Patents

Literature

46results about How to "Achieve temporary fixation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

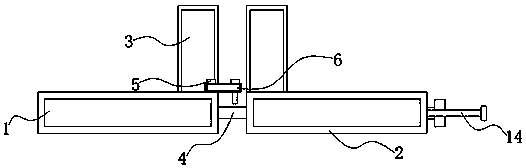

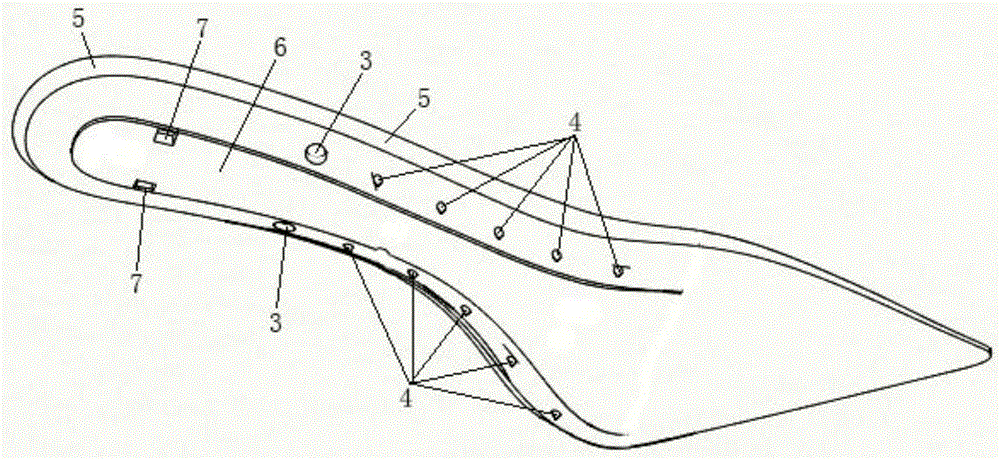

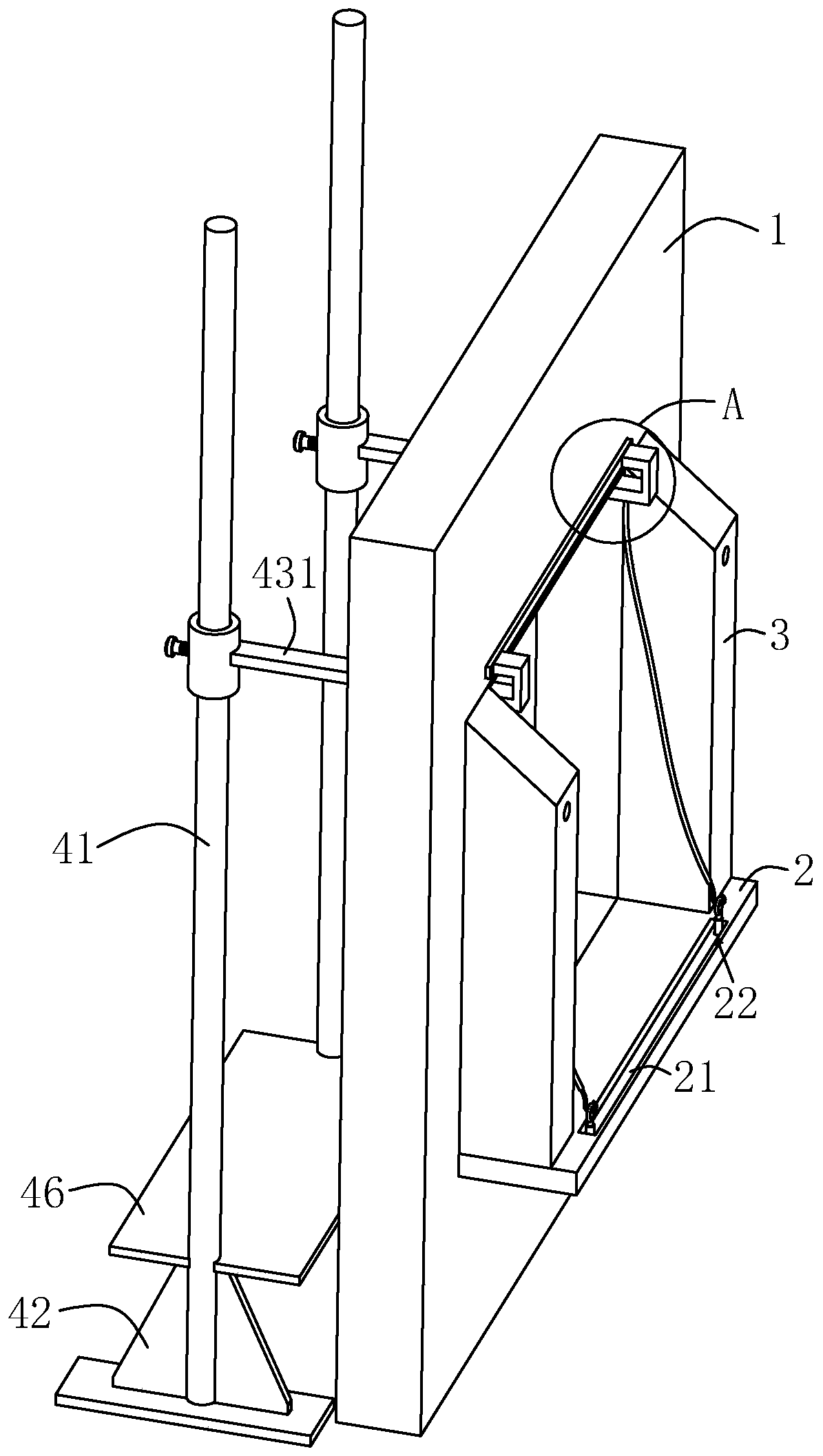

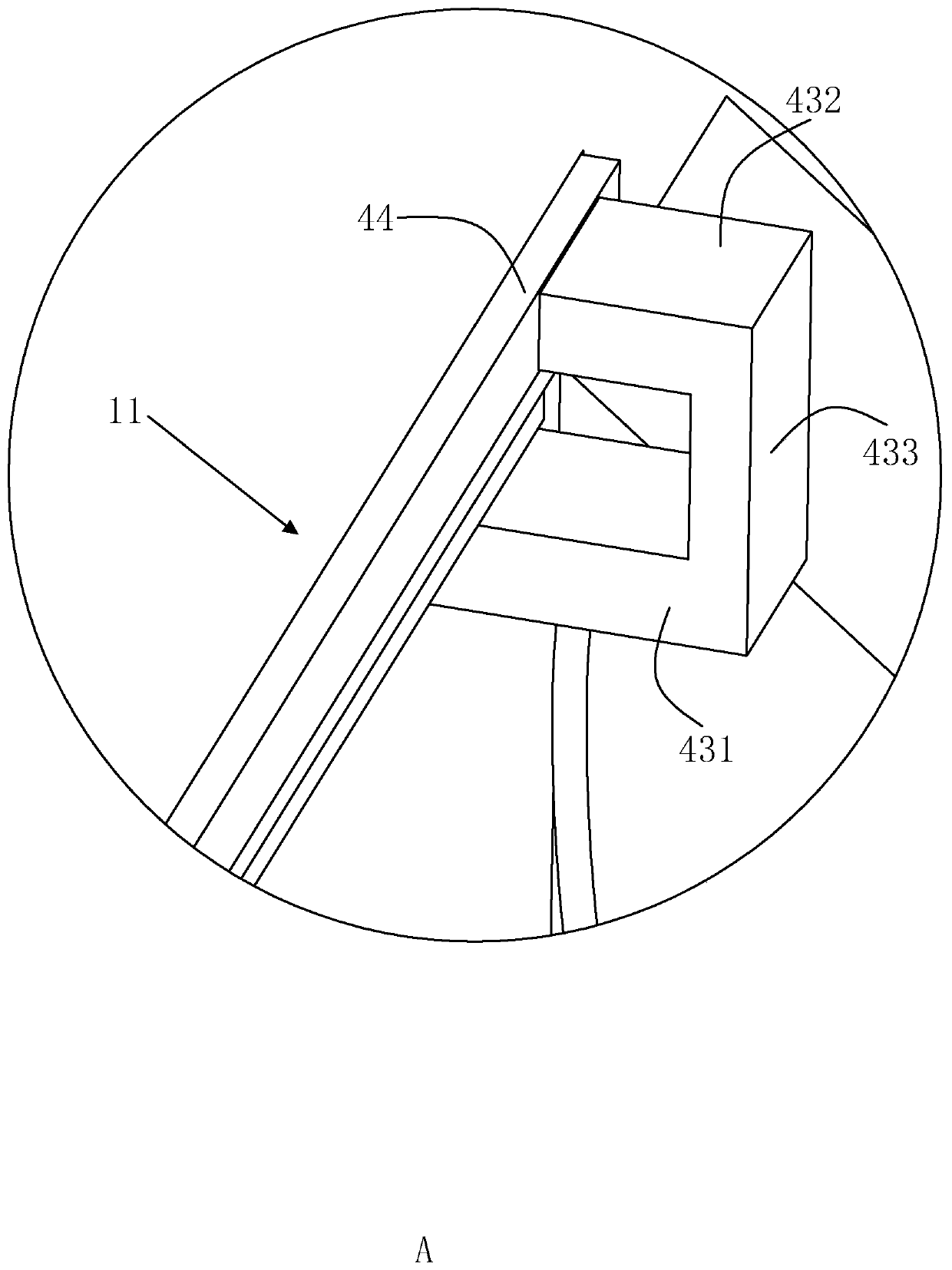

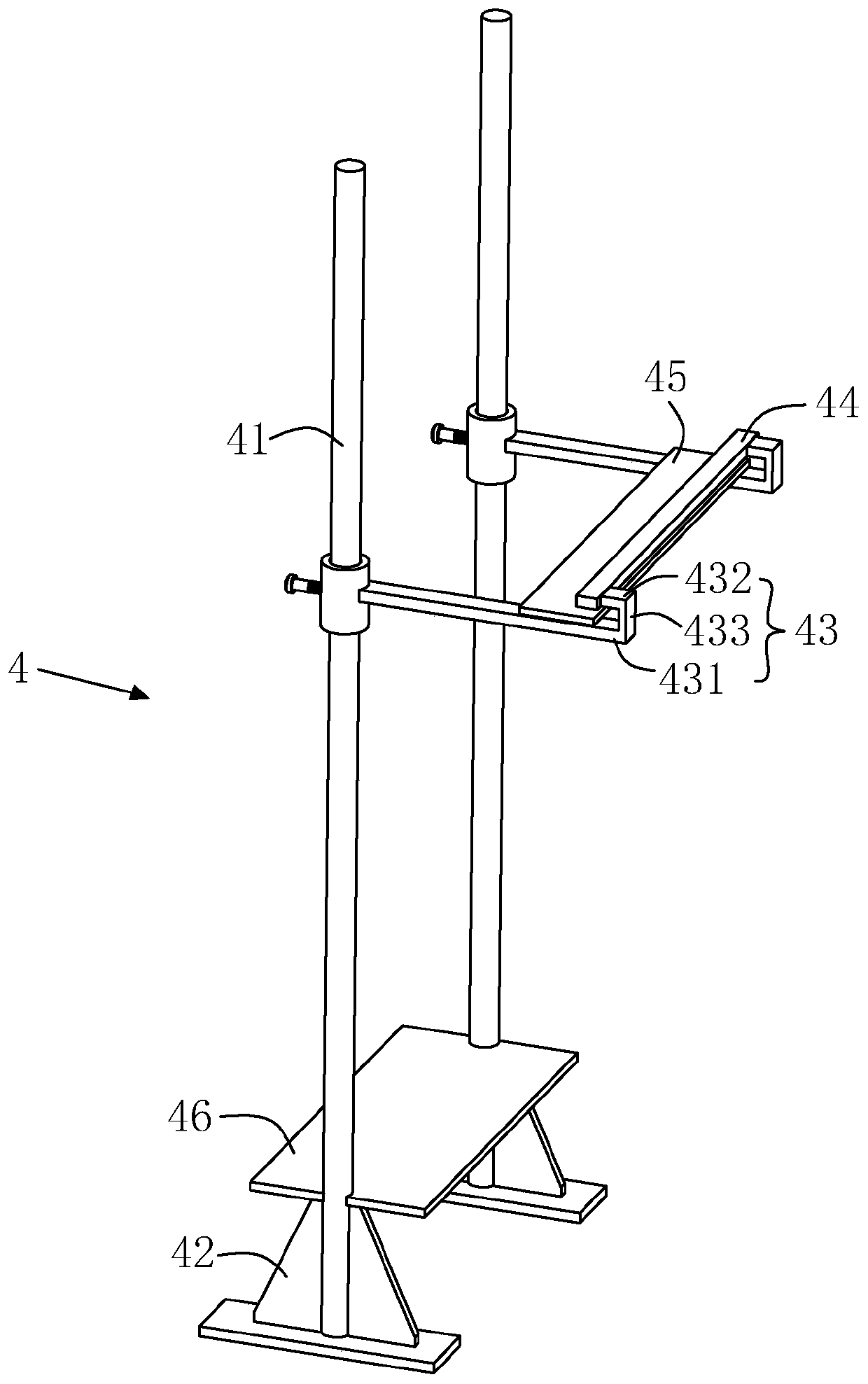

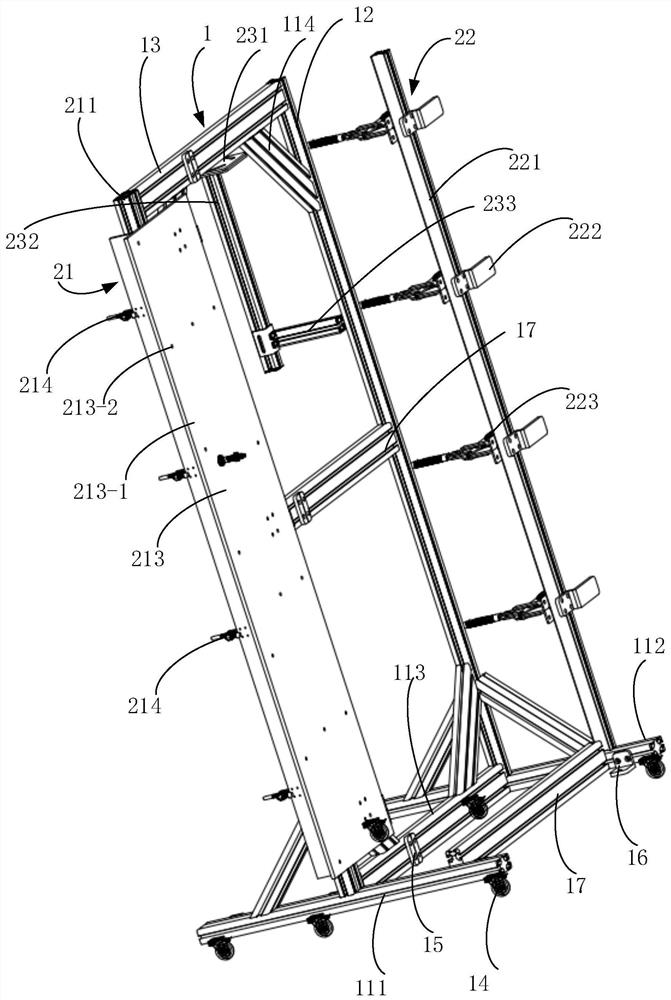

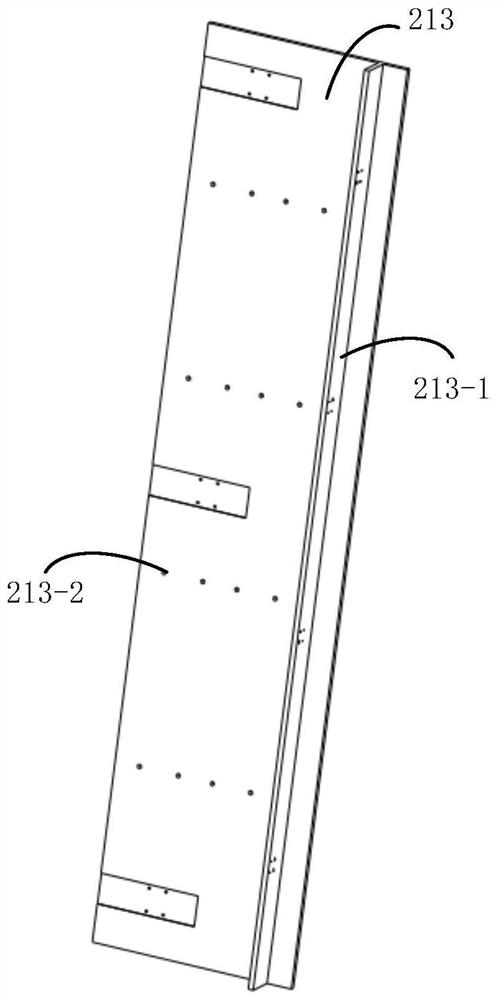

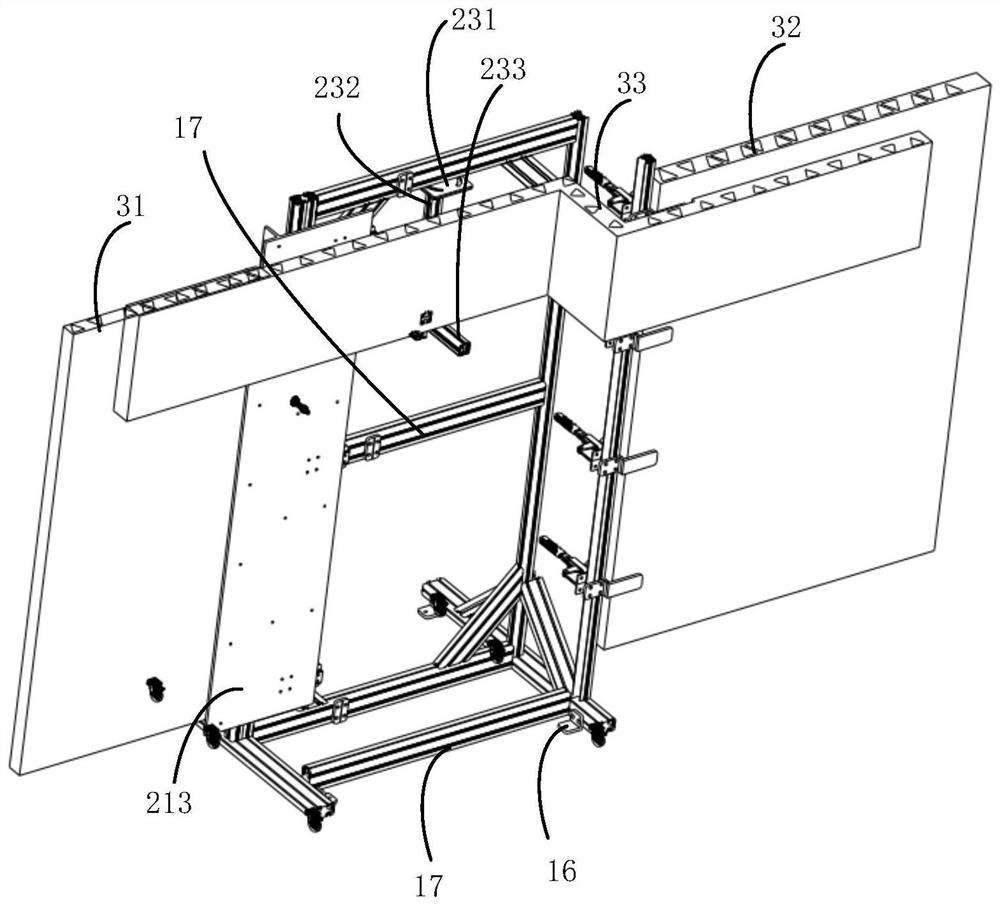

Prefabricated concrete shear wall supporting and grouting bin enclosing integrated tool system and method

ActiveCN111877603AImprove installation efficiencyReduce the number of laborWallsBuilding material handlingArchitectural engineeringSlurry

