Filling liquid filling device and preparation method thereof, and filling method of electro-wetting filling liquid

A filling liquid and device technology, applied in the field of electrowetting filling liquid filling, filling liquid filling devices and their preparation, can solve problems such as uncontrollability, waste of ink, uneven volume of ink, etc., to save consumption, avoid bubbles, Improve the effectiveness of the preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

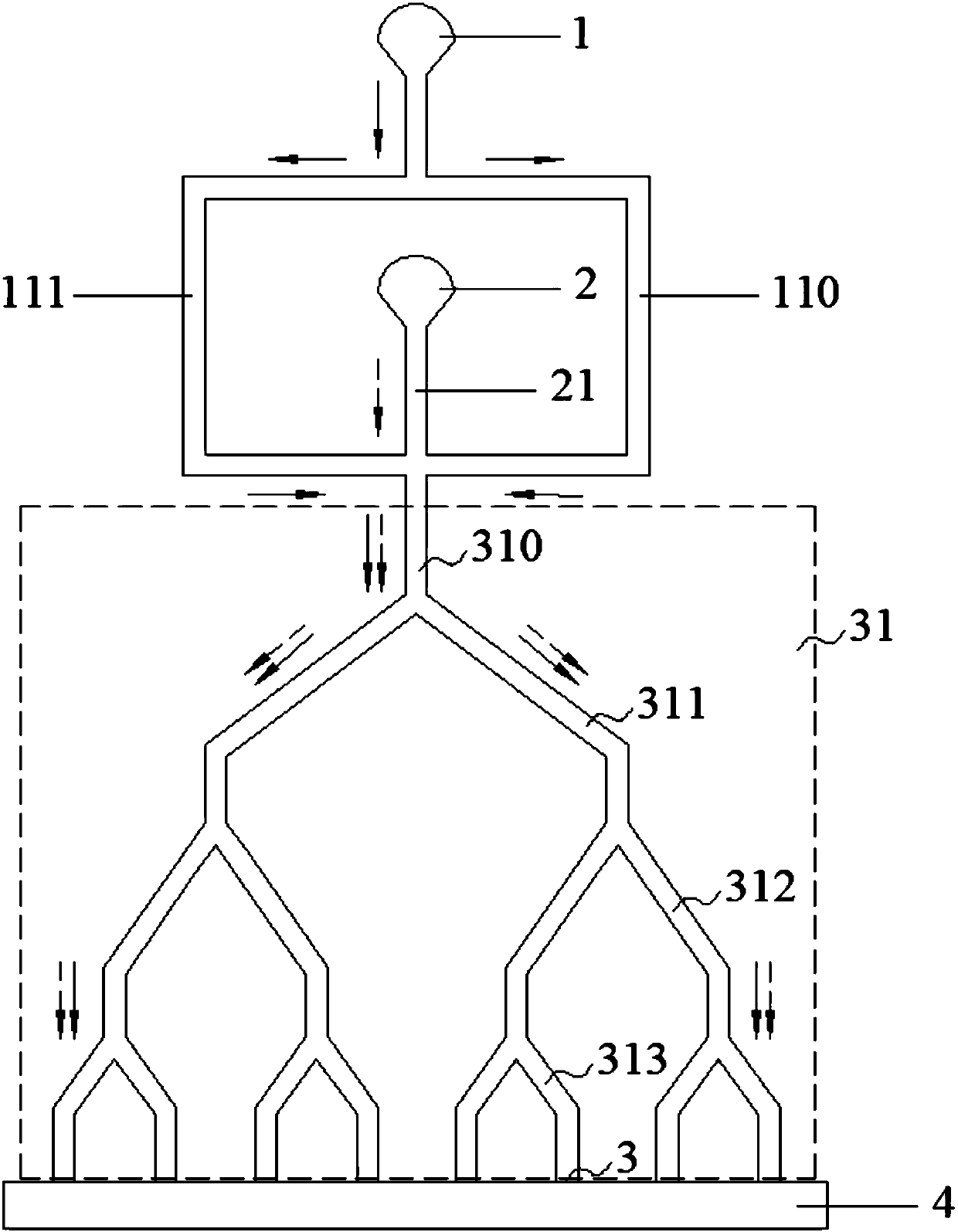

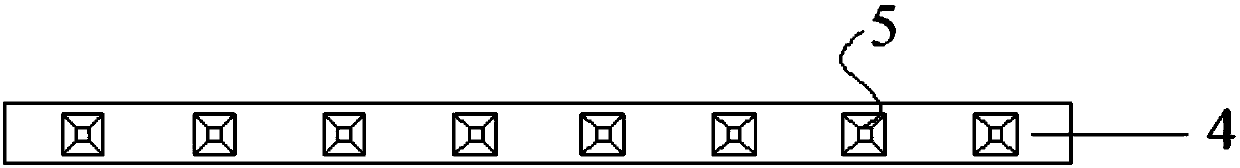

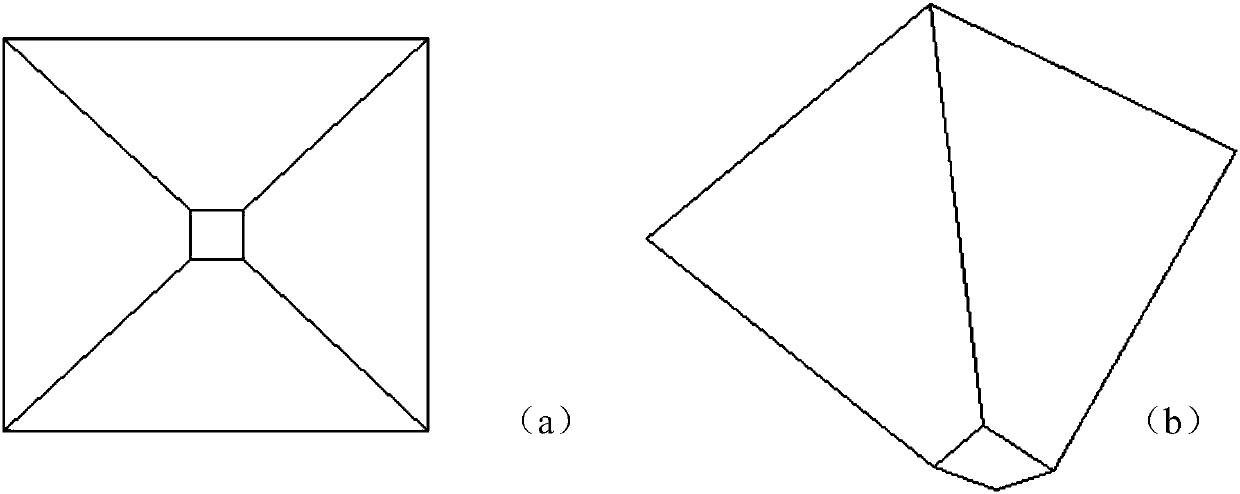

[0047] see figure 1 , the present invention provides a filling liquid filling device, comprising a filling liquid circulation device and an orifice plate 4, the orifice plate 4 has spray holes, the filling liquid circulation device includes two substrates, the substrate is composed of made of any one of silicon-based materials, glass, and polymer materials, wherein one of the substrates has a flow channel, and the flow channel is sequentially provided with a first fluid flow path, a second fluid flow path 21 and a mixing flow path 31 ( figure 1 The dotted line box in the middle is only to illustrate the position of the mixed flow, and is not a component of the filling liquid filling device. The flow channel inside the dotted line box is a mixed flow channel), the first fluid flow channel has a first fluid inlet 1, and the first fluid flow channel has a first fluid inlet 1. The fluid flow path has a branch 110 and a branch 2 111, the branch 110 and the branch 111 are located on...

Embodiment 2

