Method for repairing moving cone of cone crushing machine

A repair method and cone crushing technology, applied in the field of crusher parts, can solve the problems of waste of resources, high production cost and high cost of spare parts, and achieve the effects of reasonable repair process, reduction of production cost and cost of spare parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

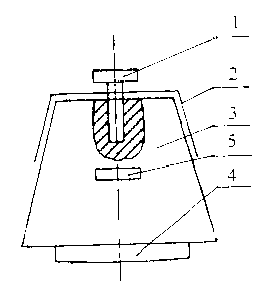

[0021] It can be seen from the figure that the moving cone of the cone crusher is composed of a crushing wall 2, a cone body 3 and a cone bottom 4. A through hole is set in the center of the crushing wall 2, and an M220 bolt 1 is inserted into it. The craft builder 5 is used for repairing the temporary construction of the moving cone. For the "sticking" repair method of HP500 cone crusher motor cone bolts, follow the steps below:

[0022] 1). Build the craft stand Set at least 3 equally divided craft stand on the side of the moving cone, 400-550mm away from the bottom, welded and fixed, the stand table is perpendicular to the center line of the M220 bolt, for processing and clamping ;

[0023] 2).Installing and setting up the lathe Three pressure plates of equal thickness are clamped on the three process supports. The lathe plate is fixed on the pressure plate by bolts, and the claws of the lathe are stuck on the outer circumference of the copper part at the bottom for mainte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com