Packaging device for thin film capacitor production

A technology for film capacitors and packaging devices, which is applied in the direction of packaging capacitor devices, capacitors, capacitor manufacturing, etc., can solve the problems of manpower consumption and low efficiency, and achieve the effects of saving labor costs, good sealing effect, and high filling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

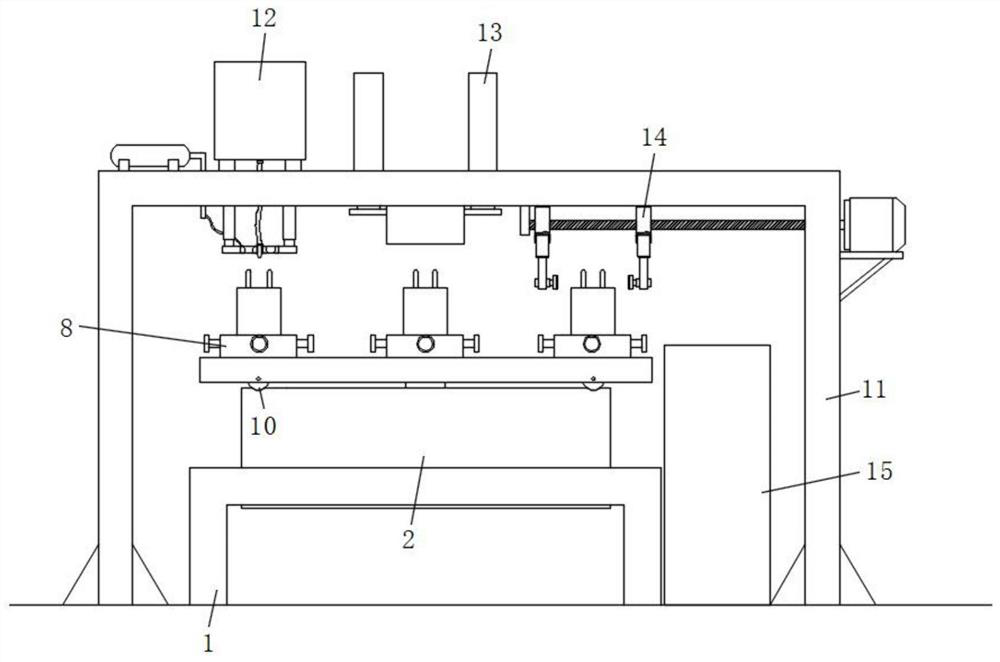

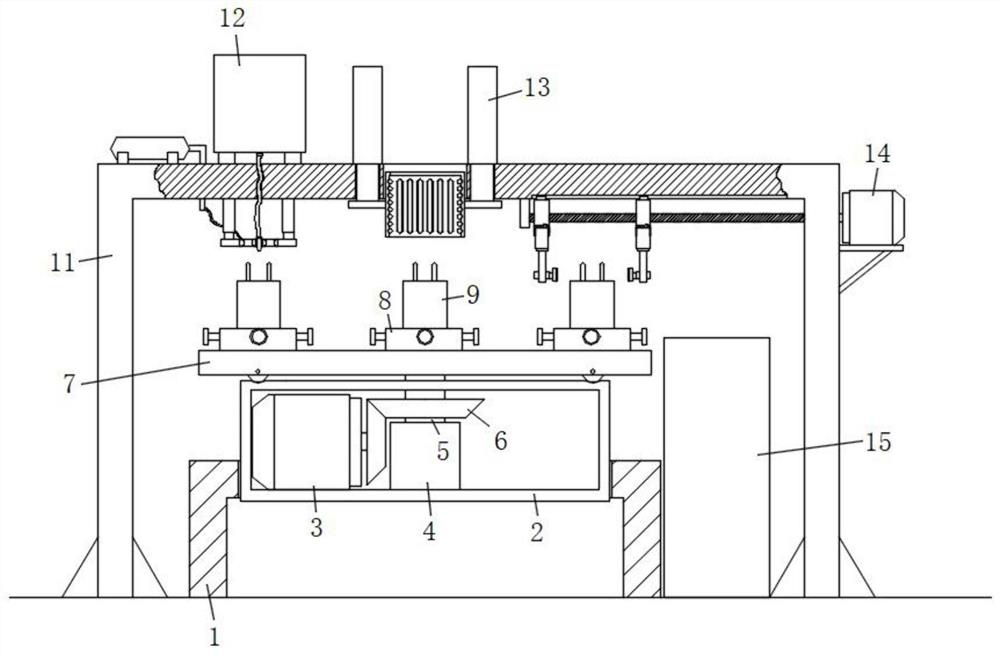

[0034] refer to Figure 1-6, a packaging device for film capacitor production, comprising a mounting frame-1, the top surface of the mounting frame-1 is provided with a mounting hole, the inner wall of the mounting hole is fixed with a drive box 2 by screws, and one side of the bottom surface of the drive box 2 passes through The screw is fixed with a servo motor 3, and the center of the inner bottom surface of the drive box 2 is also fixed with a stabilizing column 4, and the top surface of the stabilizing column 4 is connected with a mounting column 5 through a rolling bearing. Through the bevel gear set 6 rotation connection, the top of the mounting column 5 passes through the top surface of the drive box 2 and is fixedly connected with the rotating disc 7. The outer side of the top surface of the rotating disc 7 is fixed with a capacitor temporary fixing mechanism 8, and the capacitor temporary fixing mechanism 8 is placed There is a capacitor body 9, mounting frame 1 is p...