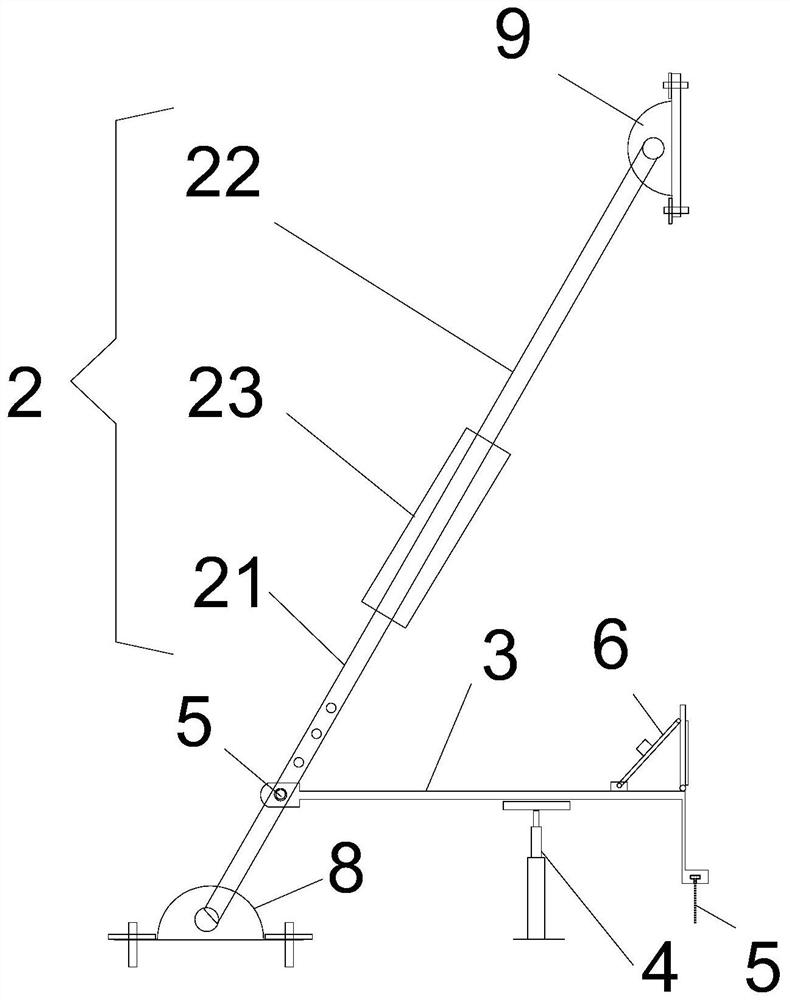

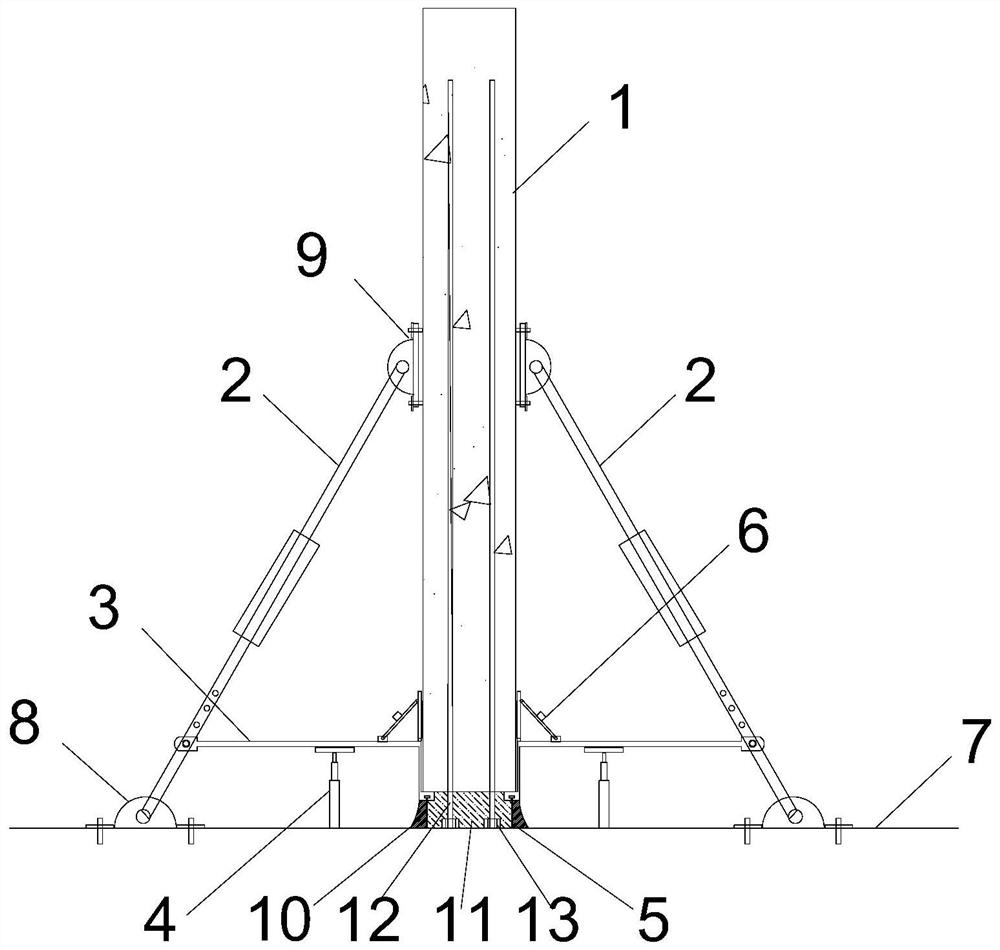

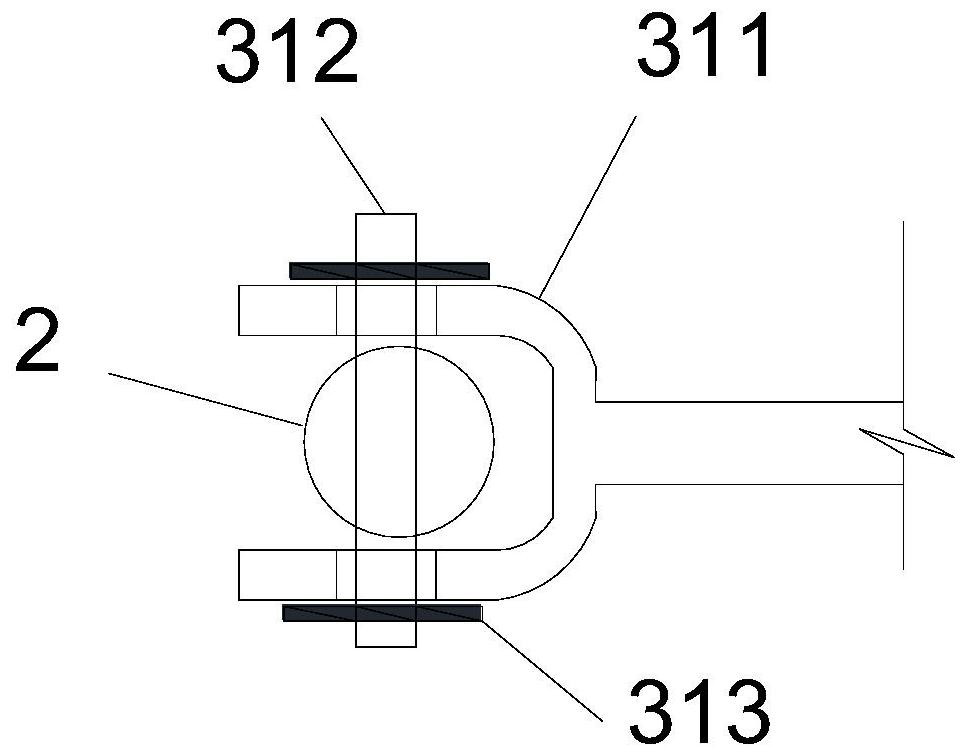

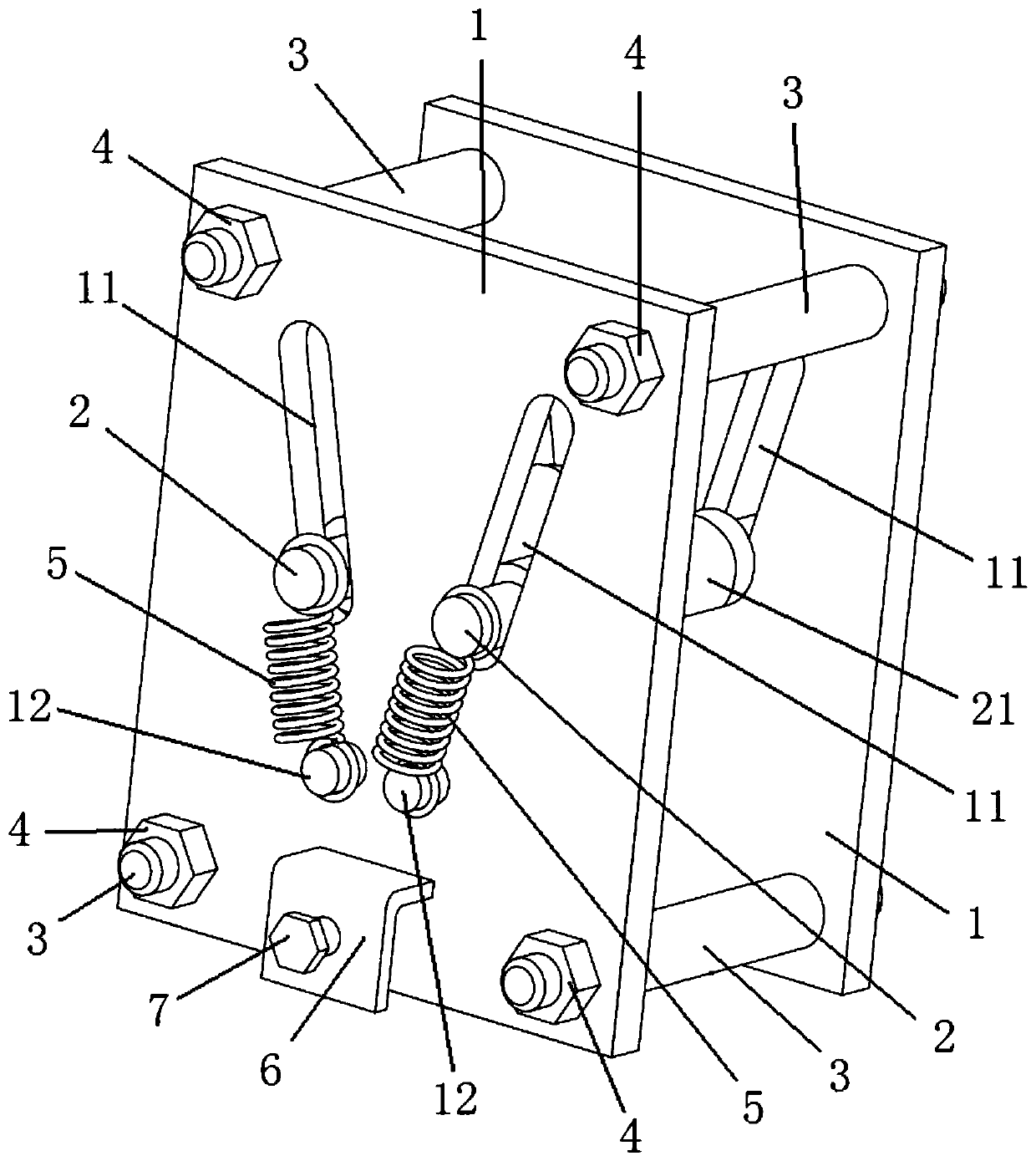

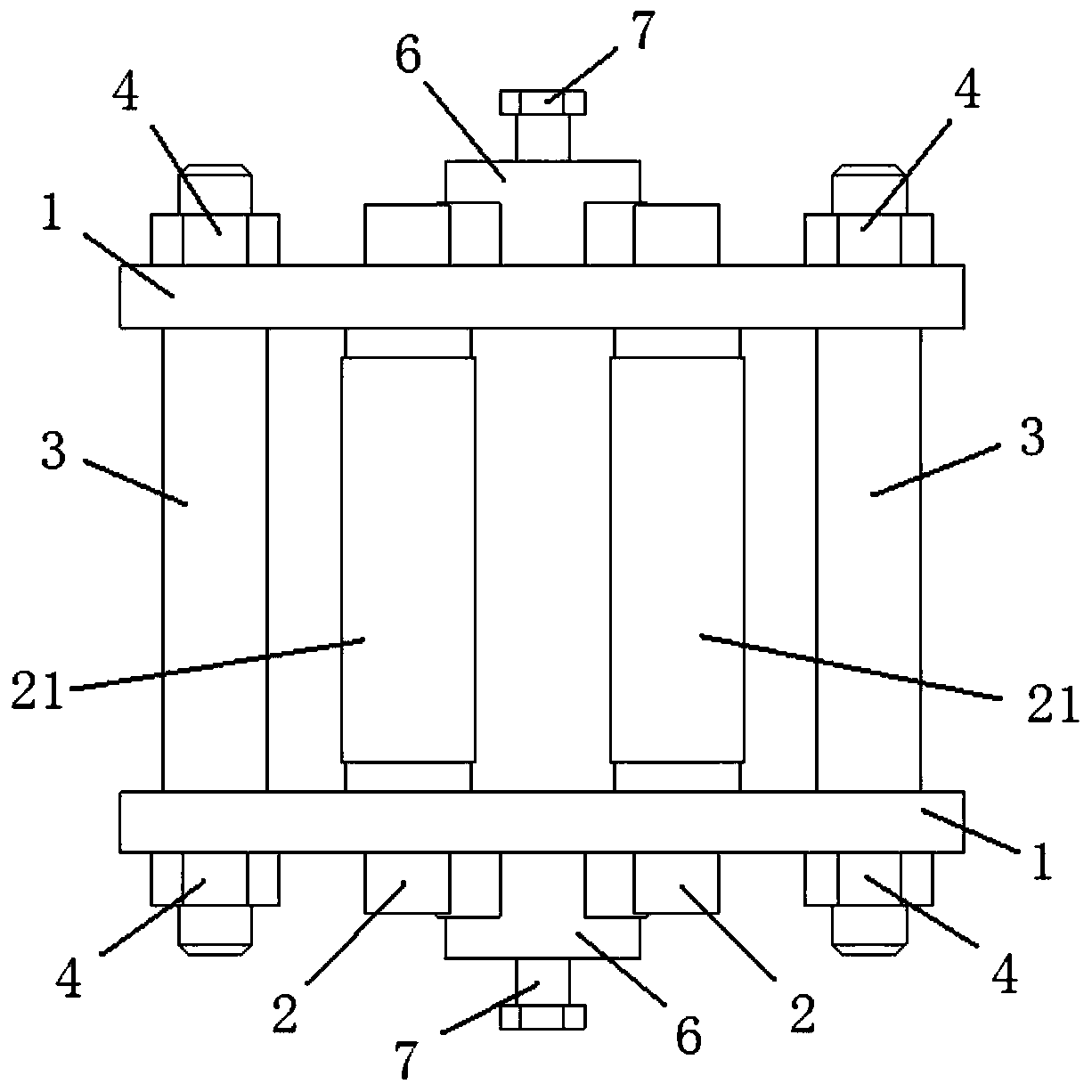

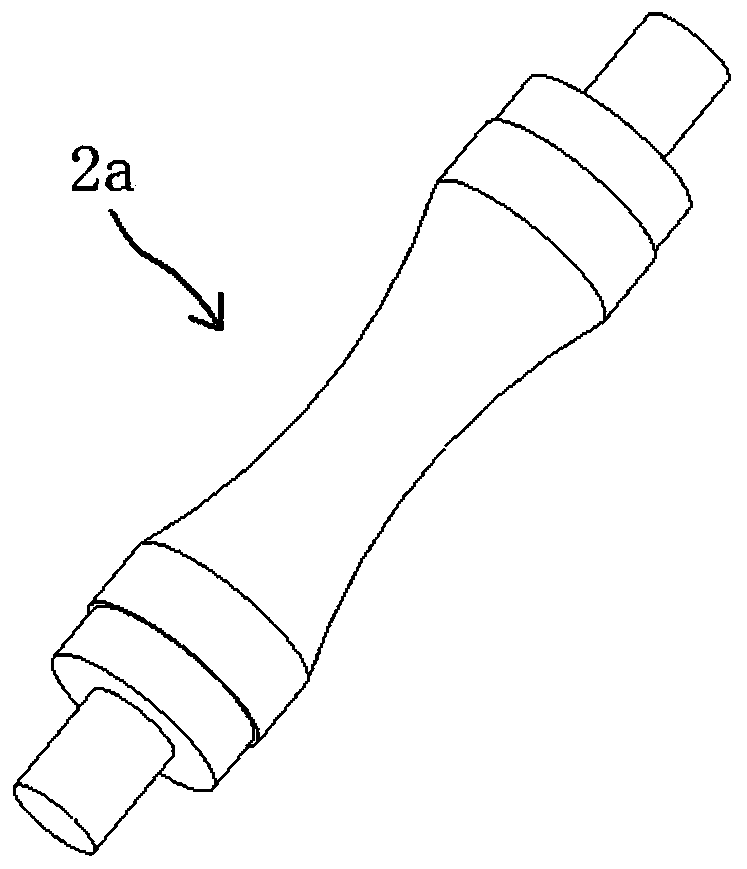

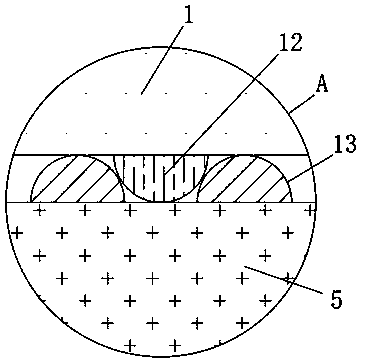

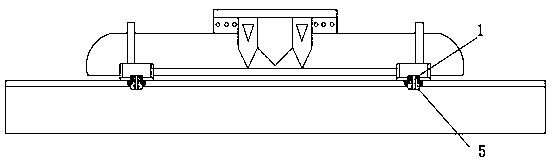

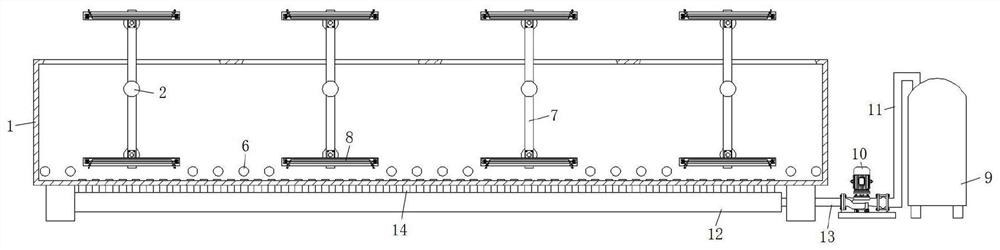

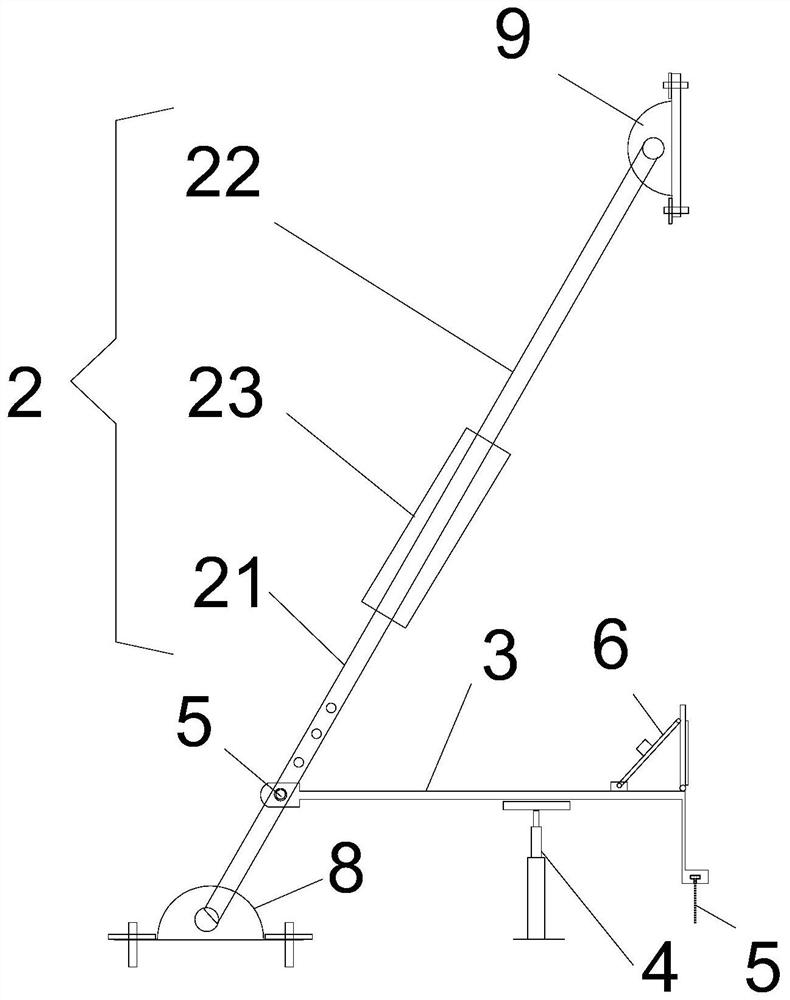

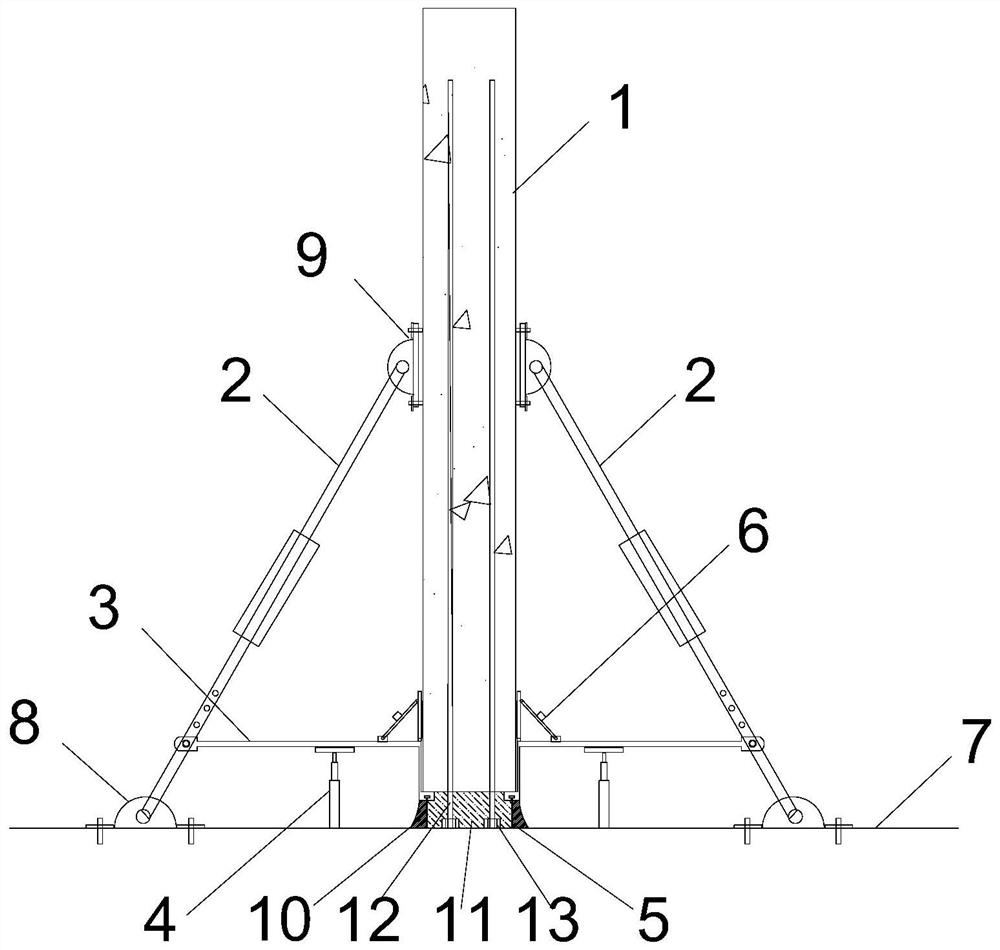

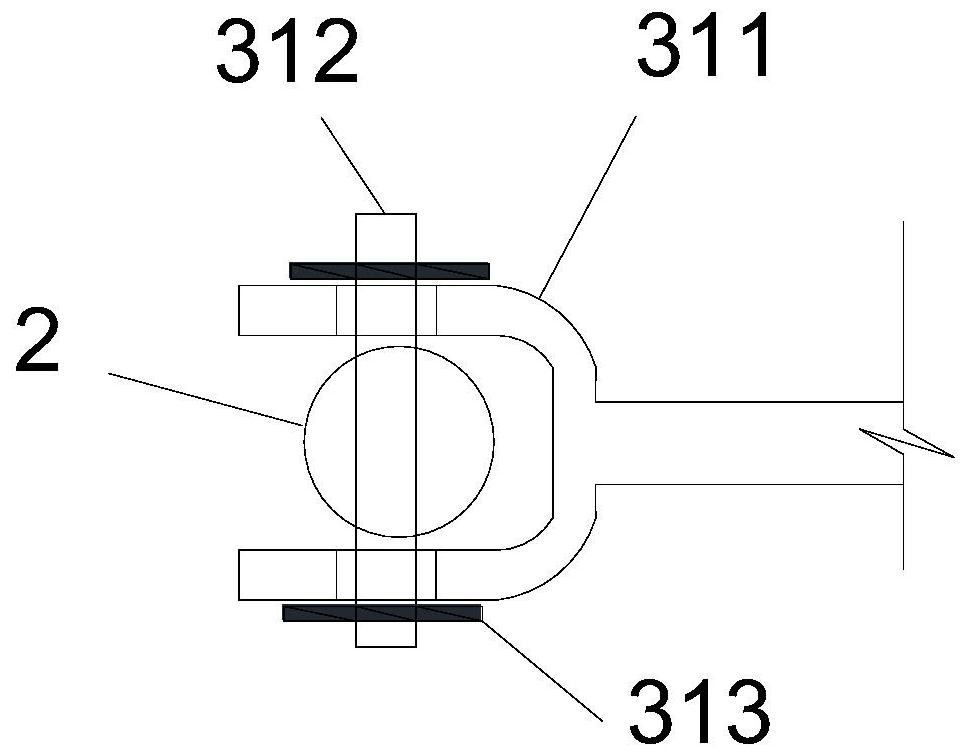

The invention provides a prefabricated concrete shear wall supporting and grouting bin enclosing integrated tool system and method. The system comprises a plurality of grouting inclined strut structures, each grouting inclined strut structure comprises telescopic inclined supporting rods, counter-force supporting rods, jacks and bin sealing plates, and each counter-force supporting rod comprises ahorizontal rod and a vertical rod; one end away from the vertical rod, of each horizontal rod is arranged on the corresponding telescopic inclined supporting rod in a sleeving mode and can move alongthe corresponding telescopic inclined supporting rod, a supporting part is arranged at the lower end of each vertical rod, a right-angle groove for containing prefabricated concrete shear walls is formed by the upper surface of each supporting part and the outer side surface of the corresponding vertical rod, and the supporting part is connected with the upper end of each bin sealing plate. Eachjack drives the corresponding horizontal rod to move up and down to adjust the mounting height of the prefabricated concrete shear wall, and the perpendicularity of the prefabricated concrete shear wall can be adjusted through the corresponding telescopic inclined supporting rod, so that multiple procedures such as temporary supporting of prefabricated concrete shear wall splicing construction, and slurry setting and bin sealing of sleeve grouting are integrated into an integrated single procedure. The mounting efficiency is improved.

