Blowout prevention self-lifting and pressure logging construction process

A construction technique and well logging technology, applied in measurement, wellbore/well parts, earthwork drilling and production, etc., can solve the problems of high cost and limited scope of application, and achieve low equipment cost, convenient movement, and small size and weight Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

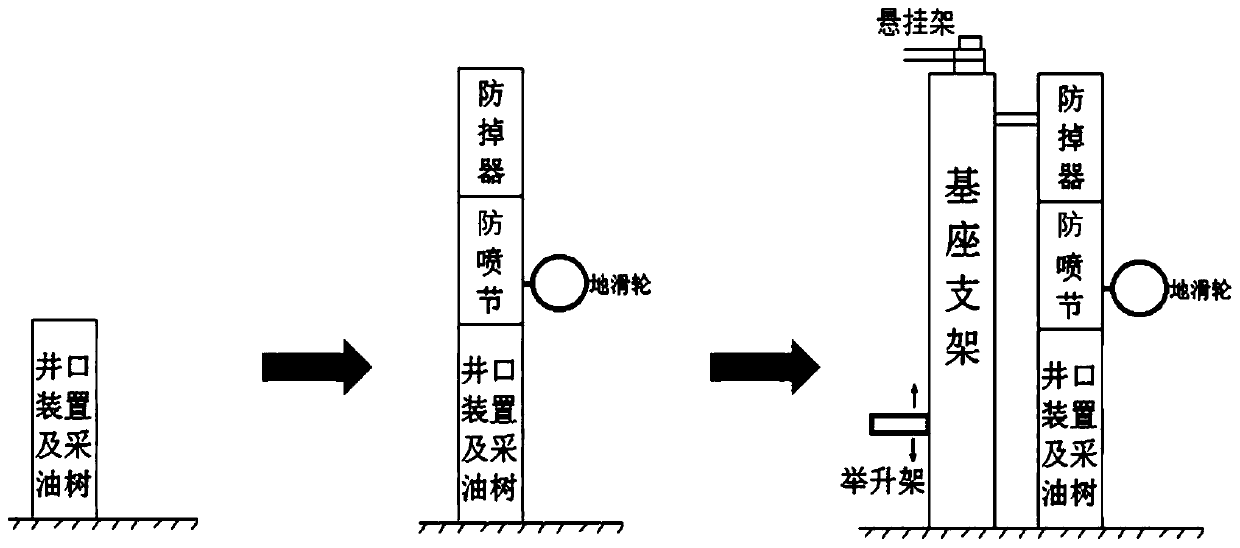

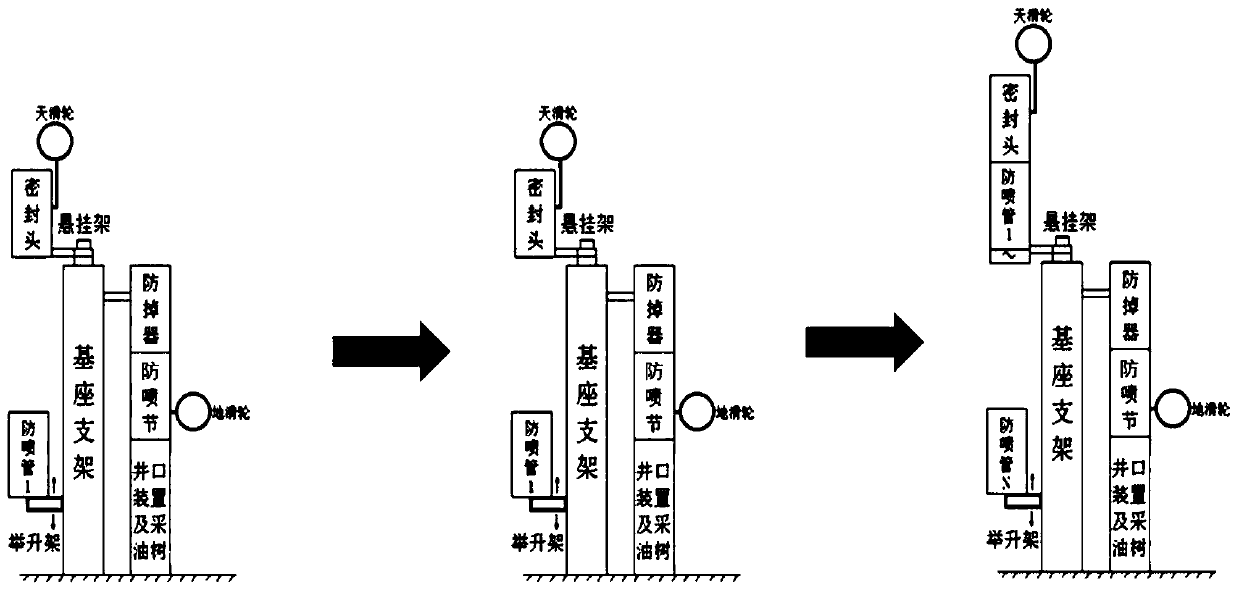

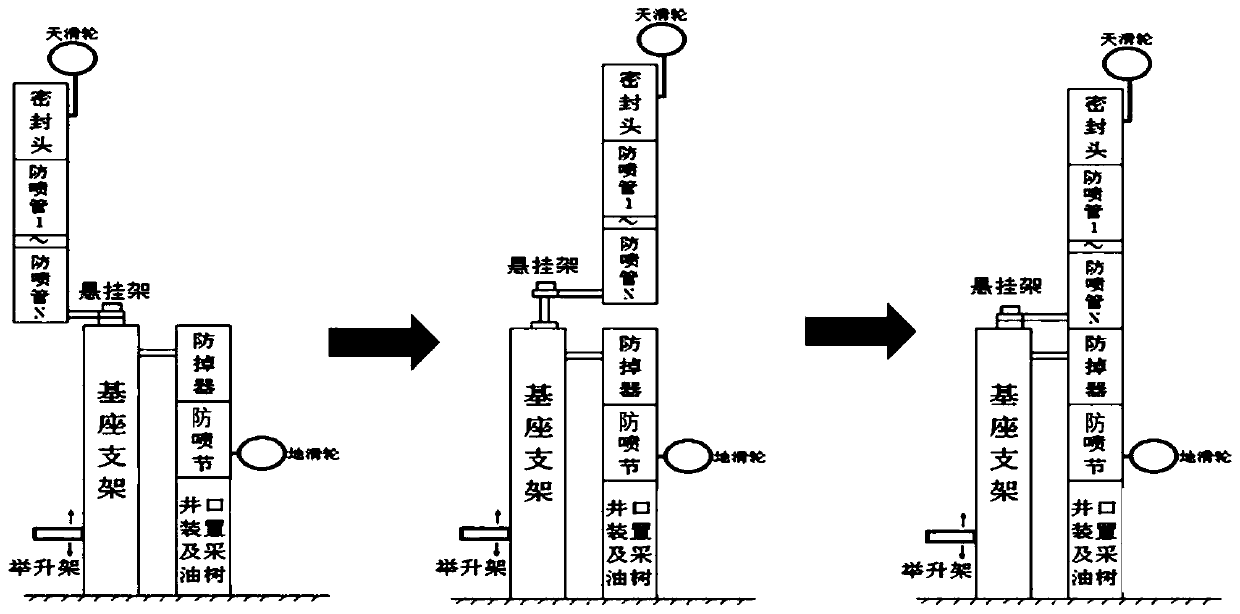

[0052] Such as Figure 1~3 As shown, a kind of blowout prevention self-lifting well logging construction technology under pressure of the present invention comprises the following steps:

[0053] Step 1: First connect the blowout preventer with the wellhead Christmas tree, then install the anti-dropout device above the blowout preventer, install the ground pulley outside the blowout preventer, and connect the anti-dropout device with the base bracket through the mechanical connection mechanism Together, the bottom of the base bracket is fixed to the ground by the adjustment rod, forming a solid foundation for the entire lifting system.

[0054] Step 2: Install the suspension frame on the top of the base bracket, install the cable in the sky pulley, install the sealing head above the suspension frame, and temporarily fix the sealing head at this position through the limit slip 8. Put the first blowout preventer vertically on the lifting frame by manpower, turn on the motor 5 t...

Embodiment 2

[0063] Well Logging in Island Type Well Fields in Water Network Areas by Utilizing the Technology of the Present Invention

[0064] Logging process step is the same as embodiment one

