Patents

Literature

67results about How to "Skip the installation process" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

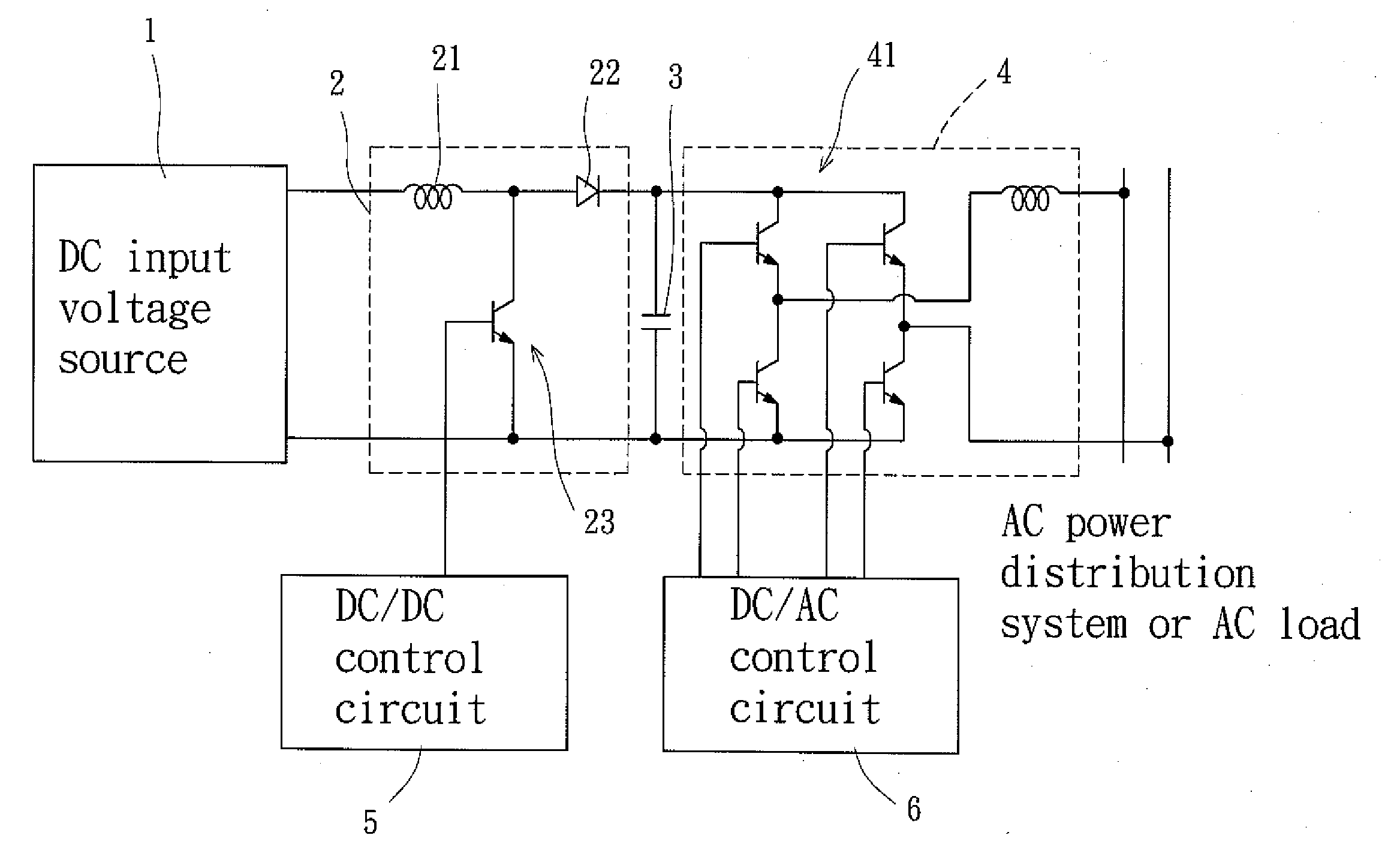

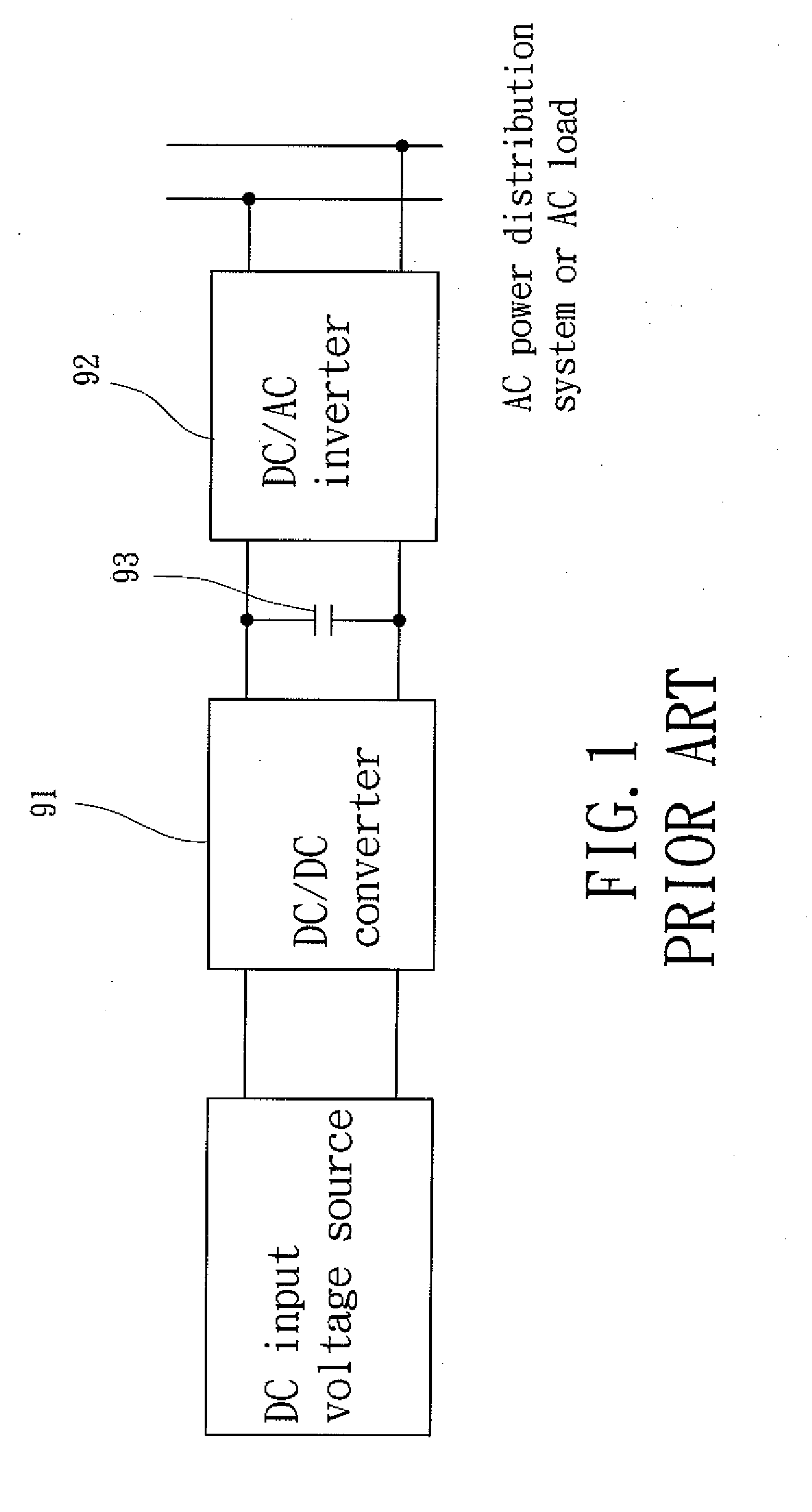

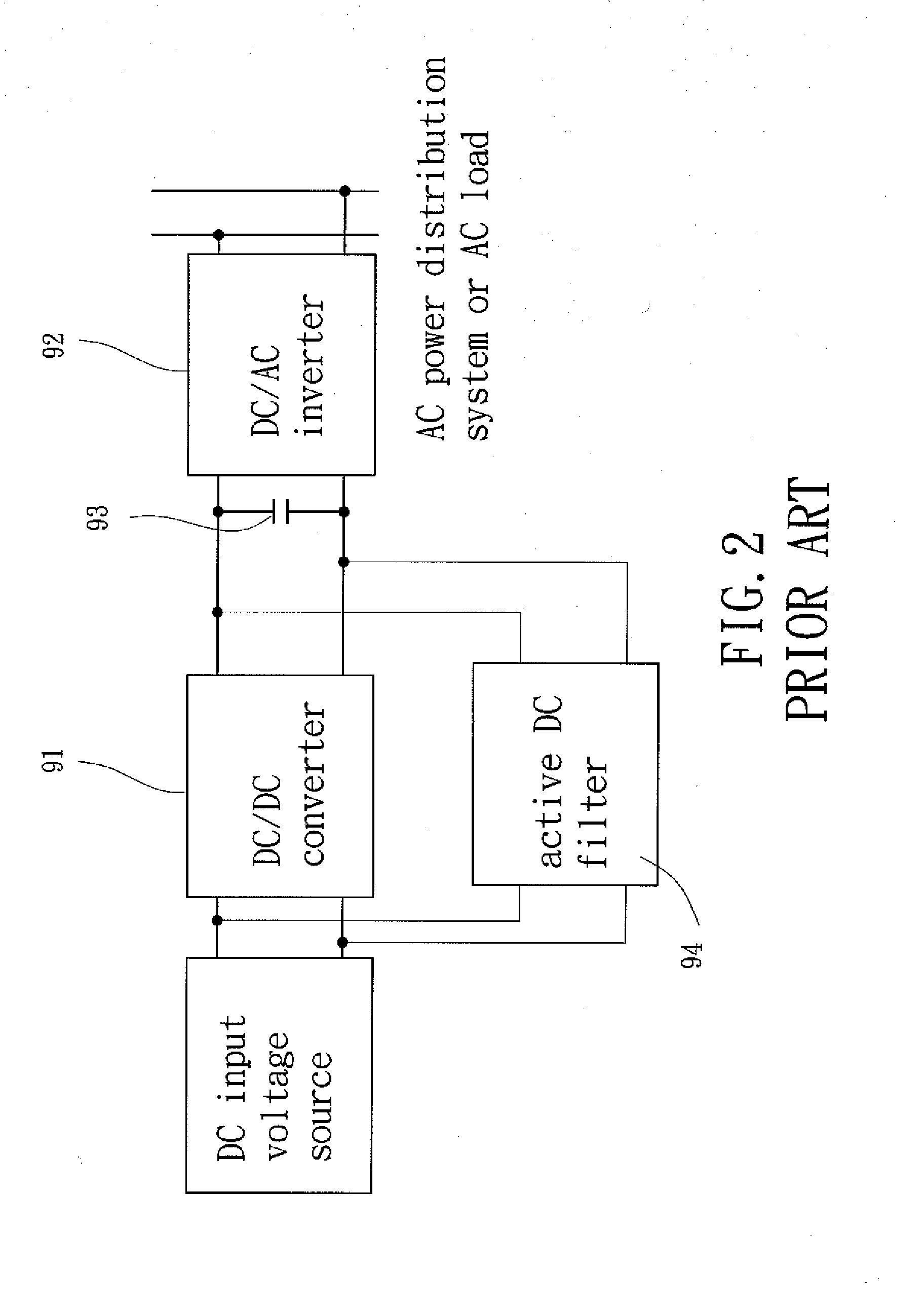

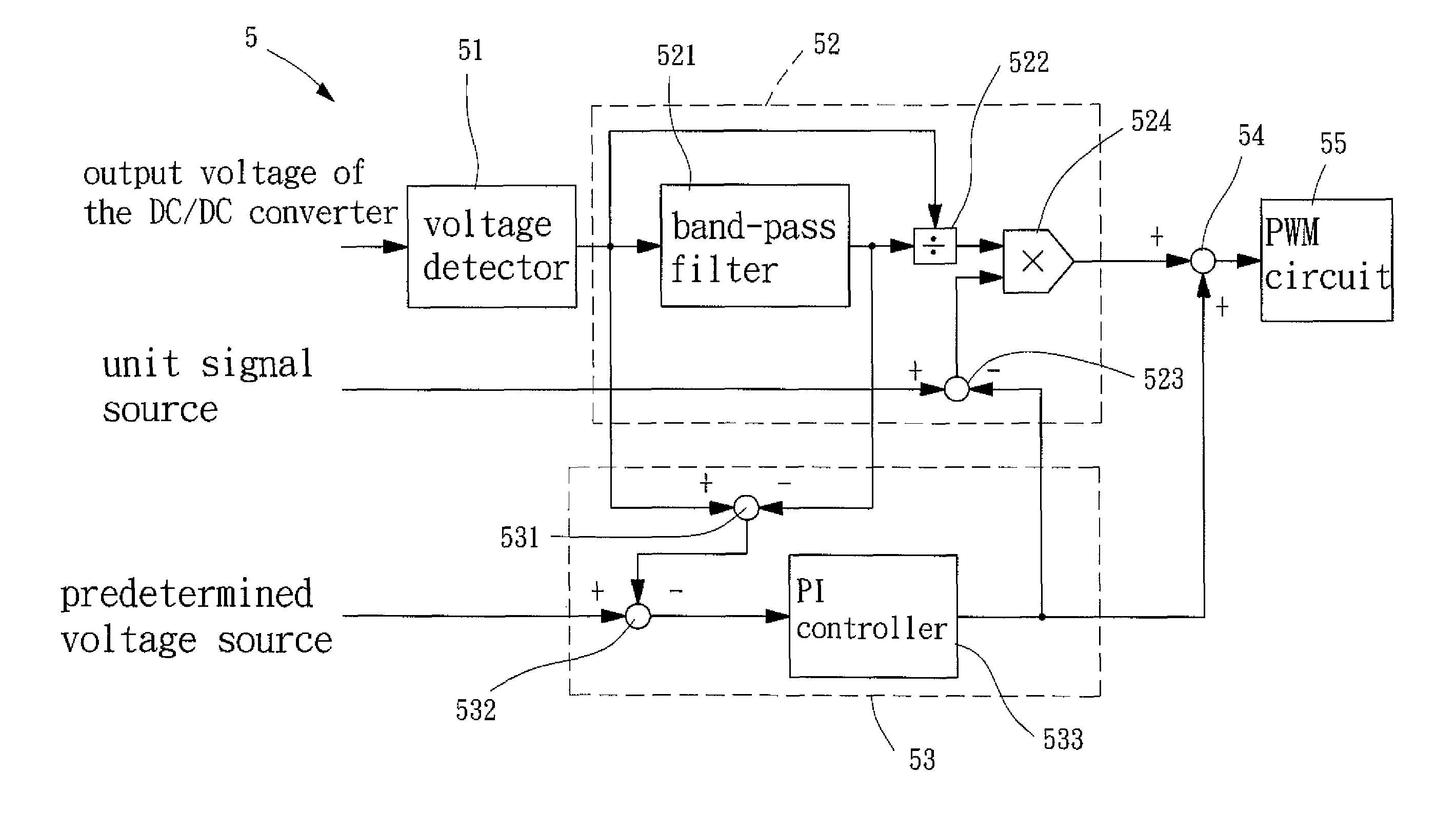

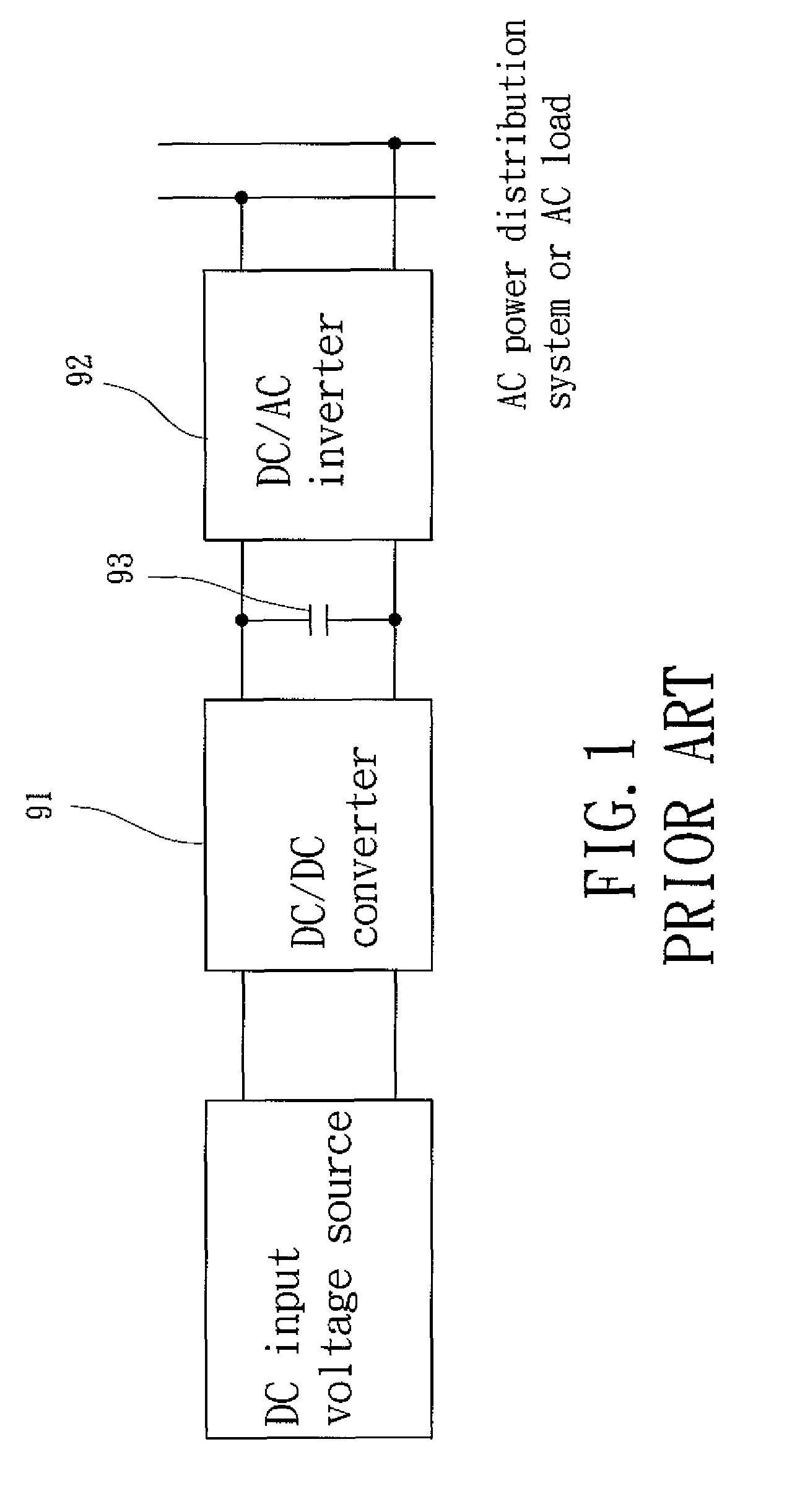

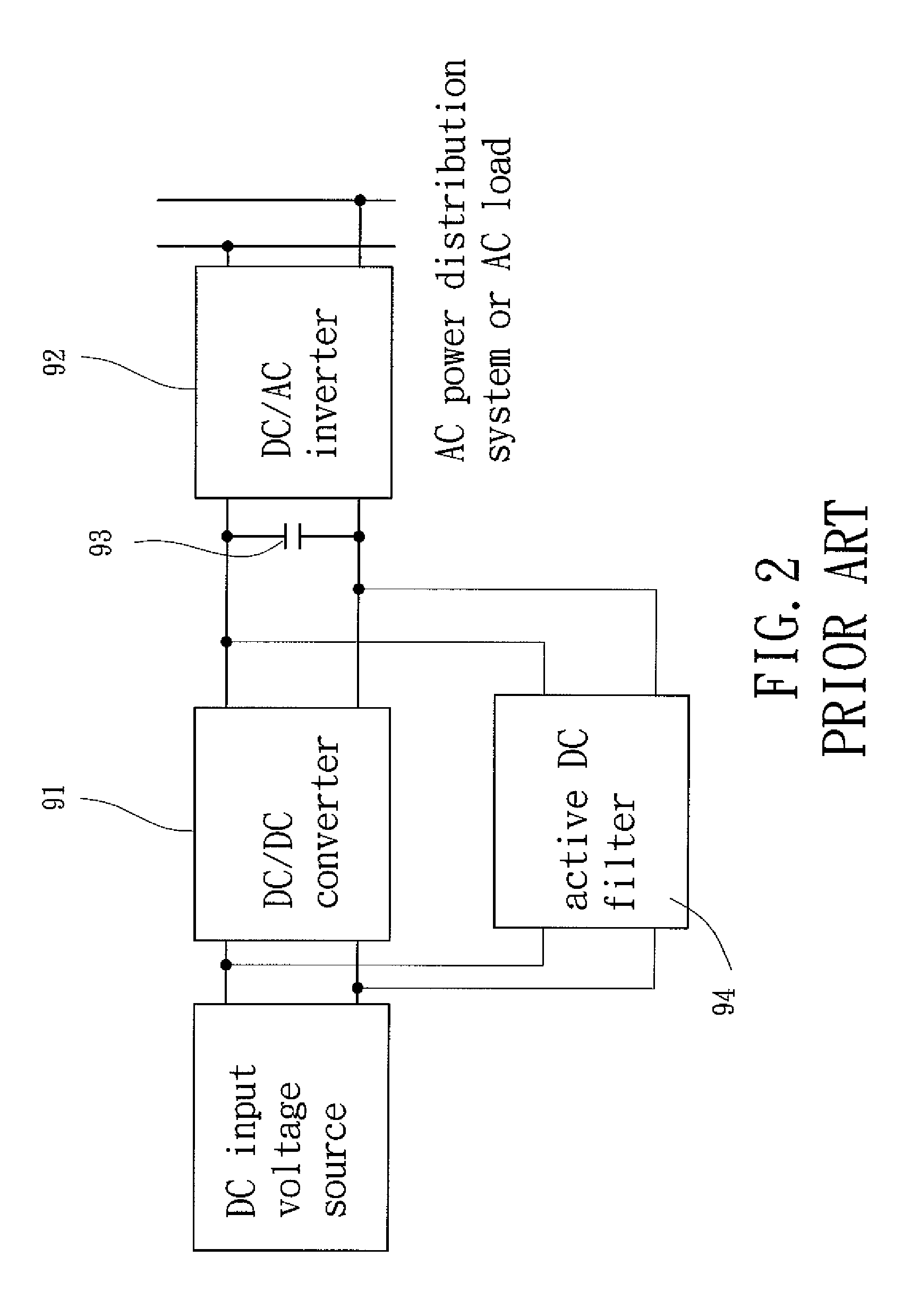

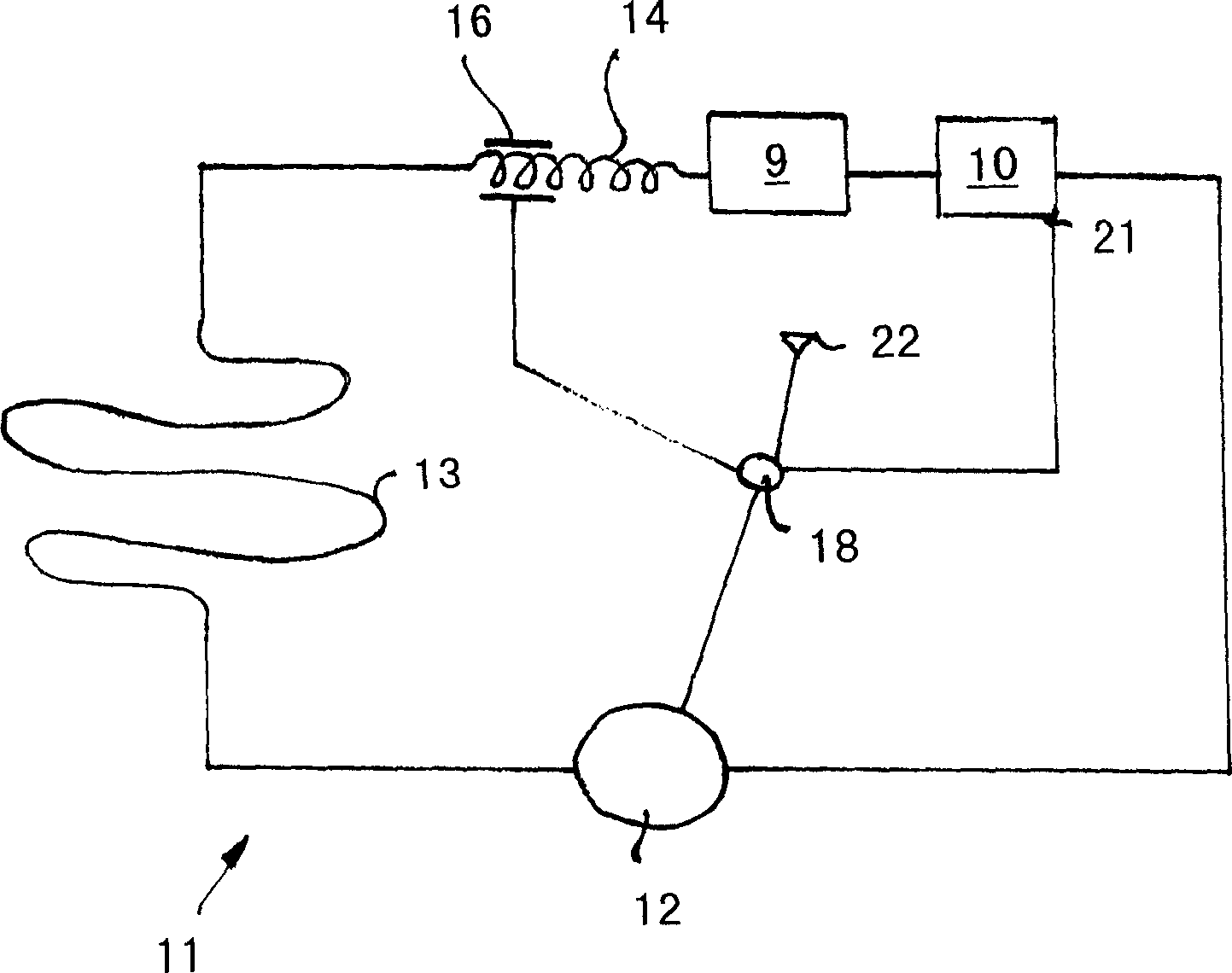

Ripple Voltage Suppression Method for DC/DC Converter and Apparatus Thereof

ActiveUS20100085784A1Improve efficiencyLow costConversion with intermediate conversion to dcDc-dc conversionControl signalElectronic switch

A ripple voltage suppression apparatus includes a DC / DC converter and a control circuit. The DC / DC converter has a power electronic switch. The control circuit has a voltage detector detecting a DC output voltage of the DC / DC converter, a ripple voltage suppression circuit receiving the detected DC output voltage to generate an AC control signal for controlling an AC component of a duty ratio of the power electronic switch, an output voltage regulation circuit receiving the detected DC output voltage to generate a DC control signal for controlling an DC component of a duty ratio, an adder adding the AC and DC control signals to form a combined control signal, and a PWM circuit converting the combined control signal into a PWM signal to control the power electronic switch. Only the DC output voltage of the DC / DC converter has to be detected for the control circuit.

