Patents

Literature

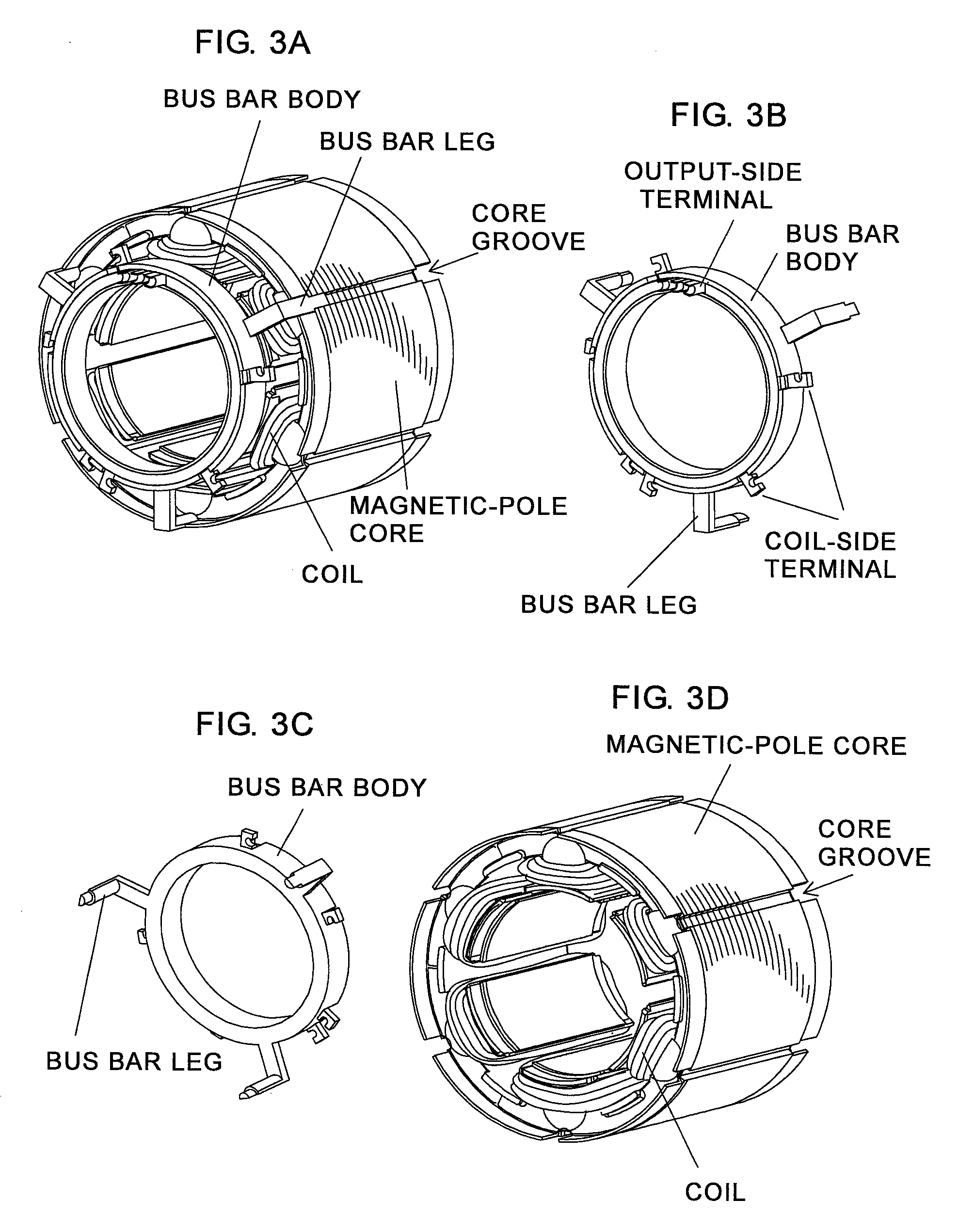

83results about How to "Reduce motor size" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

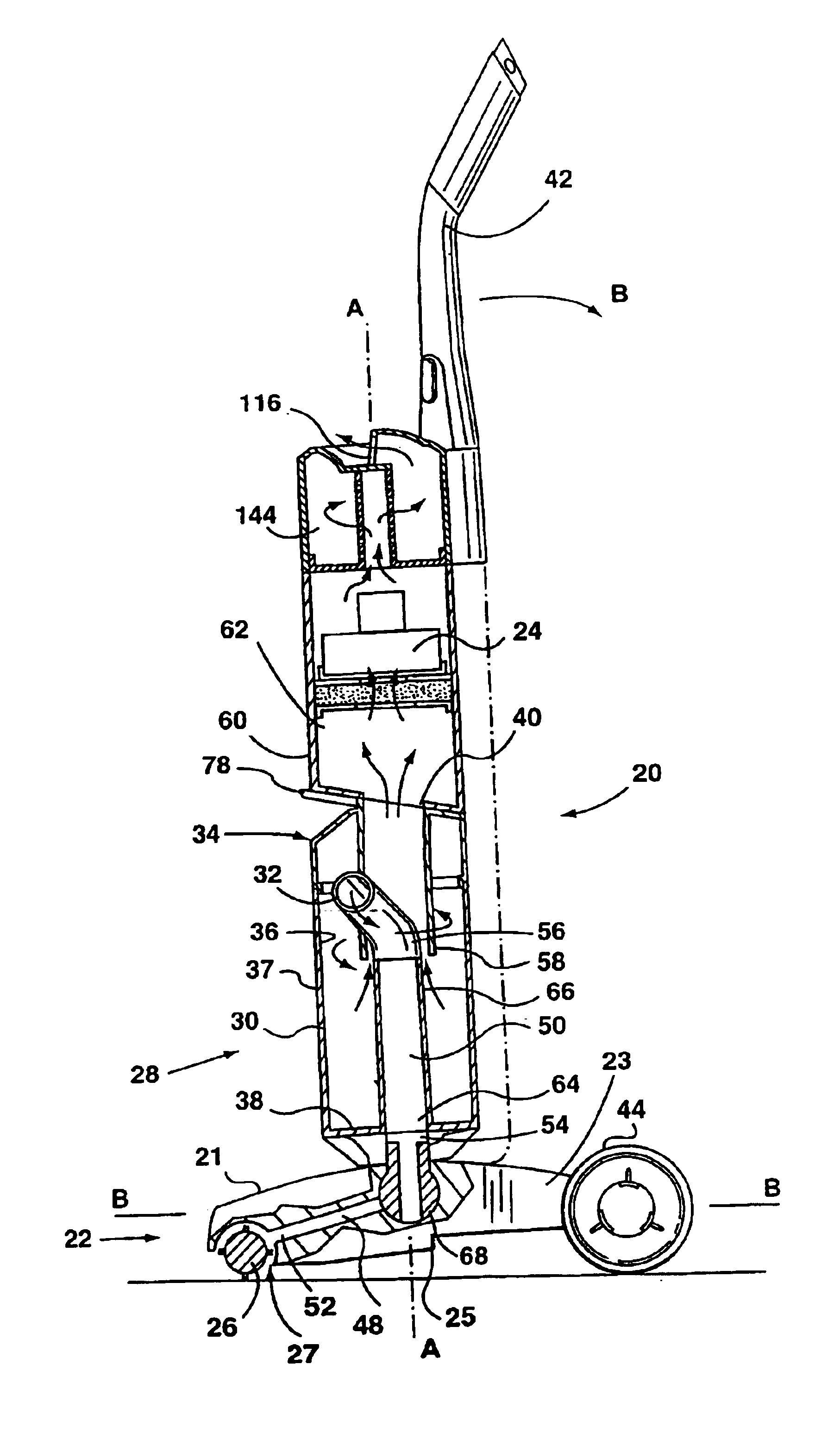

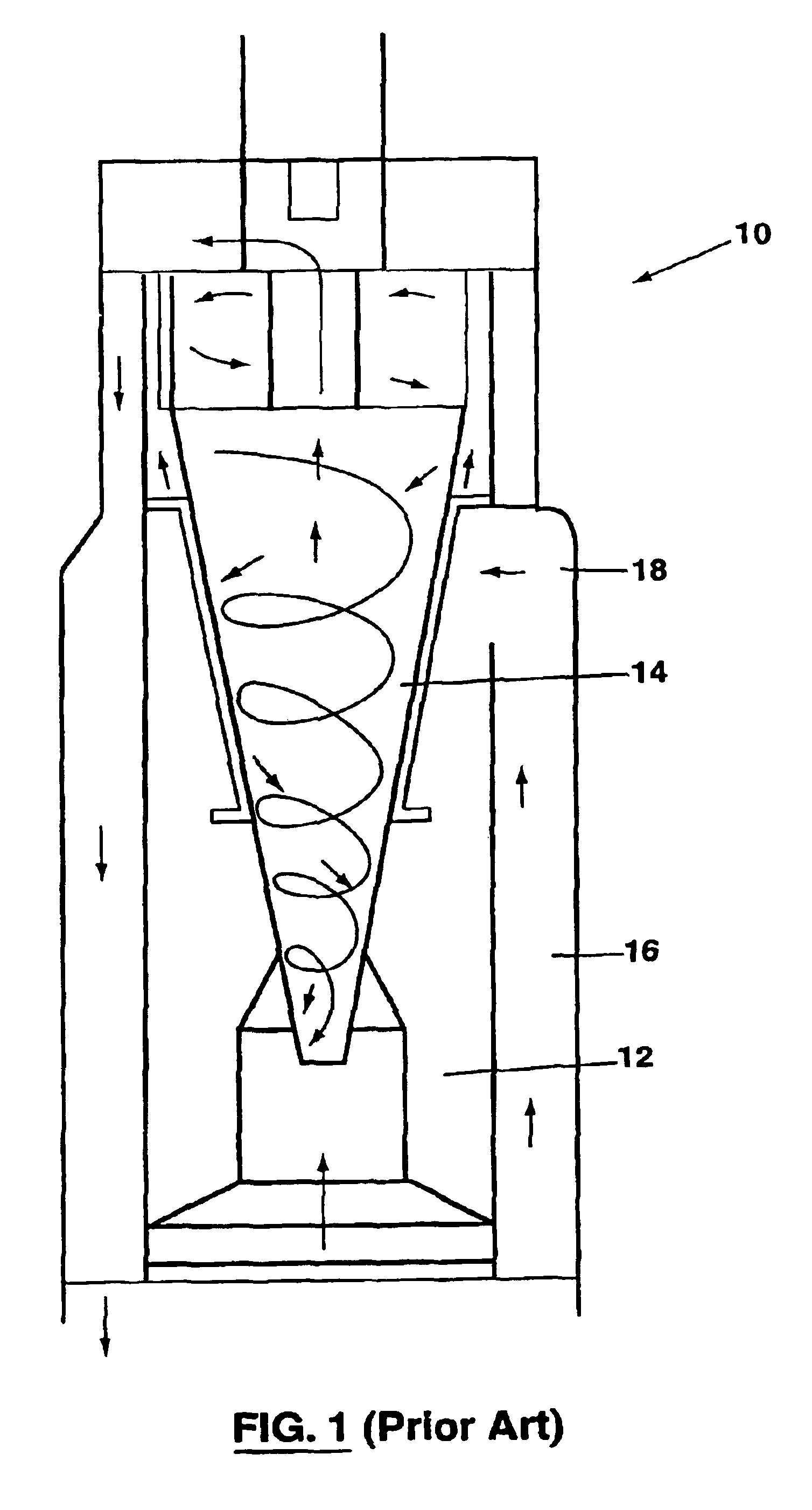

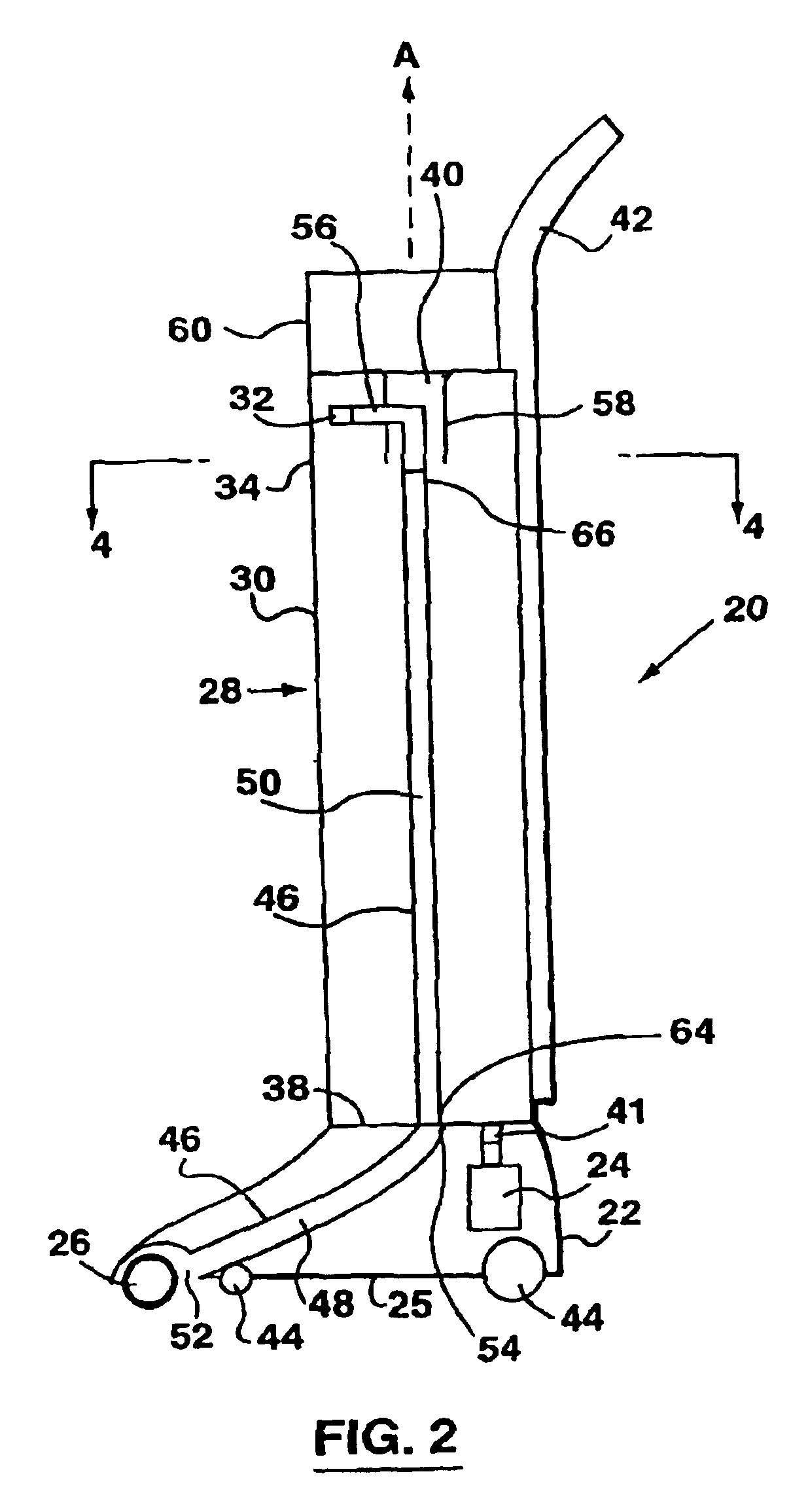

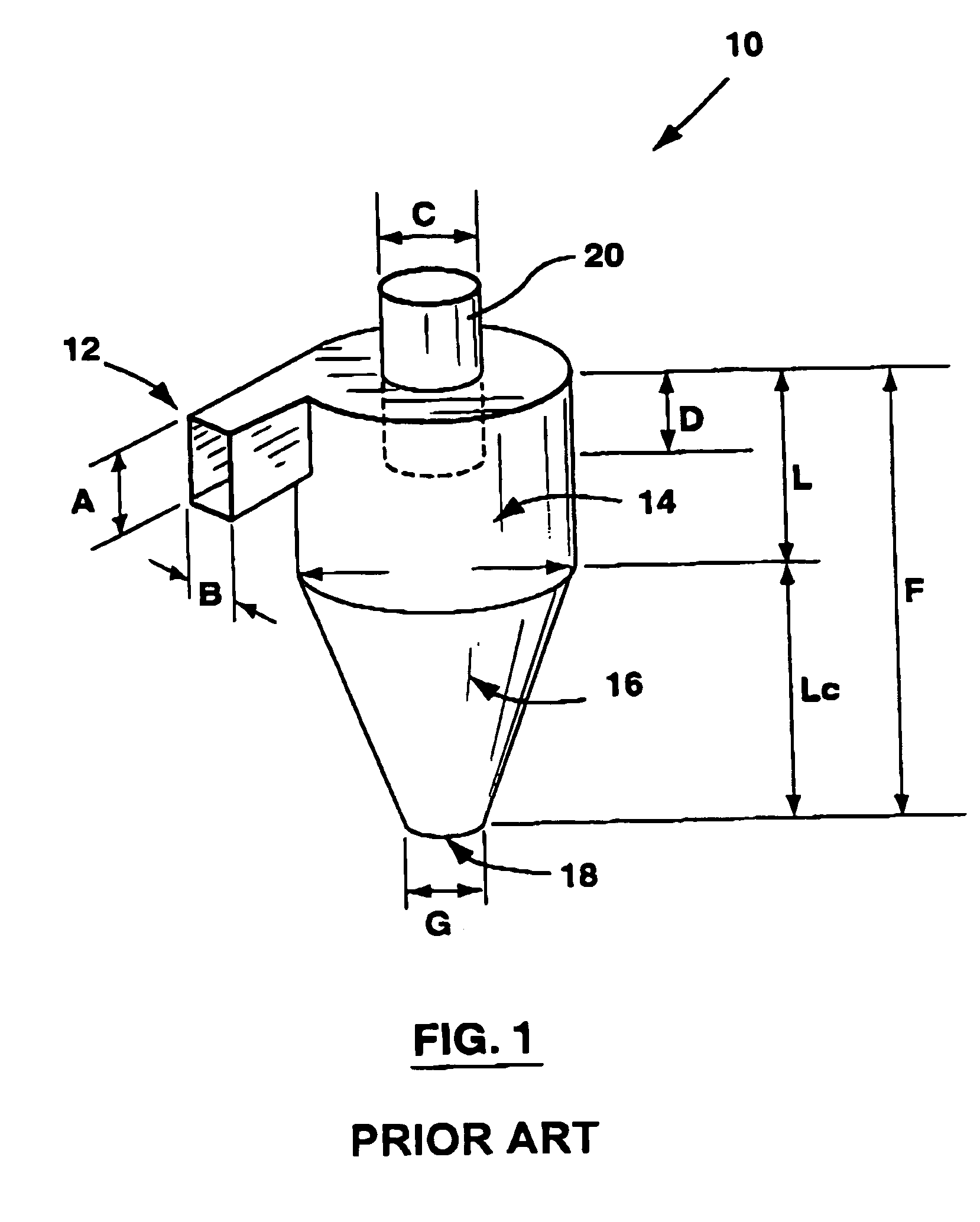

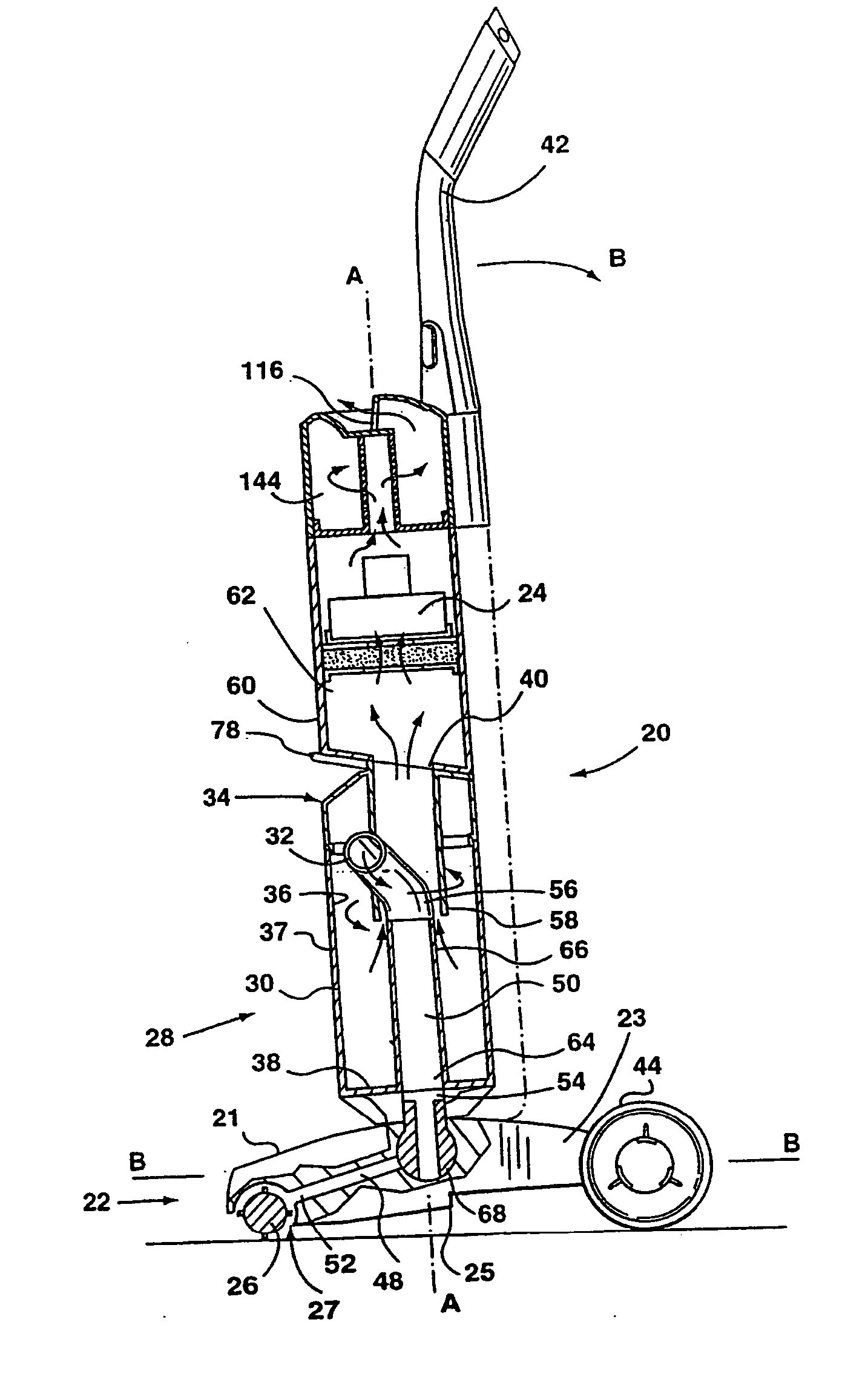

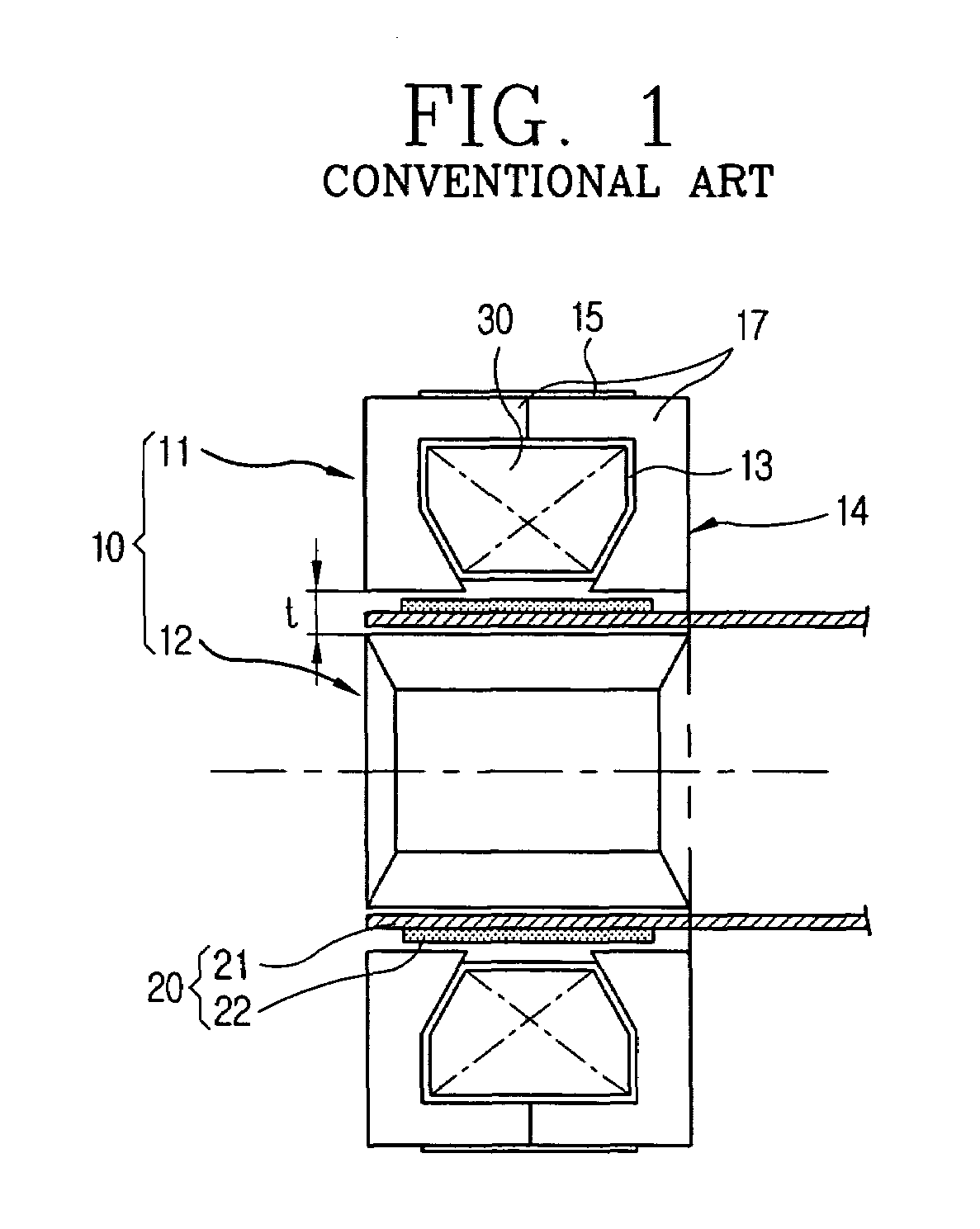

Air flow passage for a vacuum cleaner

InactiveUS6902596B2Reduce back pressureImprove performanceCleaning filter meansSuction filtersCycloneCyclonic separation

A vacuum cleaner is provided having improved pressure loss characteristics. A fluid supply conduit in flow communication with an inlet to a cyclone is integrally formed as part of a cyclone bin. The present invention may be adapted for use with cyclonic separation devices of all types, including single- and multi-stage cyclonic separators.

