Touch sensitive layer and manufacturing method thereof

A fabrication method and technology of a sensing layer, which are applied to instruments, electrical digital data processing, and input/output processes of data processing, etc., can solve the problems of prone to breakage or bubbles, high cost, poor perspective, etc., to avoid folding. Effect of damage or bubble phenomenon, saving equipment cost and reducing production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

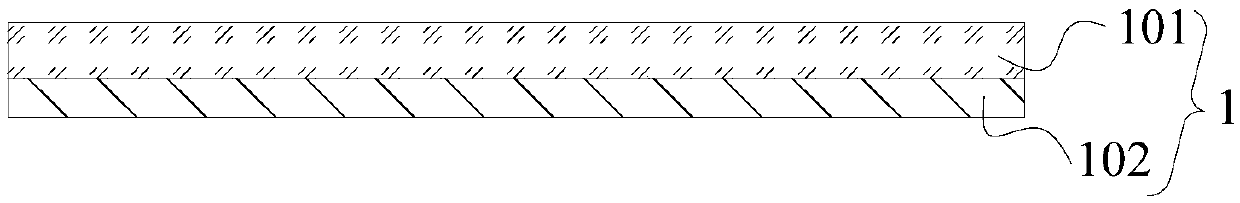

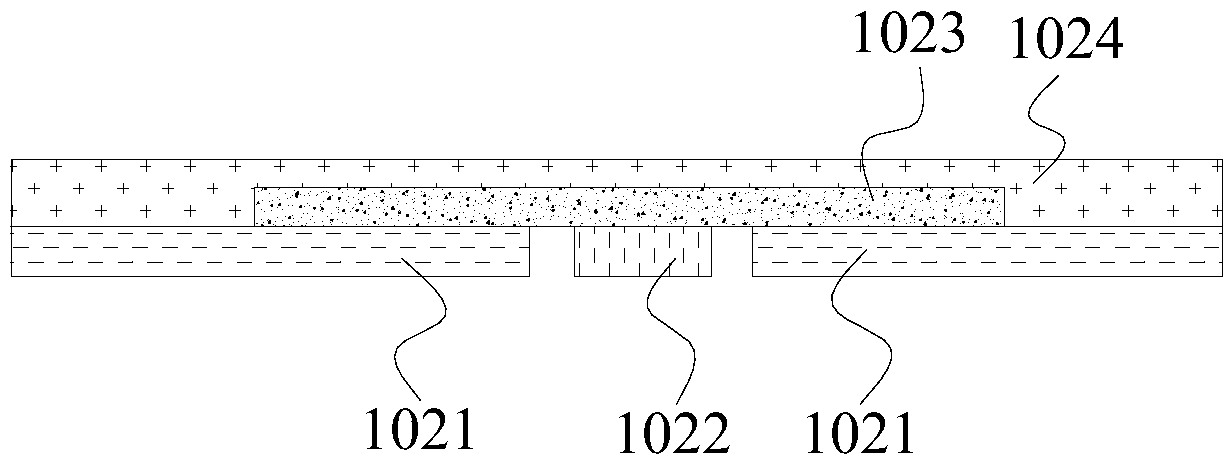

[0074] like figure 1 and figure 2 As shown, the touch sensing layer 1 provided by an embodiment of the present invention includes a flexible transparent conductive layer 102 and a flexible protective film attached to the flexible transparent conductive layer 102. The flexible transparent conductive layer 102 includes a plurality of sensing lines, a plurality of driving A circuit and bridge structure, a plurality of the sensing circuits extend along a first direction and are parallel to each other, a plurality of the driving circuits extend along a second direction and are parallel to each other, the first direction and the second direction are perpendicular to each other, so The induction circuit includes a plurality of cascaded induction electrode blocks (R X ITO) 1021, the drive circuit includes a plurality of cascaded drive electrode blocks (T X ITO) 1022, the bridge structure includes an insulating layer 1023 and a bridge 1024 formed by printing transparent photosensit...

