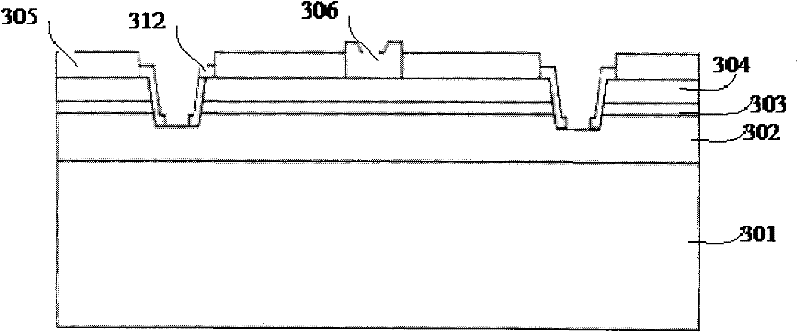

ActiveCN109860224AAvoid air bubblesGuaranteed electrical connection performanceSolid-state devicesSemiconductor devicesAnisotropic conductive filmInsulation layer

The invention discloses a display substrate and a manufacturing method thereof, a display panel and a display device, and belongs to the field of displays. The display substrate includes a bonding area, a plurality of bonding pads arranged at intervals are arranged at the bonding area, the bonding pads are separated from one another through an insulation layer, and the insulation layer between atleast two adjacent bonding pads is provided with a groove. The insulation layer between at least two adjacent bonding pads is provided with the groove to allow an ACF (Anisotropic Conductive Film) toflow to the grooves when pressing-down of the ACF is performed to ensure the uniform distribution of the ACFs between the at least two adjacent Pads so as to solve the unfairness caused by difficult ACF glue discharge between the display substrate and a drive IC (Integrated Circuit), avoid a condition that bubbles are generated due to unfairness of the ACFs and ensure the electrical connection performance between the display substrate and the drive IC.

Owner:BOE TECH GRP CO LTD +1

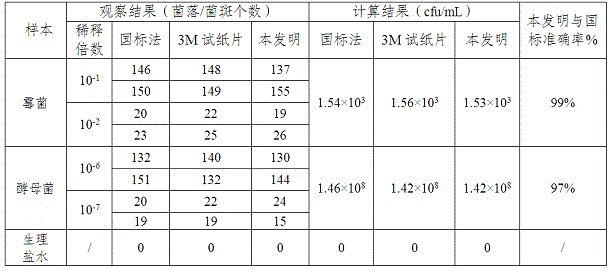

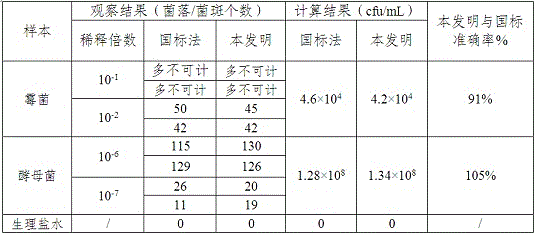

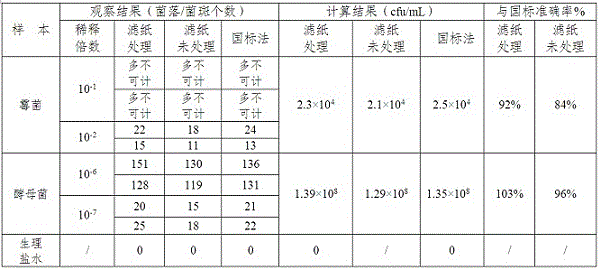

Detection vessel for rapidly detecting moulds and yeasts and preparation method

InactiveCN105483204AImprove breathabilityImprove adsorption capacityMicrobiological testing/measurementYeastMetabolite

The invention provides a detection vessel capable of rapidly culturing and detecting moulds and yeasts at the same time. A biochemical reaction characteristic of microorganisms is utilized, types and reaction conditions of endoenzymes of the microorganisms are determined as main bases for microorganism classification and identification, a microorganism specific enzyme chromogenic substrate is added into an isolation medium or a selective medium, and when target bacteria grow on the medium, the chromogenic substrate can be degraded by specific enzymes and metabolites in special colors can be generated to realize specific colors or forms of colonies, thereby implementing culturing and detection of the microorganisms in a sample. The detection vessel has the advantages of convenience in operation, low cost, labor saving, simple judgment result, reliable detection result, short detection time and the like, and can play an important role in microorganism detection, and accuracy of a detection result reaches 90 percent or over 90 percent of a national standard detection method.

Owner:贵州勤邦食品安全科学技术有限公司

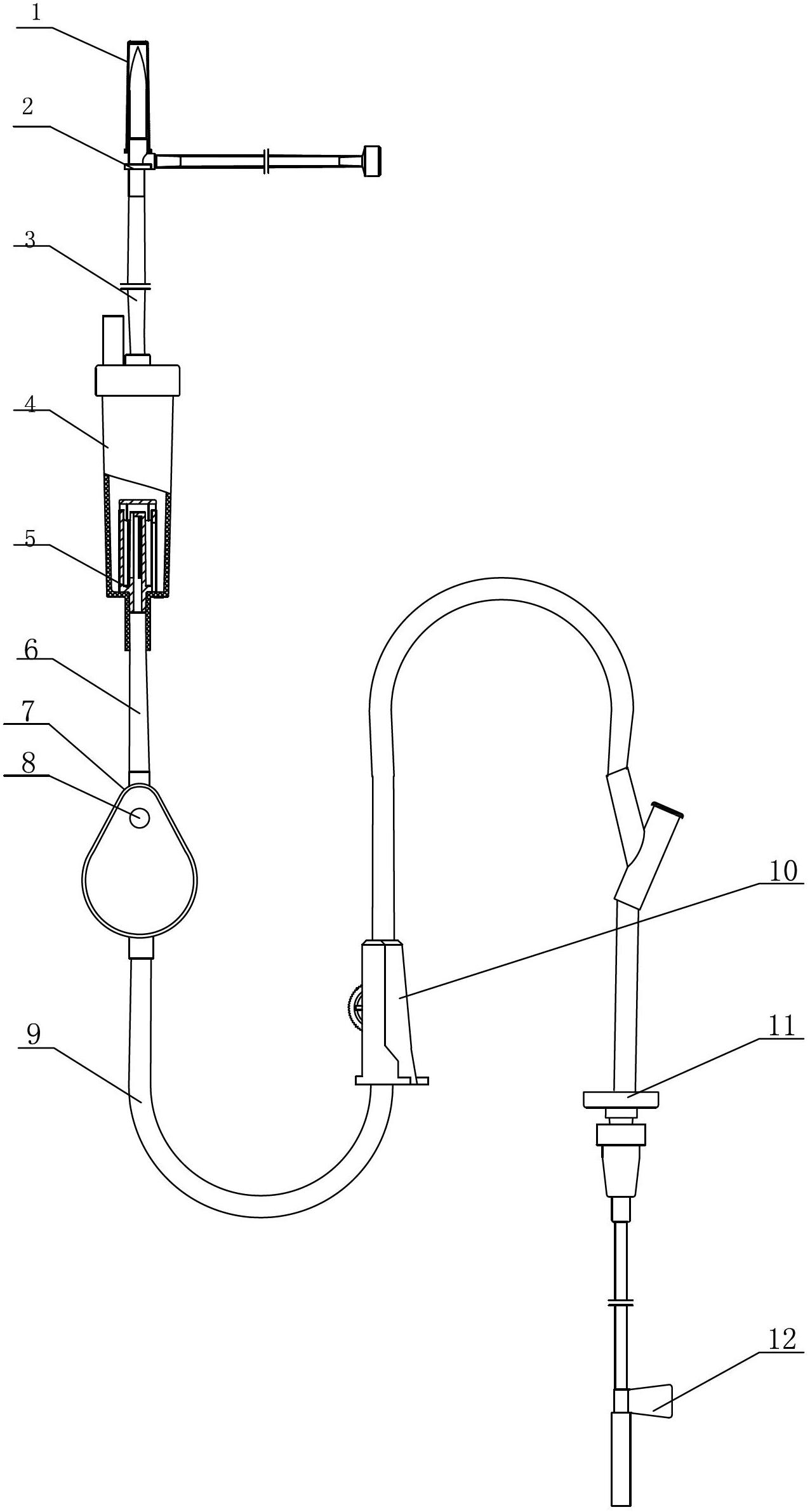

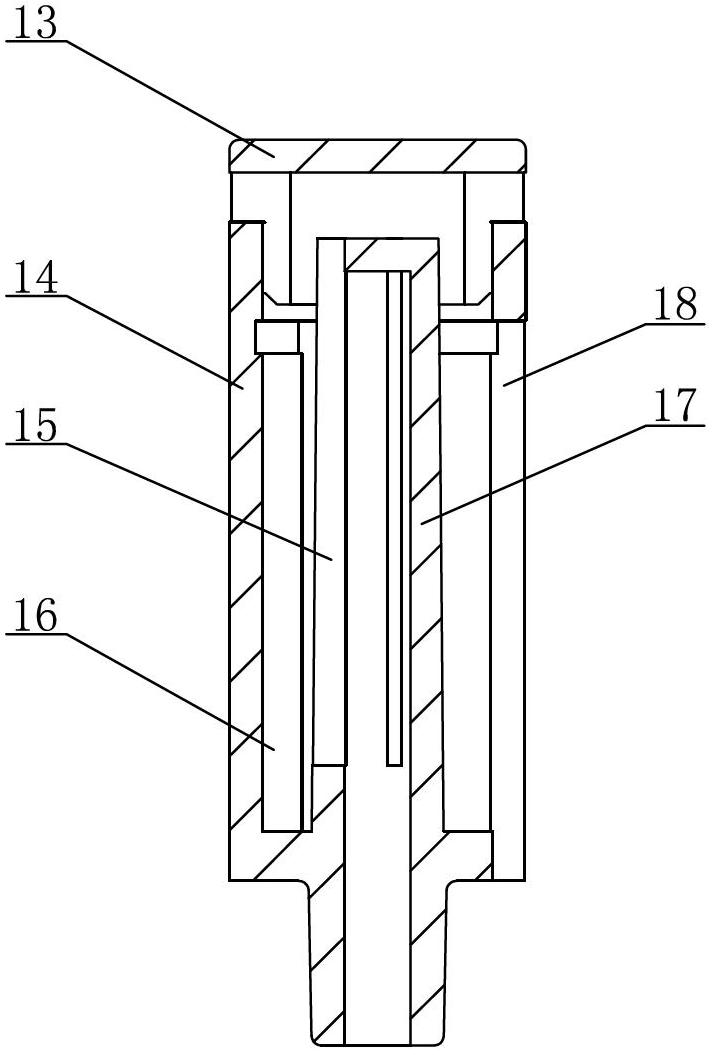

Full automatic infusion set

The invention belongs to the field of medical equipment, and particularly relates to a full automatic infusion set used for clinical intravenous infusion. The full automatic infusion set comprises a bottle stopper puncture device, a first transfusion tube, a drip chamber, a second transfusion tube, a liquid medicine filter, a third transfusion tube, a Luer and an intravenous infusion needle which are connected in sequence, wherein a flow regulator is installed on the third transfusion tube; an exhaust device is arranged in the drip chamber; the exhaust device comprises an exhaust seat, an exhaust pipe and a nut cap; the bottom of the exhaust seat is fixed on a liquid dripping opening formed at the bottom end of the drip chamber, and is in close fit with the liquid dripping opening; the hollow exhaust pipe communicated with the liquid dripping opening is arranged in the exhaust seat; a liquid inlet gap is formed between the exhaust pipe and the exhaust seat; liquid inlet slots are formed on the side walls between the exhaust pipe and the exhaust seat; the nut cap is arranged at the top of the exhaust seat; the nut cap is fastened on the exhaust seat; and at least two exhaust grooves are formed on the side wall of the nut cap. The full automatic infusion set with a reasonable structure can achieve automatic exhaust, automatic liquid filling and automatic liquid stopping when in use rather than inverting or squeezing the drip chamber, is fast and convenient to use, and is safe and reliable.

