Patents

Literature

90results about How to "Shorten exhaust time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

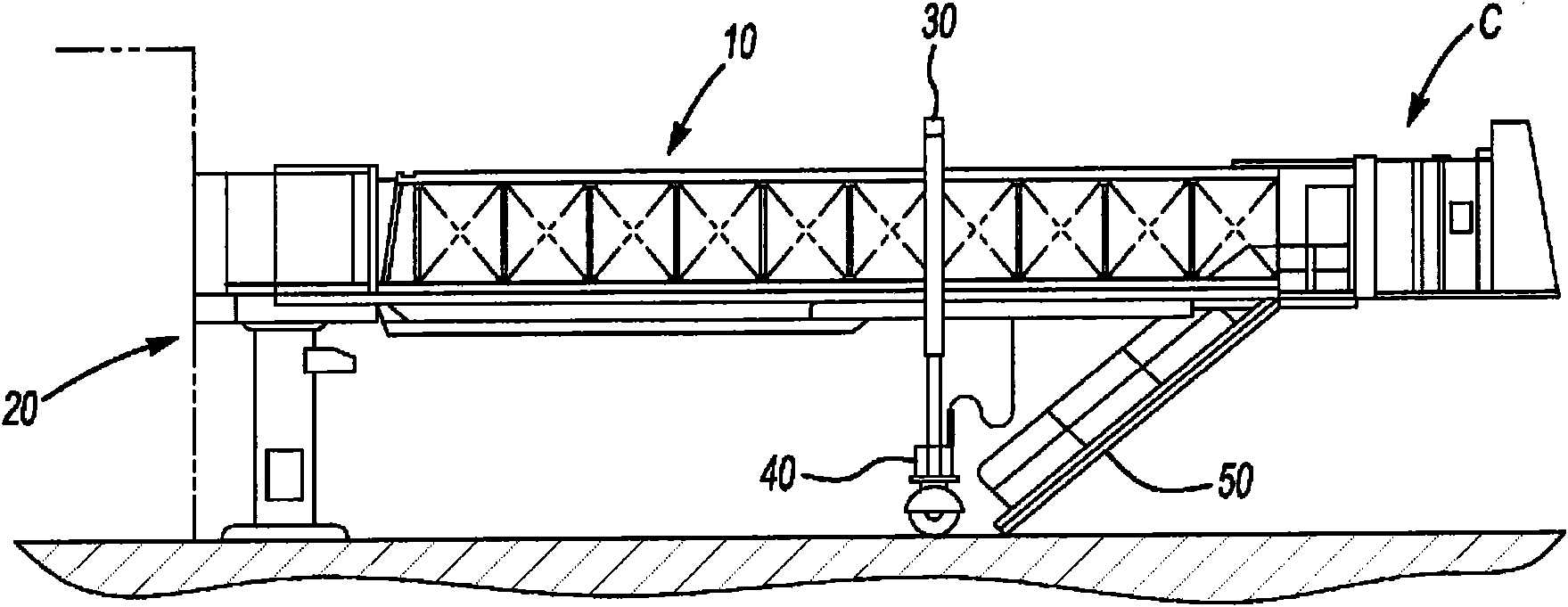

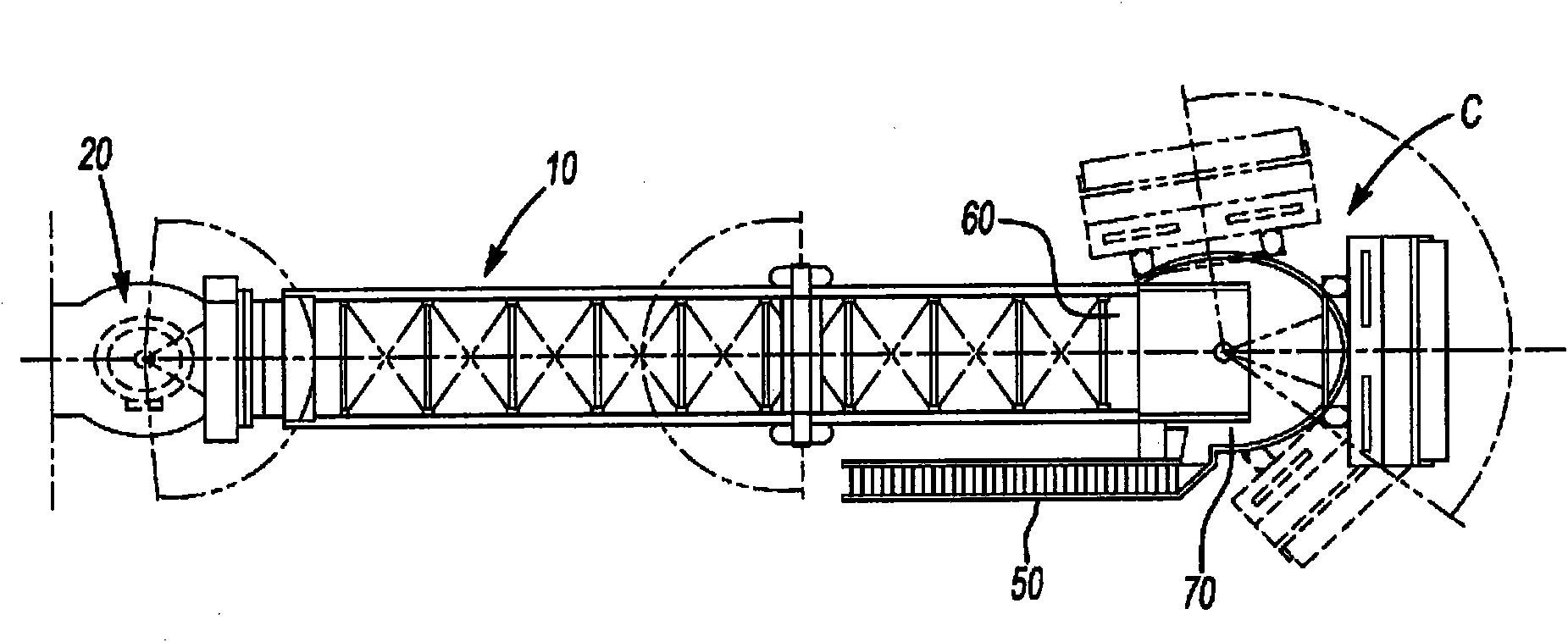

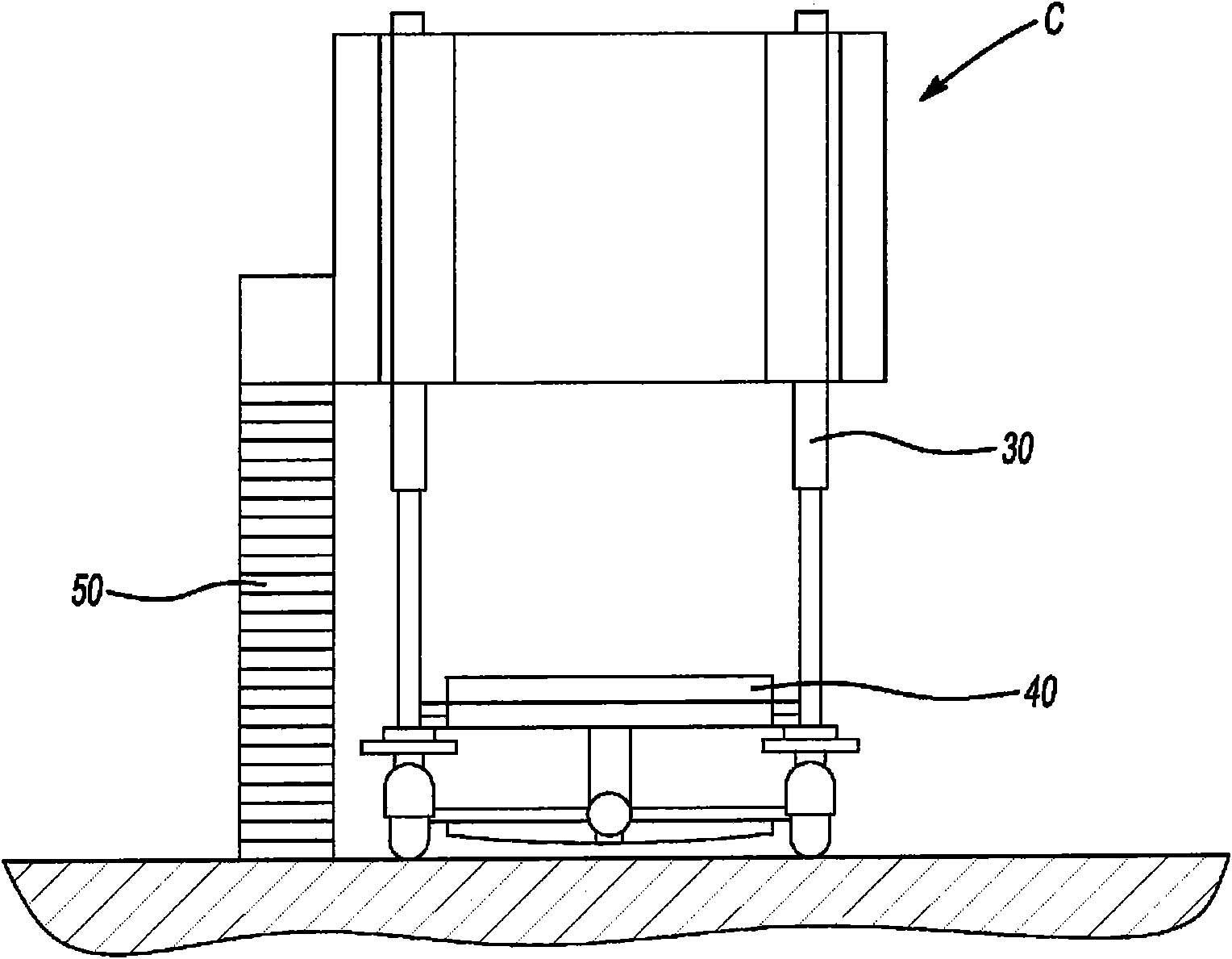

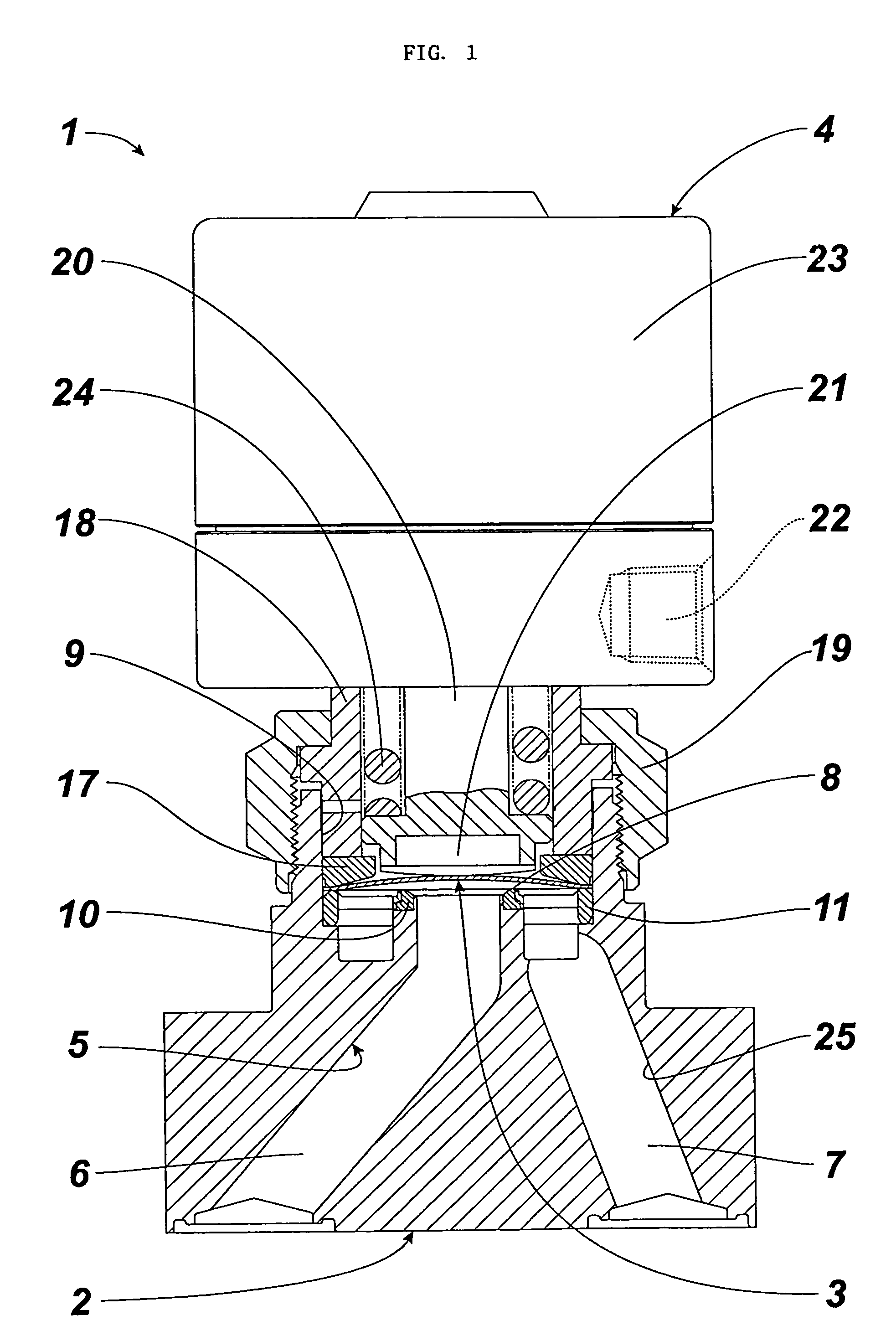

Osculating device for boarding bridge canopy

InactiveCN101910001ADoes not reduce sealing effectDon't care about damagePassenger handling installationsEngineeringElectrical and Electronics engineering

An exemplary osculating device for a mobile boarding bridge includes an air charge part that is attached to the end of the canopy of a mobile boarding bridge and that can inject air. A buffer material is provided in the air charge part that can maintain a fixed shape, even if the air is discharged from the air charge part.

