Patents

Literature

110results about How to "Save on spare parts costs" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

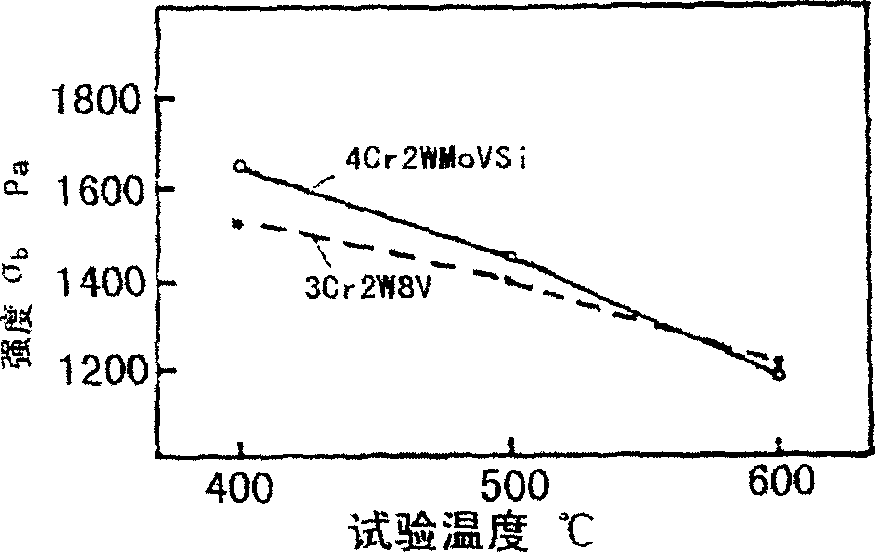

Hot work die steel and its preparation method

ActiveCN1912165AReasonable compositionEasy to useMetal-working apparatusHeat treatment process controlSteelmakingHot work

The invention relates to hot-work die steel and its manufacturing method. It includes the following alloying element: 0.40-0.48wt% C, 0.60-1.00wt% Si, 0.30-0.80wt% Mn, less than 0.030wt% P, S, 2.20-2.70wt% Cr, 0.90-1.20wt% W, 0.80-1.00wt% Mo, 0.70-1.00wt% V, rest Fe and impurity. The method includes the following steps: adopting common steel facility, common medium steel smelting technology to smelt as the given constituent; forging; heat processing; making hot-work die. It has the advantages of reasonable alloy element composition, simplifying technology, lowering the cost. And it is fit for making tool die at 400-650 degree centigrade, such as cutting edge etc.

Owner:MAANSHAN IRON & STEEL CO LTD

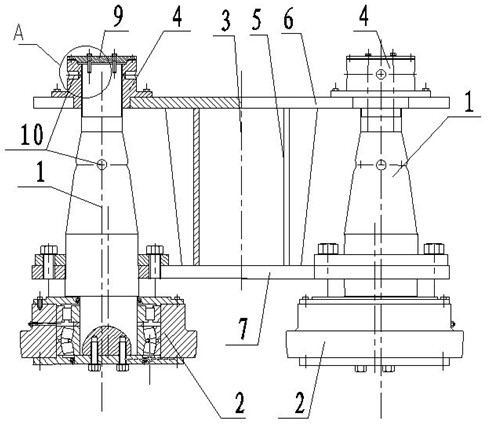

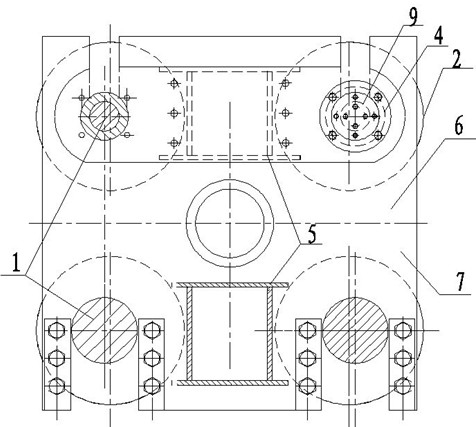

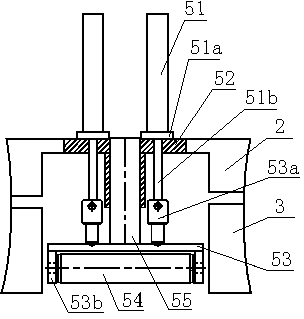

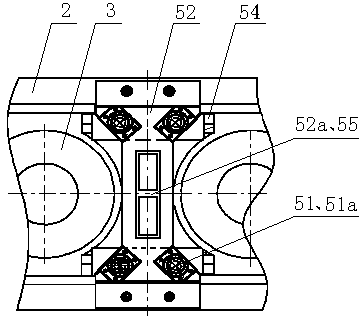

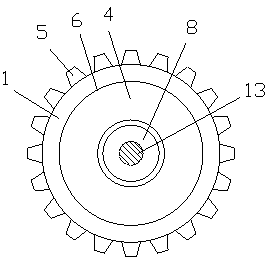

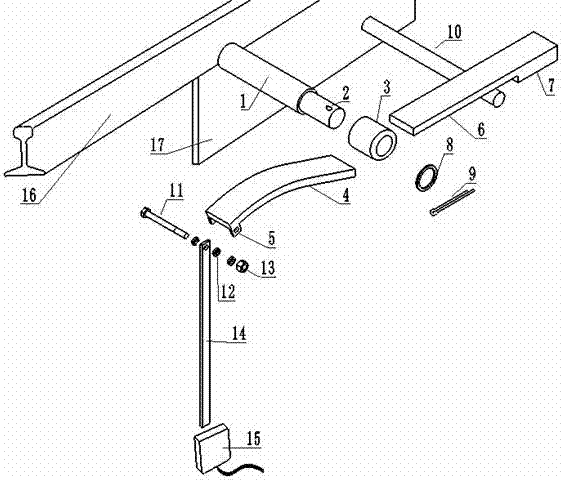

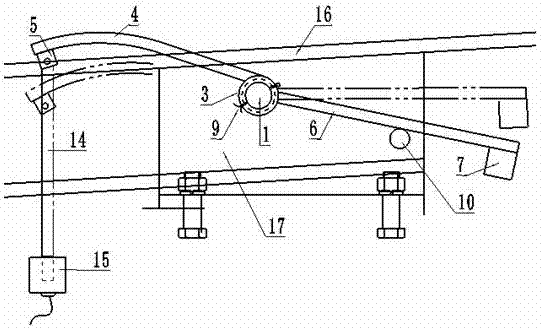

Horizontal wheel displacement adjusting method and displacement-adjustable horizontal wheel group

InactiveCN102431894AIncrease the range of practical orbitsExtended service lifeTravelling gearAgricultural engineeringScrew thread

The invention relates to displacement adjustment of a horizontal wheel of a crown block traveling mechanism, and discloses a horizontal wheel displacement adjusting method and a displacement-adjustable horizontal wheel group, concretely, a horizontal wheel is connected to a bracket through a wheel shaft, the wheel shaft is an eccentric shaft, the horizontal wheel is arranged at the lower end of the wheel shaft, a screw thread is processed on the outside of the upper end of the wheel shaft, the upper end of the wheel shaft is provided with a nut, and the lower end of the nut is provided with a flange plate; the bracket is provided whit a through hole at the mounting position of the wheel shaft, the nut is arranged on the through hole, and the screw thread is formed on the outside of the wheel shaft so as to be matched with the nut, in this way, vertical and horizontal displacement of the horizontal wheel is realized by rotating the wheel shaft; with the method provided by the invention, the practical rail range of the horizontal wheel is increased, service life of wheels and rails is prolonged, and cost of spare parts is reduced; and the horizontal wheel group is convenient to mount and detach and excellent in maintenance performance, the horizontal wheel can accurately guide the travel of a cart, the problem of rail gnawing is avoided, cost of production, use and maintenance is reduced, and the service life of the rail and the horizontal wheel is improved.

Owner:ZHUZHOU TIANQIAO CRANE

Method for repairing converter supporting ring

The invention relates to a method for repairing a converter supporting ring. The method comprises the following steps that (1) an old converter supporting ring is disassembled, and a transmission side trunnion and a non-transmission side trunnion assembly are obtained; (2) a tangential key on the transmission side trunnion is removed; (3) a large gear on the transmission side trunnion is dismounted; (4) new supporting ring fan-shaped sections are designed and made optimally; (5) two trunnion assemblies are repaired and the ends of the trunnion are sealed; (6) the two trunnion assemblies and the two fan-shaped sections are assembled on site; (7) the two trunnion assemblies and the two fan-shaped sections are welded and annealed on site. The method is used for repairing the converter supporting ring, greatly shortens the manufacturing period of the supporting ring, guarantees repairing quality and saves a great number of spare part expenses for enterprises.