Owner:OMACHRON INTPROP

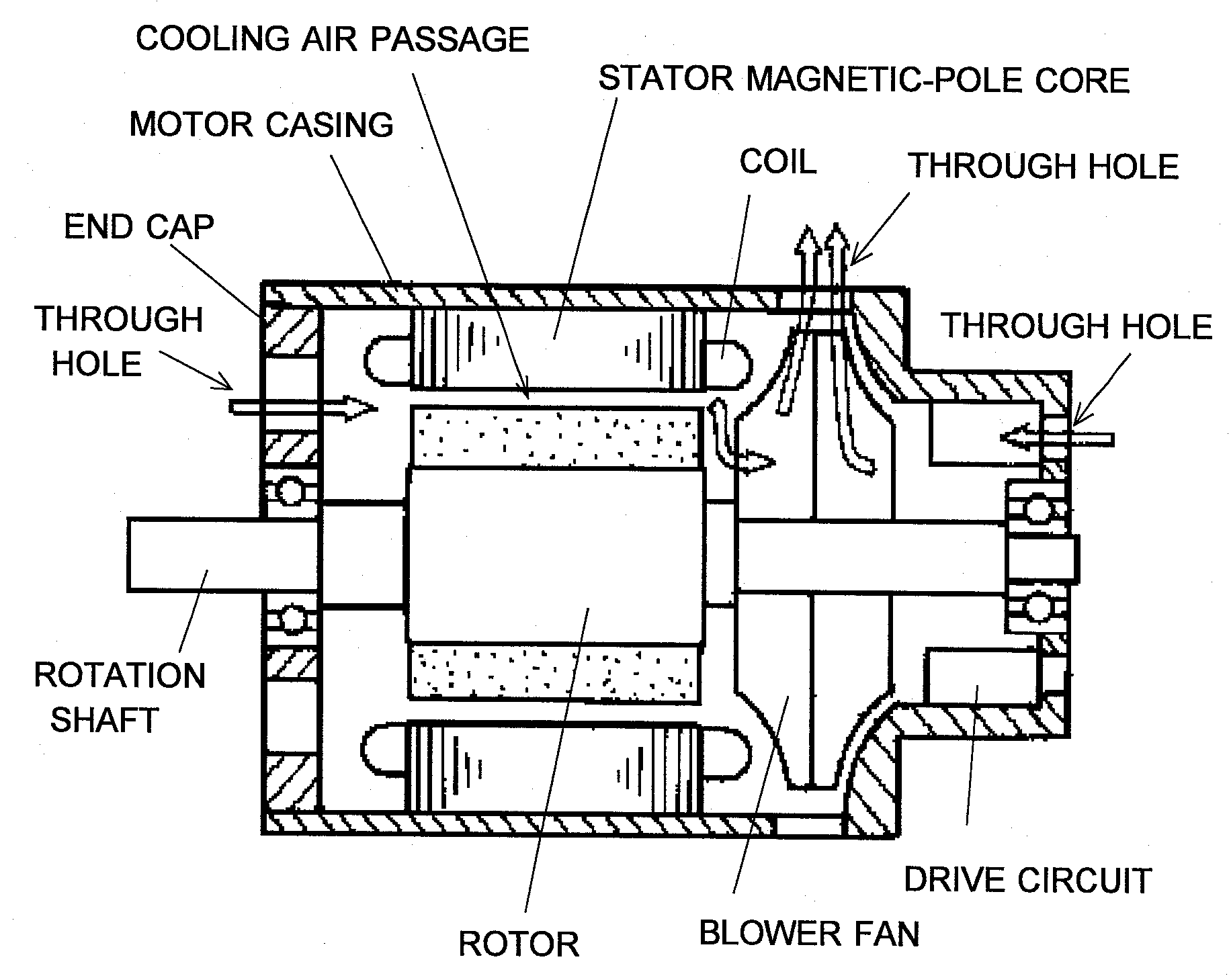

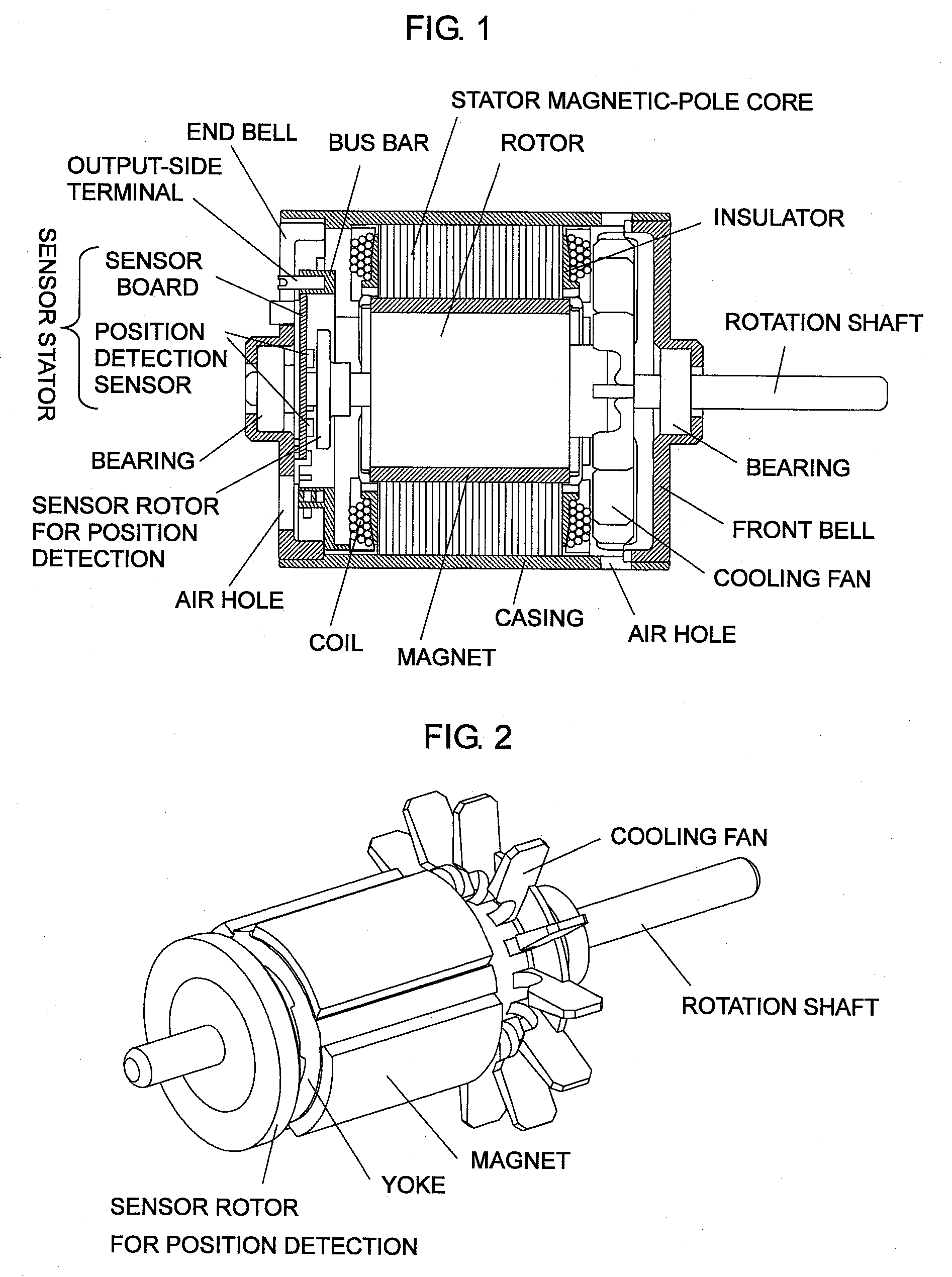

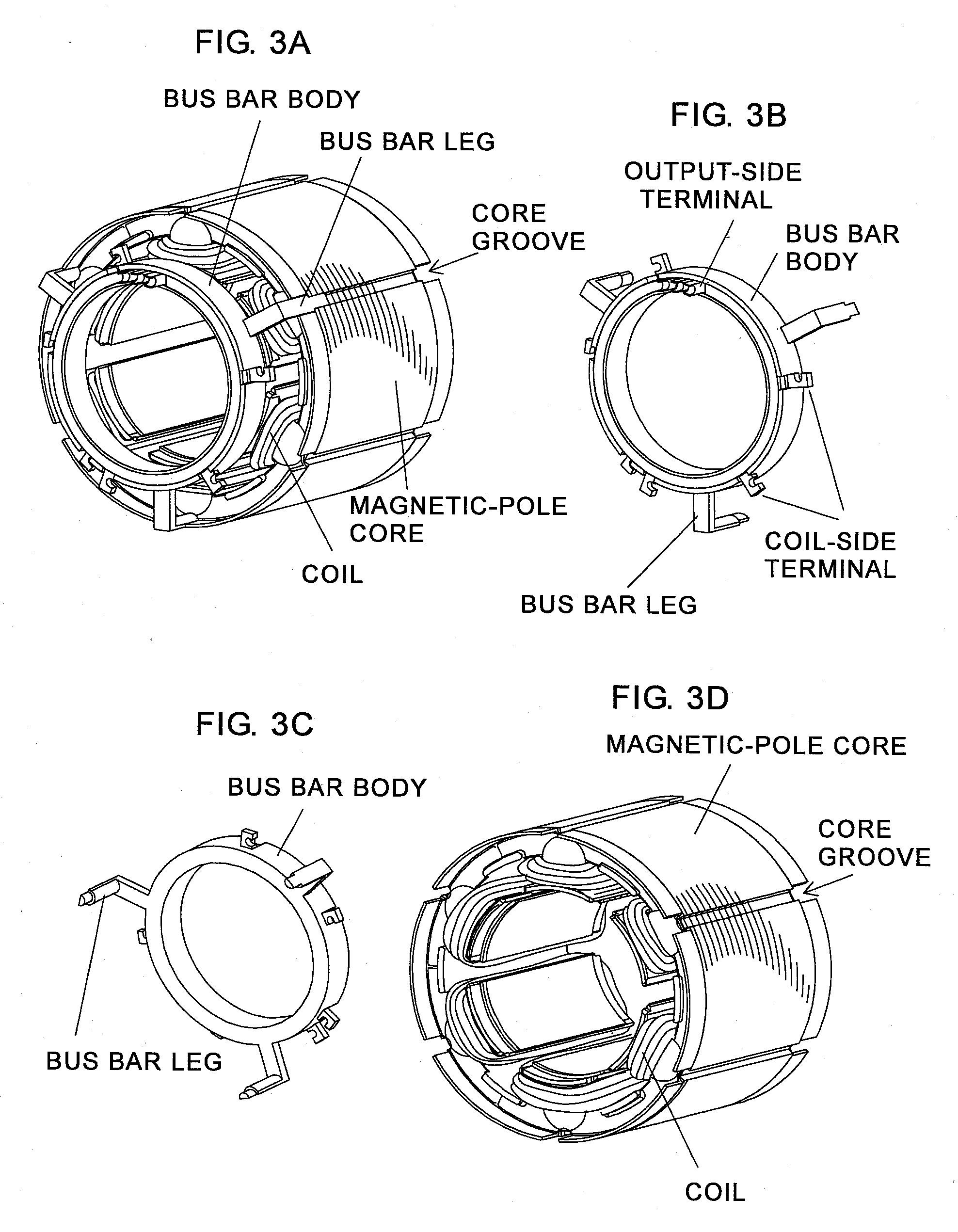

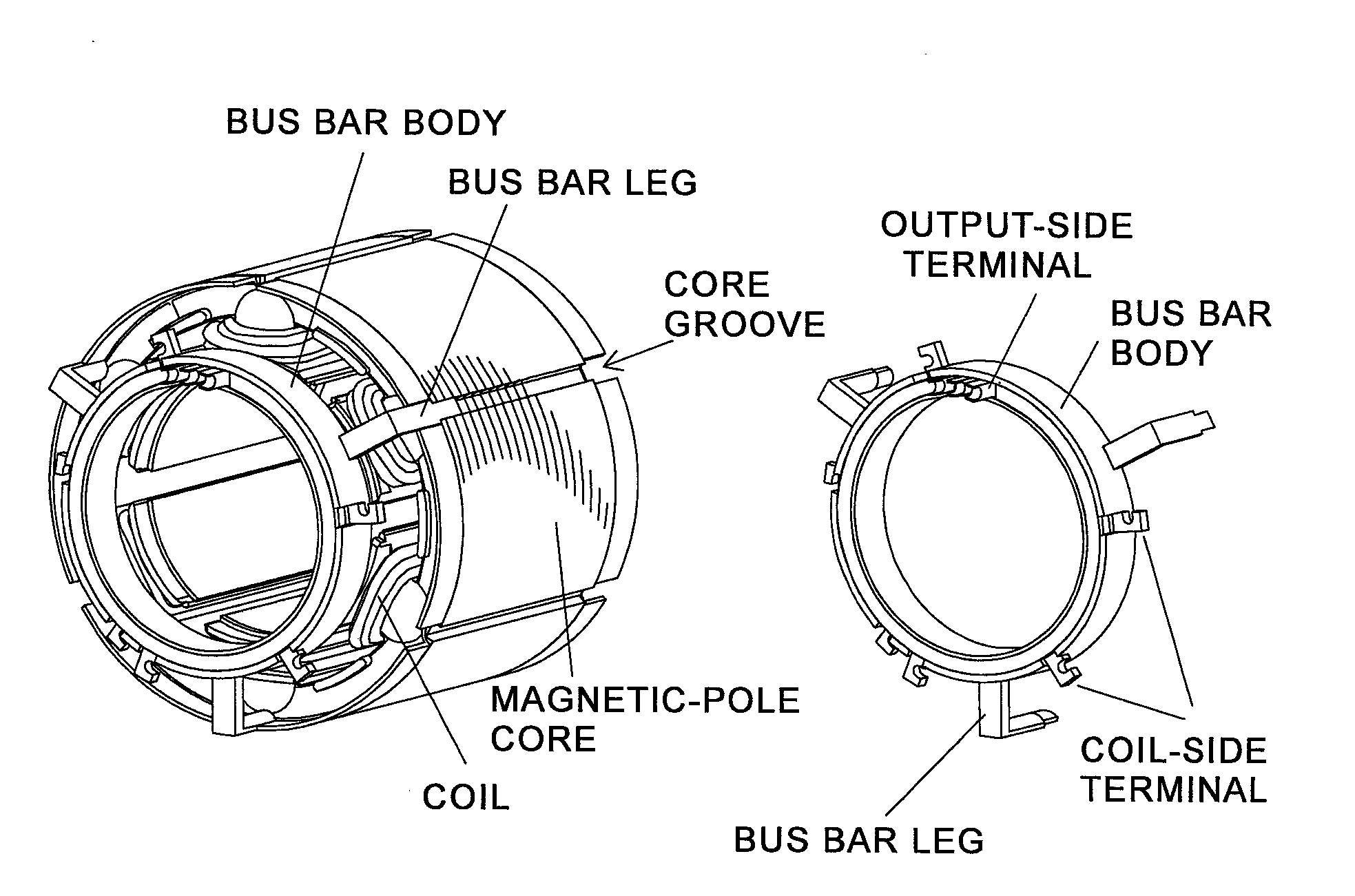

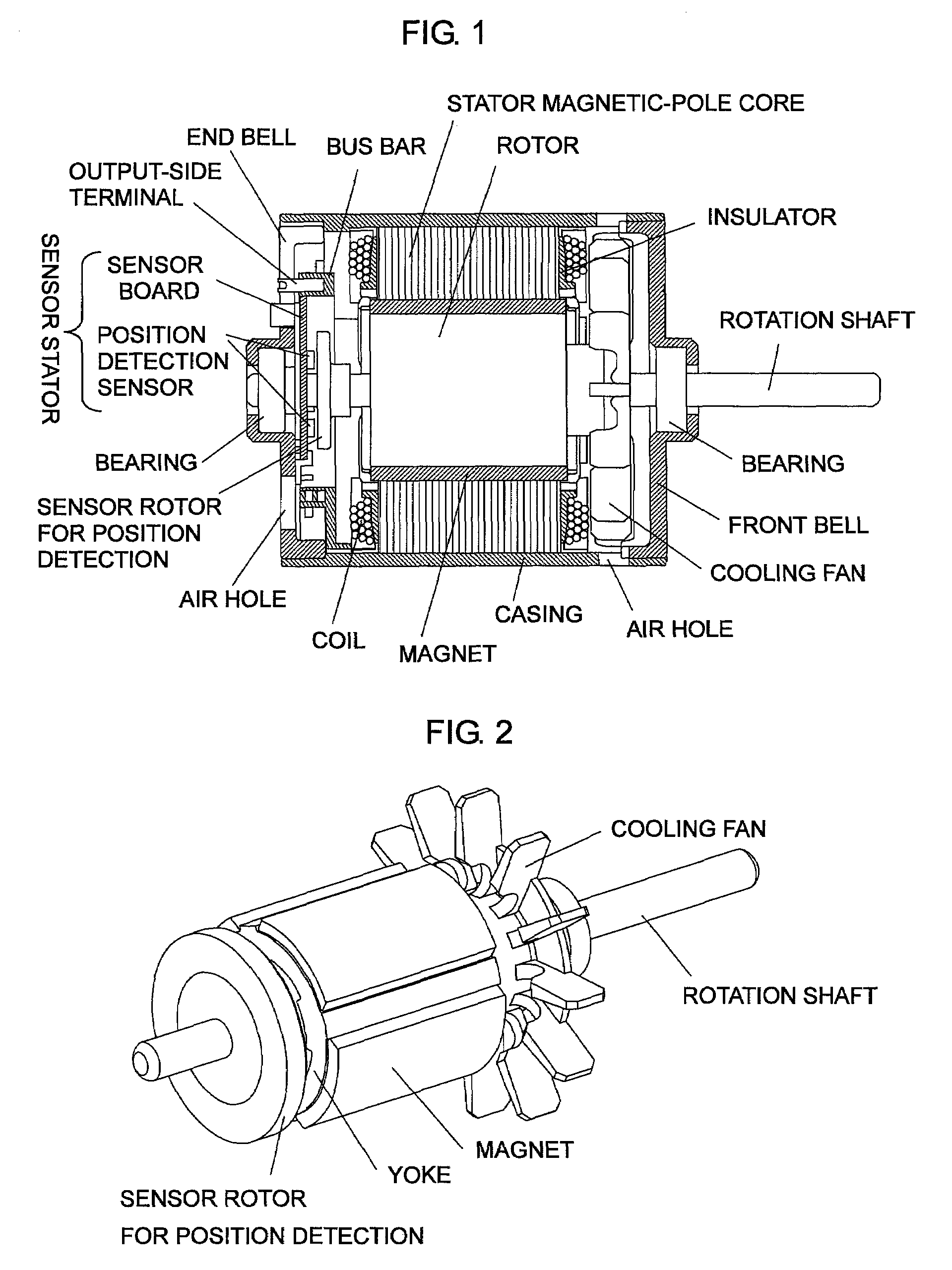

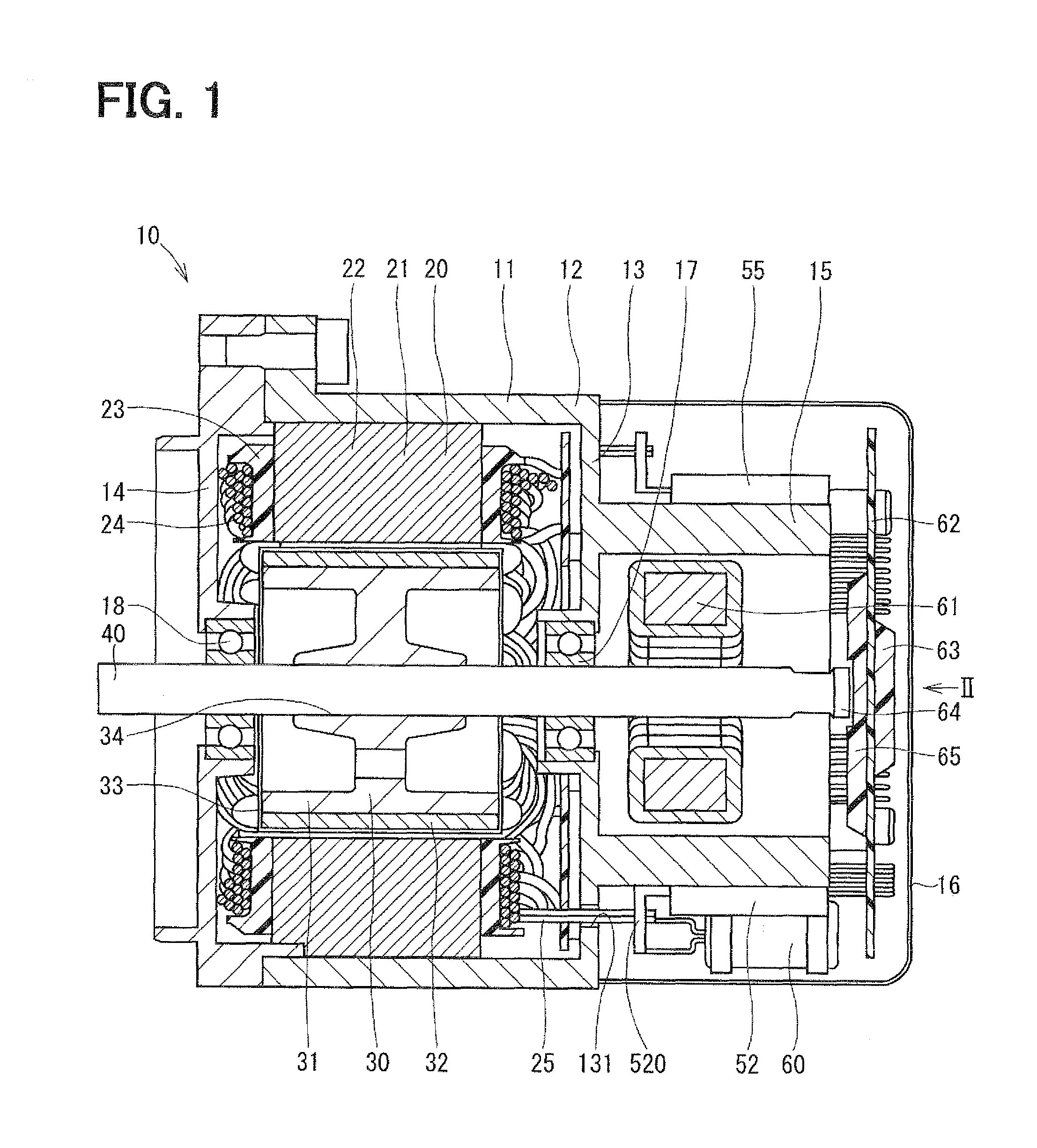

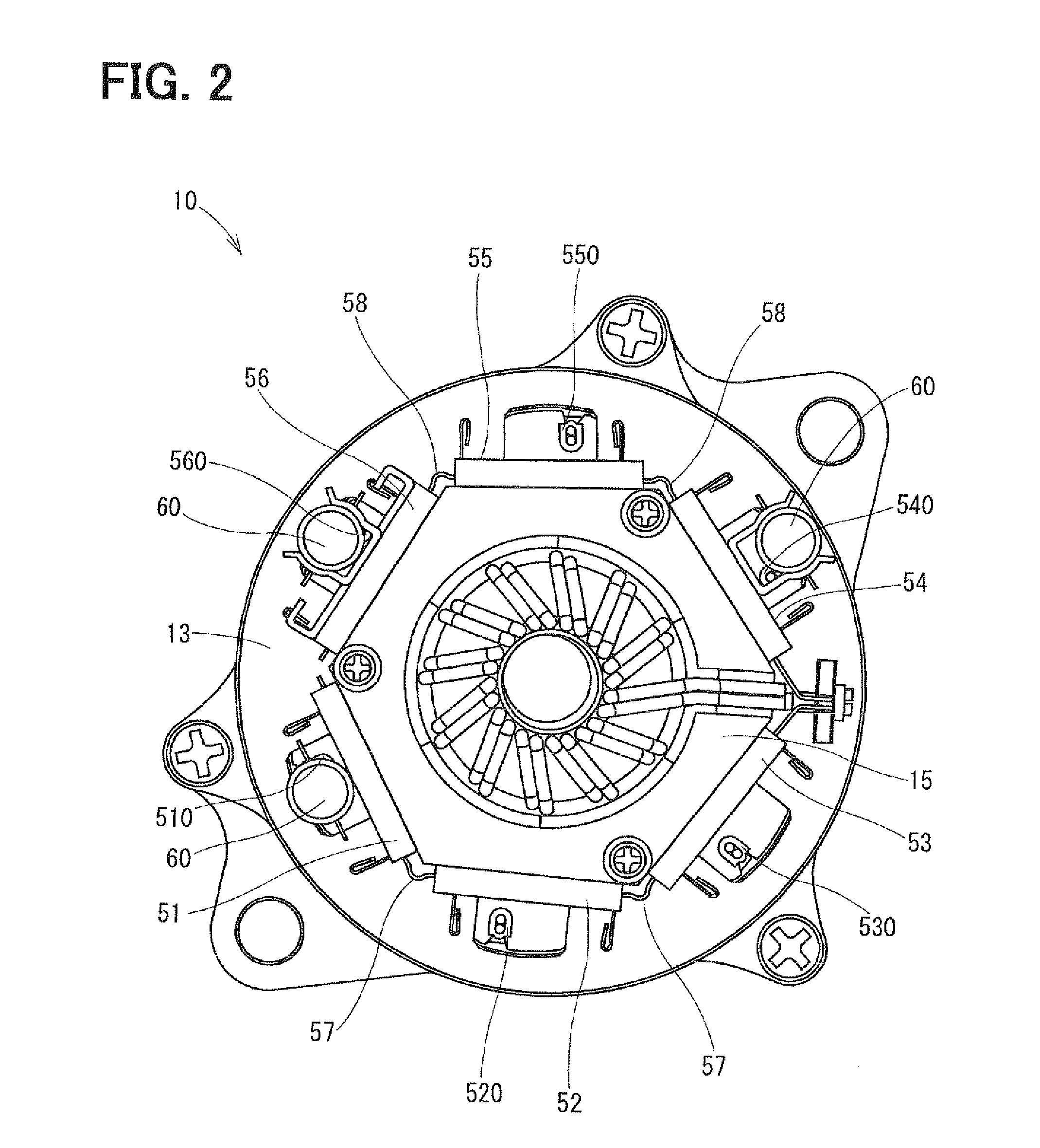

Brushless motor

InactiveUS20070273221A1Improve cooling efficiencyIncrease airflowWindingsDC commutatorBrushless motorsMagnetic poles

A plurality of coils wound around a stator magnetic-pole core are connected together and connected to output wires by use of a bus bar. The bus bar having a generally cylindrical body portion is disposed at one axial end of the stator magnetic-pole core, around which the coils are wound such that clearances are formed within magnetic-pole core slots, with an axial clearance formed between the bus bar and the coils. The body portion has such a radial dimension that at least a portion of the clearances within the magnetic-pole core slots is left uncovered. Air holes are formed in the motor housing on opposite sides of the stator magnetic-pole core to thereby form cooling air passages extending through the magnetic-pole core slots.

Owner:MABUCHI MOTOR

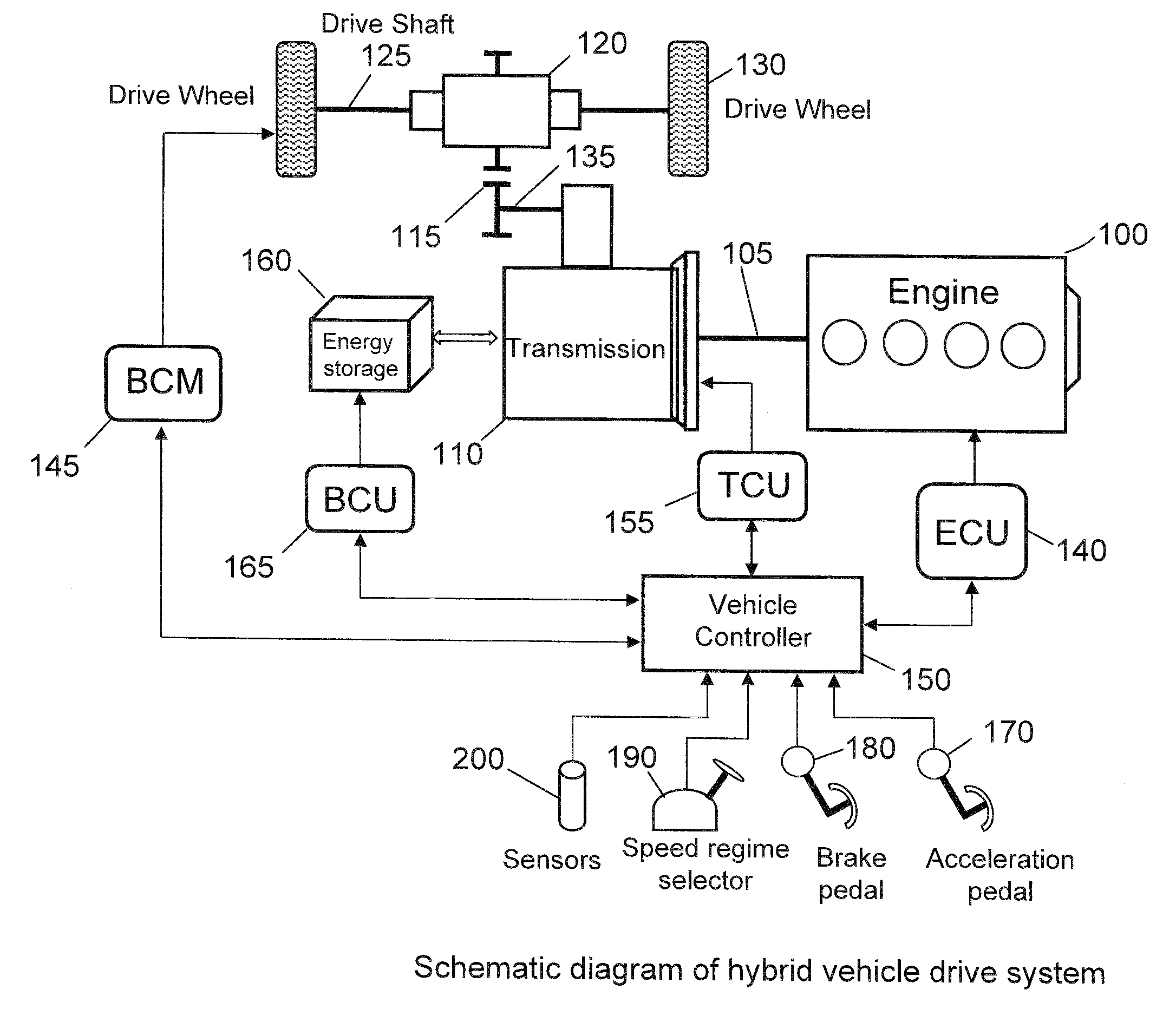

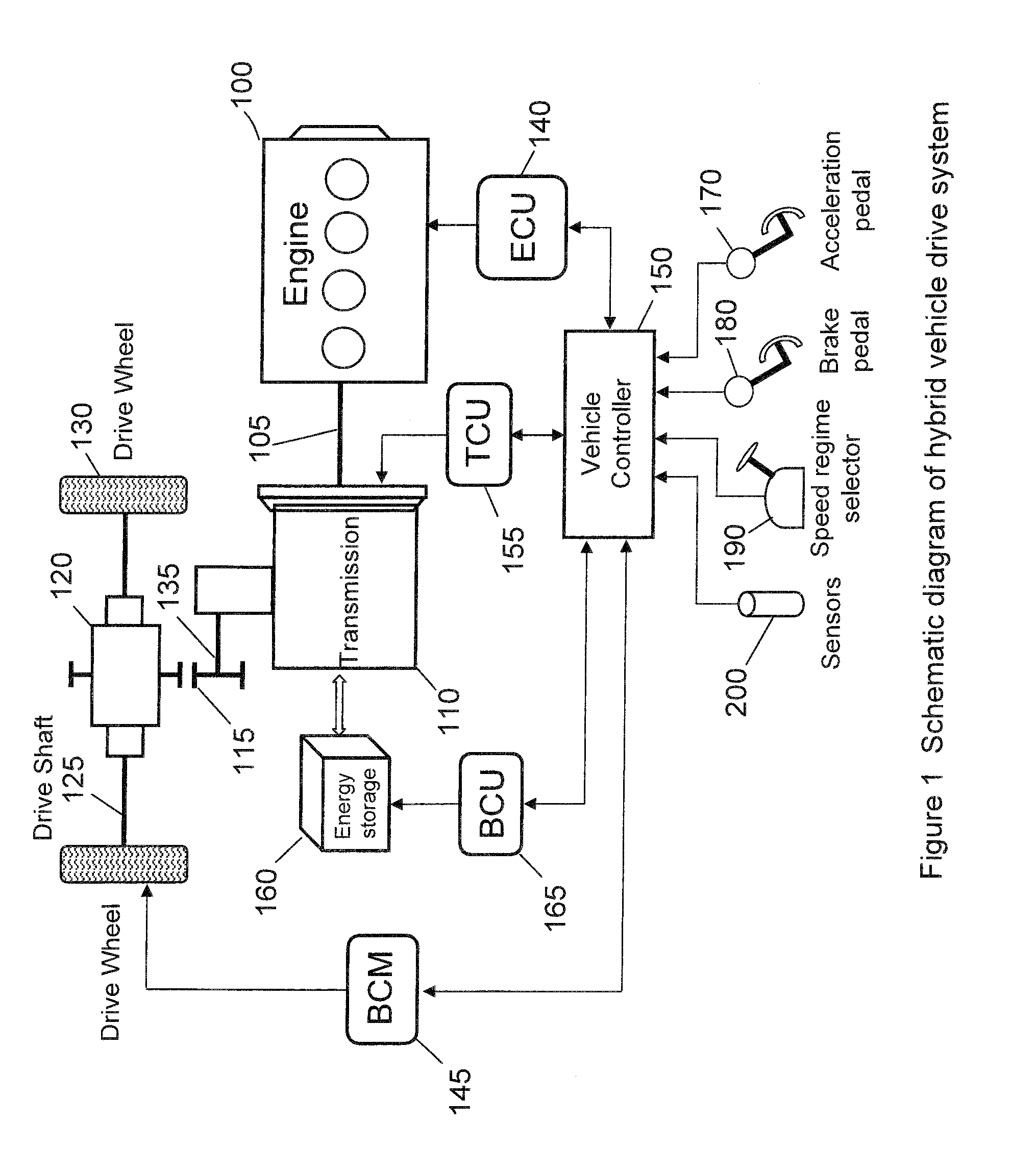

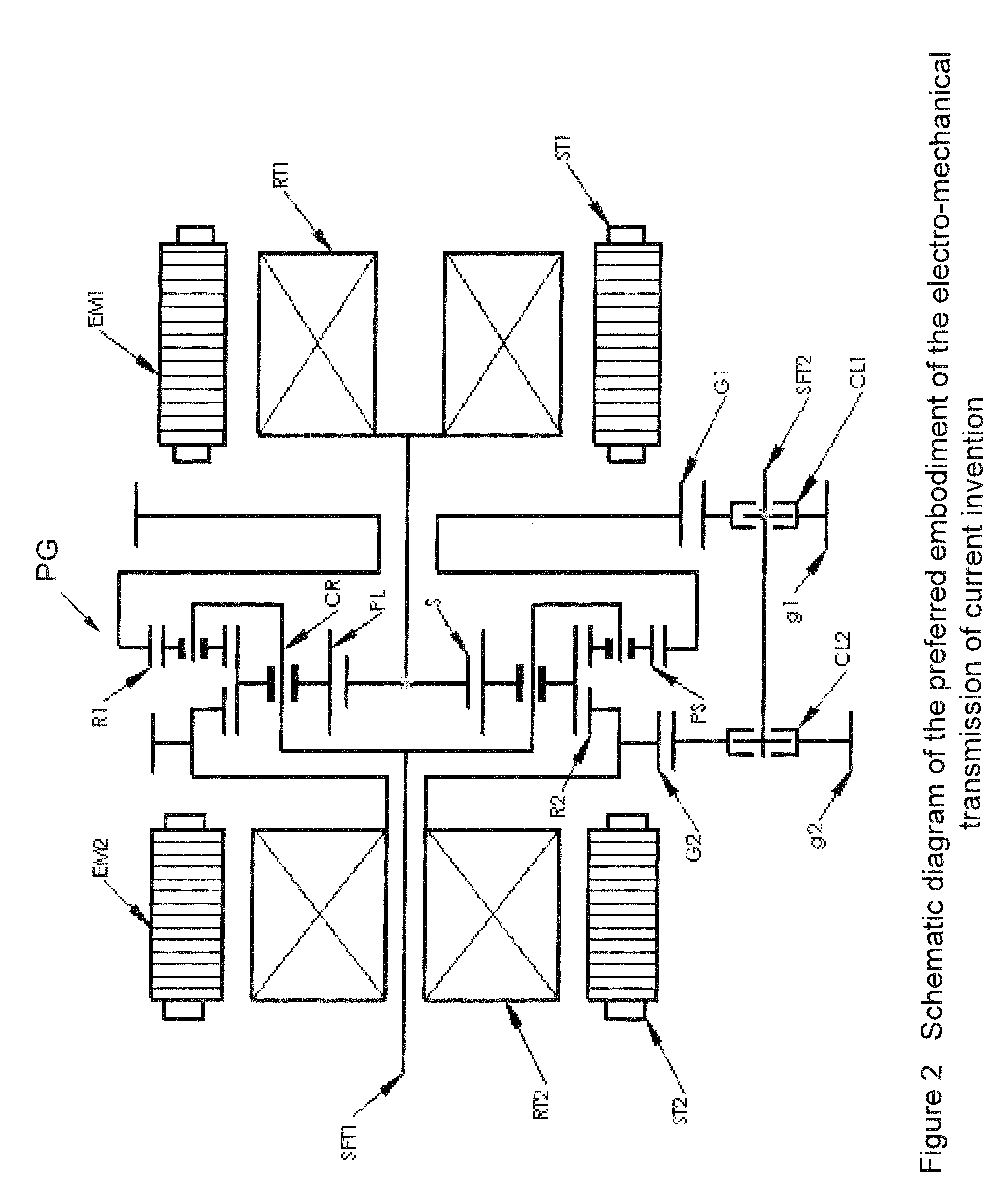

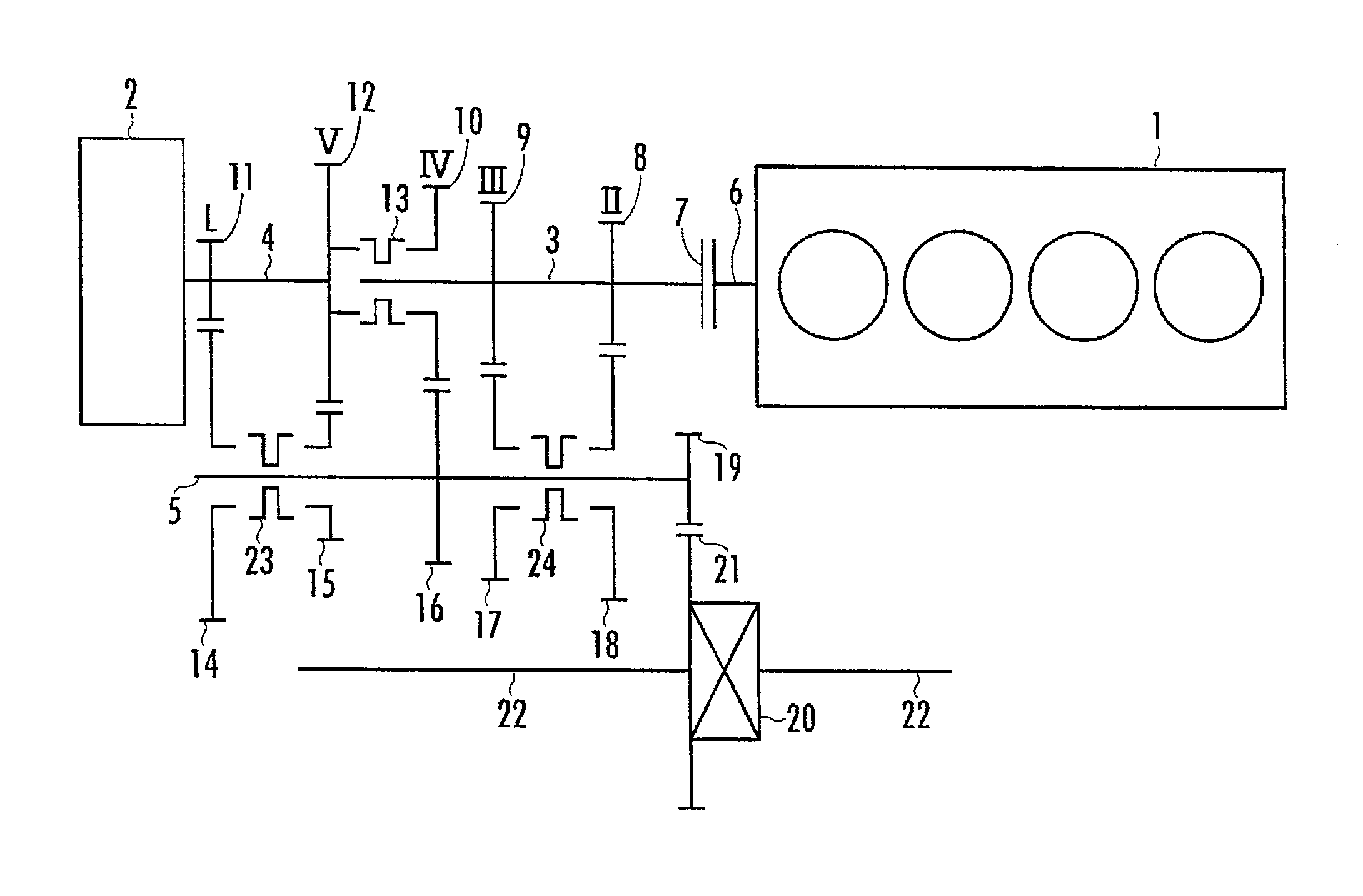

Two mode electro-mechanical transmission and control

ActiveUS20090209381A1Improve efficiencyWide range of speed ratioHybrid vehiclesDigital data processing detailsPower splitDifferential signaling

A two mode power-split electric hybrid system and a method of control said hybrid system. The hybrid system is comprised of an engine, a transmission, an energy storage device and a control system for effecting said control method. Said transmission is a reconfigurable power split system, comprising a power-splitting device and an output power path selecting device. The power splitting device includes a compound planetary gear system and two electric machines which form a local series electric hybrid system. Said transmission regulates the output power state of said hybrid system by controlling power flow within said local series hybrid system. The hybrid system provides at least two operating mode, an output power split mode and a compound power split mode. Said control system includes multiple controllers and control modules. In accordance with the operating conditions of the hybrid system, said control system computes and sets system power requirement, allocates ob board power resources and sets engine operating speed and torque. In addition, said control system sets the operation mode of the transmission and controls the engine speed by adjusting operating torque of electric machines, based on the differential signal between reference engine speed and actual engine speed. Said control system is also capable of controlling engine torque through engine controller.

Owner:SHANDONG LIANCHENG GREENMAX TECH

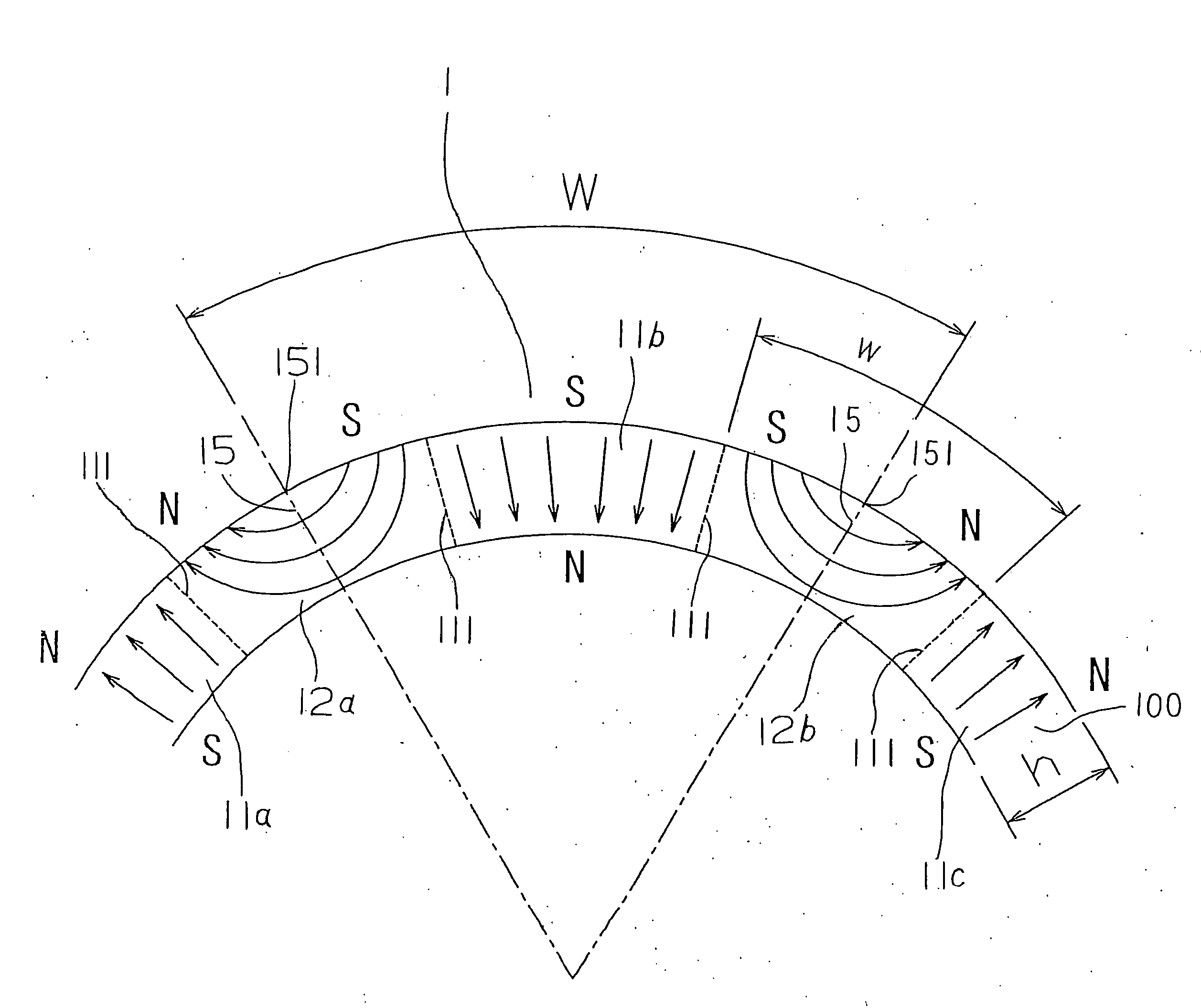

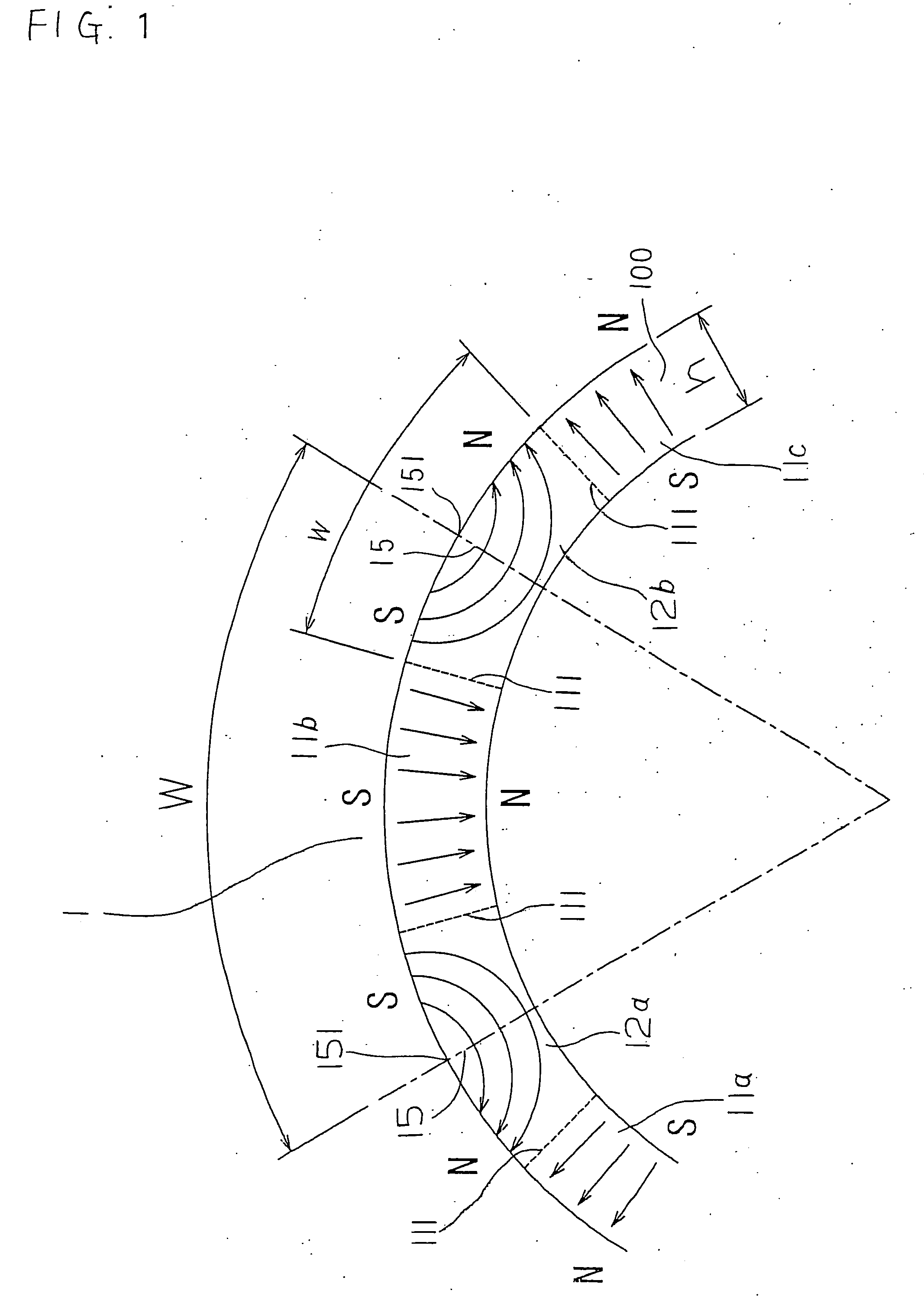

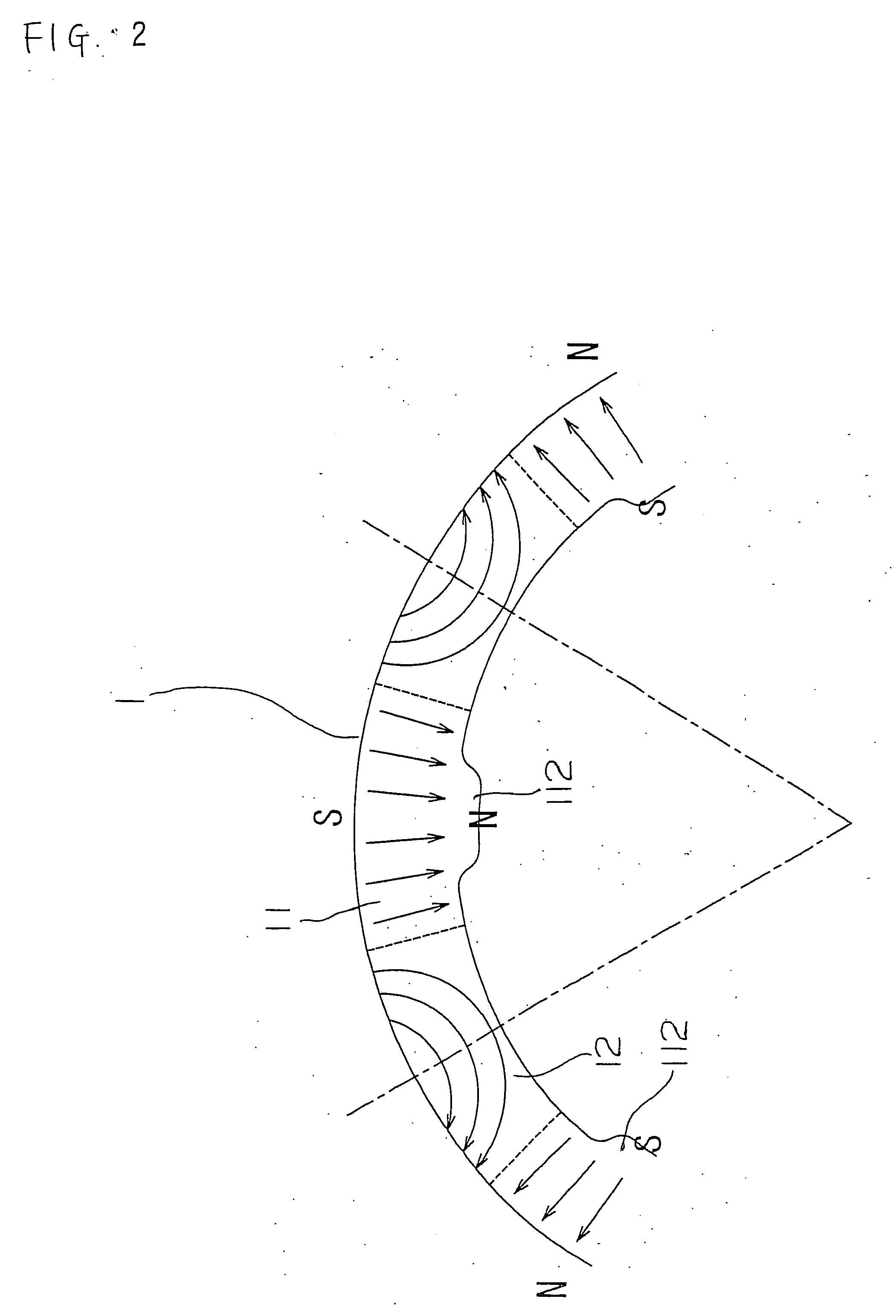

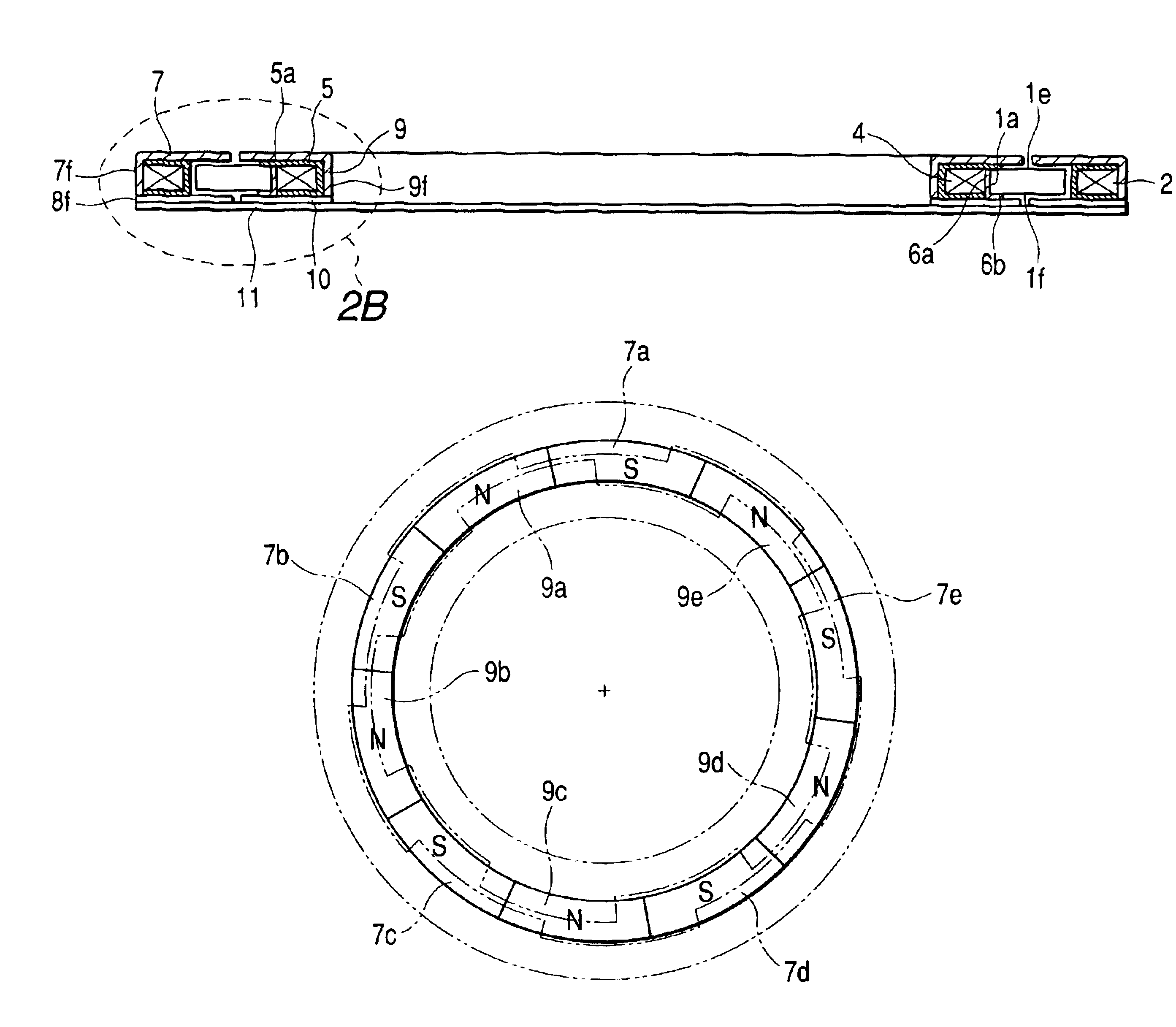

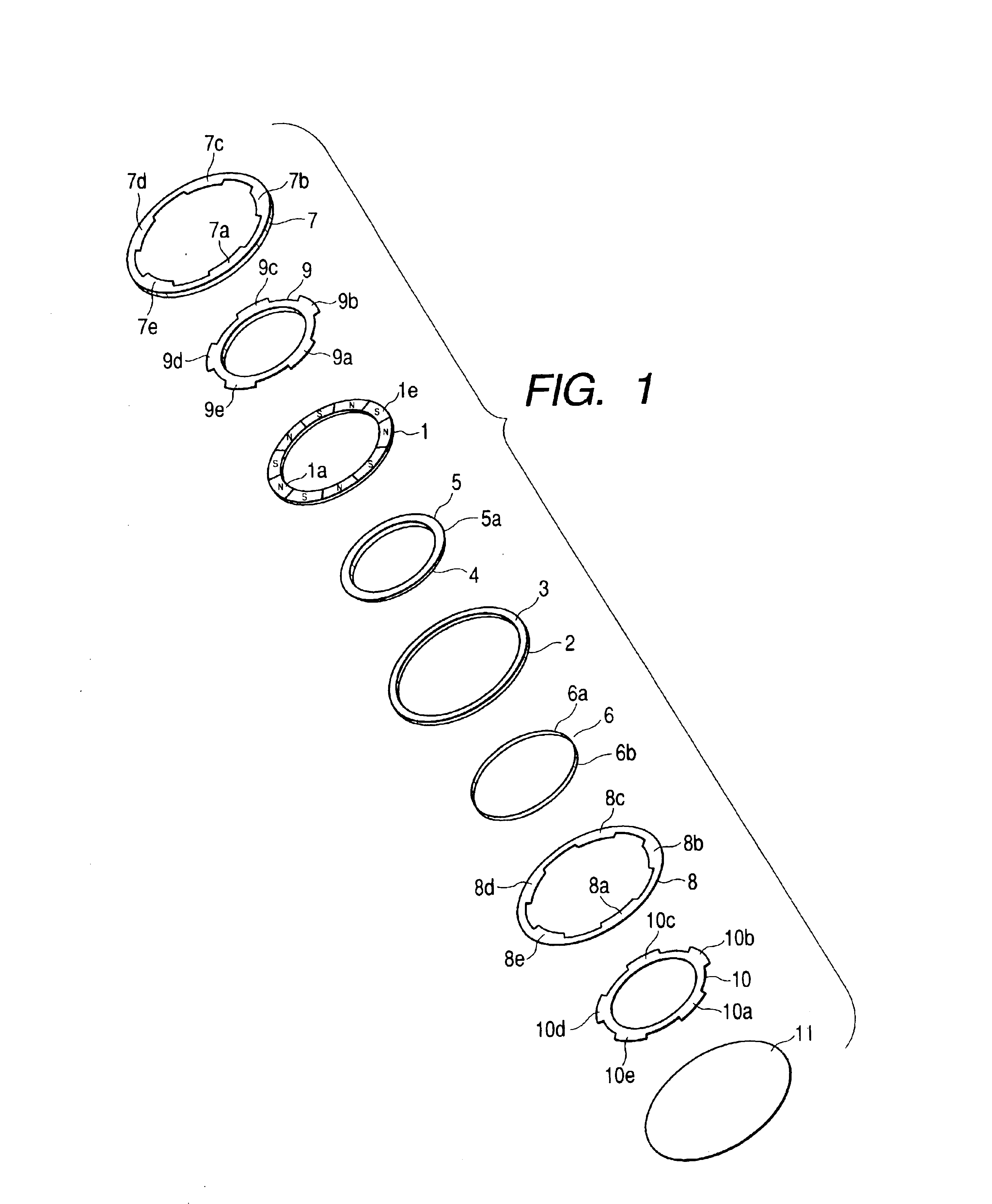

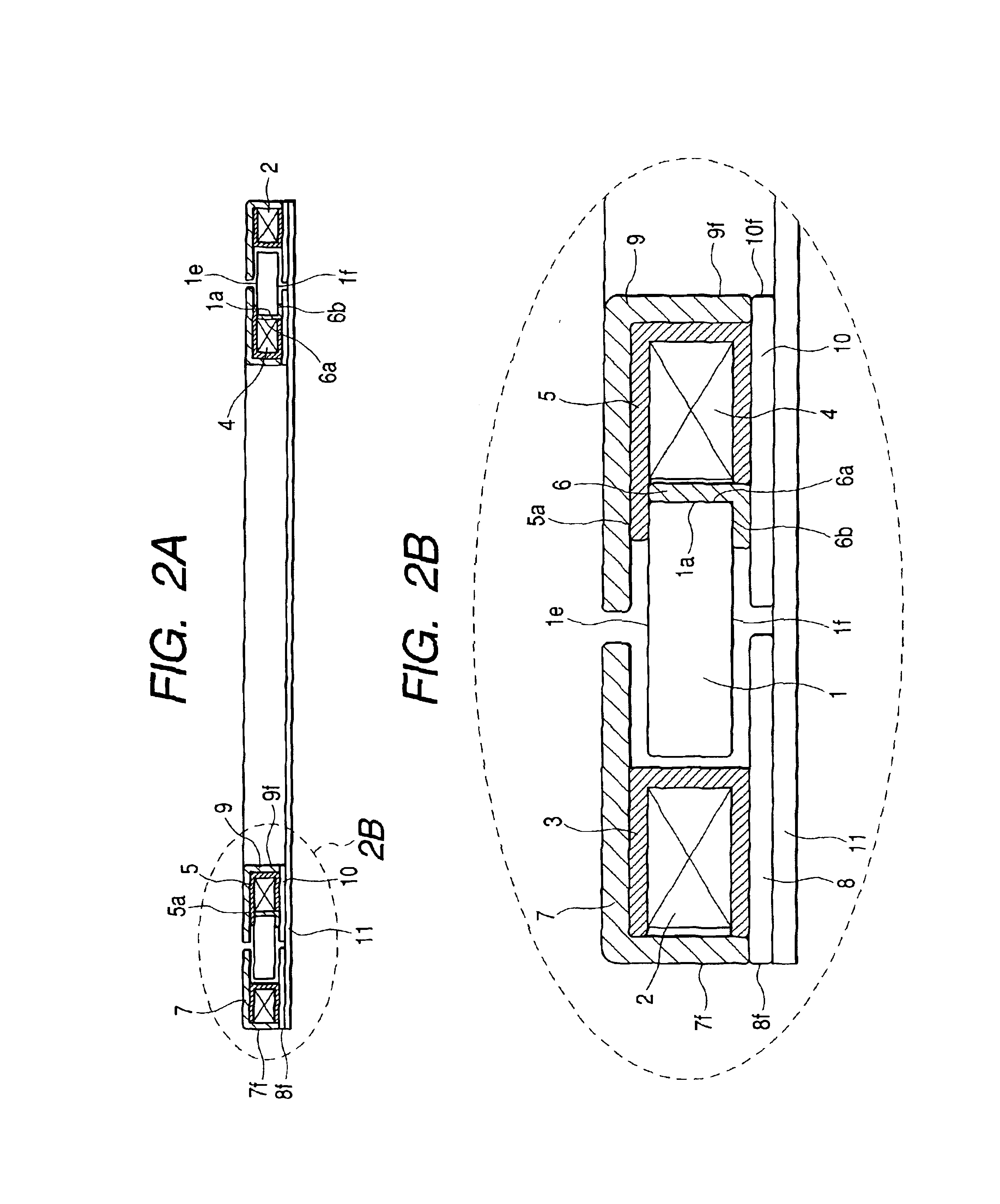

Thin hybrid magnetization type ring magnet, yoke-equipped thin hybrid magnetization type ring magnet, and brush-less motor

ActiveUS20060113857A1Decrease in cogging torqueIncrease in torque per unit volume of magnetMagnetic circuit rotating partsPermanent magnetsBrushless motorsMagnetization

The present invention provides miniaturization of brushless motors and brush motors used in electric devices, a ring magnet which simultaneously achieves both high torque and a reduction in cogging torque, a ring magnet with yoke, and a brushless motor. The thin hybrid magnetized ring magnet of the present invention is structured of, in a ring magnet comprised of a plurality of magnetic poles, a radially magnetized main pole and an interface for which the interface of the adjoining main pole is polar anisotropic. When the thin hybrid magnetized ring magnet structured in this manner is applied to a brushless motor, in the case of radial magnetizing, the abrupt change in magnetic flux of the interface between the magnetic poles becomes smooth and cogging torque is greatly reduced due to polar anisotropic magnetization of the interface. At the same time, by polar anisotropically magnetizing the interface between the magnetic poles, magnetic flux is concentrated on the radially magnetized main pole, and in comparison to only radial magnetization, maximum surface magnetic flux improves and it is possible to attain high torque.

