Patents

Literature

83results about How to "Reduce damage frequency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

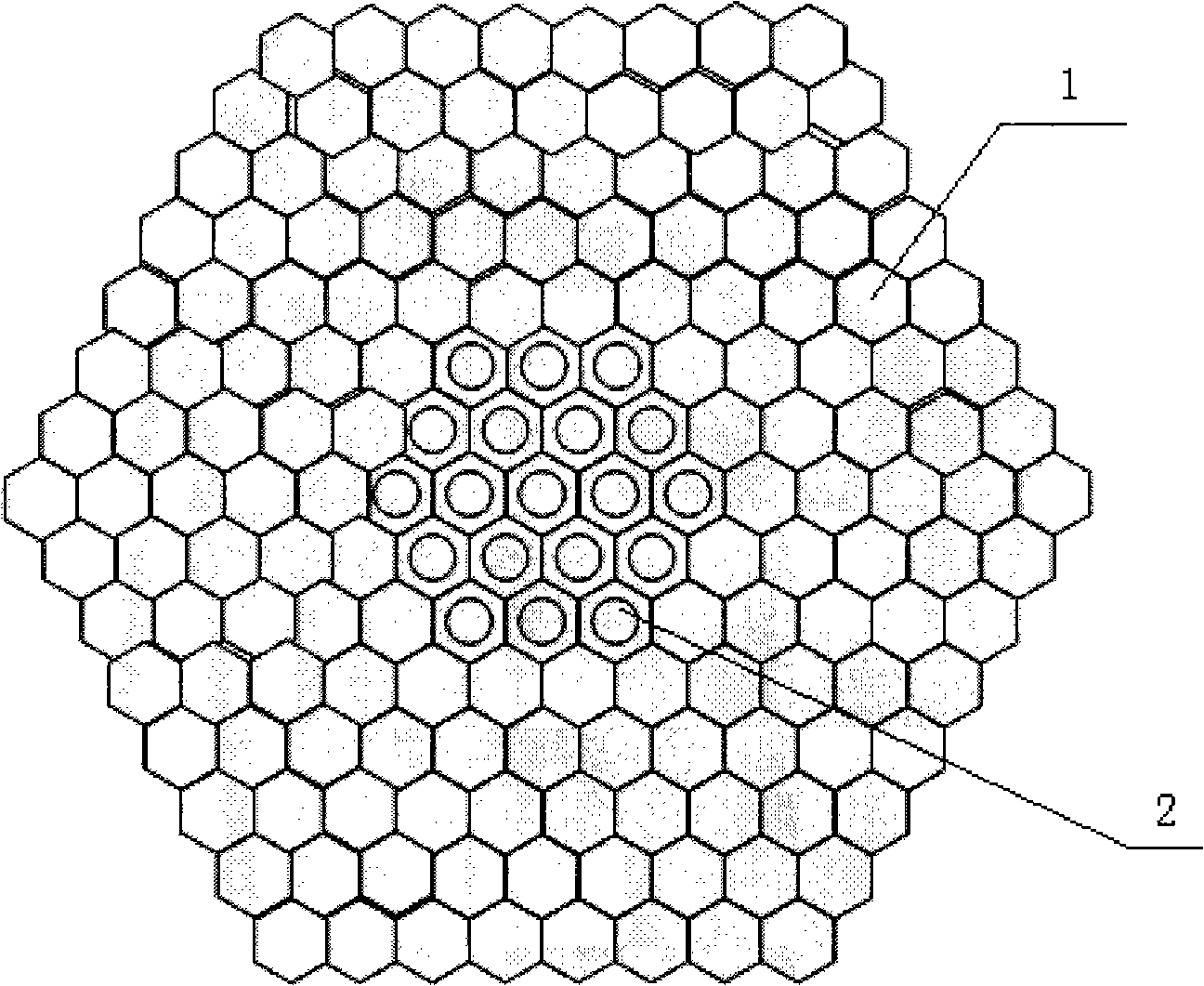

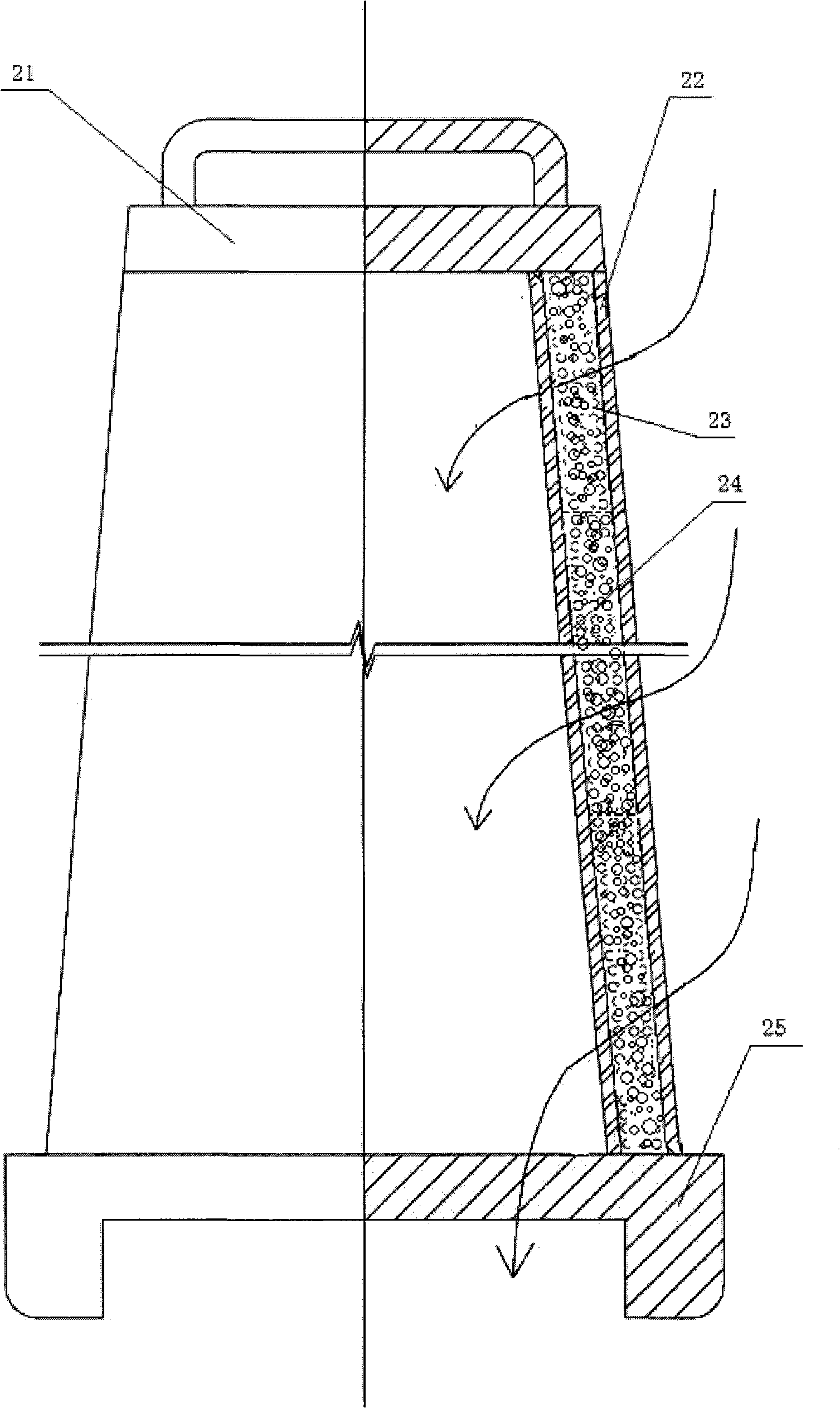

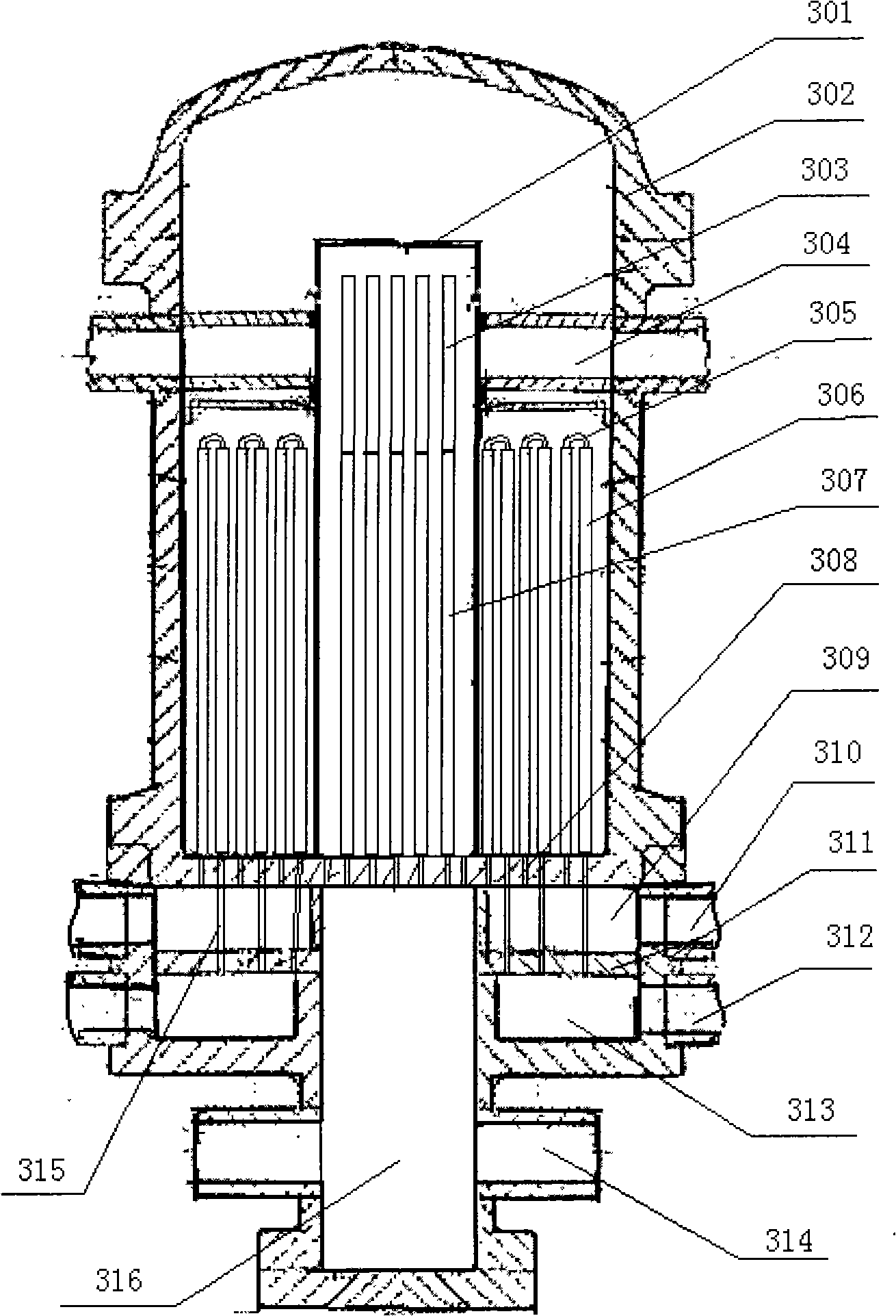

Stack core of water-cooling double-section breeding nuclear reactor as well as nuclear reactor using the same

InactiveCN101299351AIncrease temperatureInclusiveNuclear energy generationShieldingNuclear reactor coreNuclear reactor

The invention belongs to the technical field of the nuclear reactor engineering, particularly to the water-cooling two-region multiplication nuclear reactor core and the nuclear reactor adopting the same, wherein the water-cooling two-region multiplication nuclear reactor core includes a fast neutron energy spectrum area adopting the coating grain sheath fuel assembly and a thermal neutron energy spectrum area adopting the dense rod bundle fuel assembly or the coating grain sheath fuel assembly. The water-cooling two-region multiplication nuclear reactor core of the invention adopts the coating grain sheath fuel assembly, which breaks through the restrain of the stainless steel shell to the outlet scream temperature, realizes the higher coolant outlet temperature, meanwhile the fast neutron core is leaked to the thermal neutron energy spectrum core constituted by the rod bundle fuel assembly dense boom at the subcritical to be multiplied.

Owner:张育曼 +1

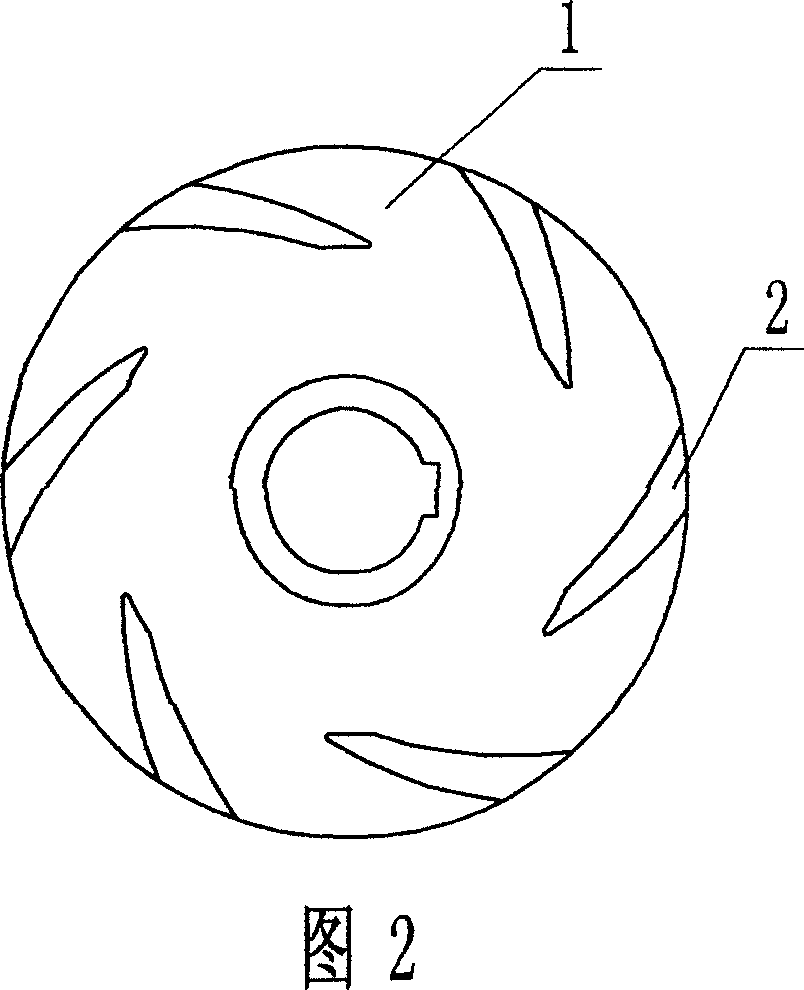

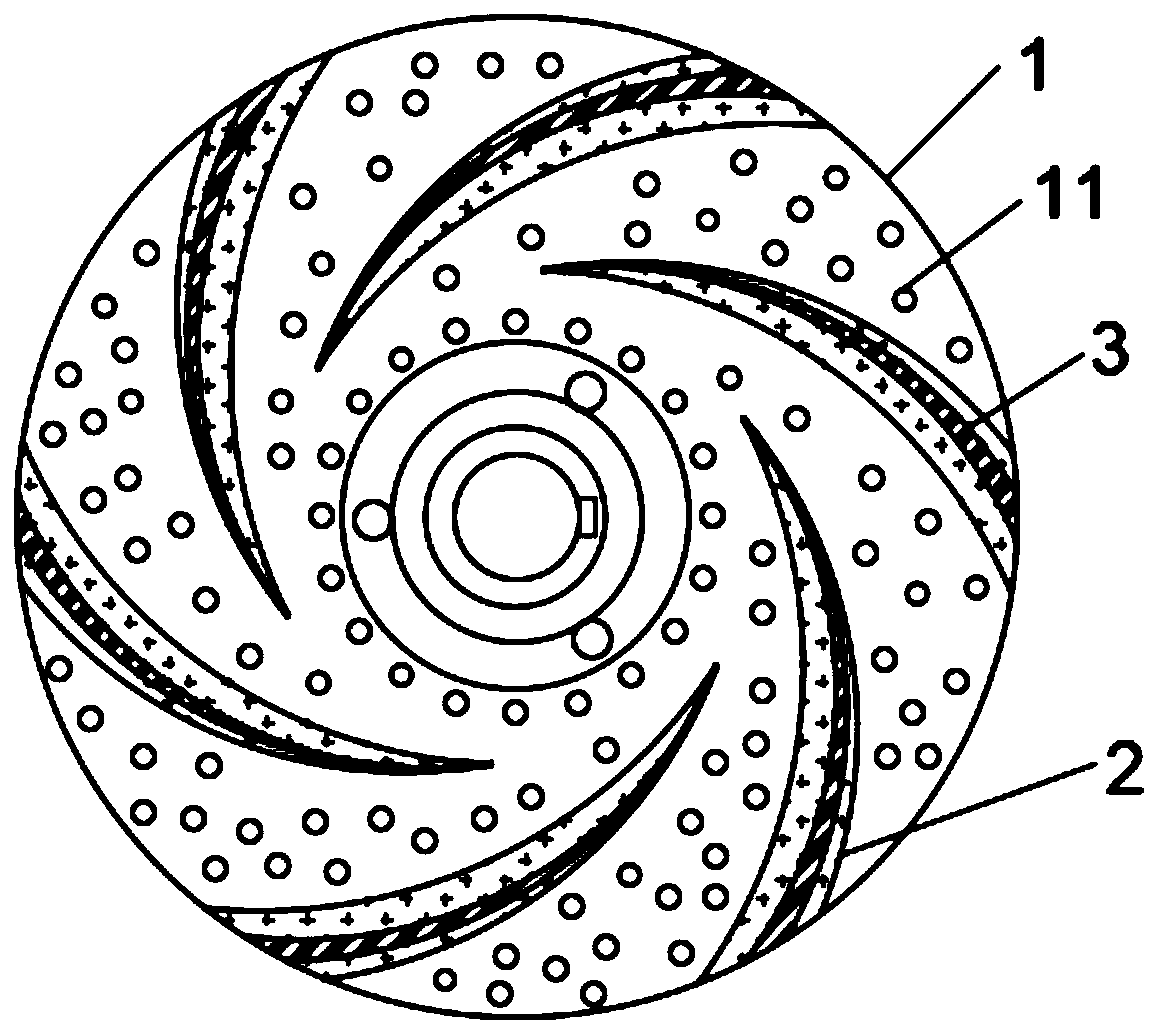

Combined antiwearing blades

InactiveCN1975172AExtended service lifeReduce damage frequencyPump componentsPumpsEngineeringEnergy conservation

