Glue filling process for tire pressure monitoring sensor

A tire pressure monitoring and sensor technology, which is applied to the surface coating liquid device, pretreatment surface, coating, etc., can solve the problems of poor control of baking time, increase of product production cost, cost increase, etc., and achieve improvement Glue filling production efficiency, stable and controllable process, and the effect of avoiding air bubbles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

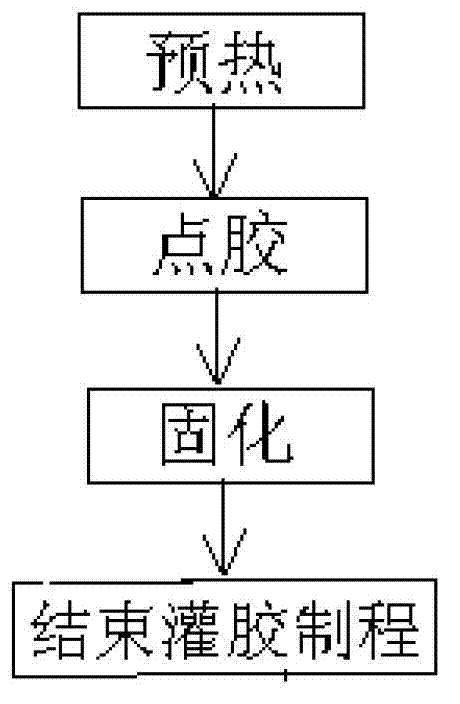

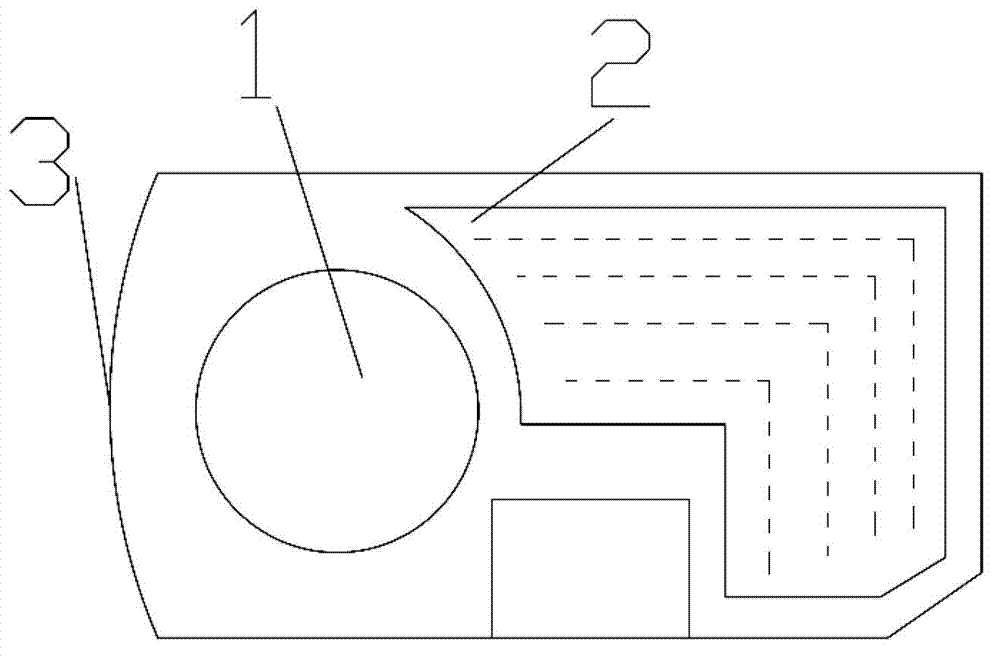

[0029] as attached figure 1 As shown, it is an embodiment of the glue filling process of the tire pressure monitoring sensor of the present invention, a kind of glue filling process of the tire pressure monitoring sensor, as attached figure 2 As shown, the sensor includes a lithium battery 1 used as a power supply, a circuit board 2 and an installation housing 3, and the lithium battery 1 and the circuit board 2 are fixed in the installation housing 3; the glue filling process includes the following steps:

[0030] Step 1: preheating, preheating the sensor, for example, the preheating temperature in this embodiment is 80°C, and the time is 5 minutes;

[0031] Step 2: Vacuumize and preheat the glue material: vacuumize the glue material required for glue filling and preheat the glue material for 30 minutes; the glue material in this embodiment is a high-performance epoxy resin adhesive, more specifically Can be epoxy resin AB glue;

[0032] Step 3: Glue dispensing; place the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com