Owner:SHANGHAI CONSTRUCTION GROUP

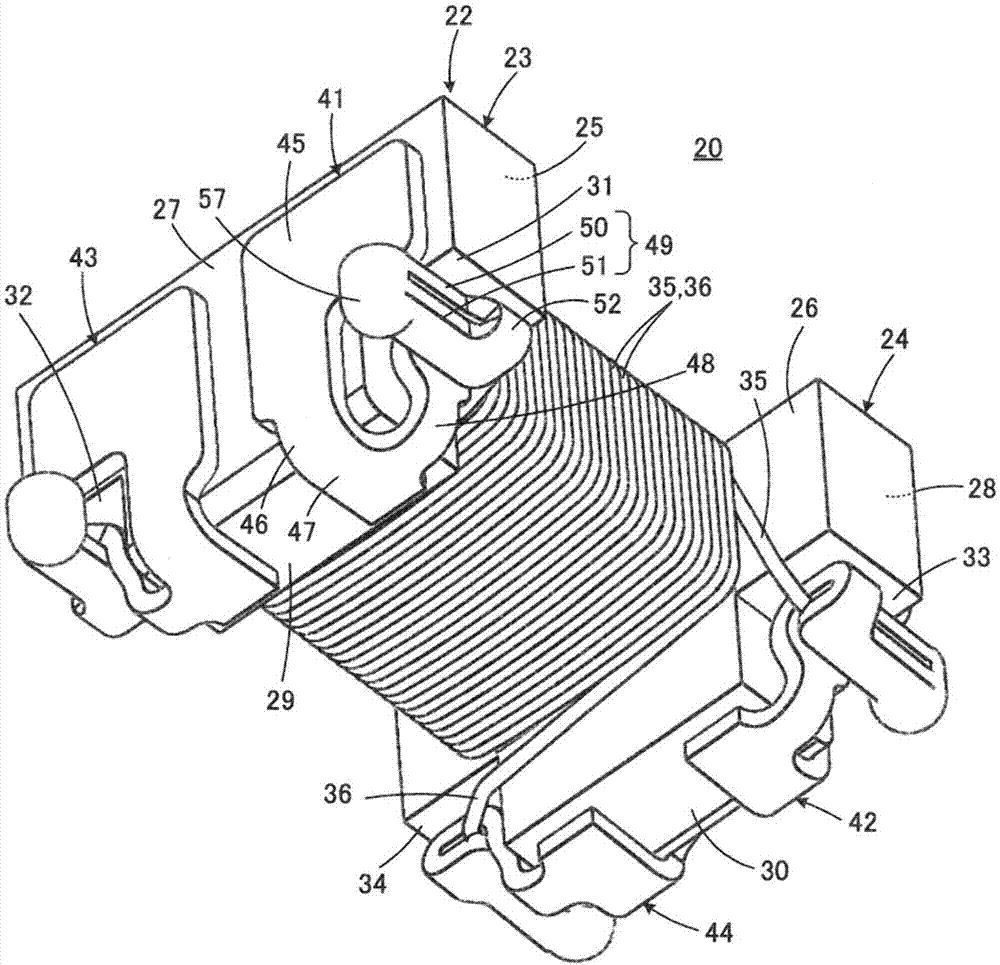

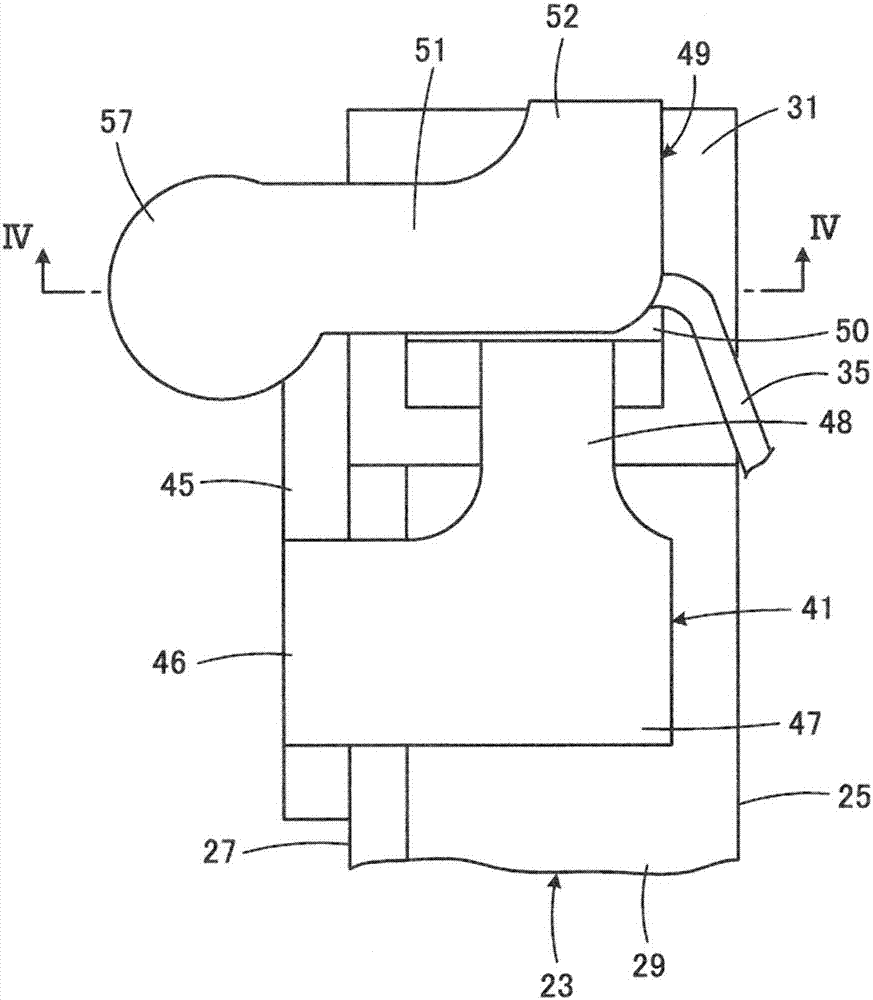

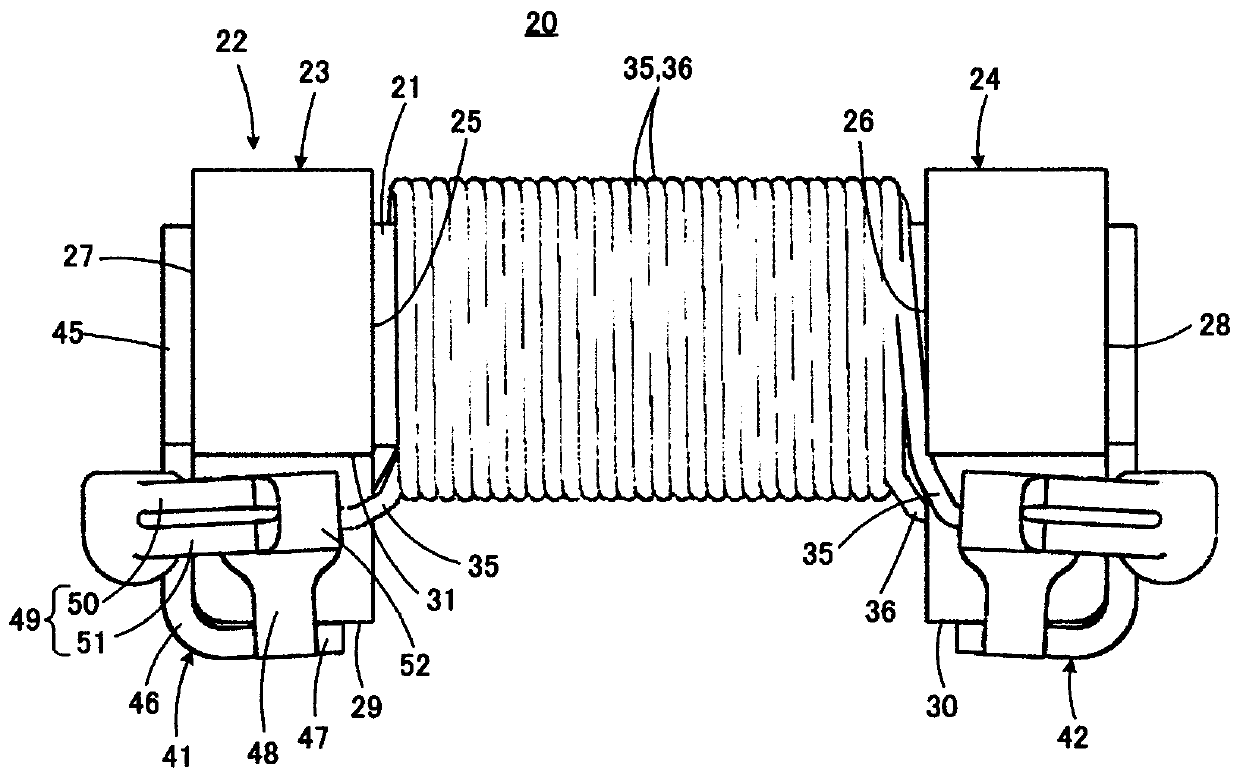

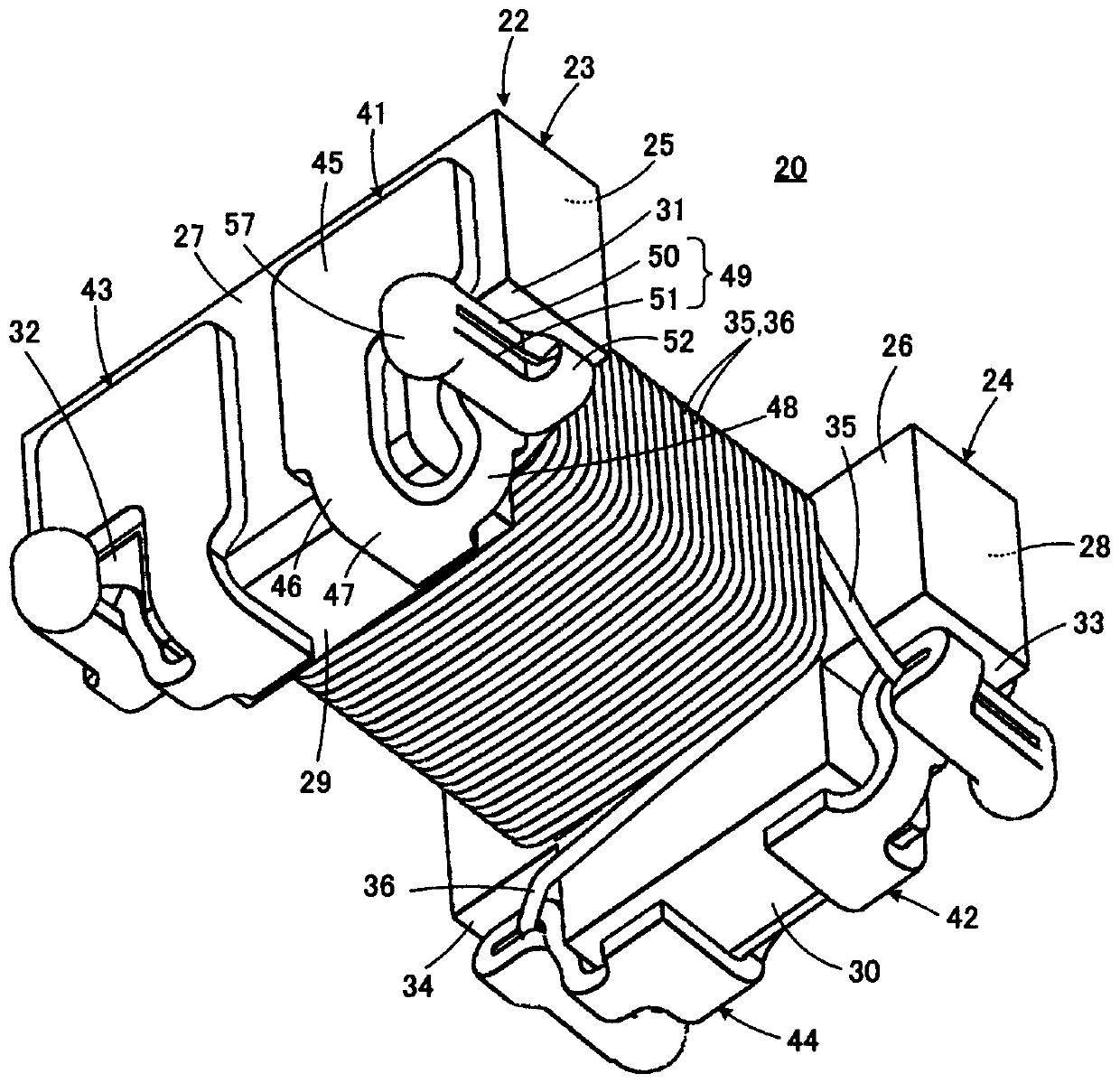

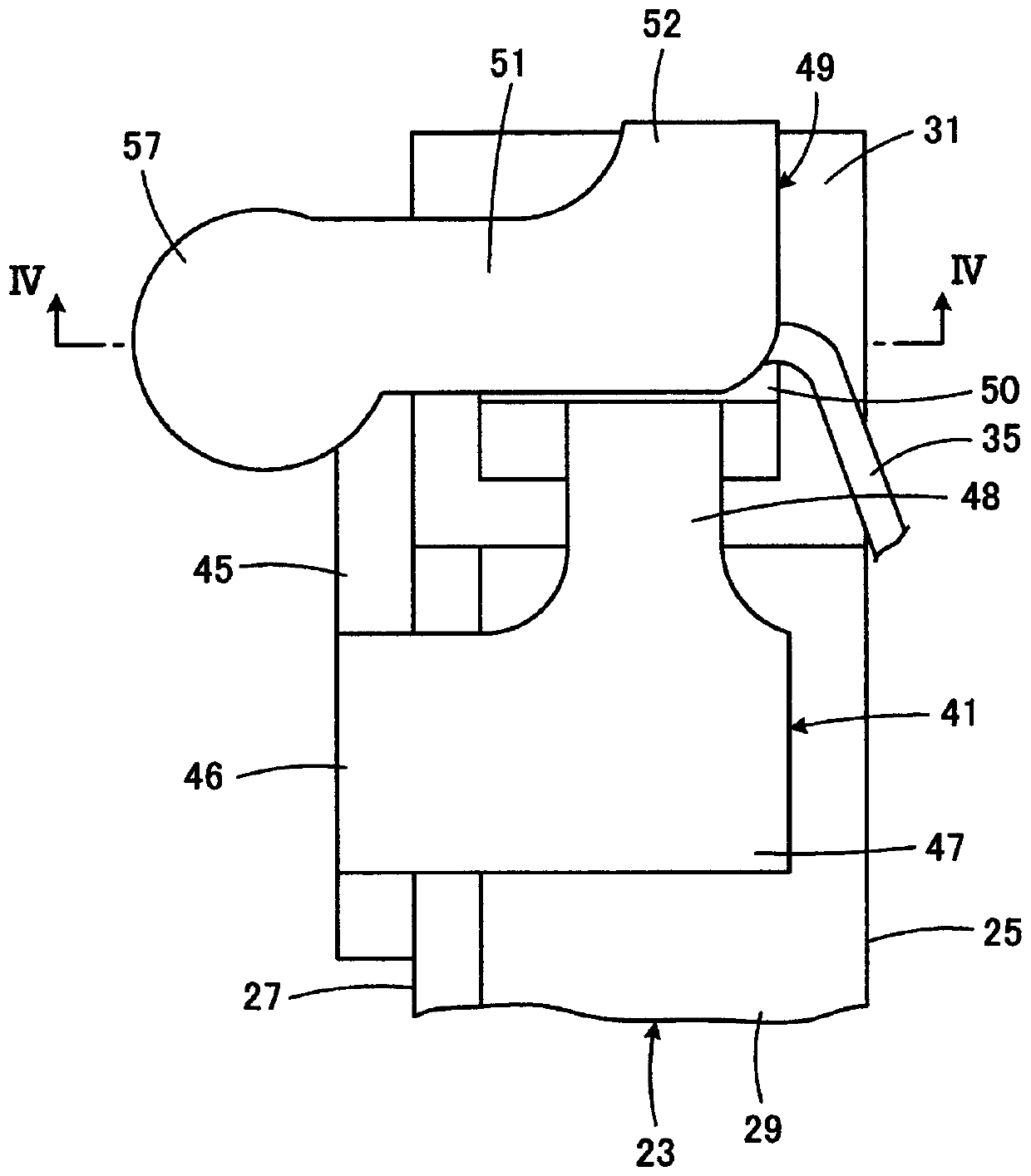

Method of manufacturing coil component

ActiveCN107887159AAchieve temporary fixationSimple manufacturing equipmentContact member assembly/disassemblyTransformers/inductances detailsResin coatingLaser beams

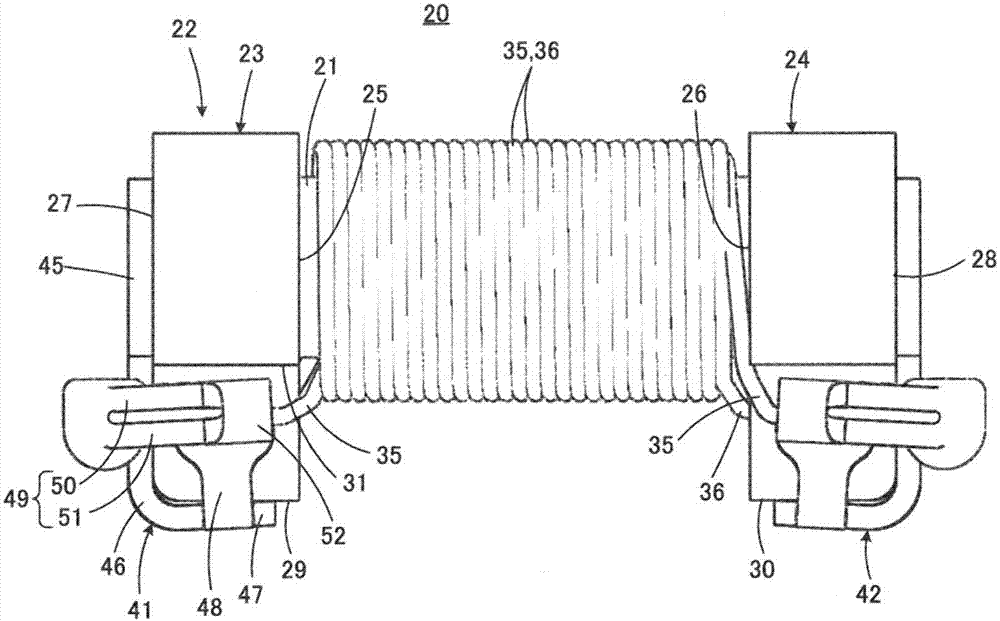

The invention provides a method of manufacturing a coil component which can reduce the complexity of the shape of metal terminals, the complexity of machining for obtaining metal terminals and the complexity of apparatuses for connecting wires and metal terminals. A metal terminal where a connecting portion (49) has a receiving portion (50) which receives a wire (35) and a contact segment (51) which extends from the receiving portion by way of a bending scheduled portion (55) is prepared. By applying heat and pressure in a state where the wire is placed on the receiving portion for temporarilyfixing the wire, the wire is adhered to the receiving portion using a molten or softened insulating resin coating (39) as an adhesive agent. Next, the connecting portion is bent by way of the bendingscheduled portion such that the contact segment faces the receiving portion by way of the wire and the contact segment is brought into contact with the wire. Next, by irradiating a laser beam to a portion of the metal terminal, the wire and the metal terminal are welded to each other.