Owner:AICHI STEEL

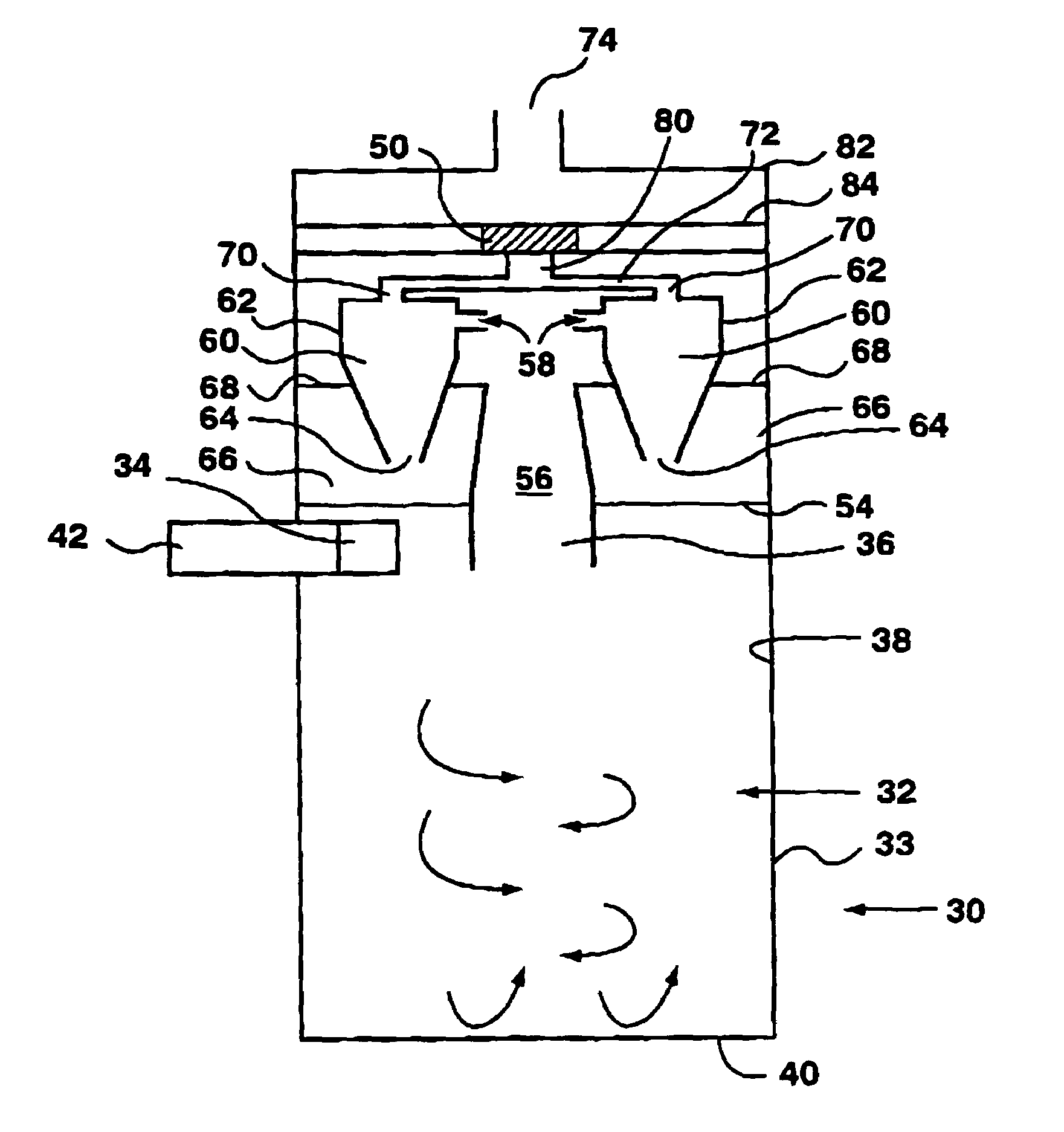

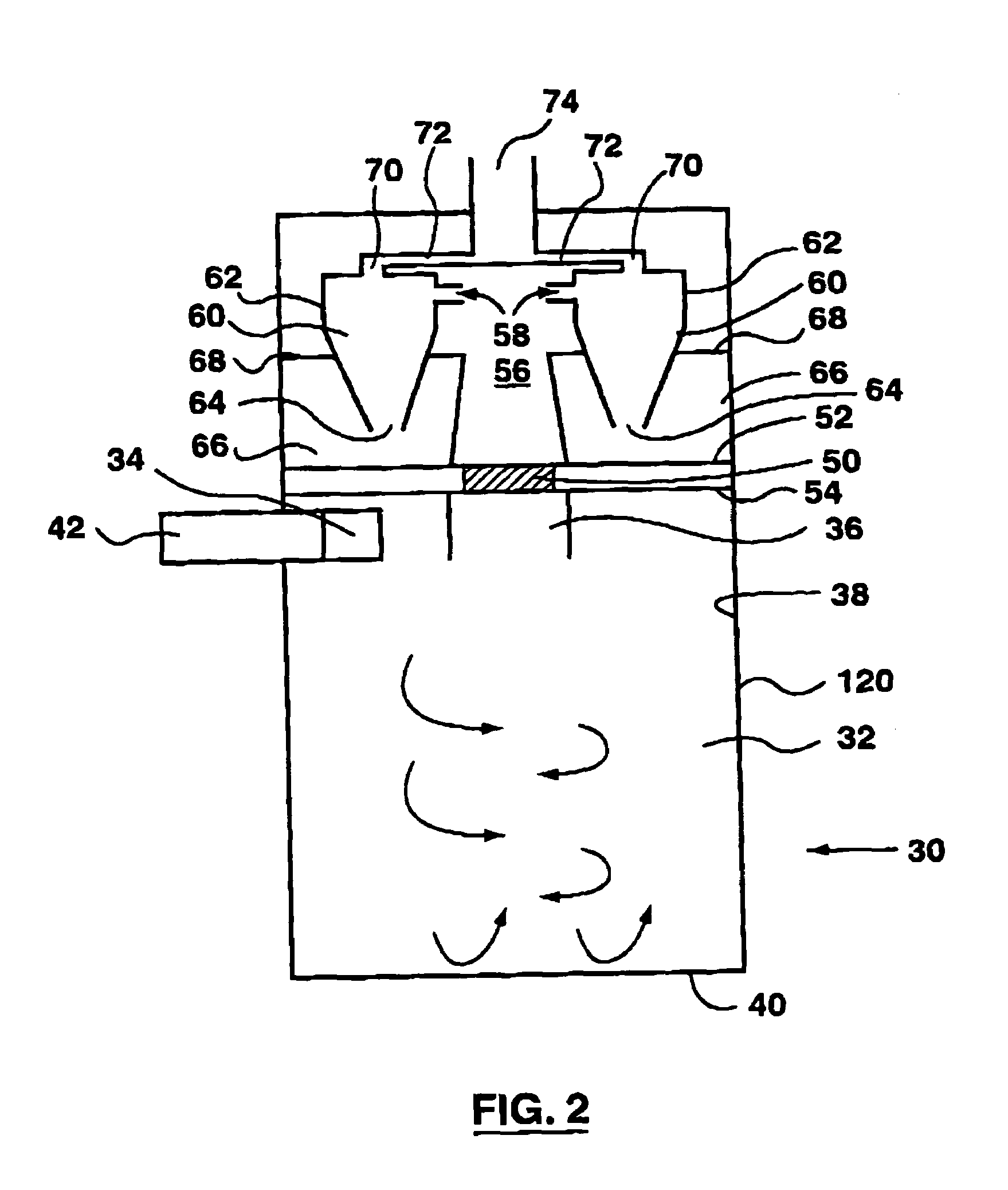

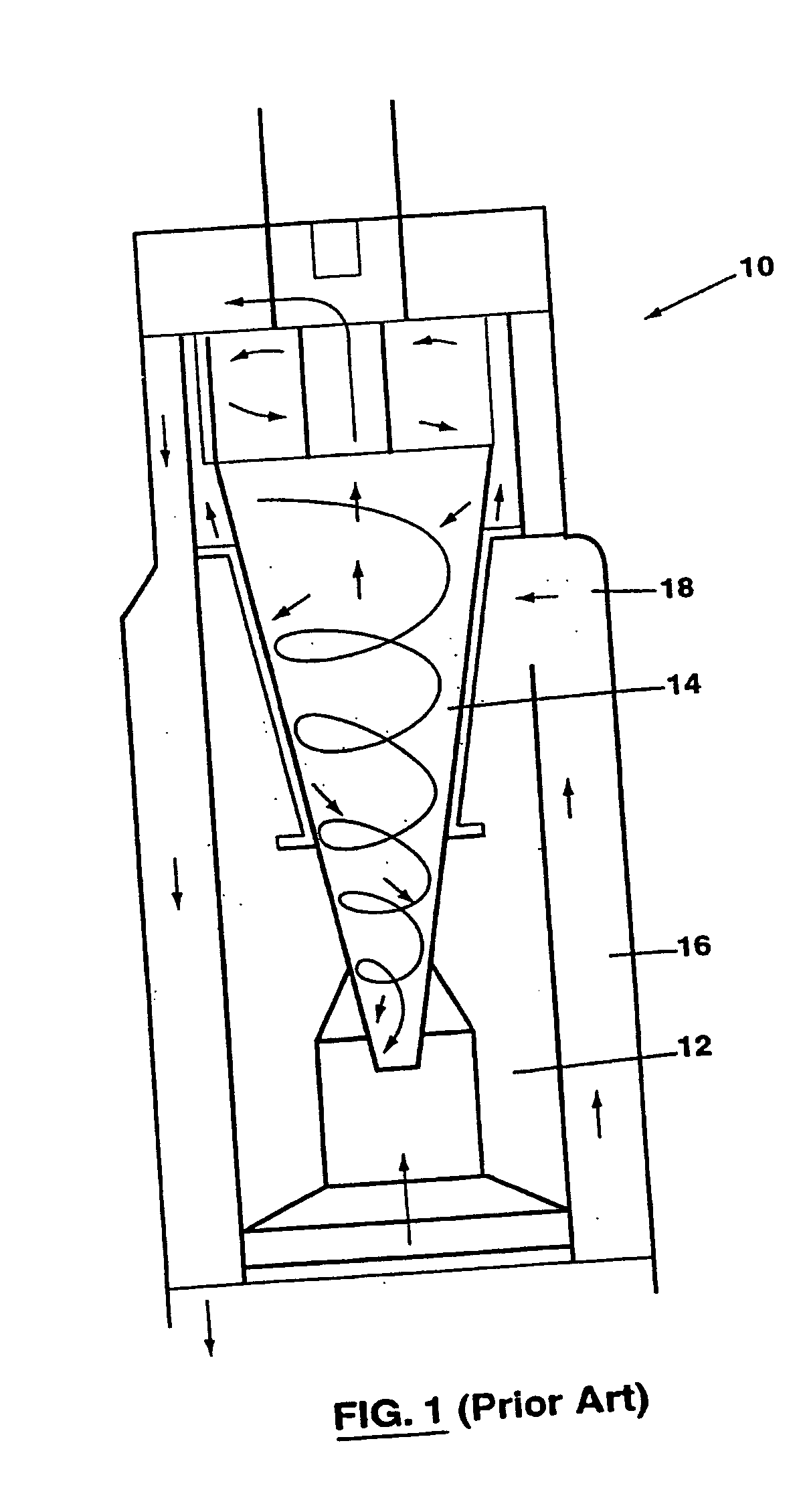

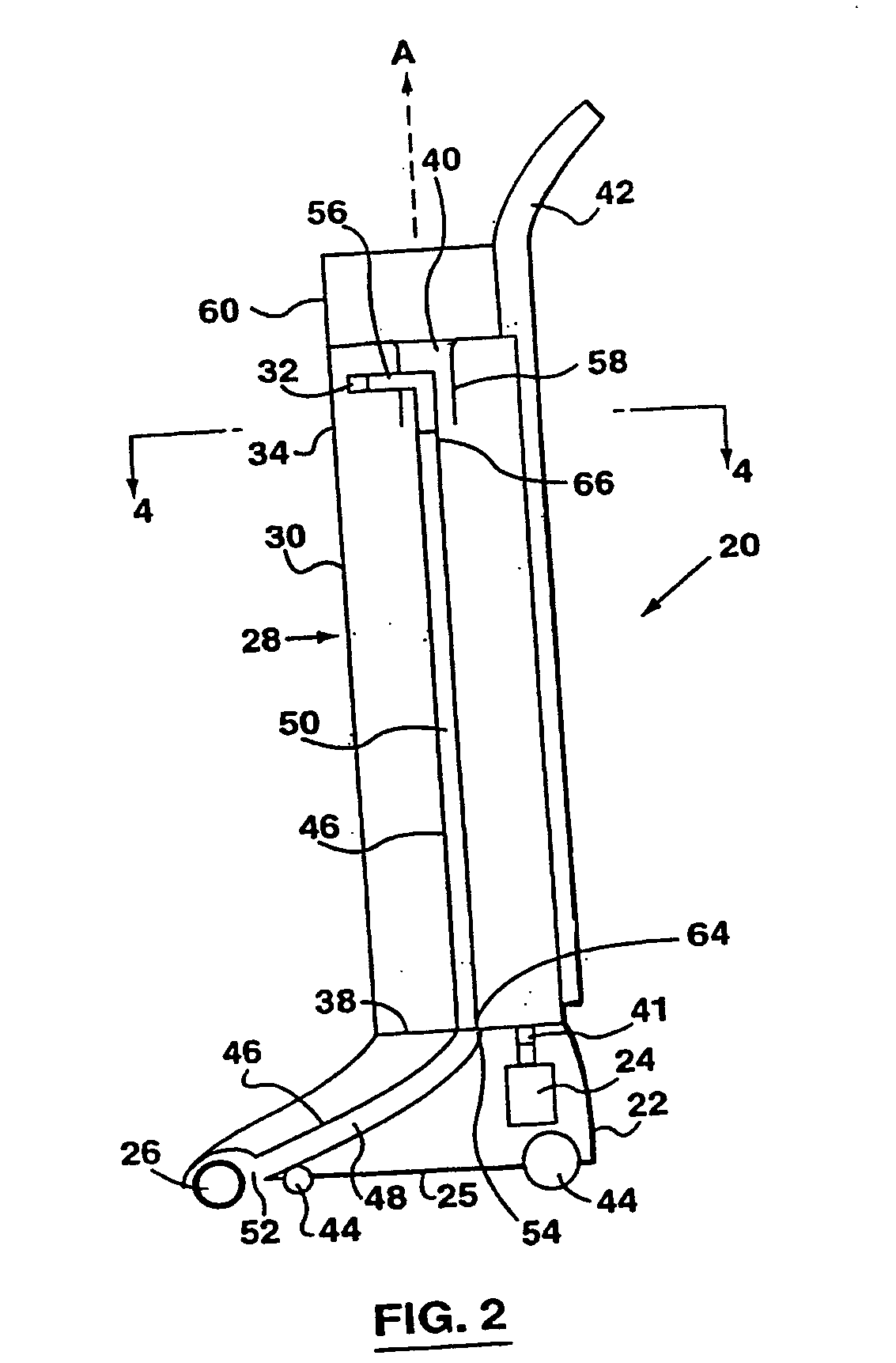

Vacuum cleaner

InactiveUS7179314B2Improve the level ofLarge resistanceCleaning filter meansCombination devicesCyclonic separationFiltration

A method for filtering a dirty air stream in a vacuum cleaner to obtain a clean air stream comprises subjecting the dirty air stream to a first cyclonic separation stage to obtain a partially cleaned air stream and subjecting the partially cleaned air stream to an electronic filtration stage and optionally a second cyclonic separation stage to obtain the clean air stream. The electronic filtration stage is optionally removable with a cyclonic cleaning stage from the vacuum cleaner. The electronic filtration stage is optionally an electrostatic precipitator which utilizes air flow through the vacuum cleaner to generate the voltage used by the electrostatic precipitator.

Owner:POLAR LIGHT

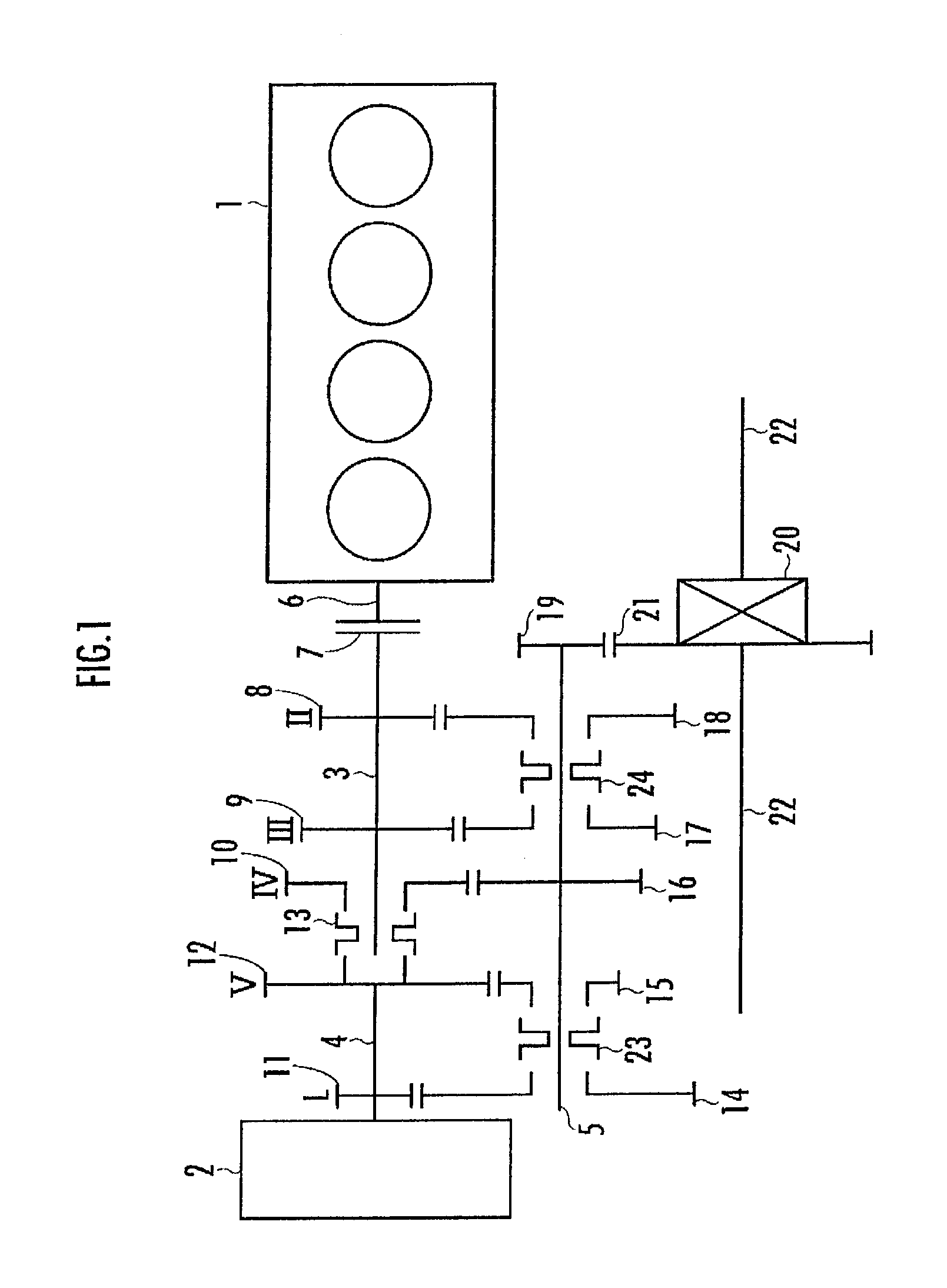

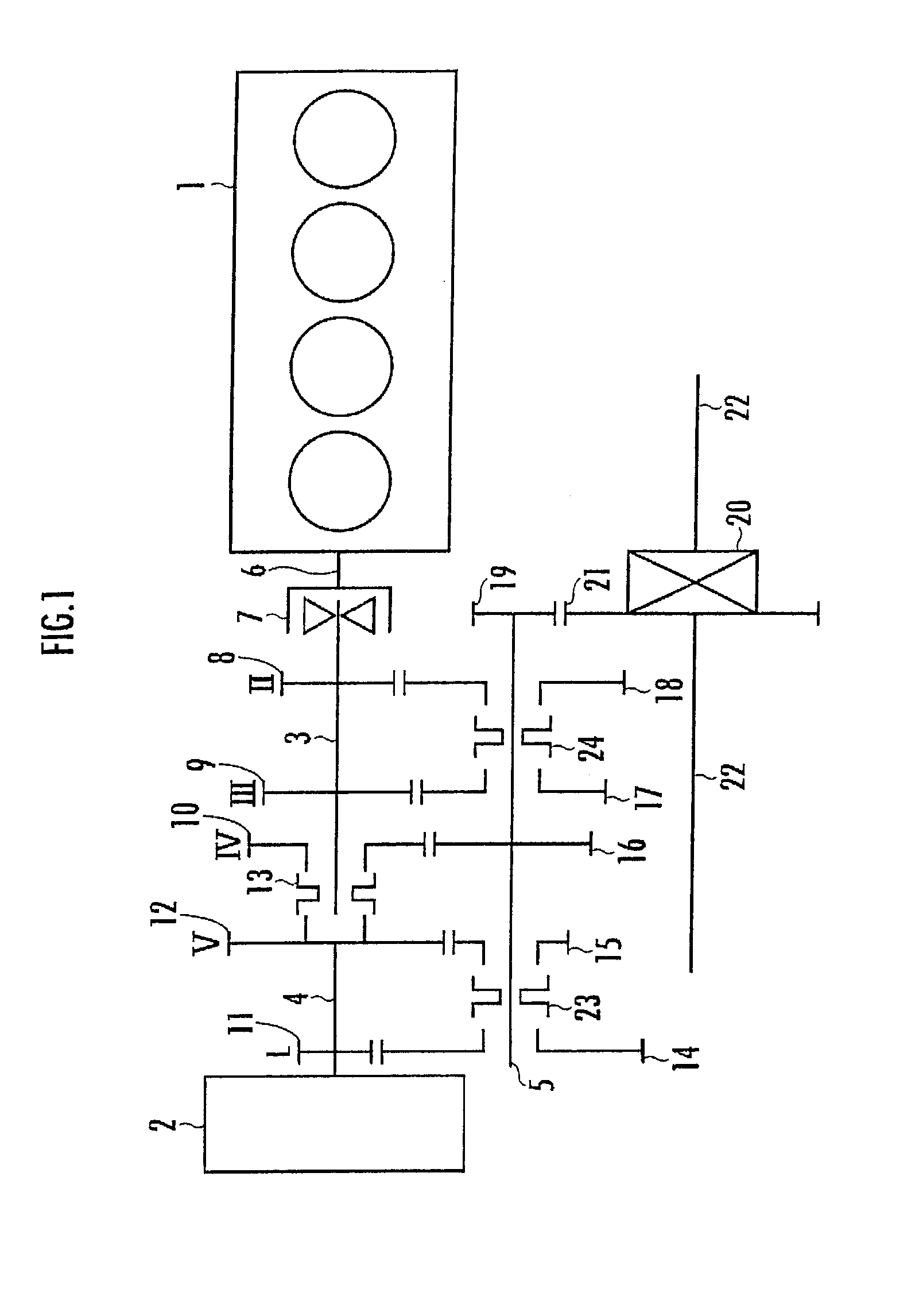

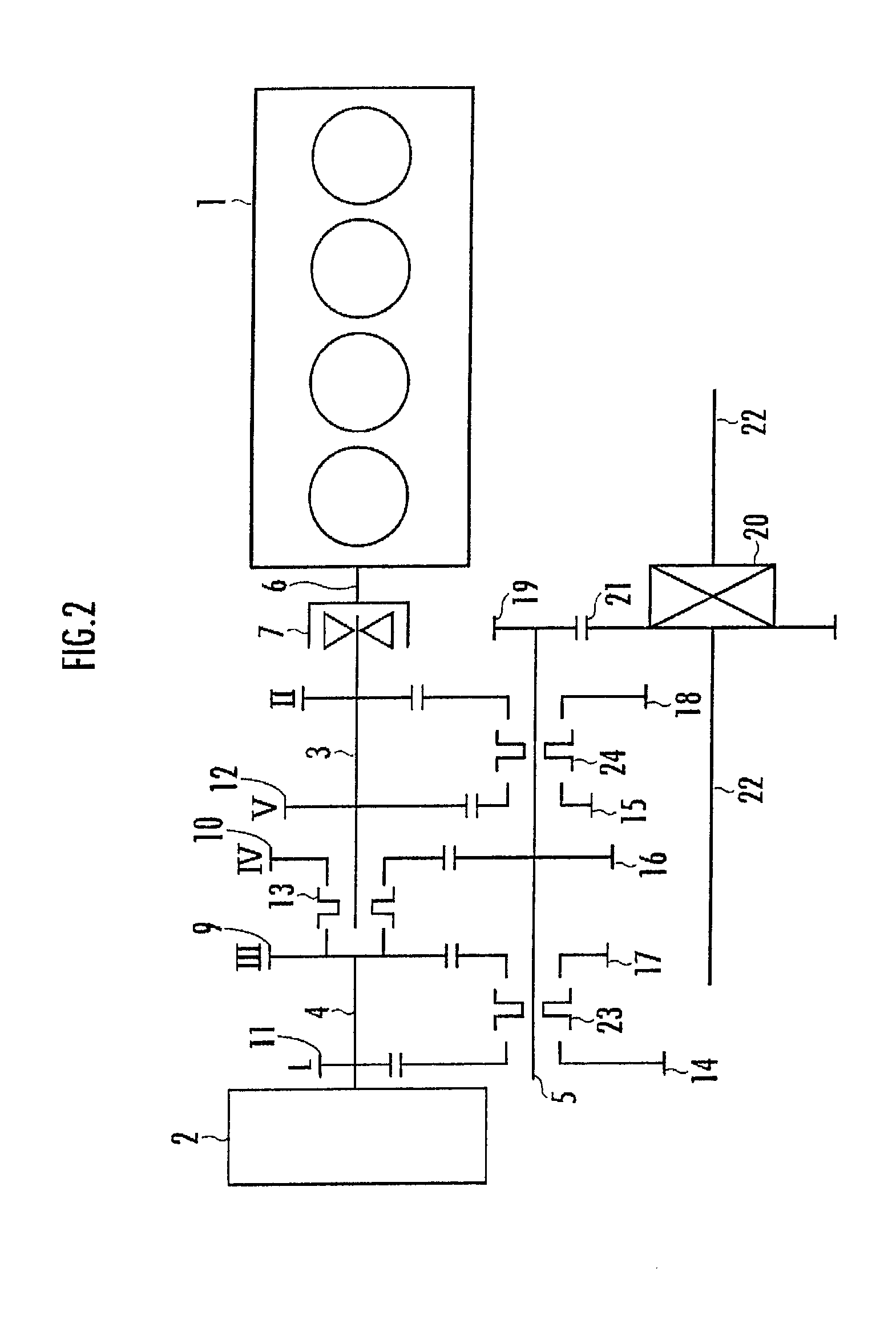

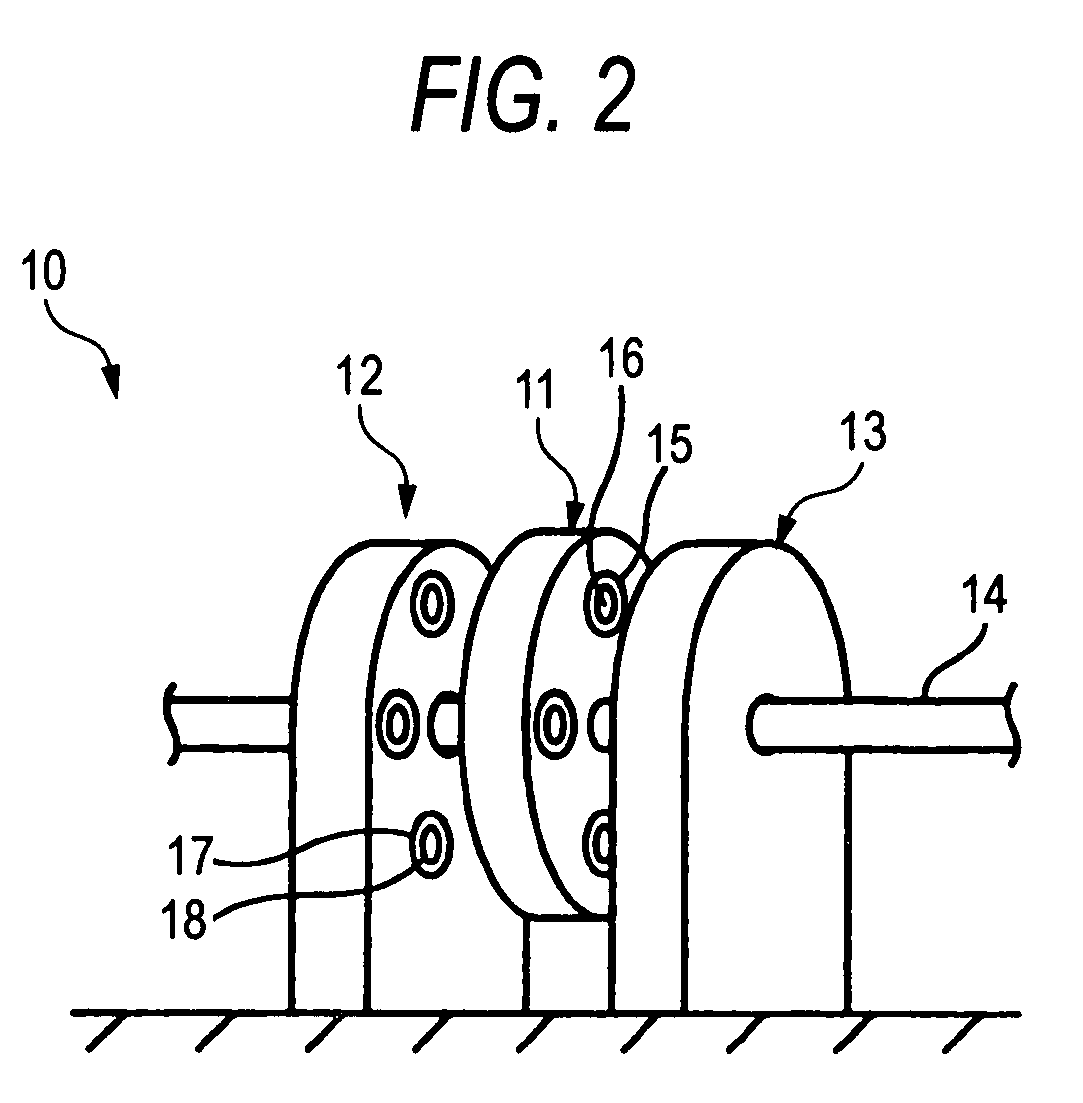

Power transmission device for hybrid vehicle

InactiveUS20110239820A1Reduce motor sizeEasy constructionSpeed controllerGearingReduced sizeInternal combustion engine

Provided is a lightweight, compact power transmission device for a hybrid vehicle which permits a simplified construction of a speed changing unit that establishes a plurality of gear shift stages and a reduced size of a motor. The power transmission device is provided with a first speed changing unit which has a first input shaft 3 connected to a power shaft 6 of an internal combustion engine 1 and which establishes a plurality of gear shift stages, and a second speed changing unit which has a second input shaft 4 connected to a power shaft of a motor 2 and which establishes a plurality of gear shift stages which is different from that of the first speed changing unit. The power transmission device is provided with a connecting unit 13 which disconnectably connects the first input shaft 3 and the second input shaft 4.

Owner:HONDA MOTOR CO LTD

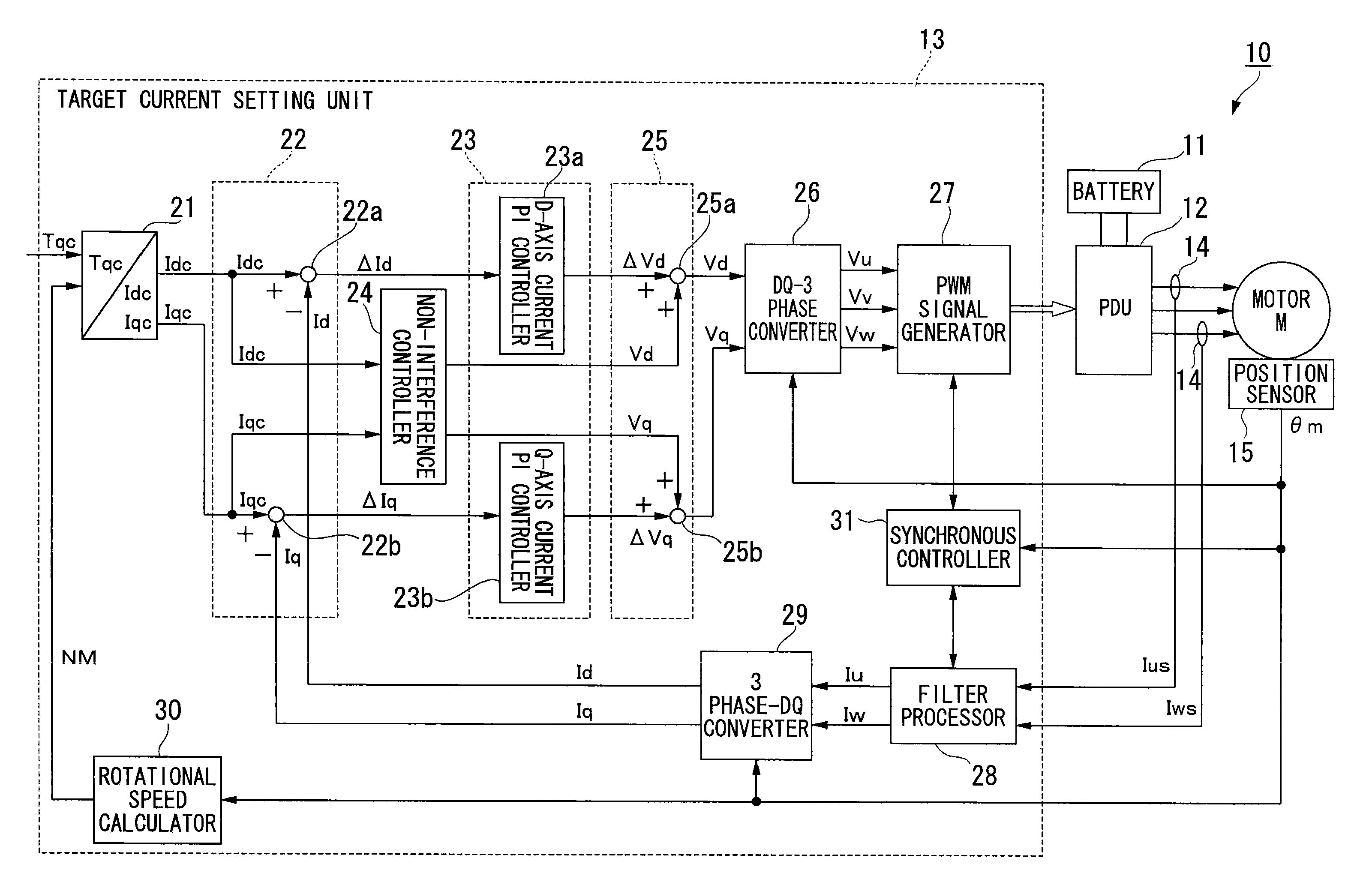

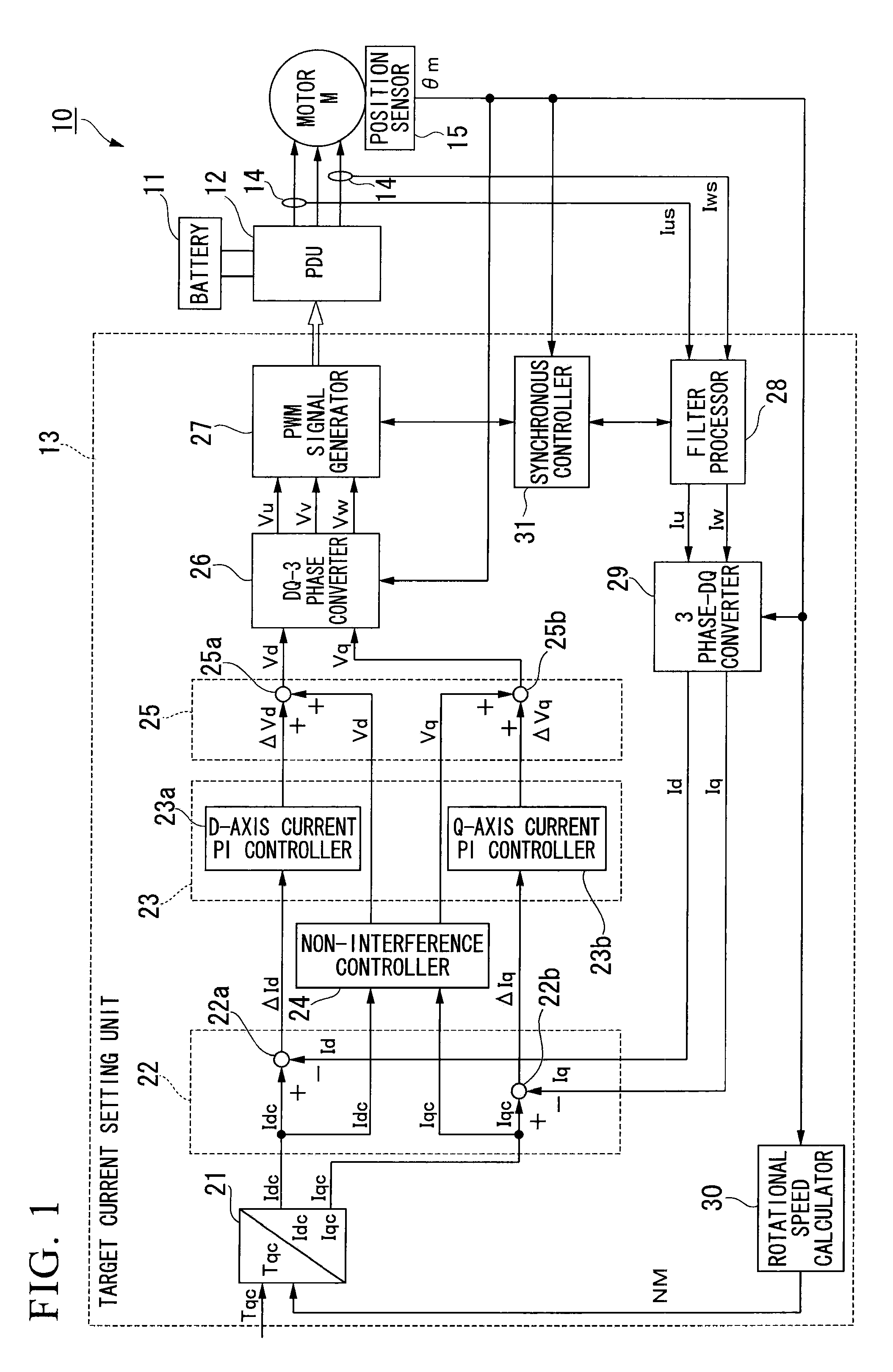

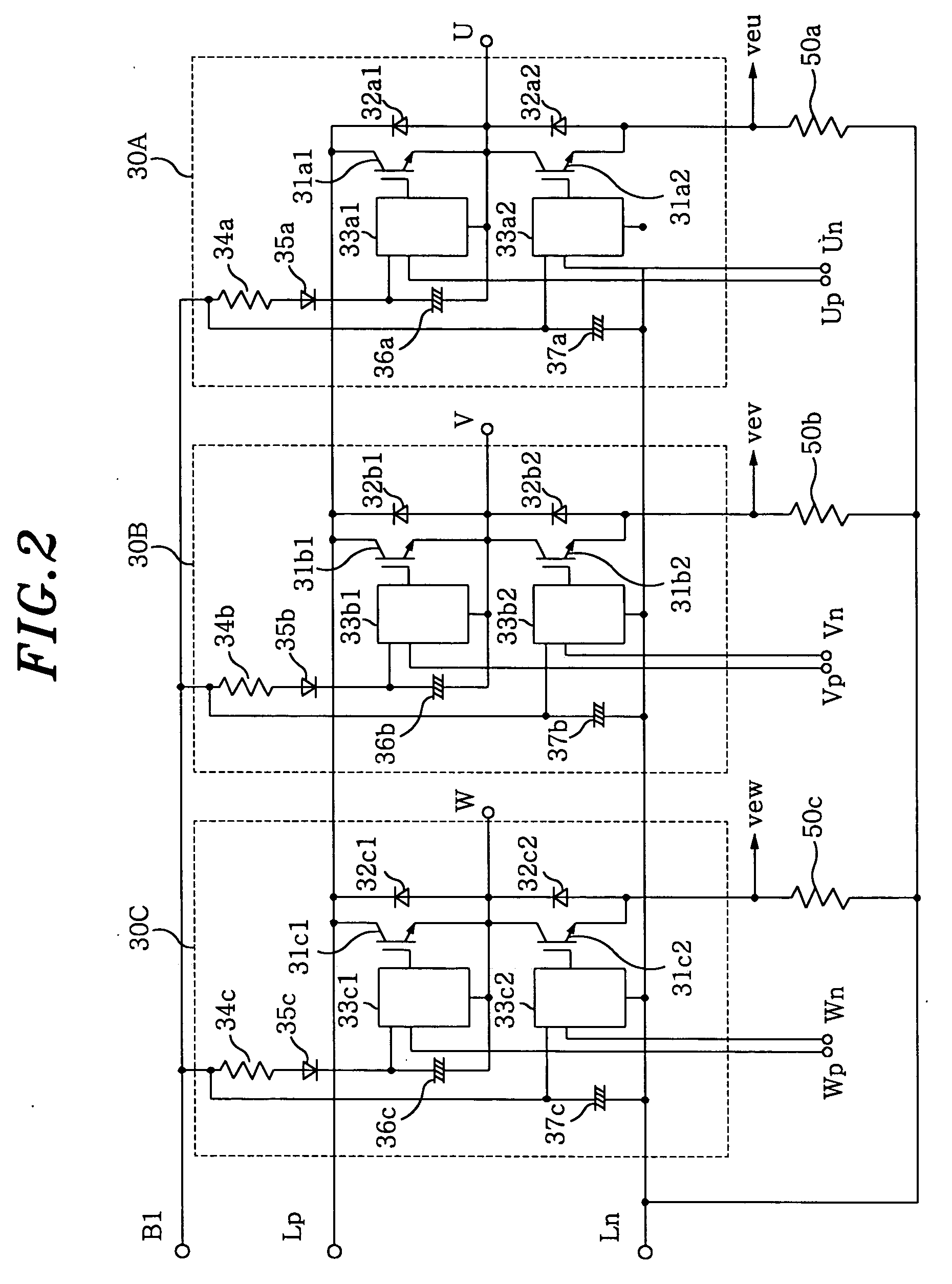

Motor control apparatus

InactiveUS20080265831A1Excessive execution of processingAvoid oscillationAC motor controlVector control systemsPhase differenceCarrier signal

A motor control apparatus provided with an inverter for successively commutating the current to a motor using a PWM signal; a PWM signal generating device for generating the PWM signal using a carrier signal; a rotational state quantity sensor for detecting a rotational state quantity; a phase difference detecting device for detecting the phase difference between the carrier signal and the rotational period based on the rotational state quantity; a frequency setting device for setting a frequency of the carrier signal to a value in accordance with a multiplier for one period in terms of electrical angle of the rotational period of the motor, when the rotational frequency is equal to or greater than a specified frequency and the phase difference is equal to or less than a specified value; and a synchronizing device for synchronizing a control period of the carrier signal to the rotational period.