Owner:甘肃酒钢集团西部重工股份有限公司

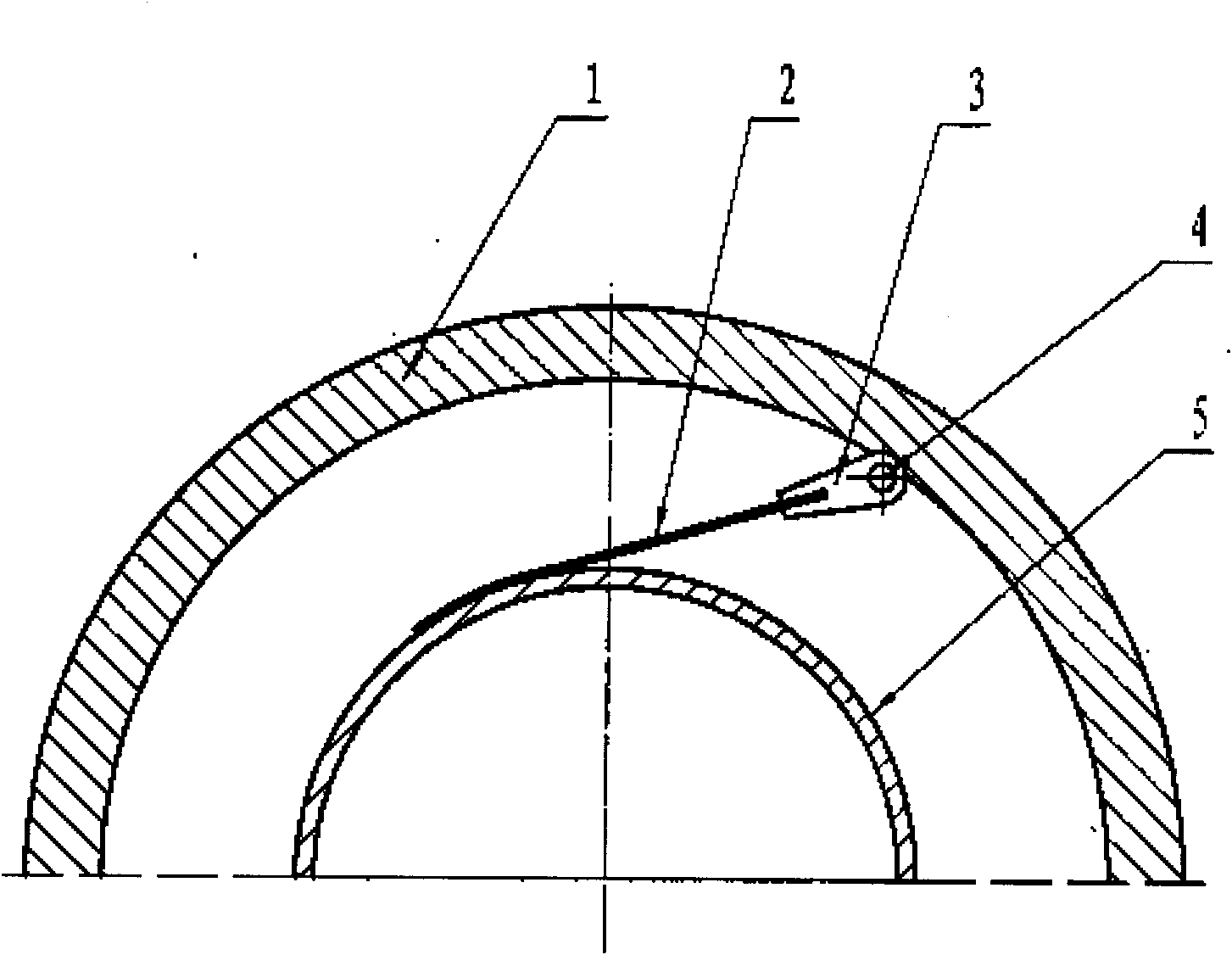

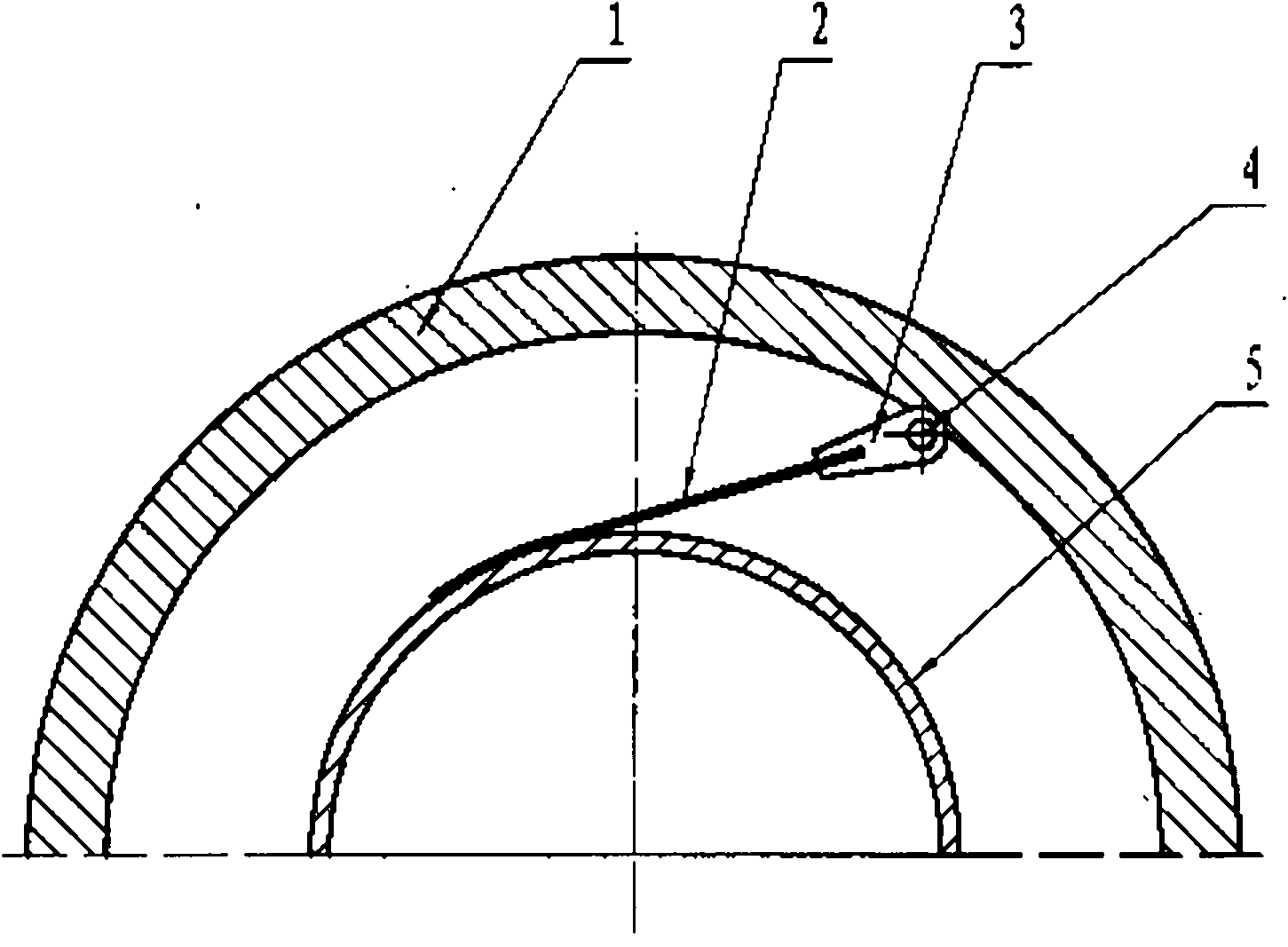

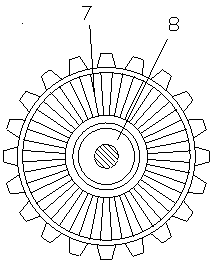

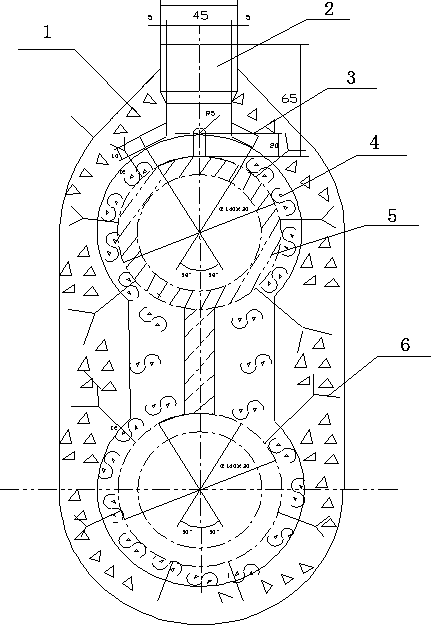

Rotary kiln heavy gear ring repairing method

InactiveCN101852547ASkip the installation processSave on spare parts costsRotary drum furnacesChemical industryRepair time

The invention discloses a rotary kiln heavy gear ring repairing method, and relates to a rotary kiln repairing method which is used in metallurgy, building materials and chemical industries. The method is characterized in that a repairing operation process comprises the following steps that: (1) a spring board and heavy gear ring connecting lug is cut off, and a heavy gear ring is removed; (2) the heavy gear ring is cleaned and set the heavy gear ring round; (3) the turned over heavy gear ring is hoisted and aligned; and (4) a pin shaft is installed, and a spring board and a new lug are welded. The rotary kiln heavy gear ring repairing method turns over and repairs the heavy gear ring under the circumstance of not replacing a tube section and the spring board, first cuts the spring board and heavy gear ring connecting lug, keeps a tube body and the original spring board unchanged, removes the gear ring and turns over the same and then replaces the new lug and the pin shaft; and after the heavy gear ring is aligned, the new lug and the original spring board are welded firmly. The rotary kiln heavy gear ring repairing method effectively saves the cost for the tube section, the spring board, a rivet and other spare parts, omits spring board installation, hole drilling, riveting and other procedures, and saves a certain repairing time.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

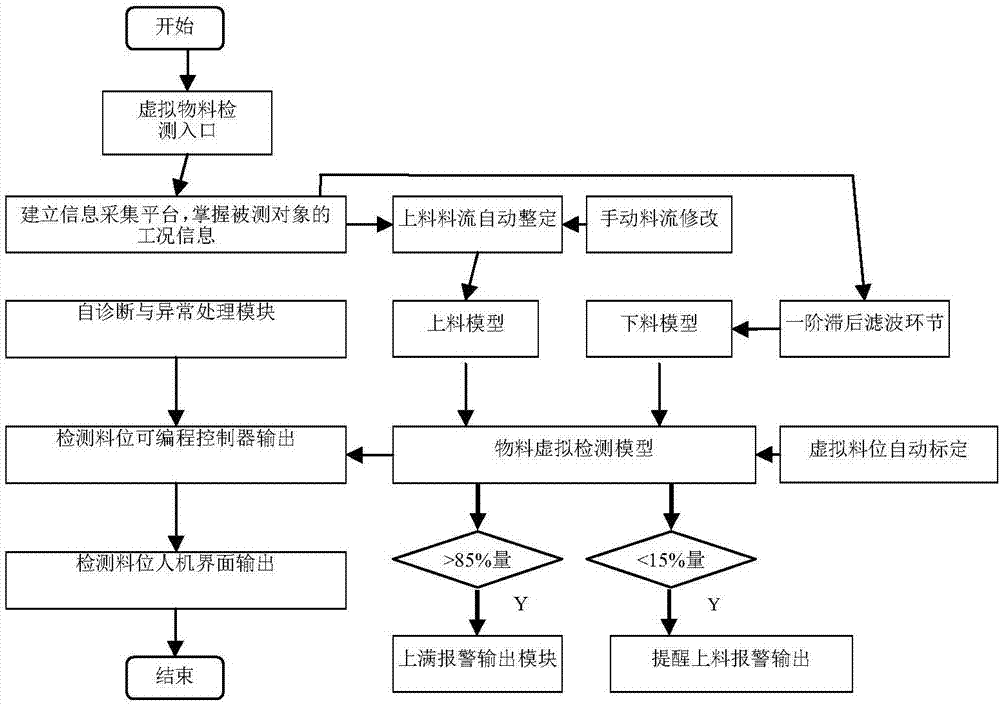

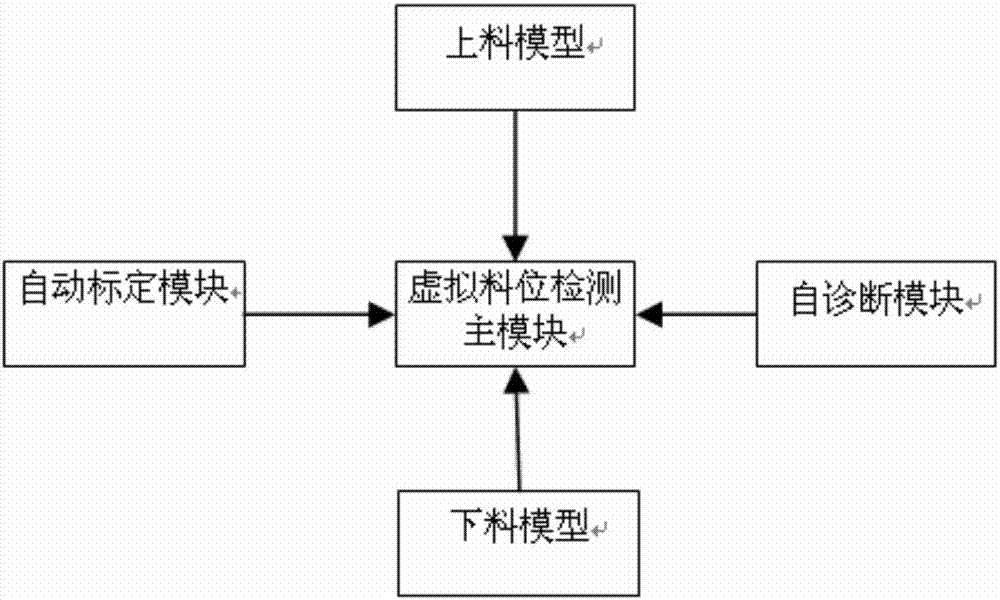

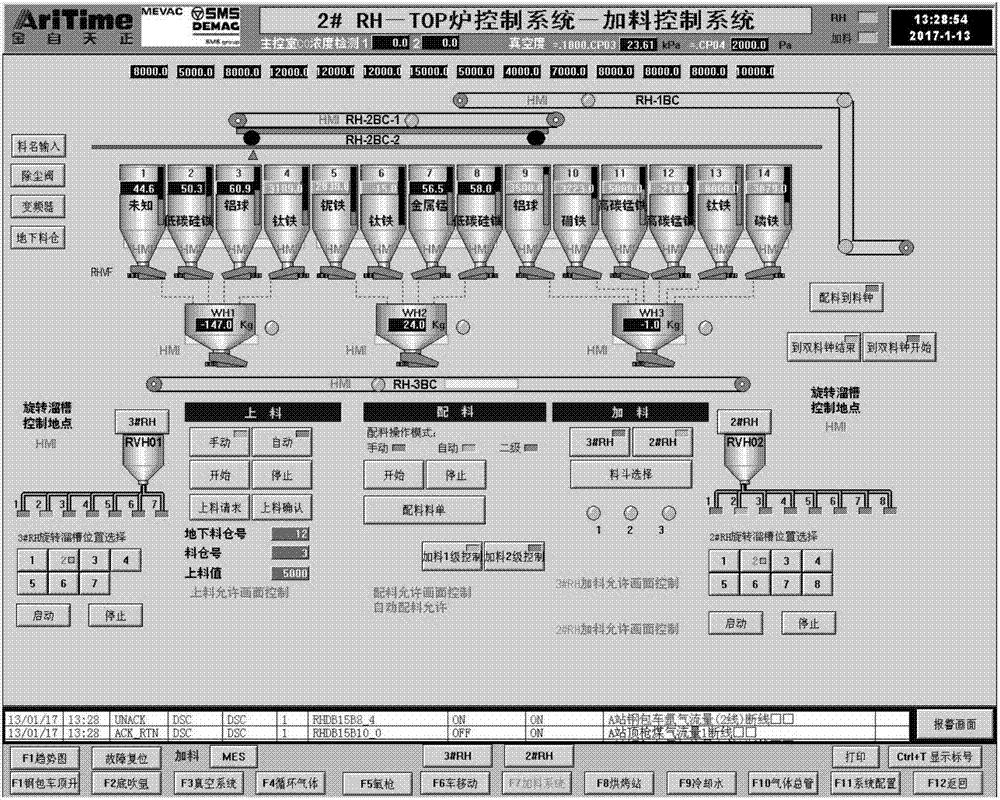

Software virtualization technology based material level detection method

ActiveCN106919127ASmooth supplyLow investment costProgramme controlComputer controlVirtualizationClosed loop

The invention relates to a software virtualization technology based material level detection method. The material level detection method comprises the steps of building an information acquisition platform, performing statistics on input and output conditions of materials, and recording working condition information of a detected object; building a loading model, modeling the materials by category, performing integral processing according to material flow data acquired in an earlier stage and inputting the modeled materials to the loading model; building a blanking model, and calculating a blanking accumulated value; building a material virtual detection model, wherein a virtual material level value displayed by the virtual material level in the module is formed by a difference value of real-time outputs of a loading module and a blanking module; and formulating a virtual material level automatic calibration module, performing analysis on an error, adjusting parameters and realizing closed-loop control. According to the method, the hardware investment cost can be greatly saved, a circumstance of material waiting is greatly improved, and a condition of material stacking caused by excessive material loading is completely eradicated, and the materials are supplied more smoothly; and the dust-exposed working time of workers is greatly reduced, occupational health conditions are improved, and production requirements are fully met.

Owner:BENGANG STEEL PLATES +1

Coiler side guide plate control method for preventing steel coils on hot rolling production line from staggering

InactiveCN103203365AAvoid splittingAvoid wear and tearRare end control deviceMetal rolling arrangementsProduction lineControl manner

The invention relates to a coiler side guide plate control method for preventing steel coils on a hot rolling production line from staggering, and belongs to the technical field of metallurgical plate production process. The technical scheme includes that programming is changed in a PLC (programmable logic controller) for controlling a coiler side guide plate, a force control link is added into a side guide plate control logic of a position control side, the side guide plate of the position control side is switched to the force control link and presses strip steel after a coiler mandrel is loaded, and then positions are controlled. The coiler side guide plate control method has the advantages that the problem that a side guide plate of a position control side cannot press strip steel is effectively solved, tail staggering of the steel coils is prevented, compared with an improved side guide plate control mode, the coiler side guide plate control method enables the side guide plate of the position control side to automatically position the edge of the strip steel without manual intervention and is efficient, safe and reliable, owing to double-sided pressure control, the strip steel is more rapidly pressed as compared with traditional one-sided pressure control, scrolling of inner rings can be more effectively controlled, and as the problem of swing after pressing of the side guide plate is solved, the replacement cycle of a transmission mechanism for the side guide plate can be prolonged, the expense of spare parts is saved, and maintenance time is shortened.

