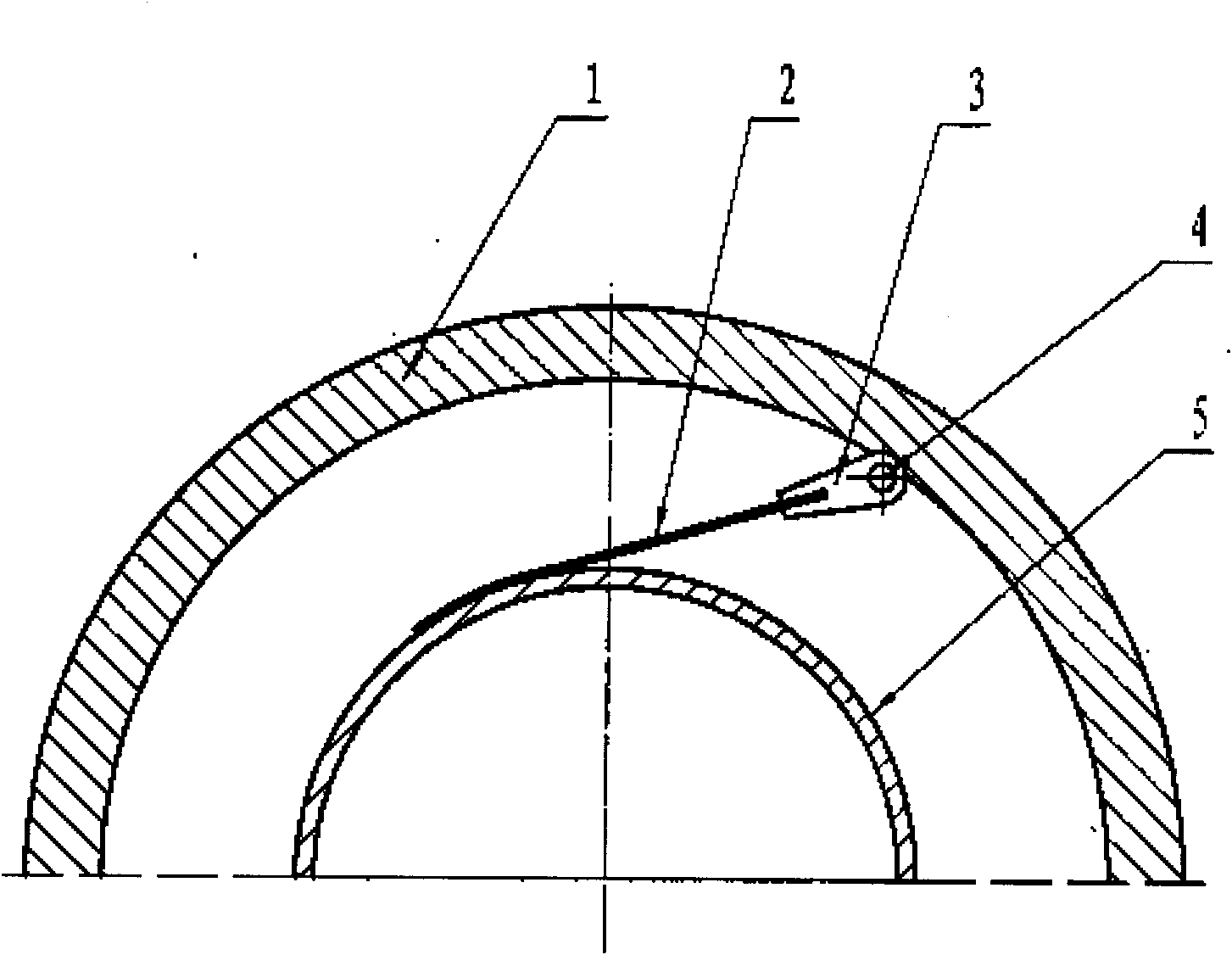

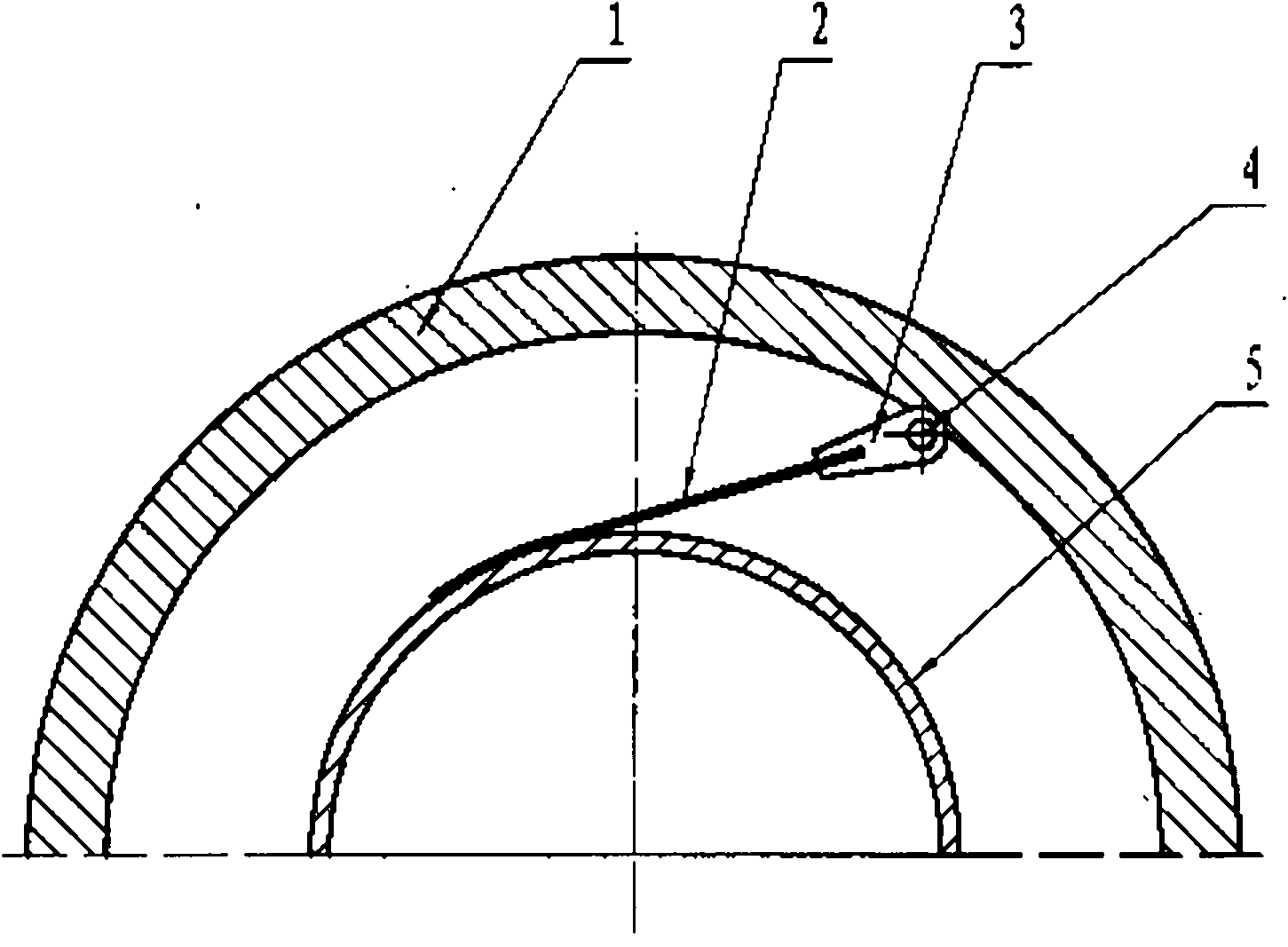

Rotary kiln heavy gear ring repairing method

A large ring gear and rotary kiln technology, applied in the direction of rotary drum furnace, furnace, lighting and heating equipment, etc., can solve the problems of increasing construction procedures, and achieve the effect of saving repair time and omitting installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0016] During the maintenance operation of the large ring gear of the rotary kiln, the specific operation steps are as follows:

[0017] 1. Set the rotary kiln tool.

[0018] 2. Measure the original radial runout of the large ring gear and the lower barrel section of the large ring gear.

[0019] 3. Stop the large ring gear in a horizontal position, remove the large ring gear counterpart bolts, and locate the pin bolts.

[0020] 4. Cut off the spring ear plate and remove the upper half ring gear.

[0021] 5. Rotate the kiln body, turn the lower half of the ring gear to the upper side, cut off the spring ear plate, and remove the lower half of the ring gear.

[0022] 6. Clean up the residual welding meat and iron oxide on the spring plate. After processing, each spring plate should be tested with the processed lug plate.

[0023] 7. Clean and align the large ring gear.

[0024] 8. Install the large ring gear

[0025] 8.1 When hoisting the ring gear, it should be lowered f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com