Owner:OTIS ELEVATOR CO

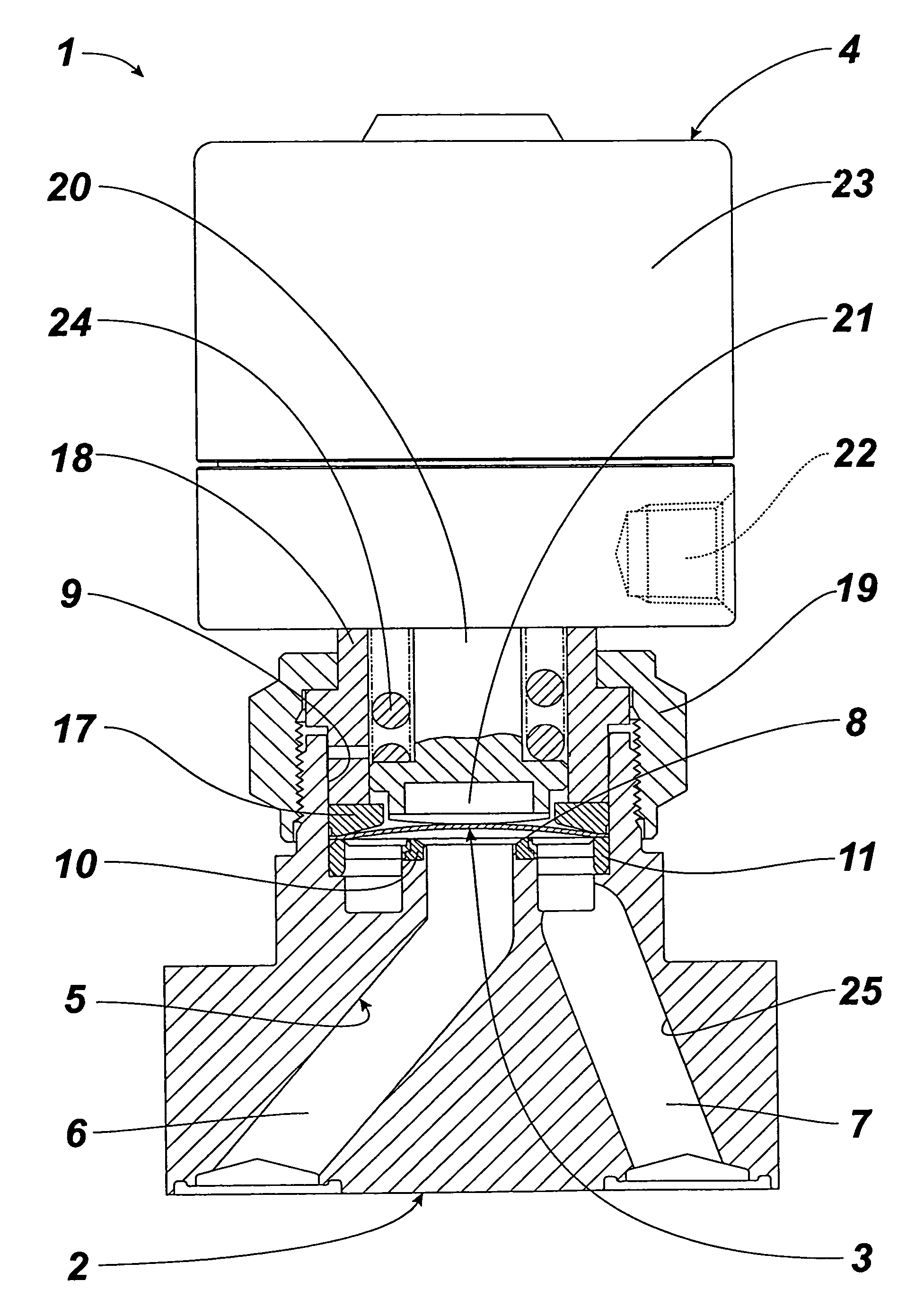

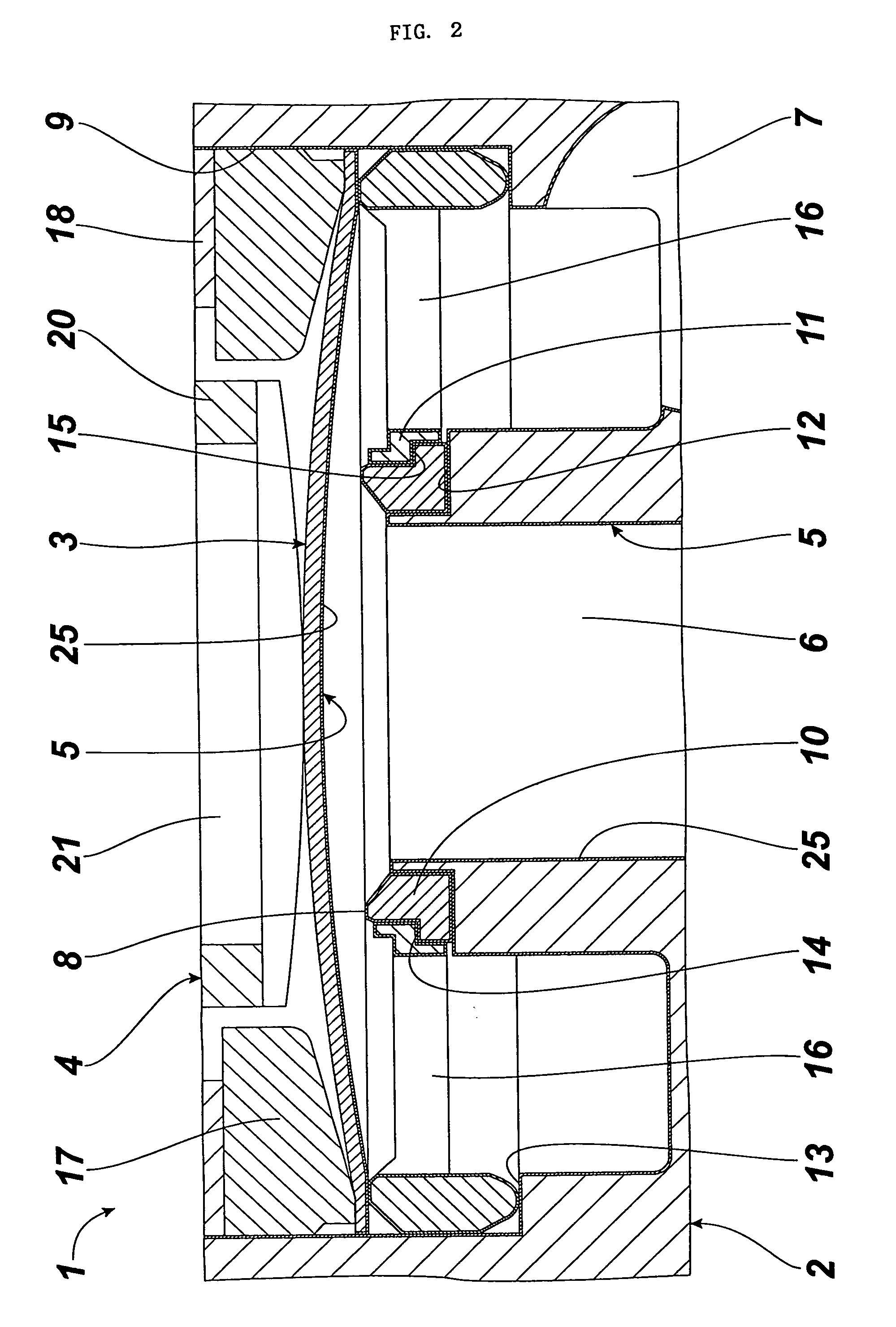

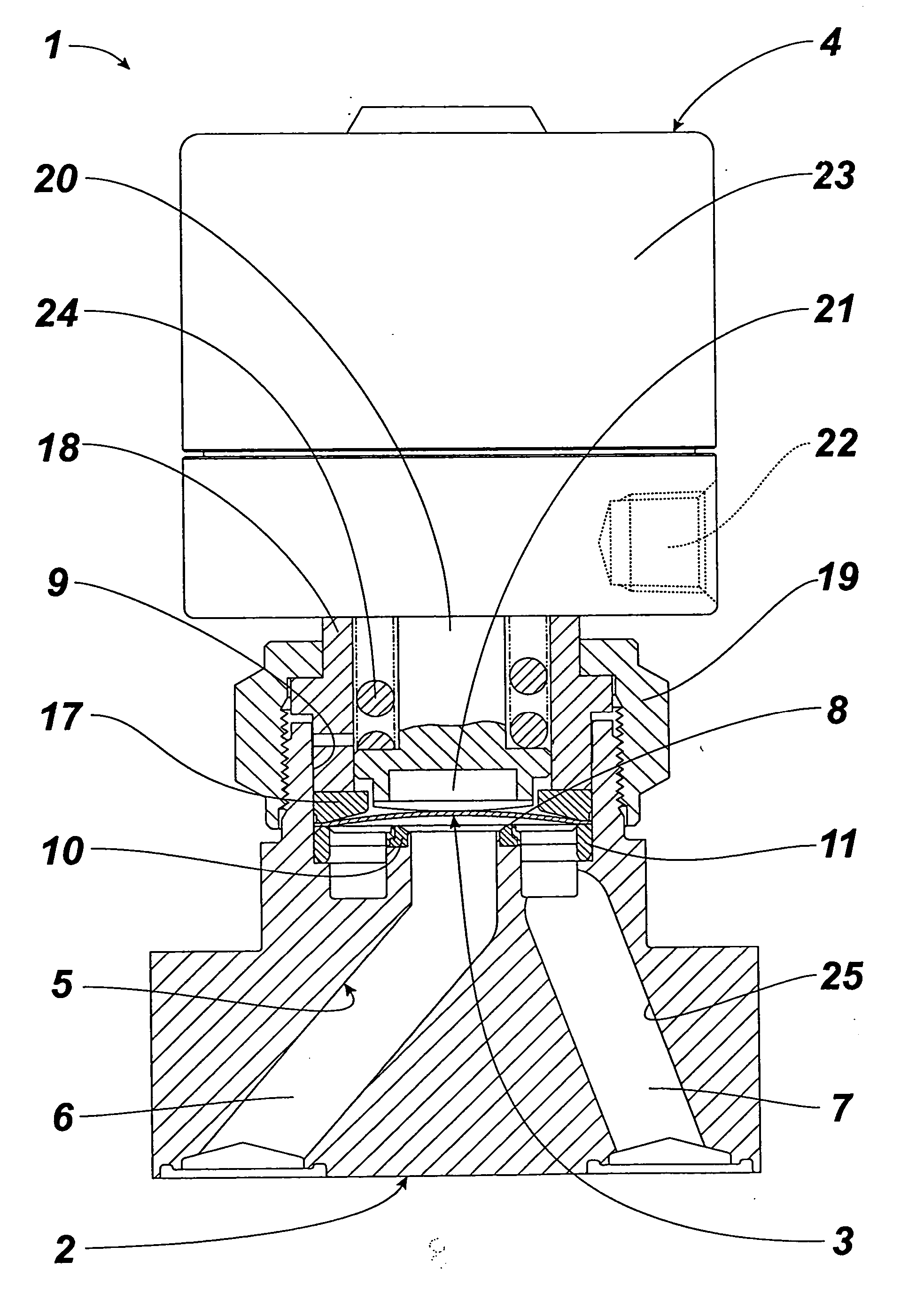

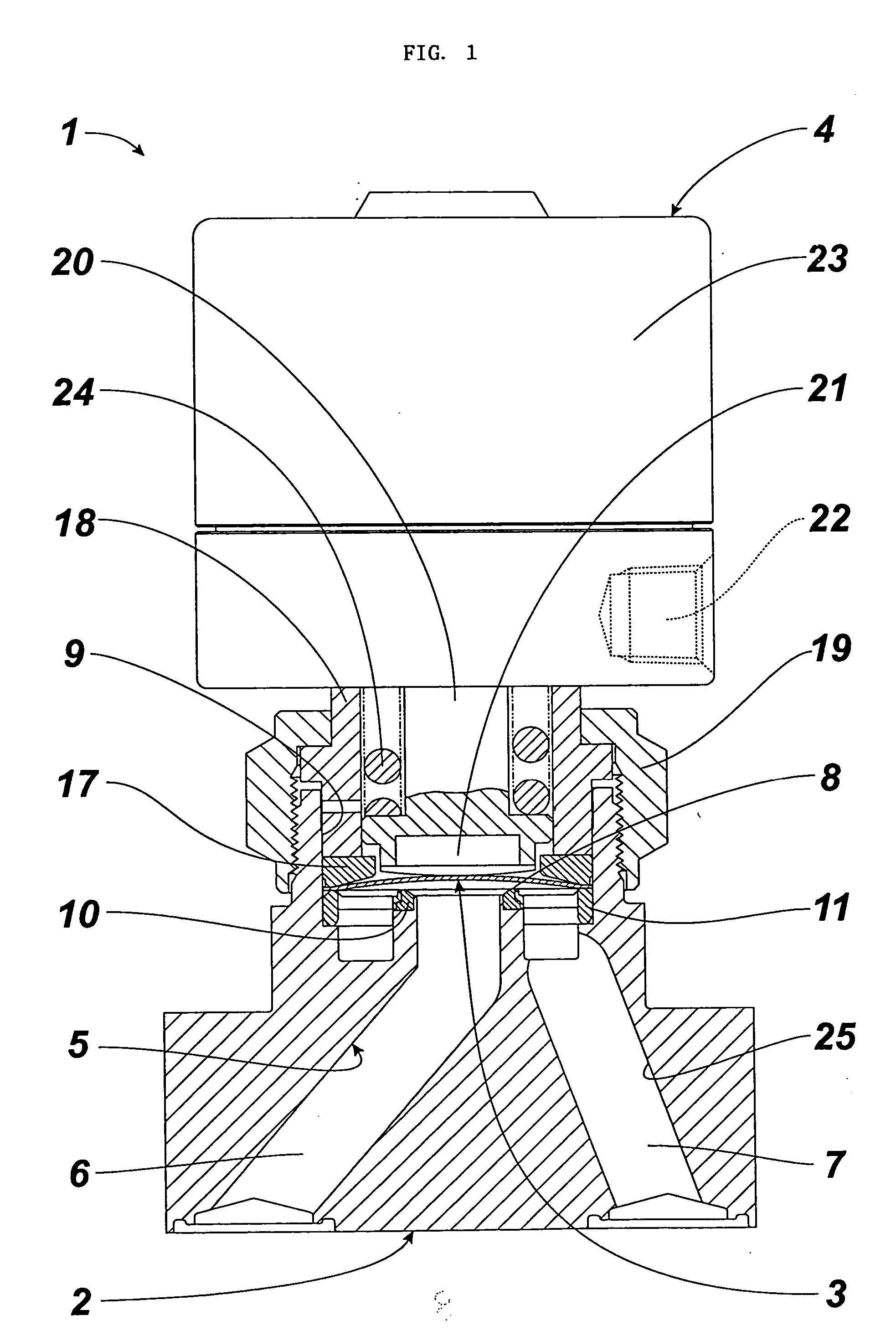

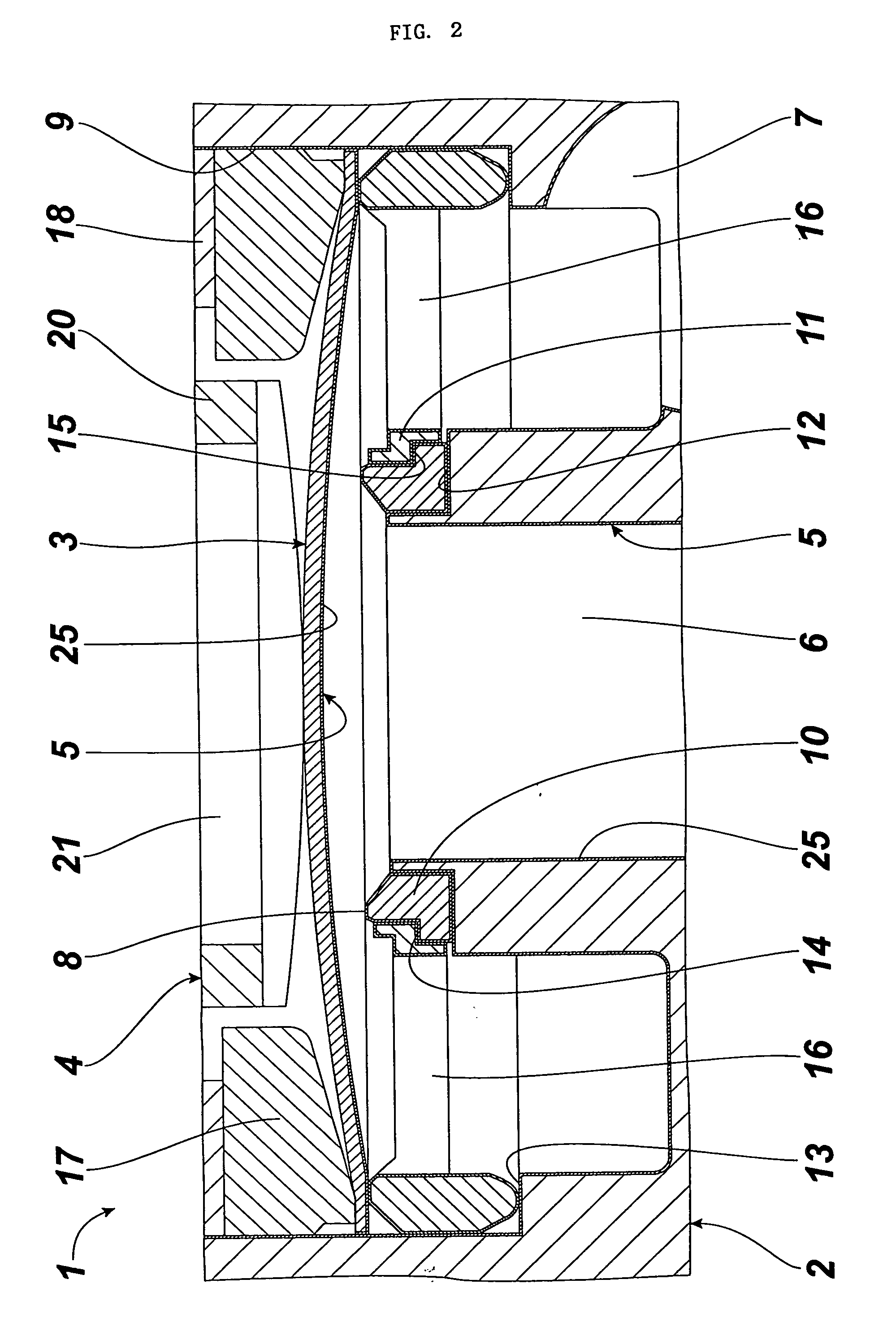

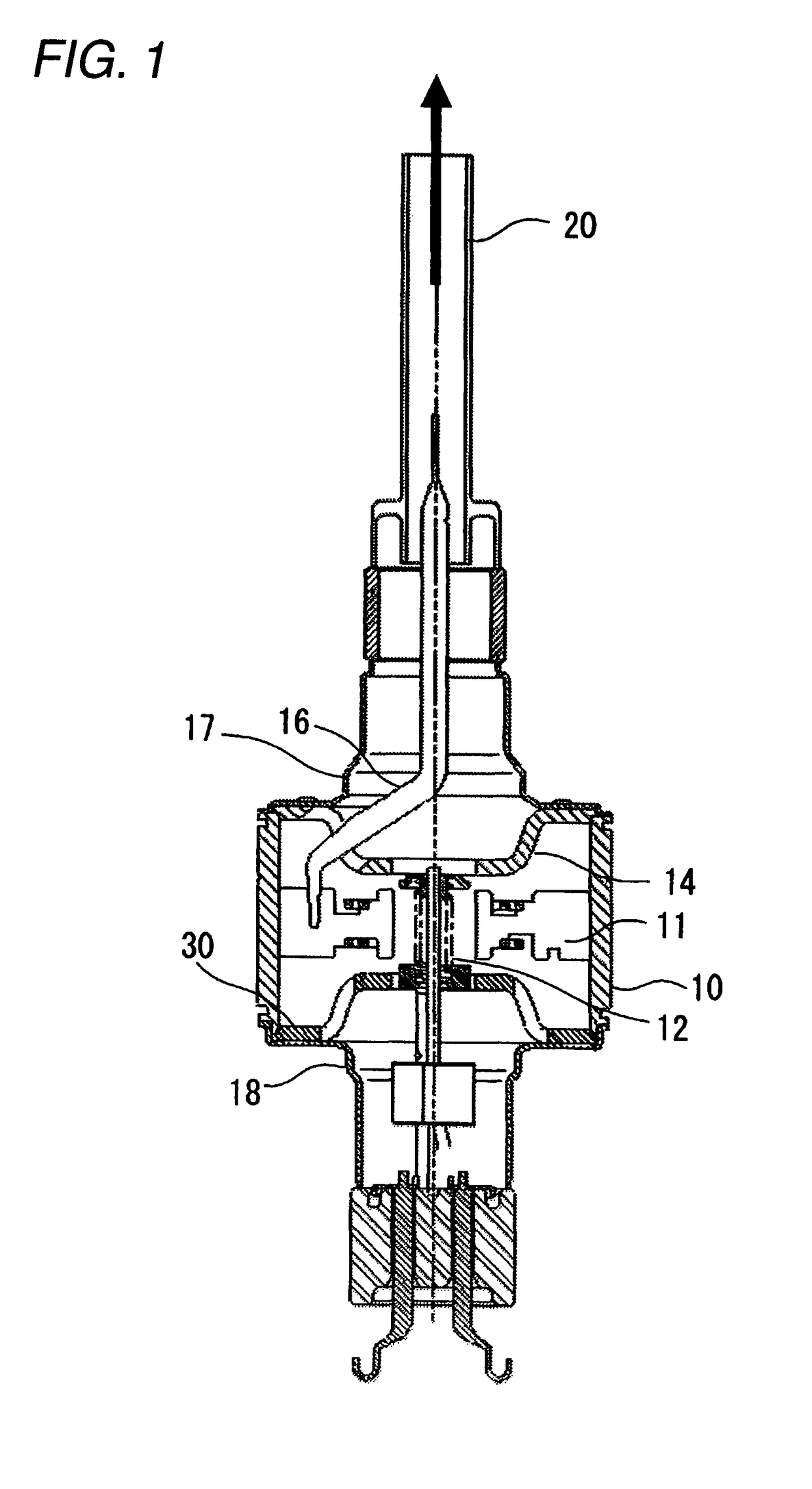

Diaphragm valve for the vacuum exhaustion system

ActiveUS7416165B2Reduce the overall diameterAvoid corrosionDiaphragm valvesOperating means/releasing devices for valvesEngineeringDiaphragm valve

A diaphragm valve 1 is provided with a body 2 having a flow-in passage 6, a flow-out passage 7, and a valve seat 8 formed between the passages; a diaphragm 3 installed in the body 2 and permitted to rest on and move away from the valve seat 8; and a driving means 4 installed on the body 2 to allow the diaphragm 3 to rest on and move away from the valve seat 8, wherein synthetic resin films 5 of predetermined thickness are coated on fluid-contacting parts 25 of the afore-mentioned body 2 and diaphragm 3. A diaphragm valve in accordance with the present invention prevents corrosion of the valve members caused by accumulation and adherence of substances produced by thermal decomposition, and prevents clogging caused by substances produced, and prevents seat leakage when applied in the vacuum exhaust system of a semiconductor manufacturing facility.

Owner:OHMI TADAHIRO +1

Berry can and processing method thereof

The invention relates to a new can processing method which is applicable to a berry raw material and a berry can processed through the method, and the can processing method is characterized in that the tissue improvement method in line with the characteristics of berry is adopted, a calcium preparation and the sugar impregnation are combined for treatment so as to increase the strength of the skin part and pulp part of the berry, and the complete and due taste of fruit granules can be maintained during the follow-up heat treatment process; a formula with special flavor and nutritional attributes is utilized for the preparation of canned soup, thereby greatly improving the health-care and beautifying effects of the product; according to the actual nutritional requirement of the berry raw material, a safe thermal sterilization way is adopted, the thermal degasification temperature and sterilization temperature in the traditional process are reduced by about 10 DEG C, the nutritional value and sensory quality of the product are better protected, the natural taste of the berry raw material is maintained, energy is saved, and the can processing method can be maturely applied to berry can products and is applicable to actual situations of the majority of can food production enterprises.