Owner:HANGANG GRP HANBAO IRON & STEEL +1

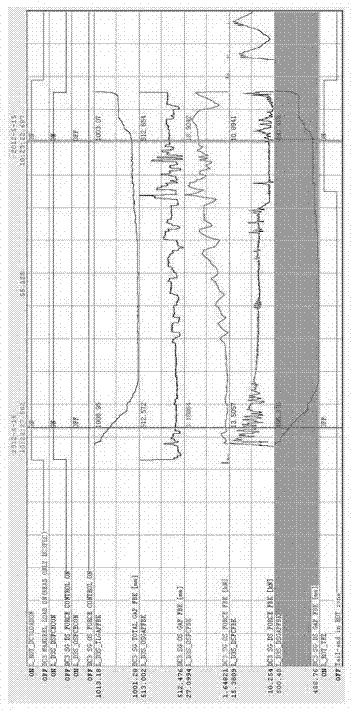

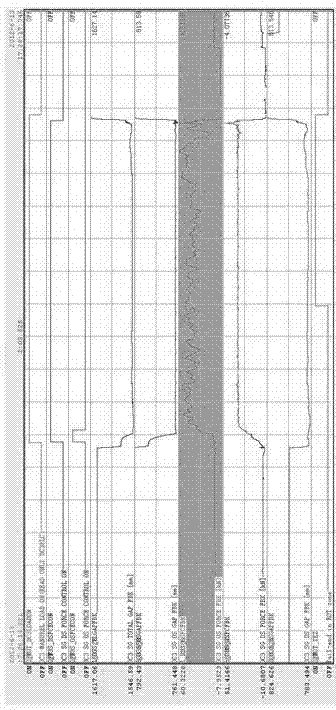

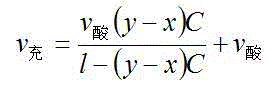

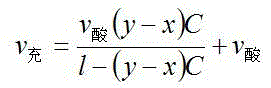

Acid washing cold rolling combined unit inlet loop filling speed control method

InactiveCN103978045AExcellent charging speedLower runRare end control deviceFlexible work arrangmentsProduction lineAcid washing

An acid washing cold rolling combined unit inlet loop filling speed control method belongs to the technical field of cold rolling production line speed control and is used for controlling the loop filling speed. A loop filling speed formula is shown in the description, v is the loop instantaneous optimum loop filling speed, v is the acid washing process section main speed, x is the loop filling quality percentage at the beginning of the loop filling, y is the loop filling full quantity percentage, and C is a constant. Loop filling is conducted by adopting the optimum loop filling speed, and the belt loop filling speed and the loop vehicle operation speed are greatly reduced. Especially when belt steel and high strength steel with the specification lower than 3.0 are rolled, the loop vehicle speed is reduced by over 50%, and stable operation of loops is not endangered. Due to the fact that the whole loop filling process tends to be mild, accidents like belt steel off tracking and breaking are avoided in production thin belt steel. The method has remarkable innovativeness, advancement and economical benefit and can be popularized and applied in acid washing cold rolling combined units.

Owner:HANGANG GRP HANBAO IRON & STEEL

Coke ovenlow pressure ammonia valve changing method for preventing gas discharging

InactiveCN106701115AReduce replacement timeReduce the temperatureCoke oven safety devicesLower limitCombustion system

The inventionprovides a coke ovenlow pressure ammonia valve changing method for preventing gas discharging. Before changing, the pressure of a gas collecting tube is set to a lower limit of 95-105 Pa; when the temperature of the gas collecting tube is too high so that the pressure surge greatly exceeds an upper limit, a manual operation is performed at the scene; a high pressure ammonia valve with a corresponding oven number is opened with a small open degree of 1 / 5-1 / 4, and high pressure ammonia is temporarily used to replace the low pressure ammonia to cool raw coke oven gas; during the changing process, the opening degree of the high pressure ammonia valve is less than 1 / 4, to ensure the pressure in a coking chamber is higher than the pressure of a combustion system at the same level; after the change is completed, the high pressure ammonia valve is closed in time to prevent the temperature of the gas collecting tube from continuously increasing. The invention can greatly shorten the valve change time, and reduce the raising of the temperature of the gas collecting tube and pressure surge, thereby effectively avoiding environmental pollution caused by coke oven discharging, preventing the pipe fitting of the gas collecting tube from being damaged, and reducing costs for replacement parts.

Owner:ANGANG STEEL CO LTD

Control method for preventing core pulling in coil discharging of strip steel coiling machine

The invention provides a control method for preventing core pulling in coil discharging of a strip steel coiling machine. When the coiling machine is prepared to start to discharge coils, a coil-discharging trolley control PLC is used for controlling a coil-discharging trolley to ascend at low pressure; after the coil-discharging trolley makes contact with a steel coil, the coil-discharging trolley control PLC controls the coil-discharging trolley to ascend at high hydraulic pressure; high pressure is utilized for compensating for decrease of the height of a hydraulic cylinder, caused by dead weight of the steel coil after retraction of a central spindle of the coiling machine, of the coil-discharging trolley, and it is avoided that the height of the hydraulic cylinder of the coil-discharging trolley is decreased, so that the inner ring of the steel coil makes contact with a rubber roll of the central spindle. The height of the coil-discharging trolley is kept stable, it is effectively avoided that after the central spindle of the coiling machine retracts, the inner ring of the steel coil makes contact with the rubber roll of the central spindle, the situation that when an exit trolley discharges coils, core pulling of the steel coil happens is greatly reduced, the replacement period of the roll of the central spindle of the coiling machine is prolonged, cost for spare parts is saved, the production cost of the strip steel is reduced, the defective rate of the strip steel is decreased, the service life of the roll of the central spindle of the coiling machine is prolonged, and normal production is guaranteed.

Owner:HBIS COMPANY LIMITED HANDAN BRANCH COMPANY

Method for shortening single furnace operation time of coke tank truck

InactiveCN101693838ACommunication signal transmission is normal without interruptionImprove efficiencyCoke quenchingFrequency changerTransducer

The invention relates to a method for shortening single furnace operation time of a coke tank truck, aiming at improving the utilization efficiency of automatic equipment and increasing the coke output. The method comprises the following steps: setting the highest automatic-travelling speed parameter of the coke tank truck to be 180m / min and the on-site operation speed parameter to be 150m / min; dividing speed change parameter set values of different sections into six sections according to the distance between a starting position and an end position; adjusting the position of an induction limit switch; increasing a new deceleration accurate park linkage point of a coke tank; increasing a signal point allowed to enter a lifter region at a control part of the coke tank truck aiming at the characteristic of long distance between a big furnace relatively and a dry quenching furnace; improving a starting control triggering mode of a transducer, controlling a main contactor of the transducerby the output of a PLC digital output module, controlling the main contactor to be installed in an electric cabinet, and selecting signal standby point wiring of a PLC digital output template to the main contactor; and increasing a new wireless communication line, and ensuring that communication signals of vehicles are transmitted normally.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

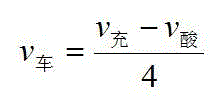

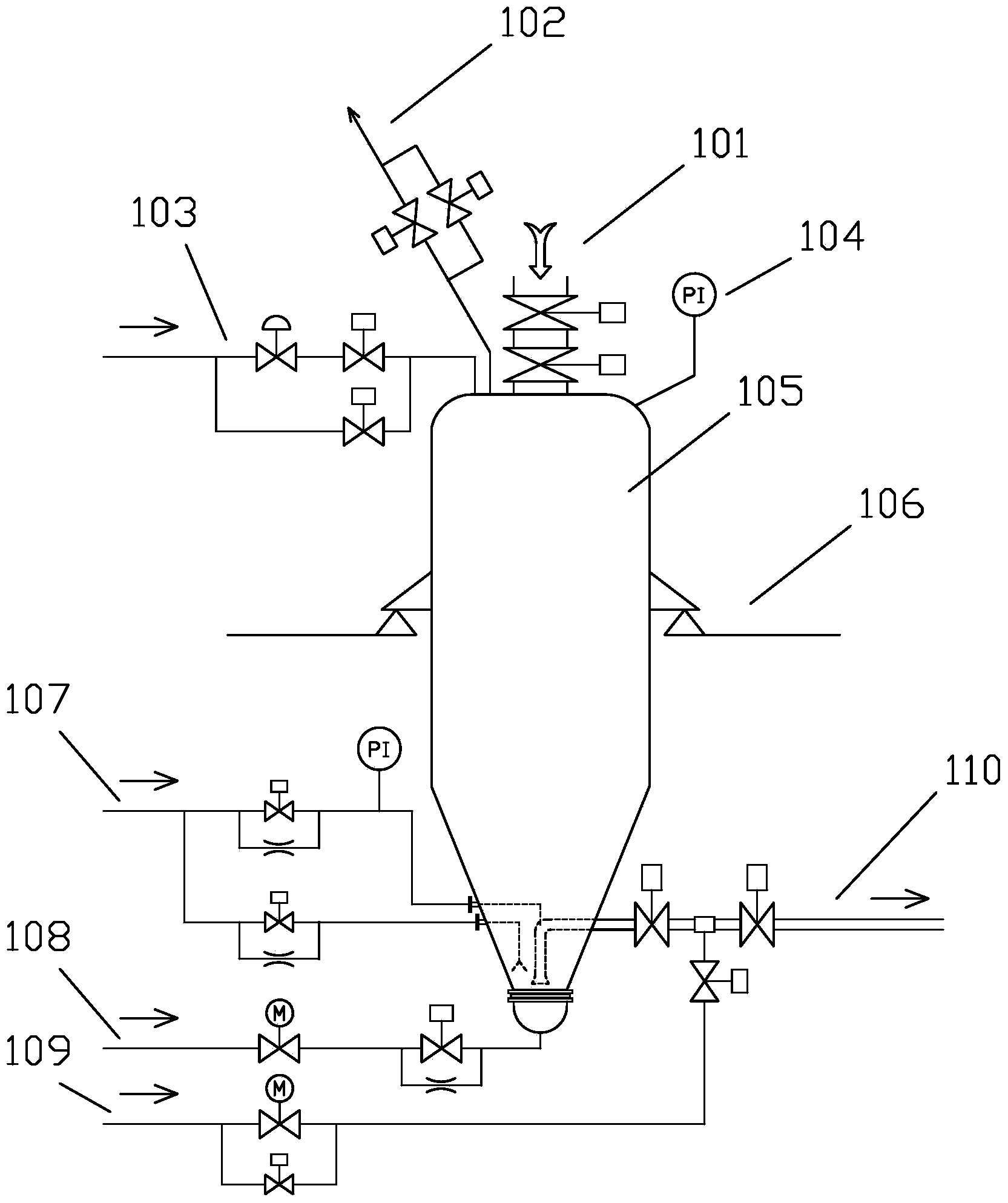

Blowing rate adjusting system for pulverized coal blowing tank

ActiveCN103820593AMove quicklySave resourcesBlast furnace componentsBlast furnace detailsMeasuring instrumentEngineering

The invention relates to the field of gas delivery, and in particular relates to a blowing rate adjusting system for a pulverized coal blowing tank. The blowing rate adjusting system comprises a charging pipeline, a pressure charging pipeline, an exhaust pressure relief pipeline, a tank body, a weighing and pressure measuring device, a tank cone adjusting pipeline, a bottom boiling pipeline, a gas supply pipeline and a coal conveying pipeline, wherein the tank cone adjusting pipeline comprises an angle seat quick-switching valve, a cleaning orifice and a pressure measuring instrument; the bottom boiling pipeline comprises an adjusting valve, a stop valve and a normally open orifice; the gas supply pipeline comprises an adjusting valve, a stop valve and an angle seat quick-switching valve which is parallel to the adjusting valve. By adopting the blowing tank, the problems of large coal discharge fluctuation and intermittent coal break at the initial stage of pulverized coal injection tank replacement are solved, the blowing rate of coal which is difficult to blow can also be quickly and stably adjusted, and meanwhile, the adverse condition of a poor boiling fluidization effect caused by the coal seepage and accumulation of a boiling chamber is eliminated.

