Cooling system of three-roller rolling mill for rolled aluminum alloy rod

A cooling system, three-roll mill technology, applied in the direction of metal rolling stands, metal rolling mill stands, rolls, etc., can solve the problems of damage, increased frequency of bearing and gear damage, and large stress on bearings and gears. The degree of temperature drop, the reduction of cooling and lubrication effect, and the effect of ensuring high temperature plasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

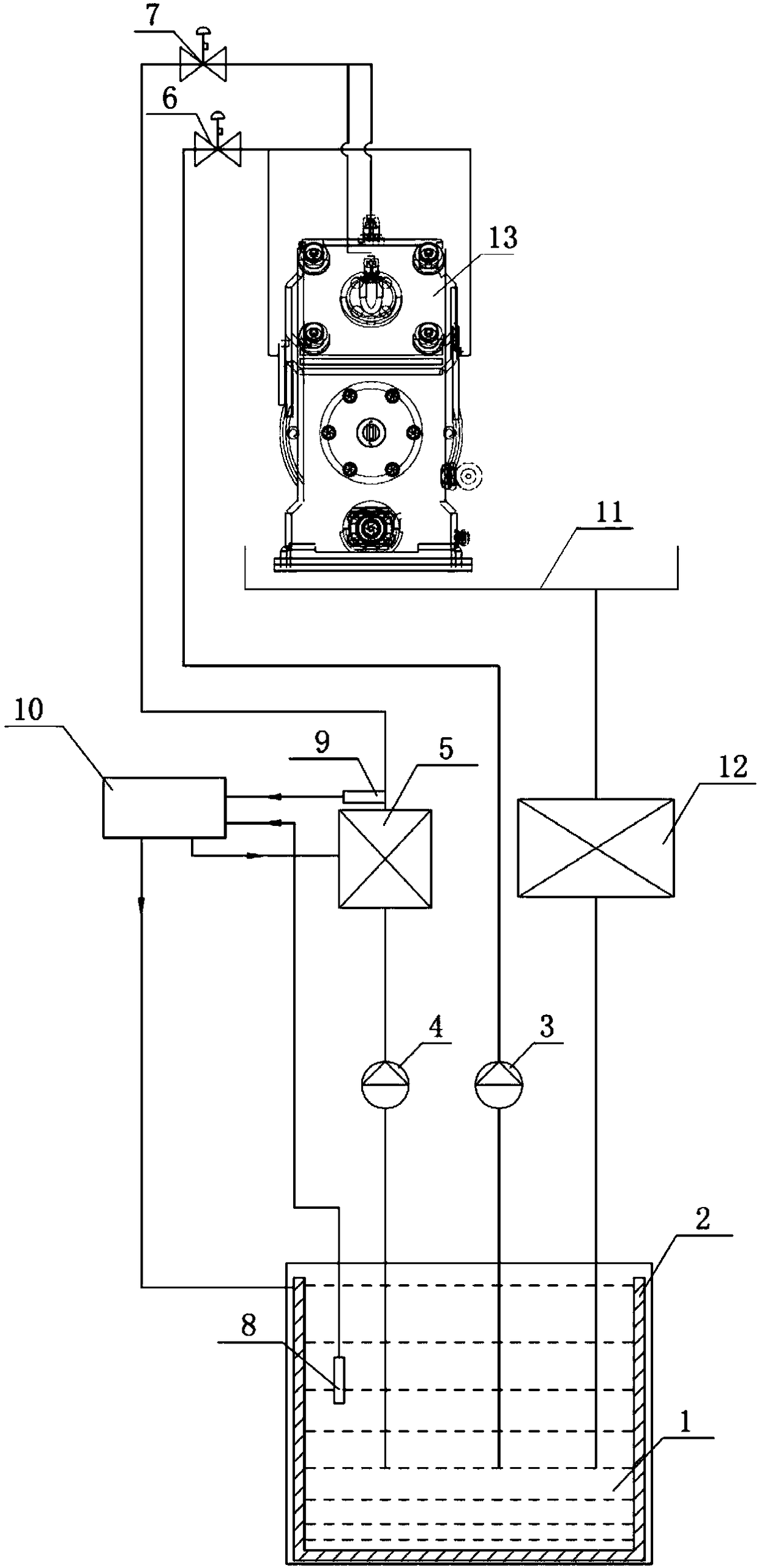

[0020] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

[0021] Such as figure 1 As shown, a cooling system of a three-roll mill for rolling aluminum alloy rods; including an emulsion tank 1, a heating device 2, a first emulsion circulation pump 3, a second emulsion circulation pump 4, a cooling device 5, a first valve 6 and second valve 7;

[0022] The heating device 2 is arranged in the emulsion tank 1;

[0023] The first emulsion circulation pump 3 and the second emulsion circulation pump 4 communicate with the emulsion tank 1 through pipelines, and the outlet of the first emulsion circulation pump 3 communicates with the first valve 6 through pipelines Connected, the outlet of the first valve 6 communicates with the pipeline used for cooling and lubricating the rolls and the import and export guide positions in the three-roll rolling mill 13;

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com