Patents

Literature

38results about How to "Reduce machine size" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

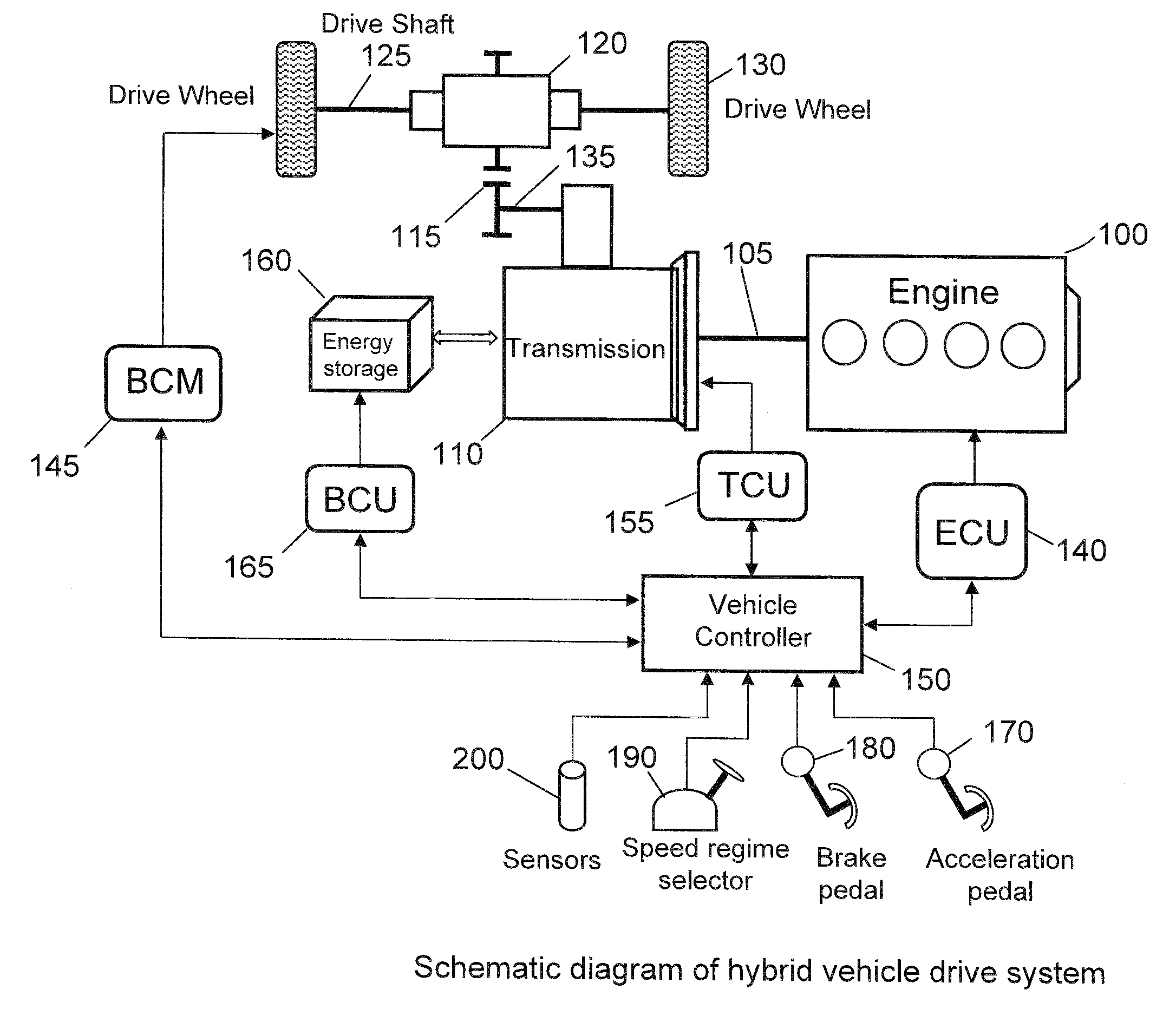

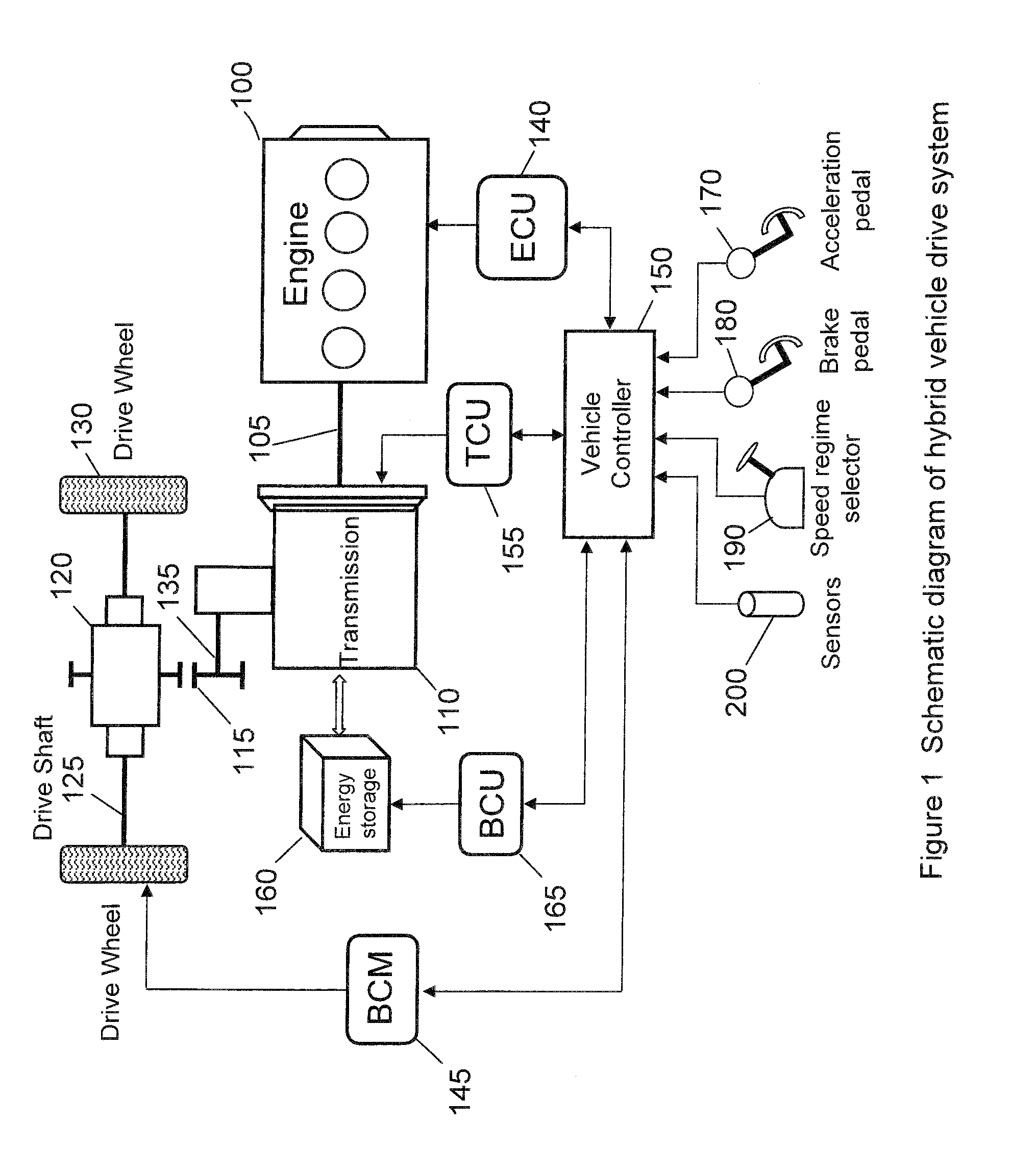

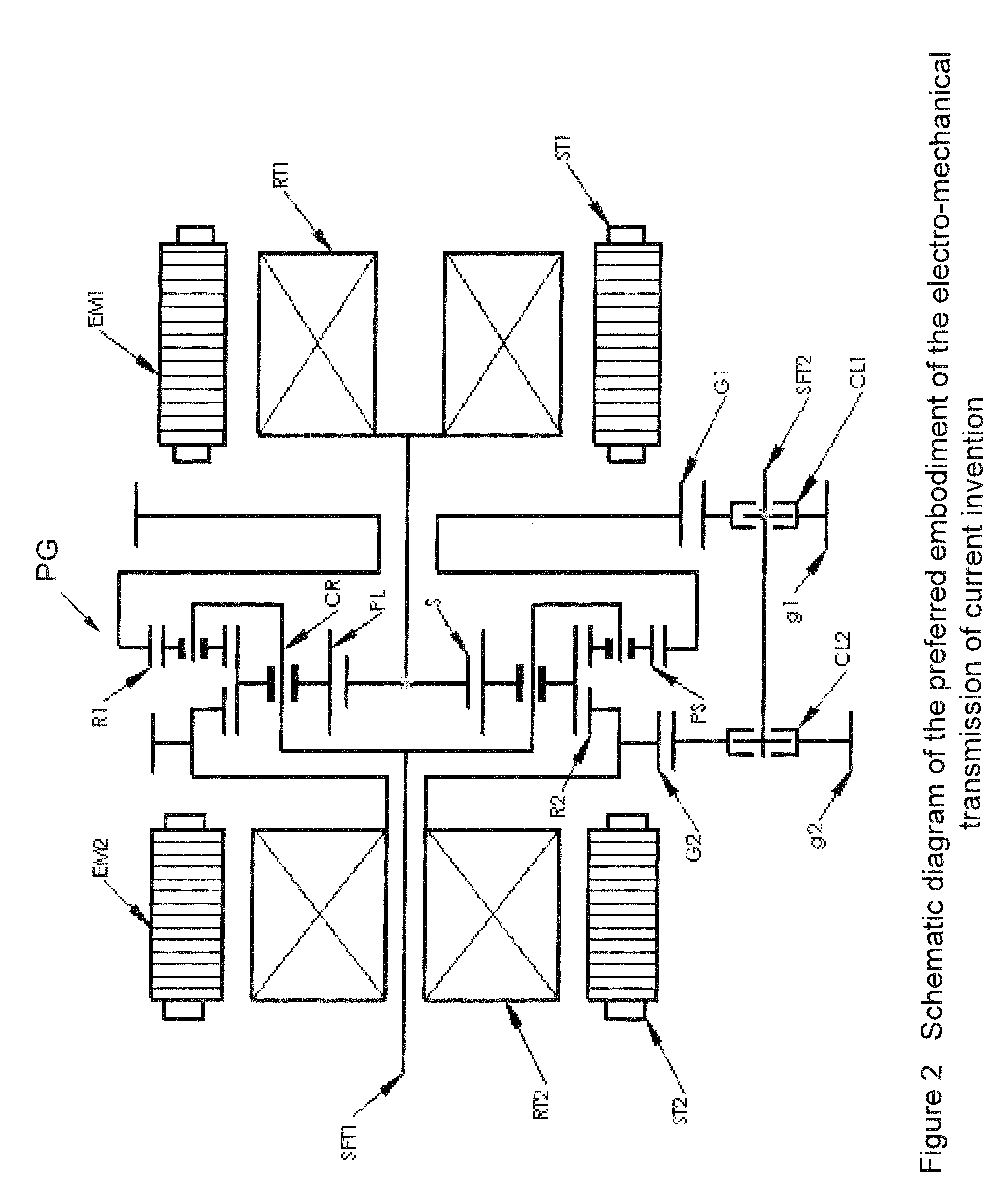

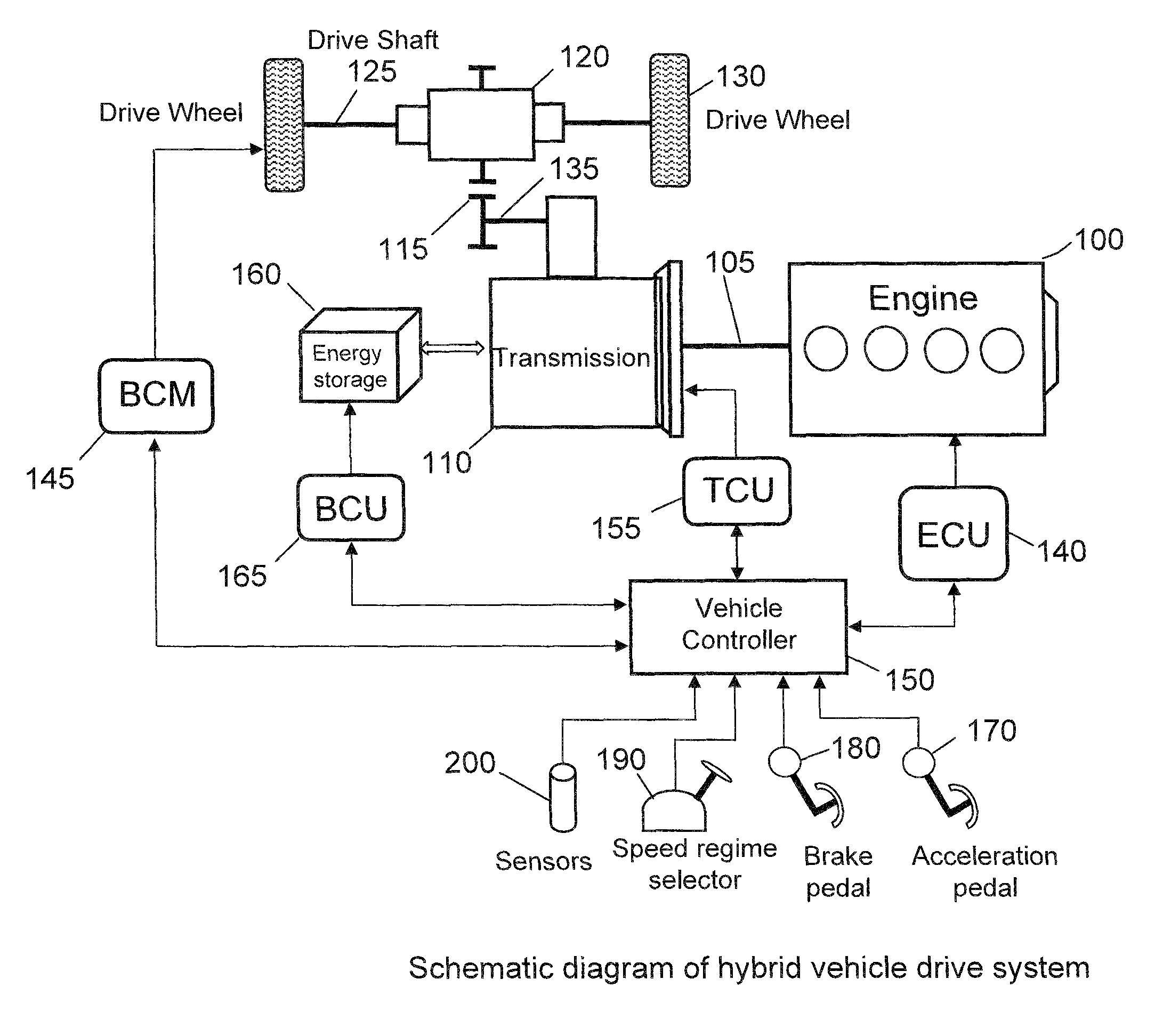

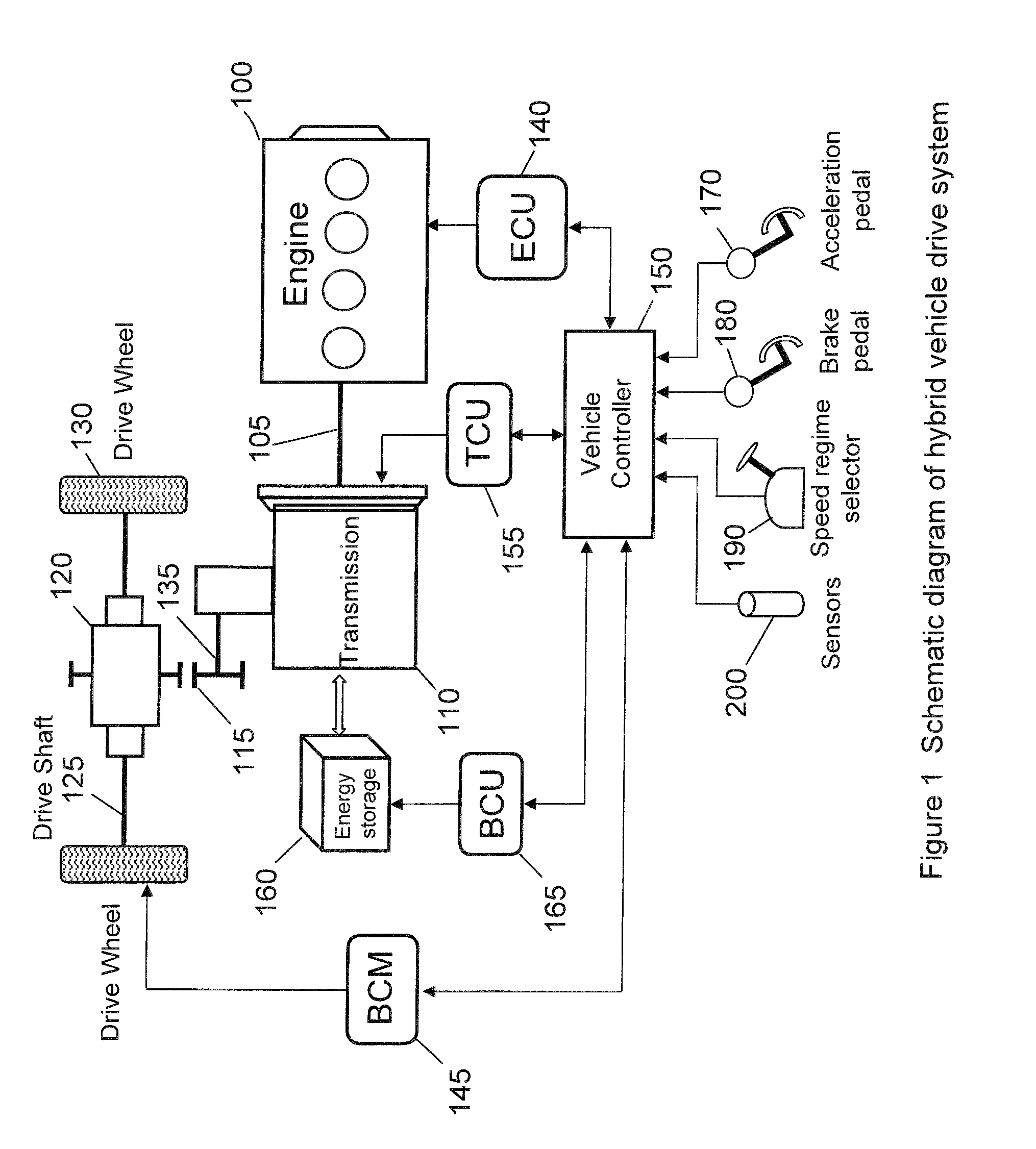

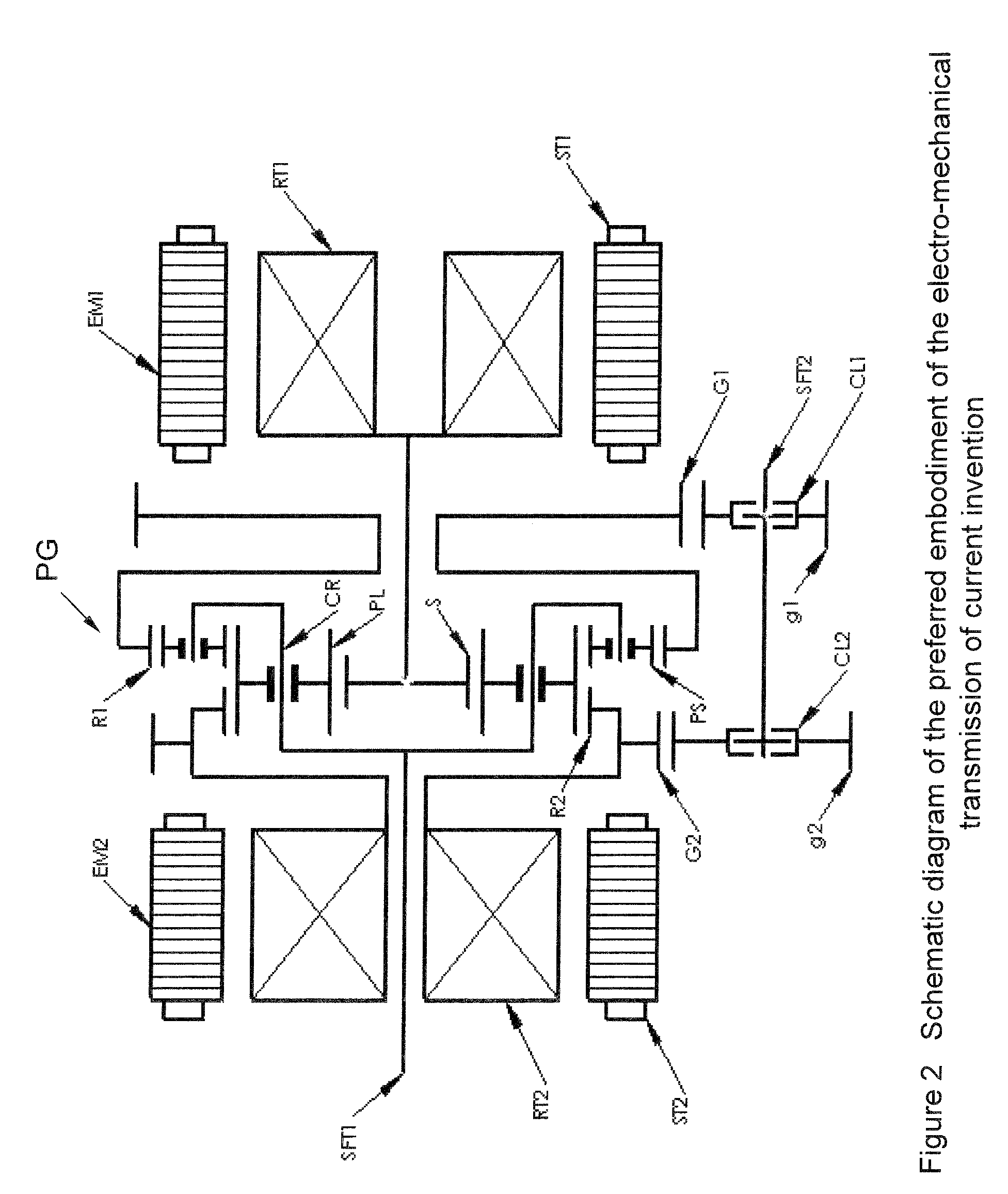

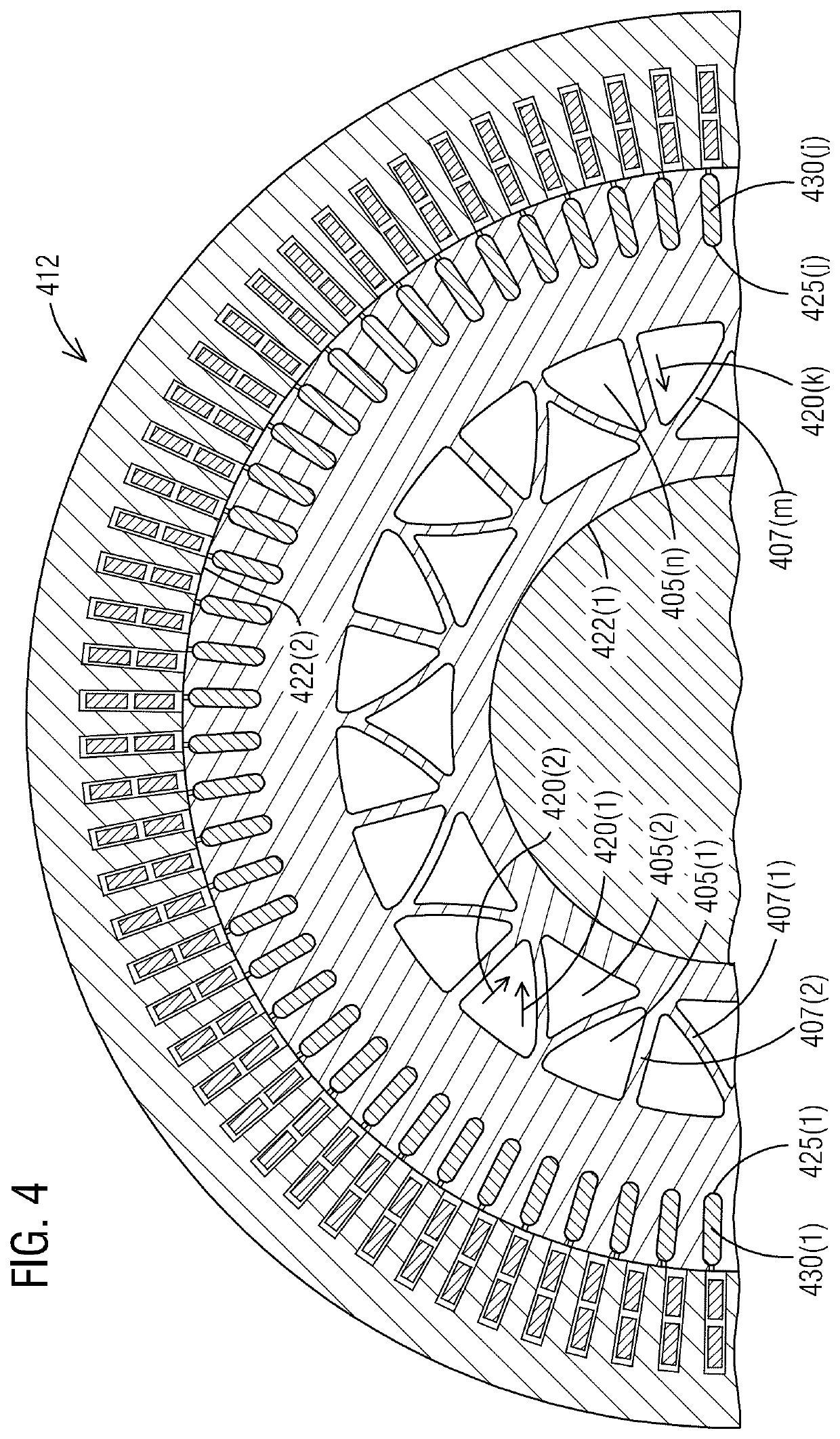

Two mode electro-mechanical transmission and control

ActiveUS20090209381A1Improve efficiencyWide range of speed ratioHybrid vehiclesDigital data processing detailsPower splitDifferential signaling

A two mode power-split electric hybrid system and a method of control said hybrid system. The hybrid system is comprised of an engine, a transmission, an energy storage device and a control system for effecting said control method. Said transmission is a reconfigurable power split system, comprising a power-splitting device and an output power path selecting device. The power splitting device includes a compound planetary gear system and two electric machines which form a local series electric hybrid system. Said transmission regulates the output power state of said hybrid system by controlling power flow within said local series hybrid system. The hybrid system provides at least two operating mode, an output power split mode and a compound power split mode. Said control system includes multiple controllers and control modules. In accordance with the operating conditions of the hybrid system, said control system computes and sets system power requirement, allocates ob board power resources and sets engine operating speed and torque. In addition, said control system sets the operation mode of the transmission and controls the engine speed by adjusting operating torque of electric machines, based on the differential signal between reference engine speed and actual engine speed. Said control system is also capable of controlling engine torque through engine controller.

