Fire hose box

A fire hose and box frame technology, applied in fire rescue, etc., can solve the problems of high labor intensity for firefighters, unfavorable emergency rescue, low transportation efficiency, etc., to facilitate on-site transfer or long-distance transfer, improve transportation efficiency, and stabilize storage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

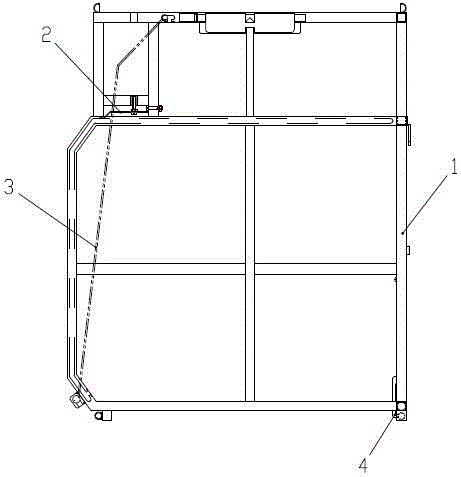

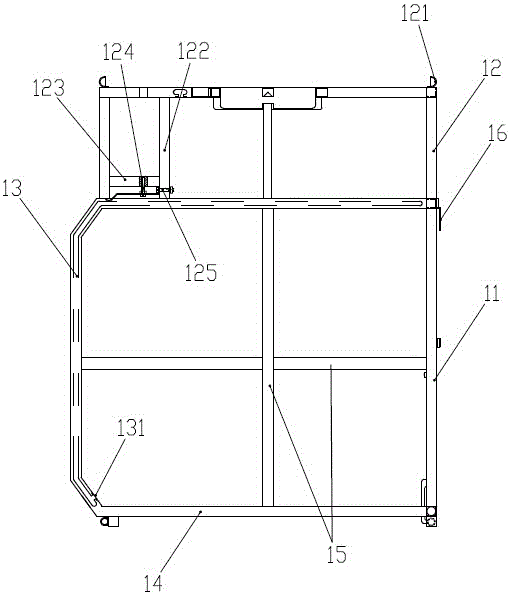

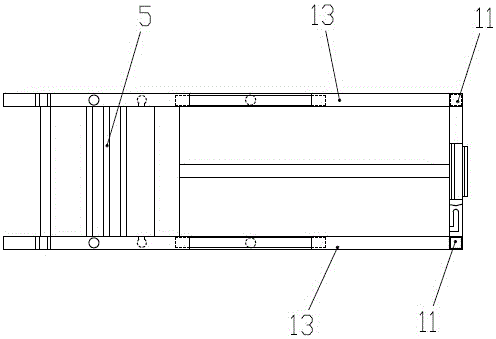

[0034] Such as Figure 1-Figure 4 As shown, the fire hose box of this embodiment includes a box frame 1, and the box frame 1 is provided with 10 hanging belt slide bars 5 for hanging and fixing the fire hose, and the hanging belt slide bars 5 Sliding along the box frame 1, the box frame 1 is provided with a damping assembly 2 for preventing the hanging belt slide bar 5 from falling, and the box frame 1 is provided with a clamping assembly 4 for fixing it on the transportation tool.

[0035] In this embodiment, the box frame 1 includes a vertical strut 11 and a U-shaped strut, the vertical strut 11 and the U-shaped strut form a rectangular parallelepiped frame structure, and the two ends of the U-shaped strut are connected to the The upper and lower ends of the vertical struts 11 are connected, and the box holder 1 of this embodiment includes 2 parallel vertical struts and 2 parallel U-shaped struts.

[0036] In this way, the suspended fire hose is neat and flat. When in use, ...

Embodiment 2

[0049] Such as Figure 1-Figure 4 As shown, the fire hose box of this embodiment includes a box frame 1, and the box frame 1 is provided with five hanging belt slide bars 5 for hanging and fixing the fire hose, and the hanging belt slide bars 5 Sliding along the box frame 1, the box frame 1 is provided with a damping assembly 2 for preventing the hanging belt slide bar 5 from falling, and the box frame 1 is provided with a clamping assembly 4 for fixing it on the transportation tool.

[0050] In this embodiment, the box frame 1 includes a vertical strut 11 and a U-shaped strut, the vertical strut 11 and the U-shaped strut form a rectangular parallelepiped frame structure, and the two ends of the U-shaped strut are connected to the The upper and lower ends of the vertical struts 11 are connected, and the box holder 1 of this embodiment includes 3 parallel vertical struts 11 and 3 parallel U-shaped struts.

[0051] Specifically, such as figure 1 and figure 2 As shown, the U-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com