Owner:ZENITH STEEL GROUP CORP

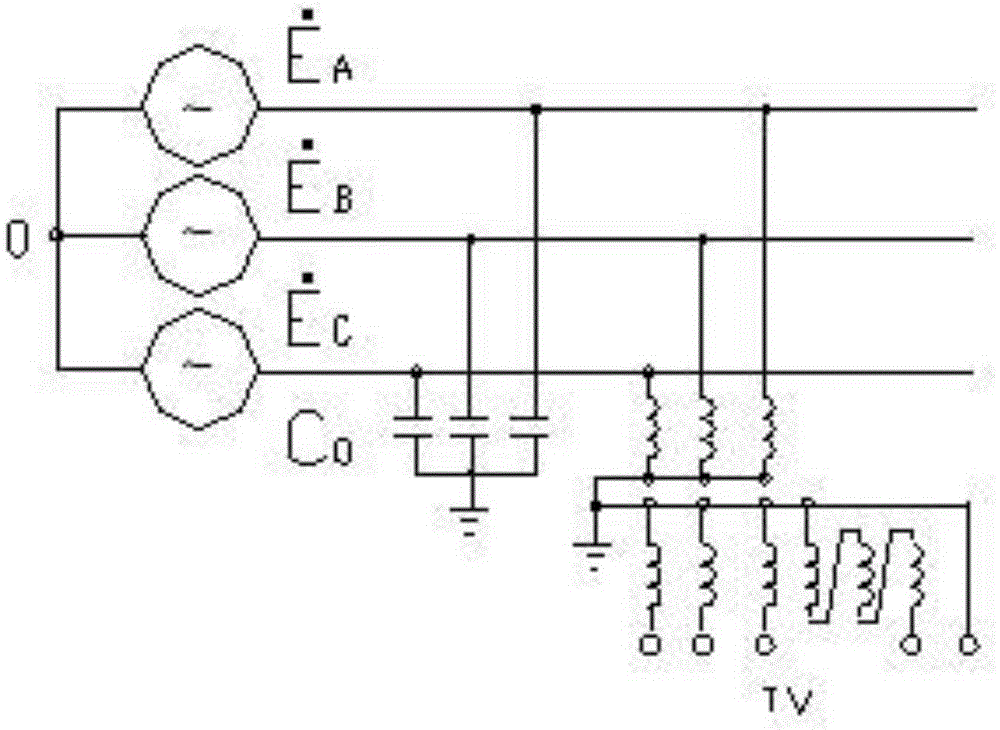

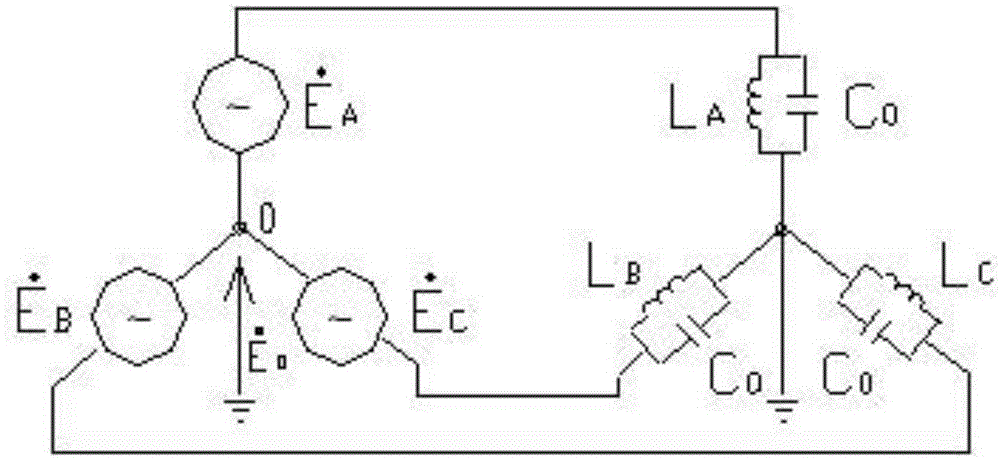

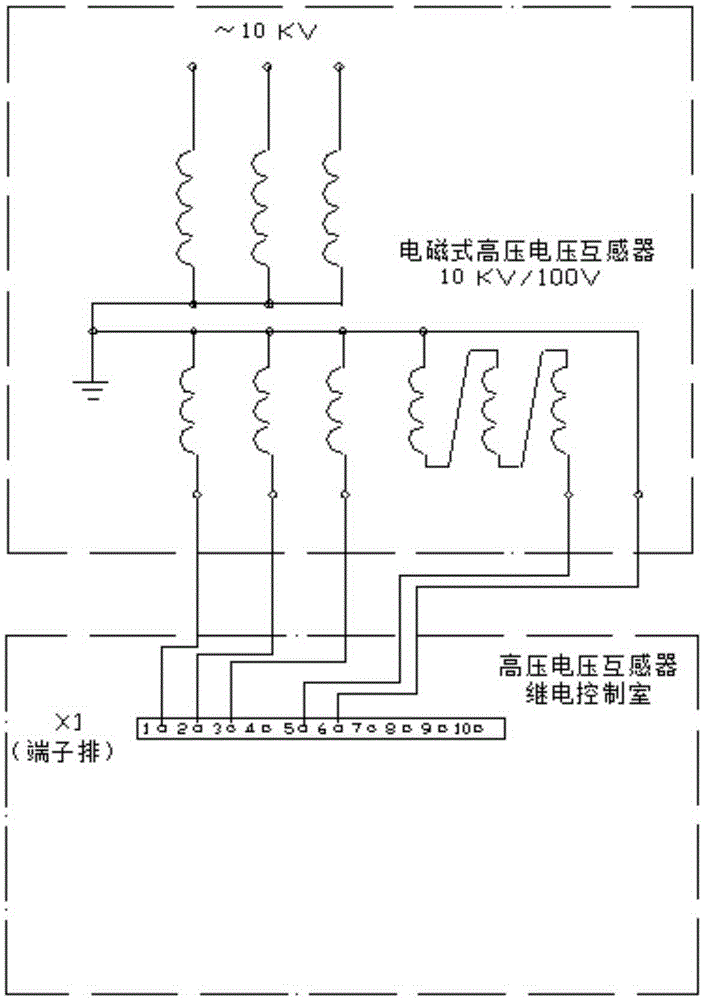

Substitution device of manufacturing-plant high-voltage electromagnetic voltage transformer and method thereof

ActiveCN105425005AAvoid power system failuresEasy to useVoltage/current isolationOvervoltageEngineering

The invention discloses a substitution device of a manufacturing-plant high-voltage electromagnetic voltage transformer and a method thereof. A used transformer and a three-phase step-down transformer are included. The used transformer is connected to the three-phase step-down transformer through a used substation and feed switch type vacancy switch. A secondary winding of the three-phase step-down transformer is directly connected to an inlet wire terminal of a PT-cabinet high-voltage transformer relay control room. A scope of twice voltage reduction of the used transformer and the three-phase step-down transformer is the same with a scope of one voltage reduction of the high-voltage electromagnetic voltage transformer. The used transformer and a voltage measurement transformer are used to substitute the electromagnetic high-voltage transformer so that a problem of ferromagnetic-resonance overvoltage existing in electromagnetic high-voltage transformer usage is solved.

Owner:MAANSHAN IRON & STEEL CO LTD

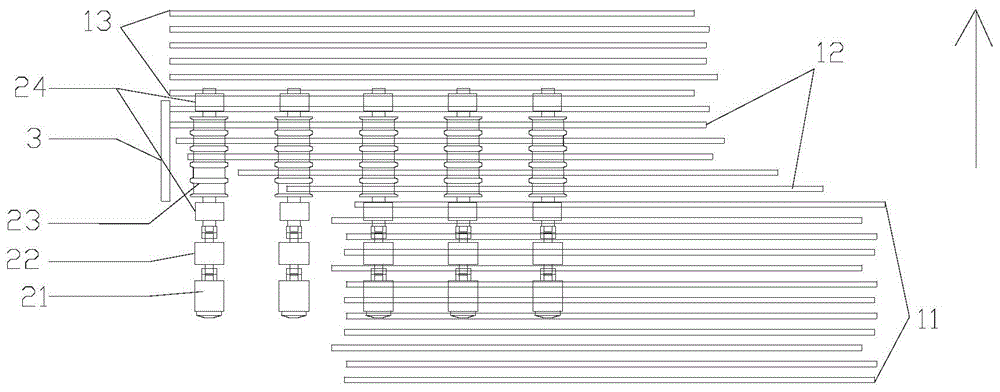

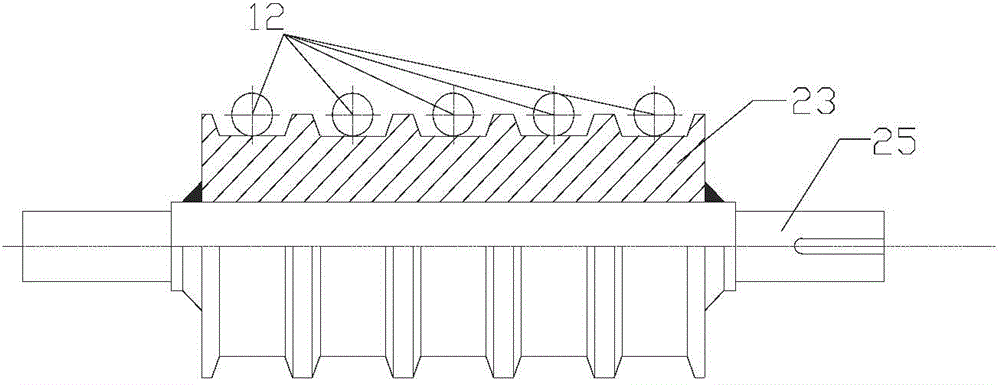

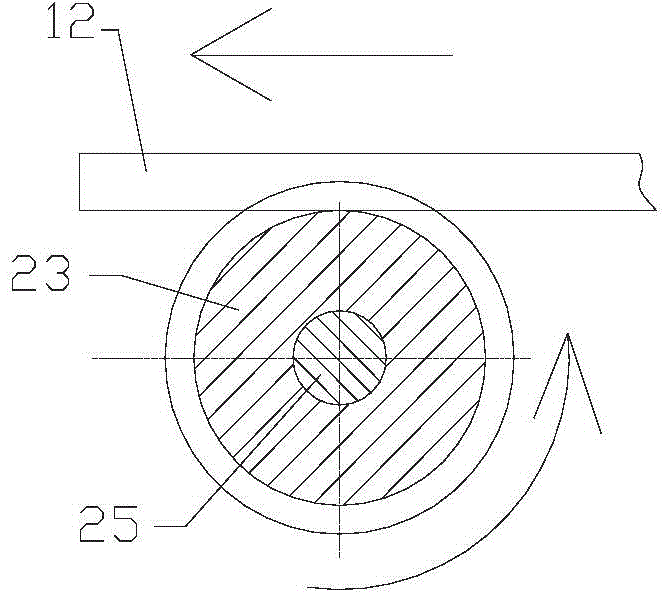

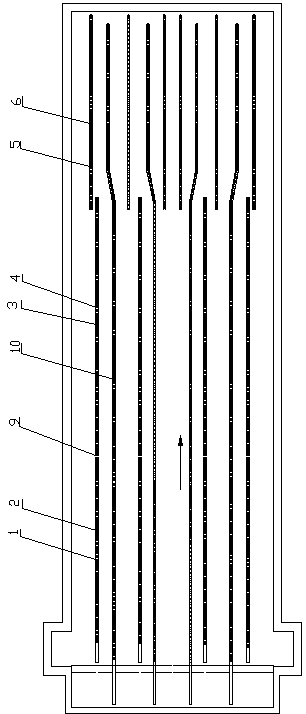

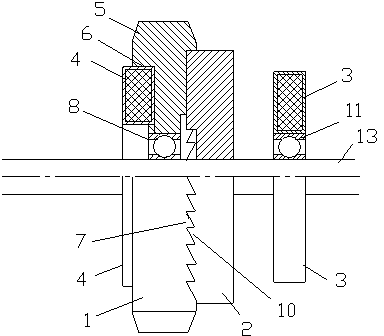

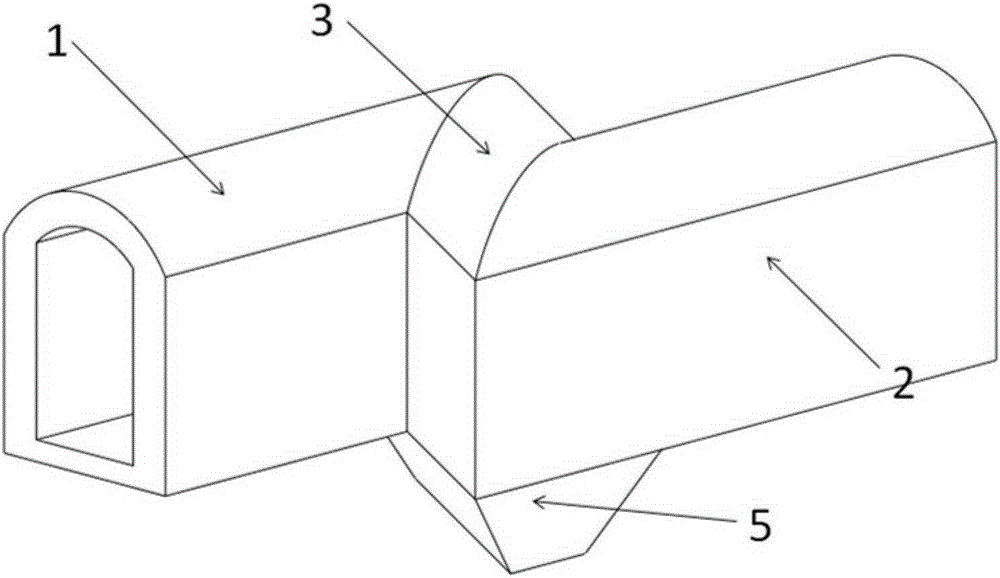

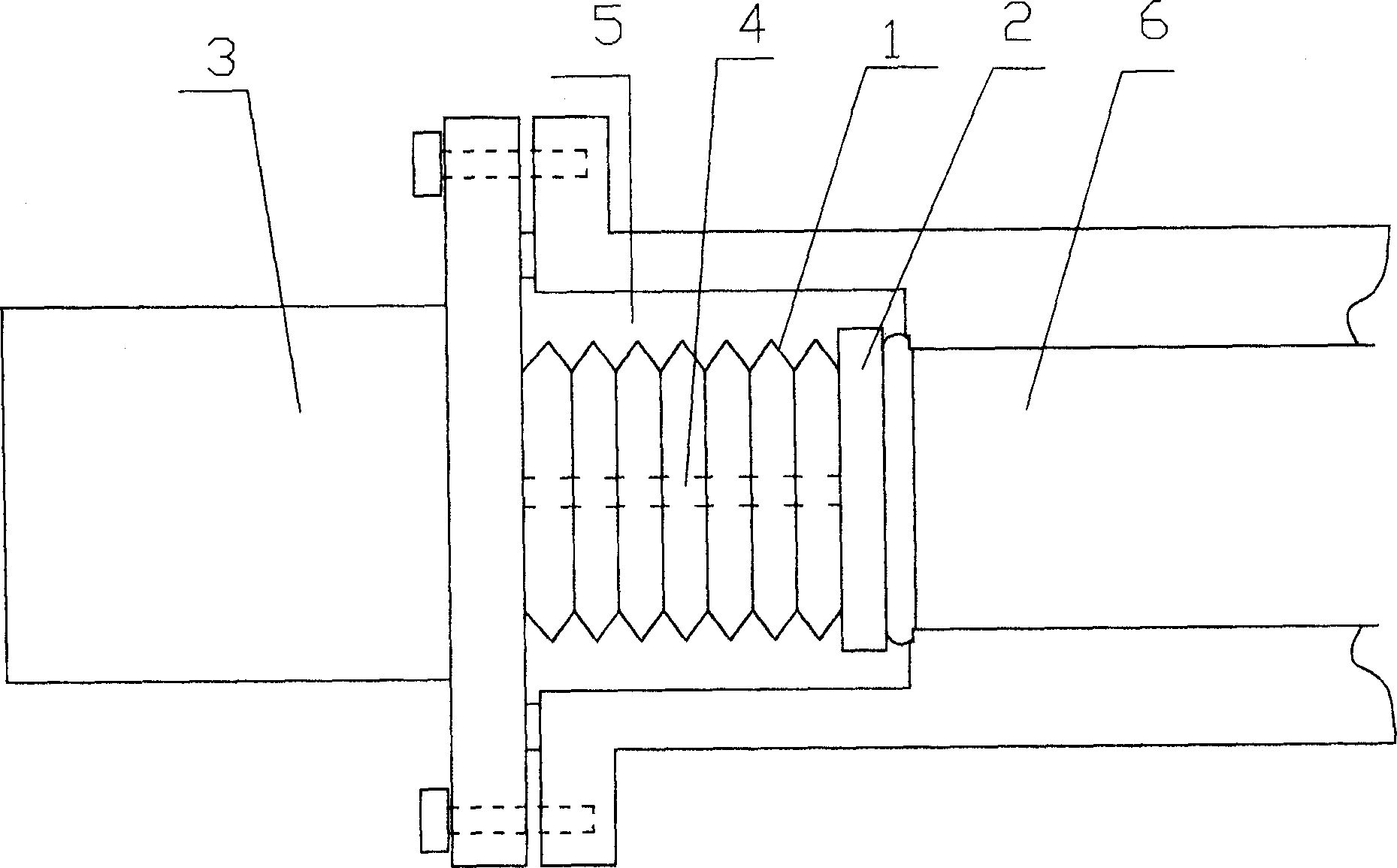

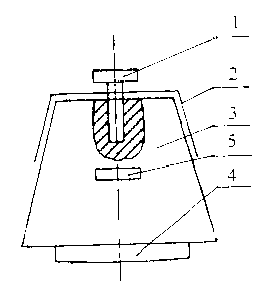

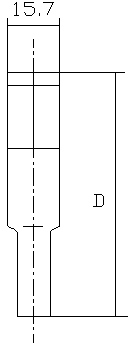

Alignment roller used for bar cold bed

ActiveCN104942030ASave on spare parts costsCooling bedsMetal rolling arrangementsDrive shaftPulp and paper industry

The invention provides an alignment roller used for a bar cold bed. The alignment roller comprises a transmission shaft and multiple roller rings, each roller ring is of a flat ring-shaped structure, and a guide groove used for allowing a bar to pass through is formed in the outer side wall of each roller ring in the peripheral direction; the inner side wall of each roller ring forms a connecting hole, the transmission shaft is sleeved with the multiple roller rings in sequence in a stacked mode, and the roller rings are detachably connected with the transmission shaft. According to the alignment roller, the integral alignment roller is divided into the multiple split type roller rings which are installed in a stacked mode. When the guide groove of a certain roller ring is abrased severely, the corresponding roller ring is replaced, and the other roller rings of good states can be continued to use, so that the replacement part cost can be saved remarkably.