Owner:SHANDONG LIANCHENG GREENMAX TECH

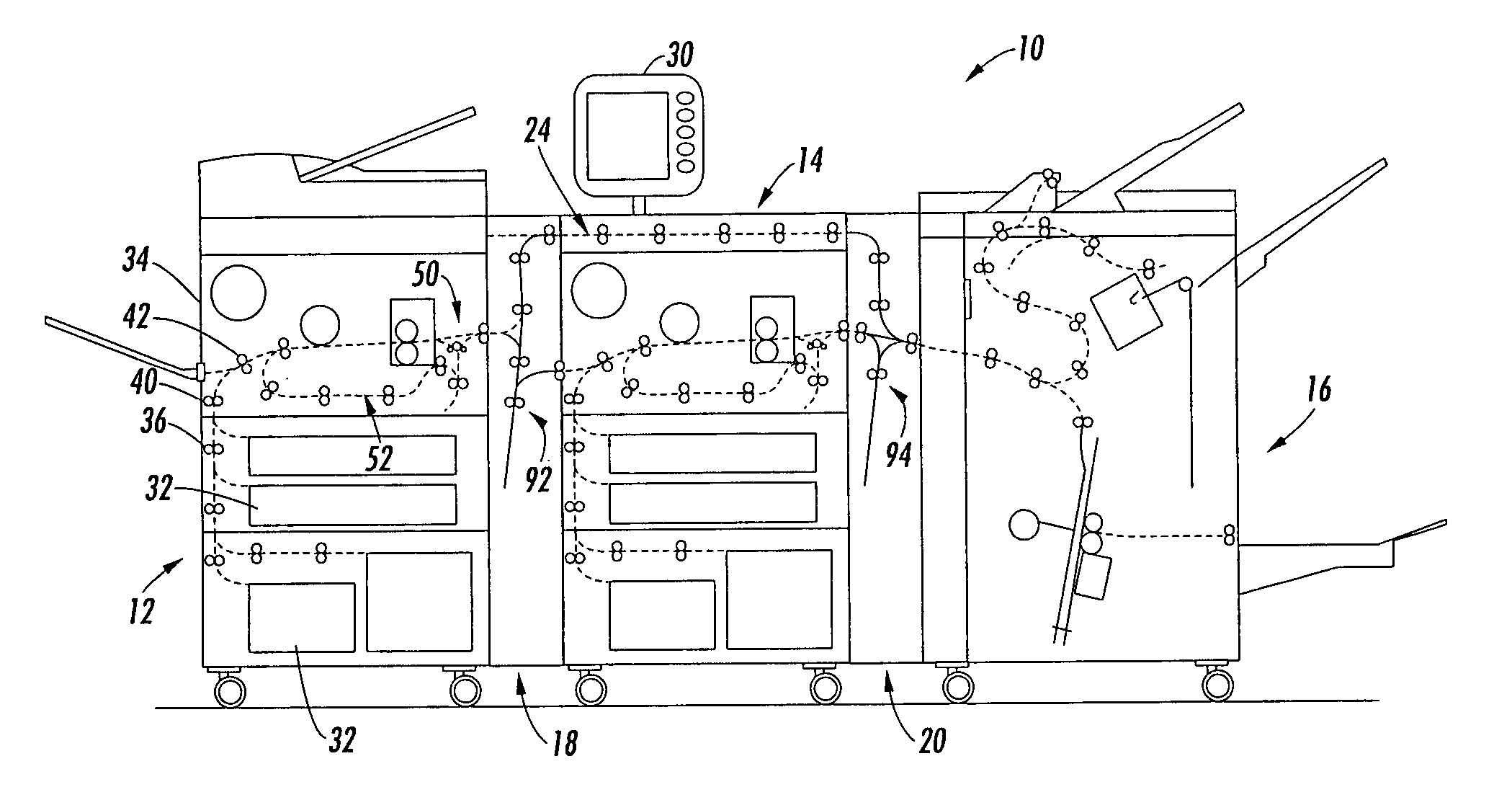

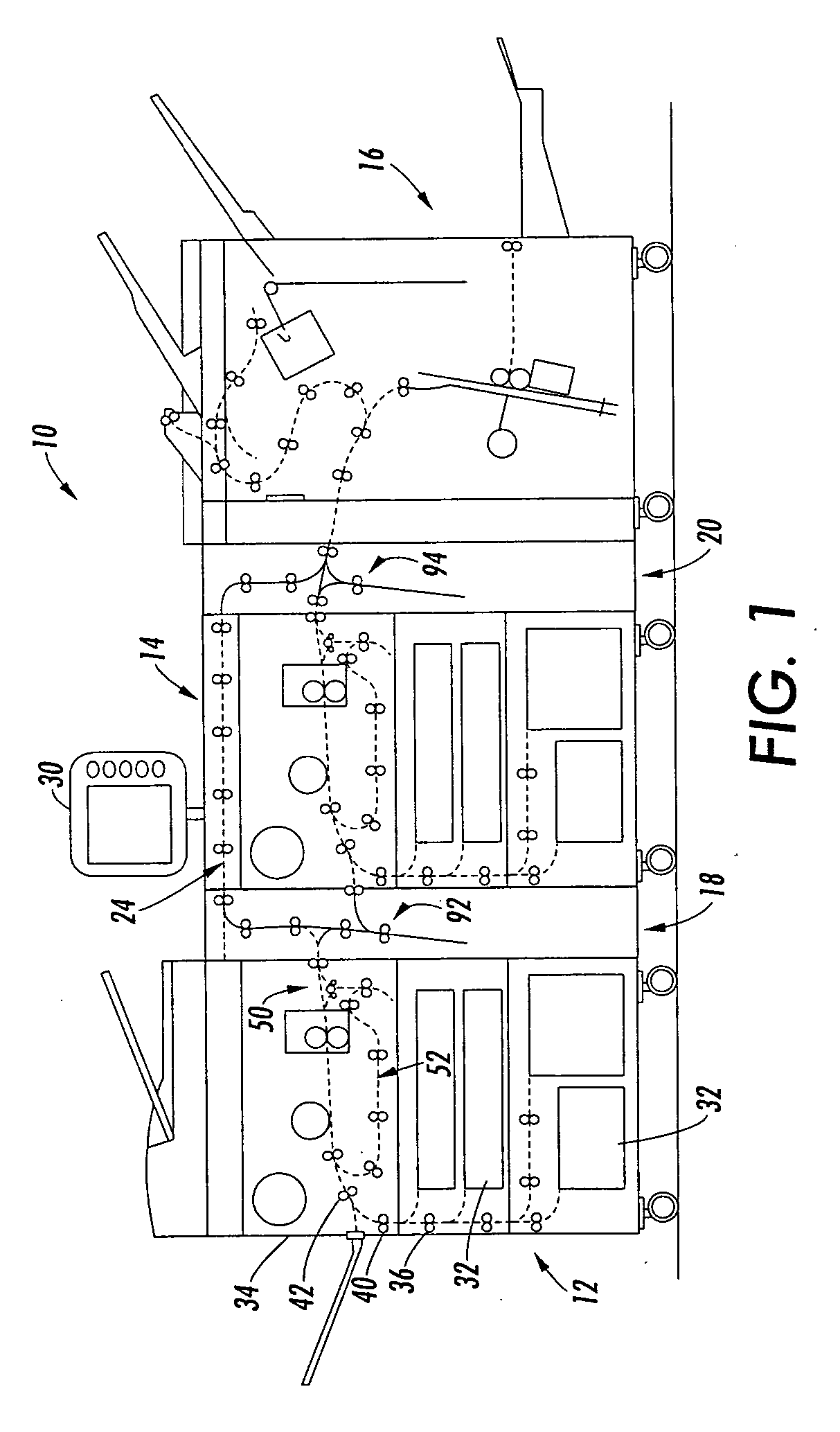

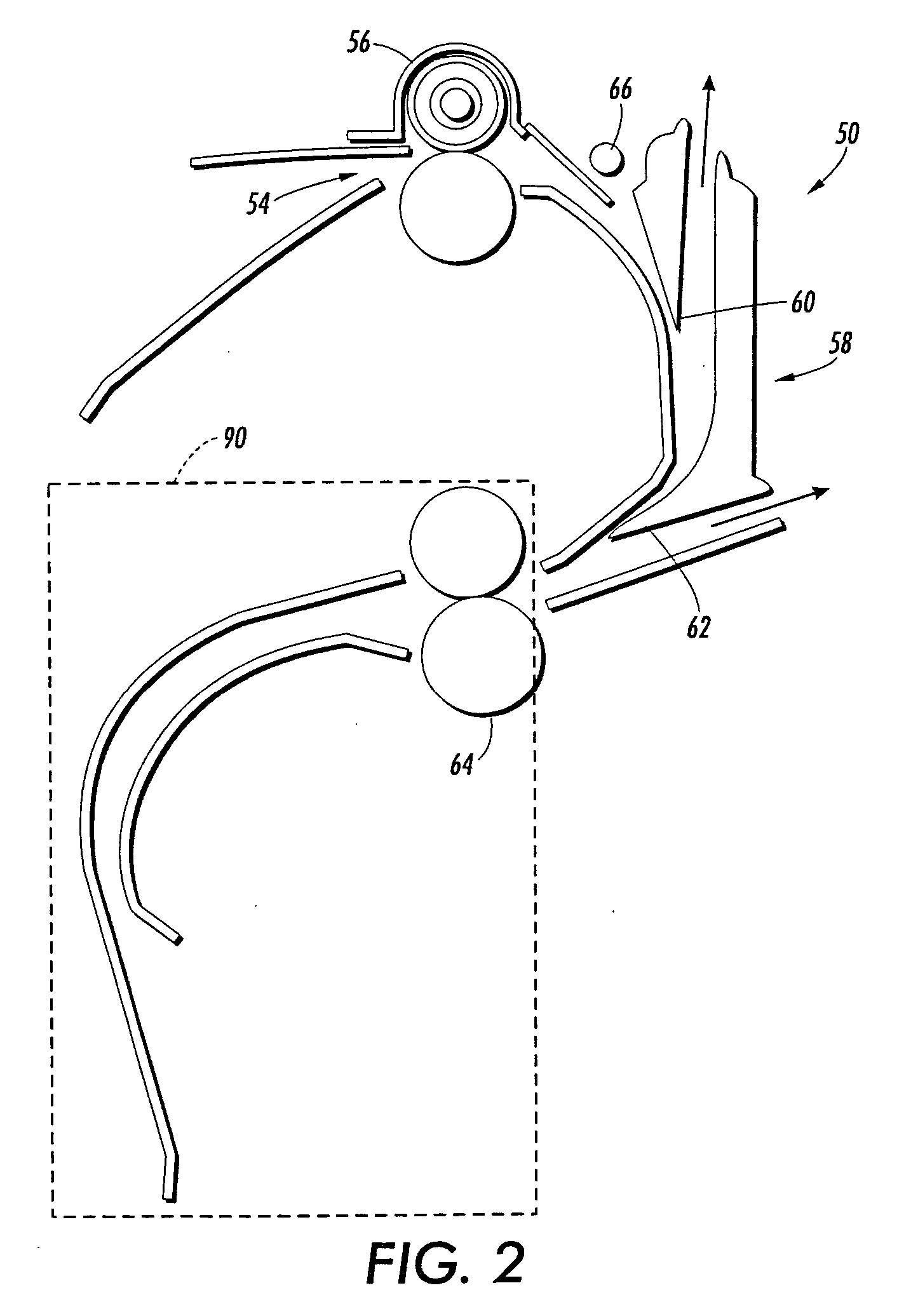

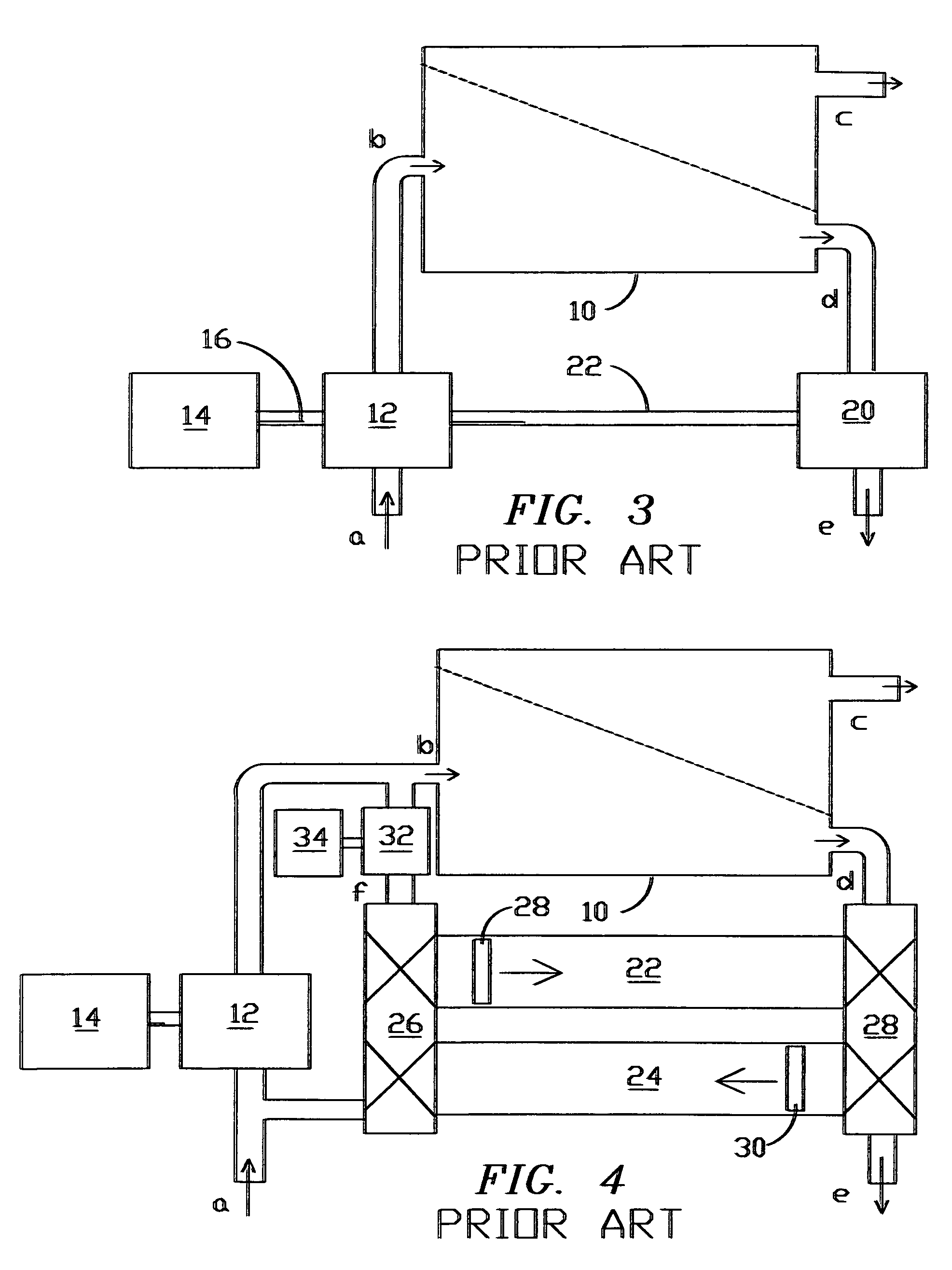

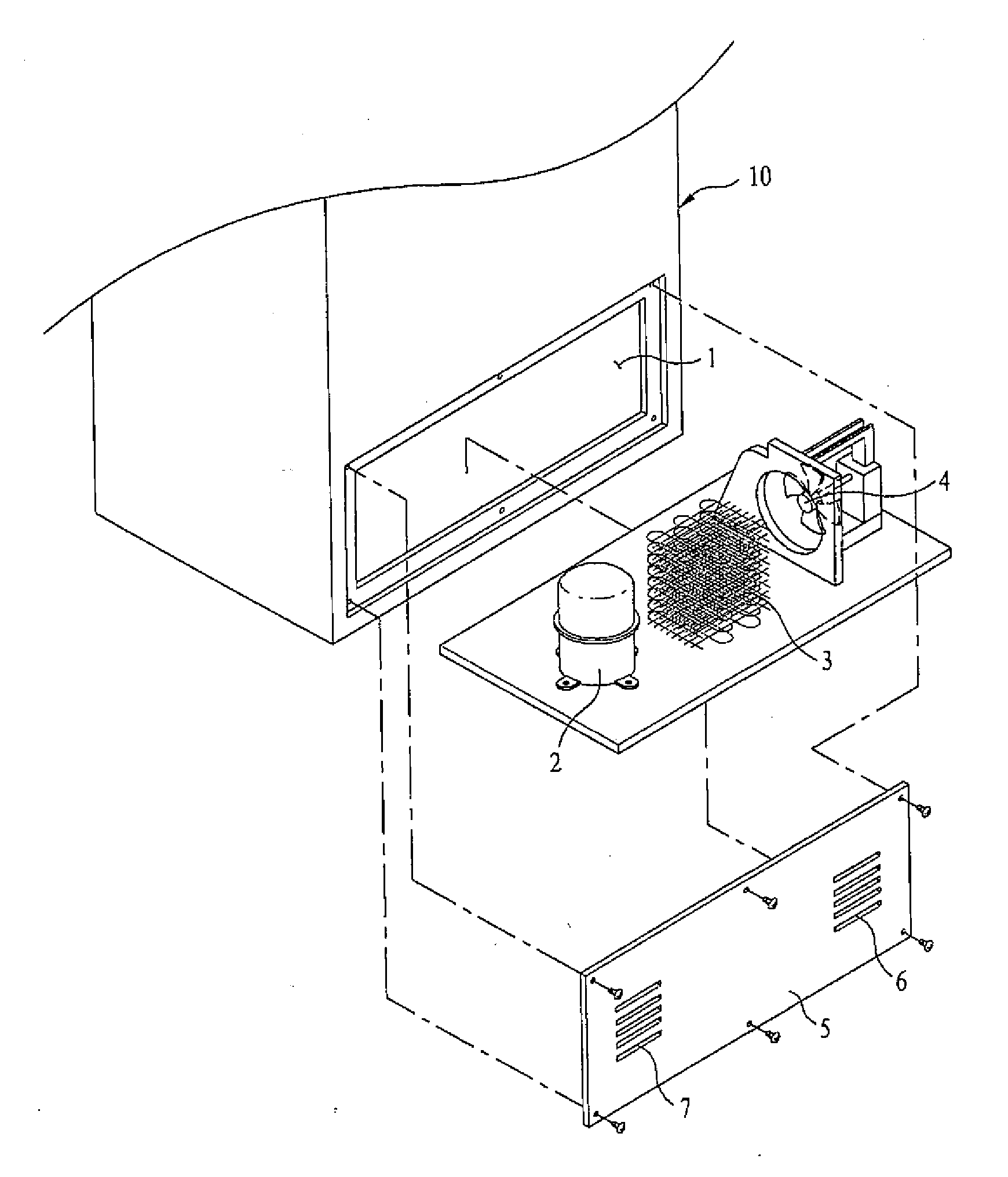

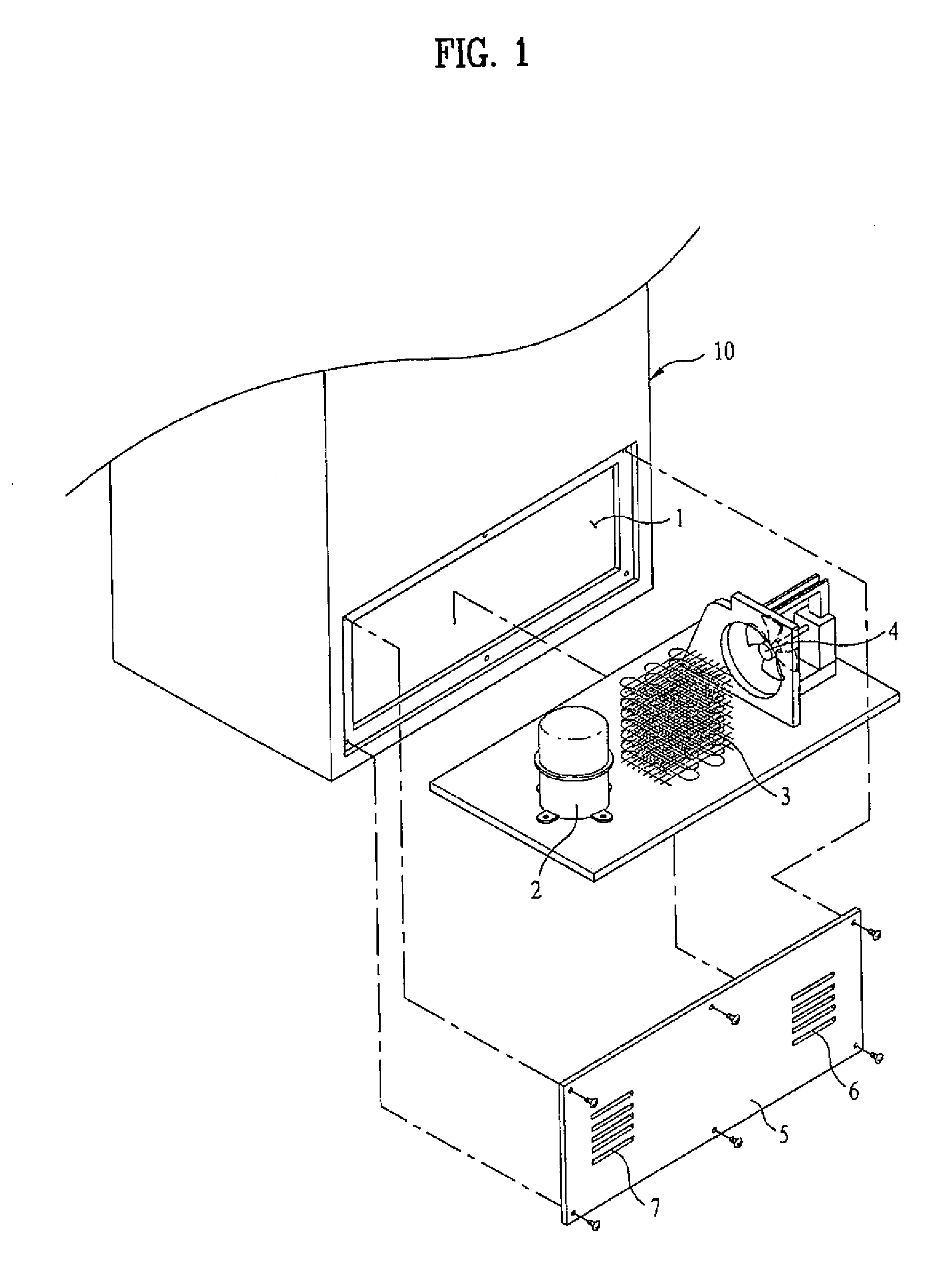

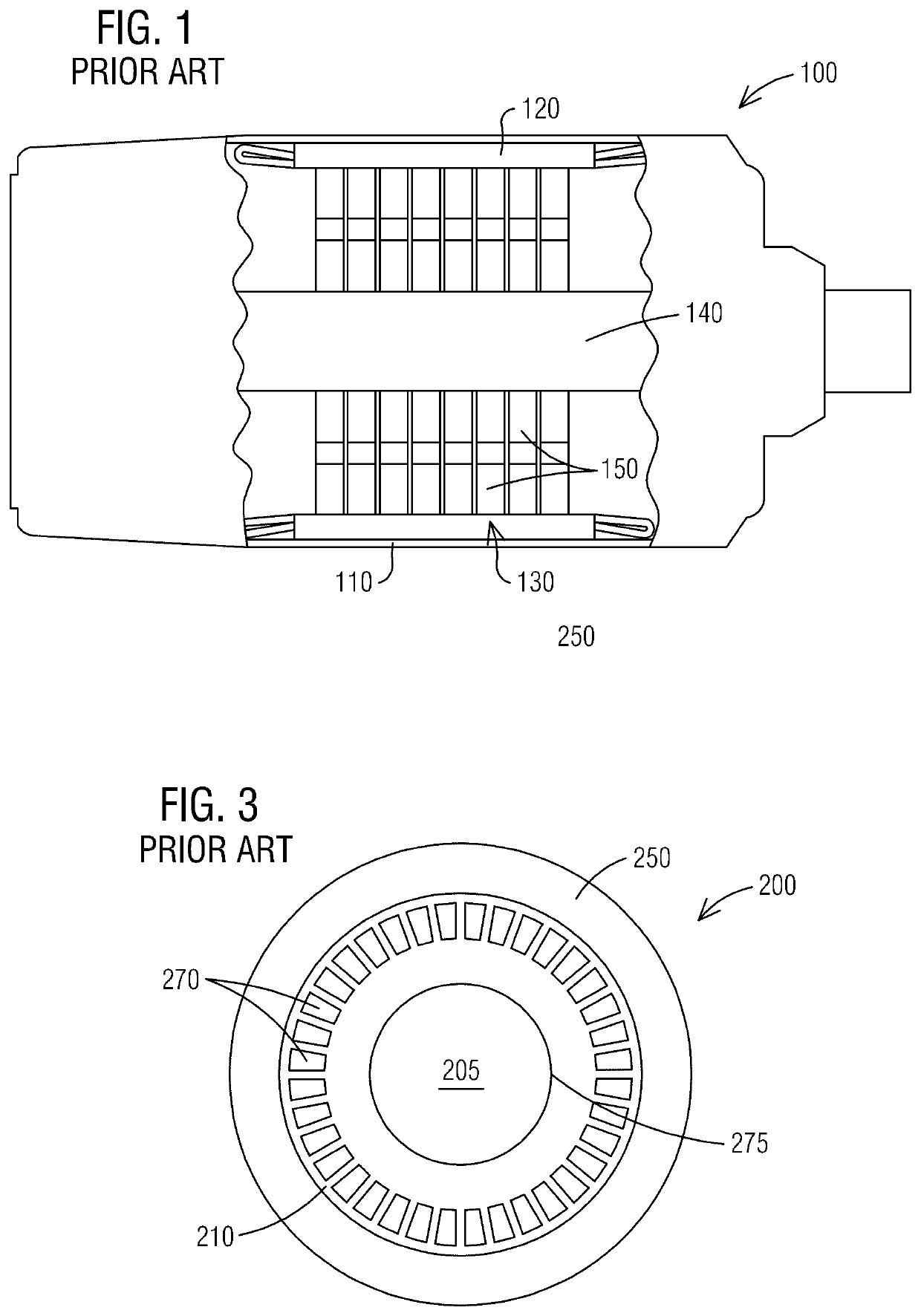

Printing system with inverter disposed for media velocity buffering and registration

InactiveUS20060039728A1Complete efficientlyEffective decouplingElectrographic process apparatusEngineeringPaper document

Parallel printing systems and methods incorporate inverter assemblies for not only inverting media during transport through the system but also to register the media or provide a velocity buffer transports with different drive velocities. The inverter assemblies can include the capability to optionally deskew the media and provide lateral registration corrections. The inverter assembly nip rollers are sufficiently spaced from process drive nip rollers to decouple a document in the inverter assembly from the highway paths. The method comprises combining the inverting function selectively with either the registering or the velocity buffering functions.

Owner:XEROX CORP

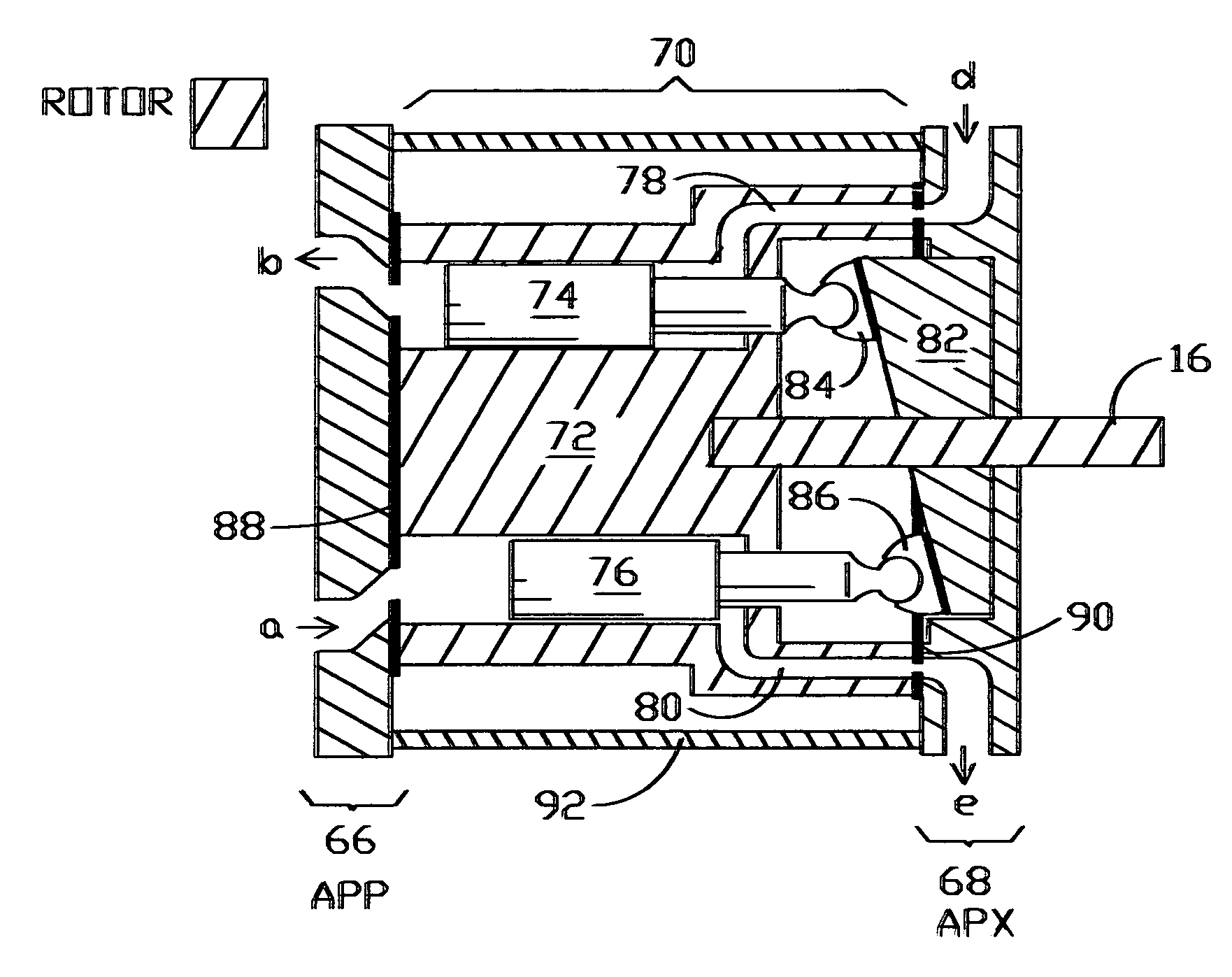

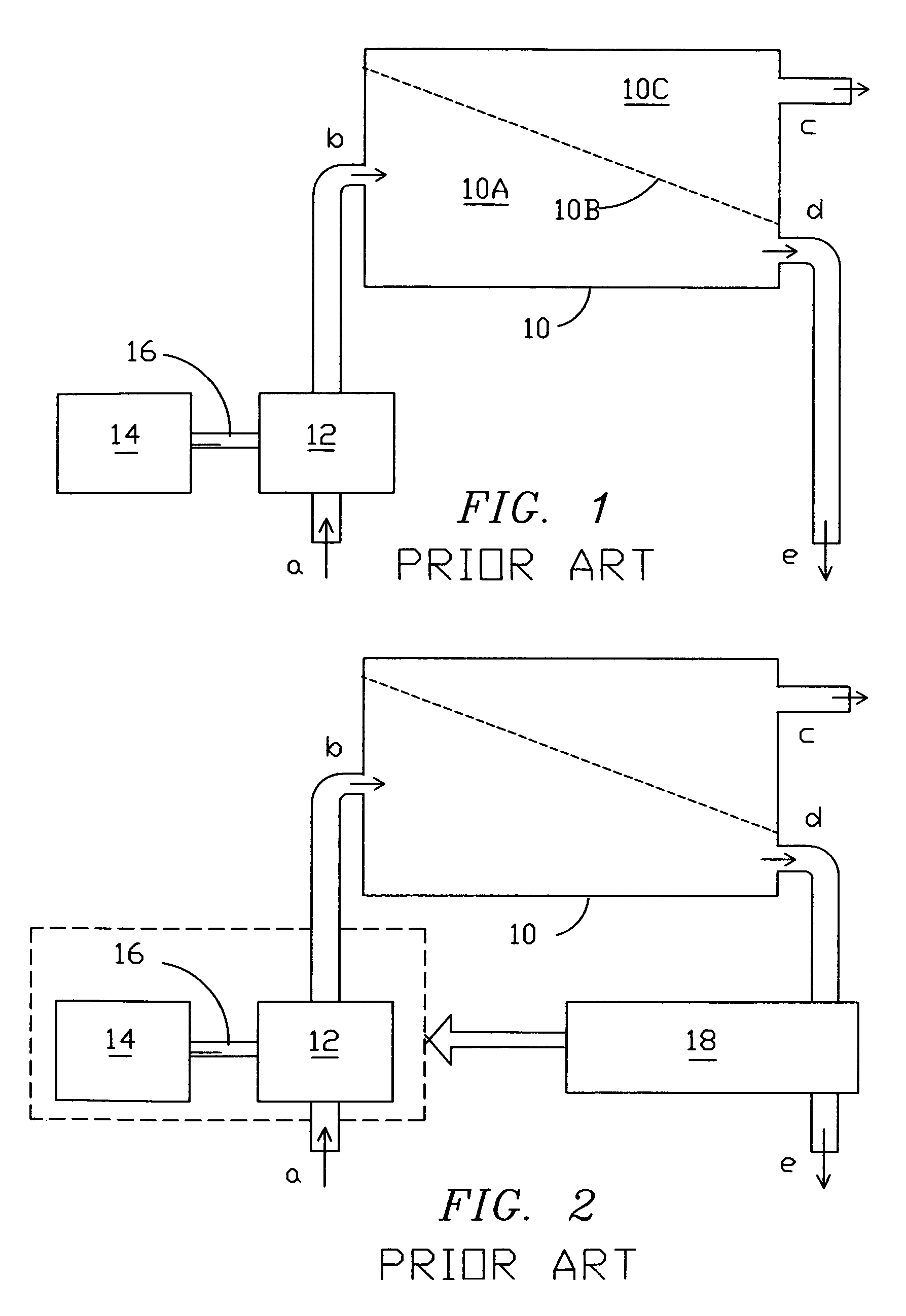

Combined axial piston liquid pump and energy recovery pressure exchanger

InactiveUS7799221B1Improve welfareMinimize the numberMembranesGeneral water supply conservationReciprocating motionEnergy recovery

A pumping machine, that can serve a system as the sole main pump for pressurizing a primary liquid flow, incorporates, in a single machine, a rotor-drum type AP (axial piston) pump and a PX (pressure exchanger) that recovers energy from a secondary liquid flow such as the brine discharge from an RO seawater desalination system, with benefits including fewer moving parts and small machine size along with lower capital and operating costs. A single rotor-drum containing the cylinders and pistons is located between two end blocks, one or both configured with manifold passageways, ports and sliding valves. A swash-plate at one end reciprocates the pistons axially when the rotor-drum is rotated. Two working chambers, primary and secondary, are formed at opposite ends of a single piston in each cylinder, thus enabling the single rotor-drum to function as a primary liquid-pressurizing axial pump (AP) with sliding valves at the primary end enabling primary liquid pumping, and as a secondary outflow-driven pressure exchanger (PX) recovering energy from pressure drop in the secondary liquid flow and thus contributing work to primary pumping, saving energy and reducing operating costs.

