Display panel glue pouring and laminating device and method capable of achieving streamlined operation

A technology for a display panel and a laminating device, which is applied to devices and coatings that apply liquid to the surface, can solve the problems of low lamination efficiency and large equipment investment, reduce equipment costs, improve production efficiency, and improve sticking. The effect of synthetic yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

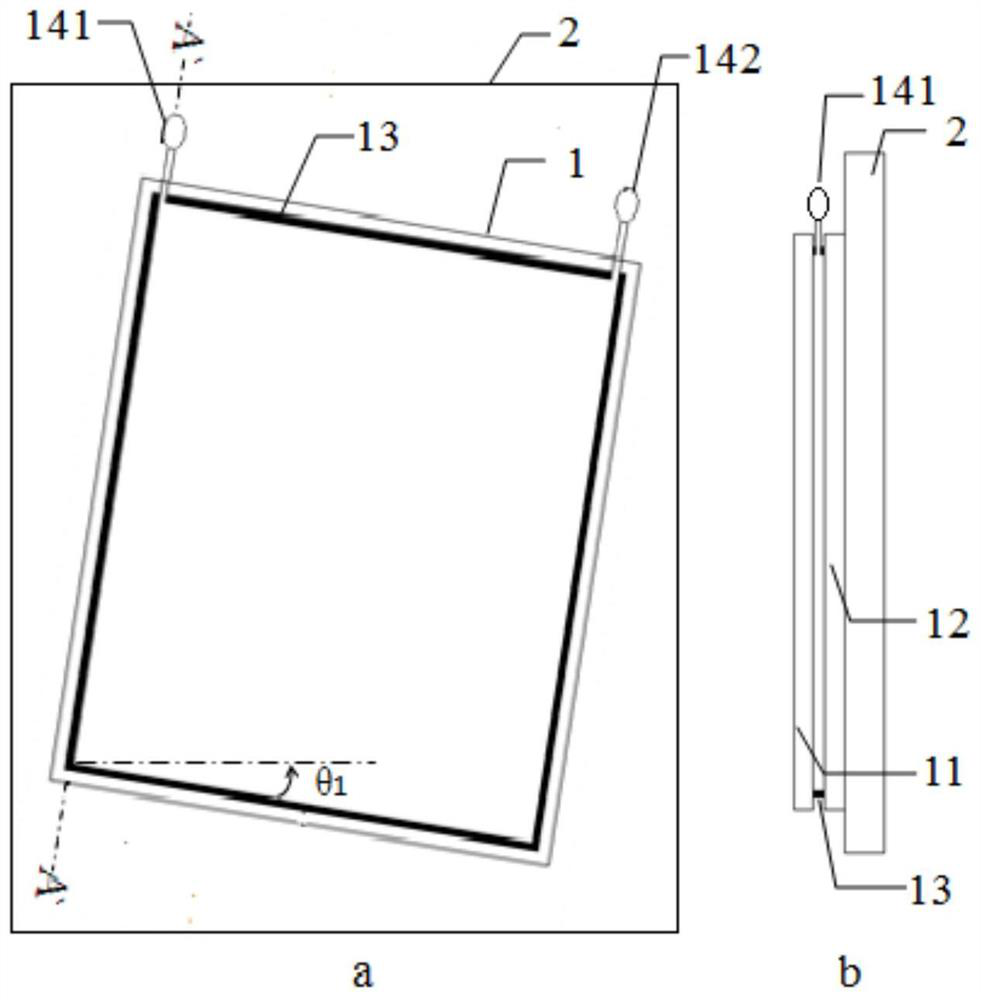

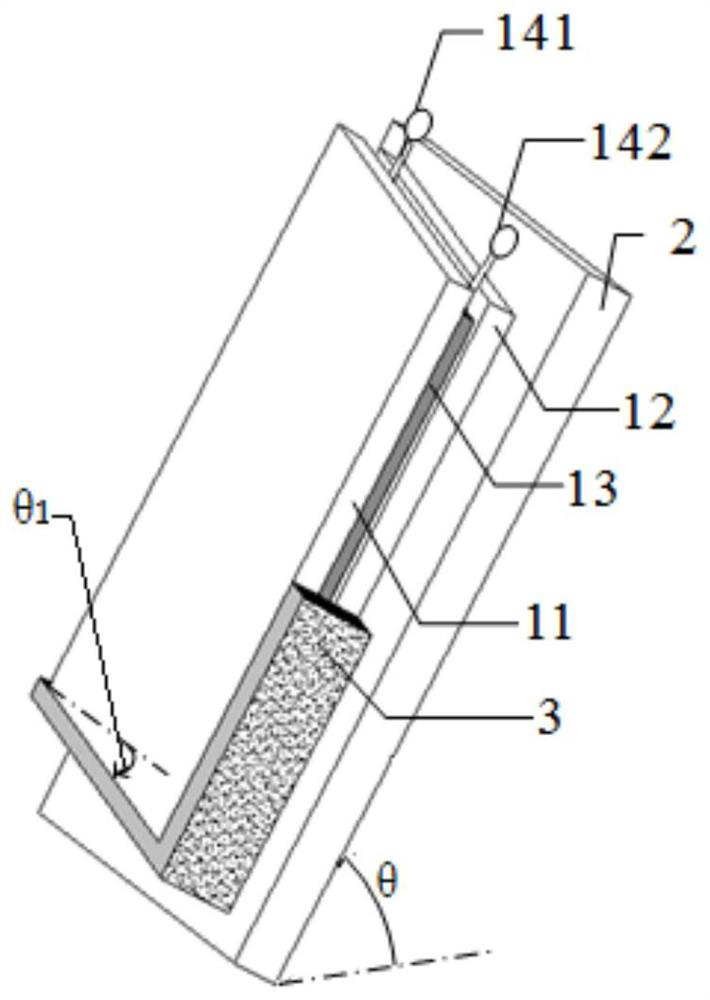

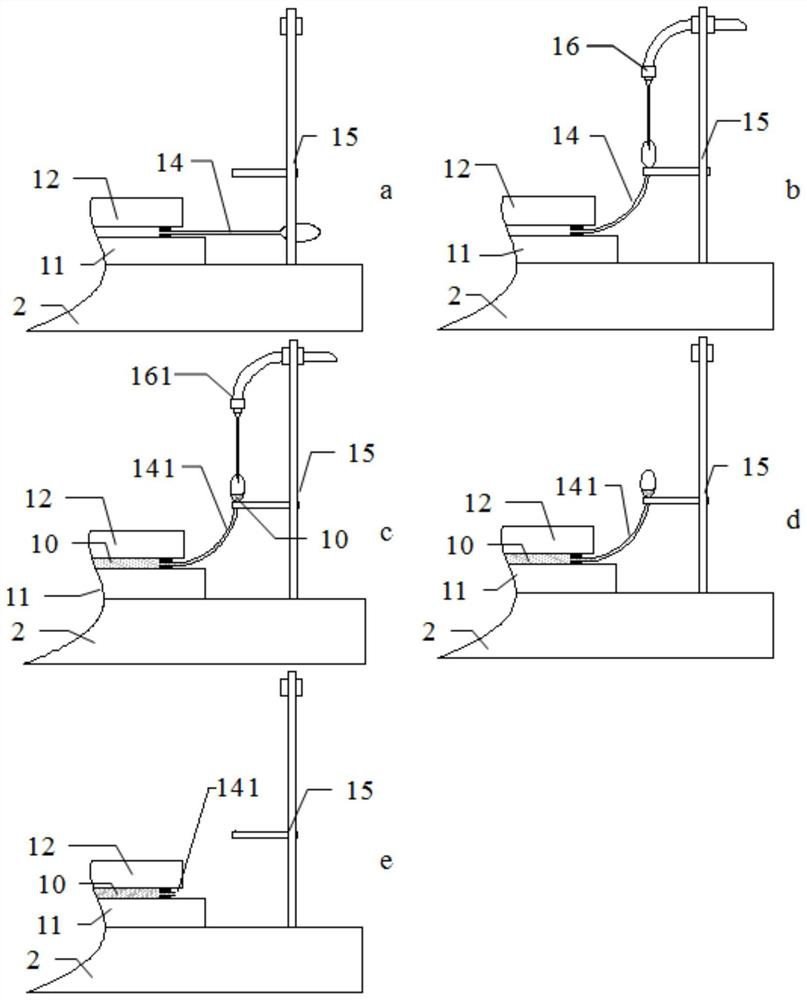

[0046]A water glue pouring and laminating device capable of streamlining a display substrate, which includes: a plurality of panel laminating platforms 2 that can move with the assembly line. The panel laminating platform 2 can be rotated along a rotating shaft parallel to the bottom edge. Obliquely stand at a certain angle θ with the horizontal plane, such asfigure 2 , There is a set of fixing frames 15 on the side opposite to the bottom (such asimage 3 a), the transparent rubber tube 14 used to fix the glue inlet and the air outlet and the support limit glue gas inlet and outlet pipe 16; the above-mentioned assembly line that can be streamlined includes, but is not limited to the following station groups: laminating panel group production station Group A1, panel positioning oblique station group A2, water glue filling station group A3, water glue curing station group A4; next to the water glue filling station A3 of the above assembly line, there are two separate glue inlet pipes 1...

Embodiment 2

[0057]In the first embodiment, the control θ1=15 º, θ=85º, constitutes the second embodiment of the present invention

Embodiment 3

[0059]In the first embodiment, in order to better prevent and control the glue overflow, set the minimum glue control amount as Vmin=98% S×d (where S is the effective glue bonding area of the panel, and d is the thickness of the glue layer Minimum), when the glue volume reaches or approaches the minimum amount Vmin, the laminating platform rotates to the horizontal state of θ=0º, and at the same time controls the glue speed, and finally adjusts the glue slightly until the transparent rubber tube 141 of the air outlet of the panel assembly, there is When the water glue 10 overflows, stop the glue filling. At this time, the laminating platform rotates to the level and stands still, such asimage 3 c; Pull out the glue injection needle to separate the transparent rubber tube from the glue inlet and outlet pipes, such asimage 3 d, so that the laminating platform 2 can continue to move freely along the pipeline, which constitutes the third embodiment of the present invention

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com