Rubber tube cutting machine

A rubber tube and cutting machine technology, applied in metal processing and other directions, can solve the problems of pulling deformation at the gap, affecting the appearance, and uneven cutting, so as to achieve the effect of neat gap and avoid pulling deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

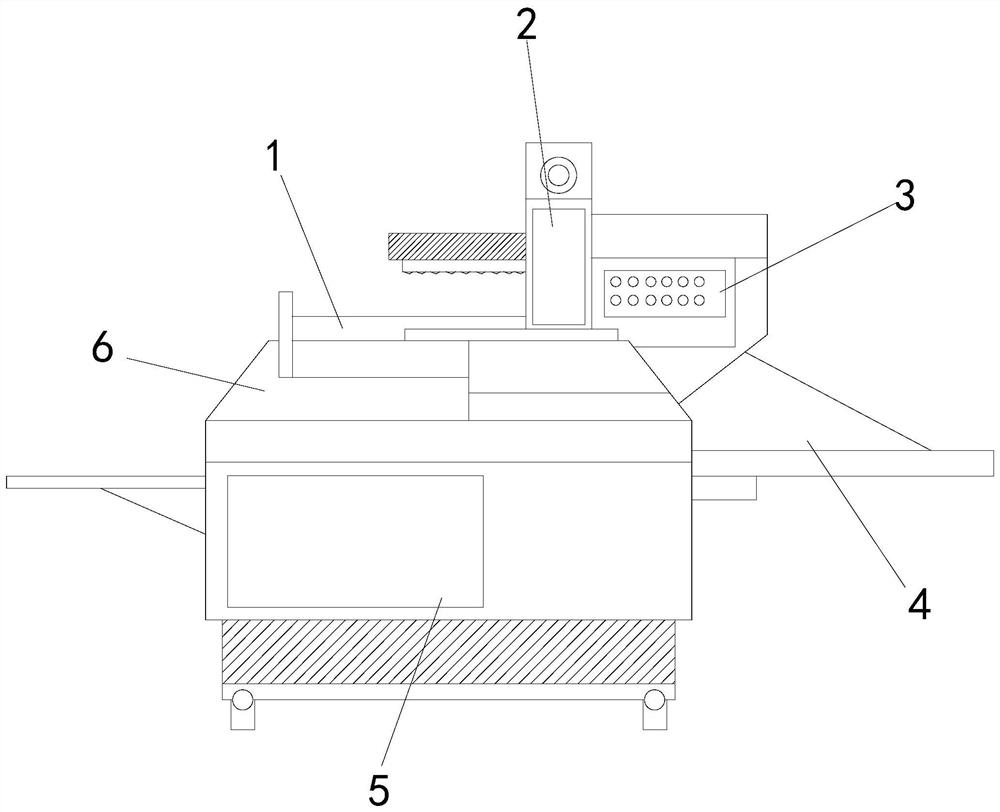

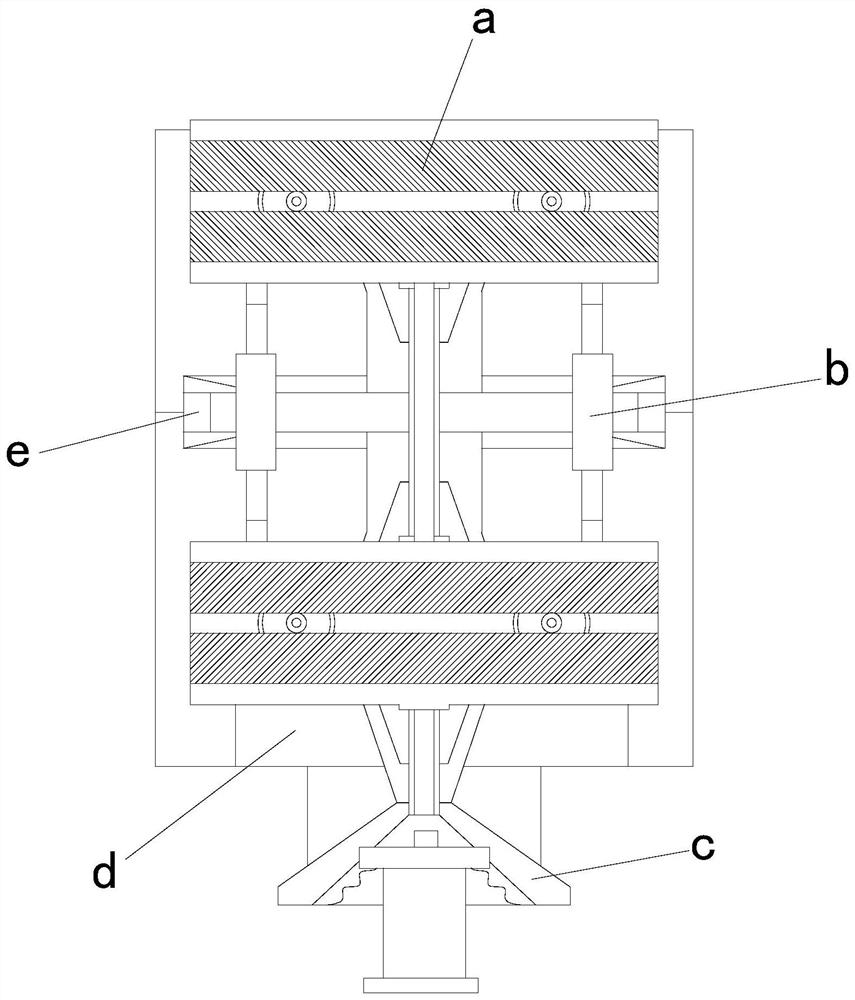

[0025] see Figure 1-Figure 2 , the present invention provides a rubber tube cutting machine technical solution: its structure includes: clamping platform 1, cutting knife group 2, controller 3, transfer platform 4, distribution box 5, protective cover plate 6, the controller 3 Installed on the right side of the cutting knife group 2 and electrically connected with the cutting knife group 2, a power distribution box 5 is arranged below the controller 3, and the power distribution box 5 is locked with the controller 3, and the power distribution box 5 A clamping platform 1 is provided on the surface, and the clamping platform 1 is locked with the distribution box 5. A protective cover plate 6 is provided on the side of the clamping platform 1, and the protective cover plate 6 is locked with the clamping platform 1. Then, the right side of the clamping platform 1 is provided with a transfer platform 4, and the clamping platform 1 includes a fixed block device a, a telescopic fra...