Owner:丹东美比食品有限公司

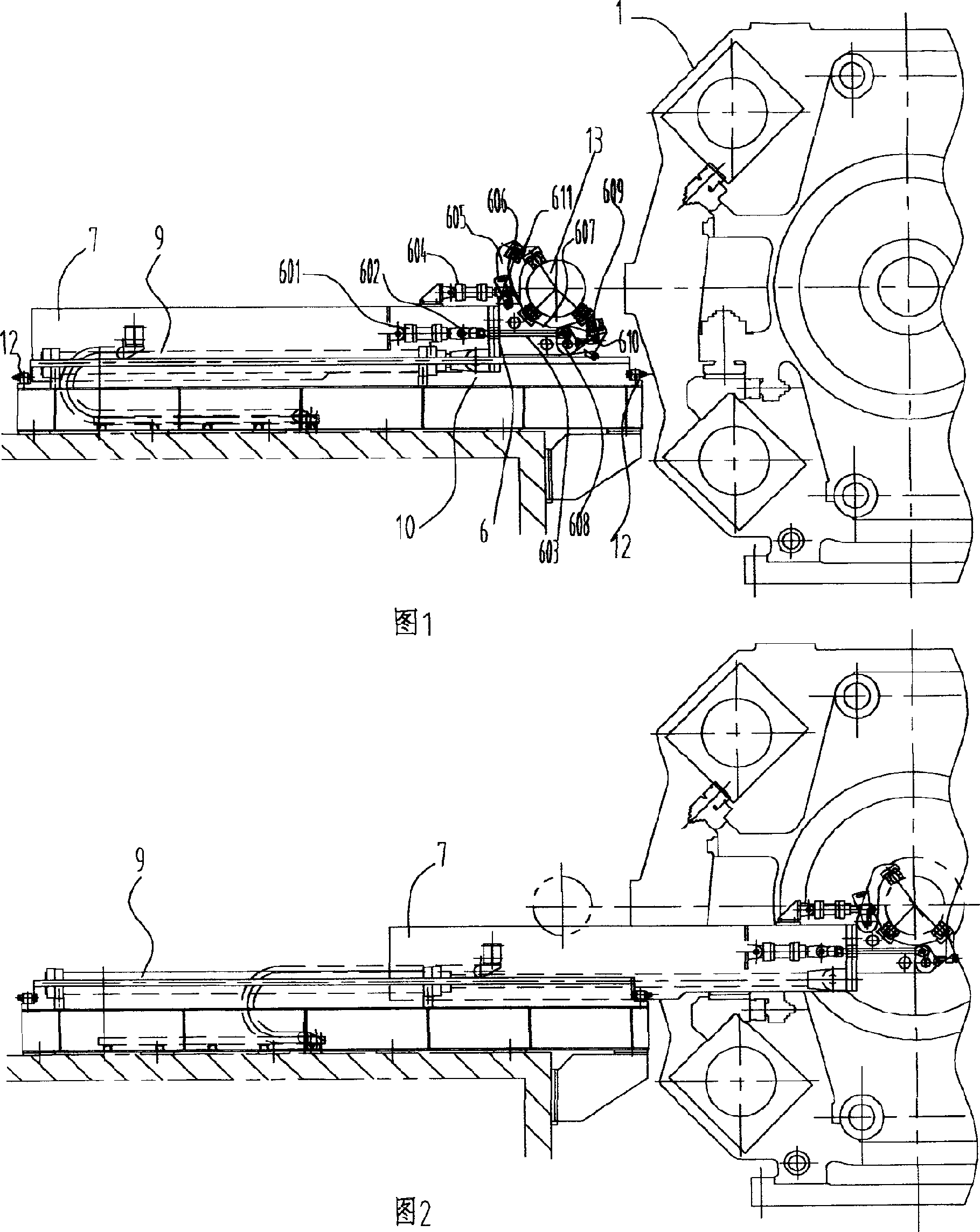

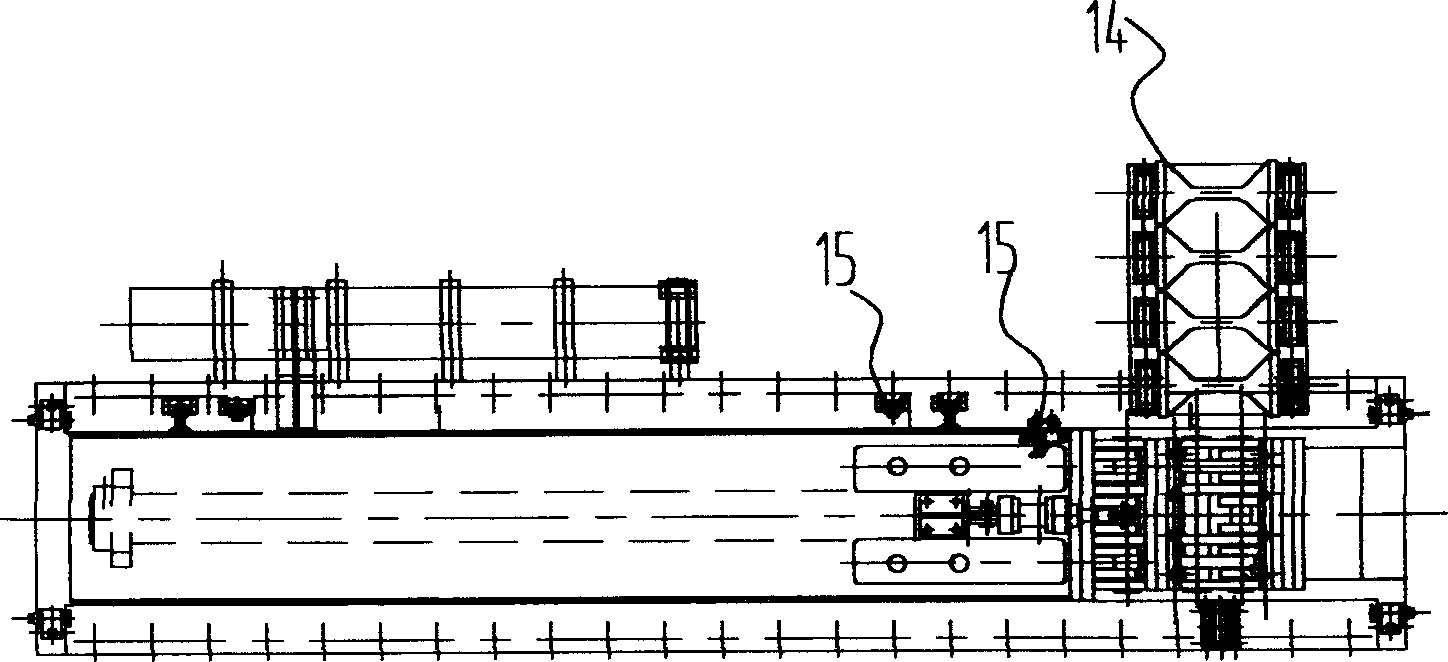

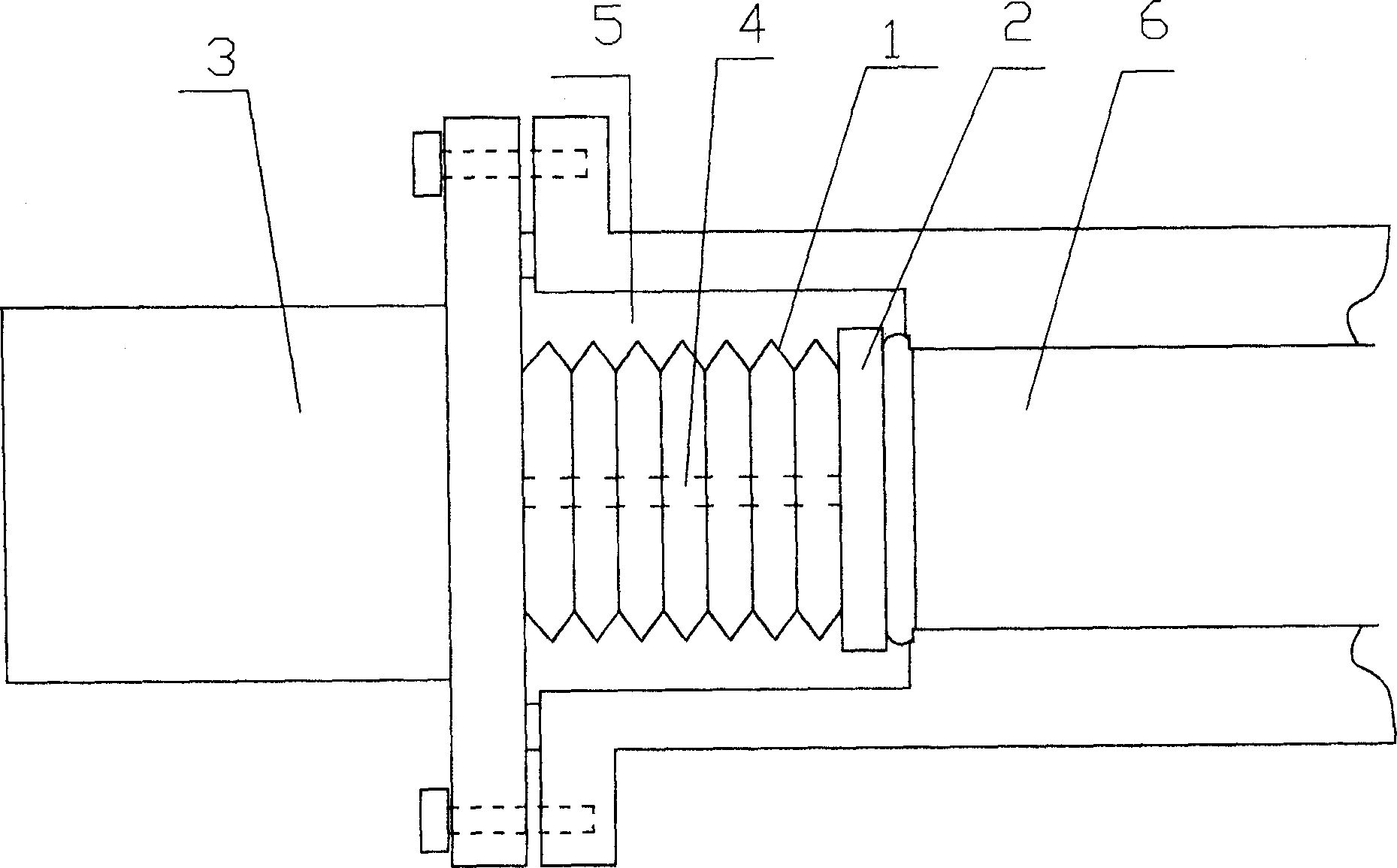

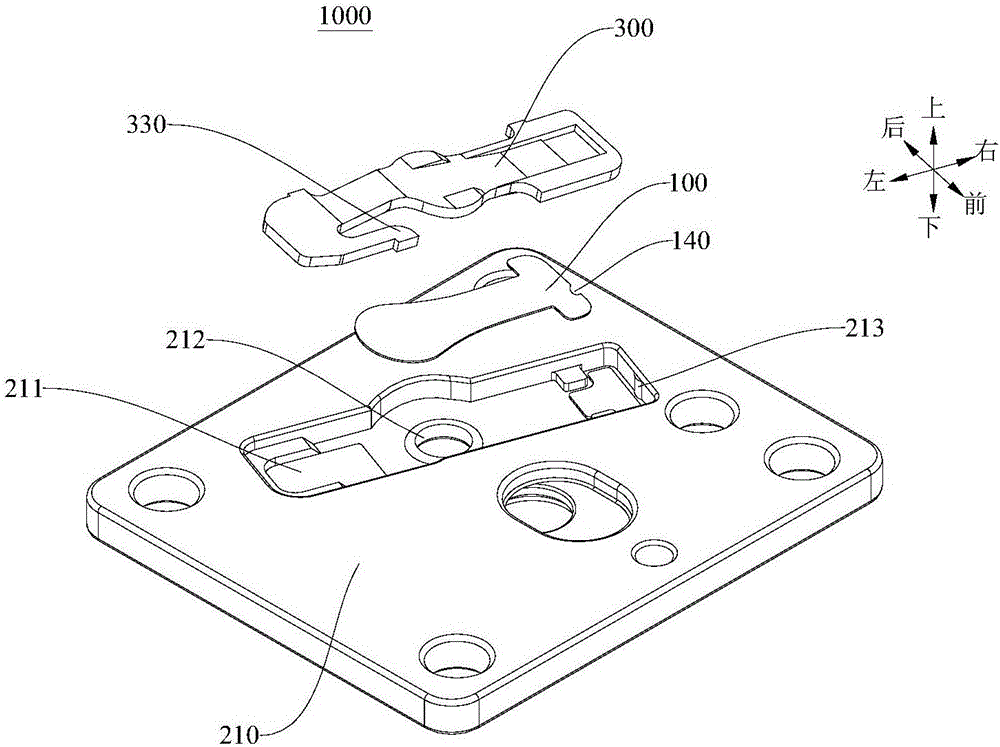

Short path aluminium extrusion machine front feeding system and its gripping pliers type adaptive ingot supply device

A front feeding system for short-stroke squeezer of aluminium part and its clamp-type adaptive ingot supplying system has squeezer with fixed pressing block, clamp-type adaptive ingot supplying system consisting of manipulator, master arm and slide block, master arm cylinder, slide guider and pressing plate, pressing rod, the hydraulic control units for lateral cylinder and pressing rod and ingot supplying unit, and electric control unit.