Owner:SHINVA ANDE HEALTHCARE APP CO LTD

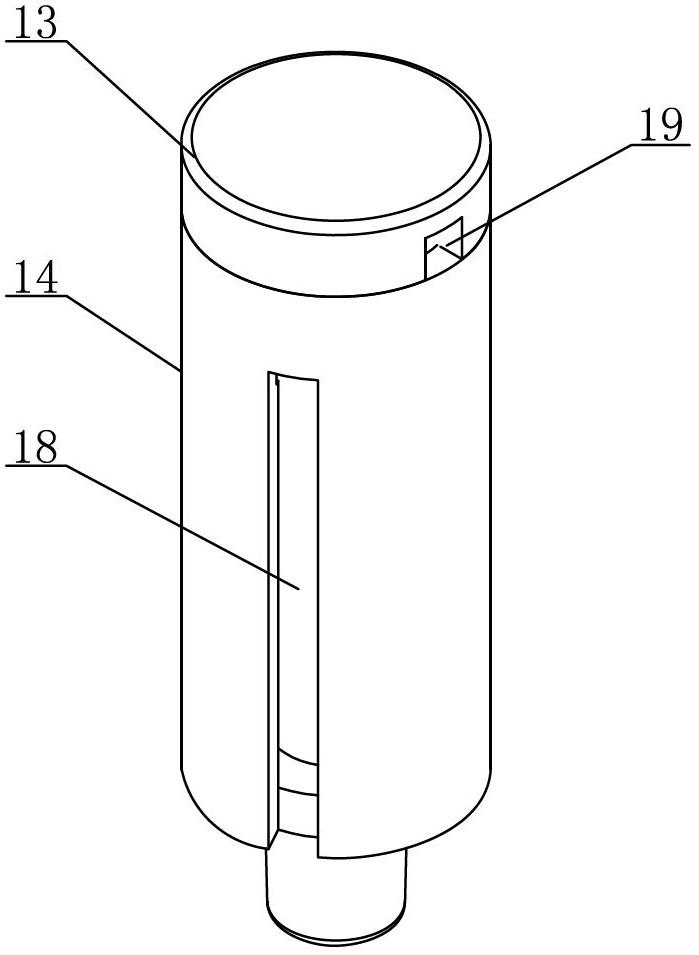

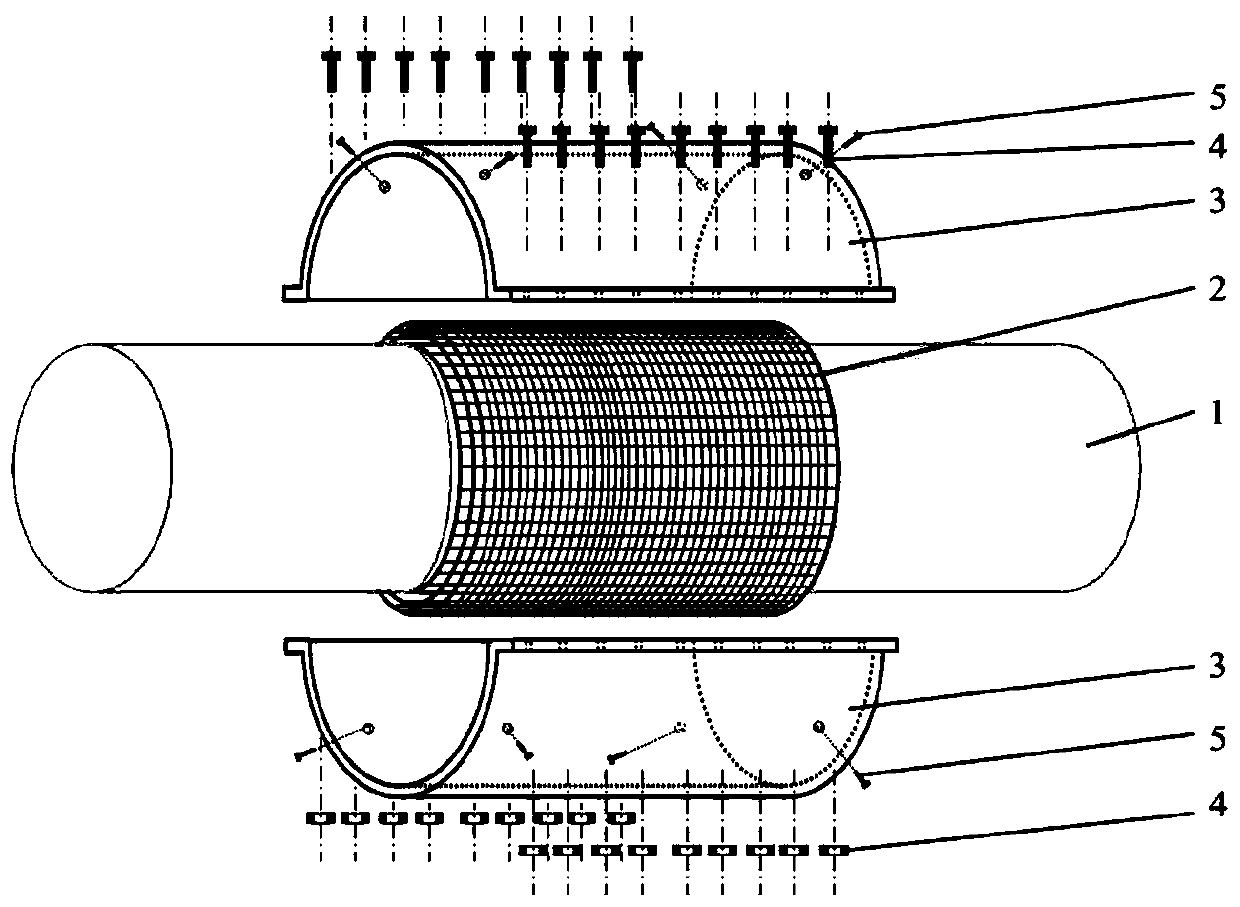

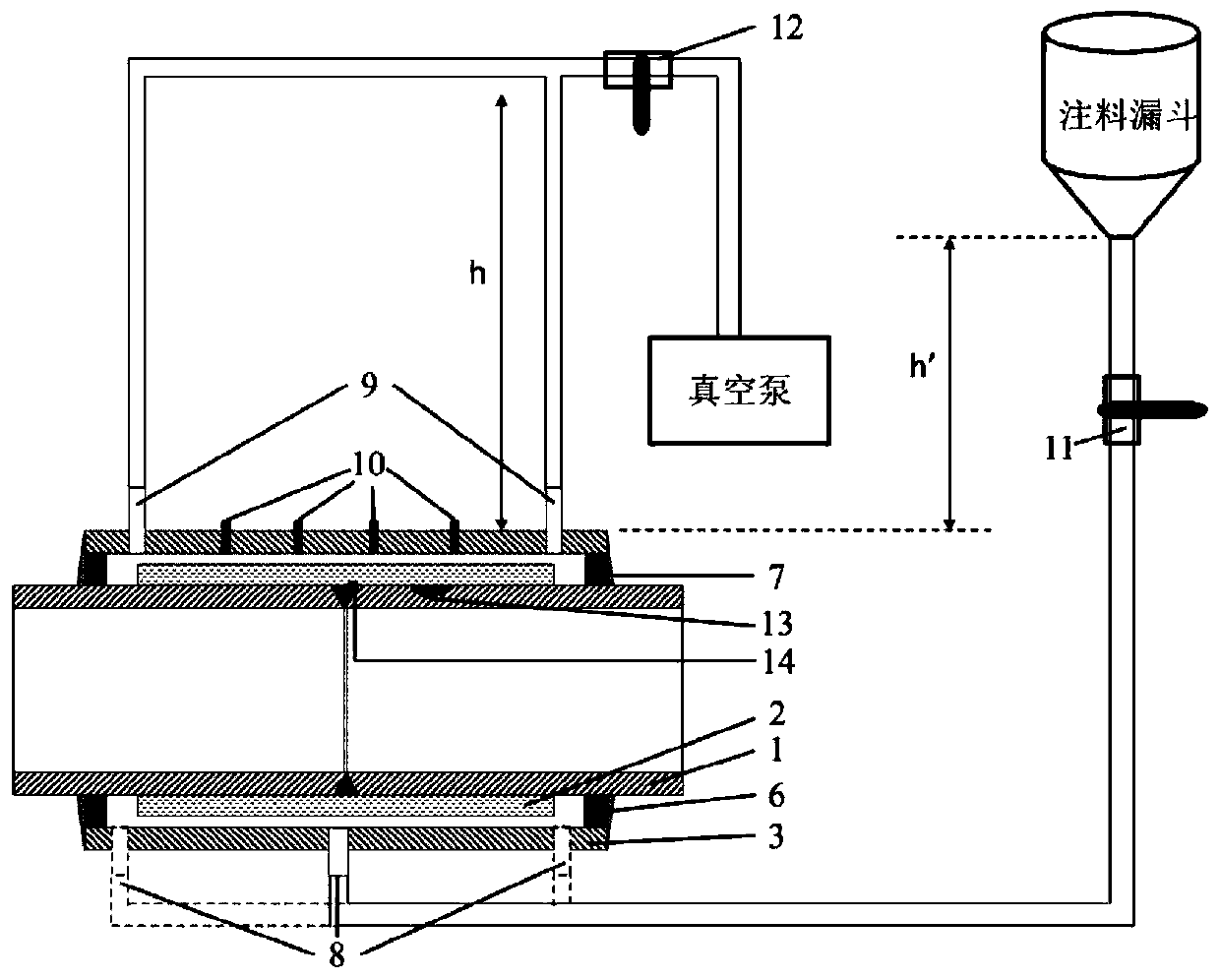

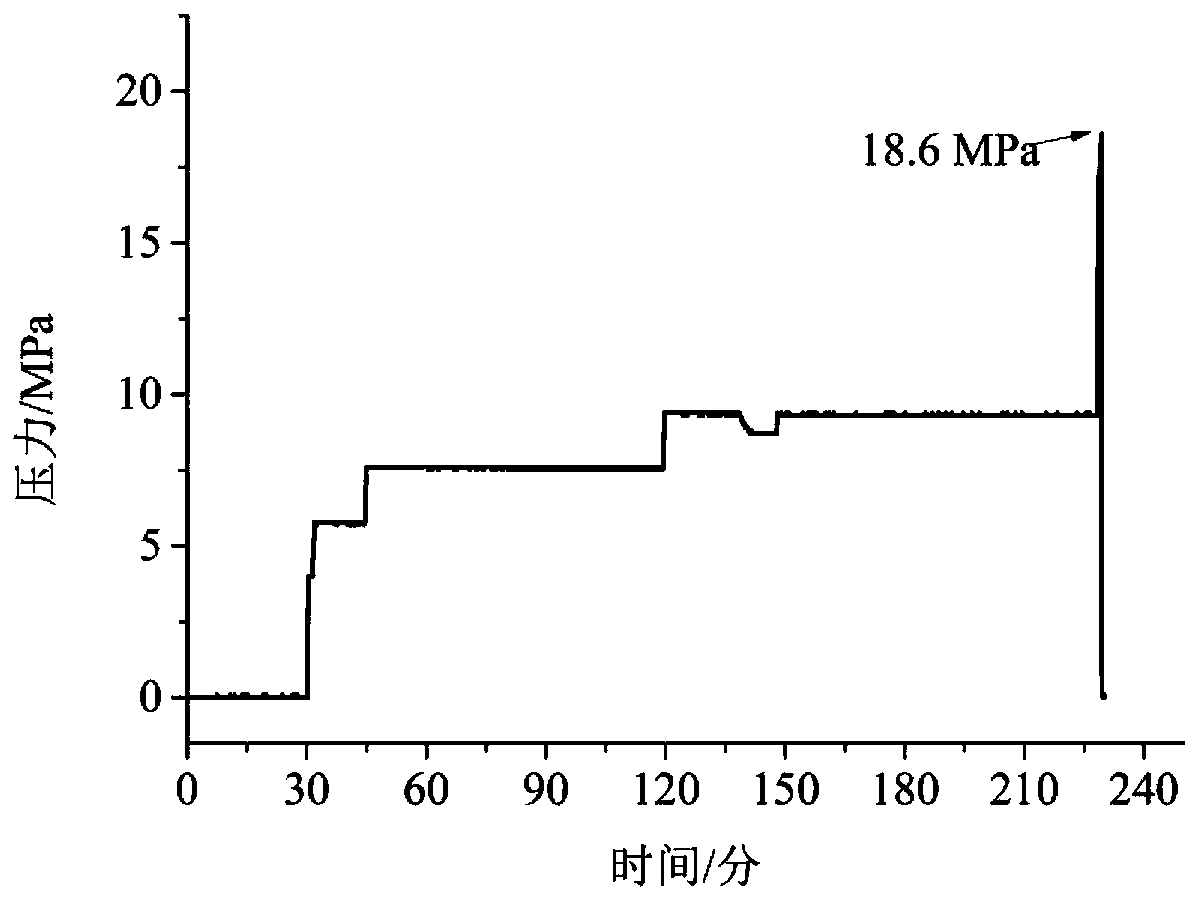

Device and technology for repairing pipeline circumferential weld defects through epoxy steel sleeve

The invention discloses a device and technology for repairing pipeline circumferential weld defects through an epoxy steel sleeve. The device comprises the composite epoxy steel sleeve, a vacuum pumpand a colloid filling device. The steel sleeve is arranged on the outer side of a to-be-repaired pipeline. Fiber cloth is wound around the outer wall of the to-be-repaired pipeline. A gap is formed between the fiber cloth and the inner wall of the steel sleeve. Sealing bodies are arranged between the inner walls of the two ends of the steel sleeve and the pipeline. Filling colloid is arranged in the gap among the steel sleeve, the to-be-repaired pipeline and the sealing bodies. A locating thread hole is formed in the steel sleeve in the radial direction. A vacuumizing opening / colloid overflowing opening and an exhausting / observing hole are formed in the top of the steel sleeve in the flowing direction of the colloid. The invention discloses a repairing technology. According to the device and the technology, the problems of tender cracking, curing bubble and cavities of filling resin of a traditional epoxy steel sleeve can effectively solved, good compatibility can be ensured between the composite epoxy steel sleeve and a steel pipe body, the circumferential load and the axial load borne by pipeline circumferential weld are shared, and axial cracking of the circumferential weld defects is restrained.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Diphenylmethane diisocyanate monomer addition product capped by methyl ethyl ketoxime and preparation method thereof

InactiveCN101941925ASimple processCreate pollutionCarbamic acid derivatives preparationOrganic compound preparationSolventEthyl acetate

The invention relates to a diphenylmethane diisocyanate monomer addition product capped by methyl ethyl ketoxime and a preparation method thereof, which is used for directly capping the diphenylmethane diisocyanate monomer by adopting a capping agent of the methyl ethyl ketoxime and avoiding bringing impurities to components by using the capping agent. The diphenylmethane diisocyanate monomer addition product capped by the methyl ethyl ketoxime is prepared from the following components in parts by weight: 15-30 parts of methyl ethyl ketoxime, 20-35 parts of diphenylmethane diisocyanate and 40-60 parts of ethyl acetate or xylene solvent. The preparation method comprises the following steps of: capping the isocyanate monomer under a certain condition by adopting the methyl ethyl ketoxime so as to obtain a closed isocyanate monomer addition product capable of stably existing at a room temperature. The closed isocyanate monomer addition product of the invention is used as a modified component of a self adhesive and can obviously improve the adhesion strength and the storage stability of the adhesive and prolong the shelf life.

