Electric control signal reflection fan clutch

A signal reflection and clutch technology, applied in clutches, fluid clutches, machines/engines, etc., can solve problems such as inaccurate speed, unfavorable energy saving and environmental protection, and delays in central processing unit adjustment, so as to ensure accuracy and save production and assembly costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

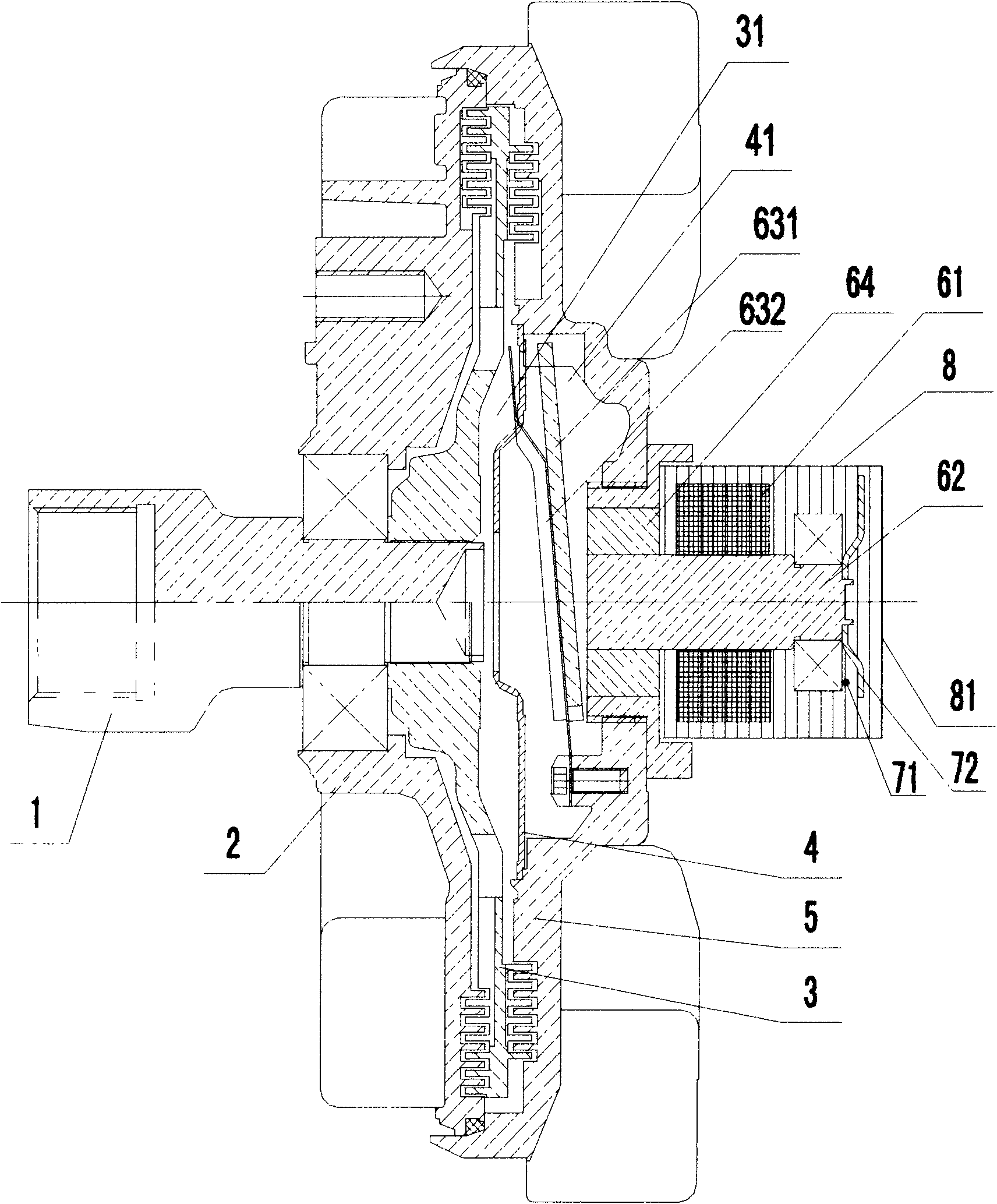

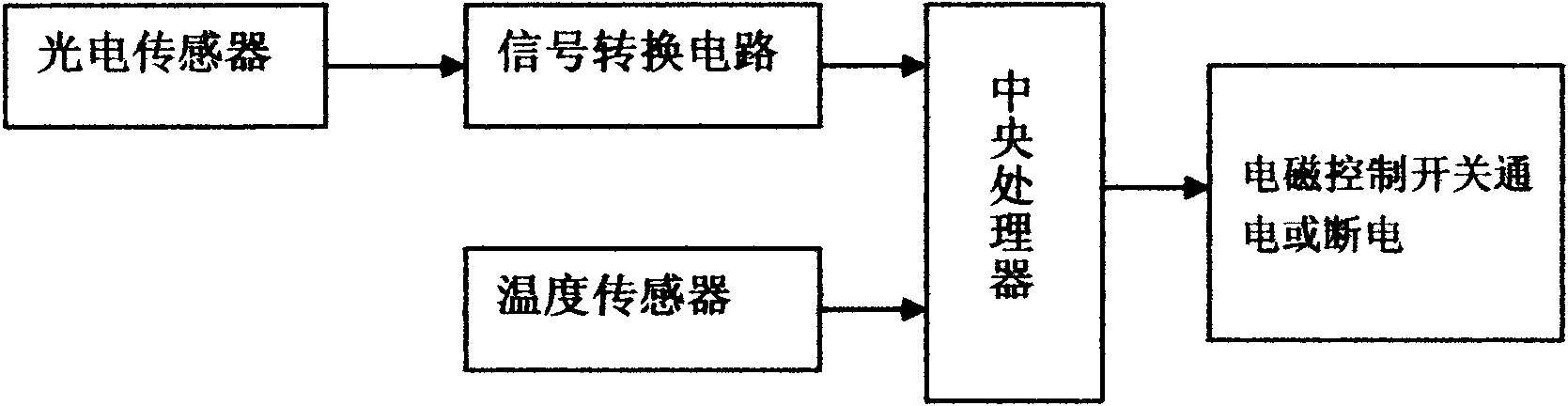

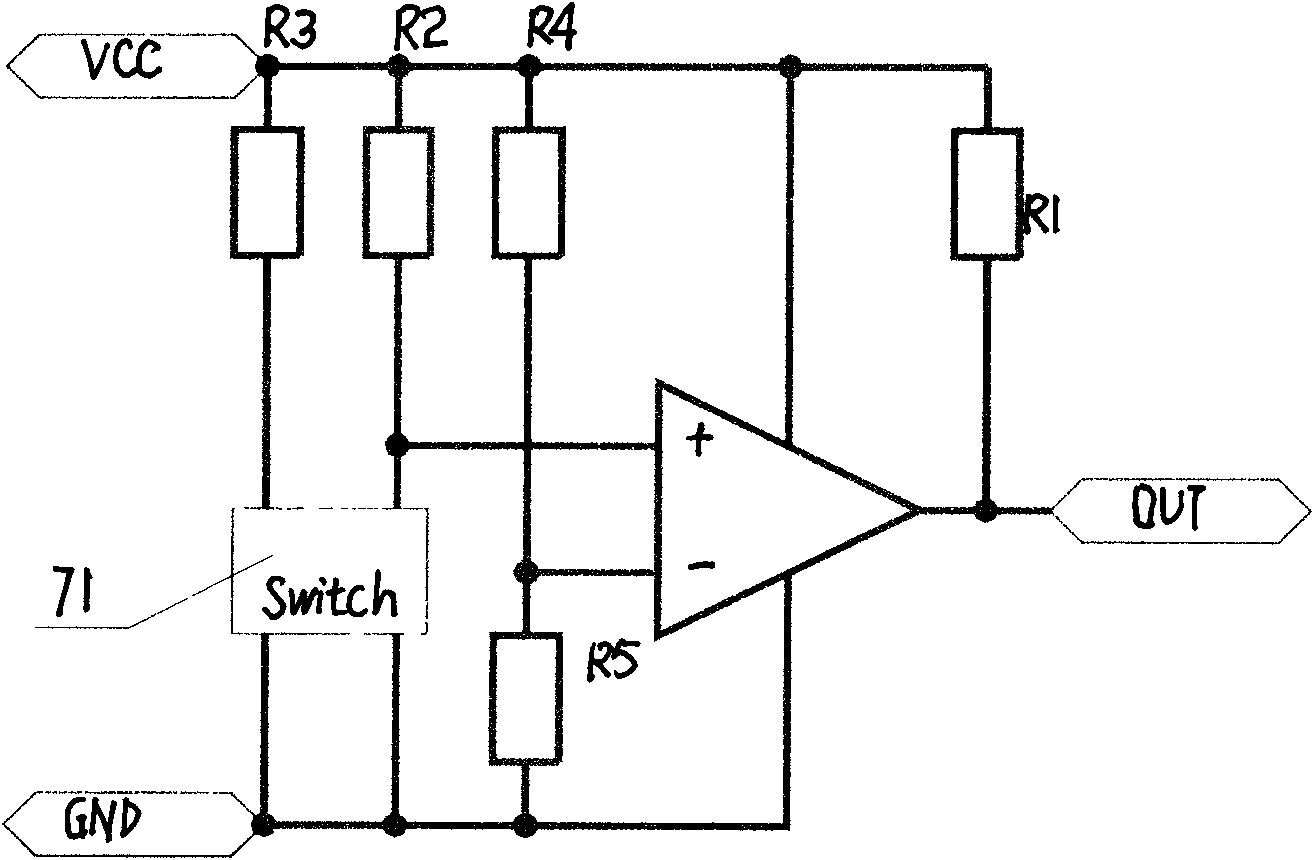

[0017] In view of the present invention, a preferred embodiment is now given and explained in conjunction with the drawings: the electric control signal reflection fan clutch includes a driving shaft 1, a housing 2, a driving plate 3, a driven plate 4, an end cover 5, an electromagnetic control Switch, fan speed test kit, see figure 1 , figure 2 , image 3 ,in:

[0018] The drive shaft 1, which rotates synchronously with the engine shaft, has a housing 2 fixed on the drive shaft 1 through bearings; the drive shaft 1 is fixedly connected with the drive plate 3 that rotates with the drive shaft; the end cover 5 is located at the front end of the drive plate 3 , and fixed together with the housing 2 by screws, the end cover 5 and the housing 2 are correspondingly provided with tooth grooves, the front and rear tooth saws on the active plate 3 mesh with the tooth grooves on the end cover 5 and the housing 2 respectively; Driven plate 4 is positioned between active plate 3 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com