Reutilization method of work roll bearing and intermediate roll bearing of cold rolling mill

A technology of work rolls and cold rolling mills, applied in the direction of metal rolling stands, metal rolling mill stands, metal rolling, etc., can solve the problems of low effective utilization rate of bearings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

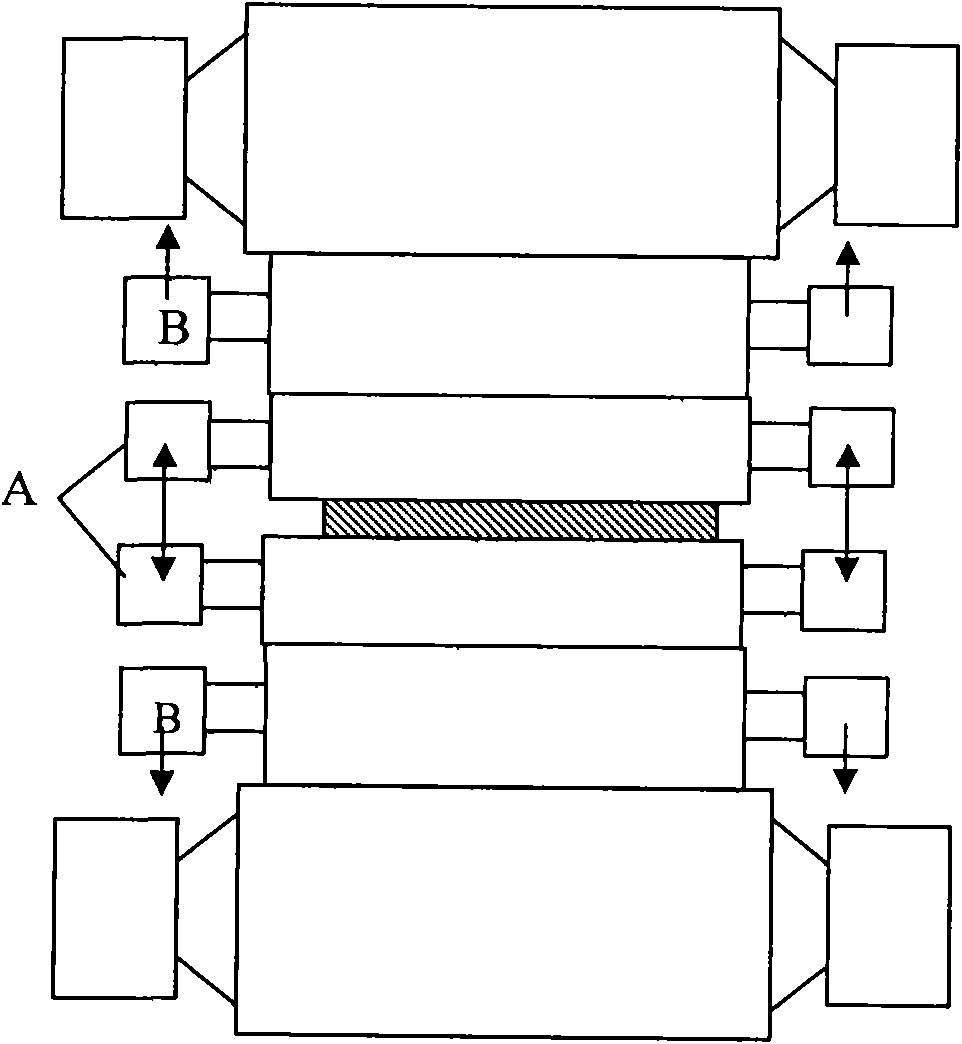

[0012] The reutilization method of cold rolling mill work roll bearing and intermediate roll bearing of the present invention, its steps are:

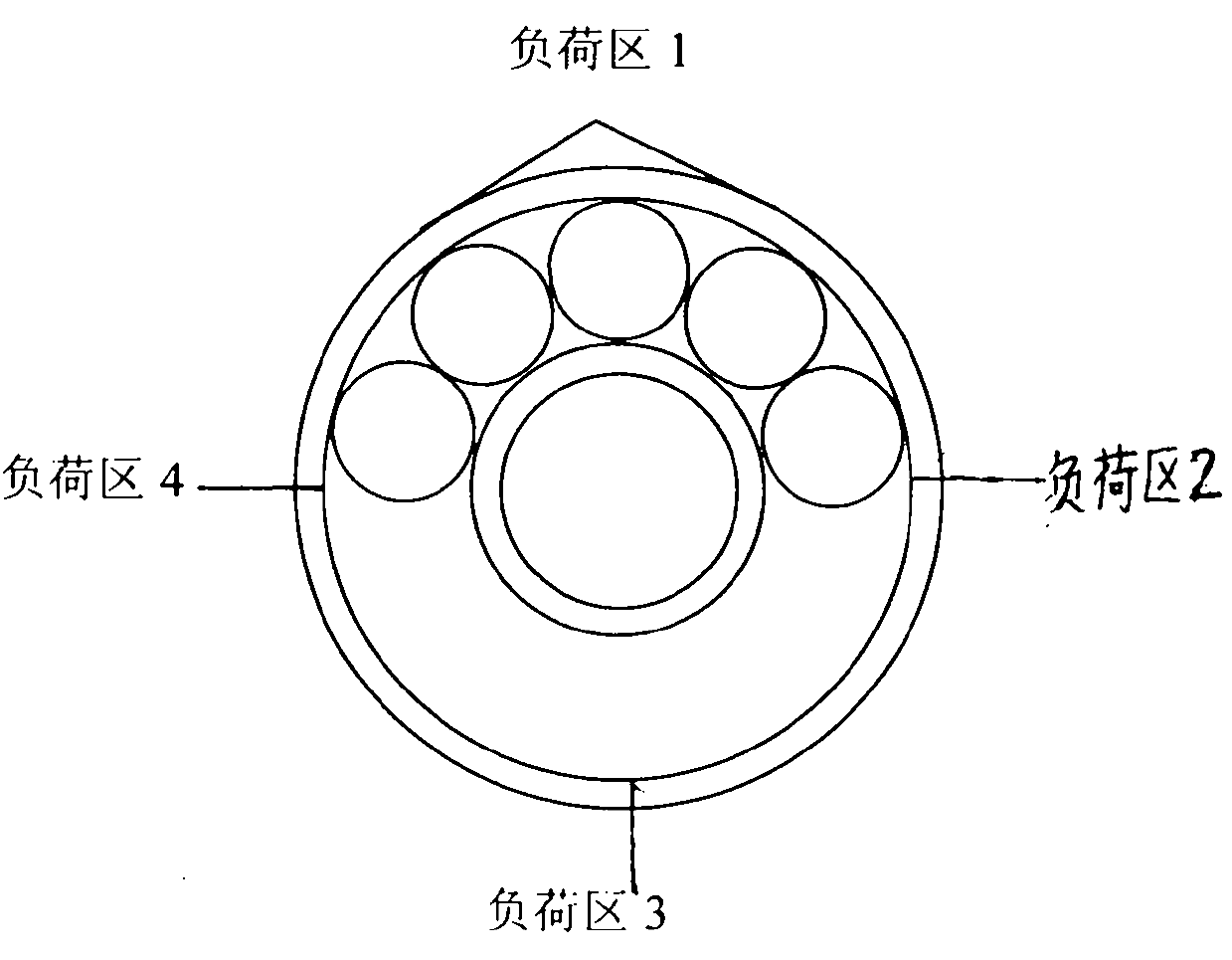

[0013] (1) First, select bearings from the bearings that have been scrapped normally after using the 1st, 2nd, 3rd, and 4th four working load areas, and check whether the outer ring, inner ring, roller and cage of the bearing are intact ;