Owner:HENAN SIWEI TECH

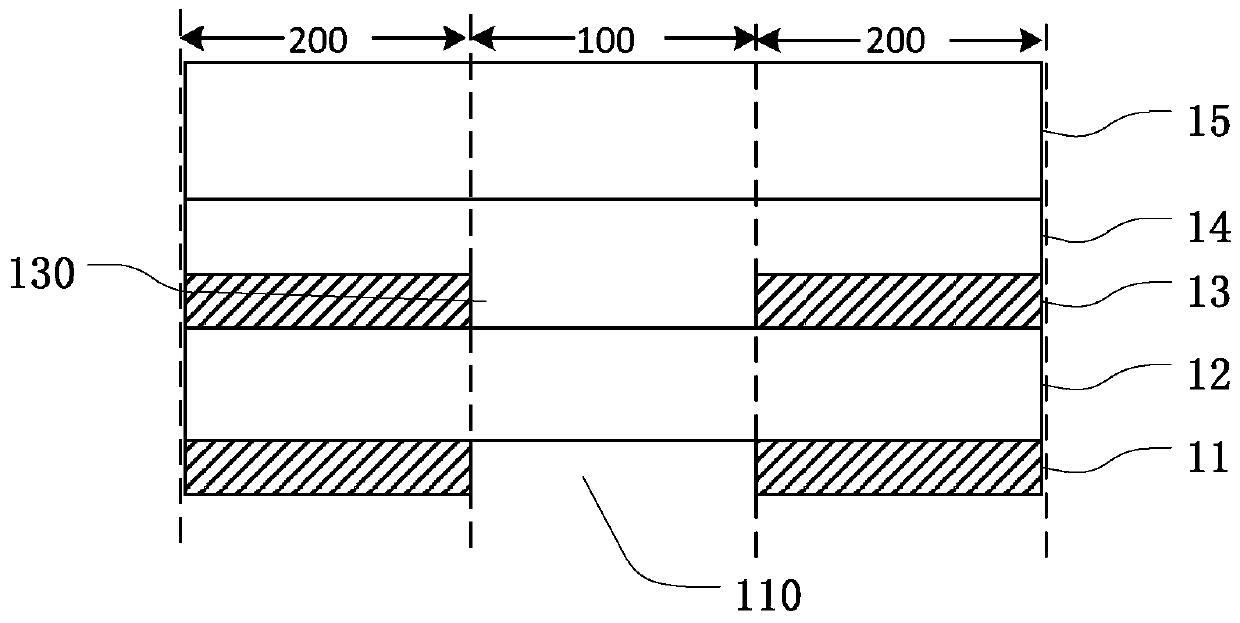

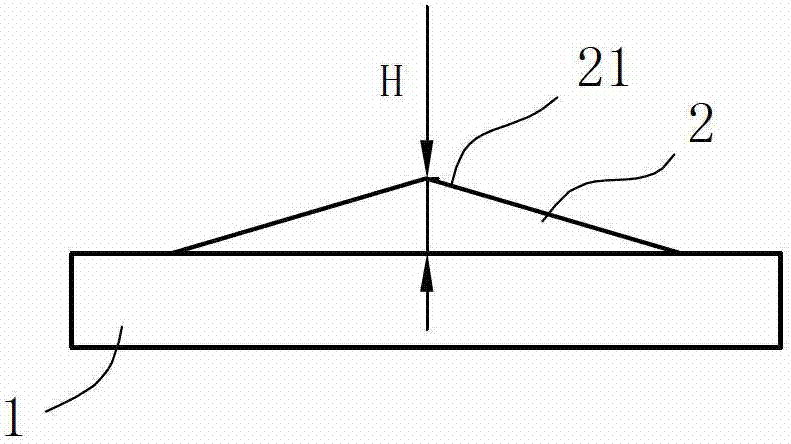

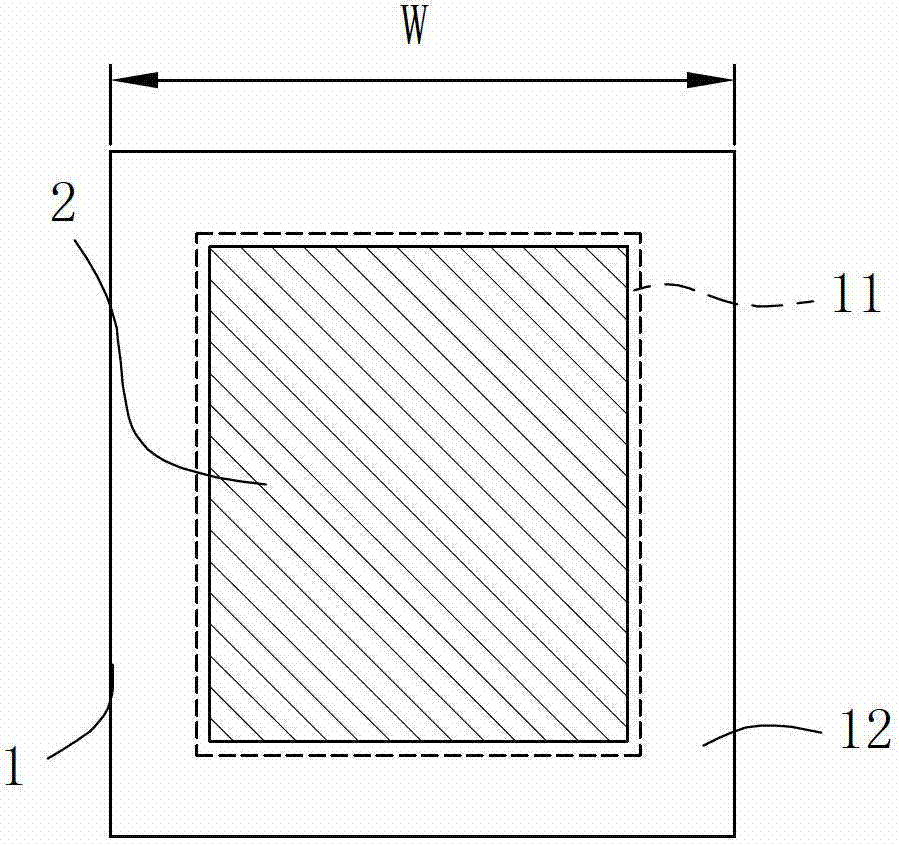

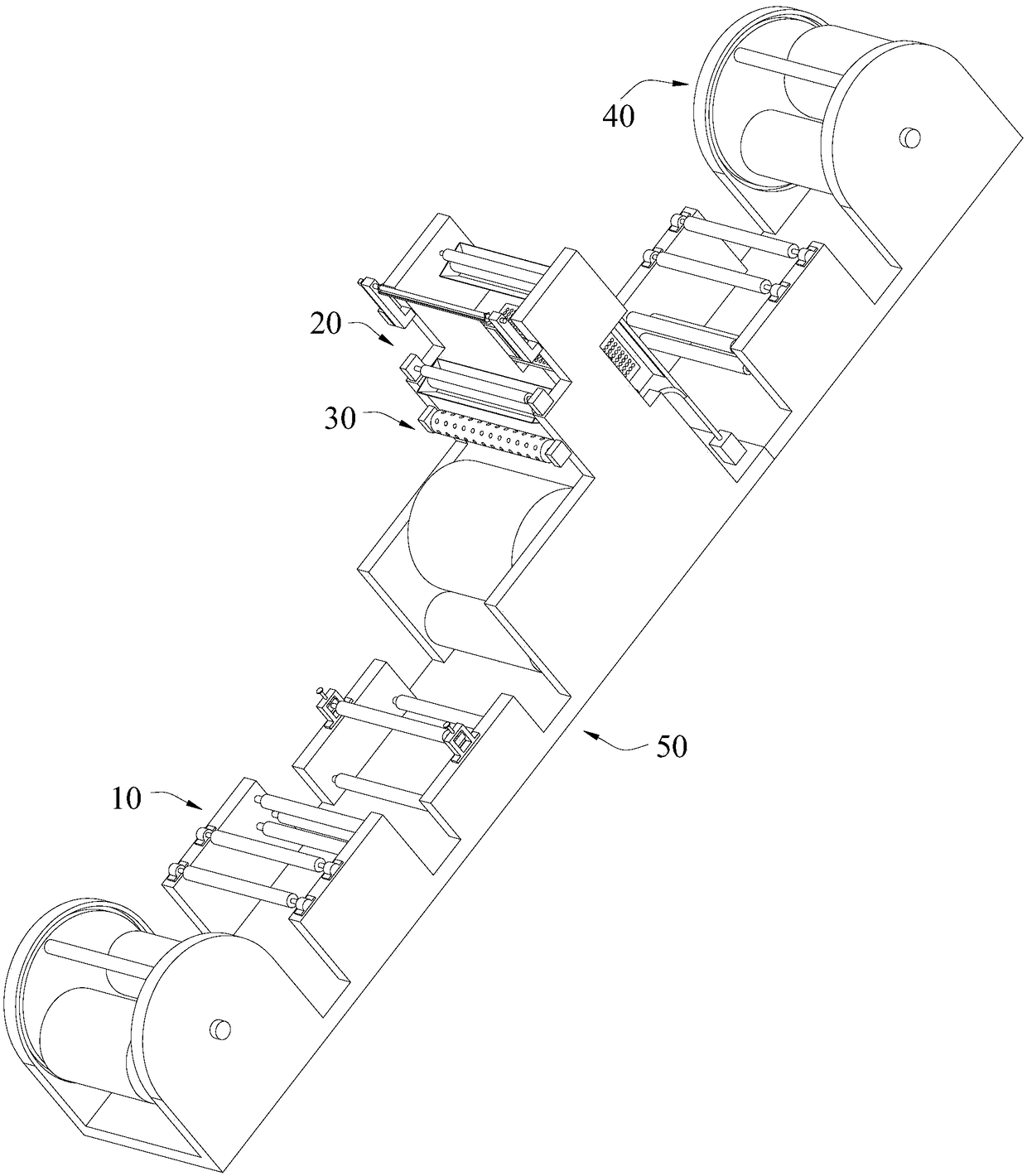

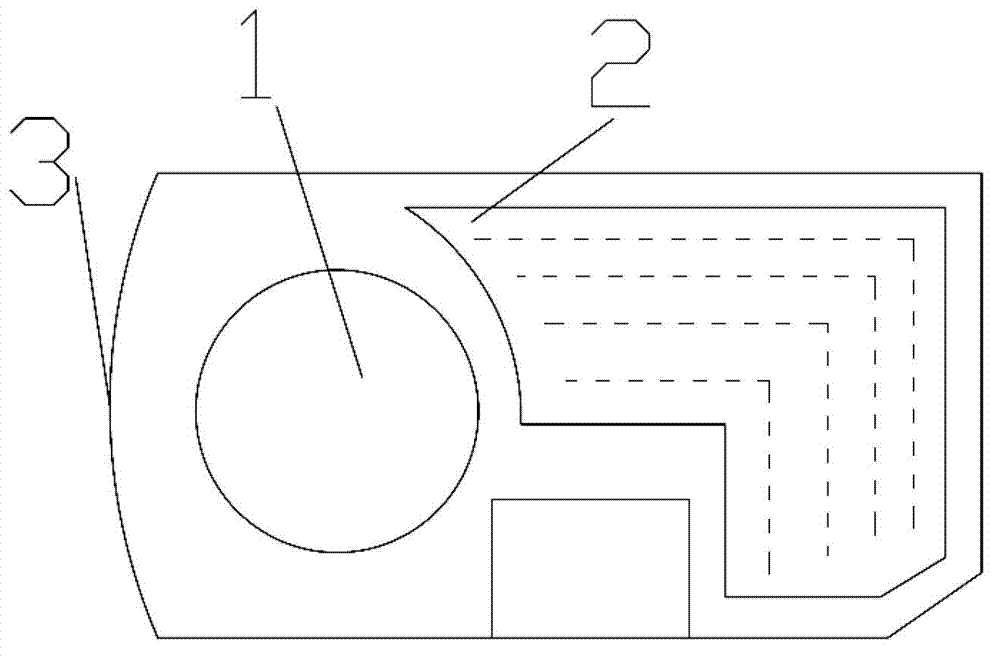

Rigid panel adhesion method and smearing module utilized thereby

InactiveCN102815080AAvoid air bubblesImprove fit qualityAdhesive processesLiquid surface applicatorsAdhesion processEngineering

The invention discloses a rigid panel adhesion method including a smearing step and a pressing step. The smearing step smears glue on a surface of a first rigid panel to form a glue layer. The glue layer has a single contact portion being in one-dimensional form of a dot or line. The glue layer has a coverage ratio of no less than 50% over the surface of the first rigid panel. The pressing step touches the contact portion of the glue layer with a second rigid panel, and slowly presses the first and second rigid panels together to discharge gases between the first and second rigid panels, thereby adhering the first and second rigid panels to each other and preferably the glue layer has a coverage ratio of 50% to 70% over the surface of the rigid panel. The rigid panel adhesion method can control the contact between glue and two rigid panels to prevent bubbles from forming during the adhesion process of the rigid panels, thereby improving the adhesion quality and product yield rate.

