Display panel and preparation method thereof

A display panel and one-sided technology, applied in television, optics, instruments, etc., can solve problems such as insufficient absorption rate of OCA optical adhesive layer difference, air bubbles in the camera area, etc., to improve bonding yield, quality, and light transmittance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

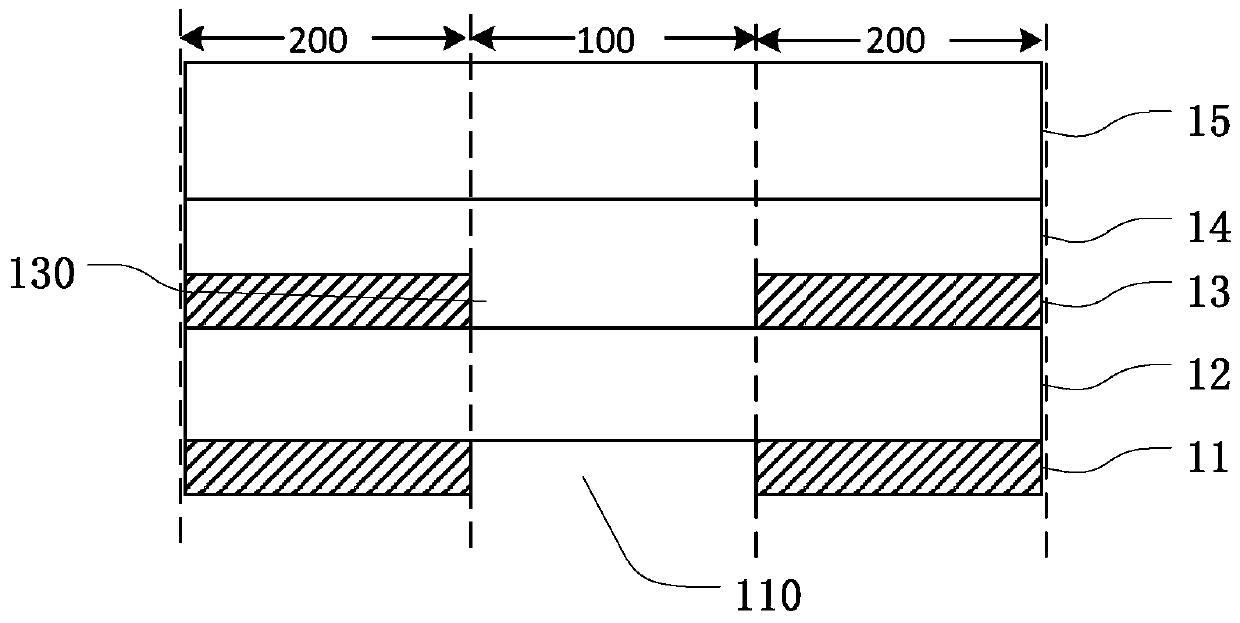

[0036] Such as figure 2 As shown, this embodiment provides a display panel, including an imaging area 10 and a display area 20 , and the display area 20 surrounds the imaging area 10 . The display panel includes a first substrate 21 , a first polarizer 22 , a liquid optical adhesive layer 23 , a cover plate 24 and a solid optical adhesive layer 25 .

[0037] The first substrate 21 is a color filter substrate, and generally includes a substrate, a black matrix (BlackMatrix, BM) and a color filter layer formed on the substrate. Wherein, the color filter layer includes a plurality of filter units of different colors, such as red, green and blue green light units formed by using red, green and blue photosensitive resins respectively, and the black matrix is used to define the space between each filter unit. In order to prevent light leakage between adjacent filter units, the edges of the filter units are usually overlapped on the black matrix, and each filter unit is not forme...

Embodiment 2

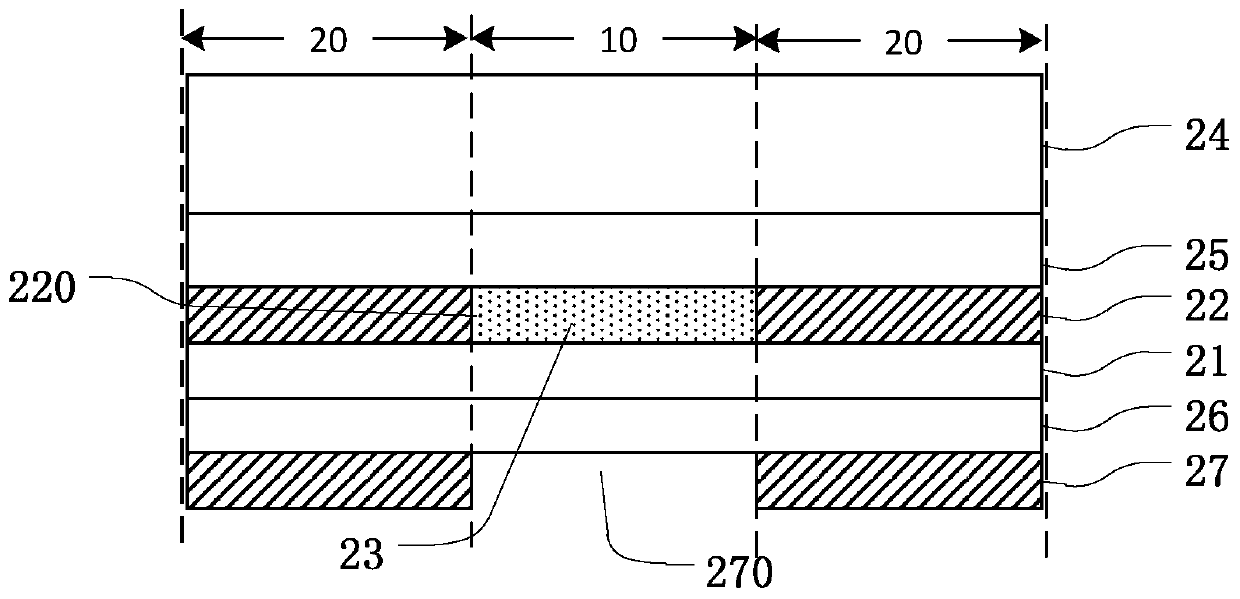

[0051] Such as Figure 4 As shown, this embodiment provides a display panel, including an imaging area 10 and a display area 20 , and the display area 20 surrounds the imaging area 10 . The display panel includes a first substrate 21 , a first polarizer 22 , a liquid optical adhesive layer 23 , a cover plate 24 and a solid optical adhesive layer 25 .

[0052] The first substrate 21 is a color filter substrate, and generally includes a substrate, a black matrix (BlackMatrix, BM) and a color filter layer formed on the substrate. Wherein, the color filter layer includes a plurality of filter units of different colors, such as red, green and blue green light units formed by using red, green and blue photosensitive resins respectively, and the black matrix is used to define the space between each filter unit. In order to prevent light leakage between adjacent filter units, the edges of the filter units are usually overlapped on the black matrix, and each filter unit is not forme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com