Owner:MURATA MFG CO LTD

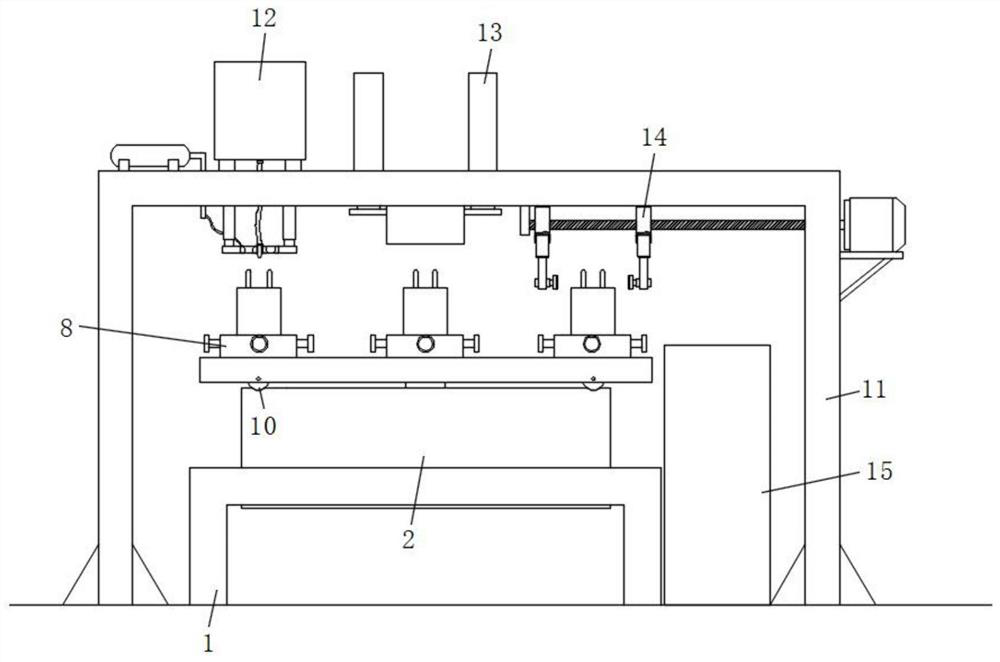

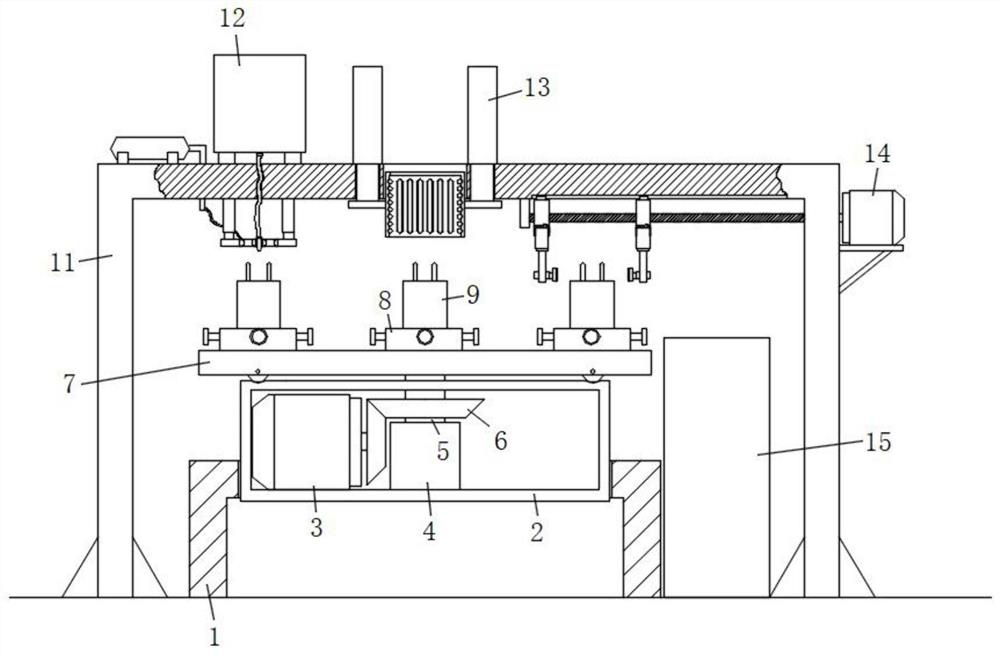

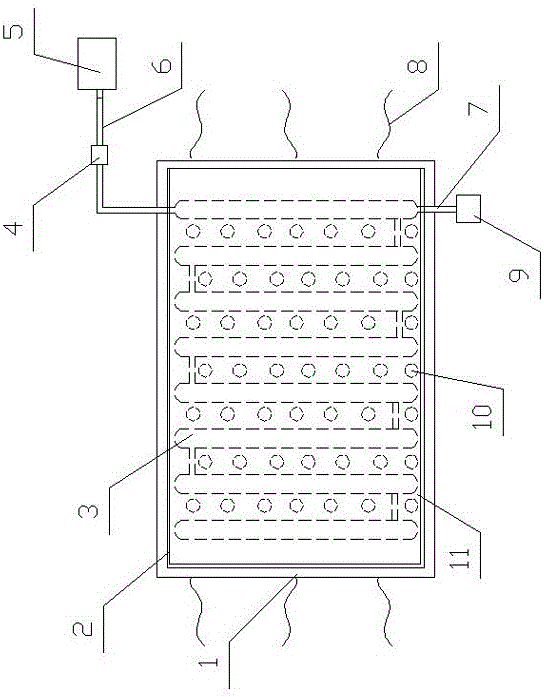

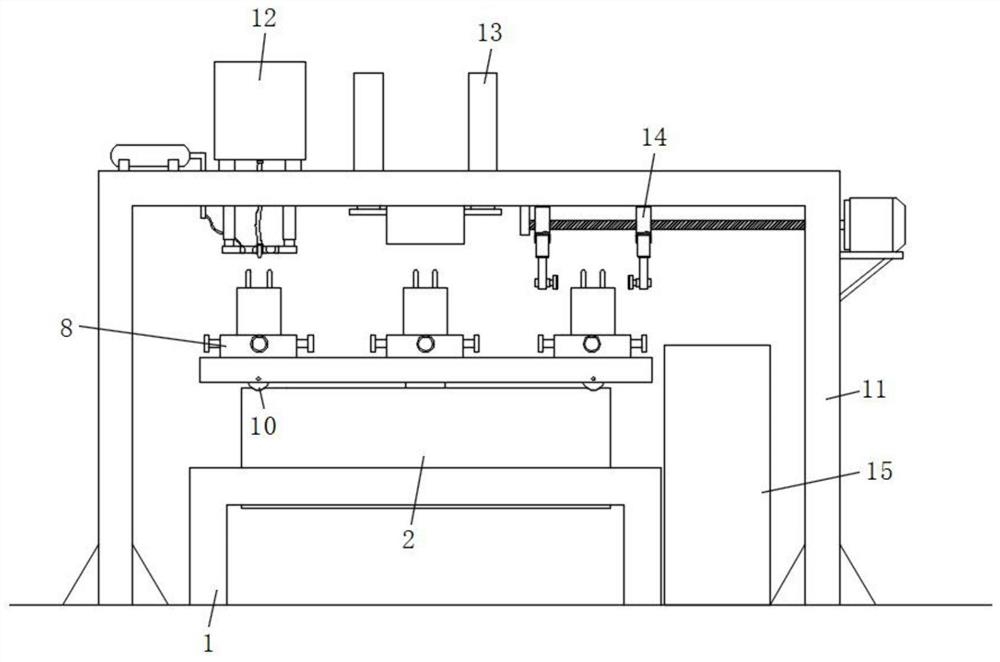

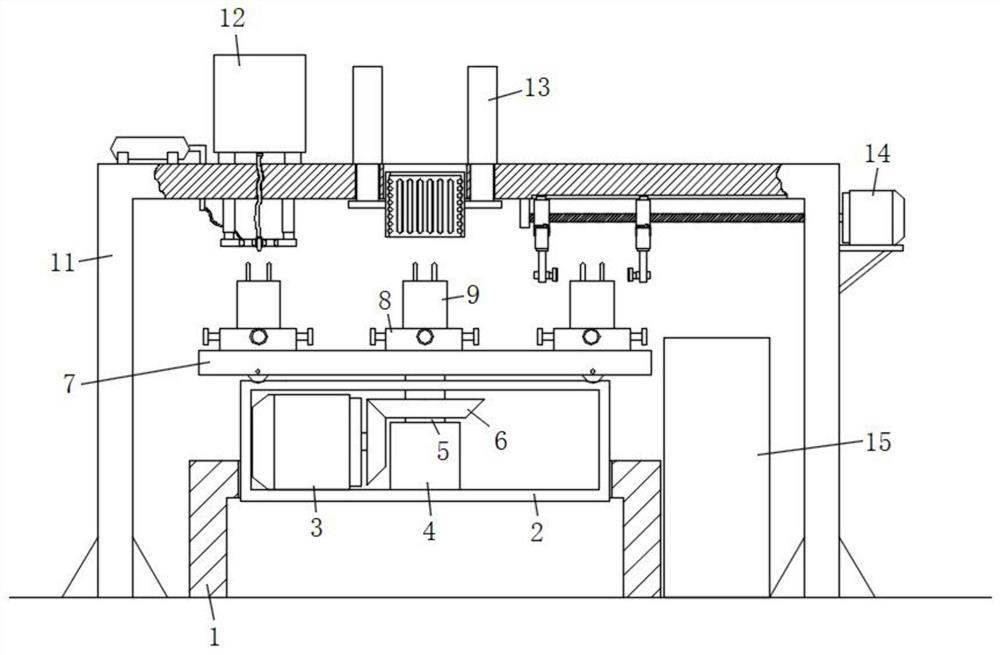

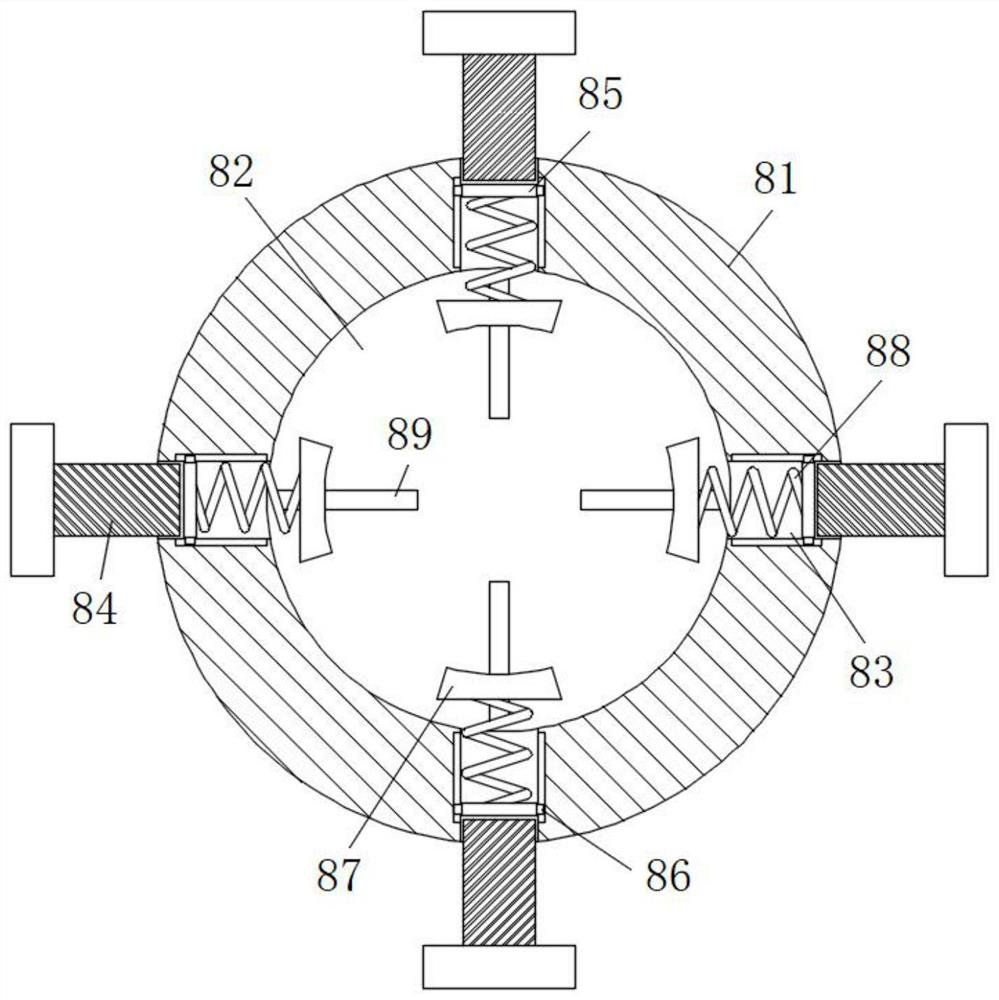

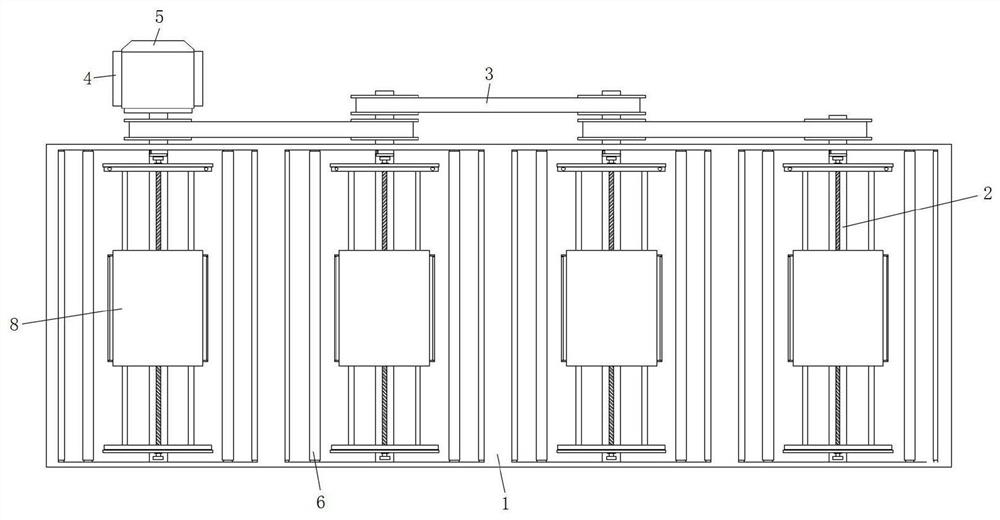

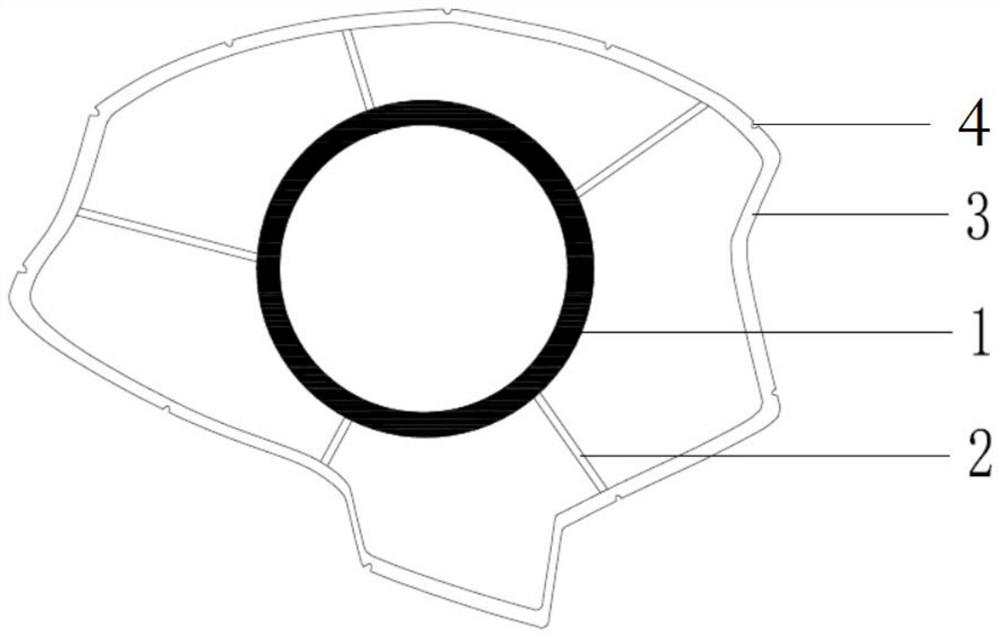

Packaging device for thin film capacitor production

ActiveCN113223875AImprove sealingReasonable designEncapsulating capacitors apparatusEngineeringStructural engineering

A packaging device for thin film capacitor production disclosed by the invention comprises a first mounting rack, wherein a mounting hole is formed in the top surface of the first mounting rack in a penetrating manner, a driving box body is fixedly connected to the inner wall of the mounting hole through a screw, a first servo motor is fixedly connected to one side of the inner bottom surface of the driving box body through a screw, a stabilizing column is further fixed to the center position of the inner bottom surface of the driving box body, a mounting column is rotationally connected to the top surface of the stabilizing column through a rolling bearing, the output end of the servo motor I is rotationally connected with the mounting column through a bevel gear set, the top end of the mounting column penetrates through the top surface of the driving box body and is fixedly connected with a rotating disc, a capacitor temporary fixing mechanism is fixed to the outer side of the top surface of the rotating disc, capacitor bodies are placed on the capacitor temporary fixing mechanisms, and a second mounting frame is erected on the outer side of the first mounting frame. The packaging device is reasonable in design, stable in device operation, high in filling efficiency and good in sealing effect during capacitor filling, and a certain guarantee is provided for high-quality preparation of capacitors.

Owner:ANHUI MASCOTOP ELECTRONICS

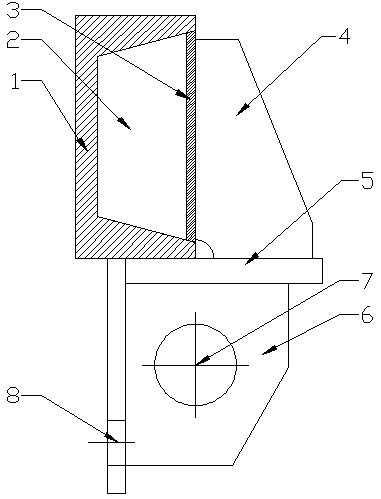

Temporary fixer for cement wire pole

InactiveCN108179914AReduce labor intensityImprove securityTowersArchitectural engineeringUltimate tensile strength

The invention discloses a temporary fixer for a cement wire pole. The temporary fixer comprises a first fixed plate and a second fixed plate, wherein casing pipes are fixedly connected to the upper parts of the first fixed plate and the second fixed plate, the two casing pipes are mutually matched, sliding holes are symmetrically formed in the second fixed plate, insertion rods are connected to the two sliding holes in a sliding manner, one ends of the two insertion rods are provided with external threads, the other ends of the two insertion rods penetrate through the insertion holes and extend outside the second fixed plate, and rotating blocks are arranged at extending ends of the insertion rods; and first threaded slots in threaded connection with the external threads are symmetricallyformed in the first fixed plate, mounting cavities are formed in the first fixed plate and the second fixed plate, and servo motors are arranged on the inner walls of the mounting cavities. The temporary fixer is strong in stability and convenient to mount and dismount, the security coefficient of the wire pole is increased, meanwhile, the labor intensity of workers is alleviated, and the workingefficiency of the workers is improved.

Owner:盐城市新驰工贸有限公司

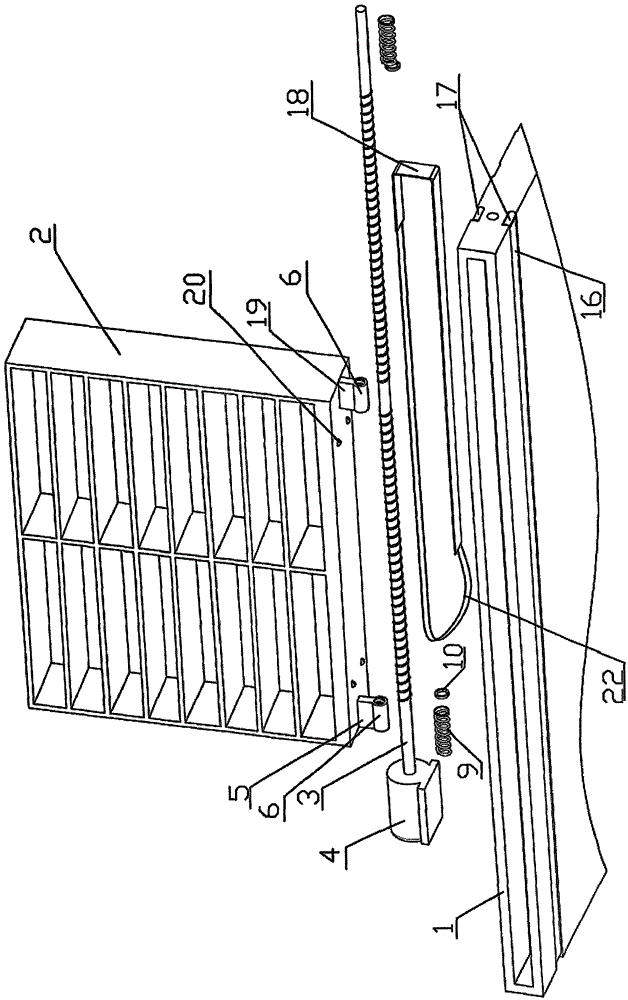

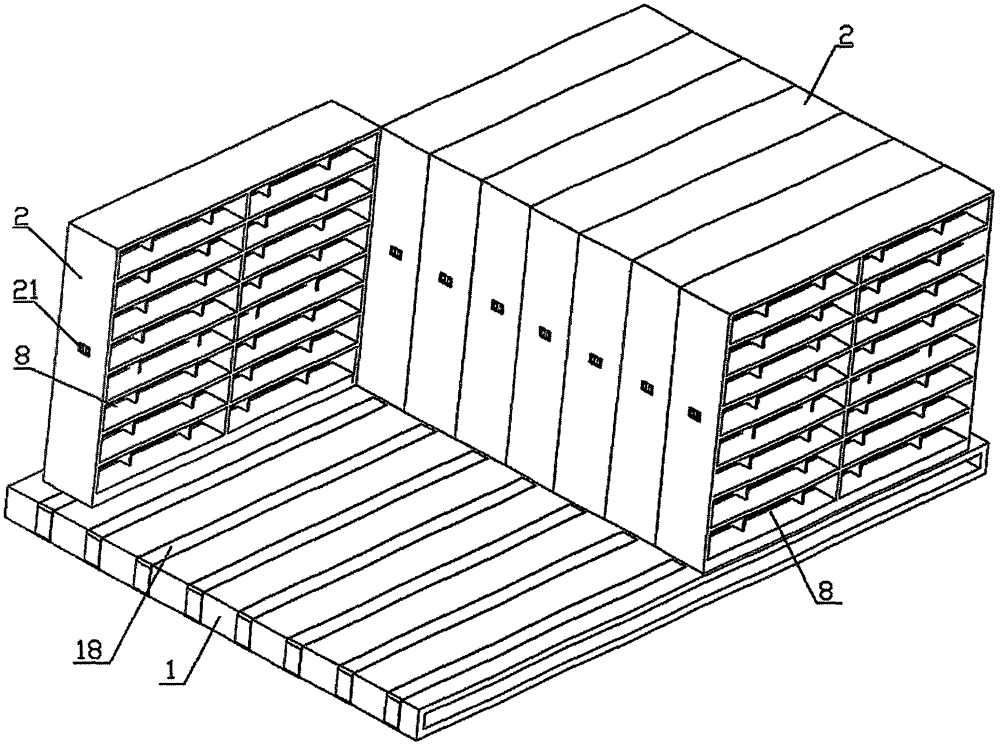

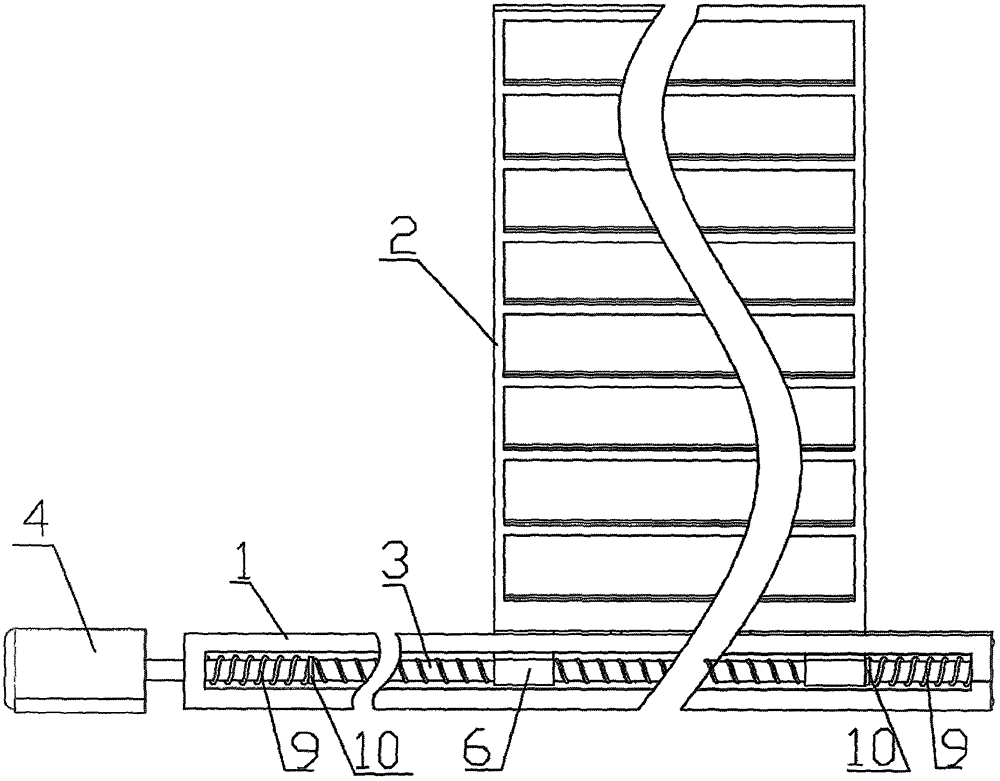

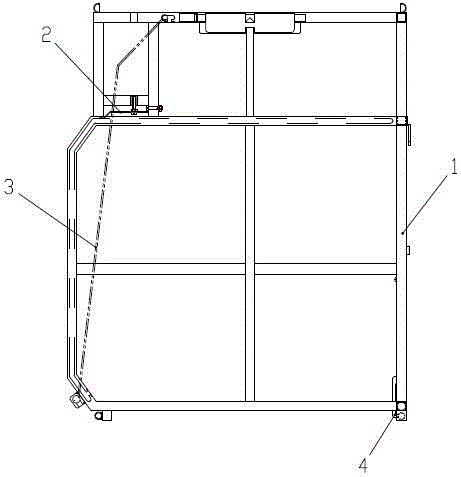

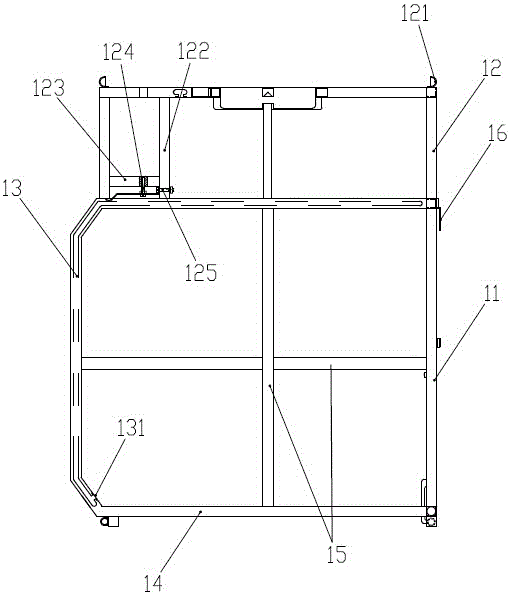

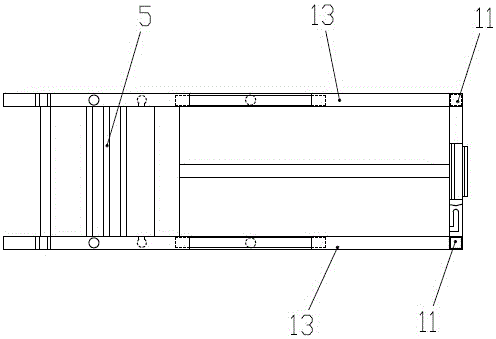

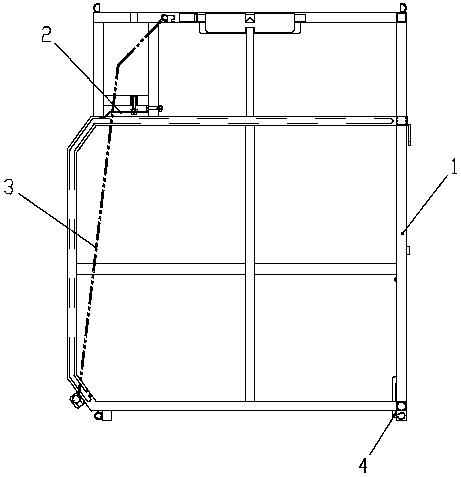

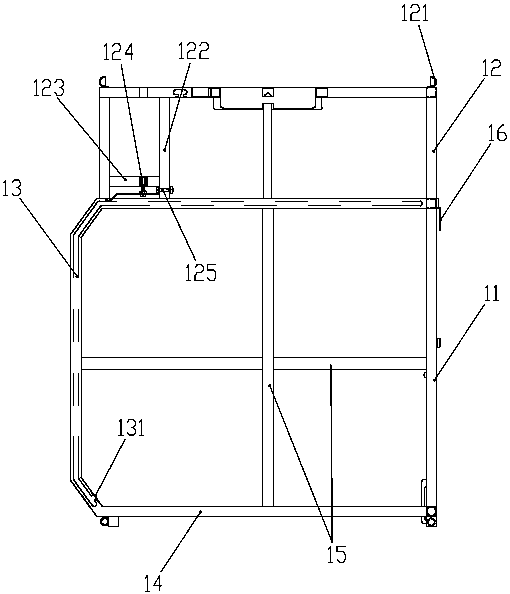

Multifunctional file cabinet device used for storing files in hospital medical file room

InactiveCN106377084ASolve the problem of moving other filing cabinetsReasonable structureBook cabinetsFeetElectric machineryWorkload

The invention discloses a multifunctional file cabinet device used for storing files in a hospital medical file room. The multifunctional file cabinet device comprises a base, wherein a plurality of cabinet bodies are arranged on the base; the plurality of cabinet bodies are in parallel arrangement; transmission posts are arranged in the base and are in corresponding arrangement to the cabinet bodies; one end of the transmission post is fixedly connected with a motor; two support blocks are fixedly arranged at the two ends of the bottom surface of one cabinet body; the bottom end of each support block is fixedly provided with a fixing sleeve; the transmission posts and the fixing sleeves are connected through screw thread pairs; each cabinet top plate is provided with a first slide groove; the support blocks are glidingly matched with the first slide grooves; a plurality of transverse plates and vertical plates are arranged in the cabinet bodies; the transverse plates and the vertical plates form a plurality of file lattices; file bag fixing devices are arranged in the file lattices. The multifunctional file cabinet device provided by the invention has the advantages that the structure is reasonable; the storage quantity is great; the operation is flexible; the problem that other file cabinets need to be moved when one file cabinet is used can be effectively solved; the workload of workers can be effectively reduced; the time is saved; the work efficiency is improved.