Owner:TAIYUAN HEAVY IND

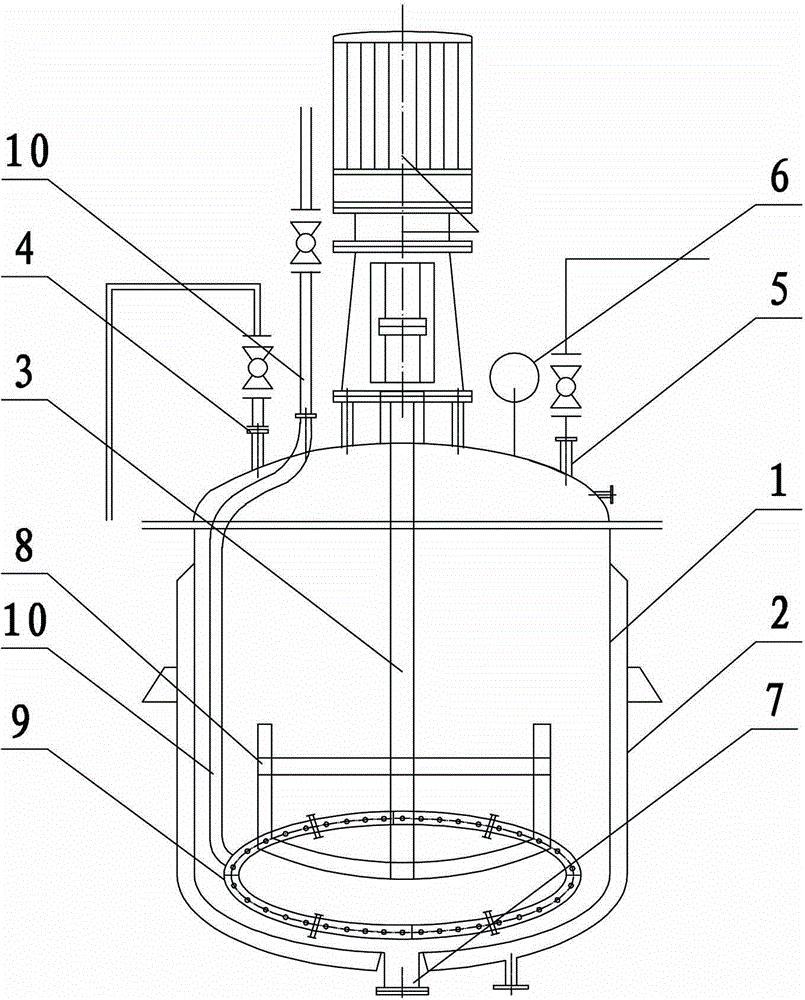

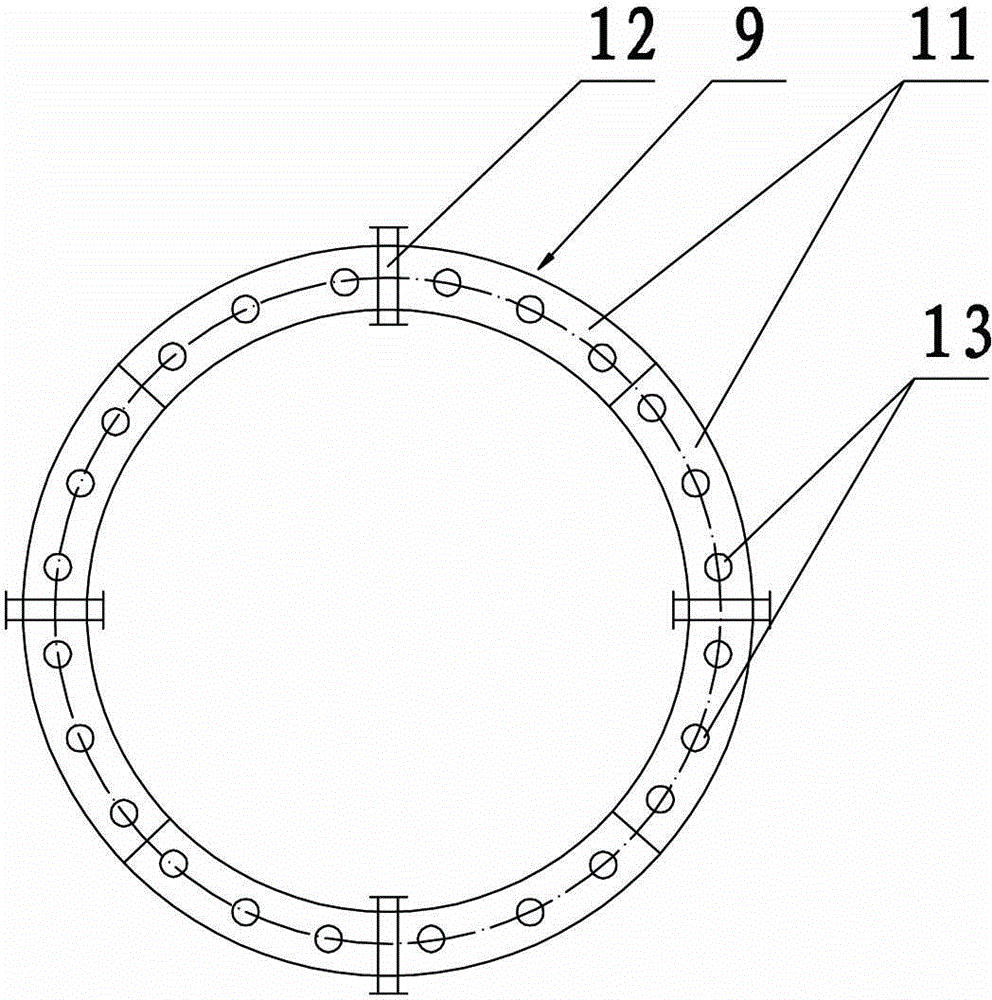

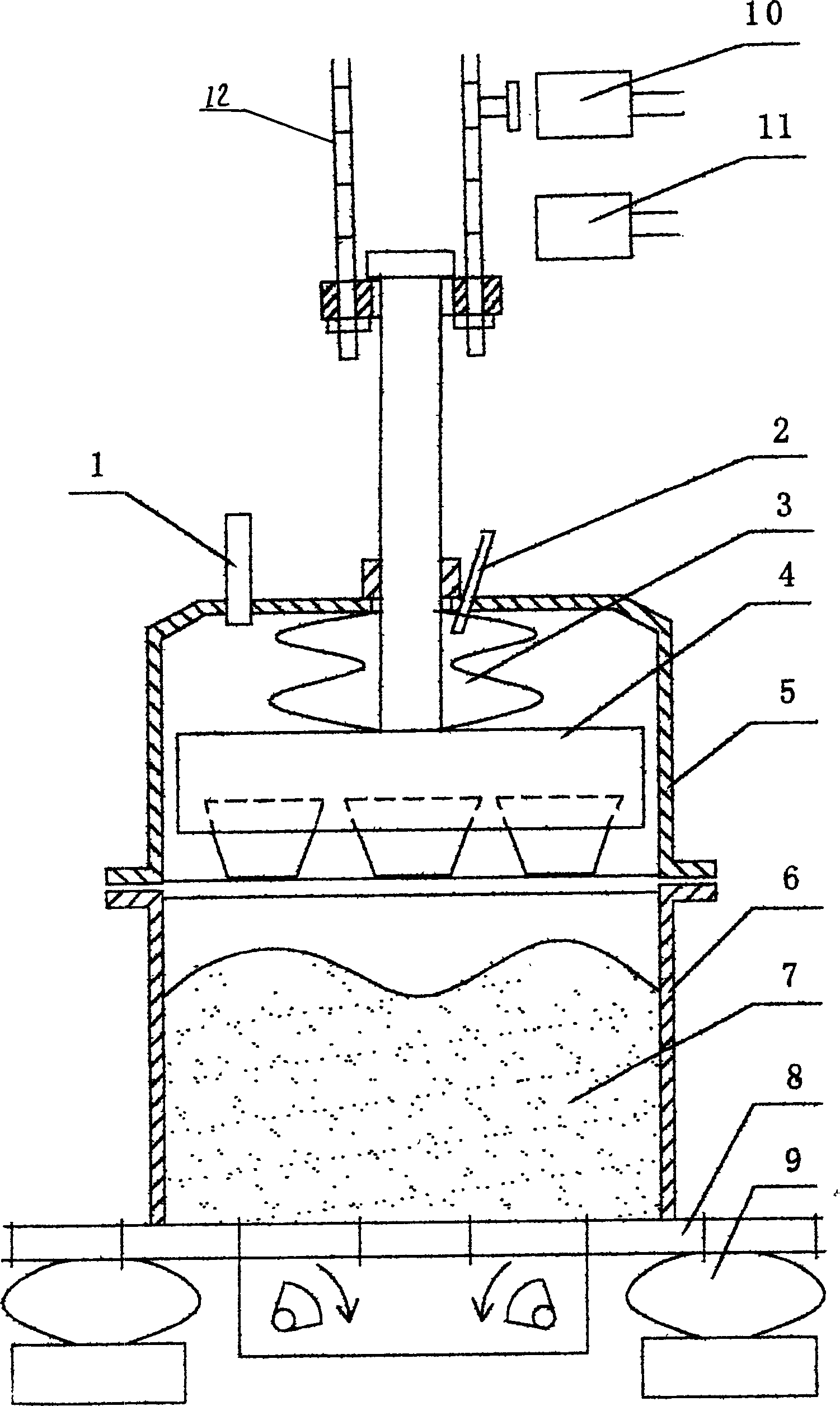

Ammonification reaction vessel for rapidly recycling ammonia gas

InactiveCN105327665AEvenly distributedShorten exhaust timeChemical/physical/physico-chemical stationary reactorsLiquid-gas reaction processesNitrogenMechanical equipment

The invention relates to the field of chemical mechanical equipment, and provides an ammonification reaction vessel for rapidly recycling ammonia gas. The ammonification reaction vessel comprises a reaction vessel body, a stirring device is arranged in the reaction vessel, a feed inlet is arranged at the top of the reaction vessel, a discharge port is arranged at the bottom of the reaction vessel; a distance between the bottom of the stirring device of the stirring device and the bottom of the reaction vessel is 10-20cm, a annular gas distributor is installed at the reaction vessel bottom below the stirring device, a nitrogen pipe is installed at the top of the reaction vessel, and the nitrogen pipe extends along an inner wall of the reaction vessel to the vessel bottom and is communicated with gas inlets of the annular gas distributor; the annular gas distributor is composed of four arc pipes which are connected end to end, a central section of each arc pipe is installed at the reaction vessel bottom by a clamp, and an upper part of each arc pipe is opened with several uniformly distributed small holes; the ammonification reaction vessel has the advantages of simple structure, design benefit, and installation and maintenance convenience, substantially increases recovery speed of ammonia gas after reaction is carried out in the ammonification reaction vessel, reduces usage amount of nitrogen, and improves production power of the equipment.

Owner:HUBEI BIOCHEM PHARMA TECH

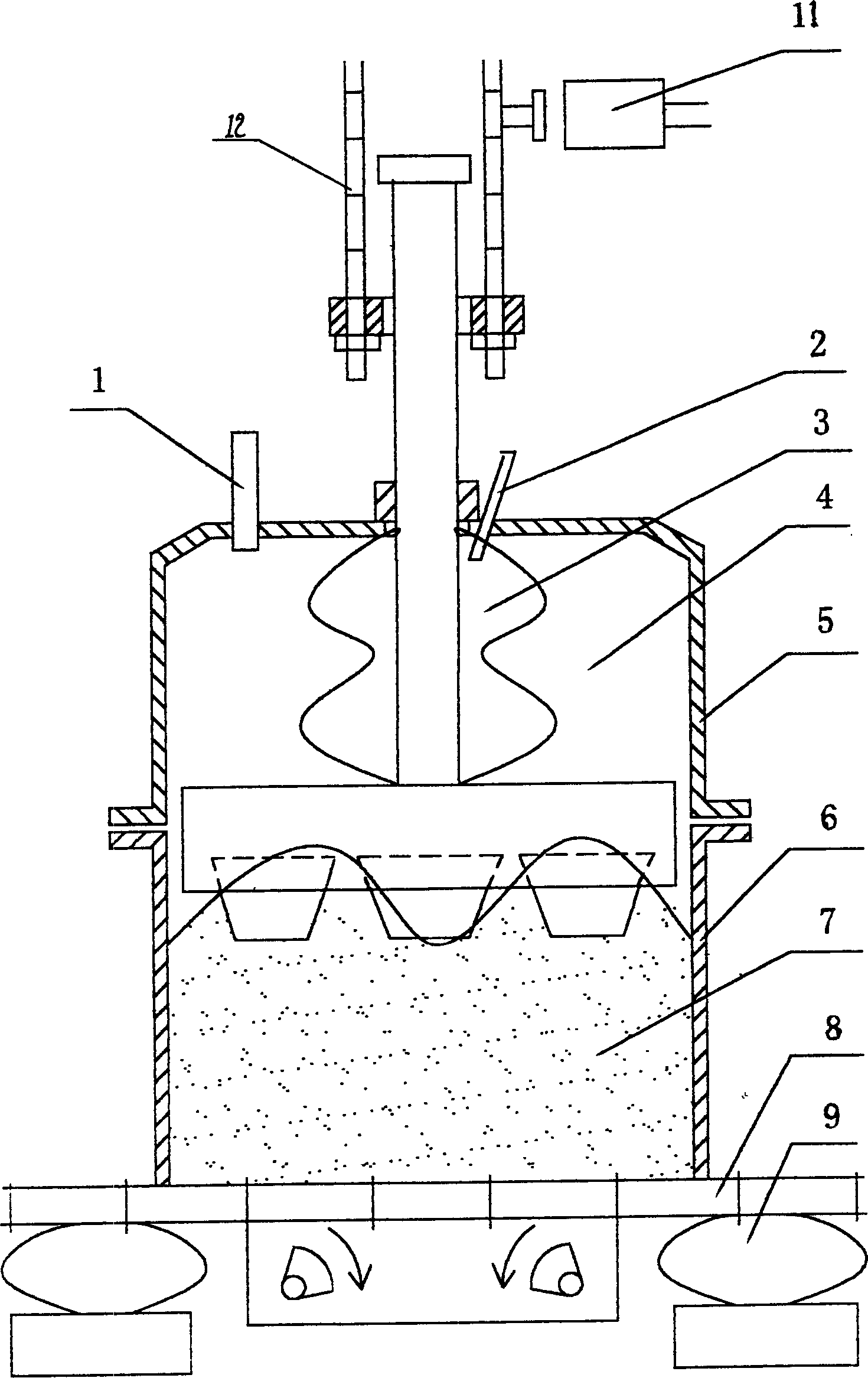

Anodic carbon block vibrating and shaping method for aluminium

InactiveCN1614096AHigh bulk densityHigh densityCeramic shaping apparatusVacuum pumpingDischarge efficiency

This invention relates to anode carbon blocks formed by vibration. Firstly, the heavy punch (4) and the heavy punch mantle (5) were lifted and the paste filler (7) was filled in the mould (6). Secondly, the two-bearing vibration table (8) was lifted to fall down the heavy punch and the heavy punch mantle to guarantee the he heavy punch mantle locked the mould closely. The heavy punch was stopped before it pressed the paste filler. When the vibration time was set, the heavy punch was fallen down rapidly to press the paste filler. When it was close to on / off (11), the heavy punch was forced. The system was vibrated until the set time to stop vibration was over. Then, it was demoulded and the carbon block discharged. The system began vibration before the heavy punch pressed the paste filler to provide the chance that the surface of the paste filler was flat automatically .During the vibration, the paste filler was from natural accumulation to vibration accumulation to discharge the gas in the filler and to improve the air discharge efficiency and shorten its time by the vacuum-pumping system.