Owner:HONDA MOTOR CO LTD

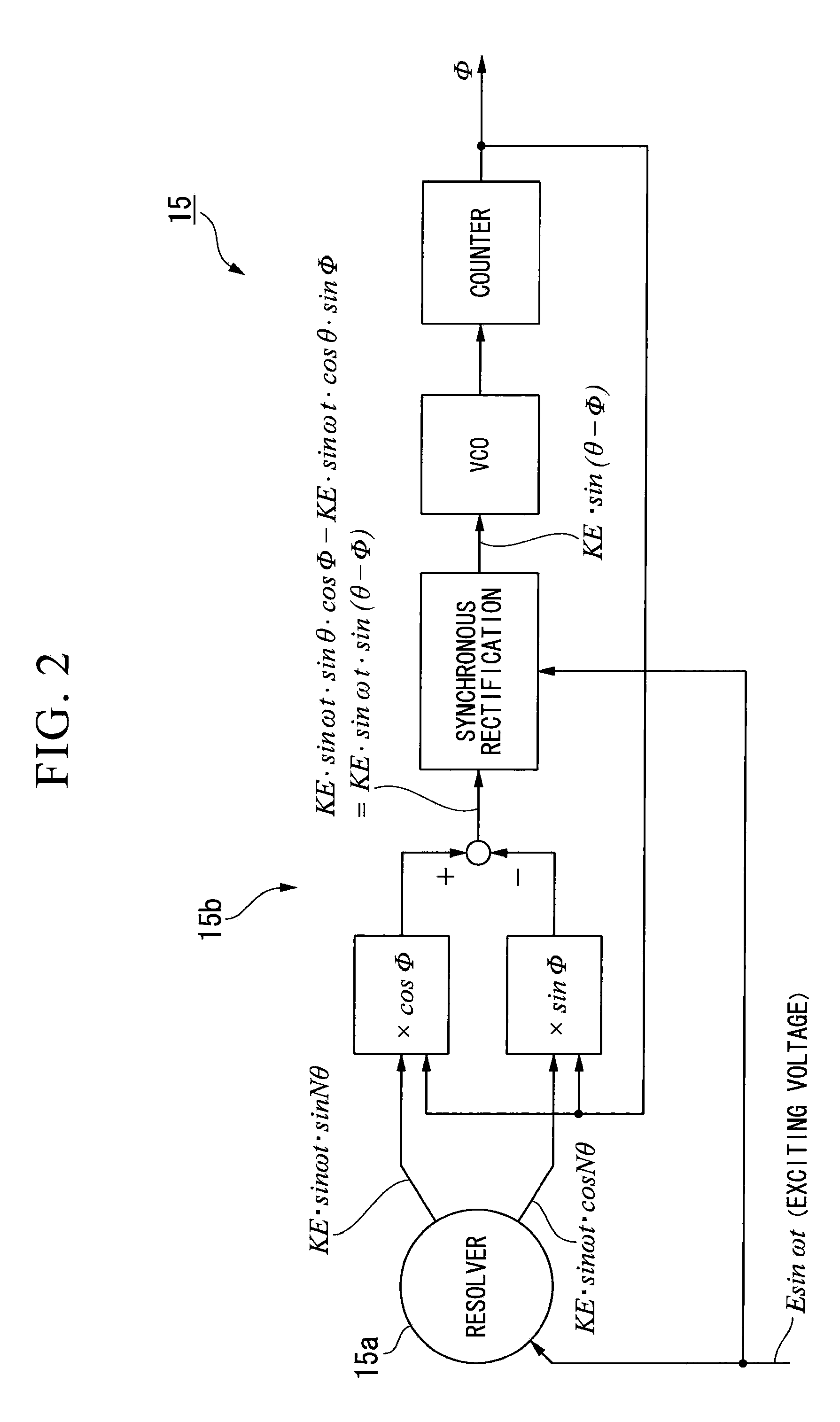

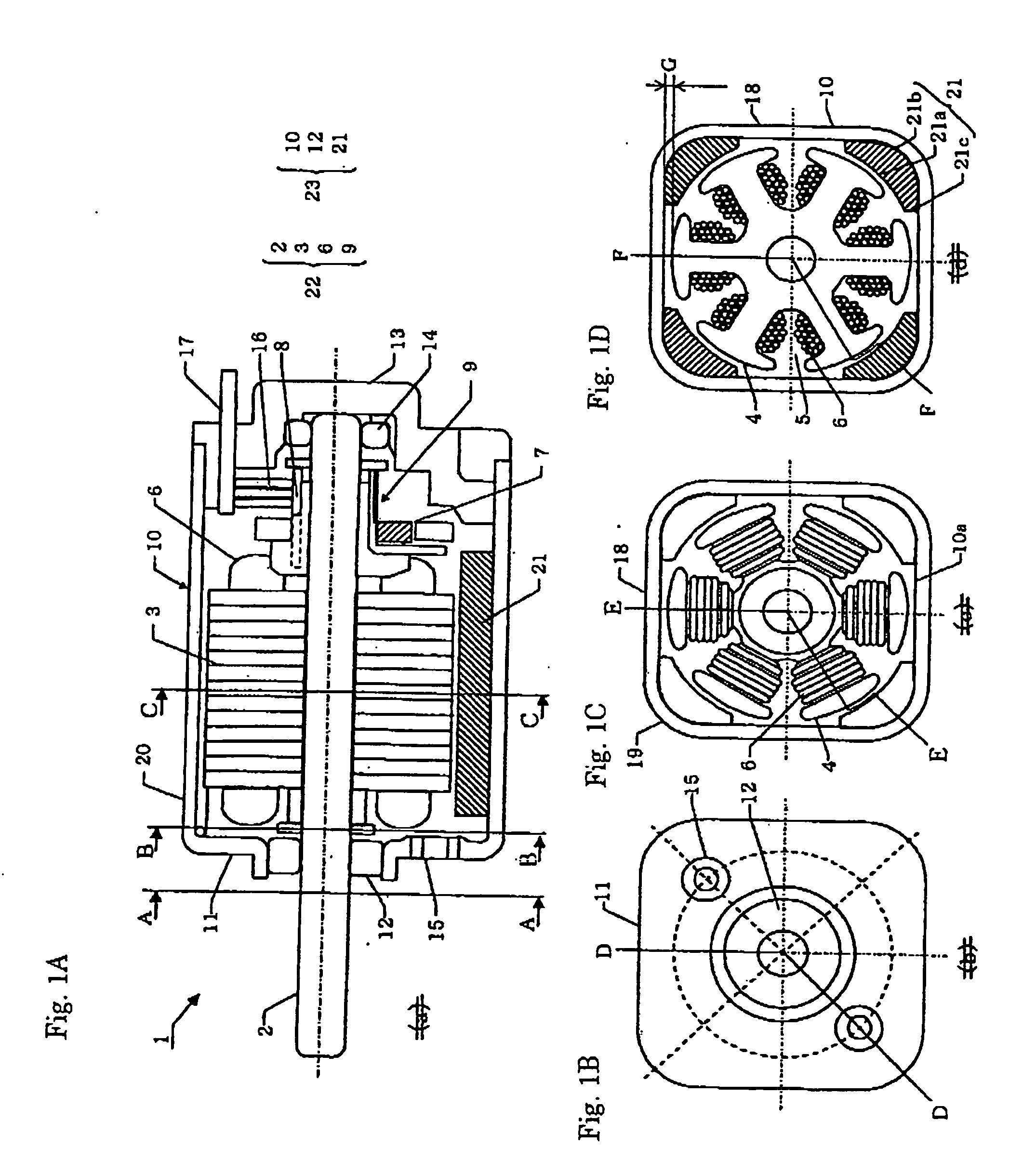

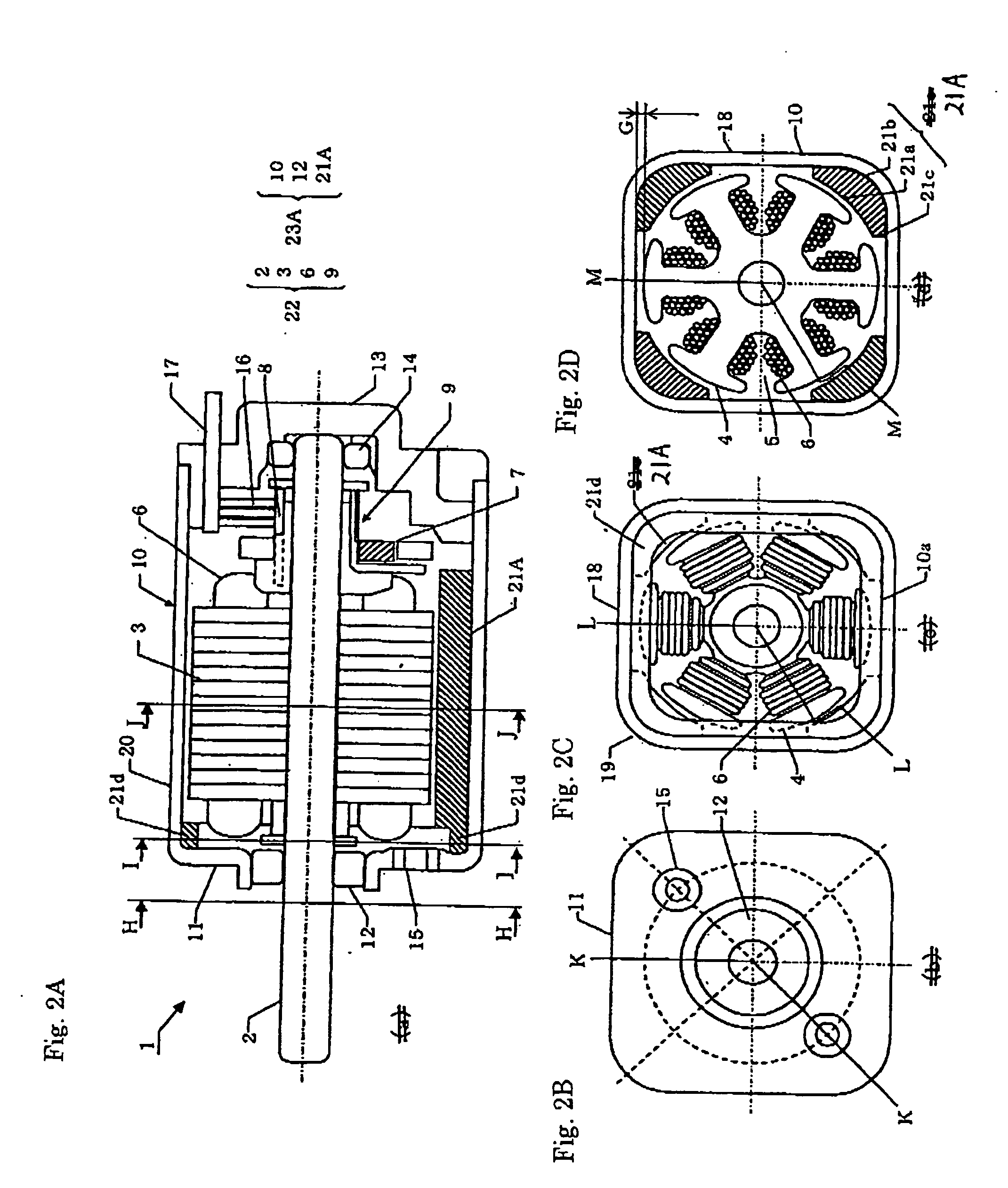

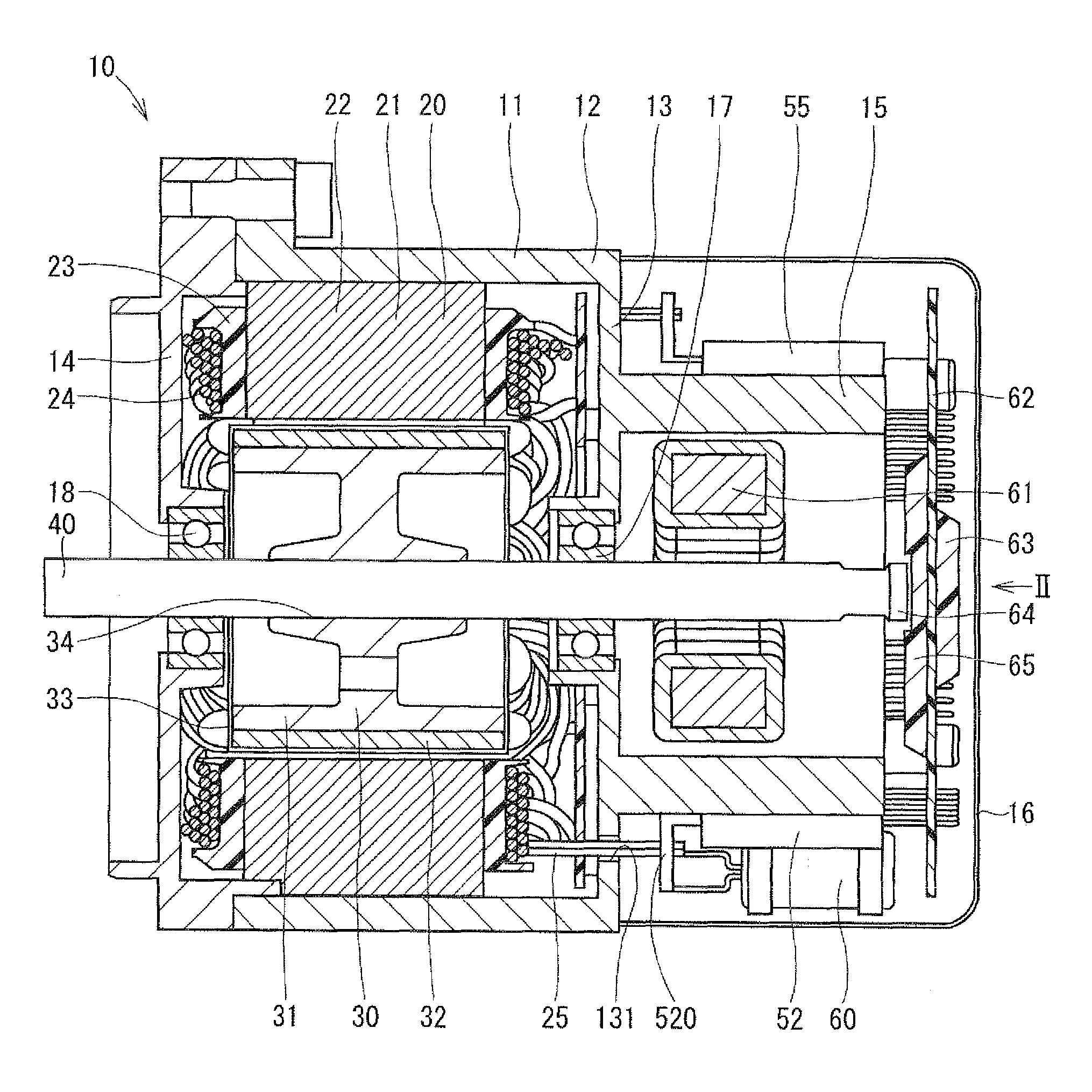

Brushless motor

InactiveUS7652402B2Reduce space volumeSpeed up the flowWindingsStructural associationBrushless motorsMagnetic poles

Owner:MABUCHI MOTOR

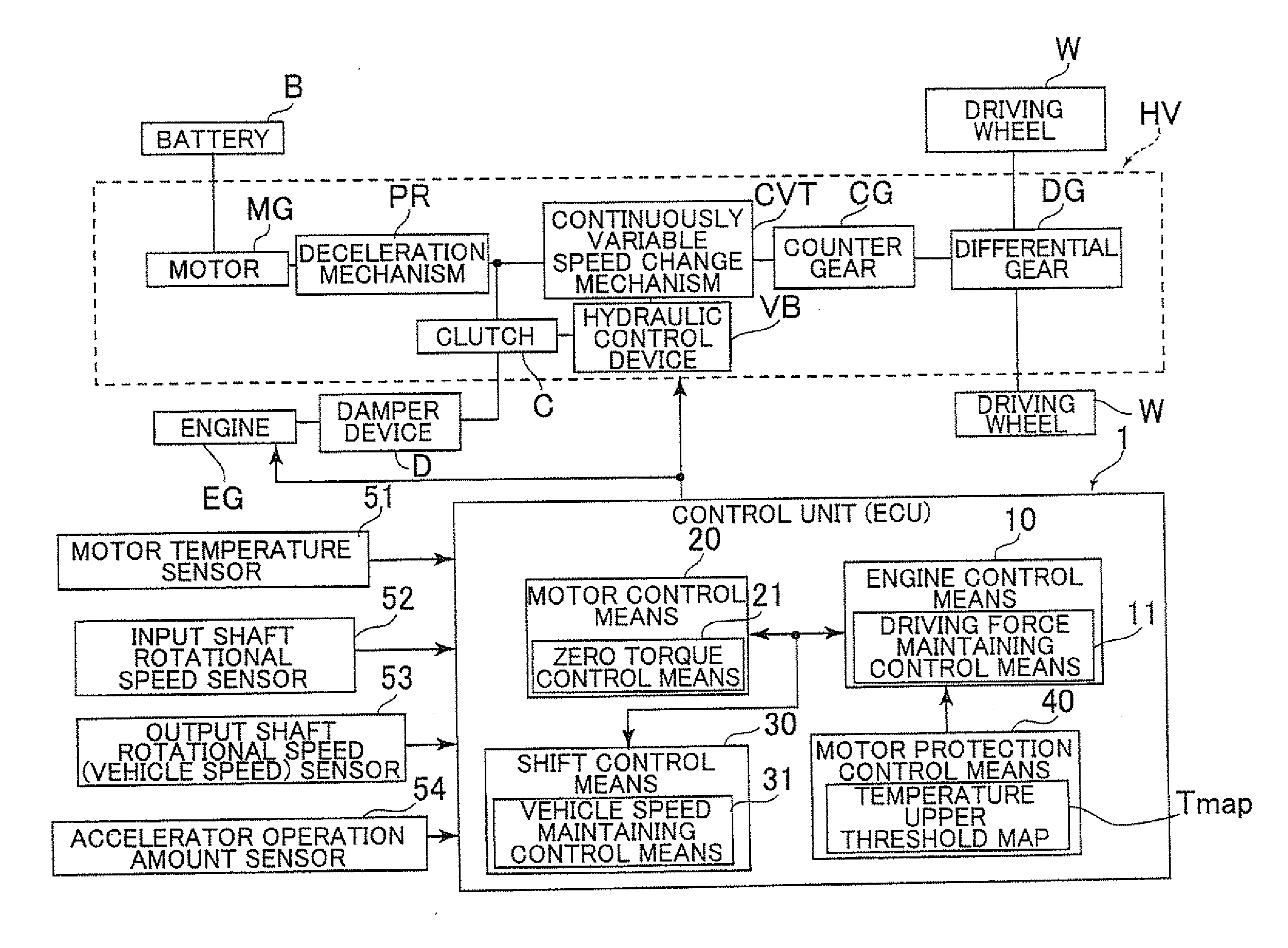

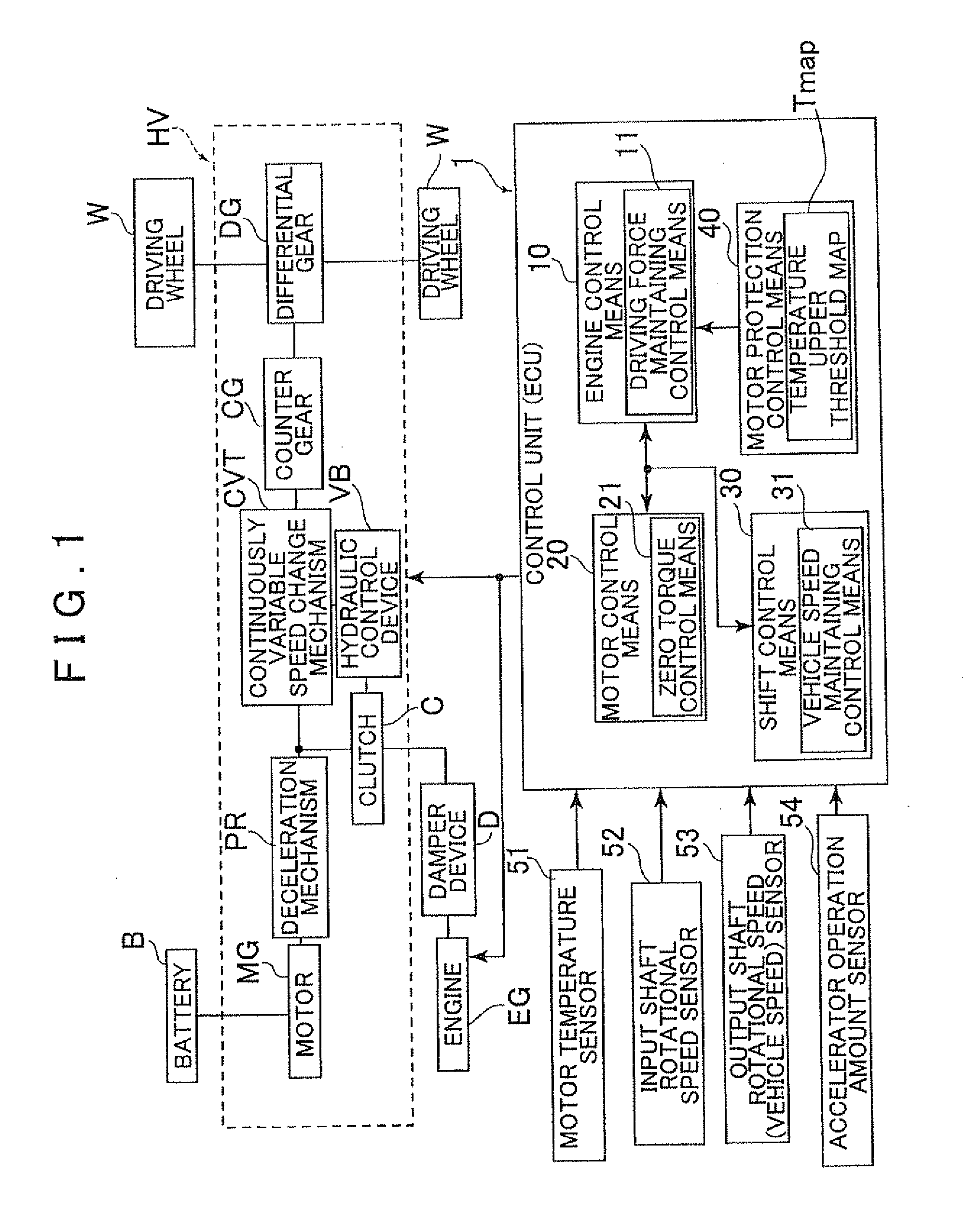

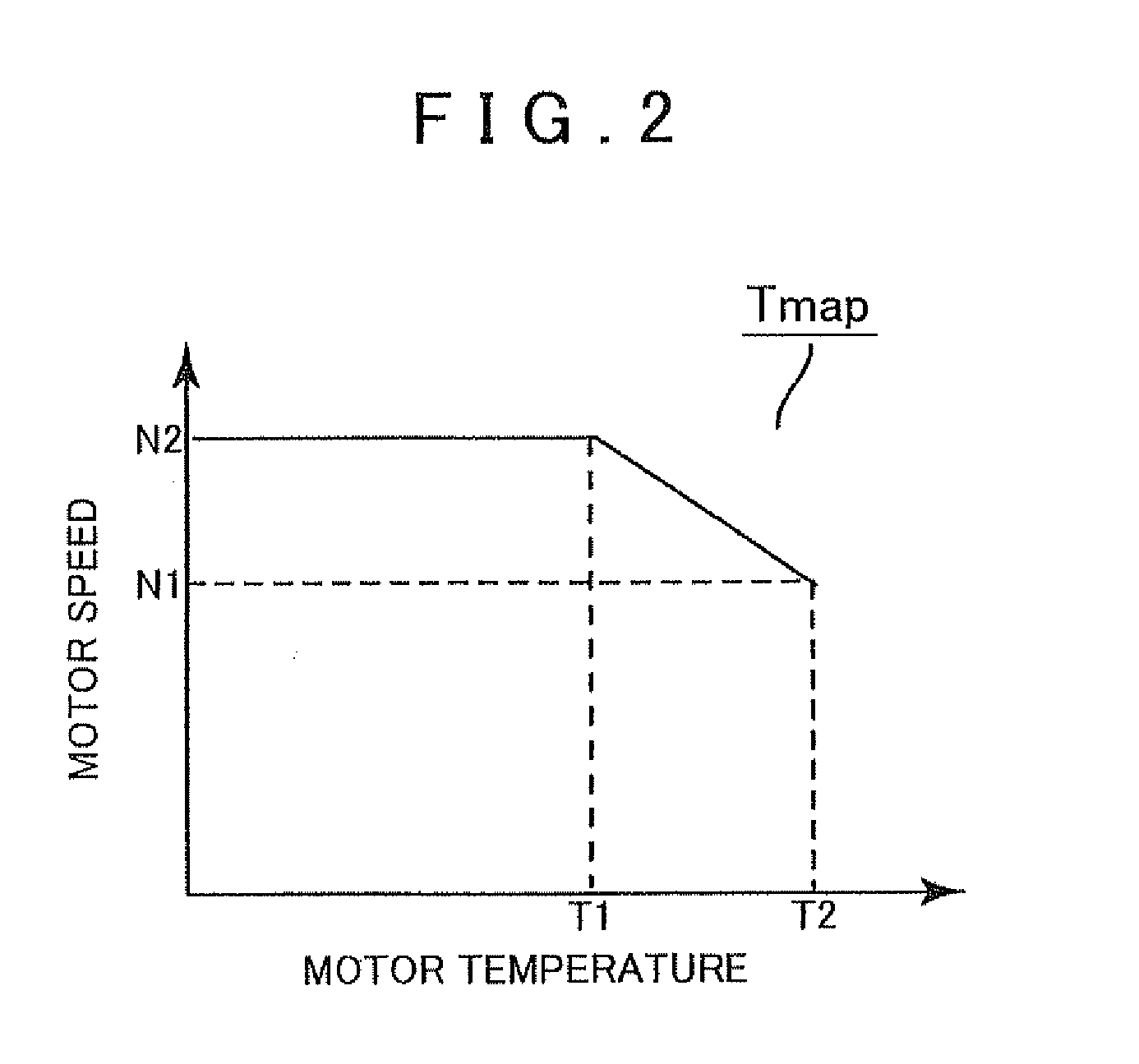

Control device of hybrid vehicle

InactiveUS20110232980A1Compact structureLow costSpeed controllerElectric devicesDrive wheelControl theory

A control device of a hybrid vehicle, configured with an engine; a motor that rotates together with the engine at least during traveling by using a driving force of the engine, and a speed change mechanism that shifts rotation of the engine and the motor to transmit the shifted rotation to a driving wheel. A zero torque control unit controls output torque of the motor to zero torque when a rotational speed of the motor reaches a predetermined rotation speed or more by driving rotation of the engine, and a motor temperature detection unit that detects a temperature of the motor. A motor protection control units that reduces a rotational speed of the engine when the temperature of the motor reaches an upper threshold value or more while the motor is being rotated at the predetermined rotational speed or more by the driving rotation of the engine.

Owner:AISIN AW CO LTD

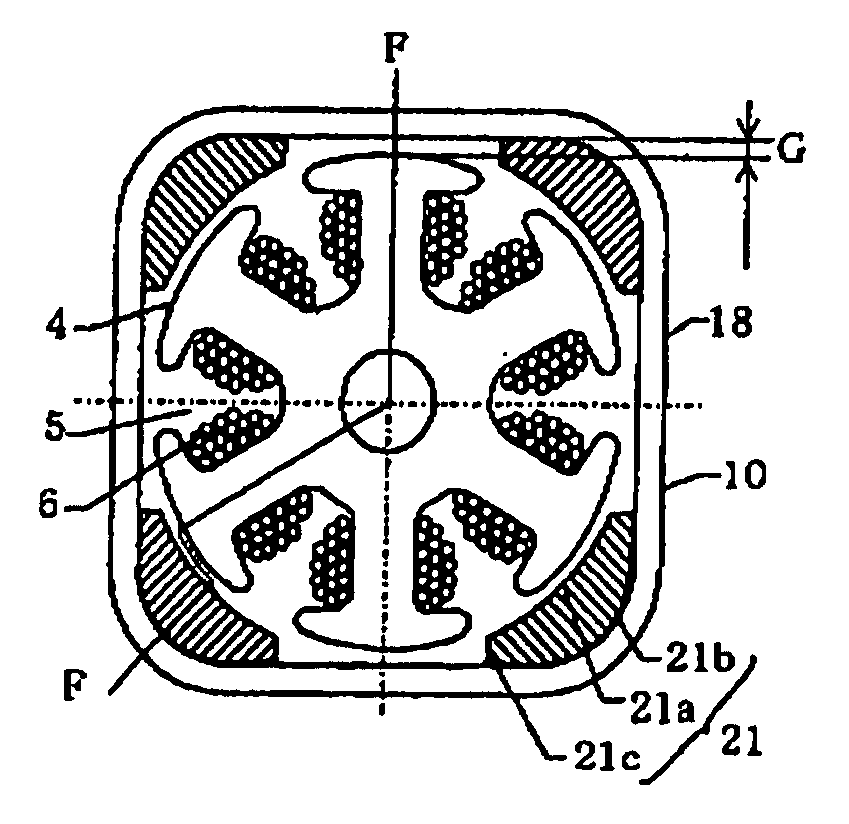

Small DC motor

ActiveUS20070007838A1Quantity minimizationReduce motor sizeElectrostatic generators/motorsDC commutatorEngineeringDC motor

A small DC motor includes: a motor frame including a cylindrical portion, the cylindrical portion having a constant thickness and having a cross section in a shape that includes four sides and connecting portions, each of the connecting portions connecting adjacent two of the four sides and being located inward from a corresponding corner in a quadrangle including the four sides; field magnets; and an armature assembly, wherein the field magnets are provided so as to be spaced apart from each other, and the small DC motor includes an air gap between each of the four sides and a radially outermost surface of the armature assembly, the air gap being a minimum size needed to rotate the armature assembly.

Owner:MINEBEA MOTOR MFG

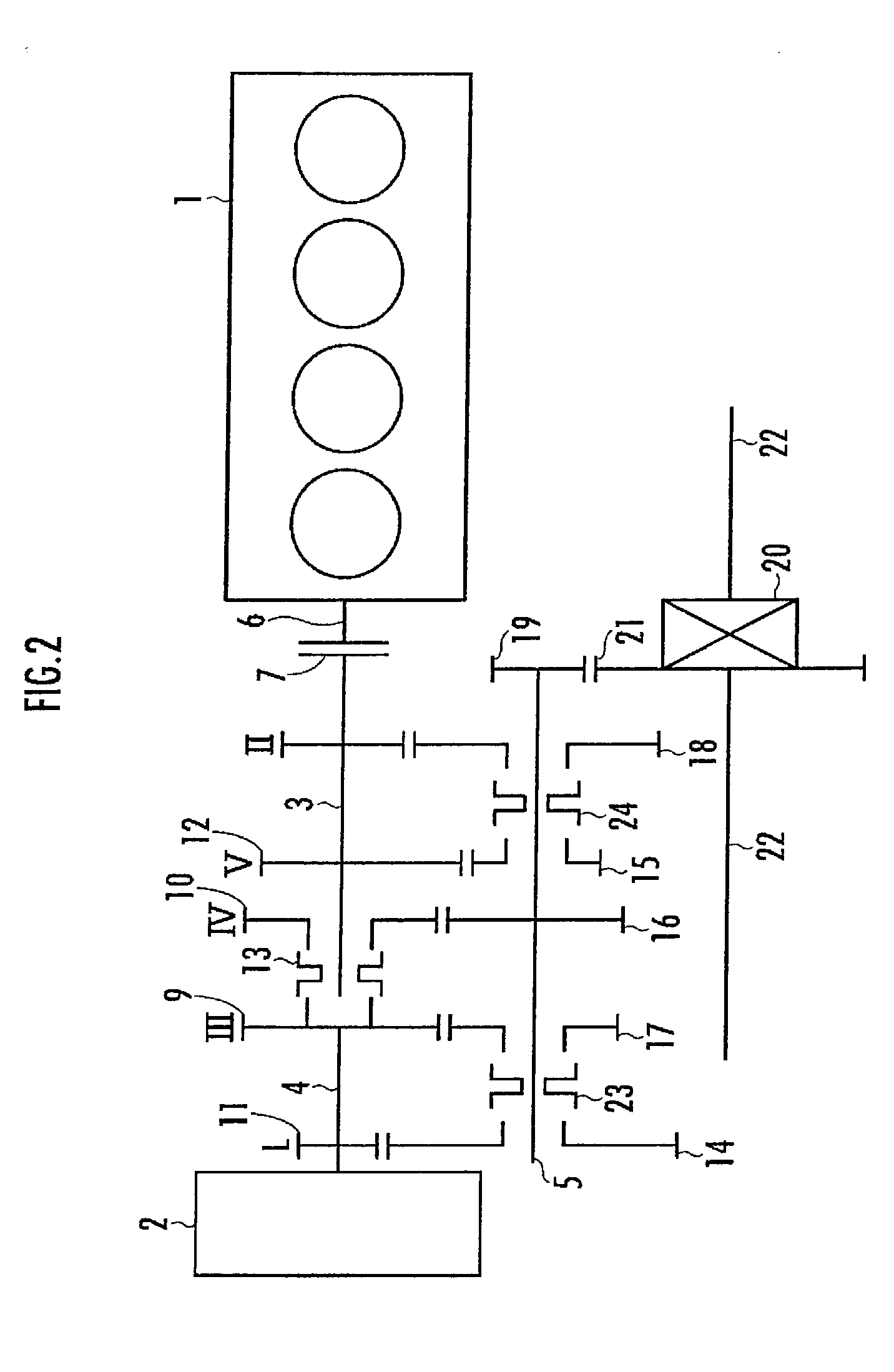

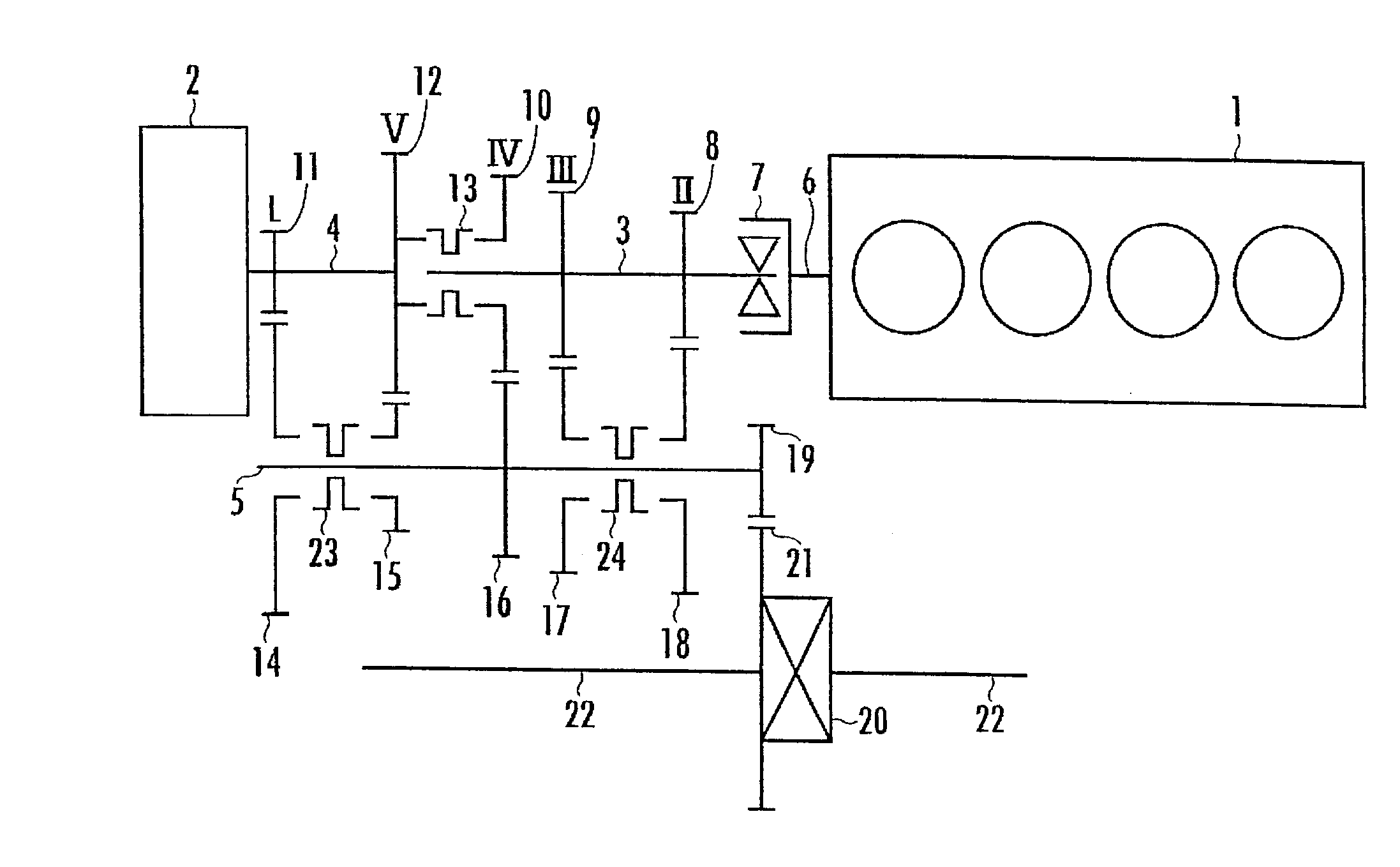

Transmission for hybrid vehicle

InactiveUS20110239819A1Small sizeCompact processGearingPropulsion using engine-driven generatorsTransmitted powerInternal combustion engine

Provided is a transmission for a hybrid vehicle which permits a compact, lightweight structure and yet allows the power of an internal combustion engine to be disconnected and which is capable of efficiently transmitting power without complicating the control. The transmission includes a speed changing unit which has a first input shaft 3 connected to a power shaft 6 of an internal combustion engine 1 and a second input shaft 4 connected to a power shaft of a motor 2 and which establishes a plurality of gear shift stages. A one-way clutch 7 is interposed between the power shaft 6 of the internal combustion engine 1 and the first input shaft 3. The one-way clutch 7 disengages the connection between the power shaft 6 of the internal combustion engine 1 and the first input shaft 3 when the rotational speed of the power shaft 6 of the internal combustion engine 1 is lower than the rotational speed of the first input shaft. 3.