Owner:鲁艳

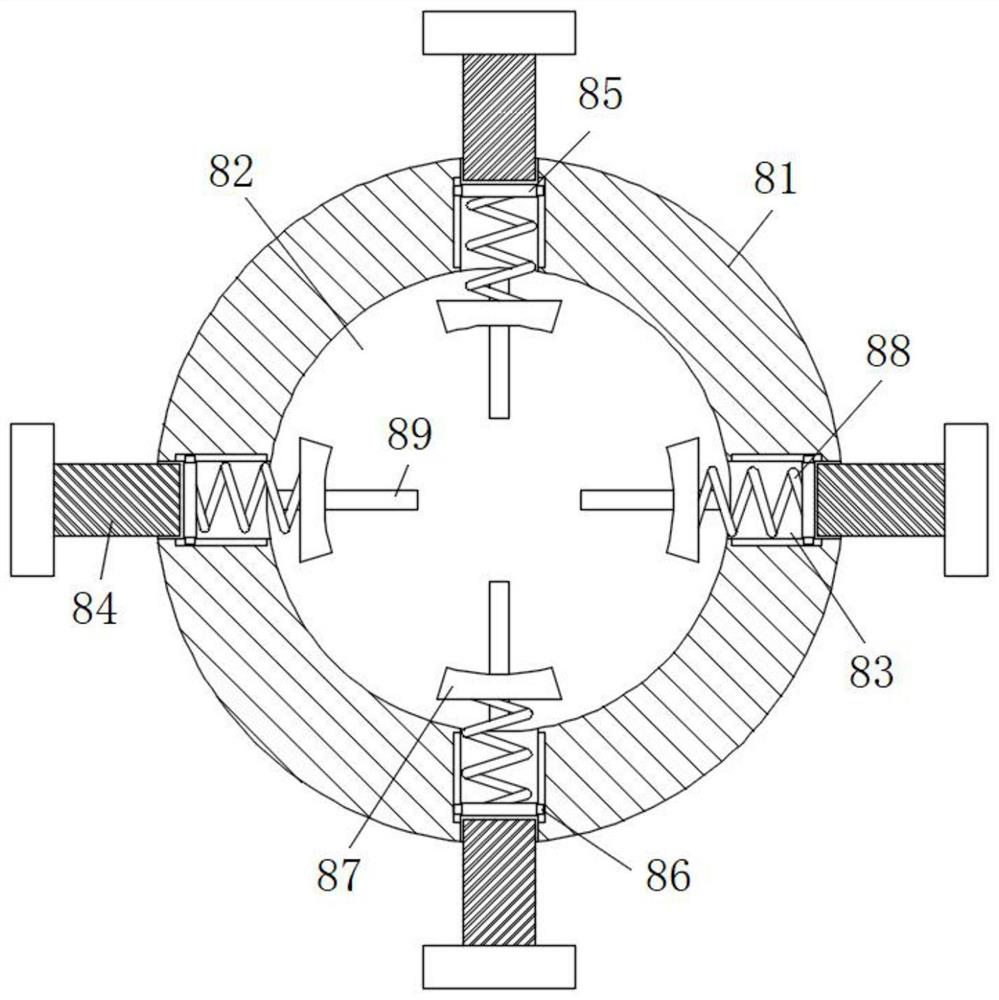

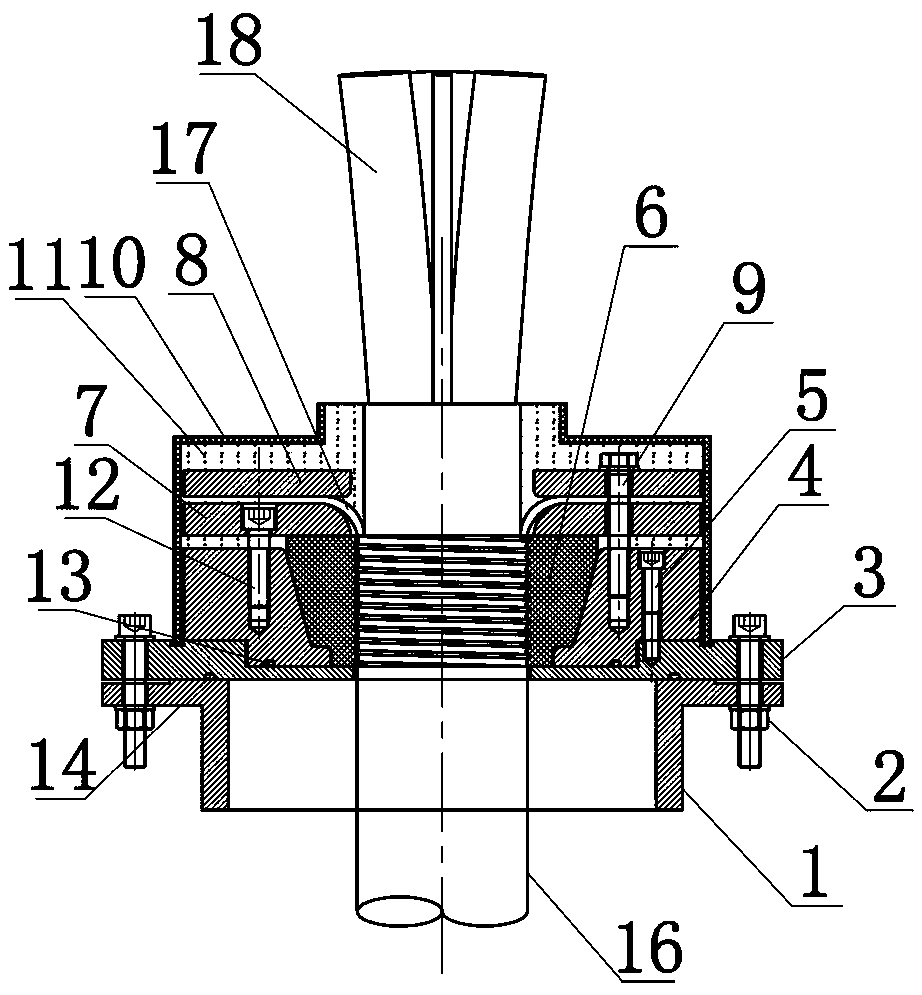

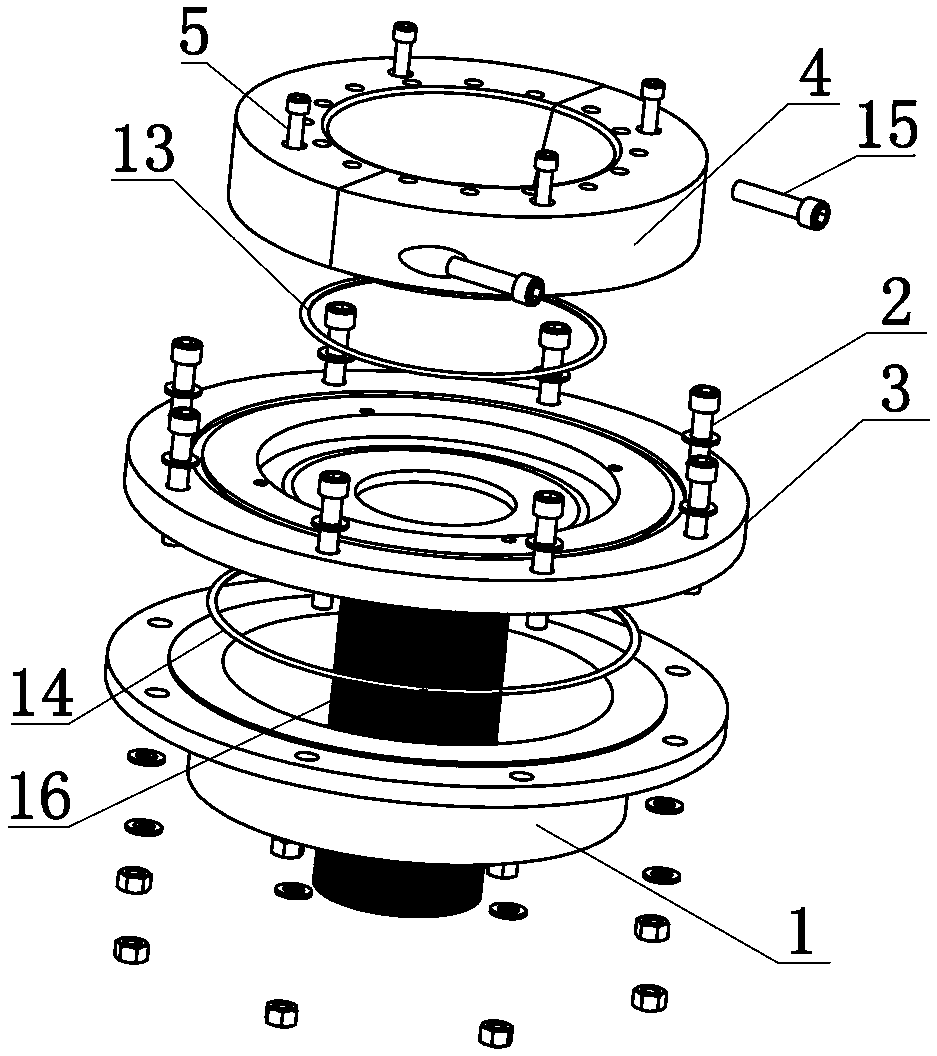

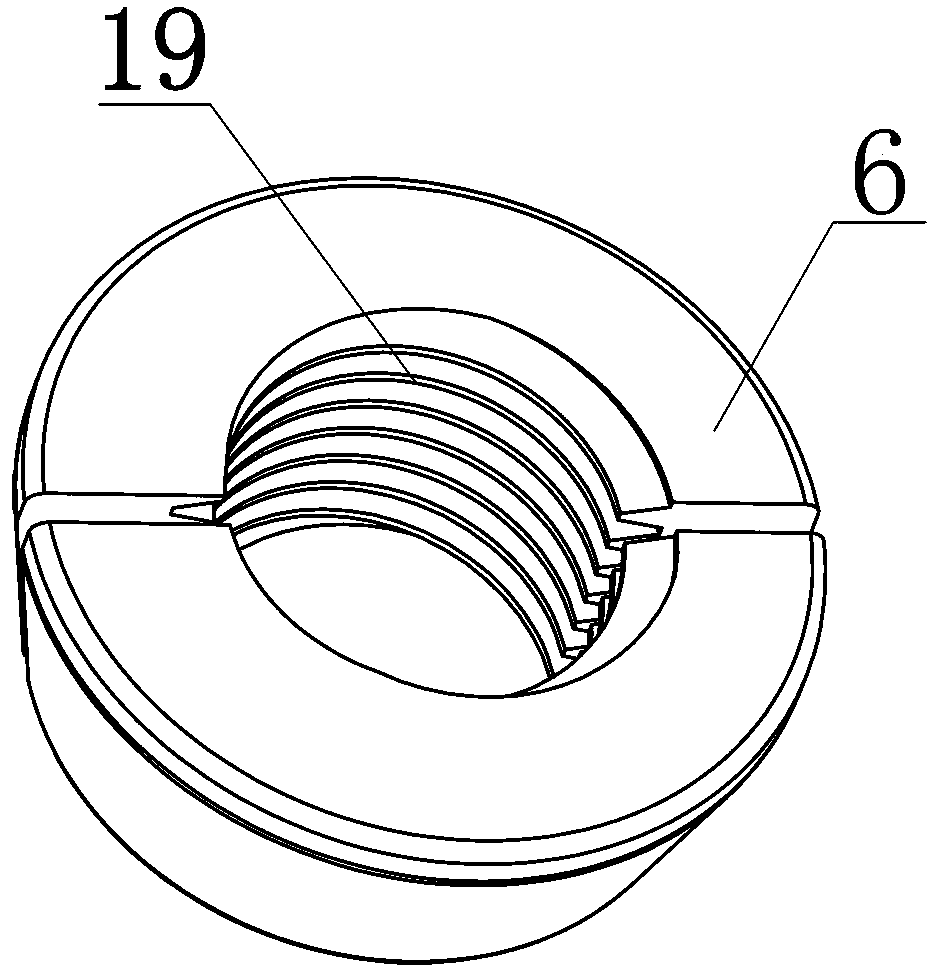

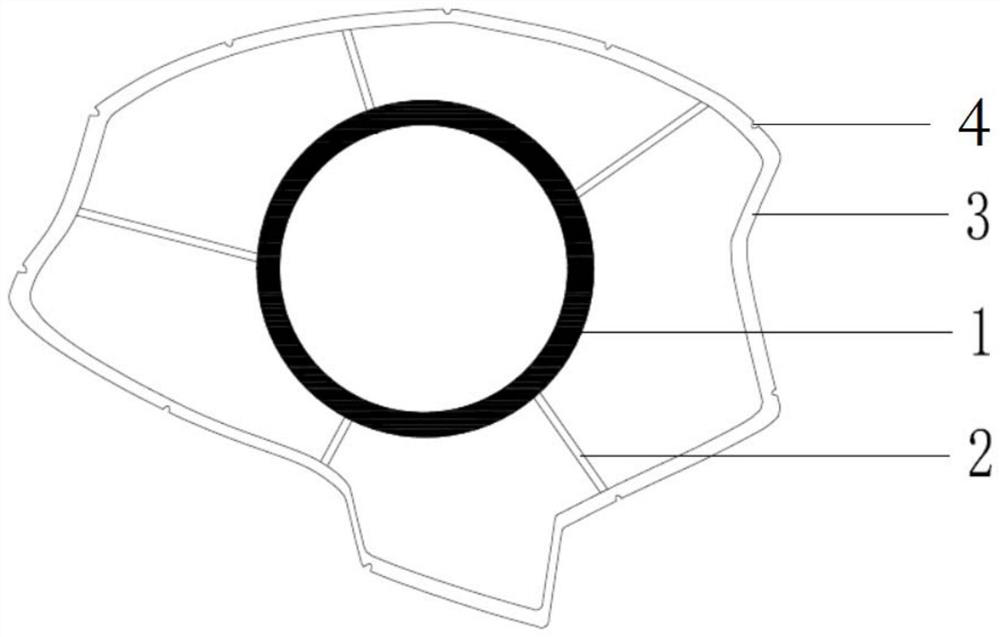

Airtight platform anchoring device

PendingCN109235369AAchieve temporary fixationAchieve airtightnessShipping equipmentEngineeringFlange

The invention discloses an airtight platform anchoring device. The device comprises a base, a ring seat, a PU temporary clamp, a backing plate, a pressure plate and a cover. The base shape is matchedwith a platform top flange and is detachably fixed to the upper side of the platform top flange, the ring seat is detachably fixed to the upper side of the base, a truncated-type through hole matchedwith the shape of the PU temporary clamp is formed in the ring seat, the outer side of the PU temporary clamp is a truncated type and is arranged in the through hole of the ring seat, the backing plate is disposed on the upper portion of the PU temporary clamp, the backing plate is detachably fixed to the ring seat, the pressure plate is disposed on the upper side of the backing plate and is detachably fixed to the backing plate and the ring seat, the cover is disposed outside the ring seat, the backing plate and the pressure plate, and the lower end of the cover is fixed to the upper side ofthe base. The device integrates the temporary clamp into the platform anchoring device, and not only achieves the temporary fixing effect of the lightweight temporary clamp on a submarine cable, but also achieves the airtightness of the inside of platform anchoring.

