Fuel gas supply system of vessel

A gas supply and fuel supply technology, applied in ship propulsion, loading system, oil supply device, etc., can solve problems such as excessive power consumption, and achieve the effects of convenient management, cost saving and manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Hereinafter, configurations and effects of exemplary embodiments of the present invention will be described with reference to the accompanying drawings. In addition, the following exemplary embodiments can be changed in various forms, so the technical scope of the present invention is not limited to the following exemplary embodiments.

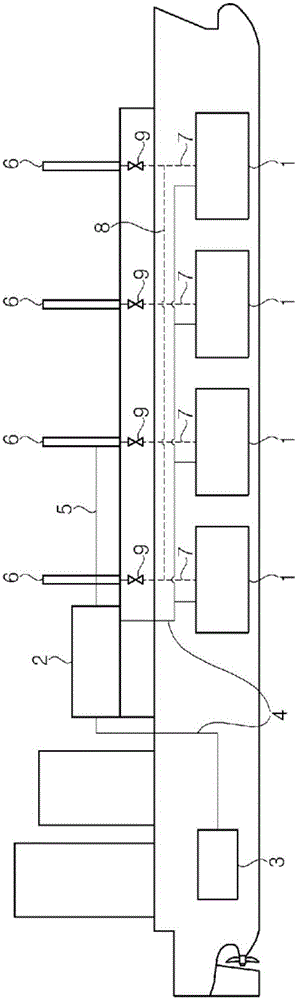

[0031] figure 1 is a schematic diagram of a gas supply system of a ship according to an exemplary embodiment of the present invention. Such as figure 1 As shown, the gas supply system of the ship according to the exemplary embodiment of the present invention supplies natural gas from the cargo tank 1 of the ship to the engine 3 through the fuel supply line 4 .

[0032] The ship according to the exemplary embodiment of the present invention may be any one of a liquefied natural gas carrier, a liquefied petroleum gas carrier, an ethane carrier, and a very large crude oil carrier (VLCC).

[0033] The cargo tank 1 is installed in a ship ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com