Owner:ABLEREX ELECTRONICS CO LTD

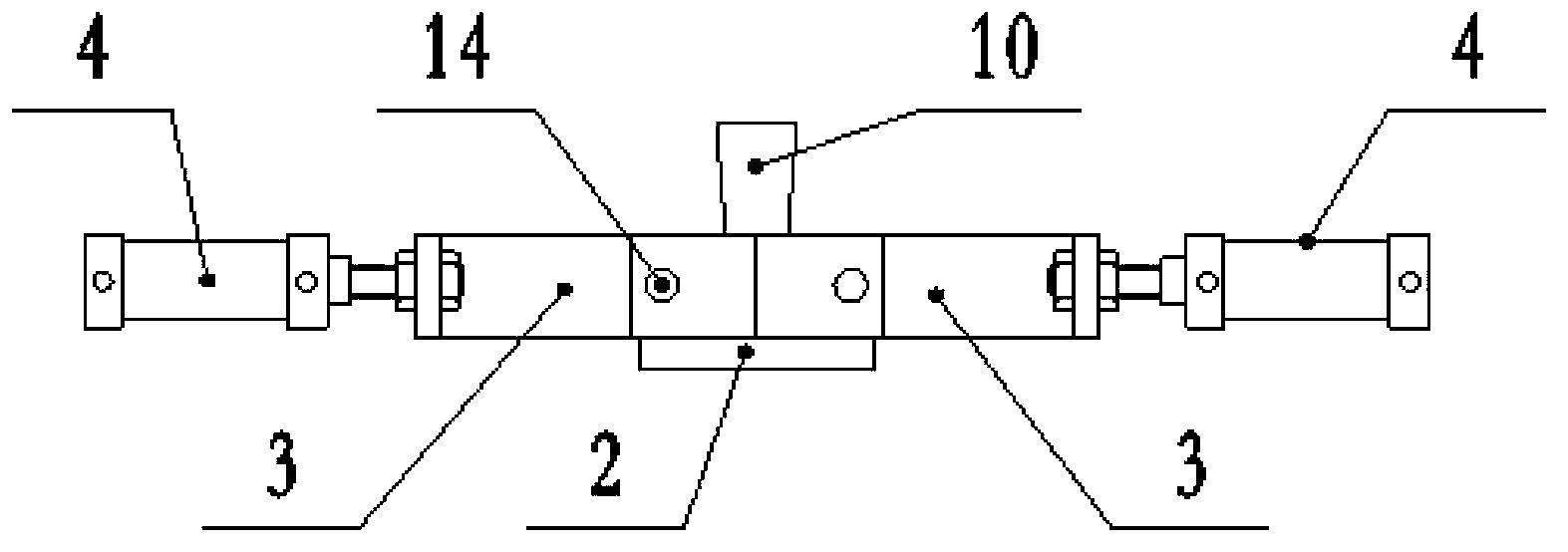

Nanometer electric generator utilizing sliding friction and electricity generating method

ActiveCN103368453ASkip the installation processPackaging technology is convenientFriction generatorsExternal circuitElectricity

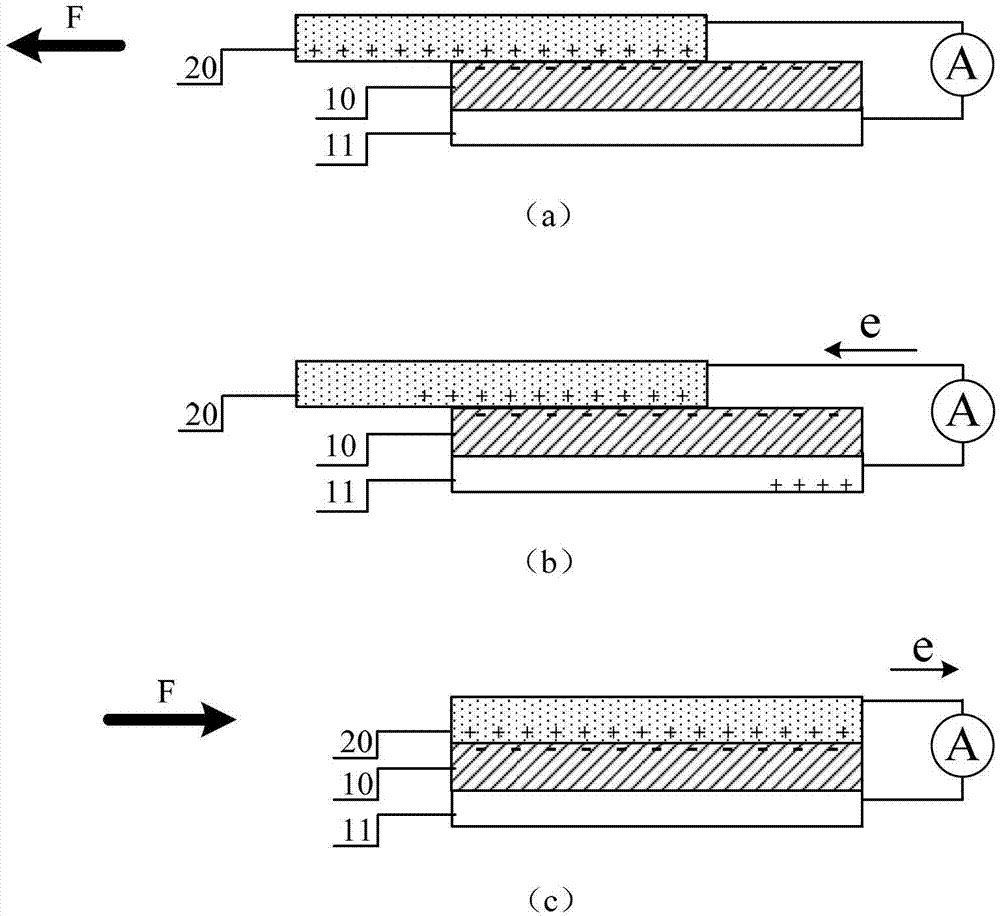

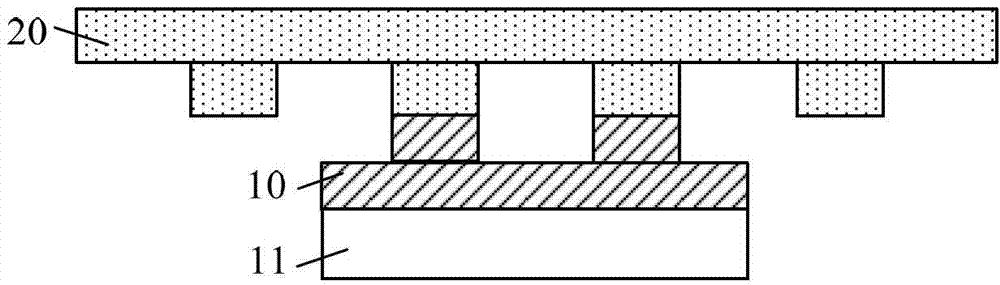

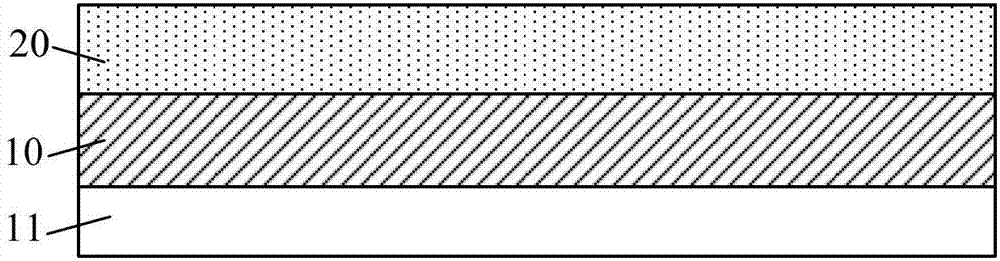

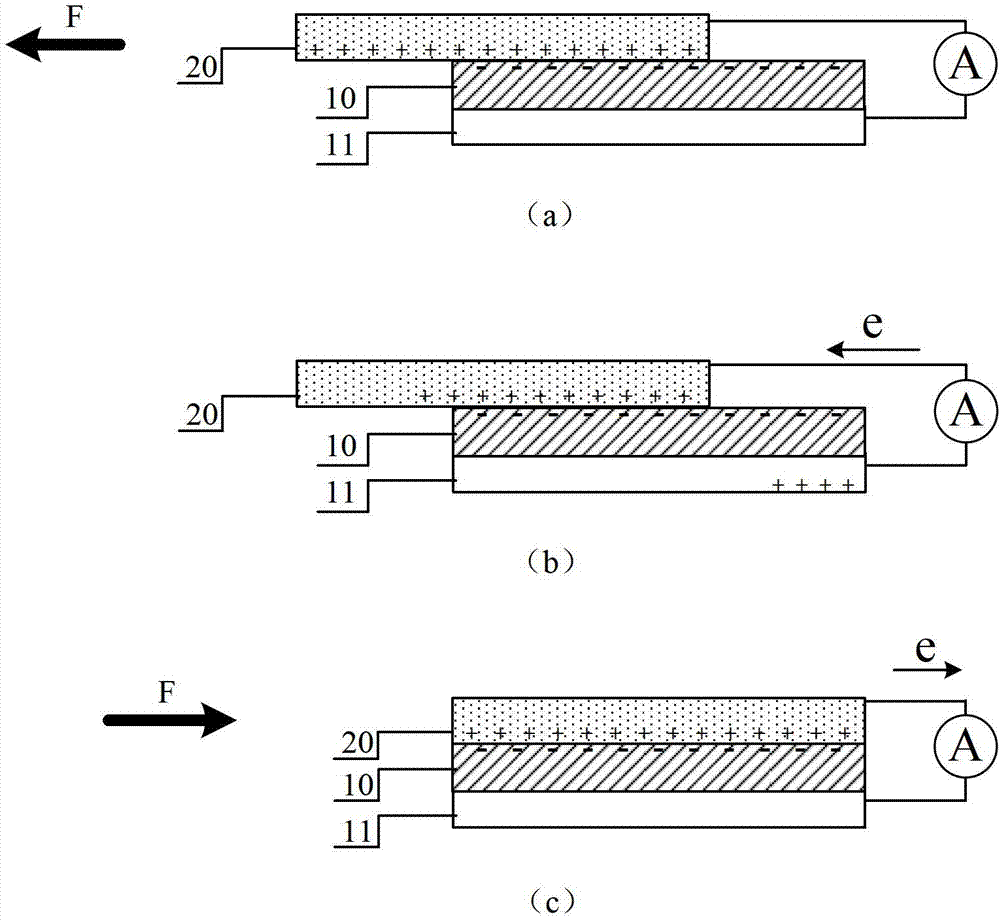

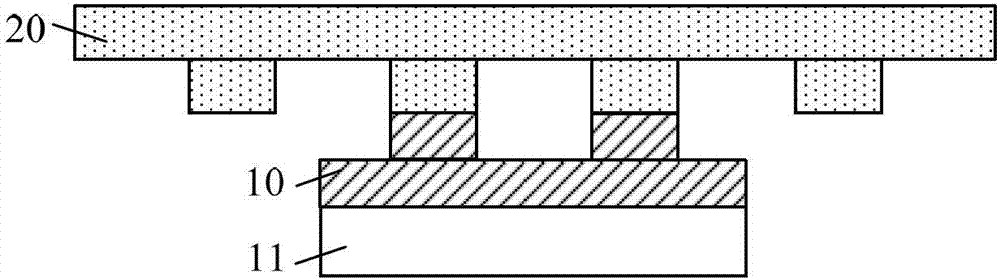

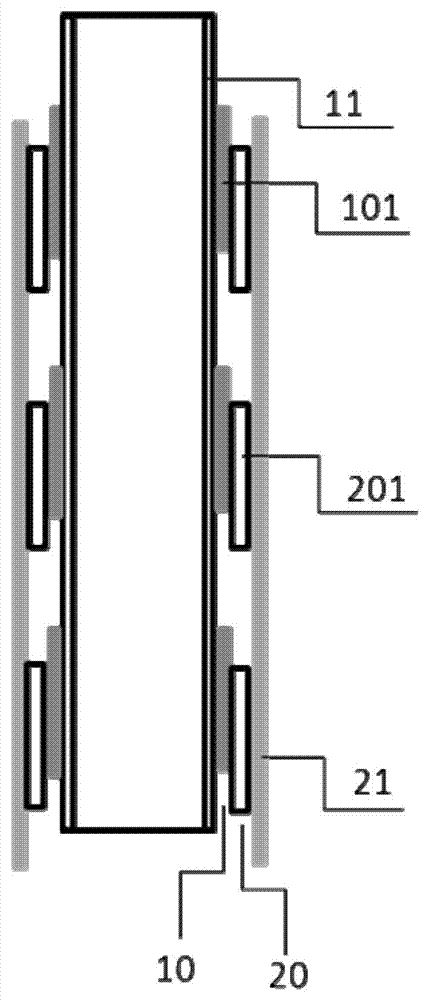

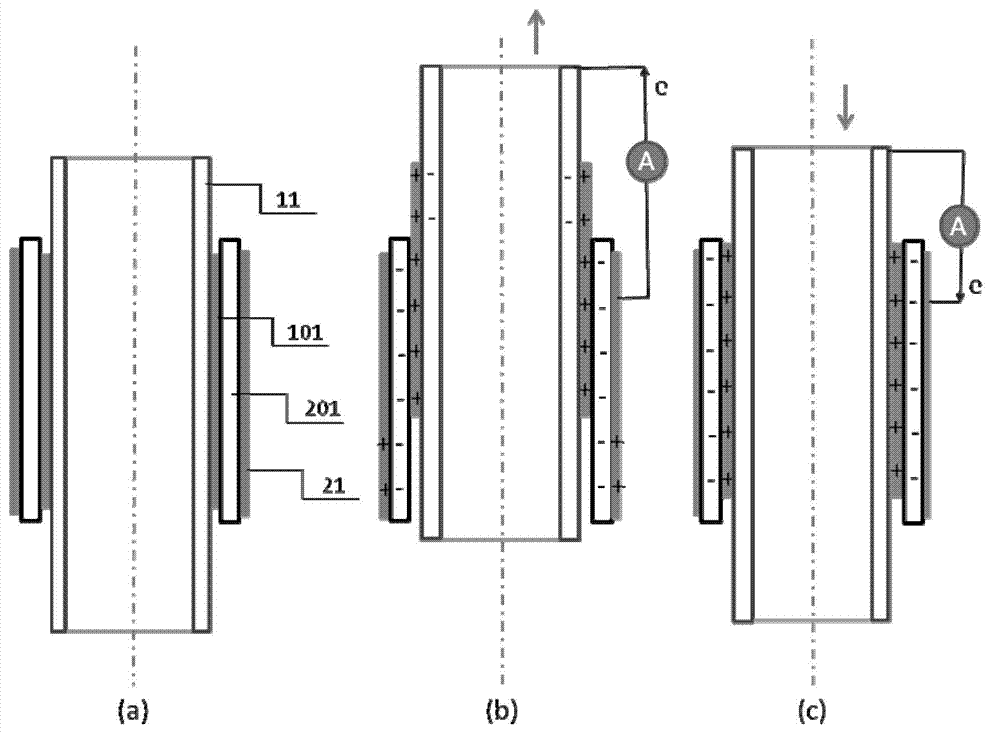

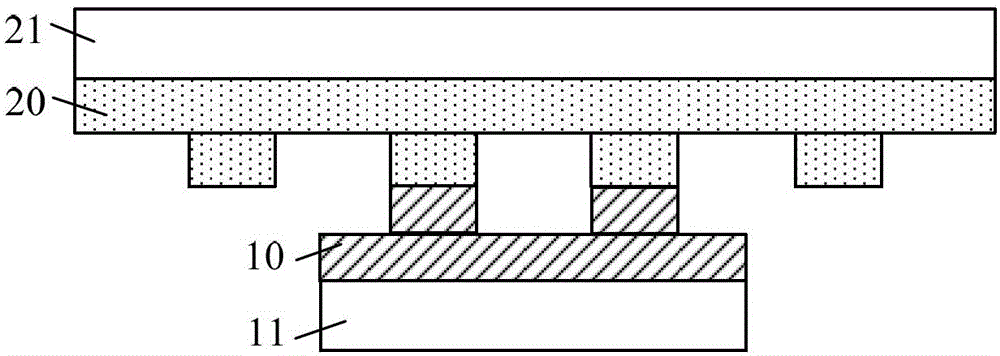

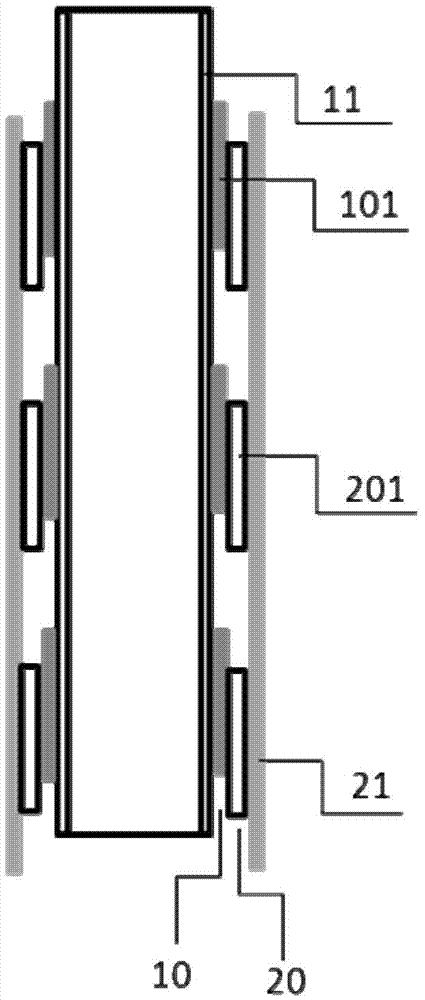

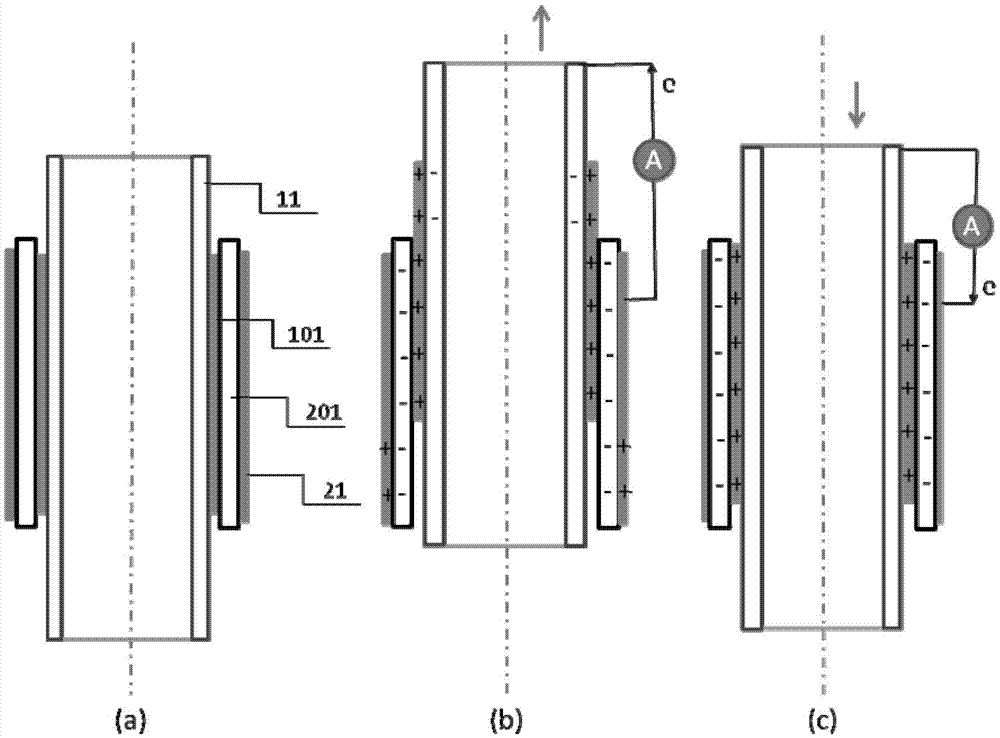

The invention provides a nanometer electric generator utilizing sliding friction. The nanometer electric generator utilizing sliding friction comprises a conducting layer, a friction layer and a conducting element, wherein the conducting element is arranged under the friction layer in a contact way; the upper surface of the friction layer and the lower surface of the friction layer are arranged oppositely; when tangent and relative sliding friction occurs between the upper surface of the friction layer and the contact surface and between the lower surface of the conducting layer and the contact surface under the effect of an external force, and the friction area is changed in the sliding process at the same time, an electrical signal is output to an external circuit by the conducting element and the conducting layer; when a periodic tangential external force is exerted to the nanometer electric generator utilizing sliding friction, alternating current pulse signal output is formed between the conducting element and the conducting layer.

Owner:BEIJING INST OF NANOENERGY & NANOSYST

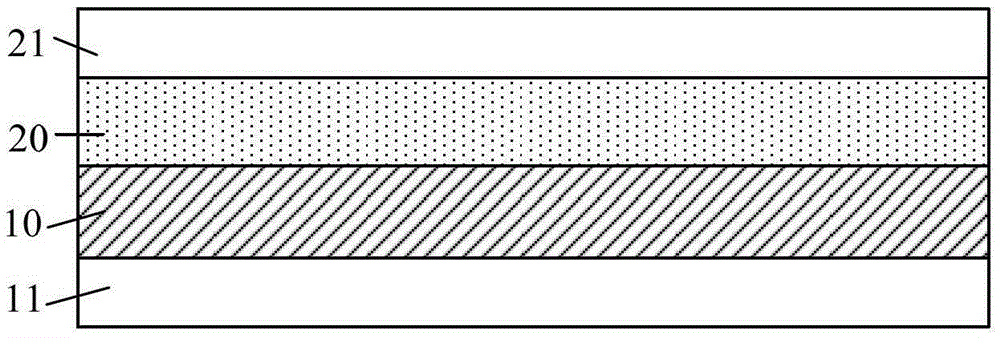

Nanometer electric generator utilizing sliding friction

ActiveCN103368449ASkip the installation processPackaging technology is convenientFriction generatorsEngineeringAlternating current

The invention provides a nanometer electric generator utilizing sliding friction. The nanometer electric generator comprises a friction layer, a conducting element and a conducting layer, wherein the conducting element is arranged under the friction layer in a contact way; the upper surface of the friction layer is arranged opposite to the lower surface of the conducting layer; when relative sliding friction occurs between the upper surface of the friction layer and the lower surface of the conducting layer by an exerted external force, and the contact area is changed, an electric signal is output to an external circuit by the conducting element and the conducting layer; when a periodic tangential external force is exerted to the nanometer electric generator utilizing sliding friction, alternating current pulse signal output is realized between the conducting element and the conducting layer.