Owner:宜兴市宙斯泵业有限公司

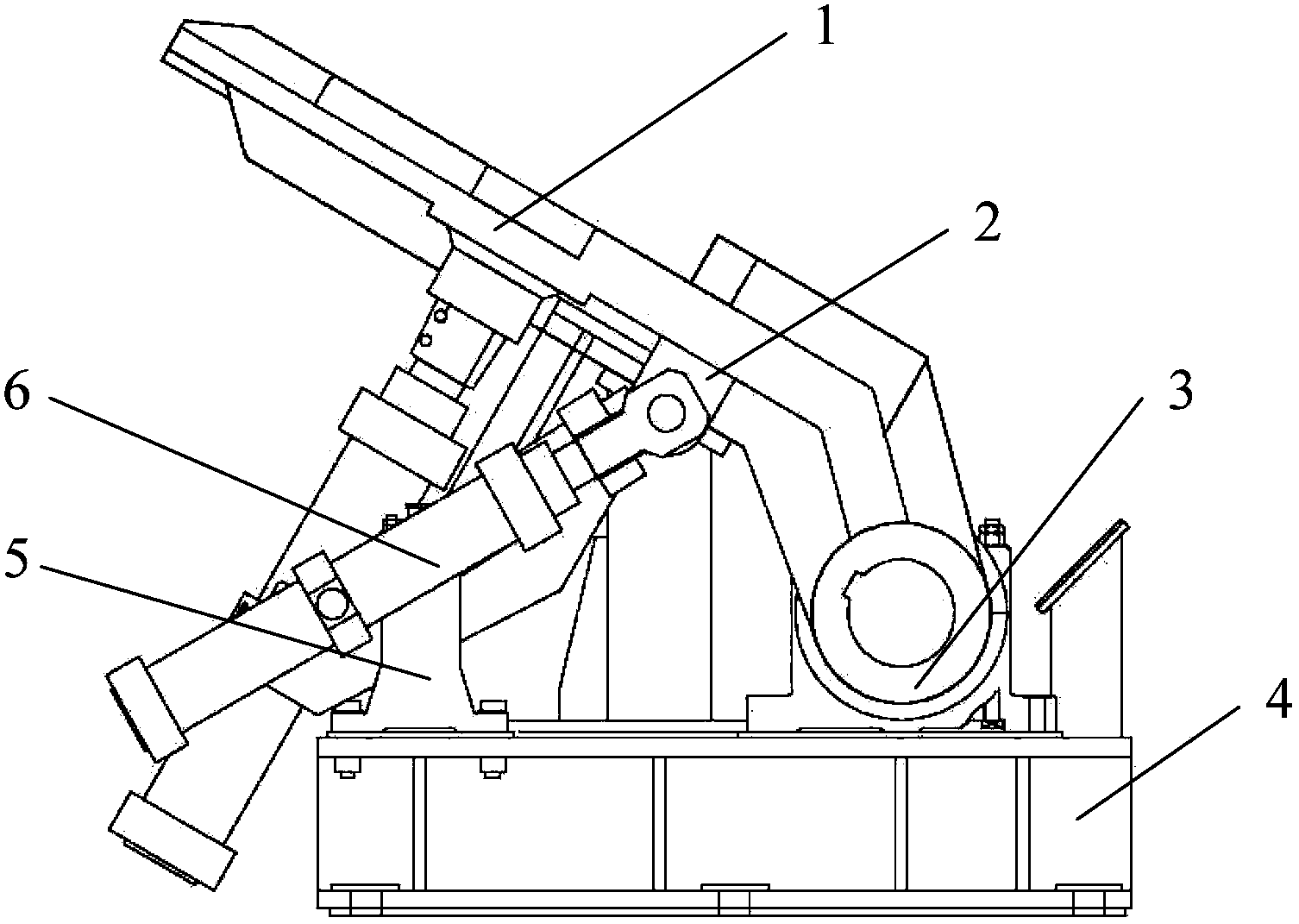

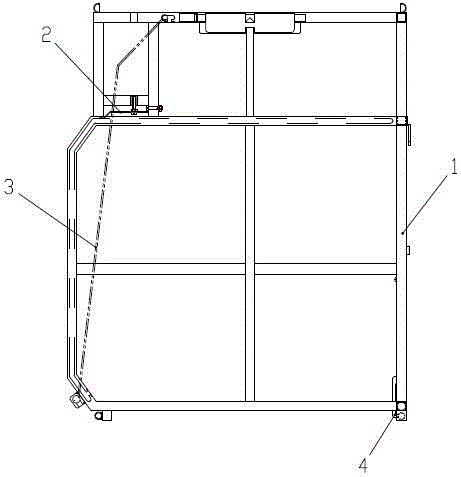

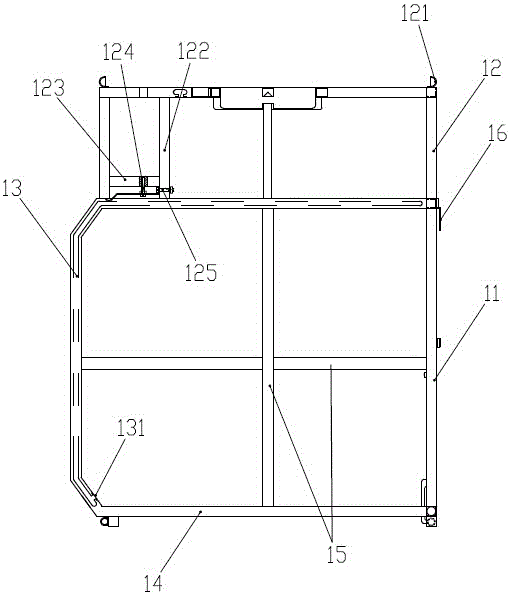

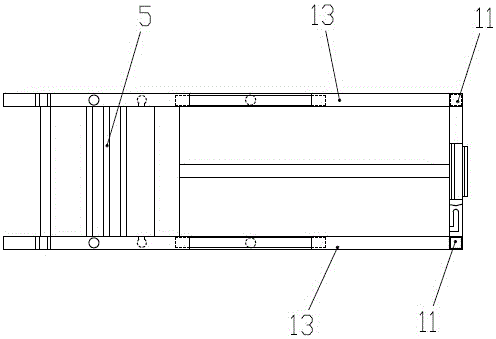

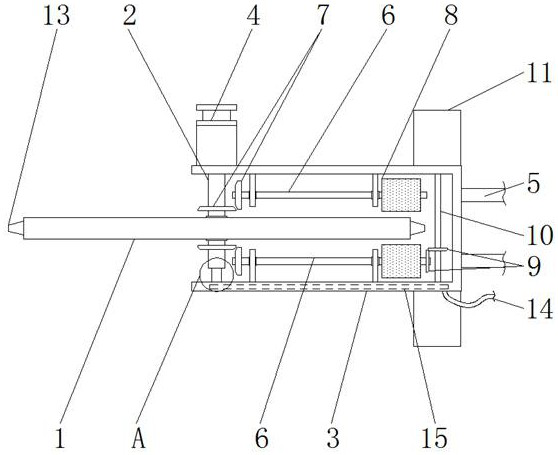

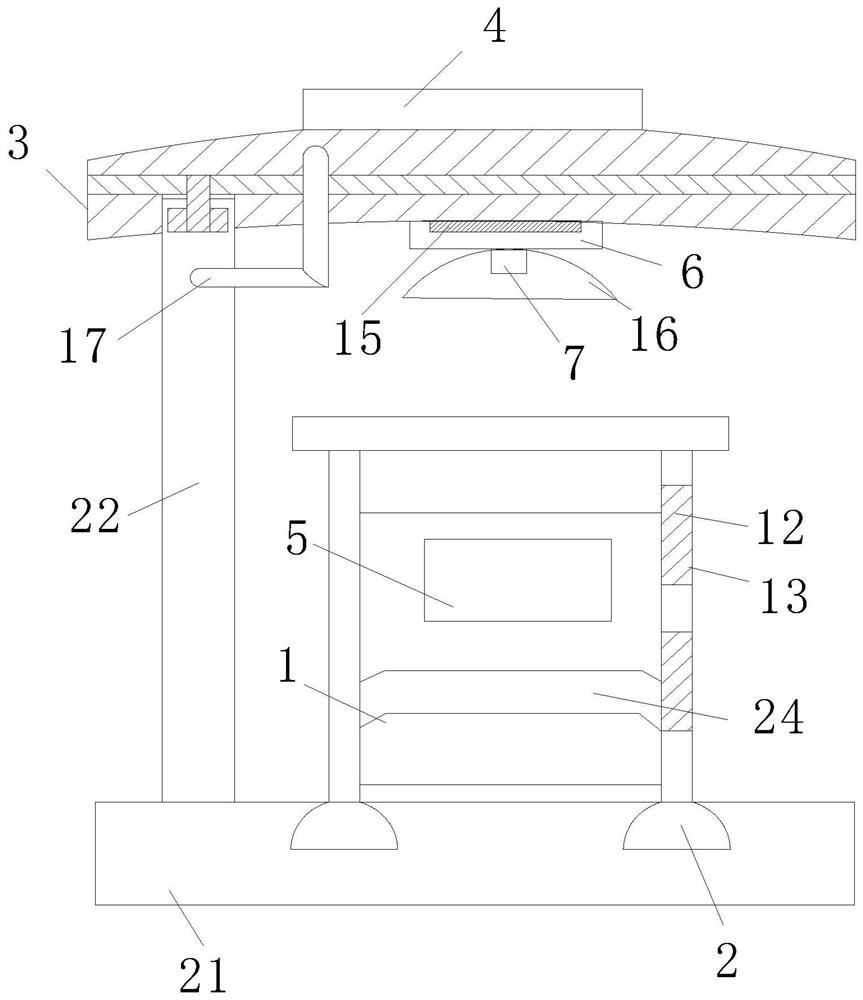

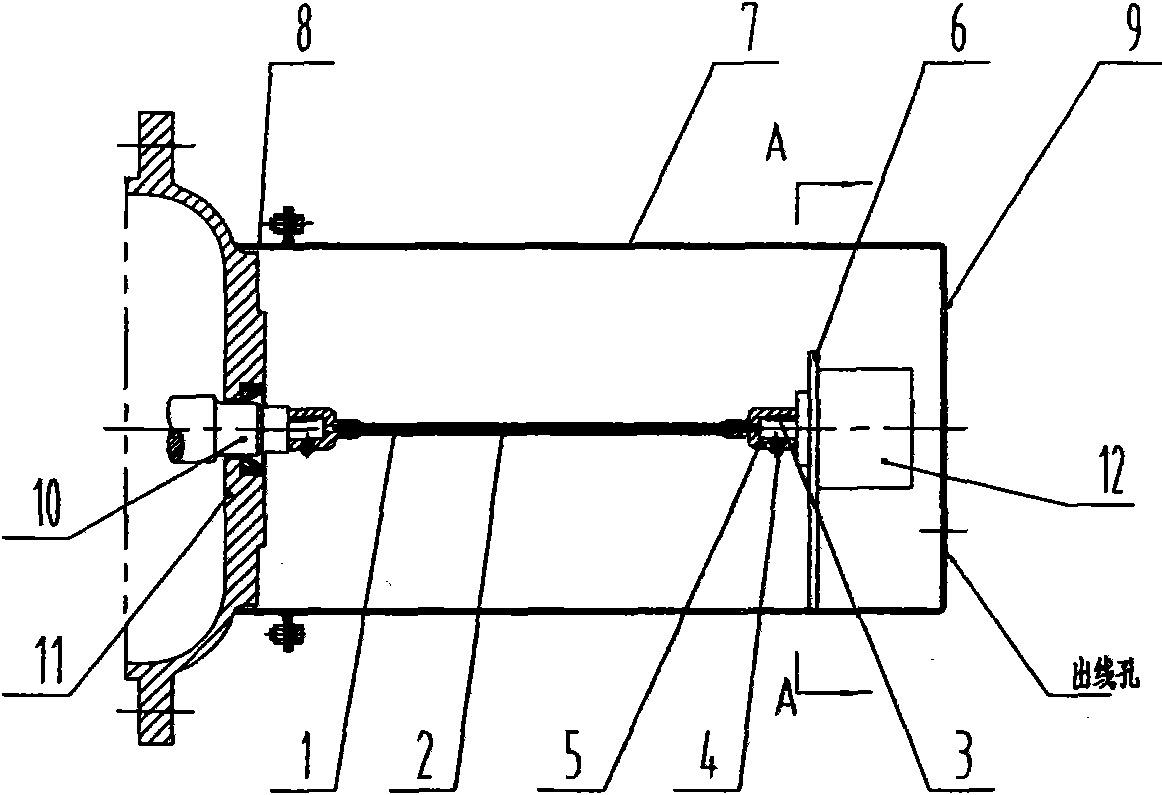

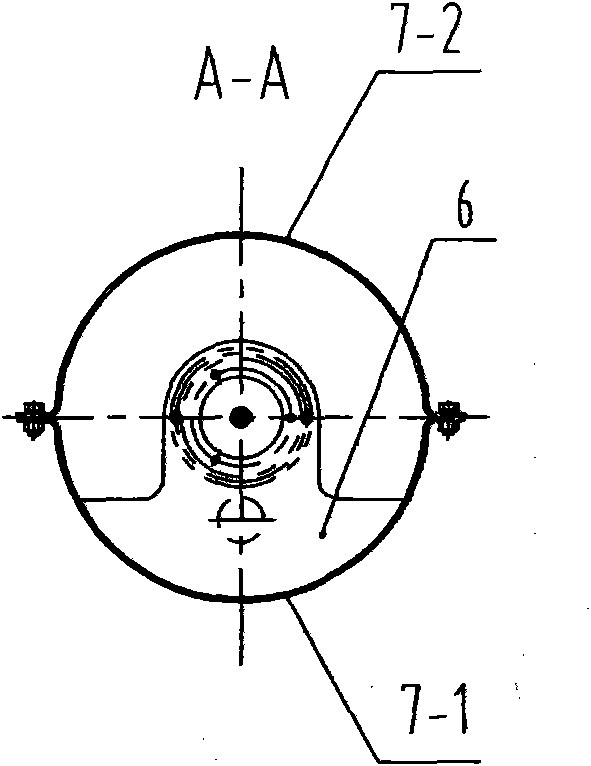

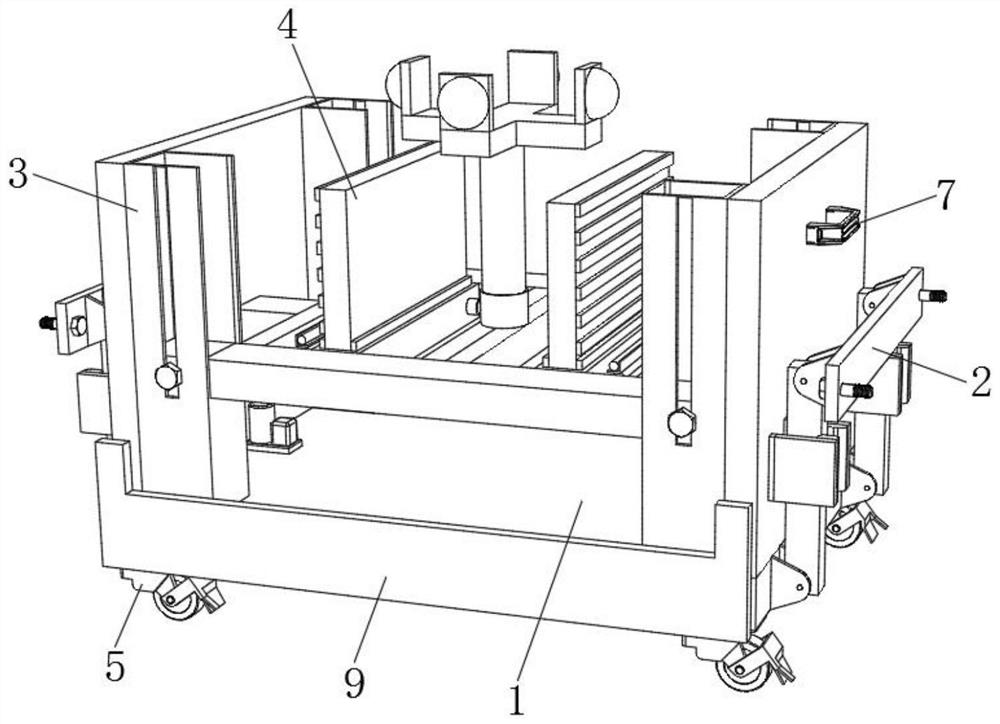

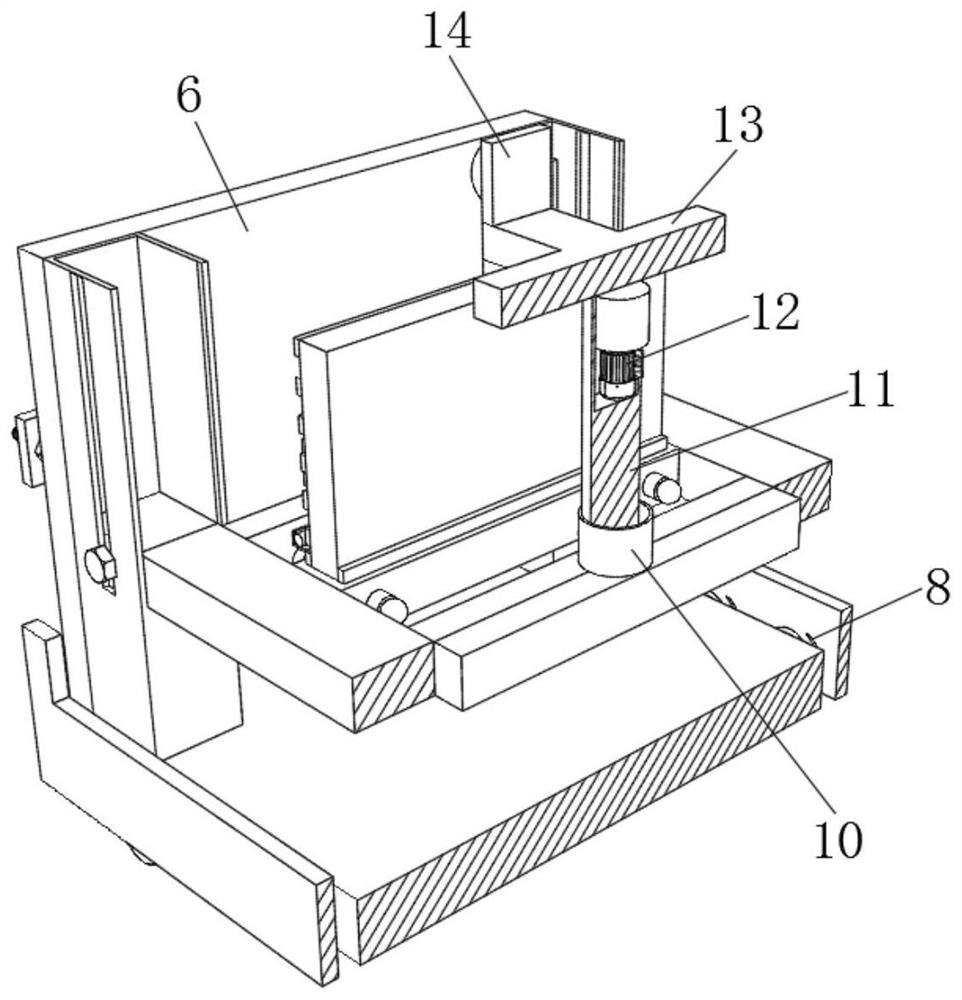

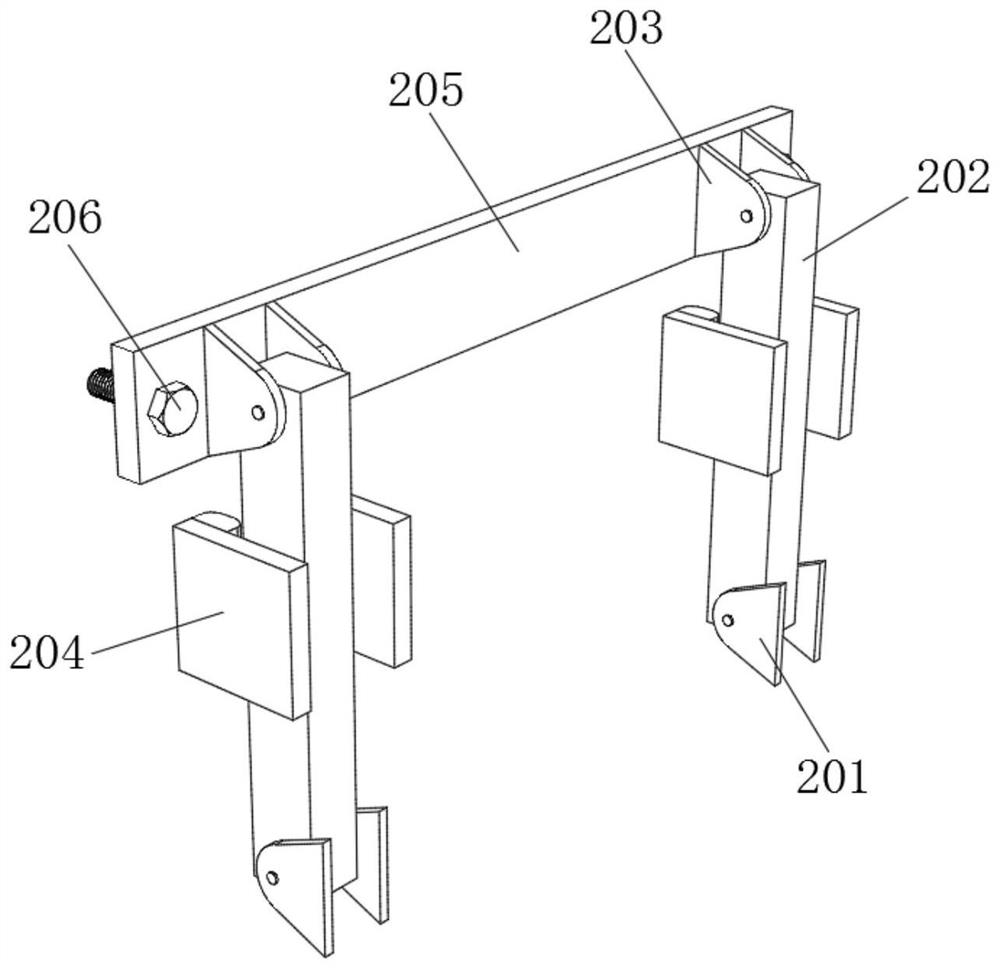

Hydraulic coil upender

InactiveCN103624090AAvoid the problem of uneven force on the left and rightReduce damage frequencyWork manipulationHydraulic cylinderRotational axis

The invention belongs to the field of steel rolling equipment, in particular to a hydraulic coil upender. The hydraulic coil upender comprises a base, a supporting base, a hydraulic cylinder, an overturning board, bearing pedestals, a rotary shaft, a left key and a right key, the supporting base and the bearing pedestals are arranged on the base, the bearing pedestals are arranged at the two ends of the rotary shaft and hinged to the rotary shaft, the overturning board is fixedly connected with the rotary shaft axially through the left key and the right key, hinged lugs are arranged at the lower bottom face of the overturning board, and the hydraulic cylinder is hinged to the overturning board through the hinged lugs; due to the fact that the hydraulic cylinder is directly hinged to the overturning board through the hinged lugs, the transmission path of overturning force is changed into directly force application to the overturning board through the hydraulic cylinder, and the problem that the left side and the right side of the rotary shaft are not stressed evenly due to a side gap formed when the left key and the right key are machined is solved.

Owner:TIANJIN TIANZHONG ZHONGZHI TECH ENG CO LTD

Variable speed control method for cooling table output roller beds

InactiveCN107600960AUniform drag forceTroubleshootingAC motor controlControl devices for conveyorsFrequency conversionWorking environment

The invention discloses a variable speed control method for cooling table output roller beds. The cooling table output roller beds are sequentially grouped when conveying towards cold shears, and a control circuit of each group of roller beds is provided with a controller used for controlling the operation speed of a roller bed motor. The principle is simple, the transform difficulty is low, the cost is low, the labor intensity is small, the control way for the cooling table output roller beds is changed through frequency conversion, grouping and PLC analog quantity control technology, the control performance for the cooling table output roller beds is improved, the noise in the working environment is lowered, energy conservation and environmental protection are achieved, the improved cooling table output roller beds are stable and reliable in operation, and production efficiency is high.