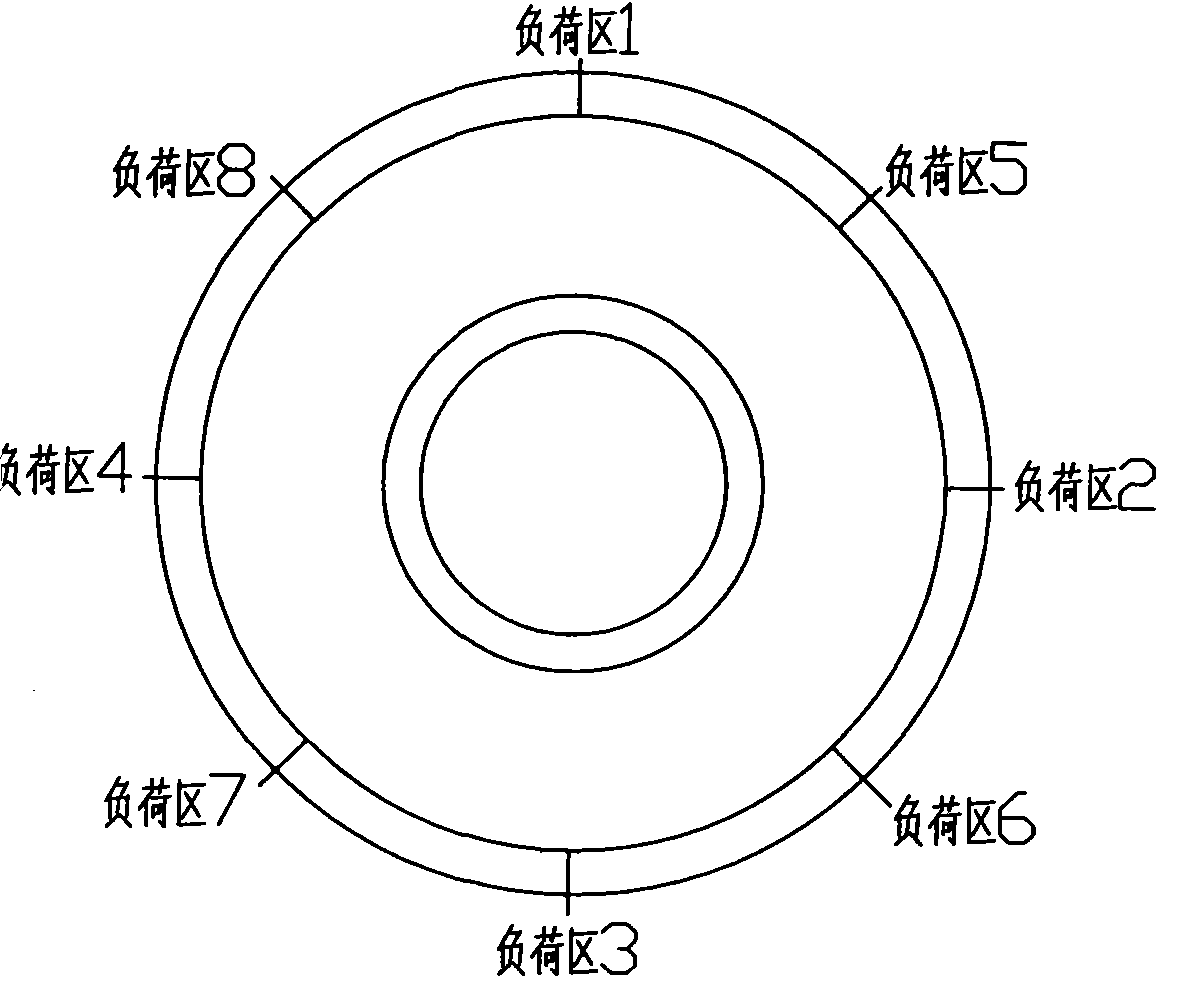

[0014] (2) Divide four new work load areas on the outer ring of the inspected bearing: that is, select the middle position of the first and second work load areas as the fifth work load area, and the second and third work load areas The middle position of is the 6th workload zone, the middle position of the 3rd and 4th workload zone is the 7th workload zone, and the middle position of the 4th and 1st workload zone is the 8th workload zone;

[0015] (3) Adjust the outer ring of the bearing to the 5th working load area in the fixed direction where the bearing bears the bending force After the roller...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com