Owner:HONDA MOTOR CO LTD

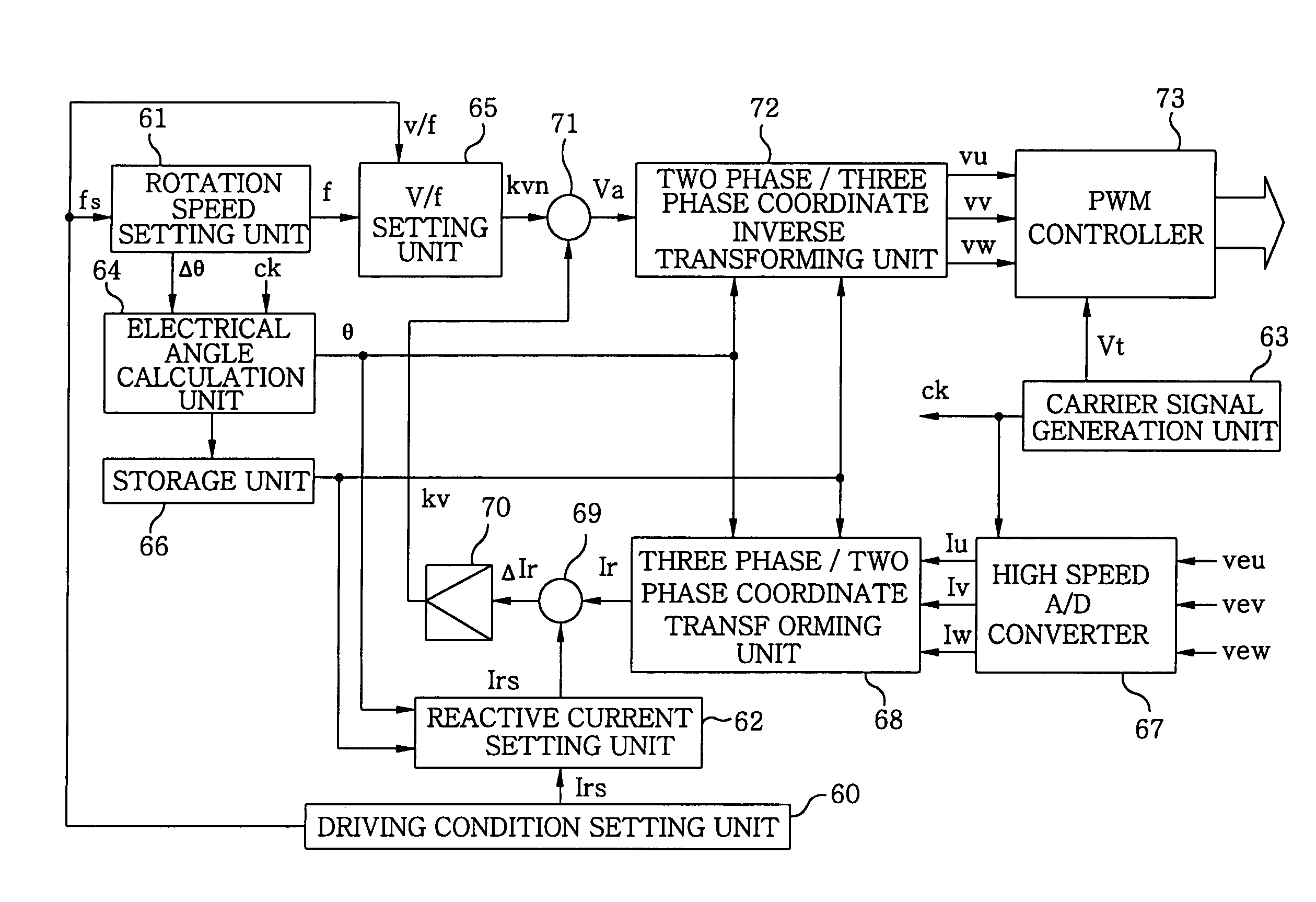

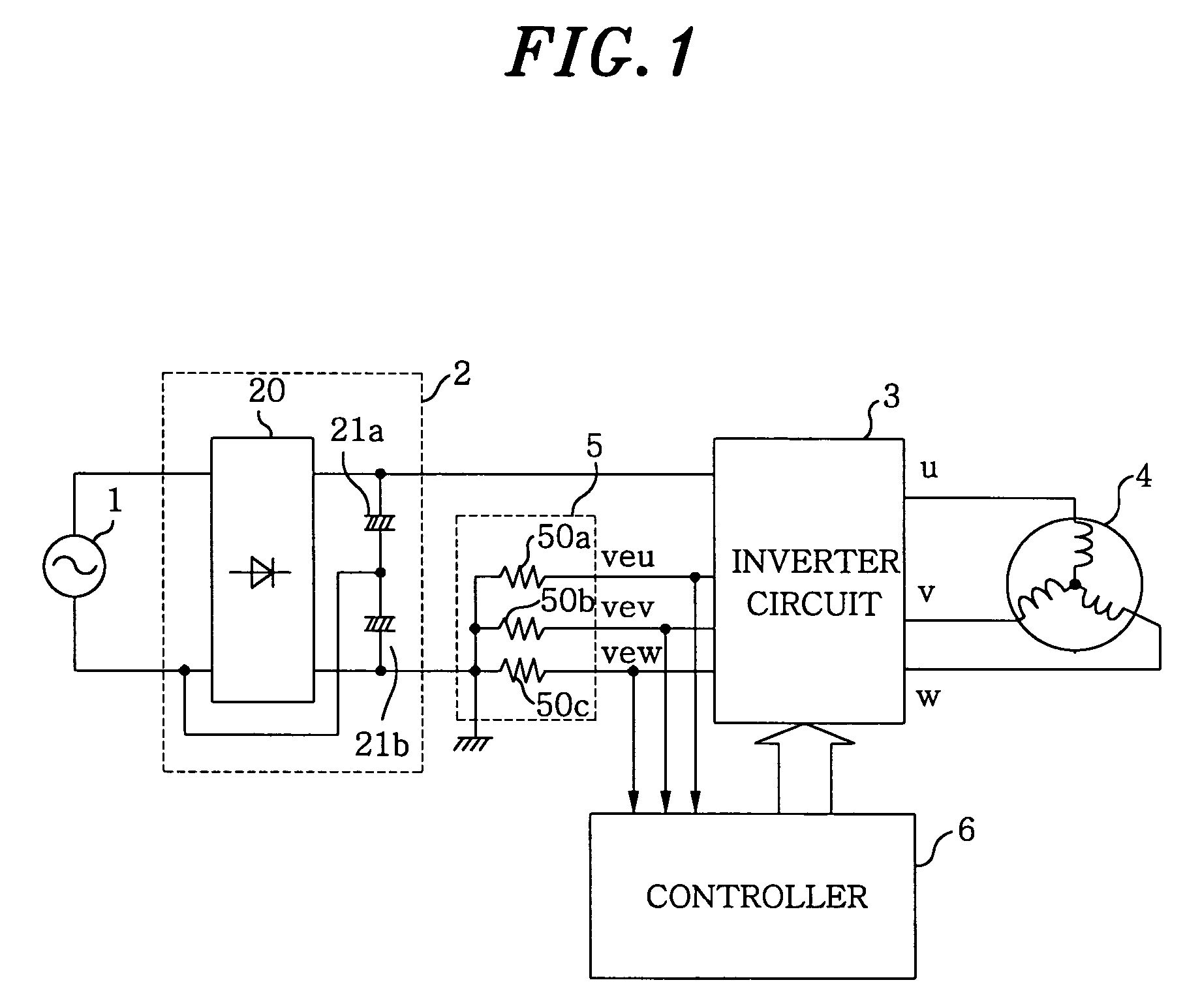

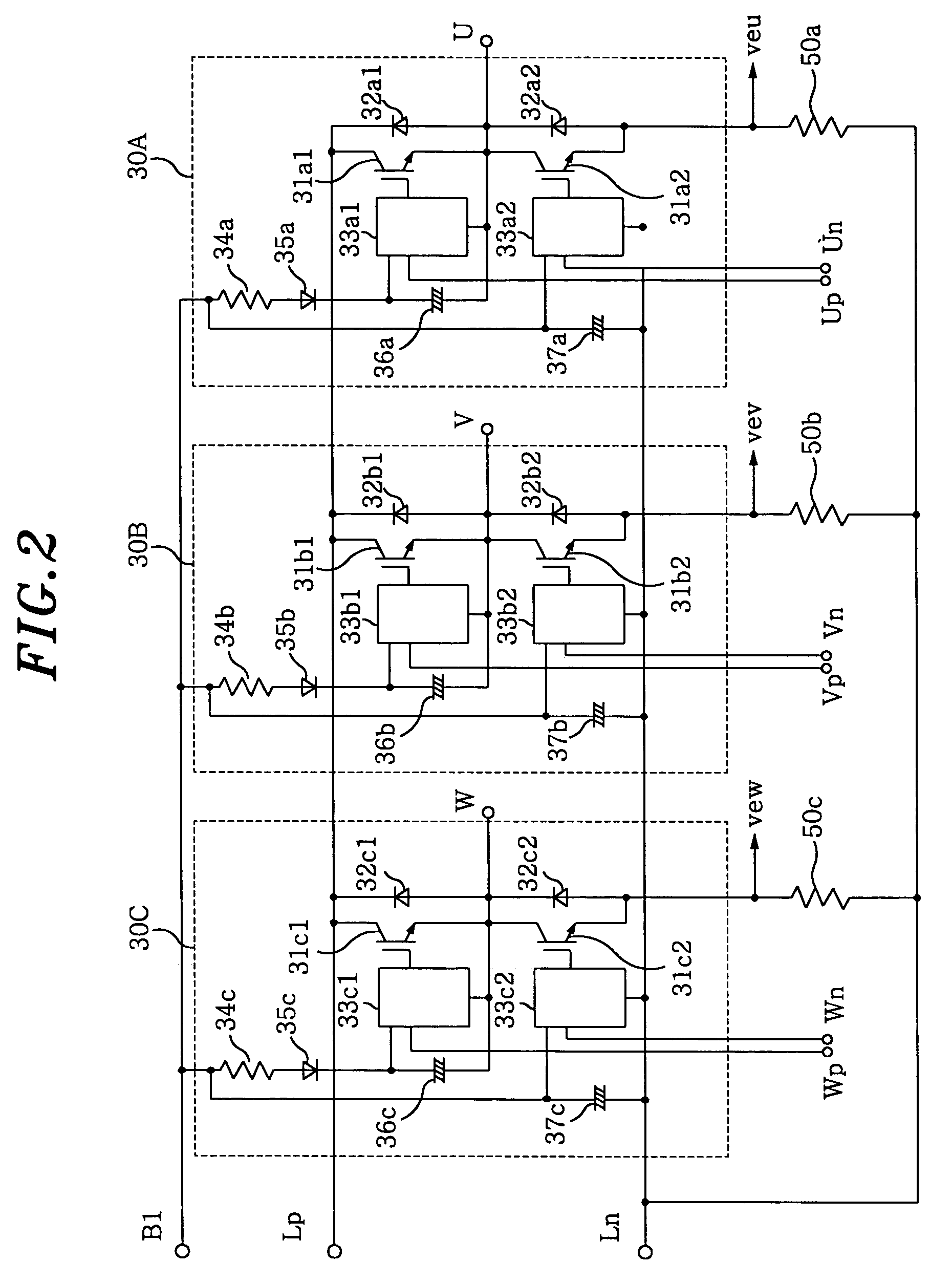

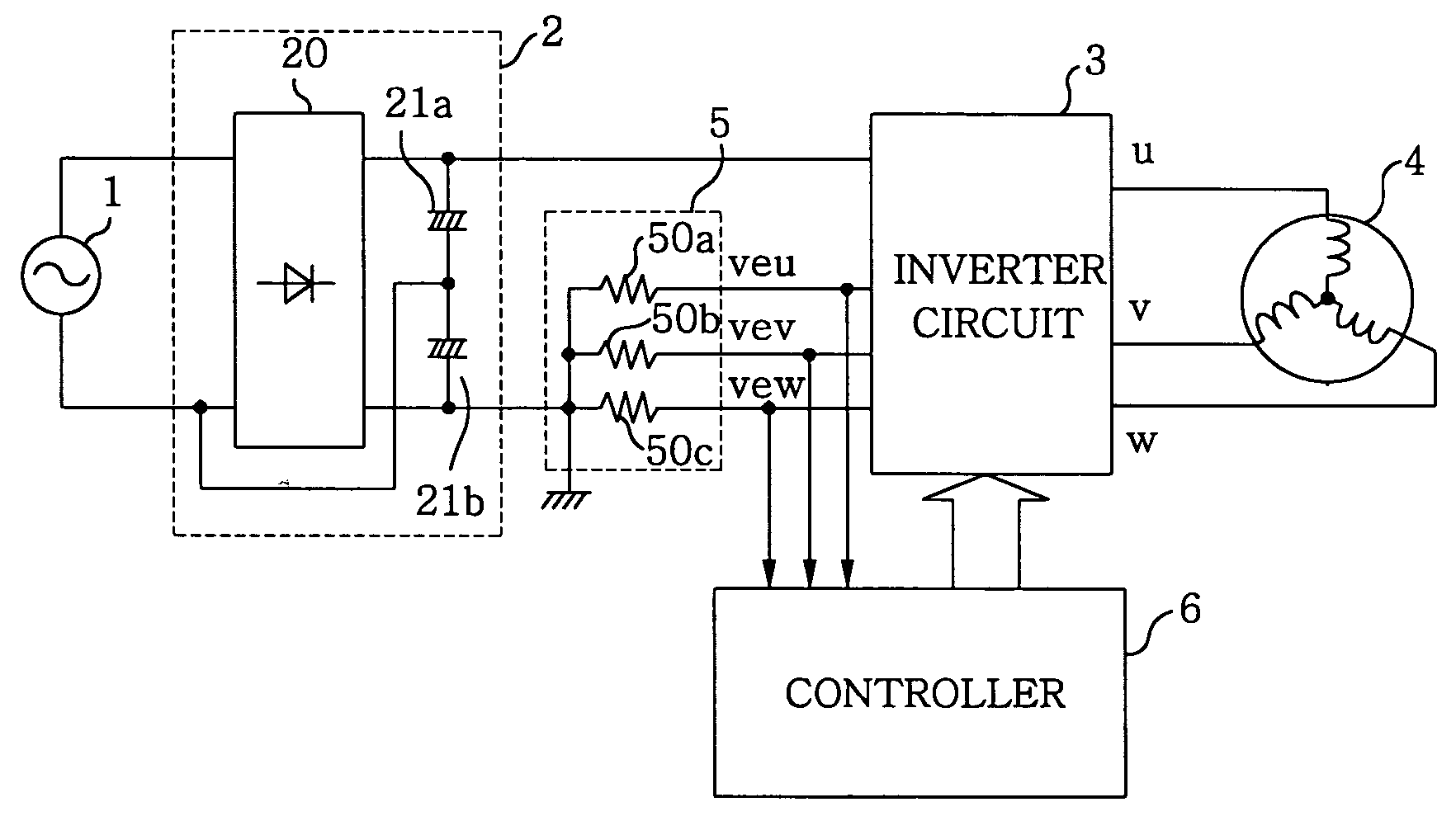

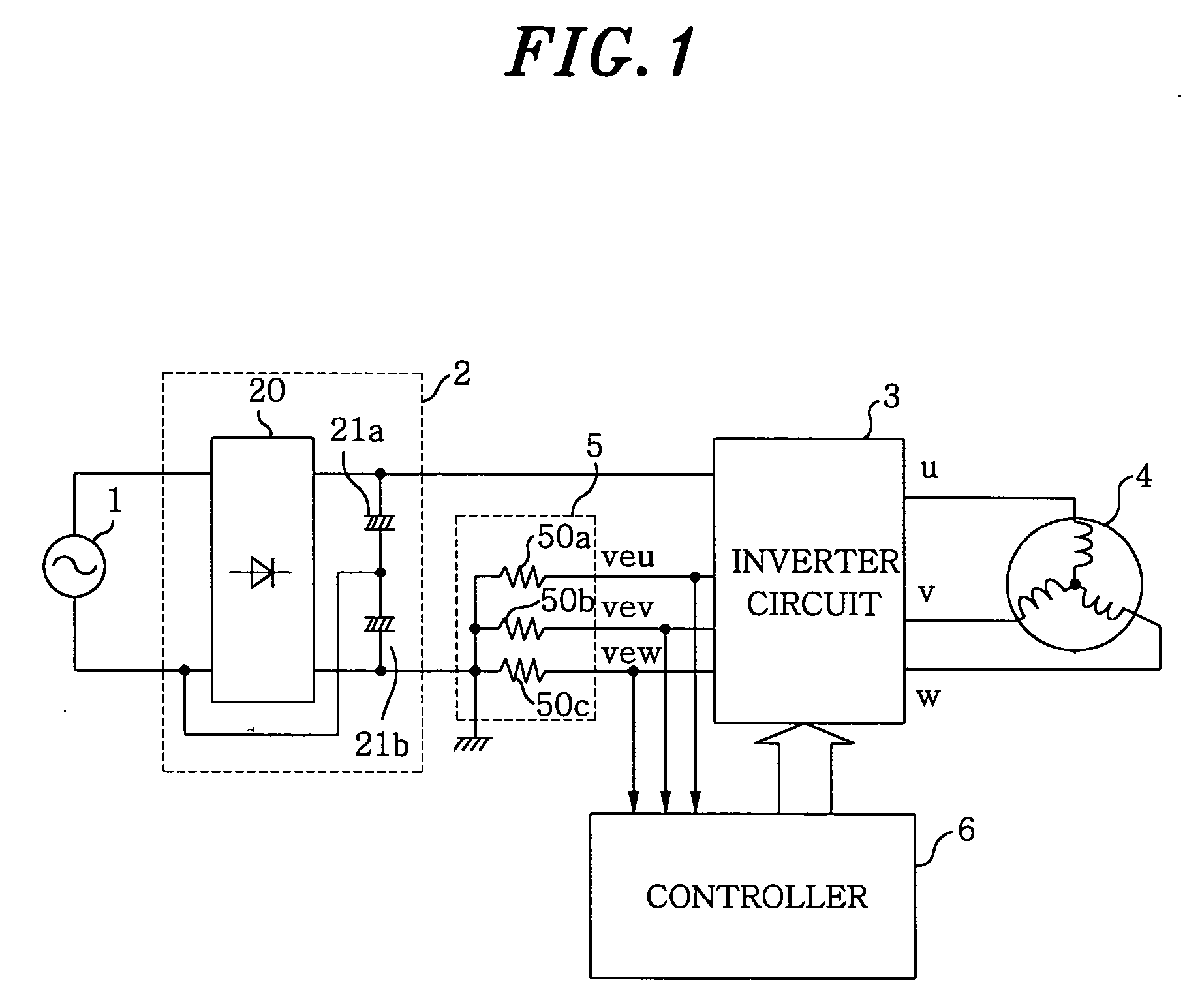

Motor driving apparatus for use in a dishwasher

InactiveUS7064517B2Reduce noiseThinner and small and cheapTableware washing/rinsing machine detailsVector control systemsMotor drivePhase difference

An apparatus for driving a motor of a dishwasher includes an AC power source, a rectification circuit for converting an AC power from the AC power source to a DC power, an inverter circuit for converting the DC power from the rectification circuit to an AC power, a motor driven by the inverter circuit to drive a wash pump and / or a drain pump, a current detector for detecting an output current of the inverter circuit, and a controller for performing a PWM (pulse width modulation) control of the inverter circuit based on an output signal of the current detector to thereby control the motor to rotate at a set rotation speed. A phase difference between an output voltage and the output current of the inverter circuit or a reactive current is controlled to have a predetermined value.

Owner:PANASONIC CORP

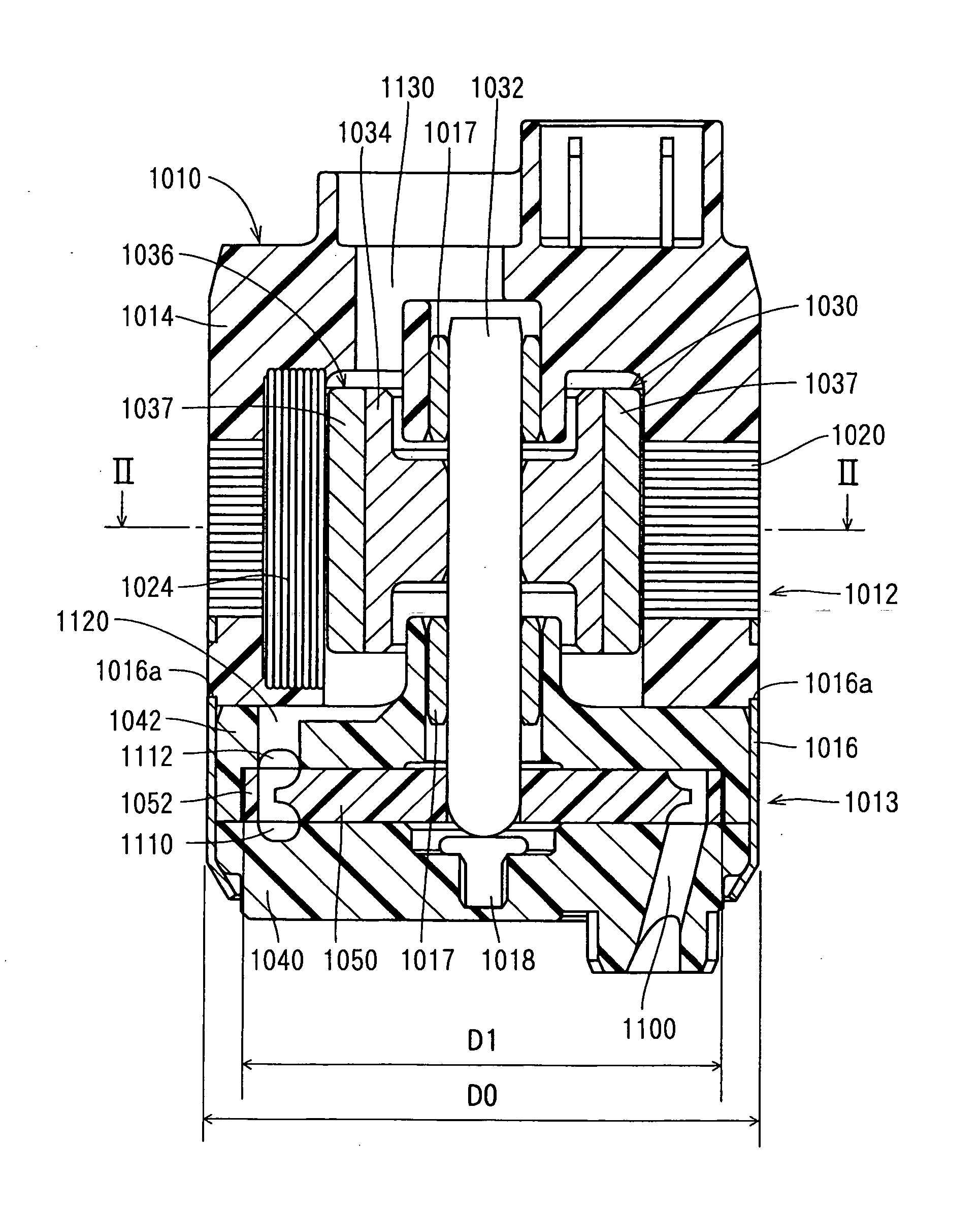

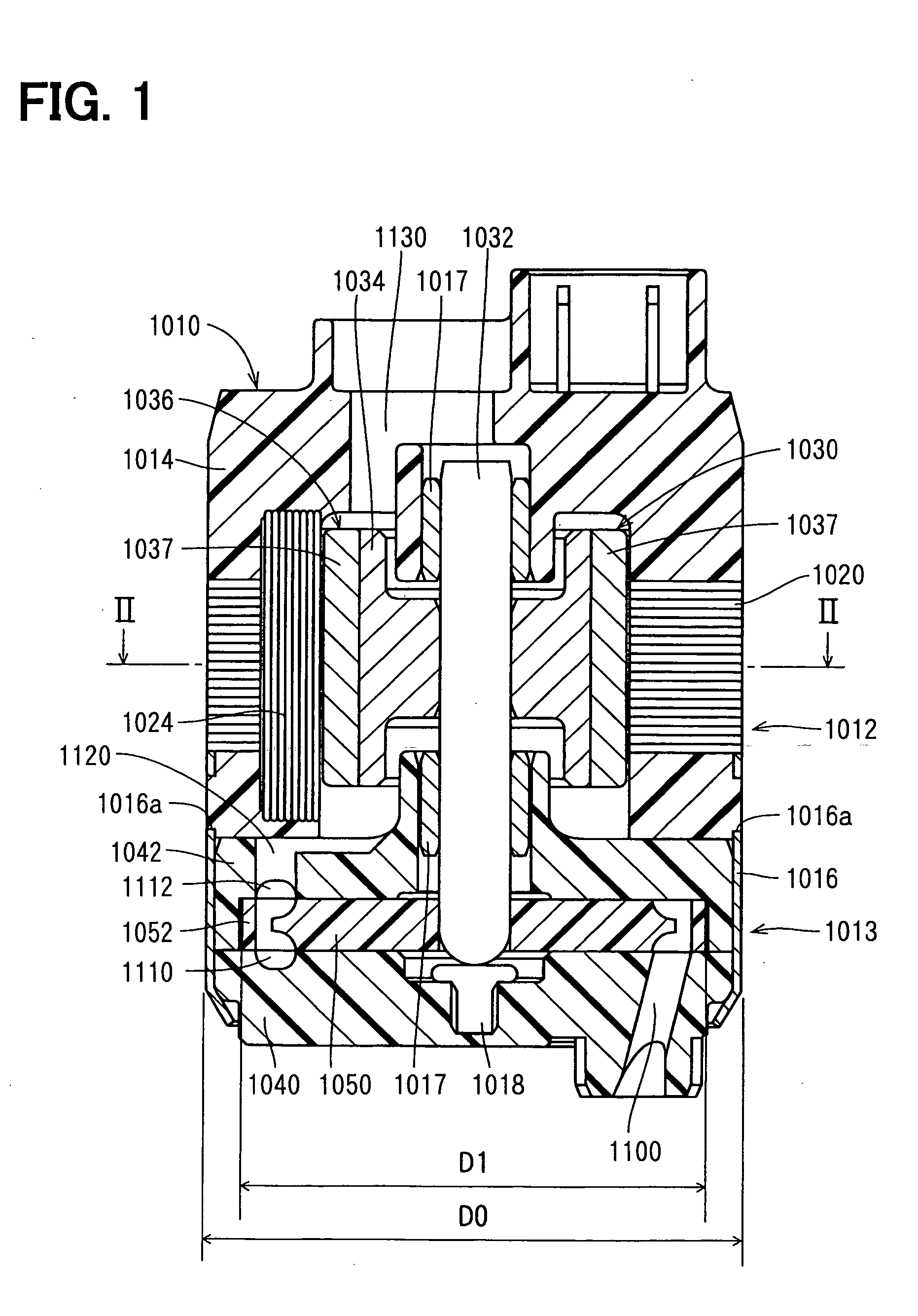

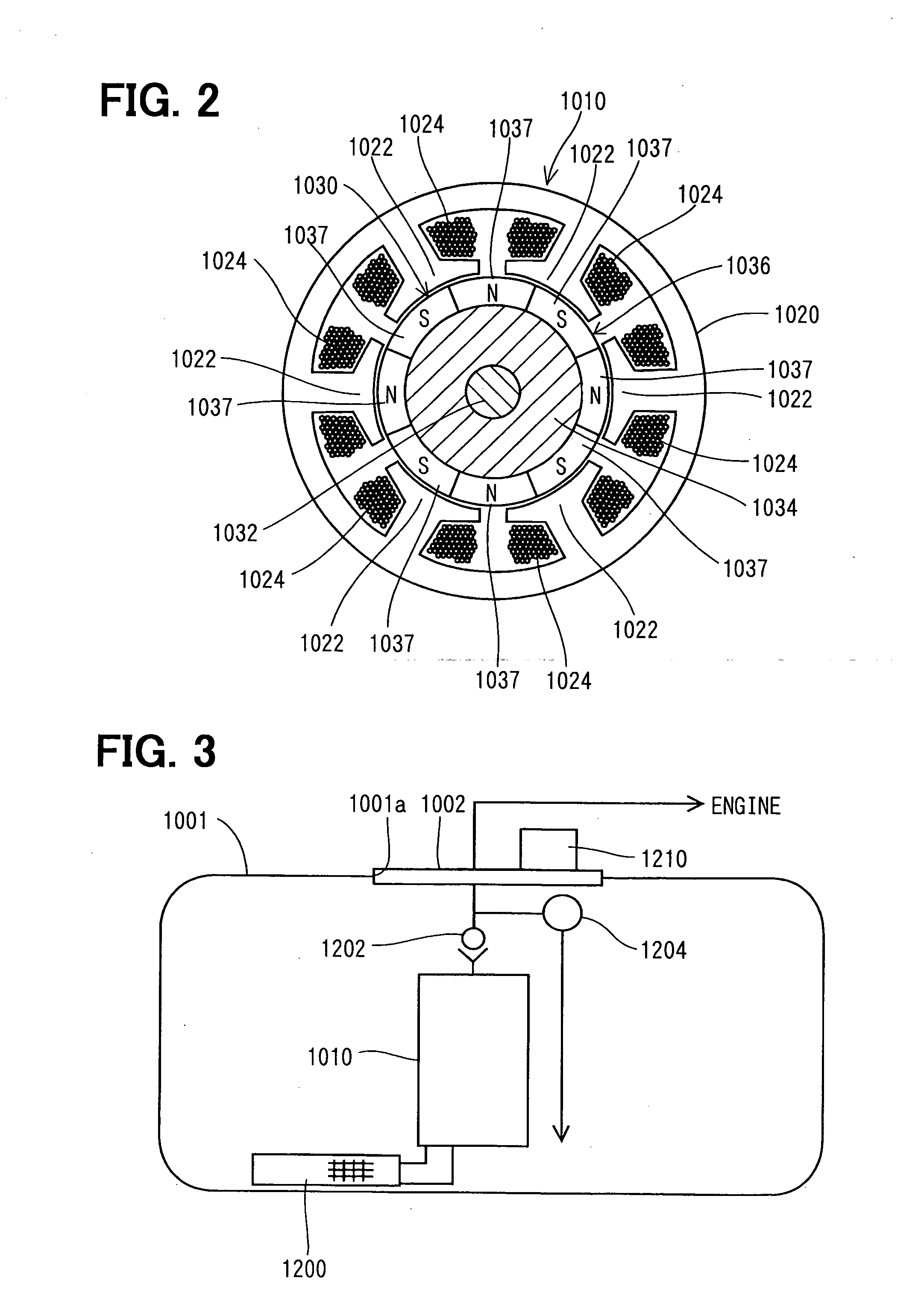

Fuel pump, fuel supply equipment using fuel pump and method for manufacturing fuel pump

InactiveUS20050220641A1Lower average currentSmall sizeCircumferential flow pumpsTransverse flow pumpsBrushless motorsMagnetic poles

A fuel pump mounted in the fuel tank for the motor cycle comprises a motor and a pump driven by the motor for increasing a pressure of the sucked fuel. The motor is a brushless motor and has a stator core, coils and a rotor. An electrical energization for the coils wound around the stator core is controlled in response to a rotating position of the rotor, thereby the rotor is rotated. The rotor has a shaft, a rotating core and a permanent magnet, and the rotor is rotatably mounted at the inner circumference of the stator core. The permanent magnet is mounted at the outer circumference of the rotating core and magnetically energized so as to form magnetic poles different alternatively in a rotating direction at the outer circumferential surface facing the stator core.

Owner:DENSO CORP

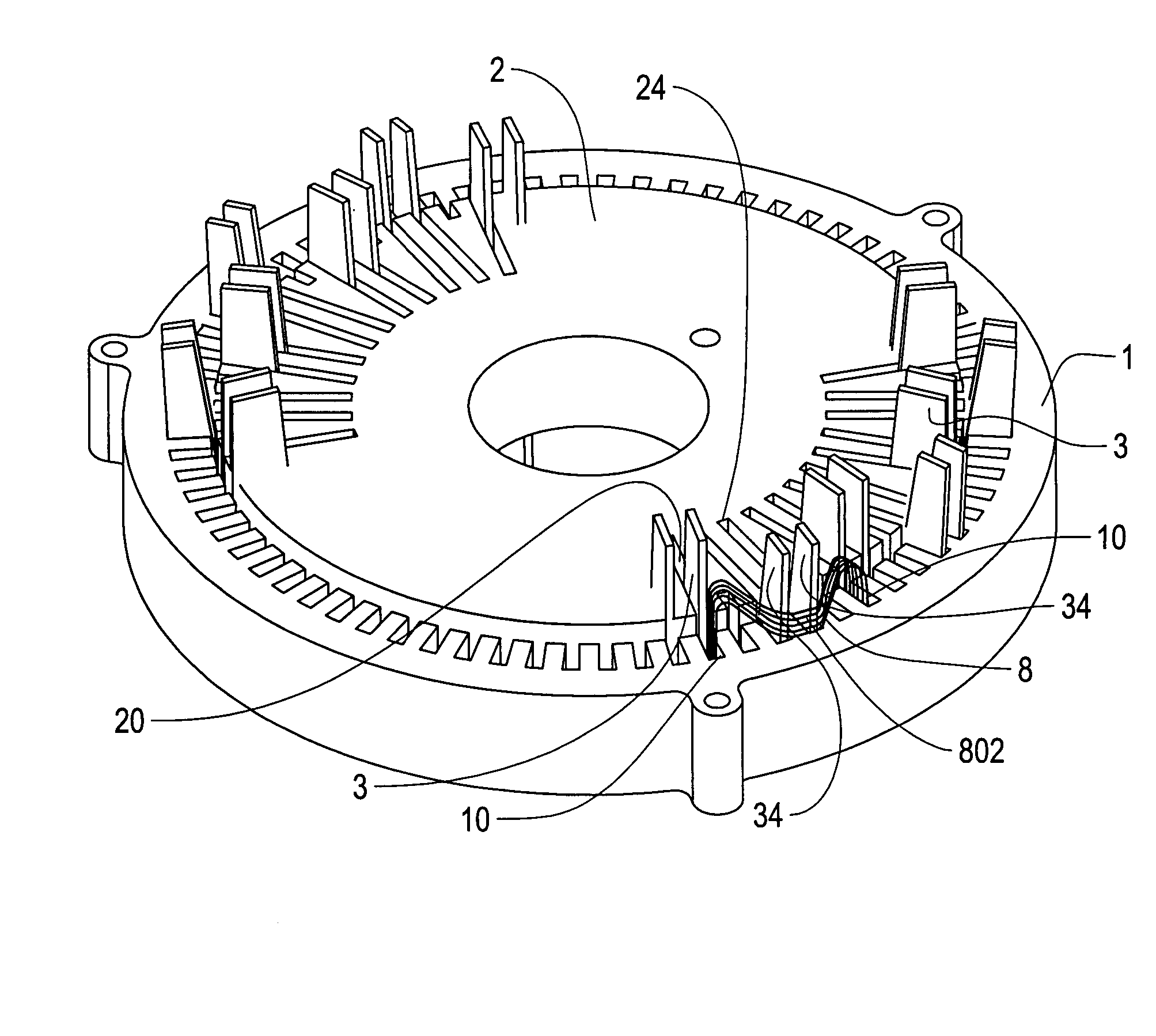

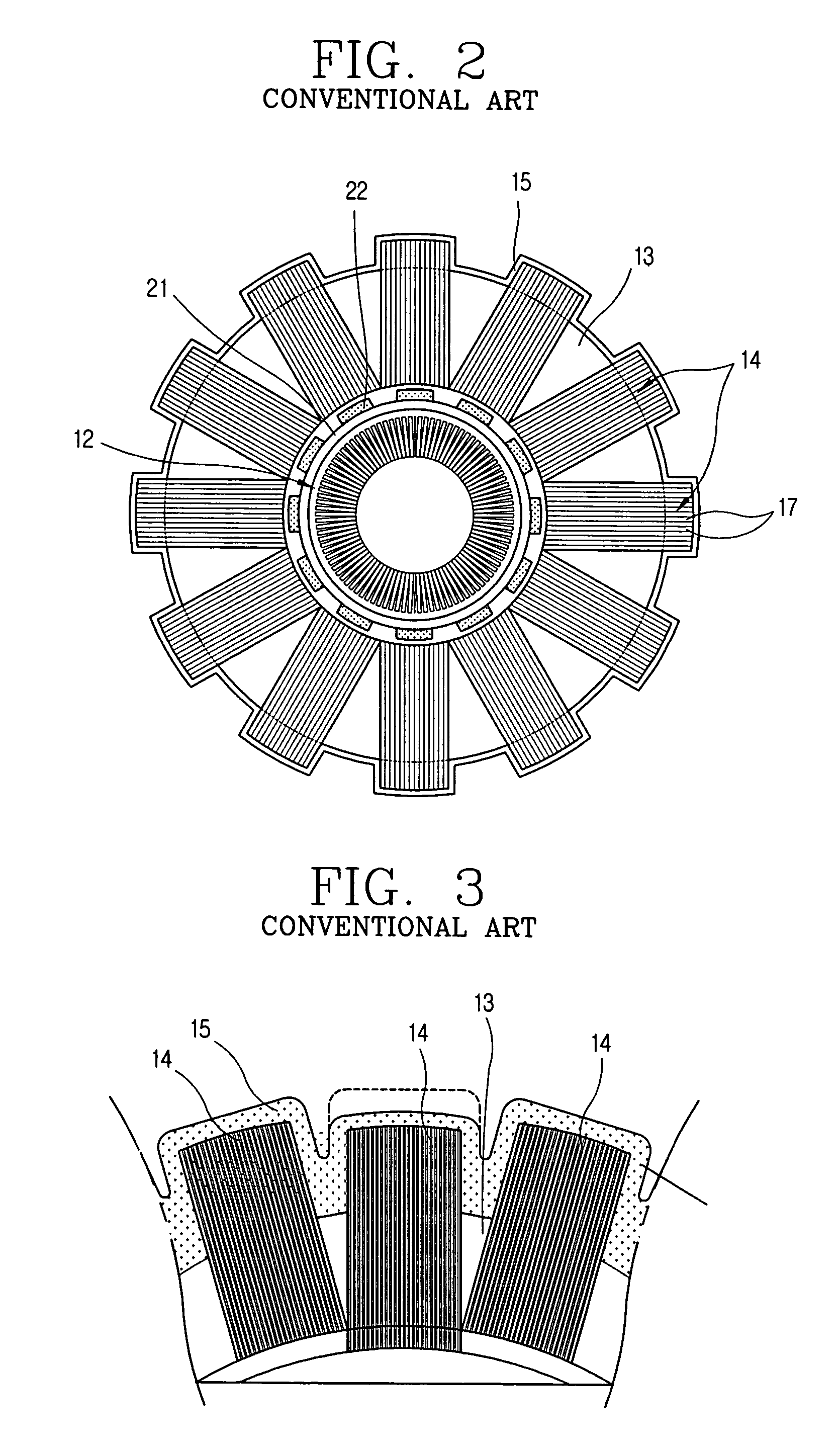

Motor manufacturing process

InactiveUS7275299B2Reduce motor sizeReduce axial sizeEmbedding prefabricated windingsMetal working apparatusEngineeringMechanical engineering

A plurality of single-pole coils are retained by a coil retaining device, the single-pole coils are arranged such that the coil insertion portions of each single-pole coil confront the inner circumference openings of the slots and may be generally parallel to the axial direction of the motor core, each single-pole coil is moved linearly toward the motor core such that the coil retaining device and the moving locus before the adjoining coil insertion portions in the adjoining single-pole coils are inserted into the slots are parallel or approach the more from the inner circumference side to the outer circumference side and the two coil insertion portions of each single-pole coil are moved such that they may start their movements simultaneously and at equal velocities.

Owner:AISIN AW CO LTD

Motor driving apparatus for use in a diswasher

InactiveUS20050127865A1Easy to detectSmall sizeTableware washing/rinsing machine detailsVector control systemsMotor drivePhase difference

An apparatus for driving a motor of a dishwasher includes an AC power source, a rectification circuit for converting an AC power from the AC power source to a DC power, an inverter circuit for converting the DC power from the rectification circuit to an AC power, a motor driven by the inverter circuit to drive a wash pump and / or a drain pump, a current detector for detecting an output current of the inverter circuit, and a controller for performing a PWM (pulse width modulation) control of the inverter circuit based on an output signal of the current detector to thereby control the motor to rotate at a set rotation speed. A phase difference between an output voltage and the output current of the inverter circuit or a reactive current is controlled to have a predetermined value.

Owner:PANASONIC CORP

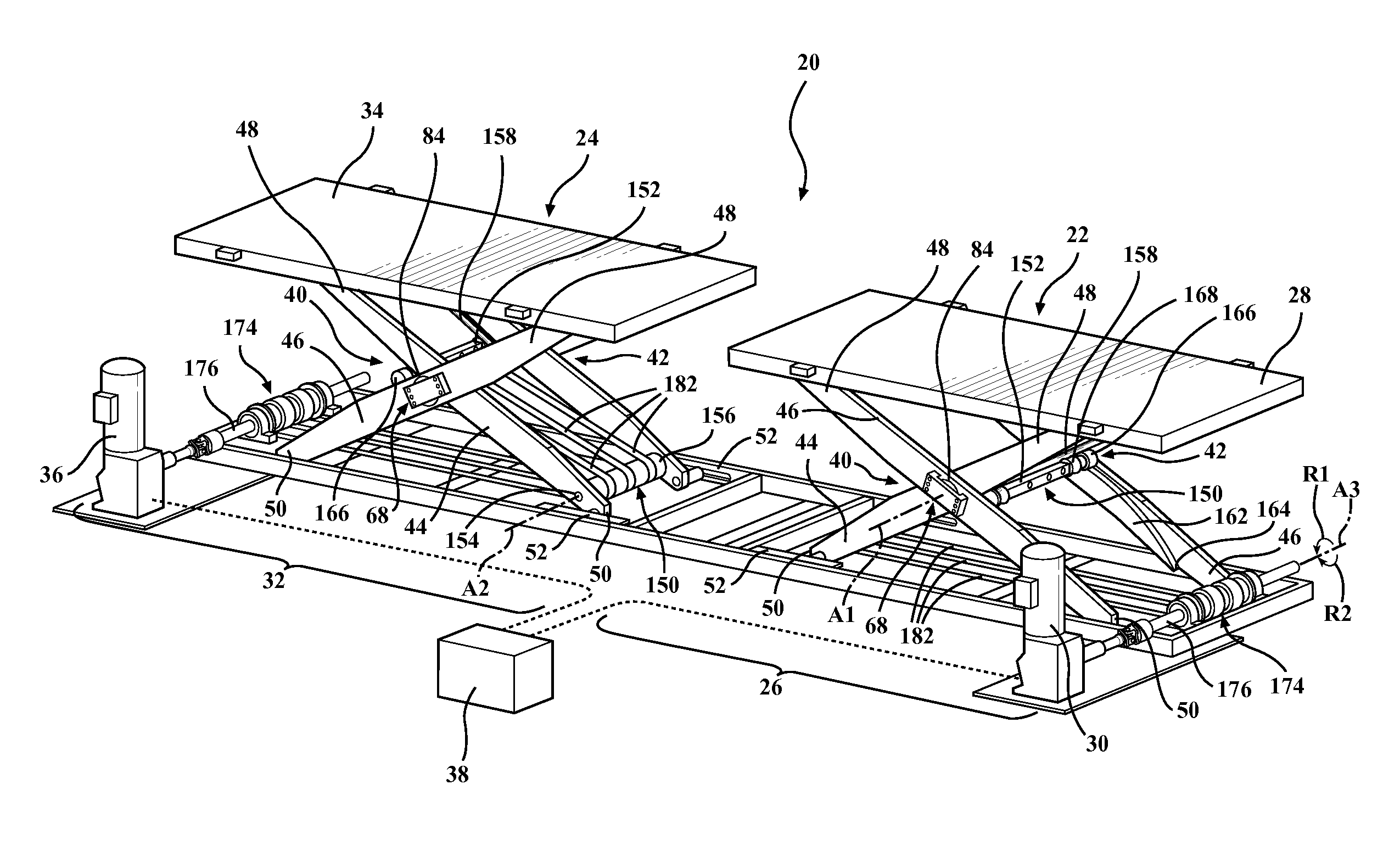

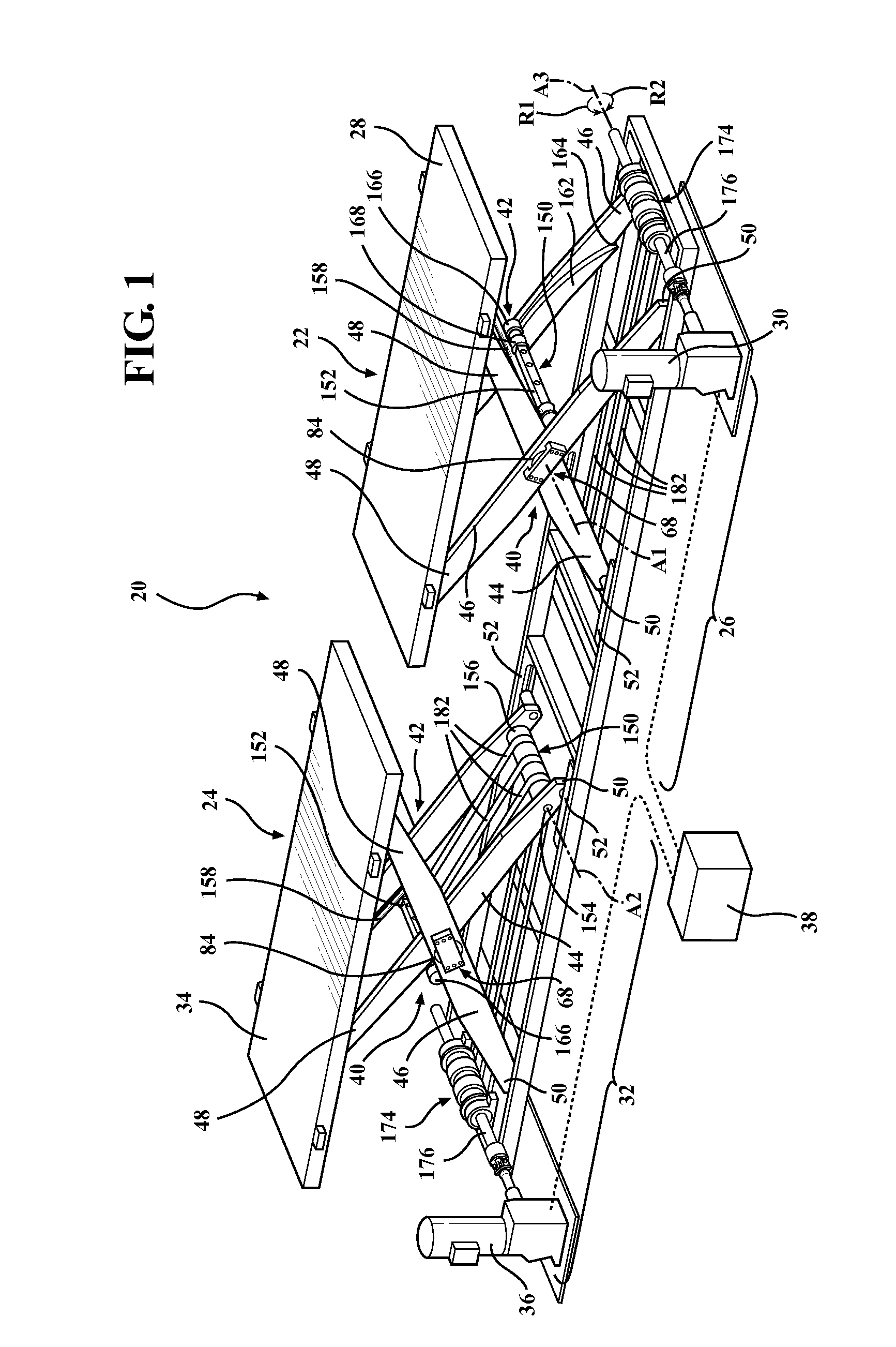

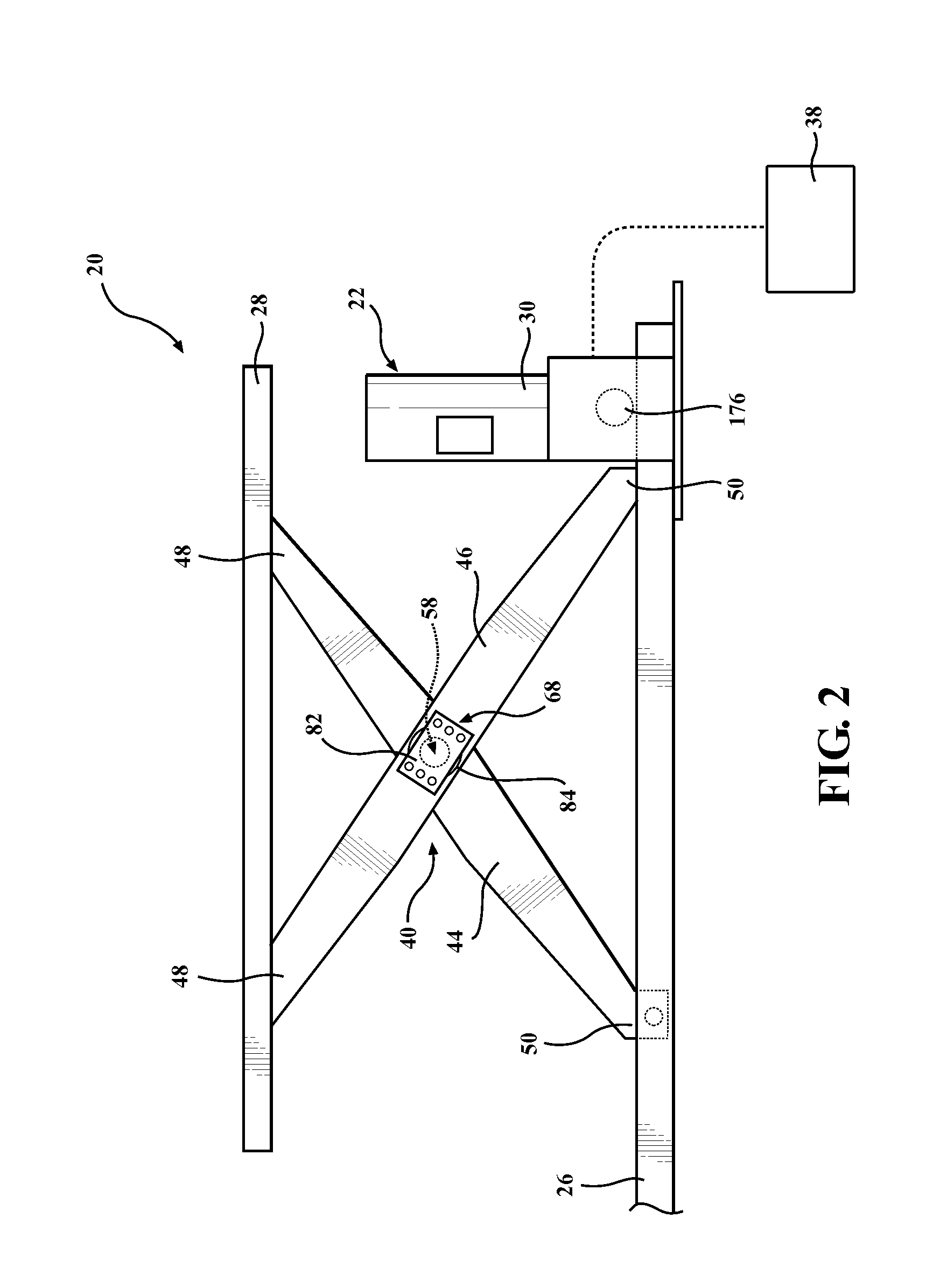

Scissor-Type Lift Assembly

ActiveUS20150034893A1Reduce wearReduce motor sizeLifting framesWinding mechanismsEngineeringLift system

The subject invention includes a lift system including a first scissor-type lift assembly and a second scissor-type lift assembly spaced from the first scissor-type lift assembly. The first scissor-type lift assembly includes a first base and a first platform coupled to the first base for movement between elevated and lowered states. The first scissor-type lift assembly includes a first motor operatively mounted to the first base. The second scissor-type lift assembly includes a second base and a second platform coupled to the second base for movement between elevated and lowered states. The second scissor-type lift assembly includes a second motor operatively mounted to the second base. The first and second motors move the first and second platforms between the elevated and lowered states. The lift system includes a controller in communication with the first and second scissor-type lift assemblies to synchronize operation of the first and second motors.