Owner:SICHUAN DESHENG GRP VANADIUM & TITANIUM CO LTD

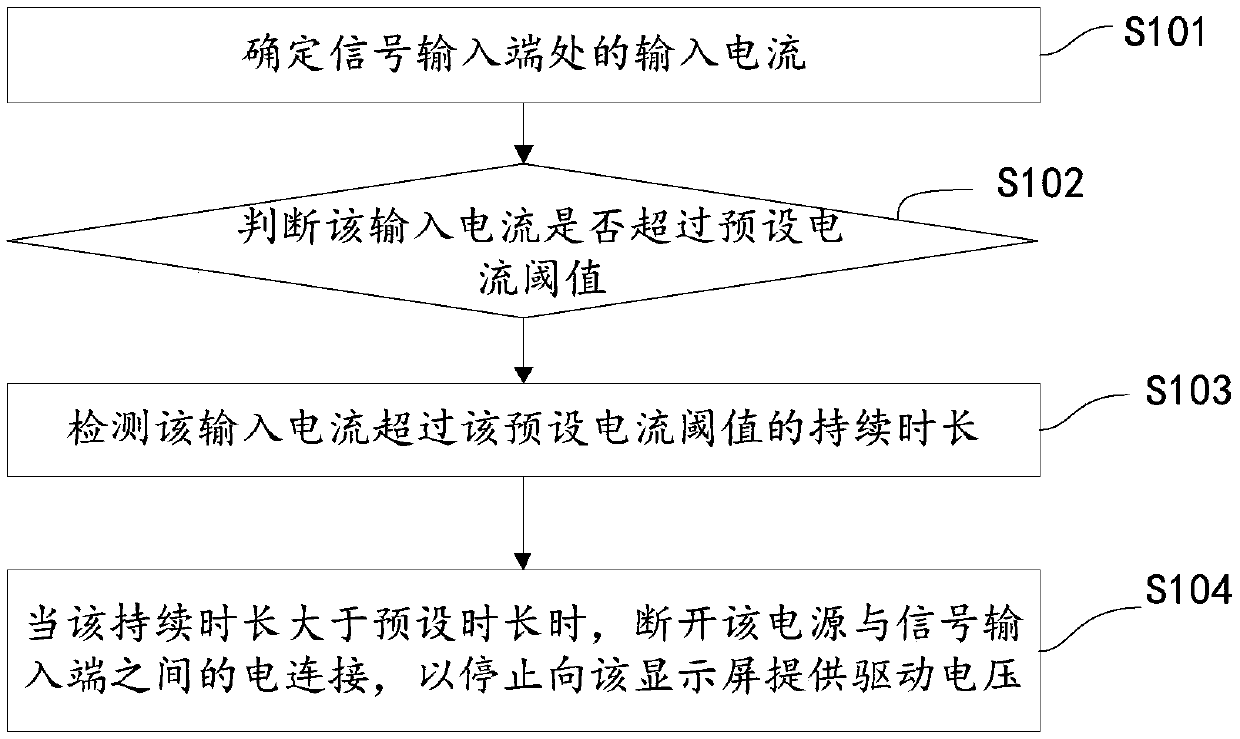

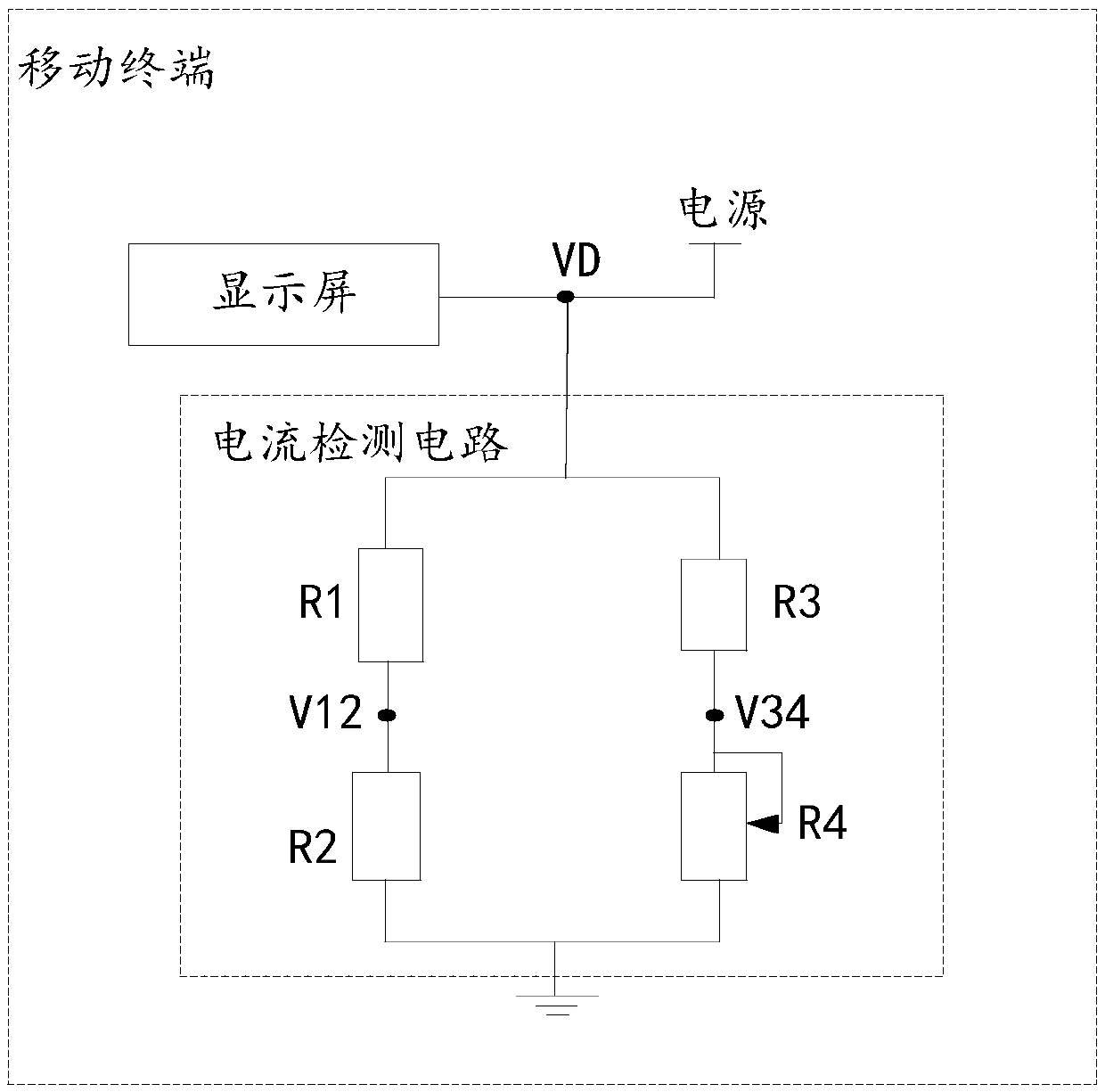

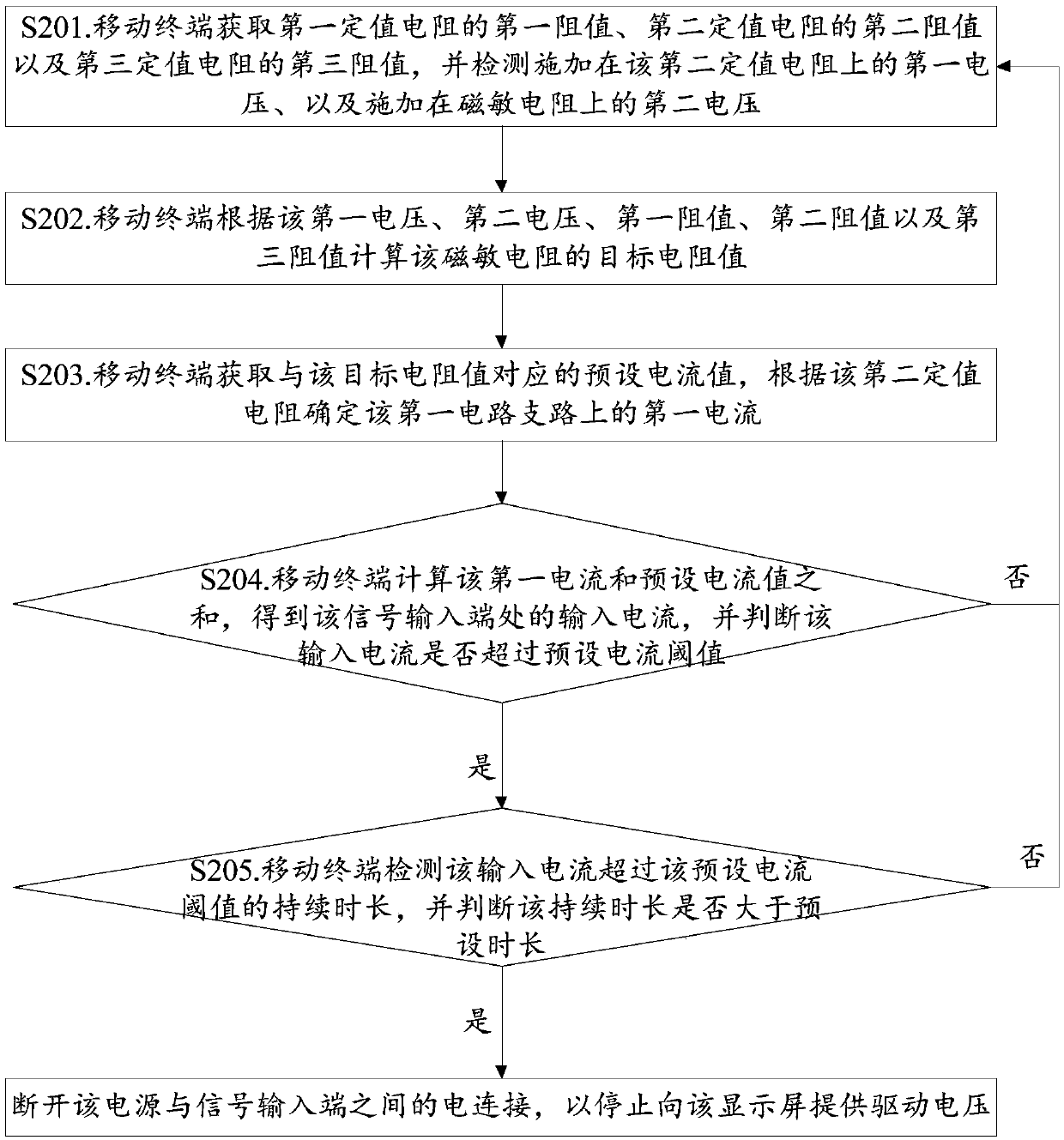

Power supply control method and device of display screen and storage medium

InactiveCN109617009AAvoid short circuitReduce damage frequencyEmergency protective arrangements for automatic disconnectionElectricityCurrent threshold

The invention discloses a power supply control method and device of a display screen and a storage medium. The power supply control method and device is applied to a mobile terminal. The mobile terminal comprises the display screen and a power supply, wherein the display screen is provided with a signal input end, the power supply is electrically connected with the signal input end so as to provide a driving voltage to the display screen, whether an input current exceeds a preset current threshold or not is judged by determining an input current at the signal input end, the continuous time when the input current exceeds the preset current threshold is detected if the input current exceeds the preset current threshold, electrical connection between the power supply and the signal input endis cut off when the continuous time is larger preset time, so that the power supply can be timely cut off according to an abnormal phenomenon of a power supply current of the display screen, the display screen is effectively prevented from being circuit-shorted, and the damage rate of the display screen is reduced. The method is simple and is high in practical.

Owner:HUIZHOU TCL MOBILE COMM CO LTD

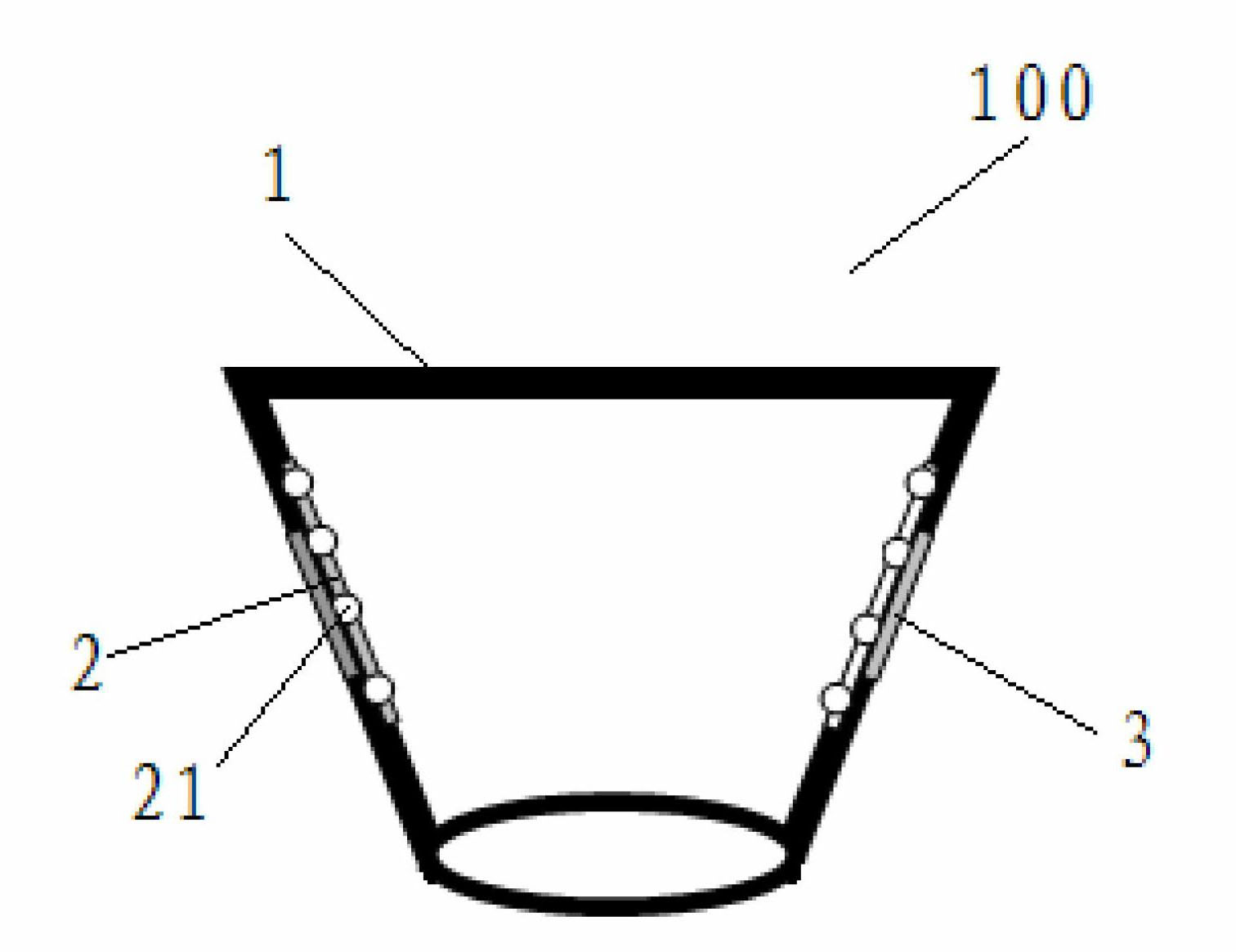

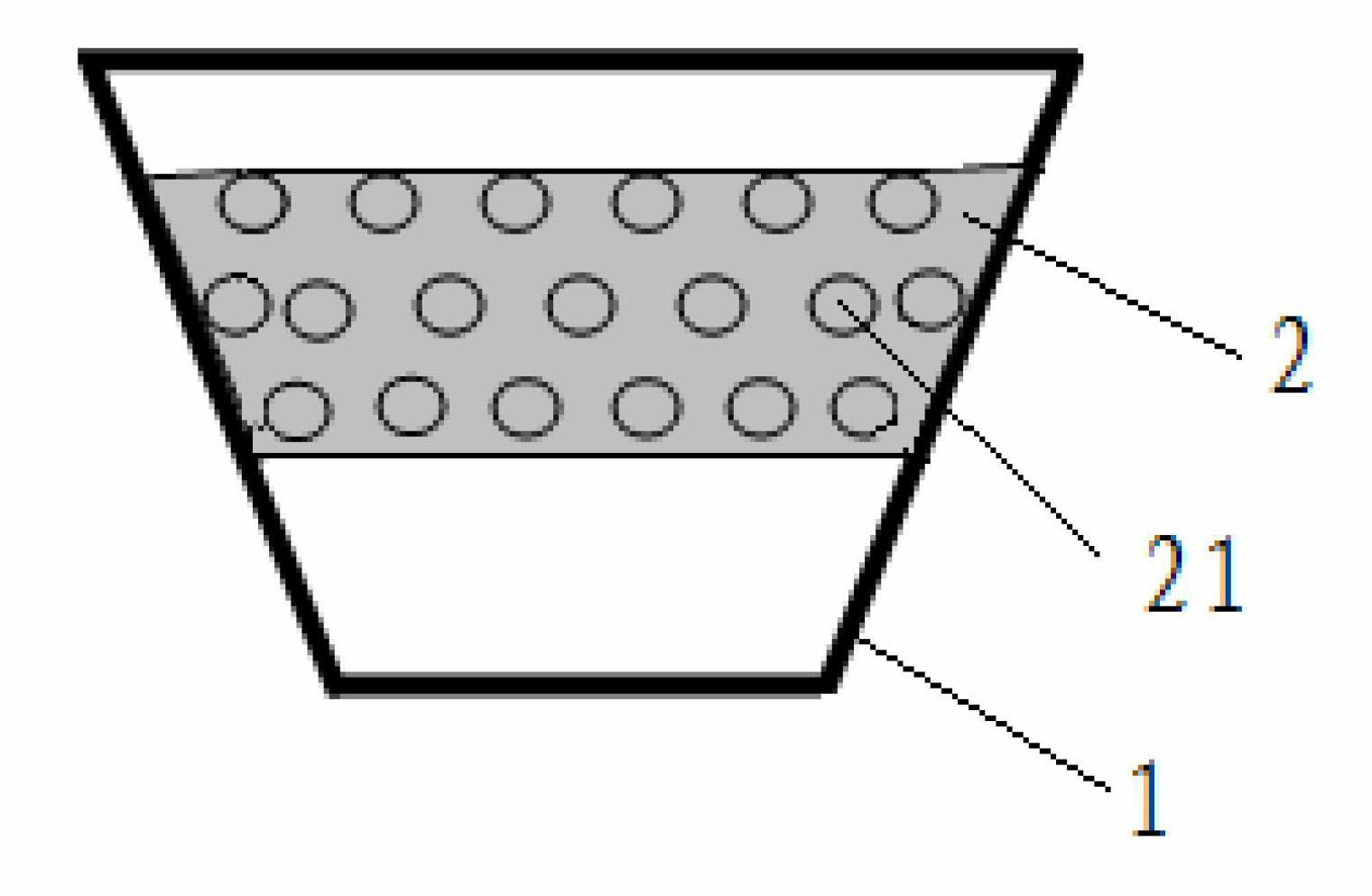

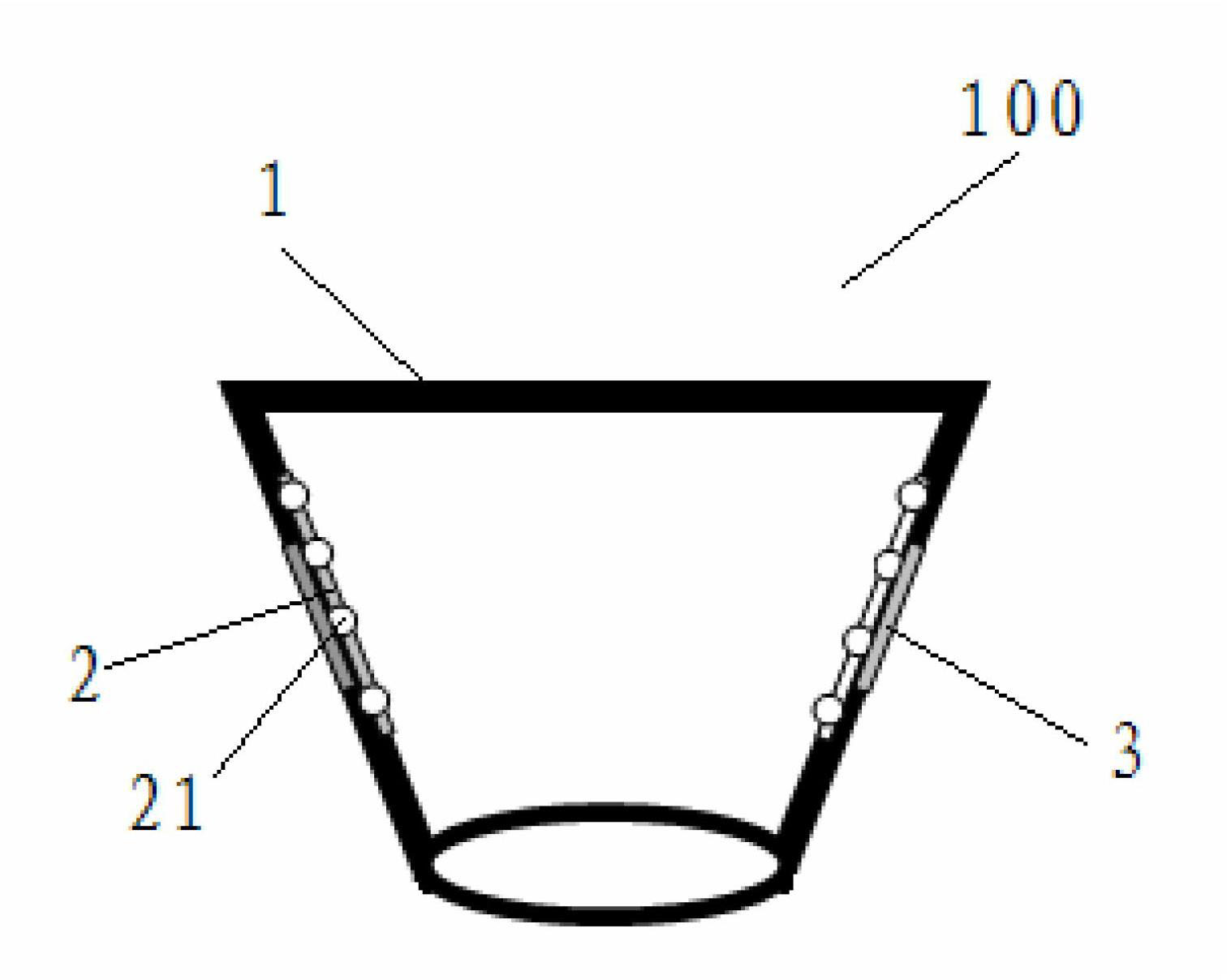

Air inflation awl for pulverized coal gasification device

InactiveCN102676233APrevent backflowGuaranteed delivery effectGranular/pulverulent flues gasificationEngineeringExternal pressure

The invention disclose an air inflation awl for a pulverized coal gasification device. The air inflation awl comprises a taper-shaped barrel and a reinforcement part, wherein the taper-shaped barrel is provided with at least one air inflation area made of sintering metal; the reinforcement part is arranged on the wall of the taper-shaped barrel and at least covers the air inflation area; and a plurality of through holes are formed in the reinforcement part. According to the air inflation awl for the pulverized coal gasification device, which is disclosed by the embodiment of the invention, the strength of the air inflation awl is improved by arranging the reinforcement part covered on the air inflation area, so that the air inflation awl can bear a higher internal and external pressure difference, the highest internal and external pressure difference of 1Mpa, which can be borne by the traditional air inflation awl, is improved to 5Mpa so as to greatly lower the damage possibility of the air inflation awl and prolong the service life of the air inflation awl to lower the cost, meanwhile, the parking times of the air inflation awl are reduced, and the production efficiency is improved. In addition, according to the air inflation awl disclosed by the embodiment of the invention, the phenomenon that the pulverized coal flows back can be effectively prevented, and the pulverized coal conveying effect is guaranteed.