Owner:OCEAN PACIFIC TECH

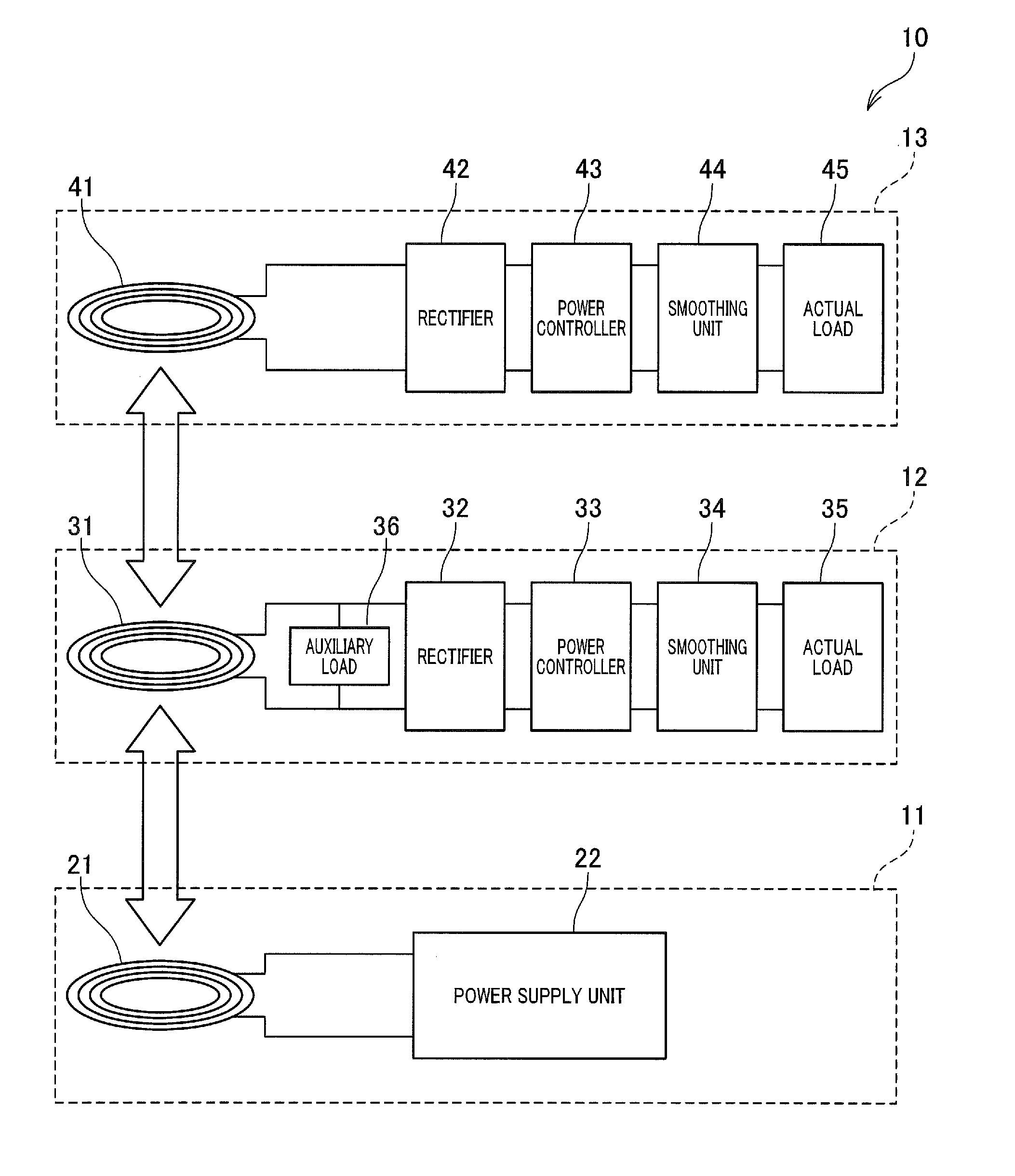

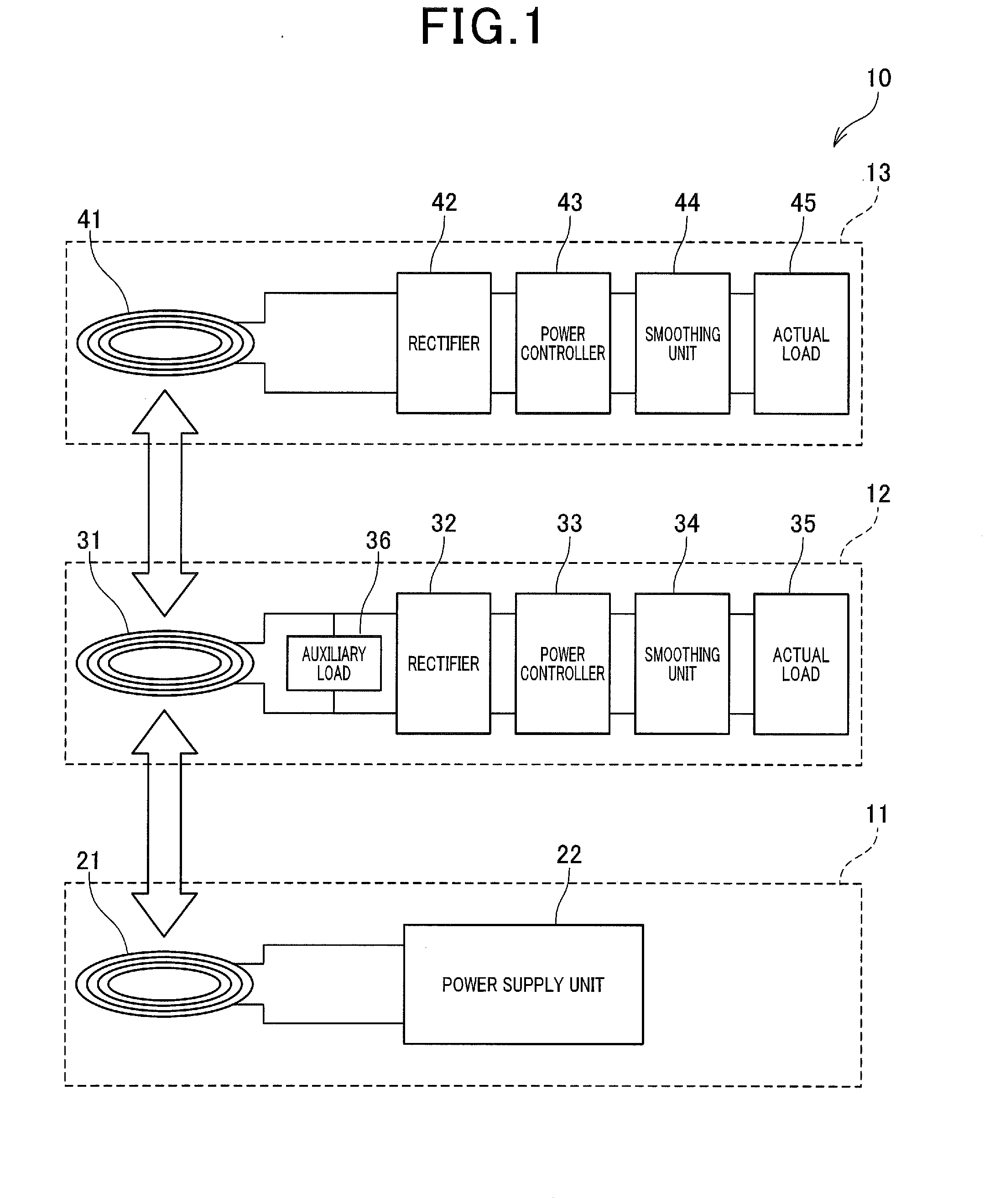

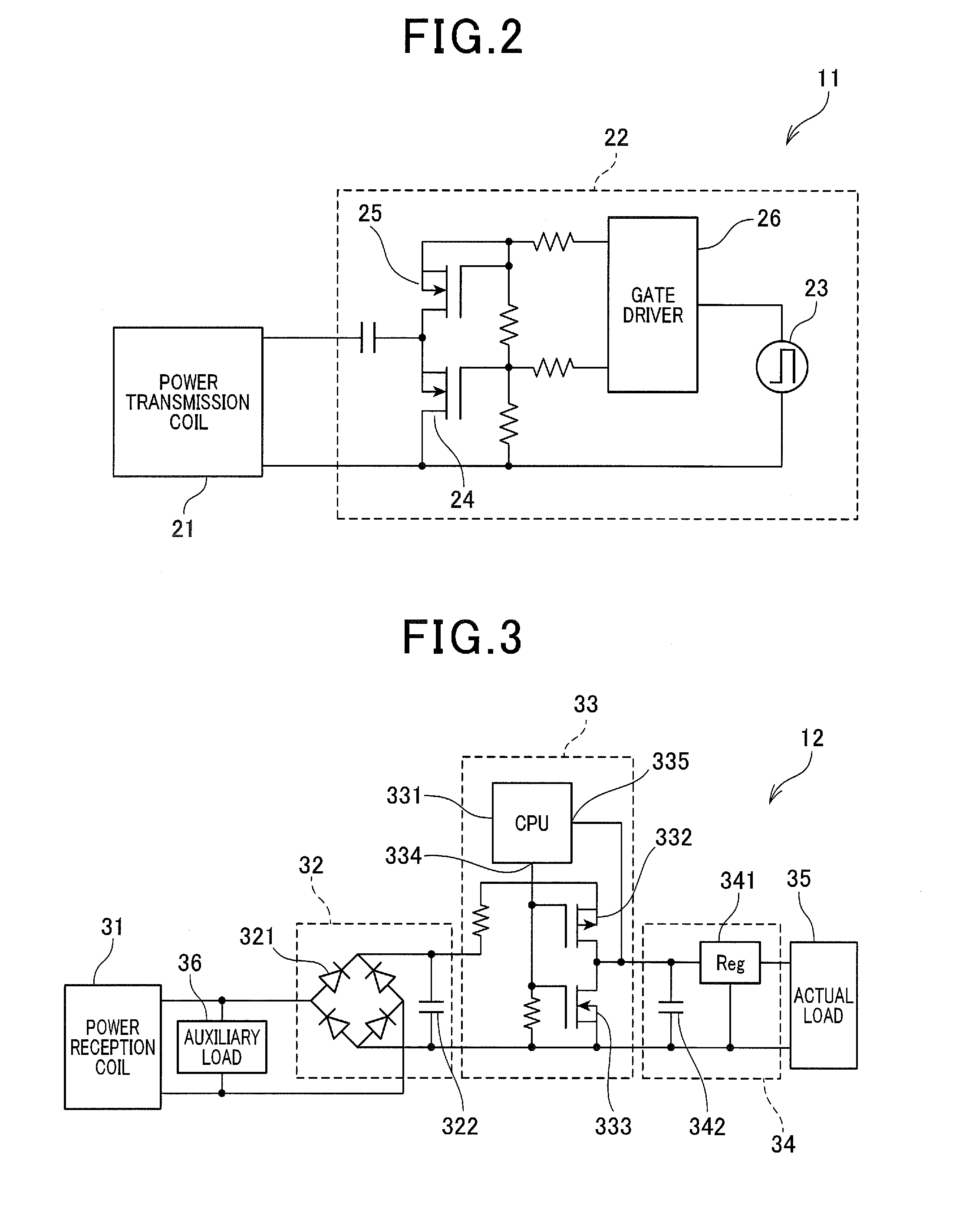

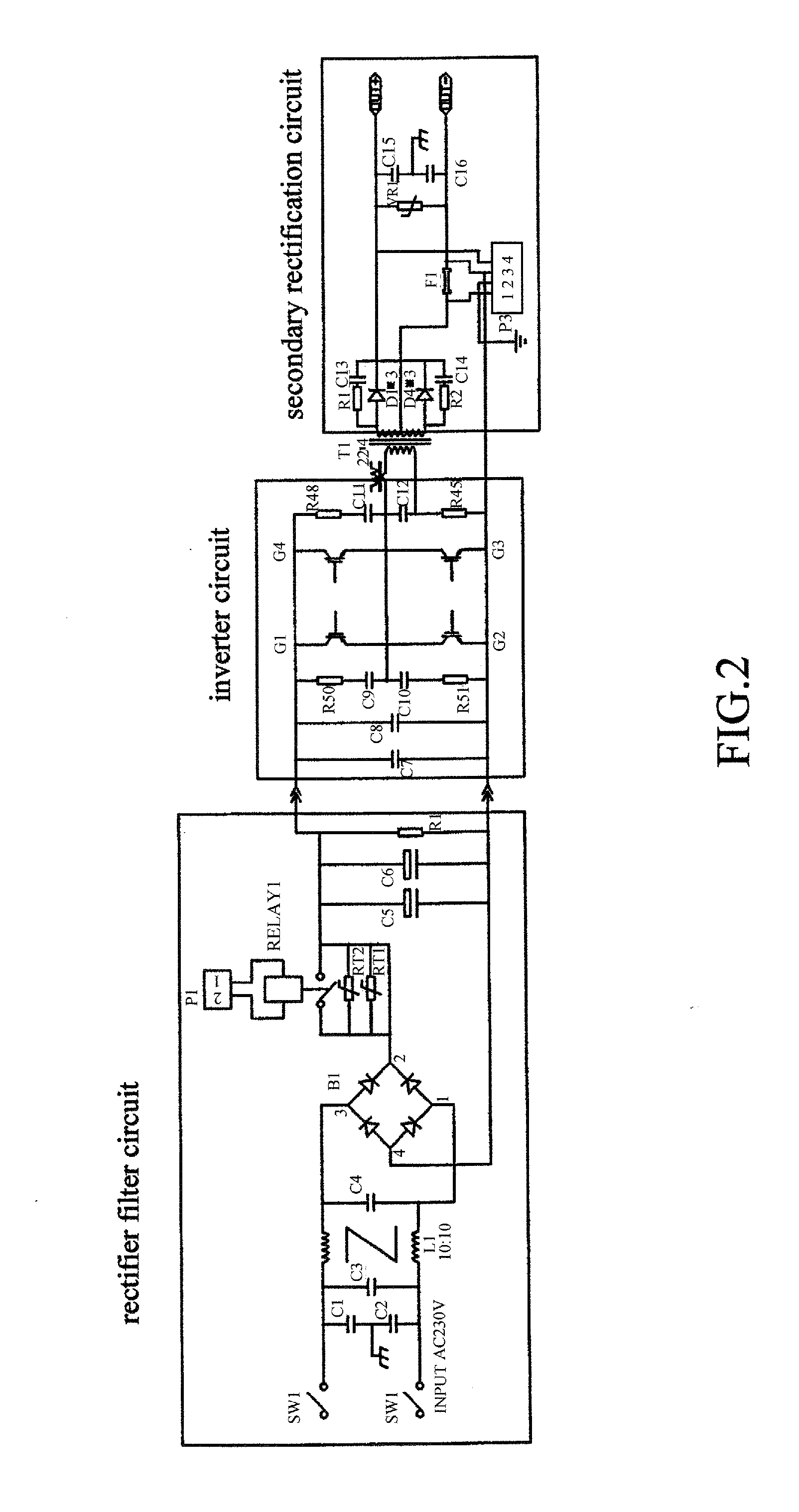

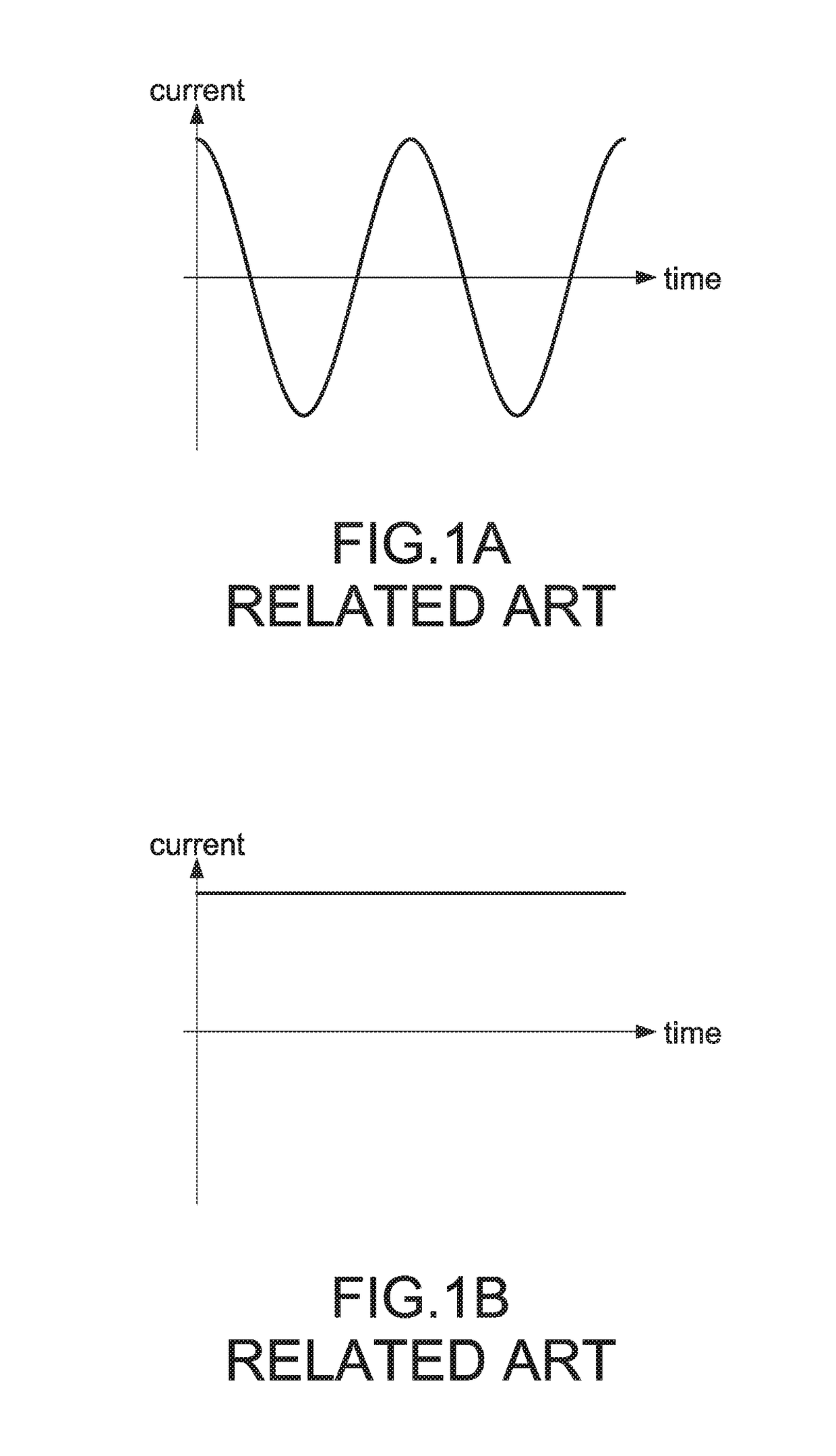

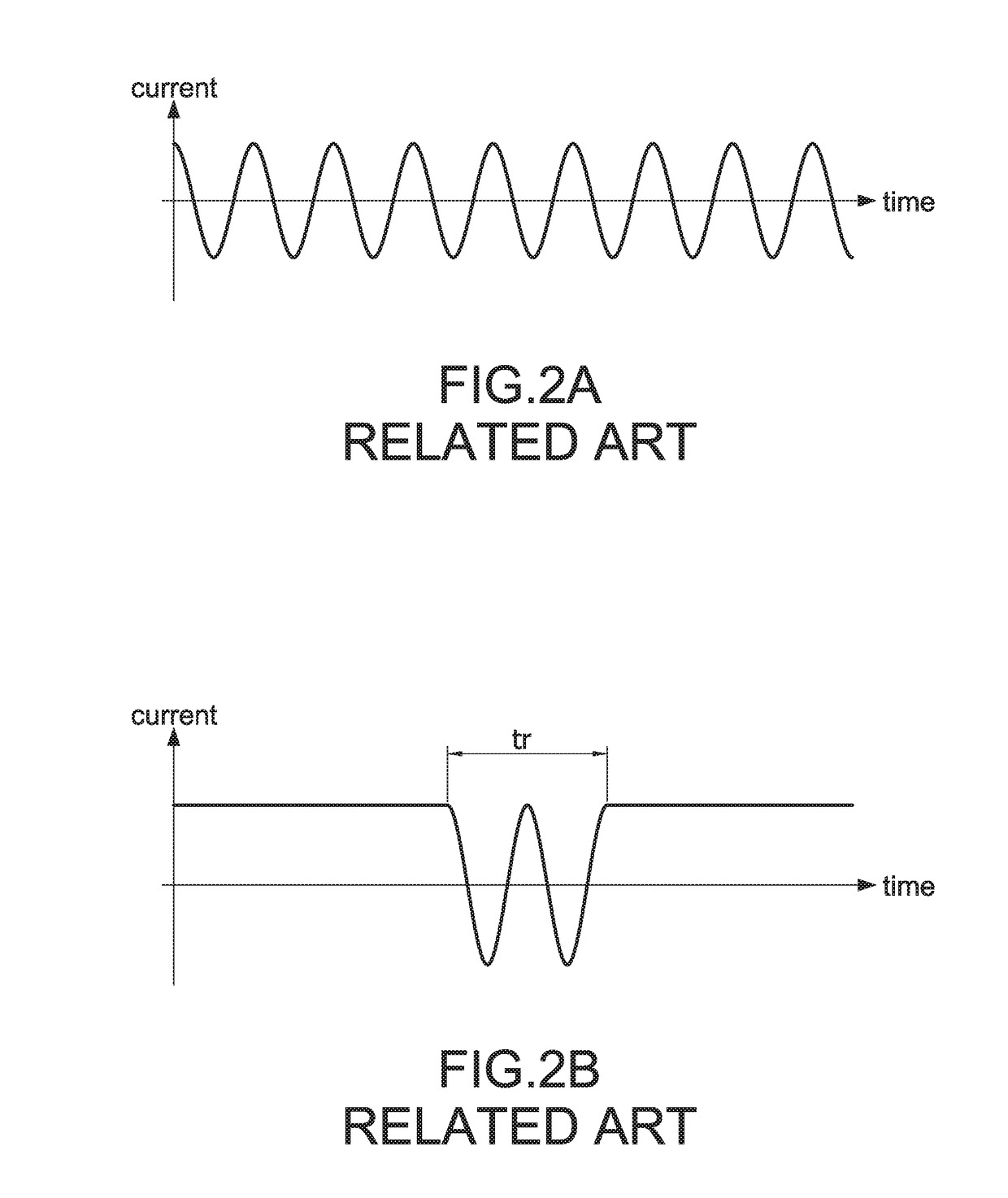

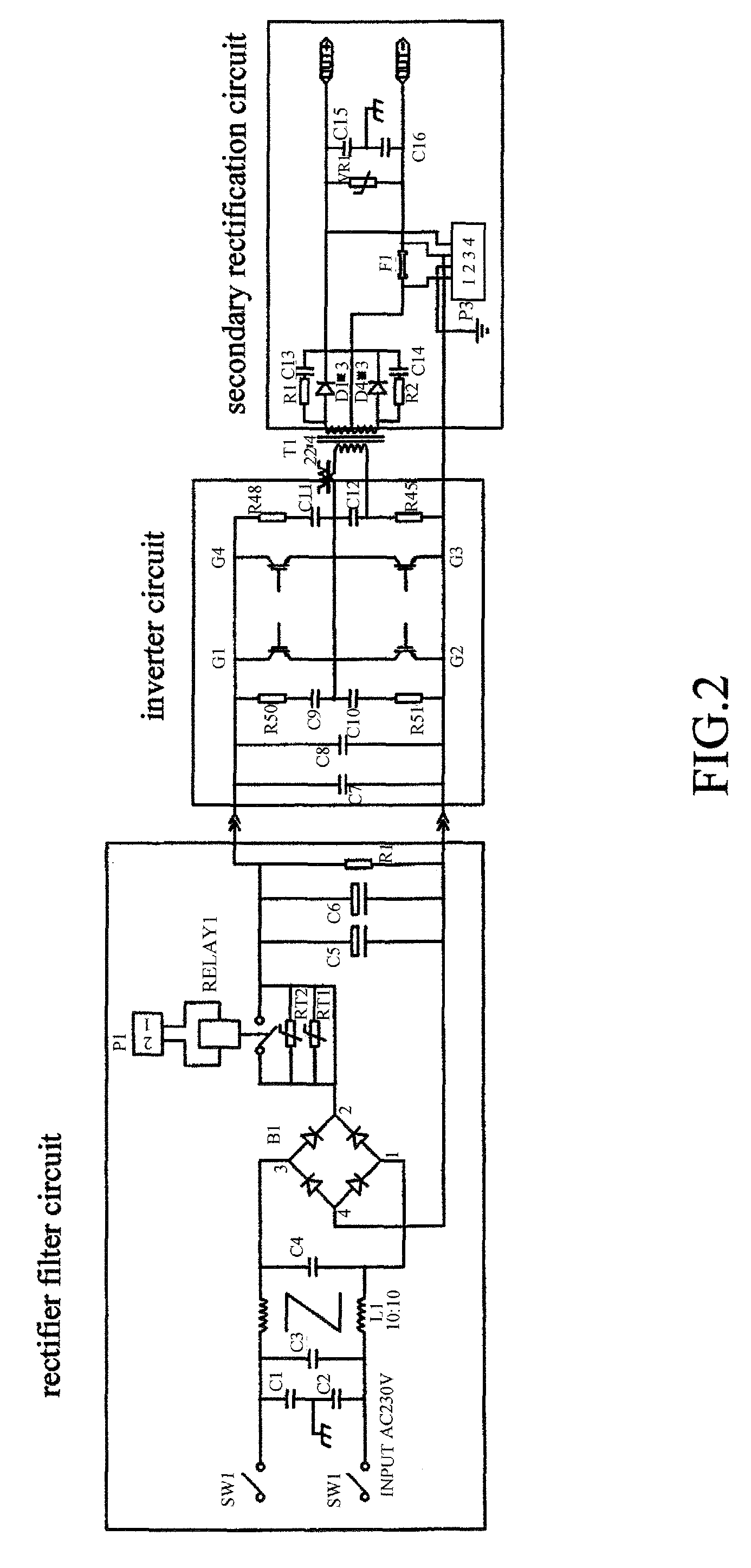

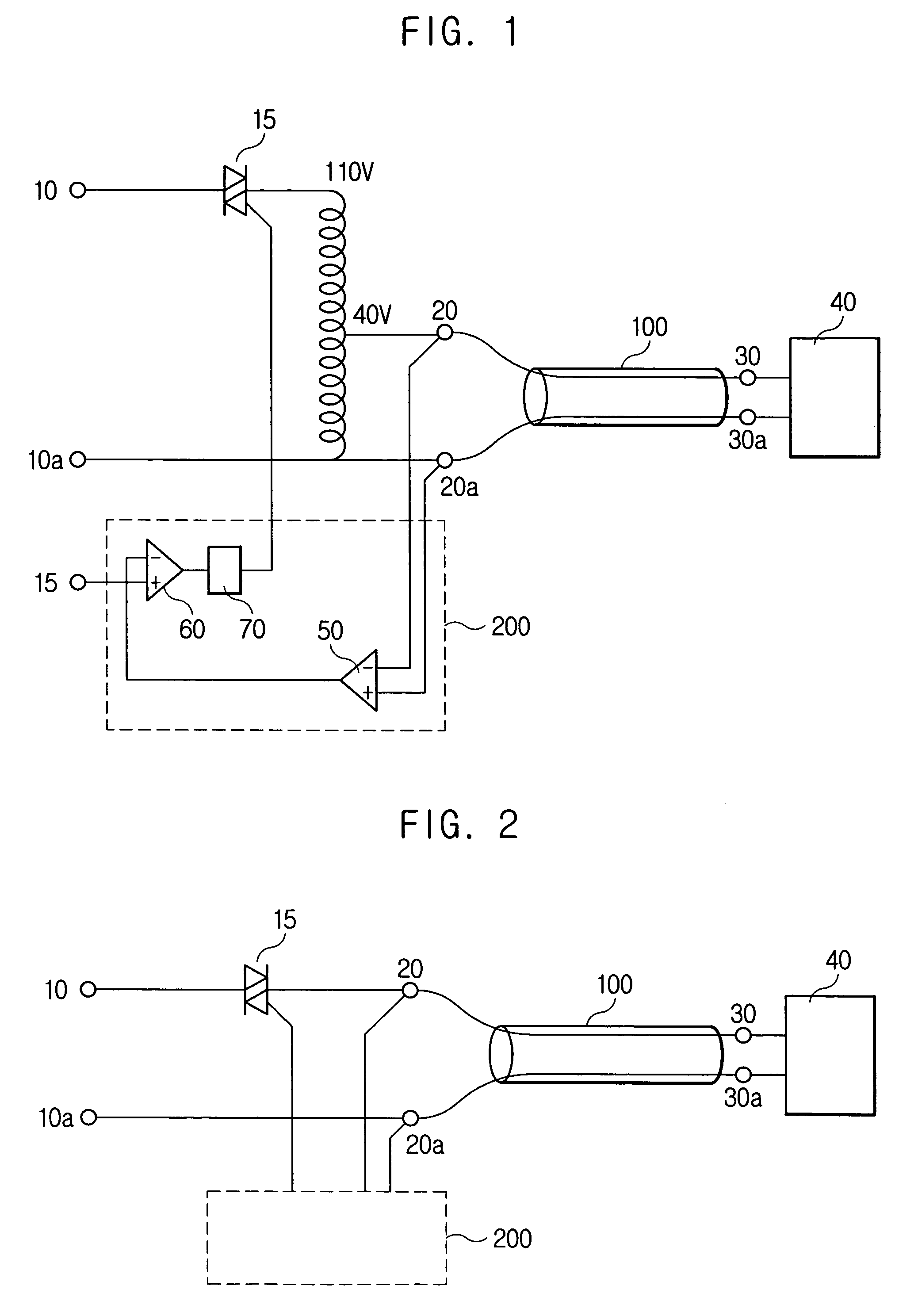

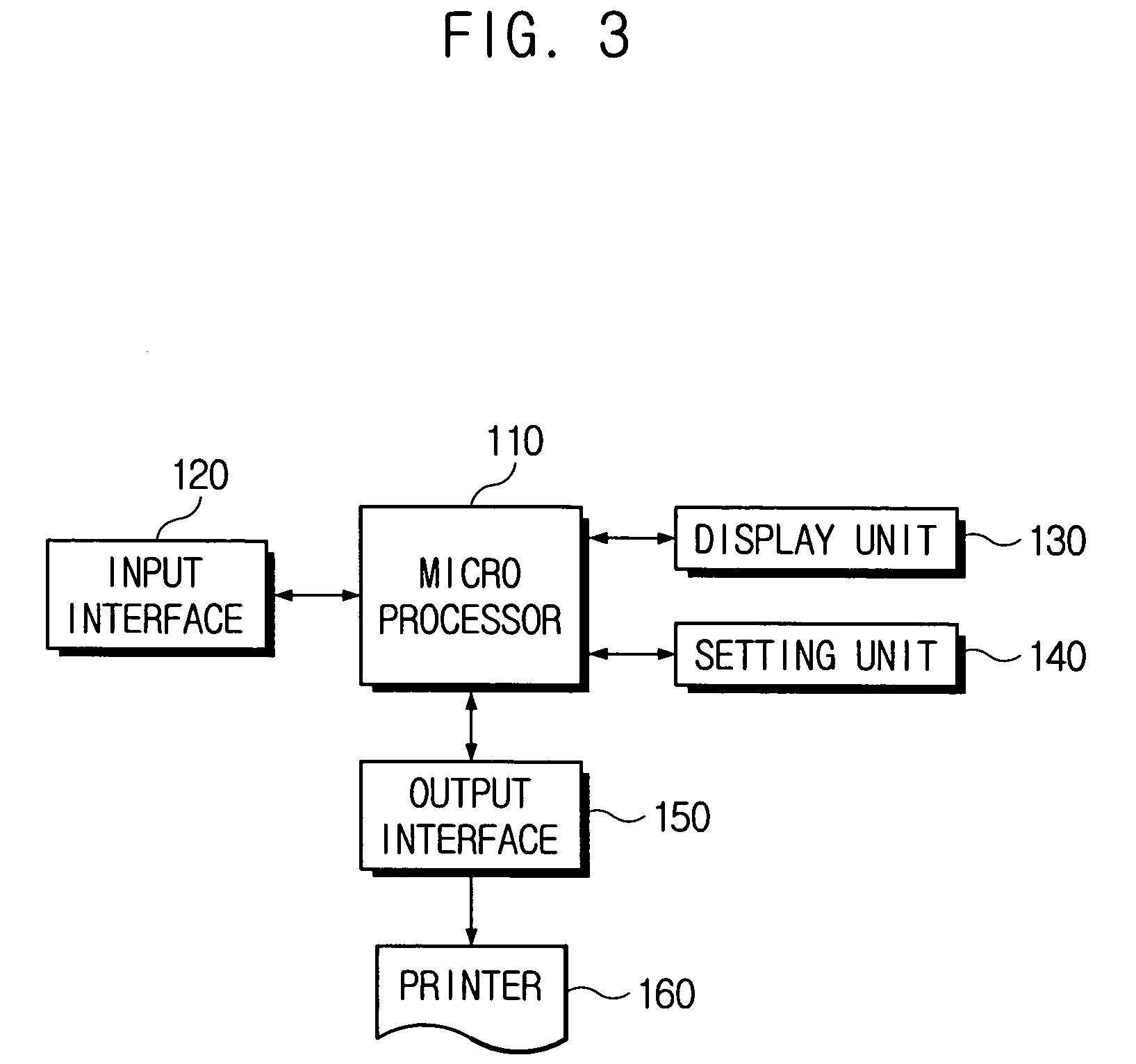

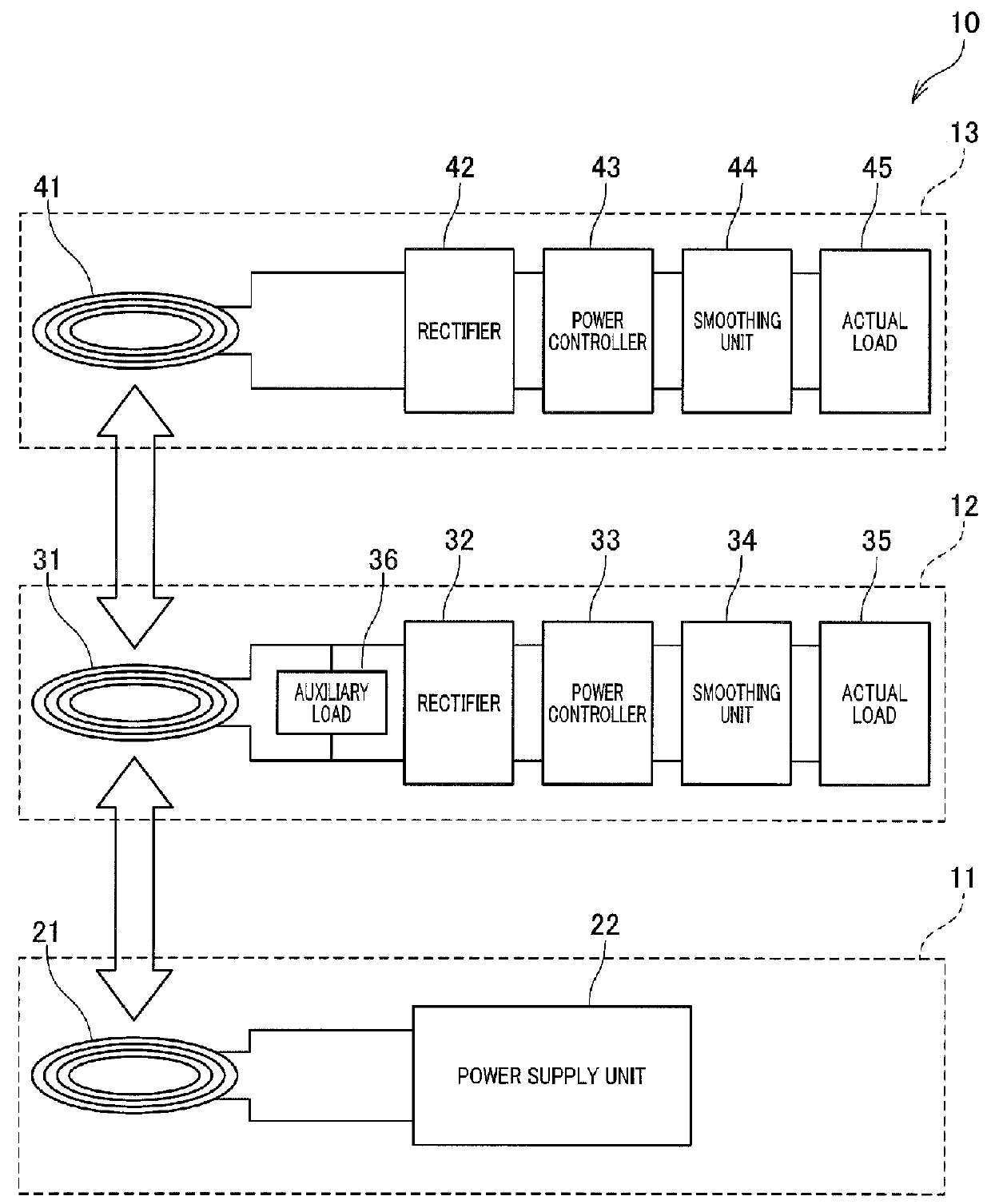

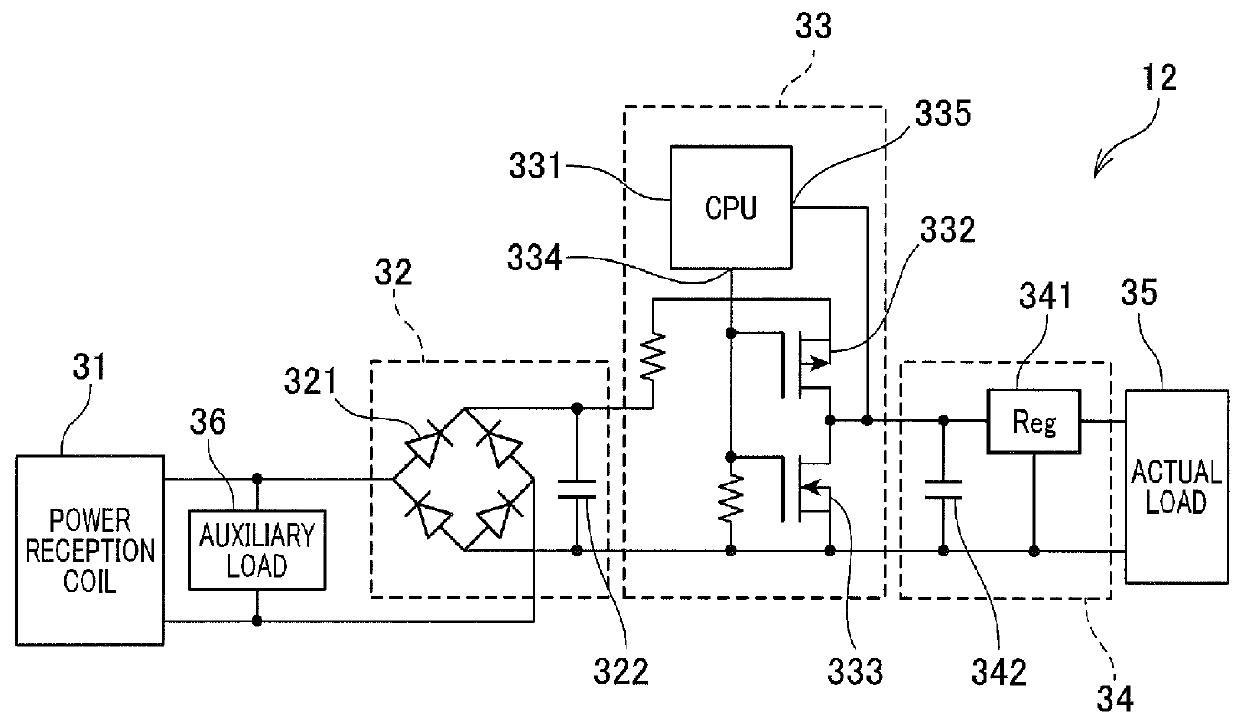

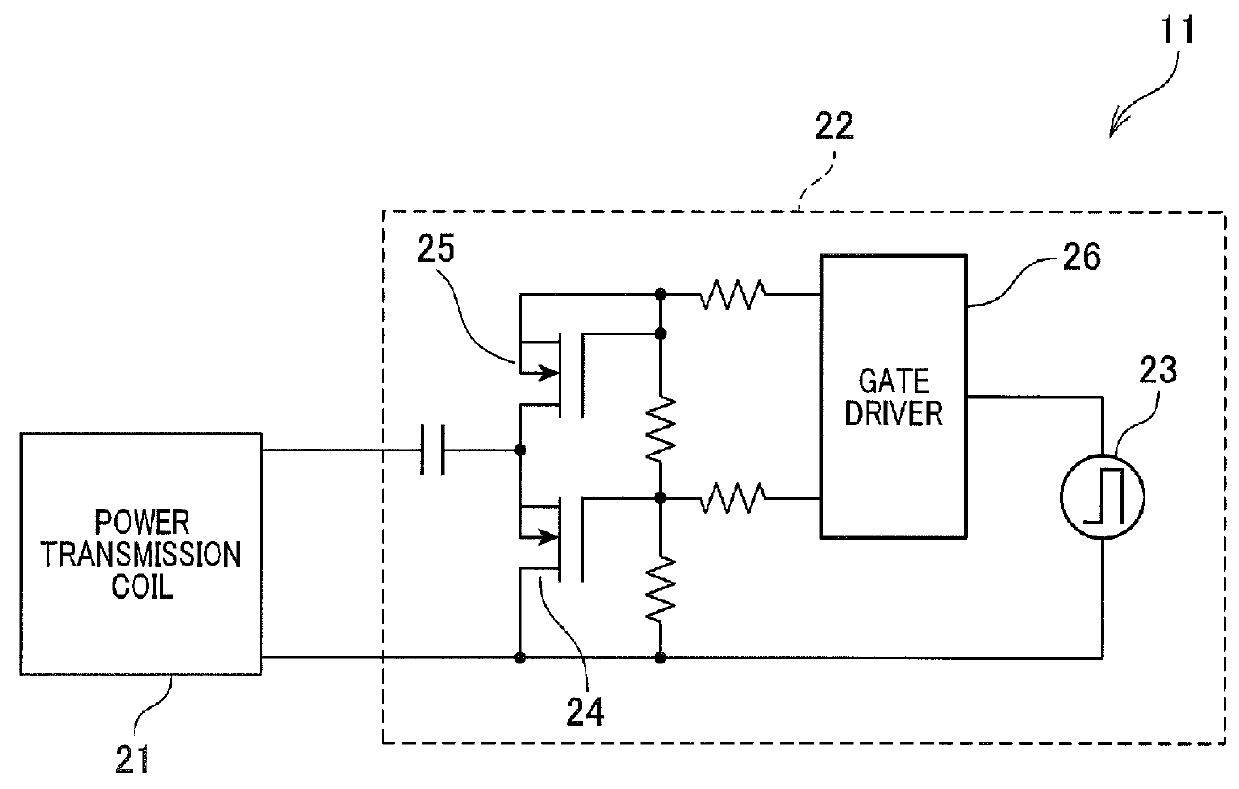

Wireless power supply apparatus, filter unit and power supply apparatus for robot using the filter unit

ActiveUS20140091635A1Reduce electromagnetic radiationEmission reductionTransformersCircuit arrangementsElectric power transmissionElectricity

A wireless power supply apparatus includes a power reception coil, an actual load and an auxiliary load. The power reception coil functions as a repeater for receiving electric power in a non-contact manner by magnetic resonance with a power transmission coil to which electric power is supplied from a power supply unit and relaying transfer of the electric power from the power transmission coil. The actual load is connected to the power reception coil and is powered by the electric power received by the power reception coil. The auxiliary load is inserted parallel to the power reception coil and the actual load and forms a closed circuit with the power reception coil when supply of the electric power to the actual load is interrupted to be in an open state.

Owner:DENSO WAVE INC +1

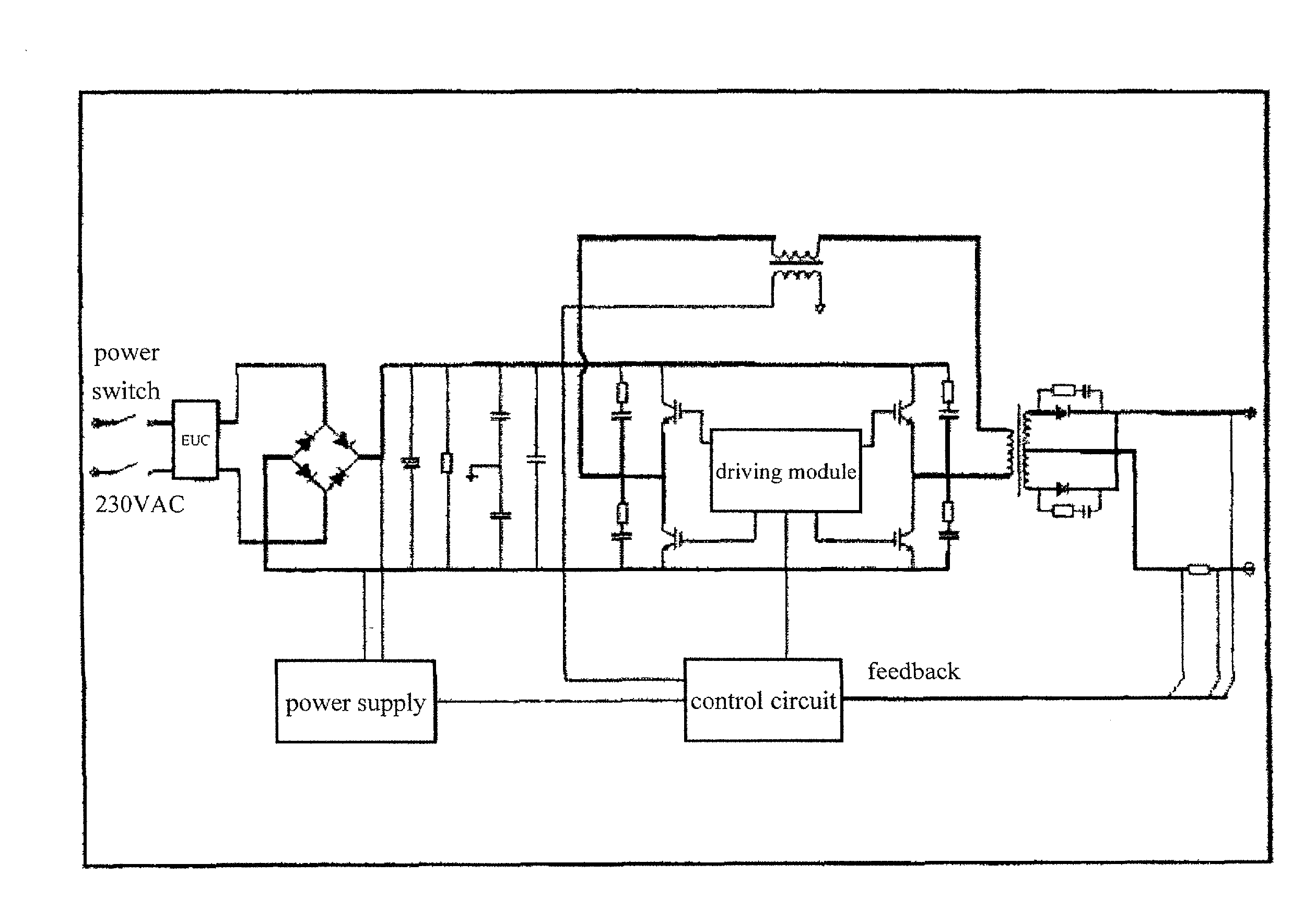

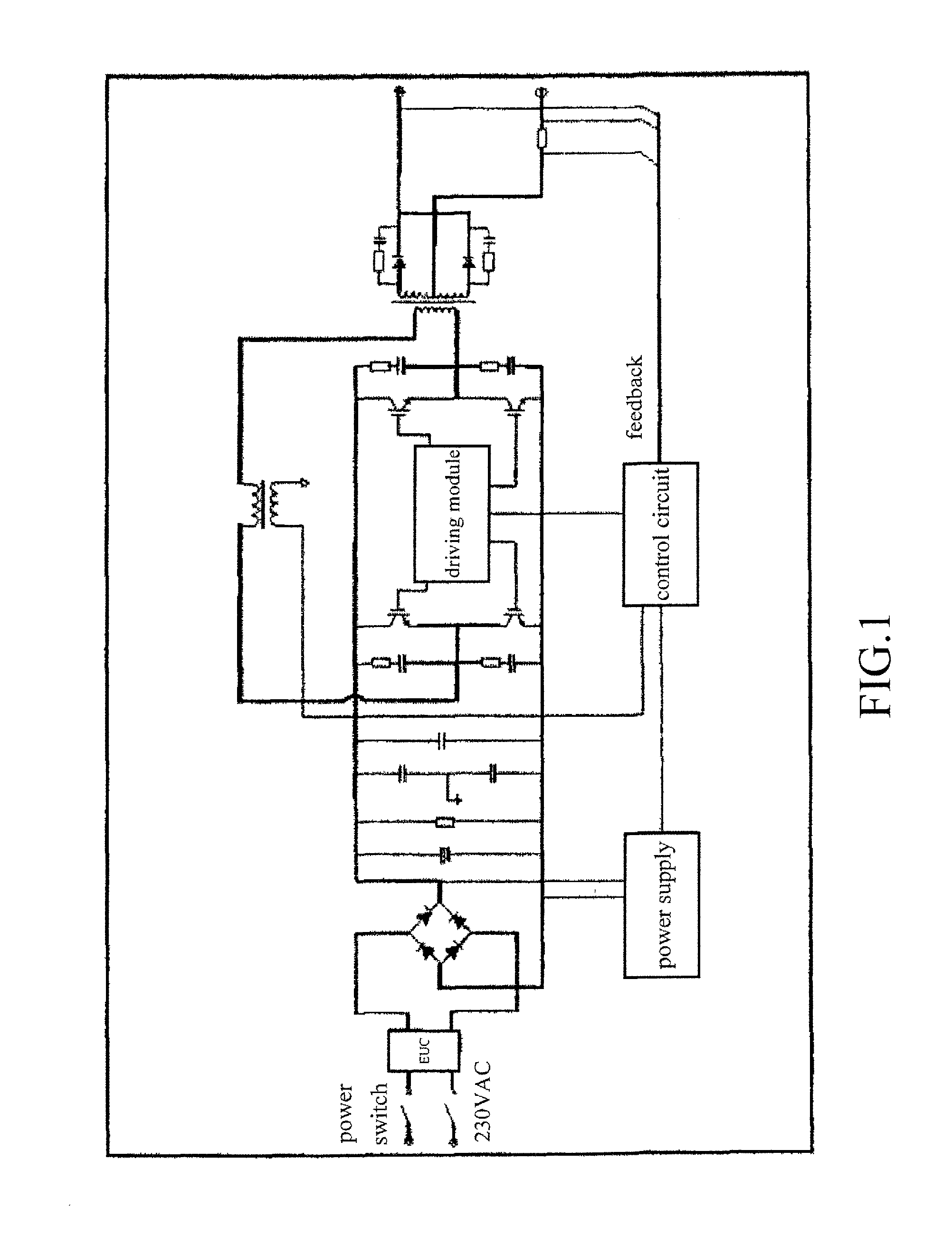

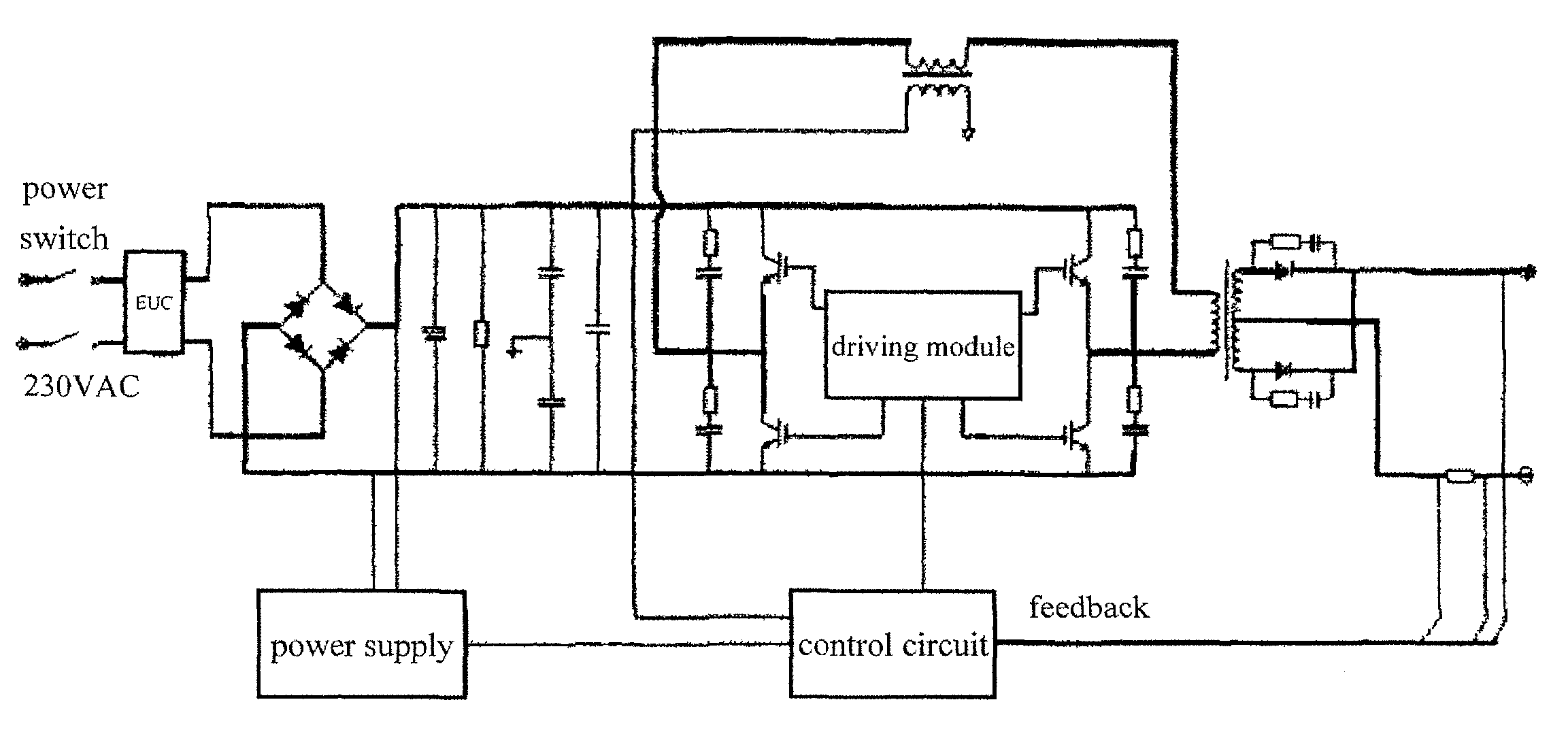

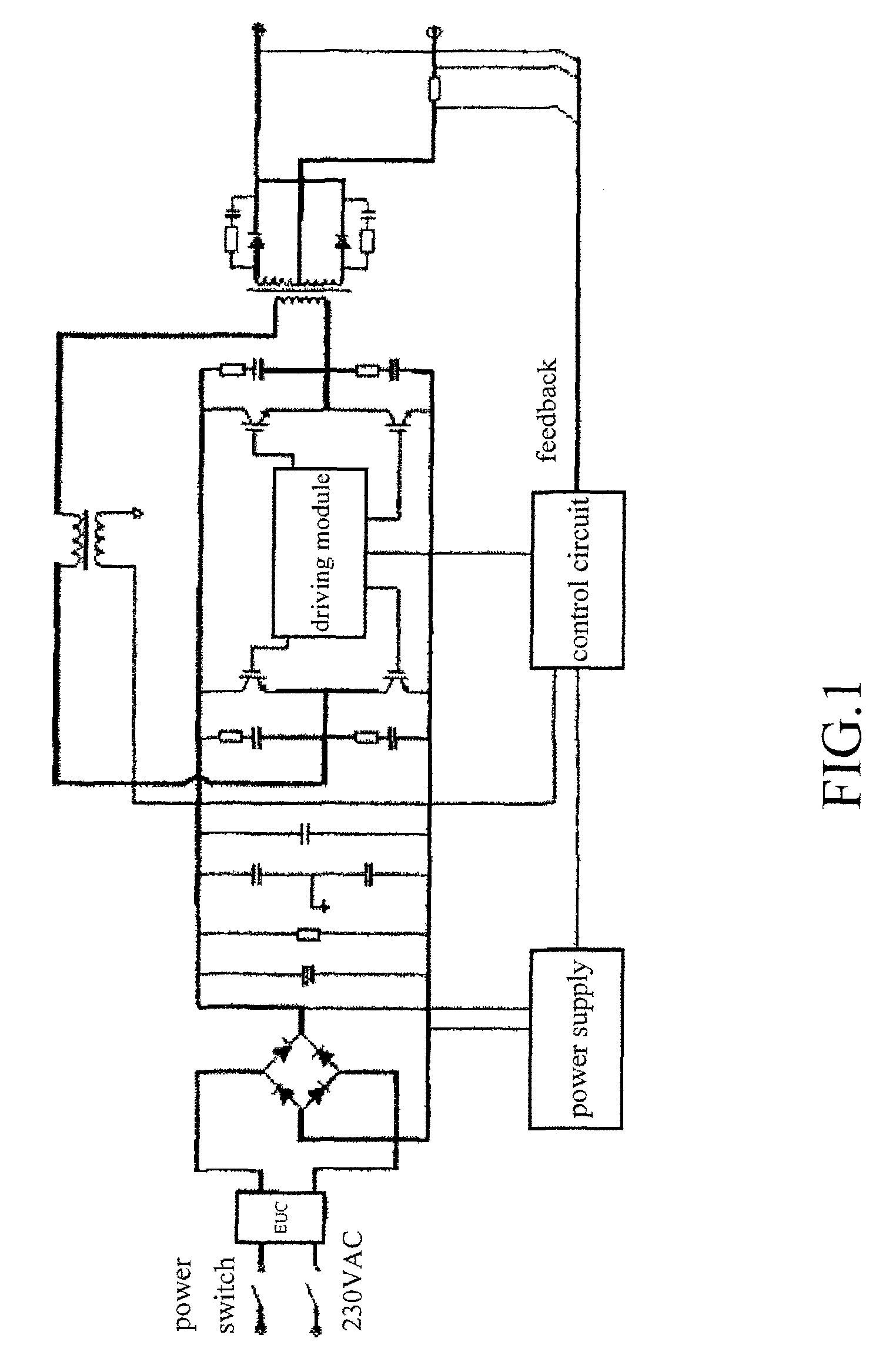

Portable IGBT arc welding machine

ActiveUS20140209586A1Large capacityLow calorific valueDc-dc conversionArc welding apparatusFull bridgeLow voltage

A portable IGBT (Insulated Gate Bipolar Transistor) of high reliability, compact size, and low cost includes a main circuit to which a control circuit and an auxiliary power supply circuit are connected. The main circuit includes, in sequence, an input rectifier filter circuit, an inverter circuit, a high-frequency primary transformer, and a secondary output rectifier circuit. The control circuit includes a PWM regulation circuit, an IGBT driving circuit, a current feedback circuit, and a current setup circuit. The inverter circuit includes a full-bridge hard switching structure, which has IGBTs constituting bridge arms that are sequentially conducted, so that their alternating conduction converts direct current into high frequency square wave alternating current, which flows through the high-frequency primary transformer and is then subjected to rectification to supply an output of low voltage direct current. Each IGBT is connected in parallel to resistor and capacitor, which constitute a peak voltage absorption circuitry.