Owner:METAL INDS RES & DEV CENT

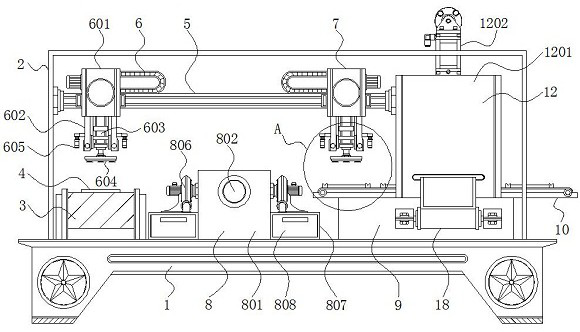

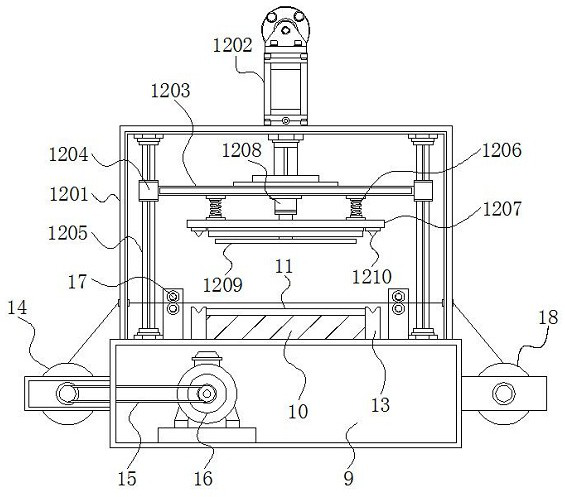

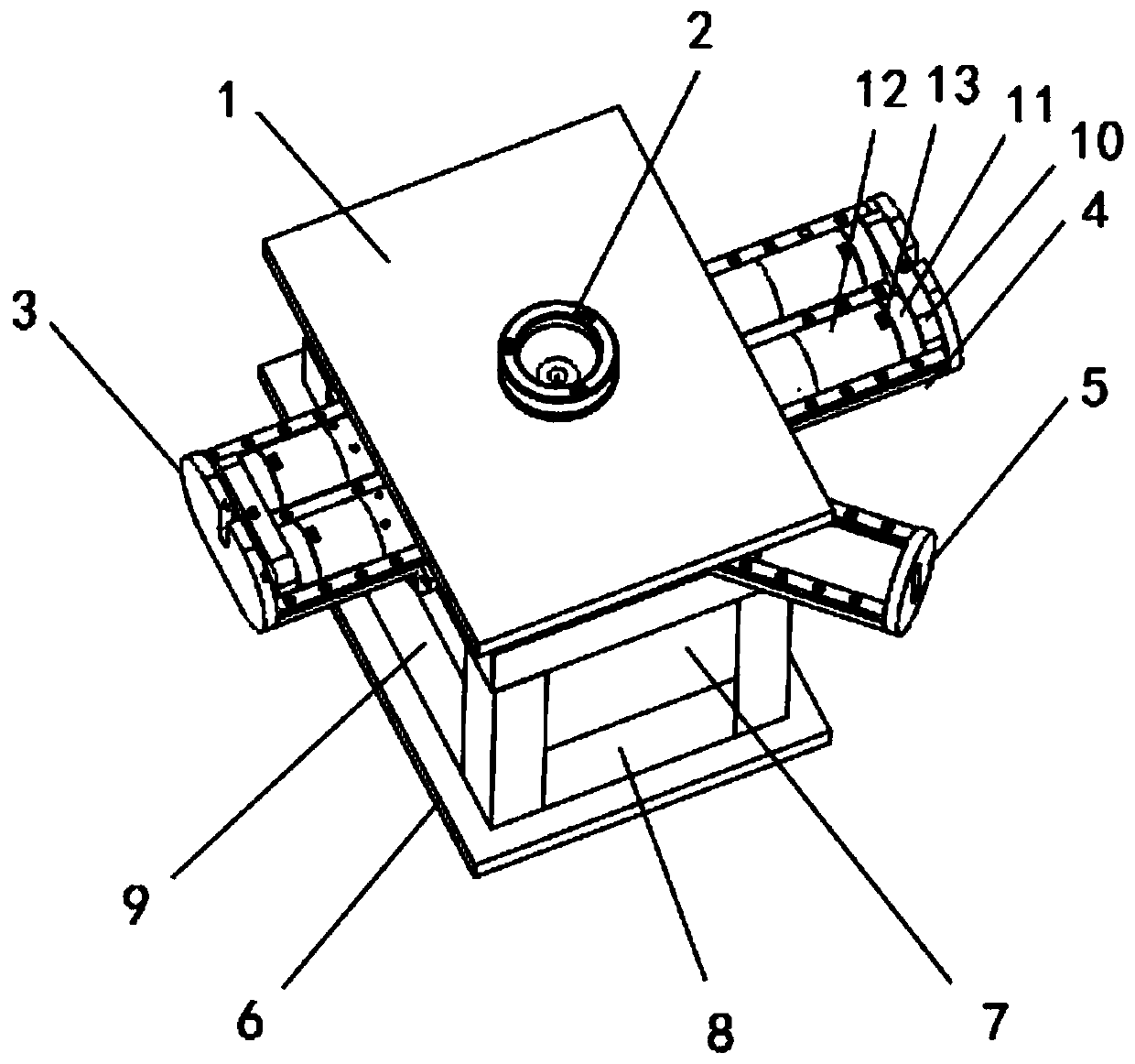

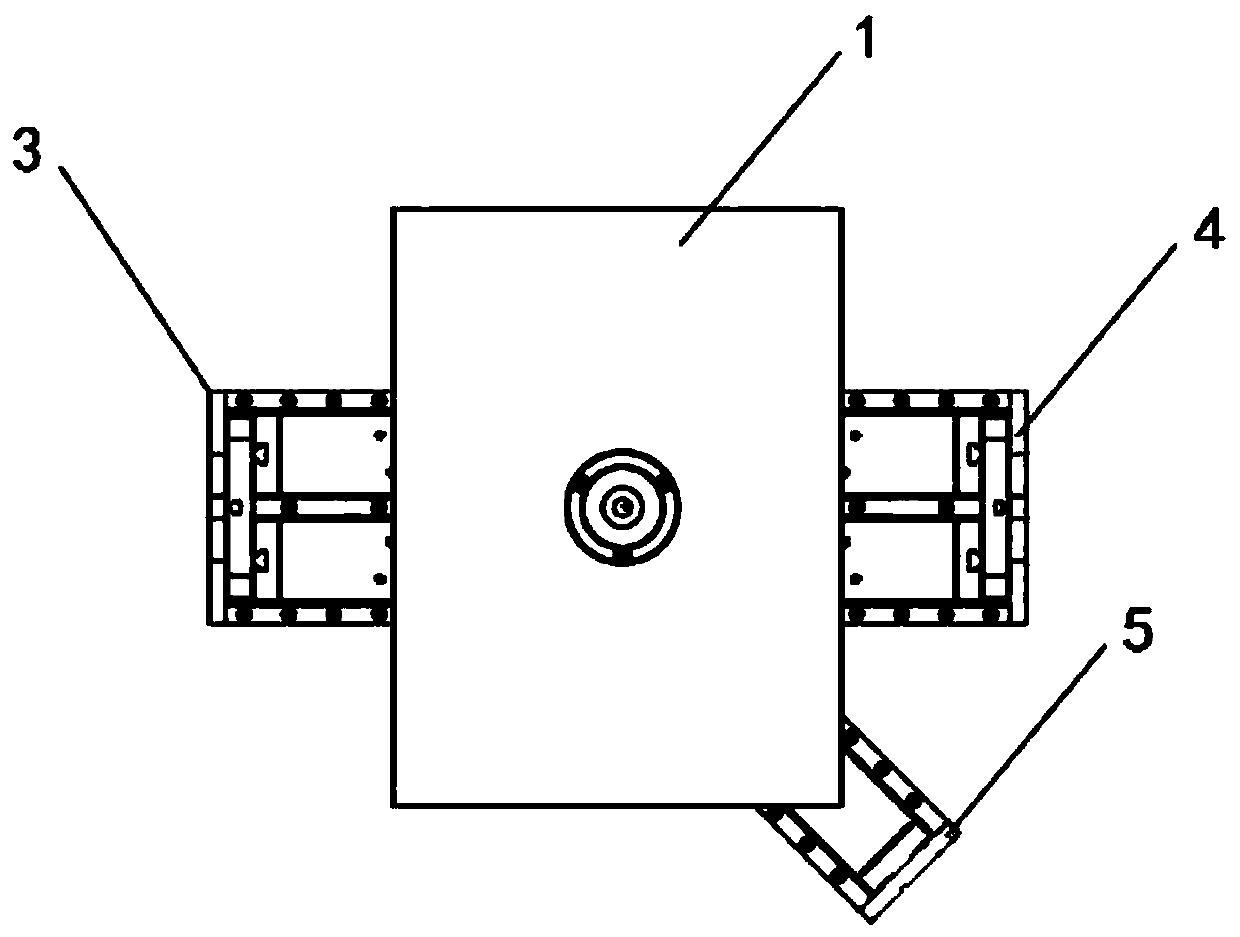

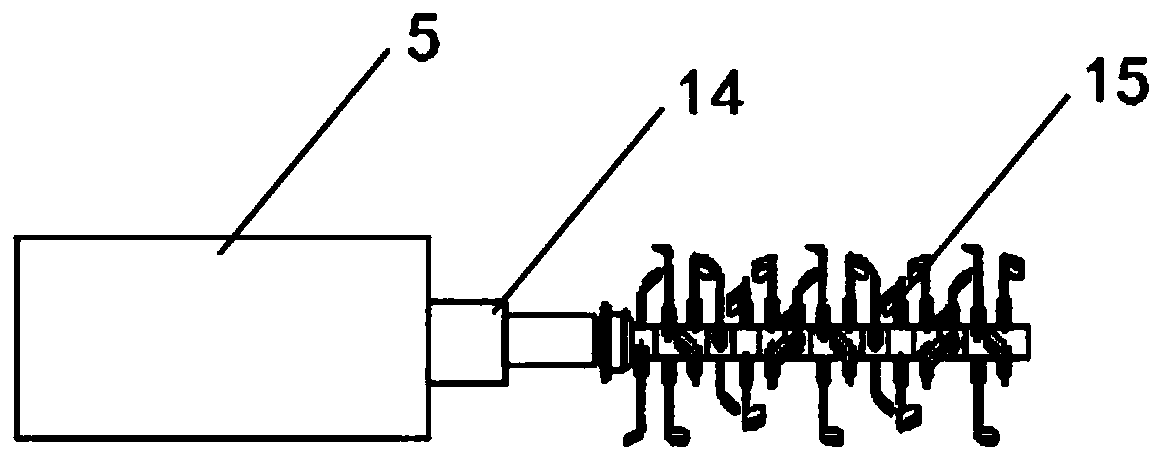

Electronic tag gluing mechanism and coating module

PendingCN109225765AQuality improvementImprove yield rateLiquid surface applicatorsCoatingsEngineeringMechanical engineering

The invention discloses an electronic tag gluing mechanism and a coating module. The electronic tag gluing mechanism comprises a gluing support, a first gluing apparatus, a second gluing apparatus anda glue storage apparatus, wherein the first gluing apparatus, the second gluing apparatus and the glue storage apparatus are separately arranged on the gluing support; the first gluing apparatus comprises a first gluing roller, a first viscose glue roller and a first glue storage hopper, the first glue storage hopper is arranged on the gluing support, the first glue storage hopper is provided with a first storage groove, two ends of the first viscose glue roller are respectively arranged on the inner side wall of the first storage groove, and the first gluing roller is arranged on the gluingsupport. A bottom material is twice glued, so that all the bottom material can be ensured to be coated with glue, the problem of incomplete lamination since the single gluing roller is lack of glue and cannot smear the glue onto the bottom material can be avoided, and the situation of bubbles when the bottom material and a surface material of an electronic tag are laminated can be avoided.

Owner:HUIZHOU HAOMING SCI & TECH

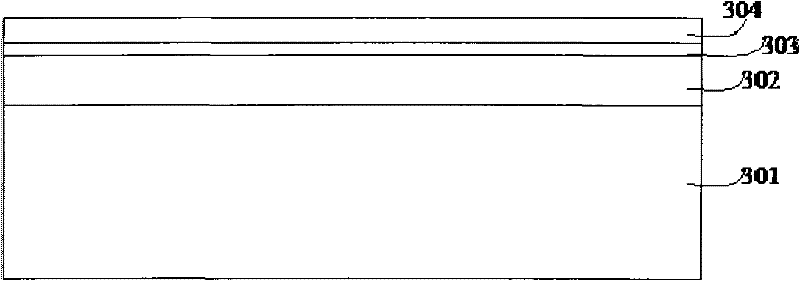

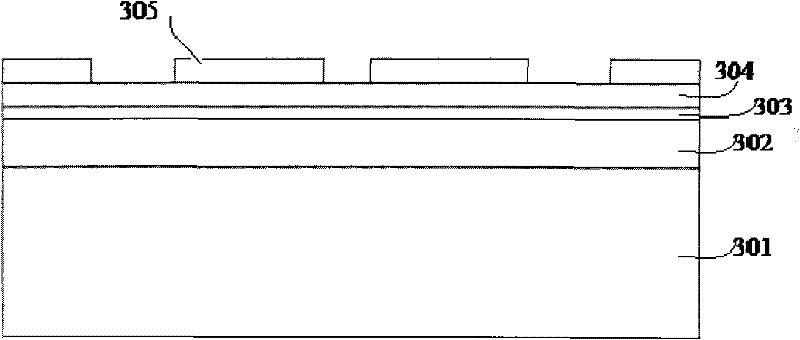

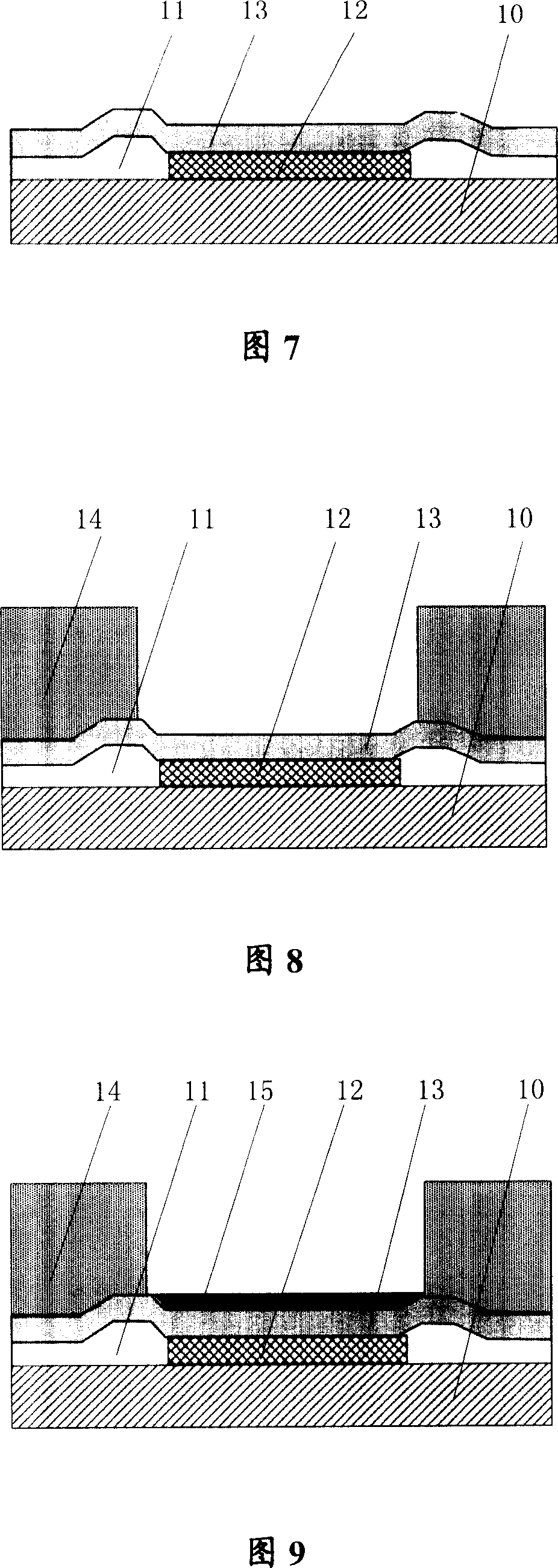

Manufacturing method of large-power vertical light-emitting diode

ActiveCN102544251AReduce the binding forceReduce difficultySemiconductor/solid-state device manufacturingSemiconductor devicesManufacturing technologyEngineering

The invention provides a manufacturing method of a large-power vertical light-emitting diode, relating to the technical field of a semiconductor photoelectric device. The manufacturing method disclosed by the invention comprises the following steps of: 1) generating an epitaxial wafer on a sapphire substrate; 2) evaporating a reflection metal layer on a P-type GaN-based semiconductor layer; 3) forming a current stopping layer on an N-electrode area and forming a protection type passivation layer on the side wall of a groove; 4) forming an isolation groove; 5) filling photoresist I into the isolation groove; 6) depositing a diffusion impervious layer on the surface of the device, electrically plating a seeding layer, etching to expose the diffusion impervious layer, and coating thick photoresist II; 7) forming a metal supporting layer above the device; 8) stripping the sapphire substrate from the device and cleaning; 9) roughening the surface and evaporating an N-type electrode; 10) cutting the device to from core particles; and 11) grinding and polishing the surface of the sapphire substrate. According to the manufacturing method disclosed by the invention, the stability of an LED (Light-Emitting Diode) in a vertical structure can be improved and the yield of the finished core particles is improved.

Owner:NANTONG TONGFANG SEMICON

Method for making lead and tin alloy protruding point

InactiveCN101123196AImprove welding effectAvoid the phenomenon of air bubblesSolid-state devicesSemiconductor/solid-state device manufacturingAlloyPhotoresist

The present invention provides a pewter bump manufacturing method comprising the following steps: to deposit an under bump metal layer on wafer; to form a photoresist layer on the under bump metal layer, and to form a photoresist opening by exposure and develop; to form a transitional pewter layer on the under bump metal layer located at the photoresist opening; to electroplate a wiping solder on the transitional pewter layer; to remove the photoresist and the under bump metal layer; to backflow the wiping solder to form pewter bump. The process of forming the transitional pewter layer is of an electroplating process, the electric current density is 0.1A / dm2 to 1A / dm2, and the time is 1-5 minutes. The density of the formed transitional pewter layer is 0.2um to 4um. The method of the present invention avoids bubble formation in pewter bump solder in electroplating process.