Owner:BEIJING INST OF NANOENERGY & NANOSYST

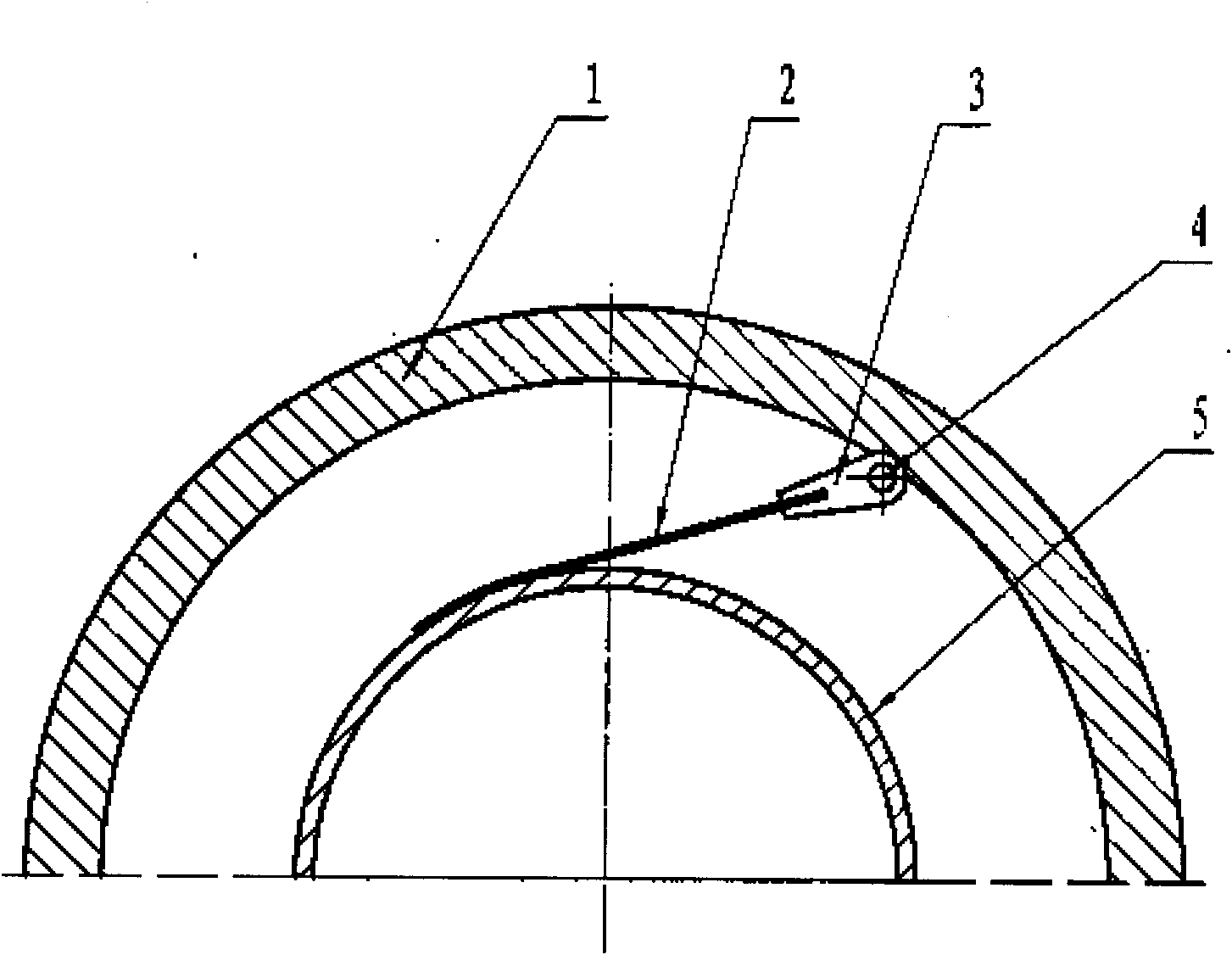

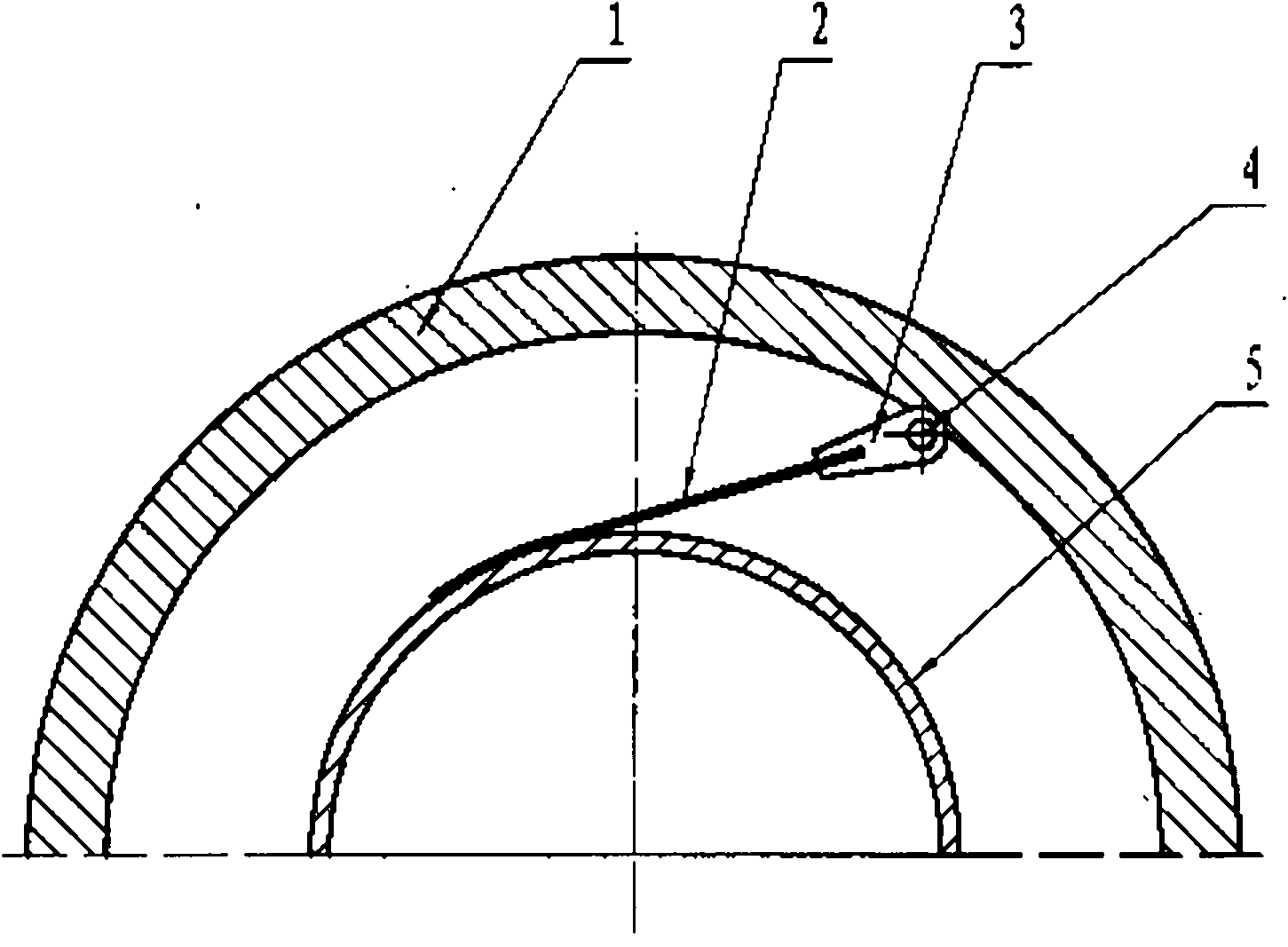

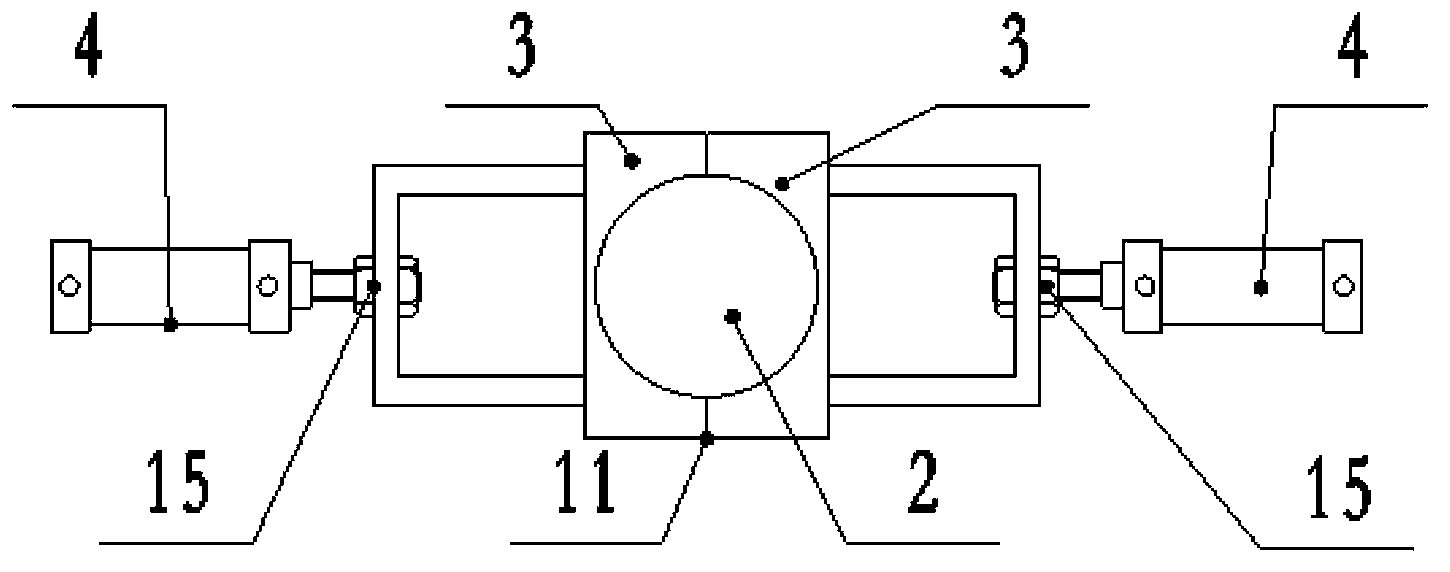

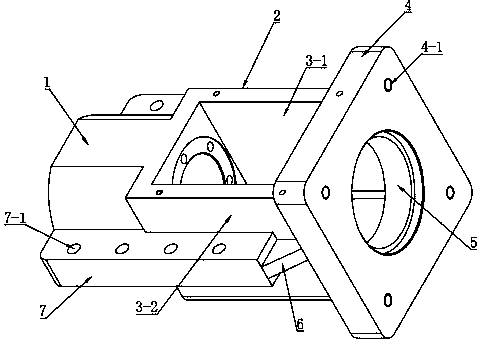

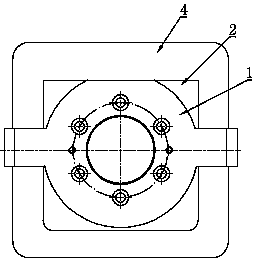

Jacket-layer sliding type friction nanometer generator

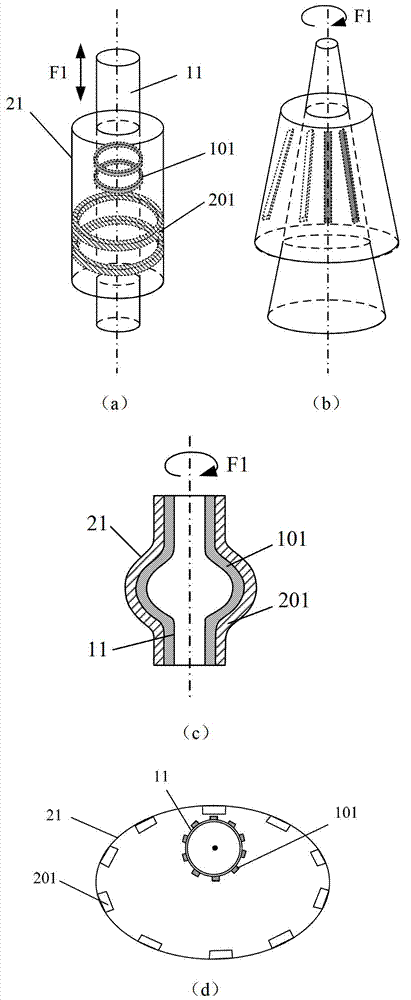

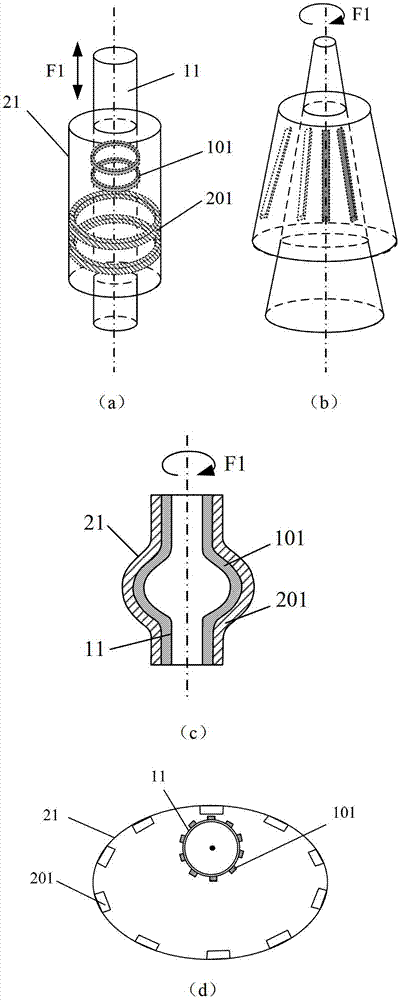

ActiveCN103780125ASkip the installation processPackaging technology is convenientFriction generatorsNew energyElectric signal

This invention discloses a jacket-layer sliding type friction nanometer generator, comprising a first conducting member, a first friction layer, a second conducting member and a second friction layer, wherein the first friction layer is positioned on the outer surface of the first conducting member in a contact manner and the second friction layer is positioned on the outer surface of the second conducting member in a contact manner. The first friction layer comprises a plurality of first friction units and the second friction layer comprises a plurality of second friction units. The outer surfaces of the first friction units belong to a first curved surface and the inner surfaces of the second friction units belongs to a second curved surfaces. The first curved surface and the second curved surface outside the first curved surface form an inside-outside jacket-layer structure. The outer surfaces of the first friction units produce relative sliding friction with the inner surfaces of the second friction units, the friction area is changed, and electric signals are outputted to the external circuit through the first conducting member and the second conducting member. The friction nanometer generator disclosed by the invention can be used as a new energy technology or a sensor technology.

Owner:BEIJING INST OF NANOENERGY & NANOSYST

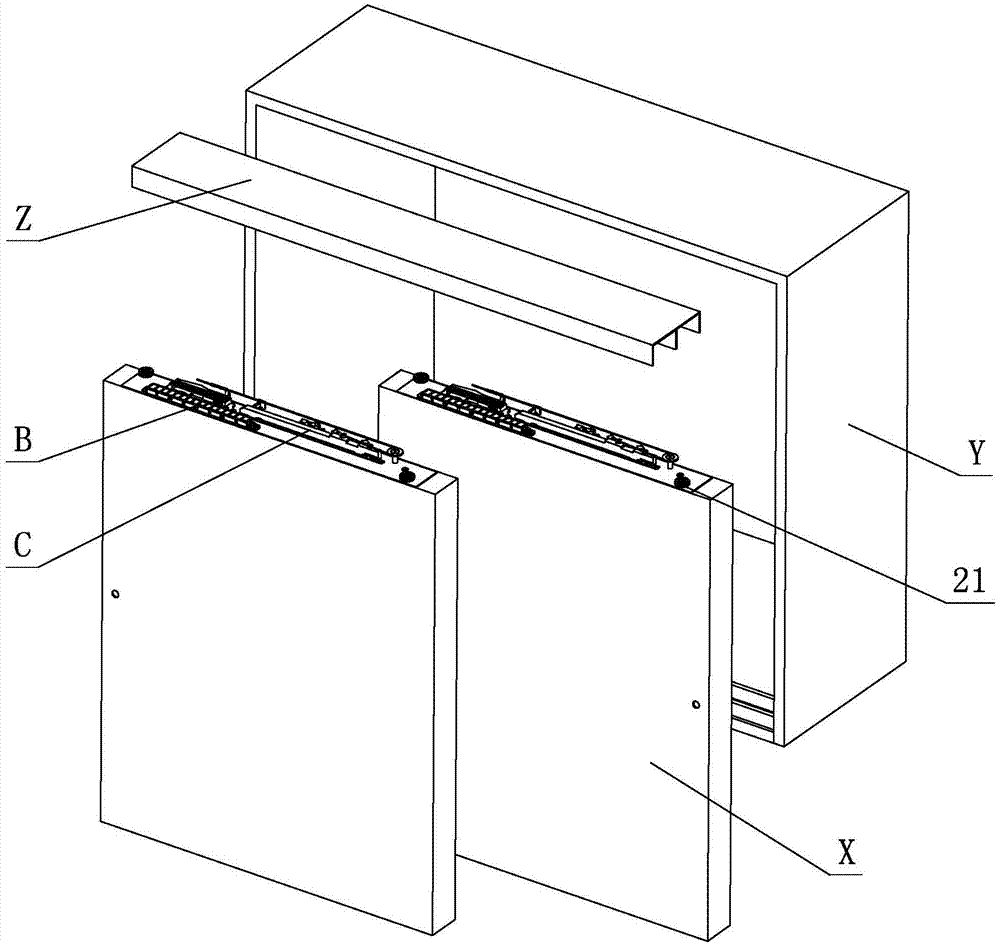

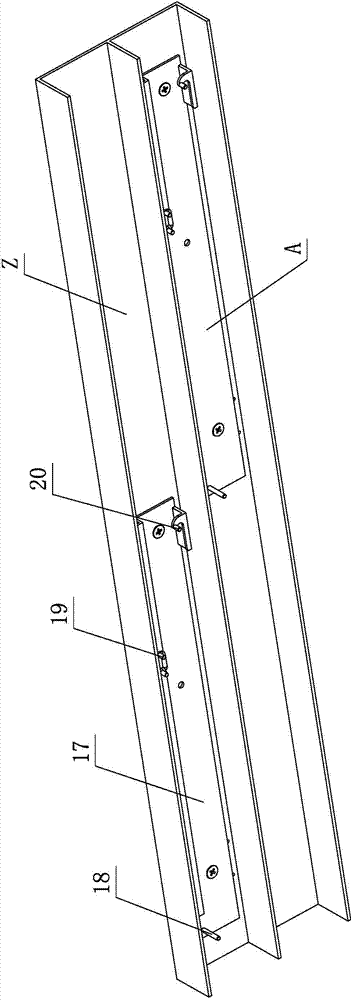

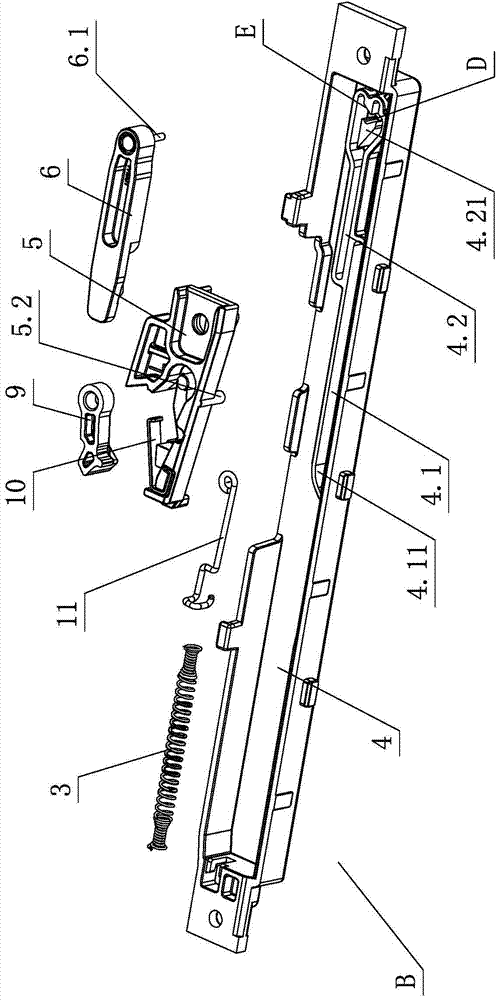

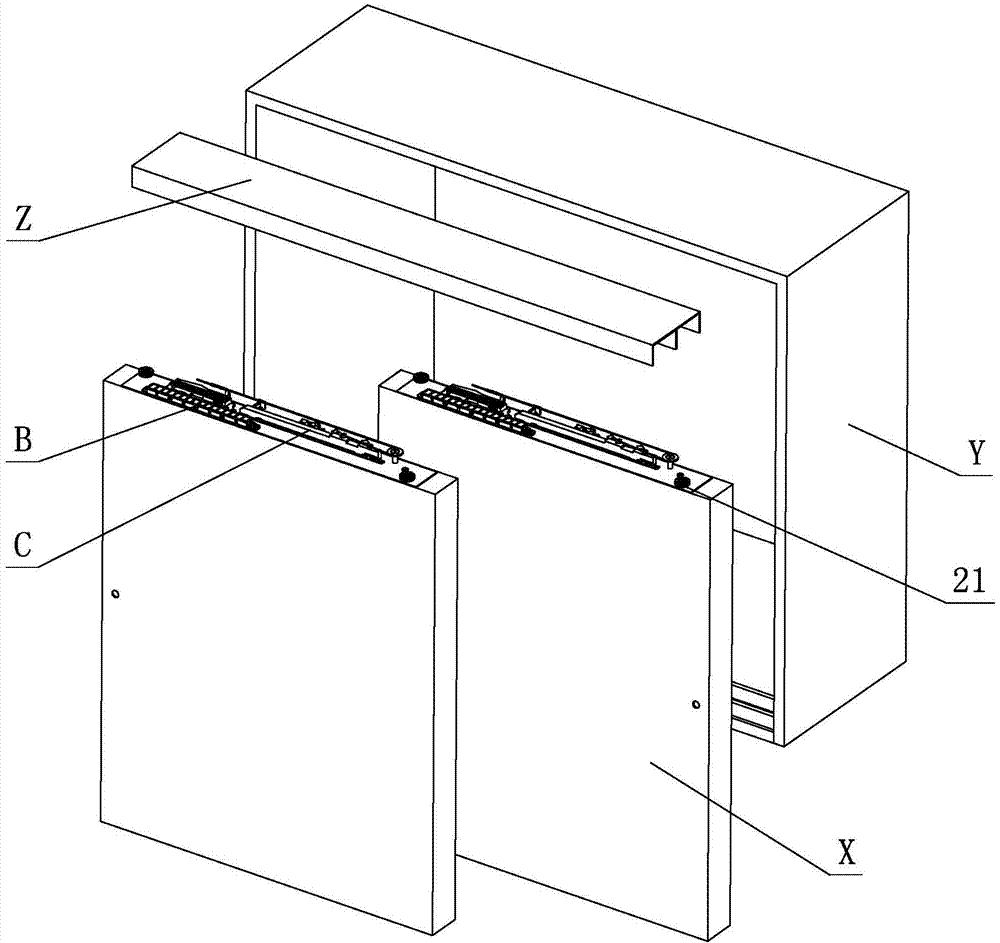

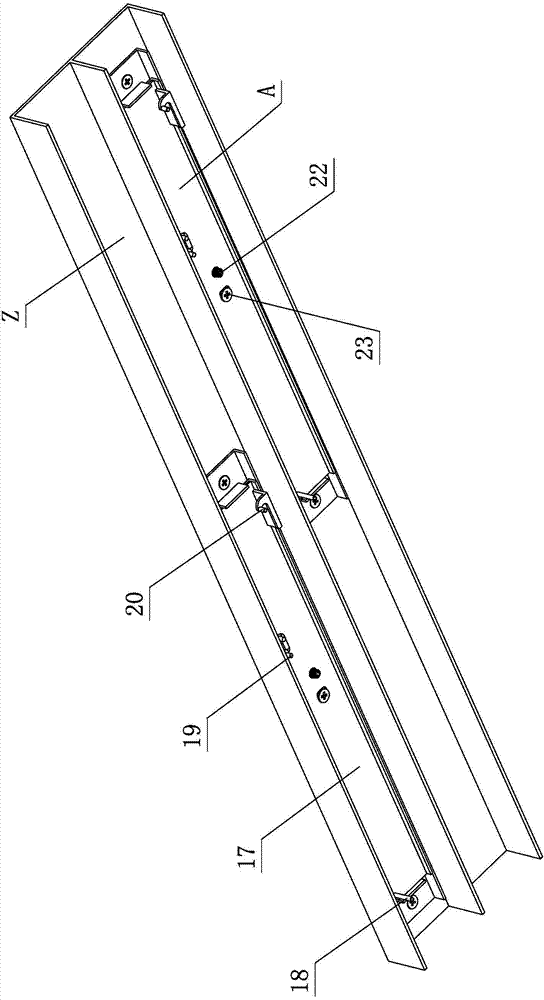

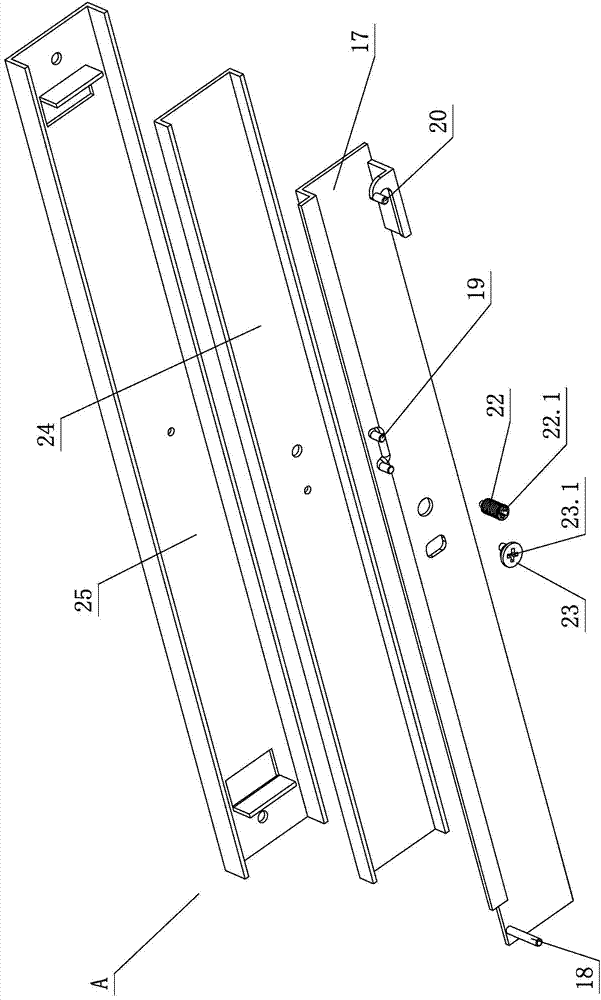

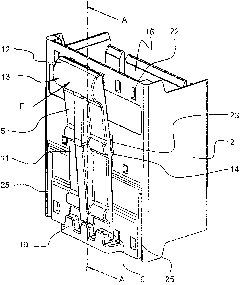

Damping press rebounding device for sliding door

ActiveCN104763261AReduce daily wear and tearExtended service lifeWing suspension devicesDrawersEngineeringForce direction

The invention discloses a damping press rebounding device for a sliding door. The damping press rebounding device for the sliding door comprises a static component, a moving component, a poking mechanism, a reverse pushing mechanism and a damping mechanism; the poking mechanism comprises a poking base and at least two poking components; the reverse pushing mechanism comprises a pushing component slidably installed on a fixing base by a reverse pushing spring; the damping mechanism comprises a swinging component slidably installed on a positioning frame by a damping spring; the positioning frame is provided with a damper; the moving component is the sliding door; the poking mechanism is installed on the static component; the reverse pushing and damping mechanisms are installed on the sliding door; at least two poking components are the first poking component and the second poking component; while the sliding door is closed for a section of the travel, the second and first poking components respectively act on the pushing component and the swinging component in the sequence, and the elastic force directions of the reverse pushing and damping springs are different; while the sliding door is closed, the first poking component acts on the swinging component, the swinging component acts on the damper, and the closing is achieved by the damping spring; and while the sliding door is opened, a section of the travel is moved along the closing direction, and the sliding door is opened by the reverse pushing spring.

