Process for concentrating and filtering magnetite concentrate

A technology of magnetite concentrate and concentrate, which is applied in the technical field of concentrating and filtering magnetite concentrate, which can solve the problems of low utilization efficiency of concentrators, large energy consumption, and inconspicuous concentration effect, and reduce energy consumption and equipment spare parts , the effect of reducing metal loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The specific implementation manner of the present invention is described below in conjunction with the embodiment given with accompanying drawing.

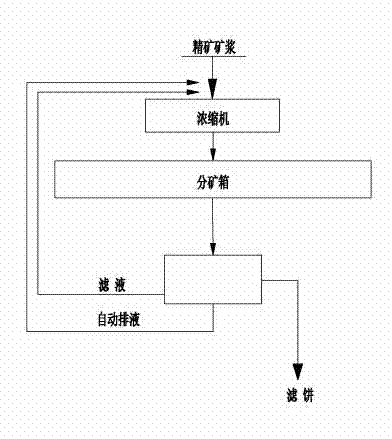

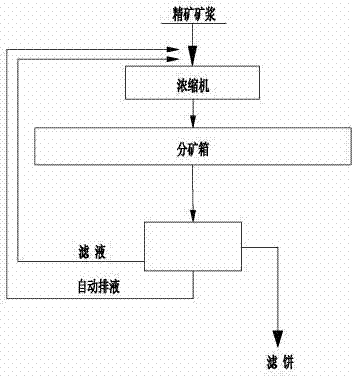

[0020] Such as figure 1 Shown, the technique of concentrated filter magnetite concentrate of the present invention is characterized in that comprising the steps:

[0021] 1) The pulp size of the flotation transport: -200 mesh accounts for 95%, and the concentrate pulp with a pulp concentration of 30%-35% is sent to the concentrator, and the concentration of the flotation transport is 30%-35% by the concentrator. The ore slurry is dewatered,

[0022] 2) The concentrated ore slurry with a concentration of 60%-65% after dehydration is pumped to the separation box through a group of concentrated ore pumps,

[0023] 3) The ore-distributing box then distributes 60%-65% of the concentrate slurry to the filter for filtration. After being filtered by the filter, the filter cake with a moisture content of 9%-10% is obtained as a co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com