Owner:SEMICON MFG INT (SHANGHAI) CORP +1

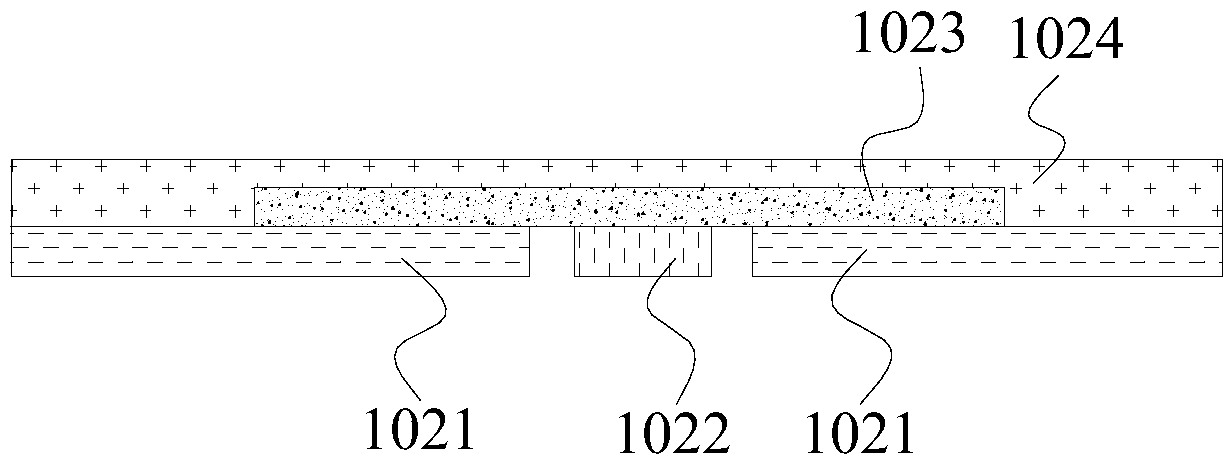

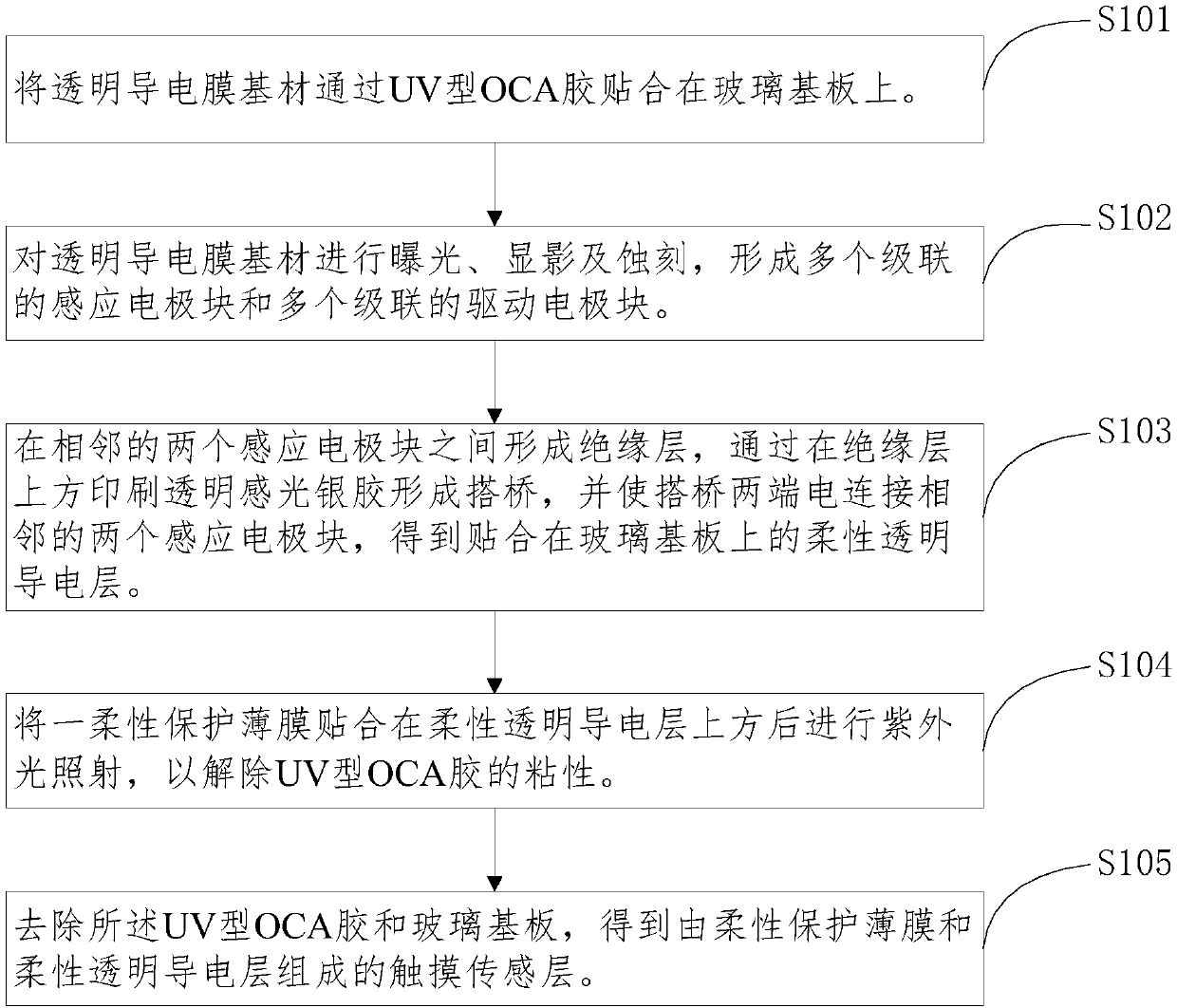

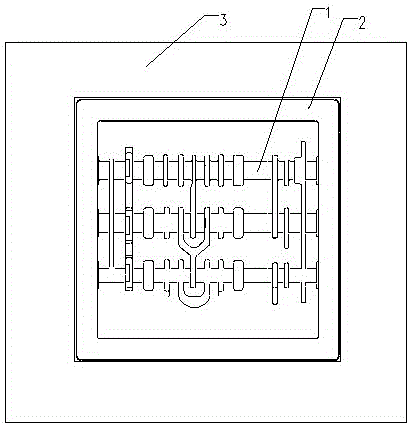

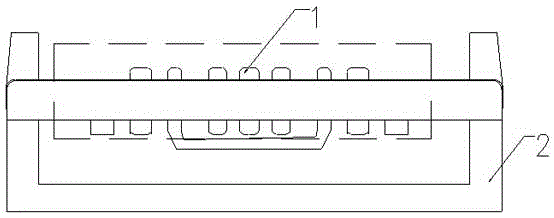

Touch sensitive layer and manufacturing method thereof

PendingCN107678587AReduce manufacturing costWiden perspectiveInput/output processes for data processingSilver pasteTouch Senses

The invention belongs to the field of a touch screen and relates to a touch sensitive layer and a manufacturing method thereof. The touch sensitive layer comprises a flexible transparent conductive layer and a flexible protective film adhere on the flexible transparent conductive layer; the flexible transparent conductive layer includes a plurality of induction lines, a plurality of driving circuits and a bridging structure; the induction lines include a plurality of cascaded induction electrode blocks; the driving circuits include a plurality of cascaded driving electrode blocks; the bridgingstructure is used for electrically connecting the adjacent induction electrode blocks and / or used for connecting the adjacent driving electrode blocks; and the bridging structure includes an insulation layer and a bridge formed by printing a transparent photo-silver colloid on the insulation layer. The touch sensitive layer adopts the transparent photo-silver colloid as the bridge, thereby greatly reducing the production cost. In addition, the touch sensitive layer is processed on a glass substrate, thus the processing difficulty of an ultrathin material in a yellow light manufacture procedure is overcome.

Owner:SHENZHEN JUNDA OPTOELECTRONICS

Manufacturing technology of oil inflow valve casting

InactiveCN104999040AStable structureHigh strengthFoundry mouldsFoundry coresManufacturing technologyEngineering

The invention relates to a manufacturing technology of an oil inflow valve casting. The manufacturing technology includes the steps that firstly, a metal mold plate required by an oil inflow valve is made of metal; secondly, the metal mold plate is heated to 180-280 DEG C; the metal mold plate is covered with molding sand which is hardened when being heated, and the molding sand is cured; the molding sand is heated and cured, and an upper shell mold and a lower shell mold are formed; four exhausting holes, a pouring gate and a boss are arranged on the shell molds; a riser runner is arranged in the boss; a water outflow groove is further arranged on the shell molds, and the four exhausting holes are connected into a whole through the water outflow groove and connected to the riser runner through the water outflow groove; a sand core of the an oil inflow valve is formed through chromite sand and fixed in the shell molds; and a cavity of the oil inflow valve is formed after the shell molds and the sand core are closed. The manufacturing technology has the beneficial effects that according to the technical scheme, due to the fact a main hole flow channel of the product is small and the exhausting holes cannot be arranged, the body riser runner must be arranged on the shell mold boss; the exhausting capacity is improved; and air holes are prevented.

Owner:南通华东油压科技有限公司

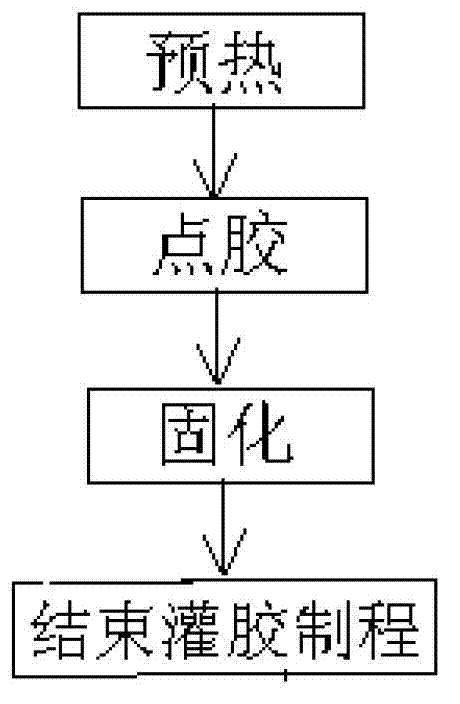

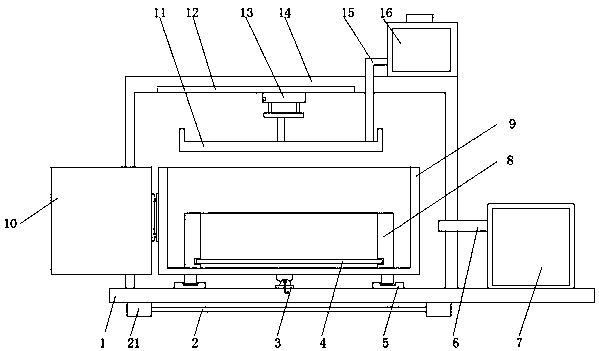

Glue filling process for tire pressure monitoring sensor

ActiveCN102784742AImprove glue filling production efficiencyAvoid air bubblesPretreated surfacesCoatingsReflow solderingEngineering

The invention discloses a glue filling process for a tire pressure monitoring sensor. The sensor comprises a power supply, a circuit board and an installation shell. A process for filling glue into the installation shell after the power supply and the circuit board are fixedly arranged on the installation shell comprises the following steps of: I, preheating: preheating the sensor; II, vacuumizing and preheating a rubber material: vacuumizing the rubber material required by glue filling, and preheating the rubber material; III, dispensing: placing the preheated sensor onto a glue filling stage, and dispensing by using the preheated rubber material; and IV, curing: placing the glue-filled sensor into a reflow soldering furnace for baking and curing to complete an entire glue filling process. The sensor is preheated and the rubber material is vacuumized and preheated before glue filling, and a secondary glue filling method and a way for baking and curing with the reflow soldering furnace are adopted during glue filling, so that the glue filling production efficiency is increased effectively, air bubbles produced in a glue filling process are avoided, an entire process is more stable and controllable, and a procedure is more concise.

Owner:SHANGHAI VEI SHENG AUTO PARTS MFG CO LTD

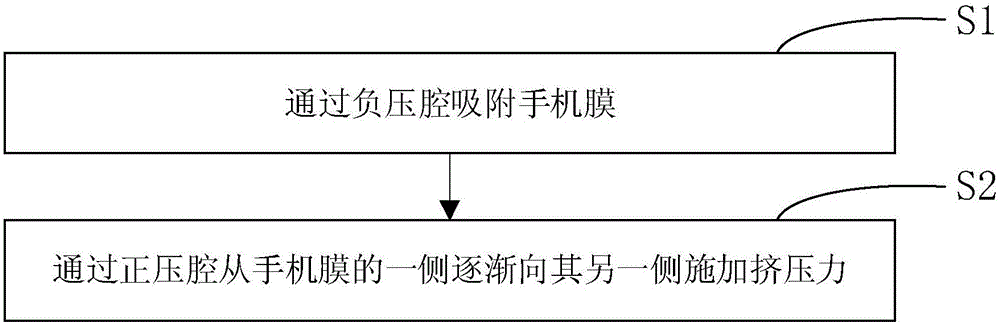

Working method of automatic film attaching device

The invention relates to a working method of an automatic film attaching device. The method includes the steps of S1, using a negative pressure cavity to suck a mobile phone film; S2, using a positive pressure cavity to gradually apply compression force from one side of the mobile phone film to the other side of the mobile phone film, that is to say, discharging gas between the mobile phone film and a mobile phone screen so as to allow the mobile phone film to tightly attach to the mobile phone screen. The automatic film attaching device has the advantages that the automatic film attaching device is provided with the low-pressure cavity and a sucking plate, the mobile phone film can be placed below one side of the low-pressure cavity, the mobile phone film is sucked by the through holes of a through hole face, fingerprints caused by hand contact can be avoided effectively, the mobile phone film sucked on the sucking plate on one side of the low-pressure cavity is gradually subjected to the pushing force of the high-pressure cavity through the gradual transition of negative pressure and positive pressure, bubbles are avoided, the mobile phone film is gradually compressed to the mobile phone screen, and film attaching is completed when the mobile phone film is separated from the low-pressure cavity and subjected to the action of the high-pressure cavity. By the automatic film attaching device, the film can be automatically attached to a mobile phone, manpower and material resources are lowered, and a good attaching effect is achieved.

