Pulling shearing conveyer device

A technology for conveying devices and conveyor belts, which is applied to conveyors, transportation and packaging, etc. It can solve the problems of increasing spare parts costs, increasing production costs, and damage to rubber roller conveyor belts, so as to save spare parts costs, reduce damage frequency, and reduce labor. intensity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

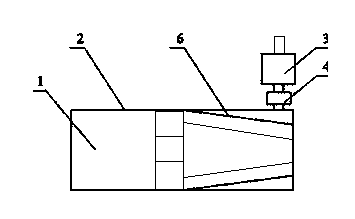

[0009] The present invention will be further explained below in conjunction with the accompanying drawings.

[0010] A pulling and shearing conveying device, characterized in that it includes a conveyor belt (1), a baffle (2), a motor (3), a motor pinion box (4), a rubber roller (5) and a copper plate (6); wherein, Two baffles (2) are respectively installed on both sides of the conveyor belt (1), and a copper plate (6) is placed on the inner side of the baffle (2) at the output end of the conveyor belt (1), and the two copper plates ( 6) The end of the conveyor belt (1) is slightly retracted inward along the running direction; the four corners of the copper plate (6) and the baffle (2) are connected by bolts, and the copper plate (5) can be changed by adjusting the position of the nut Swing angle.

[0011] The above content is only a preferred embodiment of the present invention, and is not intended to limit the implementation of the present invention. Appropriate modificatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com