Owner:伍志勇

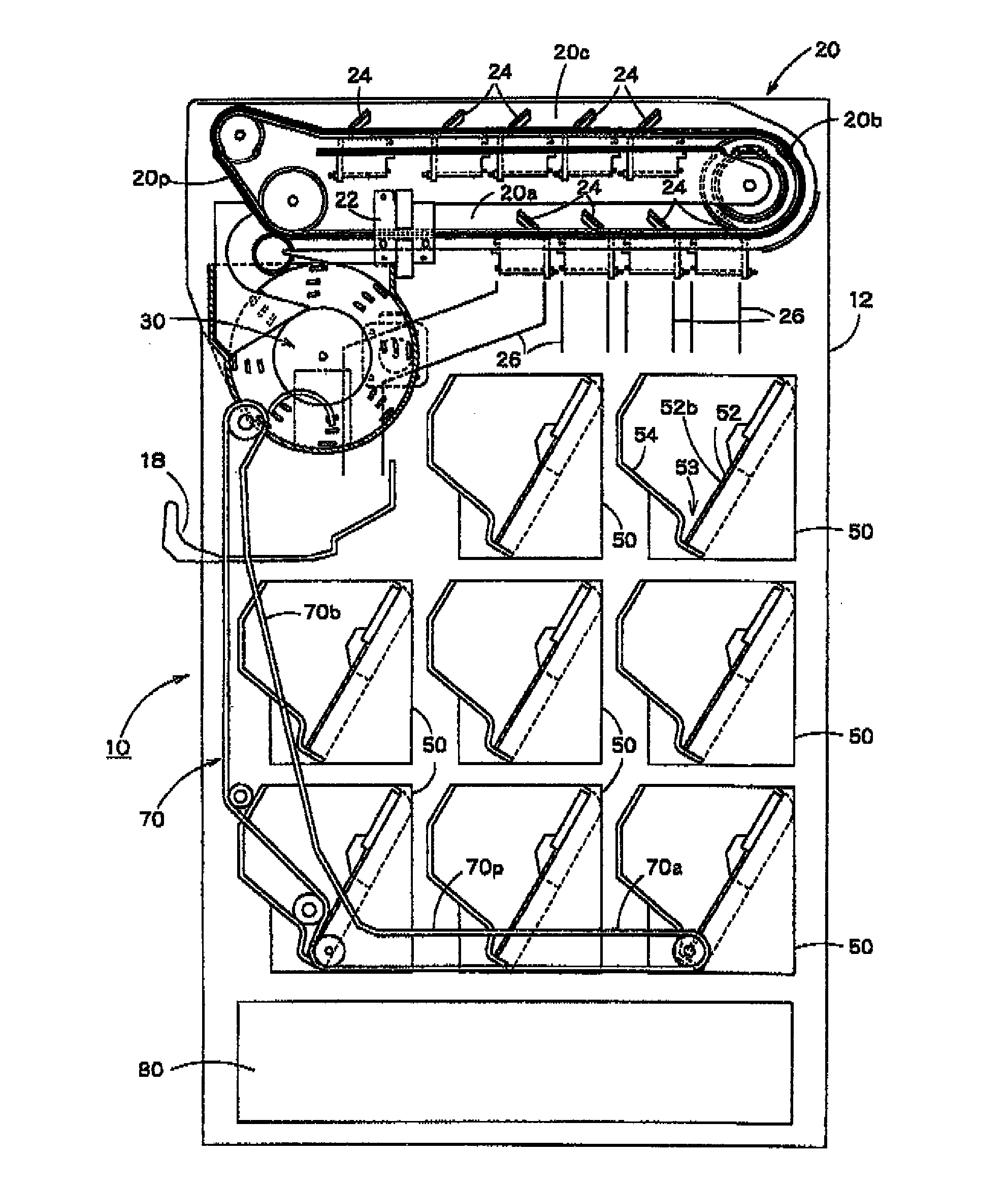

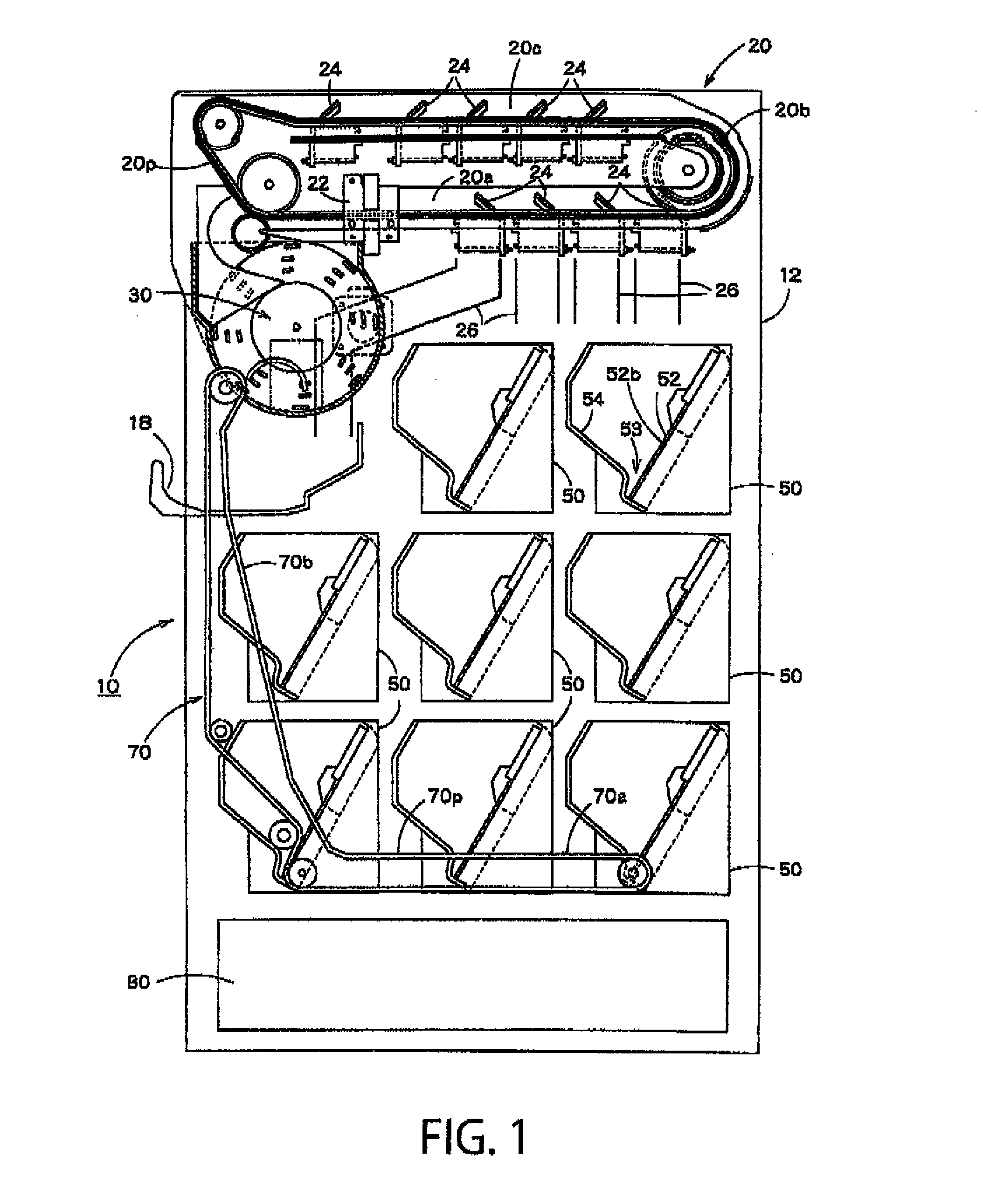

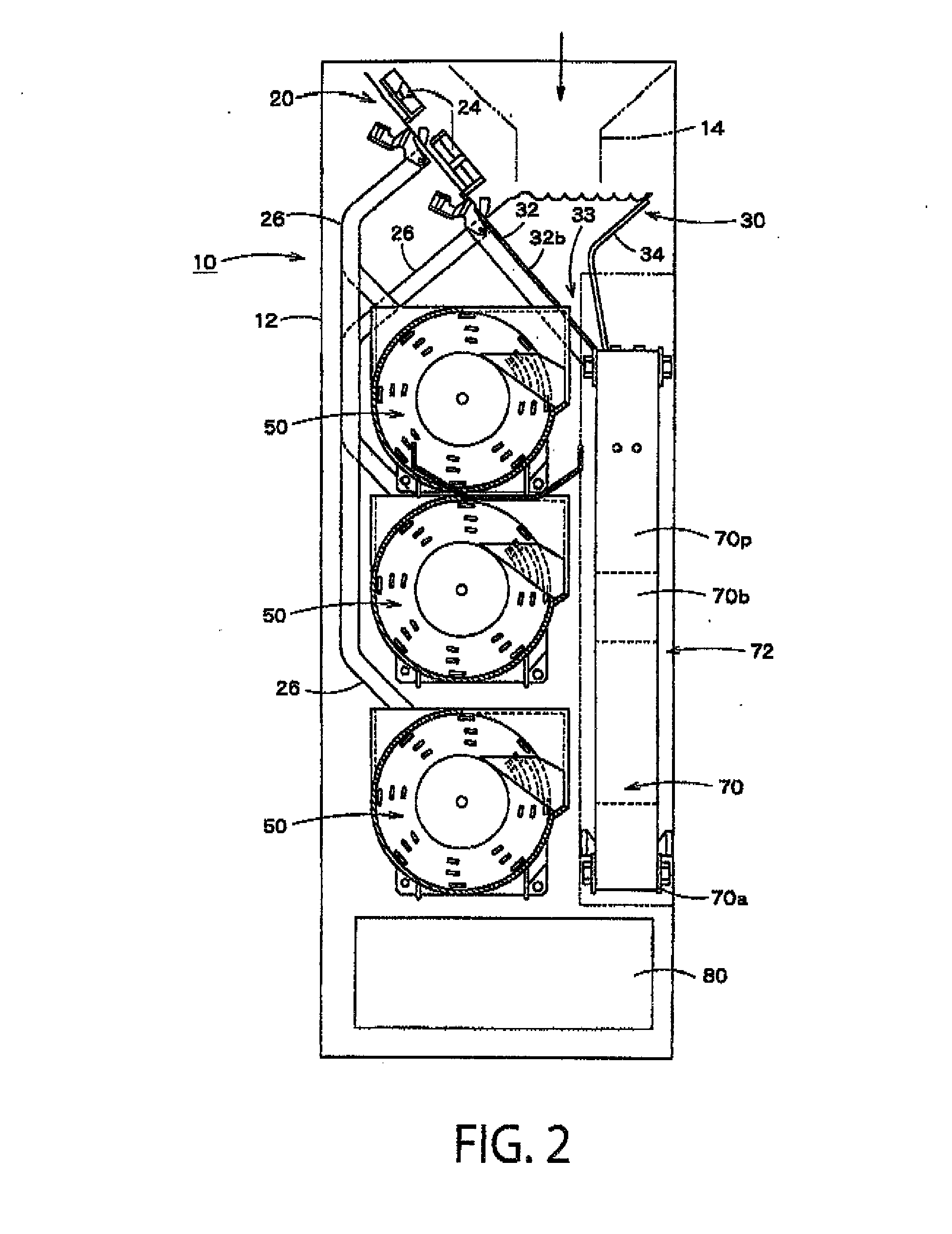

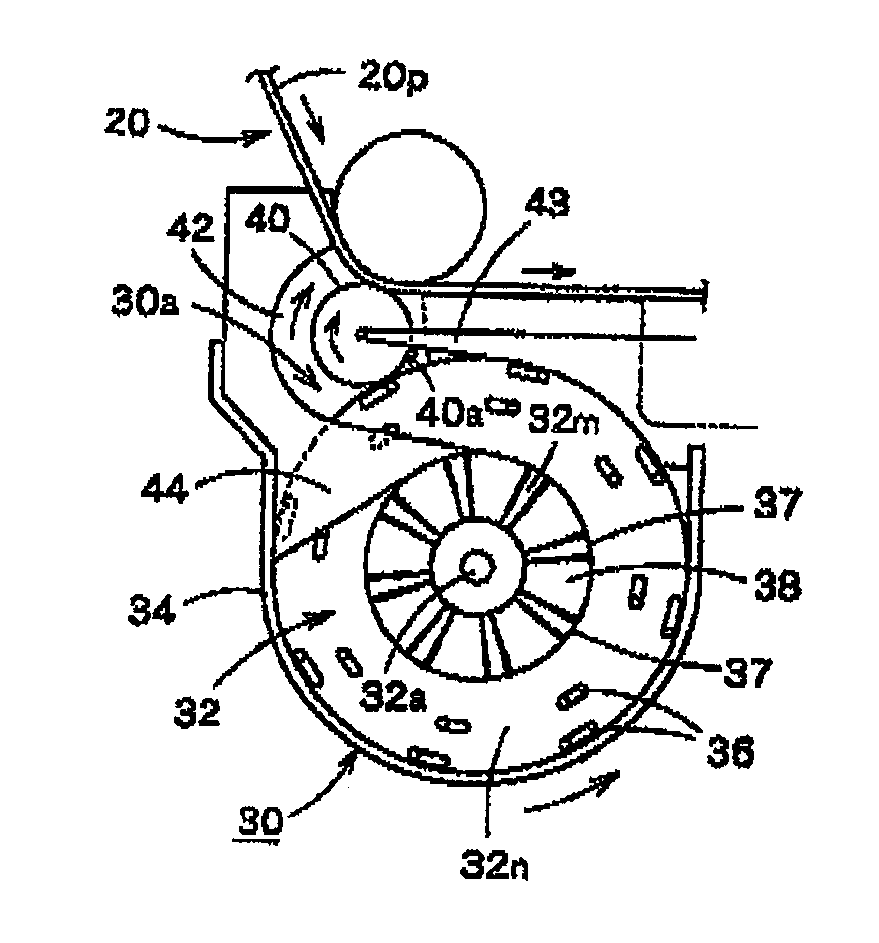

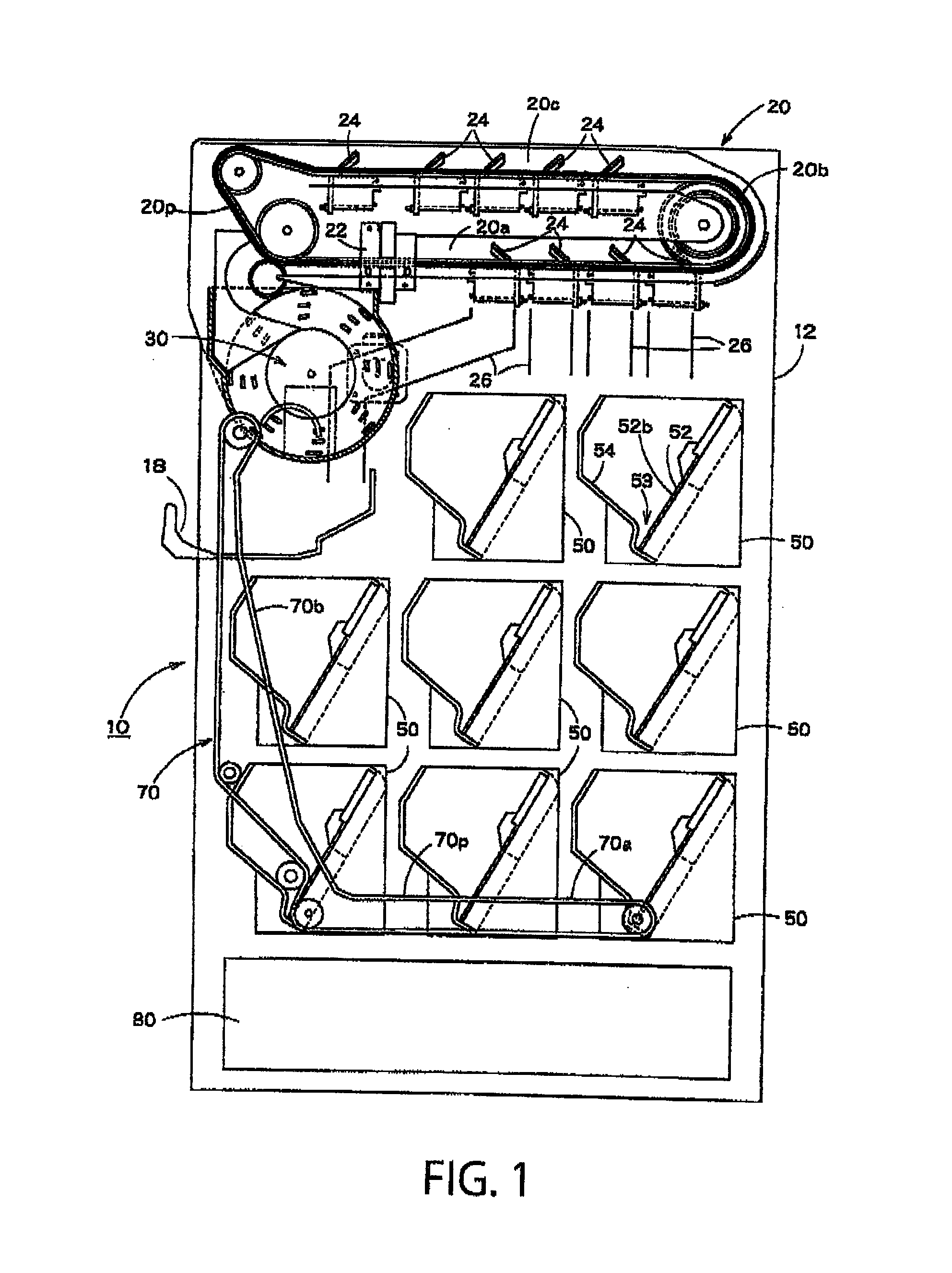

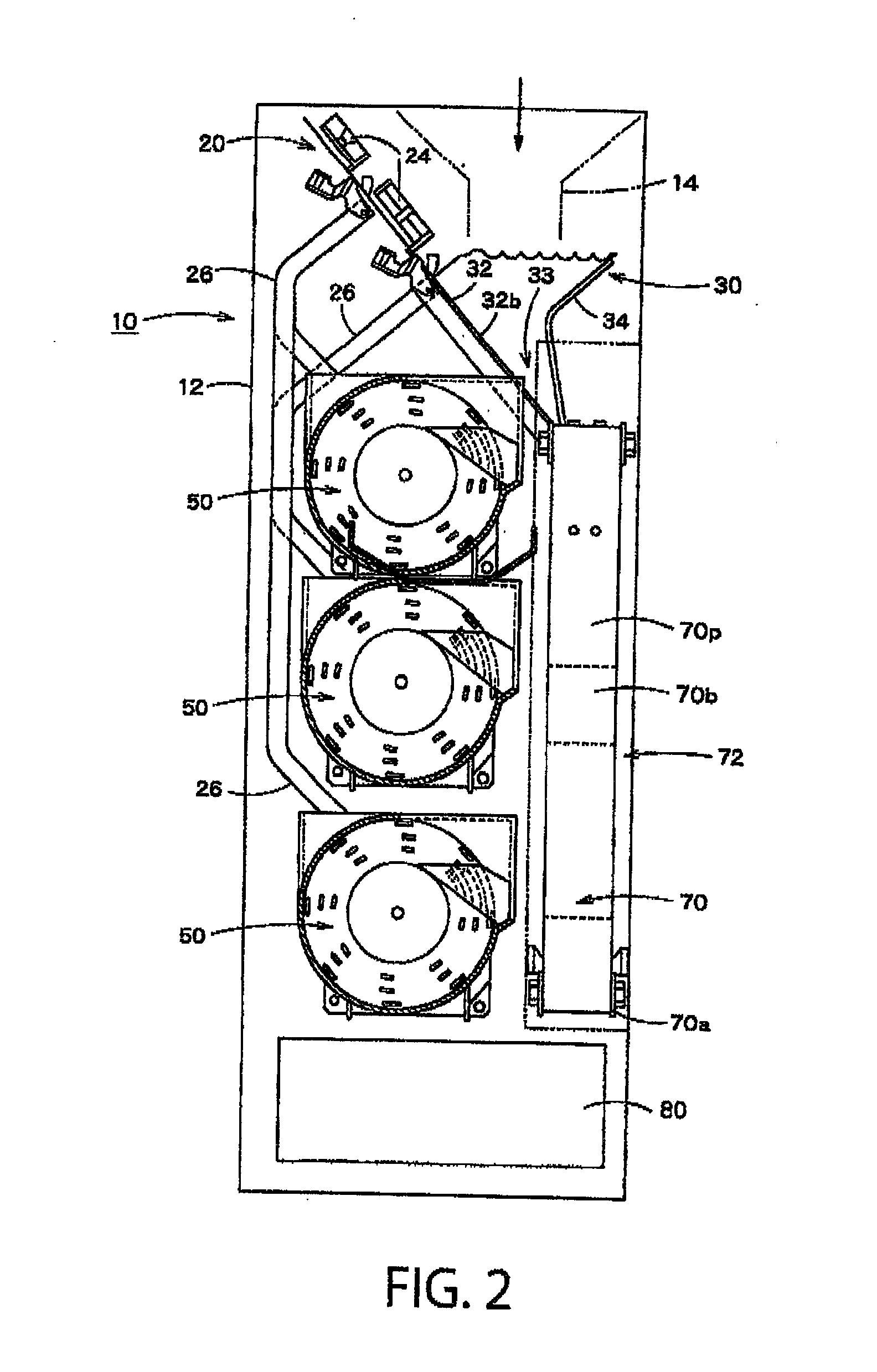

Coin depositing and dispensing machine

ActiveUS20140080395A1Decrease in coin storing capacityReduce machine sizeCoin countersCoin/currency accepting devicesEngineeringMechanical engineering

In a coin depositing and dispensing machine 10, a plurality of storing and feeding apparatuses 50 disposed below a deposited-coin transport unit 20 are arranged vertically on plural levels. A transport direction in which a coin is transported by the deposited-coin transport unit and a feeding direction in which a coin is fed out from each storing and feeding unit are substantially perpendicular to each other.

Owner:GLORY KOGYO KK

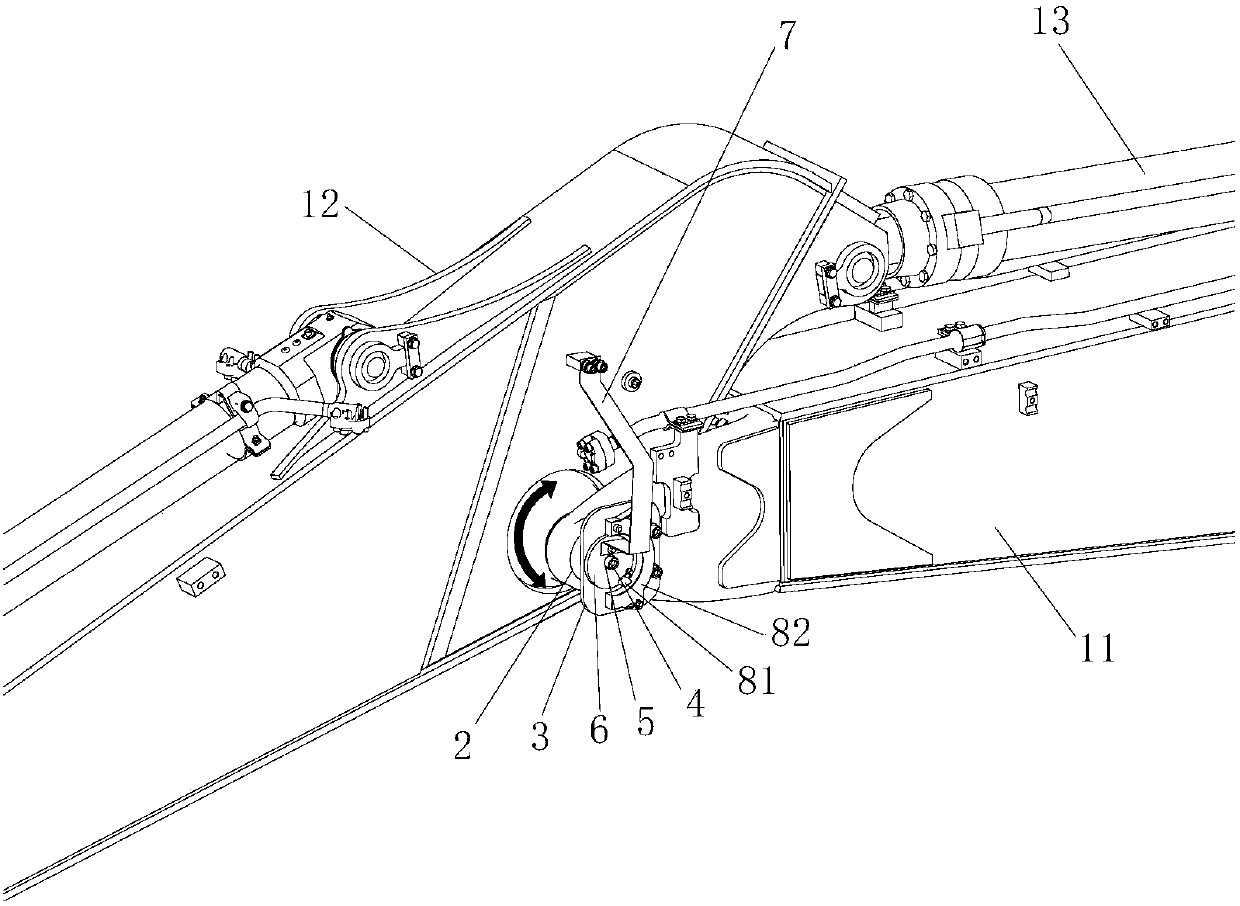

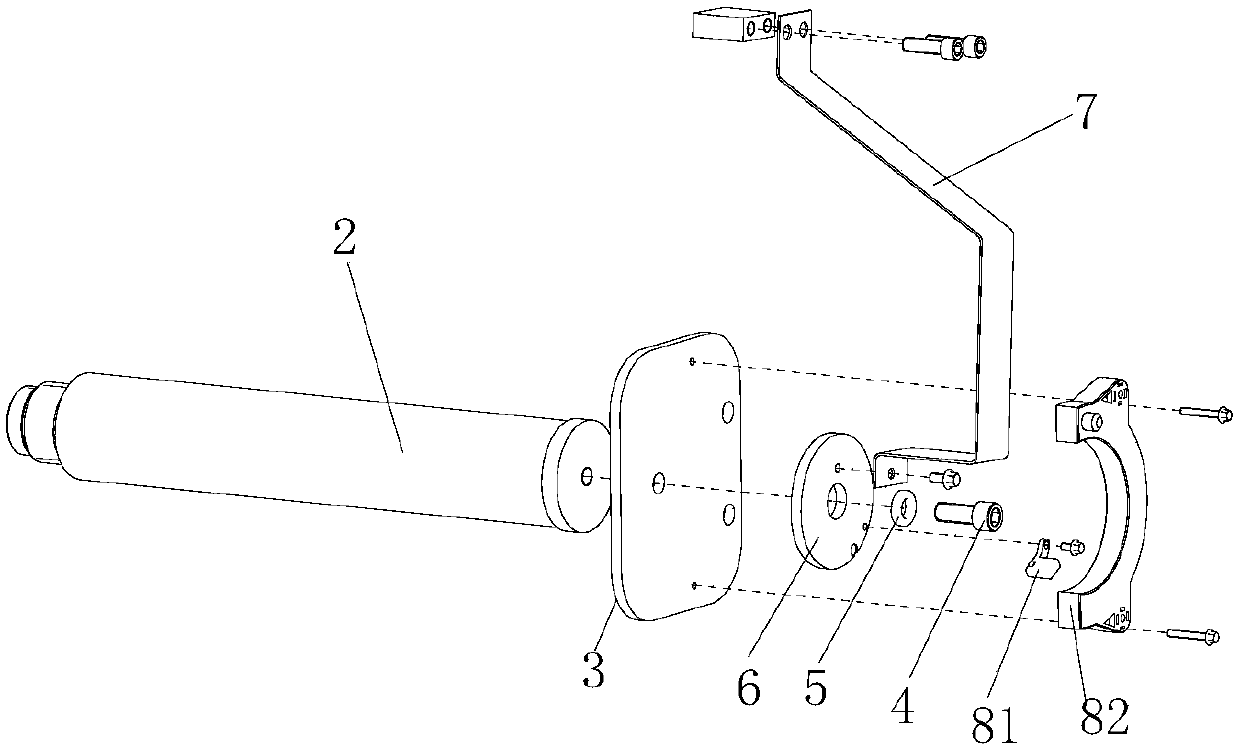

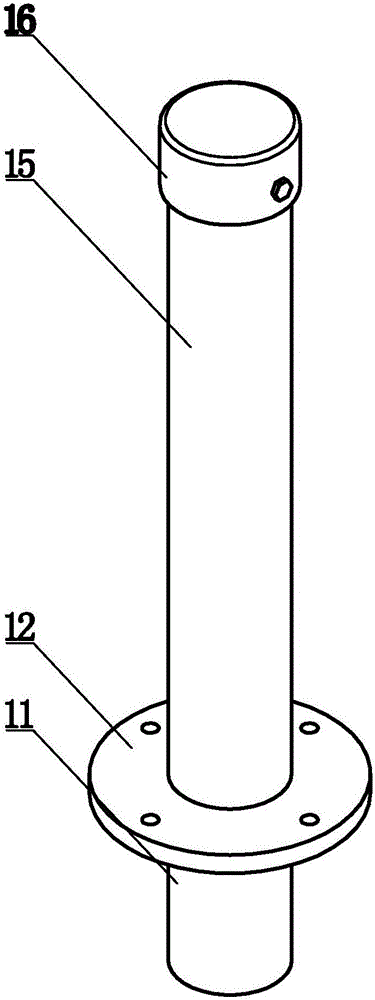

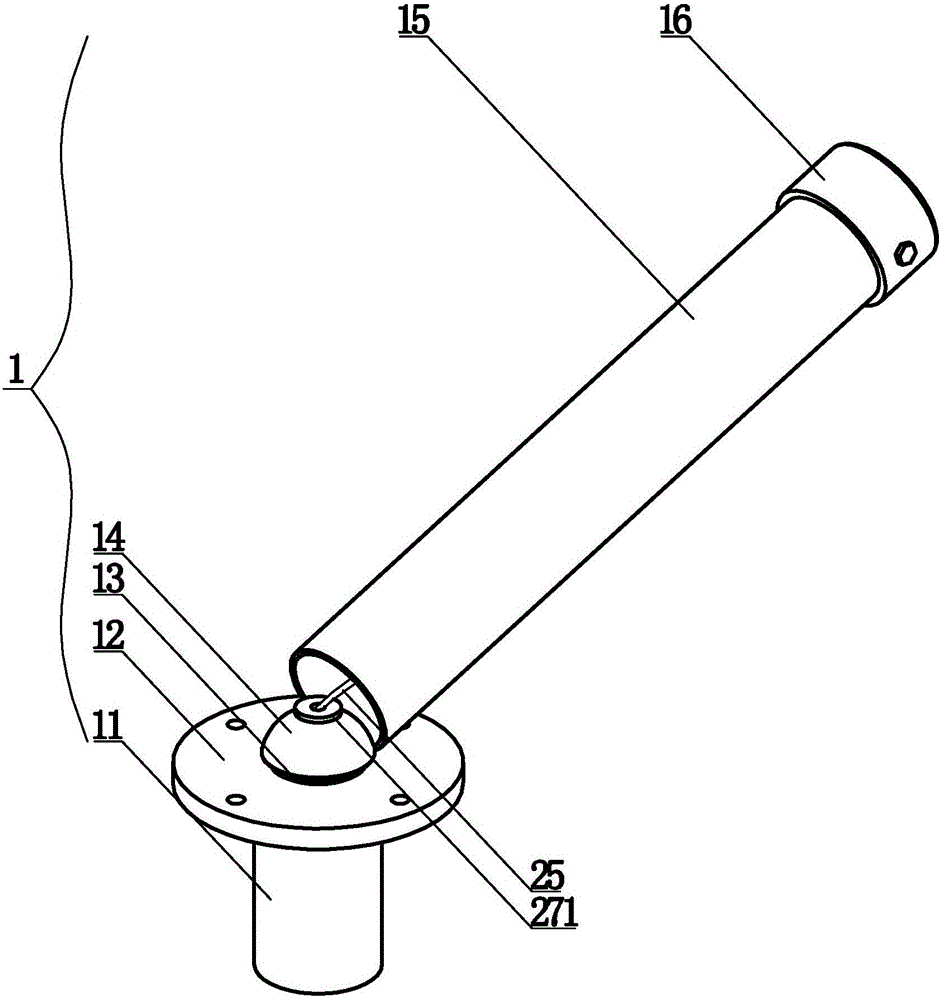

Excavator bucket rod rotation angle measuring device

ActiveCN107941144ASkip the installation processEasy to disassemble and repairMechanical machines/dredgersUsing electrical meansEngineeringExcavator

The invention provides an excavator bucket rod rotation angle measuring device. A movable arm is fixedly connected with a pin shaft; and the movable arm is hinged with a bucket rod through the pin shaft. The excavator bucket rod rotation angle measuring device comprises a rotating disc, a positioning rod, a drive rod and a magnetic resistance angle sensor. The rotating disc is provided with an assembly hole; the positioning rod is connected to the pin shaft axis center position and is co-axis with the pin shaft. The tail end of the positioning rod is assembled and connected to the assembly hole in the rotating disc through a bearing. One end of the drive rod is connected with the bucket rod, and the other end of the drive rod is connected with the rotating disc. The magnetic resistance angle sensor comprises magnet pieces and a sensor main body. The magnet pieces are arranged on the rotating disc; the sensor main body is arranged on the movable arm; and the sensor main body is internally provided with a magnetic induction element. The beneficial effects are that the device is convenient to assemble, disassemble and maintain, and can accurately measure the rotation angle of the bucket rod; and the angle sensor is high in reliability.