[0065] For island-type well sites affected by seasonal flood floodplains or the agricultural production of surrounding paddy fields, in the past, due to the limitation of the traffic capacity of logging vehicles and derrick vehicles on shallow muddy roads, they could only enter the construction site during the dry season or winter when the water body freezes Logging is implemented, and due to the short sunshine time and low temperature, only one well can be operated per day. Generally, each well can only be tested once a year. The data lag is serious, and it is impossible to grasp the changes in water injection conditions and adjust water injection policies in time, which will affect Crude oil production, waste of invalid water injection costs, and many on-site production operation risks such as...

Embodiment 3

[0068] Utilizing the technology of the present invention to carry out well logging construction on the offshore platform

[0069] During the construction of the offshore platform, the base support, downhole equipment, suspension frame, etc. are lifted from the transport ship to the vicinity of the Christmas tree with a ship crane, and the wellhead installation is completed in about half an hour by two operators, and the installation steps of the logging process are the same. Embodiment one. Utilize the technology of the present invention, needn't occupy expensive ship crane as before. Compared with the existing manpower or hydraulic simple mast-type lifting device, the vertical lifting method has a stronger operating ability due to the subtraction of the mast system and no influence of the lifting moment. The typical lifting height has been raised from 4-5m to more than 8m. Adapting to the increase of the wellhead pressure from about 14MPa to over 21MPa (more weight rods can ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com