Owner:ZHONGTIAN TECH MARINE SYST CO LTD

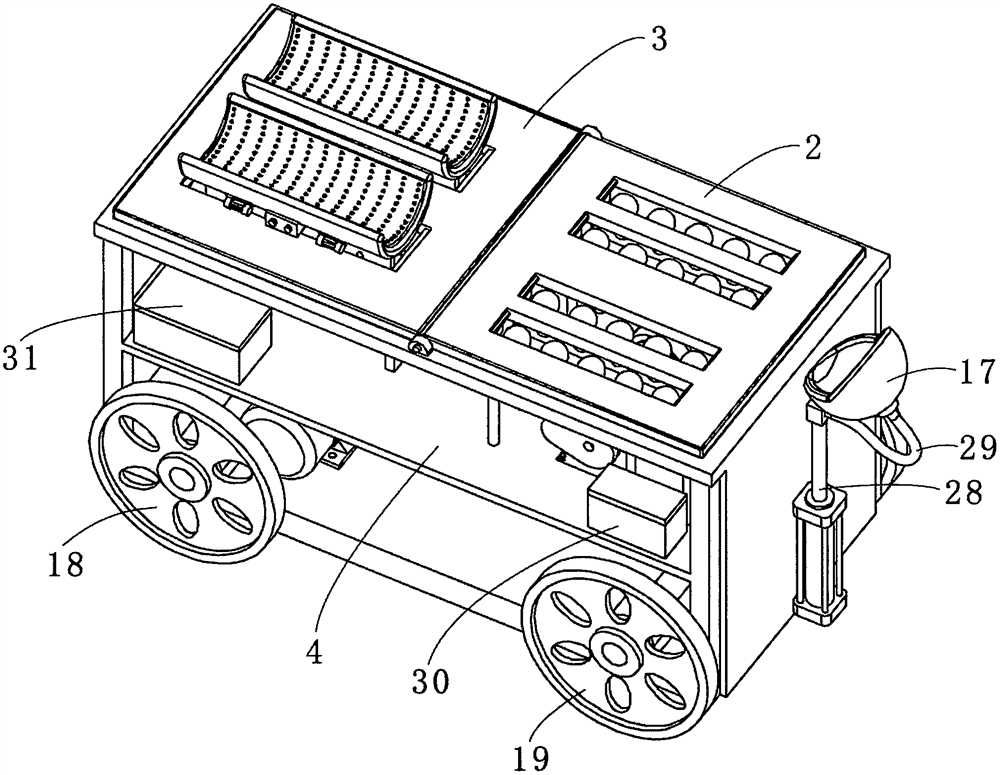

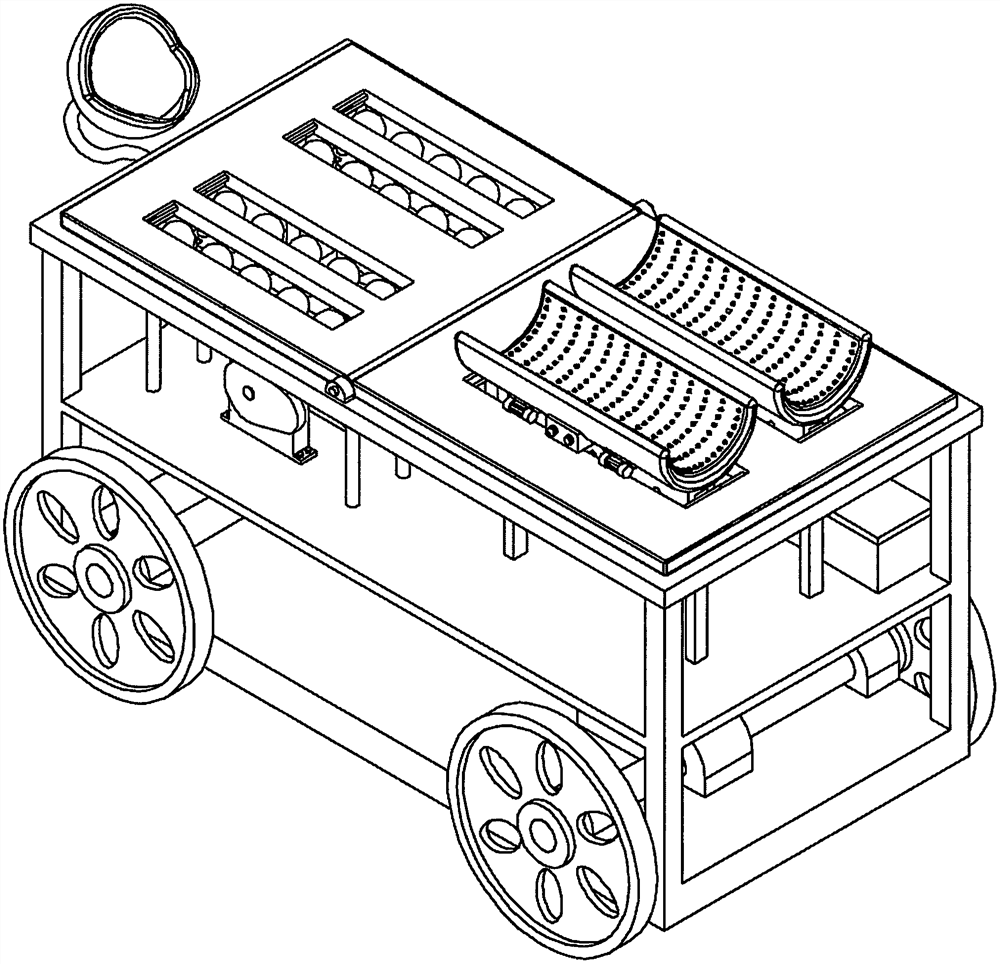

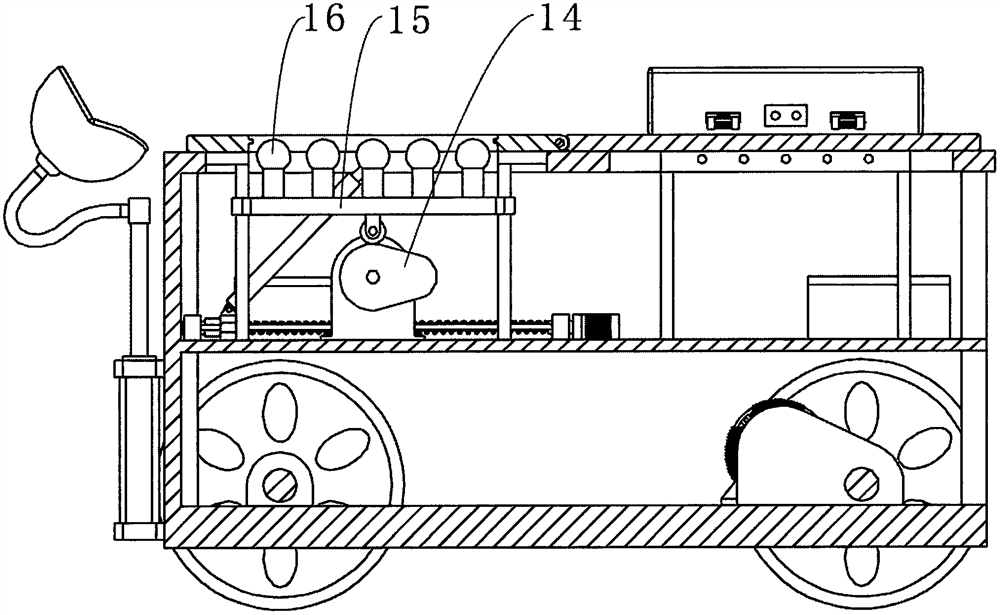

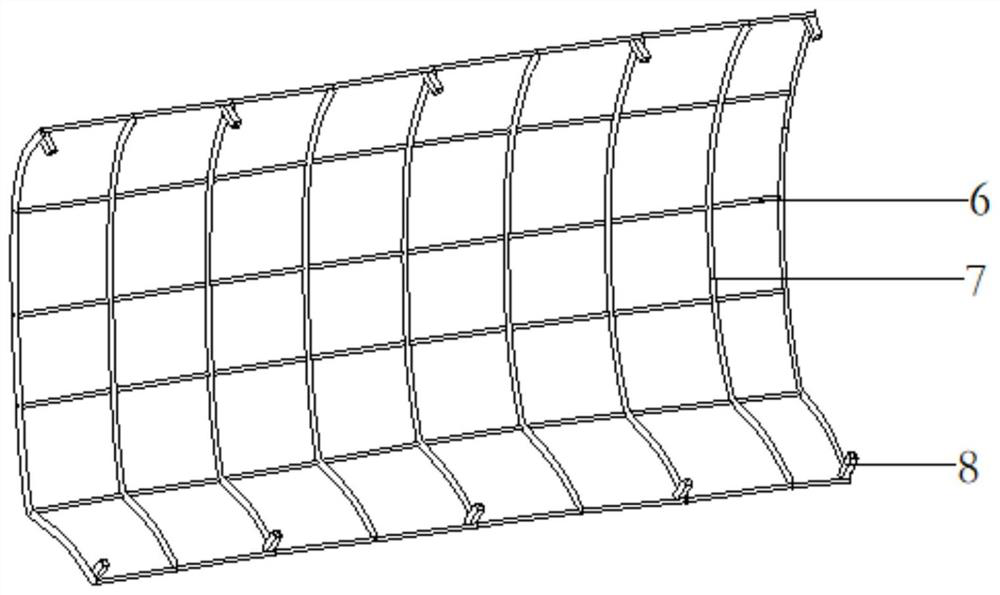

Fire hose box

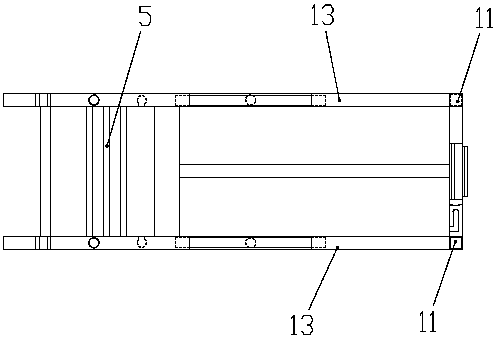

The invention discloses fire control auxiliary equipment, and particularly discloses a fire hose box.The fire hose box comprises a box rack, wherein a plurality of hose hanging sliding rods allowing fire hoses to be hung and fixed thereon are arranged on the box rack, the hose hanging sliding rods slide along the box rack, a damping component used for preventing the hose hanging sliding rods from falling off is arranged on the box rack, and a clamping component used for fixing the box rack onto a transportation tool is arranged below the box rack.By the adoption of the fire hose box, orderly arrangement and quick laying of the fire hoses can be achieved conveniently, bending and torsion of the fire hoses in the laying process are reduced, and damage frequency is reduced.Furthermore, the fire hose box can be matched with a fire hose vehicle for integral case transportation, the fire hoses can be pulled out conveniently and quickly, labor intensity is relieved, and conveyance efficiency is improved.

Owner:SICHUAN JOINER MACHINERY & AUTOMATIC EQUIP

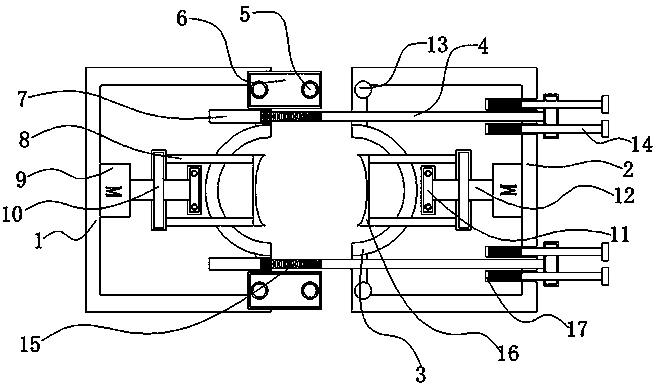

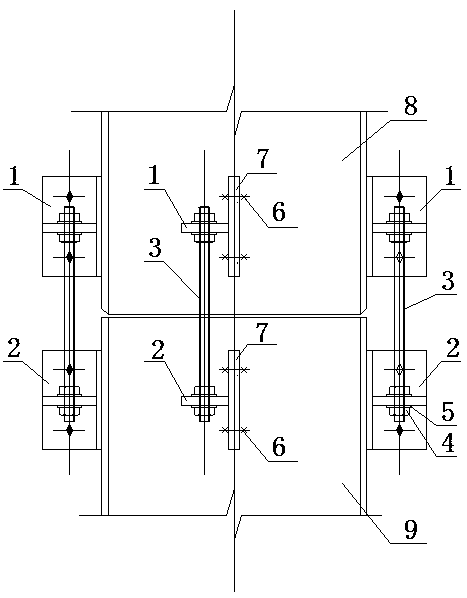

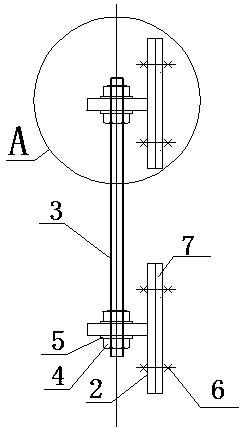

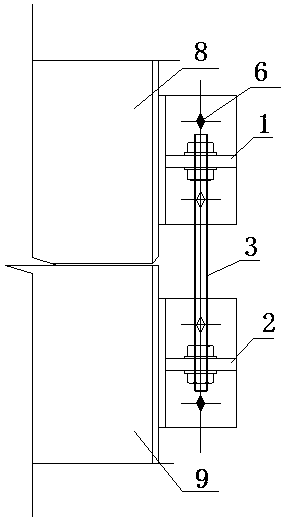

Steel column butt joint adjustment fixing device and method

InactiveCN108343163AAchieve temporary fixationAchieve regulationBuilding constructionsSteel columnsEngineering

The invention relates to a steel column butt joint adjustment fixing device and method. The steel column butt joint adjustment fixing device comprises upper T-shaped connecting pieces and lower T-shaped connecting pieces, and vertical plates of the upper T-shaped connecting pieces and vertical plates of the lower T-shaped connecting pieces are separately and fixedly mounted on lug plates of the butting ends of an upper steel column and a lower steel column through high-strength bolts, wherein the upper steel column and the lower steel column are in butt joint. Corresponding bolt holes are separately formed in horizontal plates of the upper T-shaped connecting pieces and horizontal plates of the lower T-shaped connecting pieces and the horizontal plates of the upper T-shaped connecting pieces and the horizontal plates of the lower T-shaped connecting pieces are connected through screws and nuts. After the upper steel column is hoisted in position, the upper T-shaped connecting pieces are moved up and down by adjusting the nuts on the screws, so that the upper steel column is driven to move to adjust the weld gap of steel column connecting openings and the verticality of the upper steel column. After the upper steel column is adjusted to the required accuracy, the nuts at the upper and lower ends of the horizontal plates of the upper T-shaped connecting pieces are tightened to fix the upper steel column. According to the steel column butt joint adjustment fixing device and method, the problem that a cable rope and a support are inconvenient to install and fix is solved, the work efficiency is greatly improved, the structure is simple, the construction is convenient, the three-dimensional cross work of the construction personnel is avoided, and the safety of the construction personnel is ensured.

Owner:CHINA 22MCC GROUP CORP

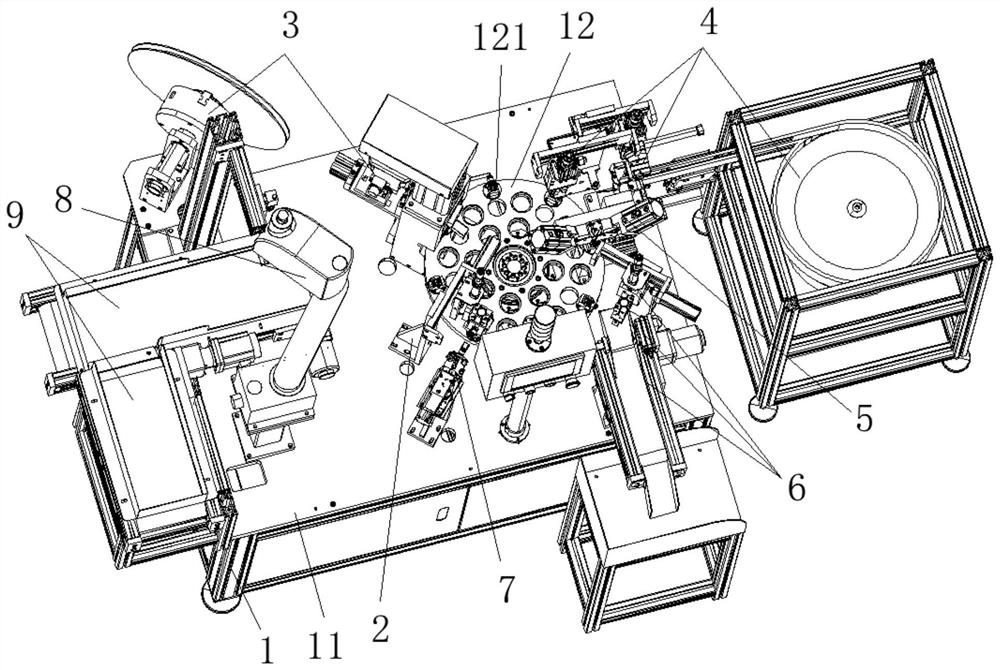

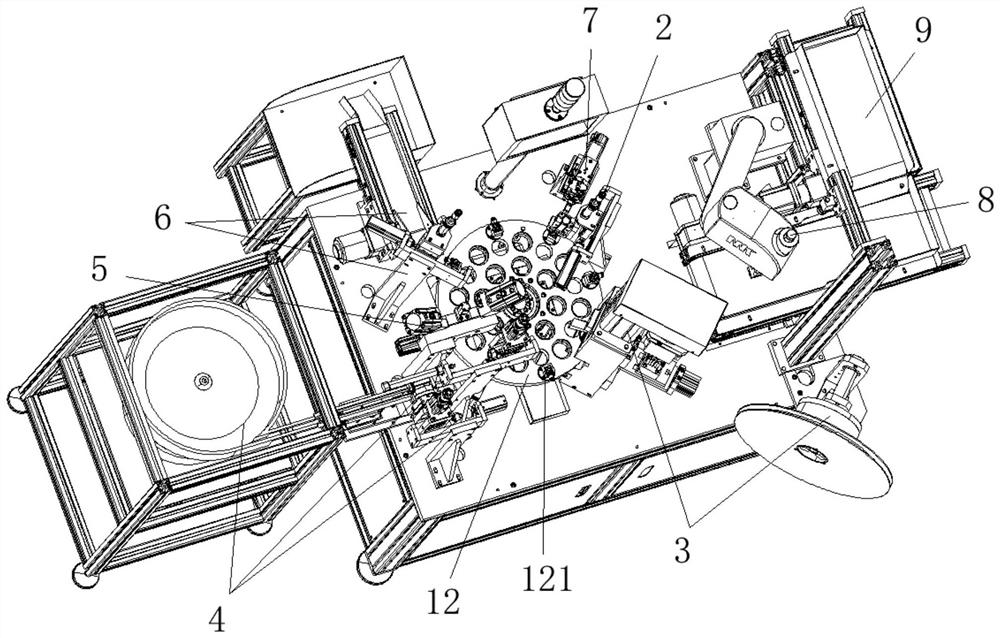

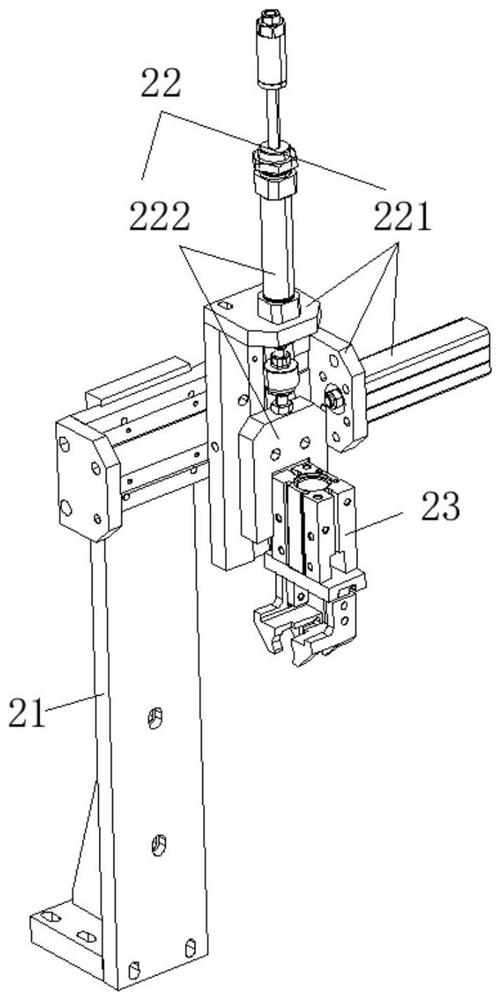

Assembling equipment for built-in soldering lug of two-way joint

ActiveCN113182740AGood for industrial processingRealize automatic feeding operationWelding/cutting auxillary devicesAuxillary welding devicesMechanical engineeringManual handling

The invention provides assembling equipment for a built-in soldering lug of a two-way joint, and belongs to the technical field of metal part machining. A base feeding mechanism, a visual grabbing mechanism, a direction adjusting mechanism, an automatic base discharging mechanism, a copper ring piece machining mechanism, a bamboo joint piece placing mechanism, an assembling and pressing mechanism and an automatic discharging mechanism are sequentially arranged beside a rotary disc. Automatic feeding operation of a base and automatic adjustment of the direction of a welding hole in the base are achieved, automatic machining and installation of a copper ring piece can be achieved at the same time, the problem that machining, transferring and manual placing are needed in advance is solved, the workload is relieved, automatic feeding of a bamboo joint piece can be achieved, the base and the bamboo joint piece are automatically and temporarily fixed, automatic discharging is conducted on the base and the bamboo joint piece which are temporarily fixed, the automation degree is higher, the machining efficiency is improved, potential safety hazards caused by manual operation are avoided, and industrialization machining of the two-way joint is facilitated.

Owner:宁波亚大自动化科技有限公司

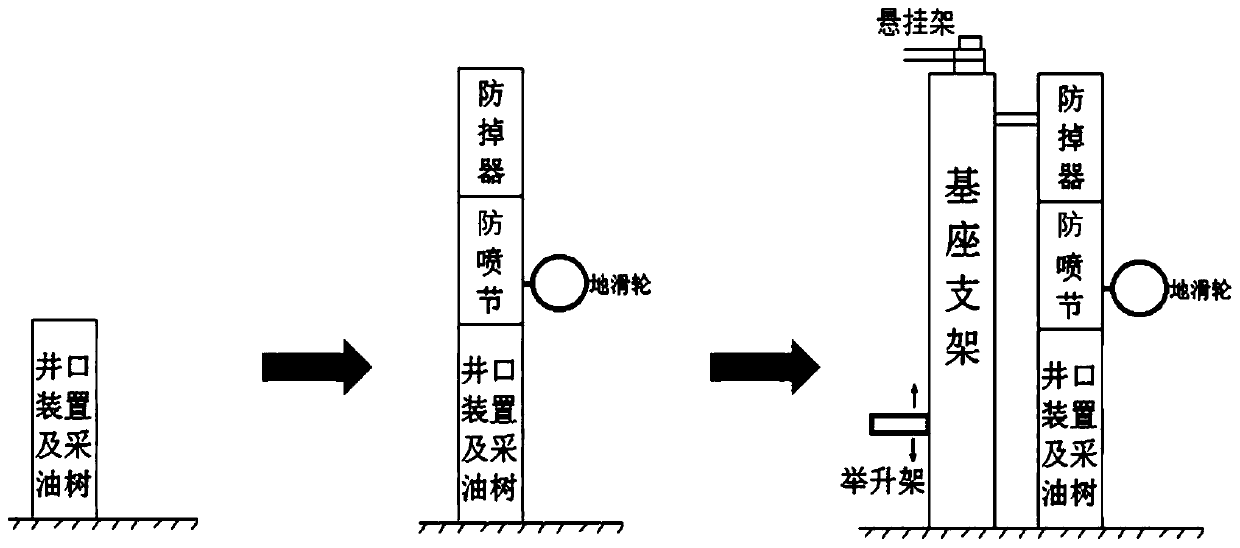

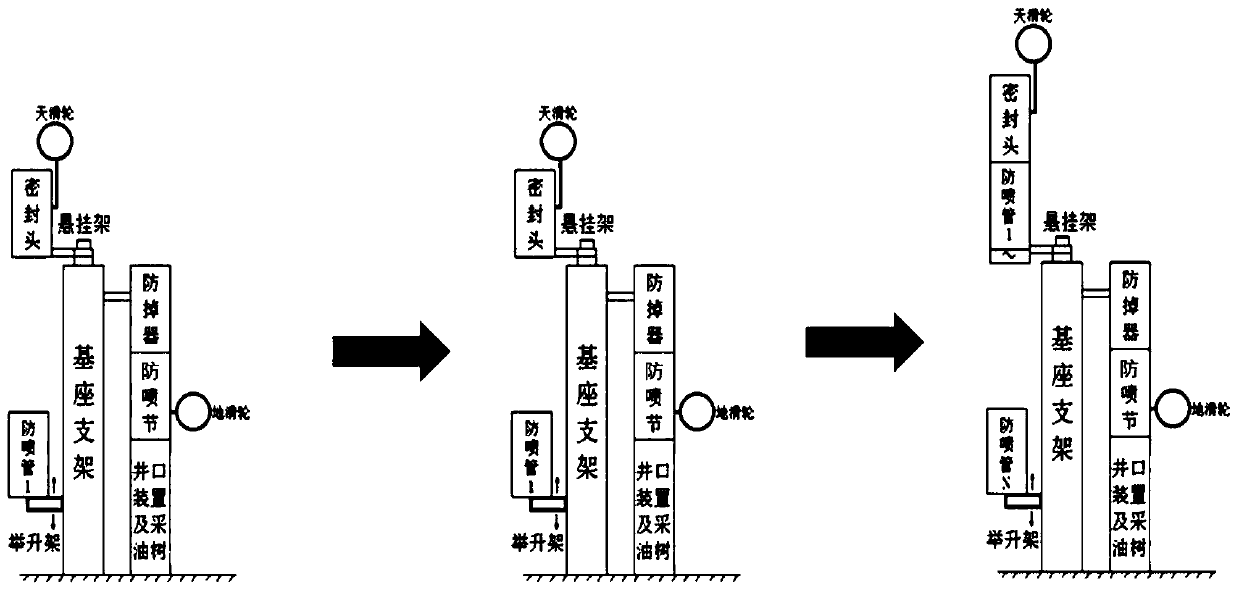

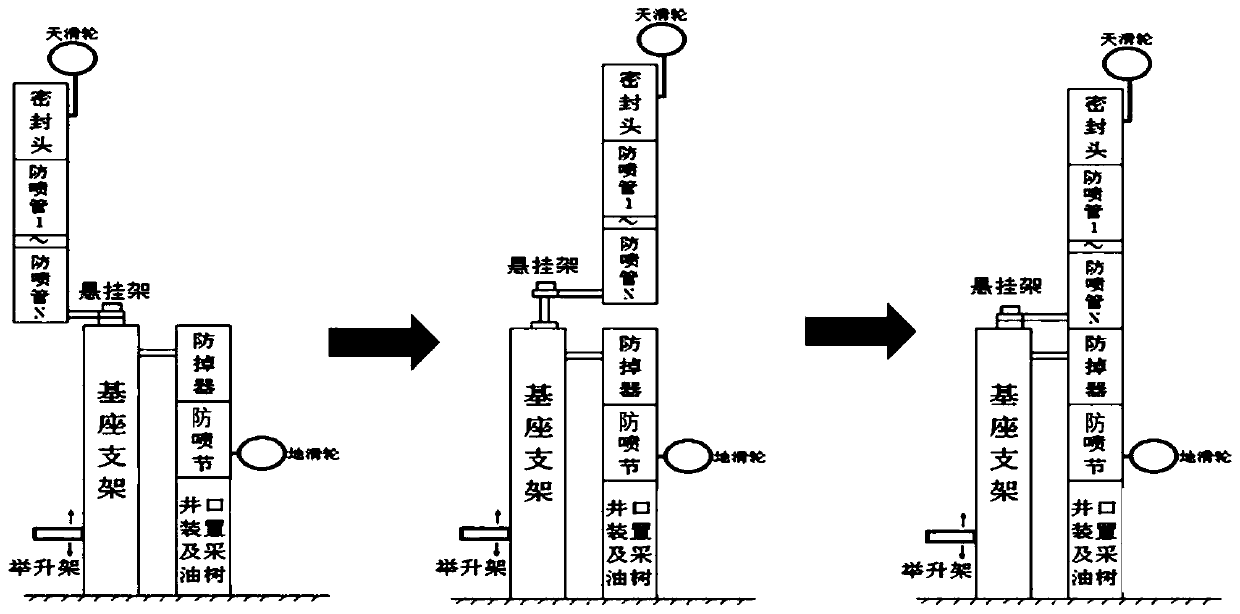

Blowout prevention self-lifting and pressure logging construction process

PendingCN111577246ASolve usabilitySolving Problems Limiting High Pressure Well LoggingSurveySealing/packingArchitectural engineeringOil field

The invention discloses a blowout prevention self-lifting and pressure logging construction process, and belongs to the technical field of oil field logging operations. The vertical installation and disassembly of a blowout prevention device are realized through a base support and a suspension frame on the base support. The autonomous lifting and pressure logging construction of the blowout prevention device under the condition of no derrick truck is achieved, the configuration of a single operation team saves one professional derrick truck and one professional operator, the construction costis greatly reduced, and compared with a derrick truck, by applying the construction process, the annual cost of each operation team can be saved by nearly 400,000 yuan, and the productivity effect issignificantly improved.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