Owner:SHENZHEN JASIC TECH

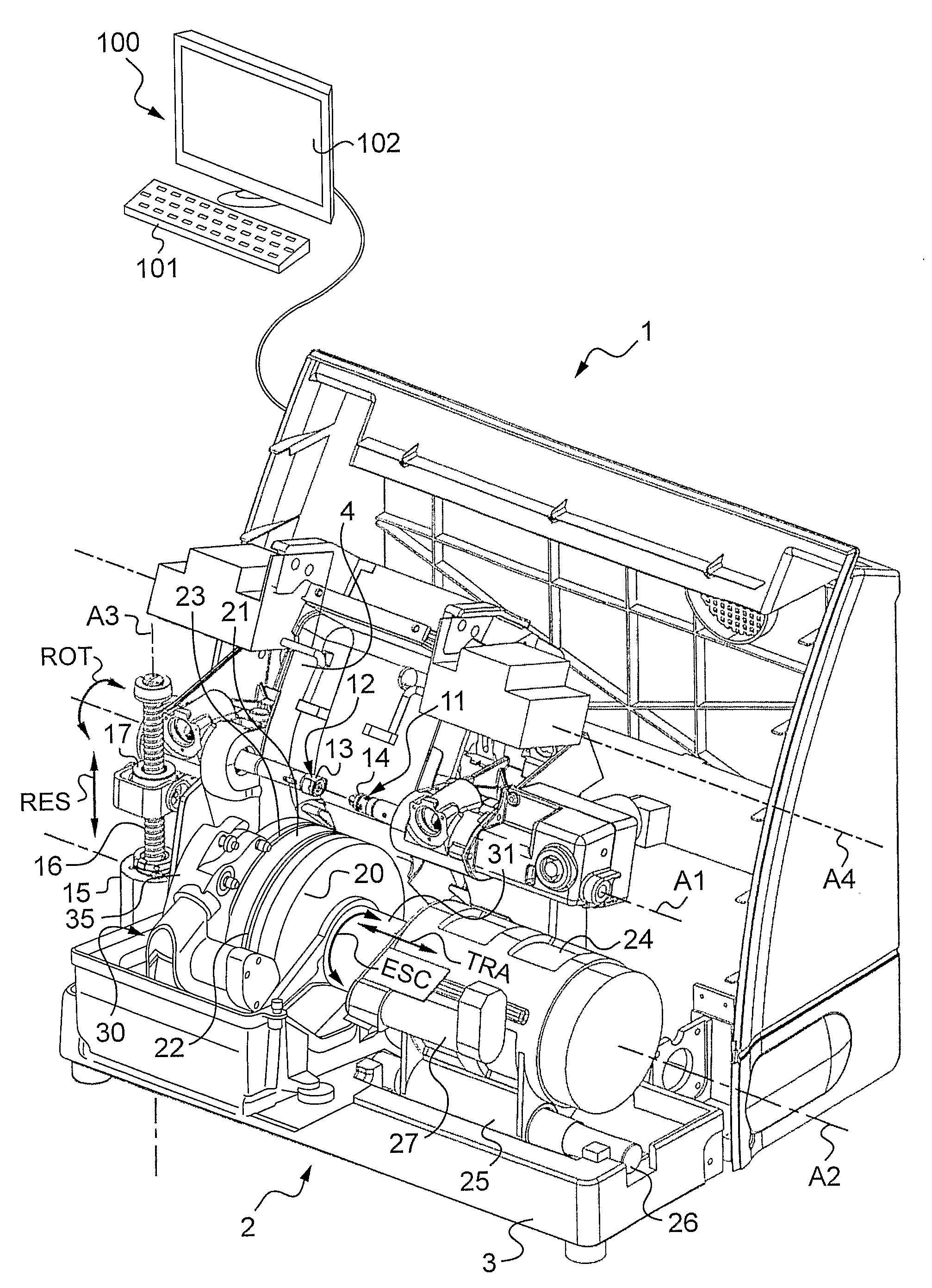

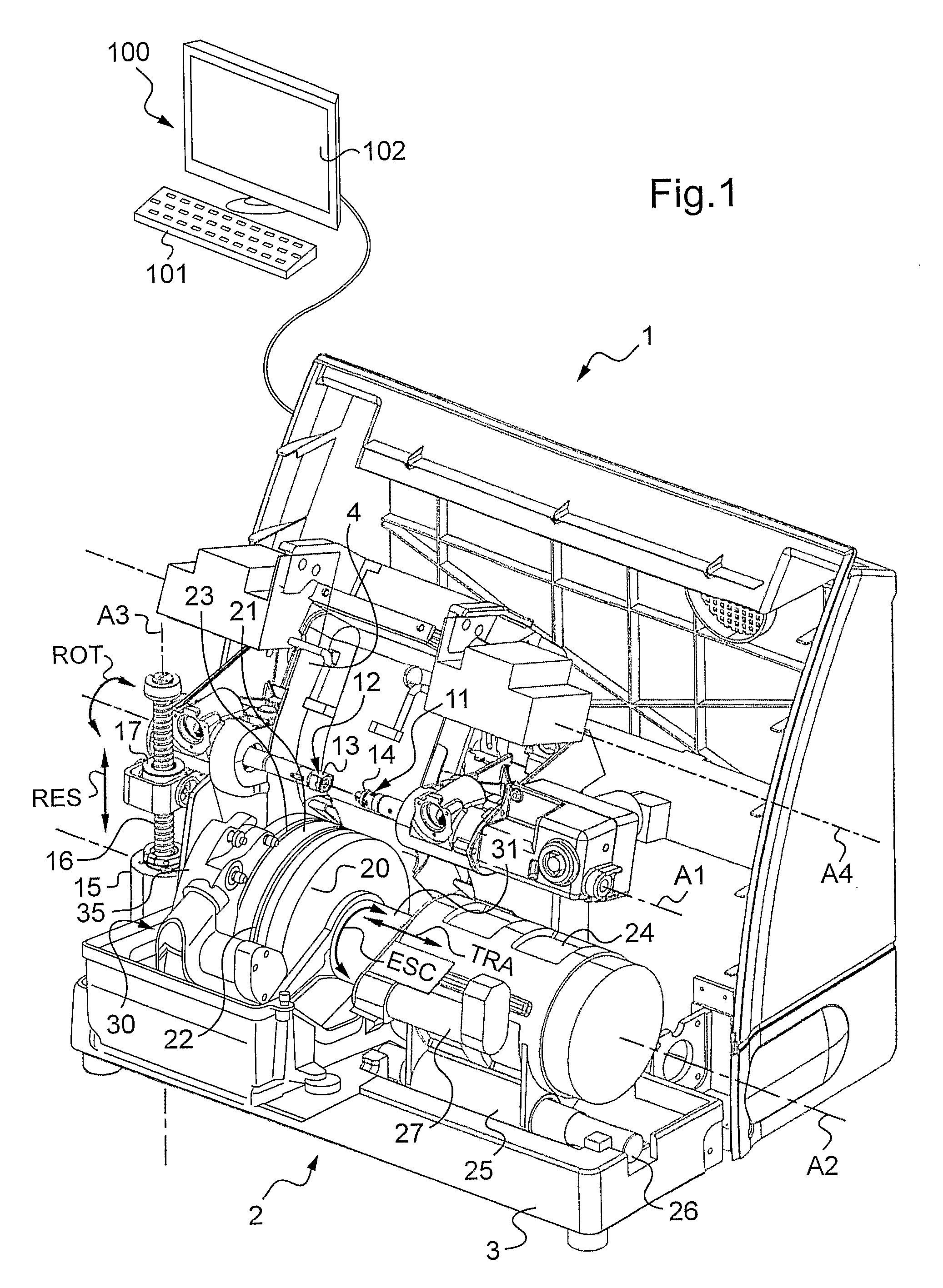

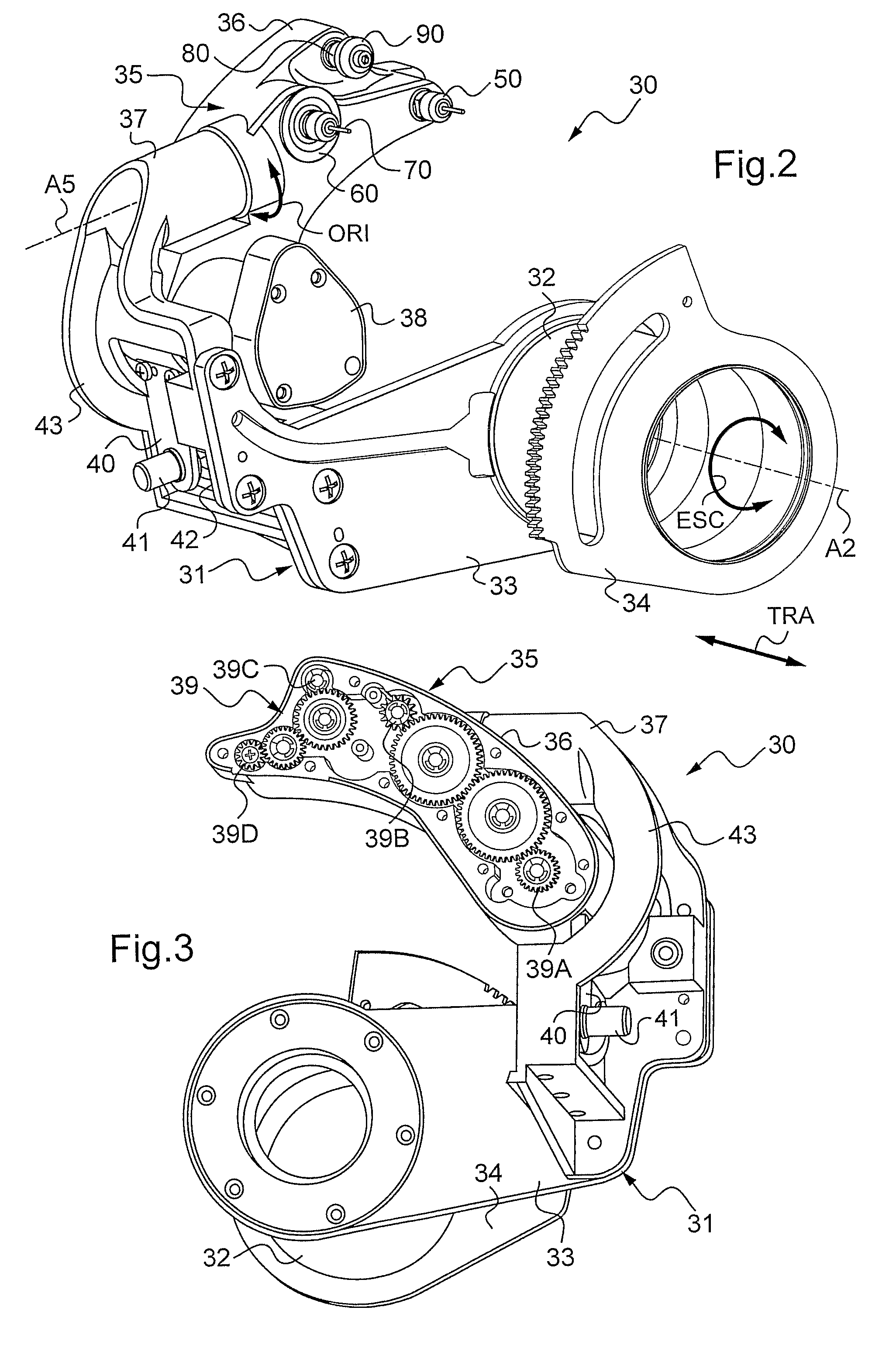

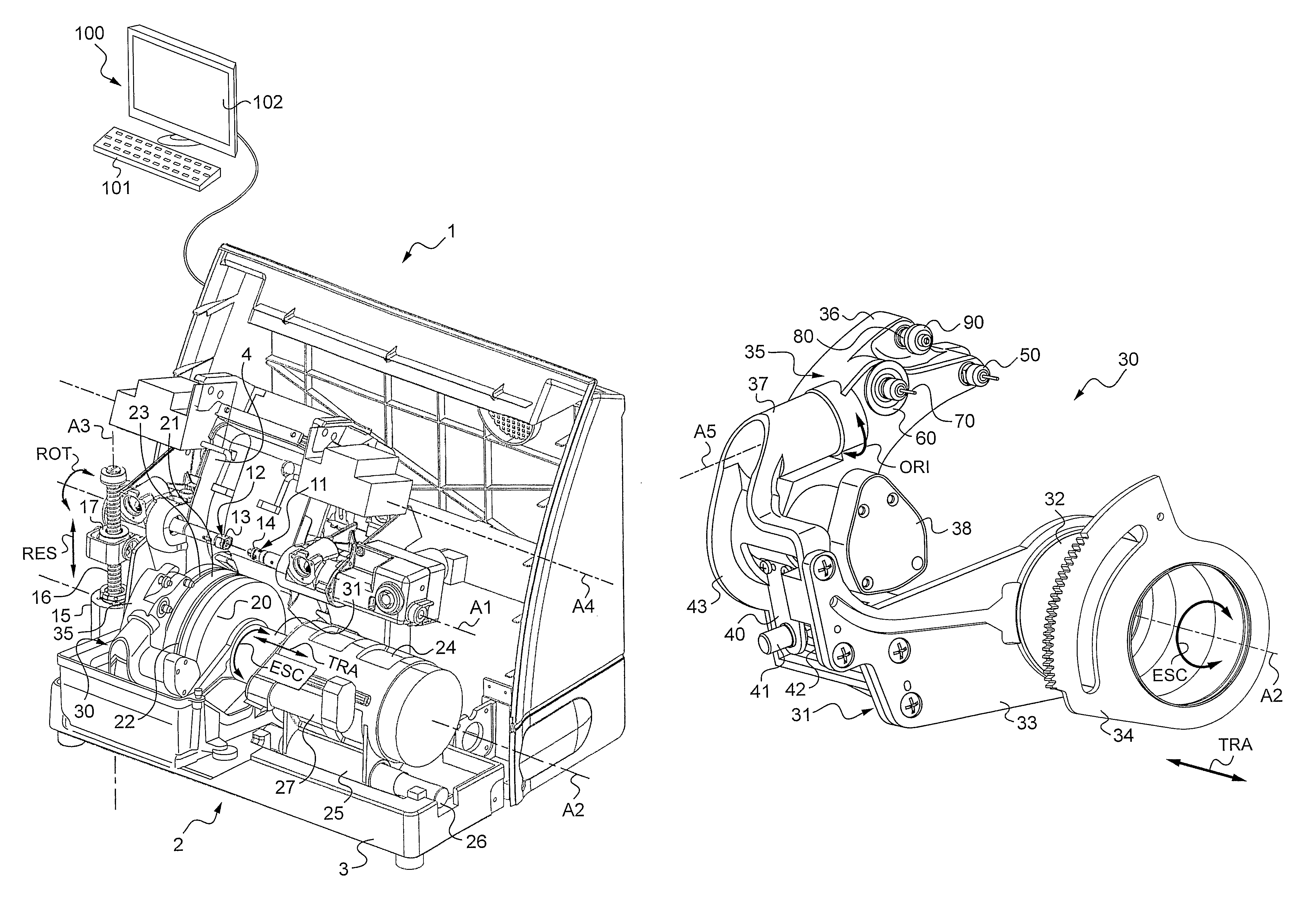

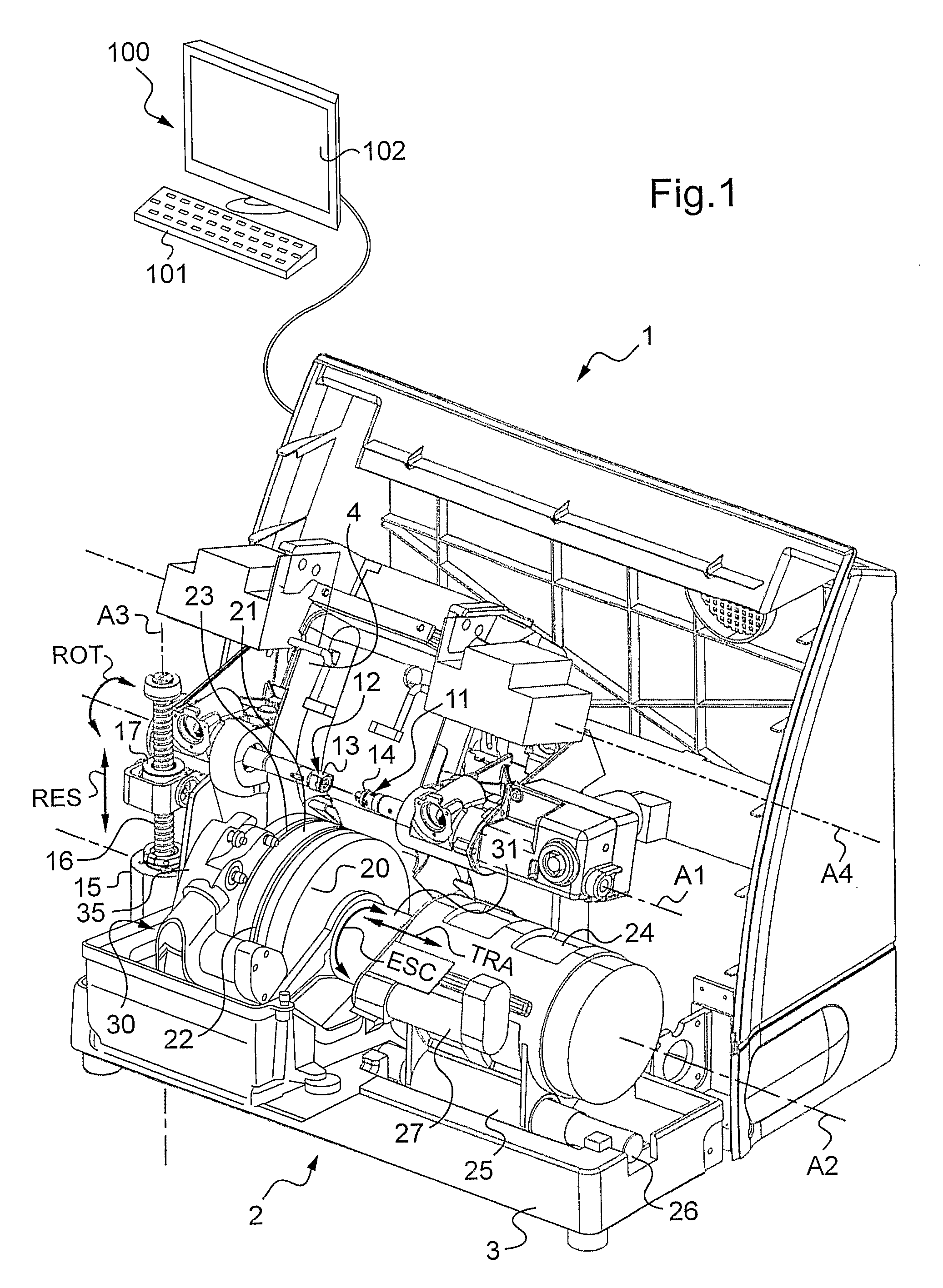

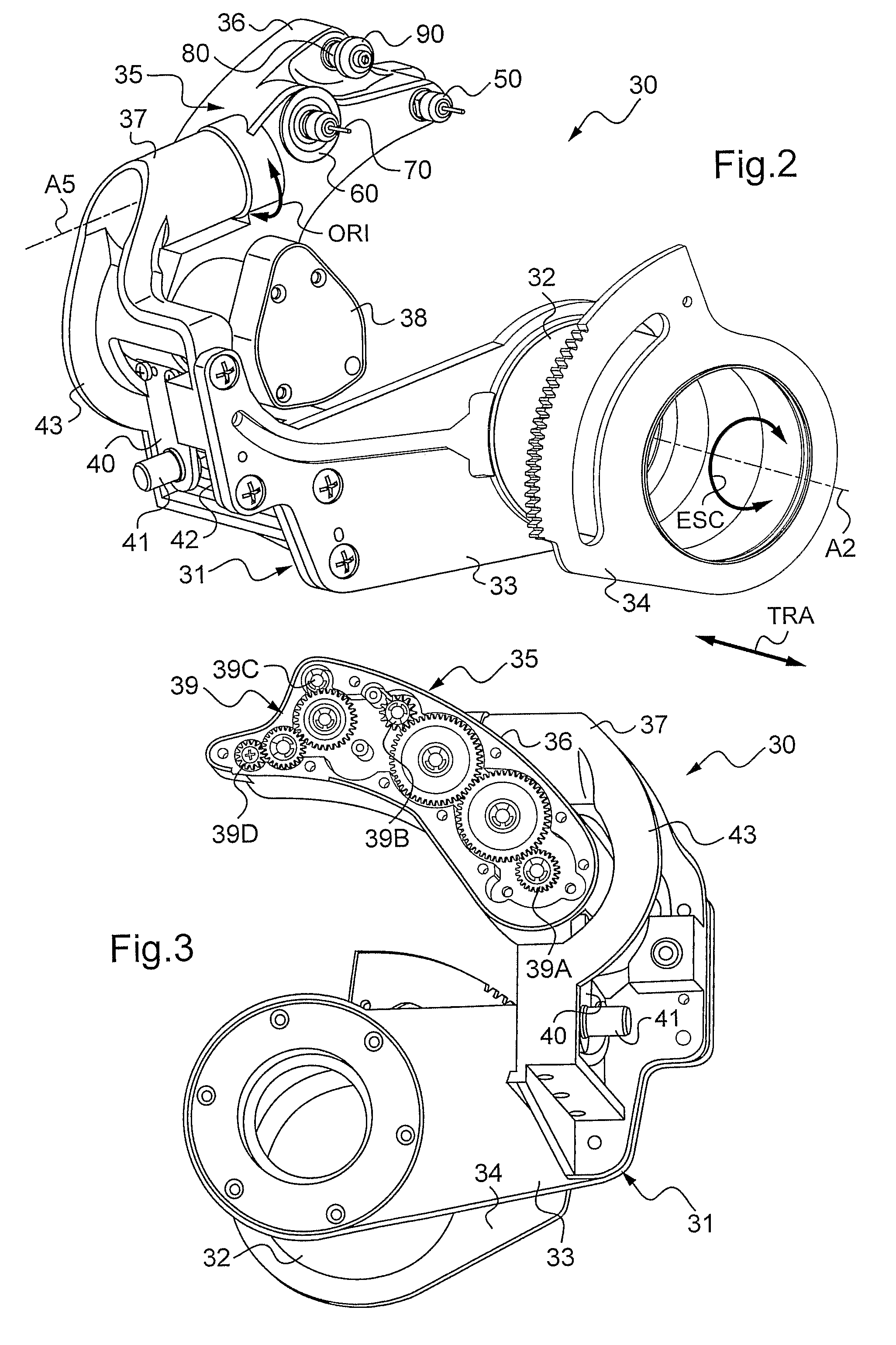

Device for machining ophthalmic lenses, the device having a plurality of machining tools placed on a swivel module

ActiveUS20100093265A1Easy maintenanceImprove accuracyEdge grinding machinesPolishing machinesEngineeringEye lens

A device (1) for machining an ophthalmic lens includes a support for the ophthalmic lens and for driving it in rotation about a blocking axis (A1), a machining module (35) that can be swiveled relative to the support and driving the lens in rotation and that is suitable for pivoting about a swivel axis that is not parallel to the blocking axis of the lens, and at least one drill tool mounted to rotate on the machining module about a first axis of rotation. The machining device includes at least one other machining tool mounted to rotate on the machining module about another axis of rotation that is distinct from the first axis of rotation and that is stationary relative to the first axis of rotation.

Owner:ESSILOR INT CIE GEN DOPTIQUE

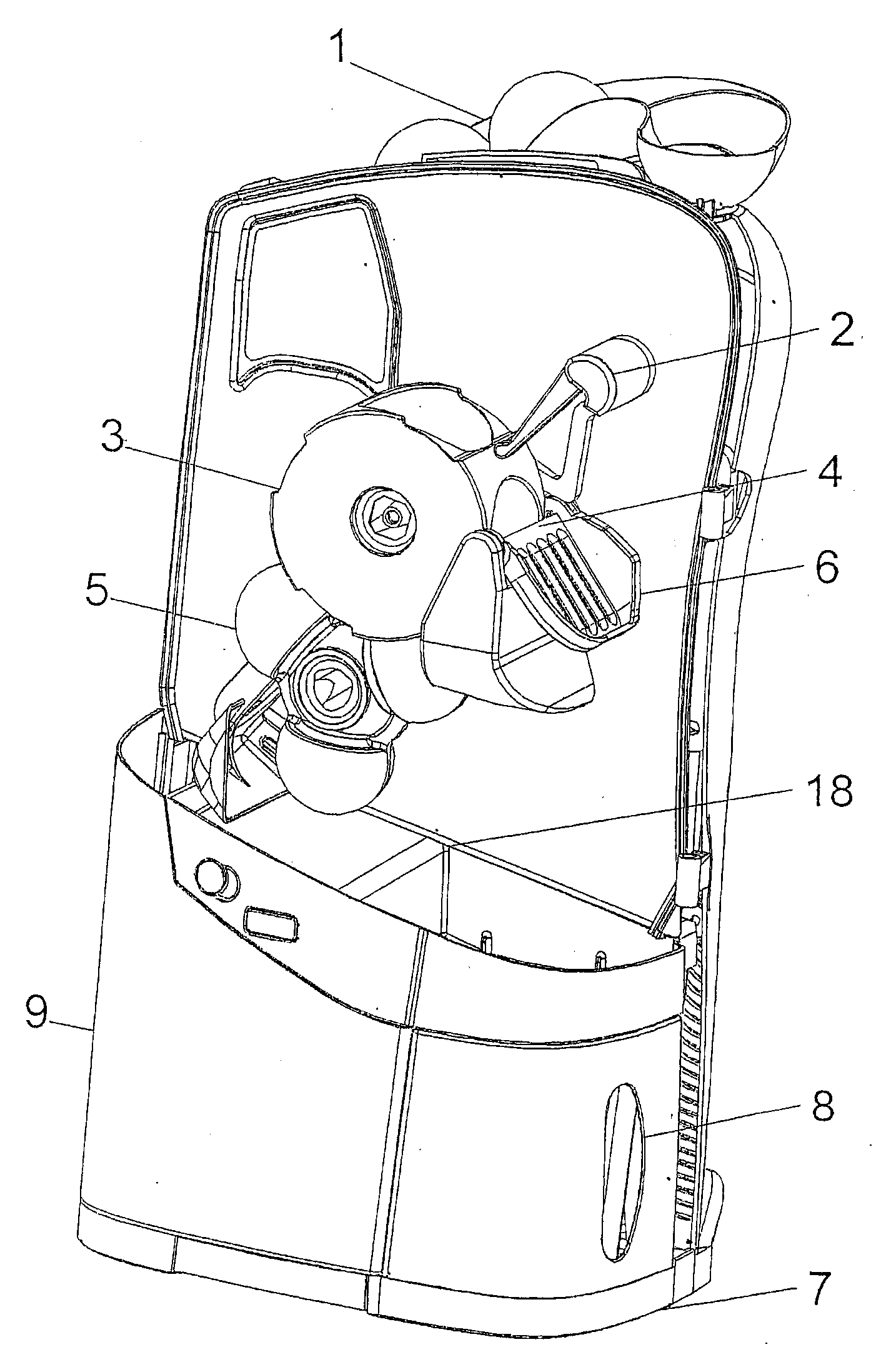

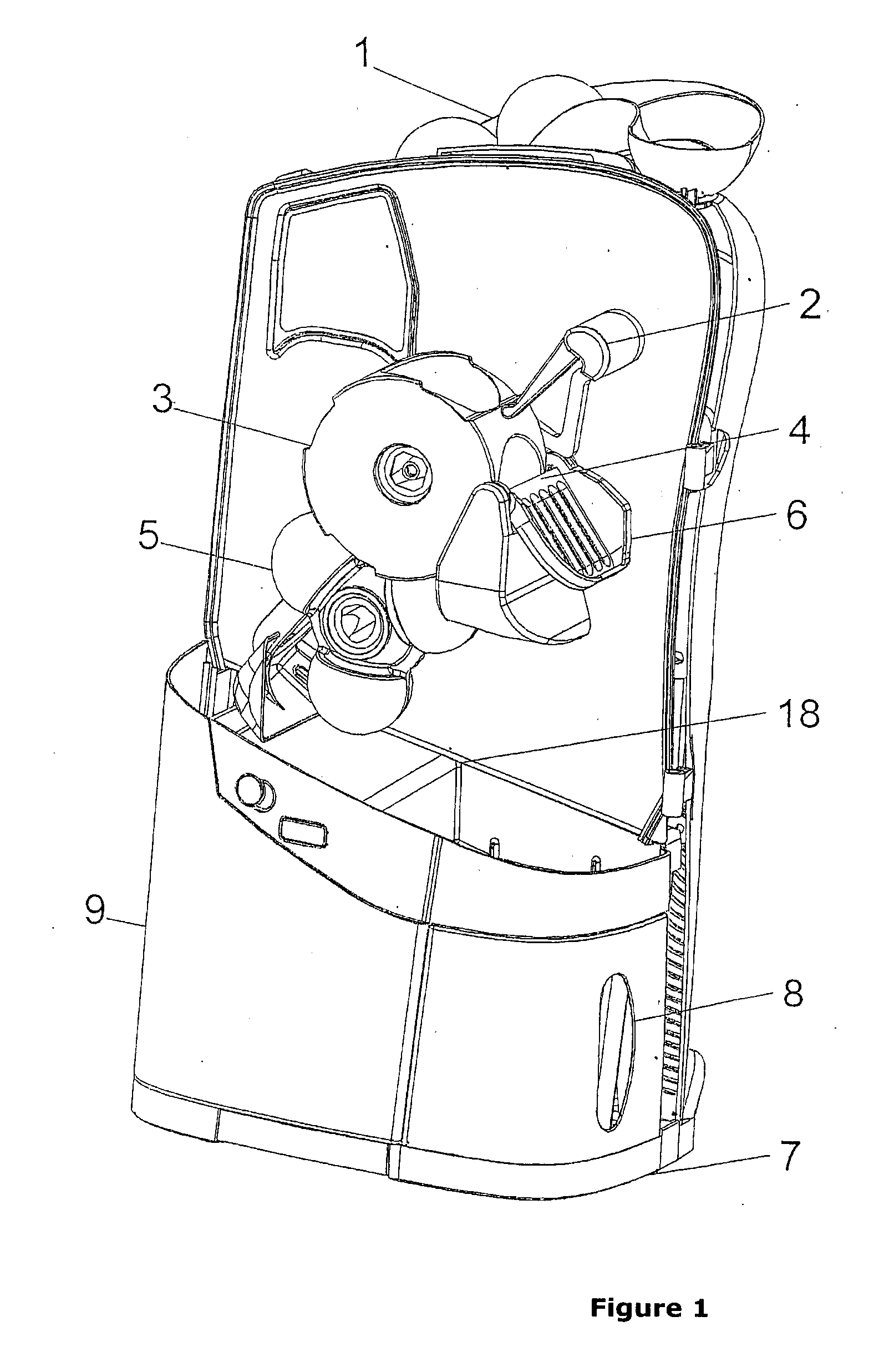

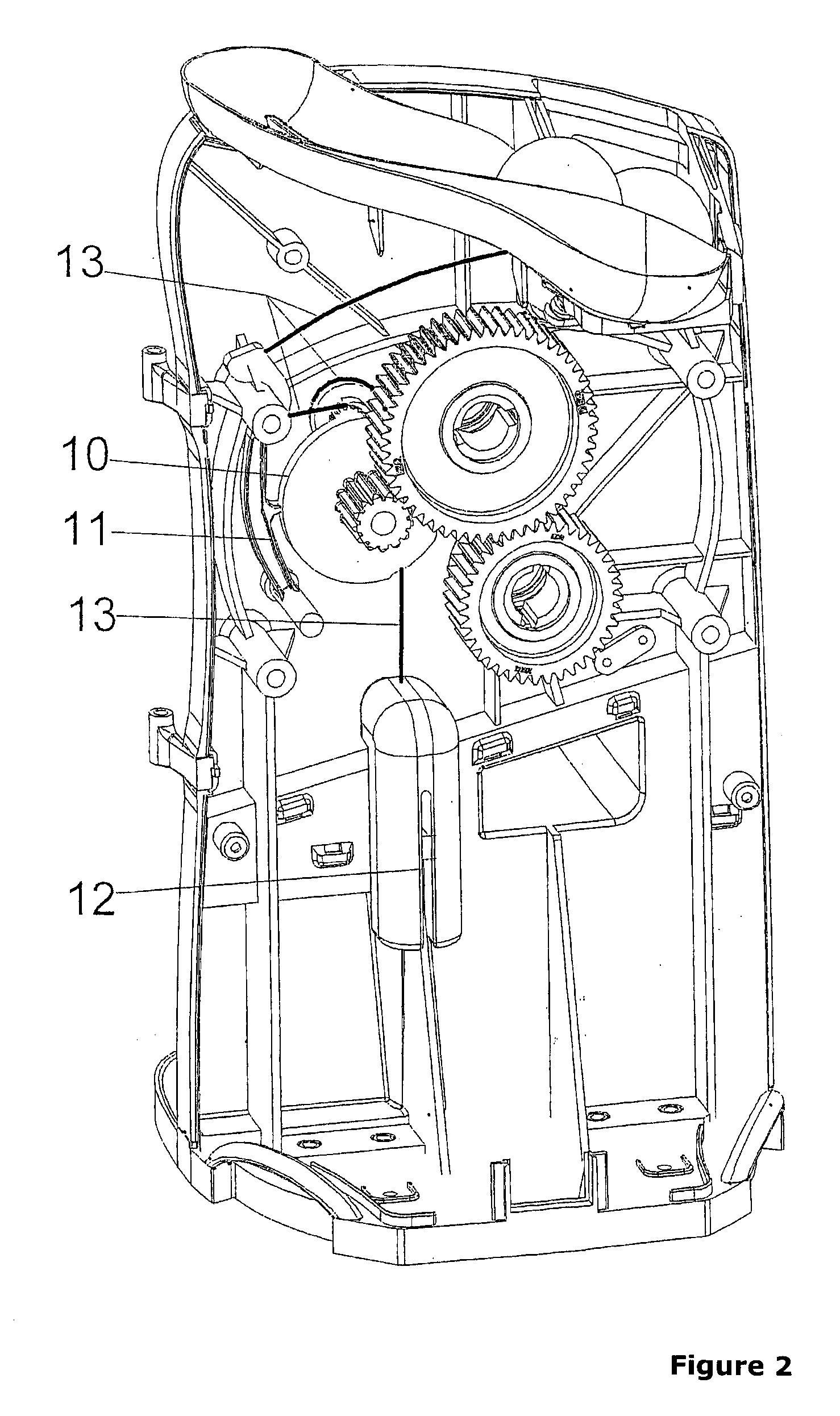

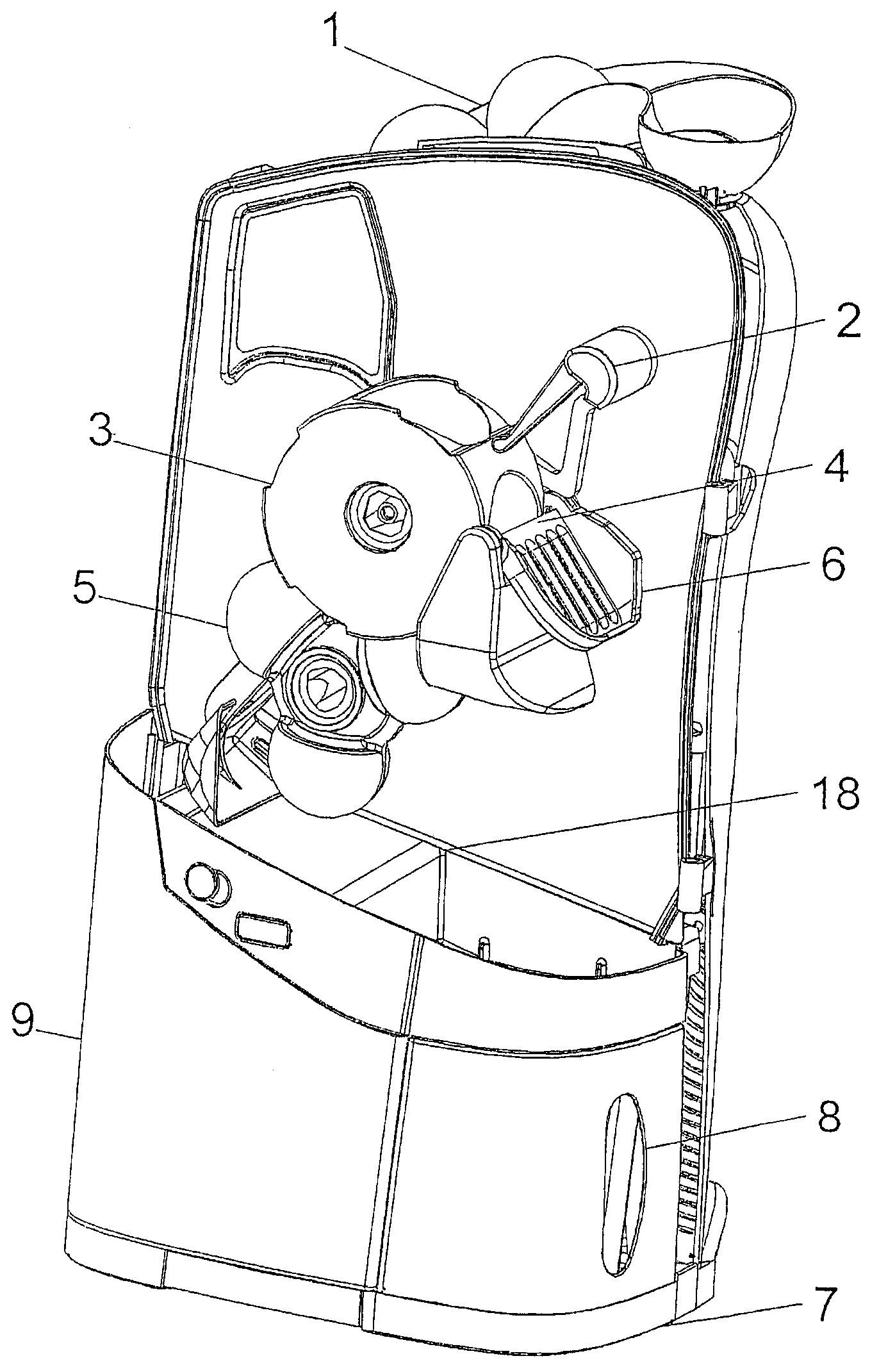

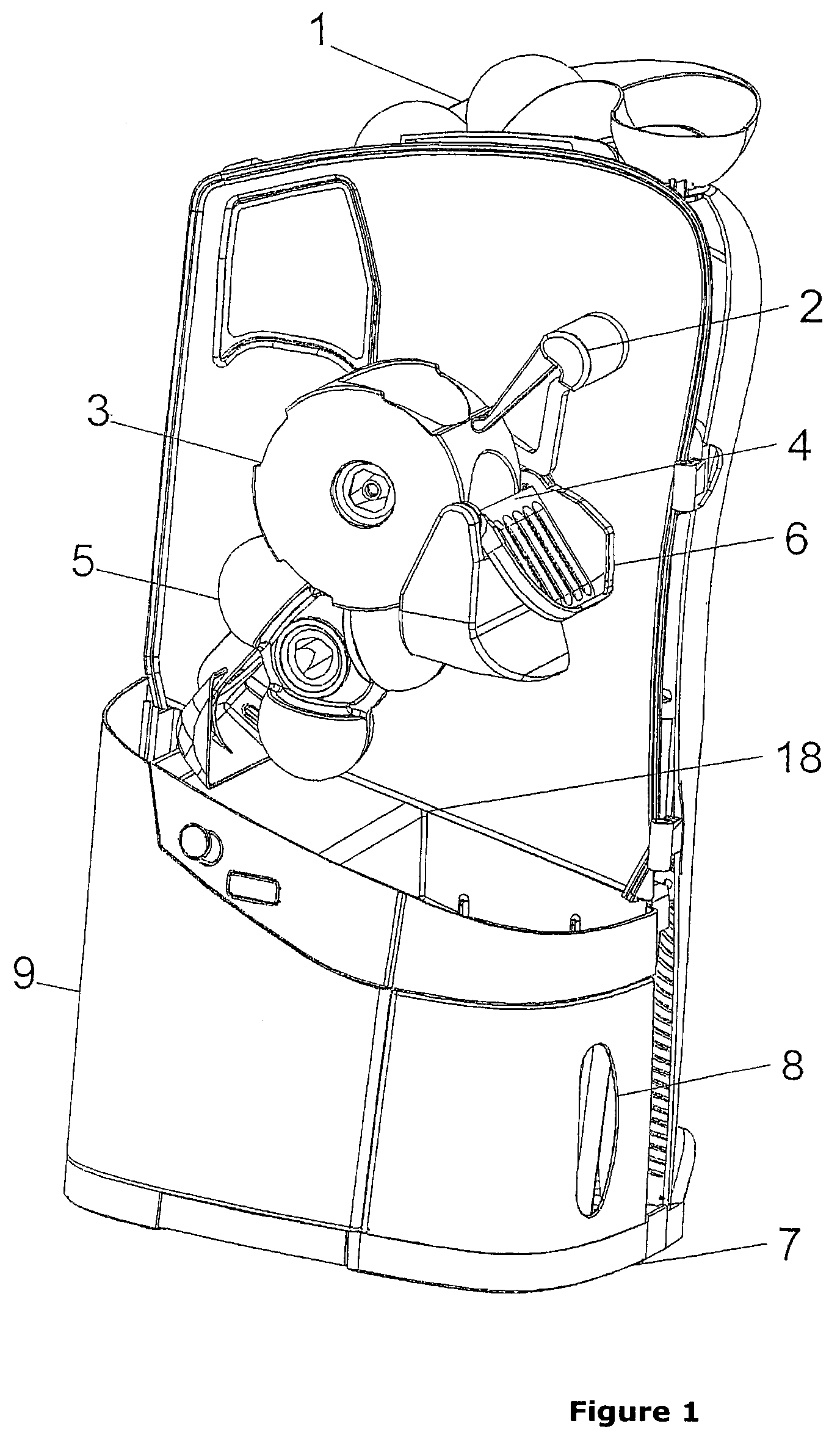

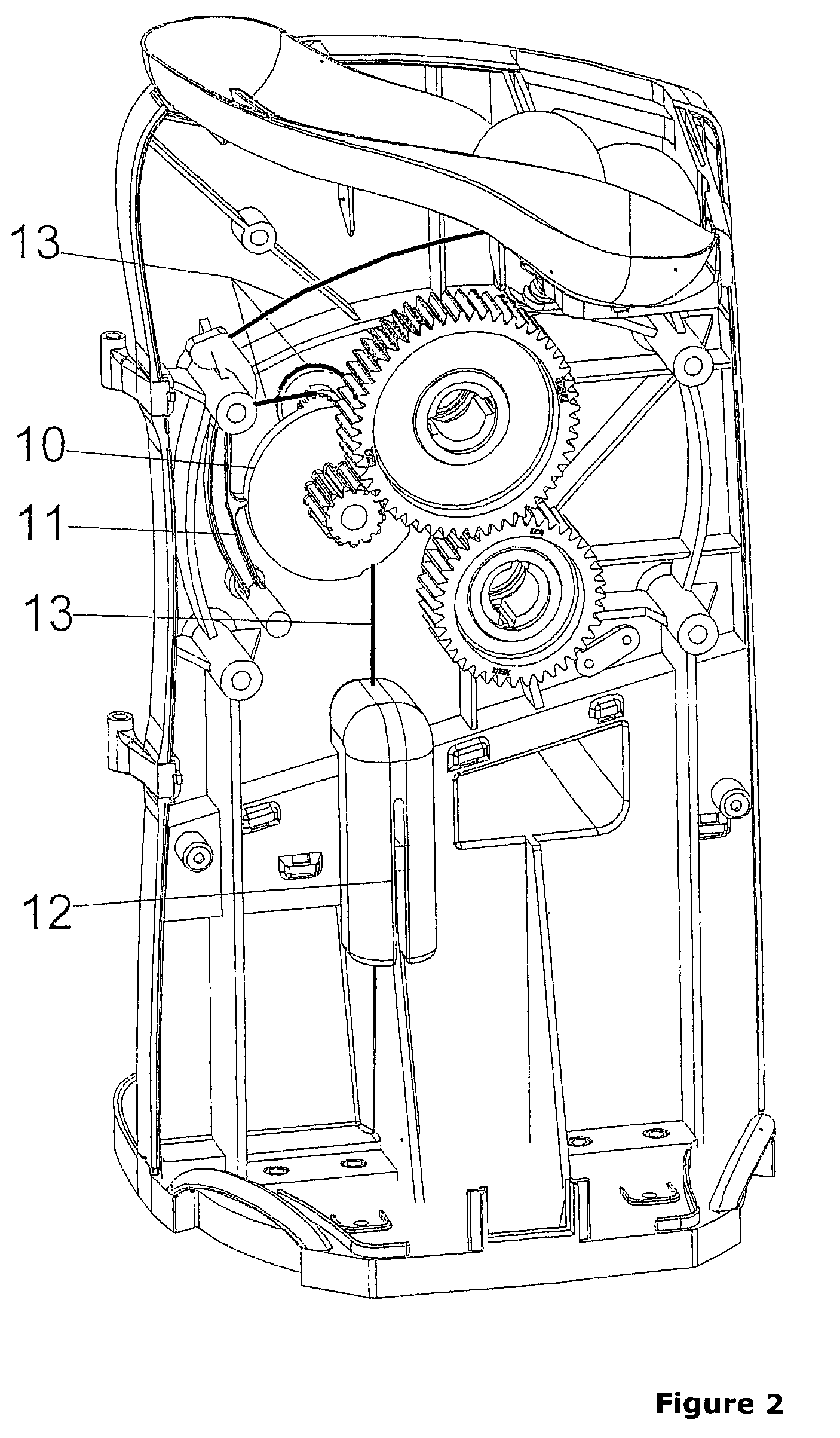

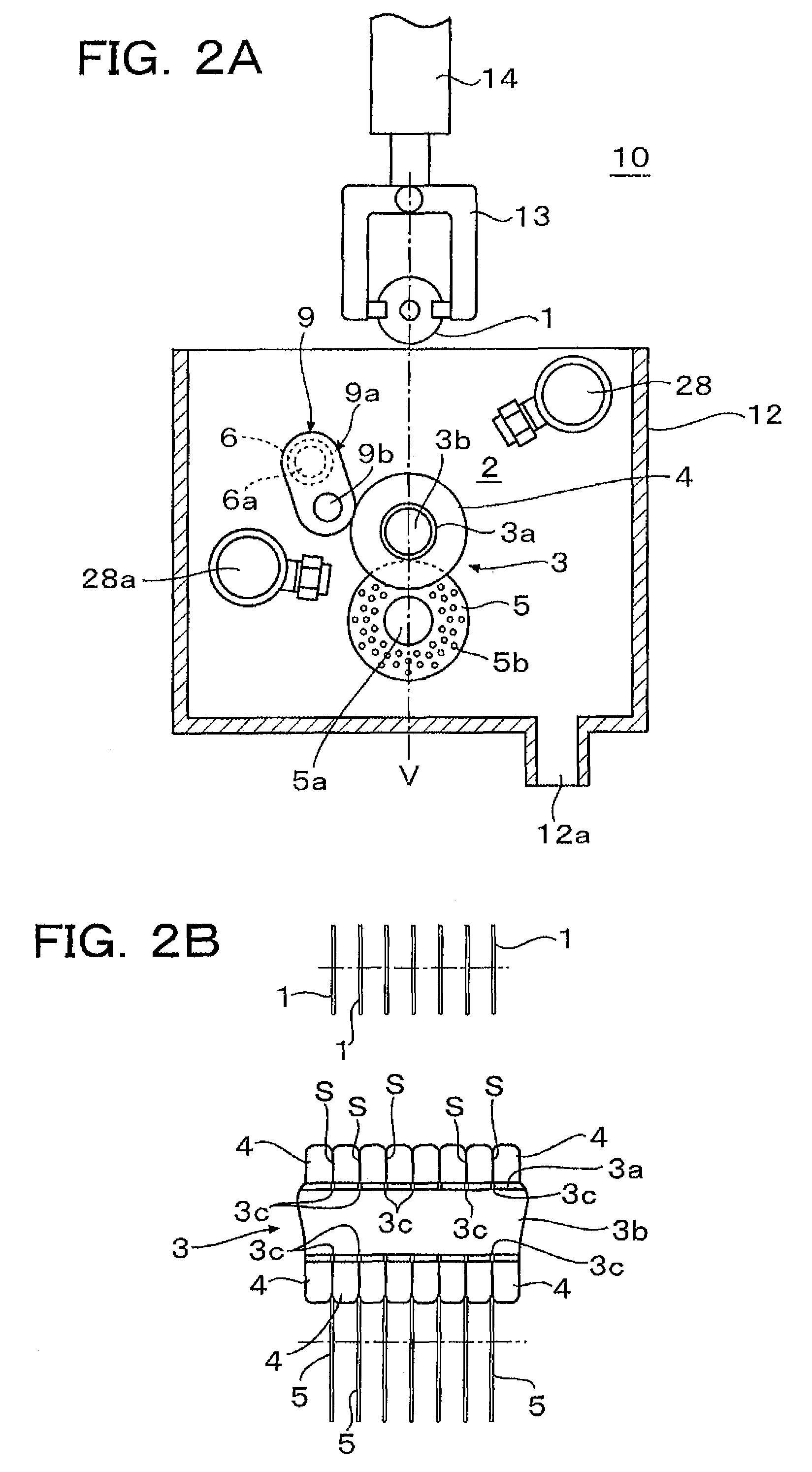

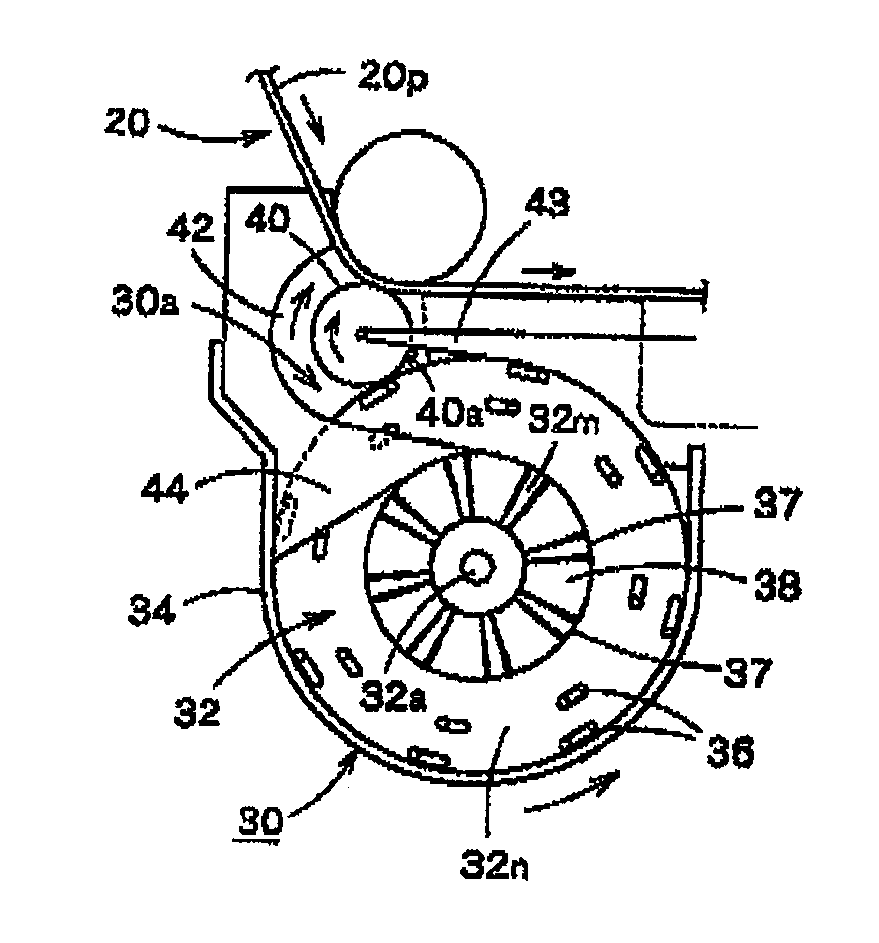

Reduced size citrus fruit juicing machine

InactiveUS20070074630A1Great degreeSame yieldJuice extractionEggs preservationReduced sizeFruit juice

This invention is a reduced size citrus fruit juicing machine that uses sets of rotating male-female drums characterized by having one sole female drum and one sole male drum with an automatically positioning blade and a retaining pendulum—turning device. These characteristics avoid having to incorporate a second set of drums into the machine since the remaining half of the fruit is turned after the cut into the following upper cavity of the female drum. In addition to maintaining the performance of similar machines of greater size, it improves hygienic conditions due to an appropriate disposition of the retaining pendulum, a ribbed opening for the fruit, a peel collector and an integrated customized juice container which are isolated from the outside, all of which make it especially attractive to hotels and restaurants that do not have much available space.