Owner:SHANDONG IRON & STEEL CO LTD

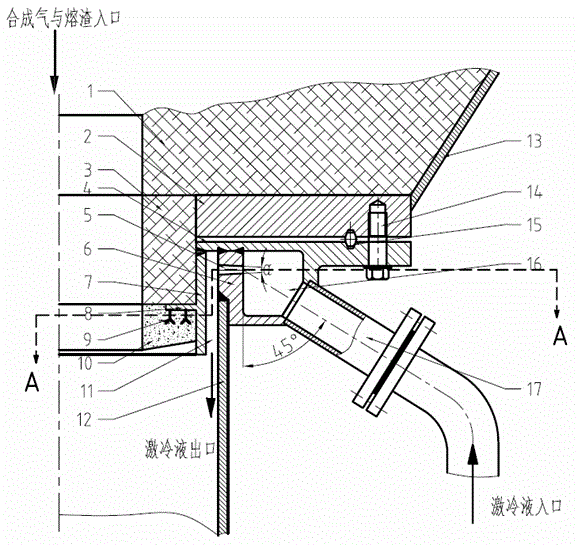

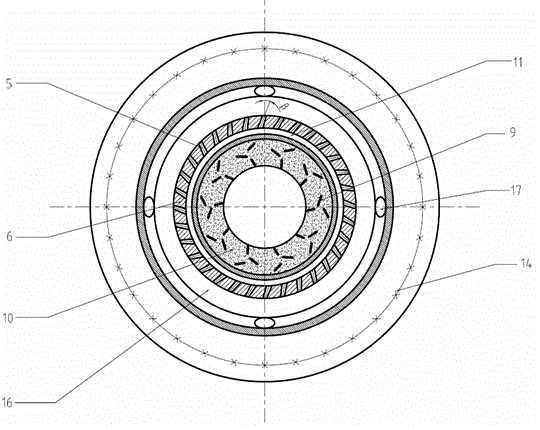

Novel quenching ring for entrained-bed gasifier

InactiveCN104611070AAvoid harmExtended service lifeGasifier mechanical detailsCombustible gas productionSyngasStructural engineering

The invention discloses a novel quenching ring for an entrained-bed gasifier. The quenching ring comprises an annular outer ring plate, an annular inner ring plate, an annular retainer and a descending pipe, wherein the annular outer ring plate comprises a horizontal ring face I and a longitudinal ring face I which is located on a lower face of the horizontal face I; the annular inner ring plate and the annular retainer are fixedly arranged inside the lower face of the horizontal ring face I, the annular retainer is located between the annular inner ring plate and the longitudinal ring face I, and the descending pipe is mounted at the lower end of the annular retainer; quenching liquid distribution chambers are formed between the annular retainer and the horizontal ring face I and between the annular retainer and the longitudinal ring face I and are connected with a quenching liquid conveyer; annular protective layers are arranged on fire-facing faces of the annular outer ring plate and the annular inner ring plate. According to the novel quenching ring disclosed by the invention, the fire facing face of the quenching ring is prevented from being directly brushed by high-temperature synthetic gas and cinders to be damaged, and the working temperature of the fire facing face of the quenching ring can be further greatly reduced, the service life of the quenching ring is prolonged, and the slagging outlet can be further prevented from being blocked. The novel quenching ring disclosed by the invention is easy to produce and relatively low in manufacturing and processing costs.

Owner:中国东方电气集团有限公司

Method for maintaining heat-resisting cushion block of stepping type heating furnace

ActiveCN103344119AExtended service lifeOvercome large amount of deviationFurnace coolingFiberEconomic benefits

The invention discloses a method for maintaining a heat-resisting cushion block of a stepping type heating furnace. The method solves the problems that a traditional water beam cushion block of a stepping type heating furnace for metallurgy is long in on-site replacement construction time, difficult to replace, and high in maintenance cost. The method comprises the following steps: (1) removing surrounding refractory materials and Y-type anchoring hooks which affect the cushion block and a press block, (2) cutting and removing cushion blocks needing to be replaced through a grinding machine, (3) grinding the portion where the cushion block is installed to be smooth through the grinding machine, (4) finding a center and a level, and installing the cushion block, (5) measuring the level of the installed cushion block through a measuring instrument, adjusting the installed cushion block to be in order, and welding the press block, (6) measuring the level of the cushion block after the press block is welded, and adjusting the cushion block in order, (7) welding the Y-type anchoring hooks, (8) installing a fiber blanket thermal insulating layer, (9) ramming repairing materials, and (10) conducting test run and ignition baking oven operation. On the premise that the service life of the water beam cushion block is prolonged, the method has the advantages that the maintenance cost is low and the replacement construction time is shortened greatly, and the economic benefits are remarkable.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

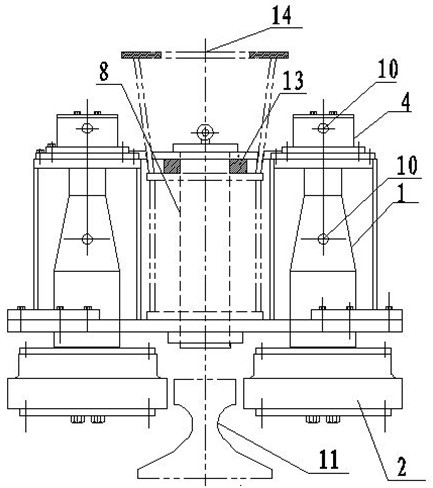

Vertical rolling mill with press roll device

ActiveCN103372577APrevent rolloverIncrease productivityGuiding/positioning/aligning arrangementsMachinePiston rod

The invention discloses an vertical rolling mill with a press roll device. The vertical rolling mill comprises a base, a rolling mill body which is disposed on the base and comprises a rolling mill stand, vertical rolls and a drive system and the press roll device. The press roll device comprises oil cylinders, an upper crossbeam, a lower crossbeam, press rolls and a guide cylinder. The oil cylinder is disposed on the upper portion of the upper crossbeam. A piston rod of each oil cylinder penetrates the upper crossbeam to be connected with a connecting rod fixed on the upper portion of the lower crossbeam. Support plates are disposed on the lower portion of the lower crossbeam. The press rolls are disposed between every two support plates. The guide cylinder is disposed between the upper crossbeam and the lower crossbeam. By the press roll device, billet rollover caused by unavailable hole patterns of the vertical rolls during vertical rolling can be prevented effectively, multi-specification rolling can be achieved on the premise that rolls of a single rolling machine need not to be replaced, time for roll replacing is saved, production efficiency is increased, and production cost is lowered.