Owner:BEIJING YINGDE QINGDA TECH

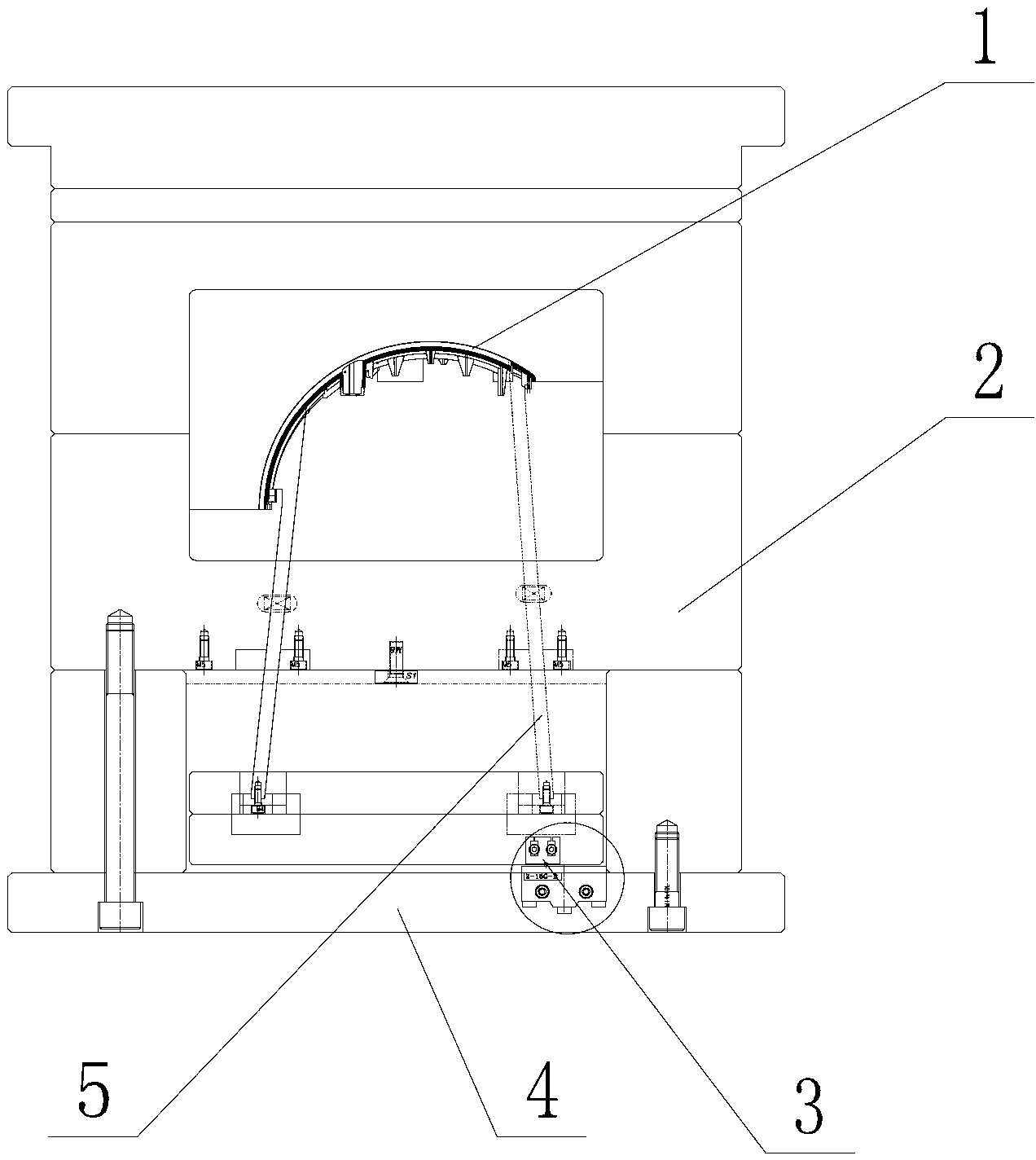

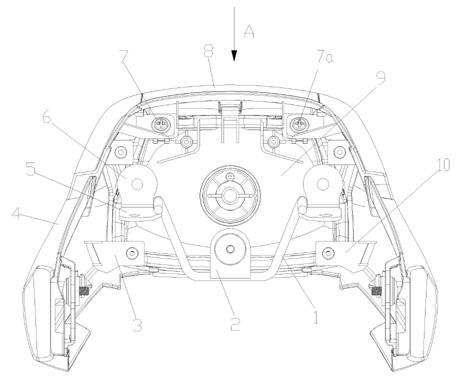

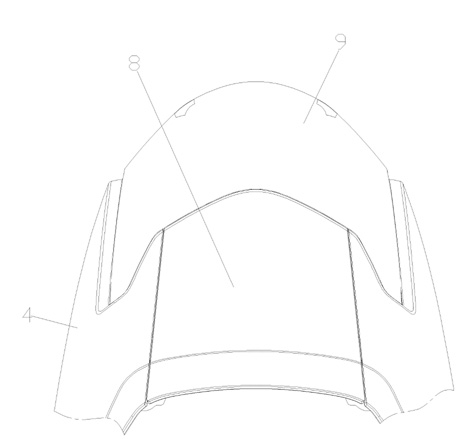

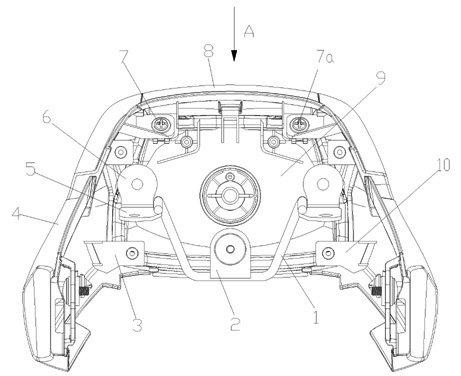

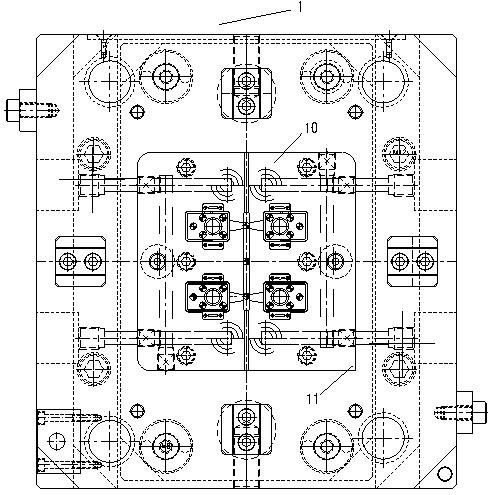

Upper cover mold of water kettle

Owner:KUNSHAN HAOKUN MACHINERY

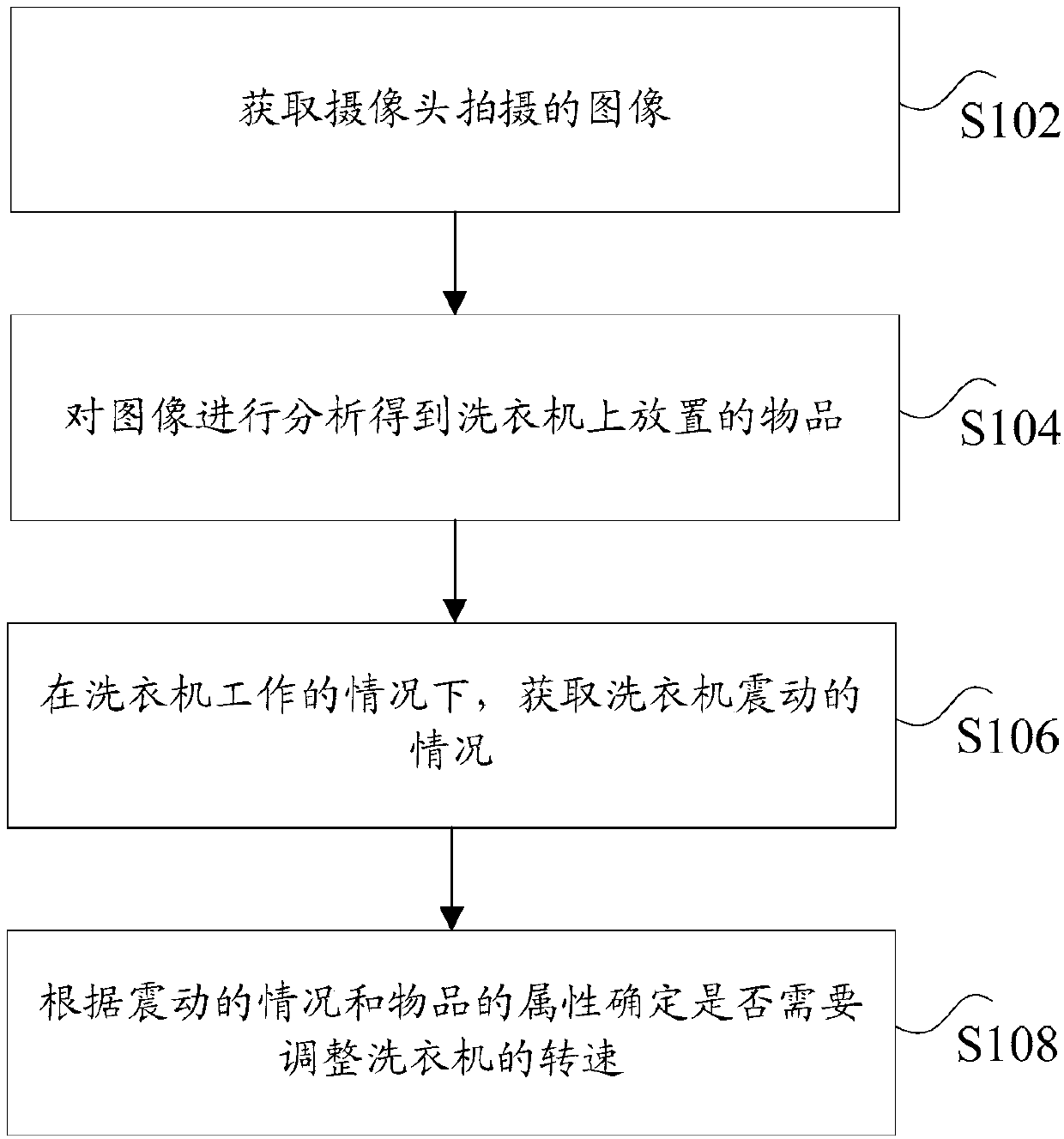

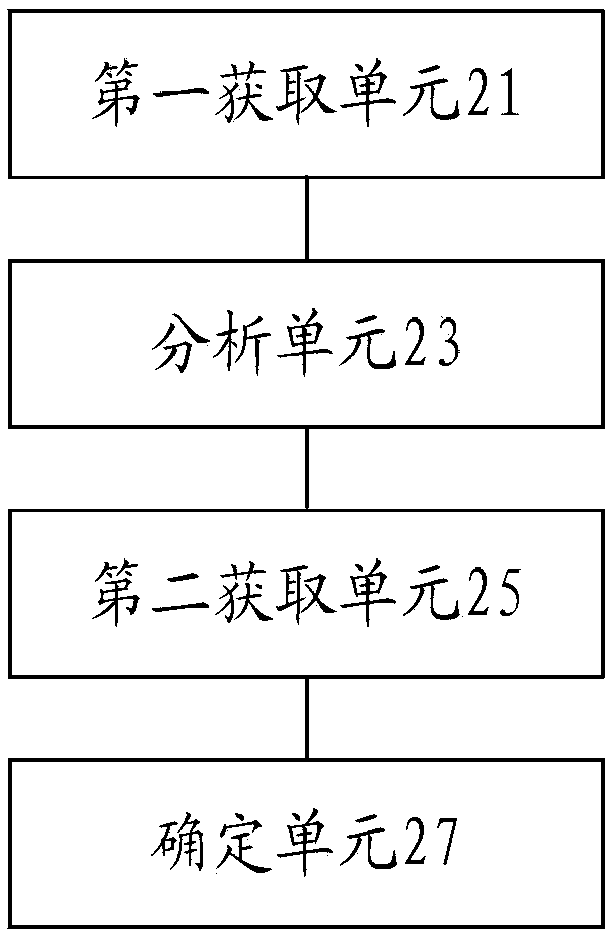

Washing machine vibration processing method and device

ActiveCN108038410ALess damageReduce the frequency of damageCharacter and pattern recognitionMachining vibrationsSimulation

The invention discloses a washing machine vibration processing method and device. The method comprises the steps that the image photographed by a camera is acquired; the image is analyzed so as to obtain the object arranged on the washing machine; the vibration situation of the washing machine is acquired under the working condition of the washing machine; and whether the rotating speed of the washing machine requires to be adjusted is determined according to the vibration situation and the attributes of the object. The technical problem of reduction of the user experience caused by the fact that the vibration of the washing machine cannot be controlled in the related technologies can be solved.

Owner:GREE ELECTRIC APPLIANCES INC

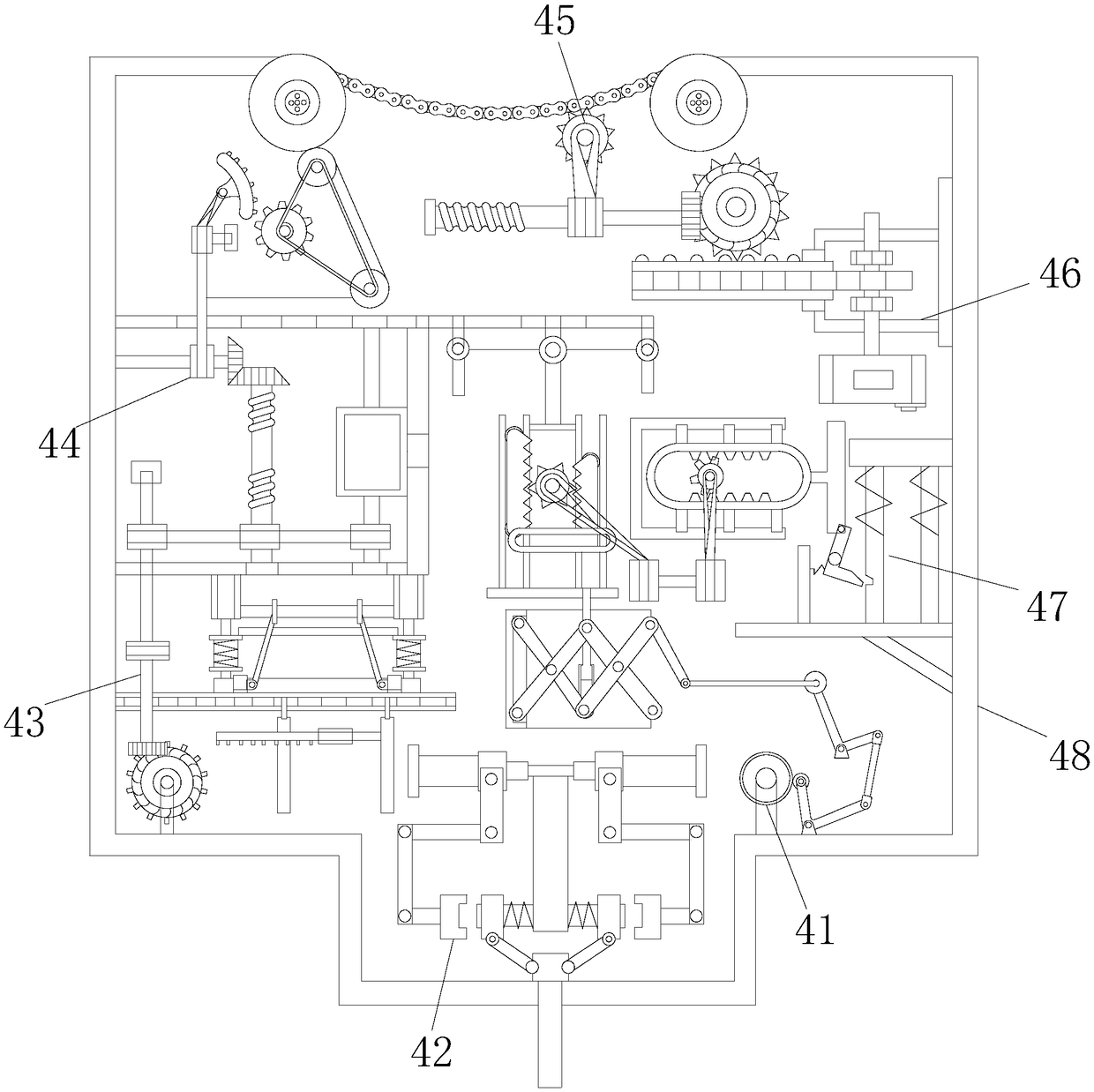

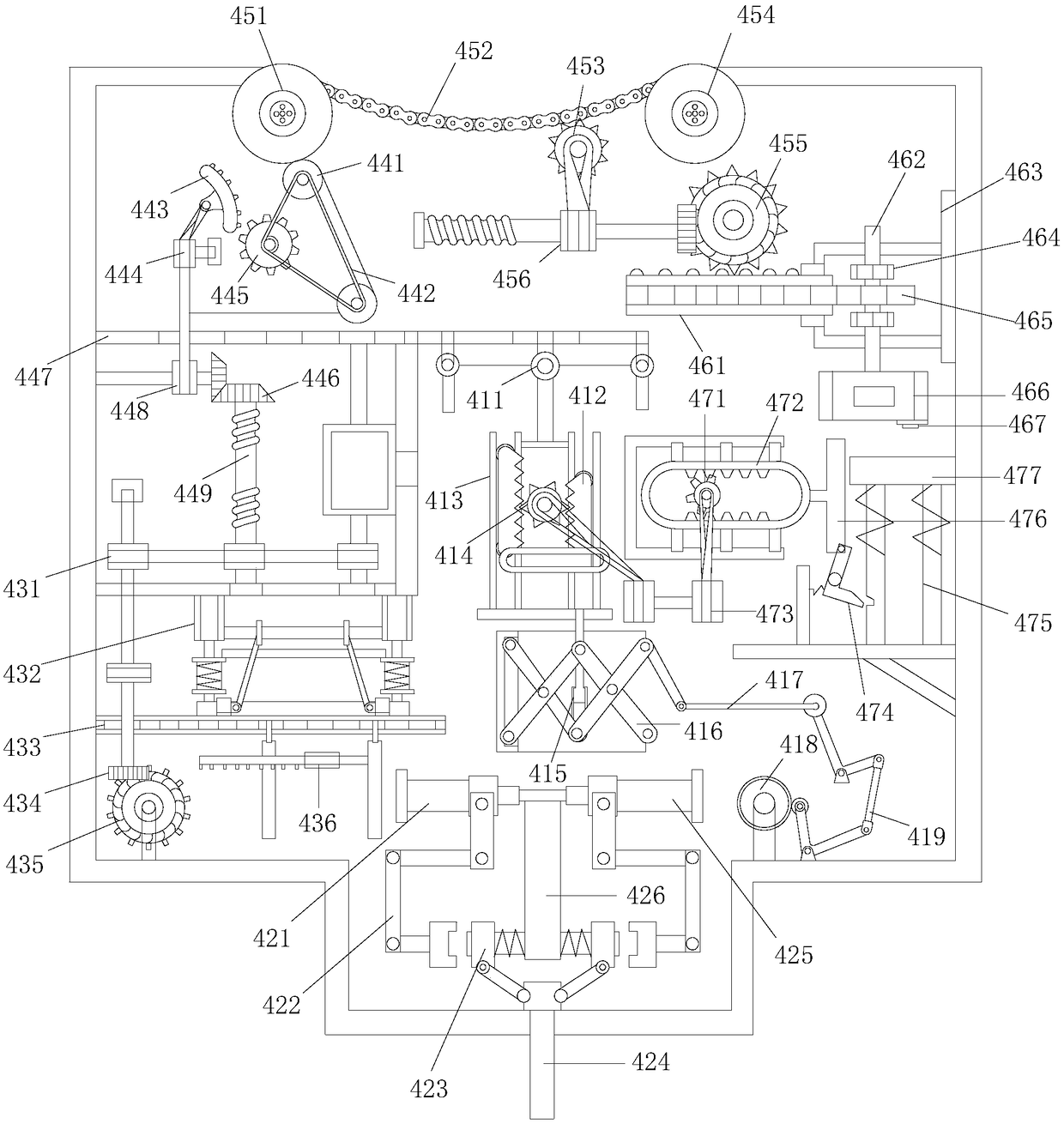

Shock-absorbing and stability-increasing brick-making mold

ActiveCN108621287AImprove convenienceImprove shock absorptionMould fastening meansBrickAgricultural engineering

The invention discloses a shock-absorbing and stability-increasing brick-making mold which comprises a shock absorbing part, a mold core assembly and a mold frame assembly, wherein the mold frame assembly comprises a transverse baffle plate and a vertical baffle plate; shock absorbing part mounting grooves are separately formed in the inner side faces of the transverse baffle plate and the vertical baffle plate in an indent manner; shock absorbing parts are arranged in the shock absorbing part mounting grooves; each shock absorbing part comprises a first fixed plate, an elastic plate and a second fixed plate; the second fixed plate is located on the outer side and a first key groove is formed in the surface in an indent manner; a second key groove corresponding to the first key groove is horizontally formed in the outer side face of the mold core assembly; and a fixed key is arranged between the first key groove and the second key groove. In this way, according to the shock-absorbing and stability-increasing brick-making mold, the elastic shock absorbing parts are additionally arranged between the mold core assembly and the mold frame assembly to adjust the accumulated tolerance ofthe mold core assembly, so that the assembling convenience of the mold core assembly in the mold frame assembly is enhanced, and the integral shock absorbing effect and the structural stability are enhanced.