Owner:HOHAI UNIV CHANGZHOU

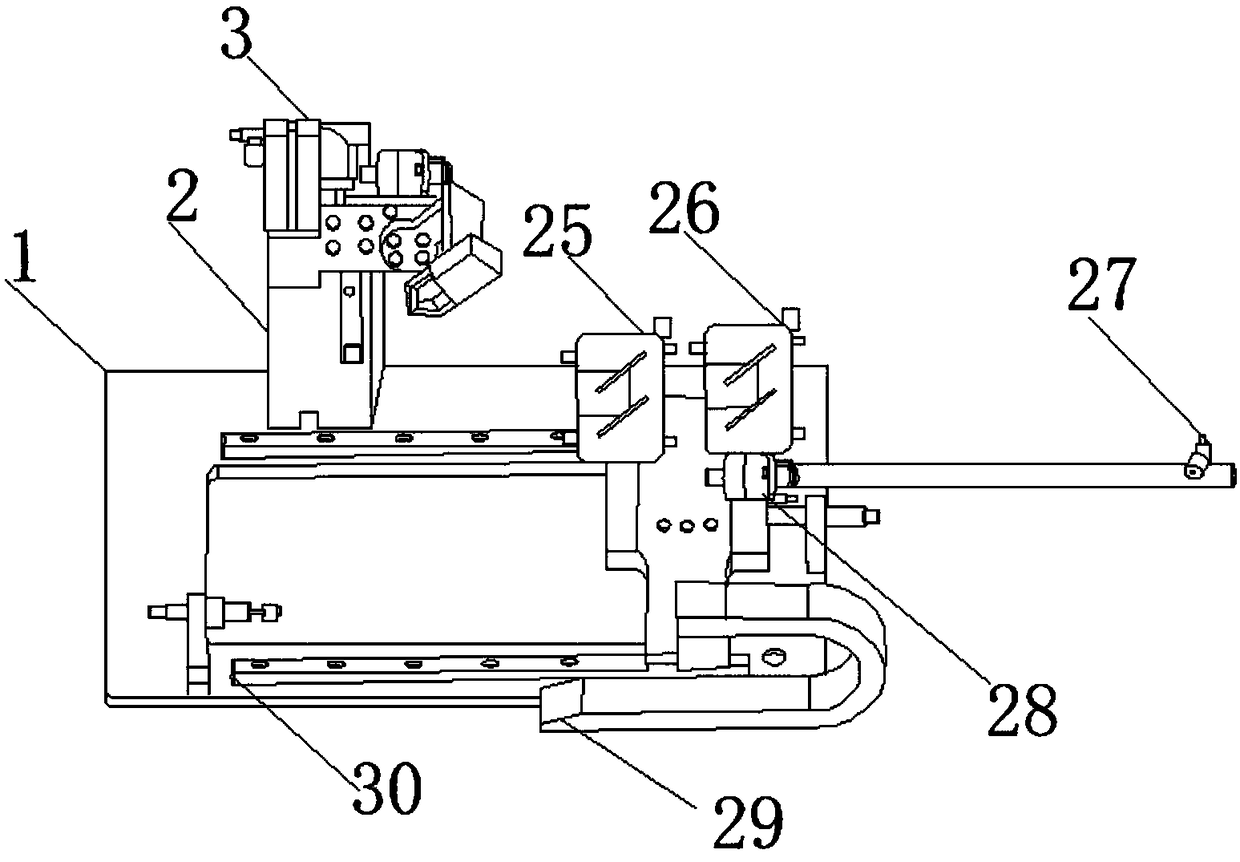

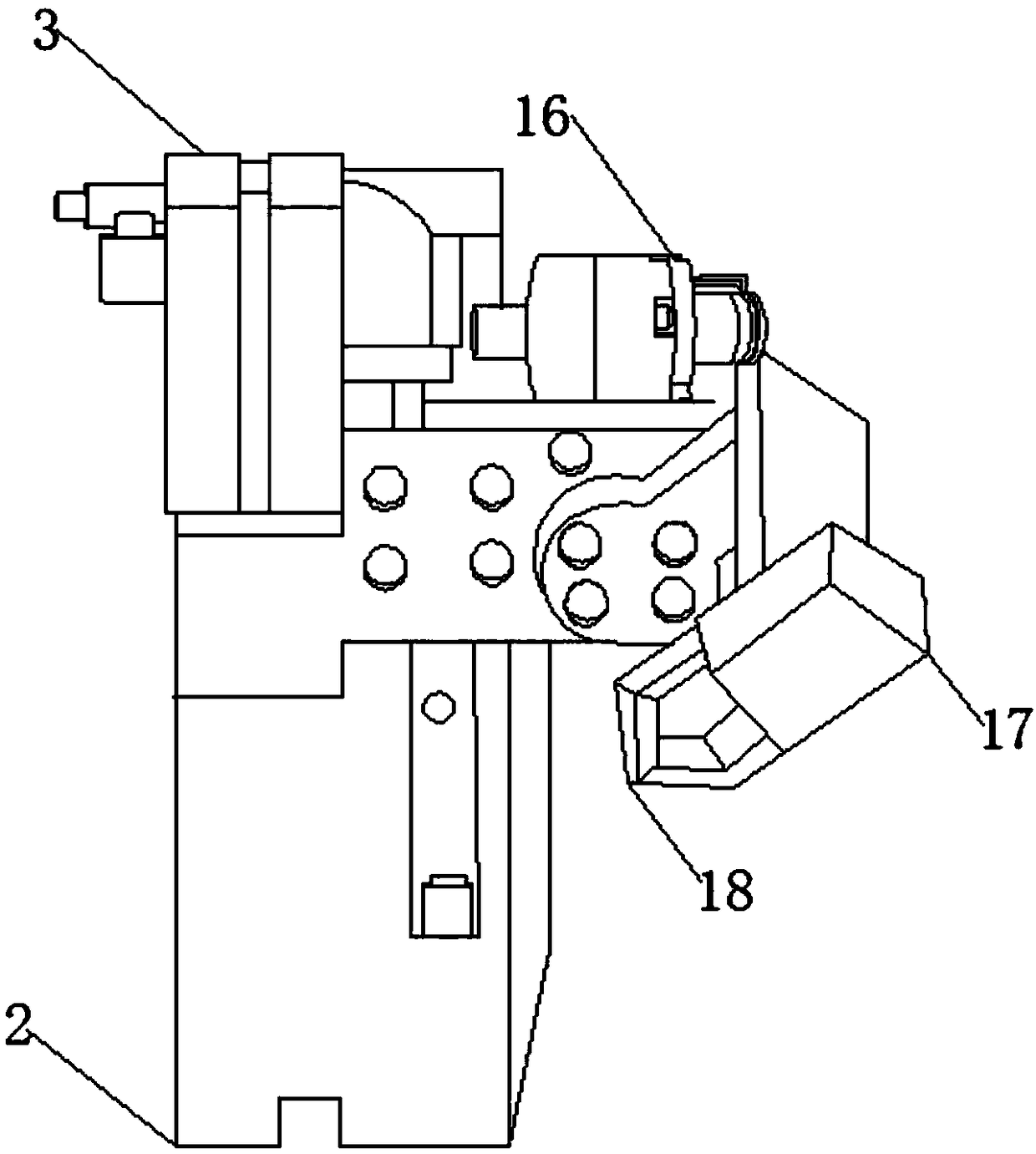

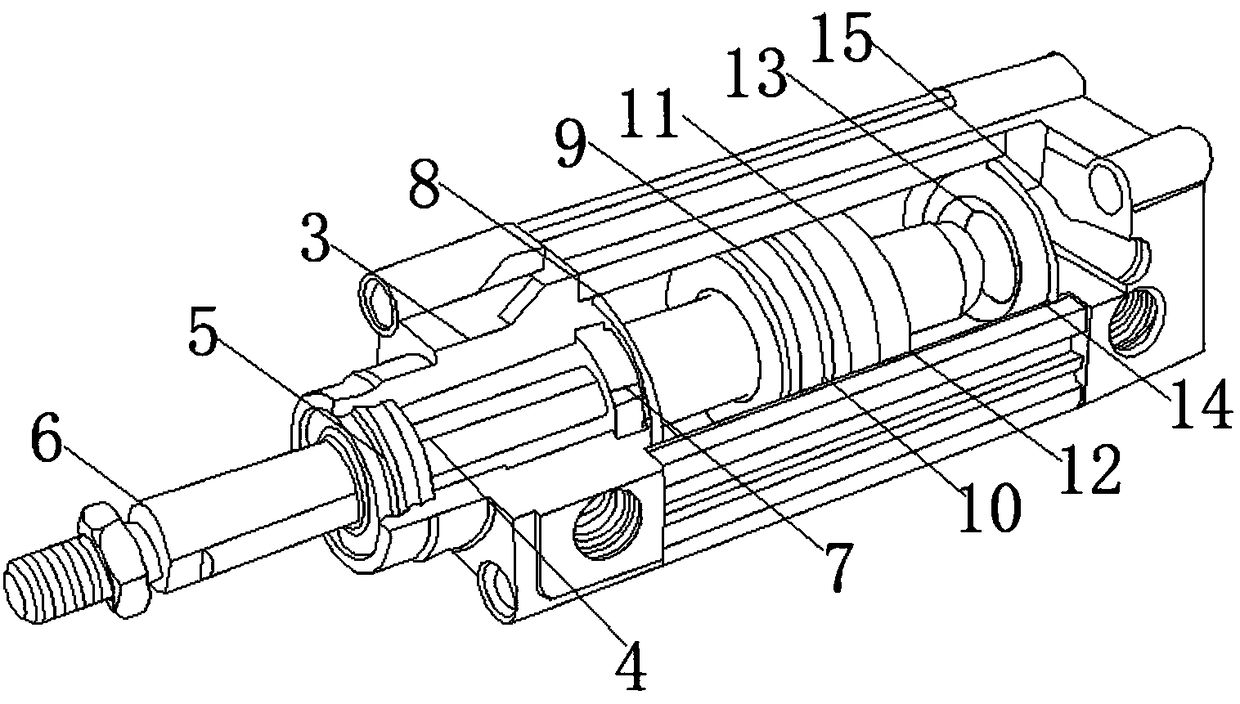

Automatic film tearing mechanism of manipulator

PendingCN108437605ALow costAvoid air bubblesLamination ancillary operationsLaminationPistonWear resistant

The invention discloses an automatic film tearing mechanism of a manipulator. The automatic film tearing mechanism of the manipulator comprises a base, wherein a mechanical column is fixedly mounted on the outer surface of one side of the upper end of the base; a film throwing lifting cylinder is fixedly mounted on the outer surface of the upper end of the mechanical column; a bearing is fixedly mounted in the center of the inside of the film throwing lifting cylinder; a plug rod sealing piece is fixedly mounted at the front end of the bearing; a plug rod is movably mounted in the center of the inner surface of the plug rod sealing piece; a buffer sealing ring is fixedly mounted on the outer surface of one side of the bearing; an end cap sealing ring is fixedly mounted on the outer surfaceof one side of the buffer sealing ring; a piston sealing piece is fixedly mounted on one side of the end cap sealing ring; a piston is fixedly mounted on one side of the piston sealing piece; a magnet is fixedly mounted on the outer surface of one side of the piston; and a wear-resistant ring is fixedly mounted on the outer surface of one side of the magnet. The film tearing mechanism is simple and practical, and is rapid and convenient, carrying films which are torn off are automatically collected in a waste box, a clamping end carries a film corner to finish film tearing, easily torn stickers are not required, and thus, costs are saved.

