Process for the production of hydroxylamine by reduction of nitrate or nitrogen monoxide

A technology for producing hydroxylamine and nitric oxide, applied in chemical instruments and methods, preparation of hydroxylamine and lactam, etc., can solve the problems of increasing the variable cost of hydroxylamine, consuming ion exchange resin, increasing the required input, etc. The effect of energy consumption, reduction of raw material consumption, and reduction of energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0064] The invention is illustrated, but not limited, by the following examples.

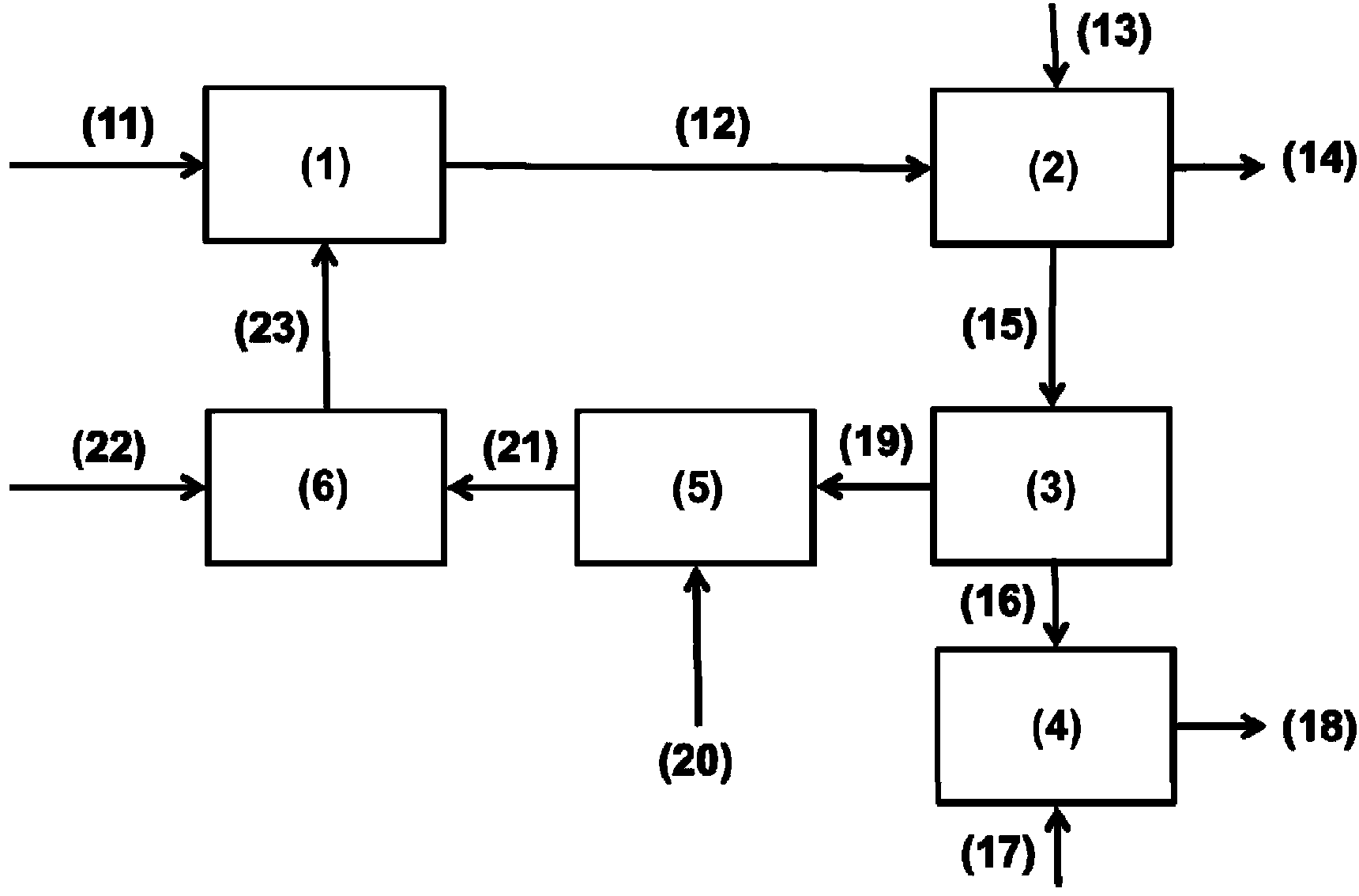

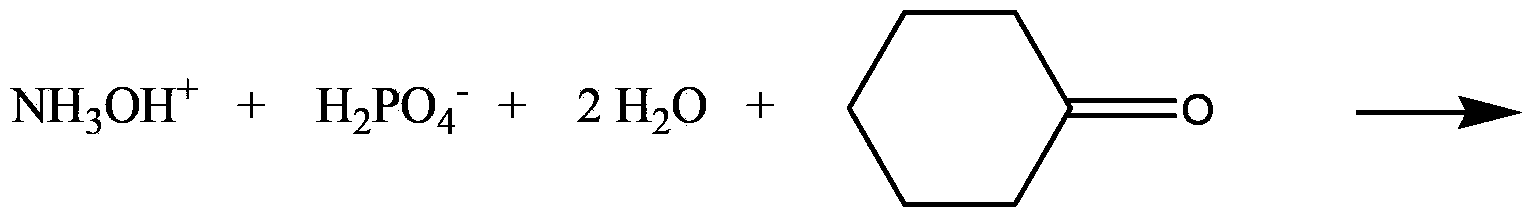

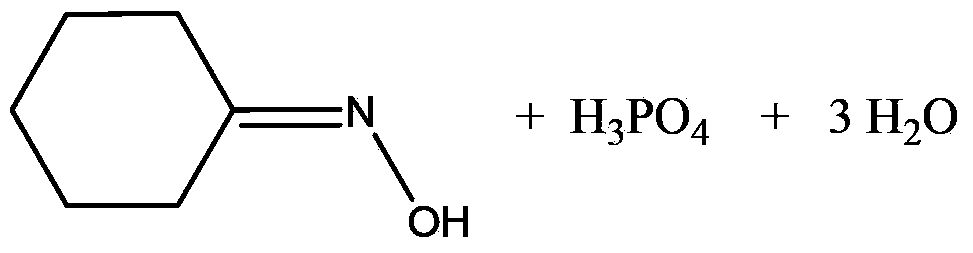

[0065] This experiment was carried out in a commercial cyclohexanone oxime facility according to The process operates. Continuous and selective reduction of nitrates with hydrogen to hydroxylamine. The prepared hydroxylamine is converted to cyclohexanone oxime by reaction with cyclohexanone in the oximation zone. The structure is mainly as figure 1 shown.

[0066] The device includes a hydroxylamine formation zone where nitrate is reduced in an aqueous phosphate buffered saline solution. Using heterogeneous catalyst Pd / C and adding accelerator GeO 2. The part of the phosphate-containing acidic aqueous solution that also contains hydroxylamine is continued to be exported and fed to the oximation zone after removal of the catalyst by filtration. In the oximation zone the aqueous hydroxylamine solution is contacted with cyclohexanone dissolved in toluene. The oximation zone was operated ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com