Guardrail capable of inclining

A technology of guardrails and cables, applied in the field of dumpable guardrails, which can solve the problems of short service life, overall guardrail damage, collision, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

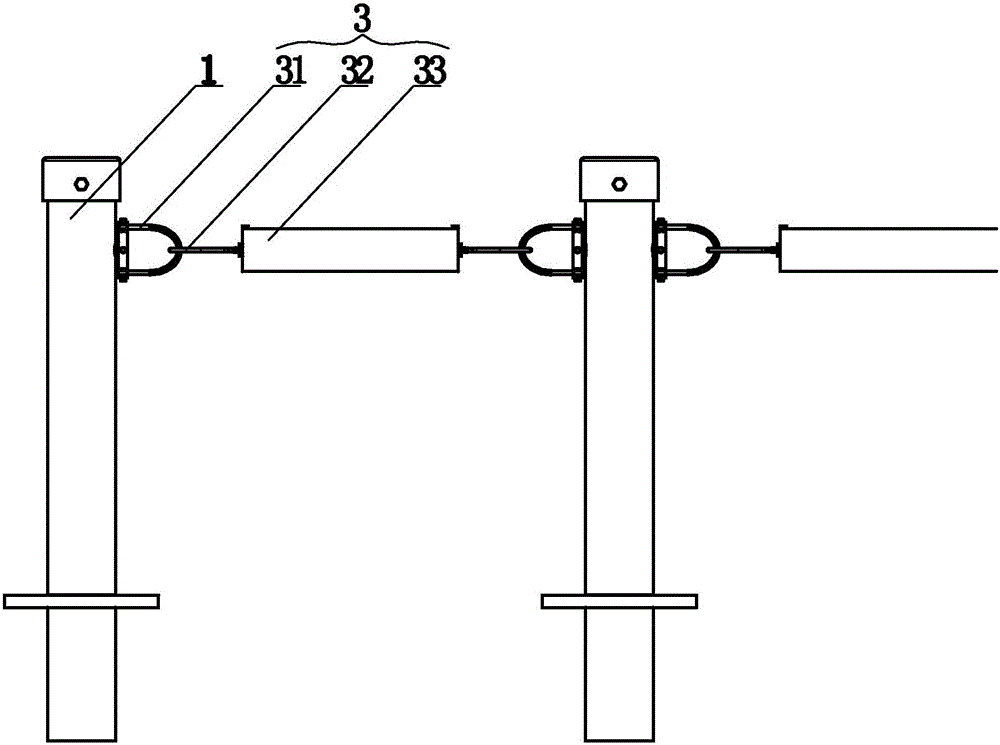

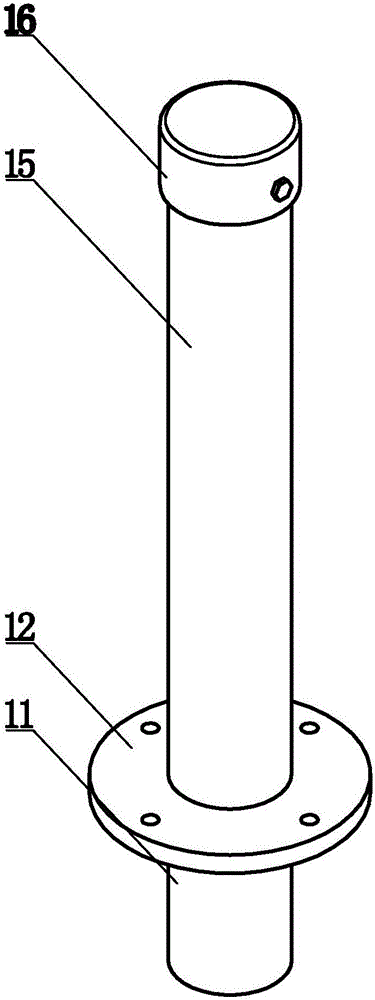

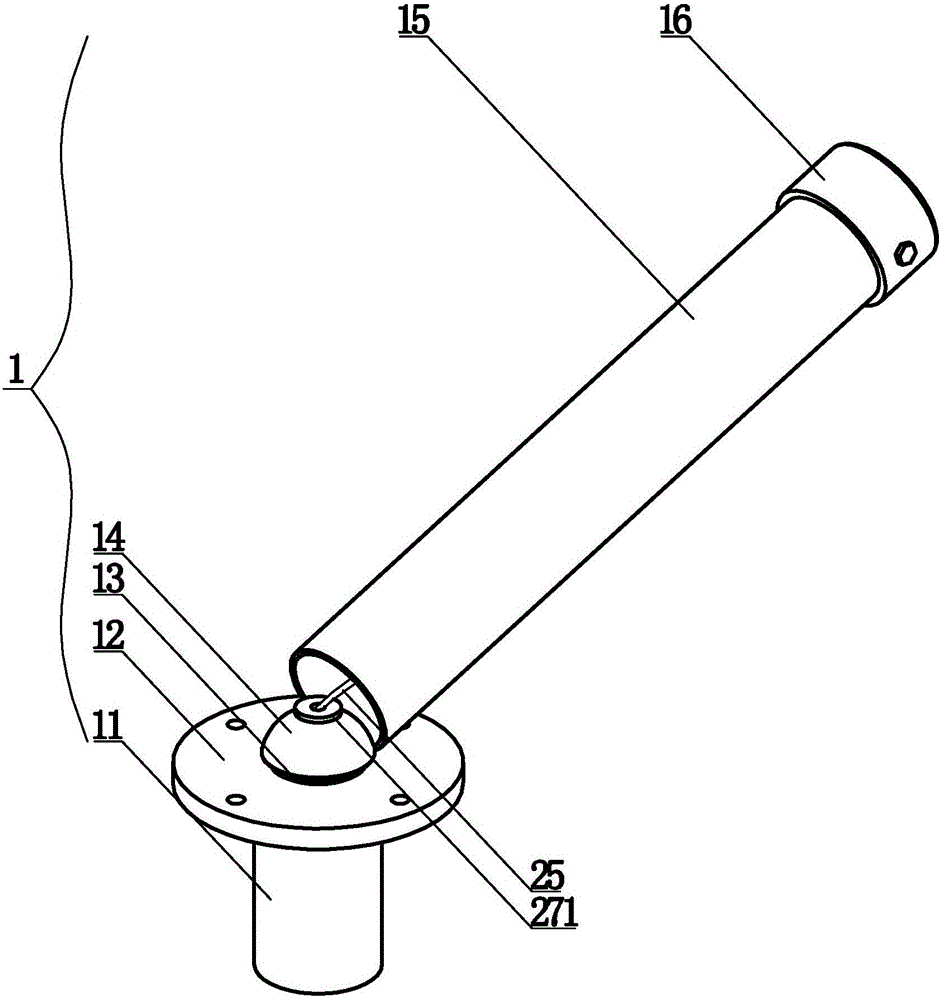

[0030] The dumpable guardrail of this embodiment, combined with figure 1 , figure 2 , image 3 and Figure 4, consisting of an isolation column 1, an adjustment mechanism 2 and a connector 3, wherein the isolation column 1 is composed of a column foot 11, a limit groove 13, a hemisphere 14, a column cylinder 15 and a column cover 16, and an abutment is set above the column foot 11 12. A hemisphere 14 is set above the base 12, and a limit groove 13 is set at the connection between the hemisphere 14 and the base 12, and the limit groove 13 is set around the lower bottom surface of the hemisphere 14; the adjustment mechanism 2 is located on the cylinder 15, including hanging beam 21, spring 22, limit frame 23, spacer 24, adjusting cable 25, limit block 26, adjusting block 27, fixed ball 28 and upper fixed block 29, and hanging beam 21 two ends are fixed on column On the upper part of the inner side of the tube 15, the upper end of the spring 22 is connected with the hanging b...

Embodiment 2

[0036] The setting and working principle of this embodiment are the same as that of Embodiment 1, the difference is that a pulley is set at the hanging beam 21, the lower end of the spring 22 is fixed on the edge of the perforation 241 of the spacer 24, and the adjusting cable 25 passes through the perforation 241 Finally, the pulley is upwardly circled through the middle part of the spring 22, and the upper fixed block 29 on the adjustable cable 25 after the circuit is connected downward with the upper end of the spring 22. This way can extend the length of the running path of the adjustable cable 25, thereby as far as possible Alleviate the effect of external force.

Embodiment 3

[0038] The setting and working principle of this embodiment are the same as that of Embodiment 1, the difference is that the gasket 24 can be fixed in the cylinder 15 by thread or electric welding, and the setting of the limit frame 23 can be omitted in this way, and the overall structure is simpler , Easy assembly.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com