Owner:HUBEI SHILI MOLD MATERIAL

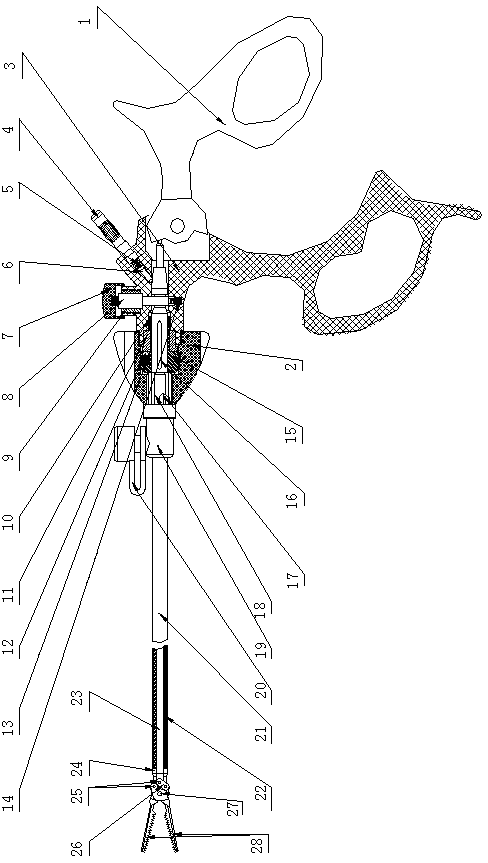

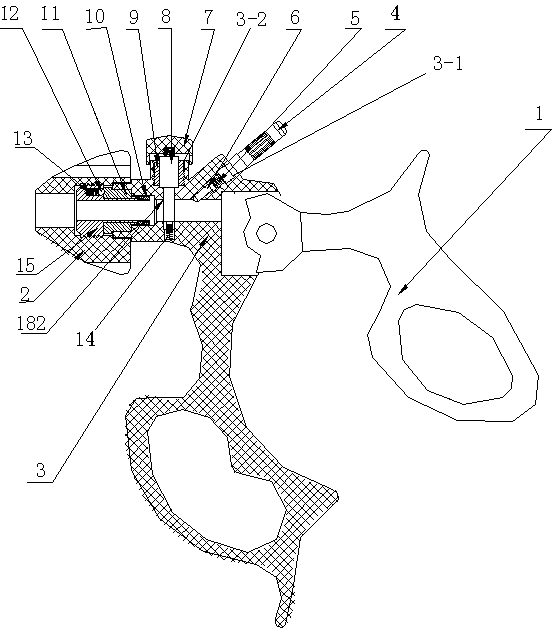

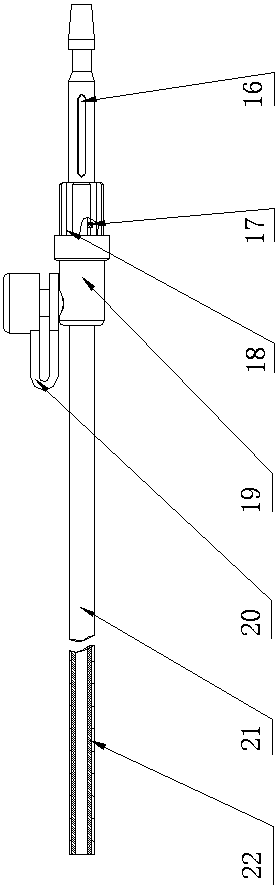

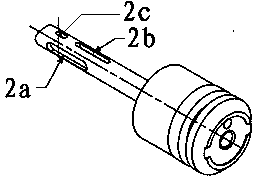

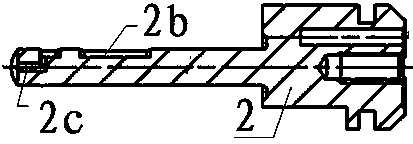

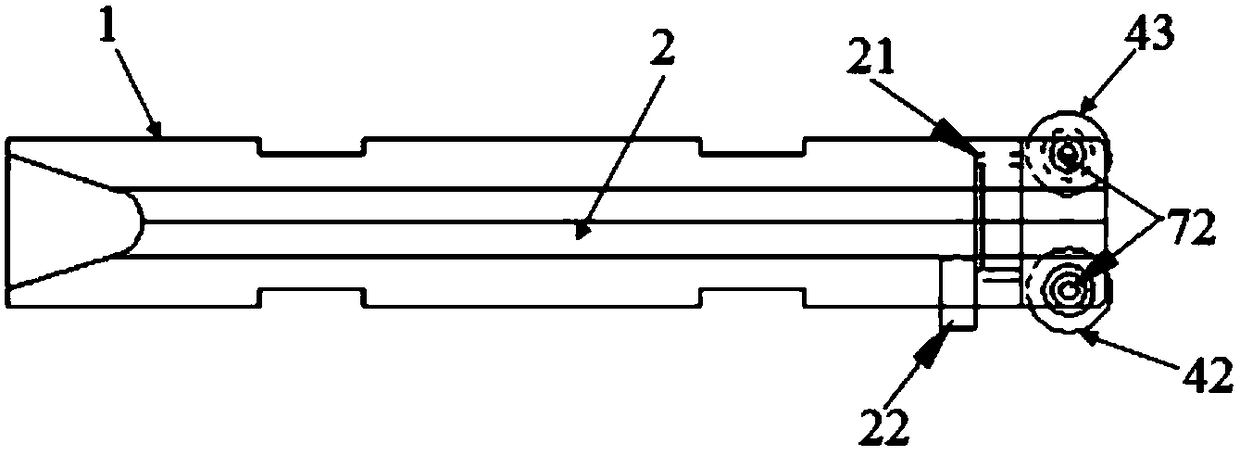

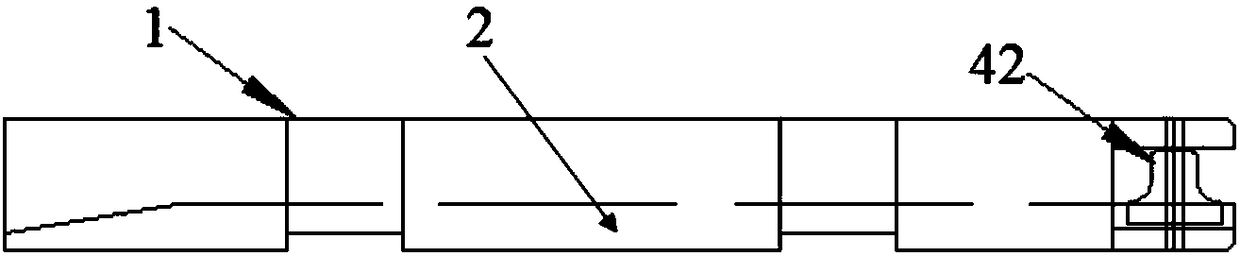

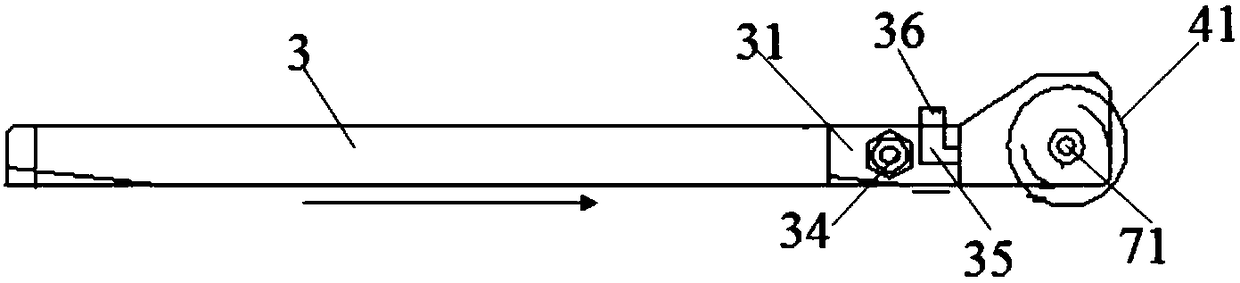

Tri-detachable type endoscope minimally invasive forceps

The invention discloses tri-detachable type endoscope minimally invasion forceps comprising a forceps handle part, a forceps lever part and a forceps head pull rod part. The forceps handle part is composed of a rear forceps handle, a turning-wheel component, a front forceps handle, an electrical plug, a plug spring, a conducting rod, a demounting cap, a demounting rod, a fixing ring, a stop ring, a demounting spring and a turning-wheel seat; the conducting rod, the plug spring and the electrical plug are arranged in an electrical-plug inclined hole; the demounting spring, the demounting rod and the fixing ring are arranged in a demounting hole; the turning-wheel component is connected with the front forceps handle in a matched manner; the forceps lever part is composed of spring pieces, a sealing ring, a forceps lever shaft, a flushing connector, a connector cap, a protecting cap and a forceps tube; a forceps tube bayonet is formed in the forceps tube, forceps lever shaft grooves are formed in the forceps lever shaft, a demounting rod hole is formed in the forceps lever shaft, the spring pieces are mounted in the forceps lever shaft grooves, the sealing ring is mounted in the forceps lever shaft grooves, the forceps tube is connected with the forceps lever shaft, and the flushing connector is connected with the forceps lever shaft; the forceps head pull rod part is sleeved on the forceps lever part which is connected with a turning wheel in a matched manner. Compared with the prior art, the tri-detachable type endoscope minimally invasion forceps have the advantages of reasonable structure, convenience in use, good popularity, good security, lower cost on training and spare parts and the like.

Owner:钟晓鹏

Brake clutching device used for rear brake of automobile

InactiveCN104228788AImprove braking performanceShorter braking distanceBraking element arrangementsMechanical braking transmissionEngineeringMechanical engineering

The invention provides a brake clutching device used for a rear brake of an automobile, and belongs to the technical field of automobile braking equipment and the brake clutching device is used for improving the braking effect. The technical scheme is as follows: a gear brake disc, a gear brake pad, a releasing electromagnet and a suction electromagnet are mounted on half shafts on two sides of the automobile respectively; the gear brake disc is opposite to one side of the gear brake pad and a disc surface is engaged with a fluted disc on the disc surface; the suction electromagnet is fixedly connected onto the gear brake disc; the releasing electromagnet sleeves the half shaft on the other side of the gear brake pad. In a braking process, the gear brake pad is engaged with the gear brake disc and the power of the half shafts is transmitted to a braking gear through the gear brake disc so that a braking pull rod drives a U-shaped brake plate to brake. The brake clutching device does not generate a slipping phenomenon so that the brake clutching is very tight and reliable and the braking effect of a rear brake device of the automobile is greatly increased. The brake clutching device is simple in structure, convenient to mount, good and reliable in use effect and low in cost, and is particularly suitable for being mounted and used on the rear brake device of the automobile.

Owner:NORTH CHINA UNIVERSITY OF SCIENCE AND TECHNOLOGY

Dry quenching primary dust collector structure and dedusting method thereof

ActiveCN105289113AHigh strengthExtended service lifeCoke quenchingDispersed particle separationBrickQuenching

The invention discloses a dry quenching primary dust collector structure and a dedusting method thereof. The dry quenching primary dust collector structure includes a dust collector inlet, a dust collector outlet, a dedusting channel, and a dust hopper arranged at the bottom of the dedusting channel; the dedusting channel is provided with at least one Z-shaped channel structure, a corner of the Z-shaped channel structure is transversely provided with two dedusting retaining walls which are arranged oppositely, a gas flow channel is formed between the retaining walls, and the dust hopper is arranged at the bottom of the Z-shaped channel structure. Compared with the prior art, the dry quenching primary dust collector structure has the beneficial effects that the dry quenching primary dust collector structure has an original upper retaining wall structure cancelled, the Z-shaped channel structure is arranged, and the two transversely oppositely arranged dedusting retaining walls are added, so that the overall strength of a primary dust collector is improved, and the dedusting efficiency is increased; the structure is more steady, the shedding of brick bodies is reduced, the service life of the primary dust collector is extended, and the maintenance time and costs of spare parts are saved.

Owner:ACRE COKING & REFRACTORY ENG CONSULTING CORP DALIAN MCC

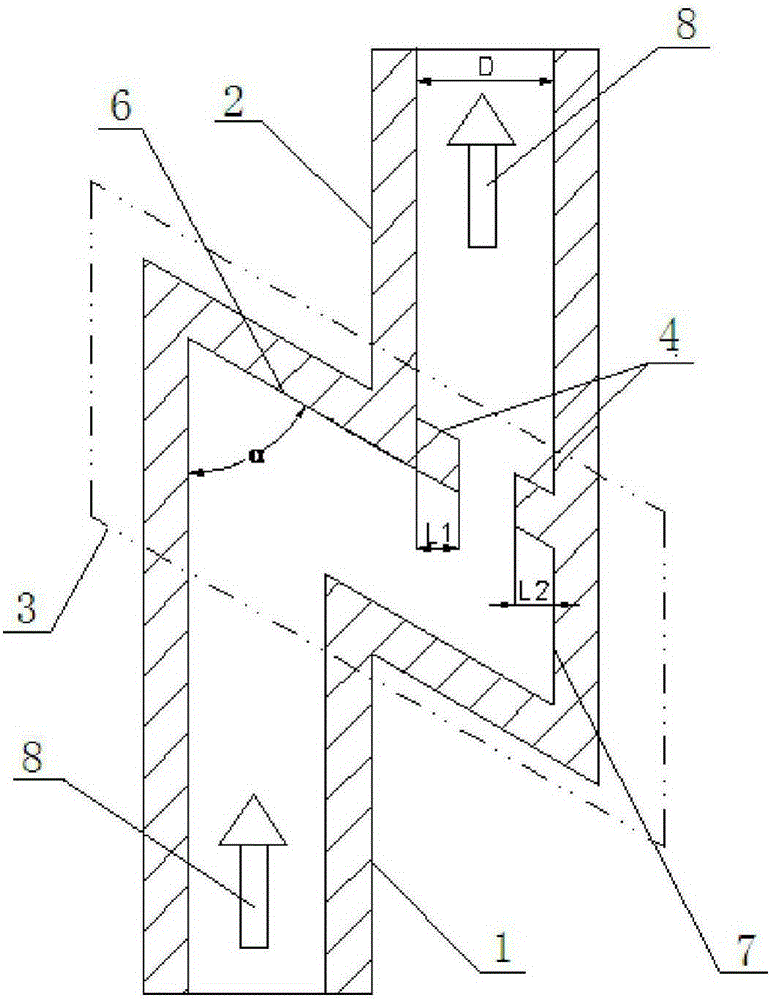

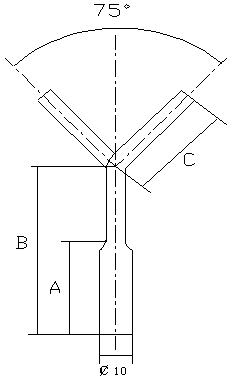

Three-component mixing head for injection molding

The invention discloses a three-component mixing head for injection molding. The mixing head comprises a pressure regulating core block and a small piston. The pressure regulating core block comprises a small piston push rod installing hole, a color paste feeding hole, a color paste discharging hole, an ISO feeding hole, an ISO discharging hole, a POL feeding hole, a POL discharging hole, a horizontal mixing and injecting zone and a mixture discharging. An included angle is formed between the color paste feeding hole and the horizontal mixing and injecting zone. The push rod of the small piston is provided with a first high pressure circulating groove, a second high pressure circulating groove and a color paste circulating groove, wherein the first high pressure circulating groove and the second high pressure circulating groove are symmetrically arranged, and the color paste circulating groove is located on the symmetrical center line of the first high pressure circulating groove and the second high pressure circulating groove. The push rod of the small piston is slidably mounted in the small piston push rod installing hole in the pressure regulating core block through clearance fit and can carry out linear reciprocating motion along the small piston push rod installing hole. The three-component mixing head has the following advantages: sufficient bumping of three components is realized, a good mixing effect is obtained; ISO and POL do not flow backward relative to the center hole of the small piston during pouring, the color paste injection center hole of the small piston does not have obstruction fault, production efficiency is improved, processing time and maintenance time are saved, and cost for spare parts is reduced.

Owner:TIANHE FUAO AUTO SAFETY SYST CHANGCHUN

Method for repairing valve for filling nitrogen in manufacturing equipment of magnetron

A method for repairing nitrogen charging valve used on equipment for producing magnetron includes shearing damaged bellows in valve along vertical direction of its diameter , grinding two edges of corrugated sheet , applying high vacuum glue to bind two edges of said corrugated sheet and to let said glue fill full of seam of corrugated sheet , placing it in room temperature and drying it by air to let it be bound firmly , grinding it for ensuring evenness of vacuum glue to let it stretch out and draw back freely , setting repaired valve on leakage tester for checking whether repaired valve is on specification or not .

Owner:GUANGDONG WITOL VACUUM ELECTRONICS MFR

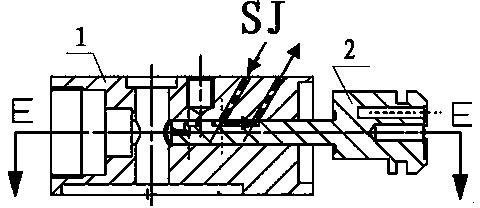

Sealing device for rolling mill CVC shifting roller coupling mechanism

ActiveCN105508432ARealize the sealing functionReduce leakageEngine sealsMetal rolling stand detailsCouplingEngineering

The invention provides a sealing device for a rolling mill CVC shifting roller coupling mechanism. The sealing device comprises a bearing seat, a coupling inner sleeve, a thrust self-aligning roller bearing sleeving the coupling inner sleeve, a roller side inner sleeve sleeving the coupling inner sleeve, a through cover, a gland, a sealing sleeve, a left compensation sealing sleeve and a right compensation sealing sleeve; the left compensation sealing sleeve and the right compensation sealing sleeve are respectively sealed with the through cover and the gland and can achieve radial and axial movement within a certain range in the inner chamber of the through cover; a spring circumferentially mounted in a through cover circular ring is propped against the outer circumferential surfaces of the left compensation sealing sleeve and the right compensation sealing sleeve to generate a pretightening force, so that the contact surface between the left compensation sealing sleeve and the sealing sleeve and the contact surface between the right compensation sealing sleeve and the sealing sleeve form mechanical sealing surfaces. According to the sealing device for the rolling mill CVC shifting roller coupling mechanism, the originally designed framework sealing is changed to be surface-surface mechanical sealing and a sealing surface formed by an O-ring; by dynamically compensating deviation of an eccentric angle, the sealing effect can be improved, and the leakage of lubricating oil is reduced; furthermore, emulsion is prevented from entering a lubrication system, the service lives of the thrust self-aligning roller bearing and the sealing sleeve are prolonged, and the costs of spare parts and the maintenance time are reduced.