Owner:马二红

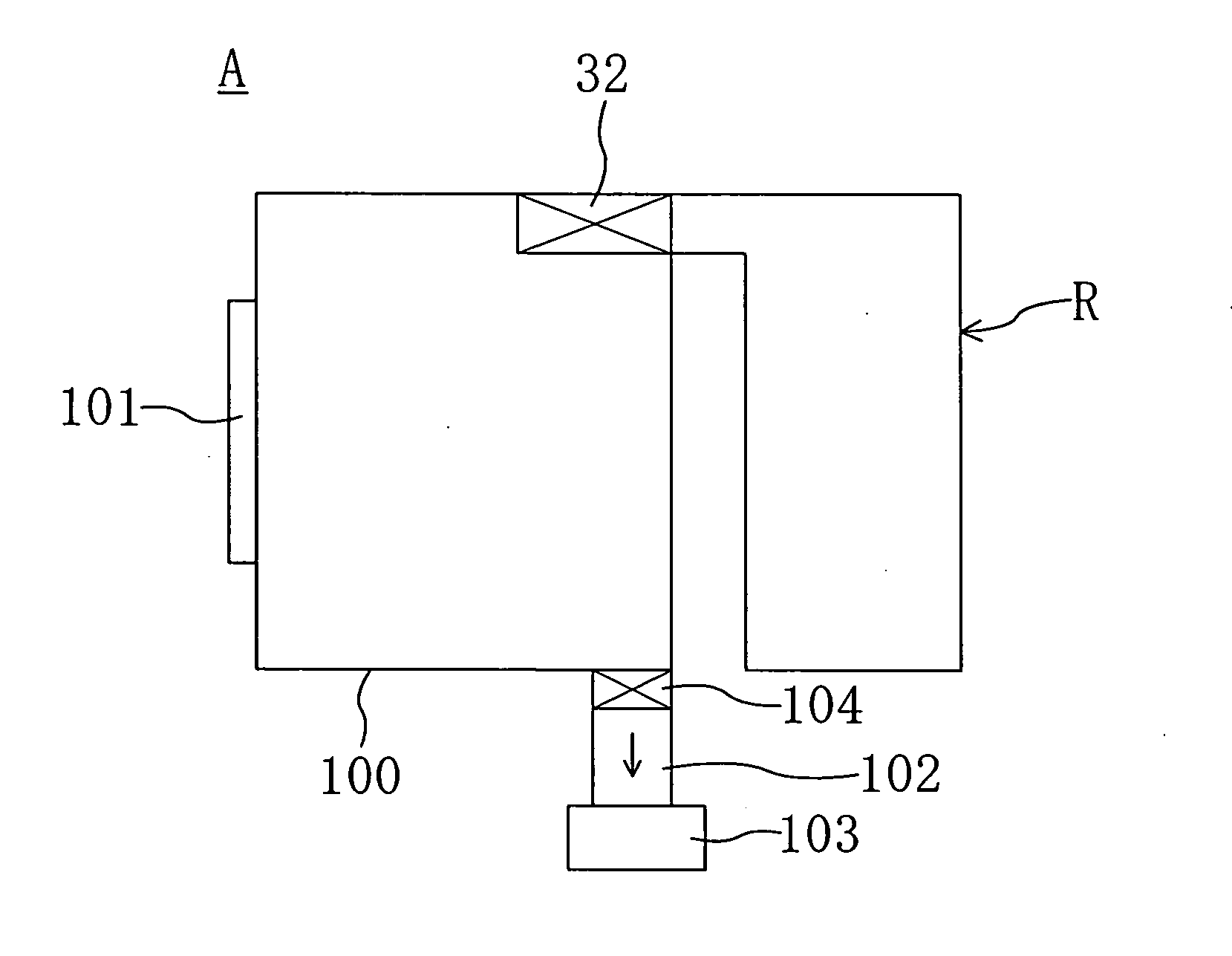

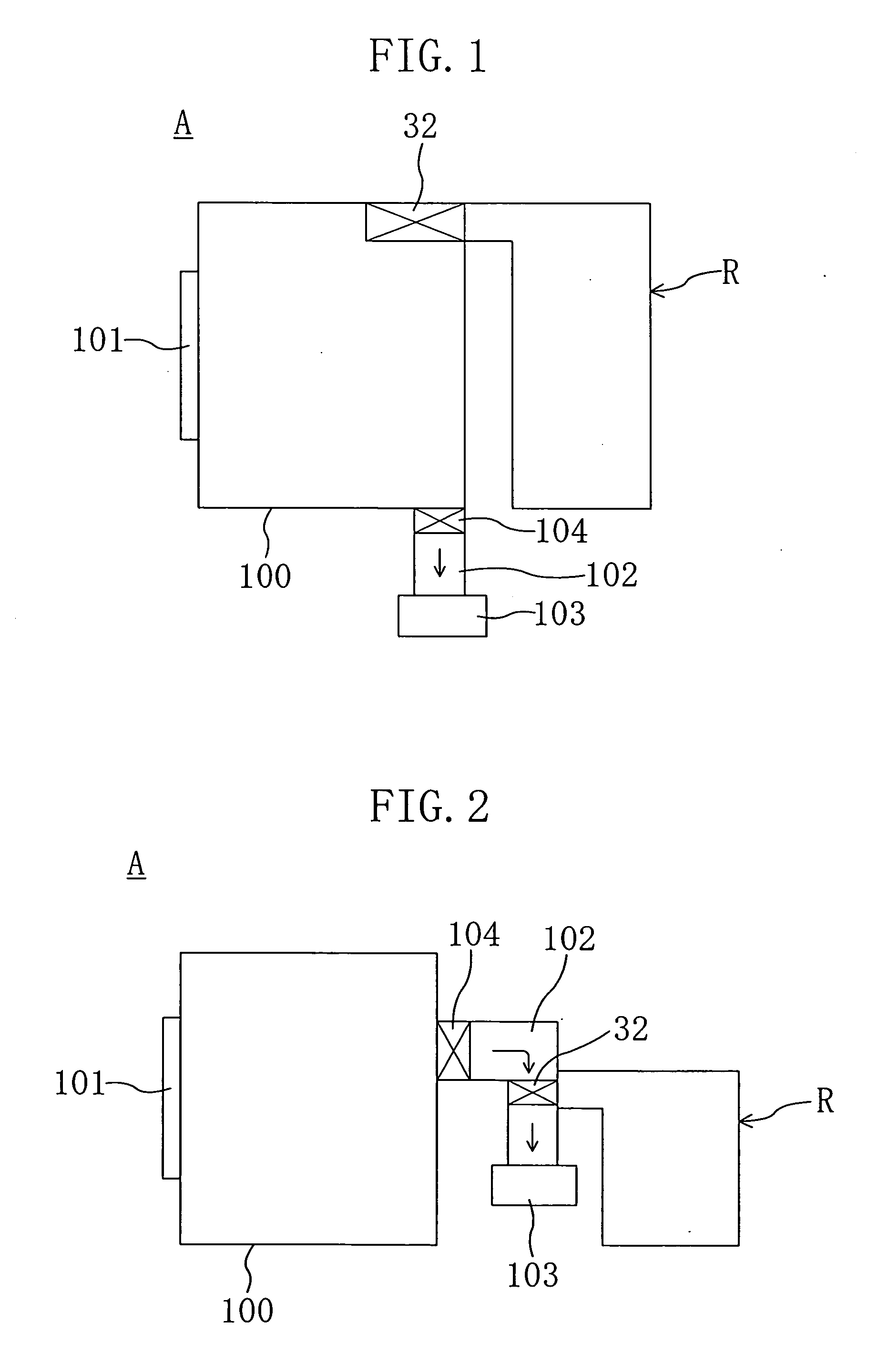

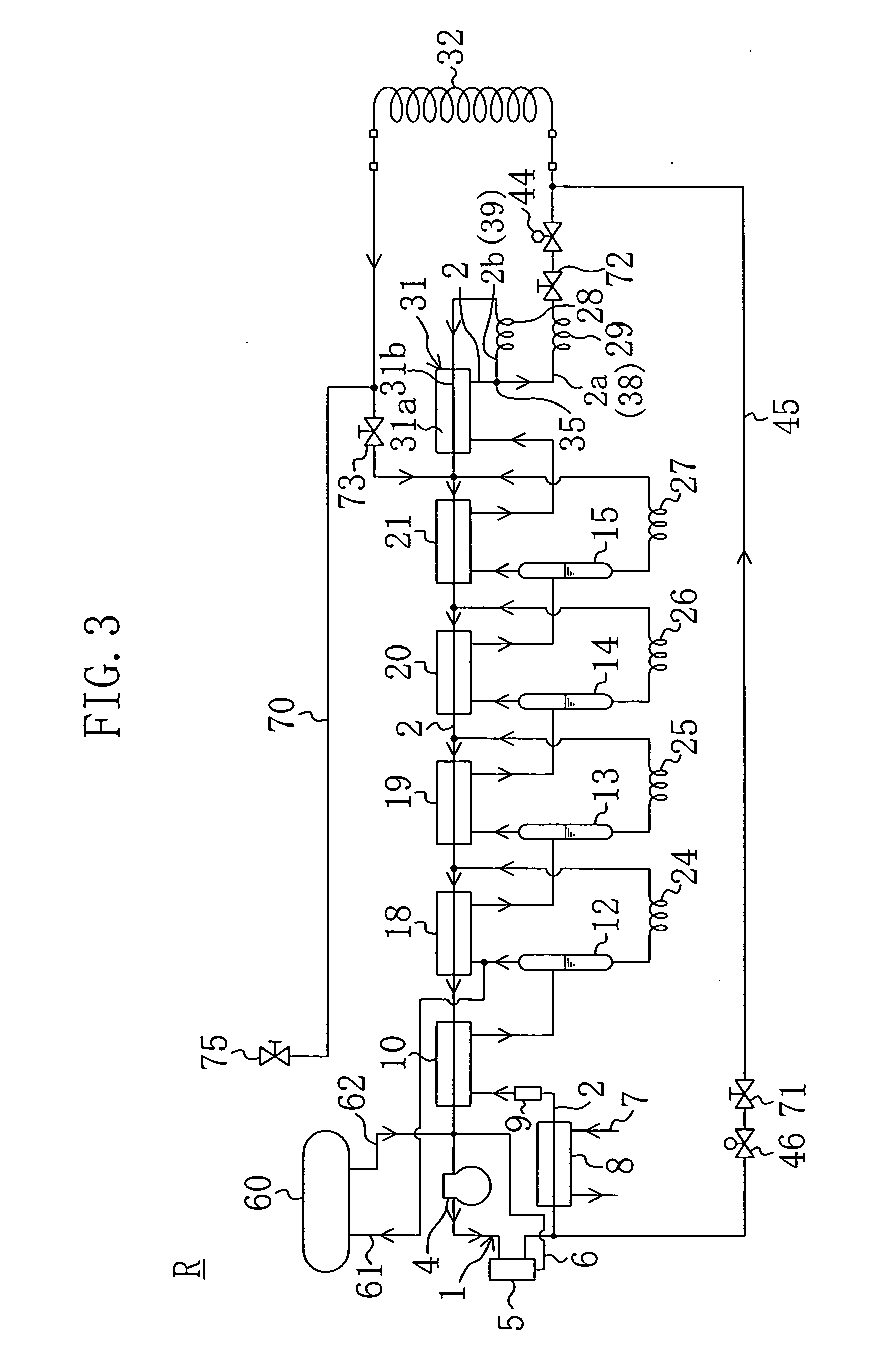

Ultra-low temperature freezer, refrigeration system and vacuum apparatus

InactiveUS20090188270A1Improve cooling efficiencyReduce CooldownCompression machines with non-reversible cycleDomestic refrigeratorsUltra Low Temperature FreezerHigh rate

In an ultra-low temperature freezer (R) using refrigerant mixture in which plural kinds of refrigerants having different boiling points are mixed, in order to ensure the flow rate of liquid refrigerant into a supercooler (31) and enhance the cooling efficiency of a cryocoil (32), the ultra-low temperature freezer (R) comprises: a main refrigerant circuit (38) provided with the cryocoil (32) and a capillary tube (29); and a sub refrigerant circuit (39) that is connected at the upstream end to the upstream end of the main refrigerant circuit (38) to branch off therefrom and provided with a capillary tube (28), and the ultra-low temperature freezer (R) is configured so that the sub refrigerant circuit (39) is lower in height than the main refrigerant circuit (38). Thus, gas-liquid mixture refrigerant discharged from the primary side (31a) of the supercooler (31) flows into the sub refrigerant circuit (39) at a higher rate than into the main refrigerant circuit (38) and, in turn, liquid refrigerant flows more into the sub refrigerant circuit (39) than into the main refrigerant circuit (38).

