Motor base for numerically-controlled machine tool

A technology of CNC machine tools and motor seats, which is applied in the direction of electromechanical devices, electrical components, electric components, etc., can solve the problems of easy loosening and unfavorable normal operation of CNC machine tools, and achieve the problems of avoiding loose components, solving the replacement of electronic seats, and convenient and quick installation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described below in conjunction with drawings and embodiments.

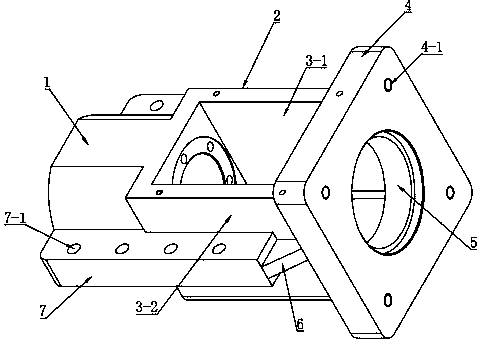

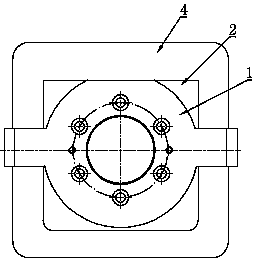

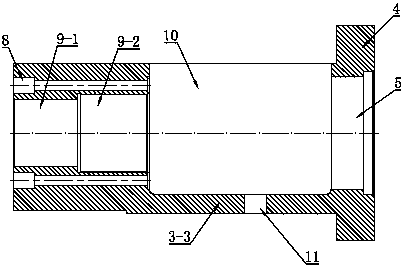

[0011] Such as figure 1 , figure 2 and image 3 As shown, the present invention includes a shaft hole seat 1 , an installation seat 2 and a base 4 in order from left to right. The shaft hole seat 1, the mounting seat 2 and the base 4 are integrally formed structures.

[0012] The shaft hole seat 1 is a cylindrical structure, and the inner ring is provided with stepped shaft holes, which are respectively the first-level shaft hole 9-1 and the second-level shaft hole 9-2, and the diameter of the first-level shaft hole 9-1 is less than The diameter of the second-stage shaft hole 9-2. Counterbore holes 8 with the same interval angle are distributed around the shaft hole, and the counterbore holes 8 run through both ends of the shaft hole seat 1 .

[0013] The mounting seat 2 is a square seat, and its three sides are enclosed by the side plate 3-1, the side plate 3-2 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com