Owner:HERKULES EQUIP

Air flow passage for a vacuum cleaner

InactiveUS20050262658A1Improve performanceReduction in cleaning efficiencyCleaning filter meansSuction filtersCycloneCyclonic separation

Owner:G B D

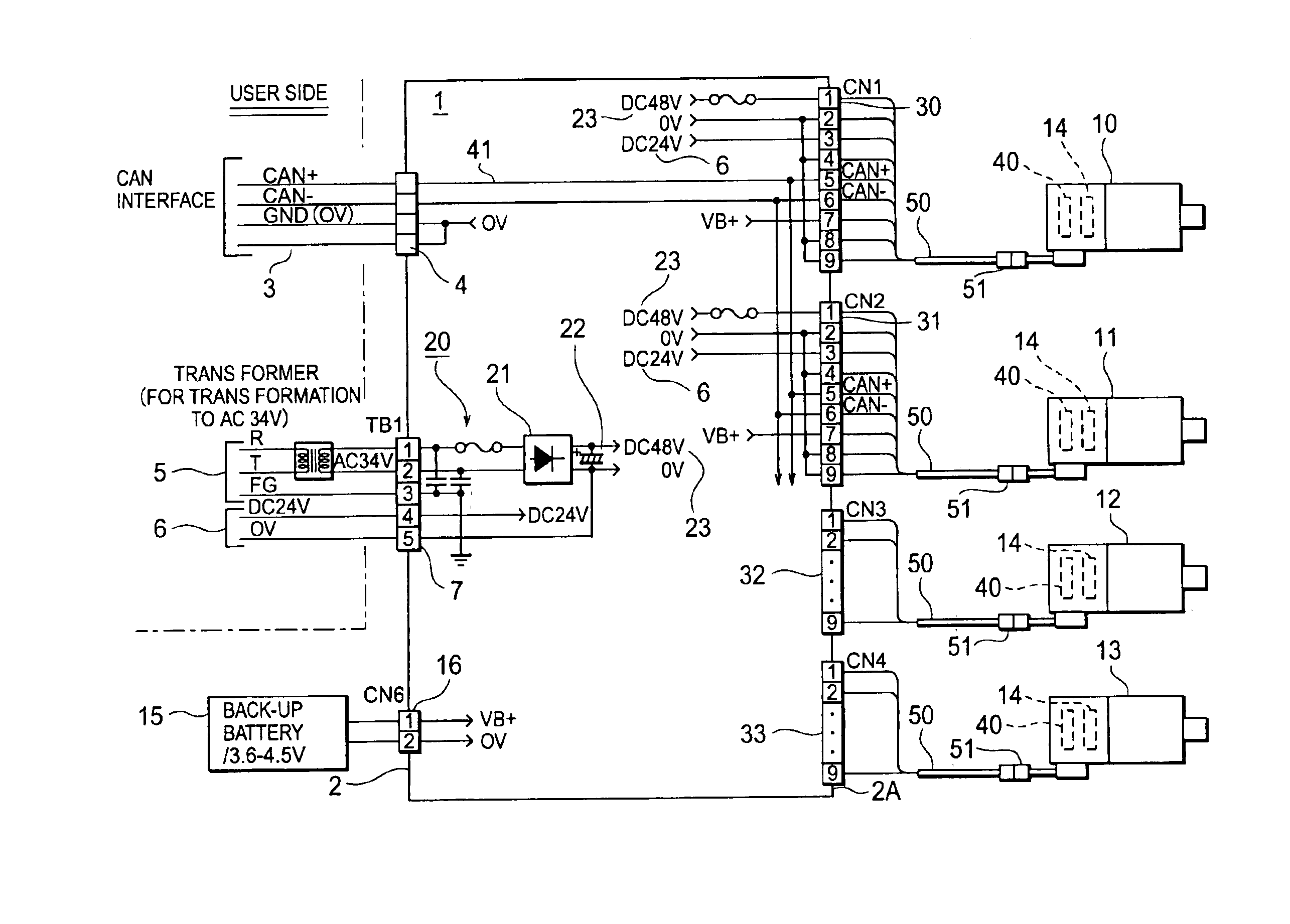

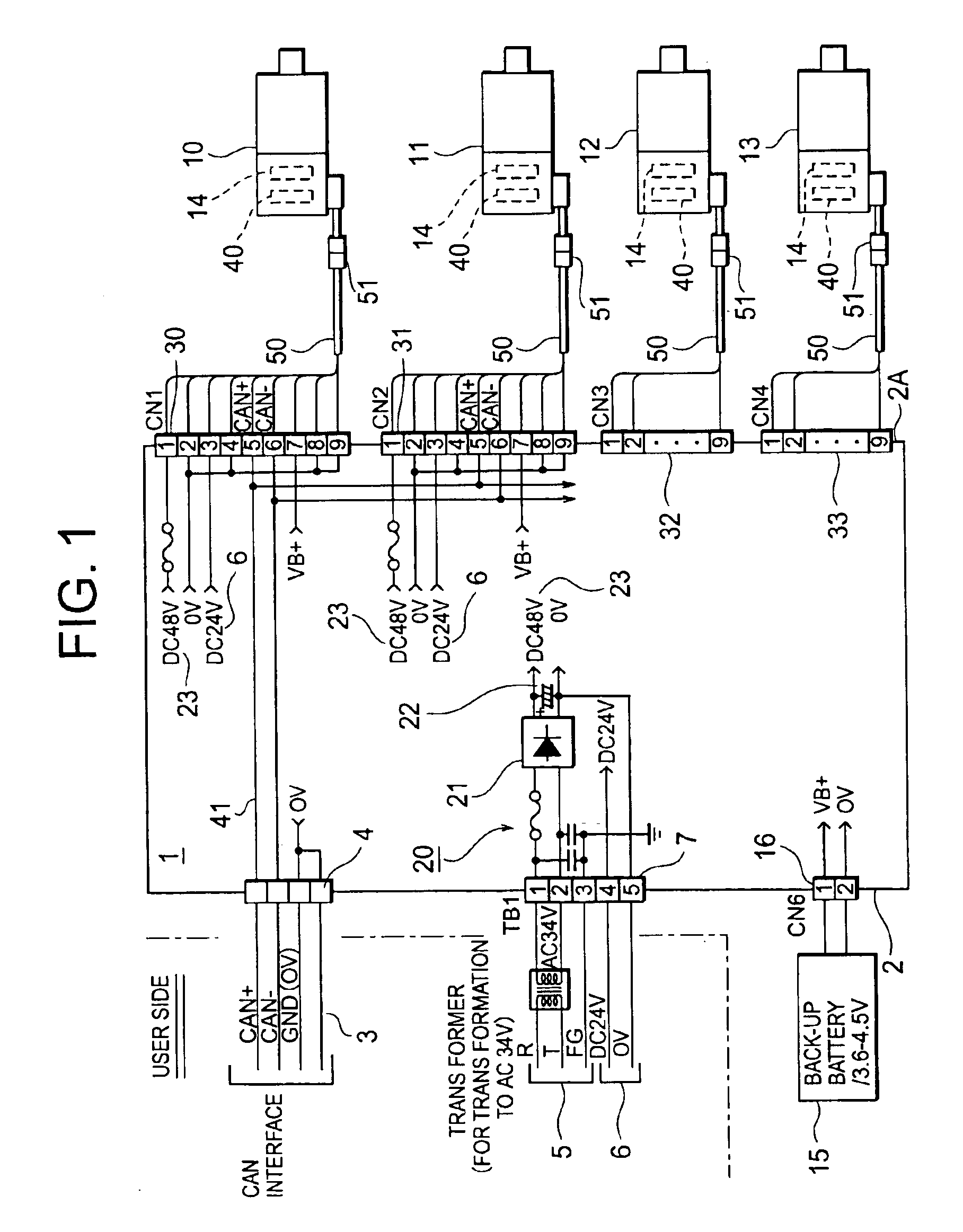

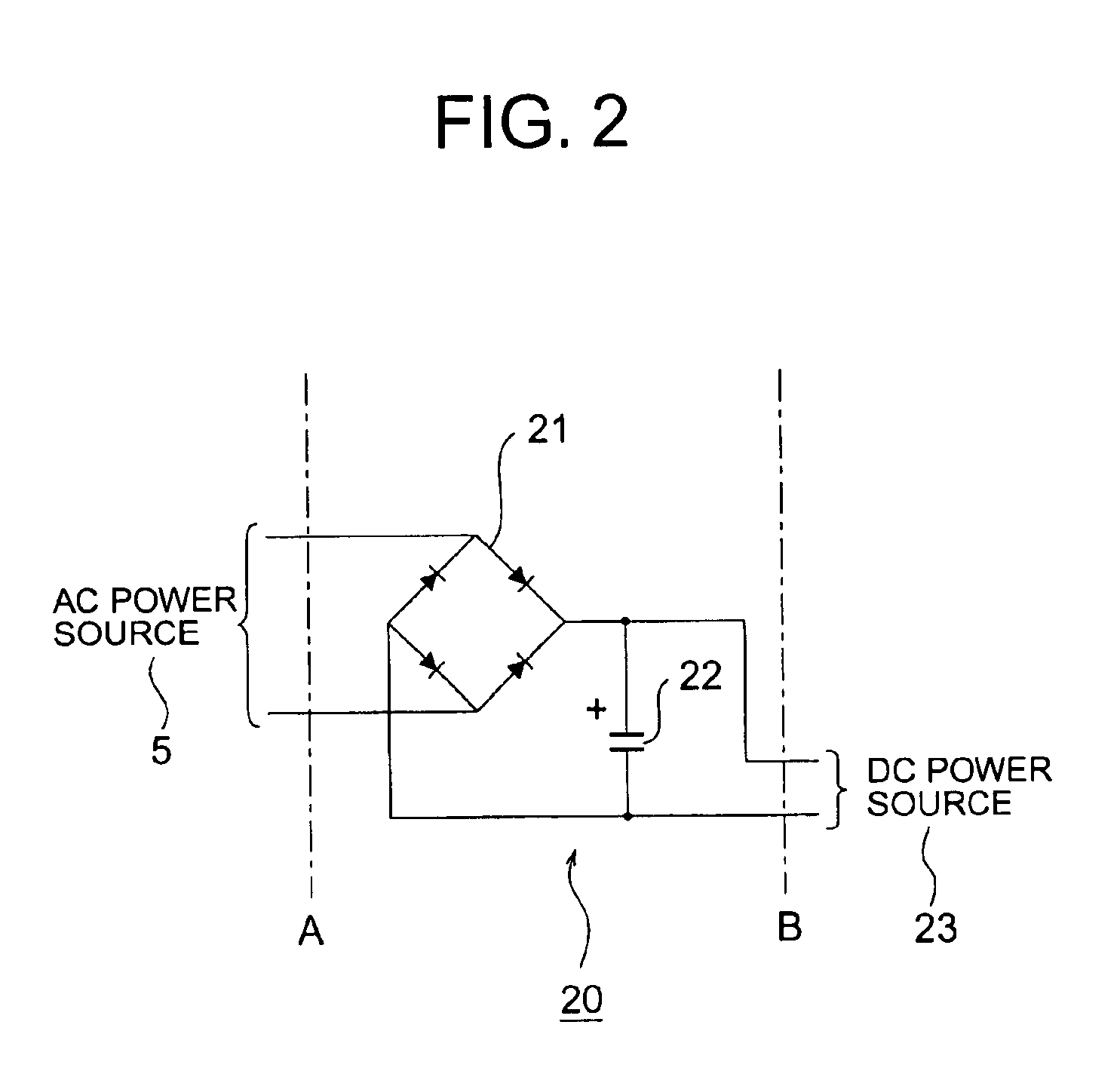

Method of driving a servo motor with a built-in drive circuit

InactiveUS6933698B2Reduction in servo motor sizeEasy to installDc network circuit arrangementsMultiple dynamo-motor startersEngineeringDistributed power

Disclosed is a method of driving a servo motor with a built-in drive circuit in which a common rectifying circuit is provided on a distribution board to which a plurality of the servo motors with built-in drive circuits are connected, to thereby achieve a reduction in size of each servo motor. In this method, there is used a common distribution board for distributing power to be supplied to a plurality of servo motors with built-in drive circuits and for distributing a communication line, an external communication signal and external input power are supplied through the distribution board.

Owner:TAMAGAWA SEIKI CO LTD

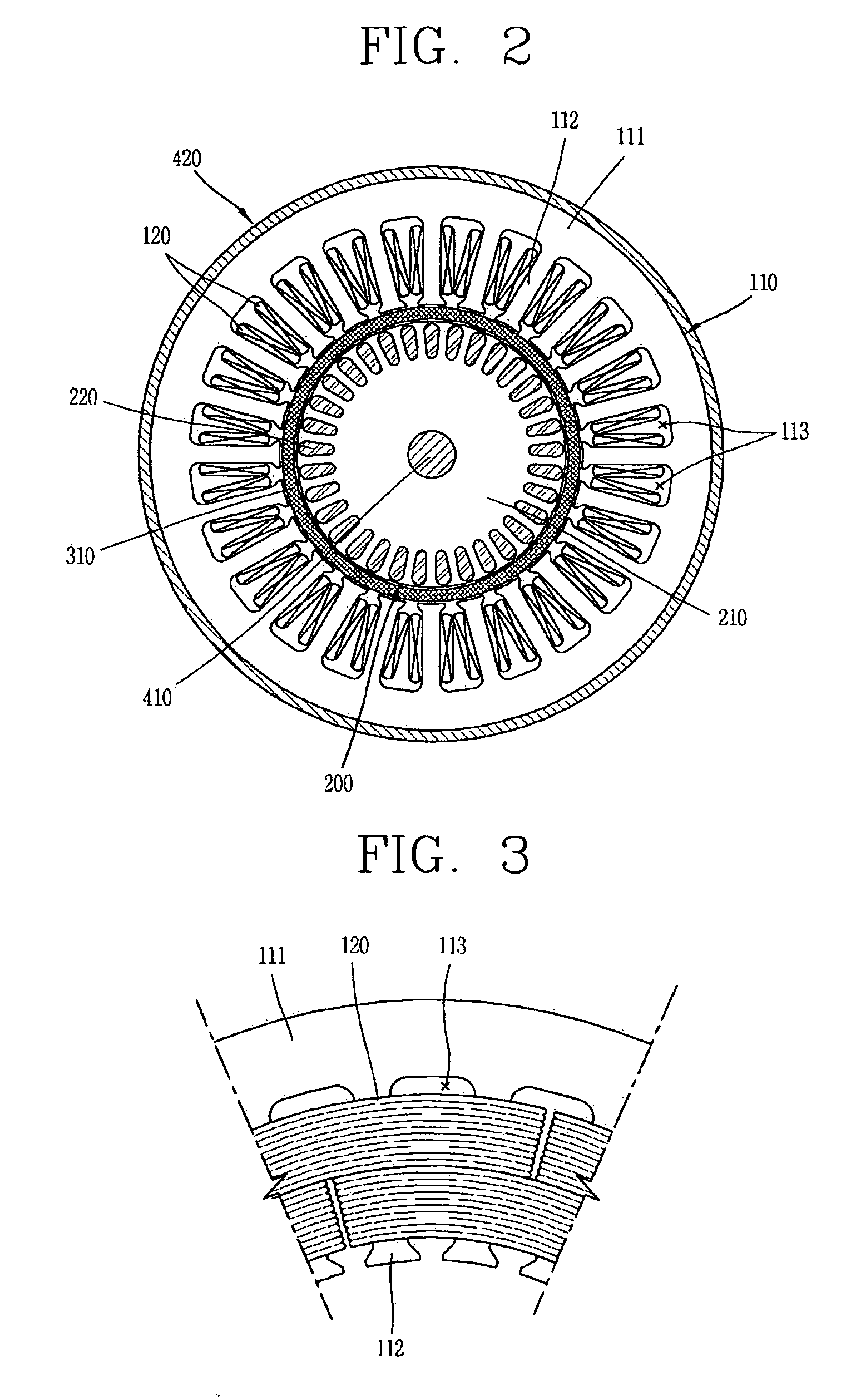

Induction motor

InactiveUS20060284509A1Reduce in sizeManufacturing cost be reduceSynchronous generatorsWindingsMagnetEngineering

An induction motor includes: a stator in which a plurality of winding coils wound in a central direction of a stator core are arranged; an induction rotor rotatably inserted into the stator; and a synchronous rotor including a magnet and rotatably inserted into an air gap between the stator and the induction rotor, so that the induction motor reduces the size of the whole motor and has a structure of a compact size to thereby reduce installation space and manufacturing cost and increase output power and efficiency.

Owner:LG ELECTRONICS INC

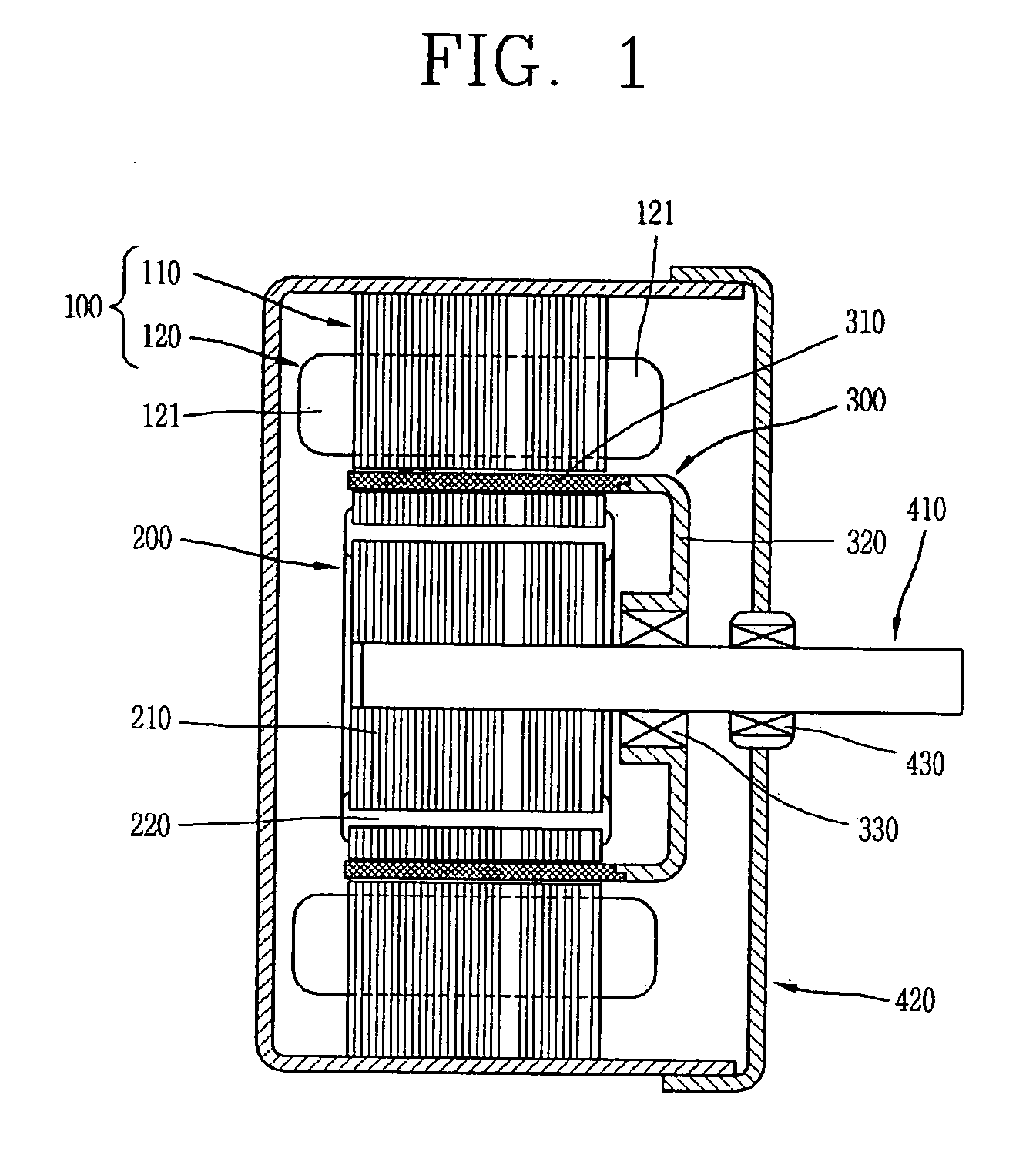

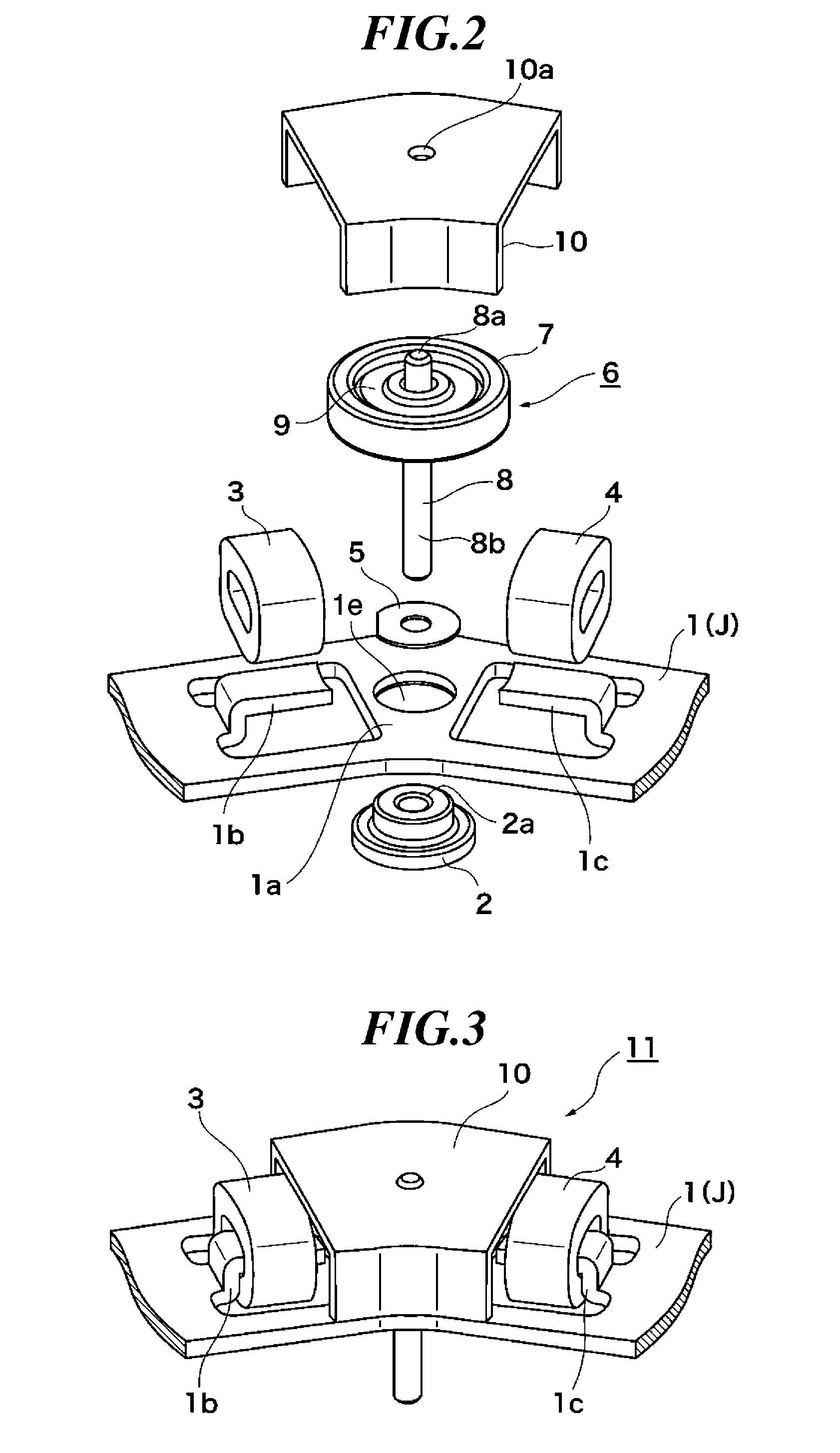

Motor

InactiveUS6897579B2Reduce motor sizeHigh torqueSynchronous generatorsWindingsMagnetic polesEngineering

A motor includes a magnet formed into a hollow disc shape and having at least one flat surface circumferentially divided and alternately magnetized to opposite poles, a first coil having an inner peripheral surface opposing the outer peripheral surface of the magnet, a second coil having an outer peripheral surface opposing the inner peripheral surface of the magnet, first magnetic pole portions opposing one flat surface of the magnet, formed from a plurality of teeth extending in the radial direction of the magnet, and excited by the first coil, second magnetic pole portions formed on the opposite side to the first magnetic pole portions via the magnet at positions opposing the first magnetic pole portions, third magnetic pole portions opposing one flat surface of the magnet, formed from a plurality of teeth extending in the radial direction of the magnet, and excited by the second coil, and fourth magnetic pole portions formed on the opposite side to the third magnetic pole portions via the magnet at positions opposing the third magnetic pole portions.

Owner:CANON KK

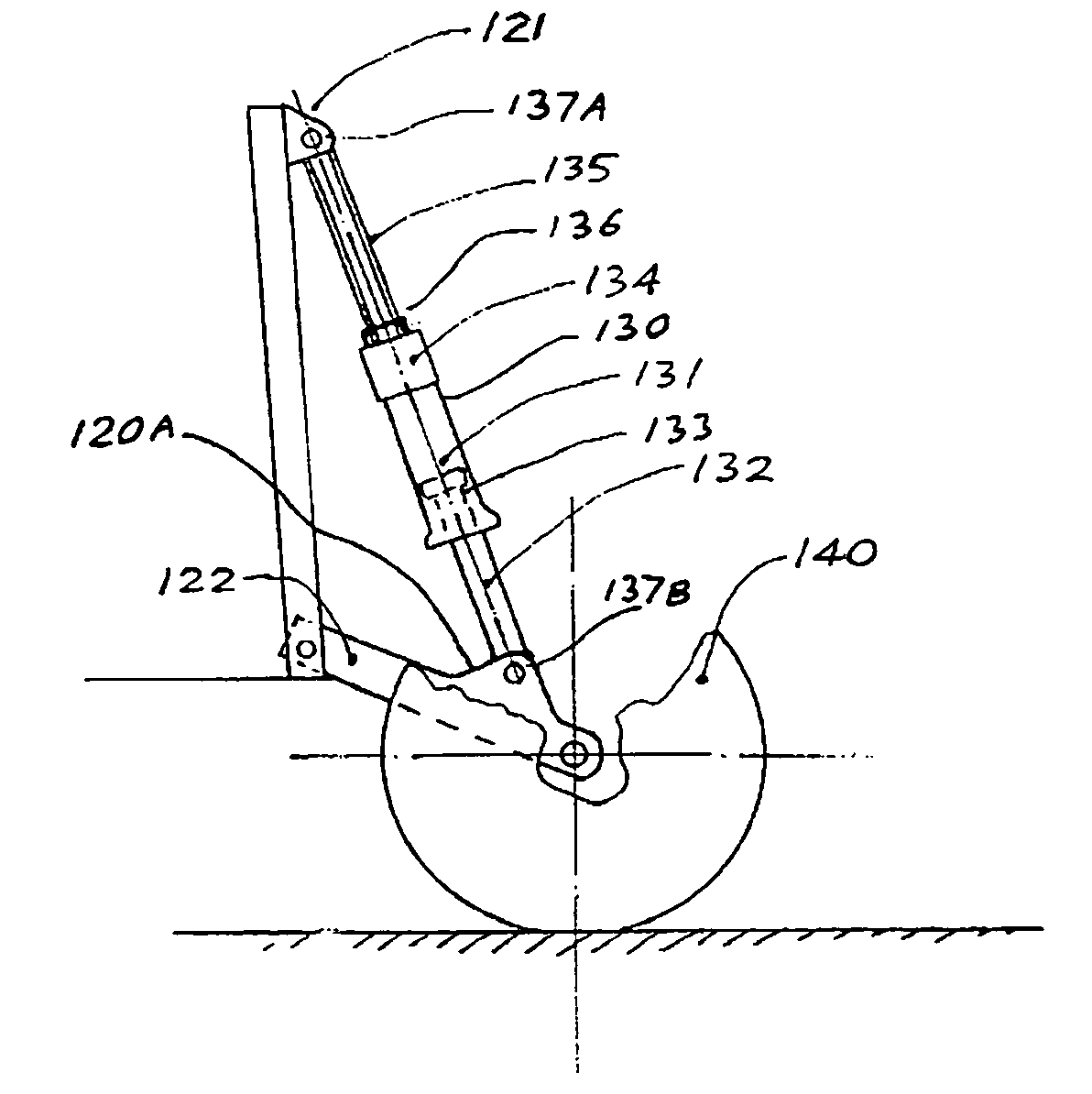

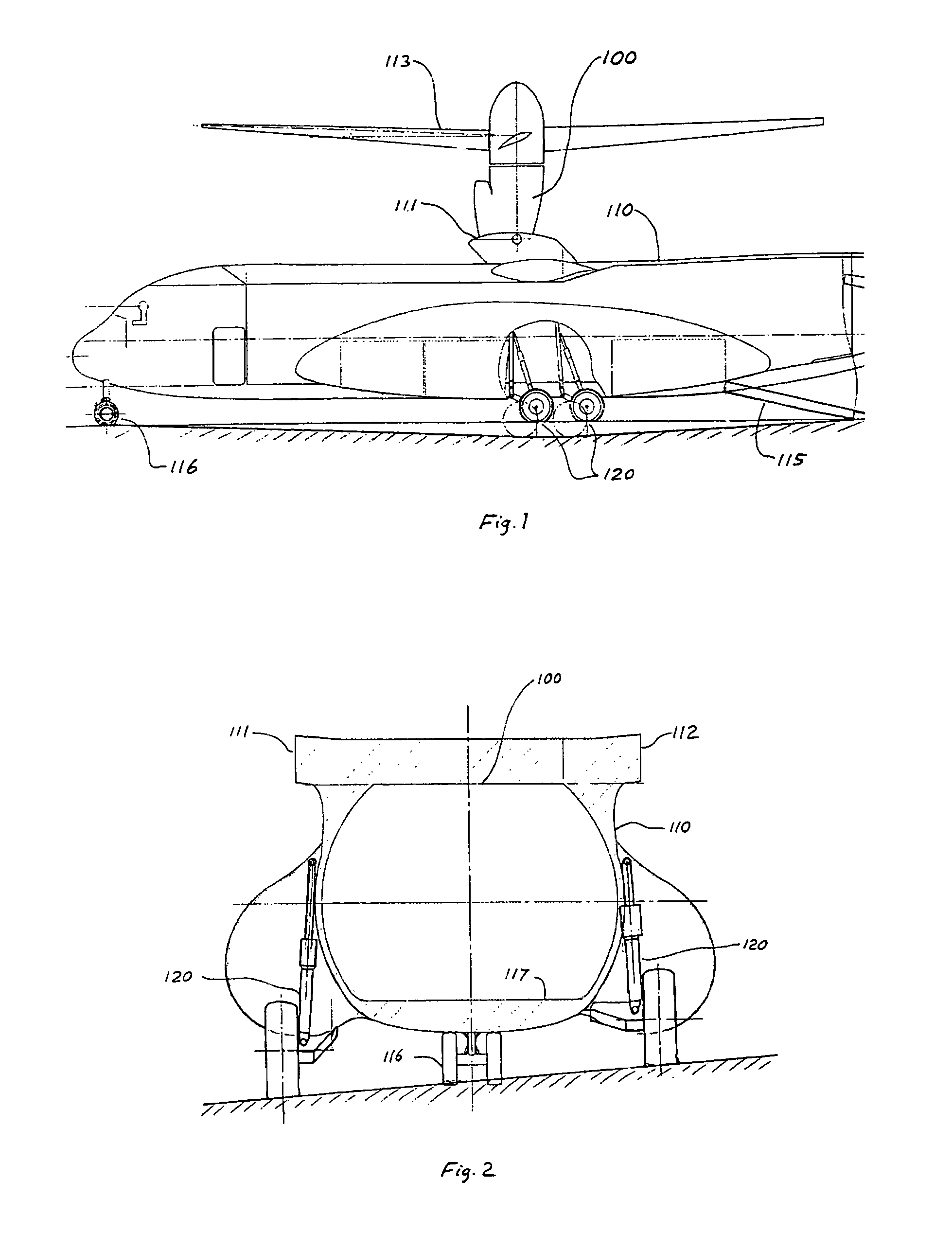

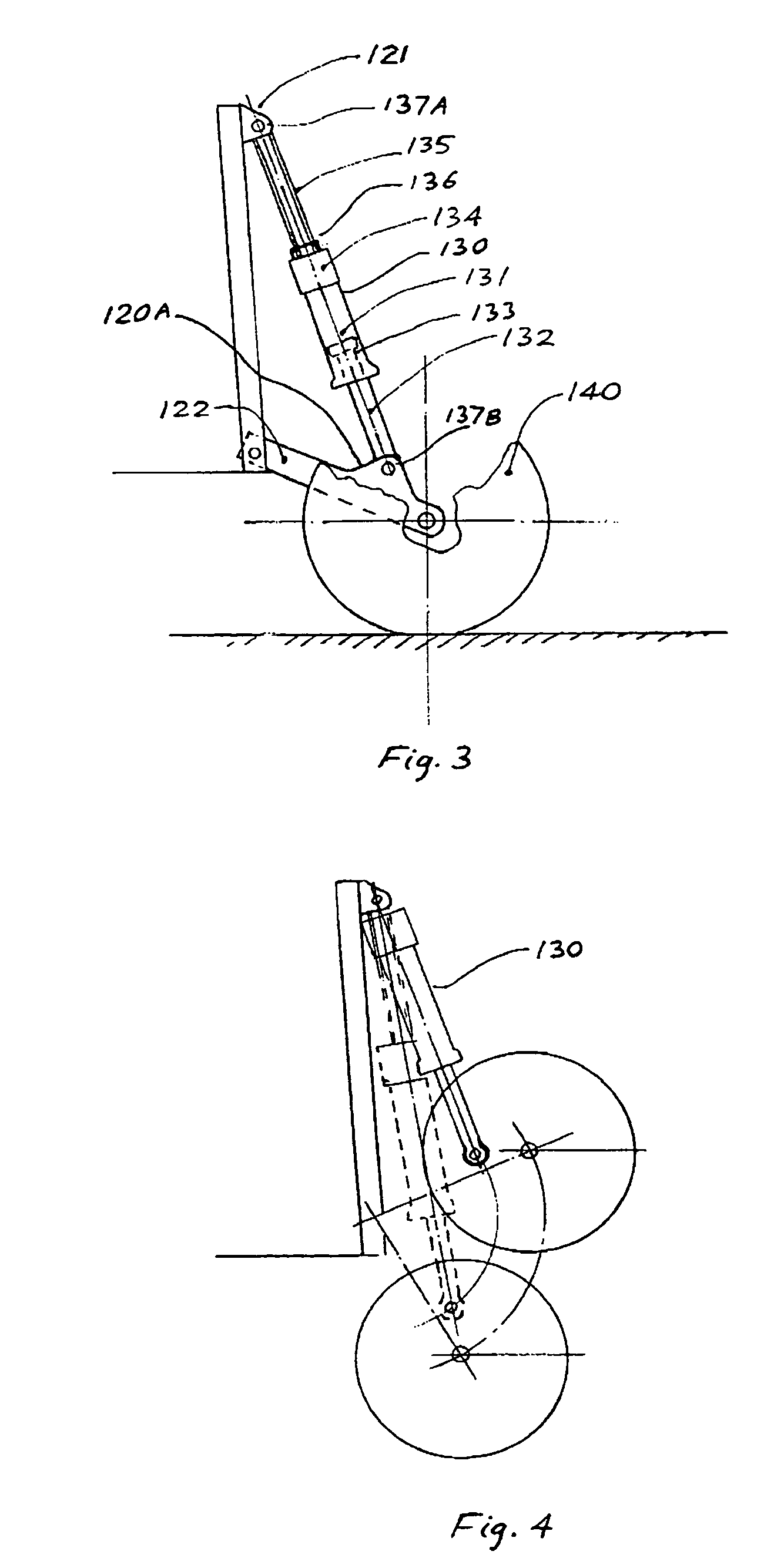

Aircraft landing gear with integrated extension, retraction, and leveling feature

ActiveUS7942366B2Saving substantial amountImprove operationVertical landing/take-off aircraftsUndercarriagesAircraft landingActuator

Electrically controlled and / or actuated landing gear mechanisms are presented that allow for adjustment of aircraft attitude on the ground as well as for retraction and extension of the landing gear in a single unit. Most preferably, the electric actuator is positioned within the diameter of the strut to thereby form a compact and load bearing structure.

