A rail vehicle installation tool and using method

A technology for installing tooling and rail vehicles, which is applied to railway car bodies, transportation and packaging, and railway car body parts, etc. It can solve problems such as dependence, slow installation speed, and artificial influence on installation effects, and achieve simple structure and fast installation speed , The installation effect is stable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

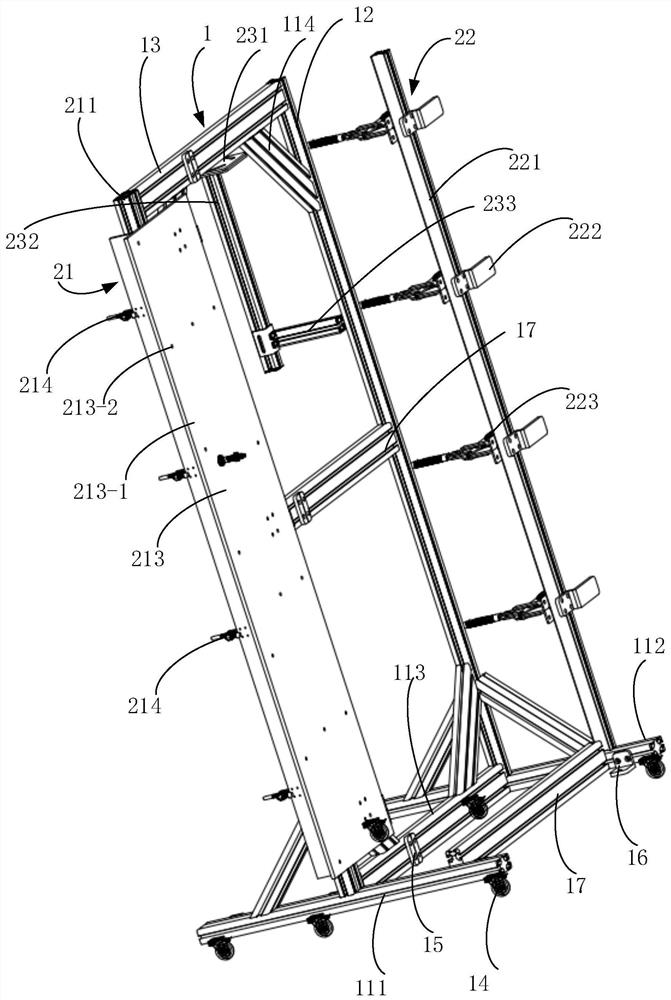

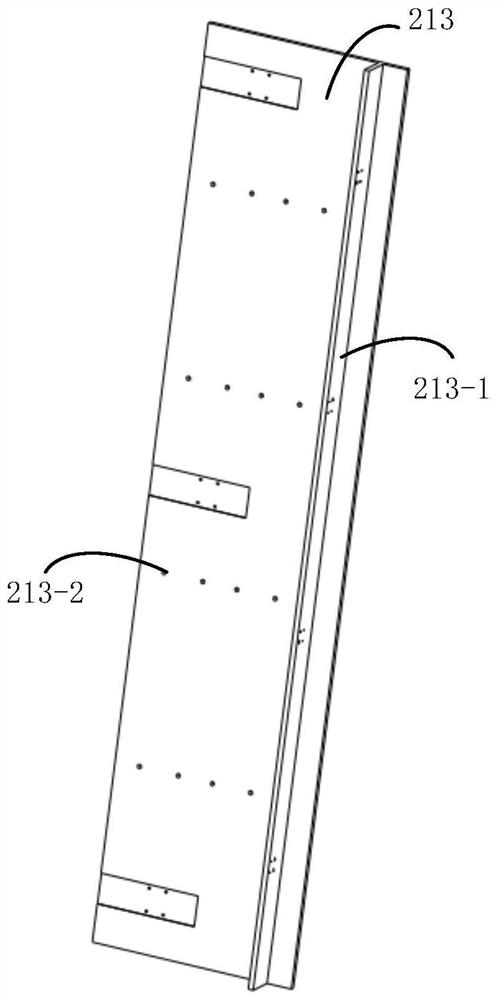

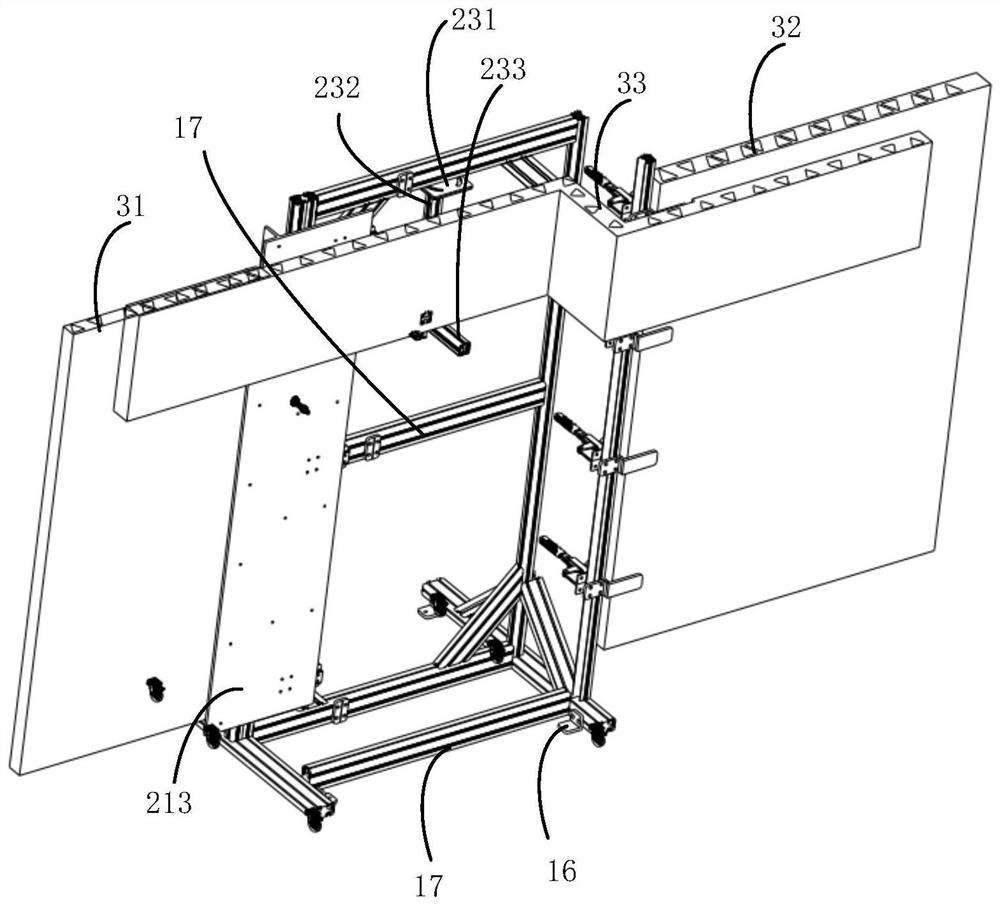

[0035] figure 1 It is a schematic diagram of an installation tool for a rail vehicle according to an embodiment of the present application; figure 2 for figure 1 Schematic diagram of the skateboard for the installation tooling shown; image 3 for figure 1 A schematic diagram of the installation tool carrying two vertical walls to be installed and a connecting beam; Figure 4 bit image 3 A schematic diagram of another angle.

[0036] Such as figure 1 , figure 2 , image 3 with Figure 4 As shown, the installation tooling of the rail vehicle of the embodiment of the present application includes:

[0037] support frame 1;

[0038] A fixing assembly, the fixing assembly is installed on one side of the width direction of the support frame 1, and the side of the fixing assembly away from the support frame 1 is used to fix the vertical wall to be installed;

[0039] Wherein, the fixing assembly can move and lock along the supporting frame.

[0040] The rail vehicle ins...

Embodiment 2

[0104] The usage method of the embodiment of the present application is the usage method of the installation tool described in the first embodiment, comprising the following steps:

[0105] Step S10: Positioning the preset installation position of the first vertical wall to be installed, the preset installation position of the second vertical wall to be installed and the preset installation position of the connecting beam on the vehicle body;

[0106] Specifically, a three-dimensional laser marking instrument is used for positioning. The positioning includes positioning in the horizontal direction and positioning in the longitudinal direction, and the deviation between the positioning size and the theoretical value is not greater than 0.5mm;

[0107] Step S20: placing the first vertical wall to be installed, the second vertical wall to be installed and the connecting beam at their respective preset installation positions;

[0108] Specifically, the first vertical wall to be in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com