Steel column butt joint adjustment fixing device and method

A technology of fixing devices and steel columns, which is applied in the direction of construction and building construction, can solve problems such as increased labor input in construction technical measures, difficulty in installing high-rise and super high-rise structures, increased workload and working hours, etc., to avoid Effects of construction cross-operation, improvement of construction safety, and labor cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the examples, the purpose is only to better understand the contents of the present invention, therefore, the examples given do not limit the protection scope of the present invention.

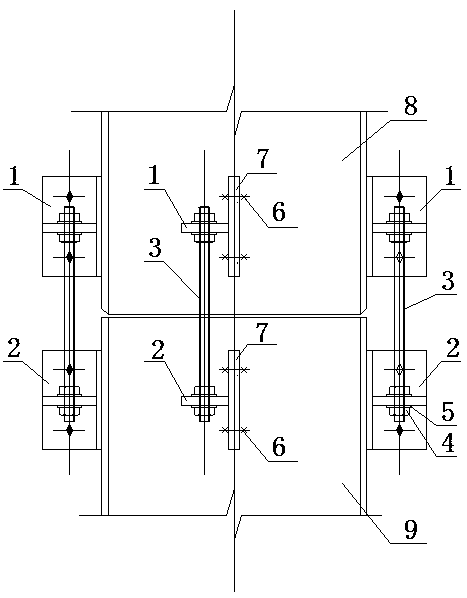

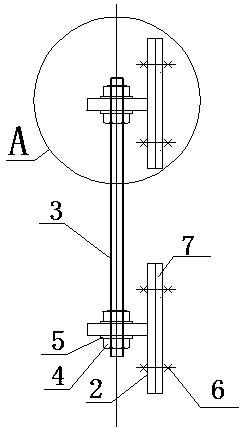

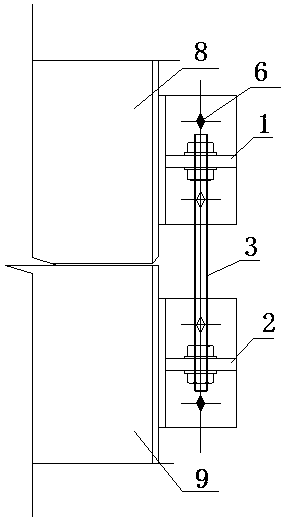

[0025] see figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , a butt joint adjustment and fixing device for steel columns, comprising an upper T-shaped connector 1 and a lower T-shaped connector 2, and the horizontal plates 10 of the upper T-shaped connector 1 and the lower T-shaped connector 2 are respectively processed with corresponding In the bolt hole connected with the screw rod 3, the vertical plate 11 of the upper T-shaped connector 1 and the lower T-shaped connector 2 are respectively processed with bolt holes for connecting with the ear plate 7 of the steel column, and the upper T-shaped connector 1 and The vertical plates 11 of the lower T-shaped connector 2 are respe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com