Owner:QINGDAO LOVOL EXCAVATOR

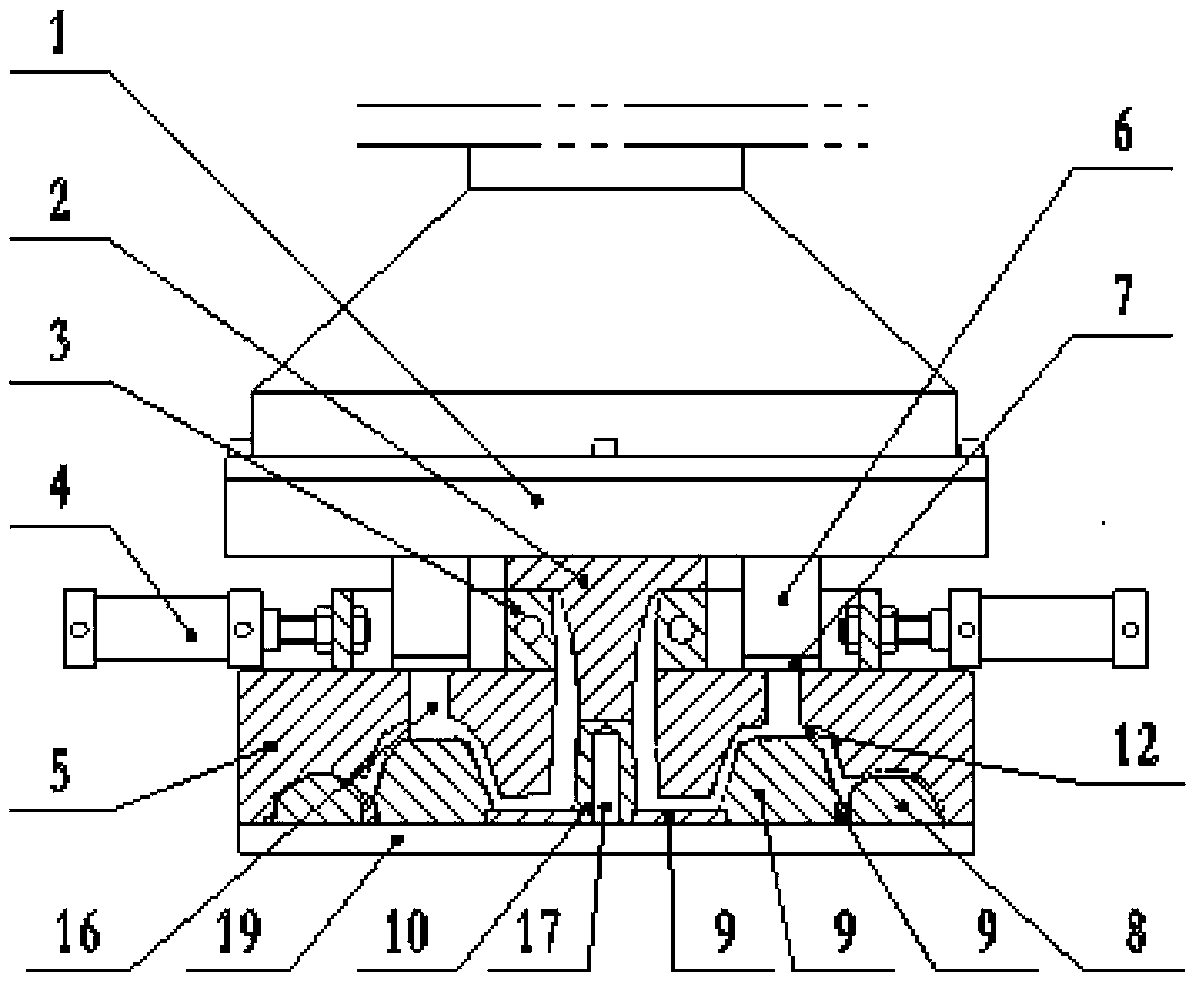

Rotary kiln heavy gear ring repairing method

InactiveCN101852547ASkip the installation processSave on spare parts costsRotary drum furnacesChemical industryRepair time

The invention discloses a rotary kiln heavy gear ring repairing method, and relates to a rotary kiln repairing method which is used in metallurgy, building materials and chemical industries. The method is characterized in that a repairing operation process comprises the following steps that: (1) a spring board and heavy gear ring connecting lug is cut off, and a heavy gear ring is removed; (2) the heavy gear ring is cleaned and set the heavy gear ring round; (3) the turned over heavy gear ring is hoisted and aligned; and (4) a pin shaft is installed, and a spring board and a new lug are welded. The rotary kiln heavy gear ring repairing method turns over and repairs the heavy gear ring under the circumstance of not replacing a tube section and the spring board, first cuts the spring board and heavy gear ring connecting lug, keeps a tube body and the original spring board unchanged, removes the gear ring and turns over the same and then replaces the new lug and the pin shaft; and after the heavy gear ring is aligned, the new lug and the original spring board are welded firmly. The rotary kiln heavy gear ring repairing method effectively saves the cost for the tube section, the spring board, a rivet and other spare parts, omits spring board installation, hole drilling, riveting and other procedures, and saves a certain repairing time.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

Ripple voltage suppression method for DC/DC converter and apparatus thereof

ActiveUS8009446B2Low costImprove efficiencyConversion with intermediate conversion to dcDc-dc conversionControl signalElectronic switch

A ripple voltage suppression apparatus includes a DC / DC converter and a control circuit. The DC / DC converter has a power electronic switch. The control circuit has a voltage detector detecting a DC output voltage of the DC / DC converter, a ripple voltage suppression circuit receiving the detected DC output voltage to generate an AC control signal for controlling an AC component of a duty ratio of the power electronic switch, an output voltage regulation circuit receiving the detected DC output voltage to generate a DC control signal for controlling an DC component of a duty ratio, an adder adding the AC and DC control signals to form a combined control signal, and a PWM circuit converting the combined control signal into a PWM signal to control the power electronic switch. Only the DC output voltage of the DC / DC converter has to be detected for the control circuit.

Owner:ABLEREX ELECTRONICS CO LTD

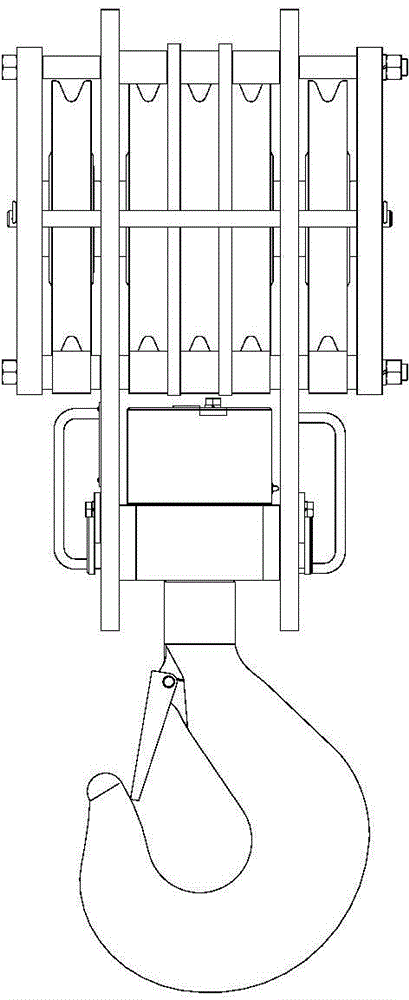

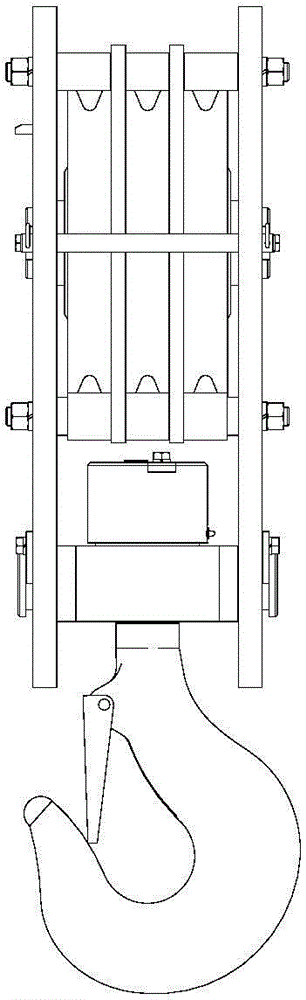

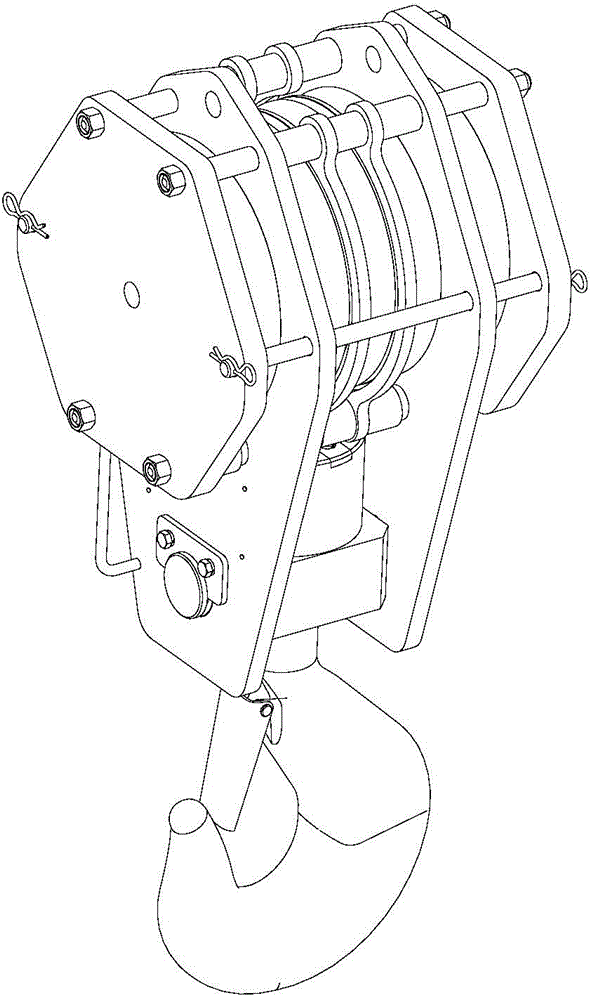

Lifting hook and crane

ActiveCN105197772ALow transportation costSimple structureLoad-engaging elementsBlock and tackleEngineering

The invention discloses a lifting hook and a crane, relates to the technical field of engineering machinery, and solves the technical problem that in the prior art, the lifting hook replacement time is long. The lifting hook comprises a lifting hook body, a detachable connection structure and one or more auxiliary demountable pulley blocks, wherein the lifting hook body comprises a hook head part and a pulley block part; the pulley block part comprises two pulley yoke boards being opposite in position and a pulley arranged between the two pulley yoke boards; the hook head part is connected with the pulley yoke boards; each auxiliary demountable pulley block comprises a mounting rack and a pulley mounted in the mounting rack; each mounting rack comprises two mounting rack boards being opposite in position and a connection rack body connected between the two mounting rack boards; mounting rack boards and / or connection rack bodies are detachably connected with the pulley yoke boards through the detachable connection structure. The crane comprises the lifting hook. The lifting hook and the crane have the advantages that the replacement time of the lifting hook is shortened, and thus the heavy load lifting efficiency is improved.

Owner:XUZHOU HEAVY MASCH CO LTD

Damping press rebound adjusting device for sliding door

ActiveCN104763264AReduce daily wear and tearExtended service lifeBuilding braking devicesWing suspension devicesBacksteppingEngineering

A damping press rebound adjusting device for a sliding door comprises an immovable element, a movable element, a toggling mechanism, a backstepping mechanism, and a damping mechanism. The toggling mechanism comprises a toggling seat and at least two toggling elements. The backstepping mechanism comprises a pushing element that is slidingly installed on a fixing base through a backstepping spring. The damping mechanism comprises an oscillating element that is slidingly installed on a locating frame through a damping spring. The locating frame is provided with a damper. The movable element is at least a sliding door. The toggling mechanism is installed on the immovable element. The backstepping mechanism and the damping mechanism are installed on the sliding door and are provided with rollers. The at least two toggling elements sequentially and respectively act on the pushing element and the oscillating element after the sliding door is at least closed by a certain degree. The toggling mechanism is provided with an up-down adjusting element and a front-back adjusting element which are used for adjusting the upper position, the lower position, the front position and the back position of the toggling mechanism. The damping press rebound adjusting device for the sliding door is strong in practicality.

Owner:伍志勇

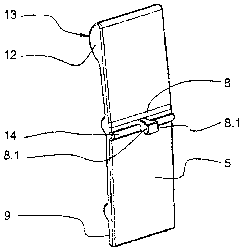

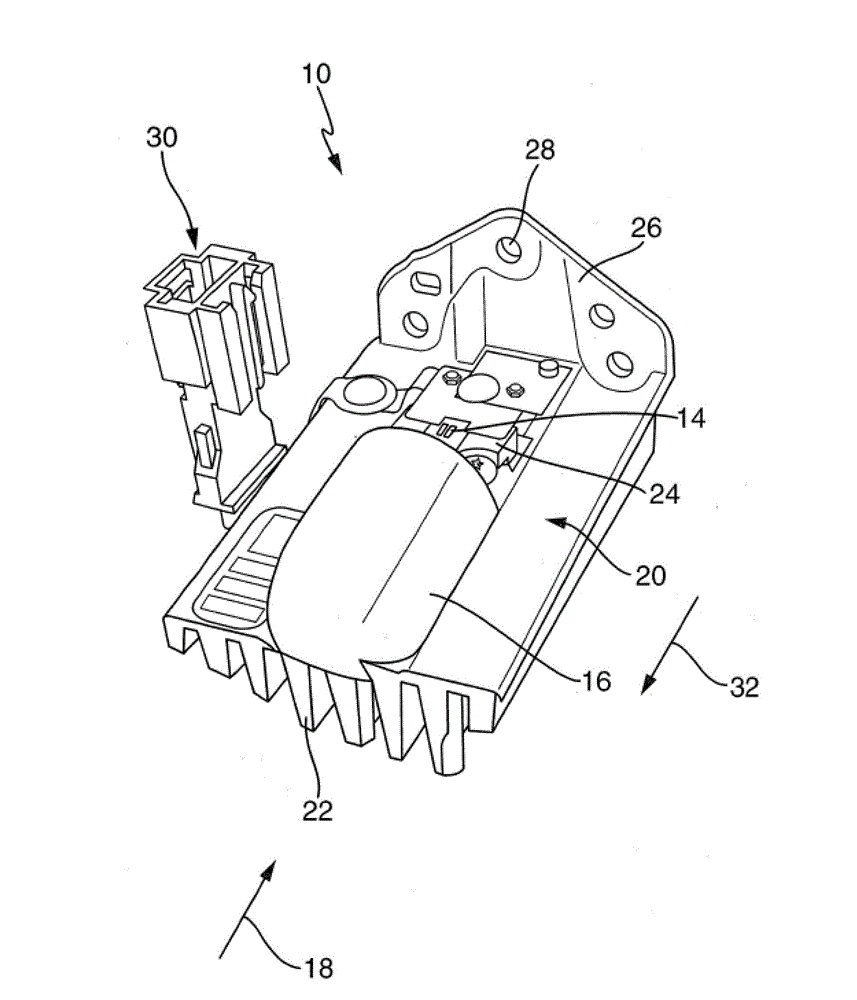

Plug connector device with unlocking device

ActiveCN102195206ADiverse and variable application possibilitiesImprove legibilityCouplings bases/casesEngineeringElectrical and Electronics engineering

The present invention relates to a plug connector device (1) which is provided with a connector housing (2) that is used for accommodating at least one socket component (3,3.1), wherein, at least one socket component (3,3.1) is accommodated in the connector housing (2) through a locked mode. The plug connector device is also provided with an unlocking device (4) with an unlocking lever (5) for releasing the locked accommodation of at least one socket component (3,3.1) in the connector housing (2), wherein the unlocking lever (5) is pivotably provided on a wall (6) of the connector housing (2) so the wall (6) is at least partially deformable for releasing the locking between the socket component (3,3.1) and the connector housing (2) when the unlocking lever (5) is operated.

Owner:WAGO VERW GMBH

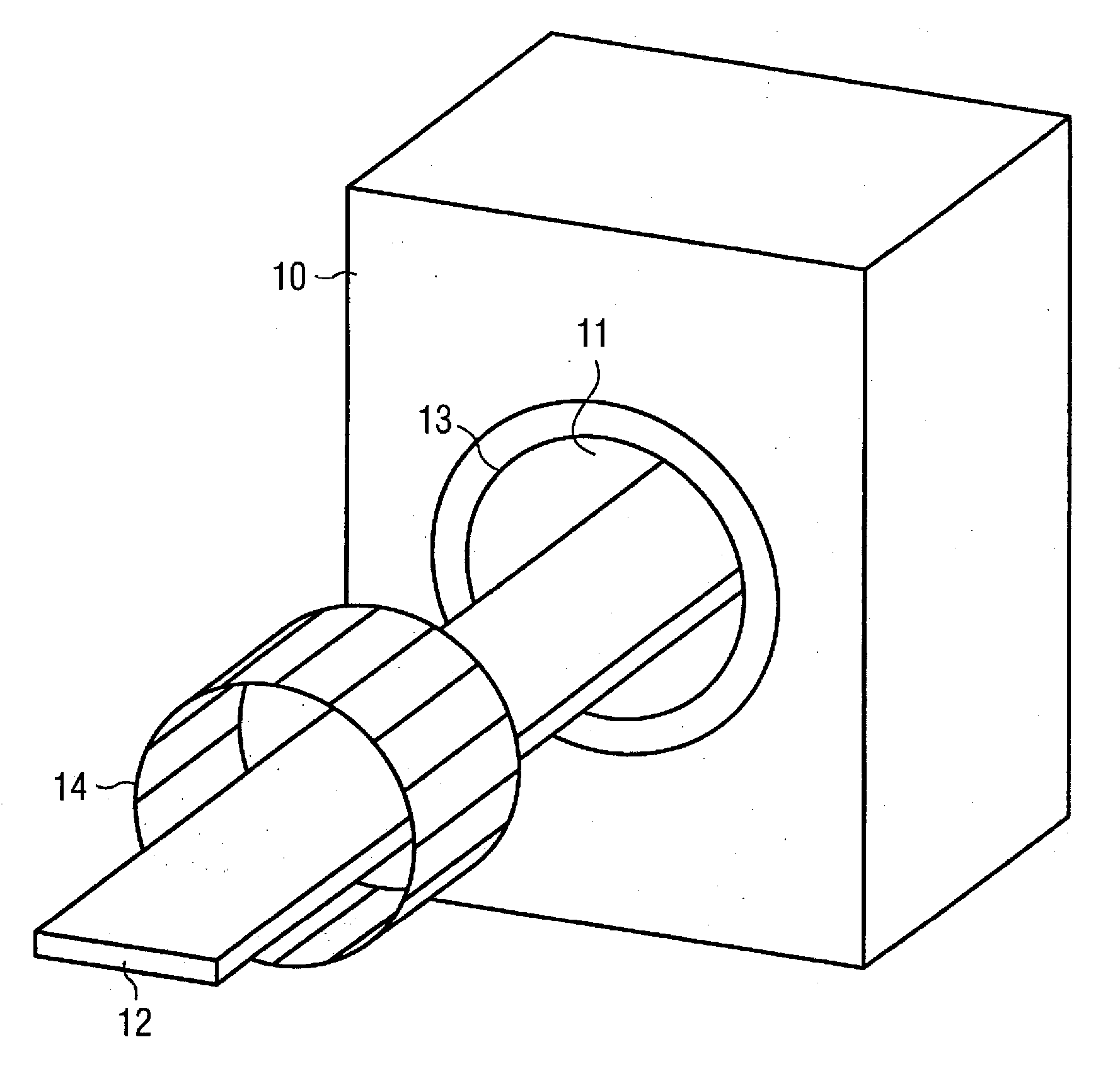

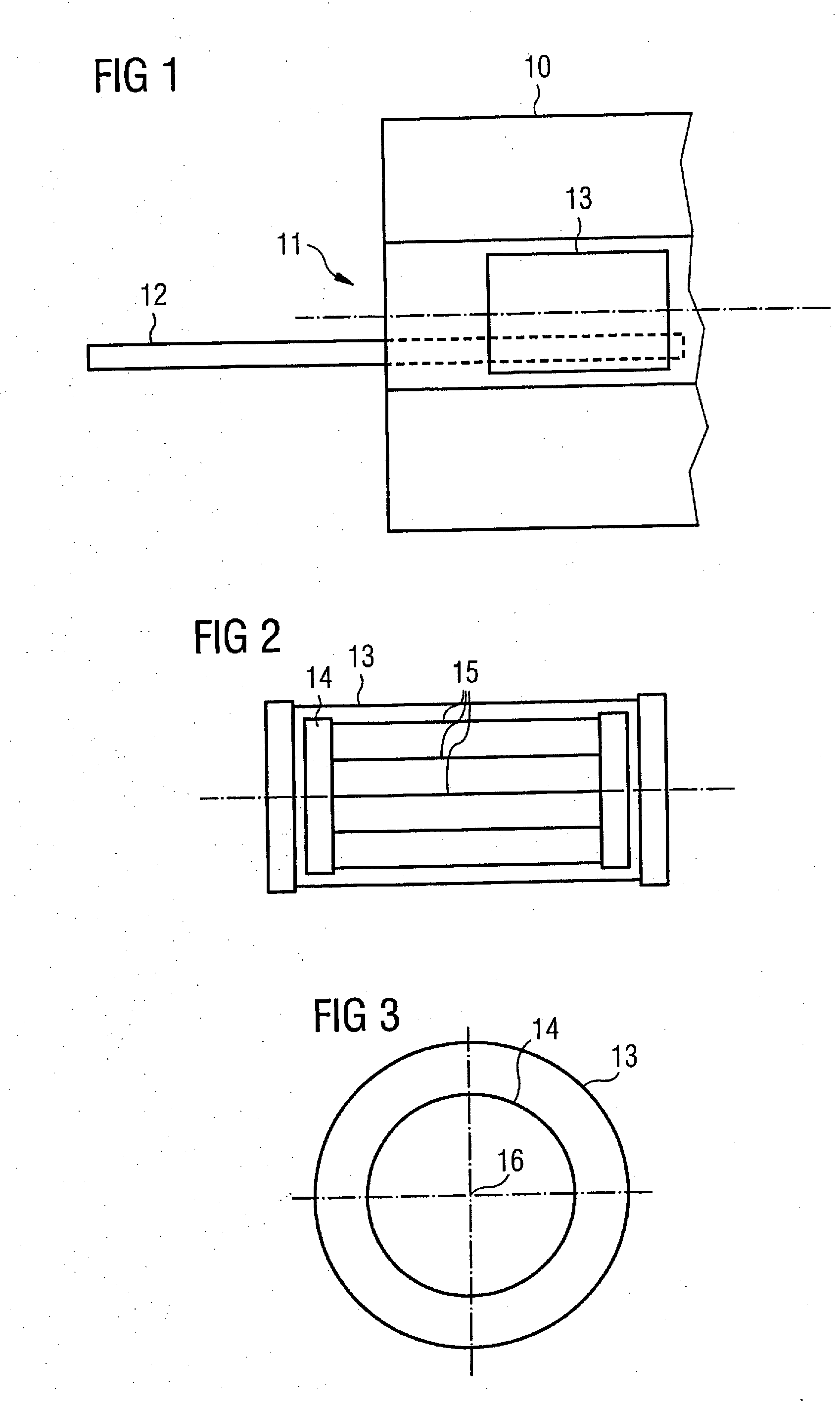

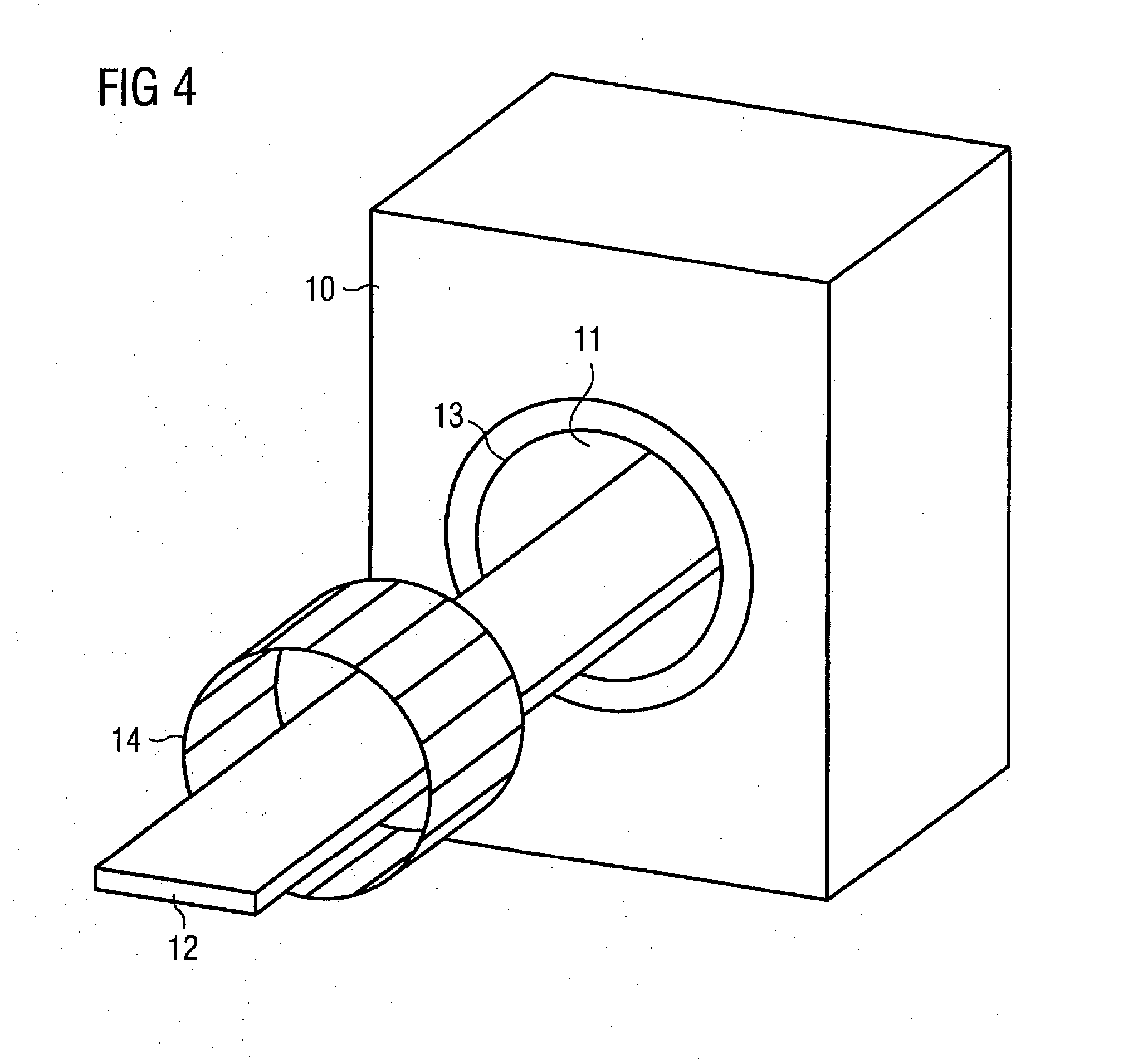

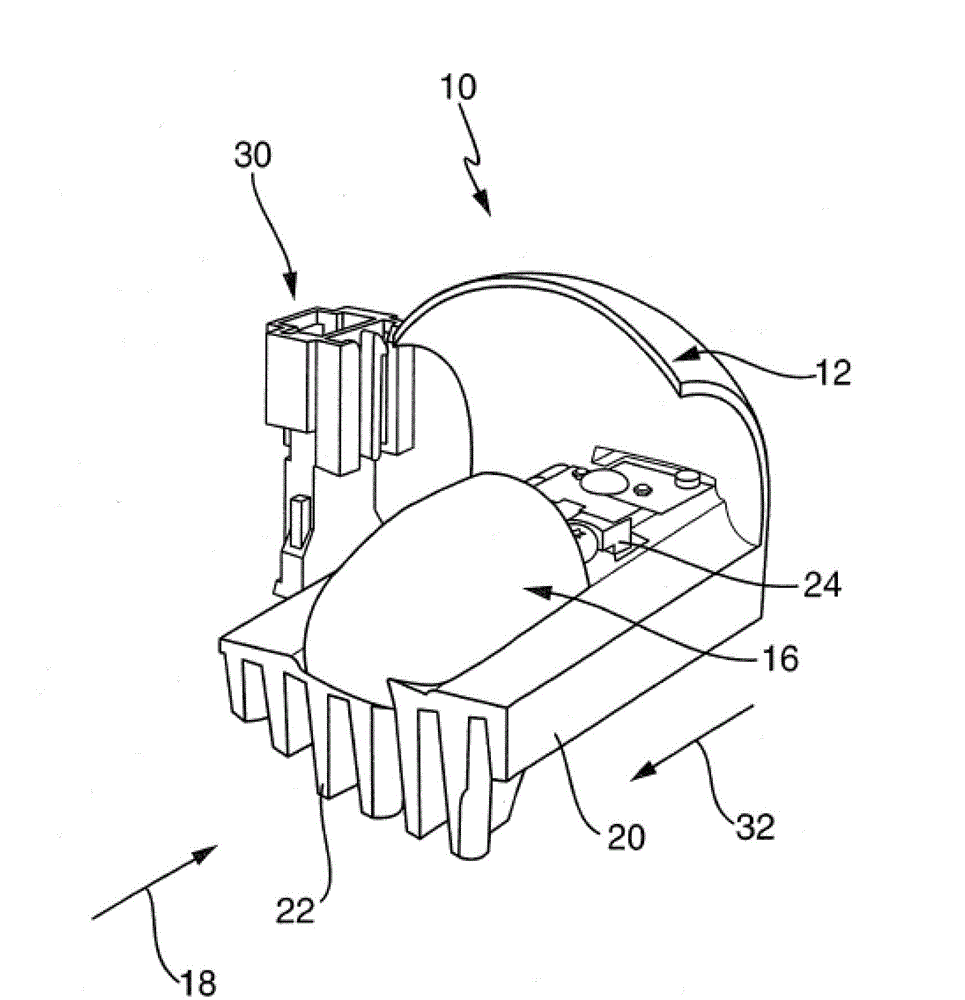

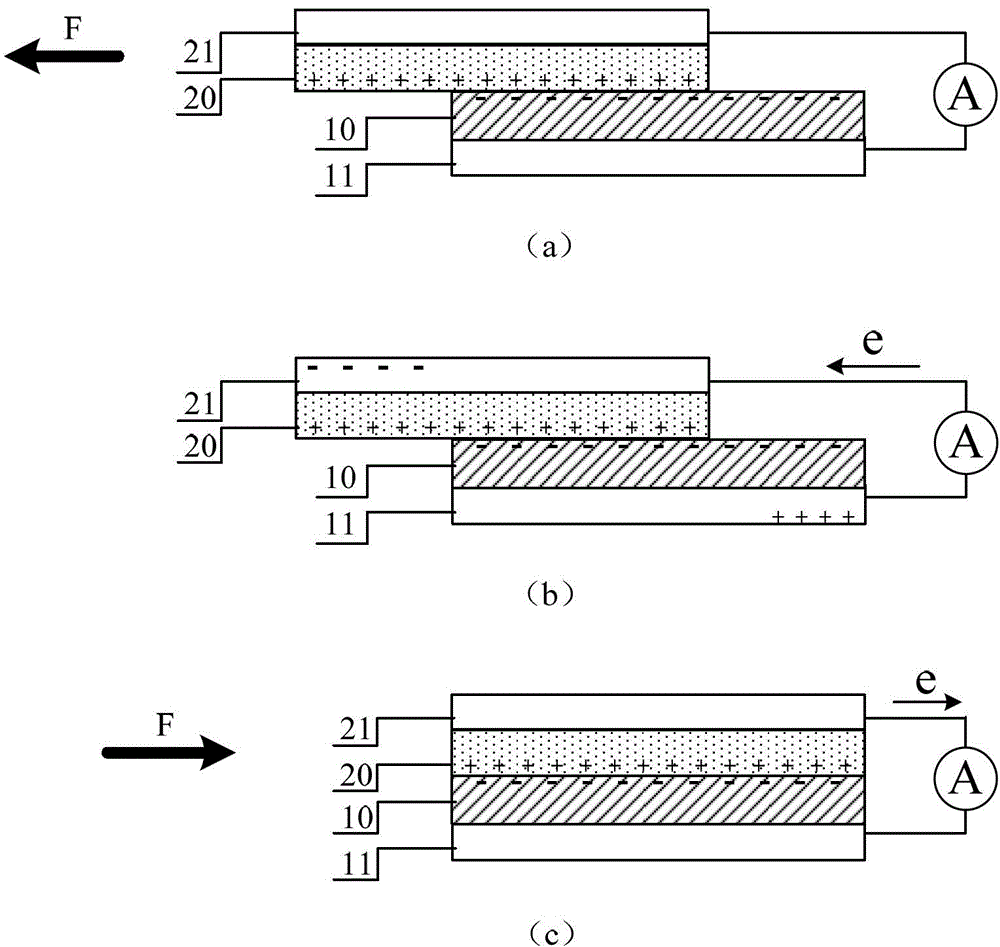

Radio-frequency transmission arrangement for a magnetic resonance system

InactiveUS20080079430A1Reduce interactionSkip the installation processElectric/magnetic detectionMeasurements using magnetic resonanceResonanceB1 field

A radio-frequency transmission arrangement for an MR system for generation of a total B1 field which has a first antenna device that generates a first portion of the total B1 field and at least one antenna insert that generates a second portion of the total B1 field, such that the resulting B1 field is generated by the first antenna device and the at least one antenna insert.