Owner:KAREM AIRCRAFT INC

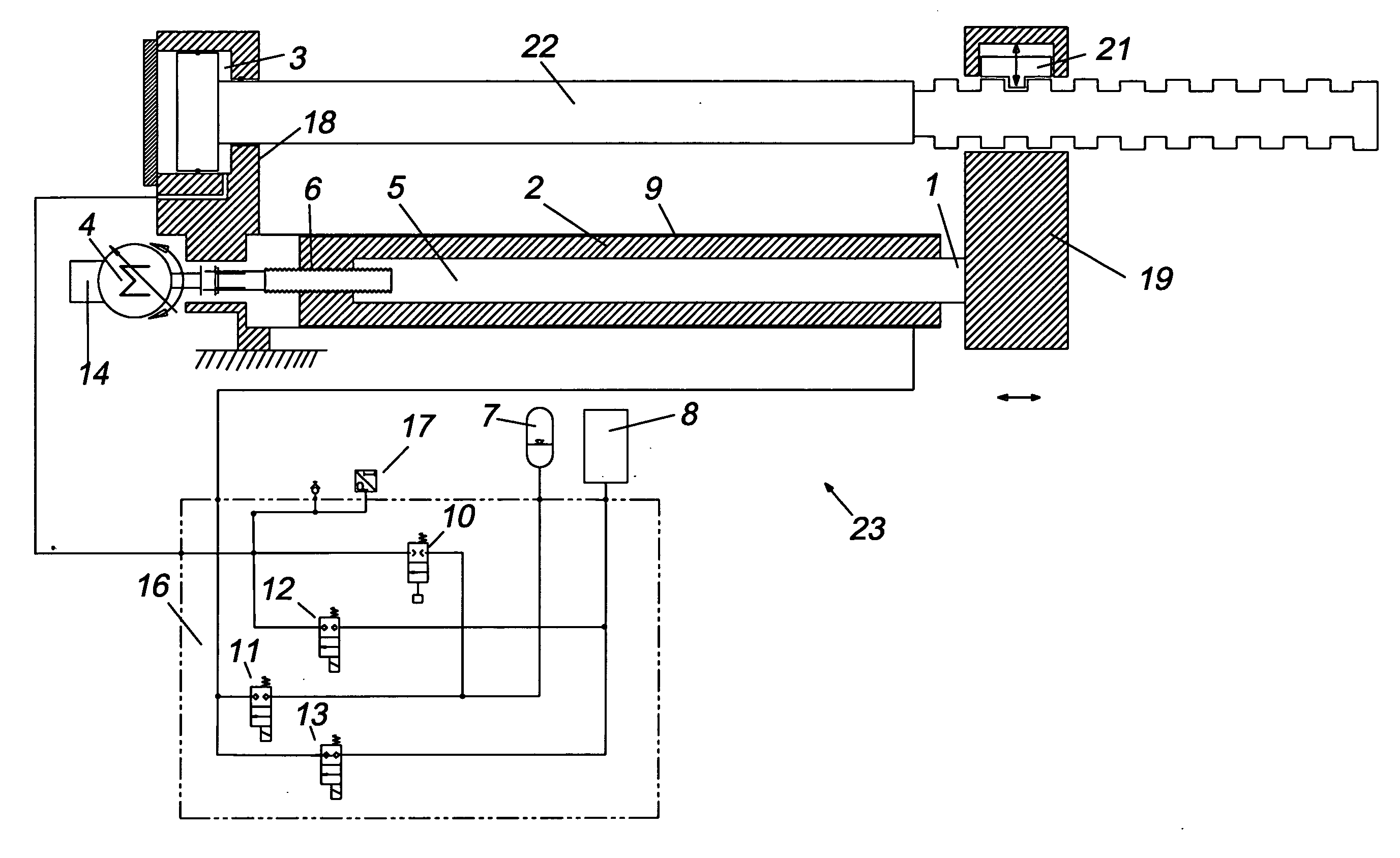

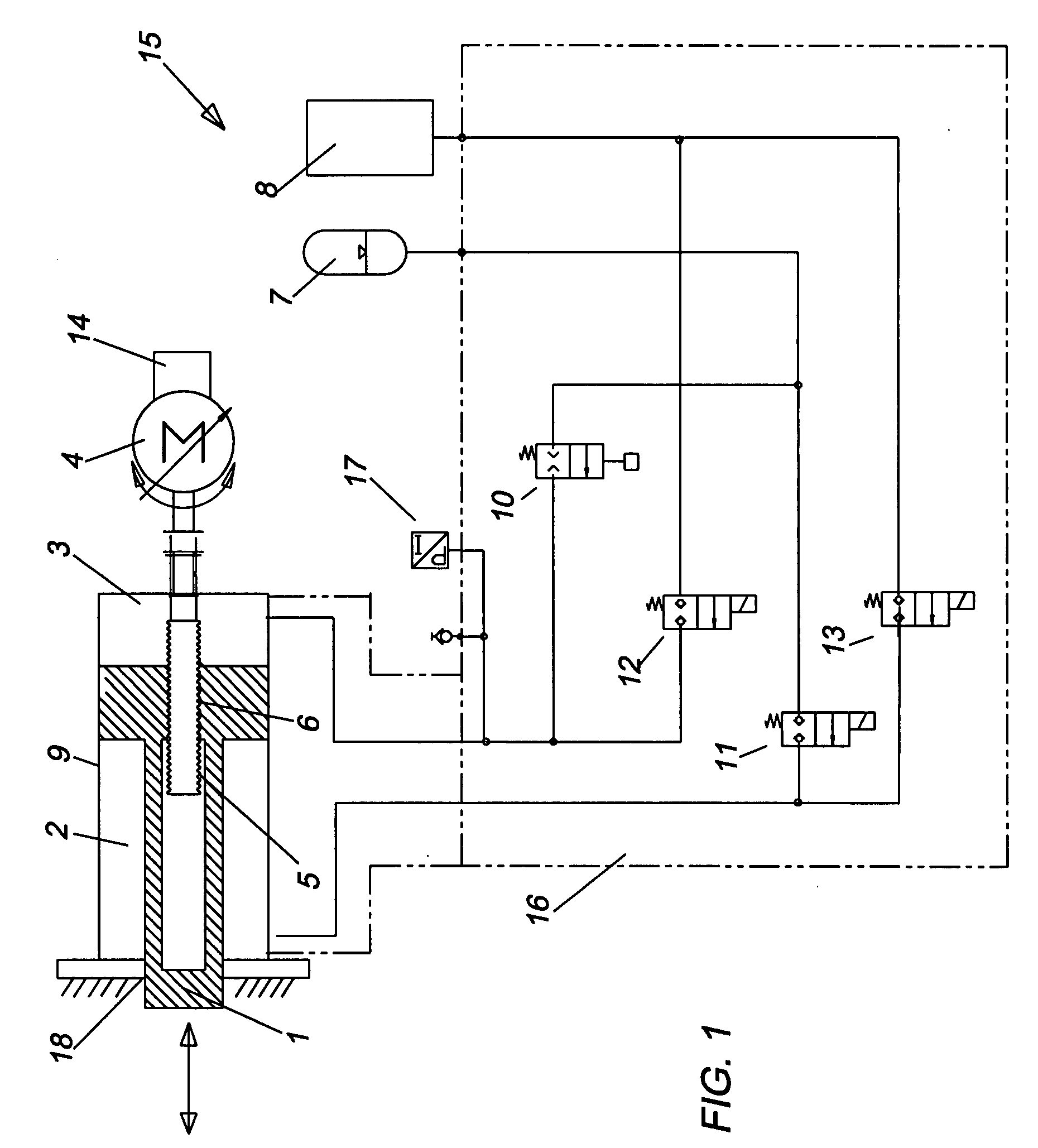

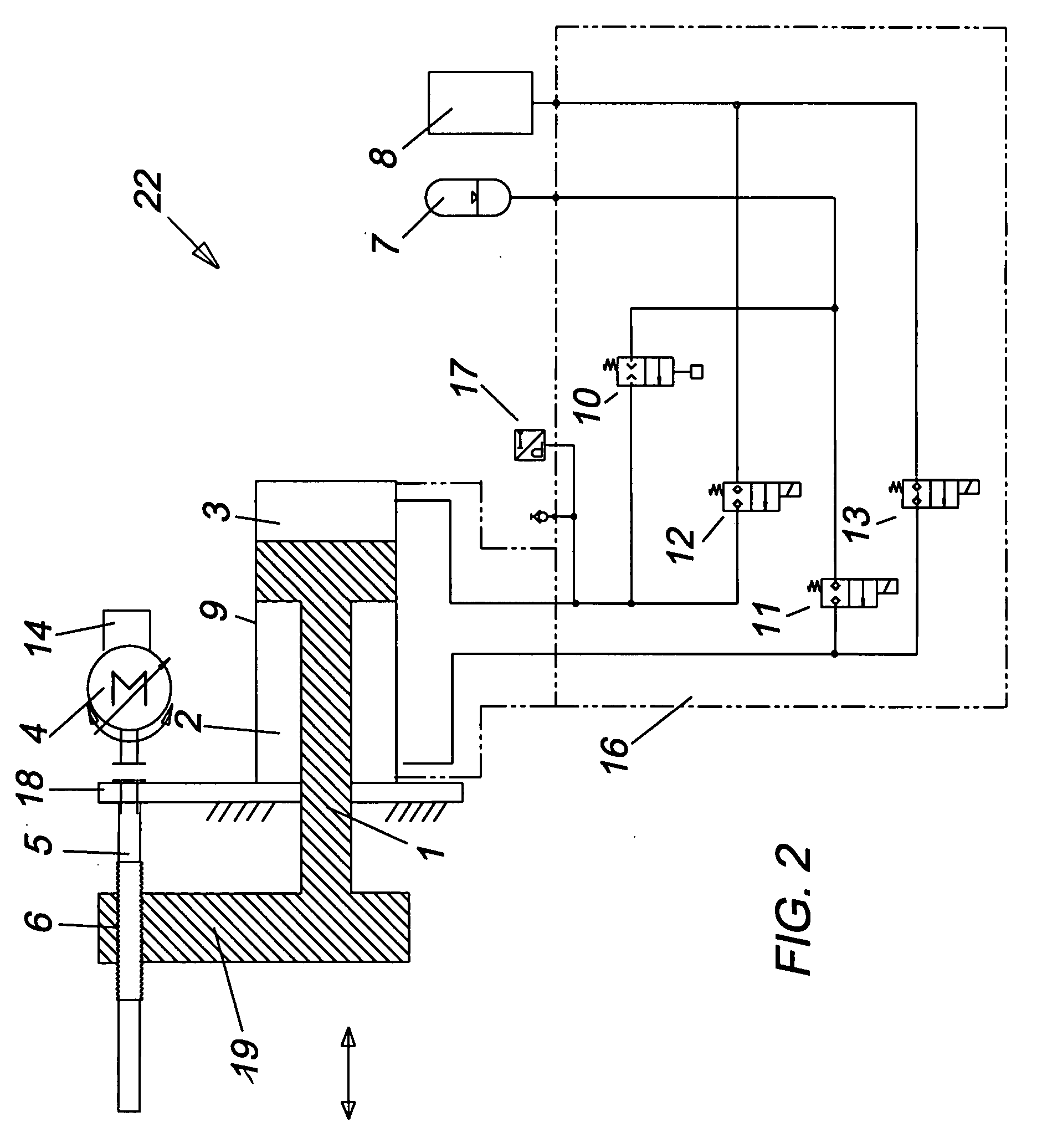

Machine and integrated hybrid drive with regenerative hydraulic force assist

InactiveUS20080202115A1Reduce energy consumptionShorten cycle timeBraking element arrangementsRotary clutchesControl systemClosed loop

A mechanical-hydraulic machine and an integrated hybrid drive with a regenerative force assist for eliminating pumps and intensifiers and reducing the energy consumption, operating costs, investment costs, weight and size of machines and improving their performance. The integrated hybrid drive is comprised of common mechanical and hydraulic components. The regenerative hydraulic force assist converts gravitational and deceleration forces of the machine into fluid pressure, stores the fluid pressure and applies the fluid pressure to clamping of dies or molds and / or performing machine operations. A closed loop control system controls the flow of fluid between the hydraulic drive and regenerative force assist.

Owner:GEIGER INNOVATIVE TECH

Motor

InactiveUS8415845B2Reduce motor sizeSmall sizeSynchronous generatorsAssociation with control/drive circuitsConductor CoilTransistor

In a motor, a stator with a three-phase winding set and a rotor are located in an operation region of a motor casing having a side wall. An inverter circuit constructed with power modules is located in a control region that is located on the opposite side of the operation region across the side wall in an axial direction of the motor. Each power module has a pair of transistors and a common terminal connected to the pair of transistors. A lead of a winding corresponding to one phase and a lead of a winding corresponding to another phase extend in the axial direction to cross over from the operation region to the control region and are connected together to the common terminal of a corresponding power module.

Owner:DENSO CORP

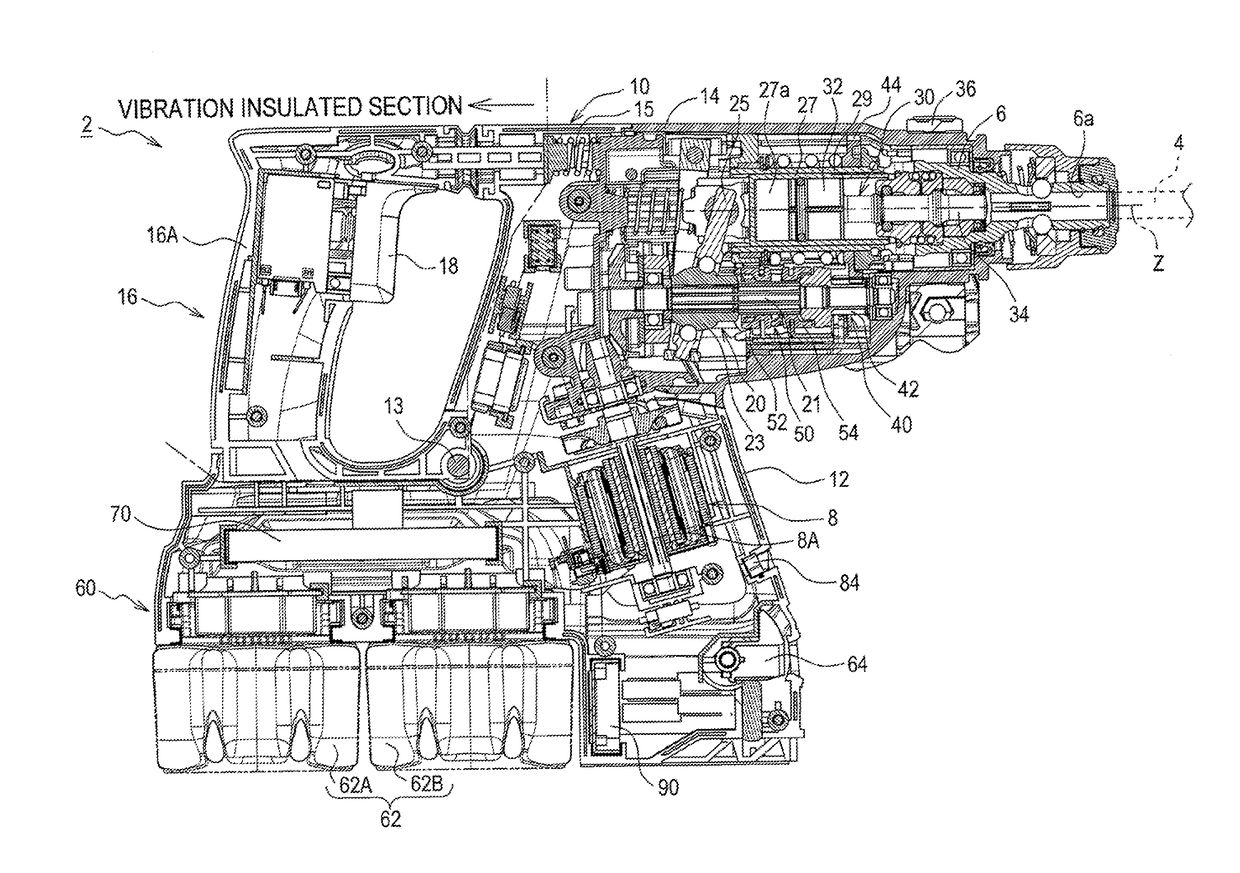

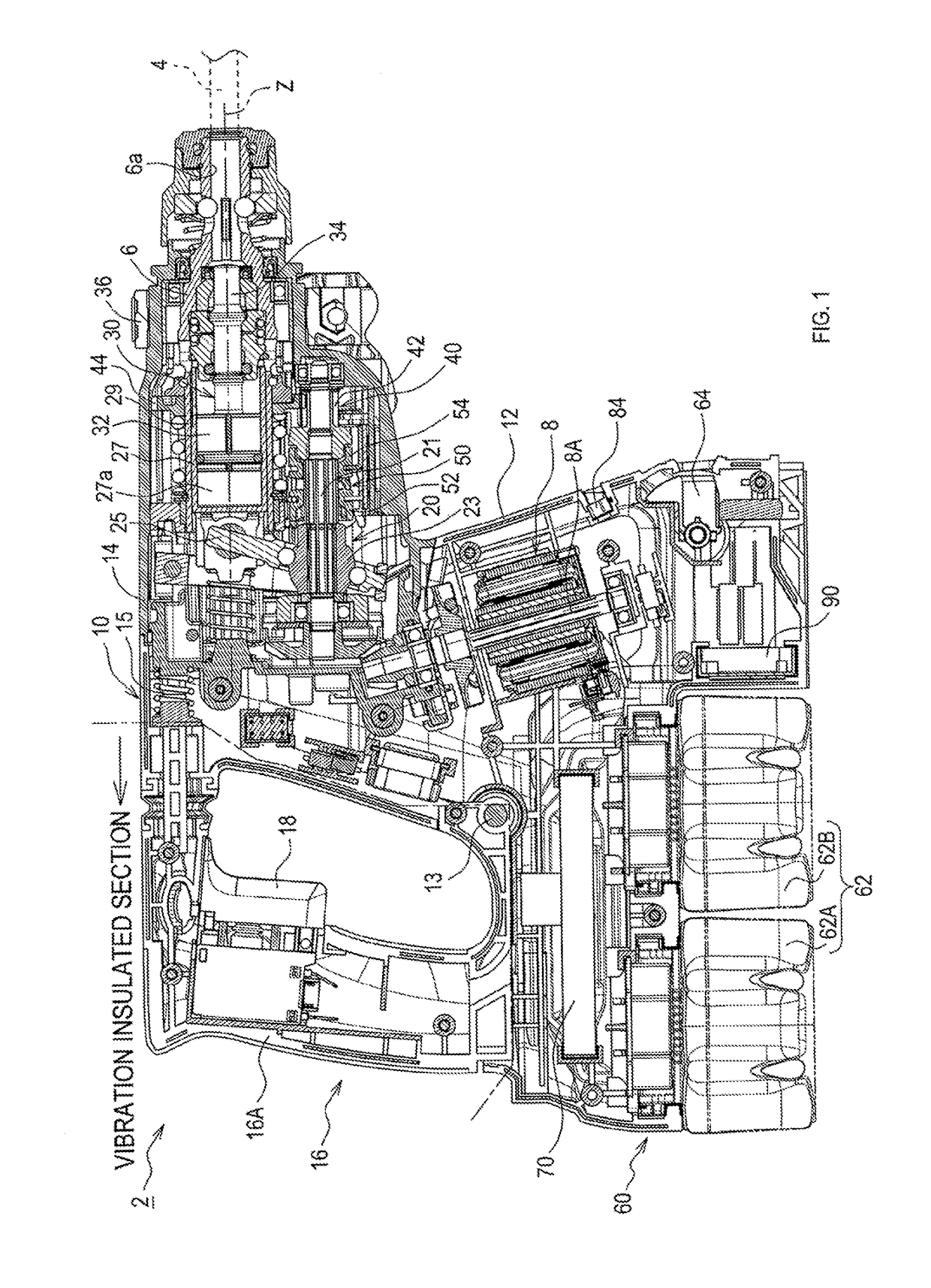

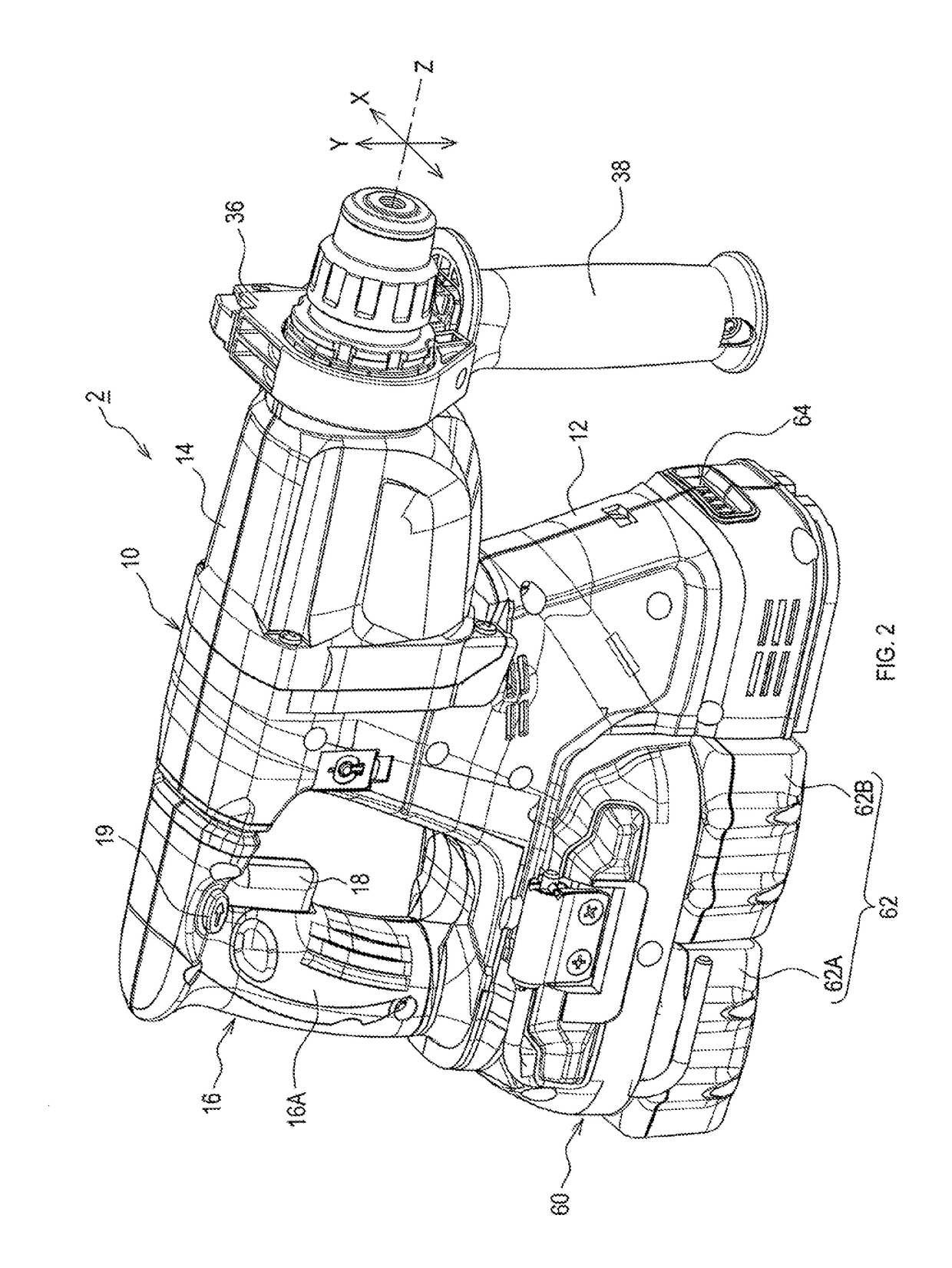

Electric power tool and method of assembling electric power tool

InactiveUS20180099399A1Improve precisionReduce vibrationPortable percussive toolsPortable power-driven toolsPower toolMotion detector

An electric power tool in one aspect of the present disclosure includes a housing; a motor; an output shaft; a rotation transmission; a motor controller; and a twisted-motion detector. The twisted-motion detector is disposed in the housing independently from the motor controller. The twisted-motion detector detects a twisted-motion of the housing in the circumferential direction of the output shaft and outputs a result of the detection to the motor controller.

Owner:MAKITA CORP

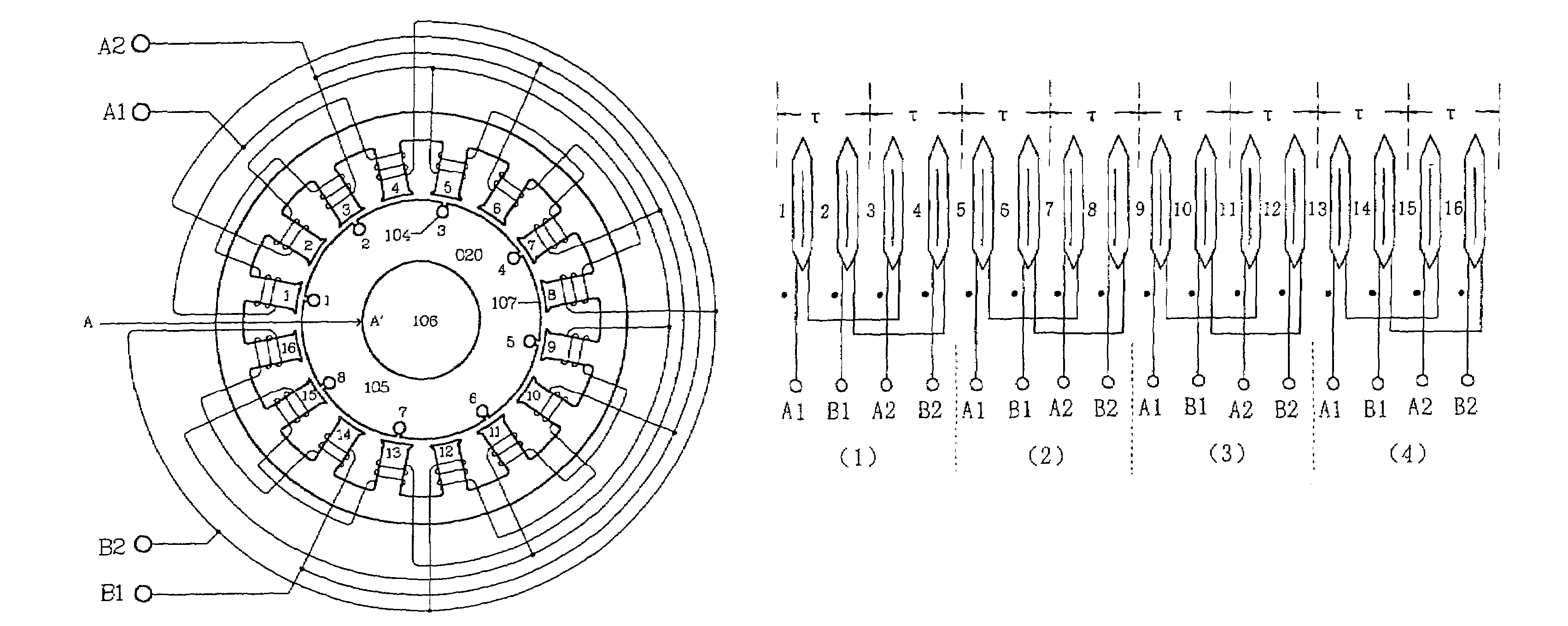

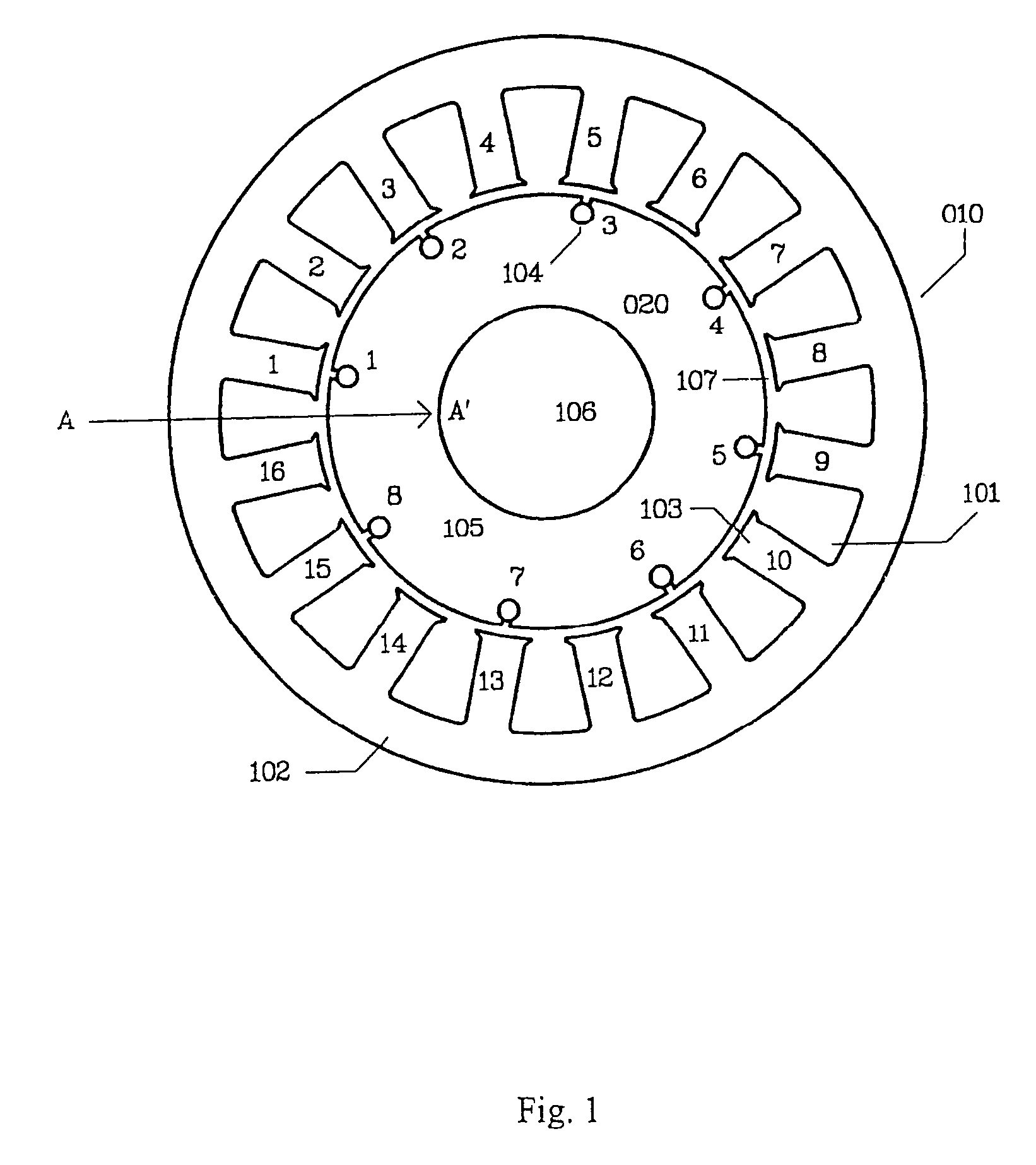

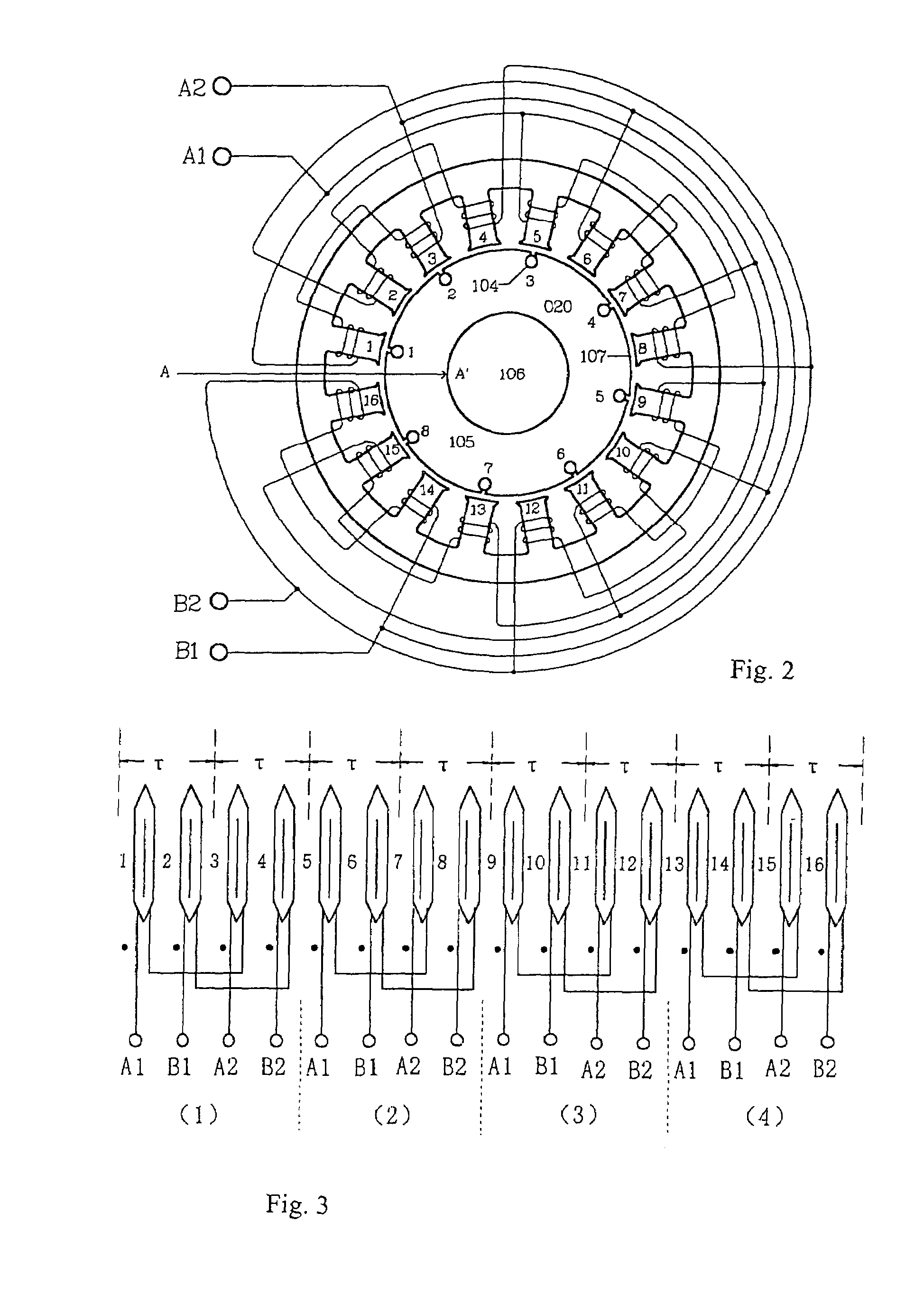

Switching pattern AC induction motor

InactiveUS7239061B2Wide speed rangeReduce manufacturing costSingle-phase induction motor startersAC motor controlFrequency characteristicPulse width modulated

Both the stator core and the rotor core of a switching pattern AC induction motor are fabricated by soft magnetic material laminations or ferrite material, etc., both of which have corresponding frequency characteristic. The rotor is a squirrel cage rotor. Switching pattern excitation is adopted in the stator pole, of which the excitation voltage is sine wave pulse width modulated or sine wave pulse amplitude modulated within the frequency range of voice and ultrasonic. Under the condition of the same power output, the present motor reduces its size and mass to a fraction of or tenth of that of an ordinary one. Meanwhile, it reduces the cost of manufacture. It realizes stepless speed regulating from zero to several thousand rpm while keeping well mechanical characteristic performance.

Owner:HUANG YOUGUO +1

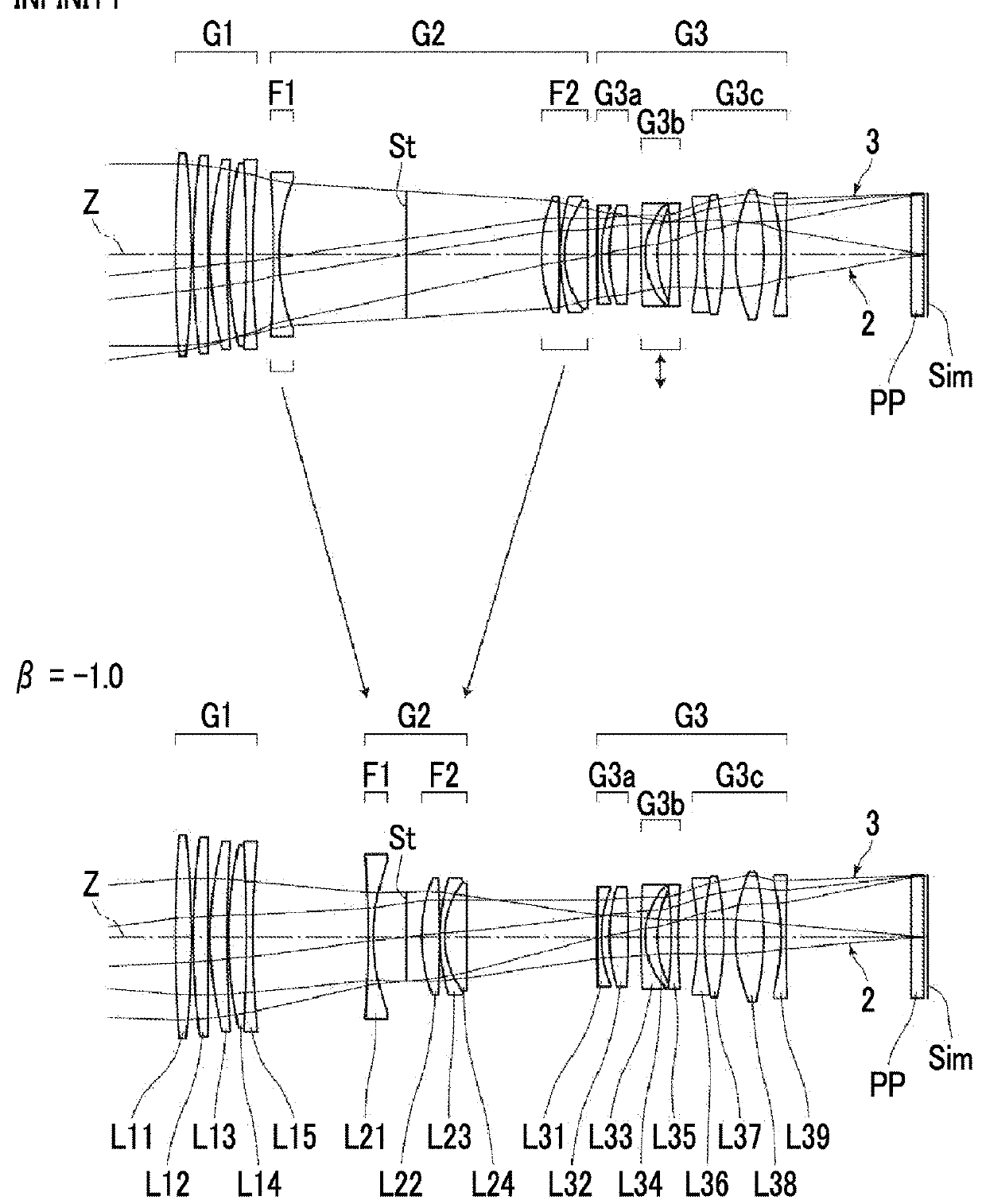

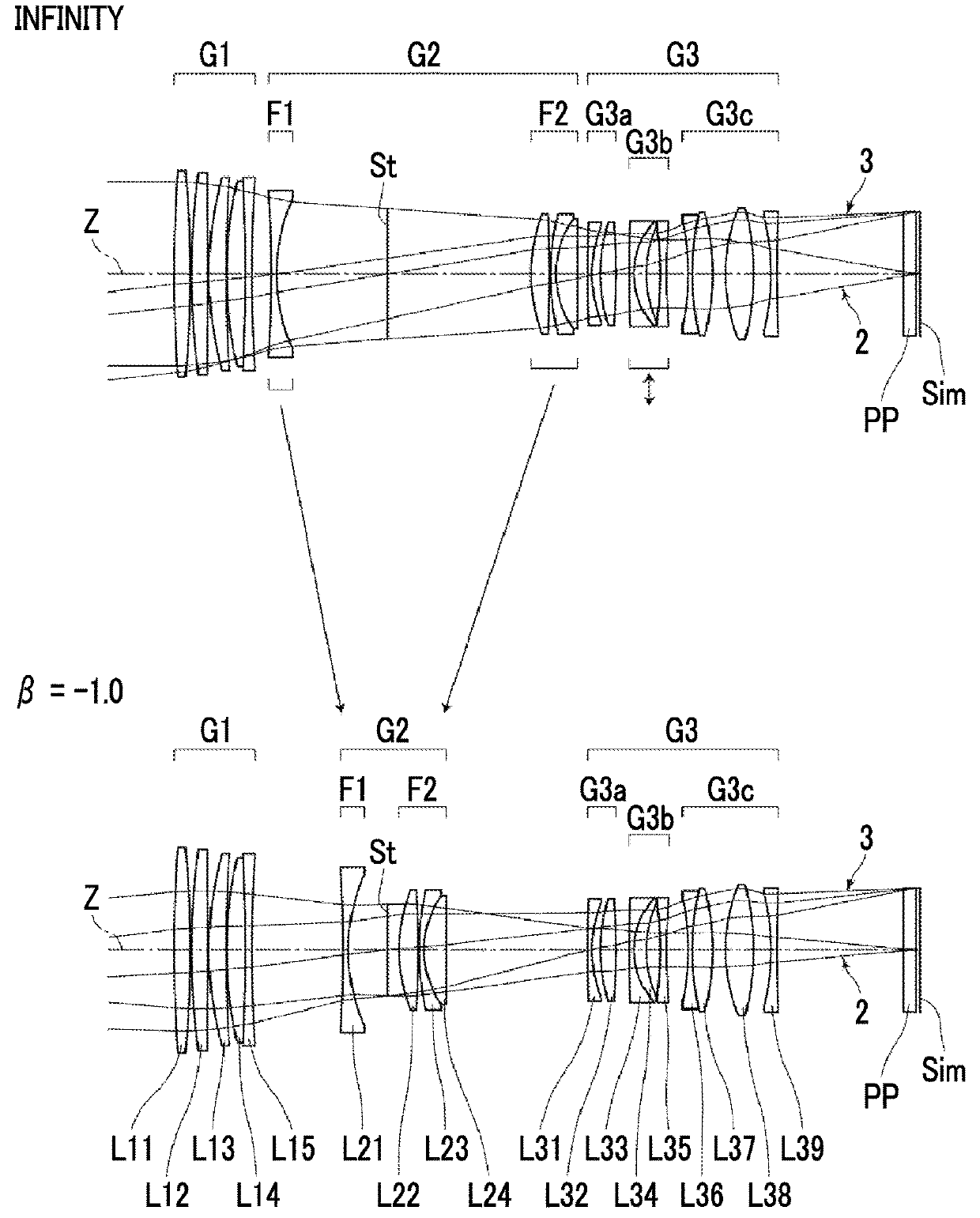

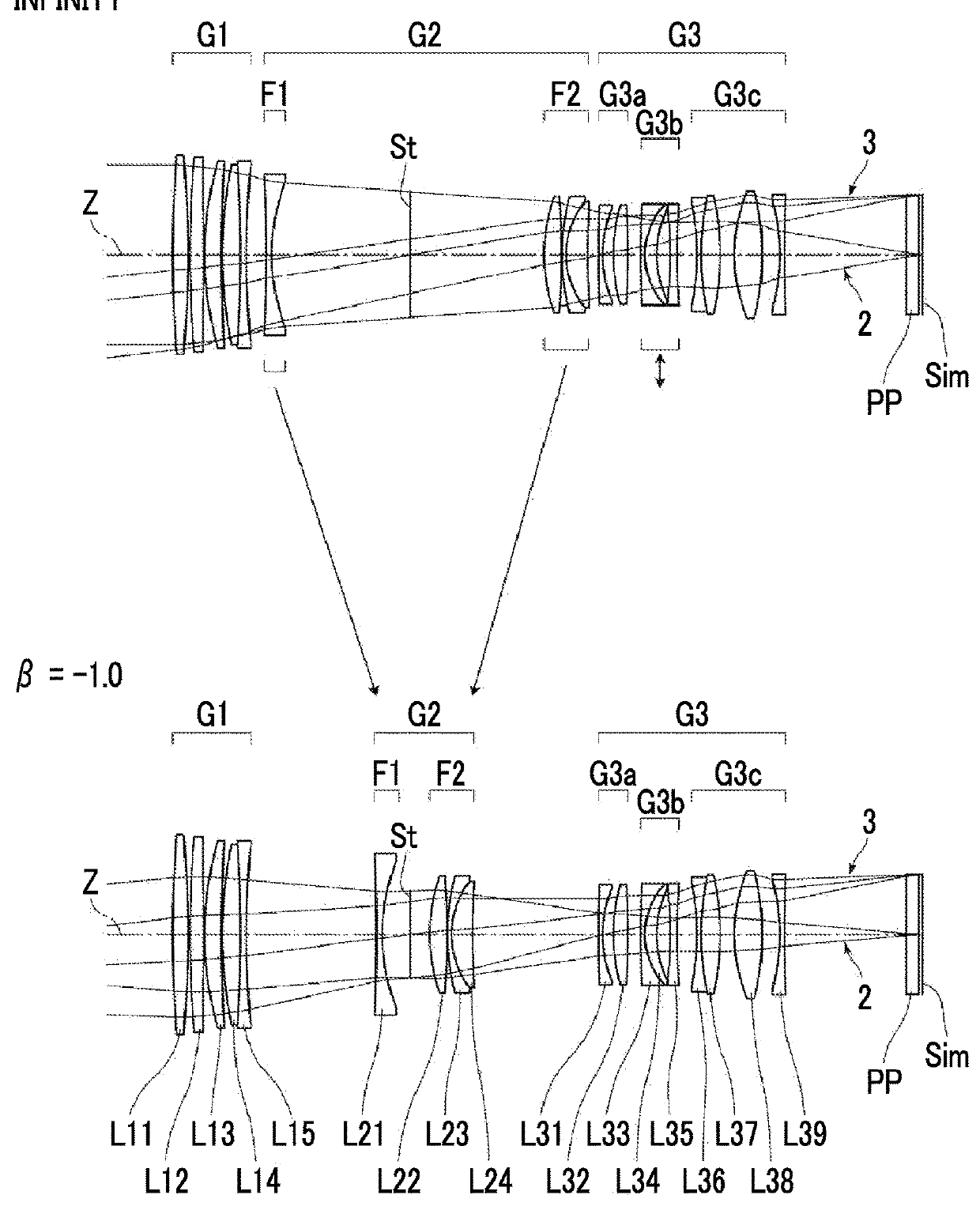

Imaging lens and imaging apparatus

The imaging lens consists of, in order from the object side, a first lens group having a positive refractive power, a second lens group, and a third lens group. In the second lens group, a first focus lens group having a negative refractive power is disposed to be closest to the object side, and a second focus lens group having a positive refractive power is disposed to be closest to the image side. During focusing, only the first and second focus lens groups move by changing the mutual spacing therebetween. The first lens group has two positive lenses and one negative lens. The first focus lens group consists of two or less lenses including a negative lens. Predetermined conditional expressions are satisfied.