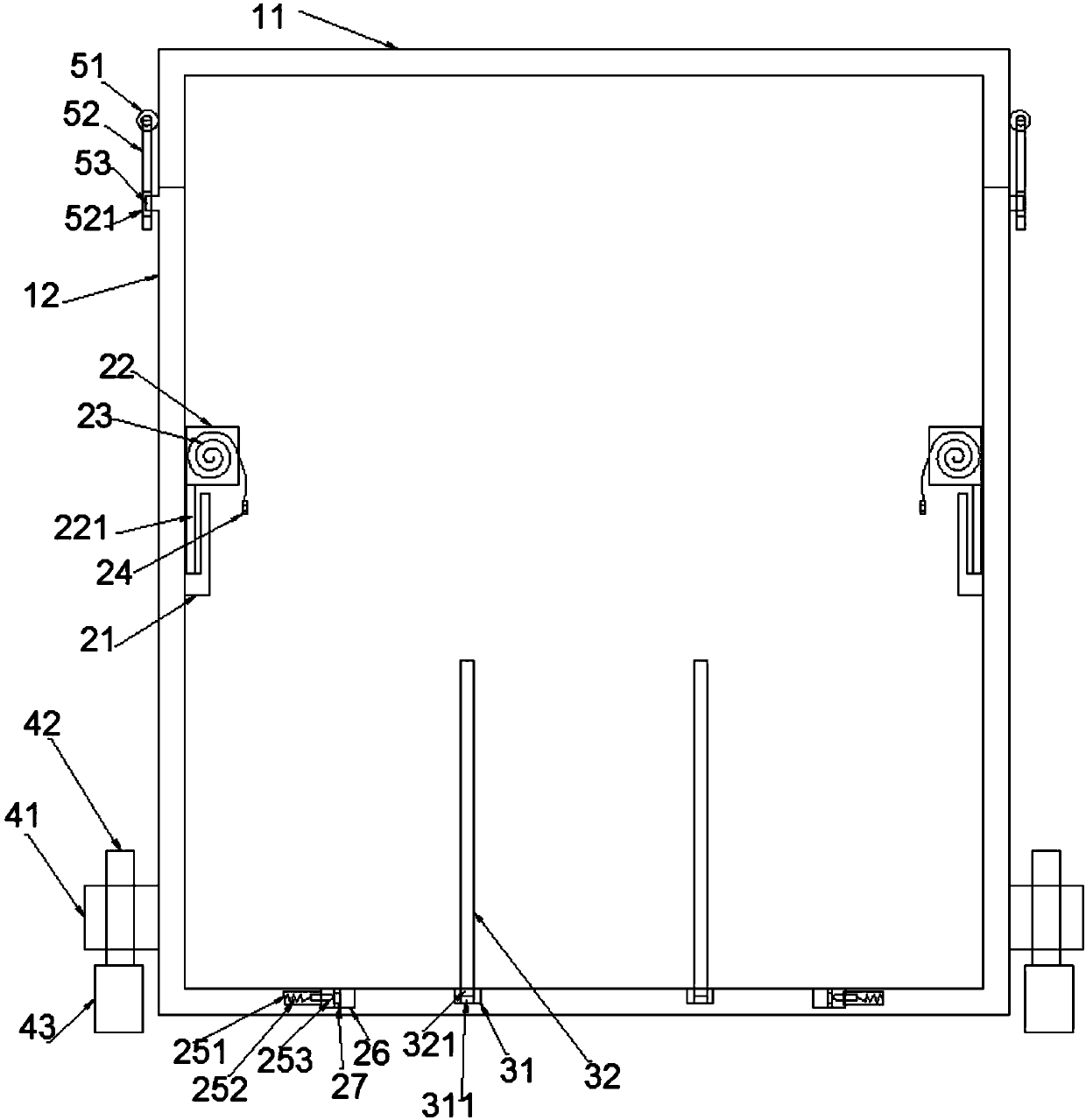

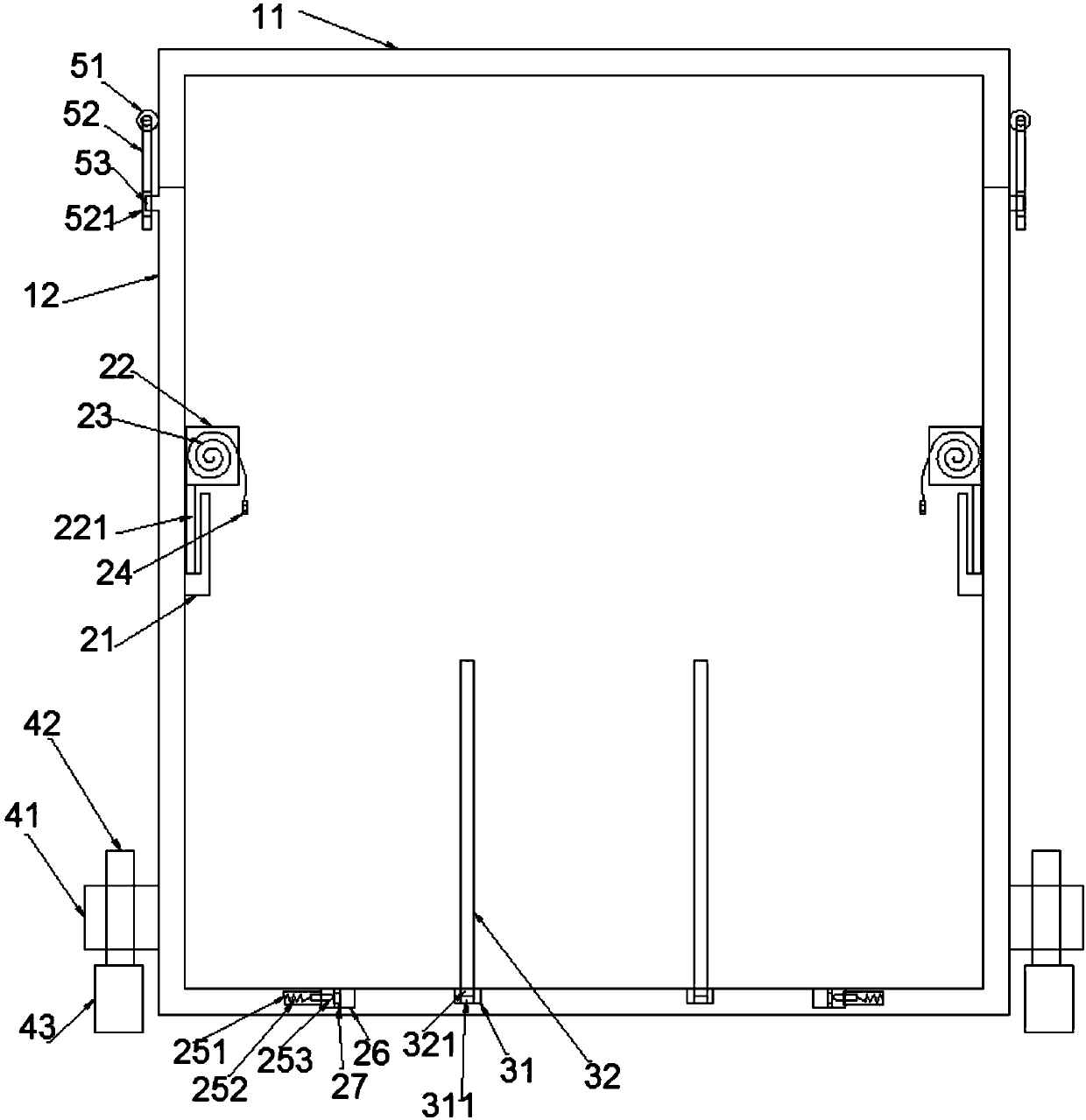

Container with cargo binding function

The invention discloses a container with a cargo binding function. The container comprises a box body, a tightening mechanism, a separating plate mechanism and a moving mechanism; the box body comprises an upper box body and a lower box body; the binding mechanism comprises a shell, a tightening belt and a clamping part, the tightening belt is arranged on the shell, one end of the tightening beltextends out of the shell, a buckle is arranged at the extending end of the tightening belt, the clamping part is arranged on the inner bottom surface of the lower box body, the shell is arranged on the inner side wall of the lower box body, and the buckle can be clamped into the clamping part; the upper box body is connected with the lower box body through a fixing mechanism; and the fixing mechanism comprises a pin roll, a clamping plate and a convex plate, the pin roll is arranged on the outer side wall of the upper box body, one end of the clamping plate is hinged to the pin roll, a clamping hole is formed in the other end of the clamping plate, the convex plate is arranged on the outer side wall of the lower box body, and the convex plate can be clamped into the clamping hole.

Owner:韶关市南北通汽车用品有限公司

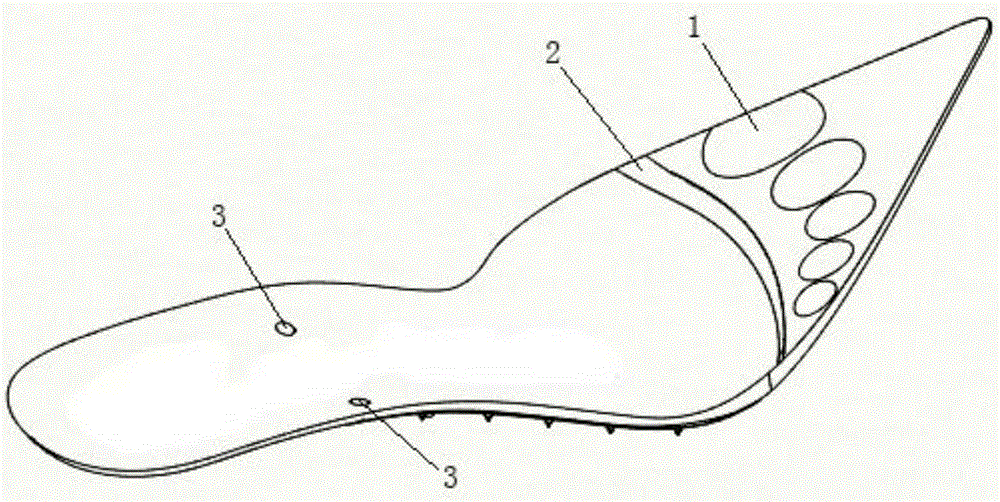

High-heeled shoe last base plate and insole simulation design method and simulated insole

The invention belongs to the field of daily use articles and concretely provides a high-heeled shoe last base plate simulation design method. The high-heeled shoe last base plate simulation design method comprises the following steps of acquiring a foot sole model, 3D scanning the foot sole model, 3D scanning a standard shoe last base plate, model fitting a 3D data image model and adjusting and correcting a shoe last base plate 3D data image model. The invention further provides an insole simulation design method based on the high-heeled shoe last base plate simulation design, and a simulation insole. The beneficial effects of the simulation design method are that the high-heeled shoe insole prepared by the insole simulation model is advantaged by fitting foot, conserving fabric and assembly fast; and problems of discomfort due to unsuitable high-heeled shoes and high-heeled shoe diseases such as big foot disease can be effectively prevented and reduced.

Owner:广州下季鞋业有限公司

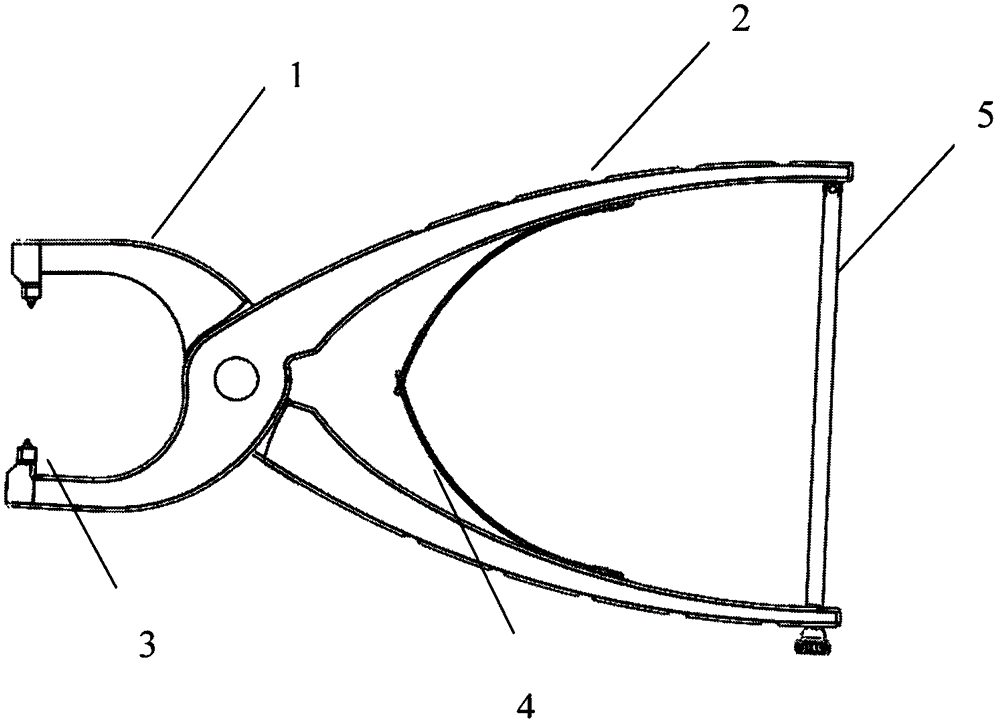

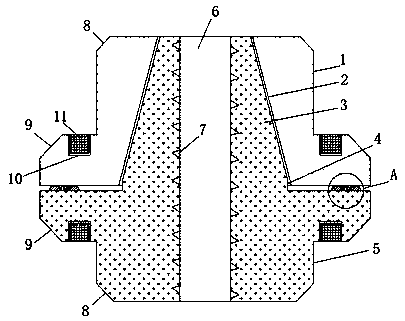

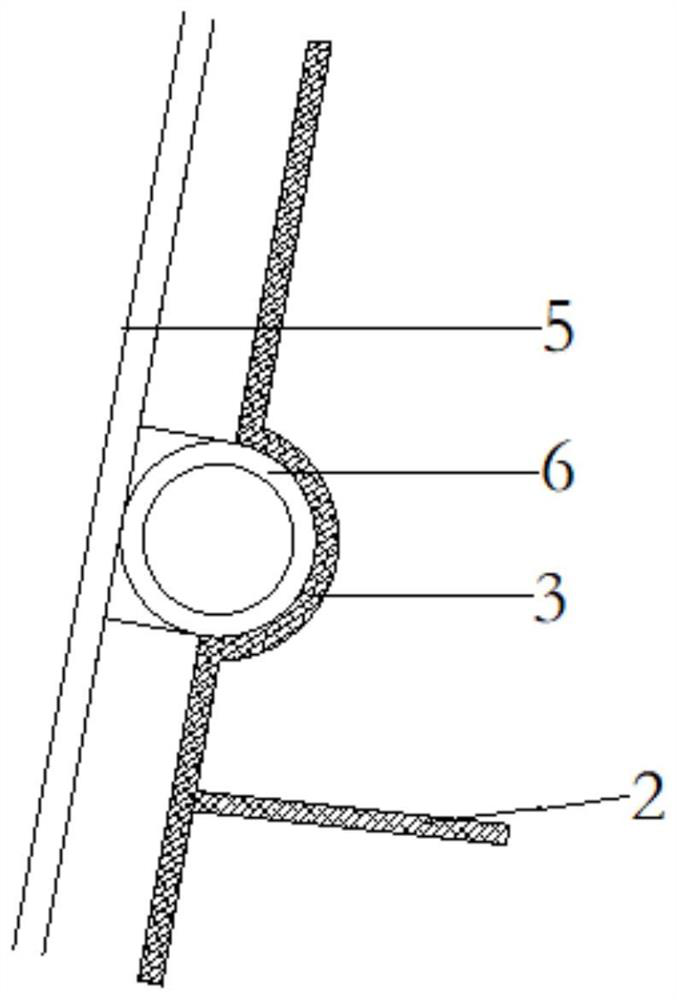

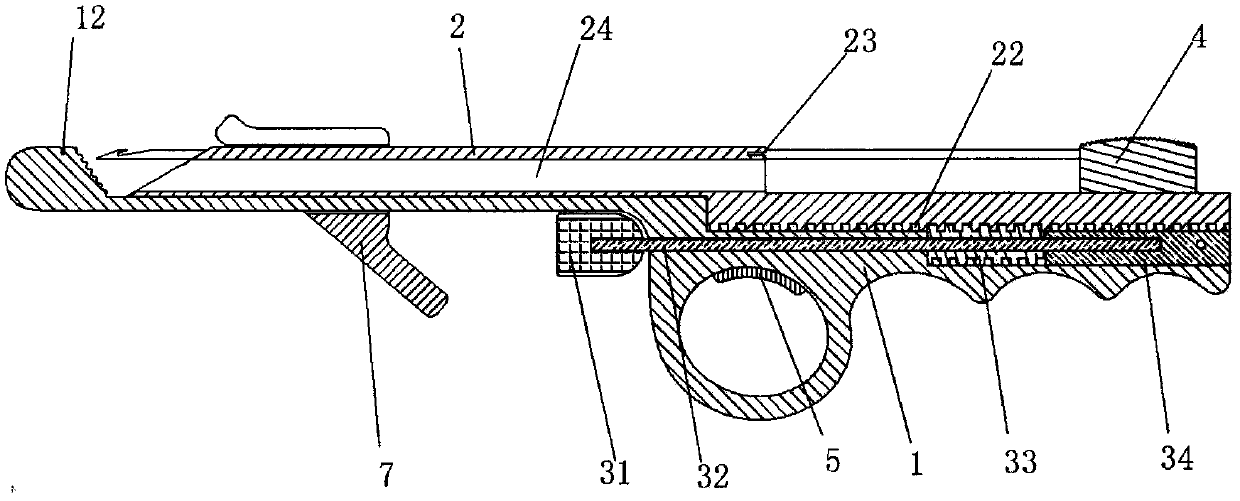

Oblique bone fracture reduction forceps

The invention belongs to the field of medical apparatus and instruments, in particular to a pair of oblique bone fracture reduction forceps. The pair of oblique bone fracture reduction forceps is provided with forceps arms (1), handles (2), reset teeth (3), reset springs (4) and a locking rod (5), and is characterized in that when the two handles (2) are extruded towards each other, the reset springs (4) are deformed; when the two handles (2) get close to each other, then the forceps arms (1) are used for driving the two reset teeth (3) to clamp two ends of an oblique bone fracture end; the reset teeth (3) are used for driving the bone fracture end to reset and clamp; when the locking rod (5) is used for locking, the clamping state of the reset teeth (3) can be kept to achieve a temporary fixing effect after resetting, so that a long oblique bone fracture can be corrected in a minimally invasive orthopedics surgery, and the displacement is shortened, and a temporary fixing effect is achieved. The pair of oblique bone fracture reduction forceps has the advantages of simple structure, convenience in operation, small wounds, good resetting and fixing effects, and the like.

Owner:毕宏政

First-aid fracture fixture

The invention relates to a first-aid fracture fixture. The first-aid fracture fixture comprises base cloth and isolation cloth, wherein a bandage is disposed on the outer side of the base cloth; at least four long-striped air sacs are disposed abreast between the base cloth and the isolation cloth; an air inlet tube and an air outlet tube are disposed on one of the long-striped air sacs; a plurality of air vents are formed in the base cloth between two adjacent long-striped air sacs; the isolation cloth is made of two-layer medical gauzes; three sides of the two-layer medical gauzes are fixed and the other sides of the two-layer medical gauzes are opened; a pharmaceutical containing chamber is disposed between the two-layer medical gauzes; an exhaust valve is disposed on the air outlet tube; an air charging device is connected to the tail end of the air inlet tube; a one-way valve is disposed at the connecting part of the air charging device and the air inlet tube; the air charging device comprises an air charging pump and a controller; a microprocessor is disposed in the controller; the exhaust valve and the air charging pump are connected with the microprocessor via a signal line. The first-aid fracture fixture is simple in structure, convenient to use and low in usage cost, can be used as long as the air sacs are fully charged, and does not occupy a space when the fixture is placed.

Owner:张勇

Auxiliary massage and nursing device for neurology department

PendingCN113456457AAchieve massageAchieve temporary fixationOperating tablesDevices for pressing relfex pointsBody typeEngineering

The invention discloses an auxiliary massage and nursing device for the neurology department. The auxiliary massage and nursing device comprises a nursing bed body, a leg massage mechanism, a back massage mechanism and a head massage mechanism. The angle of the front bed plate of the nursing bed body can be adjusted through the lead screw mechanism and the telescopic air cylinder, so that a patient can lie and sit; a clamping jaw in the leg massage mechanism can pass through a first opening in a rear bed plate of the nursing bed main body from top to bottom and is movably clamped with a supporting frame below so as to temporarily fix the leg massage mechanism, and meanwhile, the leg massage mechanism can be adjusted front and back through the structure so as to adapt to patients of different body types; a rubber massage head in the back massage mechanism can pass through a second opening in a front bed plate of the nursing bed body from bottom to top, and a cam drives the massage head to move up and down, so that the back of a patient can be comprehensively massaged; the head massage mechanism is arranged at the front end of the front bed plate, so that the head of the patient can be massaged.

Owner:HEBI CITY PEOPLES HOSPITAL

Packaging device for film capacitor production

ActiveCN113223875BImprove sealingReasonable designEncapsulating capacitors apparatusStructural engineeringMechanical engineering

The invention discloses a packaging device for film capacitor production, which comprises a mounting frame 1, a mounting hole is opened through the top surface of the mounting frame 1, and a driving box is fixed on the inner wall of the mounting hole through screws, and one side of the bottom surface of the driving box is passed through. The screw is fixedly connected with the servo motor 1, and the center of the bottom surface of the drive box is also fixed with a stabilizing column. The top surface of the stabilizing column is connected to the mounting column through a rolling bearing. The top of the installation column passes through the top surface of the drive box and is fixedly connected with a rotating disk. A temporary fixing mechanism for capacitors is fixed on the outer side of the top surface of the rotating disk. Capacitor bodies are placed on the temporary fixing mechanisms for capacitors. frame two. The invention has reasonable design, stable operation of the device, high filling efficiency and good sealing effect when filling capacitors, thereby providing a certain guarantee for high-quality preparation of capacitors.

Owner:ANHUI MASCOTOP ELECTRONICS

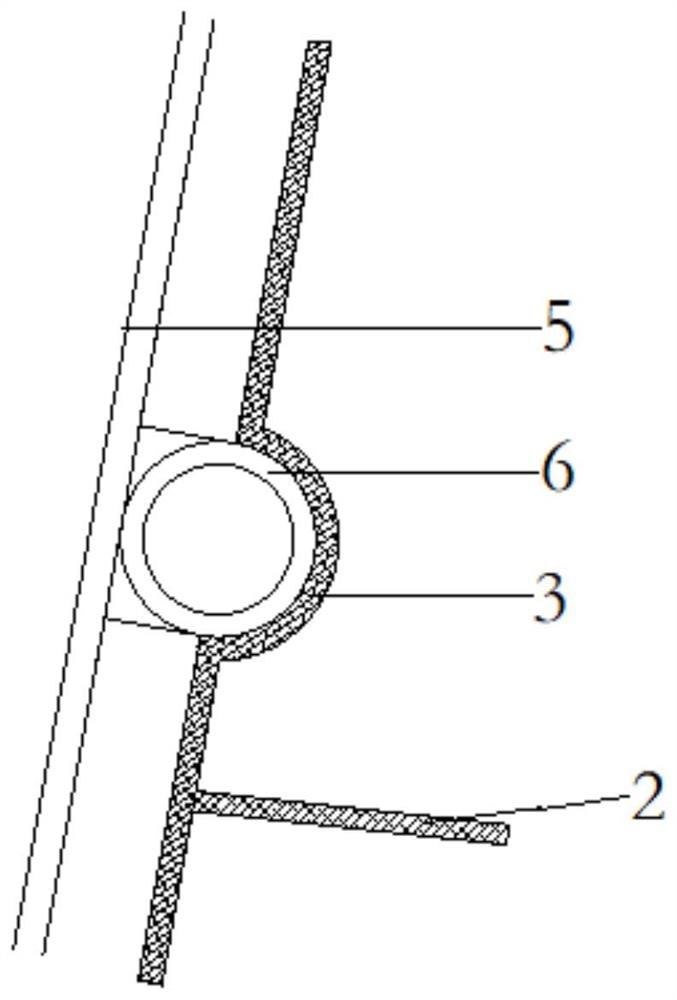

Prefabricated bay-window and construction method thereof

ActiveCN109869069AImprove lightingAchieve temporary fixationFrame fasteningBase framesWindow openingArchitectural engineering

The invention relates to a prefabricated bay-window and a construction method thereof, and belongs to the technical field of fabricated buildings. The prefabricated bay-window comprises a mounting frame, a bottom plate and two side plates are fixedly connected to the mounting frame along the edge of a window opening, the two side plates are located on the two sides of the window opening correspondingly, the bottom plate is perpendicular to the side plates, the mounting frame, the bottom plate and the side plates are integrally formed, and a connecting steel bar is reserved on the mounting frame; and a mounting groove is formed in the mounting frame, the mounting groove and the side plates are located on the same side of the mounting frame, the mounting groove is located on the sides, awayfrom the bottom plate, of the side plates, and the side, away from the mounting frame, of the bottom plate exceeds the edge of the side plates. The invention further provides the construction method,and the construction method comprises the steps of reservation of a mounting opening, mounting of the prefabricated bay-window and pouring. The prefabricated bay-window has the effect that the daylight effect is highly adjusted, and the construction method is simple and quick.