Owner:TAICANG FLEXSYS MOLD TECH CO LTD

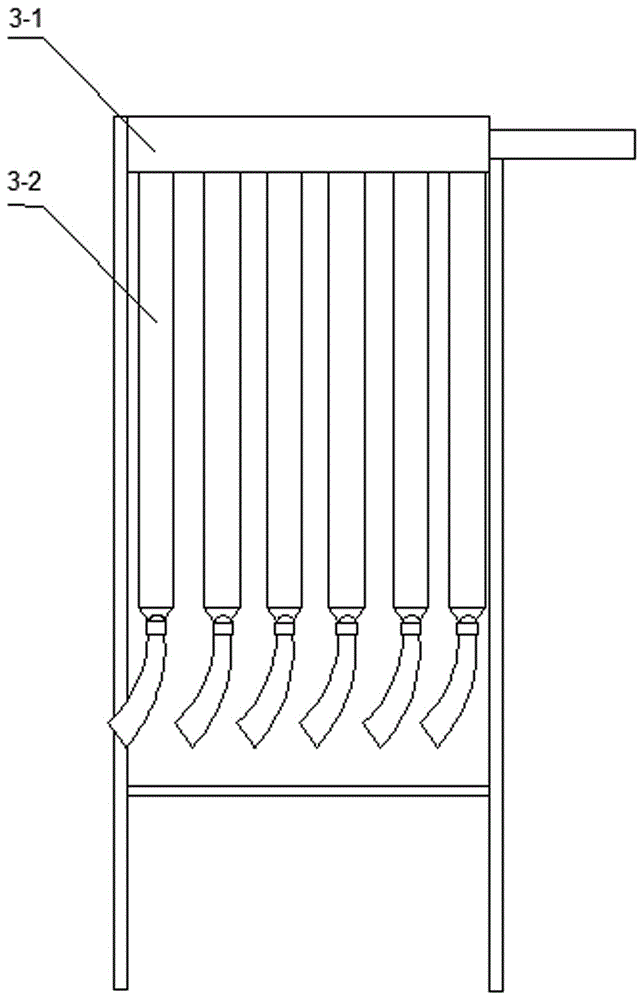

Fire hose box

The invention discloses fire control auxiliary equipment, and particularly discloses a fire hose box.The fire hose box comprises a box rack, wherein a plurality of hose hanging sliding rods allowing fire hoses to be hung and fixed thereon are arranged on the box rack, the hose hanging sliding rods slide along the box rack, a damping component used for preventing the hose hanging sliding rods from falling off is arranged on the box rack, and a clamping component used for fixing the box rack onto a transportation tool is arranged below the box rack.By the adoption of the fire hose box, orderly arrangement and quick laying of the fire hoses can be achieved conveniently, bending and torsion of the fire hoses in the laying process are reduced, and damage frequency is reduced.Furthermore, the fire hose box can be matched with a fire hose vehicle for integral case transportation, the fire hoses can be pulled out conveniently and quickly, labor intensity is relieved, and conveyance efficiency is improved.

Owner:SICHUAN JOINER MACHINERY & AUTOMATIC EQUIP

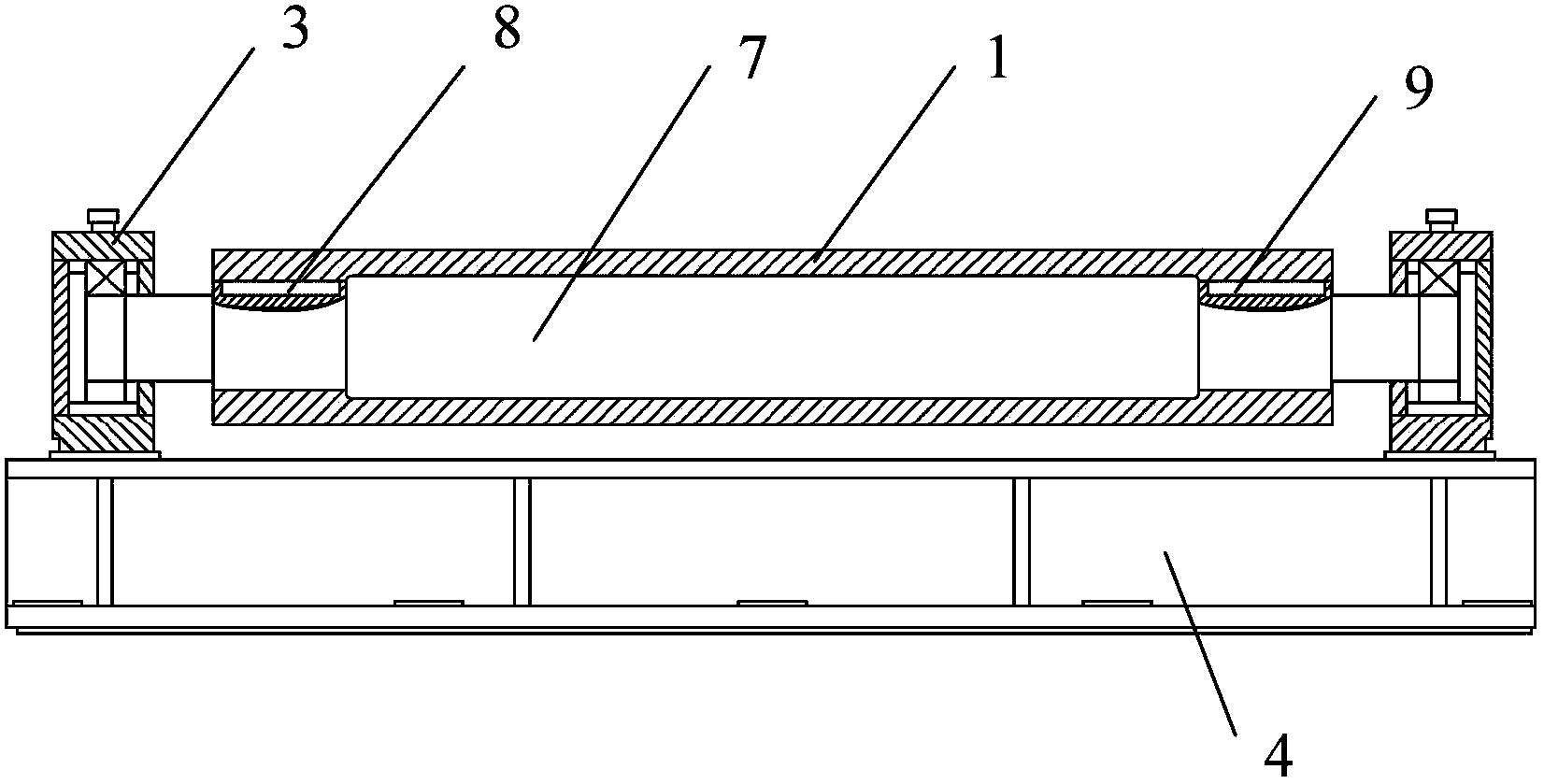

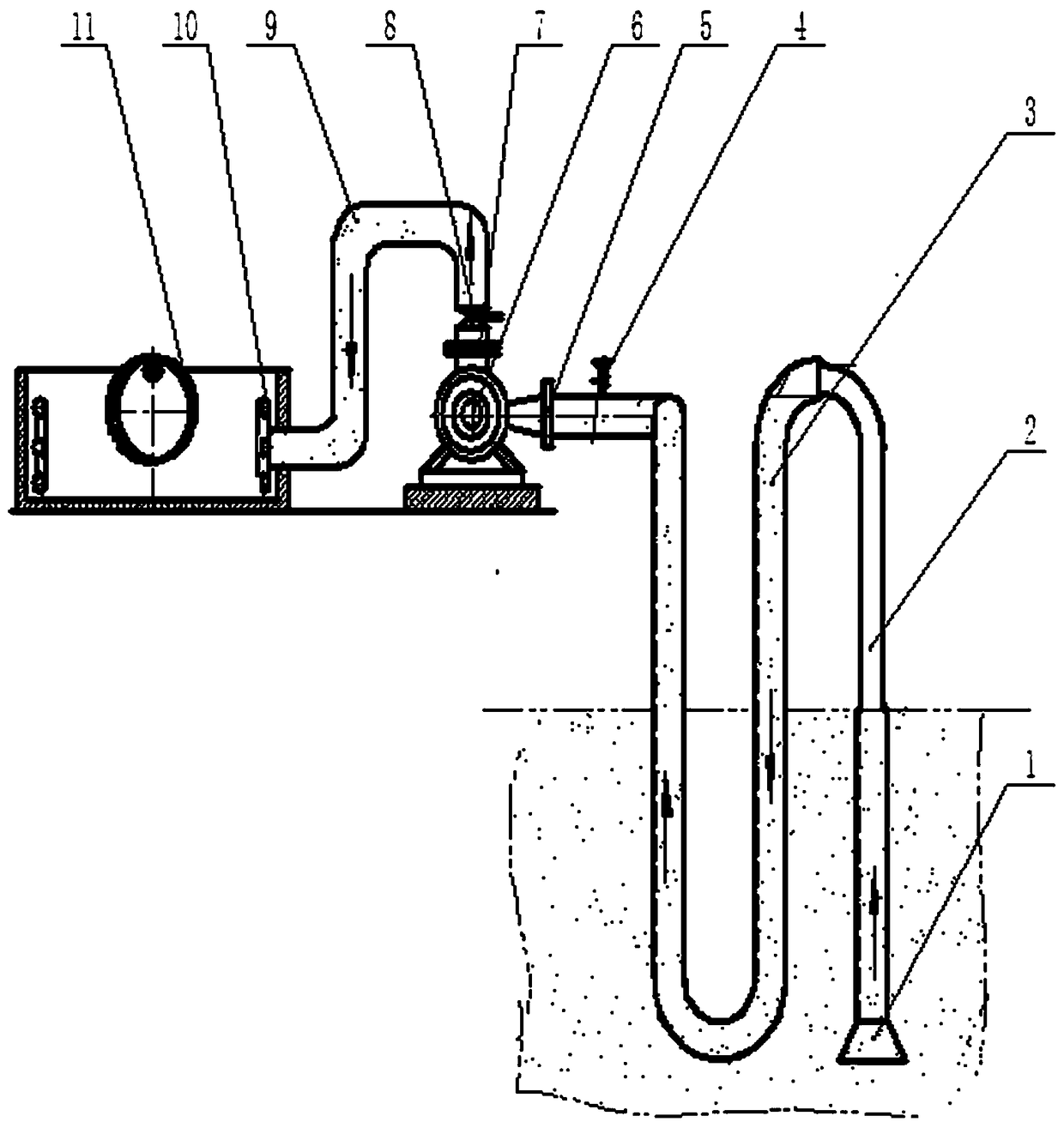

Steel wire high-pressure water flushing method and device thereof

ActiveCN108941006AReduce damage frequencyGuaranteed cleaning qualityCleaning using liquidsEngineeringHigh pressure water

The invention discloses a steel wire high-pressure water flushing device. A horn-shaped steel pipe DN150 and a U-shaped steel pipe DN150 are connected through a middle connecting steel pipe DN110. Thewater inlet end of a multi-stage horizontal centrifugal pump is connected with a connecting flange I and is sequentially connected with a ball valve DN15, and the water inlet and outlet end of the multi-stage horizontal centrifugal pump is connected with a connecting flange II and is sequentially connected with a check valve DN150, a conveying pipeline DN150 and a water spraying pipe set. Duringhigh-pressure water flushing, the ball valve DN 15 is opened, led water passes through the U-shaped steel pipe DN150, the ball valve DN15 is closed, the multi-stage horizontal centrifugal pump is started, at that time, the water is sucked into the middle connecting steel pipe DN110 from the horn-shaped steel pipe DN150, enters the U-shaped steel pipe DN150 and arrives at the water spraying pipe set through the conveying pipeline DN150, and the high-pressure water is sprayed to a steel wire through a pipeline to achieve the washing purpose. By means of the steel wire high-pressure water flushing device, the damage frequency of a high-pressure water pump is reduced, the water pump flow is guaranteed, and the steel wire washing quality is ensured.

Owner:GUIZHOU WIRE ROPE

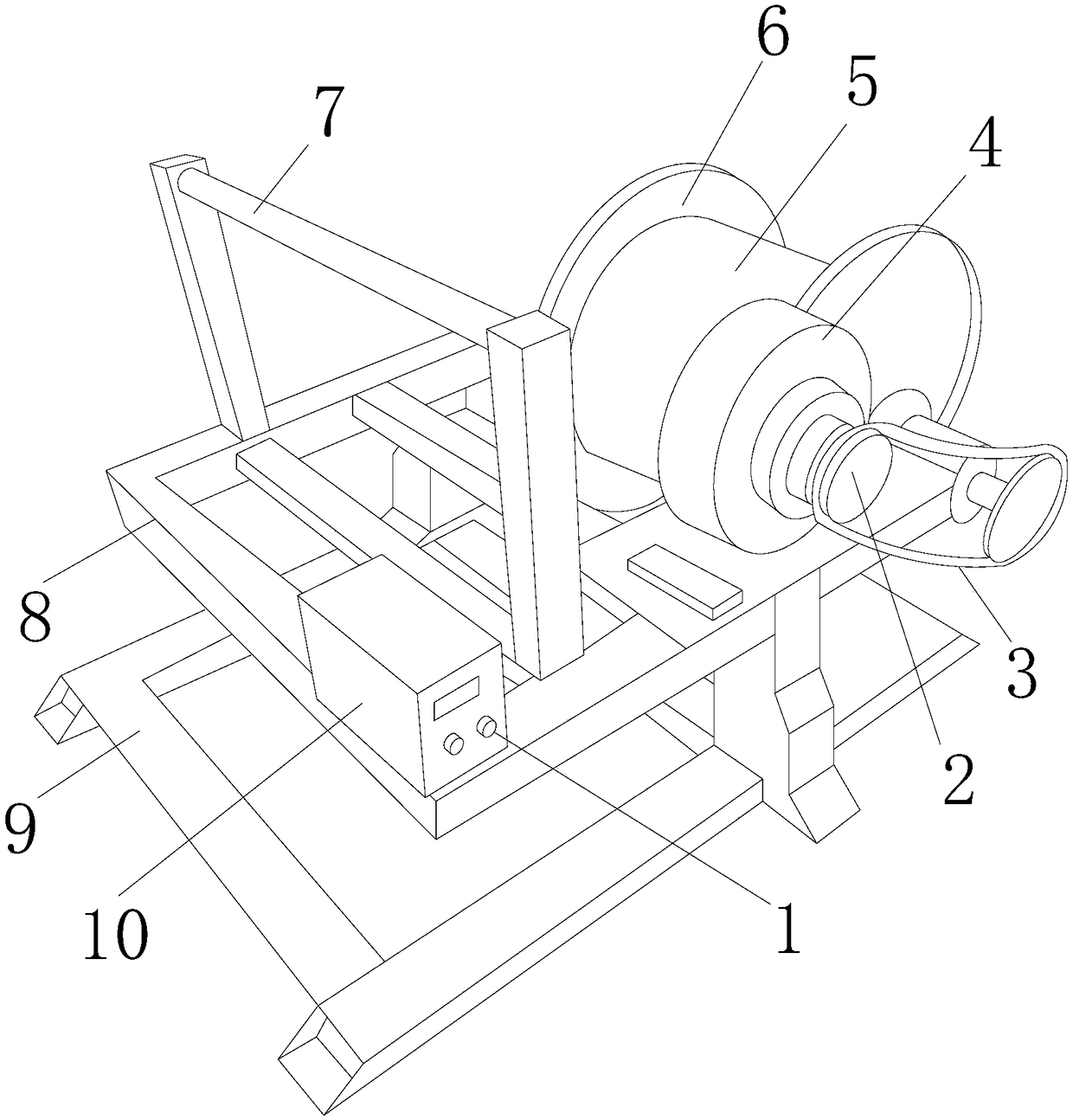

Wire unwinding device for electric construction

The invention discloses a wire unwinding device for electric construction. The device comprises a mode adjusting button, a hub, a mechanical chain, a damper device, a wire unwinding disc, a limiting plate, a connecting rod, a metal bracket, a base and a controller; and the damper device is provided with a linkage trigger device, an ascending adjusting device, a turbine driving device, a transmission device, a friction speed reducing device, a movable adjusting device, a trigger startup device and a metal edge frame. The device has the following beneficial effects: the motion resistance can beprovided through the added damper device; and the wire unwinding tension is preferably controlled through a motion energy reducing device, and the wire unwinding tension of leads is always stabilizedat a critical value between deformation and no deformation, so that ultrafine leads are preferably protected, wires can be arranged at a wiring end more stably, the conditions of wire breakage and flight are reduced, the long-time ordered construction work is facilitated, and the construction period is shortened.

