Method for refining methane chloride crude product

A methane chloride and crude product technology, applied in chemical instruments and methods, organic chemistry, preparation of halogenated hydrocarbons, etc., to achieve the effect of simple operation, no reduction in product quality, and reduced alkali consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

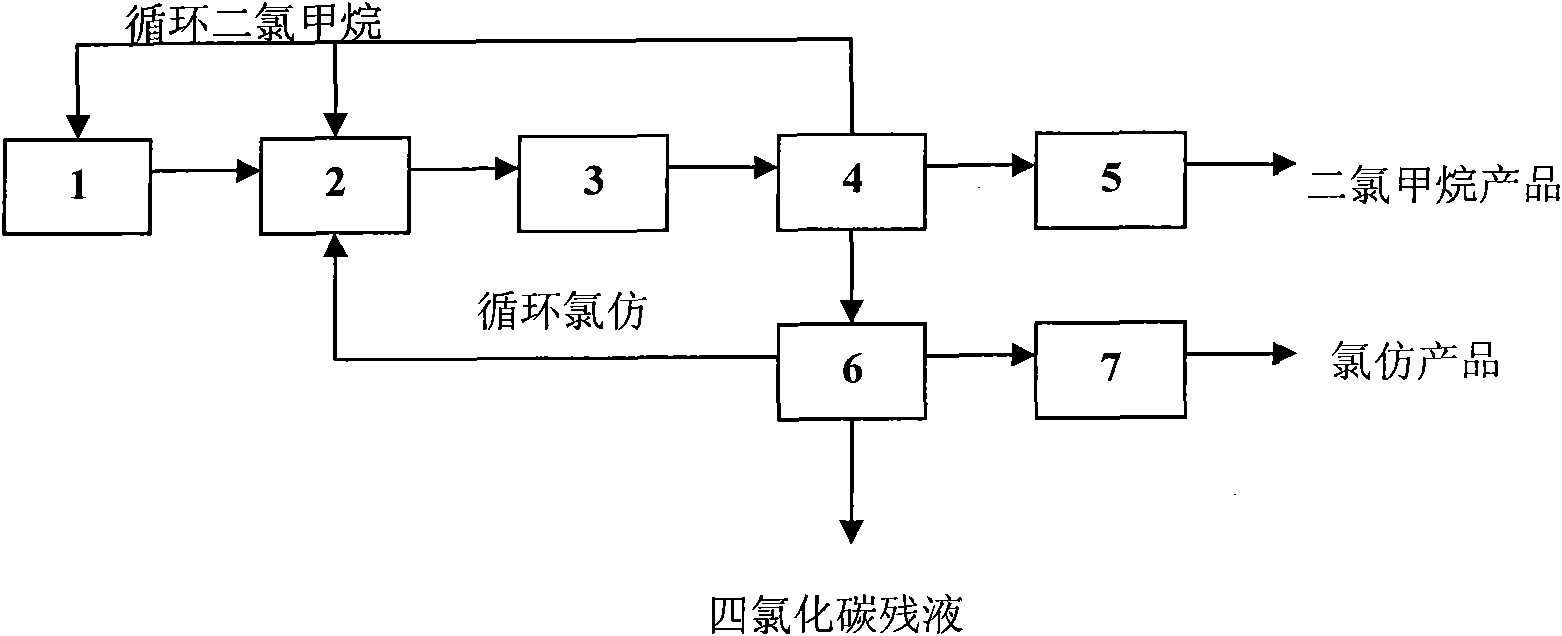

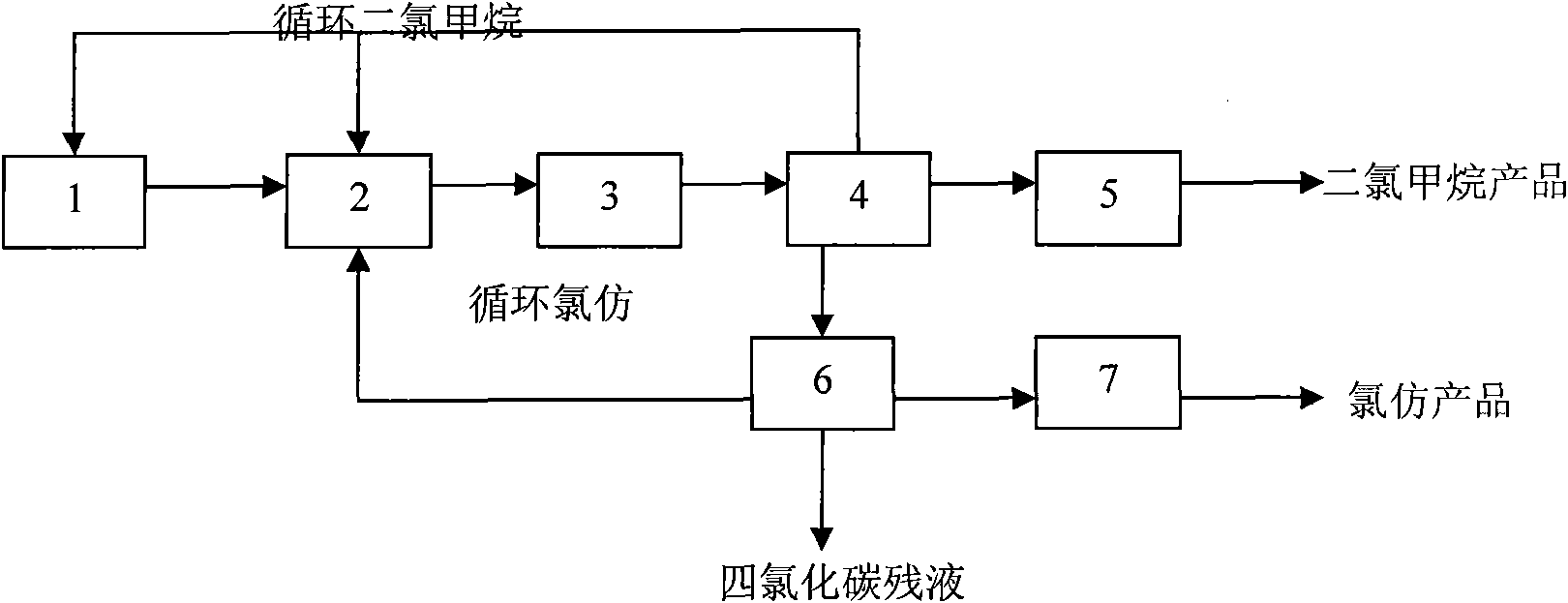

[0013] As shown in the figure, chlorine gas, chlorination catalyst and monochloromethane enter the chlorination reactor 1 react. Chlorination Reactor 1 The crude product mixture that comes out passes through the hydrogen chloride / monochloromethane recovery tower 2 , the hydrogen chloride / chloromethane from the hydrogen chloride / chloromethane recovery tower 2 Recycling at the top of the tower. Hydrogen chloride / chloromethane column 2 The crude product at the bottom of the tower is discharged into the crude product tank 3 , the crude product directly enters the dichloromethane tower without alkali washing and water washing 4 , It can be rectified at normal pressure or under pressure, the temperature is controlled at 40-130°C, and the pressure is controlled at 0-0.25MPaG. Dichloromethane tower 4 A small amount of acid-containing dichloromethane at the top of the tower can be recycled back to the chlorination reactor 1 , can also be returned to the hydrogen chloride / chloro...

Embodiment

[0016] The crude product is directly rectified without alkali washing, the temperature is controlled at 40-130°C, and the pressure is controlled at 0-0.25MPaG. 4 , 6 The extracted dichloromethane and chloroform products pass through the solid alkali processor 7 , The product quality is not reduced, the waste water is reduced, and the energy consumption is saved.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com