Owner:SIEMENS HEALTHCARE GMBH

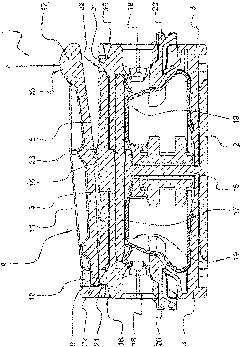

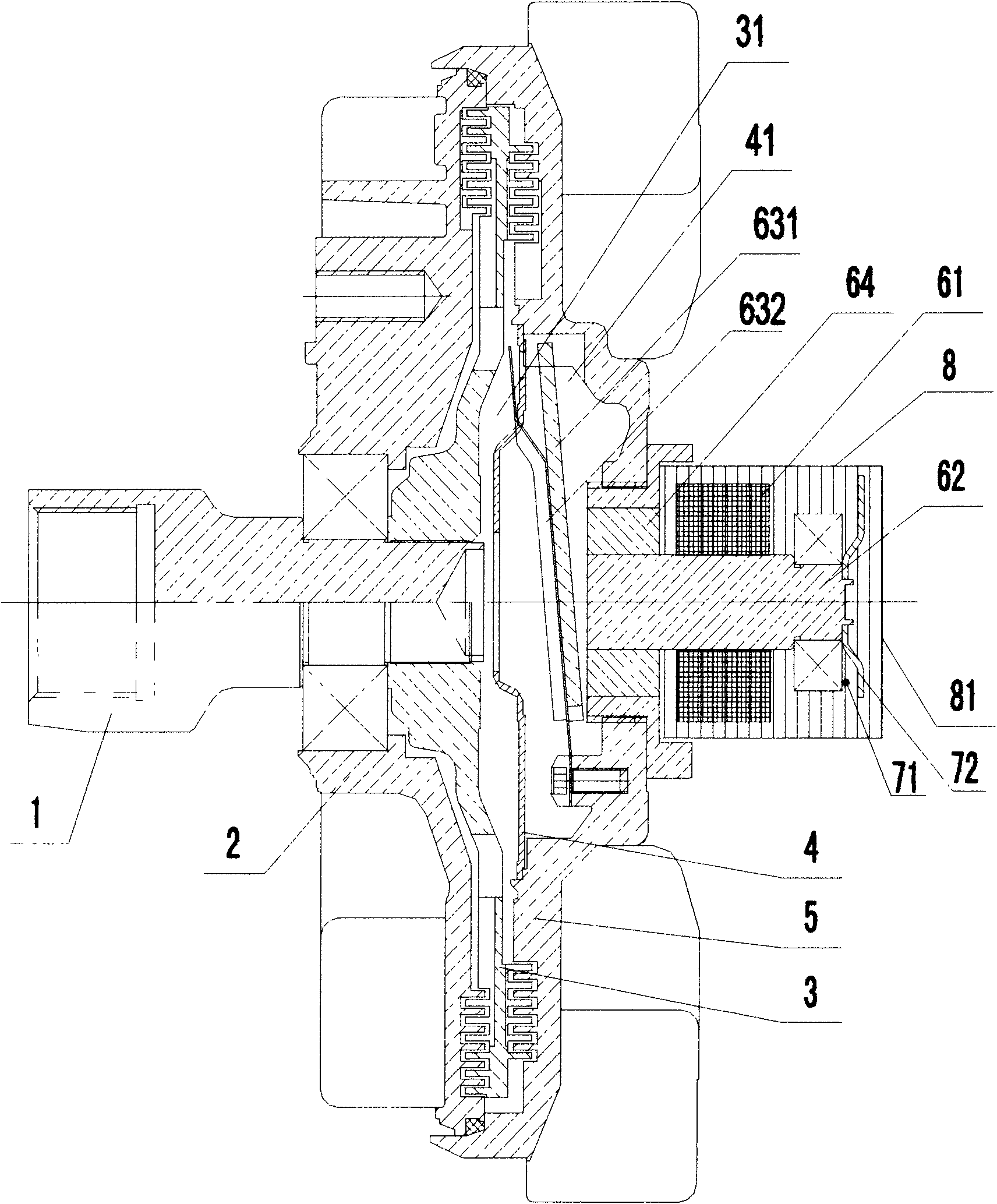

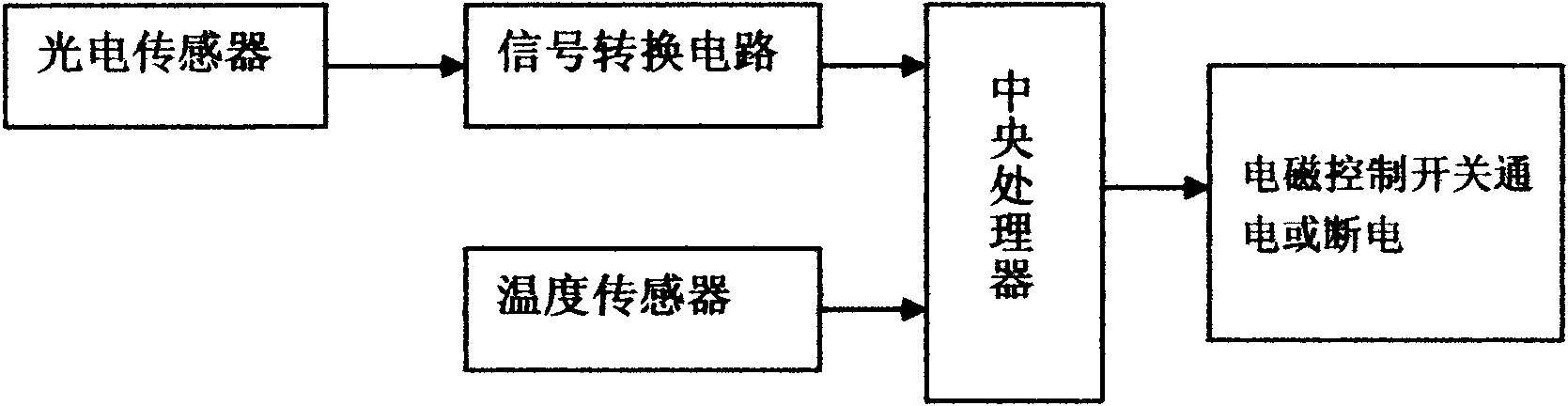

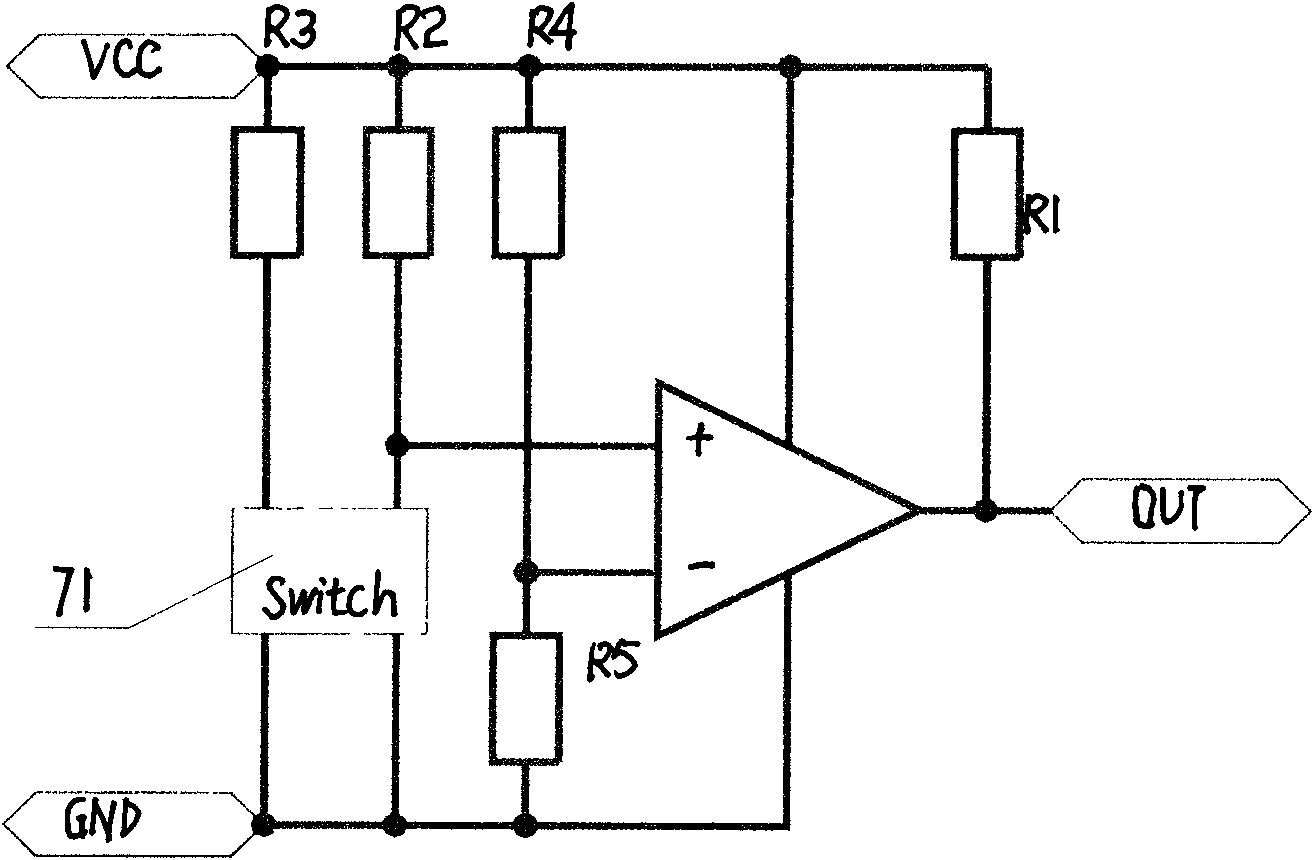

Electric control signal reflection fan clutch

InactiveCN102003265AGuaranteed accuracySkip the installation processCoolant flow controlMachines/enginesDrive shaftSpeed test

The invention relates to an electric control signal reflection fan clutch which comprises a driving shaft, a shell, a driving plate, a follower plate, a photoelectric induction type fan speed test component and a central processing unit, wherein the shell is installed on the driving shaft through a bearing; the driving plate is fixed on the driving shaft; the follower plate is fixed on an end cover; the fan is installed on the follower plate; the end cover and the shell are fixed integrally; an oil storing cavity and a working cavity are arranged between the end cover and the shell; the oil storing cavity and the working cavity are communicated by an oil inlet and an oil return hole; the oil inlet is controlled by an electromagnetic control switch to be opened and closed; the photoelectric induction type fan rotate speed test component tests the fan rotate speed; and the central processing unit receives the test signals. The fan rotate speed test component with the structure is unaffected by the magnetic field of an electromagnetic switch, and has accurate speed measuring, energy saving and environmental protection.

Owner:SUZHOU RISING AUTO PARTS

Integrated molding mould of dead head and casting cavity

ActiveCN103357823ASo as not to damageQuality assuranceFoundry mouldsMoulding machinesComposite materialNozzle

The invention discloses an integrated molding mould of a dead head and a casting cavity. The integrated molding mould comprises a core injection machine, an upper mould of a casting mould, a molding template of an upper mould closing box of the casting mould, a dead head molding mould, an upper core, and a lower core on the molding template, wherein an injection nozzle of the core injection machine is connected with a sand injection hole of the upper mould of the casting mould; the dead head molding mould is arranged on the upper mould of the casting mould and is provided with a molding hole; the upper mould of the casting mould is provided with a mould hole communicated with the molding hole; the top of the upper core is fixed on the upper end of the dead head molding mould; the bottom end of the upper core and the top of the lower core respectively stretch into the molding hole or the mould hole to be in butt joint; a dead head molding cavity is formed by a cavity among the upper core, the lower core, the molding hole and the mould hole. According to the integrated molding mould disclosed by the invention, the integrated molding of the dead head and the casting cavity is realized, the defects in transportation and installation processes of the dead head are overcome, time and labor are saved, the cost is low, and the quality of a casting product can be guaranteed.

Owner:ANHUI XINNING EQUIP

Guardrail capable of inclining

InactiveCN105064243AAvoid harmSkip the installation processRoadway safety arrangementsEngineeringSeparation column

The invention relates to a guardrail capable of inclining, and belongs to the technical field of traffic facilities. The guardrail consists of a separation column, a regulating mechanism and a connecting component, wherein the separation column consists of four parts of a column foot, a base, a column barrel and a column cover; the base is arranged on the column foot, a hemispheric body is arranged on the base, and a limiting groove is formed between the hemispheric body and the base; the regulating mechanism is positioned in the column barrel and comprises a spring, a regulating cable, a limiting block, an upper fixing block, a regulating block and a fixing ball, the spring is hung under a hanging beam in a buckling manner, a spacer is arranged at the lower end of the spring, the limiting block is mounted on the regulating cable in a sleeving manner, the regulating block is connected to the lower end of the regulating cable, and the fixing ball is fixed at the tail end of the regulating block; the tail end of the regulating cable is fixedly connected with the hemispheric body through the regulating block and the fixing ball, and then semi-moving connection between the column barrel and the base is realized through the interaction among the spring, the spacer and the limiting block and the regulating cable, the regulating block, the fixing ball and the hemispheric body. The guardrail disclosed by the invention can be applied to traffic routes and has the advantages of high safety, good practicality and the like.

Owner:孟国华

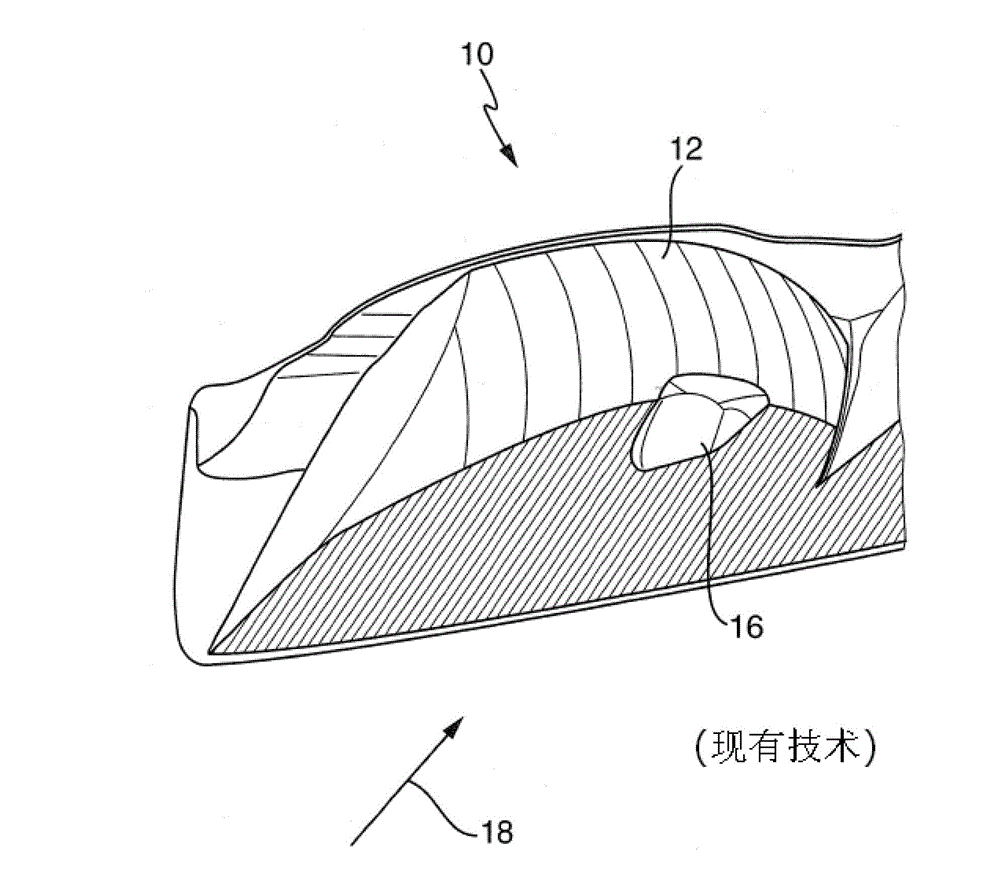

Optical module of motor vehicle lightning device

InactiveCN103062696AReduce manufacturing costReduce installation costsNon-electric lightingVehicle headlampsOptical ModuleThermal contact

The invention relates to an optical module (10) of a motor vehicle lightning device. The optical module (10) has: at least one semiconductor light source (14) for emitting light; a main optical unit (12) for constricting at least one part of the light emitted by the at least one semiconductor light source (14); a light shield (16) subject to the at least one semiconductor light source (14); and a cooling piece (20) in at least indirect thermal contact with the at least one semiconductor light source (14). In order to fabricate the optical module (10) simply and cost-effectively, at least one part of the light shield (16) is suggested to be an element of integration of the cooling piece (20).

Owner:AUTOMOTIVE LIGHTING REUTLINGEN GMBH

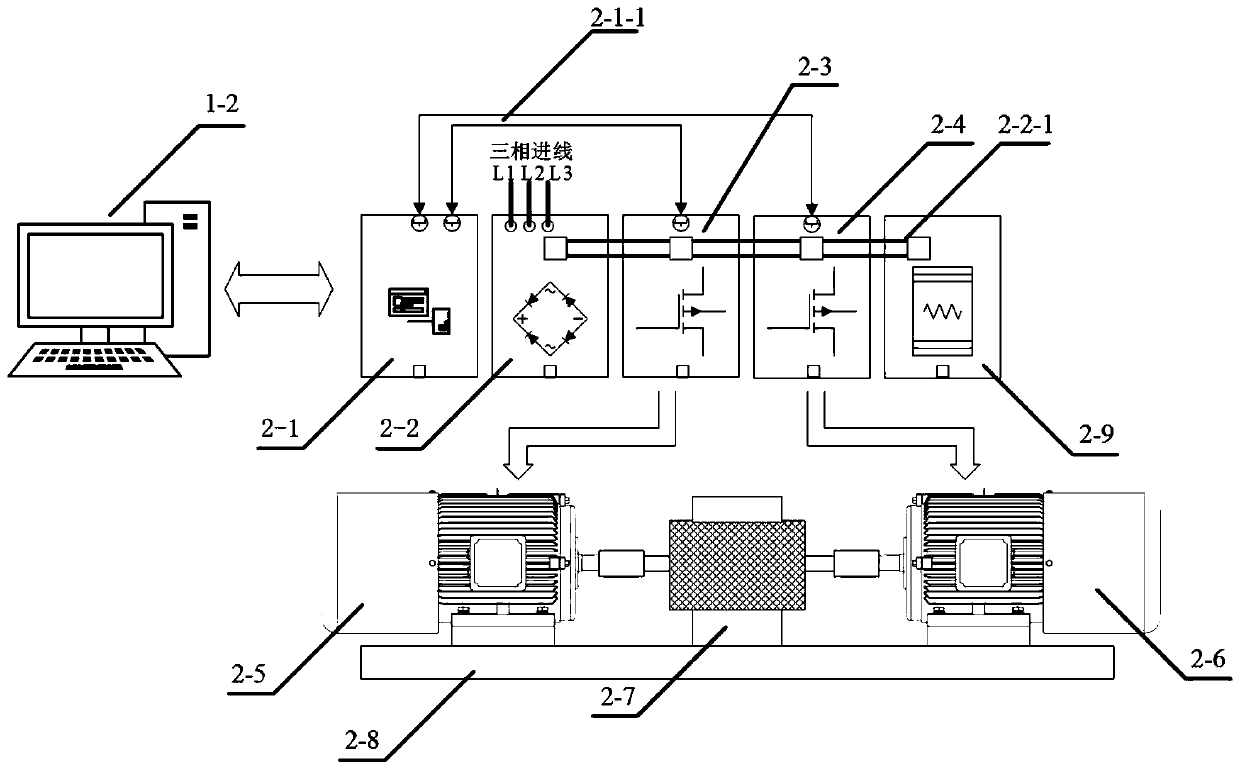

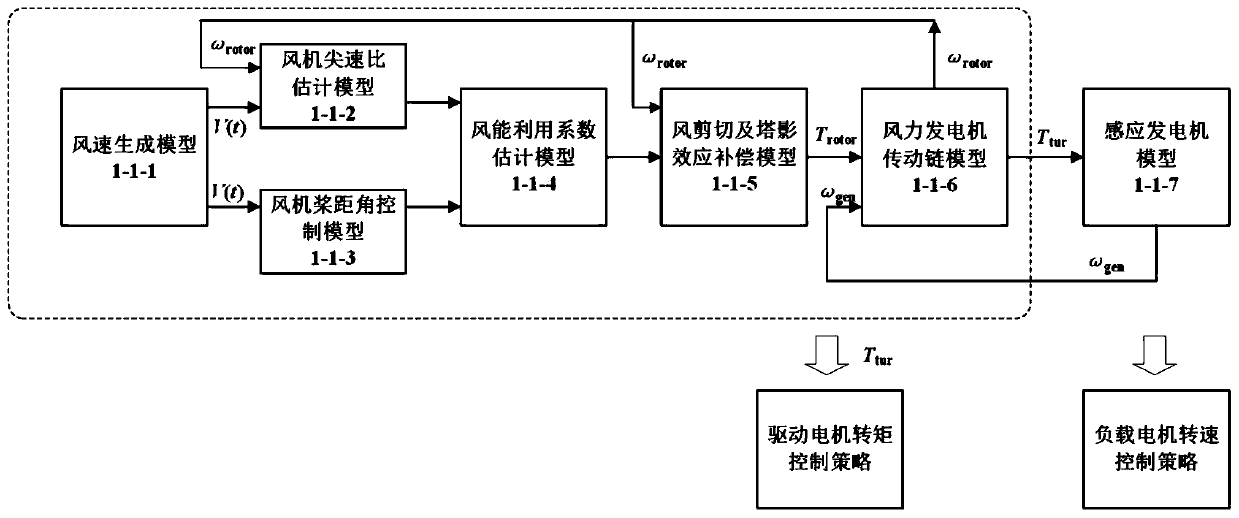

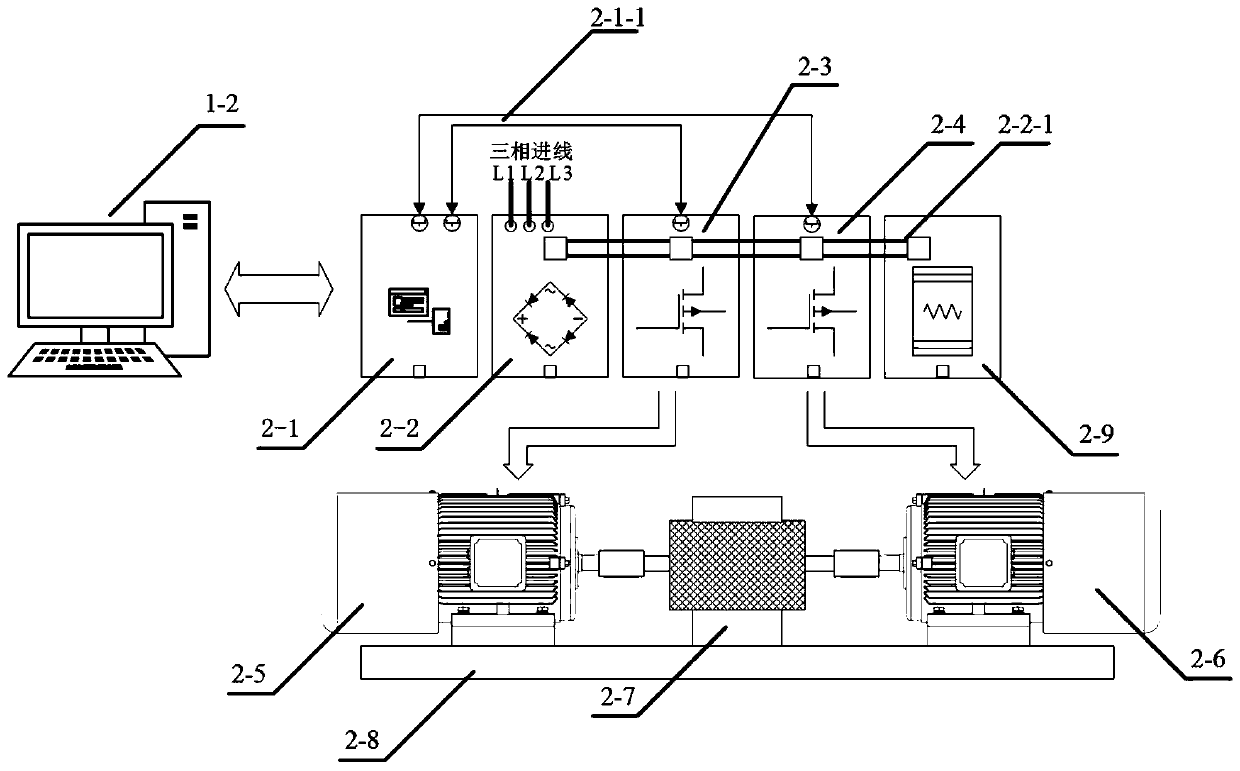

Real wind regime and wind power generation simulation device and method with wind shear and tower shadow effect

InactiveCN111120222AImprove utilization efficiencyExhibits an oscillating dynamic characteristicMachines/enginesWind motor monitoringWind drivenSoftware system

The invention discloses a real wind regime and wind power generation simulation device with a wind shear and tower shadow effect. The real wind regime and wind power generation simulation device comprises a simulator control system and an electromechanical servo system, the simulator control system comprises a software system and a hardware system, the simulator control hardware system comprises an industrial personal computer and a data collecting card; the simulator control soft system comprises a wind speed generation model, a draught fan tip speed ratio estimation model, a draught fan pitch angle control model, a wind energy utilization coefficient model, a wind shear and tower shadow effect compensation model, a wind driven generator drive chain model and an induction generator model,the electromechanical servo system comprises a programmable controller, a direct current bus power module, a frequency conversion driving unit, a frequency conversion power generation unit, a drivingmotor, a loading motor, a rotating speed torque meter and a test bed. The real wind regime and wind power generation simulation device is used for the simulation of wind power generation process andresearch and application of wind power generation control strategy under laboratory environment.