Owner:张秋达

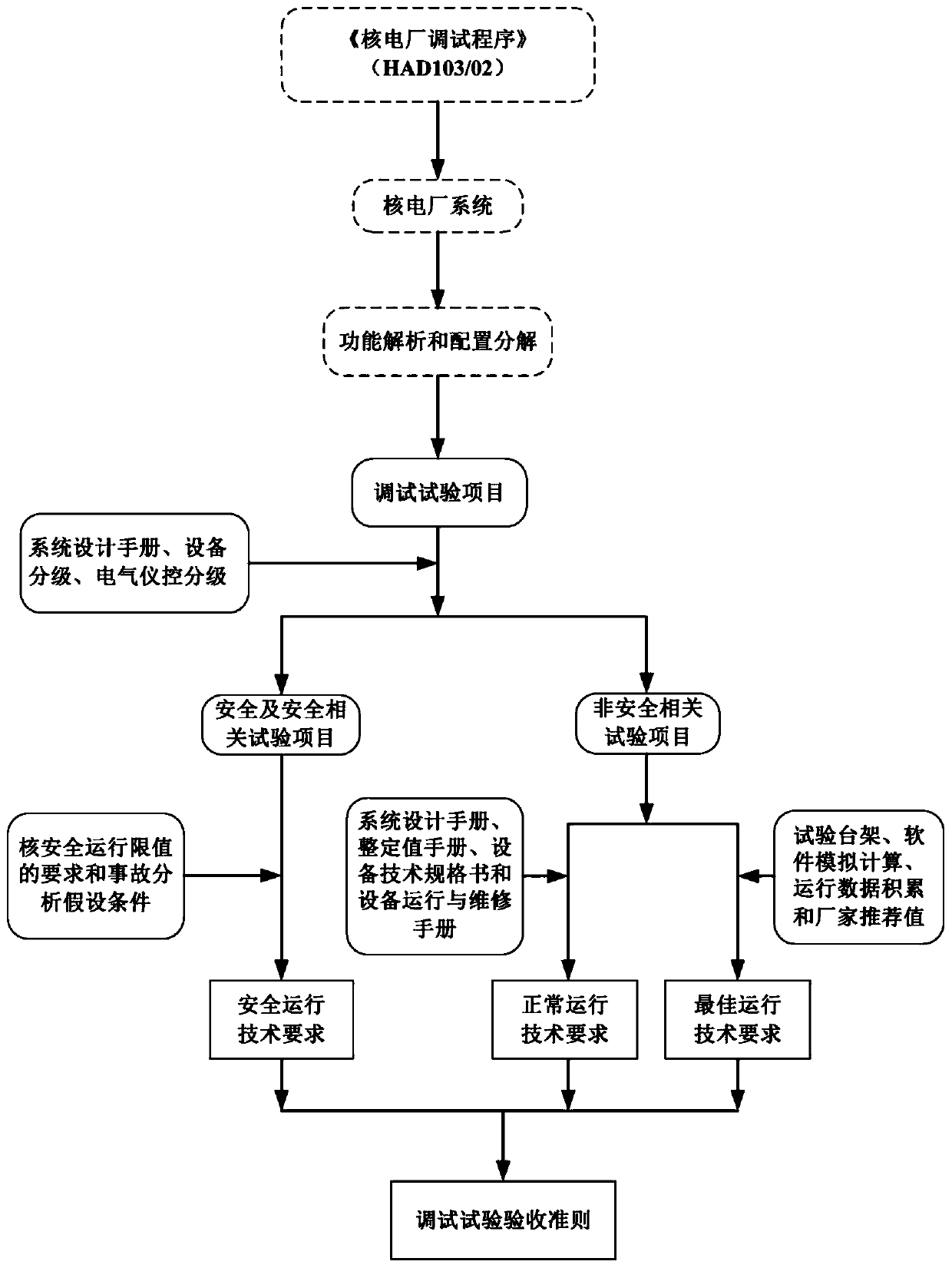

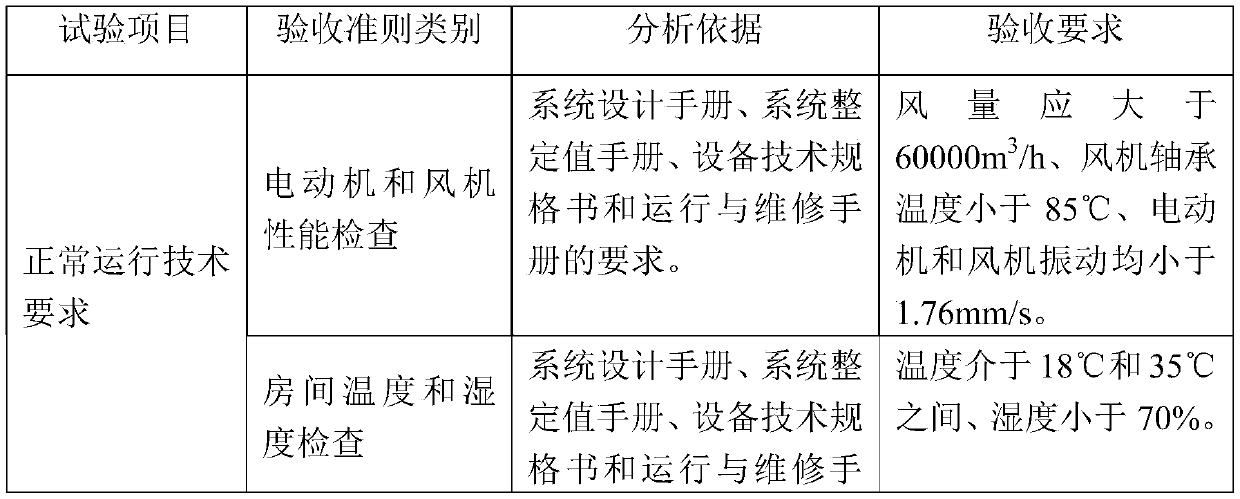

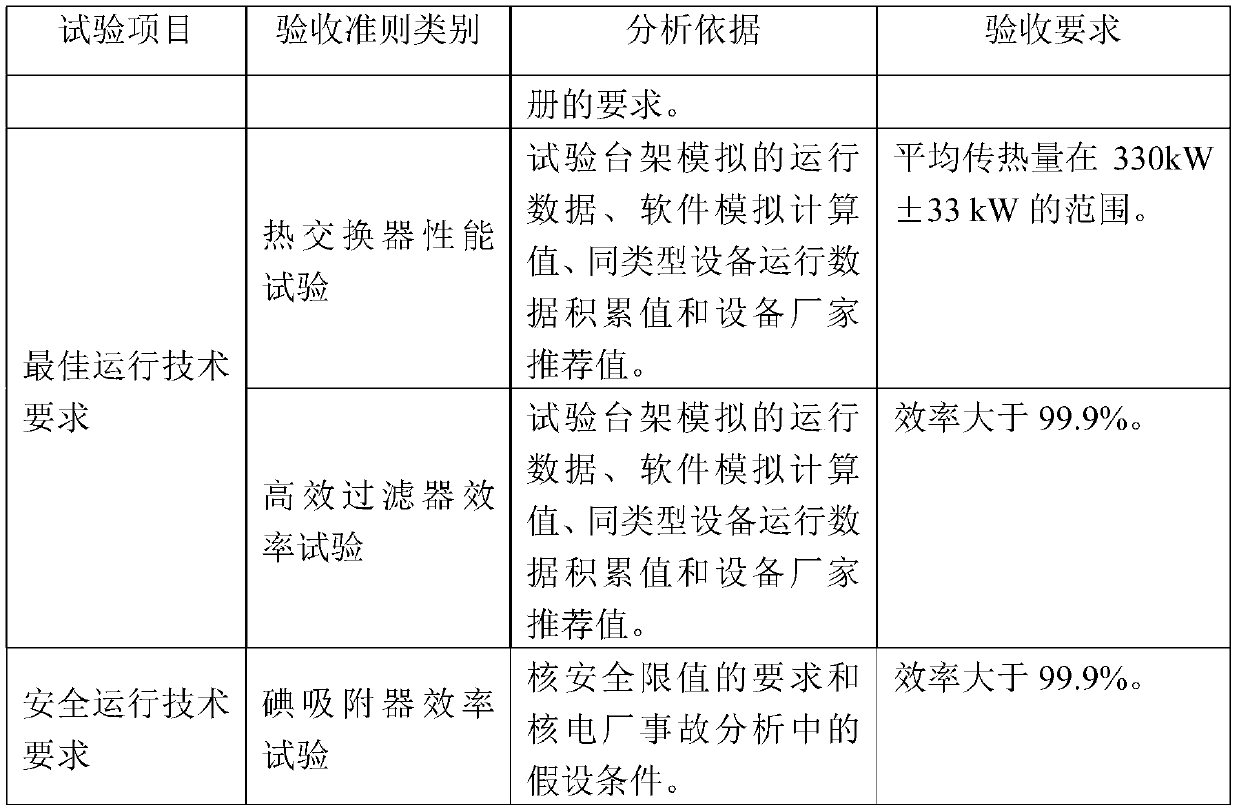

Analysis method for nuclear power plant debugging test acceptance criteria

PendingCN111582667AEnsure safetyNuclear securityNuclear energy generationNuclear monitoringNuclear plantSoftware engineering

The invention relates to an analysis method for nuclear power plant debugging test acceptance criteria. According to the method, a system forming a nuclear power plant serves as a unit, on the basis of all debugging test items, determined through system function analysis and configuration decomposition, of a single system, safety function classification and technical requirement making are conducted on each debugging test item, and therefore the final debugging test acceptance criterion is determined. According to the method, qualitative and quantitative acceptance criteria can be designed foreach debugging test, so that reasonable criteria are provided for debugging personnel to analyze the correctness of the test process and result, and whether the performance of the system and equipment meets design requirements and performance standards or not is effectively verified.

Owner:CHINA NUCLEAR POWER ENG CO LTD

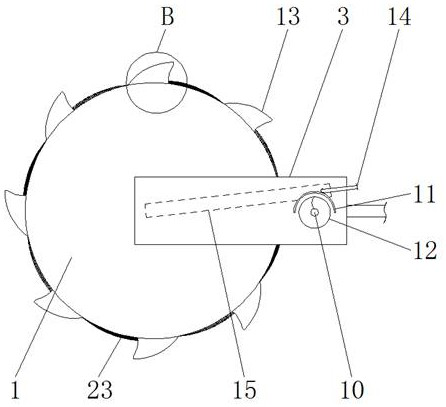

Furrow opener for water diversion construction based on water conservancy project

InactiveCN112854335AEasy to cleanEffective water coolingUsing liquid separation agentSoil-shifting machines/dredgersDrive shaftEngineering

The invention discloses a furrow opener for water diversion construction based on a water conservancy project. The furrow opener for water diversion construction based on the water conservancy project comprises a furrow opening disc, a driving shaft, a frame plate, a driving mechanism and a connecting piece, wherein the center of the furrow opening disc is fixedly mounted on the driving shaft; the driving shaft is rotatably mounted at the left end of the frame plate; the driving mechanism is mounted on the frame plate, and is connected with the driving shaft; an arc-shaped cover which is horizontally distributed is fixedly mounted on the outer wall of the frame plate; a water pipe is mounted on the surface of the frame plate; and furrow opening teeth are mounted on the furrow opening disc. According to the furrow opener for water diversion construction based on the water conservancy project, rotation of the furrow opening disc can be used as a power source to drive a cleaning structure to operate, so that the furrow opening disc can be efficiently cleaned; and reasonable rotation of the furrow opening teeth can be used, so that a furrow opening structure in the furrow opening disc can obtain effective water cooling heat dissipation, and more energy-saving and environment-friendly effects are achieved while loss is reduced.

Owner:丁晨曦

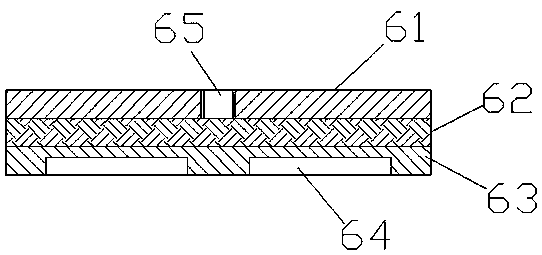

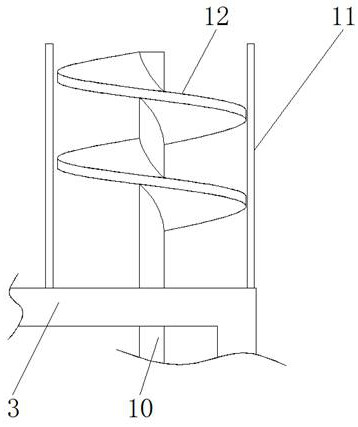

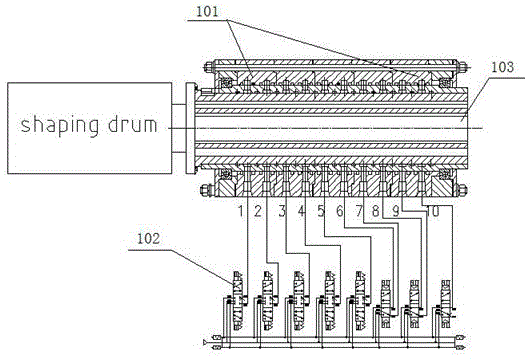

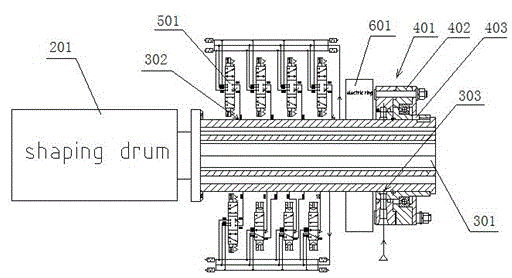

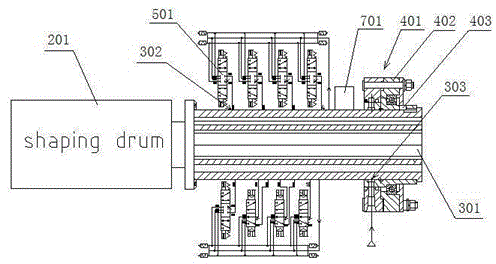

Gas supply control device of forming machine main drum driving box

The invention discloses a gas supply control device of a forming machine main drum driving box. The gas supply control device comprises a main shaft, wherein one end of the main shaft is connected with the forming machine main drum driving box; a plurality of common inner holes and a gas source inner hole are formed in the main shaft; the common inner holes are connected with a forming drum through a main shaft internal gas circuit; a rotary seal is arranged on the periphery of the gas source inner hole and is connected with a gas source; each of the common inner holes is connected with a corresponding electromagnetic valve; and the air inlet of each electromagnetic valve is connected with the gas source inner hole through the gas circuit. According to the gas supply control device of the forming machine main drum driving box, the one-path rotary seal is adopted to replace the existing multi-path rotary seal, so that the device cost is reduced and the processing and assembling difficulty is also reduced; only the one-path rotary seal is provided, so that the damage frequency and the replacing frequency of the rotary seal are reduced; and in addition, one rotary seal is replaced at one time even if the rotary seal leaks air and needs to be replaced, so that the equipment maintaining cost is reduced.

Owner:QINGDAO MESNAC ELECTROMECHANICAL ENG +1

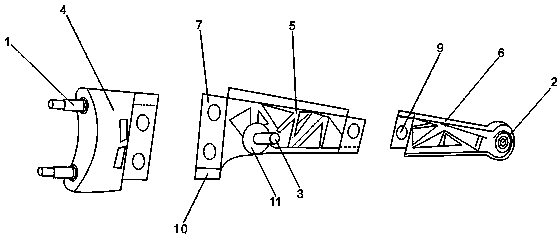

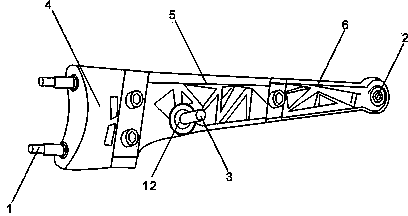

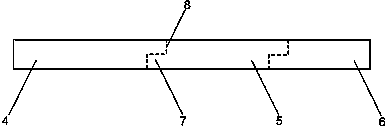

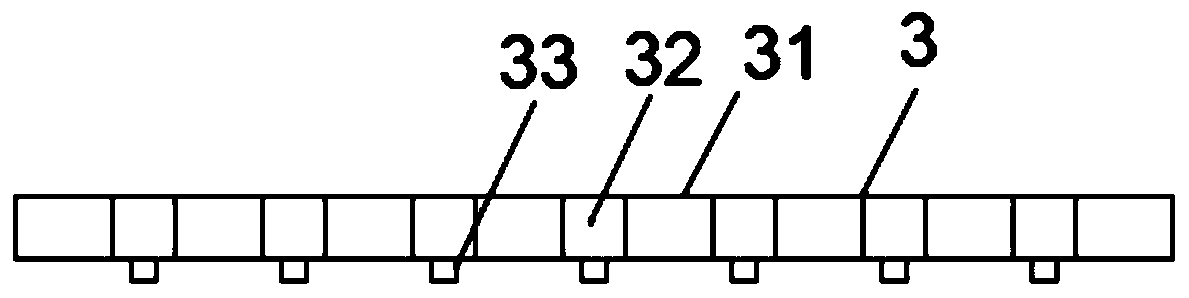

Splicing type swing rod of circular weaving machine

The invention discloses a splicing type swing rod of a circular weaving machine. A swing rod sliding block wheel shaft is arranged at the front end of the swing rod, a heald belt connecting bearing is arranged at the tail end of the swing rod, and a rotary shaft which is connected with an aluminum base is arranged on the front middle portion of the swing rod. The swing rod of the circular weaving machine is of a split type structure and comprises a plurality of splicing sections, wherein all the splicing sections are connected detachably, and the heald belt connecting bearing and the rotary shaft are located on two corresponding splicing sections respectively. According to the swing rod of the circular weaving machine, due to the fact that the split type structure is adopted, local replacement can be conducted in a targeted mode once a local part is seriously damaged, overall replacement is not needed, the maintenance workload can be greatly reduced, the maintenance time is shortened, the maintenance cost can be reduced greatly, and equipment can recover to be normal at the cost of one splicing section only instead of the whole swing rod.

Owner:鲍宗定

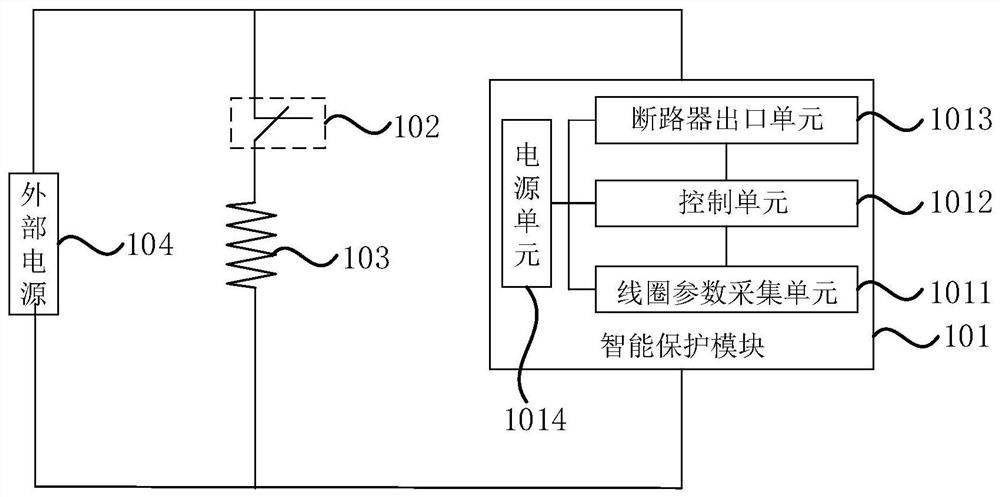

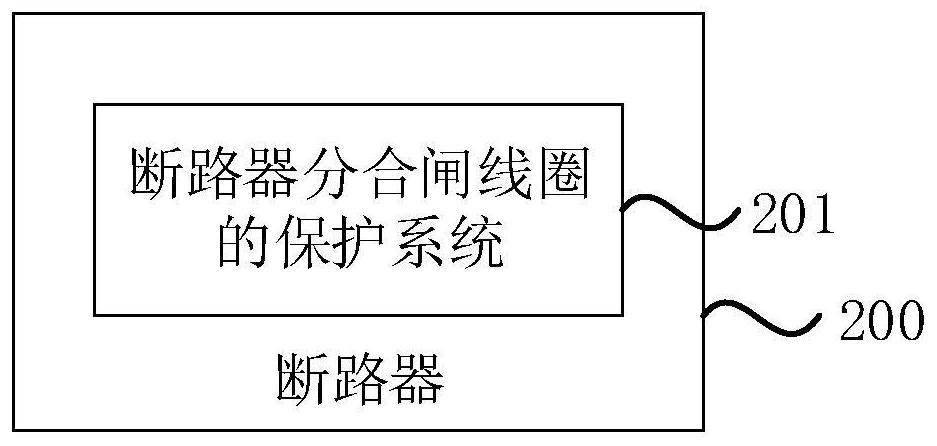

Protection system for circuit breaker switching-on and switching-off coil, and circuit breaker

ActiveCN113130266AReduce damage frequencyReduce security risksElectric switchesProtective switch operating/release mechanismsInformation controlControl engineering

An embodiment of the invention discloses a protection system for a circuit breaker switching-on and switching-off coil and a circuit breaker. The protection system comprises an intelligent protection module and an auxiliary switch module. The auxiliary switch module is connected in series with the circuit breaker switching-on and switching-off coil, and the intelligent protection module is connected in parallel with the auxiliary switch module and the circuit breaker switching-on and switching-off coil. The intelligent protection module comprises a coil parameter acquisition unit, a control unit and a circuit breaker outlet unit. The coil parameter acquisition unit is used for acquiring parameter information of the breaker switching-on and switching-off coil. The control unit is electrically connected with the coil parameter acquisition unit and is used for receiving the parameter information and analyzing and judging the parameter information to form judgment information. The circuit breaker outlet unit is electrically connected with the control unit and is used for receiving the judgment information and controlling the conduction state of the auxiliary switch module according to the judgment information. By arranging the intelligent protection module and the auxiliary switch module, the real-time state of the circuit breaker switching-on and switching-off coil is judged, the damage frequency of the circuit breaker switching-on and switching-off coil is reduced, and potential safety hazards are reduced.

Owner:GUANGDONG POWER GRID CO LTD +1

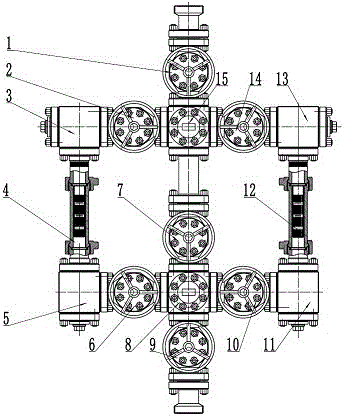

High-pressure fine filtering manifold and filtering method thereof

InactiveCN106437575AImprove filtering effectContinuous circulation filter effect is goodFlushingWell drillingFiltration

The invention relates to a high-pressure fine filtering manifold and a filtering method thereof which are mainly suitable for being applied to an oil and gas well drilling and grinding cyclic operation ground process. The manifold mainly comprises two high-pressure filtering short sections, seven manual flat gate valves, two pipeline five-way joints, four pipeline three-way joints and a manifold pipeline; the filtering manifold is of a one-in one-out structure, the two sides are controlled by adopting the manual flat gate valves and the high-pressure filtering short sections, and the middle is directly arranged. The high-pressure fine filtering manifold has the benefits that under the filtering action of the two high-pressure filtering short sections, the convenient replacement of the short sections is ensured, the uninterrupted and continuous drilling and grinding fluid cyclic filtration treatment and control are realized, the filtering capacity, the filtering efficiency and the filtering quality of mechanical impurities in drilling and grinding fluid are greatly improved, the purposes of drilling and grinding fluid cyclic fine filtration and utilization are achieved, and the erosion damage caused by the large-sized mechanical impurities in the drilling and grinding fluid to the downstream choke manifold is avoided; the high-pressure fine filtering manifold is good in continuous cyclic filtration effect, strong in practicability and suitable for being applied to the oil and gas well drilling and grinding cycle operation ground process.

Owner:CHINA NAT PETROLEUM CORP CHUANQING DRILLING ENG CO LTD CHANGQING DOWNHOLE TECH CO

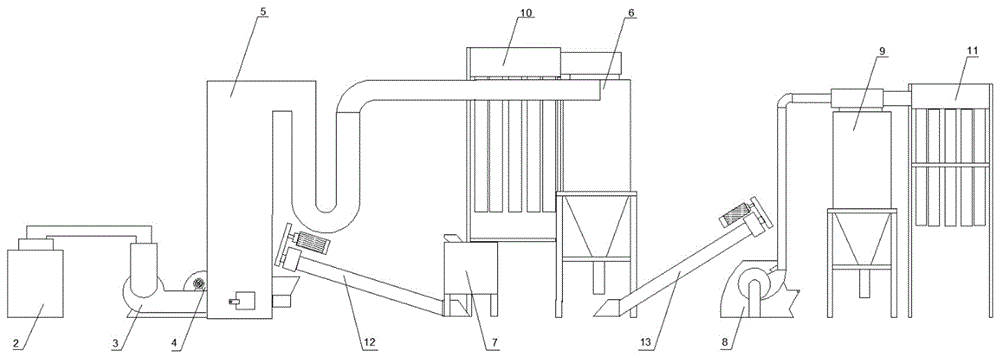

Device for rapidly preparing feed through sugarcane tail tips

ActiveCN105996087ASolve the problem of easy accumulation in the bearing and cause blockageTroubleshoot issues like downtimeFeeding-stuffCycloneTower

Provided is a device for rapidly preparing a feed through sugarcane tail tips. The device comprises a hot-blast stove, a main blower, a secondary blower, a drying tower, a main cyclone separator, pulverizers, a secondary cyclone separator and impurity collecting devices; the hot-blast stove is connected with the drying tower through the main blower, the secondary blower is installed on the other side of the drying tower and connected with a standby blast orifice of the drying tower, a feed inlet of a feeding auger conveyor is connected with the main pulverizer, a discharge hole of the feeding auger conveyor is connected with a feed inlet of the drying tower, the main cyclone separator is installed at the discharge end of the drying tower, an impurity outlet formed in the upper portion of the main cyclone separator is connected with the main impurity collecting device, a feed inlet of an auger conveyor is formed in the lower portion of the discharge hole of the main cyclone separator, a discharge hole of the auger conveyor is connected with the secondary pulverizer, a discharge hole of the secondary pulverizer is connected with the secondary cyclone separator, and a secondary impurity connecting device is installed at an impurity outlet formed in the upper portion of the secondary cyclone separator.