Owner:HANGANG GRP HANBAO IRON & STEEL

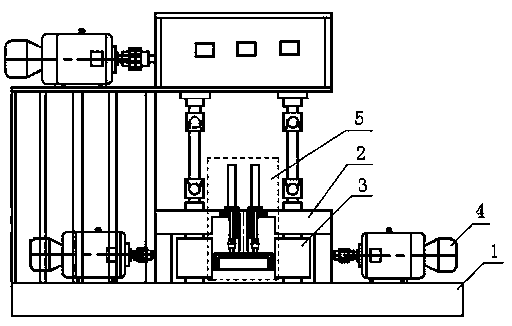

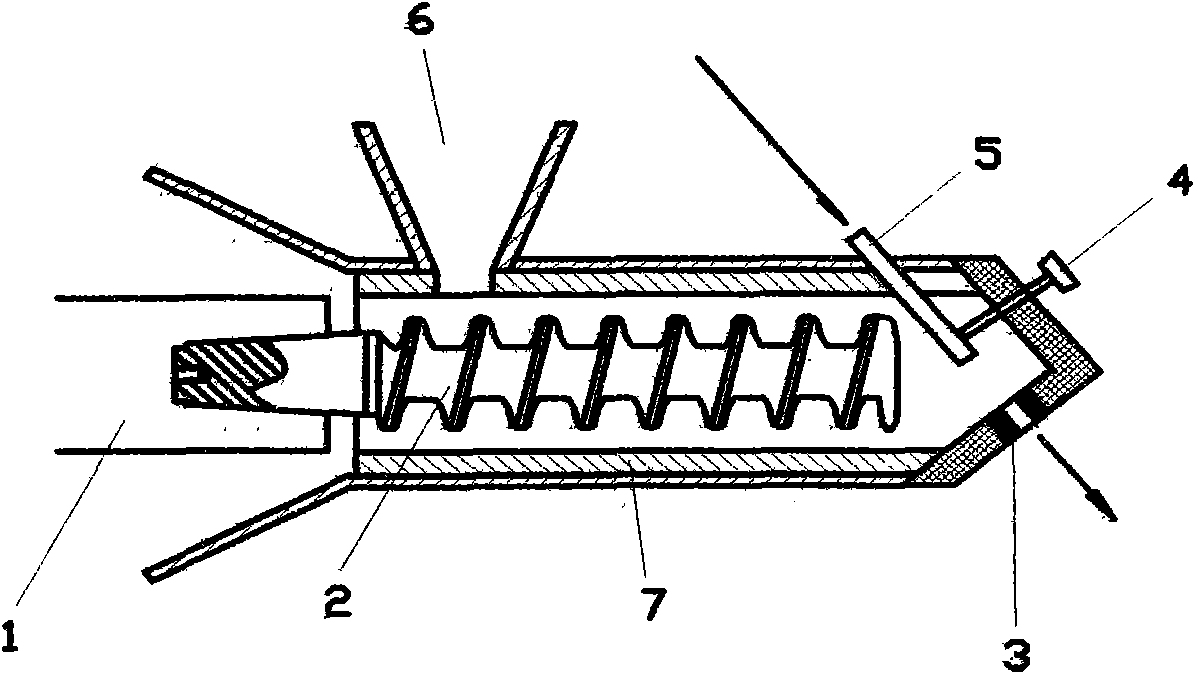

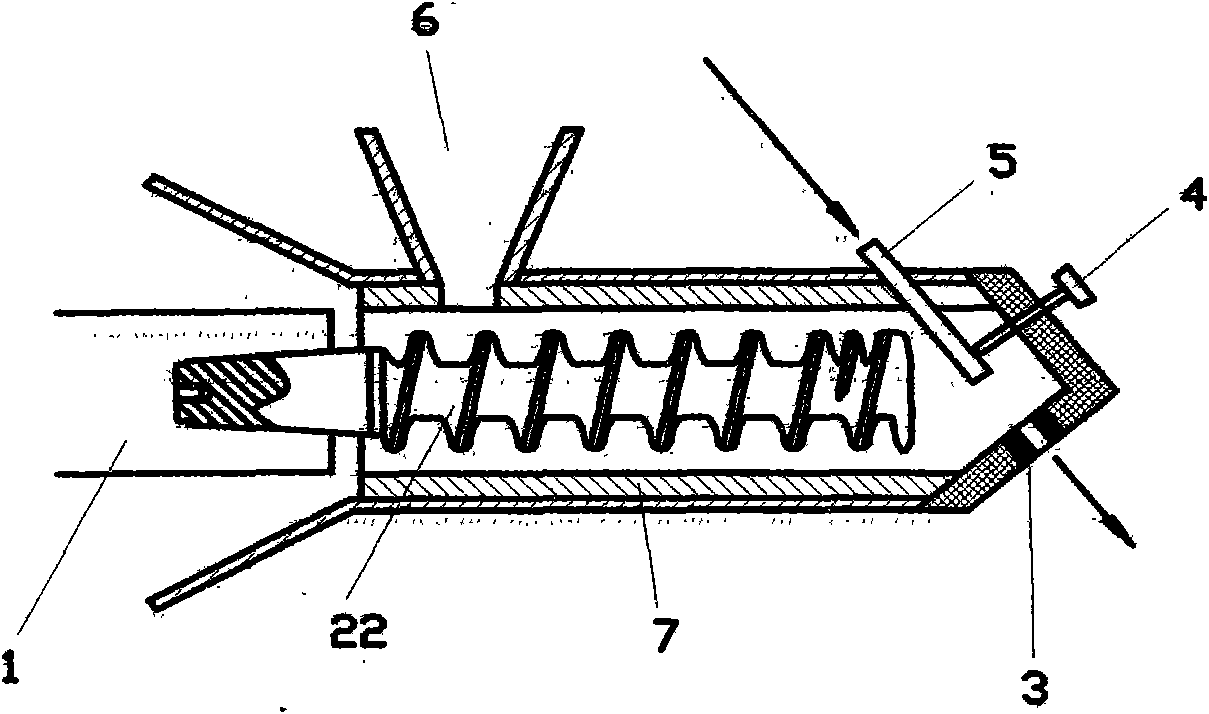

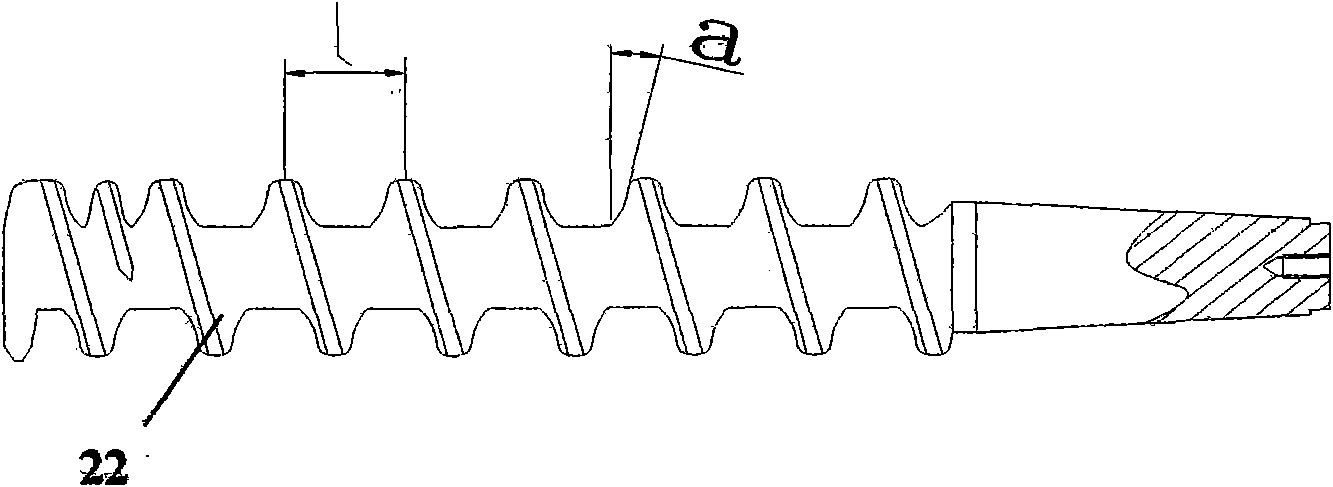

Welding rod spiral extrusion press with double-fastened reamer head

InactiveCN101767257AEasy to operateProficiency in refilling skillsWelding/cutting media/materialsSoldering mediaSkill setsEngineering

The invention provides a welding rod spiral extrusion press with a double-fastened reamer head. The welding rod spiral extrusion press comprises a powder cylinder with a powder-feeding inlet, a spiral reamer, a power source and a wire-feeding mechanism; the spiral reamer is arranged in the powder cylinder; the power source is connected with the spiral reamer; the wire-feeding mechanism is communicated with the powder cylinder; and the head of the spiral reamer is double-fastened. The invention has the following advantages that: the capacity is 25 percent higher than before; a bamboo stick is not needed any more to push powder into the powder cavity of the cylinder, and thereby the labor intensity of power feeding is reduced; the power-feeding skill can be skillfully mastered after three days of training; operation is simple; the service lives of the parts are prolonged; since the head of the spiral reamer is double-fastened, the rotating speed of the reamer is reduced, the service lives of the parts are prolonged, the average service life of the powder cylinder is about 15 days, the average service life of the spiral reamer is about 7 days, the powder cylinder can be repetitively repaired and used, consequently, the expense on the parts is reduced, and more than 200,000 yuan can be saved annually.

Owner:TIANJIN GOLDEN BRIDGE WELDING MATERIALS GRP

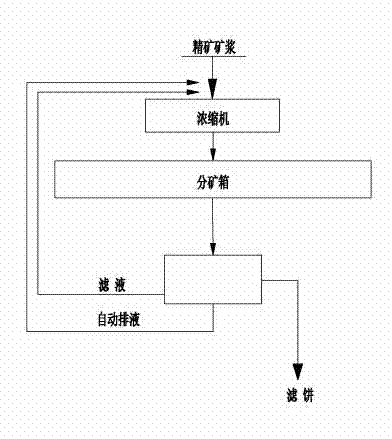

Process for concentrating and filtering magnetite concentrate

The invention relates to the technical field of thickening of magnetic concentrate, in particular to a process for concentrating and filtering magnetite concentrate. The process for concentrating and filtering the magnetite concentrate is characterized by comprising the following steps of: feeding floated and conveyed concentrate with the pulp concentration of 30 to 50 percent into a concentrator, wherein -200-mesh pulp accounts for 95 percent in terms of pulp particle size; dehydrating the floated and conveyed concentrate pulp by using the concentrator; conveying the dehydrated concentrate pulp with the concentration reaching 60 to 65 percent to a distributing box through a group of concentrate pumps; and distributing and conveying the concentrate pulp to a filter by using the distributing box, and filtering the concentrate pulp by the filter to obtain a filter cake, namely a concentrate product, the moisture content of which is 9 to 10 percent, wherein the filtrate and automatic drainage liquid generated by the concentrator are returned to the concentrator. The process for concentrating and filtering the magnetite concentrate has the following benefits that: the floated and conveyed concentrate is directly conveyed to the concentrator to be concentrated, thus the using efficiency of the concentrator is improved; spare parts of the equipment are reduced, the concentration process is optimized, and further the energy consumption is reduced; and on the premise of not reducing the quality of concentrate, loss of metal is reduced, and the yield of iron ore concentrate is increased.