Owner:ZHEJIANG UNIV

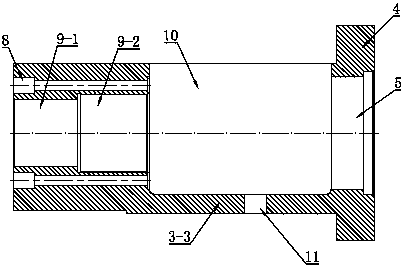

Motor base for numerically-controlled machine tool

InactiveCN104319935ASkip the installation processEasy to installSupports/enclosures/casingsNumerical controlIntegrated design

The invention discloses a motor base for a numerically-controlled machine tool. The motor base sequentially comprises a shaft hole seat, an installation seat and a base from left to right, wherein the shaft hole seat, the installation seat and the base are of an integrally-formed structure. The shaft hole seat is of a cylindrical structure, and stair-stepping shaft holes including a first-step shaft hole and a second-step shaft hole are formed in the inner ring. The installation seat is a square seat, the three surfaces of the installation seat define an installation groove through lateral plates, a square opening is formed in one surface of the installation seat, and the two ends of the installation groove are connected with the shaft hole seat and the base respectively. A square plate serves as the base, and a round through hole is formed in the middle of the square plate. Installation side plates are arranged on the outer surfaces of the shaft hole seat and the installation seat, and reinforcement ribs are arranged between the installation side plates and the base. Integrated design is adopted in the motor base, so that installation of an assembly of the motor base is omitted, and the motor base has the advantage of convenient and rapid installation.

Owner:浙江华特数控机床有限公司

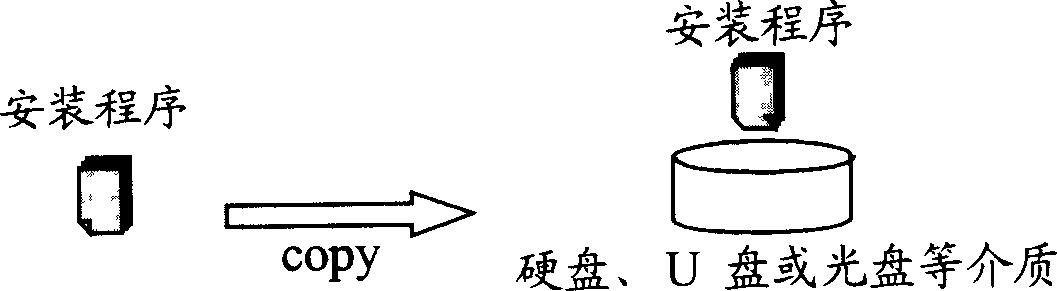

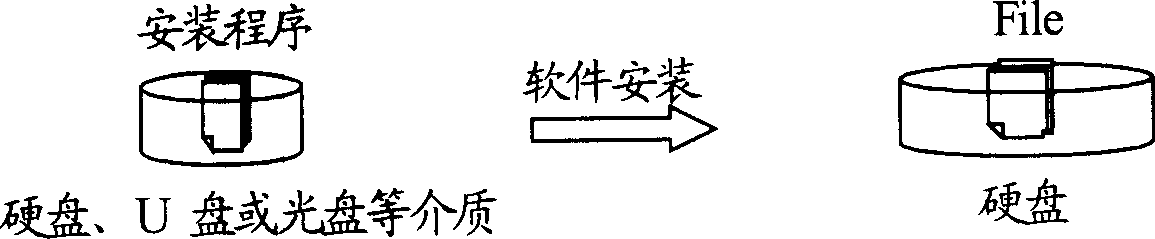

Software packaging method

InactiveCN1828534ASkip the installation processSimplify the complexity of useProgram loading/initiatingRemovable mediaSoftware

The disclosed method comprises: storing both of the software file and legal user information into a mobile storage media; calculating the file by computer, and reading out the user information to enter the normal application state. This invention can avoid the complex installation process and convenient to secrecy of user information

Owner:HUAWEI TECH CO LTD

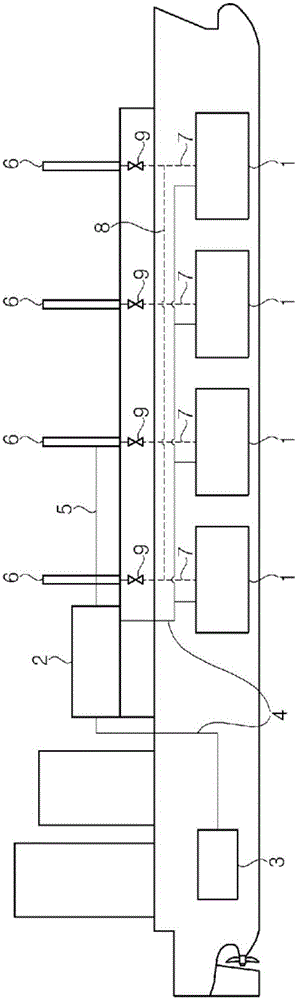

Fuel gas supply system of vessel

InactiveCN106488872ASkip the installation processInternal combustion piston enginesFuel supply apparatusLine tubingFuel supply

Disclosed is a fuel gas supply system (FGSS) of a vessel, which supplies natural gas to an engine as a fuel. The FGSS of the vessel includes: a storage tank in which a liquid cargo is stored; a vent mast connected to the storage tank; a fuel pipe line connected to the engine to supply the fuel; and a vent line connected to the fuel pipe line, wherein the vent line is connected to the vent mast.

Owner:DAEWOO SHIPBUILDING & MARINE ENG CO LTD

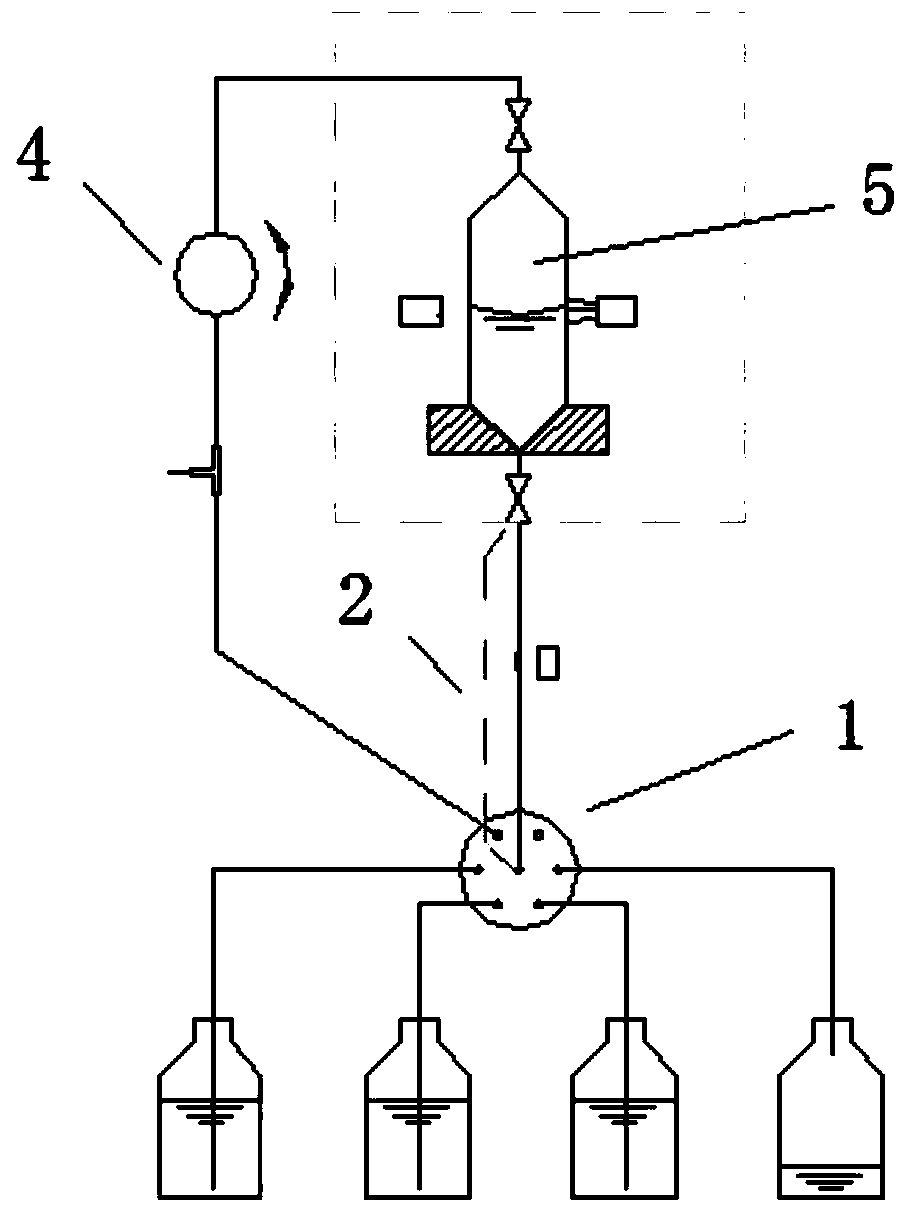

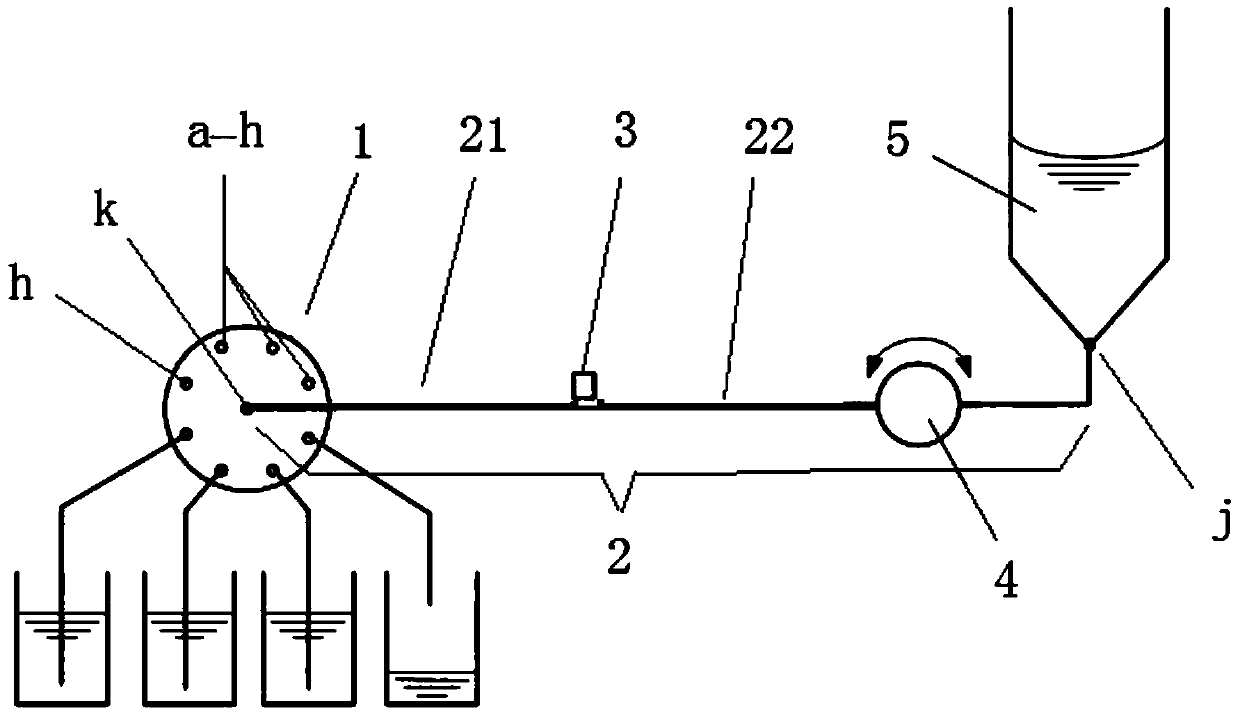

Water quality analytic system

The invention discloses a water quality analytic system which includes: a multichannel direction-selective valve (1) provided with a public port (k) and a plurality of distribution ports (a-h) which can be communicated with the public port (k) selectively; a reaction container (5), of which the bottom is provided with a channel opening (j); a metering isolation tube (2) which is connected between the public port (k) and the channel opening (j); and a liquid level detector (3) which is arranged in a pipeline of the metering isolation tube (2). The water quality analytic system also includes a fluid driver (4), which is disposed in the pipeline of the metering isolation tube (2). The upper part of the reaction container (5) is communicated with atmosphere.

Owner:桂林云璟科技有限公司

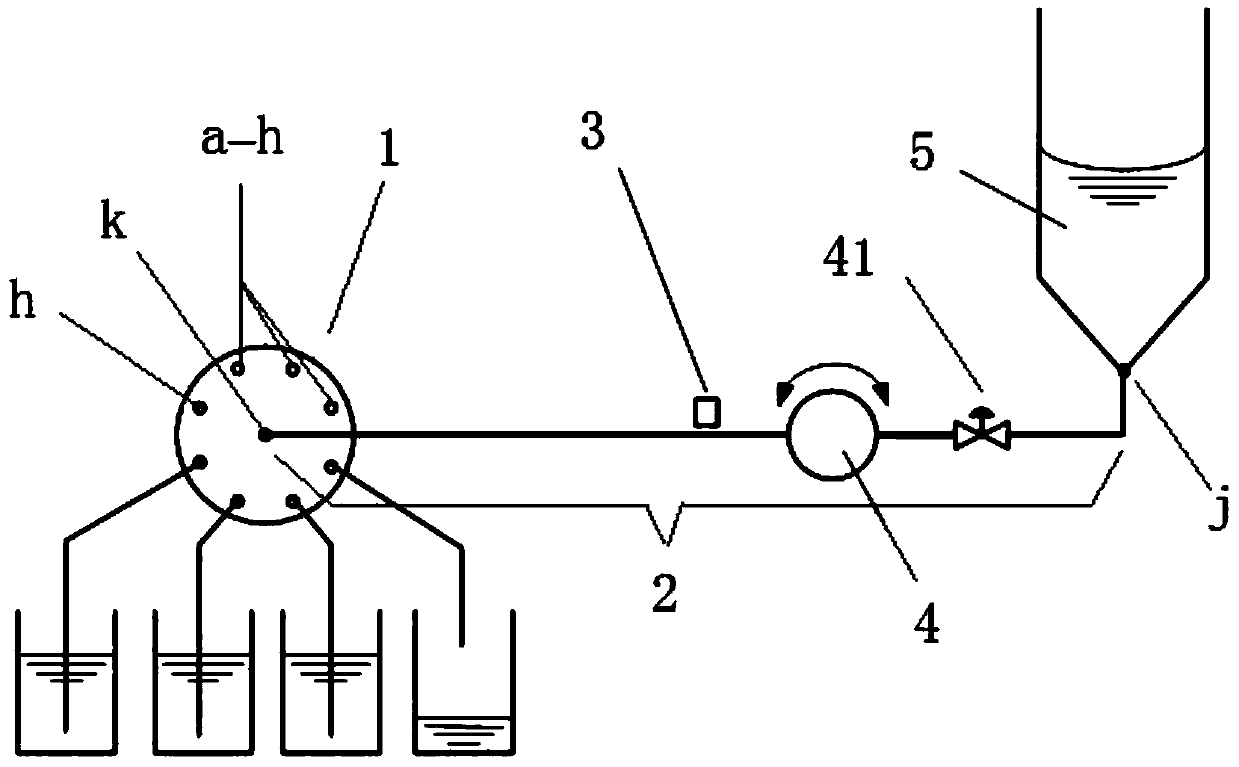

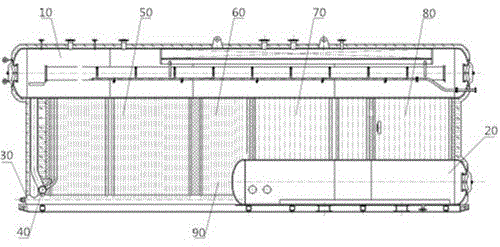

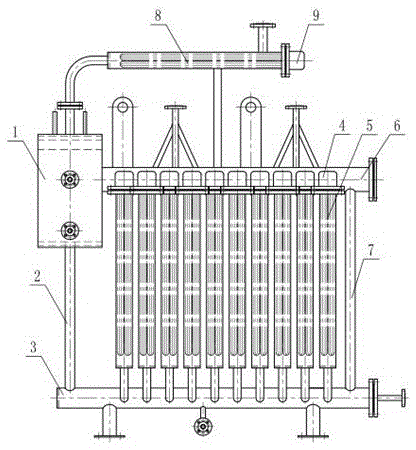

Electric-heating superheated steam boiler

InactiveCN105588099ALow costMeet needsSteam generation heating methodsSteam superheatersElectricityEngineering

The invention discloses an electric-heating superheated steam boiler. The electric-heating superheated steam boiler comprises a lower header, a saturated steam electric heater header, an upper header, a separation header and a superheated steam electric heater header. The upper header and the lower header are connected through a communication pipe I and a communication pipe II, to form an integrated structure. The saturated steam electric heater header is arranged between the upper header and the lower header. The separation header is connected with the upper header. The superheated steam electric heater header is arranged above the upper header and connected with the separation header through an elbow pipe. Saturated steam electric heaters of various specifications are arranged in the saturated steam electric heater header. A superheated steam electric heater is arranged in the superheated steam electric heater header. According to the electric-heating superheated steam boiler, the amount of generated saturated steam is stable, the temperature of superheated steam is stable, the investment cost is low, pollution is small, and the noise is low.

Owner:TAIJUNE BOILER IND KUSN

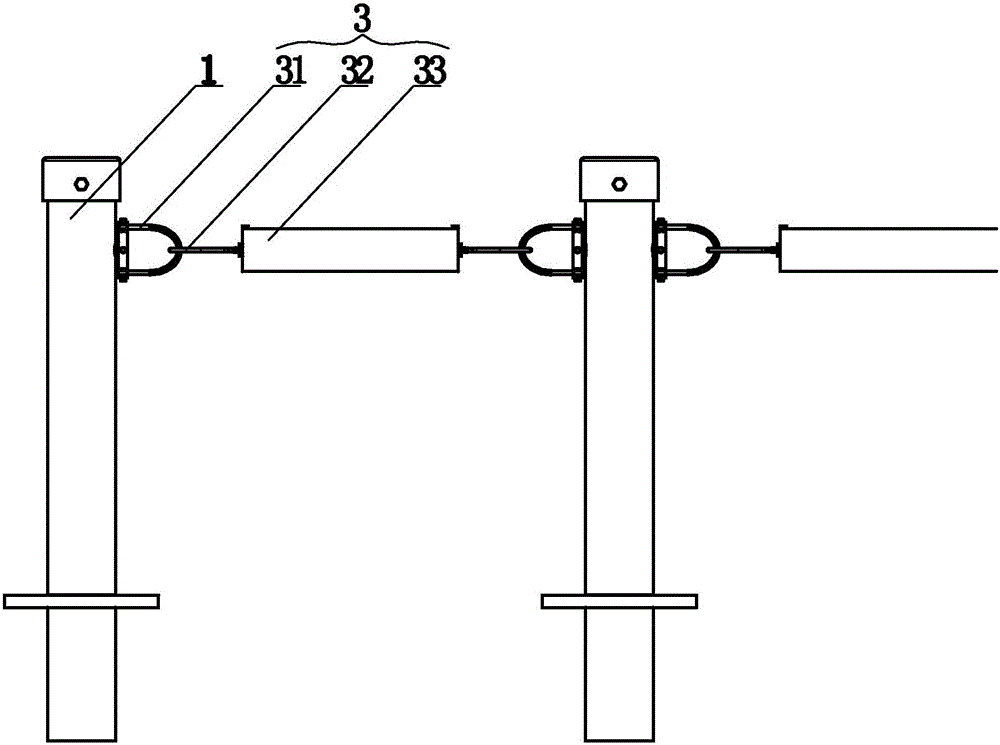

Refrigerating instrument

ActiveCN108661468ASolve fit problemsSolve the coordination problemDomestic cooling apparatusLighting and heating apparatusMechanical engineeringEngineering

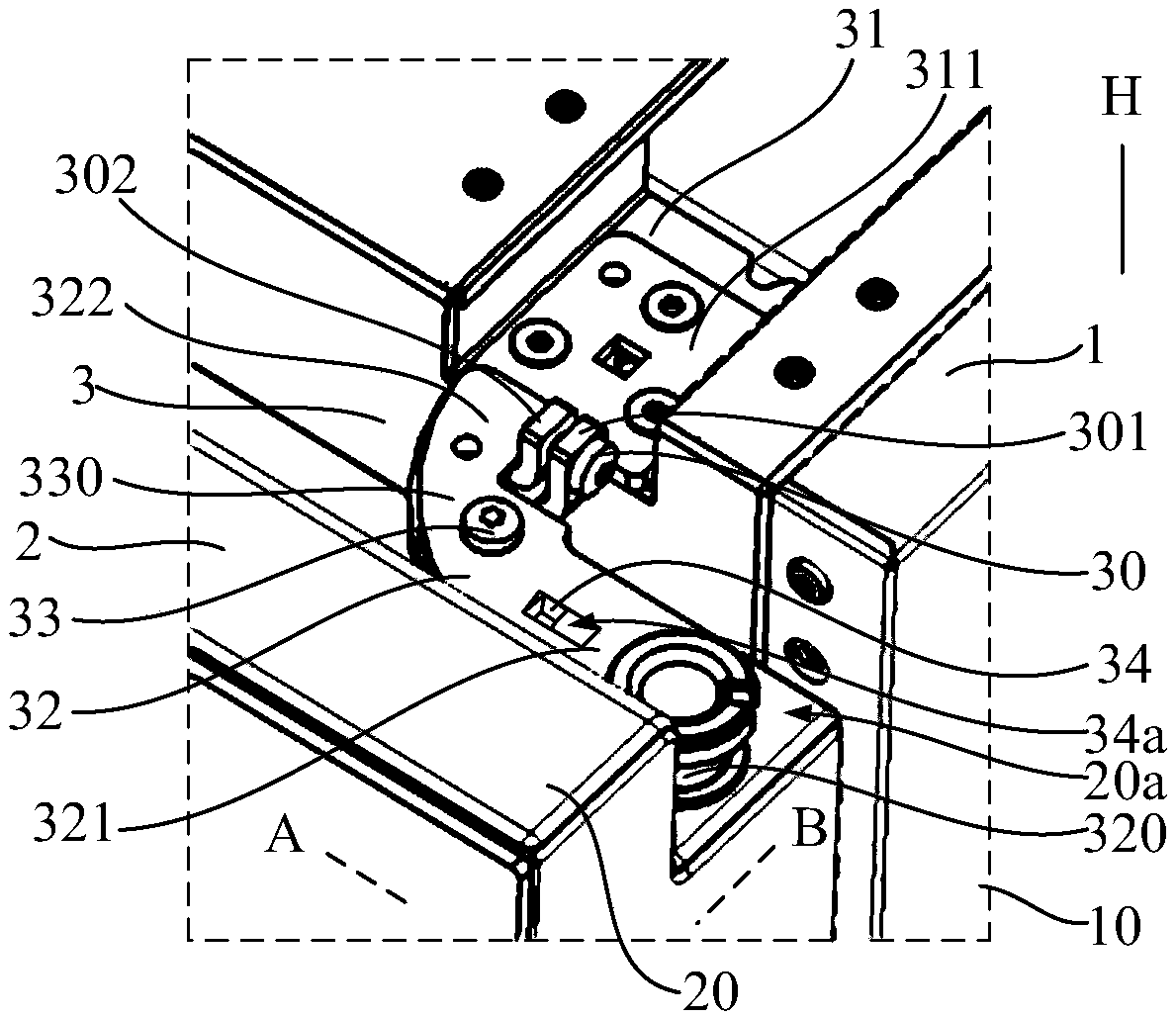

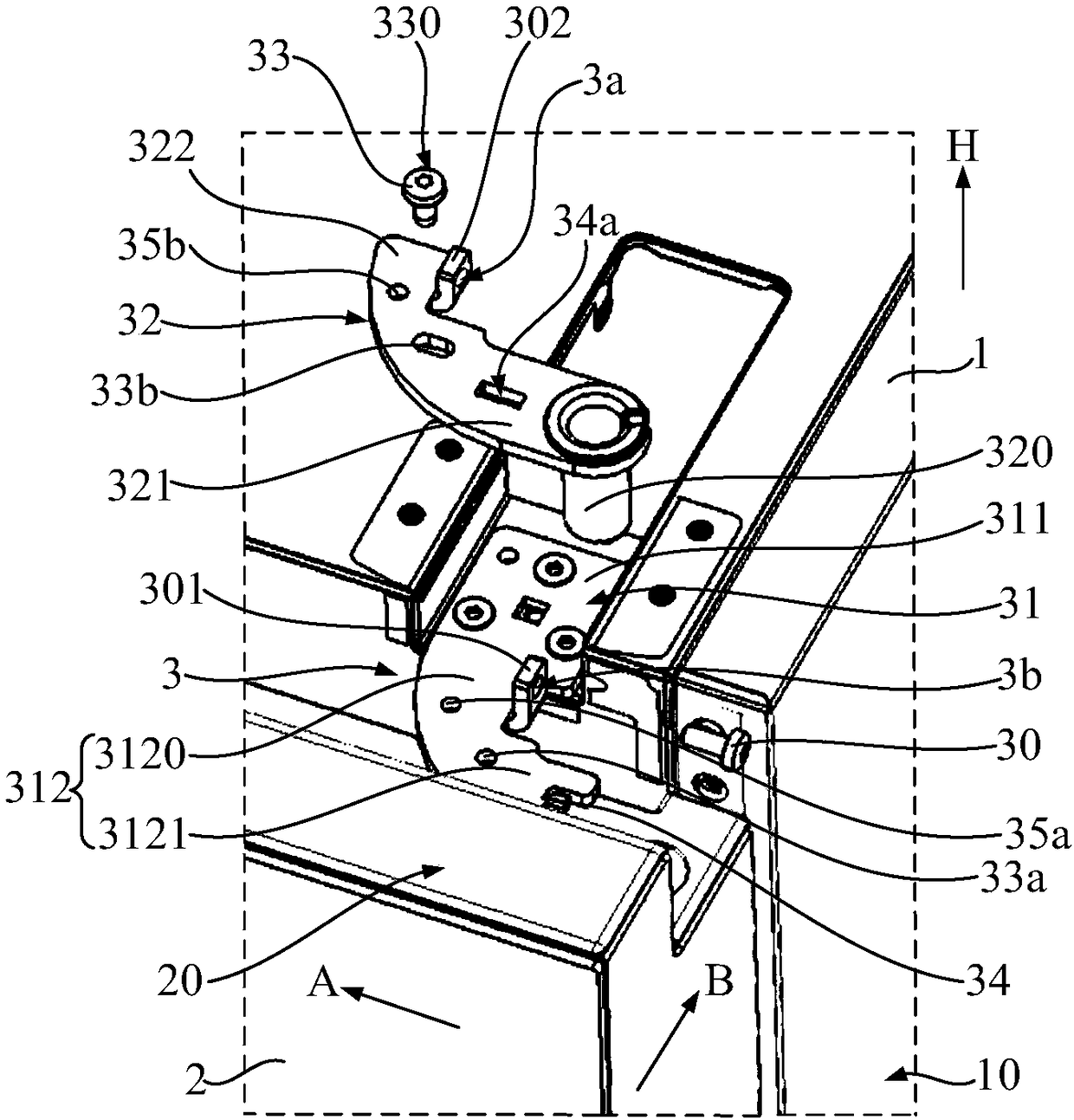

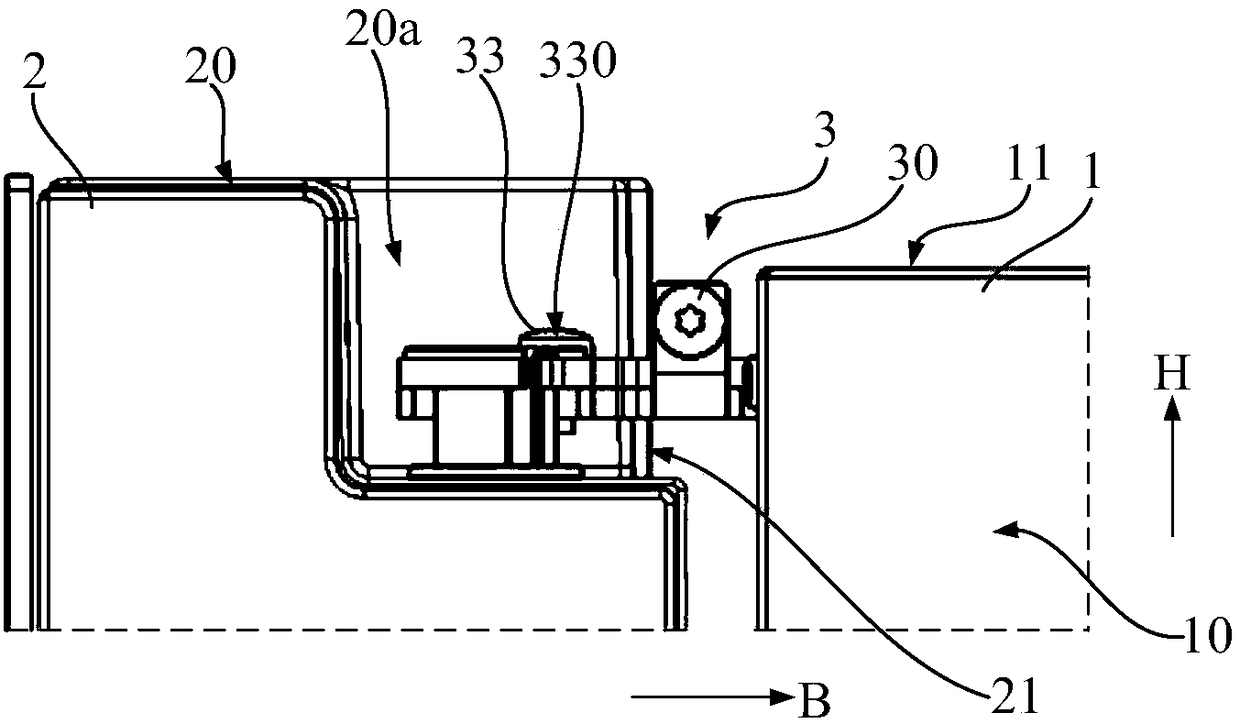

The invention discloses a refrigerating instrument. The refrigerating instrument comprises a box body (1), doors (2) and a hinge assembly (3), wherein the hinge assembly (3) is connected with the boxbody (1) and the doors (2); the hinge assembly comprises a mounting part (31), a hinge part (32) and an adjusting unit, wherein the installing part (31) is fixed on the box body (1), the hinge part (32) is connected to a hinge chain shaft (320) provided with the doors (2) of the mounting part (31); and the adjusting unit comprises an adjusting part (30) which is connected to the hinge chain part (32), the adjusting part (30) is used for adjusting the hinge chain part (32) in the adjusting direction relative to the position of the mounting part (31), and the adjusting direction is the width direction of the doors (2) or the front-back direction of the box body (1). According to the technical scheme, the problems that the appearance or sealing caused by irregular distance between two doors (2) or the doors (2) and the box body (1) is solved.