Owner:ZUMEX MARQUINAS Y ELEMENTOS S A E MONCADA

Two mode electro-mechanical transmission and control

ActiveUS8277350B2Easy constructionSpeed efficientHybrid vehiclesDigital data processing detailsPower splitDifferential signaling

A two mode power-split electric hybrid system and a method of control said hybrid system. The hybrid system is comprised of an engine, a transmission, an energy storage device and a control system for effecting said control method. Said transmission is a reconfigurable power split system, comprising a power-splitting device and an output power path selecting device. The power splitting device includes a compound planetary gear system and two electric machines which form a local series electric hybrid system. Said transmission regulates the output power state of said hybrid system by controlling power flow within said local series hybrid system. The hybrid system provides at least two operating mode, an output power split mode and a compound power split mode. Said control system includes multiple controllers and control modules. In accordance with the operating conditions of the hybrid system, said control system computes and sets system power requirement, allocates ob board power resources and sets engine operating speed and torque. In addition, said control system sets the operation mode of the transmission and controls the engine speed by adjusting operating torque of electric machines, based on the differential signal between reference engine speed and actual engine speed. Said control system is also capable of controlling engine torque through engine controller.

Owner:SHANDONG LIANCHENG GREENMAX TECH

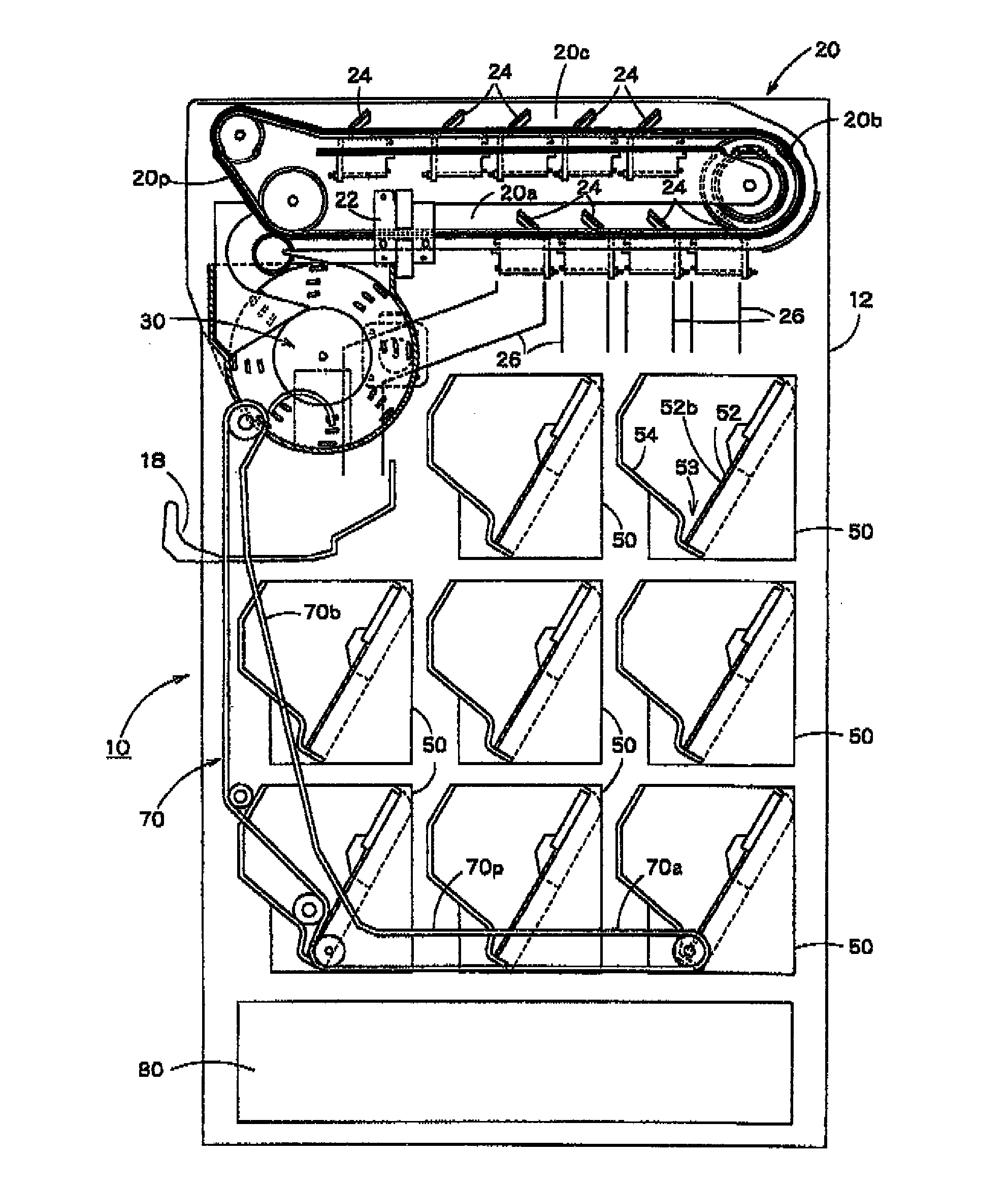

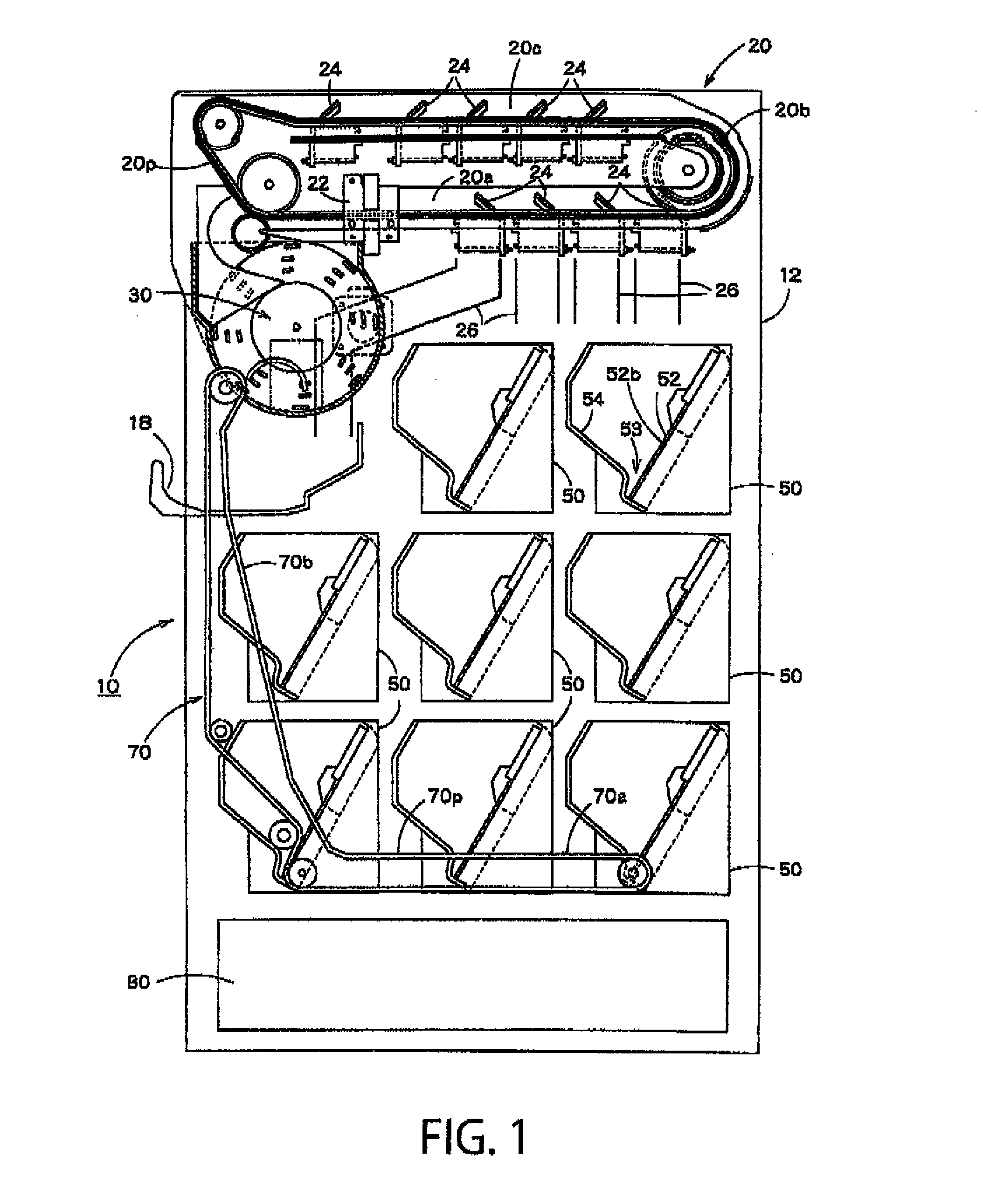

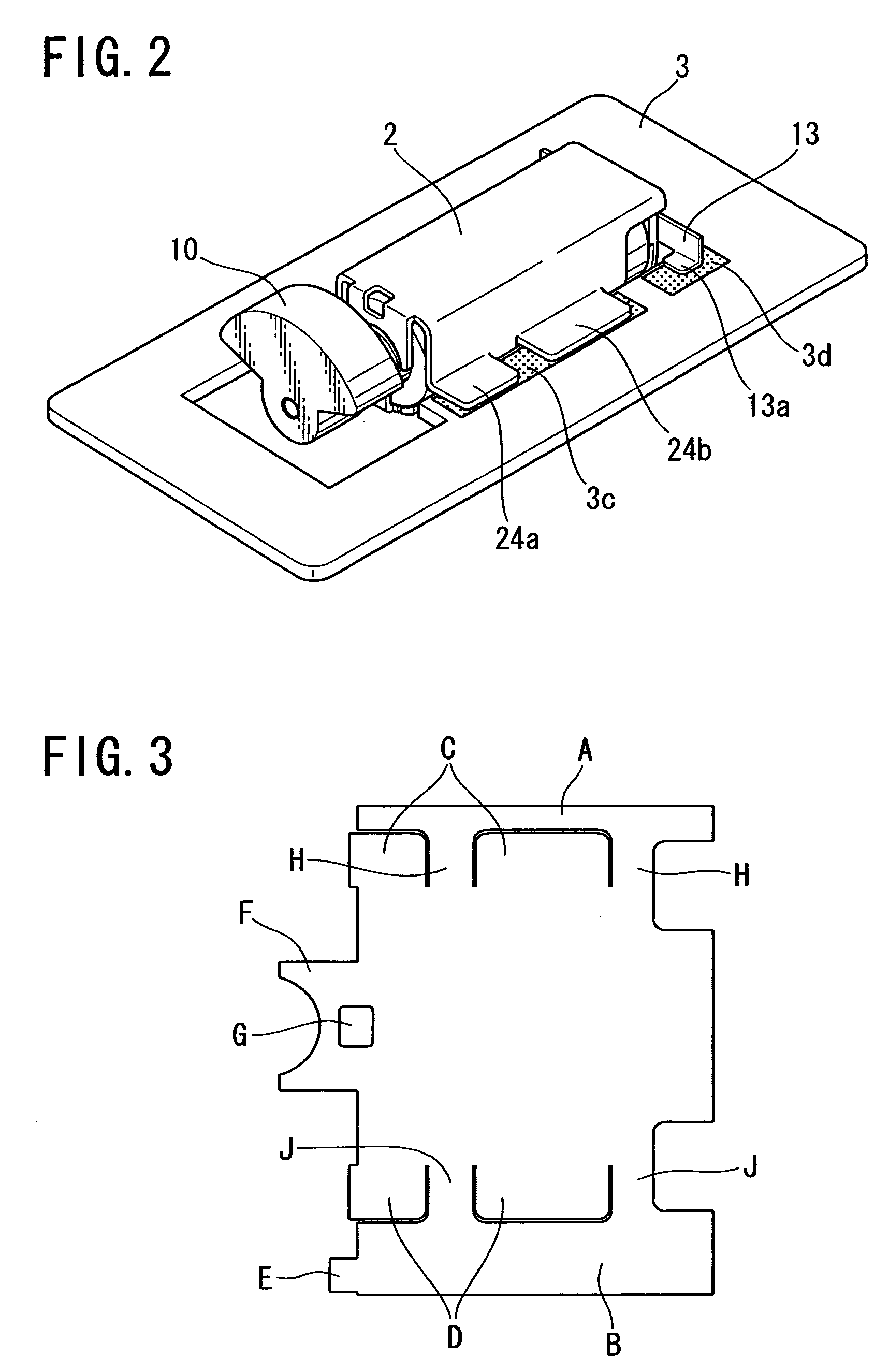

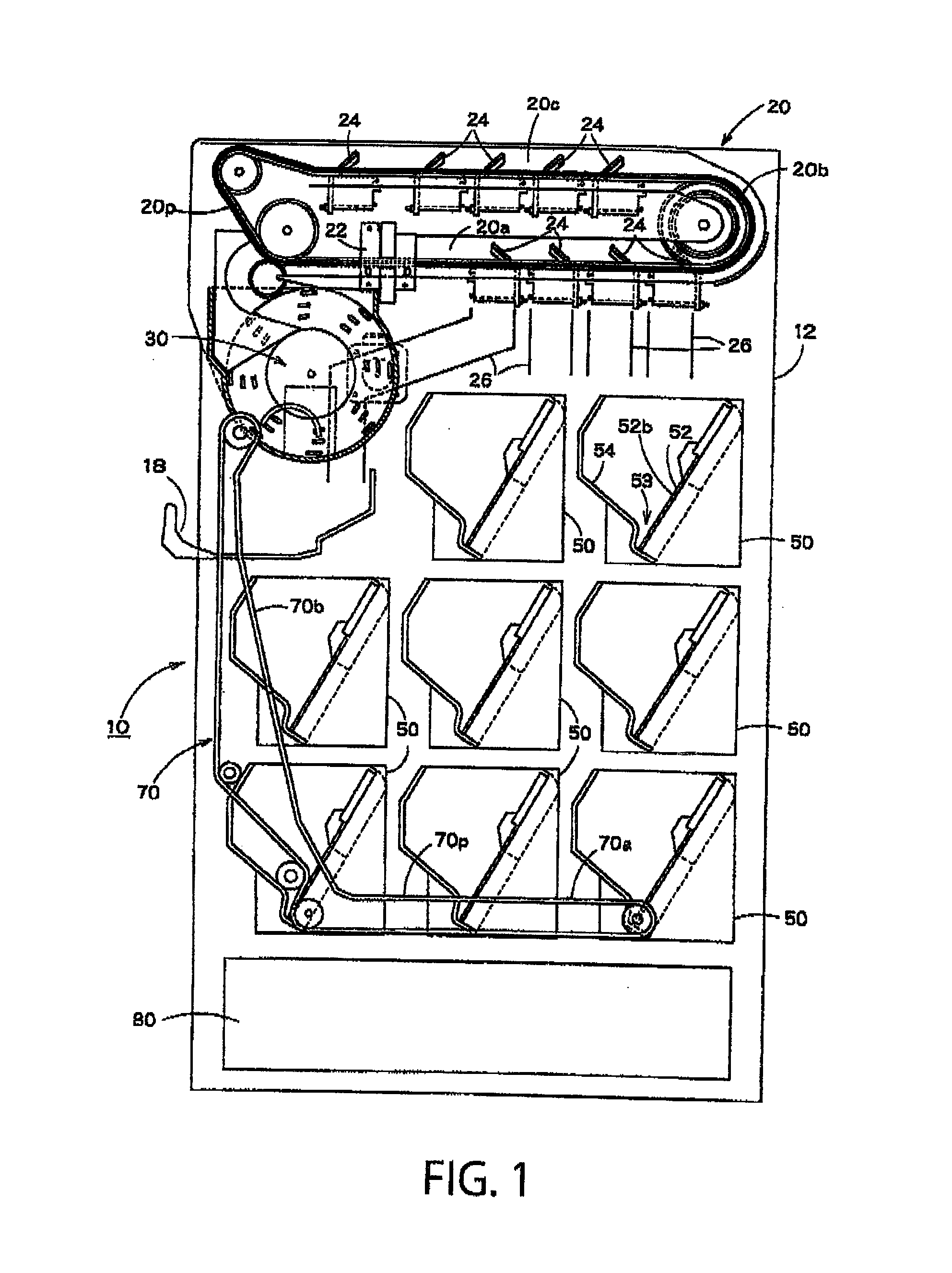

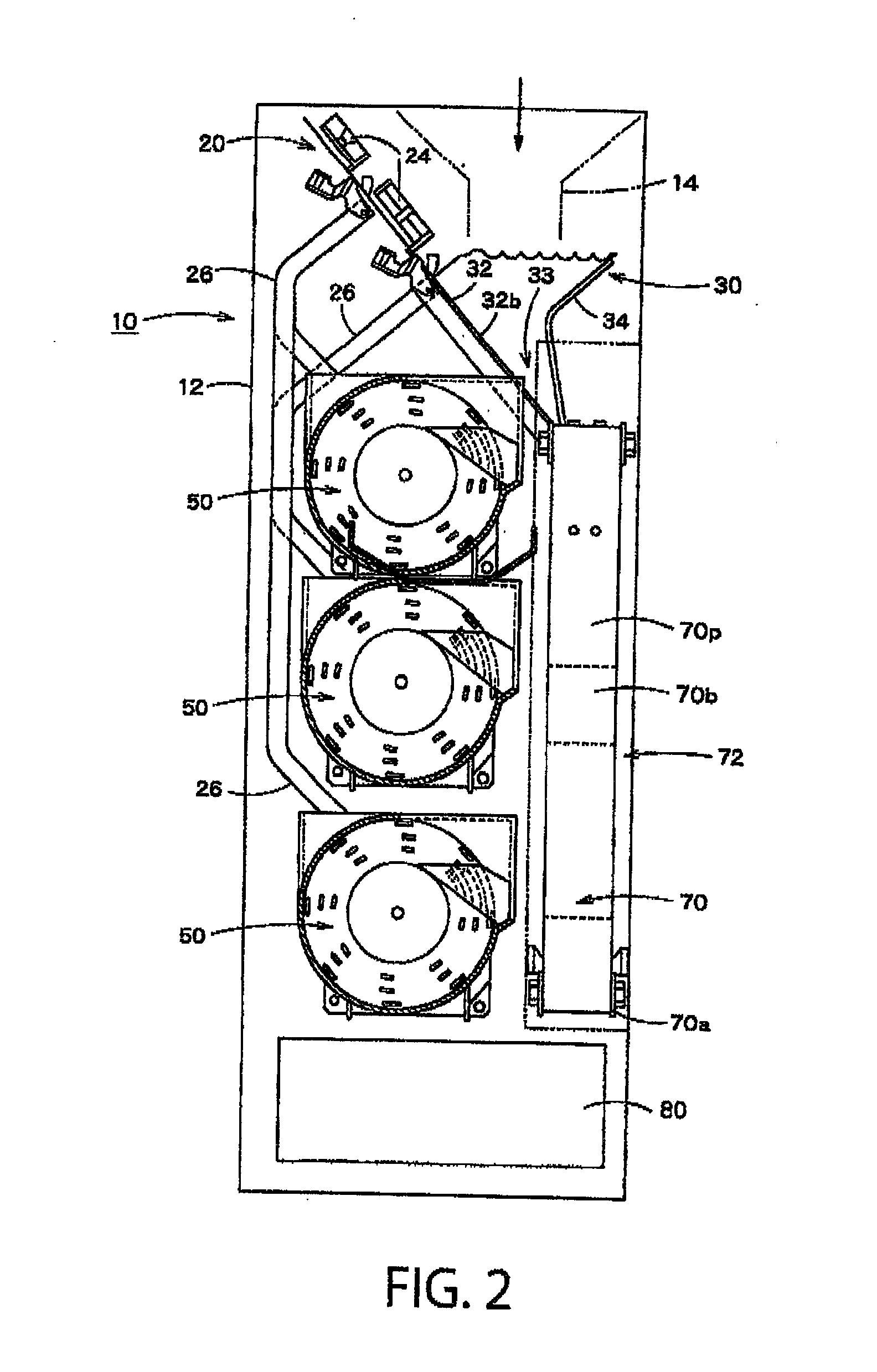

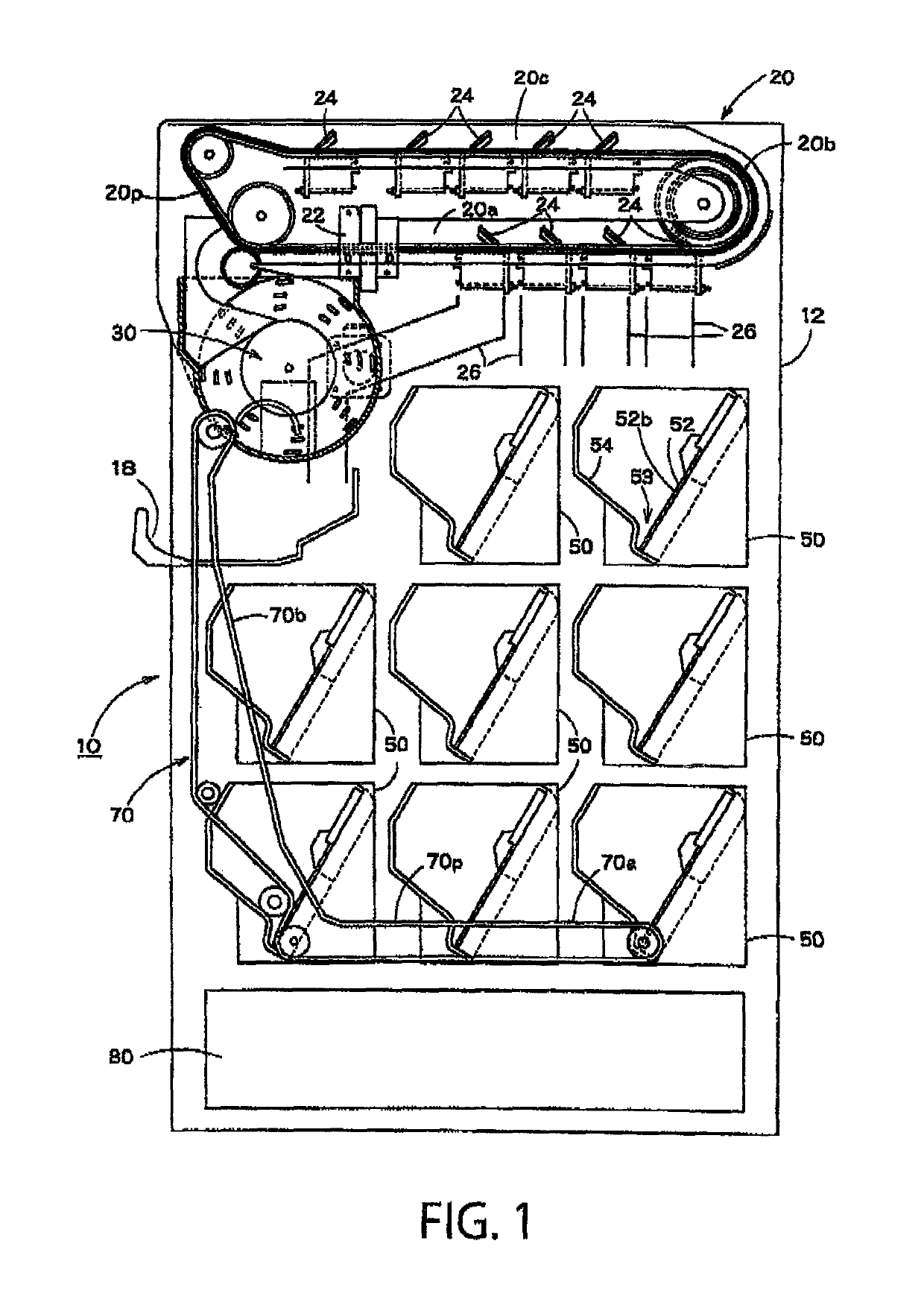

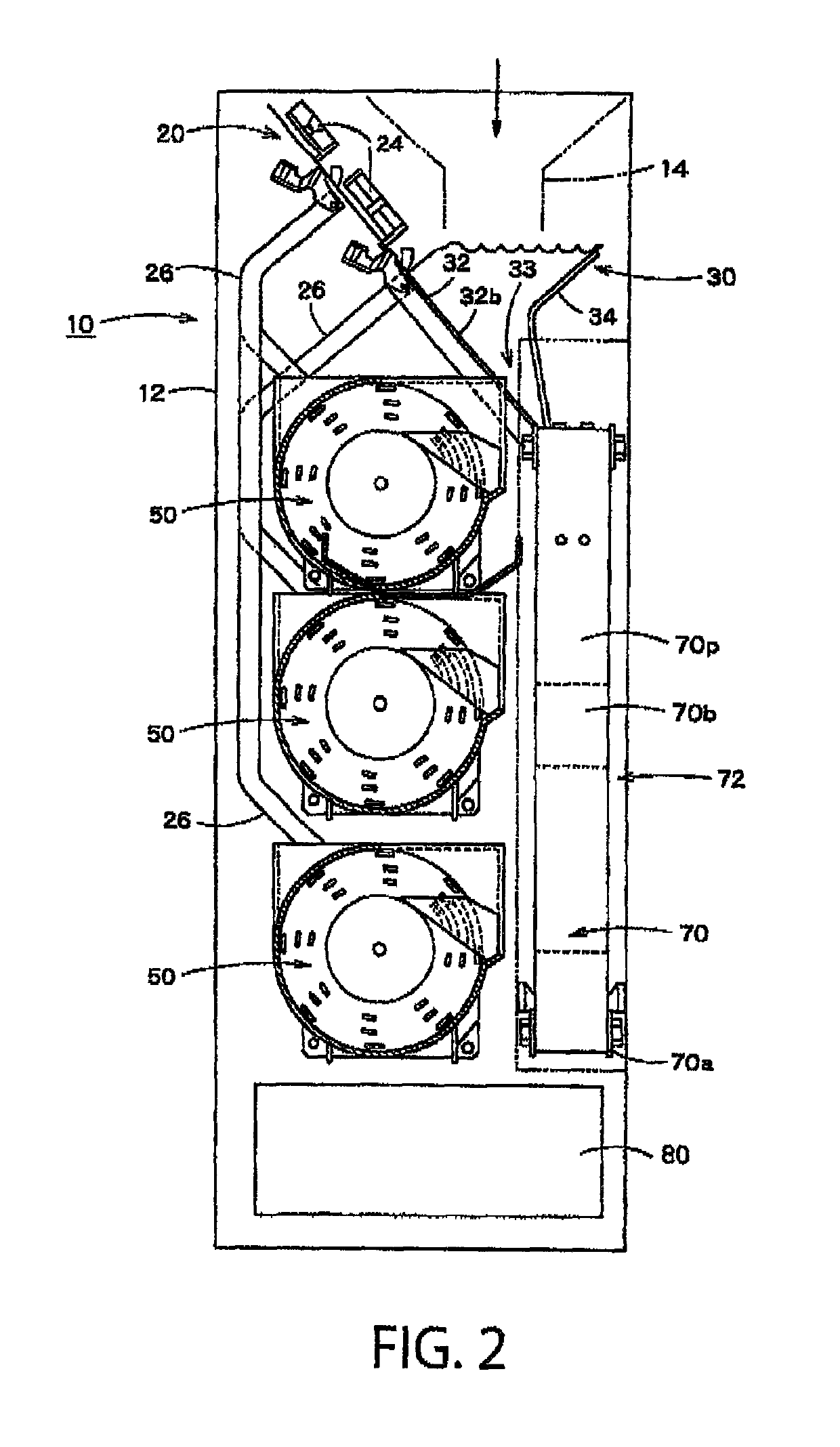

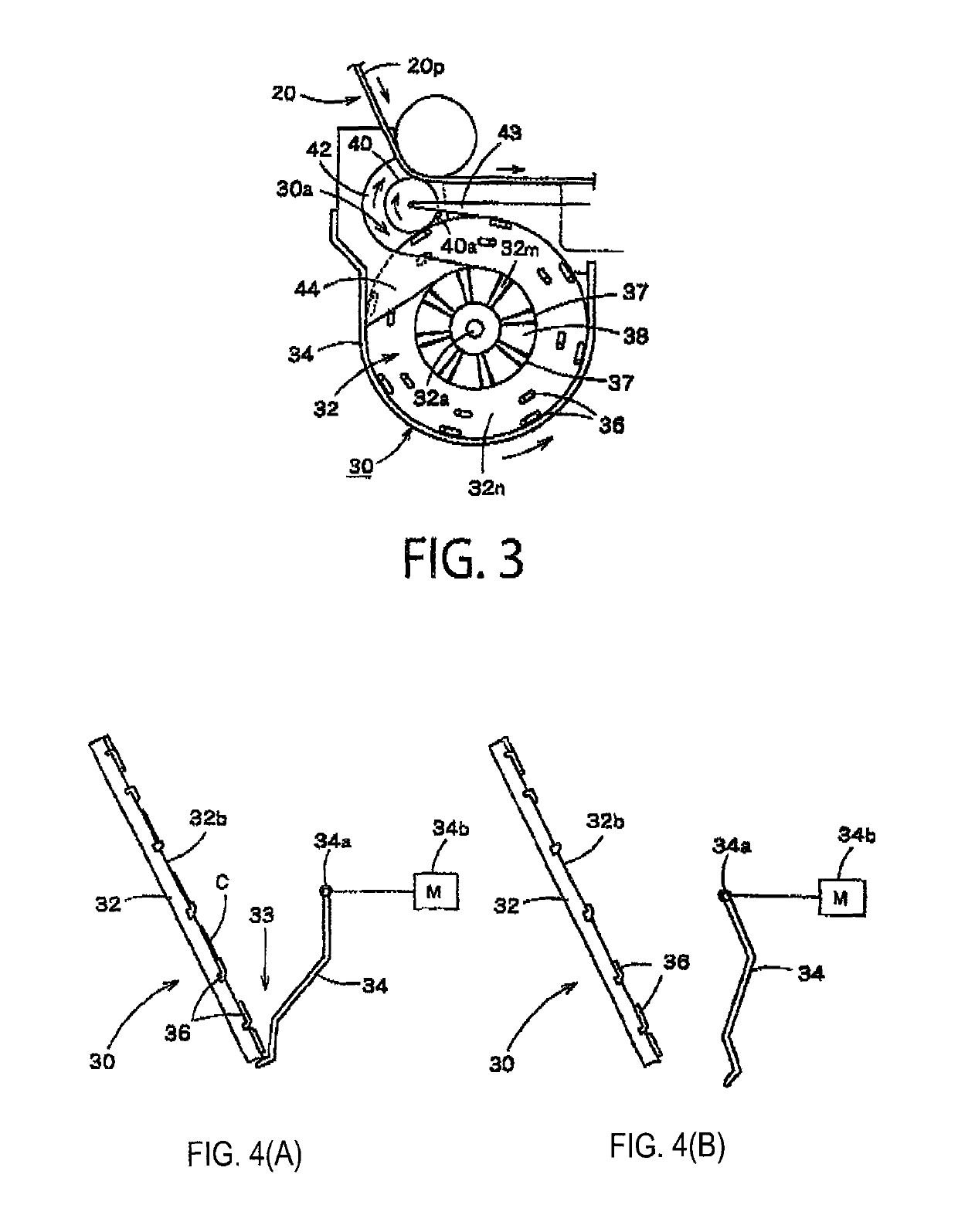

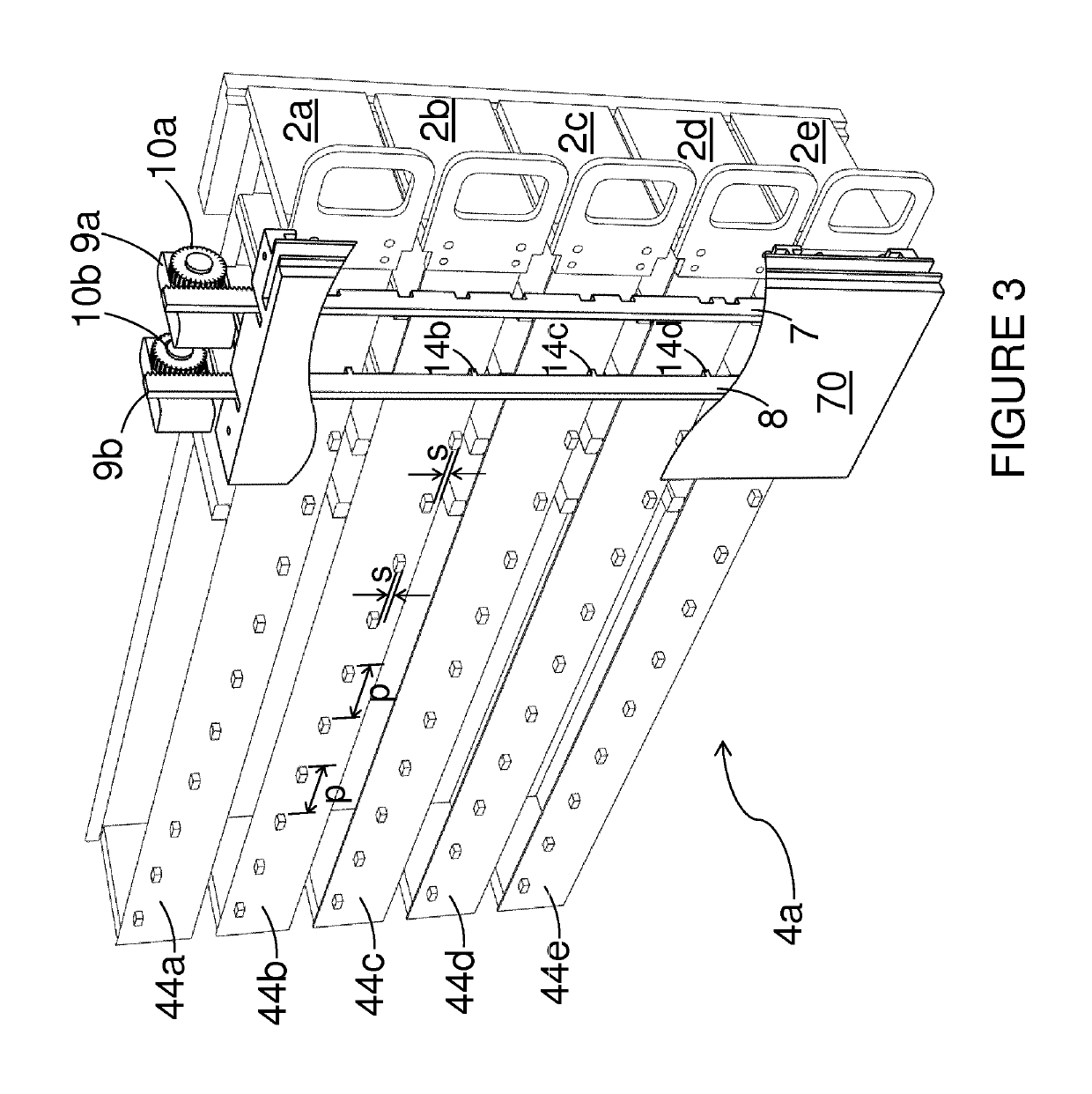

Coin depositing and dispensing machine

ActiveUS20140080395A1Decrease in coin storing capacityReduce machine sizeCoin countersCoin/currency accepting devicesEngineeringMechanical engineering

In a coin depositing and dispensing machine 10, a plurality of storing and feeding apparatuses 50 disposed below a deposited-coin transport unit 20 are arranged vertically on plural levels. A transport direction in which a coin is transported by the deposited-coin transport unit and a feeding direction in which a coin is fed out from each storing and feeding unit are substantially perpendicular to each other.