Embodiment 2

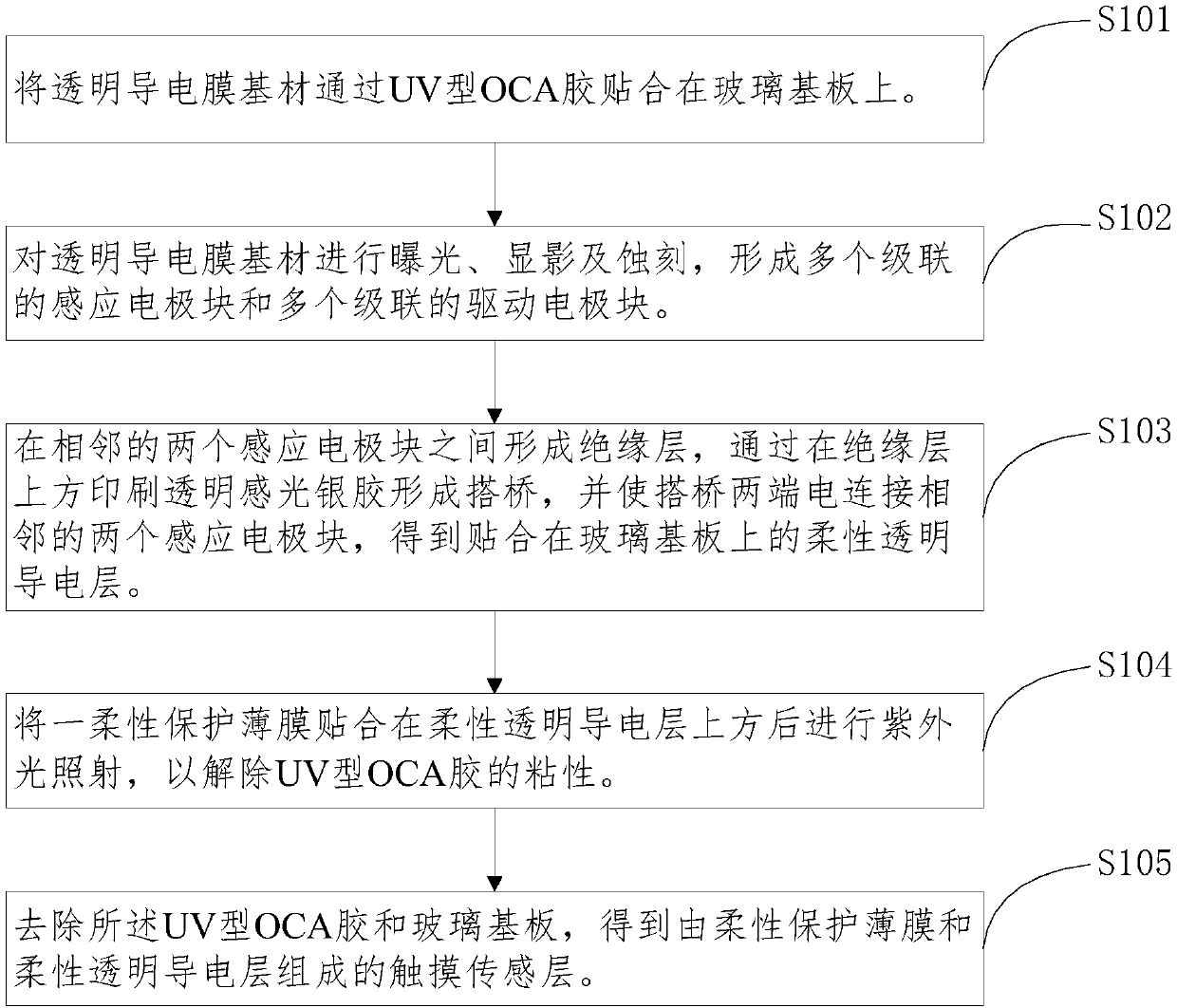

[0089] like image 3 As shown, an embodiment of the present invention also provides a method for fabricating a touch sensing layer, including the following steps:

[0090] S101, the transparent conductive film base material is pasted on the glass substrate through UV type OCA glue.

[0091] Specifically, a transparent conductive film substrate with a thickness of 23 μm was attached to the glass substrate with UV-type OCA glue.

[0092] Among them, UV-type OCA glue, as a combination of LOCA and OCA, has the advantages of two kinds of bonding materials, and thus improves their respective shortcomings. Specifically, the UV-type OCA adhesive has the advantages of LOCA that can be completely filled, and completely solves the problems of bubbles and late rebound caused by OCA lamination. The UV-type OCA glue also has the advantage of solid-state lamination of OCA, which eliminates the problem of LOCA glue overflow and eliminates the glue-wiping process. More importantly, UV-type ...

Embodiment 3

[0109] like Figure 4 As shown, the third aspect of the embodiment of the present invention provides a touch module, which includes a polarizer 3, a flexible circuit board (not shown), and the touch sensing layer 1 provided in the first embodiment. The touch sensing layer 1. The edge of the side formed with the flexible transparent conductive layer is printed with silver paste 2, and the side of the touch sensing layer 1 formed with the silver paste 2 and the polarizer 3 are bonded by the first optical glue 4, and the flexible transparent conductive layer is passed through. The silver paste 2 is electrically connected to the flexible circuit board. It can be understood that by attaching the polarizer 3, the silver paste 2 and the touch sensing layer 1, and electrically connecting the touch sensing layer 1 and the flexible circuit board, the composition has the touch sensor in the first embodiment. A touch module with all the beneficial effects of the sensing layer 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com