Owner:SHENZHEN NUOFENG OPTOELECTRONICS EQUIP

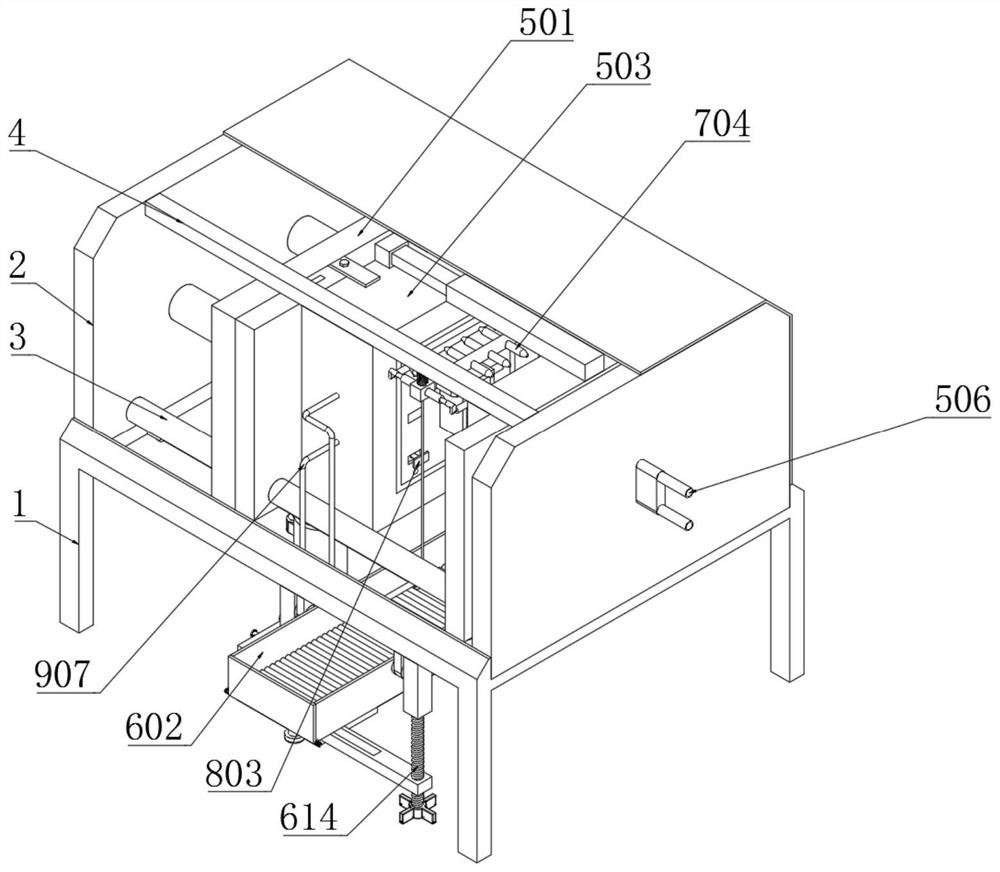

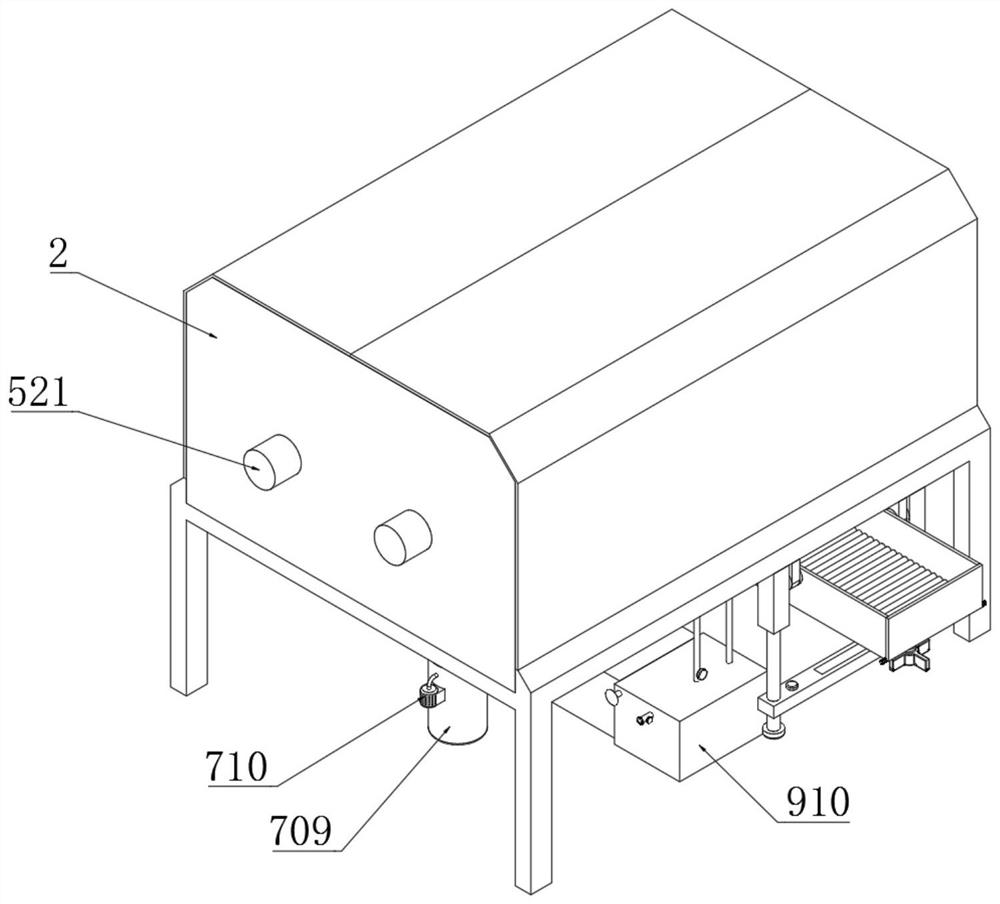

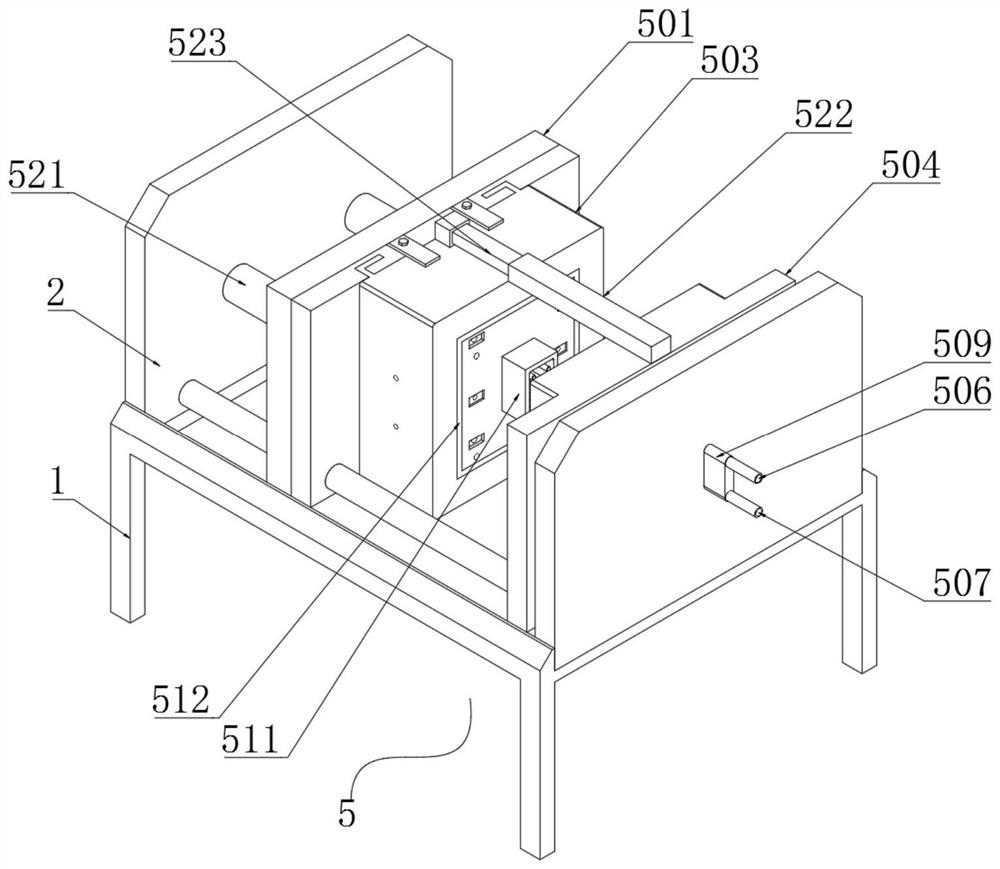

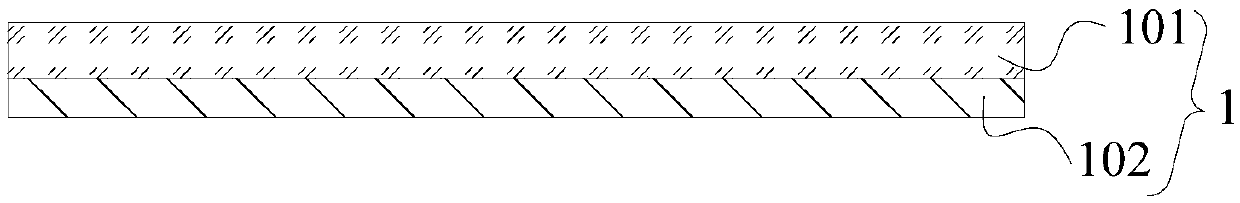

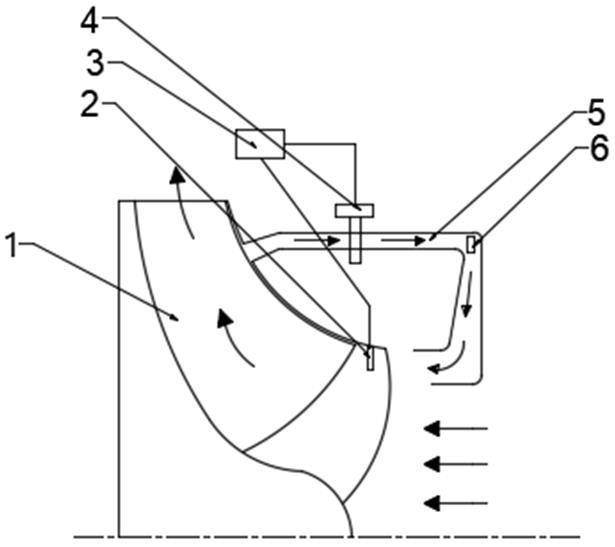

Self-circulation cavitation-preventing machine box suitable for centrifugal/mixed-flow type water pump

A self-circulation cavitation-preventing machine box suitable for a centrifugal / mixed-flow type water pump is characterized in that a backflow channel which guides high-pressure fluid on the rear portion of a water pump impeller into an inlet of the water pump is formed in the machine box so that the pressure intensity of the inlet of the water pump can be increased, and the pressure intensity ofthe fluid in the inlet of the water pump can be higher than the corresponding vaporization pressure to prevent vaporization from happening. An inlet of the backflow channel is formed in the rear portion of the water pump impeller, and an outlet of the backflow channel is formed in the inlet of the water pump. A temperature and pressure sensor is installed in the inlet of the water pump and used for detecting the pressure and the temperature of the fluid in the inlet to determine whether the pressure is equal to the saturated vapor pressure corresponding to the current water temperature or not.A valve is arranged in the backflow channel. According to the self-circulation cavitation-preventing machine box suitable for the centrifugal / mixed-flow type water pump, a backflow device is used, the high-pressure fluid on the rear portion of the impeller is jetted to the inlet of the water pump again through the backflow device, the pressure of the inlet of the water pump is improved, the phenomenon that the pressure of the fluid is equal to the vaporization pressure is avoided, the generation of vapor bubbles is avoided, and the influence of cavitation is fundamentally avoided.

Owner:TIANJIN UNIVERSITY OF TECHNOLOGY

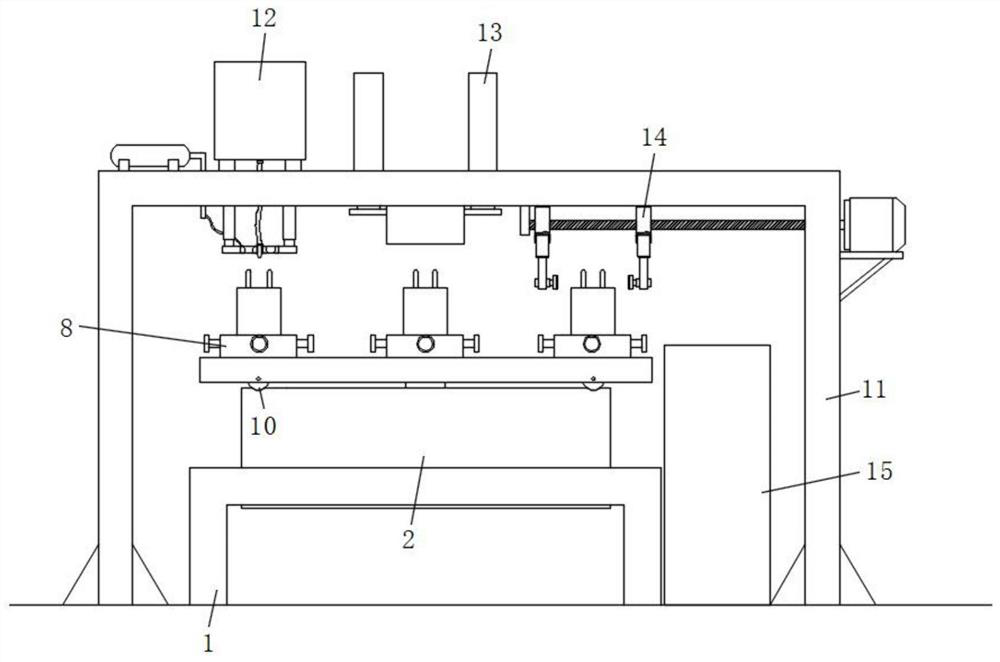

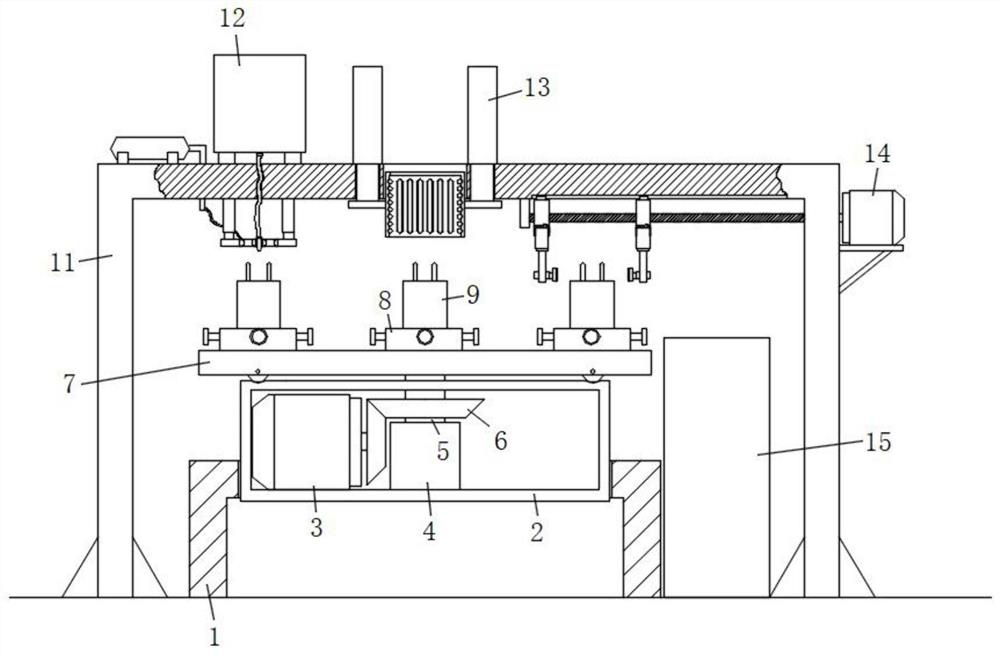

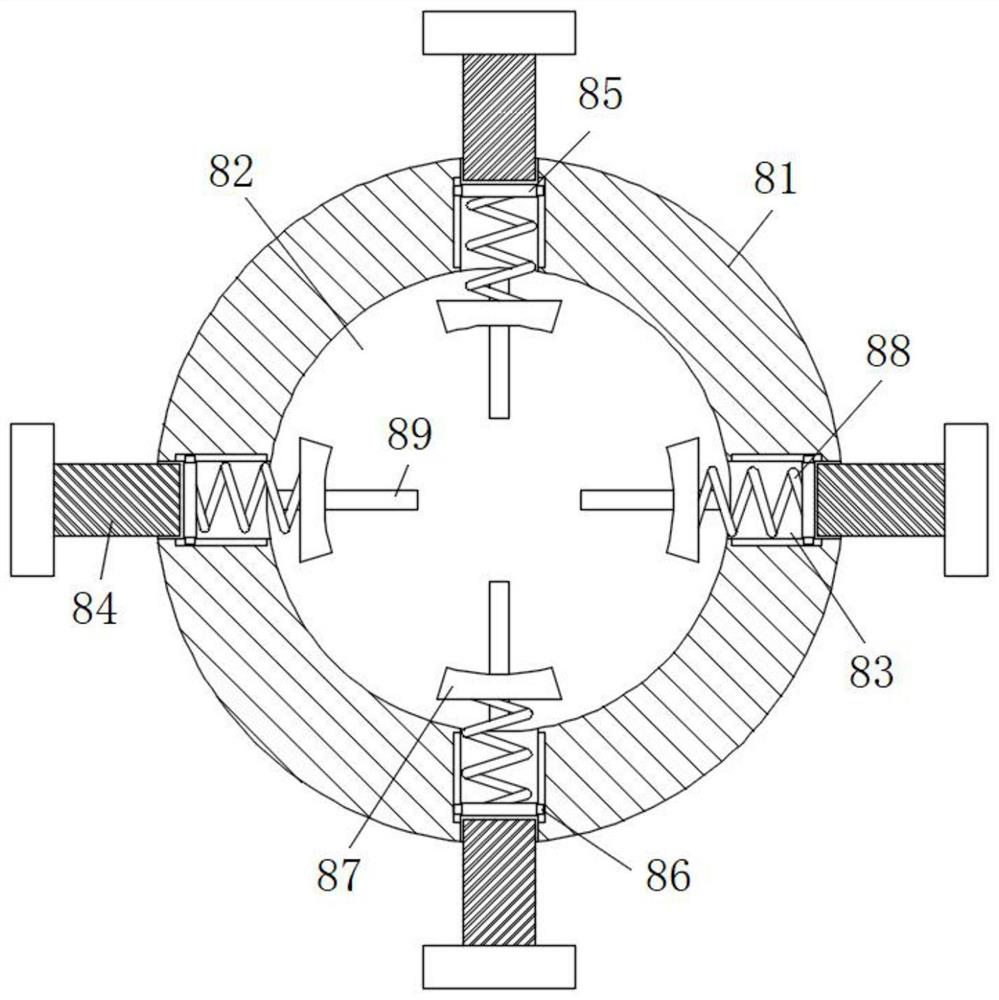

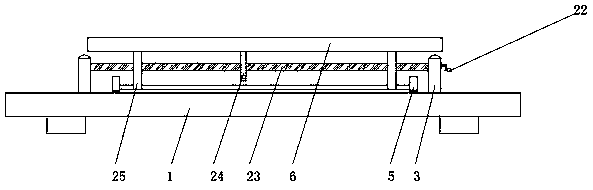

Packaging device for thin film capacitor production

ActiveCN113223875AImprove sealingReasonable designEncapsulating capacitors apparatusEngineeringStructural engineering

A packaging device for thin film capacitor production disclosed by the invention comprises a first mounting rack, wherein a mounting hole is formed in the top surface of the first mounting rack in a penetrating manner, a driving box body is fixedly connected to the inner wall of the mounting hole through a screw, a first servo motor is fixedly connected to one side of the inner bottom surface of the driving box body through a screw, a stabilizing column is further fixed to the center position of the inner bottom surface of the driving box body, a mounting column is rotationally connected to the top surface of the stabilizing column through a rolling bearing, the output end of the servo motor I is rotationally connected with the mounting column through a bevel gear set, the top end of the mounting column penetrates through the top surface of the driving box body and is fixedly connected with a rotating disc, a capacitor temporary fixing mechanism is fixed to the outer side of the top surface of the rotating disc, capacitor bodies are placed on the capacitor temporary fixing mechanisms, and a second mounting frame is erected on the outer side of the first mounting frame. The packaging device is reasonable in design, stable in device operation, high in filling efficiency and good in sealing effect during capacitor filling, and a certain guarantee is provided for high-quality preparation of capacitors.

