Axially split type pump body sealing device

A sealing device, a split technology, applied to non-variable pumps, components of pumping devices for elastic fluids, pumps, etc., can solve the high frequency of seal ring damage, friction damage between the seal ring and the impeller, costly Time-consuming and labor-intensive problems are avoided to achieve the effect of avoiding dismantling the pump for maintenance, low damage frequency, and not easy to damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

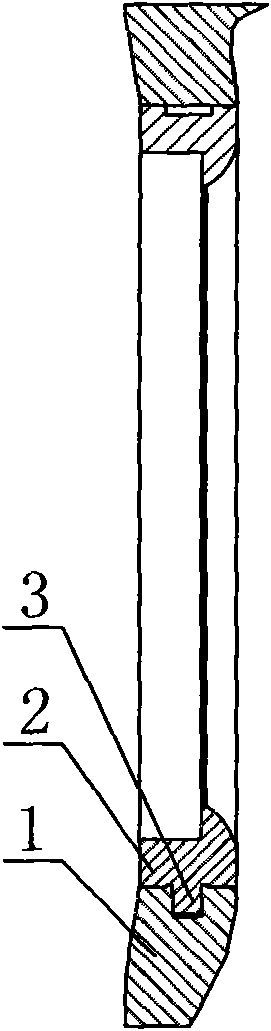

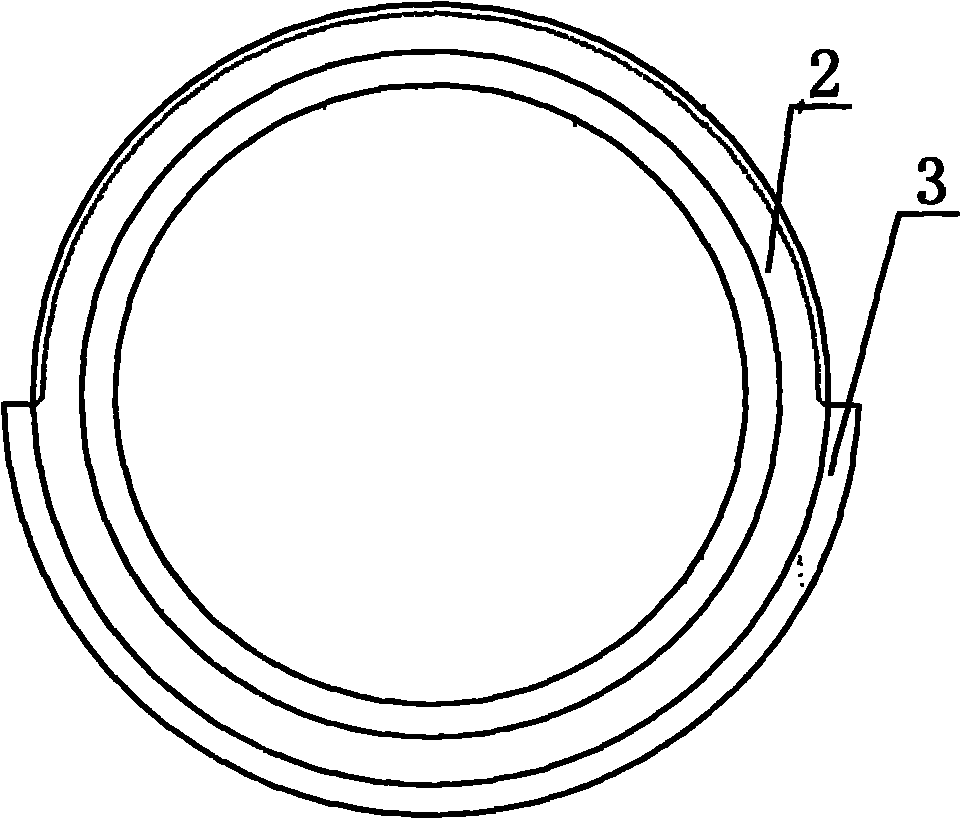

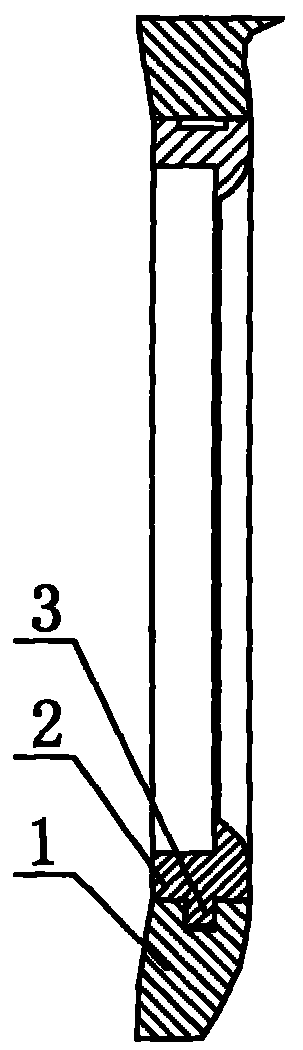

[0008] In the axially split pump body sealing device shown in the figure, the pump body 1 is provided with a sealing ring 2, and the outer circumference of the sealing ring 2 is provided with an anti-movement semicircle protrusion 3, and the pump body 1 is provided with a semicircle groove to prevent The movable semicircular protrusion 3 is embedded in the semicircular groove, and the semicircular protrusion 3 cooperates with the semicircular groove to prevent the rotation and axial movement of the sealing ring 2. The semicircular protrusion 3 is not easy to be damaged, and the frequency of damage to the sealing ring is low. It saves time and does not affect production.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com