Owner:GLORY KOGYO KK

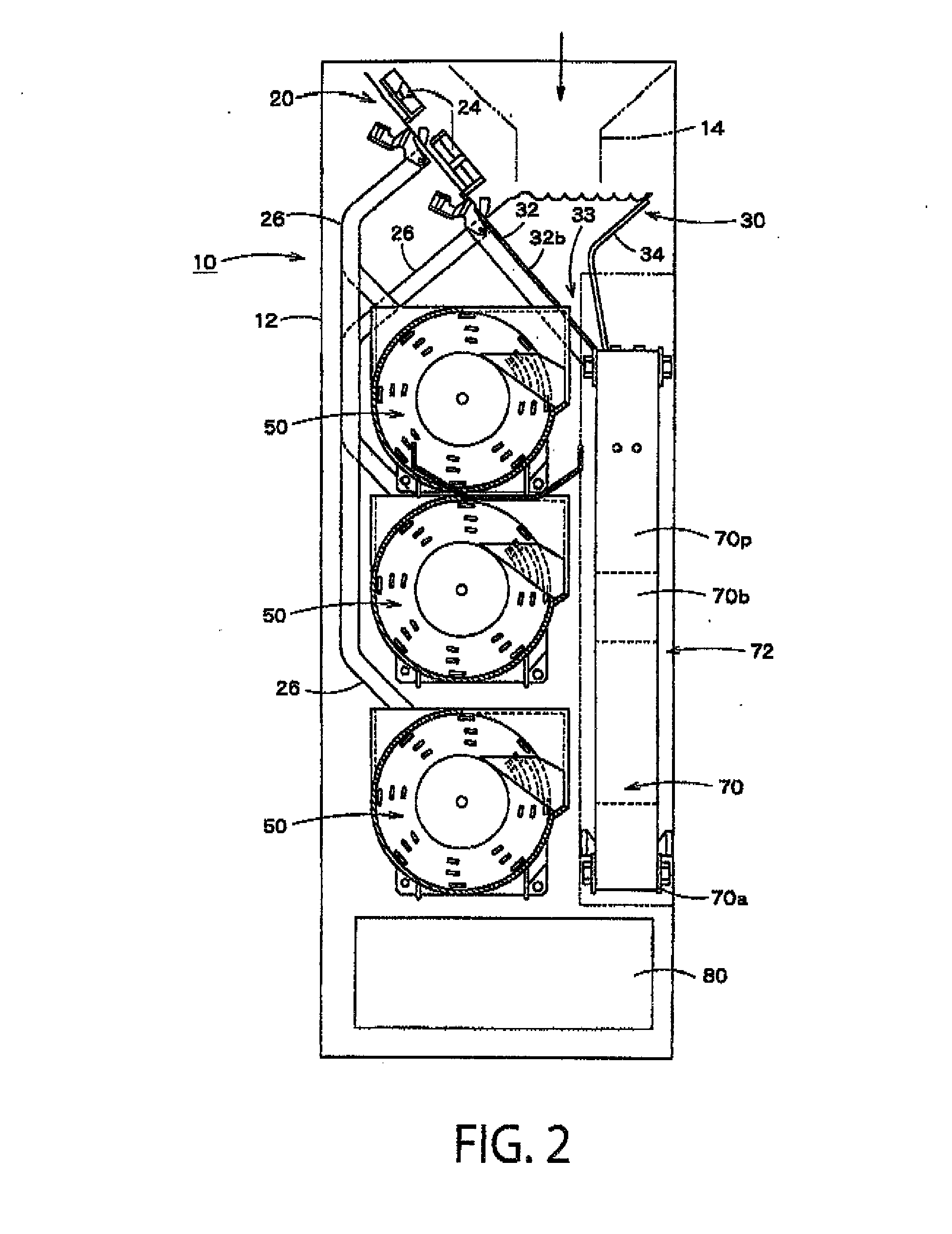

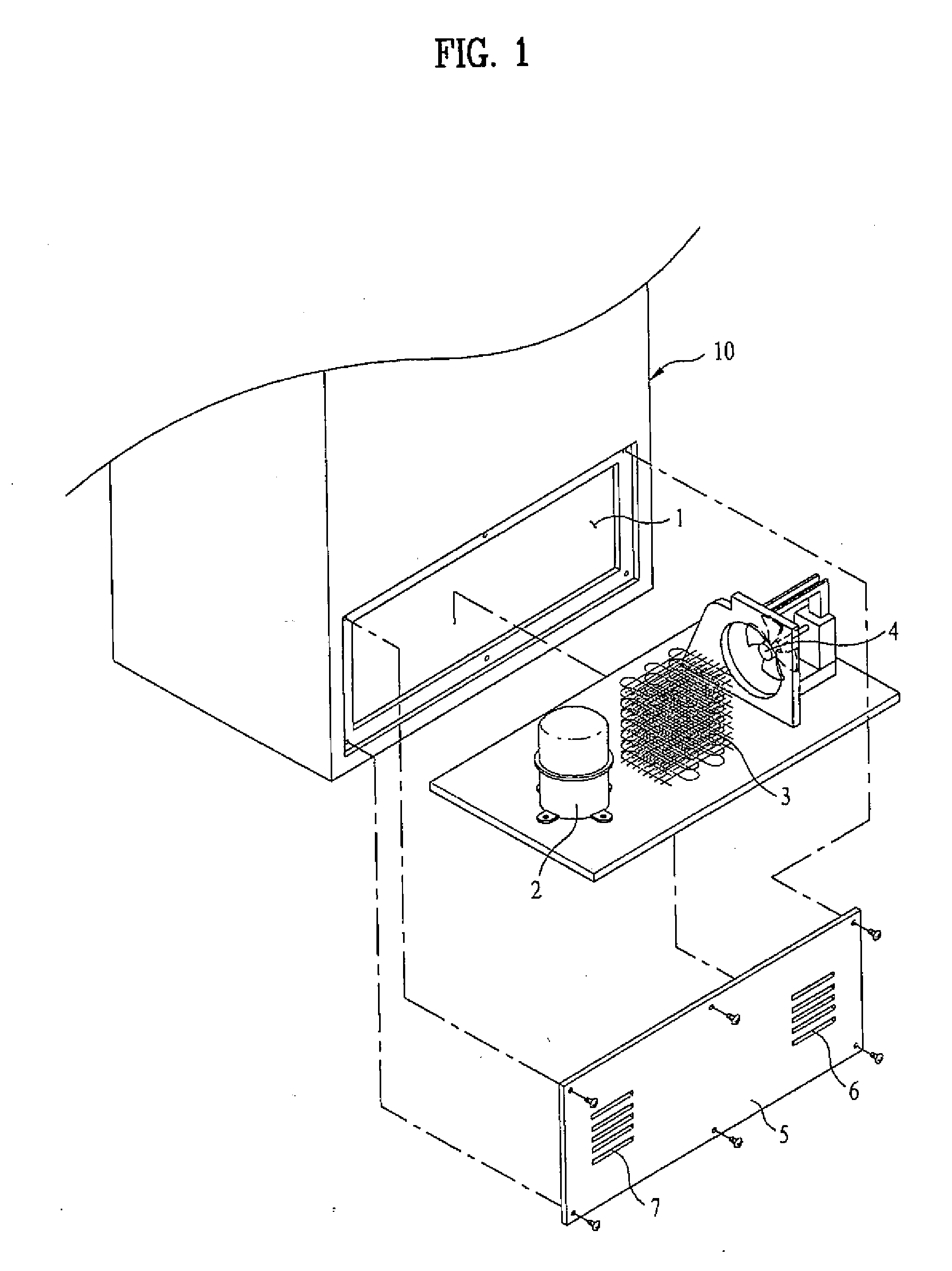

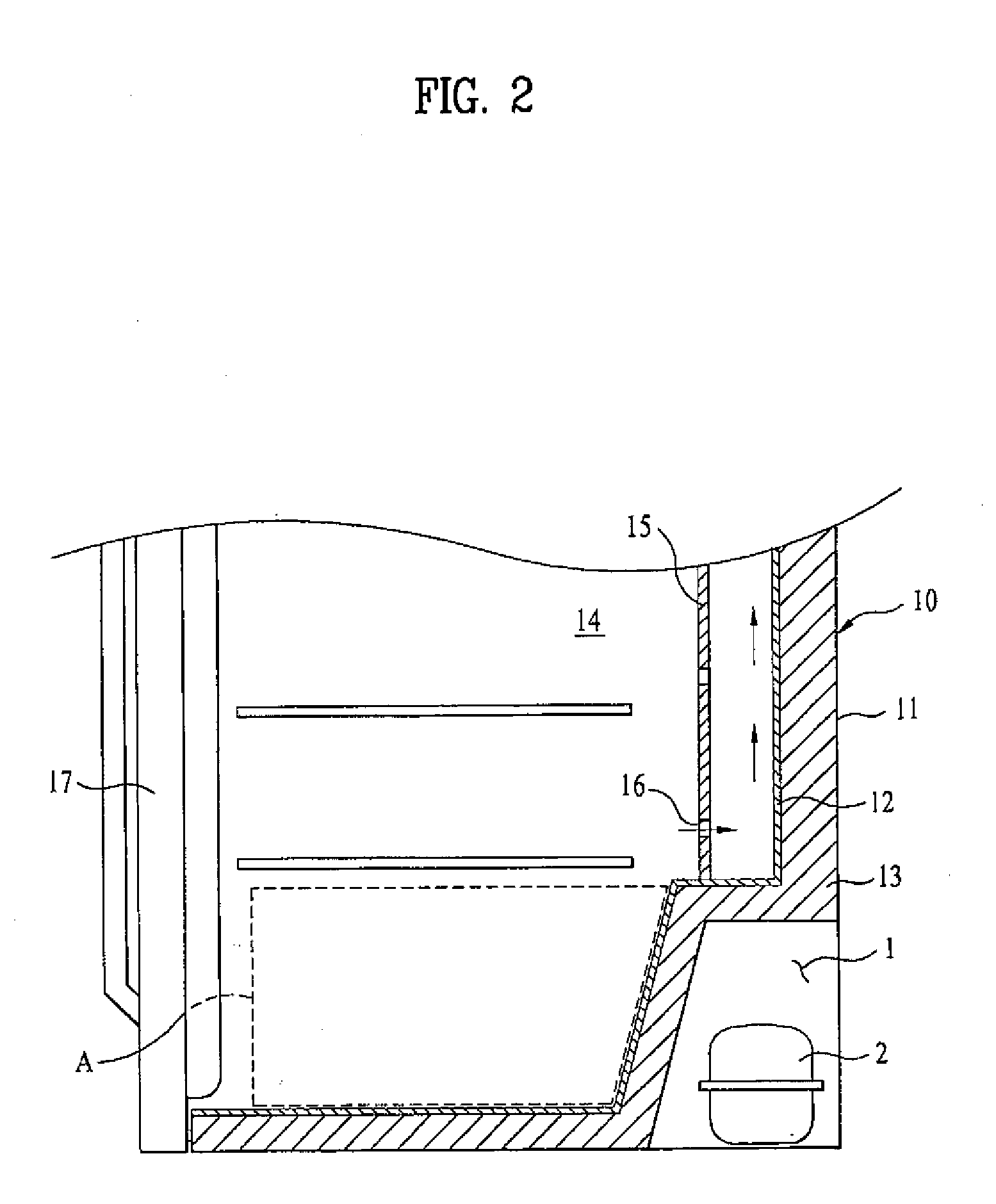

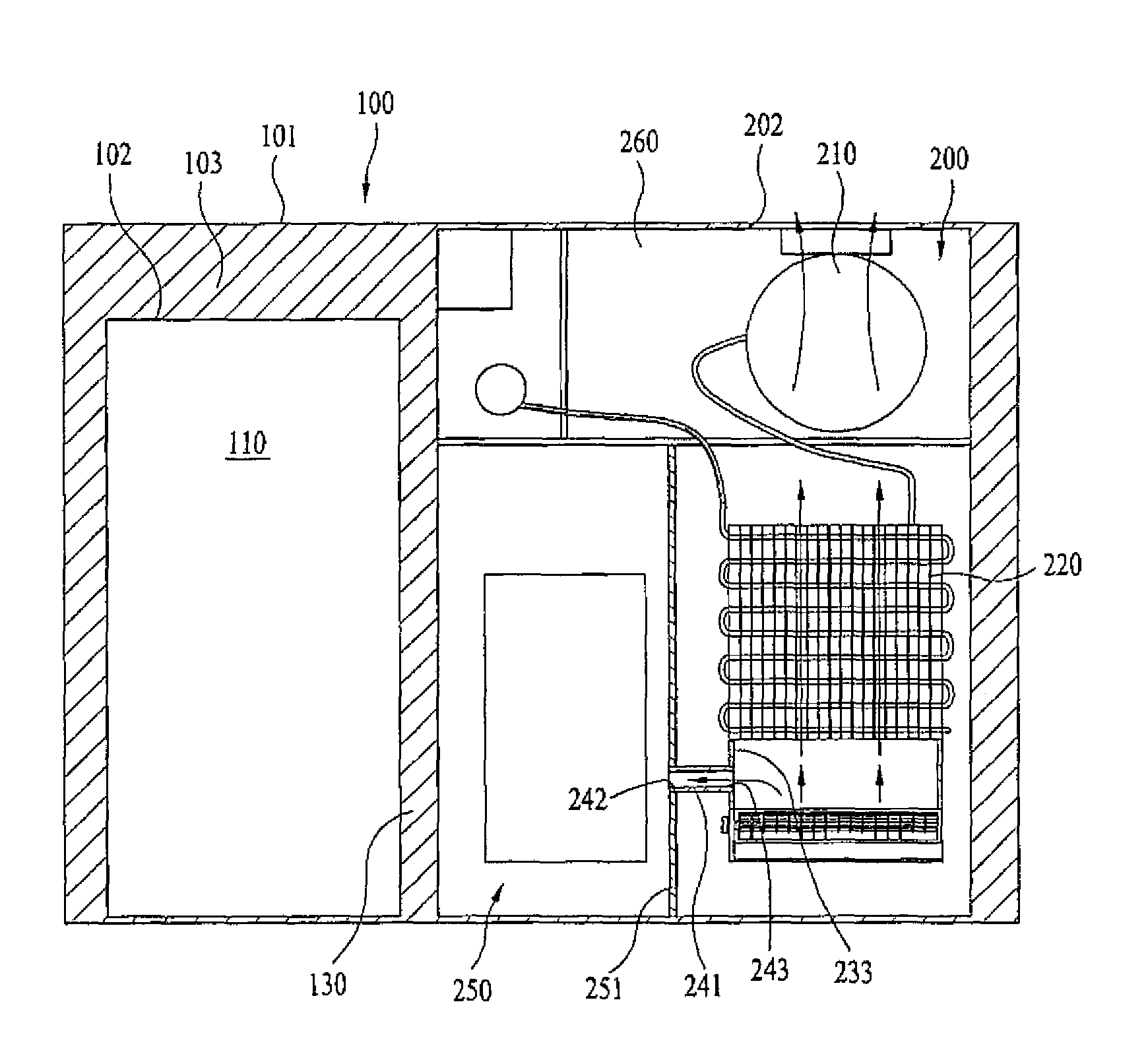

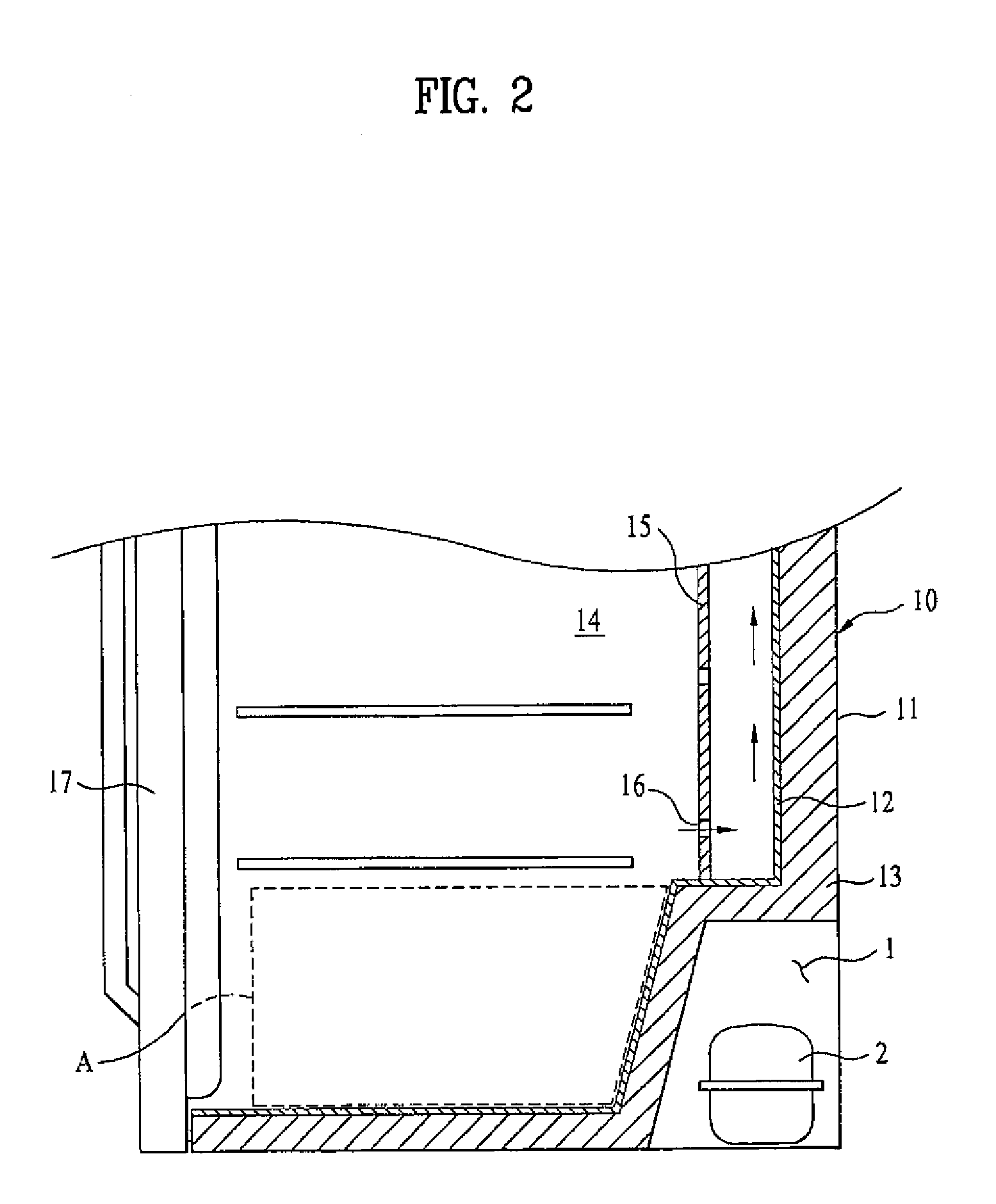

Refrigerator

InactiveUS20090013713A1Increase contentReduce machine sizeLighting and heating apparatusDomestic refrigeratorsEngineeringMechanical engineering

A refrigerator including a body having a plurality of cooling compartments separated from each other by a partition, and a machine room defined by the partition in a lower region of one of the plurality of cooling compartments. The machine room receives predetermined elements required to operate the cooling compartments.

Owner:LG ELECTRONICS INC

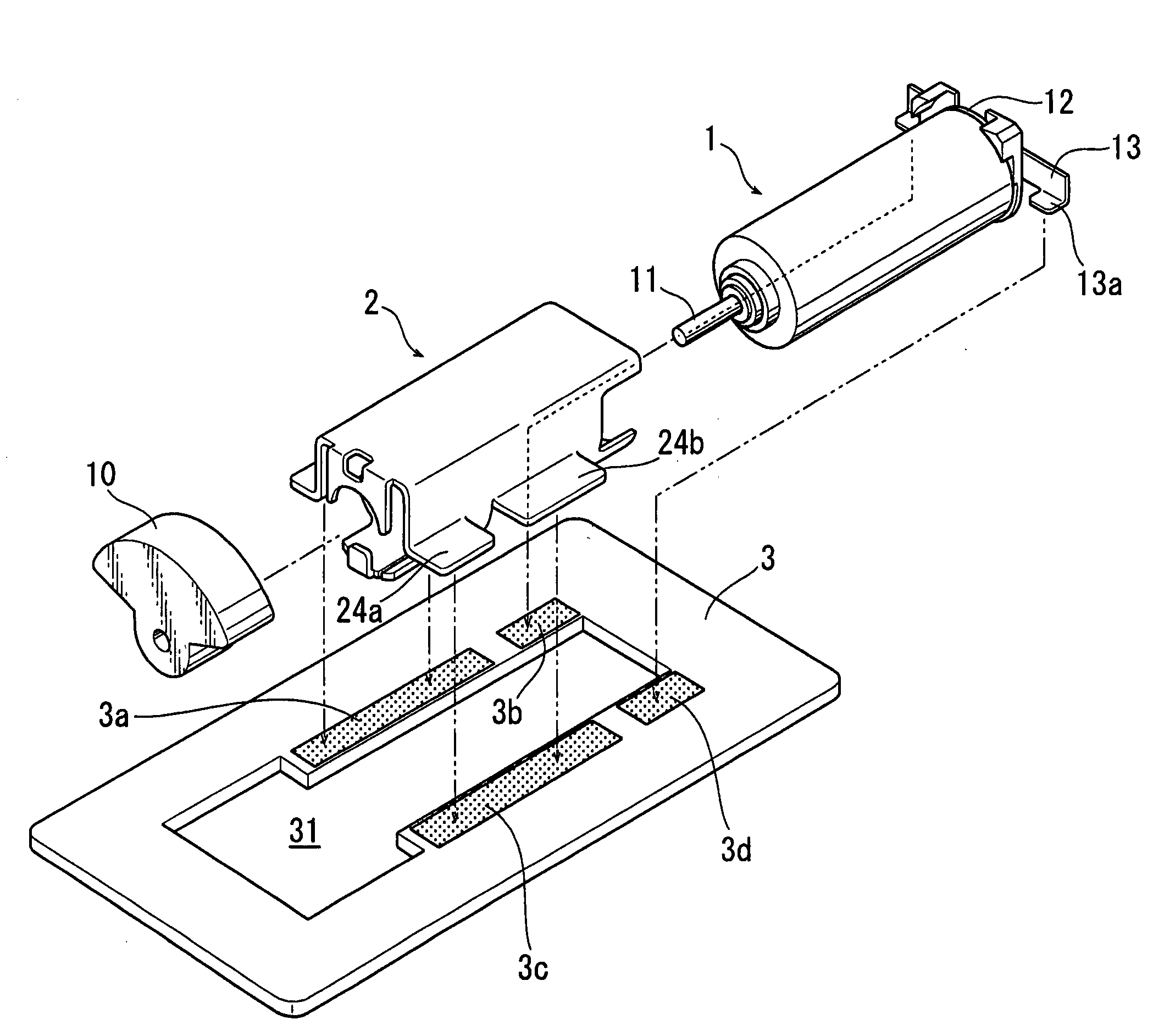

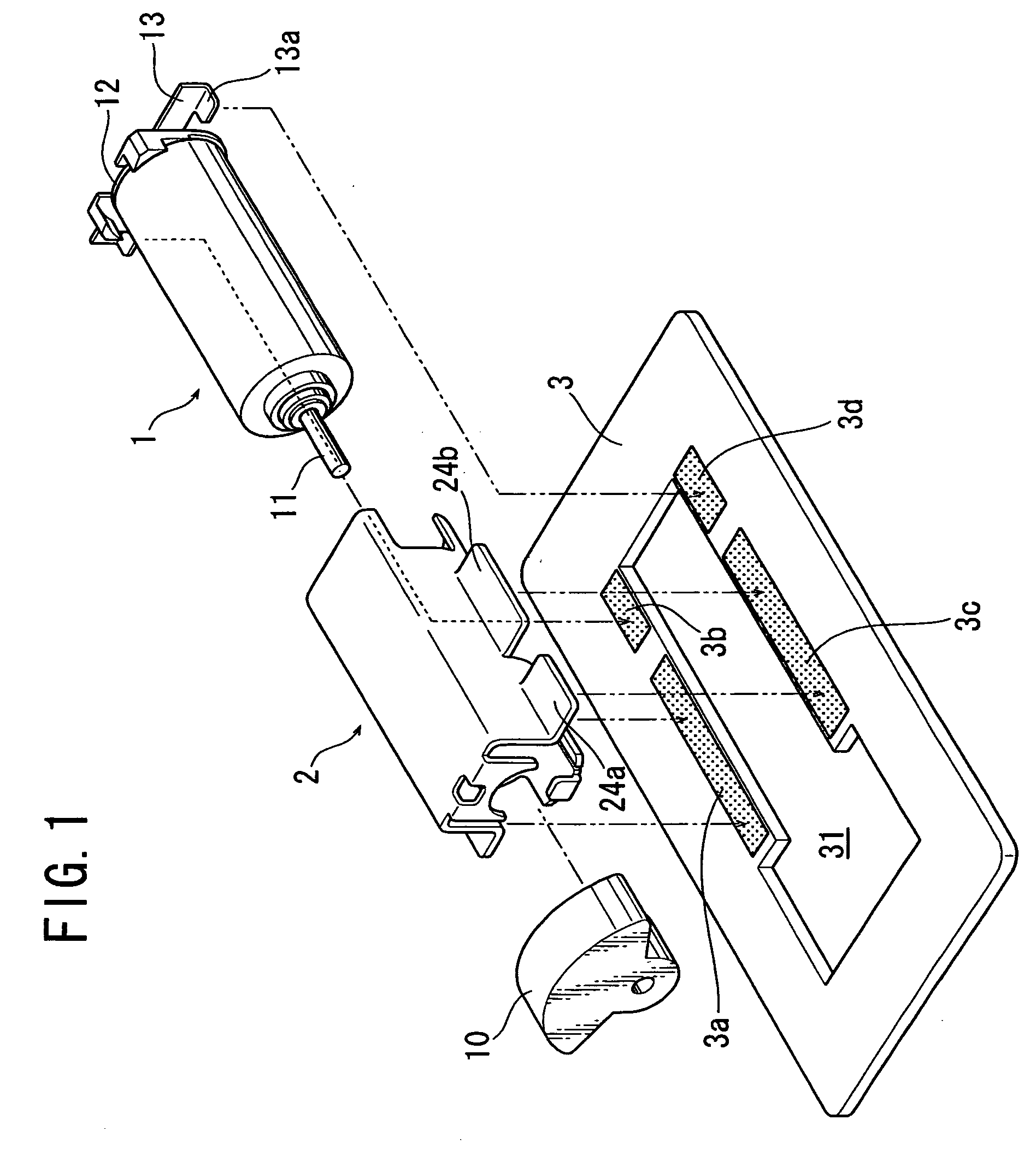

Vibration motor holding structure and vibration motor

InactiveUS20080278013A1Securely holdReduce manufacturing costMechanical energy handlingMetal working apparatusEngineeringMechanical engineering

There is provided a holding structure to hold a vibration motor on a circuit board with a sufficient holding strength using an inexpensive and simple means such as caulking and bonding and a vibration motor held on a circuit board using the holding structure. The holding structure having a holder clamps a vibration motor body having an eccentric weight at an end of the rotation shaft around the outer periphery from the outside and supports the vibration motor at the lower part.