Owner:FUJIFILM CORP

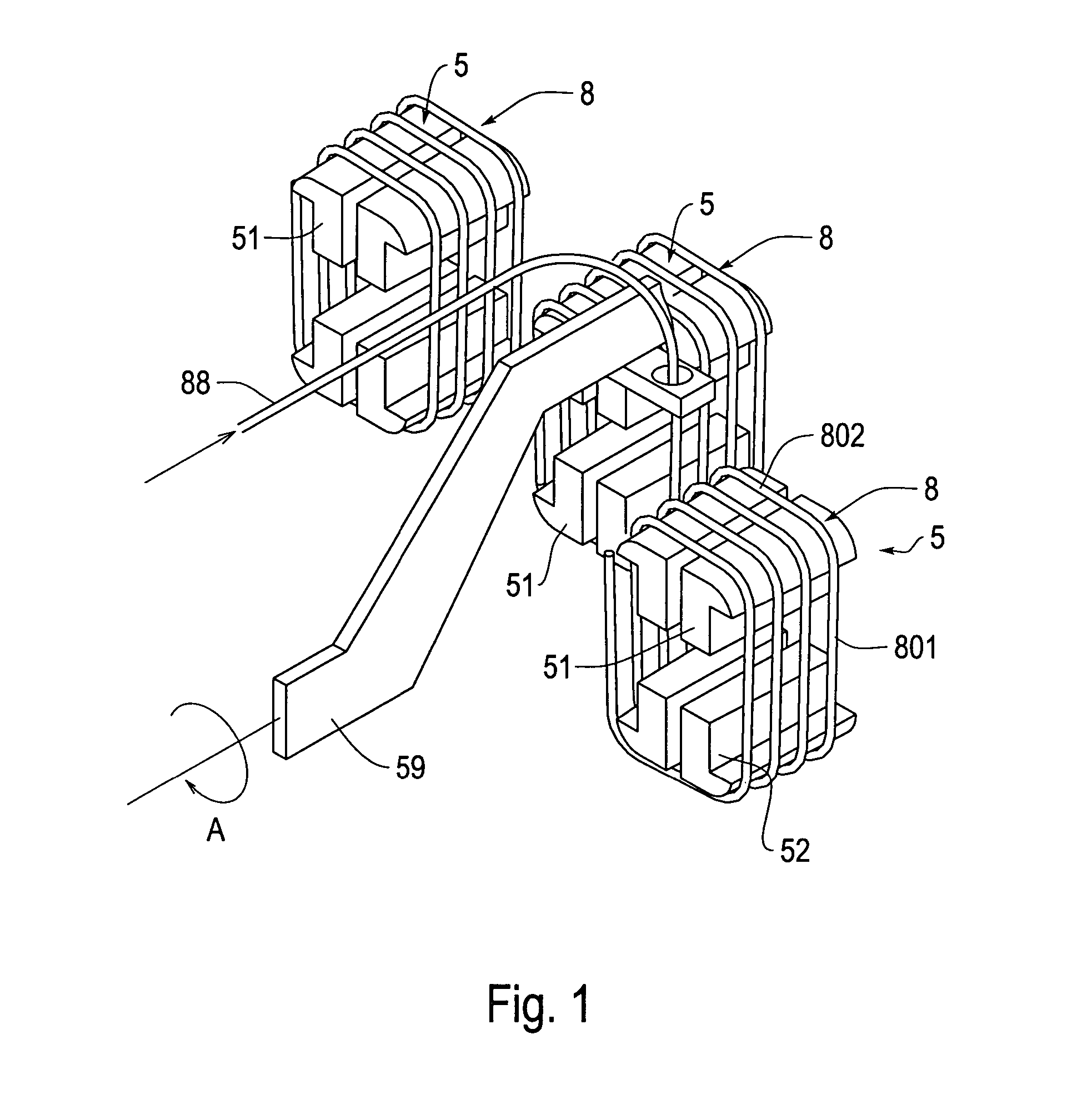

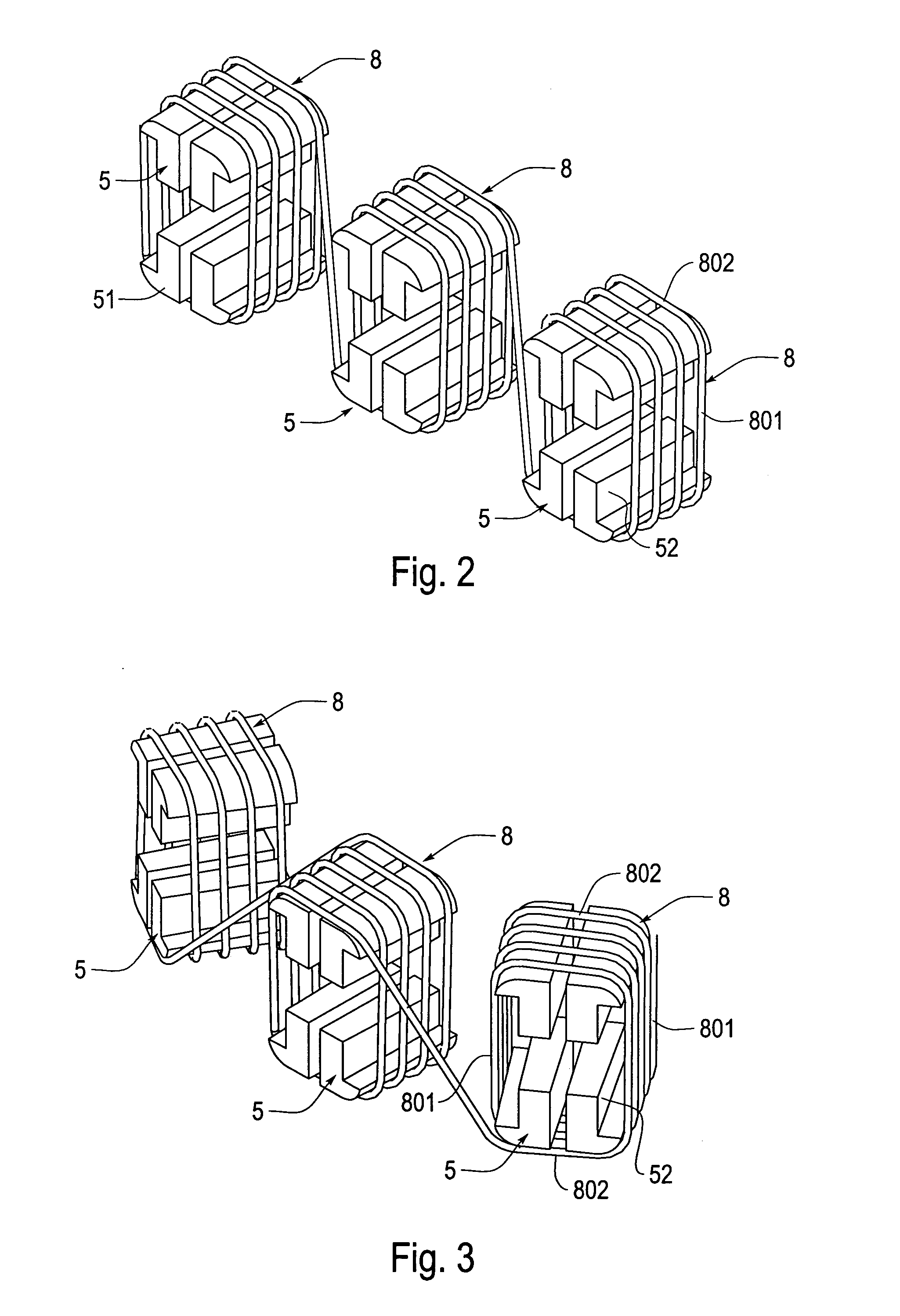

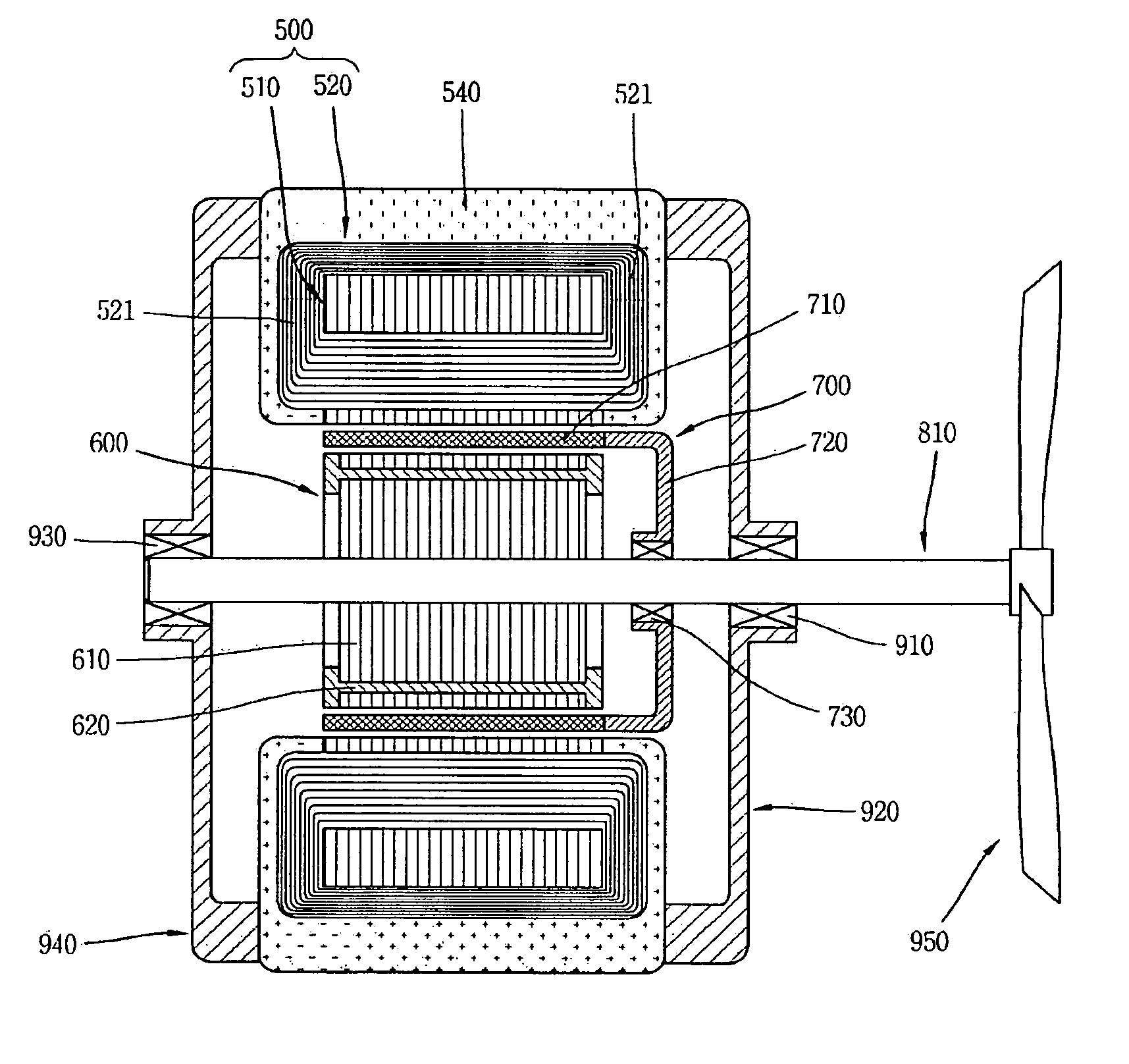

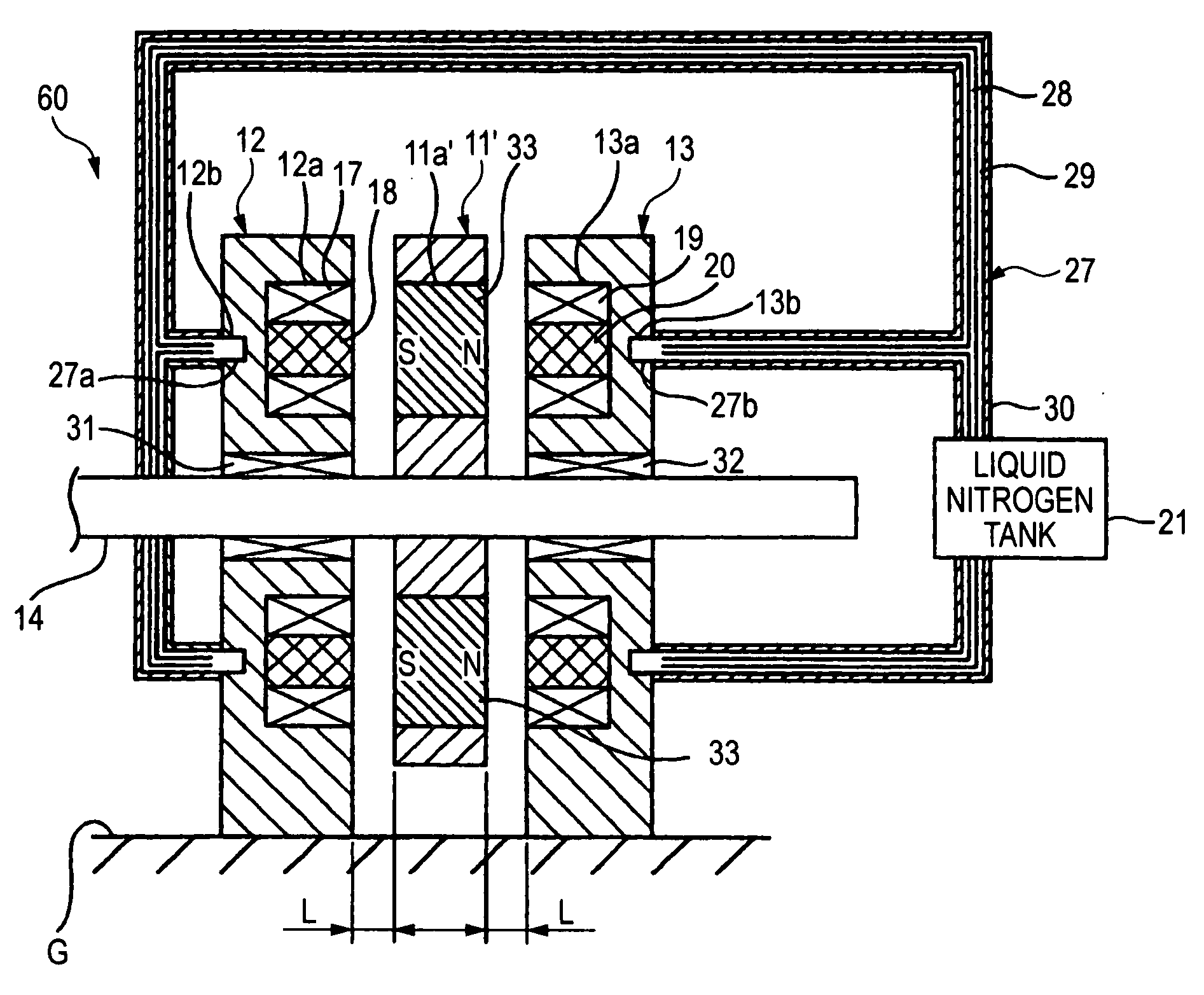

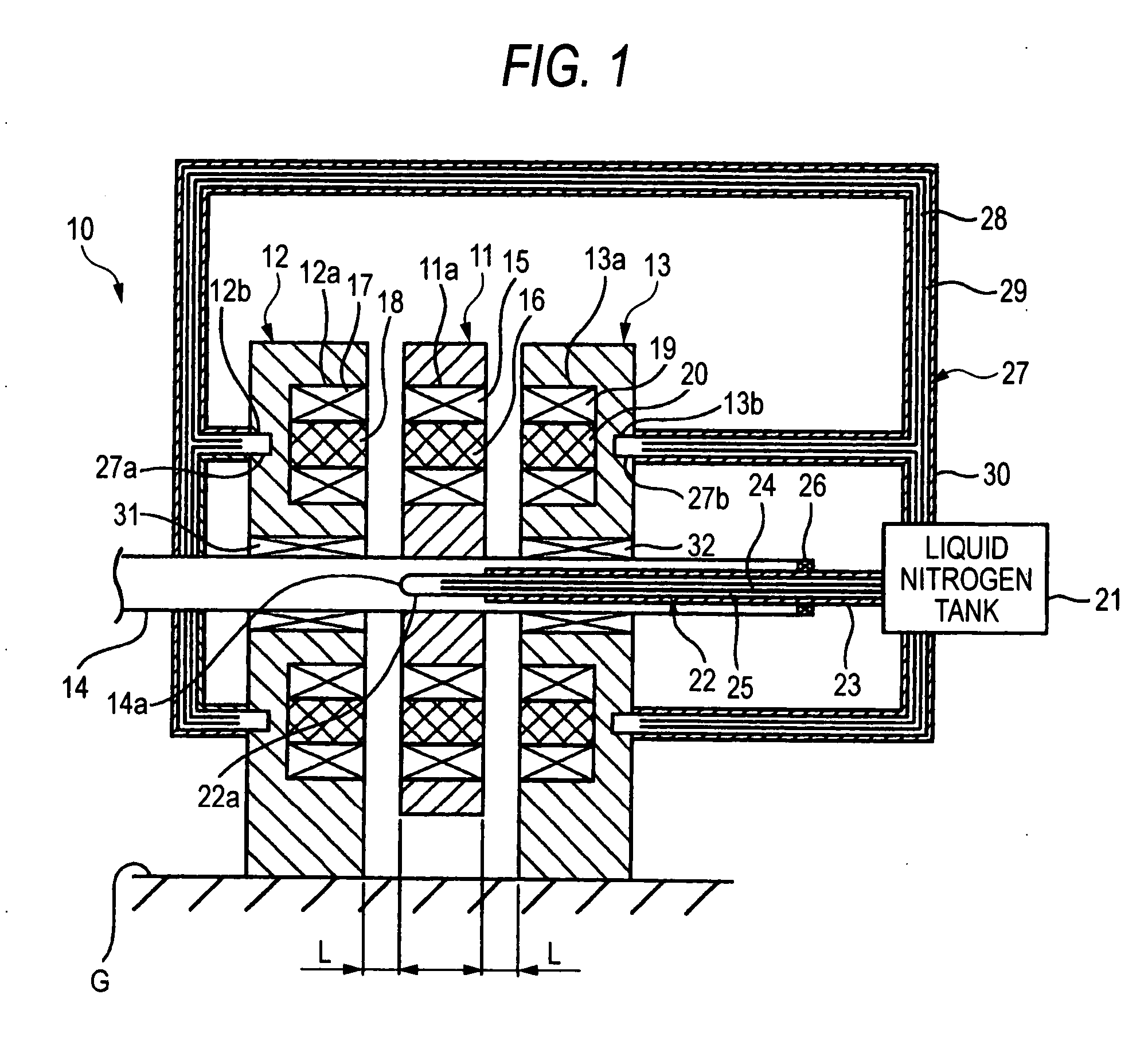

Axial Gap Type Superconducting Motor

InactiveUS20080039331A1High-output motorHigh currentMagnetic circuit rotating partsSuperconductor devicesSuperconducting electric machineElectric machine

Stators 12 and 13 are disposed with required air gaps in an axial direction of a rotor 11 so as to face each other, a plurality of field bodies 15 or permanent magnets 33 are disposed in the rotor 11, and a plurality of armature coils 17 and 19 are disposed in the stators 12 and 13 around the axis. At least one of the field bodies 15 or permanent magnets 33 and the armature coils 17 and 19 are formed from a superconductive material such that their magnetic flux directions are directed to the axial direction.

Owner:SUMITOMO ELECTRIC IND LTD +1

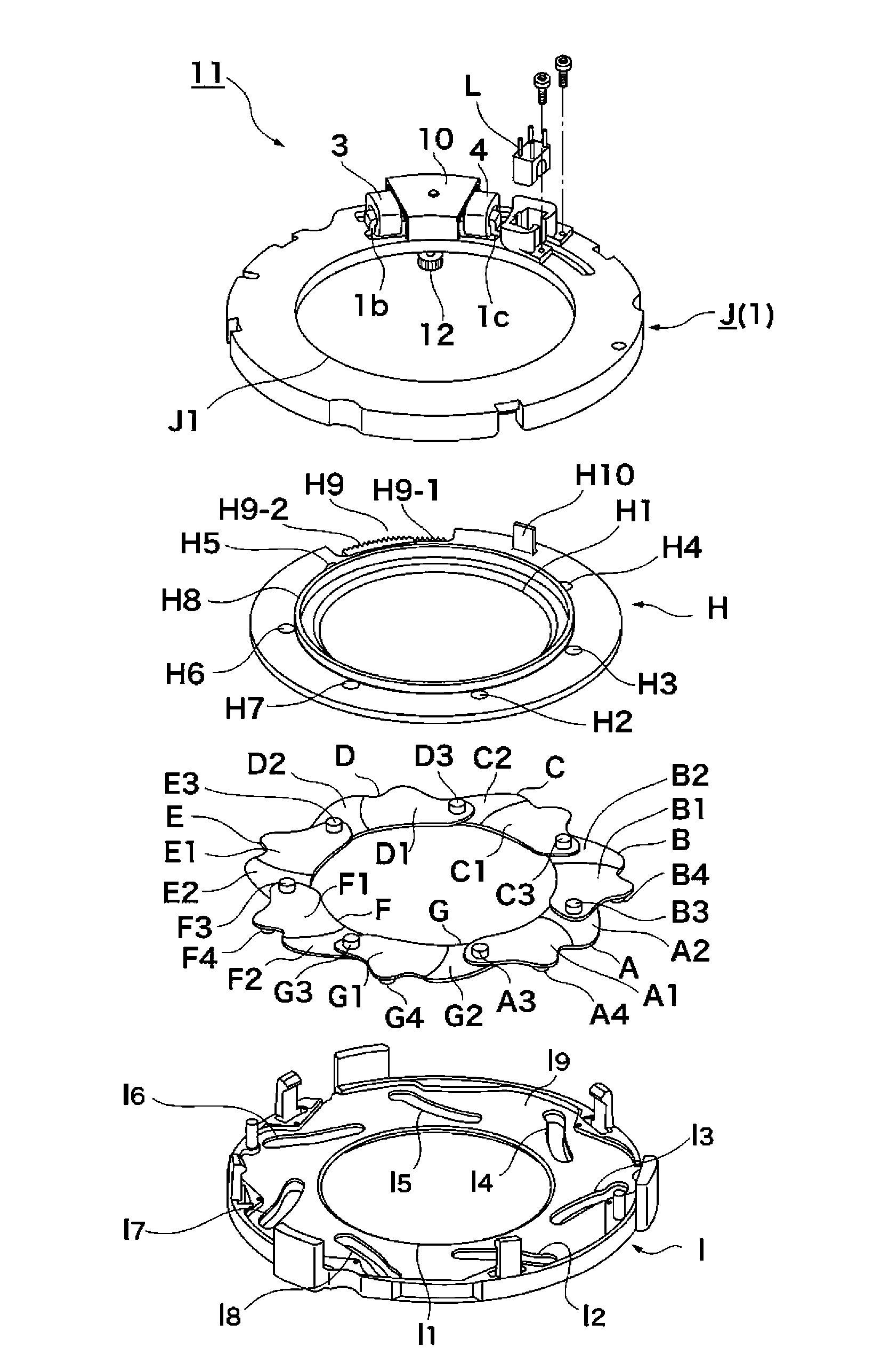

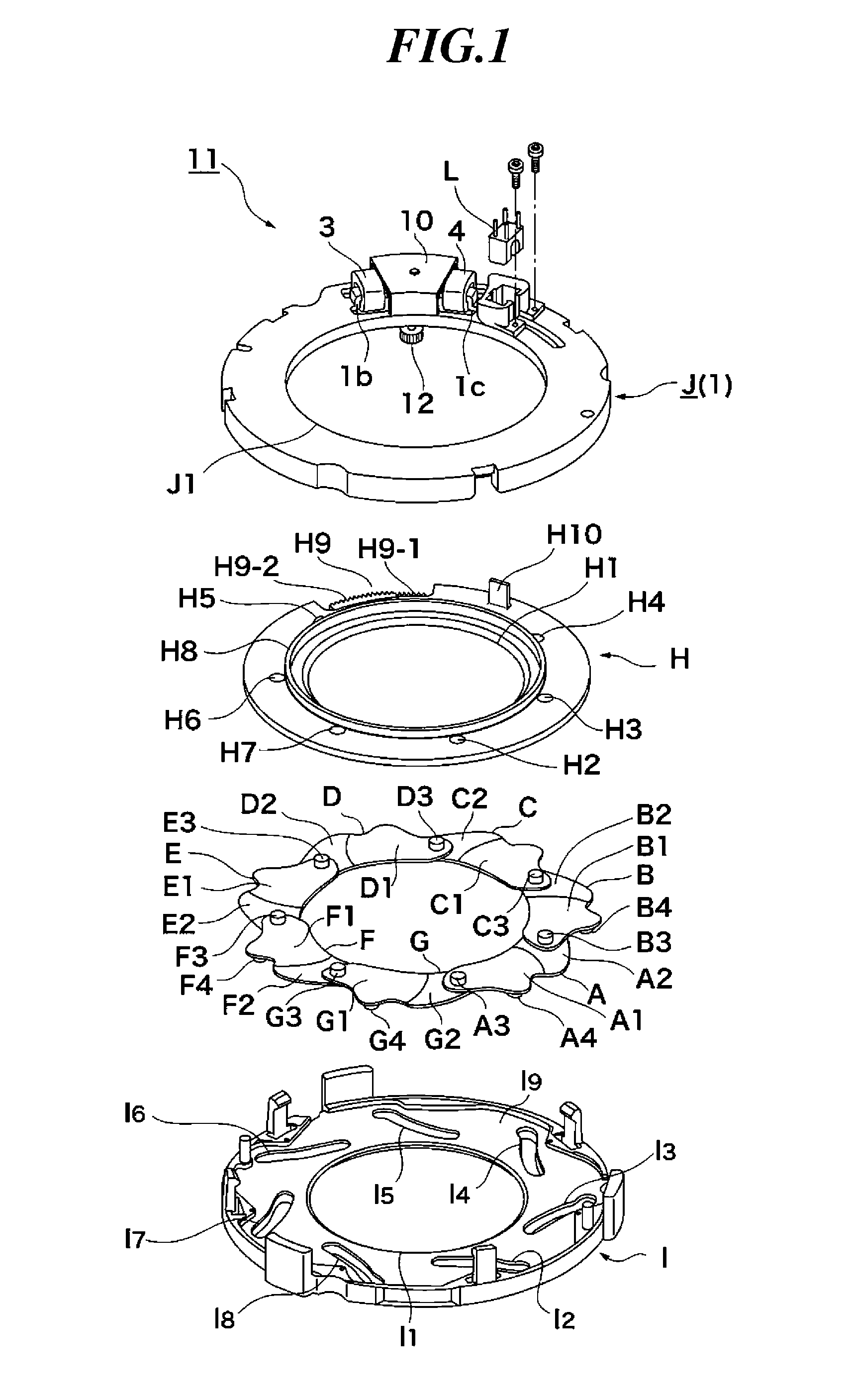

Motor having small size and high output, and light amount adjustment device equipped with the motor

InactiveUS20120063005A1Small sizeIncrease motor outputMagnetic circuit stationary partsMechanical energy handlingMotor driveMagnetic poles

A light amount adjustment device including a motor which can be reduced in size by reducing radial and axial dimensions and makes it possible to increase the motor output. The device has a stator of a motor drive mechanism formed integrally with a holding member fixed to a cam member with aperture blades and a rotary member for driving them sandwiched therebetween. A stator includes a support portion, and first and second magnetic pole portions. The first and second magnetic pole portions extend toward an outer periphery of the rotor and coils are inserted thereon from respective extending ends. The extending ends are disposed in a manner opposed to the outer periphery of the rotor. The two portions are disposed with an angle therebetween such that respective lines extending in the extending directions intersect with each other.

Owner:CANON KK +1

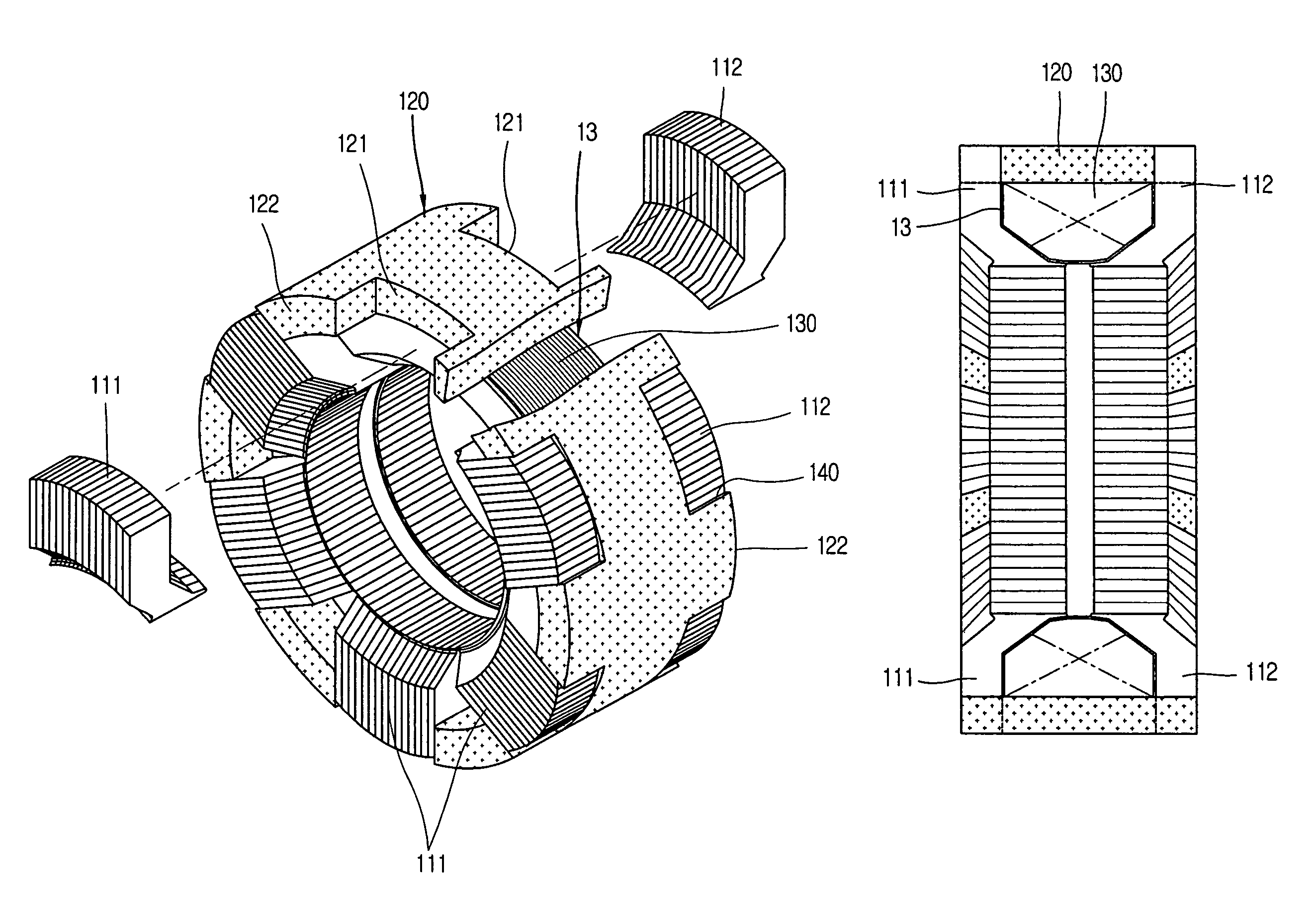

Outer stator for reciprocating motor and manufacturing method thereof

InactiveUS7323800B2Avoid deformationReduce motor sizePositive displacement pump componentsMagnetic circuit stationary partsBobbinEngineering

An outer stator of a reciprocating compressor comprises: a bobbin formed as a ring shape and provided with a winding coil therein; an outer stator frame coupled to an outer circumferential surface of the bobbin and formed of a magnetic body in which a flux flows; a plurality of first core blocks coupled to the outer stator frame and positioned radially at one side of the bobbin; and a plurality of second core blocks coupled to the outer stator frame, facing the first core blocks, and positioned at the other side of the bobbin. Accordingly, deformation which may occur during manufacturing can be prevented, and a size of a motor can be minimized.

Owner:LG ELECTRONICS INC

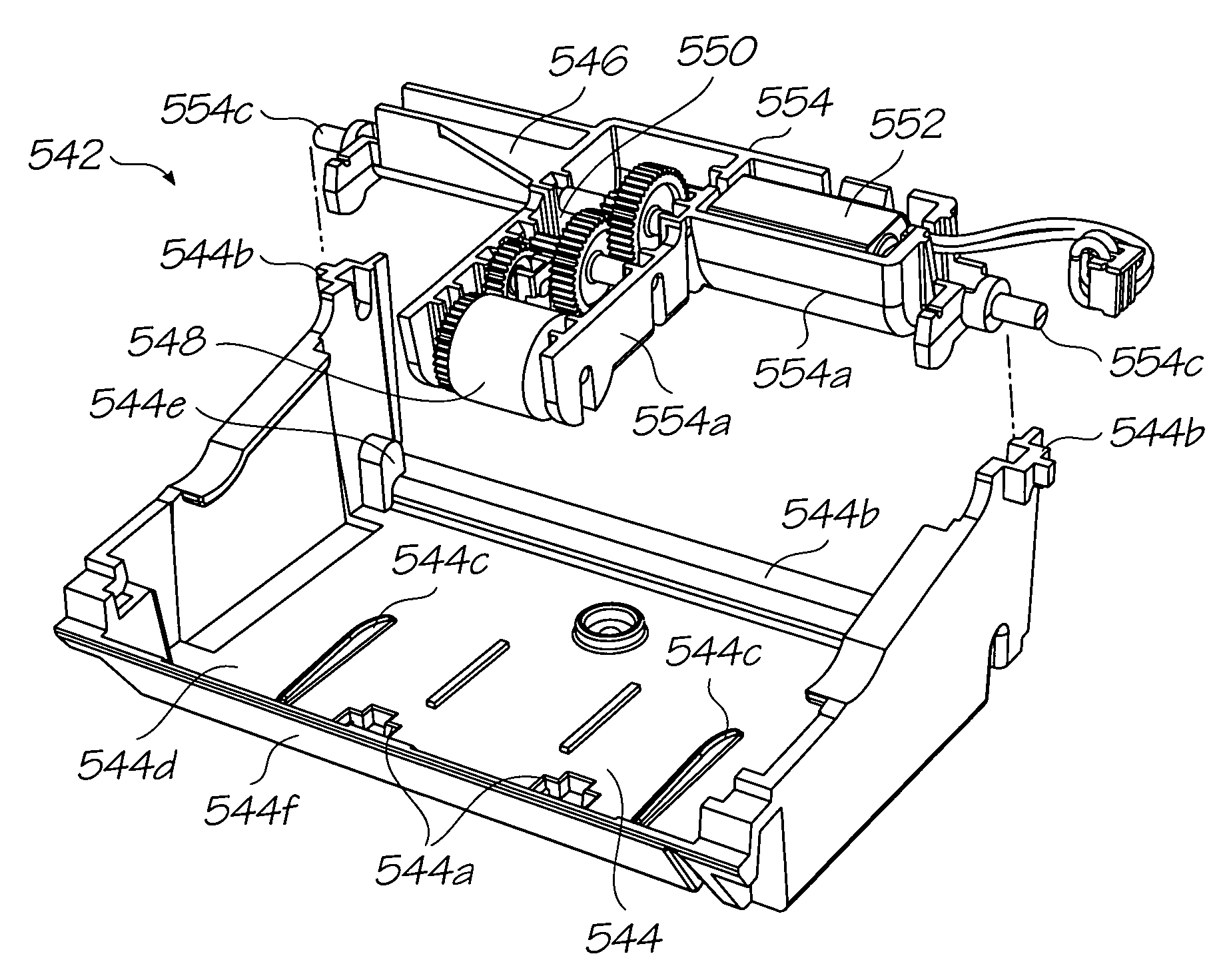

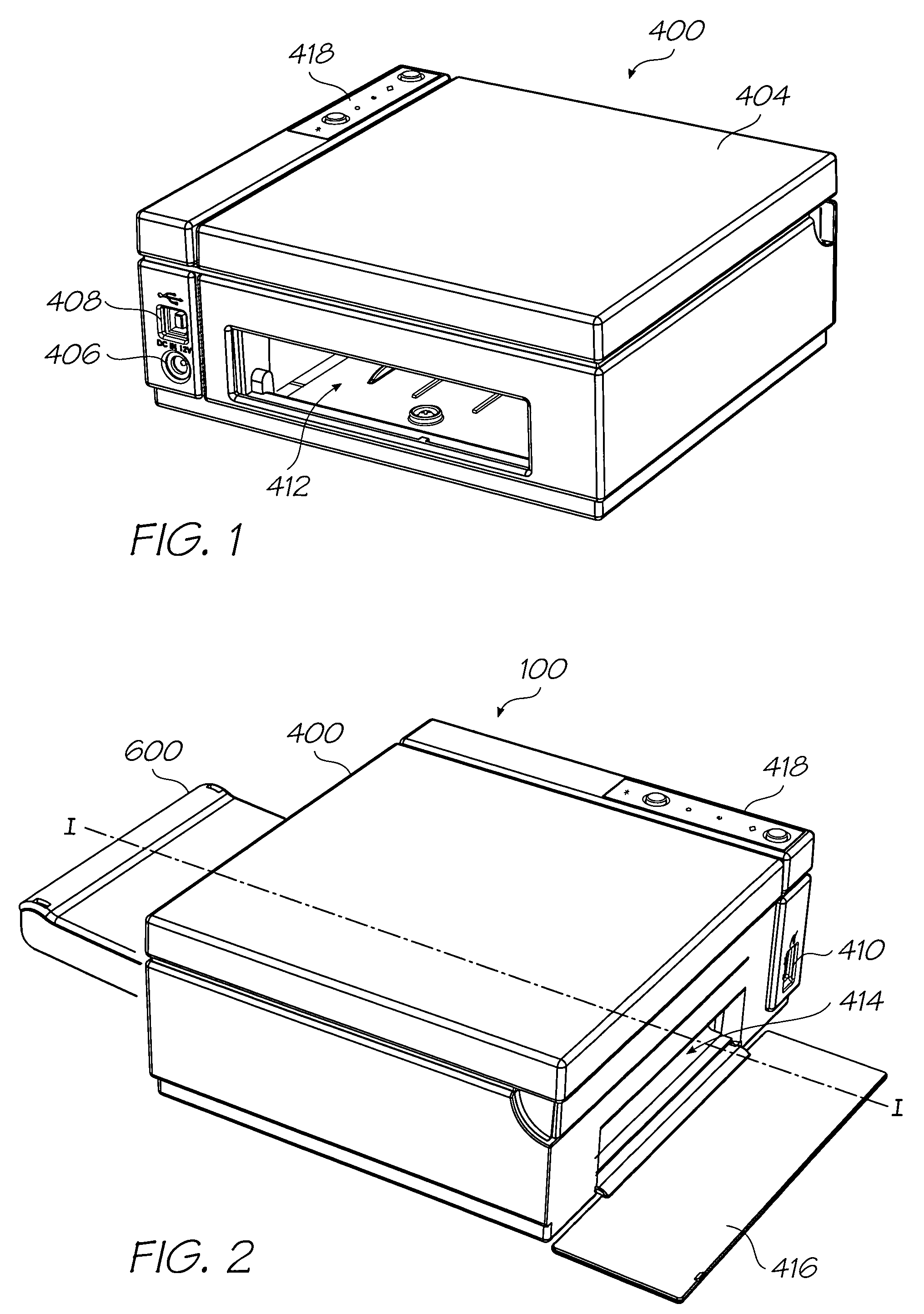

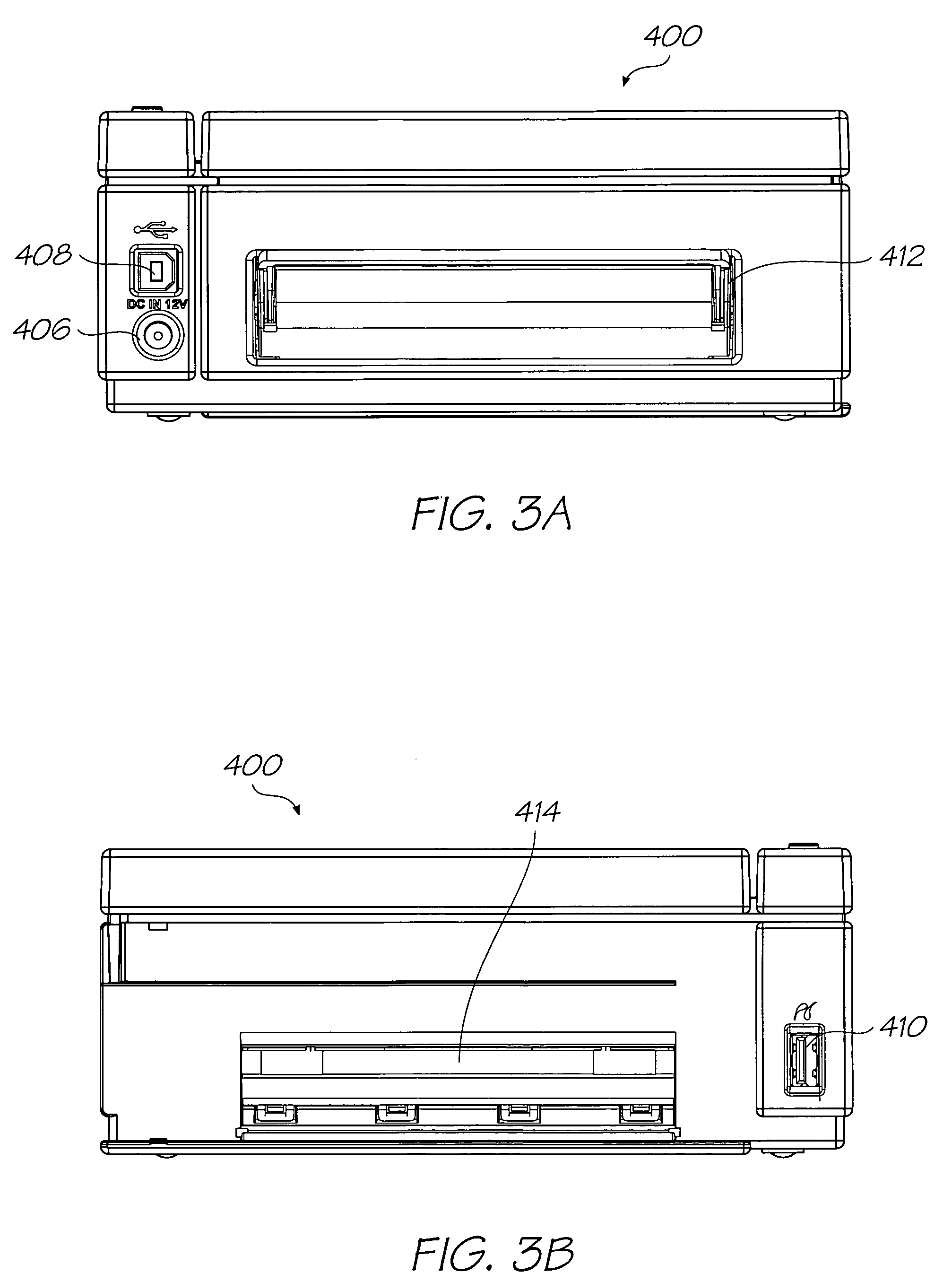

Printer having compact media pick-up device

InactiveUS7758038B2Reduce the required powerReduce motor sizeArticle feedersArticle separationEngineeringSheet material

Owner:MEMJET TECH LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com