[0050] The present invention also provides a method for preparing a filling liquid filled device, preparing a filling liquid circulation device: such as Figure 5 As shown, first, the flow channel is prepared by soft photolithography, and a photoresist 7 is coated on the silicon wafer 6, and a mask is taken. The mask has a light-transmitting part 8 and an opaque part 9, and the ultraviolet light The mask plate is irradiated on the photoresist 7 to form a silicon wafer positive mold 10 with the channel pattern shown in the first embodiment. Using PDMS material through casting, curing and peeling process to form a figure 1 The PDMS substrate 11 of the flow channel, and then the PDMS substrate 11 and another glass substrate 12 are bonded through a thermocompression bonding process, and a flow channel 13 is formed between the PDMS substrate 11 and the glass substrate 12, and the flow channel 13 has a depth of 10-50 μm, and the flow channel 13 has the same pattern as the flow chan...

Embodiment 3

[0053] The present invention also provides a filling method of electrowetting ink, such as Figure 6 shown. Take a lower substrate 16 with a pixel grid 15, use a pressure syringe pump to simultaneously inject the polar liquid and the ink used for the electrowetting display into the first liquid inlet 1 and the second liquid inlet 2 of the filling liquid filling device, and the polar liquid along Figure 6 In the direction of the solid arrow, the ink flows along the Figure 6 The middle dotted line flows in the direction of the arrow, and the polar liquid confluences with the ink from the branches on both sides at the same time. At the confluence of the polar liquid and the ink, under the action of the interfacial tension of the two-phase fluid, the ink is sheared by the polar liquid into one by one. Continuous droplet, the polar liquid wraps the ink to form a continuous filling liquid, and then when the filling liquid passes through multiple Y-shaped grading channels, it is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com