Owner:AGRI PROD PROCESSING INST GUANGXI ACADEMY OF AGRI SCI +1

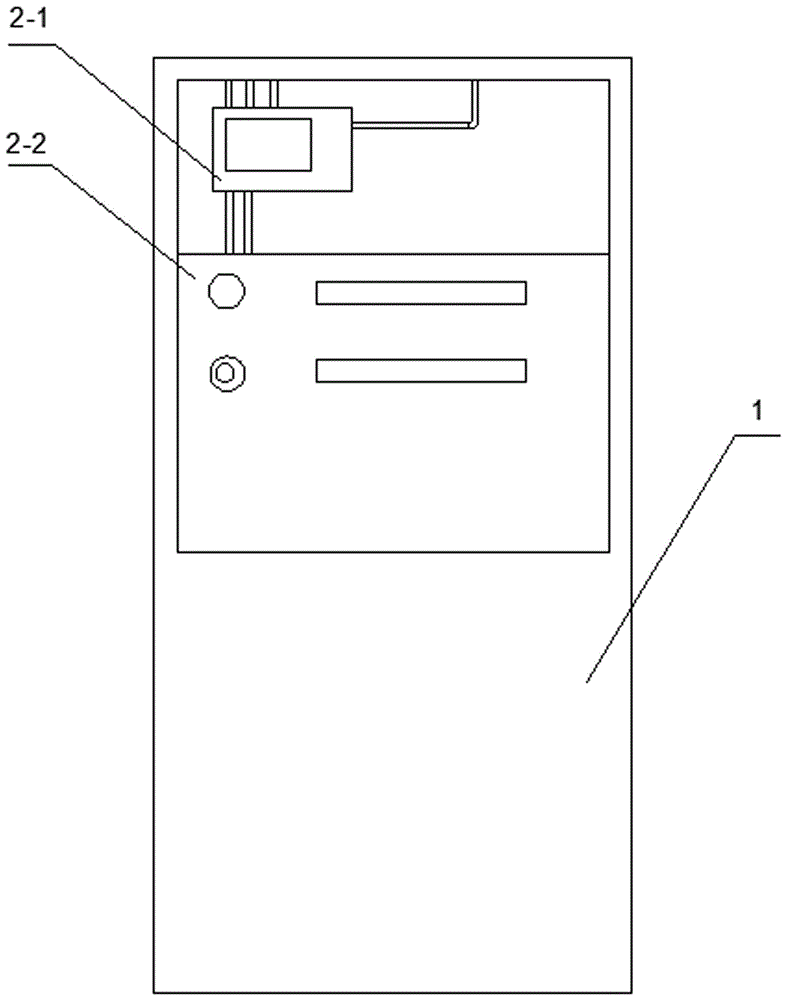

Floating type automobile charging pile

ActiveCN111823904AAvoid damageExtended service lifeCharging stationsLighting elementsStructural engineeringMechanical engineering

The invention relates to the technical field of charging piles and especially relates to a floating type automobile charging pile. The charging pile is included. A charging gun placing box is fixedlyarranged at a top end of a left side surface of the charging pile; a charging wire fixing seat is arranged below the charging gun placing box; the charging wire fixing seat is electrically connected with one end of a charging wire; the other end of the charging wire is electrically connected with a charging gun head; the charging gun head is arranged in the charging gun placing box; four groups offixing feet are arranged at the bottom end of the charging pile in a column type; and the fixing feet are clamped with placement grooves formed in the top end of the base. U-shaped buckle plates aremounted on a front end surface and a rear end surface of the charging pile; a worker lifts the automobile charging pile to a certain height through the buckle plate so that the fixing feet mounted atthe bottom are clamped with the placement grooves, and the charging pile and the base are fixed; and meanwhile, a buoyancy tank is filled with a gas through a pedal type pressing air cylinder so thatthe buoyancy tank is lifted by a certain height, and the charging pile is prevented from being damaged when used in a low-lying area with much rainwater.

Owner:李楠楠

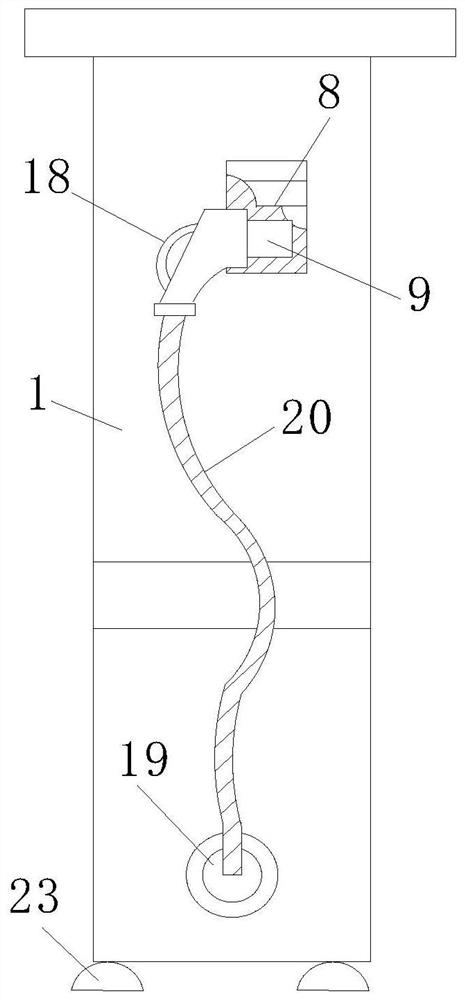

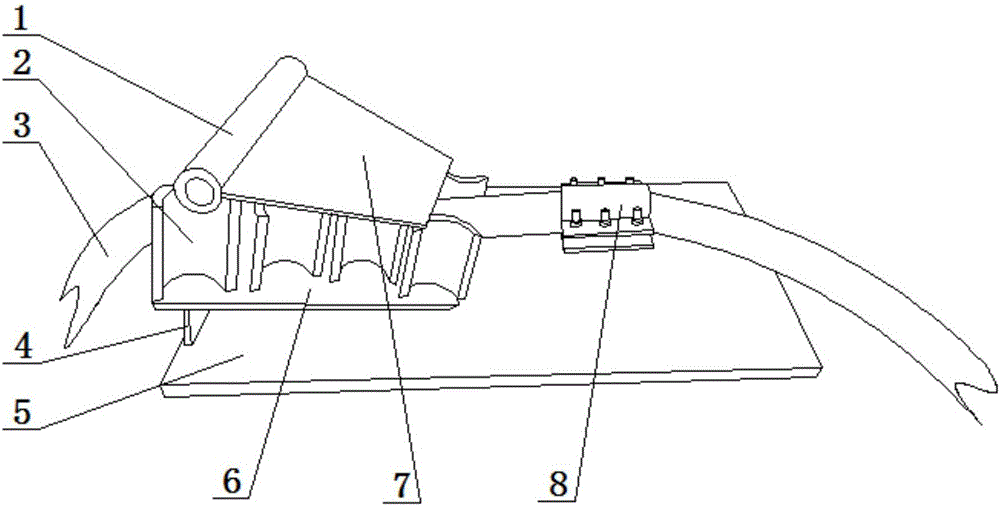

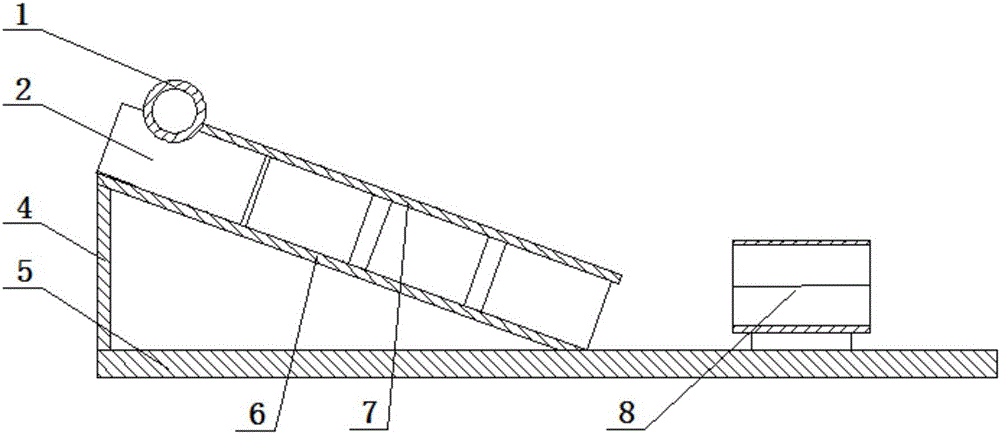

Gantry crane cable fold-back device

ActiveCN105720545AReduce labor intensityReduce the frequency of daily inspectionsCable arrangements between relatively-moving partsEconomic benefitsArchitectural engineering

The invention discloses a gantry crane cable fold-back device. The gantry crane cable fold-back device comprises a bottom plate, an upper panel and multiple arc-shaped plates; the bottom plate is arranged obliquely; the upper panel is located above the bottom plate and is parallel with the bottom plate; a gantry crane cable penetrates from space between the upper panel and the bottom plate along the inclination direction of the bottom plate; and the multiple arc-shaped plates are respectively arranged at the left side and the right side of the gantry crane. The arc-shaped plates at the left side and the right side of the gantry crane are fixedly arranged between the bottom plate and the upper panel at vertical intervals along an inclination longitudinal direction; a cylindrical vertical direction adjusting part is fixedly arranged at the back end part of the upper panel; the back end part of the upper panel is fixedly arranged at the outer wall of the vertical direction adjusting part; a fixing device is fixedly arranged in front of the bottom plate; and the gantry crane penetrates from the fixing device and is fastened by the fixing device. The gantry crane cable fold-back device is capable of reducing labor intensity of workers, increasing safety coefficient and improving economic benefits.