Owner:ANHUI MASCOTOP ELECTRONICS

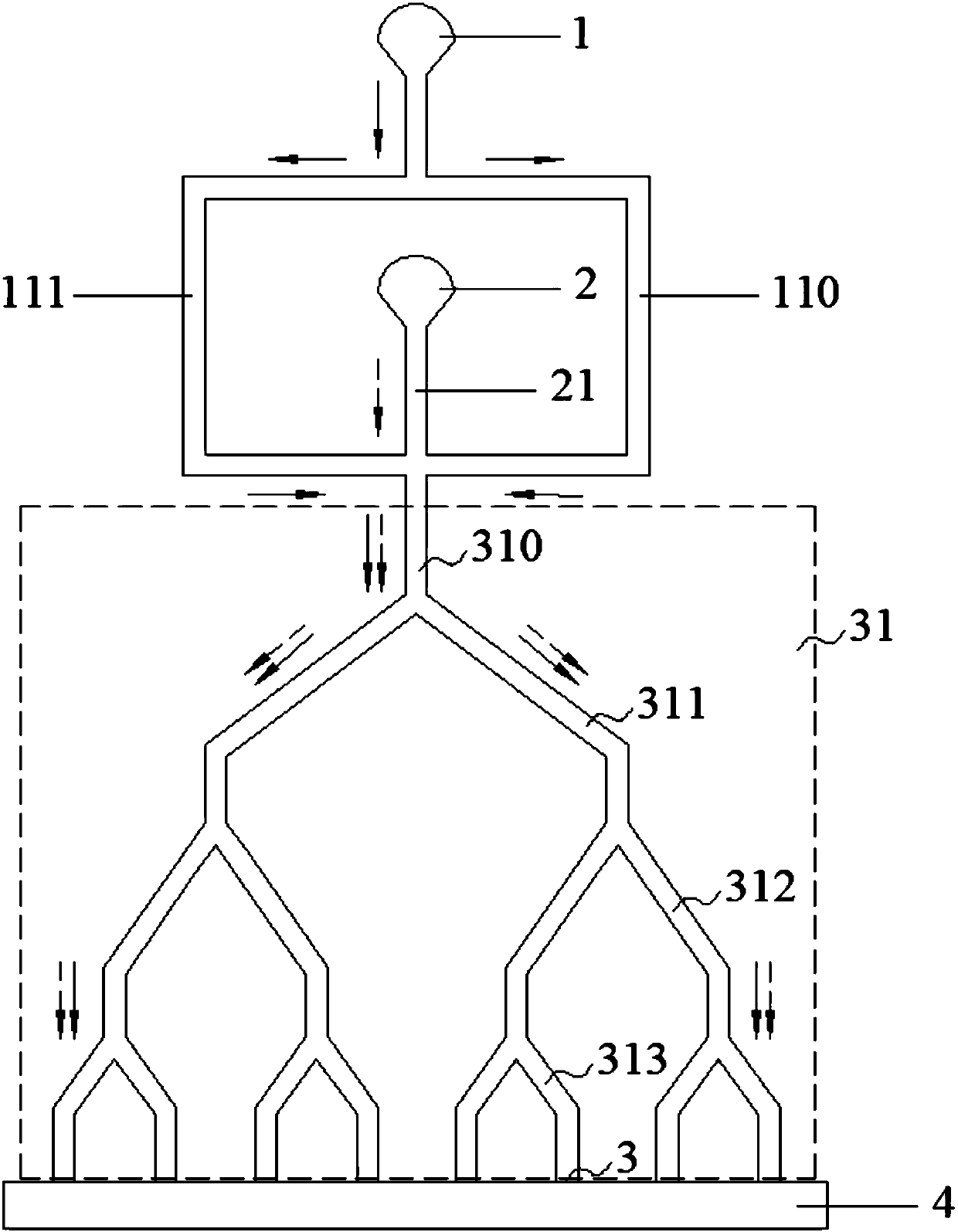

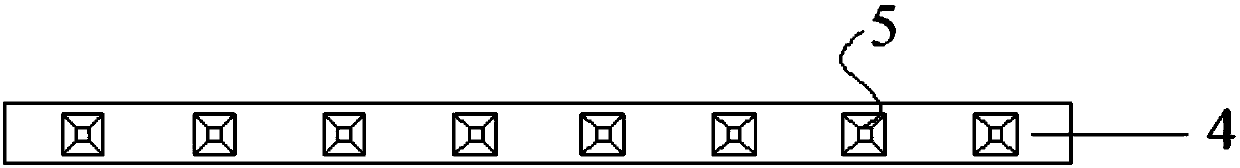

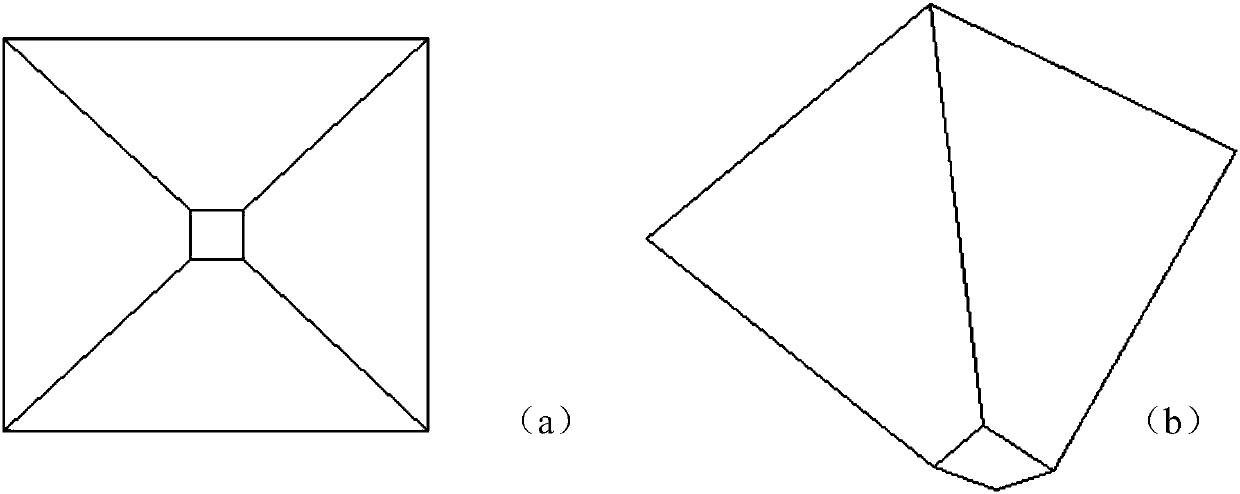

Filling liquid filling device and preparation method thereof, and filling method of electro-wetting filling liquid

The invention discloses a filling liquid filling device and a preparation method thereof, and a filling method of electro-wetting filling liquid. The preparation method of the filling liquid filling device is simple and efficient. When the filling liquid filling device prepared is used in the preparation process of an electro-wetting display device, electro-wetting display ink and polar liquid canbe filled at the same time to form filling liquid. The problem that oil filling and water filling need to be carried out separately in the traditional display device preparation process is solved. Byadjusting and changing the viscosity, surface tension, two-phase velocity and velocity ratio of two-phase fluid, the formation frequency and volume of filling liquid and the spacing between filling fluid can be controlled. Therefore, the generation of bubbles in the process of filling is avoided, and the electro-wetting display device prepared is of good repeatability.

Owner:SOUTH CHINA NORMAL UNIVERSITY

Film laminating device with display screen cleaning function and for laminating film on computer display screen

PendingCN113247348AEasy maintenanceTo achieve the effect of flippingPackaging automatic controlSynchronous motorEngineering

The invention discloses a film laminating device with a display screen cleaning function and for laminating a film on a computer display screen, and relates to the technical field of computer display screen machining. The film laminating device comprises a base, a cleaning mechanism and a film laminating mechanism, a placement frame is arranged at the position, close to the edge, of the upper end of the base, a feeding conveying belt is arranged on the left side of the upper end of the base, and a computer display screen body is placed at the upper end of the feeding conveying belt. The computer display screen body placed in a first transfer mechanism can be clamped through clamping assemblies symmetrically distributed on the two sides of a cleaning bin, the effect that the clamping assemblies drive the computer display screen body to turn over can be achieved in cooperation with an arranged synchronous motor, dust on the surface of the computer display screen body can be cleaned through cooperation with a cleaning palm brush vertically distributed in the center of the interior of the cleaning bin, lifting and rotating of the cleaning palm brush are achieved through an air cylinder and a motor arranged at the bottom, and the effect of cleaning the dust on the surface of the computer display screen body is achieved.

Owner:深圳市凤舞科技有限公司

Light concrete manufacturing method

InactiveCN111452185AFast manufacturingQuick mixFeeding arrangmentsAuxillary shaping apparatusFoaming agentClinker (waste)

The invention discloses a light concrete manufacturing method. Light concrete is obtained after slurry is poured into a die to be formed. The slurry is prepared by following components including, by weight, 300-400 parts of cement clinker, 150-180 parts of sand, 90-132.5 parts of water and 0.25-0.35 part of a foaming agent. The problems that according to an existing light concrete manufacturing method, in the usage process, the work efficiency is low, slurry is obtained after raw materials are mixed in the whole manufacturing process, the slurry needs to be conveyed and transferred into the die to be formed, on one hand, bubbles in the slurry are likely to be separated out, consequently, the quality of the formed light concrete does not reach the standard, on the other hand, time is wastedfor conveying and transferring, the slurry can be partially cured in the transferring process, consequently, the mass of the light concrete is greatly reduced, and meanwhile the existing light concrete manufacturing method cannot provide a manner method for freely switching modeling specification adjustment according to the actual requirements can be solved.

Owner:深圳市俊隆环保科技有限公司

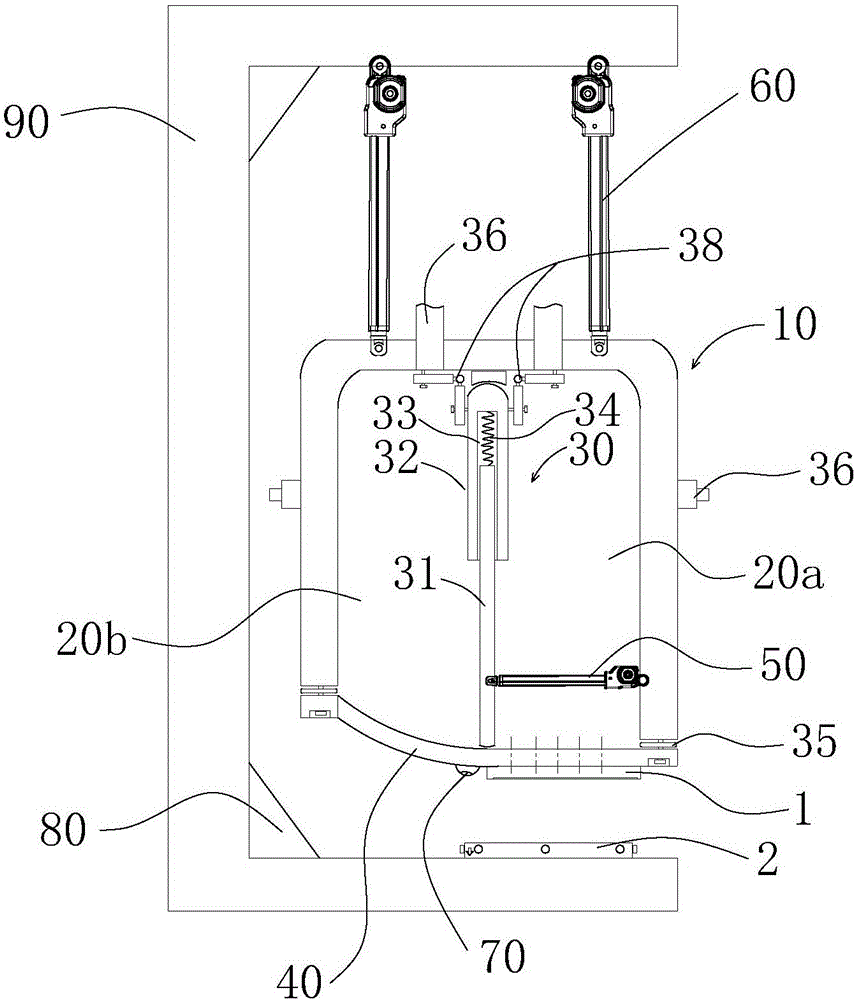

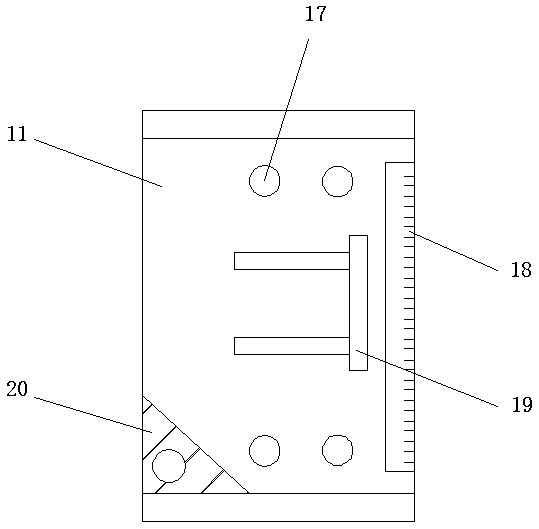

Glue pouring facility for household appliance

InactiveCN108380449AEasy to operateAvoid air bubblesLiquid surface applicatorsCoatingsFixed frameAir bubble

The invention provides a glue pouring facility for a household appliance, and relates to the field of mechanical equipment. The glue pouring facility for the household appliance comprises an operatingtable. Fixing blocks are fixedly connected with the bottom of the operating table. A fixing frame is fixedly installed on the top of the operating table, a sliding groove is formed in the inner wallof a top plate of the fixing frame, and an air cylinder and a glue pouring box are arranged inside the fixing frame. The sliding groove is connected with the air cylinder in a sliding mode through a sliding block arranged inside the sliding groove, a piston rod is fixedly connected with the output end of the air cylinder, and the air cylinder is fixedly connected with a glue guide plate through the piston rod. By the adoption of the glue pouring facility for the household appliance, the sliding groove is formed in the inner wall of the fixing frame, the air cylinder is driven by the sliding groove to slide, then the glue guide plate is driven by the air cylinder to move, and therefore operation is convenient, time and labor are saved, and the manual handheld operation is not required. Meanwhile, a vacuum pump is arranged, the air inside the fixing frame is extracted through a vacuum tube, a vacuum state is formed, and therefore the vacuum environment is provided for glue pouring, the phenomenon that bubbles exist in the glue pouring process is avoided, the sealing effect is improved, and the glue pouring quality is improved.

Owner:岳文智

Wear-resistant hydraulic hoist for controlling stable output of gate

InactiveCN108317131AAvoid air bubblesAchieve stable outputFluid-pressure actuator componentsPipingWear resistant

The invention relates to a wear-resistant hydraulic hoist for controlling stable output of a gate. The wear-resistant hydraulic hoist comprises a fuel tank, a hydraulic pump, a hydraulic cylinder, a cleaning mechanism, a water supply mechanism, a heat conducting ring and a drain pipe, wherein the cleaning mechanism comprises a cleaning disc, a rotating ring, a plurality of rotating assemblies anda plurality of cleaning assemblies; the water supply mechanism comprises a water storage tank, a filter screen, a first water pump, a water suction pipe, a water injection pipe, a second water pump, awater conduit and a water guide tube. The wear-resistant hydraulic hoist for controlling stable output of the gate absorbs heat of the heat conducting ring conveniently by continuously inputting a water flow into the drain pipe through the water supply mechanism, so that the temperature of the hydraulic cylinder is reduced, hydraulic oil is prevented from being heated to expand to generate air bubbles, and stable output of the equipment is achieved. Furthermore, oil dirt on the inner wall of the hydraulic cylinder is absorbed through the cleaning mechanism and the condition that dust enters the hydraulic oil to lead to wear of equipment parts as the hydraulic cylinder is infected with dust is avoided, the equipment operates safely and reliably, and the practicality of the equipment is improved.

Owner:SHENZHEN ANSIKE ELECTRONICS TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com