no. 2 example

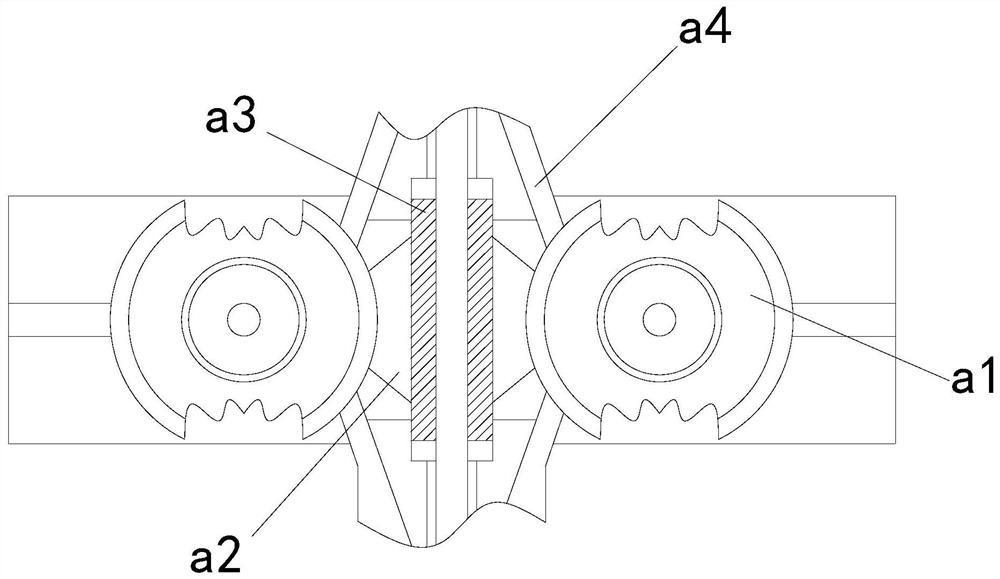

[0028] see Figure 3-Figure 5 , the present invention provides a rubber tube cutting machine technical solution: its structure includes: the fixed block device a includes a chuck device a1, a linkage groove a2, a movable groove block a3, and a track plate a4, and the chuck device a1 is installed on The inner side of the track plate a4 is buckled with the track plate a4, and the chuck device a1 is buckled with the movable slot block a3 through the linkage slot a2.

[0029] The chuck device a1 includes a connection buckle a11, a support disc a12, and an anti-skid plate a13. The anti-skid plate a13 is embedded in the inner side of the support disc a12, and the upper end of the support disc a12 is provided with a connection buckle a11. The disk a12 is locked, and the chuck device a1 performs non-slip cooperation with the outer wall of the rubber tube through the cooperation of the anti-skid plate a13.

[0030] The segmented frame device c includes a guide interlayer c1, a fixed b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com