Owner:ANSTEEL GRP MINING CO LTD

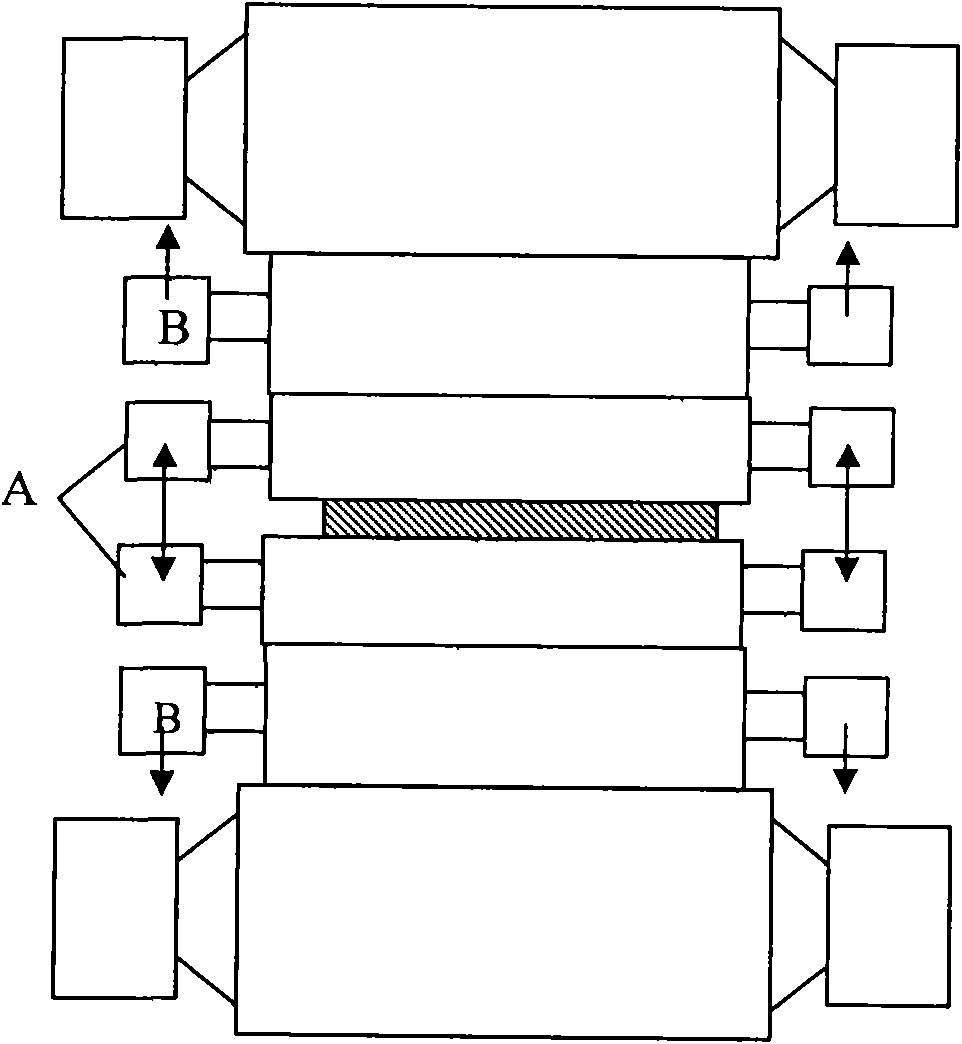

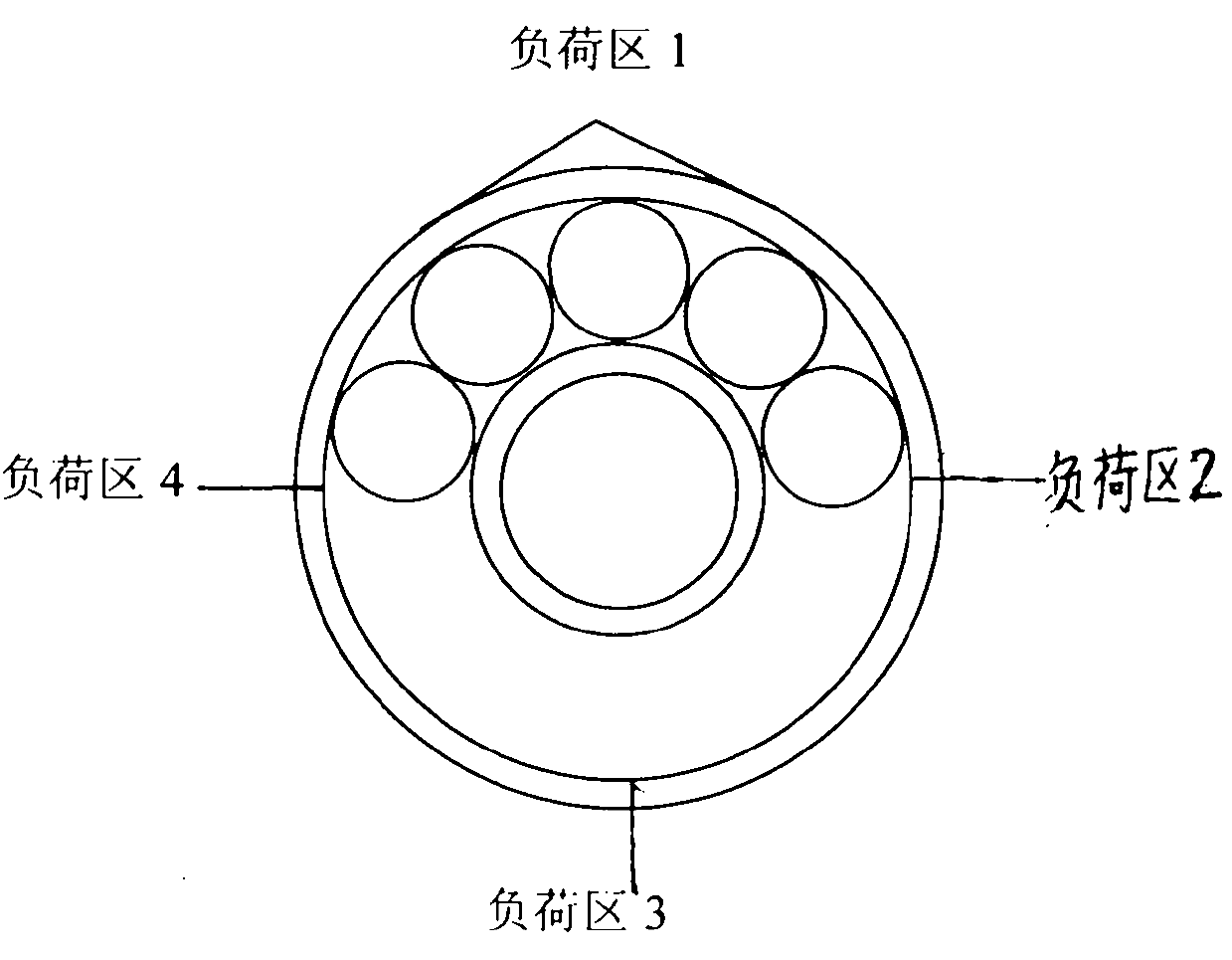

Reutilization method of work roll bearing and intermediate roll bearing of cold rolling mill

ActiveCN102000700AExtended service lifeExtend your online timeMetal rolling stand detailsMetal rolling arrangementsWork rollEngineering

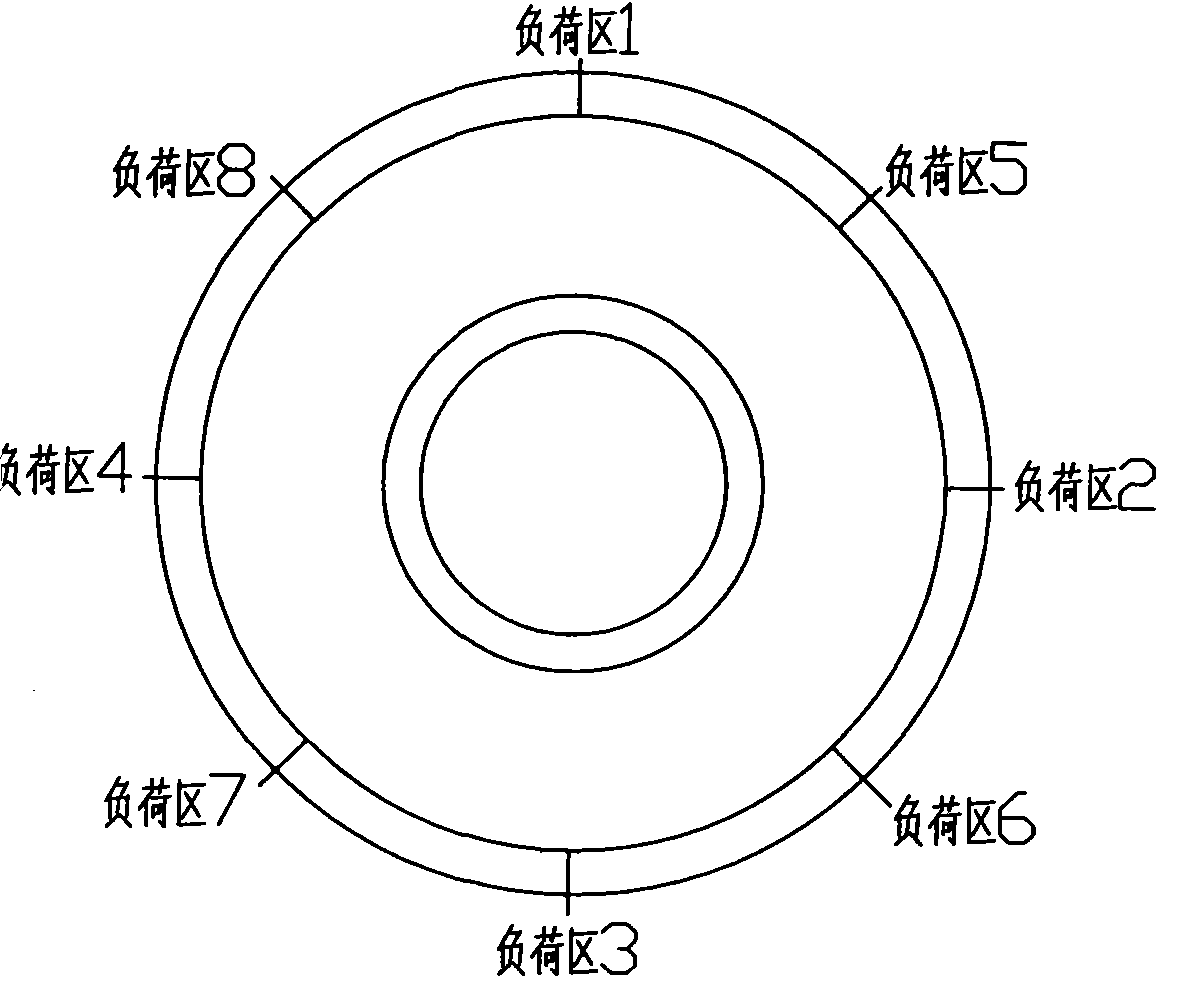

The invention discloses a reutilization method of a work roll bearing and an intermediate roll bearing of a cold rolling mill, which comprises the following steps: selecting one from bearings which are subjected to normal abandonment after four work load areas have been utilized; dividing the outer ring of the bearing into four new work load areas: selecting the middle position of a first work load area and a second work load area as a fifth work load area, selecting the middle position of the second work load area and a third work load area as a sixth work load area, selecting the middle position of the third work load area and a fourth work load area as a seventh work load area, and selecting the middle position of the fourth work load area and the first work load area as an eighth work load area; and then, regulating the outer ring of the bearing in the fixed direction of the bearing receiving a roll-bending force to the fifth work load area for first on-line utilization, regulating the work load area to the seventh work load area for on-line utilization after checking whether the bearing is in good condition three months later, and deducing the rest by analogy until the sixth work load area and the eighth work load area are utilized before being abandoned again. The method prolongs the service life of the bearing of the rolling mill.

Owner:MAANSHAN IRON & STEEL CO LTD

Method for repairing moving cone of cone crushing machine

The invention discloses a method for repairing a moving cone of a cone crushing machine, belongs to a mine crushing device, and particularly relates to a crushing machine part. The method for repairing the moving cone by M220 bolt sticking comprises the following steps: 1, setting process hasps; 2, mounting a vertical lathe; 3, cutting away exposed bolts; 4, removing residual bolts in the moving cone and carrying out secondary processing by the steps as follows: 1) drilling for the first time, 2) expanding for the first time, 3) removing scraps, 4) drilling for the second time, 5) expanding for the second time, and 6) removing bolt residues; 5, removing the process hasps; and 6, reassembling. Compared with the prior art, the method has the advantages of novel concept, reasonable repair process, simple facilities, high efficiency, quickness in recovery, favorability for ore crushing production, and capabilities of repairing the old, utilizing the waste, making the best use of everything, saving the resources, reducing the spare part expense and lowering the production cost.

Owner:MAGANG (GROUP) HOLDING CO LTD +1

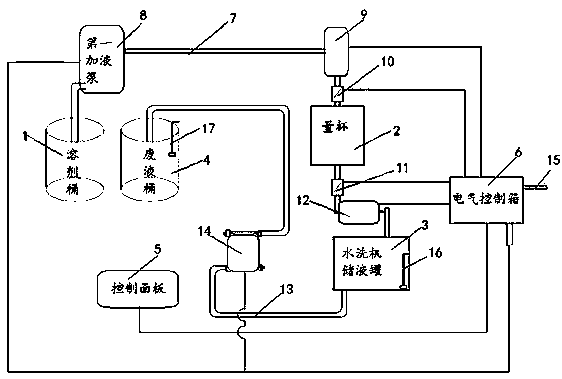

Soldering flux flow intelligent display monitoring system

InactiveCN110842322AReduce traffic instabilityAvoid the problem of poor solder jointsPrinted circuitsMetal working apparatusFlow transducerControl engineering

The invention discloses a soldering flux flow intelligent display monitoring system. The soldering flux flow intelligent display monitoring system is used for spraying soldering flux to a PCB board ona board conveying rail. The system comprises a pressure fluid storage barrel and a nozzle, wherein the nozzle communicates with the pressure fluid storage barrel through a first pipe. The soldering flux in the pressure fluid storage barrel is conveyed towards the nozzle under the action of the air pressure in the pressure fluid storage barrel. The nozzle is connected with a first electronic air valve and a second electronic air valve through a second pipe. The first pipe is provided with an electronic fluid valve and a flow sensor. The electronic fluid valve, the flow sensor, the first electronic air valve and the second electronic air valve are connected with a controller. The flow sensor is used for detecting the flow value of the soldering flux flowing through the first pipe. The controller is used for controlling the electronic fluid valve to control the flow of the soldering flux which passes through the first pipe. The soldering flux flow intelligent display monitoring system can monitor the actual amount of soldering flux in real time, and therefore, it is guaranteed that soldering flux spraying is stable in production.

Owner:FLEXTRONICS ELECTRONICS TECH SUZHOU

Maintenance method of insulation refractory material for horizontal beam of heating furnace

The invention discloses a maintenance method of insulation refractory material for a horizontal beam of a heating furnace and belongs to the technical field of maintenance of steel rolling heating furnaces. The maintenance method includes: 1, preparing before the maintenance of the insulation refractory material for the horizontal beam of the heating furnace; 2, maintaining the insulation refractory material for the horizontal beam of the heating furnace. By the use of the maintenance method, the defects that the damaged insulation refractory material on the upper portion of the traditional horizontal beam of the metallurgical step heating furnace needs long field maintenance time, replacement is difficult and maintenance cost is high are overcome. The maintenance method has the advantages that the construction time can be shortened to half of the original time on the premise of meeting users' needs, maintenance cost can be reduced to less than one third of the original cost, maintenance cost can be reduced and maintenance construction time can be greatly shortened on the premise of guaranteeing the service life by the use of the maintenance technique of the damaged insulation refractory material on the upper portion of the horizontal beam, and economic benefit is significant.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

Mechanical switch device

InactiveCN106898509ASimple structureEliminate potential safety hazardsContact operating partsEconomic benefitsMechanical engineering

The invention discloses a mechanical switch device, which comprises an inclined grate bar support seat (17) and an inclined grate bar (16). A shaft sleeve (3) is arranged on the shaft (1), the inner diameter of the shaft sleeve (3) is larger than the outer diameter of the shaft (1), and the shaft sleeve (3) rotates flexibly; arcs are respectively arranged on both sides of the shaft sleeve (3) shaped working arm (4) and counterweight arm (6); the two sides under the head of the arc-shaped working arm (4) are respectively provided with pin lugs (5), and a flat iron is set between the two pin lugs (5). (14); a counterweight (7) is provided above or below the tail of the counterweight arm (6); a stopper (10) is provided on the support seat (17) of the inclined grate bar, and the stopper (10) It is located under the counterweight arm (6); a proximity switch (15) is provided under the flat iron (14), and the proximity switch (15) is connected to the digital input module of the PLC through wires; the structure is simple, the production is simple, and the cost is low , easy to install, high reliability, ensure the safety of production and equipment, and effectively improve the economic benefits.

Owner:烟台鲁宝钢管有限责任公司

Wire rod wire rolling line guide groove and method for preventing wire rod rolling line from being scratched

ActiveCN108405638AReduce mechanical scratches/abrasionsImprove surface qualityGuiding/positioning/aligning arrangementsWire rodRolling resistance

The invention discloses a wire rod rolling line guide groove and a method for preventing a wire rod rolling line from being scratched. The wire rod rolling line guide groove comprises a guide groove base, wherein a guide groove allowing a wire rod rolled piece to pass through is formed in the guide groove base, and a guide roller assembly capable of freely rotating is arranged at one end of the guide groove base; and the guide roller assembly comprises a first guide roller, a second guide roller and a third guide roller, the first guide roller is connected to a guide groove cover plate througha support, the second guide roller and the third guide roller are symmetrically arranged on the guide groove base, and one end of the guide groove can freely rotate along the guide groove base. The guide groove is of a U-shaped groove structure, a guide rail formed by the corresponding second guide roller and the third guide roller is of a U-shaped groove structure, and the first guide roller isarranged at the open end of the guide rail U-shaped structure. The wire rod rolling line guide groove is installed at a climbing position of a rolling line straight line section, so that the traditional friction form between the four sides of the wire rod rolled piece at the climbing position and the guide groove is changed, the sliding friction is changed into rolling friction, the mechanical scratching of the wire rod rolled piece in the rolling process is reduced, and the surface quality of finished products is improved.

Owner:MAANSHAN IRON & STEEL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com