Owner:BSH ELECTRICAL APPLIANCES JIANGSU +1

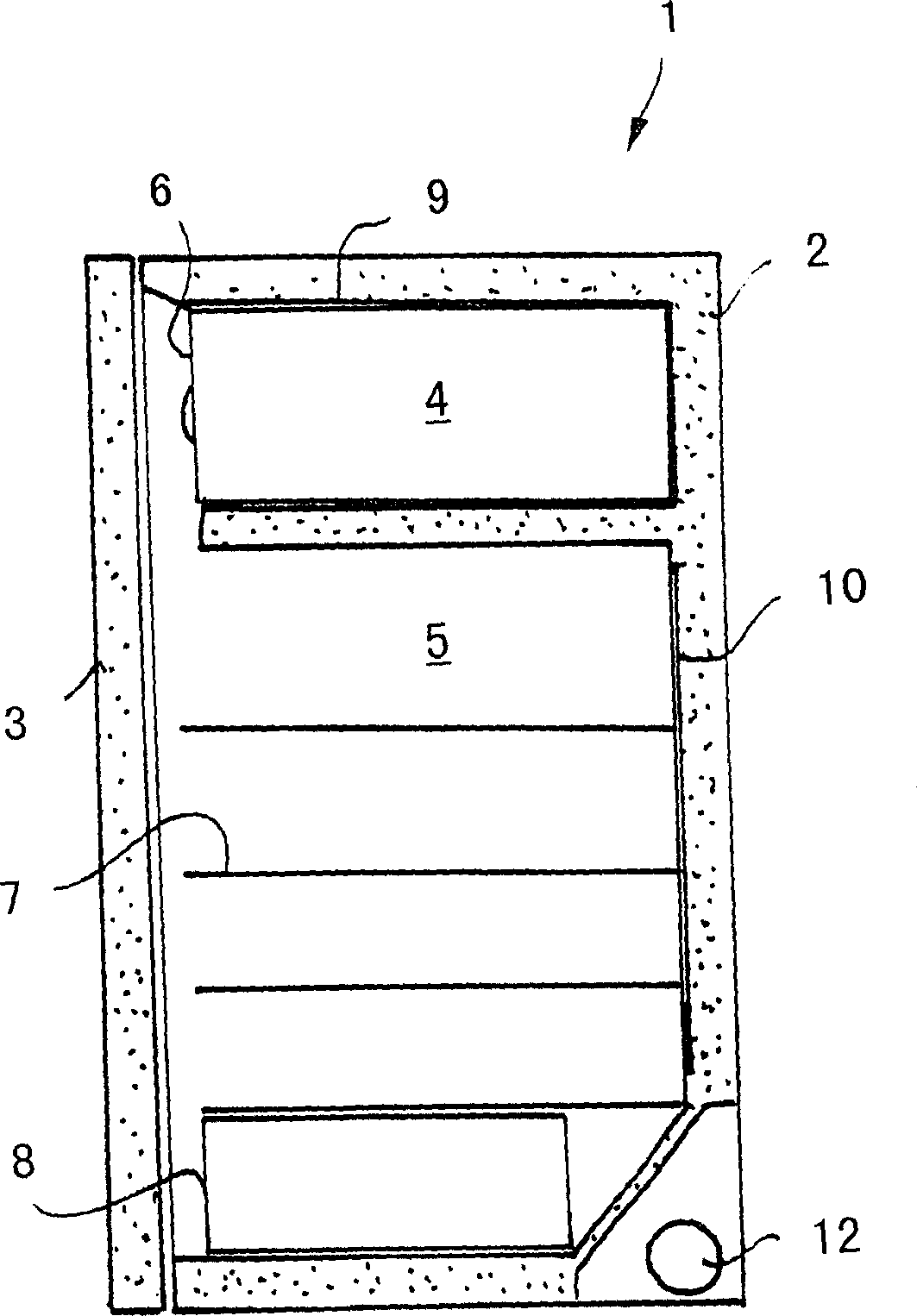

Refrigerating and/or freezing appliance and method for controlling the same

InactiveCN1865817AFlow through blockReduce generationMechanical apparatusCompression machines with several evaporatorsRefrigerantElectrical and Electronics engineering

The invention relates to a refrigeration device and / or freezer device comprising a refrigerant circuit with a compressor, a condenser, at least one capillary tube and at least one evaporator and a control device for Refrigerant flow through the refrigerant circuit is controlled. The invention further relates to a method for controlling such a refrigerating and / or freezing device, wherein at least one operating parameter and / or environmental parameter of the refrigerating and / or freezing device is detected and based on the detected operating parameter and / or ambient parameters control said refrigerant flow through the refrigerant circuit. The control of the refrigerant flow proposed according to the invention is by means of heating means to heat the capillary tubes and thus cause the refrigerant flowing through the capillary tubes to evaporate. The invention is based on the insight that the vapor generated in the capillary tubes can be significantly reduced and optionally completely prevented from flowing through the capillary tubes. The more evaporation that occurs in the capillary, the less refrigerant flow is maintained through the capillary.

Owner:利布赫尔家用器具奥克森豪森有限责任公司

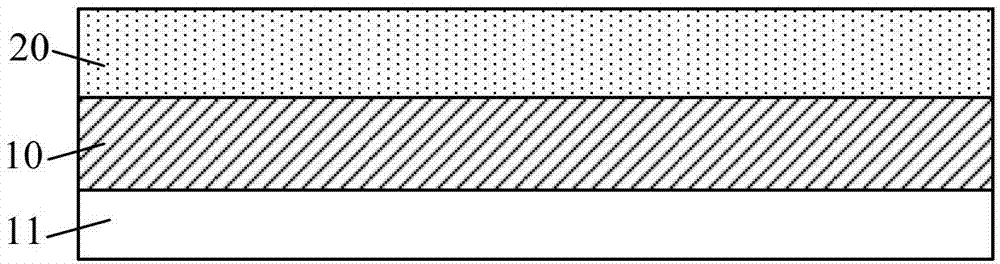

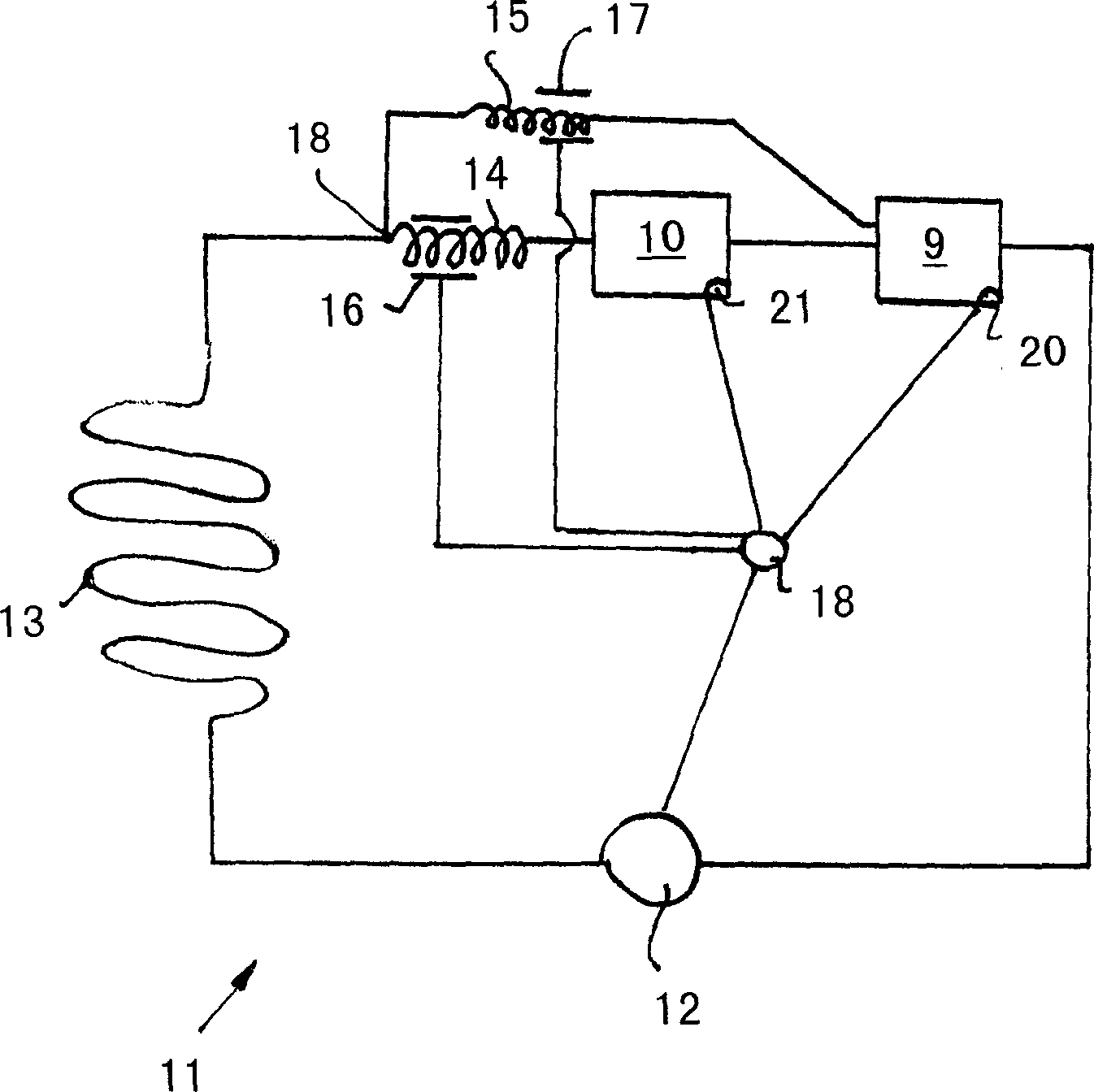

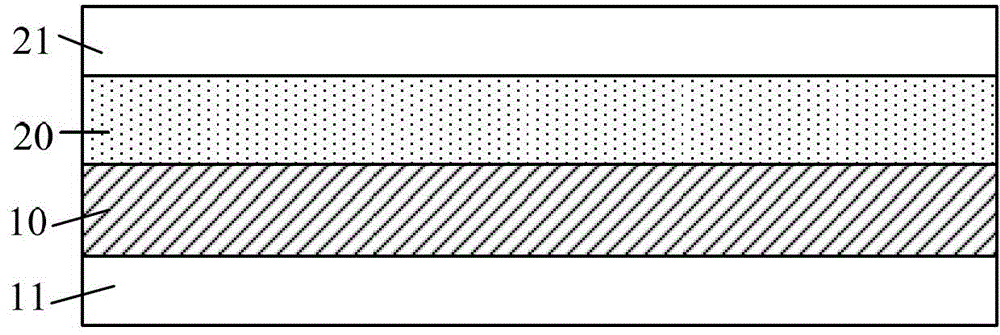

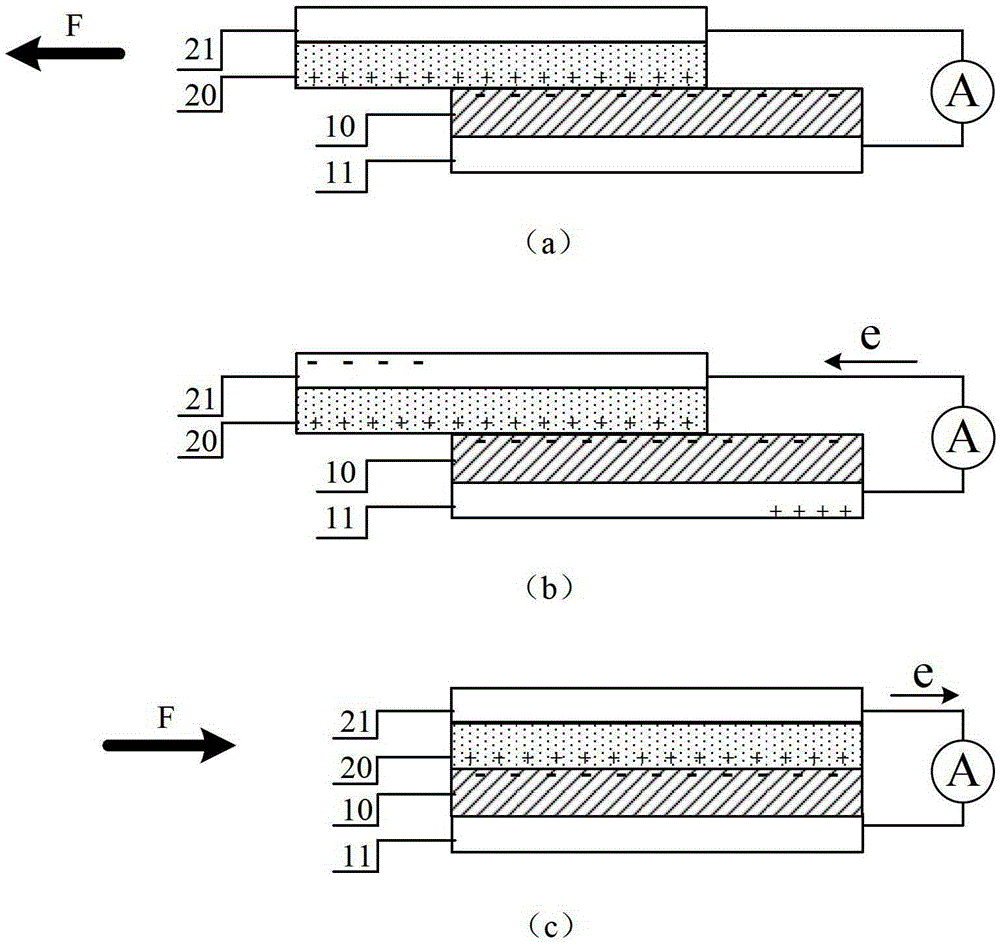

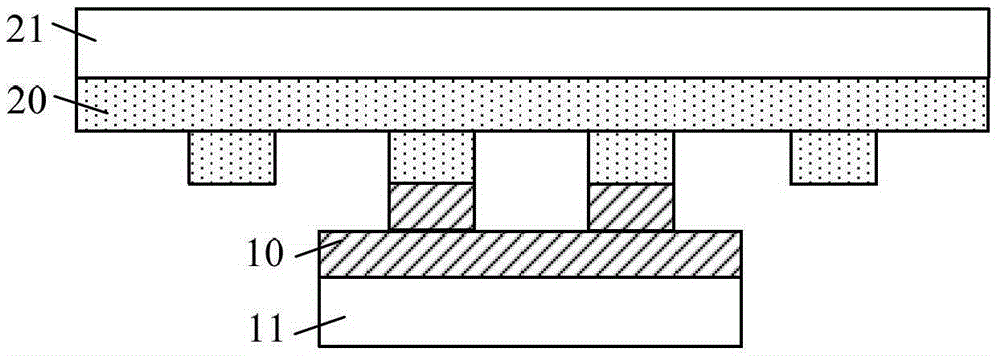

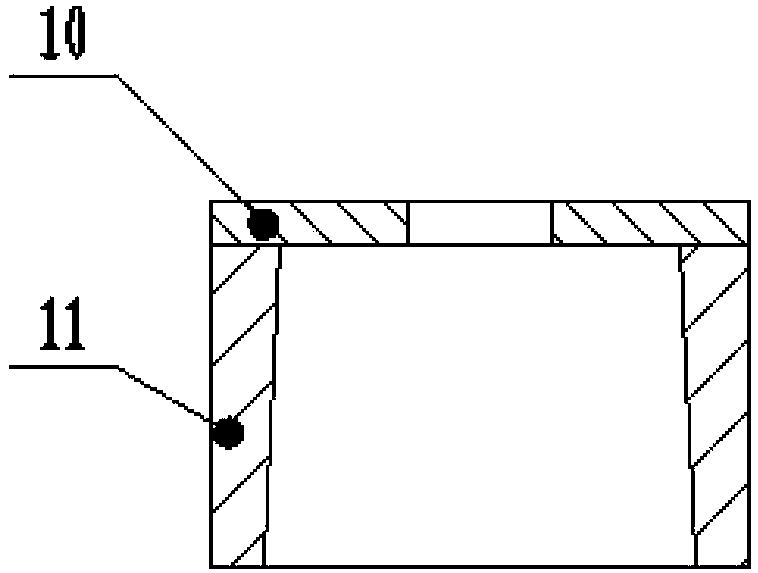

A kind of sliding friction nanogenerator and power generation method

ActiveCN103354429BSkip the installation processPackaging technology is convenientFriction generatorsEngineeringAlternating current

A sliding frictional nano generator. The sliding frictional nano generator comprises: a first frictional layer (10), a first conducting element (11) which is placed in contact with the lower part of the first frictional layer, a second frictional layer (20), and a second conducting element (21) which is placed in contact with the upper part of the second frictional layer. The upper surface of the first frictional layer and the lower surface of the second frictional layer are placed opposed to each other. The upper surface of the first frictional layer and the lower surface of the second frictional layer generate relative sliding friction tangent to a contact surface under the action of an external force; and meanwhile, the contact area is changed and an electrical signal is output to an external circuit through the first conducting element and the second conducting element. When a periodic tangential external force is applied to the sliding frictional nano generator, an alternating current pulse signal output can be formed between the first conducting element and the second conducting element.

Owner:BEIJING INST OF NANOENERGY & NANOSYST

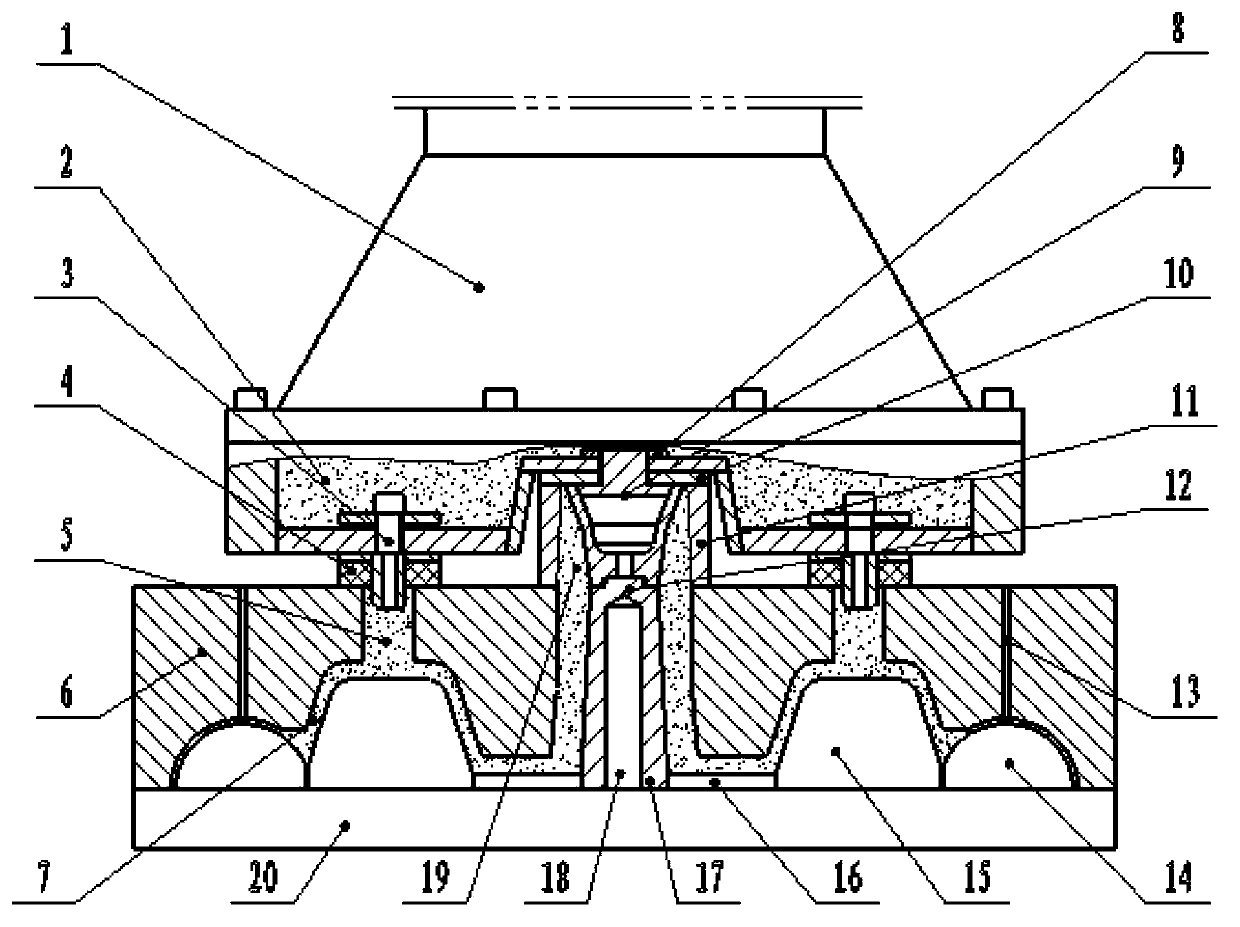

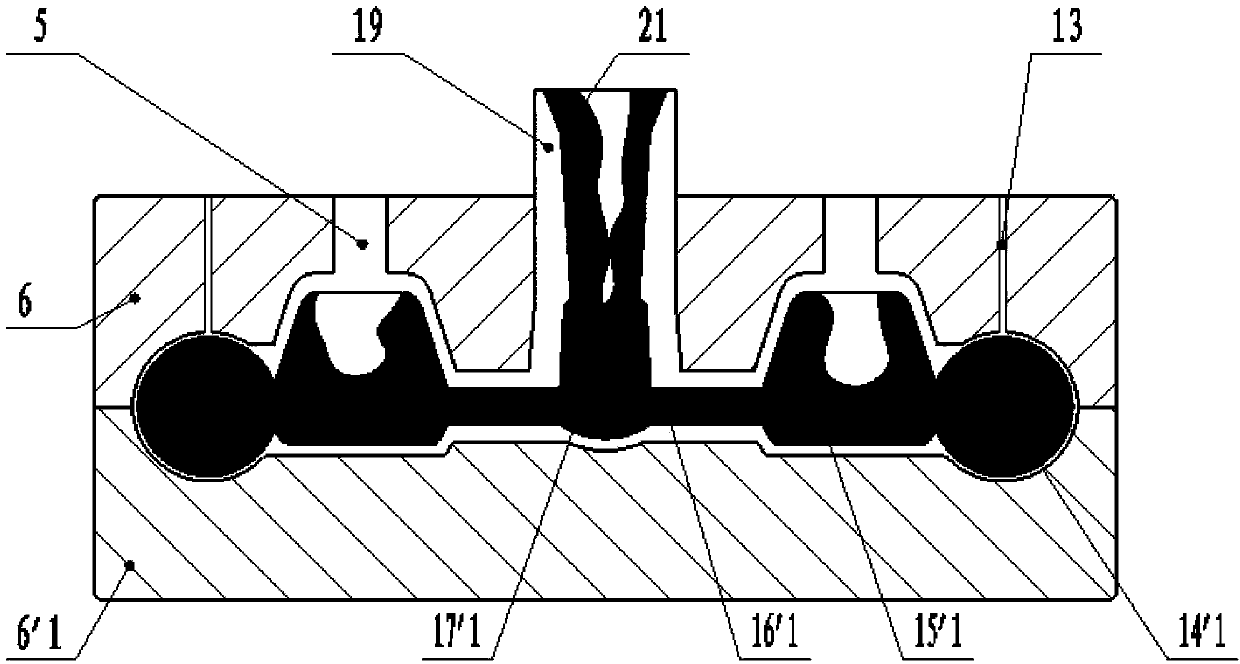

A sleeve-sliding friction nanogenerator

ActiveCN103780125BSkip the installation processPackaging technology is convenientFriction generatorsNew energyBiomedical engineering

A jacketed sliding frictional nano generator which comprises a first conducting element (11), a first frictional layer (10) which is placed in contact with the outer surface of the first conducting element, a second conducting element (21), and a second frictional layer (20) which is placed in contact with the inner surface of the second conducting element, wherein the first frictional layer comprises a plurality of first frictional units (101) and the second frictional layer comprises a plurality of second frictional units (201); moreover, the outer surfaces of all the first frictional units belong to a first curved surface; the inner surfaces of all the second frictional units belong to a second curved surface; the first curved surface and the second curved surface outside the first curved surface form an inner and outer jacketed structure; the outer surfaces of the first frictional units and the inner surfaces of the second frictional units generate relative sliding friction; meanwhile, the frictional area is changed; and an electrical signal is output to an outer circuit through the first conducting element and the second conducting element. The frictional nano generator can be used as a new energy technology or a sensing technology.

Owner:BEIJING INST OF NANOENERGY & NANOSYST

Coin depositing and dispensing machine

ActiveUS20160240027A1Decrease in coin storing capacityReduce machine sizeCoin countersCoin/currency accepting devicesEngineeringMechanical engineering

In a coin depositing and dispensing machine 10, a plurality of storing and feeding apparatuses 50 disposed below a deposited-coin transport unit 20 are arranged vertically on plural levels. A transport direction in which a coin is transported by the deposited-coin transport unit and a feeding direction in which a coin is fed out from each storing and feeding unit are substantially perpendicular to each other.

Owner:GLORY KOGYO KK

A sliding friction nanogenerator

ActiveCN103368451BSkip the installation processPackaging technology is convenientFriction generatorsEngineeringAlternating current

The invention provides a nanometer electric generator utilizing sliding friction. The nanometer electric generator comprises a first friction layer, a first conducting element, a second friction layer and a second conducting element, wherein the first conducting element is arranged under the first friction layer in a contact way; the second conducting element is arranged above the second friction layer in a contact way; the upper surface of the first friction layer is arranged opposite to the lower surface of the second friction layer; when relative sliding friction occurs between the upper surface of the first friction layer and the lower surface of the second friction layer by an exerted external force, and the contact area is changed, an electric signal is output to an external circuit by the first and second conducting elements; when a periodic tangential external force is exerted to the nanometer electric generator utilizing sliding friction, alternating current pulse signal output is realized between the first and second conducting elements.

Owner:BEIJING INST OF NANOENERGY & NANOSYST

Dead head and casting cavity integrated forming die

ActiveCN103394645ASo as not to damageAvoid influenceFoundry mouldsFoundry coresMaterials scienceDeep hole

The invention discloses a dead head and casting cavity integrated forming die which comprises a core shooter, a casting upper die and a forming template combined with the casting upper die, wherein nozzles of the core shooter are connected with core shooting holes formed in the casting upper die. The dead head and casting cavity integrated forming die also comprises a dead head forming sleeve arranged on the casting upper die; an end cover is arranged on the top of the dead head forming sleeve; a die hole communicated with a sleeve hole of the dead head forming sleeve is formed in the casting upper die. The dead head and casting cavity integrated forming die also comprises an upper core arranged in the sleeve hole and a lower core arranged on the forming template; the top of the upper core extends out of the end cover and is fixed on a spraying head of the core shooter; the bottom of the upper core and the top of the lower core respectively extend into the die hole or the sleeve hole to be butted. During the casting of products, the dead head and casting cavity integrated forming die can neither damage a dead head nor produce scattered sand; the scattered sand clearing time is shortened; the time and the labor are reduced; furthermore, the influence of the scattered sand on the cast products can be avoided; the quality of the cast products is guaranteed.

Owner:ANHUI XINNING EQUIP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com