Embodiment 2

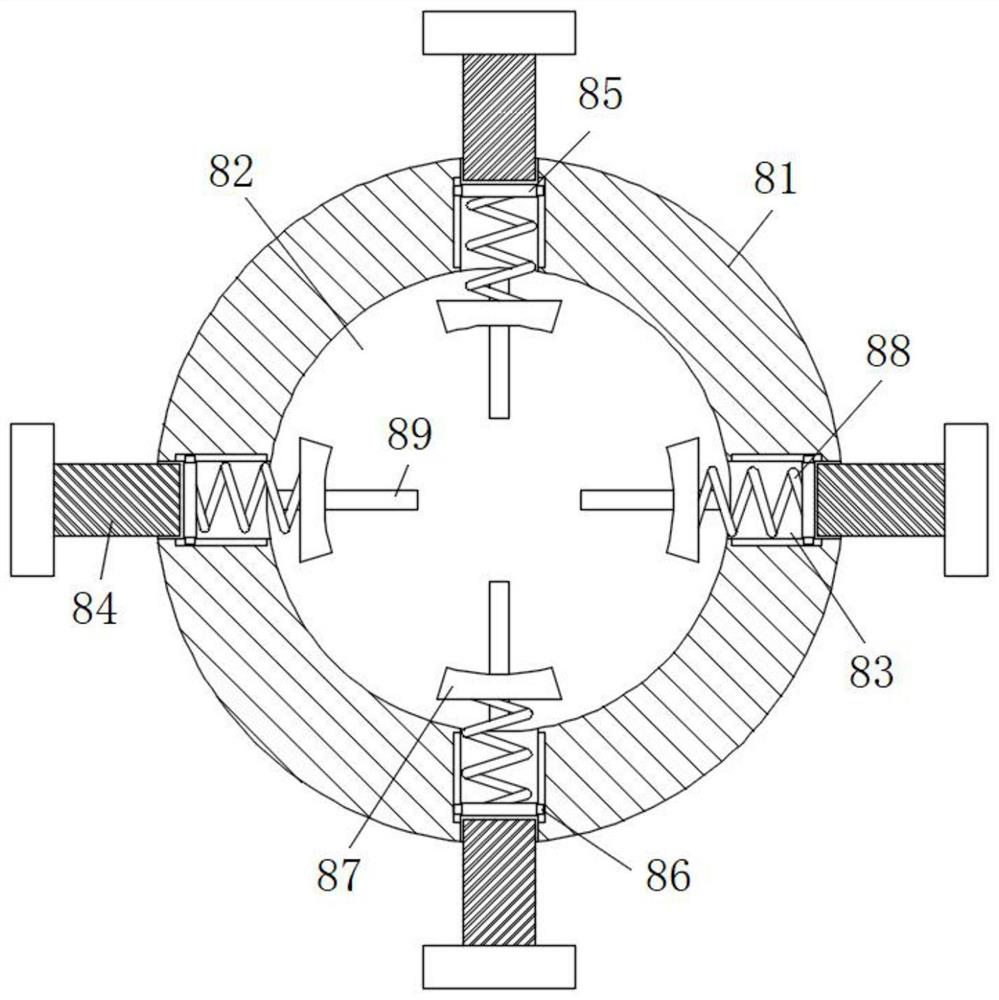

[0036] Such as figure 1 , 2 As shown in and 3, this embodiment is basically the same as Embodiment 1. Preferably, the capacitor temporary fixing mechanism 8 includes a fixed plate 81, the top surface of the fixed plate 81 is provided with a cylindrical groove 82, and the side wall of the cylindrical groove 82 is also provided with a threaded hole 83 , the inner wall of the threaded hole 83 is screwed with an adjusting rod 84, the inner wall of the threaded hole 83 is also slidably connected with a pressure plate 85, the both sides of the pressure plate 85 are fixed with a limit block 86, and the inner wall of the threaded hole 83 both sides is provided with a limit groove 1, And the limit block one 86 is all slidably connected in the limit groove one, and the side of the threaded hole 83 near the center of the cylindrical groove 82 is provided with an extrusion block 87, and an extrusion spring is fixedly connected between the extrusion block 87 and the pressing plate 85 88. ...

Embodiment 3

[0040] Such as figure 1 , 2 As shown in and 6, this embodiment is basically the same as Embodiment 1. Preferably, the unloading mechanism 14 includes a fixed block 141, and the fixed block 141 is fixed on the inner top surface of the mounting bracket 11 by screws, and one side of the fixed block 141 also rotates Connected with screw mandrel 142, the outer side of the upper end of mounting frame two 11 is fixedly connected with horizontal frame 143 by screws, and the top surface of horizontal frame 143 is fixedly connected with servo motor two 144 by screws, and the output end of servo motor two 144 is fixedly connected with screw mandrel 142. The outer wall of the rod 142 is also fixed with a mounting block 145 by threads, the top surface of the mounting block 145 is connected with the inner top surface of the mounting frame 11 by a limit block 2 146, and the bottom surface of the mounting block 145 is fixed with an electric telescopic rod by screws Three 147, the output ends...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com