Owner:上海远东杨园道桥有限公司

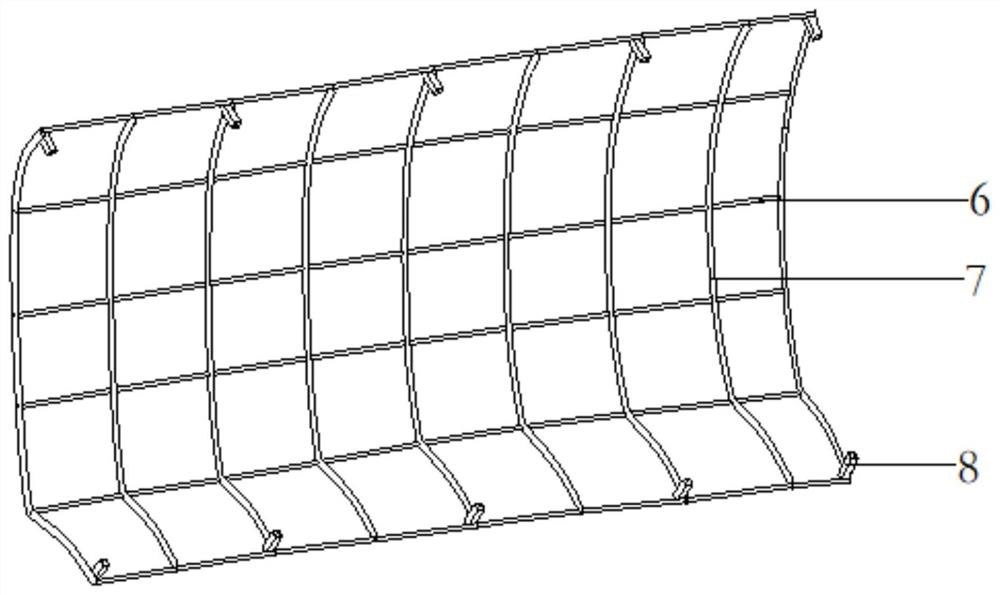

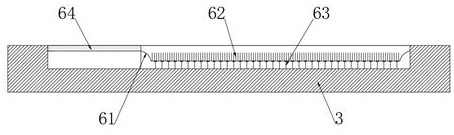

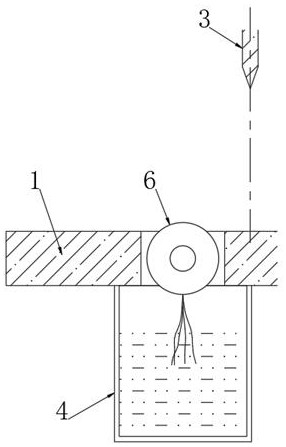

Cable fall arrester

ActiveCN108206486BSimple structureEasy to manufactureApparatus for laying cablesElectric cablesParallel arrangement

The invention belongs to the technical field of cable laying equipment, and specifically relates to a cable falling protection. The problem that the construction efficiency is low since the cable is temporarily bound and fixed by using a rope in the process of manually laying the cable is solved. The invention discloses a cable falling protector. The cable falling protector comprises two support plates and two fixed rods; two penetrating chutes are formed on each support plate, and two chutes on the same support plate are in V-shaped arrangement; two support plates are in parallel arrangement,and the chutes on two support plates are corresponding to each other; the fixed rod is located between two support plates, and two ends of the fixed rod respectively penetrate into the correspondingchutes of two support plates, and the fixed rod can freely reciprocate along the length direction of the chutes. The cable falling protector is not only simple in structure, convenient for manufacturing, operation and use, but also can quickly finish the clamping and fixation of the cable, and the construction efficiency is improved.

Owner:CHINA NUCLEAR IND FIFTH CONSTR CO LTD

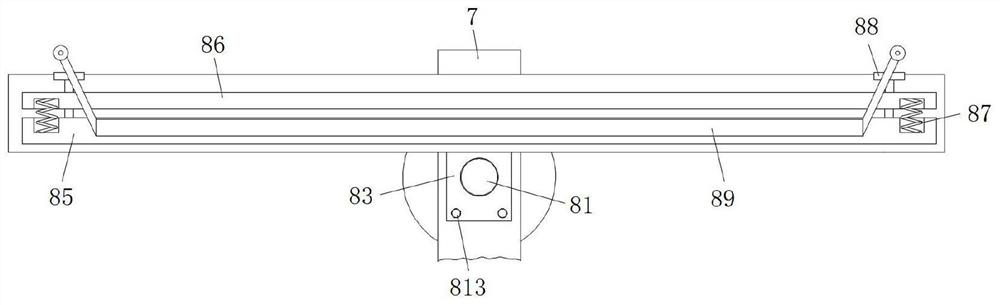

Locating type rapid-replacement chuck for brick stacking machine

The invention relates to the technical field of locating chucks of brick stacking machines, in particular to a locating type rapid-replacement chuck for a brick stacking machine. The locating type rapid-replacement chuck for the brick stacking machine comprises a brick stacking machine locating sleeve head. The surface of the brick stacking machine sleeve head is provided with a butt joint hole. Abutt joint insertion head is inserted into the butt joint hole in a connected manner. The end of the butt joint insertion head is provided with a connection portion. The connection portion is fixed to the surface of the brick stacking machine locating insertion head. The surface of the brick stacking machine locating insertion head is provided with a through opening. The inner wall of the throughopening is provided with internal threads. The locating type rapid-replacement chuck for the brick stacking machine has the beneficial effects that the locating type rapid-replacement chuck for the brick stacking machine comprises the brick stacking machine locating sleeve head and the brick stacking machine locating insertion head, brick stacking machine locating insertion heads are installed ona lower frame body at corresponding positions, then brick stacking machine locating sleeve heads are installed on the four corners of an upper frame body, by means of conical locating fit between thebrick stacking machine locating sleeve heads and the brick stacking machine locating insertion heads, the position can be rapidly determined, and fixation between the upper frame body and the lower frame body is achieved in the manner that one bolt penetrates through each through opening.

Owner:河南宾康智能装备有限公司

fire hose box

Owner:SICHUAN JOINER MACHINERY & AUTOMATIC EQUIP

Brush hair dyeing device for brush preparation

The invention discloses a brush hair dyeing device for brush preparation. The brush hair dyeing device for brush preparation comprises a dyeing box body, overturning rods are rotationally connected to the inner walls of the front end and the rear end of the upper side of the dyeing box body, the rear ends of every two adjacent overturning rods extend to the outer side of the dyeing box body and are rotationally connected with a conveying belt, and a fixing base is further arranged on one side of the rear end of the dyeing box body; a servo motor is fixedly connected to the top face of the fixing base through screws, the output end of the servo motor is fixedly connected with one overturning rod, heating pipes are further fixed to the front side and the rear side of the bottom end of the dyeing box body, vertical plates are fixed to the front ends and the rear ends of the overturning rods, and brush hair fixing assemblies are installed between the two vertical plates on the upper side and the lower side. The brush hair fixing assembly comprises a first lead screw and a second lead screw, and the front side and the rear side of the first lead screw and the front side and the rear side of the second lead screw are rotationally connected to the vertical plate. The brush hair dyeing device is reasonable in design, stable in device operation, uniform in dyeing and convenient and fast in brush hair changing operation, so that the brush hair dyeing quality is well guaranteed, and the brush hair dyeing efficiency is improved.

Owner:ANHUI ZHEN DA BRUSH IND

Prefabricated concrete shear wall support and grouting enclosure integrated tooling system and method

ActiveCN111877603BImprove installation efficiencyReduce the number of laborWallsBuilding material handlingArchitectural engineeringAssembly (construction)

The present invention provides a prefabricated concrete shear wall support and grouting enclosure integrated tooling system and method. The system includes several grouting diagonal brace structures, and each grouting diagonal brace structure includes a telescopic diagonal brace, a reaction force support rod, and a jack. And the closing plate, the reaction force support rod includes a horizontal rod and a vertical rod. The end of the horizontal rod far away from the vertical rod is sleeved on the telescopic diagonal brace and can move along the telescopic diagonal brace. There is a supporting part at the lower end, and the upper surface of the supporting part and the outer surface of the vertical bar form a right-angle groove for placing the precast concrete shear wall. Adjust the installation height of the precast concrete shear wall, and the verticality of the precast concrete shear wall can be adjusted through the telescopic diagonal brace, so that the temporary support of the precast concrete shear wall assembly construction, the grouting of the sleeve grouting, etc. The various processes are integrated into an integrated single process, which improves the installation efficiency.

Owner:SHANGHAI CONSTRUCTION GROUP

A positioning assembly for installing a sculpture panel and an installation method for the sculpture panel

ActiveCN113232447BQuick installationEasy to installOrnamental structuresSS - Stainless steelMechanical engineering

The invention provides a positioning assembly for installing a sculpture panel and an installation method for the sculpture panel, belonging to the technical field of stainless steel sculpture, wherein the positioning assembly for installing the sculpture panel includes: a positioning plate, which is annular and is suitable for connecting through a steel bracket On the main steel structure, on the main steel structure, the curvature of the positioning plate is consistent with the curvature of the sculpture panel, and the sculpture panel is suitable for being connected to the positioning plate. The present invention provides a positioning assembly for installing a sculpture panel. When the positioning plate is installed on the main steel structure, the curvature of the positioning plate is consistent with the curvature of the sculpture panel. Therefore, the installation of the sculpture panel by the positioning plate is effective. To the role of positioning, it is convenient for the quick and accurate installation of the sculpture panel, the on-site construction is convenient, time-saving and labor-saving, and the installation accuracy is high.

Owner:CHINA CONSTR SCI & IND CORP LTD

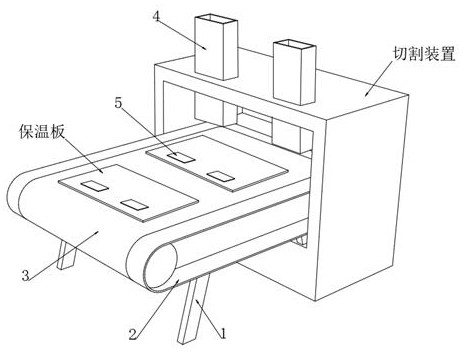

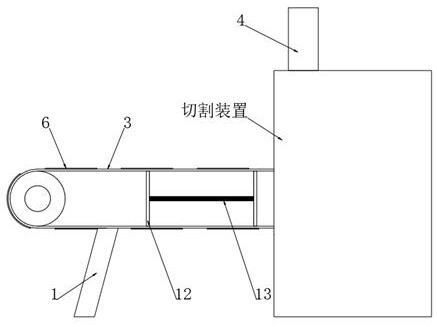

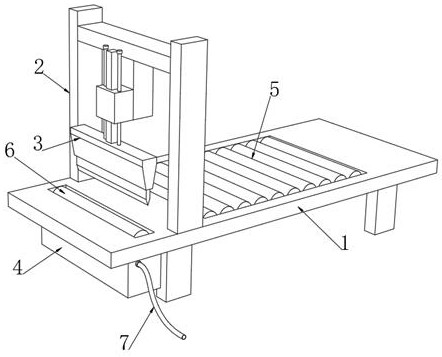

Ease-off type blanking bracket for thermal insulation board cutting device

ActiveCN113635390BReduce intensityQuality improvementMetal working apparatusControlled releaseThermal insulation

The invention discloses a slow-off type blanking bracket for a thermal insulation board cutting device, which belongs to the field of brackets. A slow-off type blanking bracket for a thermal insulation board cutting device is provided with a plurality of magnetically controlled slow-off sheets on a conveyor belt. When cutting the material, lay the magnetic stator on the surface of the insulation board first, make it absorbed and fixed by the temporary surface, and then control the power supply, under the action of magnetic repulsion, make the magnetic control slow-off sheet and the insulation board adhere and adsorb, at this time point surface replacement The liquid mechanism makes the point adsorption between the pre-separation fixed plate and the insulation plate. When reaching the end of the conveyor belt, the end of the point-adsorbed insulation plate is separated from the conveyor belt first, and the magnetic control release sheet is gradually torn as the arc of the conveyor belt tail changes. In this way, the insulation board is slowly detached from the conveyor belt. Compared with the direct drop of the insulation board in the prior art, the strength of the insulation board being bumped is significantly reduced, and the cracking phenomenon caused by blanking is greatly reduced, so that the quality of the insulation board is better. .

Owner:南通晶德盈节能环保科技有限公司

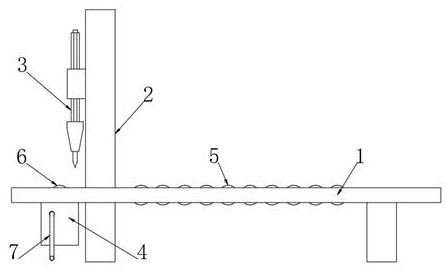

Film cutting machine capable of degrading plastic film

PendingCN114851262AAvoid stretching and deformationAchieve temporary fixationPlastic recyclingMetal working apparatusThin membraneSurface tension force

The invention discloses a film cutting machine capable of degrading a plastic film, and belongs to the field of film cutting machines.The film cutting machine capable of degrading the plastic film is characterized in that a film binding roller is arranged on the left side of a cutting assembly, before the cutting assembly conducts film cutting, a smooth shaft is controlled to rotate firstly, and a water adsorption beard rod adsorbing water is wound around the surface of the smooth shaft; after the film is cut, due to the surface tension of water on the water attaching rod, the free end of the film is adhered to the smooth shaft, and compared with the prior art, under the condition that external force is not actively applied, the end of the cut film is temporarily fixed, the situation that the free end is adhered to other objects is effectively avoided, and the cutting efficiency is improved. The situation that corners or local rolling is not prone to occurring is avoided, the winding effect and efficiency are greatly improved during discharging, and meanwhile the situation that the thin film is pulled and deformed due to pressing and limiting of the thin film is effectively avoided.

Owner:南通君越新材料科技有限公司

Coil component manufacturing method

ActiveCN107887159BAchieve temporary fixationSimple manufacturing equipmentContact member assembly/disassemblyTransformers/inductances detailsWire rodLaser light

The present invention provides a method of manufacturing a coil component capable of reducing the complication of the shape of the metal terminal, the complication of the processing for obtaining the metal terminal, and the complication of the equipment for connecting the wire rod and the metal terminal. The connecting part (49) has a receiving part (50) for receiving the wire (35) and a metal terminal (51) extending from the receiving part via the bending part (55) as the metal terminal (41). To temporarily fix the wire, the wire is bonded to the receiving portion by applying heat and pressure in a state where the wire is placed on the receiving portion, using the melted or softened insulating resin covering (39) as a bonding agent. Next, the connecting portion is bent through the bending plan portion so that the abutting piece faces the receiving portion with the wire rod interposed therebetween, and the abutting piece abuts against the wire rod. Next, the wire rod and the metal terminal are welded by irradiating a part of the metal terminal with laser light.

Owner:MURATA MFG CO LTD

Positioning component for sculpture panel mounting and sculpture panel mounting method

ActiveCN113232447AQuick installationEasy to installOrnamental structuresSS - Stainless steelMechanical engineering

The invention provides a positioning component for sculpture panel mounting and a sculpture panel mounting method, and belongs to the technical field of stainless steel sculptures. The positioning component for sculpture panel mounting comprises a positioning plate which is annular and suitable for being connected to a main body steel structure through a steel support; and on the main body steel structure, the radian trend of the positioning plate is consistent with that of the sculpture panel, and the sculpture panel is suitable for being connected to the positioning plate. According to the positioning component for sculpture panel mounting, when the positioning plate is mounted on the main body steel structure, the radian trend of the positioning plate is consistent with that of the sculpture panel, so that the positioning plate has a positioning effect on the mounting of the sculpture panel, the sculpture panel can be quickly and accurately mounted, site construction is convenient, time and labor are saved, and the mounting precision is high.

Owner:CHINA CONSTR STEEL STRUCTURE CORP LTD

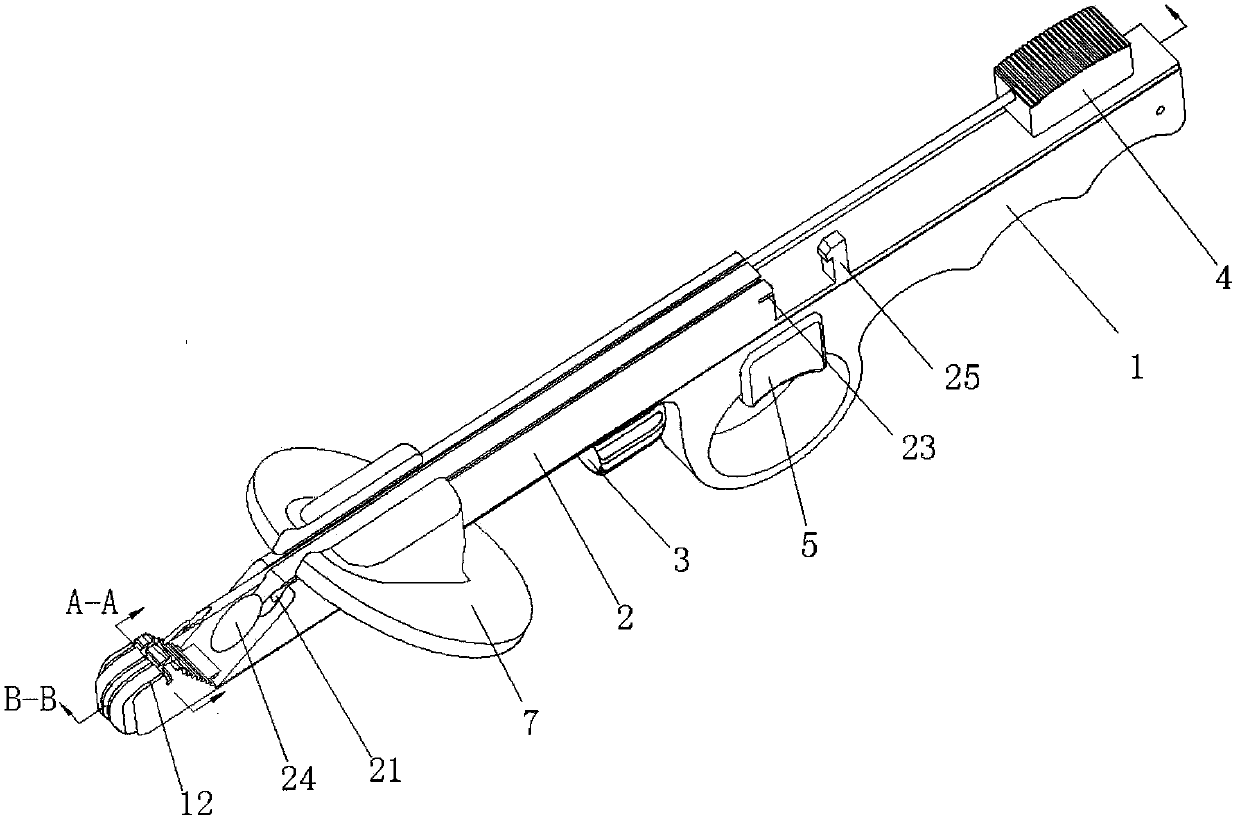

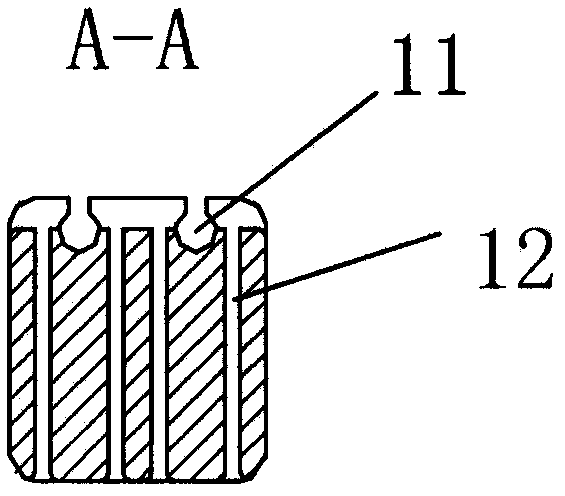

Stitching instrument

PendingCN107789020AMeet the suturing needs of tissues of different thicknessesMeet tissue suturing needsSuture equipmentsAxial displacementSuturing guide

The invention relates to a stitching instrument. The stitching instrument comprises an instrument body, a sliding cover, an adjusting assembly and a thread hooking device, at least one thread hookinggroove and thread winding grooves which are communicated with the thread hooking grooves are formed in the far-end part of the instrument body, and the thread hooking grooves are opening grooves formed in the axial direction. The sliding cover is installed on the instrument body in a sliding mode, at least one guide channel is formed in the sliding cover in the axial direction, the guide channelsand the thread hooking grooves are coaxial, and tissue containing grooves are formed between the near ends of the thread hooking grooves and the far ends of the guide channels; the adjusting assemblyis arranged on the instrument body and used for adjusting the axial displacement of the sliding cover and then adjusting the opening degree of the tissue containing grooves; the thread hooking deviceis used for guiding the thread in the thread hooking grooves through the guide channels. By means of the stitching instrument, the opening degree of the tissue containing grooves can be adjusted, andthe thread can be precisely hooked.

Owner:NINGBO SHENGJIEKANG BIOTECH

A multi-functional fixed structure for rail vehicle transport with bogies

ActiveCN107499461BAchieve temporary fixationReduce shipping costsPreventing unwanted cargo movementFor goodsBogieLinear array

The invention relates to a multifunctional fixing structure which has a function of transporting bogies and is used for railway vehicles. The multifunctional fixing structure comprises a bogie fixing mechanism and a vehicle connecting mechanism; the bogie fixing mechanism is connected to a chassis boundary beam, corresponding to the junction of bogies, of the vehicle body through a reinforcing connecting part; the bogie fixing mechanism comprises several connecting plates which are distributed in a linear array mode, the connecting plates are provided with bogie fixing rope connecting holes, the end of the connecting plate array is provided with an adaption plate used for being welded to the chassis boundary beam, and the adaption plate is perpendicular to the axis of the chassis boundary beam; the bogie fixing rope connecting holes are internally provided with bogie fixing ropes; the vehicle connecting mechanism comprises a vehicle hoisting sheet, the hoisting sheet is perpendicular to the chassis boundary beam and is provided with a vehicle connecting hole, and the vehicle hoisting sheet is welded to the chassis boundary beam and is located at the horizontal two sides of the bogie fixing mechanism. By means of the multifunctional fixing structure, temporary fixation of the bogies and the vehicle body can be achieved, and the bogies can be driven to be hoisted without a tool.

Owner:CRRC NANJING PUZHEN CO LTD

A rail vehicle installation tool and using method

ActiveCN112389479BAchieve temporary fixationFast installationRailway transportAxle-box lubricationBraced frameMechanical engineering

The embodiment of the present application provides a rail vehicle installation tool and a use method. Installation tooling for rail vehicles, comprising: a support frame; a fixing assembly, the fixing assembly is installed on one side of the support frame in the width direction, and the side of the fixing assembly away from the support frame is used to fix the vertical wall to be installed ; Wherein, the fixing assembly can move and lock along the supporting frame. The method of use is the method of using the tooling described above. The embodiment of the present application solves the technical problem that the installation of the inner end wall of the rail vehicle is completely dependent on manual installation, resulting in a slow installation speed and a large influence on the installation effect.

Owner:CRRC TANGSHAN CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com