Film cutting machine capable of degrading plastic film

A technology for degrading plastics and film cutting machines, applied in plastic recycling, metal processing, recycling technology, etc., to achieve winding effects, improve efficiency, and avoid pulling deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

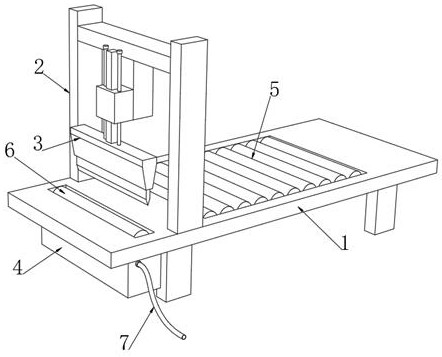

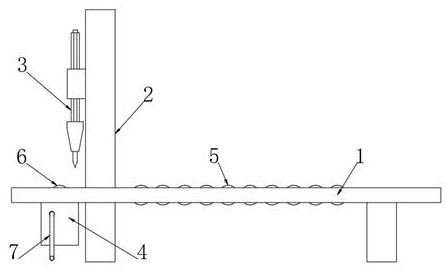

[0036] see Figure 1-2 , a film cutting machine for degradable plastic film, including an operation platform 1 with a control board, a bracket 2 is fixedly connected to the upper left end of the operation platform 1, a cutting assembly 3 is installed on the bracket 2, and the cutting assembly 3 is controlled by the control board. For cutting, two transfer ports are excavated on the operating platform 1. The transfer port on the left side of the cutting assembly 3 is connected with a film binding roller through the motorized rotating shaft. The transmission roller 5, the electric rotating shaft is connected with the signal of the control board.

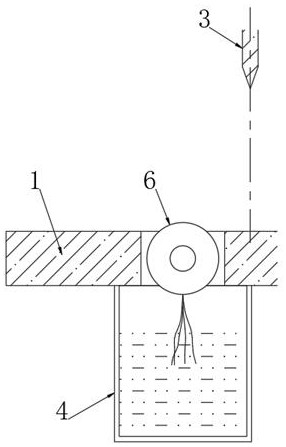

[0037] see Figure 3-4 , the lower end of the operation platform 1 is connected with a water tank 4, the water tank 4 is filled with water, the water tank 4 is connected with a water conduit 7, the water conduit 7 is connected to the water tank 4 and the external water source, the water tank 4 is located directly below the left transf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com