Owner:MINEBEA MOTOR MFG

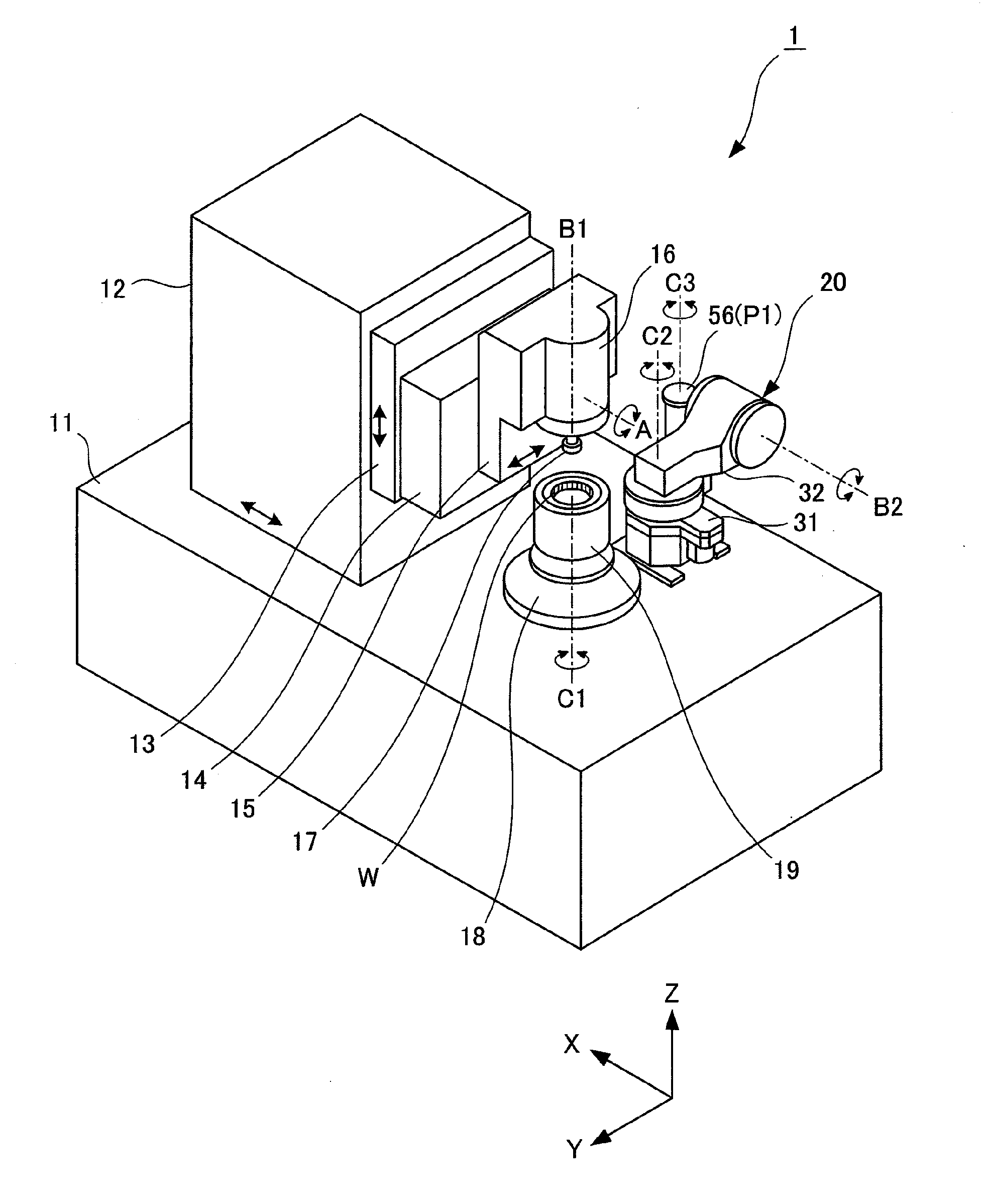

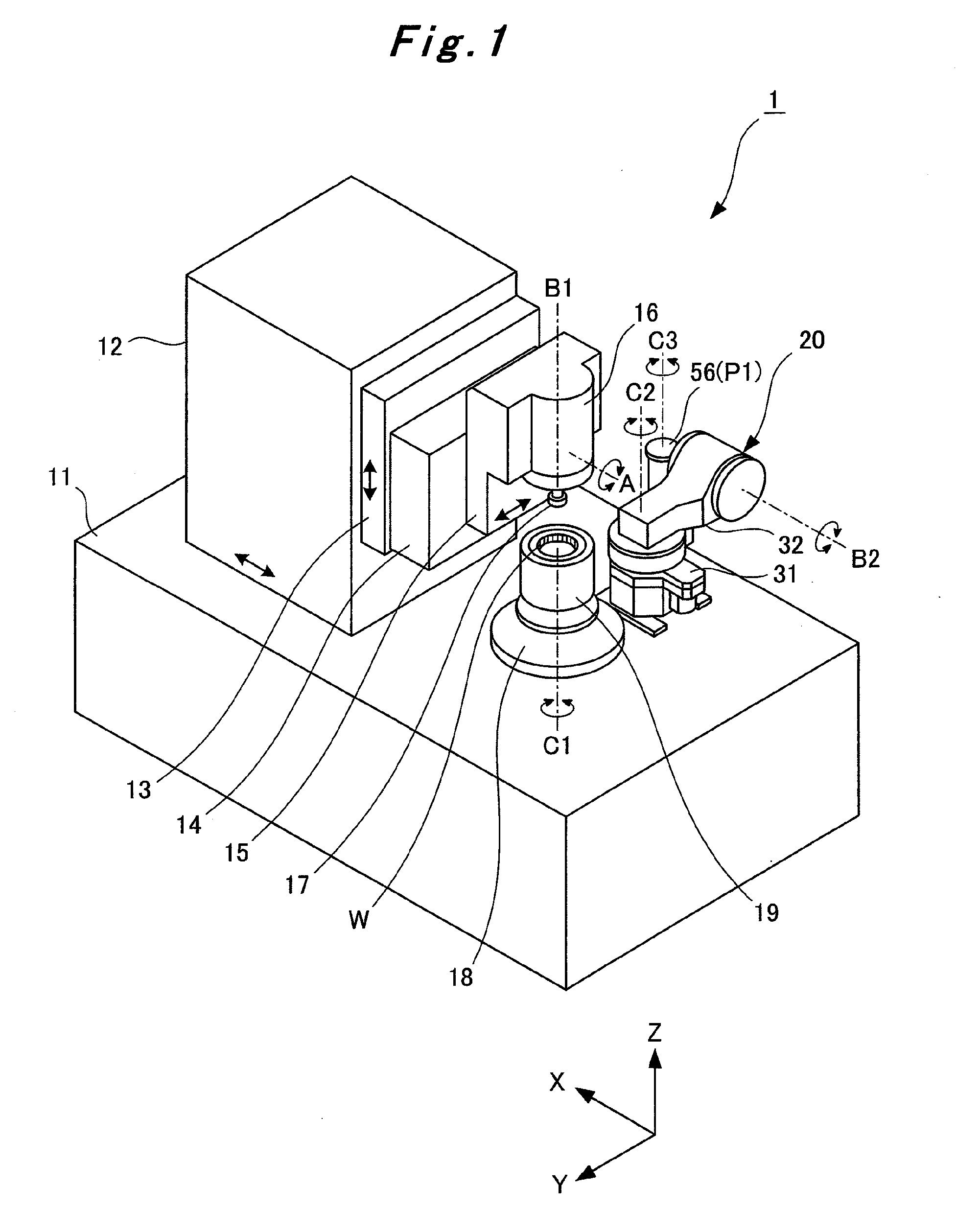

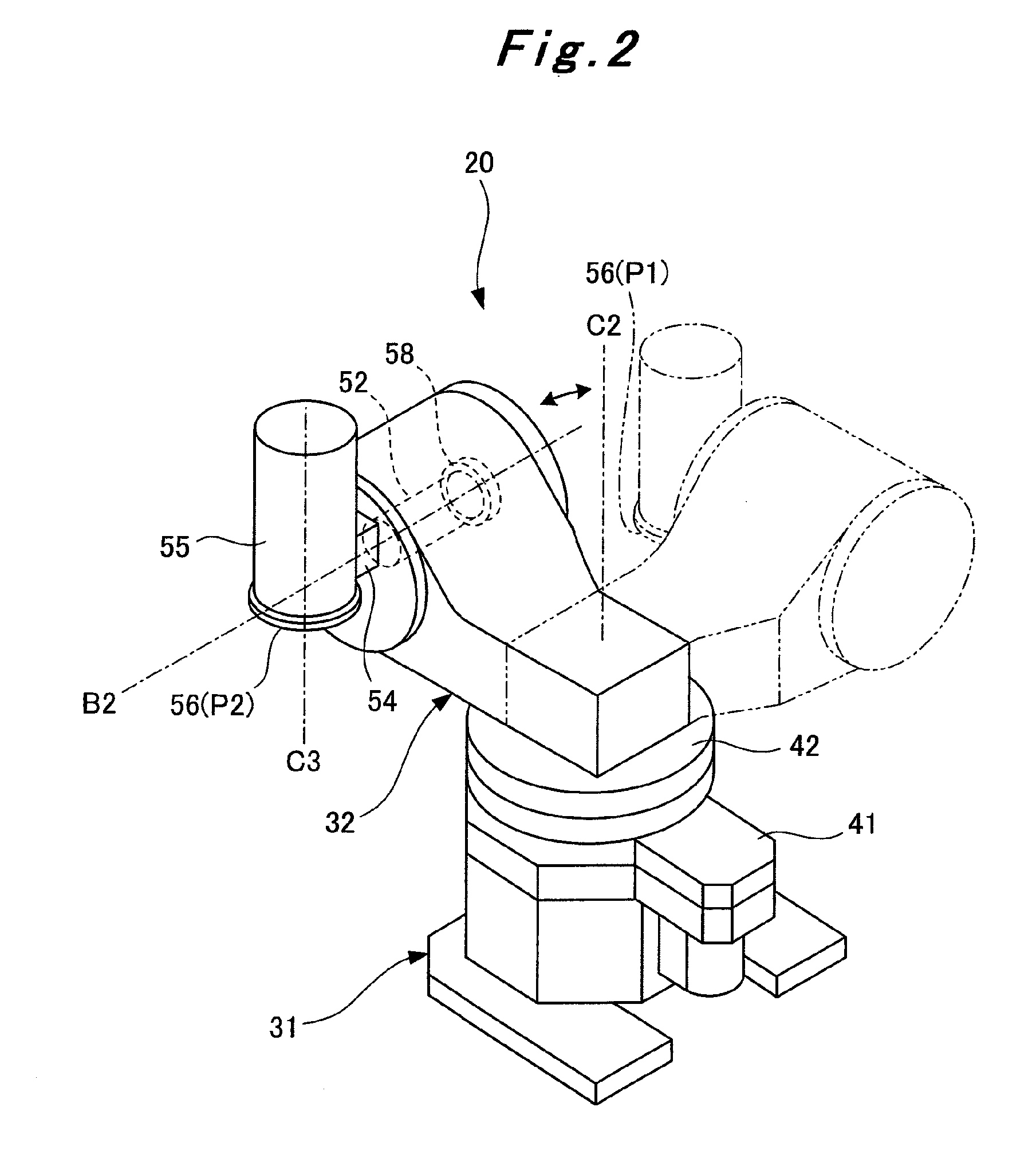

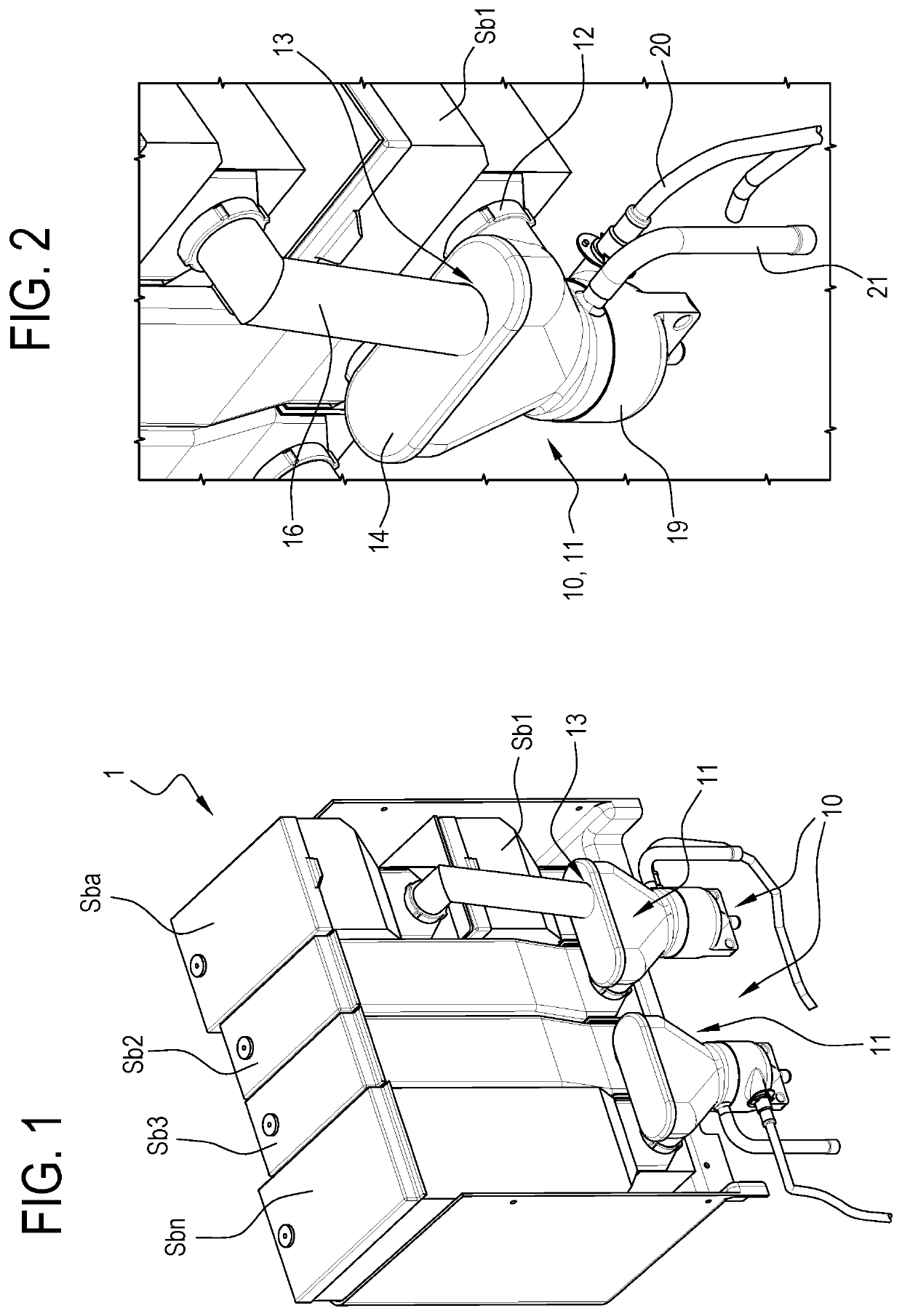

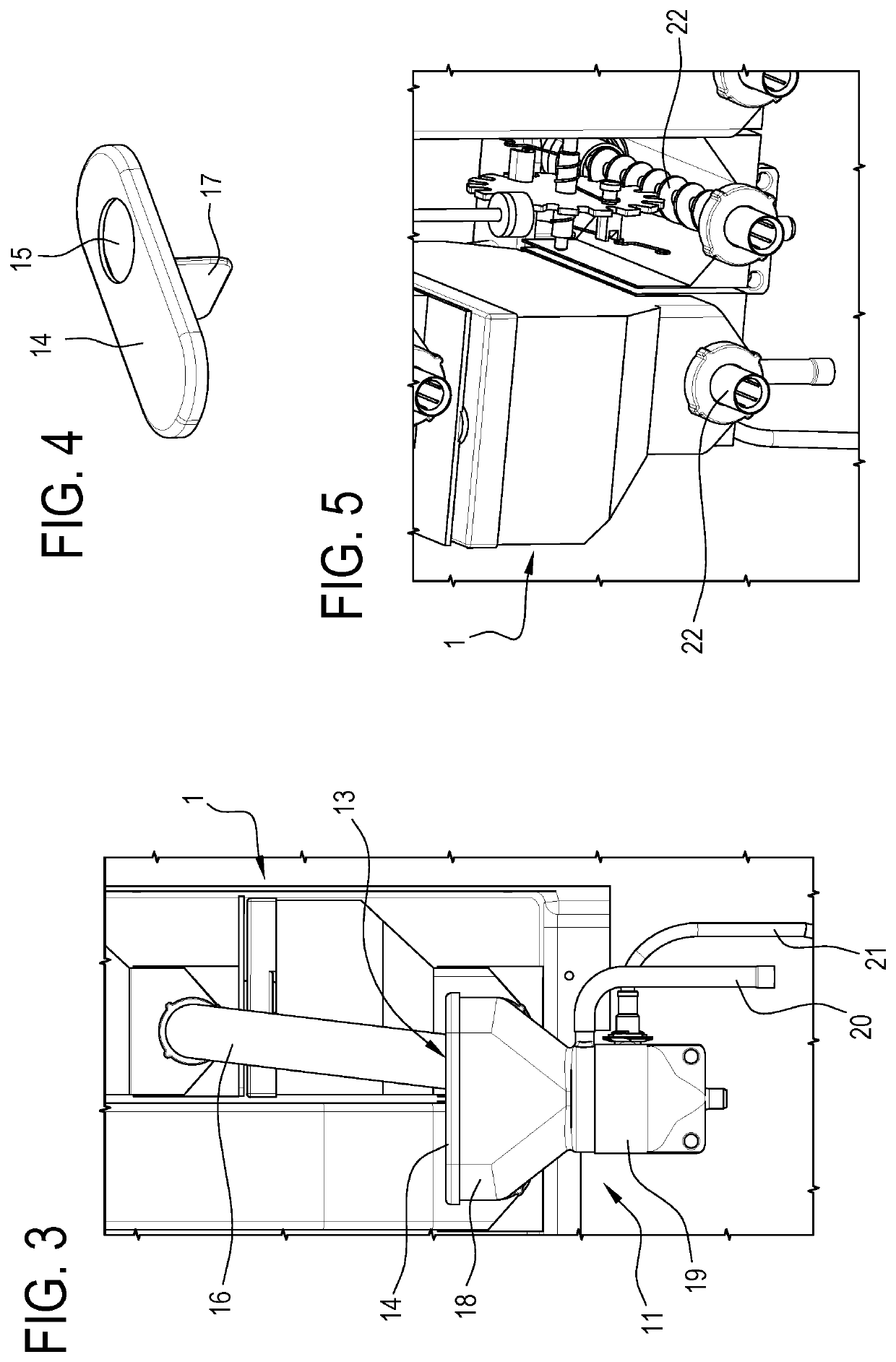

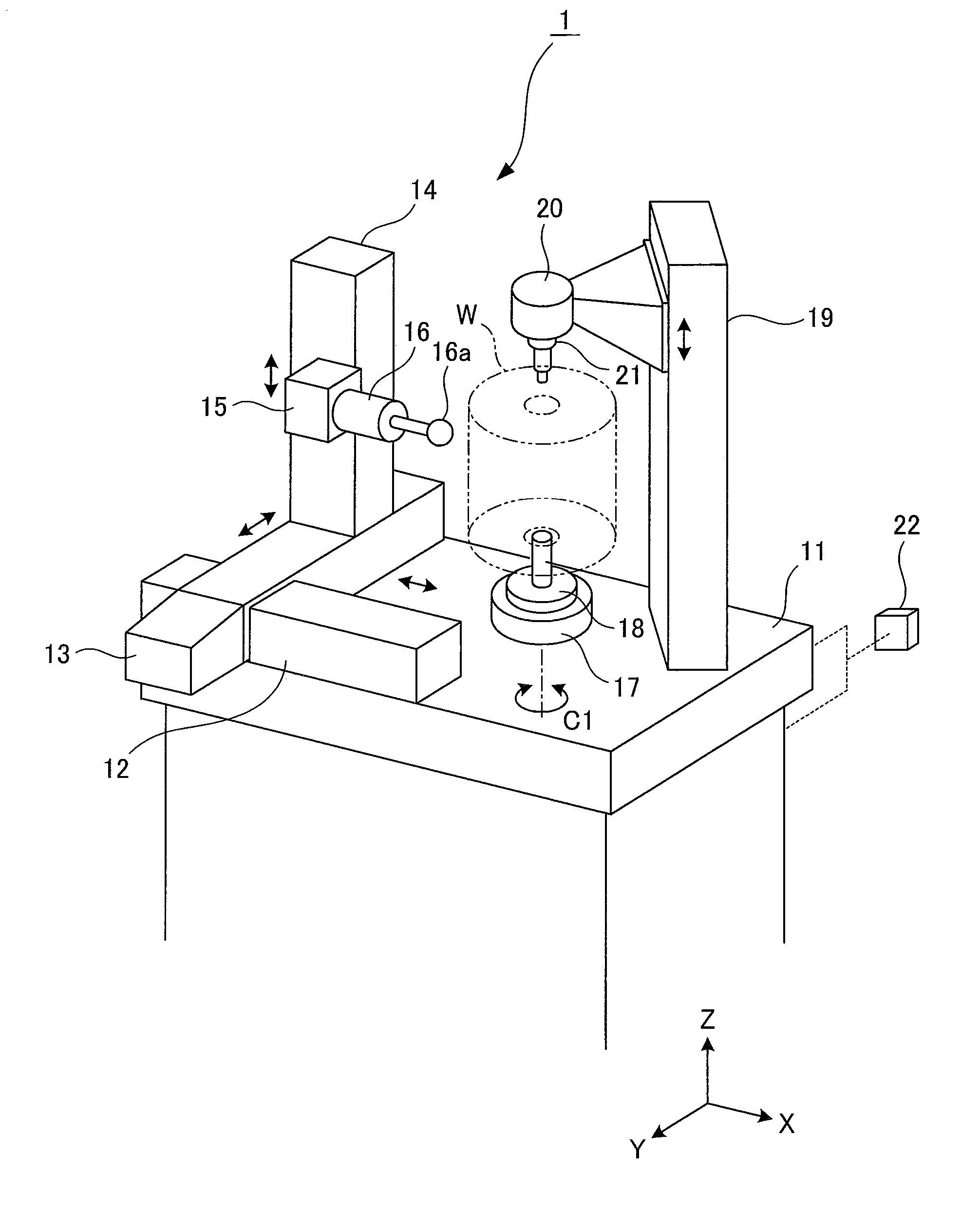

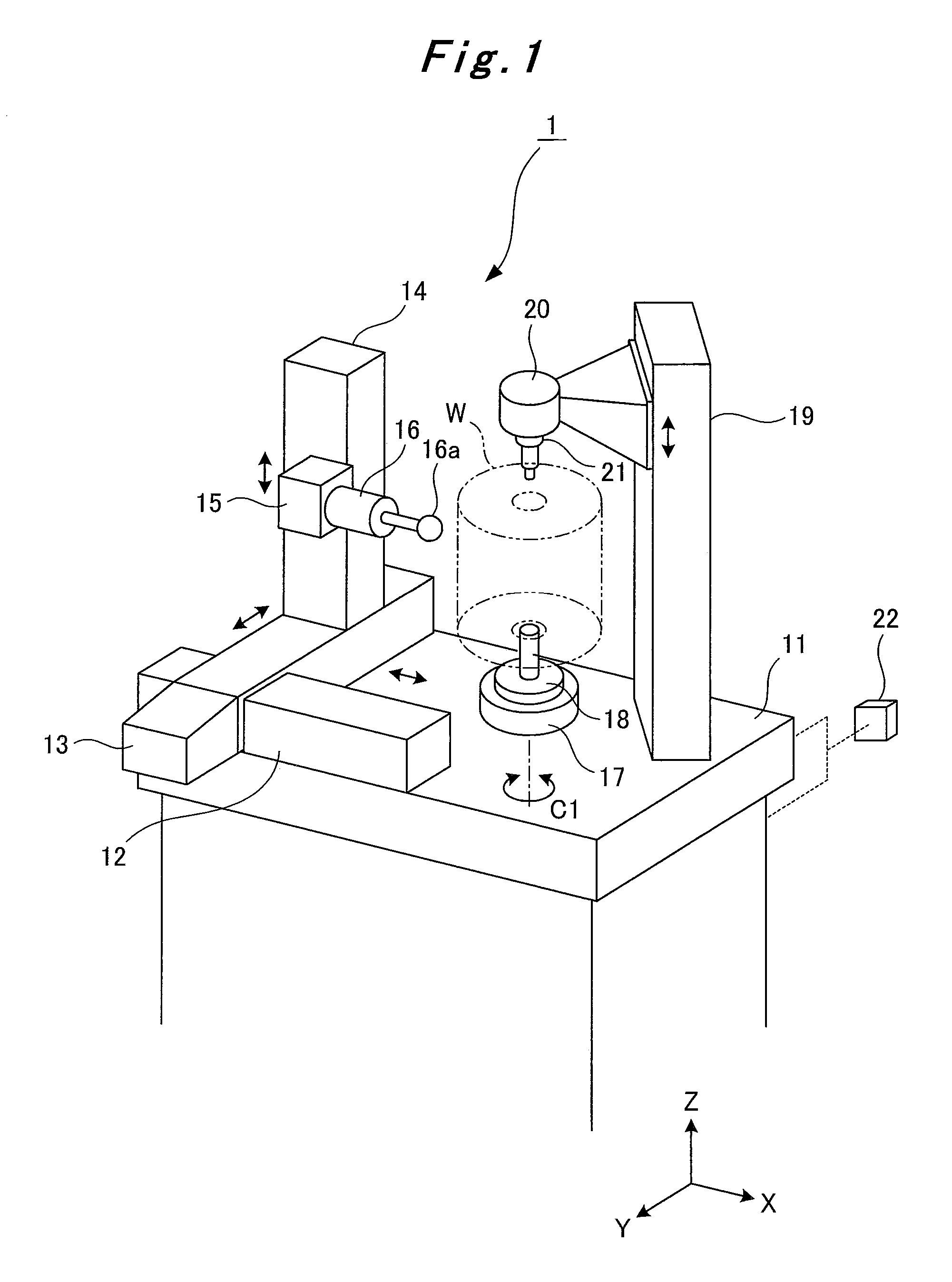

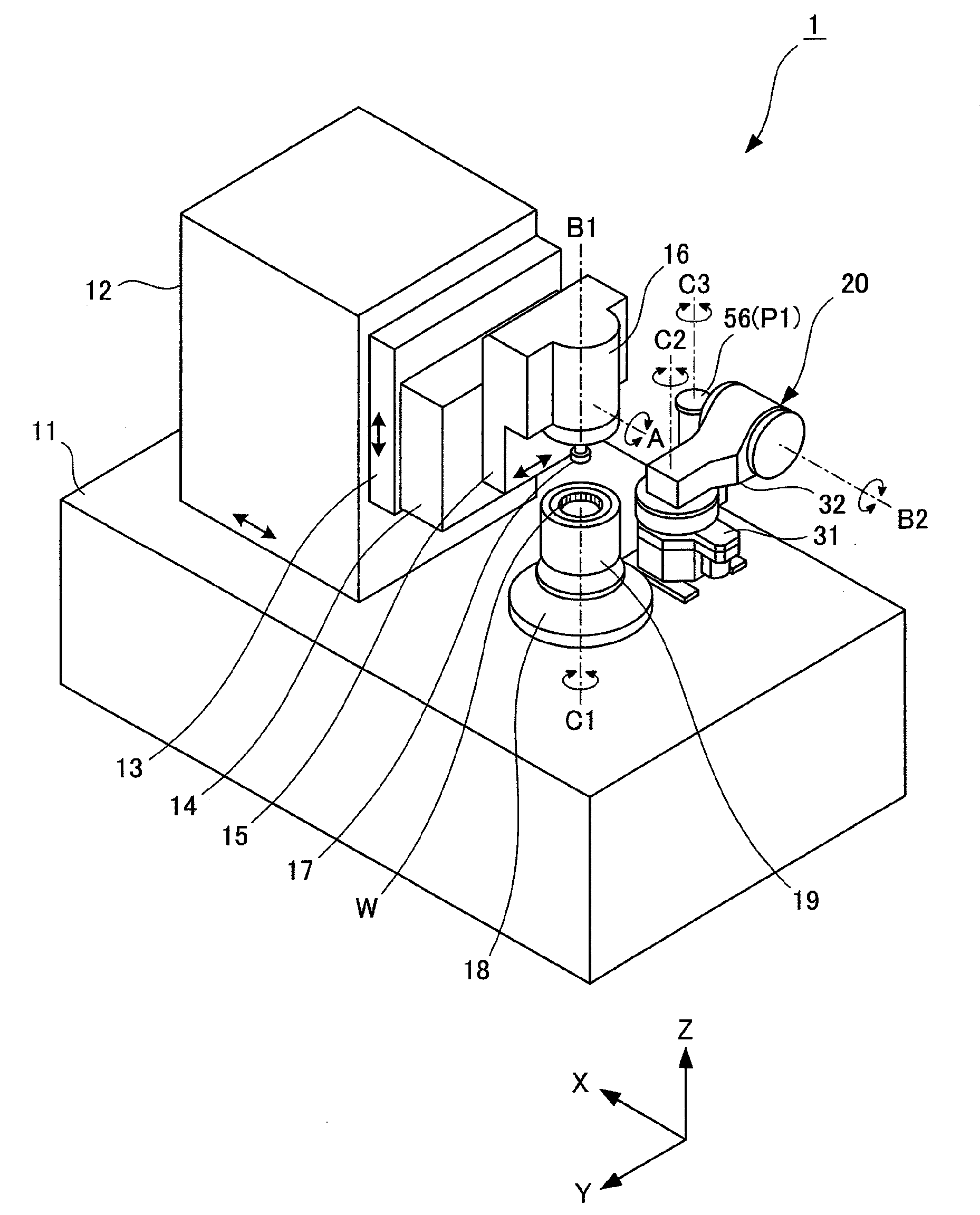

Internal gear grinding machine

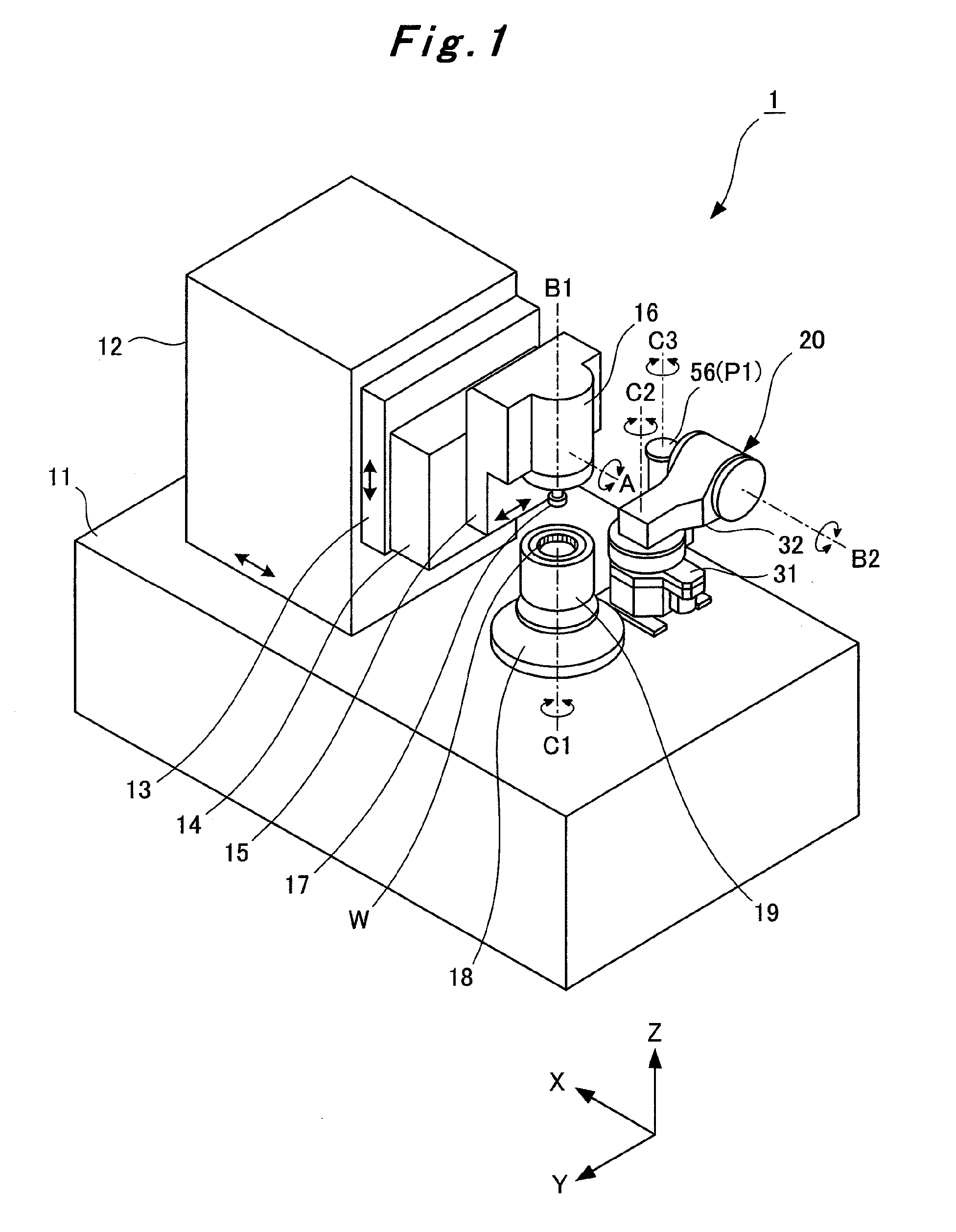

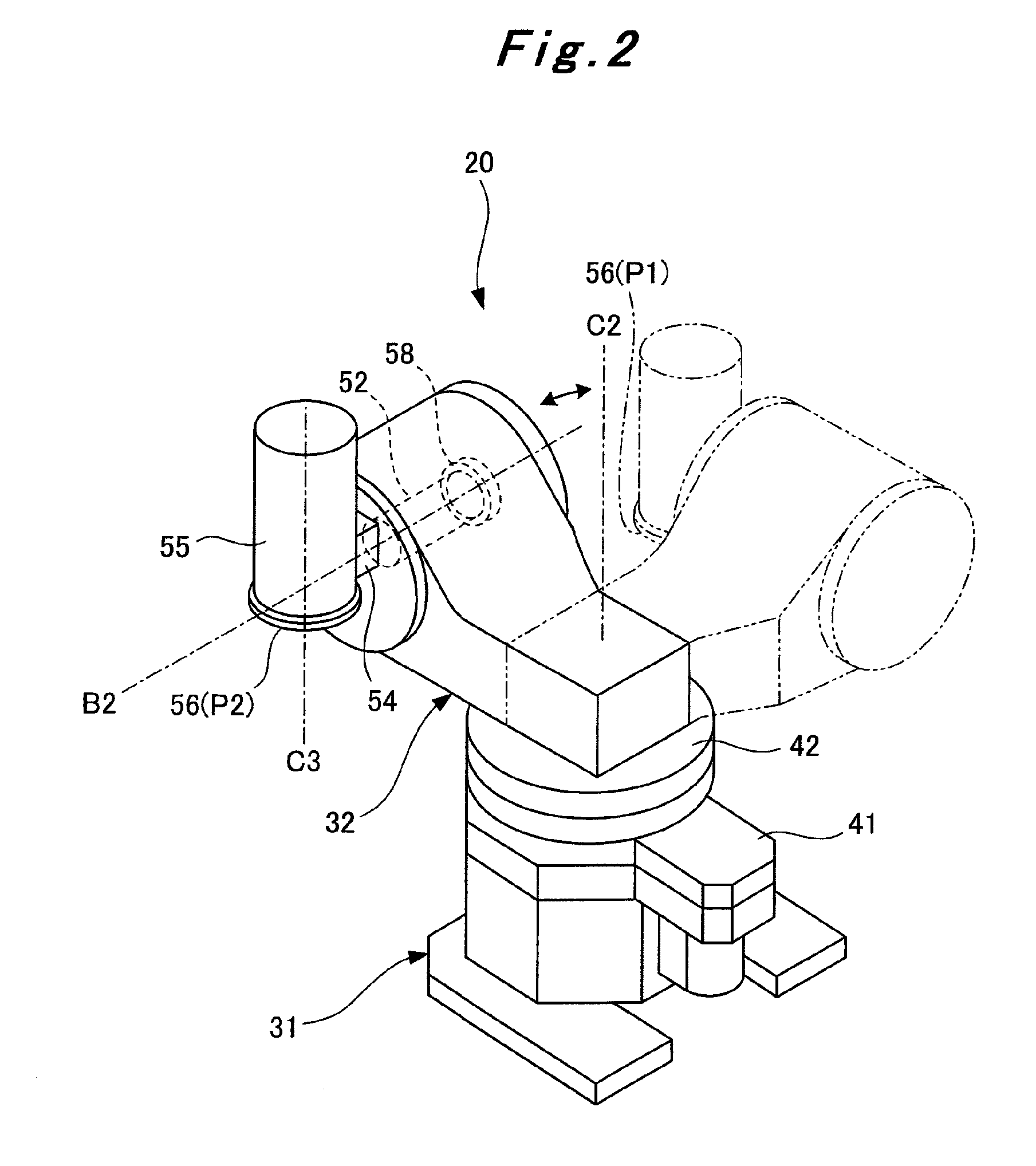

ActiveUS20110268522A1Avoid damageEasy to operateAbrasive surface conditioning devicesGear-cutting machinesGear grindingGear wheel

An object is to provide an internal gear grinding machine which makes it possible to achieve space savings and reduce the size of a machine, as well as to prevent the tools from being damaged even when an abnormal situation such as a blackout occurs, by simplifying dressing operation. To achieve the object, an internal gear grinding machine for use in grinding a workpiece (W) by synchronously rotating the workpiece (W) and a barrel-shaped threaded grinding wheel (17) in mesh with each other includes a dressing device (20) for dressing the threaded tool (17) by meshing the threaded grinding wheel (17) with a disk dresser (56). At the time of dressing, the threaded grinding wheel (17) and the disc dresser (56) are operated in accordance with the helix angle and barrel shape of the threaded grinding wheel (17), and the brake mechanism (58) applies a braking force to a dresser turn drive motor (53) to enable the disc dresser (56) to be maintained at a turned position thereof.

Owner:MITSUBISHI HEAVY IND MACHINE TOOL CO LTD

Reduced size citrus fruit juicing machine

InactiveUS7493851B2Reduce machine sizeEliminate needJuice extractionMetal working apparatusFruit juiceReduced size

This invention is a reduced size citrus fruit juicing machine that uses sets of rotating male-female drums characterized by having one sole female drum and one sole male drum with an automatically positioning blade and a retaining pendulum—turning device. These characteristics avoid having to incorporate a second set of drums into the machine since the remaining half of the fruit is turned after the cut into the following upper cavity of the female drum. In addition to maintaining the performance of similar machines of greater size, it improves hygienic conditions due to an appropriate disposition of the retaining pendulum, a ribbed opening for the fruit, a peel collector and an integrated customized juice container which are isolated from the outside, all of which make it especially attractive to hotels and restaurants that do not have much available space.

Owner:ZUMEX MARQUINAS Y ELEMENTOS S A E MONCADA

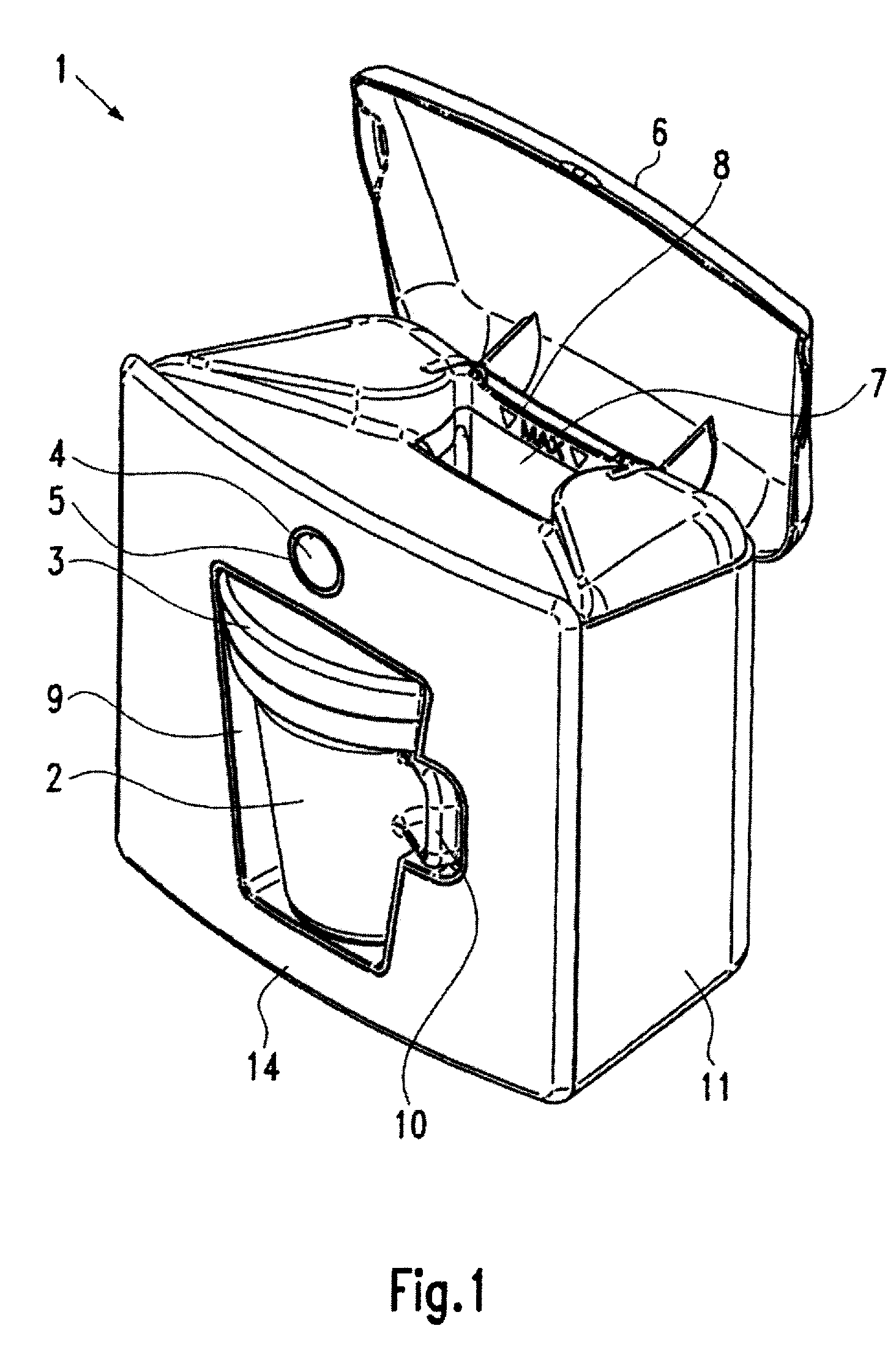

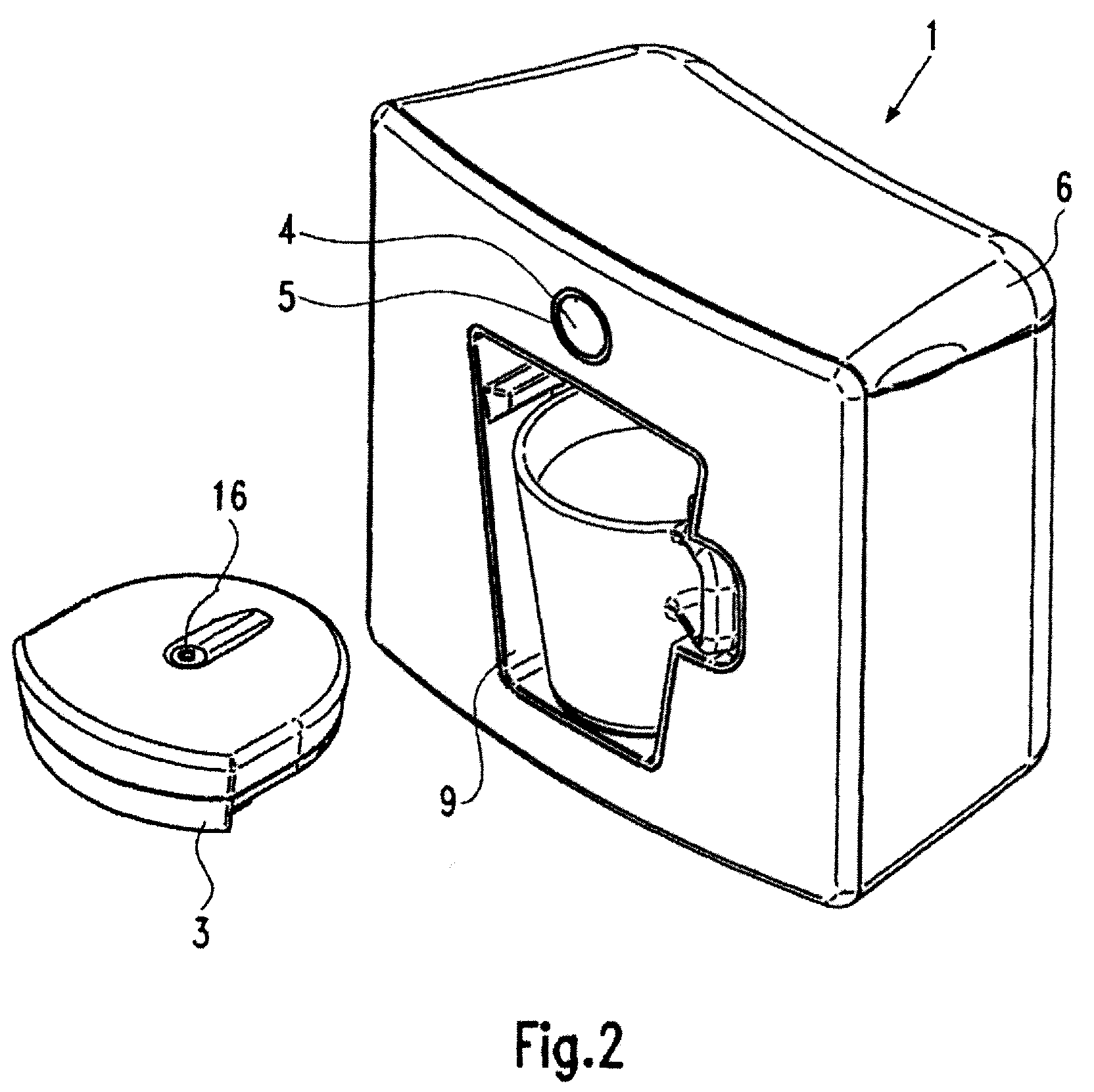

Machine for the preparation of a hot drink

A machine for the preparation of a hot drink with a water tank, a closed brewing chamber and a region for the accommodation of a cup. In order to minimize the size of the machine, to simultaneously prevent the production of germination and to save manufacturing and operating costs, the capacity of the water tank is rated such that the amount of water is only sufficient for one cup of hot drink so that the water tank is empty at the end of brewing.

Owner:WMF WURTTEMBERGISCHE METALLWARENFABRIK AG

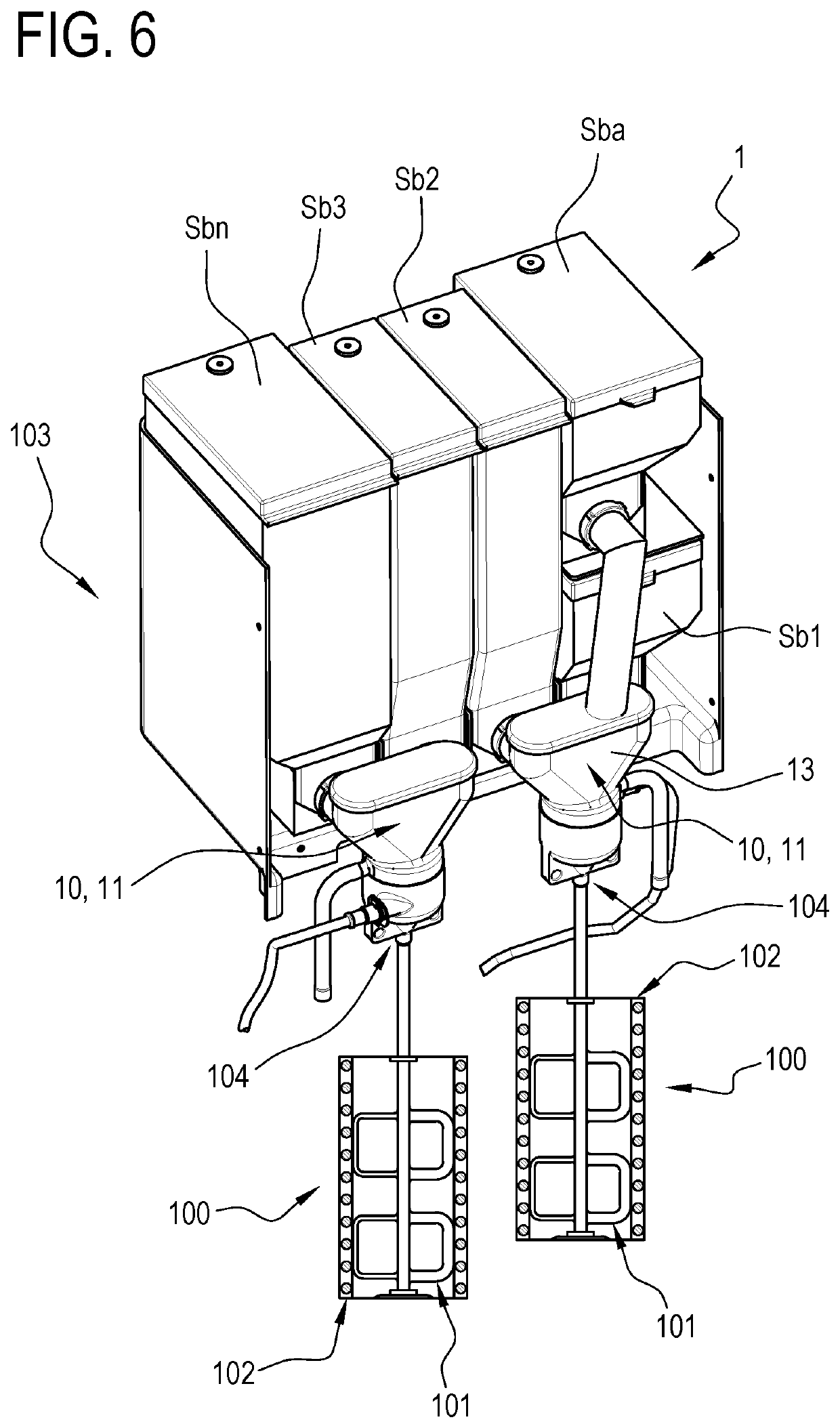

Base/additive product feeding unit for a machine for the production and/or distribution of an ice cream product and machine comprising said unit

A base / additive product feeding unit for a machine for the production and / or distribution of ice cream, or other ice cream product, comprises a plurality of storage tanks for delivering predetermined quantities of base / additive products used to prepare ice cream in a batch freezing chamber provided with a stirrer and heat treatment means. The connection between the storage tanks and the batch freezing chamber is accomplished by an intake having a plurality of side inputs connected to respective storage tanks and an additional input made in a cover of the intake and connected to a further storage tank in such a way as to allow at least two storage tanks to be superposed on each other.

Owner:ALI - CARPIGIANI GROUP

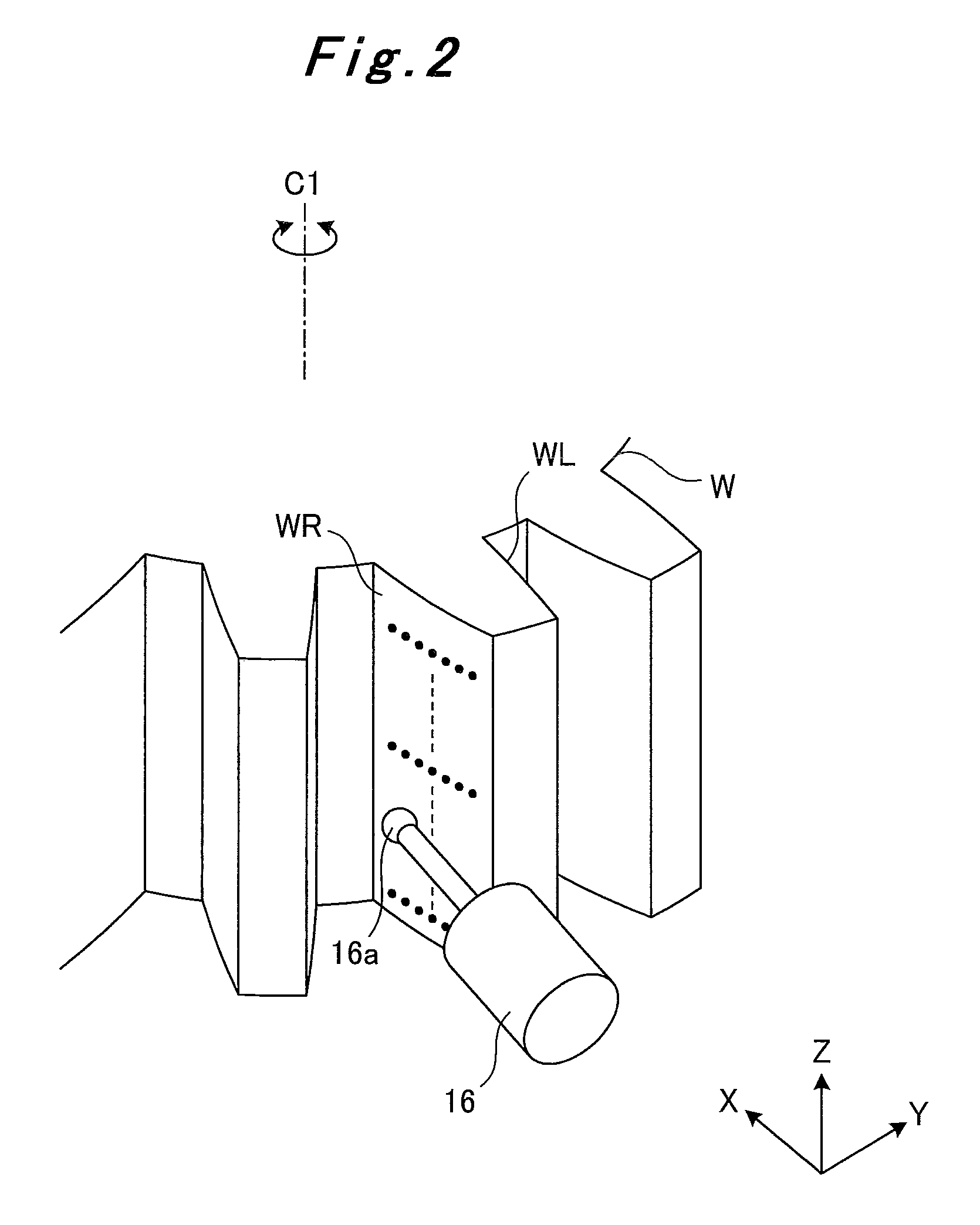

Gear measurement method

InactiveUS20110247436A1Reduced amount of travelSmall range of movementMicrometersMeasuring circumferenceSynchronous controlEngineering

An object of the present invention is to provide a gear measurement method which makes it possible to reduce the size of a machine by reducing the amount of travel of a probe and thus reducing a moving range of the probe in a measurement. To achieve the object, a gear measurement method for measuring the tooth profile of a workpiece (W) by linearly moving a probe (16a) in accordance with the rotation of the workpiece (W), with the probe (16a) in contact with a right tooth face (WR) or a left tooth face (WL) of the workpiece (W), by synchronous control of the movement of the probe (16a) and the rotation of the workpiece (W), includes setting a tangent line (L) touching the tangent point (A) rotated from a tangent point (Ao) on the base circle (Wb) of the workpiece (W) in one direction by a predetermined rotation angle (α) and a tangent line (L′) touching the tangent point (A′) positioned by being rotated from the tangent point (Ao) on the base circle (Wb) of the workpiece (W) in the other direction by the predetermined rotation angle (α), moving the probe (16a) along the tangent line (L) when measuring the right tooth face (WR), moving the probe (16a) along the tangent line (L′) when measuring the left tooth face (WL), and setting the respective midpoints of the segments connecting the measurement start points (B, B′) to the measurement end points (C, C′) at the intersection point (M) of the tangent lines (L, L′).

Owner:MITSUBISHI HEAVY IND LTD

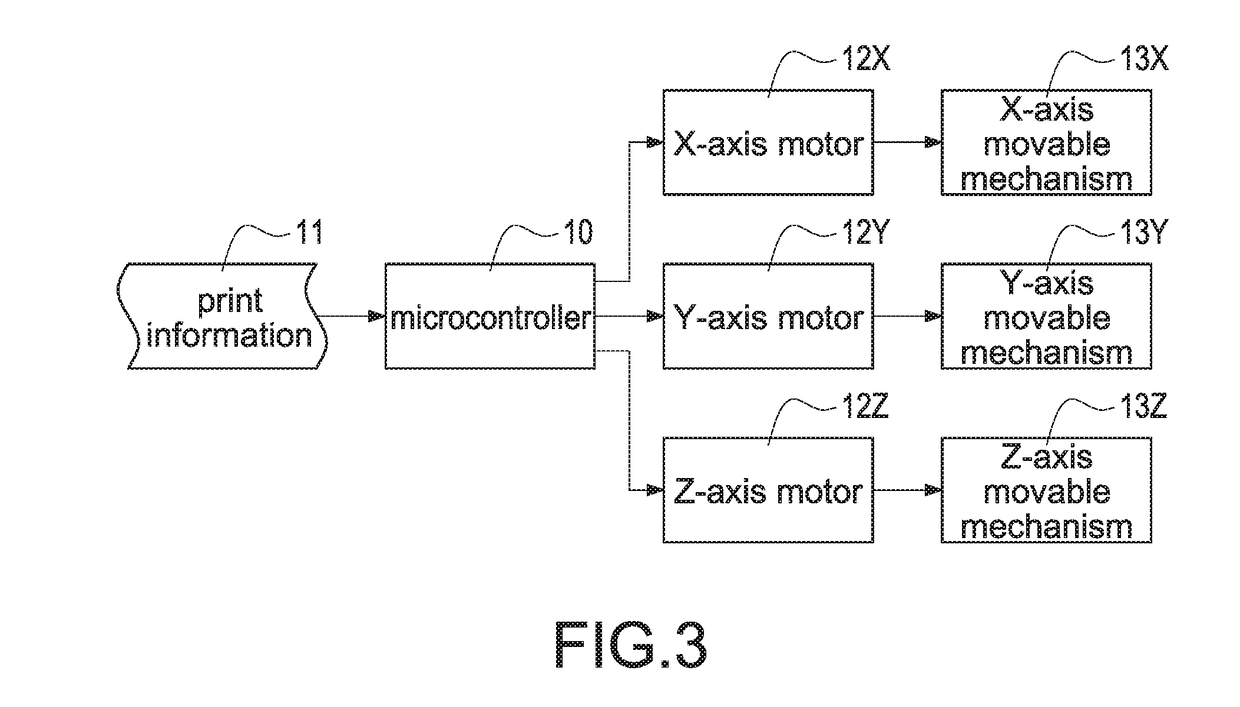

Intermittent excitation apparatus of 3D printer and method of operating the same

InactiveUS20190022933A1Limit and decrease flexibilityIncrease equipment cost3D object support structuresAdditive mnaufacturing with solid and fluidMicrocontrollerEngineering

An intermittent excitation apparatus of a 3D printer includes at least one guide, a drive rod, a movable seat, and a microcontroller. When the microcontroller controls a first motor in a non-excitation and non-rotation condition, the movable seat is fixed on the drive rod and the 3D printer performs a plane printing operation. When the microcontroller controls the first motor in an excitation and rotation condition, the movable seat moves along the drive rod. Therefore, it is to significantly reduce heat generated inside the first motor, decrease costs, and reduce the size of the 3D printer.

Owner:XYZPRINTING +1

Device for machining ophthalmic lenses, the device having a plurality of machining tools placed on a swivel module

ActiveUS8342909B2Easy maintenanceImprove accuracyEdge grinding machinesPolishing machinesEngineeringEye lens

A device (1) for machining an ophthalmic lens includes a support for the ophthalmic lens and for driving it in rotation about a blocking axis (A1), a machining module (35) that can be swiveled relative to the support and driving the lens in rotation and that is suitable for pivoting about a swivel axis that is not parallel to the blocking axis of the lens, and at least one drill tool mounted to rotate on the machining module about a first axis of rotation. The machining device includes at least one other machining tool mounted to rotate on the machining module about another axis of rotation that is distinct from the first axis of rotation and that is stationary relative to the first axis of rotation.

Owner:ESSILOR INT CIE GEN DOPTIQUE

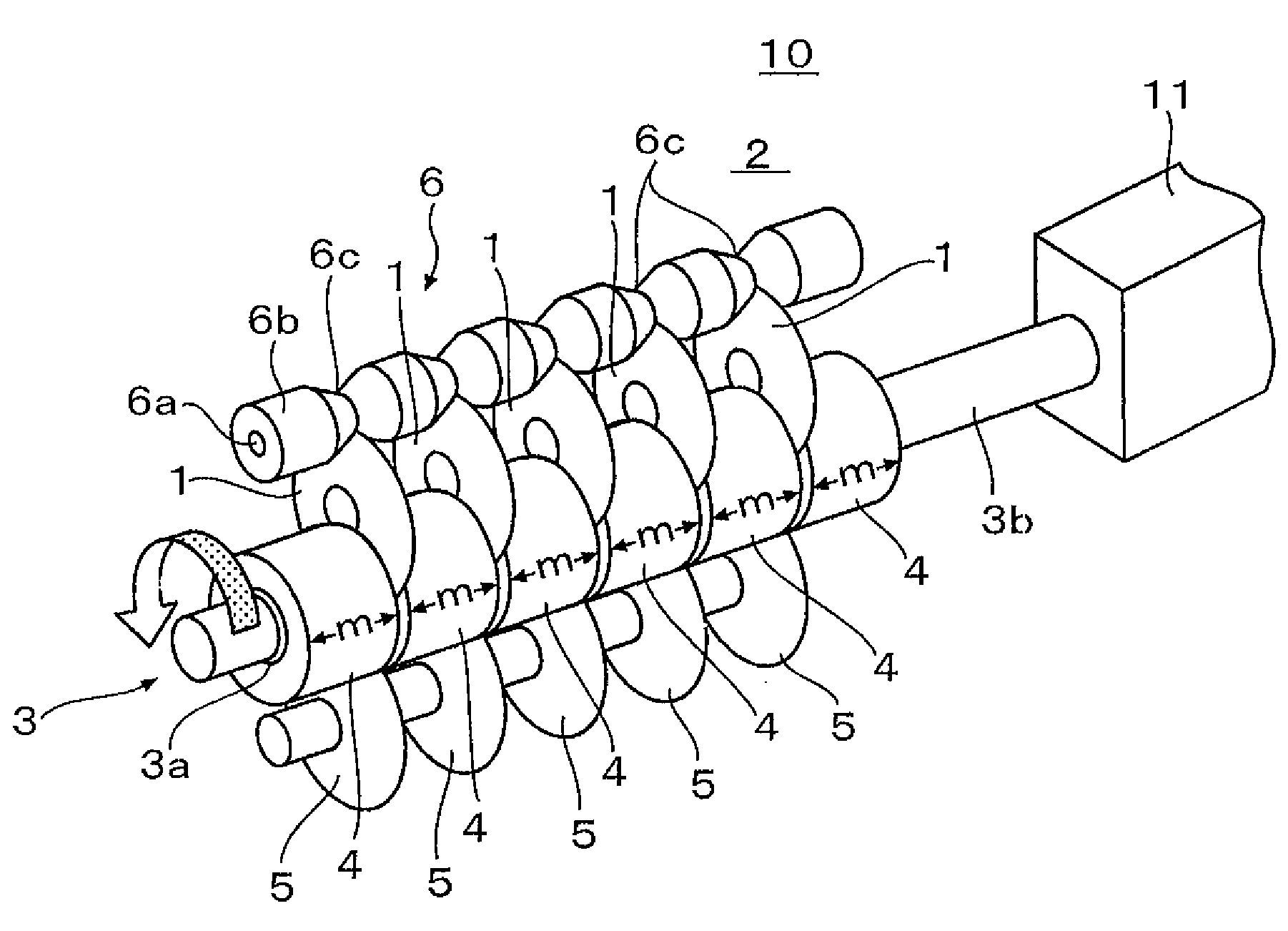

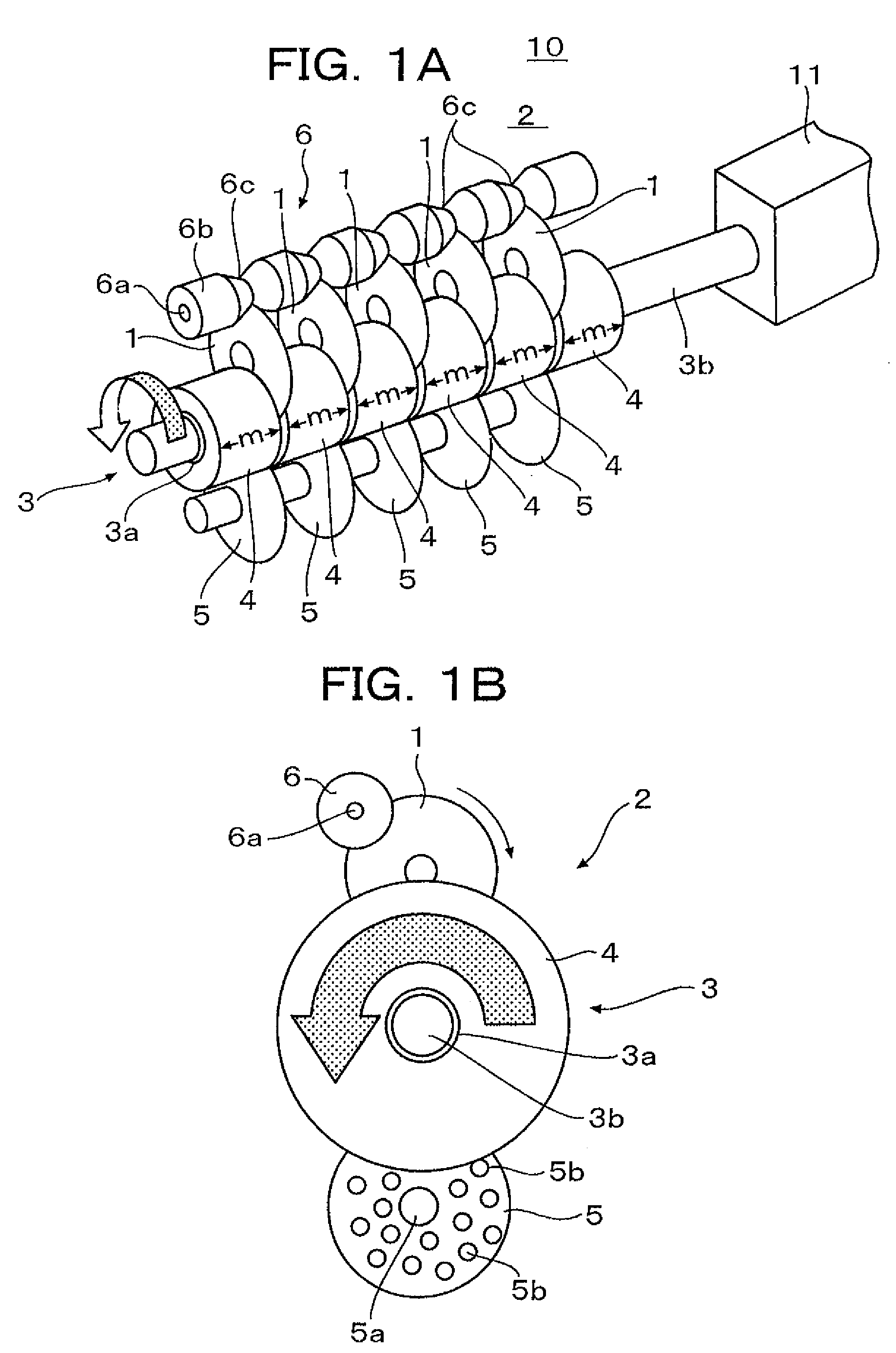

Disc cleaning machinery, disc cleaning device thereof and rotary brush thereof

InactiveUS7841035B2Improve throughputReduce machine sizeLiquid processingCarpet cleanersEngineeringMechanical engineering

A disc cleaning mechanism or device has a rotary brush having a rotary shaft on which a plurality of brushes are mounted and, between adjacent brushes of which a plurality of discs is inserted, and a disc revolution stopper for preventing the discs inserted between the brushes from revolving about the rotary shaft by rotation of the rotary brush and allowing the discs to rotate. The disc cleaning mechanism includes a core roller having an uneven inner peripheral portion of the brush as a core of the brush and an uneven outer peripheral portion and a rotary shaft on which a plurality of the core rollers are mounted. The brush and the core rollers constitute a spline joint.