Owner:NO 4 WATER TERMINAL CORP TIANJIN PORT

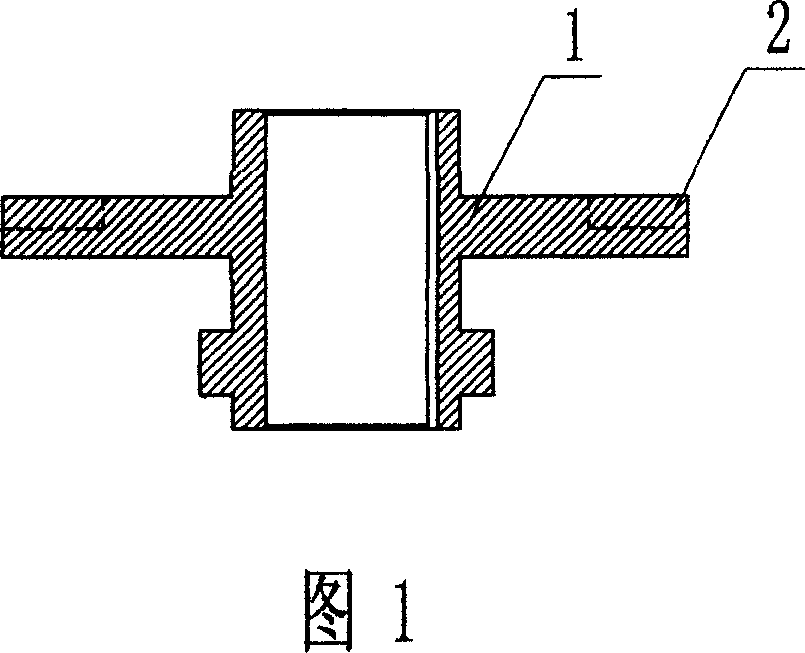

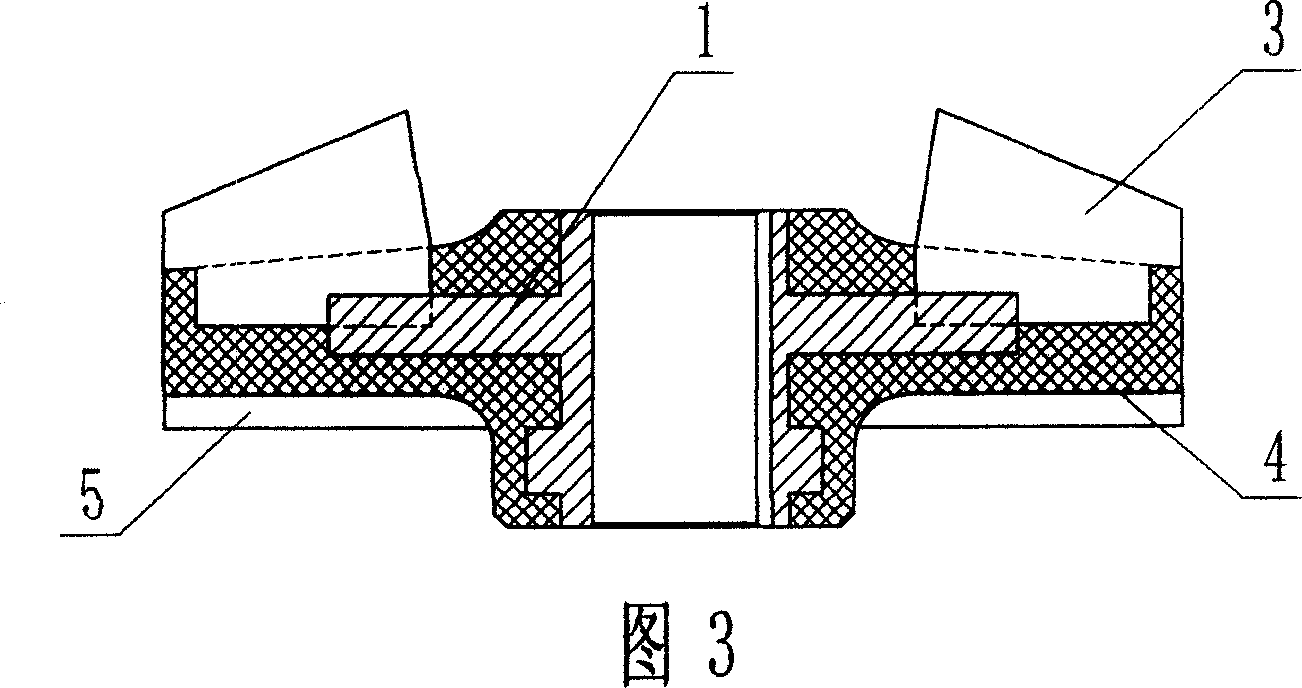

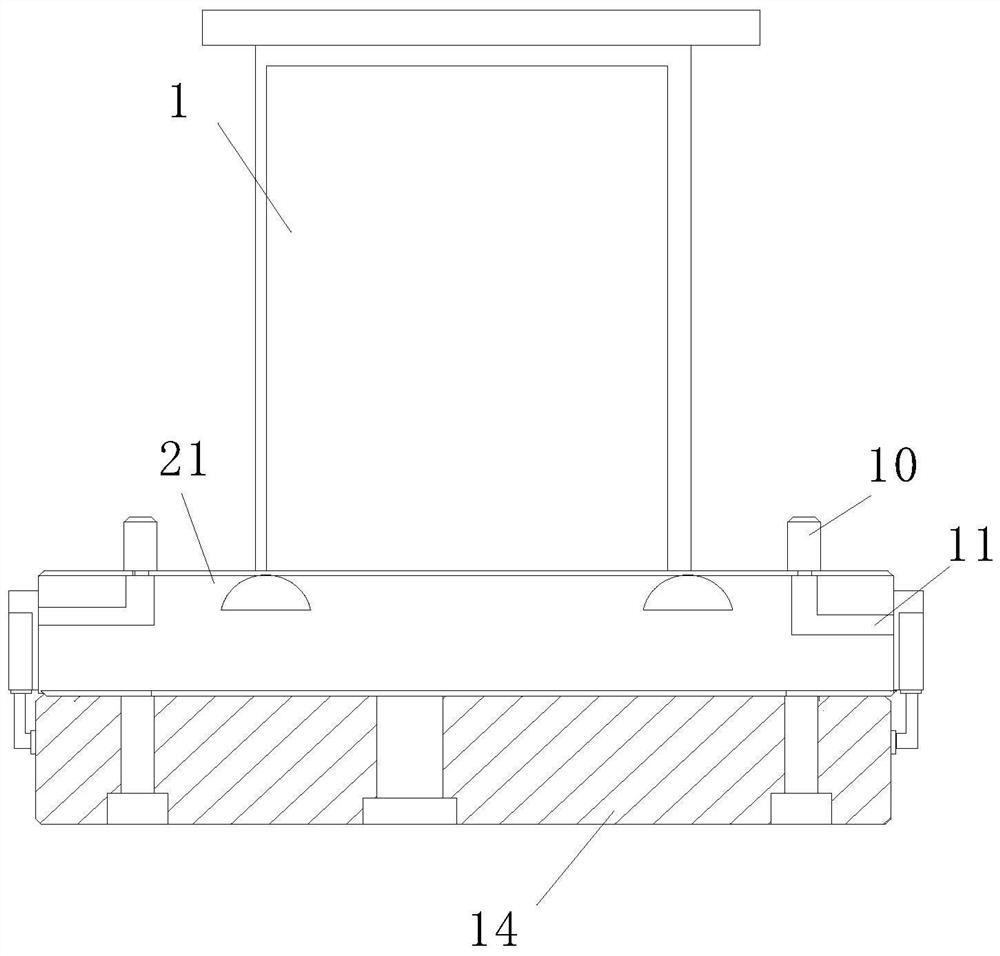

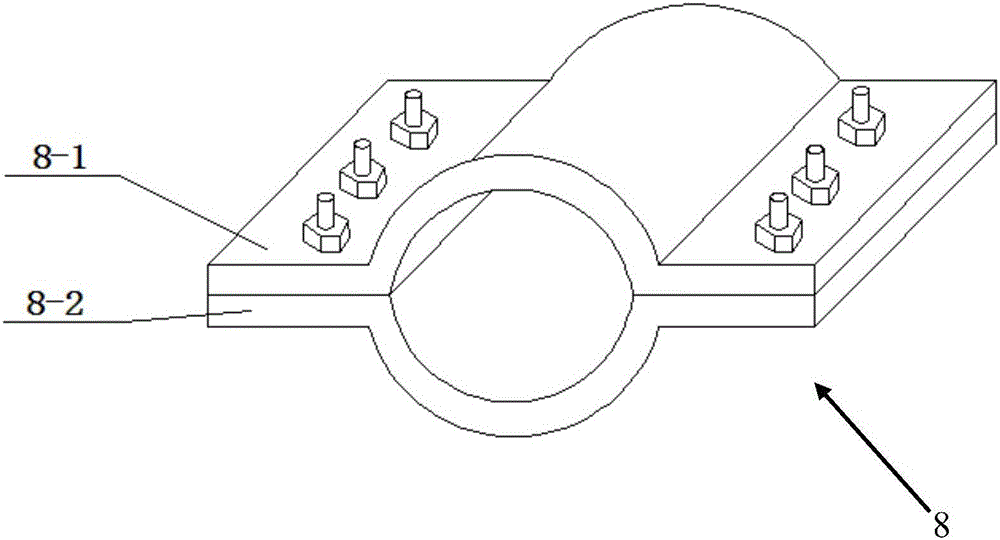

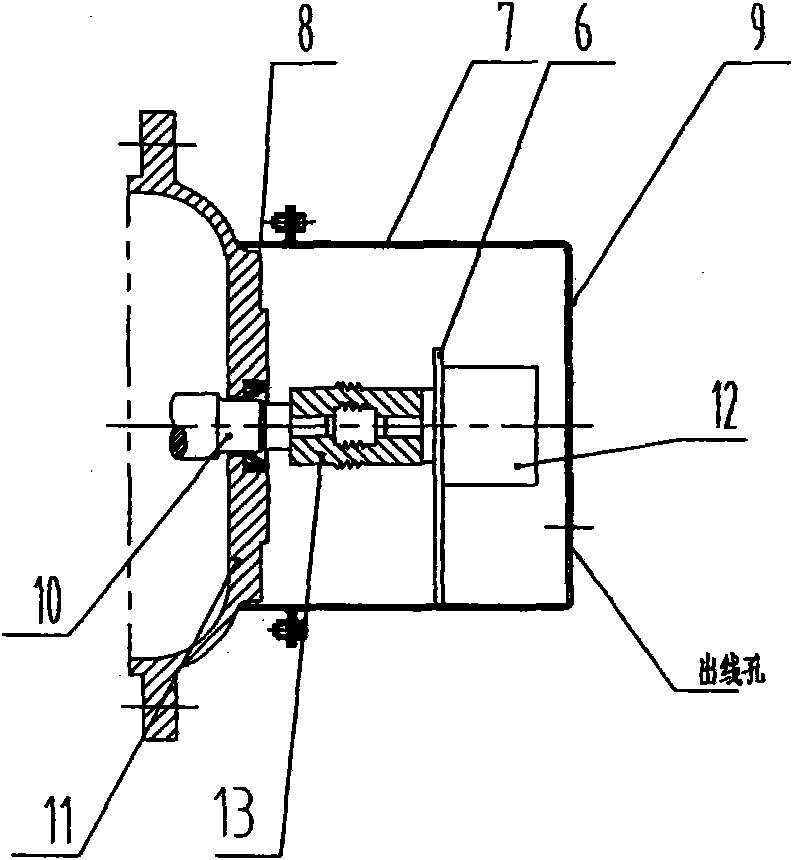

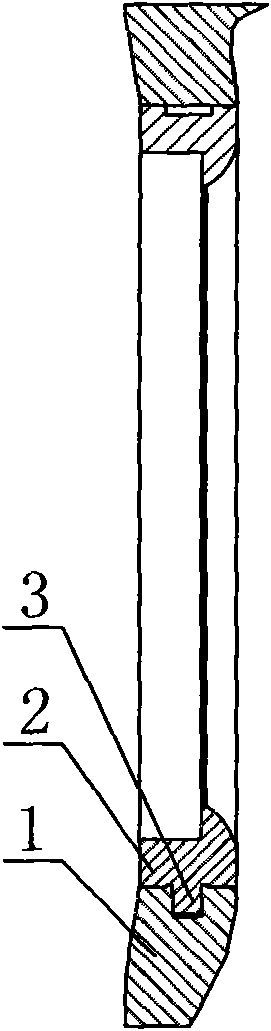

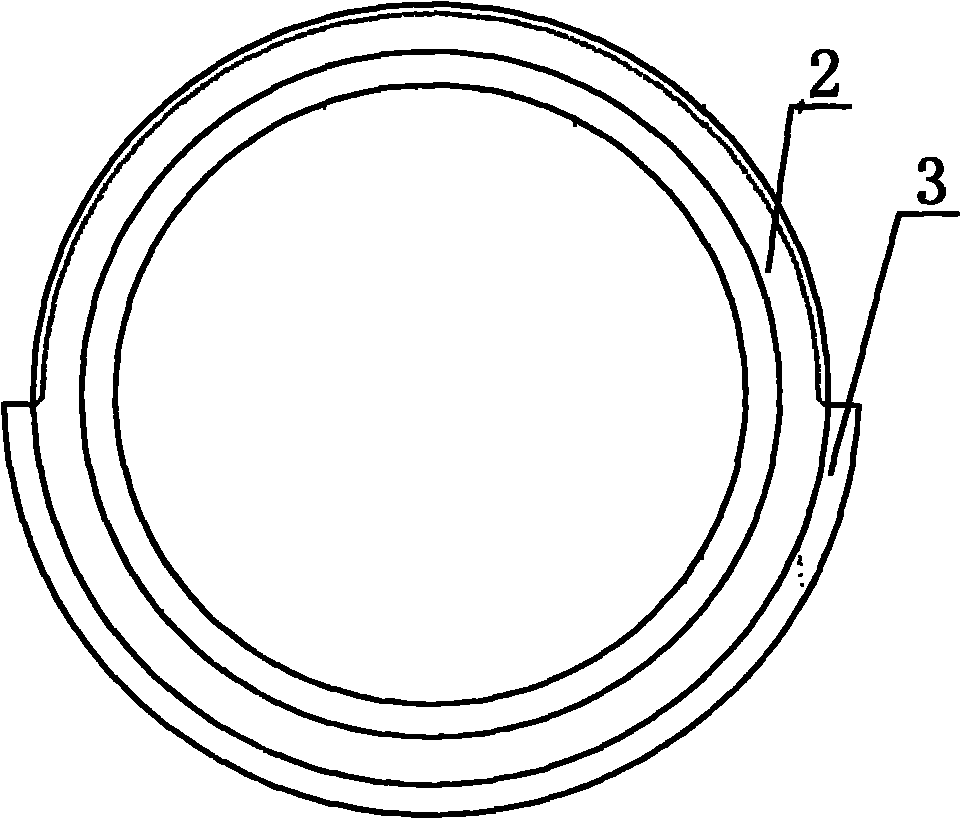

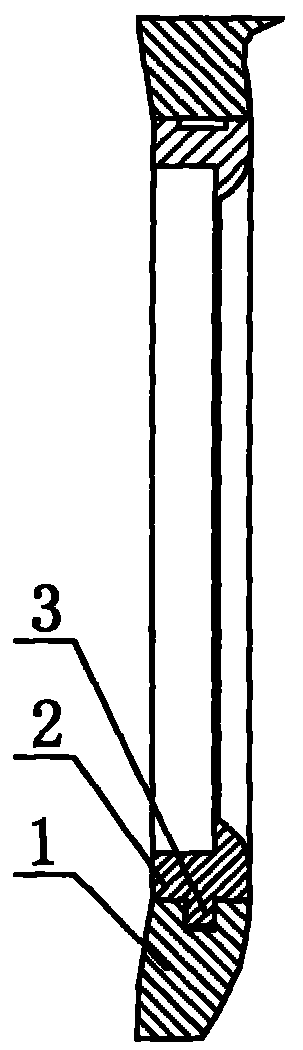

Connecting device for output shaft of mining excavator and encoder

InactiveCN101806078AReduce frequency of damageExtended service lifeSoil-shifting machines/dredgersShaft for rotary movementAerospace engineeringEngineering

The invention provides a connecting device for an output shaft of a mining excavator and an encoder, and relates to a mining mechanical excavator, which can effectively transfer output rotation speed between the encoder and the excavator output shaft in spite of coaxiality. The flexible axis connecting device is characterized by consisting of a flexible axis 1, a hose 2, keys 3, positioning screws 4 and connectors 5, wherein both ends of the flexible axis 1 are fixedly connected with the connectors 5; the connector 5 at one end of the flexible axis 1 is connected with the excavator output shaft 10 through the positioning screws 4 and the keys 3; and the connector 5 at the other end of the flexible axis 1 is connected with an output shaft of the encoder 12 through the positioning screws 4 and the keys 3. The connecting device transfers the rotation without coaxial requirements, can effectively reduce the damage frequency of the encoder, prolongs the service life of the encoder, ensures the measurement accuracy of the encoder, and improves the operational reliability of equipment.

Owner:TAIYUAN HEAVY IND

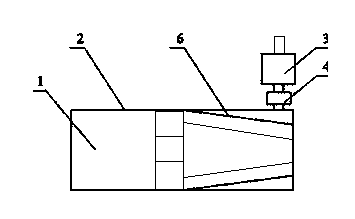

Pulling shearing conveyer device

The invention discloses a pulling shearing conveyer device. The pulling shearing conveyer device is characterized in that the device comprises a conveying belt (1), baffles (2), a motor (3), a motor pinion box (4), a rubber roller (5) and copper plates (6); the two baffles (2) are installed on the two sides of the conveying belt (1) correspondingly, each copper plate (6) is arranged on the part, at the output end of the conveying belt (1), of the inner side of the corresponding baffle (2), and the ends of the two copper plates (6) are slightly closed up inward in the operating direction of the conveying belt (1); the four corners of each copper plate (6) are connected with the corresponding baffle (2) through bolts, and the close-up angles of the copper plates (6) can be changed by adjusting the positions of nuts. According to the pulling shearing conveyer device, raw material consumption is reduced, the damage frequency of the machine is decreased, and the labor intensity of maintenance personnel is relieved; the expenses of replacement parts are reduced, considerable economic benefits are created, and the safety of operating personnel during producing is ensured.

Owner:王亚男

Warning light installation assembly of bestriding vehicle

The invention discloses a warning light installation assembly of a bestriding vehicle, comprising a warning light bracket and a warning light shield; the warning light shield is fixed on a frame of the bestriding vehicle by the warning light bracket; the warning light bracket is in a U-shaped structure which is arranged transversely and provided with an upward opening; the bottom of the U-shaped structure is fixedly connected with the warning light shield; the upper end of the U-shaped structure is connected backwards and fixedly with the warning light shield and connected forwards and fixedly with the frame of the bestriding vehicle; by adopting the warning light bracket of the rod U-shaped structure, the invention has the advantages of simple structure, light weight and capability of stably installing the warning light components without occupying a bigger space; the vibration of the warning light can be reduced effectively in the travel of the bestriding vehicle; the driving noise is reduced, the damage frequency of the warning light is reduced and the service life of the warning light is prolonged; potential safety hazards caused by the damage of the warning light are reduced, and meanwhile, and the appearance effect of the tail of the whole vehicle can be ensured after the warning light is installed.

Owner:CHONGQING LONCIN MOTOR

Traffic warning device for expressway, and warning method thereof

PendingCN112750336AReduce damage frequencyExtended service lifeAnti-collision systemsElectric machineryEngineering

The invention relates to the technical field of traffic warning, and discloses a traffic warning device for an expressway, and a warning method thereof. The device comprises a bottom plate, a moving device is fixedly connected to the upper surface of the bottom plate, an auxiliary device is fixedly connected to the interior of the moving device, and a transmission motor is fixedly connected to the interior of a connecting column; and a containing frame is inserted into the connecting column, and a warning lamp is fixedly connected to the outer side of the upper surface of the containing frame. According to the traffic warning device for the expressway, and the warning method thereof, the outer side face of a fixing plate makes contact with the ground, a fixing pin is rotated clockwise to connect the fixing plate with the ground, a supporting rod carries out auxiliary supporting on the whole, and then the situation that the device inclines or even topples in the severe weather environment is avoided, so the stability of the device during use is further enhanced, the damage frequency of parts in the device is reduced, the service life of the parts is prolonged, and the warning effect of the device is improved.

Owner:李林

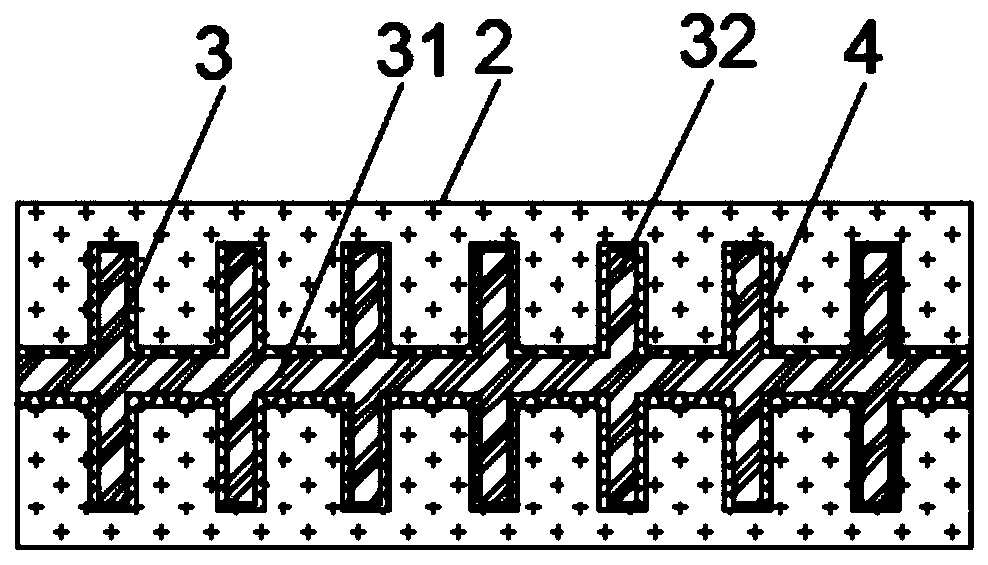

Anti-corrosion plastic-lined impeller

PendingCN110425179AOvercoming Corrosion Resistance LimitationsGuaranteed uptimePump componentsPumpsImpellerMetallic materials

The invention discloses an anti-corrosion plastic-lined impeller. The anti-corrosion plastic-lined impeller comprises a metal insert and overflowing blades, wherein reinforcing frameworks are embeddedinto the overflowing blade arch surfaces; sunken embedding groove are formed in the corresponding positions of the arched surfaces; and the reinforcing frameworks are embedded in the embedding grooves, and are poured and sealed by using anti-corrosion sealant. The overflowing blades are made of corrosion-resistant fluorine plastic, and the inner frameworks and the reinforcing frameworks used forsupporting the inner strength and the outer strength of the overflowing blades respectively are metal inserts. The inner frameworks are the metal inserts, and are wholly covered with fluoroplastics; and the fluoroplastics and the inner frameworks are integrally manufactured. The reinforcing frameworks are poured and sealed by using the anti-corrosion sealant, so that the reinforcing frameworks areintegrally sealed in the embedding grooves of the blades, the limitation of corrosion resistance of metal materials and lack of strength of all-plastic impellers are effectively overcome, and the energy is saved; and damage frequency of the impellers is reduced, the maintenance period is prolonged, maintenance cost of users is reduced, operation consumption cost of a pump is reduced, production loss caused by shutdown is reduced, and using efficiency is remarkable.

Owner:ANHUI WOLONG PUMP & VALVE CO LTD

Axially split type pump body sealing device

InactiveCN102042259AReduce damage frequencyNot easy to damagePump componentsPumpsEngineeringMechanical engineering

Owner:SHUANGLUN GRP CO LTD SHANDONG

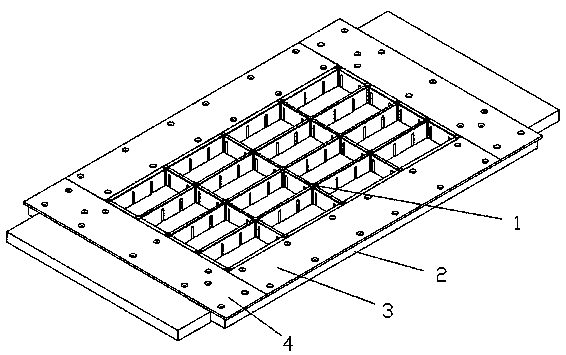

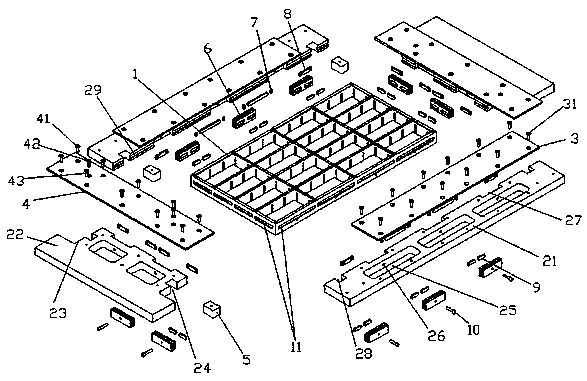

Die

The invention discloses a die. The die comprises a top plate, an upper heat insulation plate, an upper shaping plate, a lower shaping plate, a lower heat insulation plate and a bottom plate, wherein the upper heat insulation plate is arranged on the lower surface of the top plate; the upper shaping plate is arranged on the lower surface of the upper heat insulation plate; at least one of four corners of the upper heat insulation plate is a right-angle corner; at least one of four corners of the upper shaping plate is a right-angle corner; the right-angle corner of the upper heat insulation plate is opposite to the right-angle corner of the upper shaping plate; the lower shaping plate is arranged on the lower surface of the upper shaping plate; a cavity communicated with a hot runner is defined between the upper shaping plate and the lower shaping plate; the lower heat insulation plate is arranged on the lower surface of the lower shaping plate; and the bottom plate is arranged on the lower surface of the lower heat insulation plate. The die disclosed by the embodiment of the invention has the advantages of long service life, high quality and the like.

Owner:KUNSHAN TENGYUXIN METAL PROD

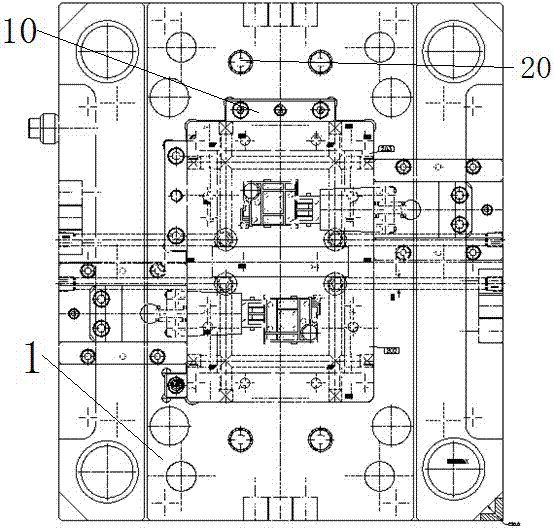

Mold for base of junction box

The invention provides a mold for a base of a junction box. The mold comprises a top plate, an upper heat insulation plate, an upper mold plate, a lower mold plate, a lower heat insulation plate, a bottom plate, a mold insert and a pressure block, wherein the upper heat insulation plate is arranged on the lower surface of the top plate; the upper mold plate is arranged on the lower surface of the upper heat insulation plate; the lower mold plate is arranged on the lower surface of the upper mold plate, and a mold cavity is defined between the upper mold plate and the lower mold plate; the lower heat insulation plate is arranged on the lower surface of the lower mold plate; the bottom plate is arranged on the lower surface of the lower heat insulation plate; the mold insert is arranged between the upper mold plate and the lower mold plate; the pressure block is arranged on the side surface of the mold insert and fixed on the upper mold plate through a fixing device, and an opening and closing device is arranged on the outer side of the pressure block. According to the mold provided by the invention, the influenced on the pressure block can be prevented by outwards adjusting the position of the opening and closing device, the damage frequency of the opening and closing device is lowered greatly, the pressure block is prevented from being stuck, the efficiency of disassembling and assembling the mold is improved, and further, the quality of the mold is improved.

Owner:昆山金九亿精密金属有限公司

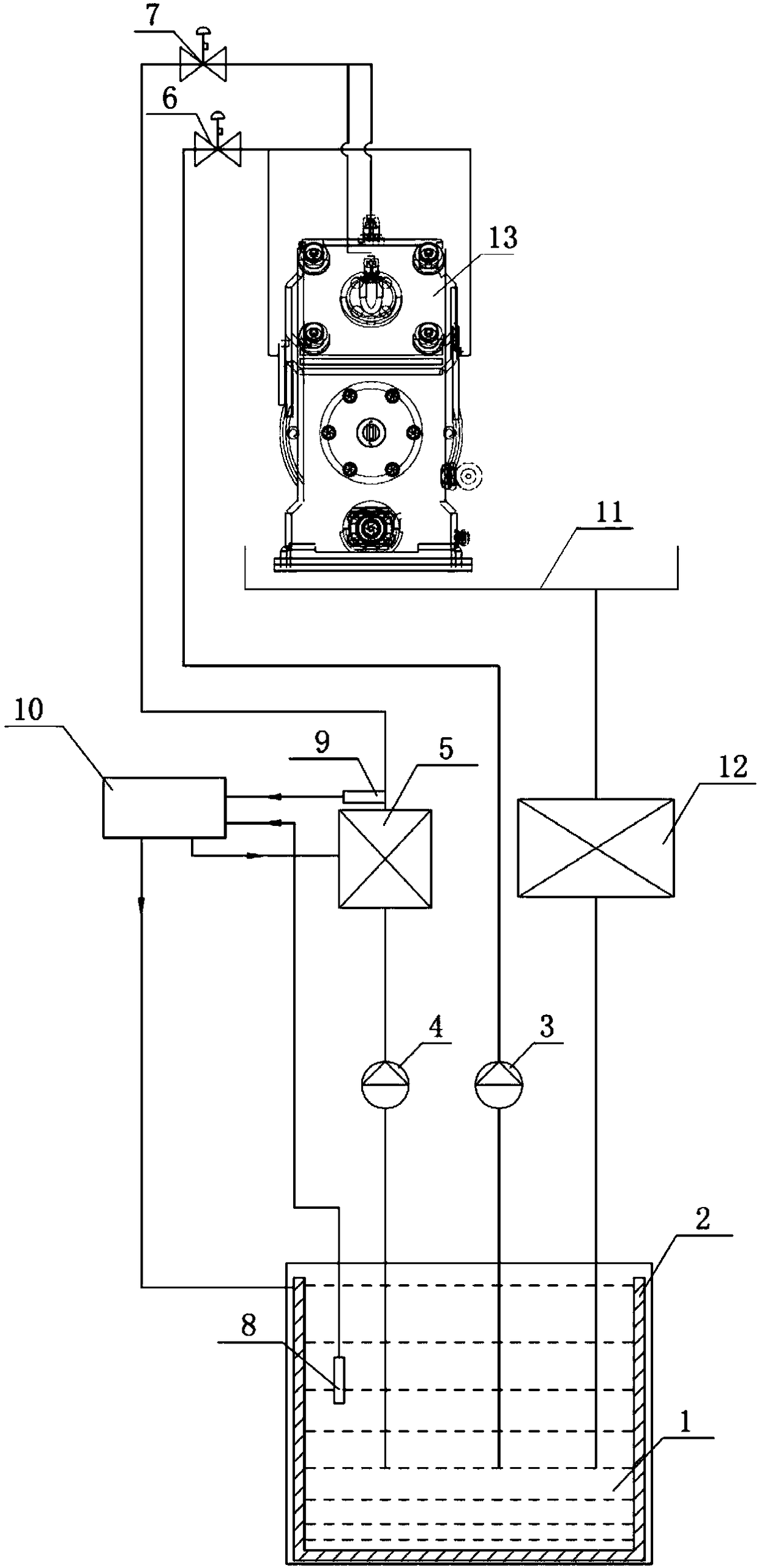

Cooling system of three-roller rolling mill for rolled aluminum alloy rod

PendingCN108296293AReduce damage frequencyGuaranteed high temperature plasticityMetal rolling stand detailsRolling equipment maintainenceEmulsionCirculating pump

The invention discloses a cooling system of a three-roller rolling mill for a rolled aluminum alloy rod. The system comprises an emulsion box, a heating device, a first emulsion circulating pump, a second emulsion circulating pump, a cooling device, a first valve and a second valve; the first emulsion circulating pump and the second emulsion circulating pump are communicated with the emulsion boxthrough pipelines, and a flow outlet of the first emulsion circulating pump is communicated with the first valve through the pipelines; a flow outlet of the first valve is communicated with the pipelines of a roller and an inlet and outlet guide in the three-roller rolling mill, wherein the roller and an inlet and outlet guide are subject to cooling and lubricating; a flow outlet of the second emulsion circulating pump is communicated with the cooling device through the pipelines, and a flow outlet of the cooling device is communicated with the second valve through the pipelines; and a flow outlet of the second valve is communicated with the pipelines of a lubricating bearing and a gear in the three-roller rolling mill, wherein the lubricating bearing and the gear are subject to the cooling and the lubricating. The temperature drop degree of the roller and a blank can be reduced, and the damage frequency of the bearing and the gear is lowered when the three-roller rolling mill is usedfor rolling the aluminum alloy with relatively strong deformation resistance at a high temperature.

Owner:江苏和拓铝线有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com