Method for repairing valve for filling nitrogen in manufacturing equipment of magnetron

A technology for production equipment and magnetrons, applied in mechanical equipment, valve details, valve devices, etc., can solve the problems of oil having a great influence on high vacuum, vacuum degree not meeting the requirements, affecting product quality, etc., and shortening exhaust gas. time, improve the vacuum degree, and ensure the effect of product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

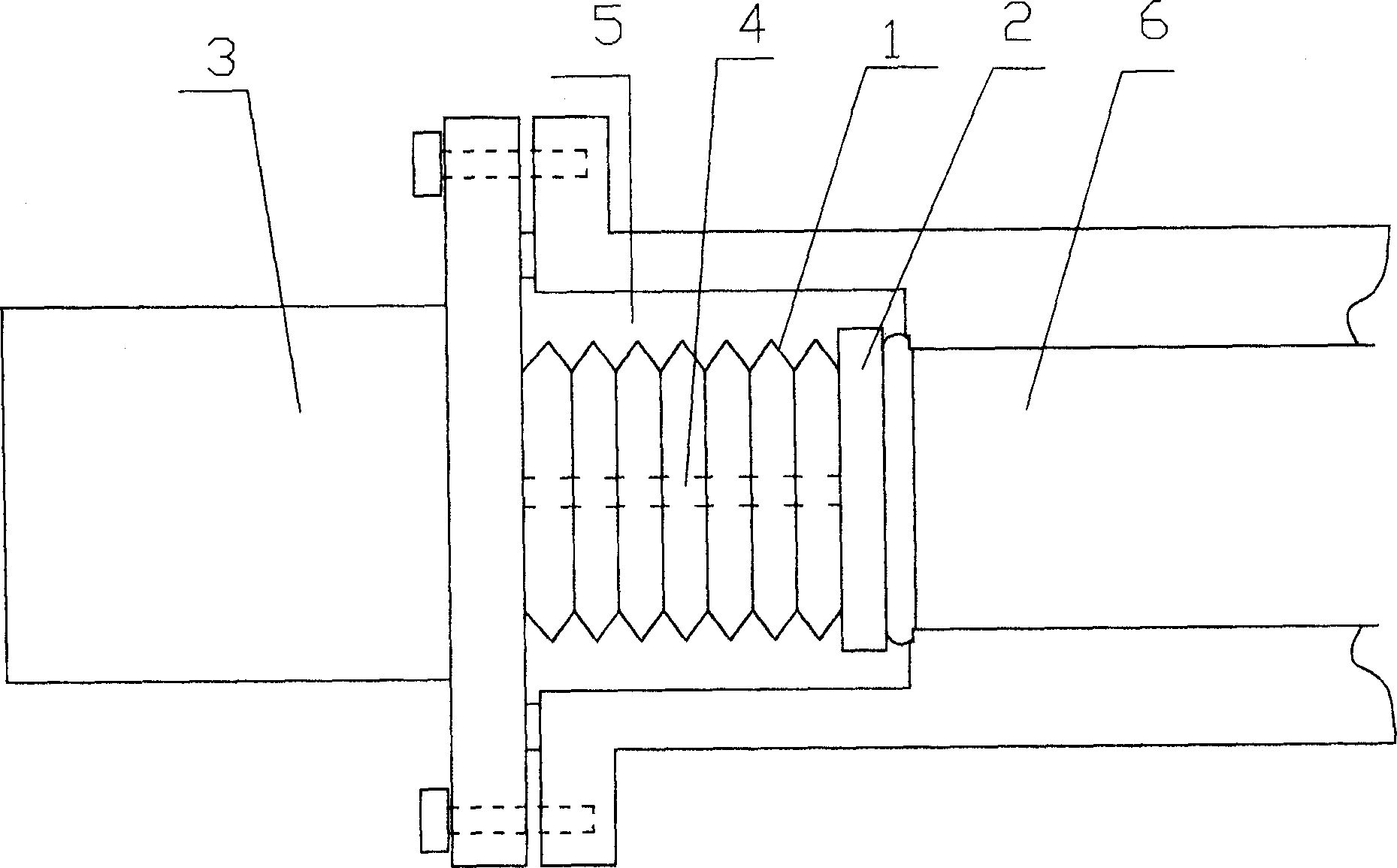

[0017] The method for repairing the nitrogen filling valve in the magnetron production equipment of the present invention comprises the following steps:

[0018] 1) Cut the damaged bellows in the valve along the vertical direction of the pipe diameter;

[0019] 2) Grind both sides of the corrugated sheet;

[0020] 3) Use high-vacuum glue to bond the corrugated sheets on both sides, and use a clamp to compress the two sides of the corrugated sheet, so that the high-vacuum glue can fully fill the gap between the corrugated sheets;

[0021] 4) Place it to dry at room temperature to make it bond firmly;

[0022] 5) Grinding and trimming the excess vacuum glue to ensure that the vacuum glue is flat and the bellows can be stretched freely;

[0023] 6) Install the repaired valve on a leak detector to detect leaks so that it meets the technical requirements of the valve.

[0024] The above step 4) is placed at room temperature for 60 to 120 minutes to dry to make it bonded firmly. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com