Owner:HITACHI HIGH-TECH CORP

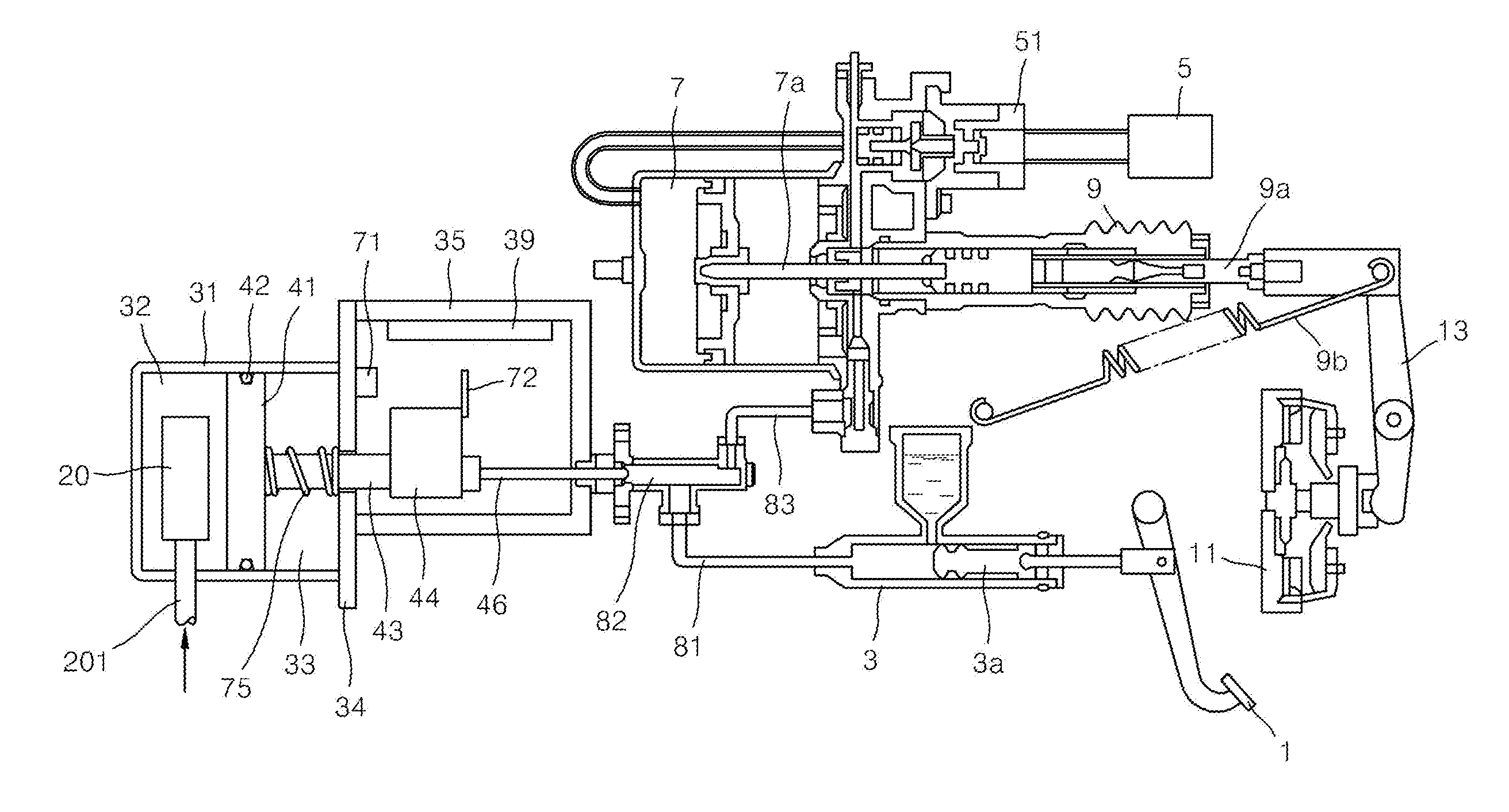

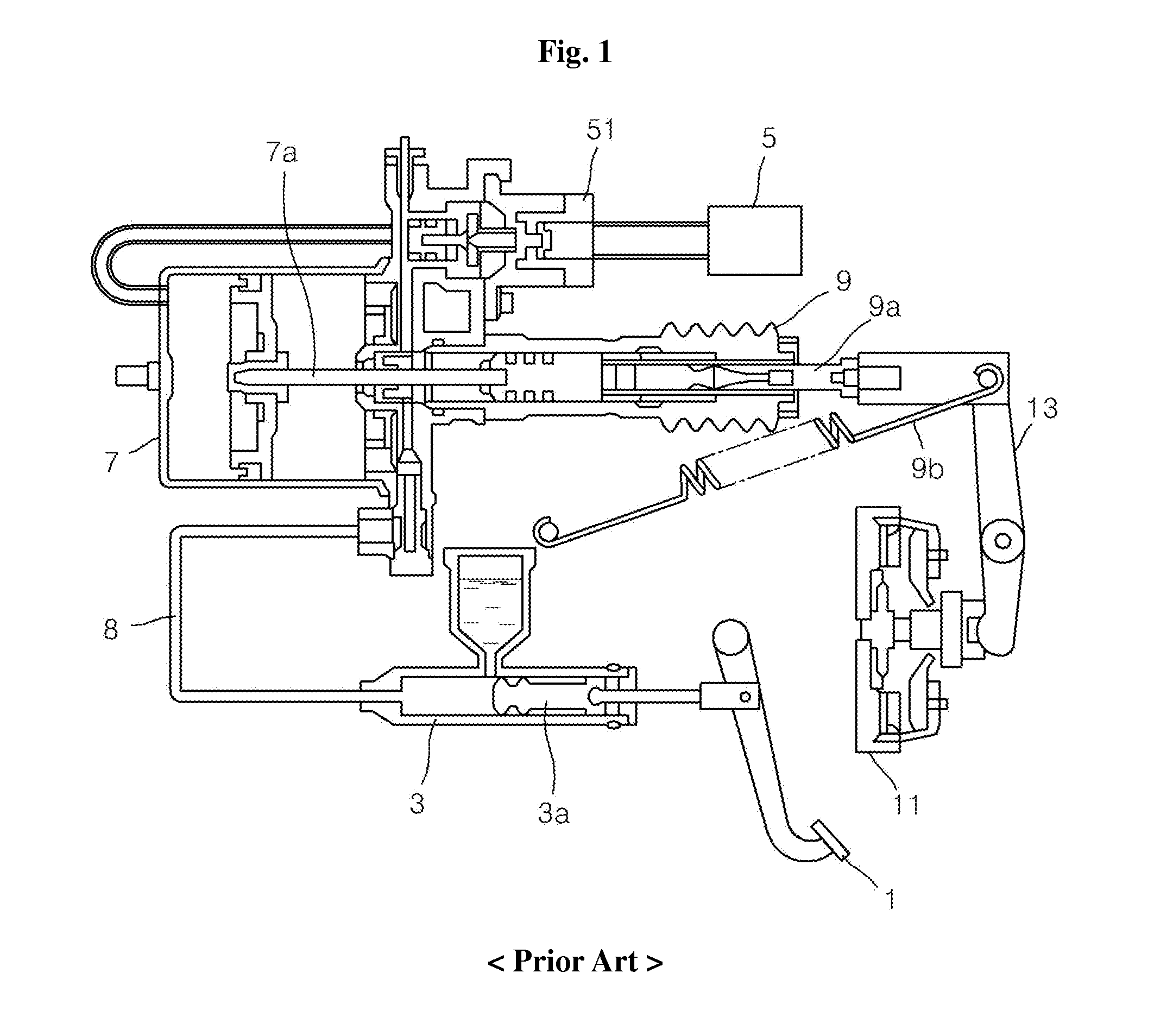

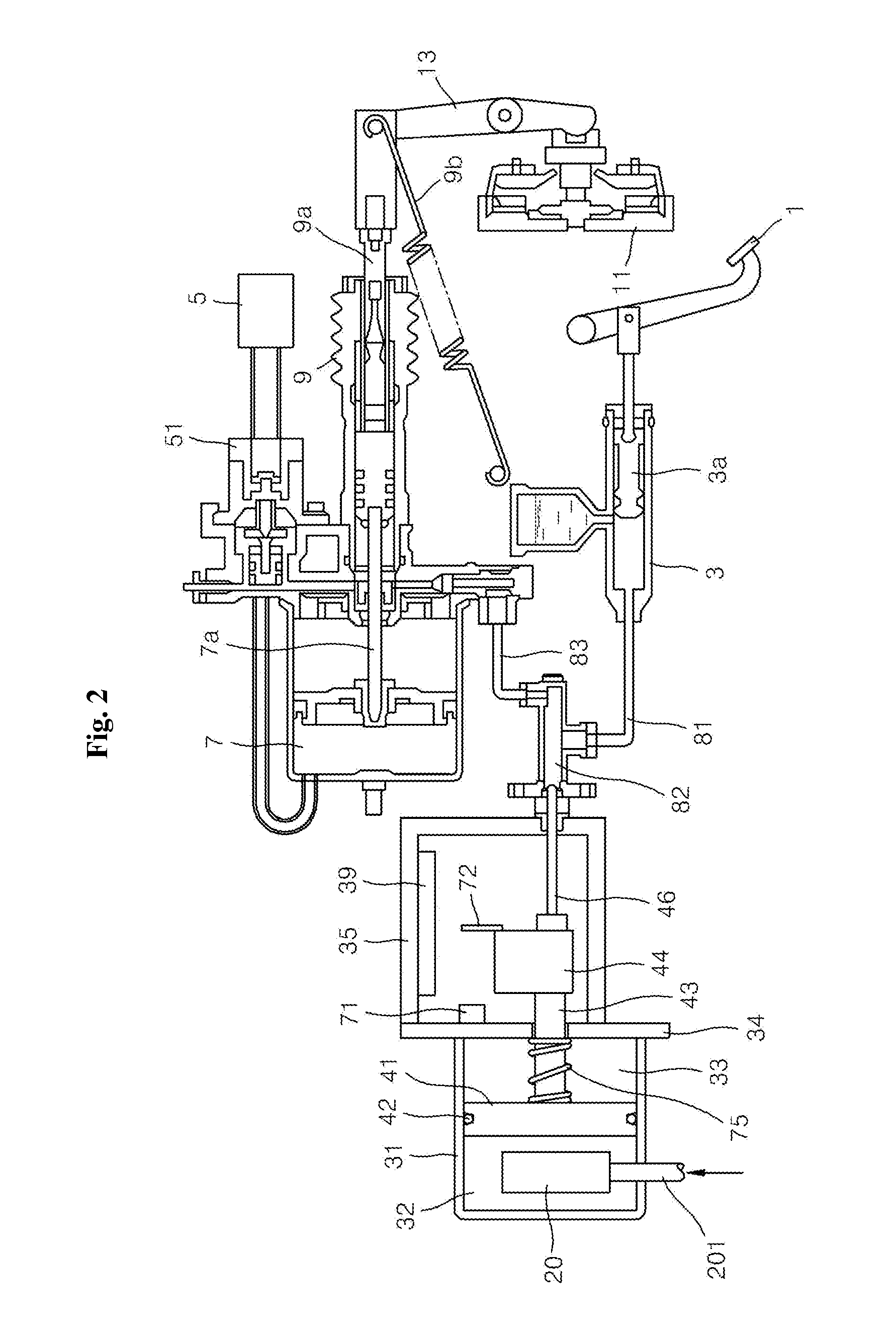

Clutch control device

ActiveUS20140332337A1Good adhesionEasy detachmentFluid actuated clutchesVehicle sub-unit featuresClutch controlSolenoid valve

The present invention relates to a clutch control device, more particularly, to a clutch control device wherein a mechanical section may be miniaturized and operational errors can be reduced using a non-contact type displacement detection system which uses a linear distance sensor for a clutch clearance and the position of the mechanical section can be accurately controlled by using a plurality of solenoid valves.

Owner:WONKWANG E&TECH

Portable IGBT arc welding machine

ActiveUS9199327B2Improve reliabilitySmall sizeDc-dc conversionArc welding apparatusFull bridgeTransformer

A portable IGBT (Insulated Gate Bipolar Transistor) of high reliability, compact size, and low cost includes a main circuit to which a control circuit and an auxiliary power supply circuit are connected. The main circuit includes, in sequence, an input rectifier filter circuit, an inverter circuit, a high-frequency primary transformer, and a secondary output rectifier circuit. The control circuit includes a PWM regulation circuit, an IGBT driving circuit, a current feedback circuit, and a current setup circuit. The inverter circuit includes a full-bridge hard switching structure, which has IGBTs constituting bridge arms that are sequentially conducted, so that their alternating conduction converts direct current into high frequency square wave alternating current, which flows through the high-frequency primary transformer and is then subjected to rectification to supply an output of low voltage direct current. Each IGBT is connected in parallel to resistor and capacitor, which constitute a peak voltage absorption circuitry.

Owner:SHENZHEN JASIC TECH

Electrofusion machine with improved functions

InactiveUS20060086711A1Good lookingReduce weightAc-dc conversionDc-dc conversionEngineeringSites treatment

Provided is an improved electrofusion machine comprising: a power supply circuit having a triac configured to have a proper regulation for dropping a commercial voltage to a voltage adapted for a fitting; and a printer unit integrated with the electrofusion unit, for printing information regarding a work result of the fitting. According to the above construction, since the electrofusion machine does not use a transformer occupying 40% of a total weight of the machine, the mobility and portability are enhanced. Also, since the size of the machine is reduced, it is advantageous to deal with the machine on the spot.

Owner:DEASON MIKE T +1

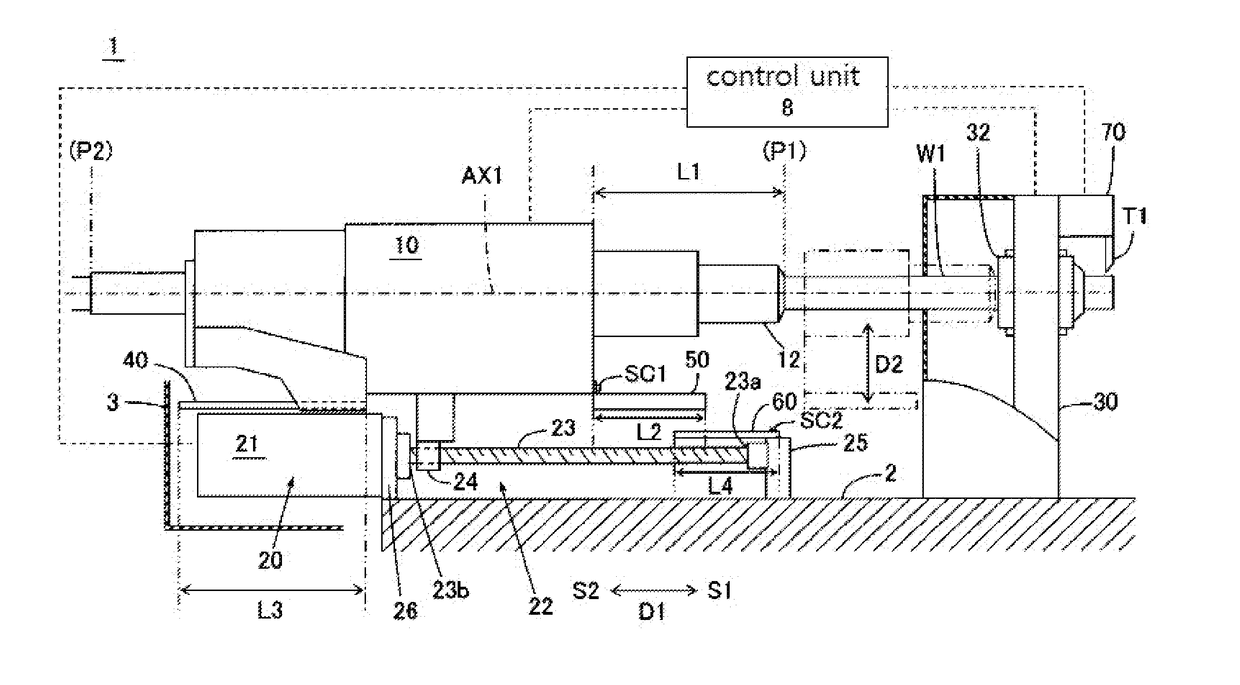

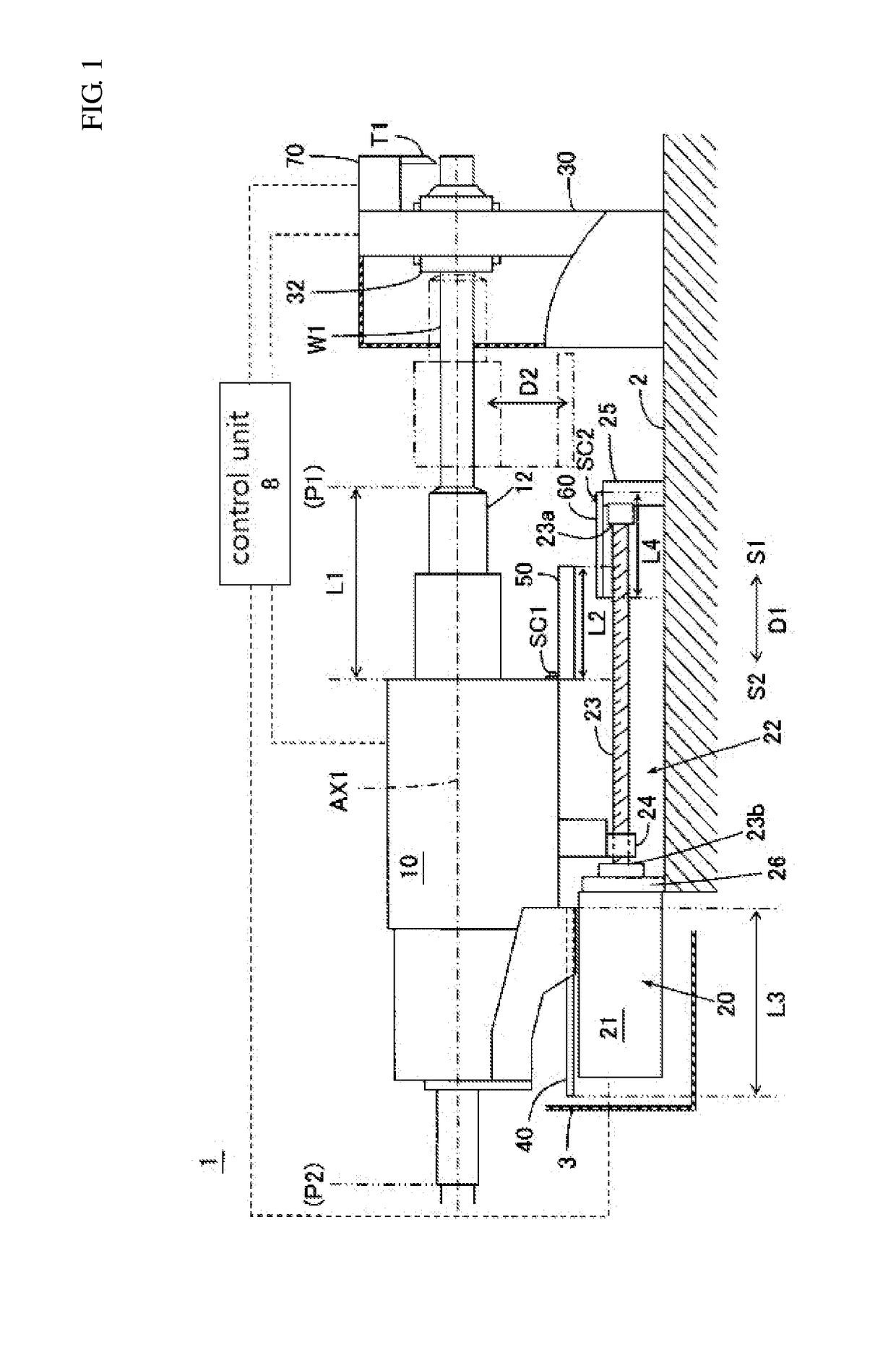

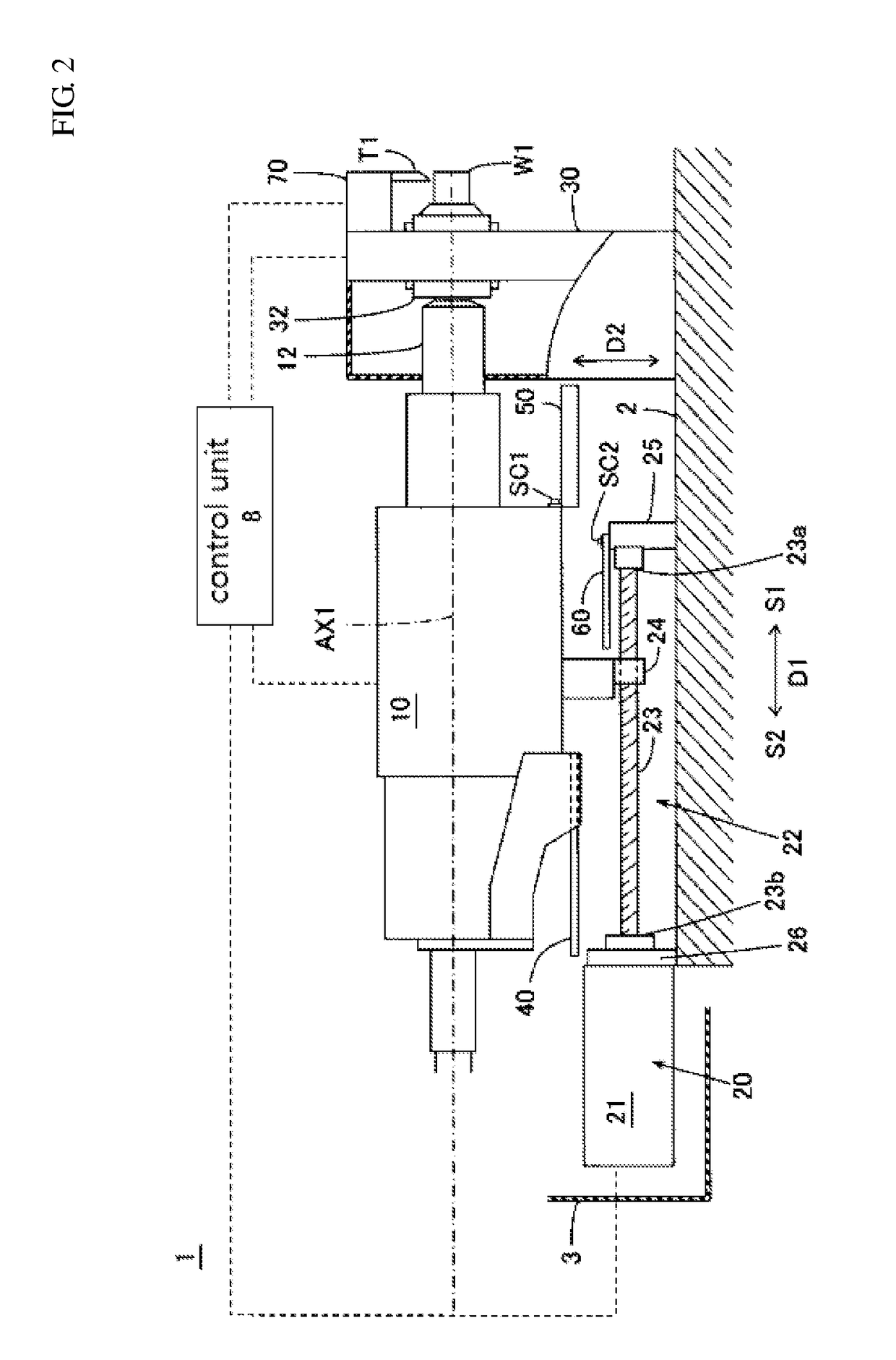

Machine tool

ActiveUS20180236622A1Reduce machine sizeAutomatic/semiautomatic turning machinesAutomatic conveying/guiding stockEngineeringMachine tool

The machine tool comprises a headstock provided with a main spindle; a driving unit which moves the headstock in a main spindle axial direction and has a feed mechanism extended in the main spindle axial direction and a front end supporter which rotatably supports a front end of the feed mechanism; a first front cover mounted on the headstock in a first position between the main spindle and the feed mechanism with respect to a diameter direction from a main spindle axis toward the feed mechanism; and a second front cover mounted on the front end supporter in a second position between the main spindle and the feed mechanism. Part of the feed mechanism is covered by both of the first front cover and the second front cover when at least part of the first front cover is on the rear side of the second front cover.

Owner:STAR MICRONICS

Coin depositing and dispensing machine

ActiveUS20160240027A1Decrease in coin storing capacityReduce machine sizeCoin countersCoin/currency accepting devicesEngineeringMechanical engineering

In a coin depositing and dispensing machine 10, a plurality of storing and feeding apparatuses 50 disposed below a deposited-coin transport unit 20 are arranged vertically on plural levels. A transport direction in which a coin is transported by the deposited-coin transport unit and a feeding direction in which a coin is fed out from each storing and feeding unit are substantially perpendicular to each other.

Owner:GLORY KOGYO KK

Refrigerator

InactiveUS8069686B2Increase contentReduce machine sizeLighting and heating apparatusDomestic refrigeratorsEngineeringMechanical engineering

A refrigerator including a body having a plurality of cooling compartments separated from each other by a partition, and a machine room defined by the partition in a lower region of one of the plurality of cooling compartments. The machine room receives predetermined elements required to operate the cooling compartments.

Owner:LG ELECTRONICS INC

Coin depositing and dispensing machine

ActiveUS10347067B2Decrease in coin storing capacityReduce machine sizeCoin countersCoin dispensersEngineeringMechanical engineering

In a coin depositing and dispensing machine 10, a plurality of storing and feeding apparatuses 50 disposed below a deposited-coin transport unit 20 are arranged vertically on plural levels. A transport direction in which a coin is transported by the deposited-coin transport unit and a feeding direction in which a coin is fed out from each storing and feeding unit are substantially perpendicular to each other.

Owner:GLORY KOGYO KK

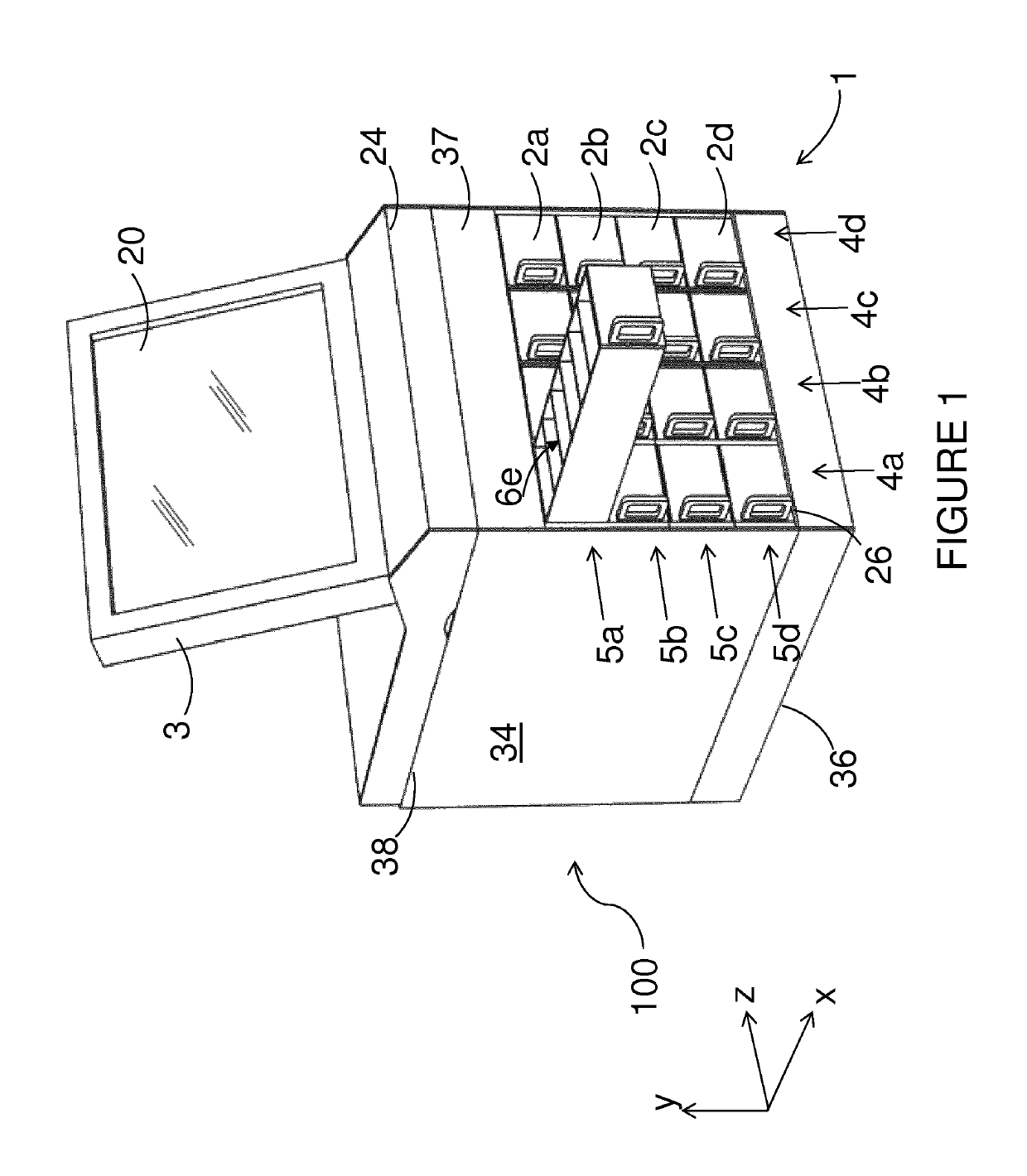

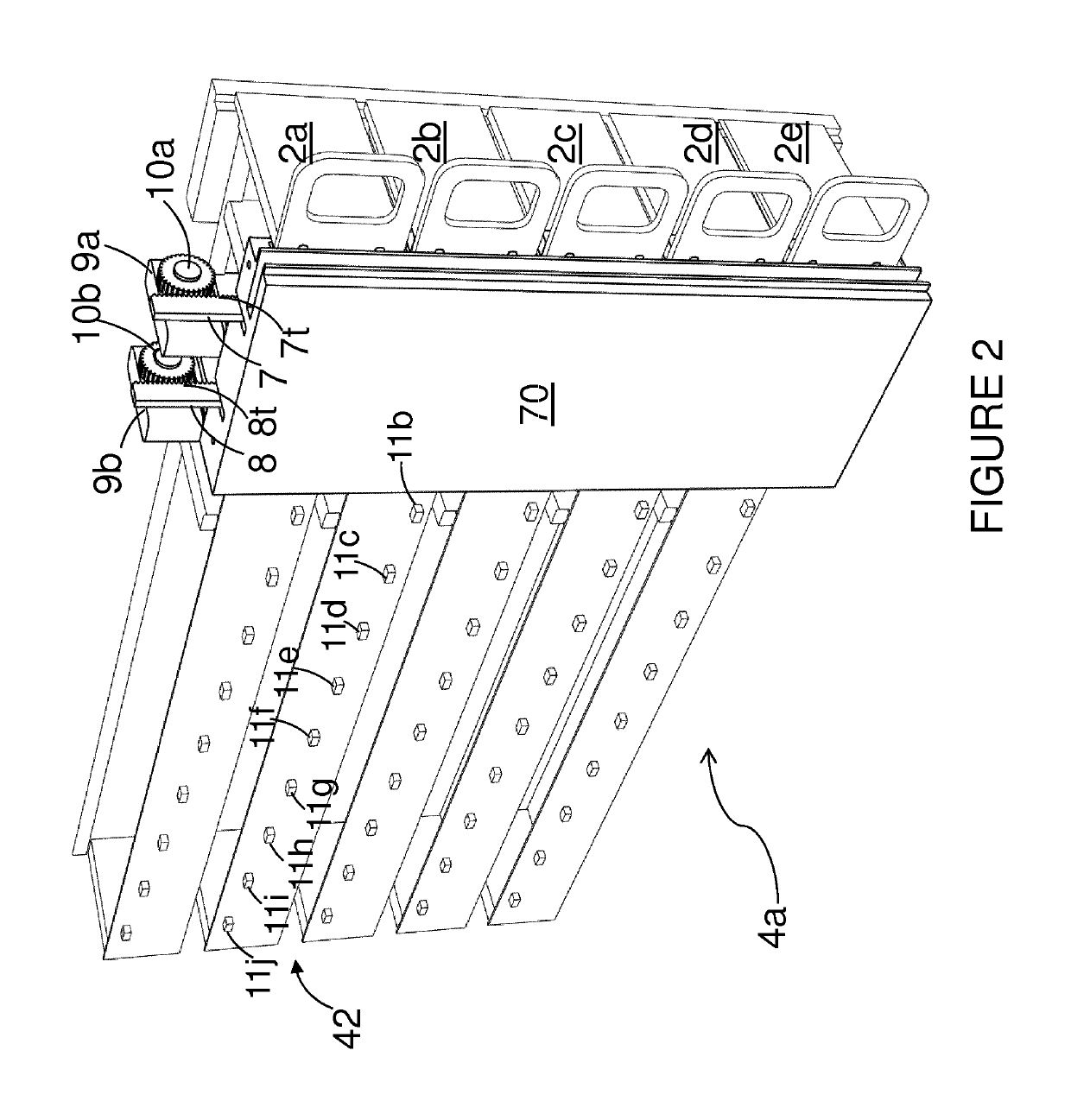

System for secure storage of and controlled access to articles and apparatus therefor

ActiveUS10269205B2Improve reliabilitySimplifies restockingComputer controlCoin-freed apparatus detailsLocking mechanismEngineering

Owner:SMART TOOLS UK LTD

Wireless power supply apparatus, filter unit and power supply apparatus for robot using the filter unit

ActiveUS9997291B2Reduce machine sizeGuaranteed normal transmissionTransformersCircuit arrangementsElectricityResonance

A wireless power supply apparatus includes a power reception coil, an actual load and an auxiliary load. The power reception coil functions as a repeater for receiving electric power in a non-contact manner by magnetic resonance with a power transmission coil to which electric power is supplied from a power supply unit and relaying transfer of the electric power from the power transmission coil. The actual load is connected to the power reception coil and is powered by the electric power received by the power reception coil. The auxiliary load is inserted parallel to the power reception coil and the actual load and forms a closed circuit with the power reception coil when supply of the electric power to the actual load is interrupted to be in an open state.

Owner:DENSO WAVE INC +1

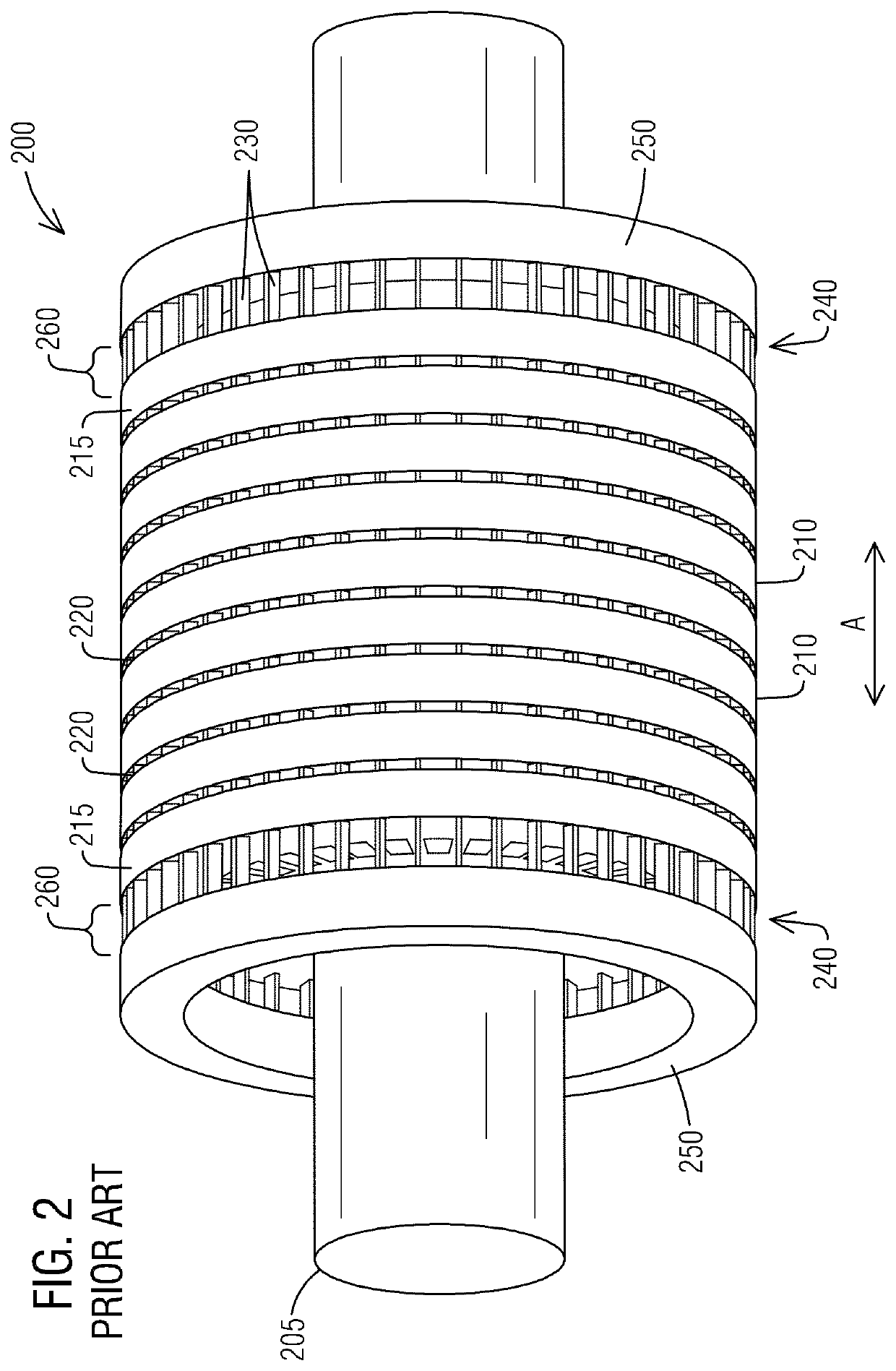

Rotor assembly for an electrodynamic machine that minimizes mechanical stresses in cooling ducts

ActiveUS11146145B2Reduce machine sizeLight weightMagnetic circuit rotating partsAsynchronous induction motorsElectrical conductorEngineering

A rotor assembly for an electrodynamic machine is provided. The rotor assembly comprises a lamination section and an end connector. The lamination section comprises rotor lamination sheets formed to define an annular array of axial cooling ducts mechanically supported by a plurality of radial and arched structural members that define an array of arched or angled supports to readily pass a magnetic flux via an optimal flux path. The lamination section further comprises rotor slots, with rotor conductor bars being disposed in the rotor slots. The end connector is supported by the rotor conductor bars. An axial space is formed in the lamination section by the annular array of axial cooling ducts for guiding a cooling fluid flow in an axial direction through the rotor assembly.

Owner:INNOMOTICS LLC

Internal gear grinding machine

ActiveUS8758093B2Avoid damageEasy to operateEdge grinding machinesRevolution surface grinding machinesGear grindingGear wheel

An internal gear grinding machine achieves space savings and reduction in size of a machine, as well as prevents the tools from being damaged even when an abnormal situation such as a blackout occurs, by a simplifying dressing operation. The internal gear grinding machine for grinding a workpiece (W) by synchronously rotating the workpiece (W) and a barrel-shaped threaded grinding wheel (17) in mesh with each other includes a dressing device (20) for dressing the threaded tool (17) by meshing the threaded grinding wheel (17) with a disk dresser (56). When dressing, the threaded grinding wheel (17) and the disc dresser (56) are operated in accordance with the helix angle and barrel shape of the threaded grinding wheel (17), and the brake mechanism (58) applies a braking force to a dresser turn drive motor (53) to enable the disc dresser (56) to be maintained at a turned position thereof.

Owner:MITSUBISHI HEAVY IND MACHINE TOOL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com