Owner:SHIN MEIWA IND CO LTD

Diaphragm valve for the vacuum evacuation system

ActiveUS20060175573A1Reduce the overall diameterAvoid corrosionDiaphragm valvesEngine diaphragmsDiaphragm valveSynthetic resin

A diaphragm valve 1 is provided with a body 2 having a flow-in passage 6, a flow-out passage 7, and a valve seat 8 formed between the passages; a diaphragm 3 installed in the body 2 and permitted to rest on and move away from the valve seat 8; and a driving means 4 installed on the body 2 to allow the diaphragm 3 to rest on and move away from the valve seat 8, wherein synthetic resin films 5 of predetermined thickness are coated on fluid-contacting parts 25 of the afore-mentioned body 2 and diaphragm 3. A diaphragm valve in accordance with the present invention prevents corrosion of the valve members caused by accumulation and adherence of substances produced by thermal decomposition, and prevents clogging caused by substances produced, and prevents seat leakage when applied in the vacuum exhaust system of a semiconductor manufacturing facility.

Owner:OHMI +1

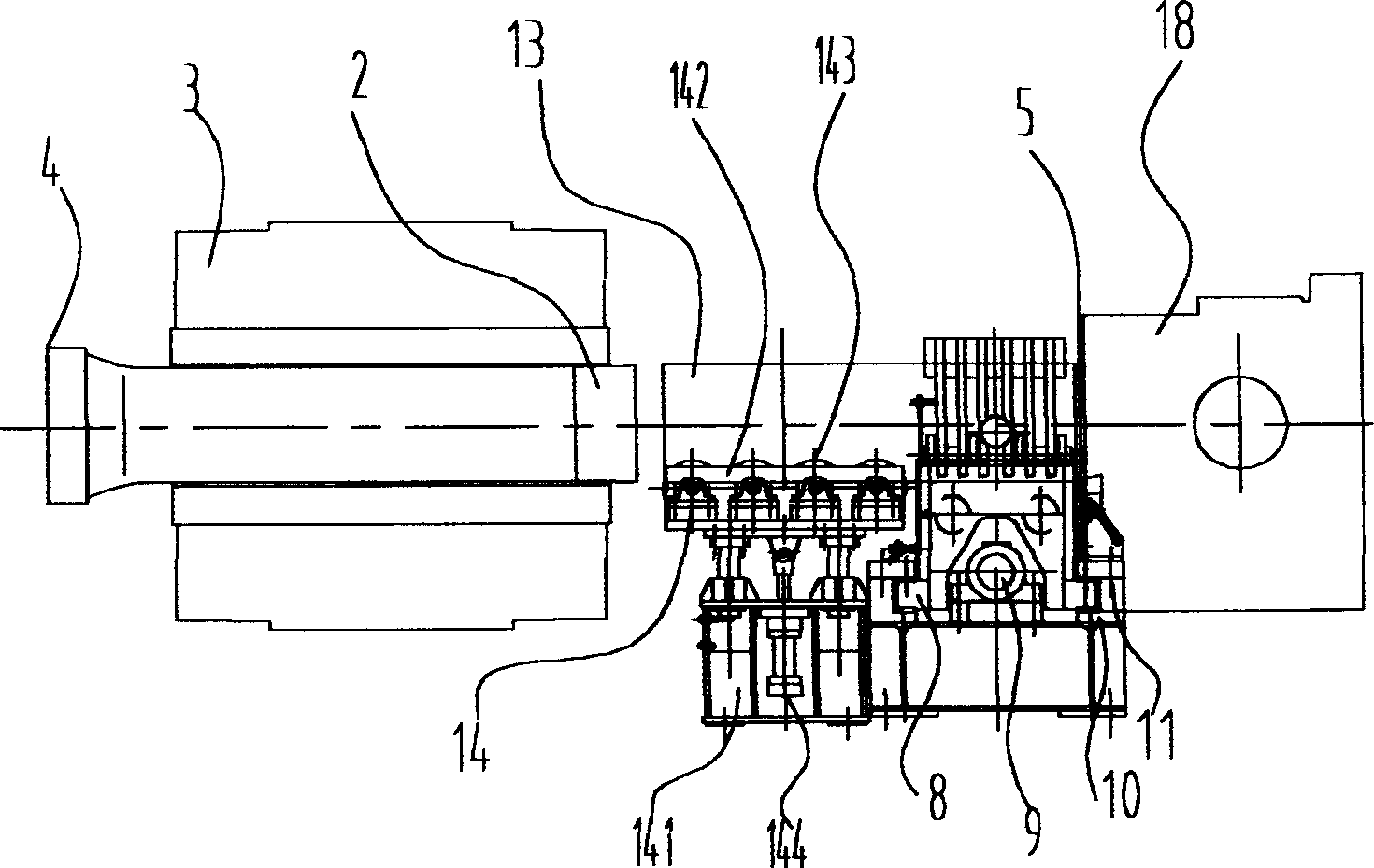

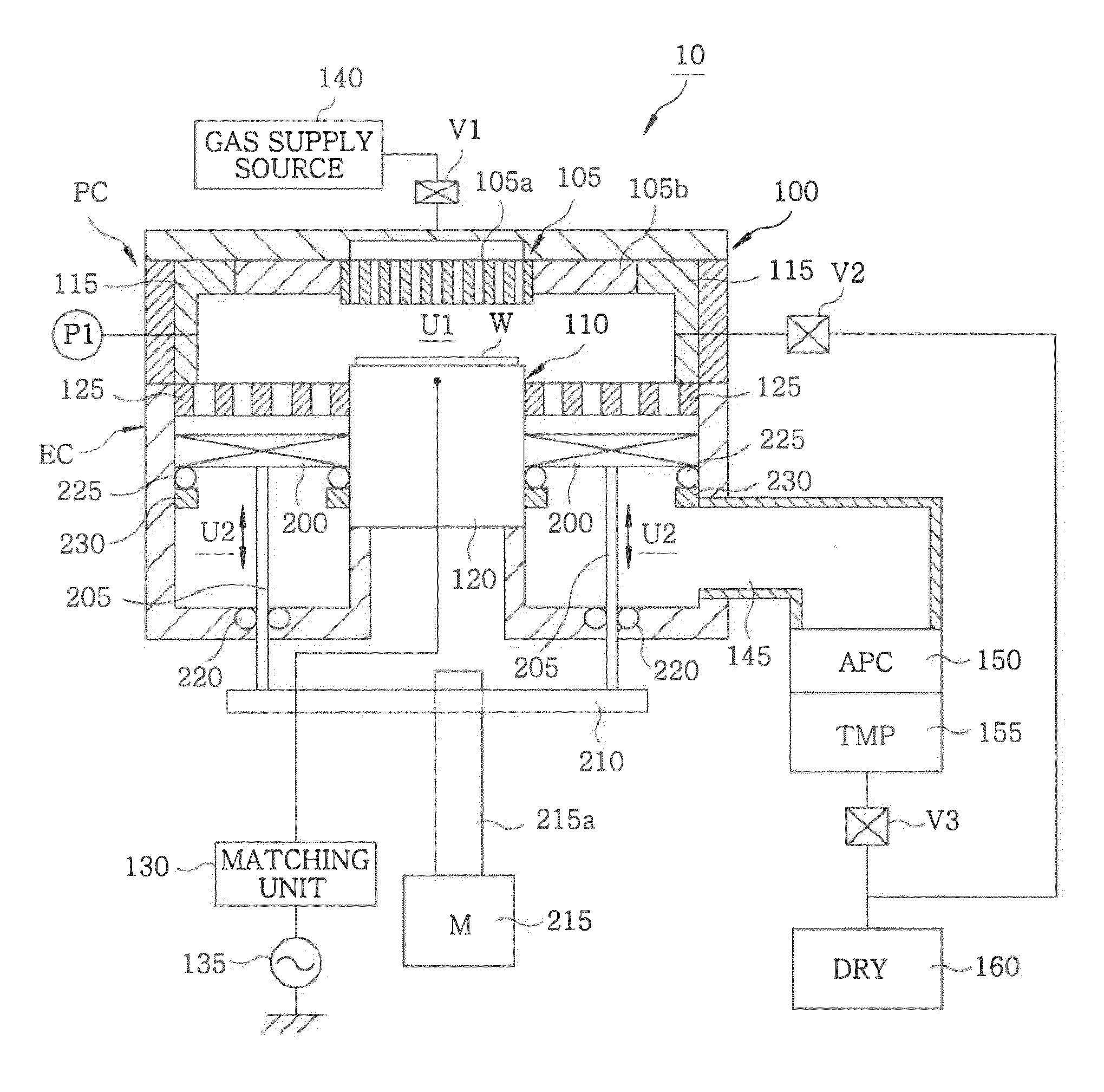

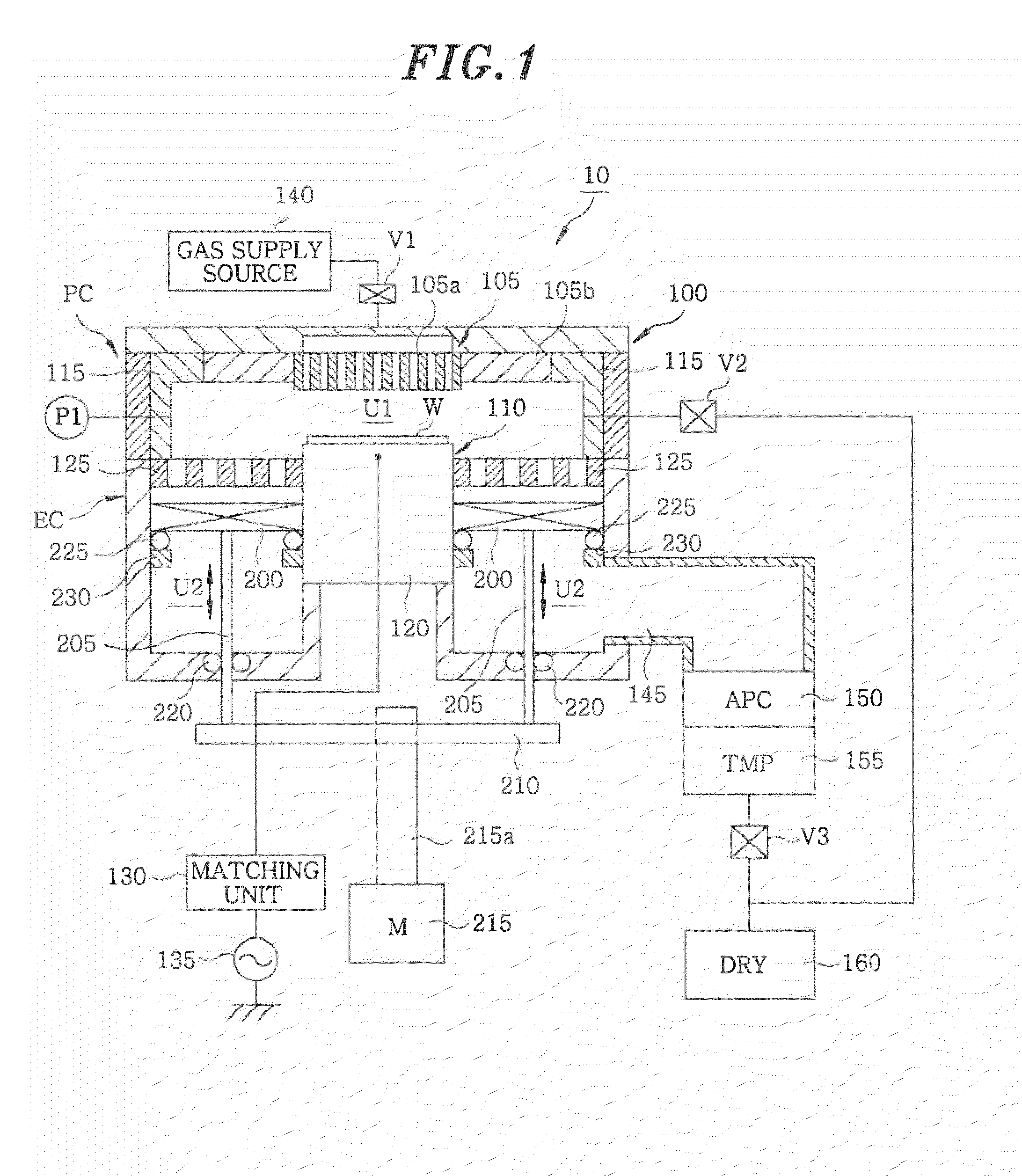

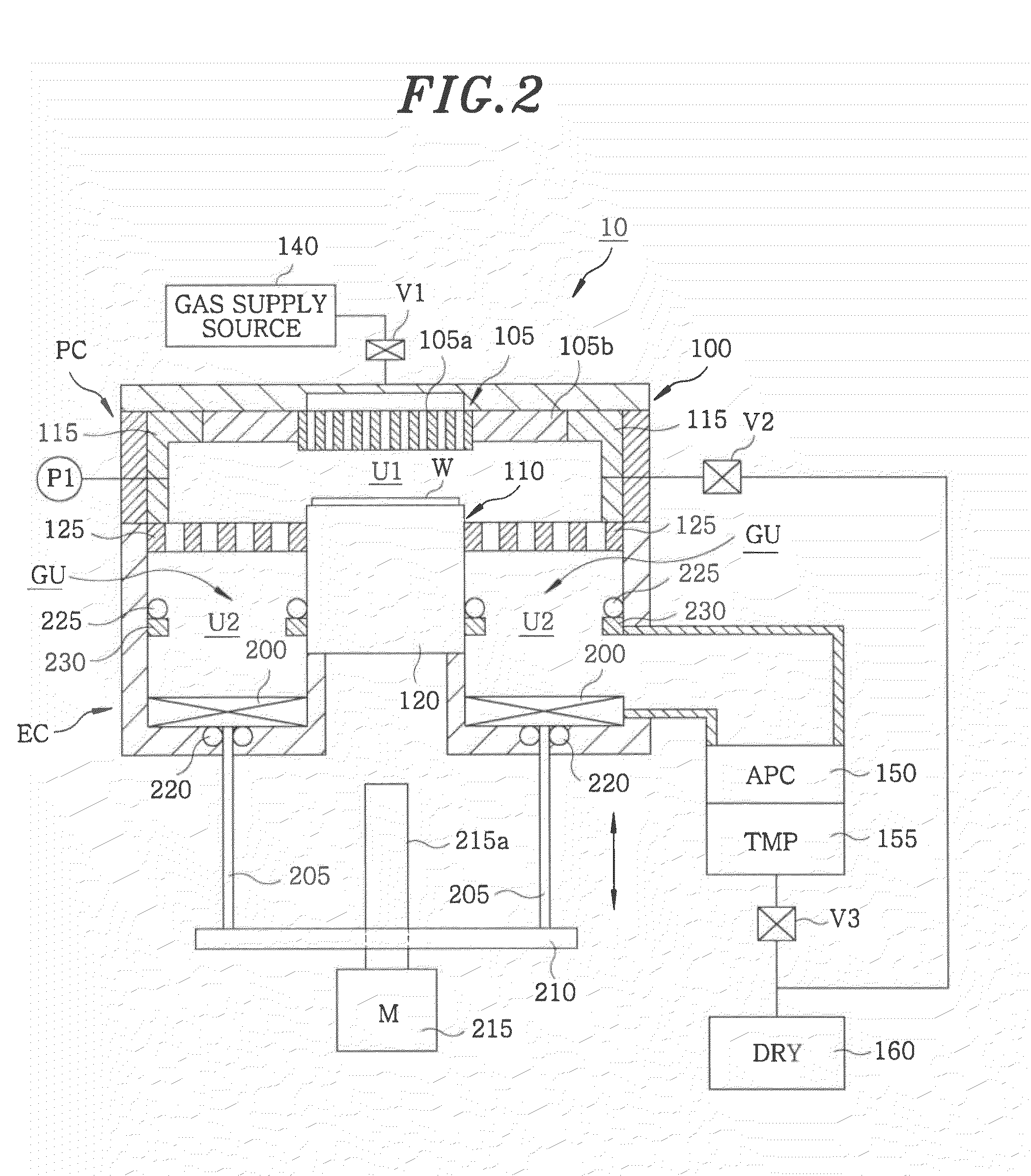

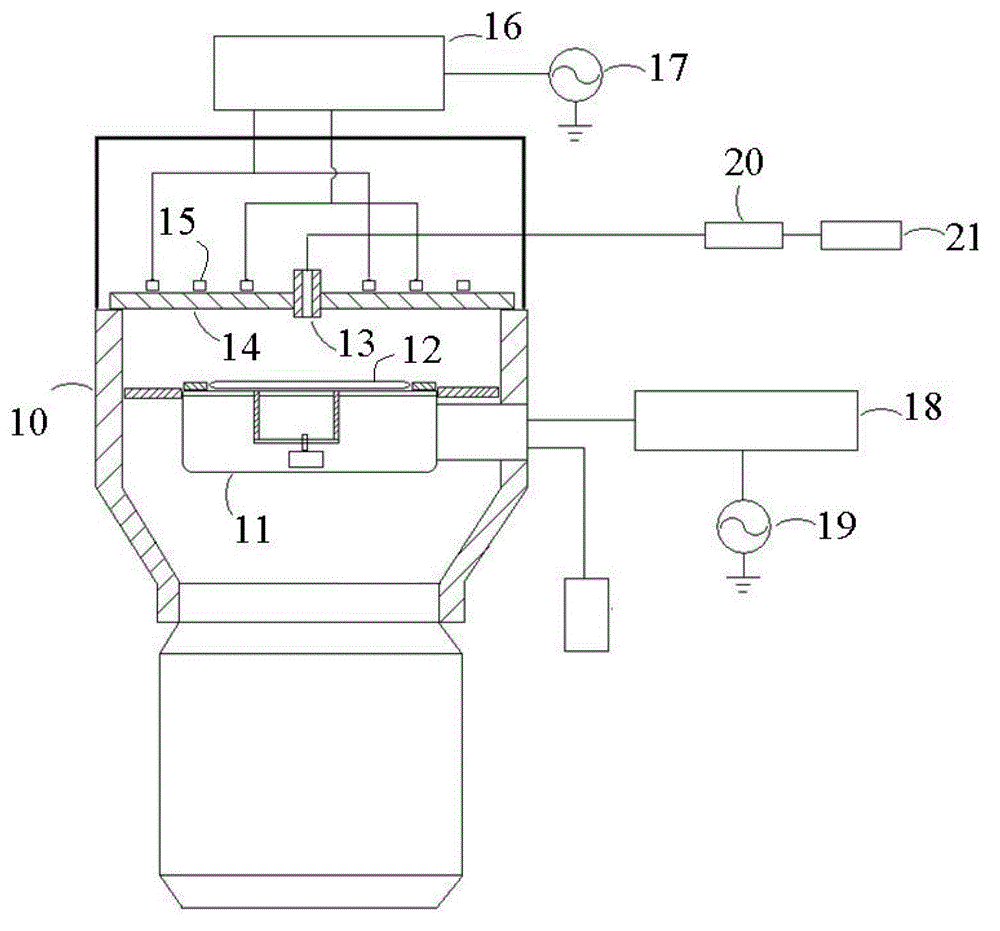

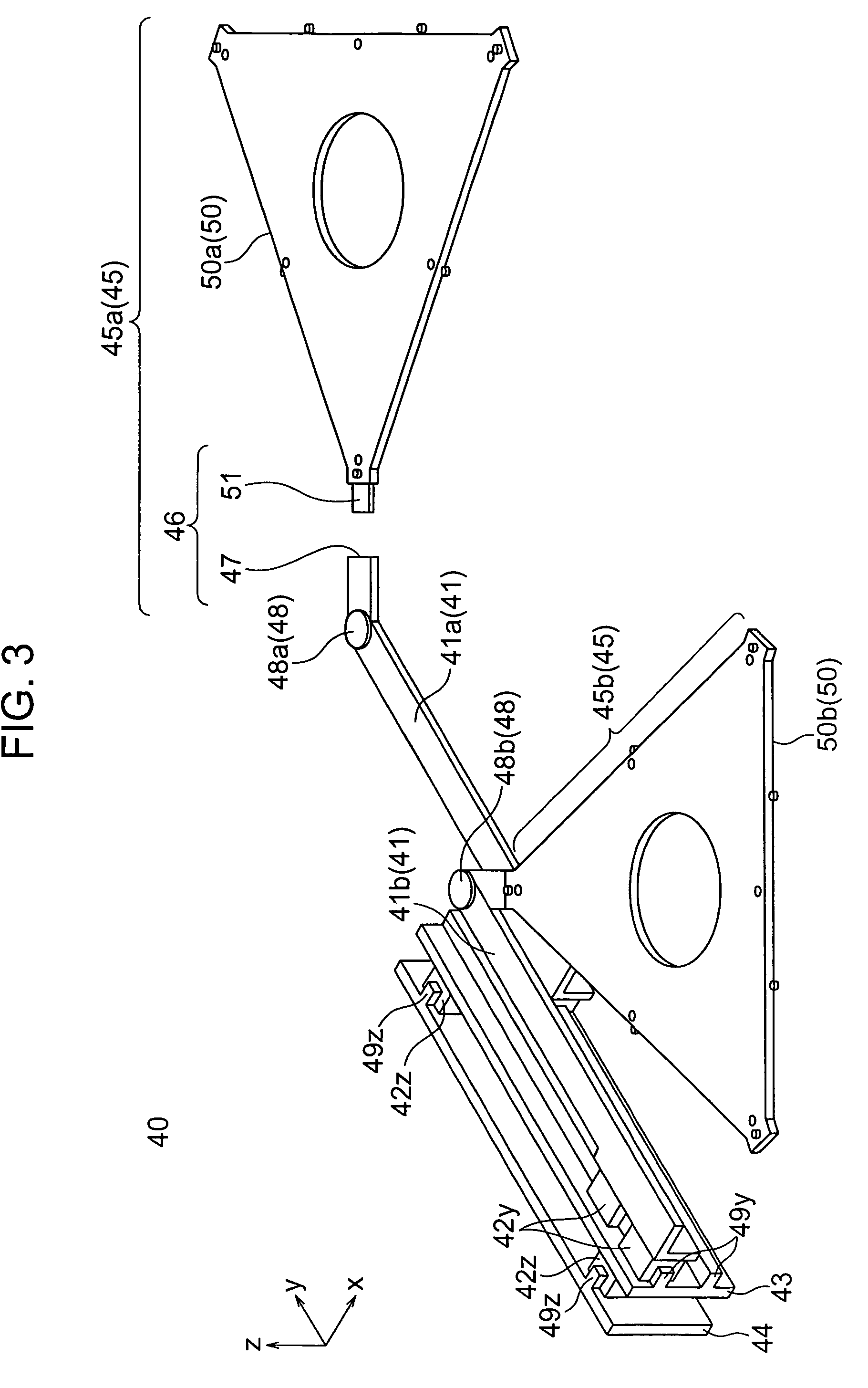

Plasma processing apparatus, and maintenance method and assembling method of the same

ActiveUS20100204810A1Shorten exhaust timeElectric discharge tubesTemperatue controlEngineeringGas supply

A plasma processing apparatus includes a processing chamber that converts a processing gas introduced from a gas supply source into plasma and performs plasma processing on a target object, an exhaust chamber that communicates with the inside of the processing chamber to exhaust a gas converted into plasma from the processing chamber, and a blocking cover that is provided in the exhaust chamber to block communication between the inside of the processing chamber and the inside of the exhaust chamber.

Owner:TOKYO ELECTRON LTD

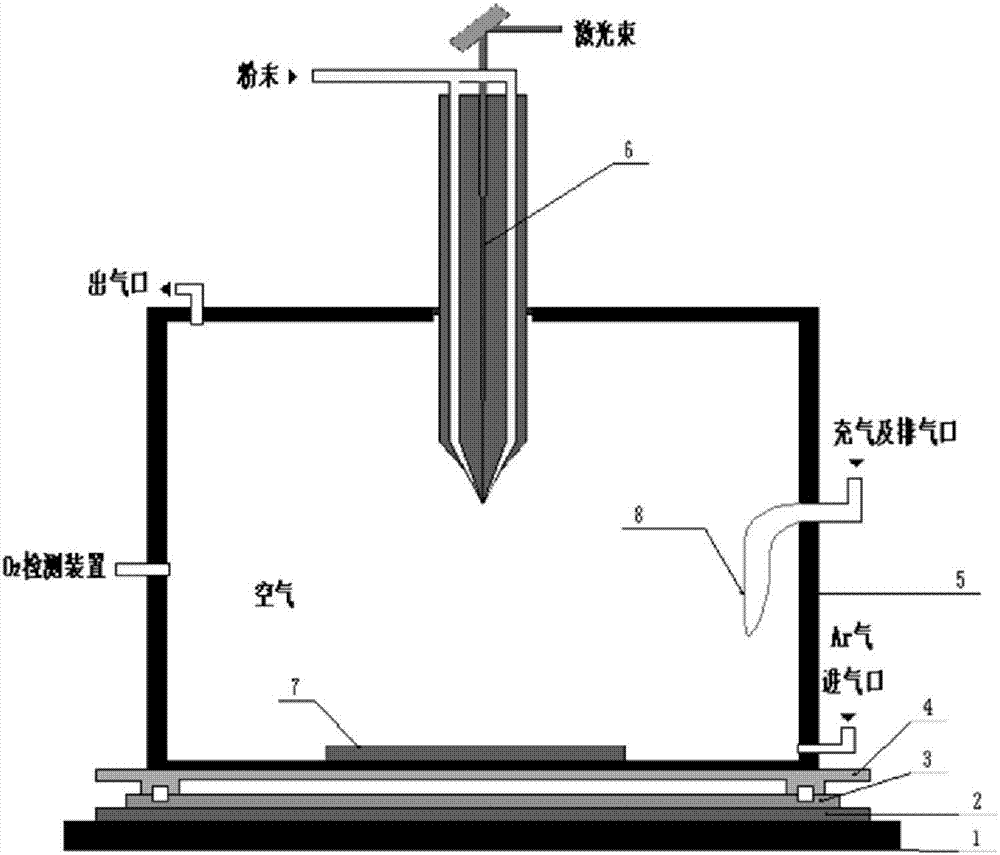

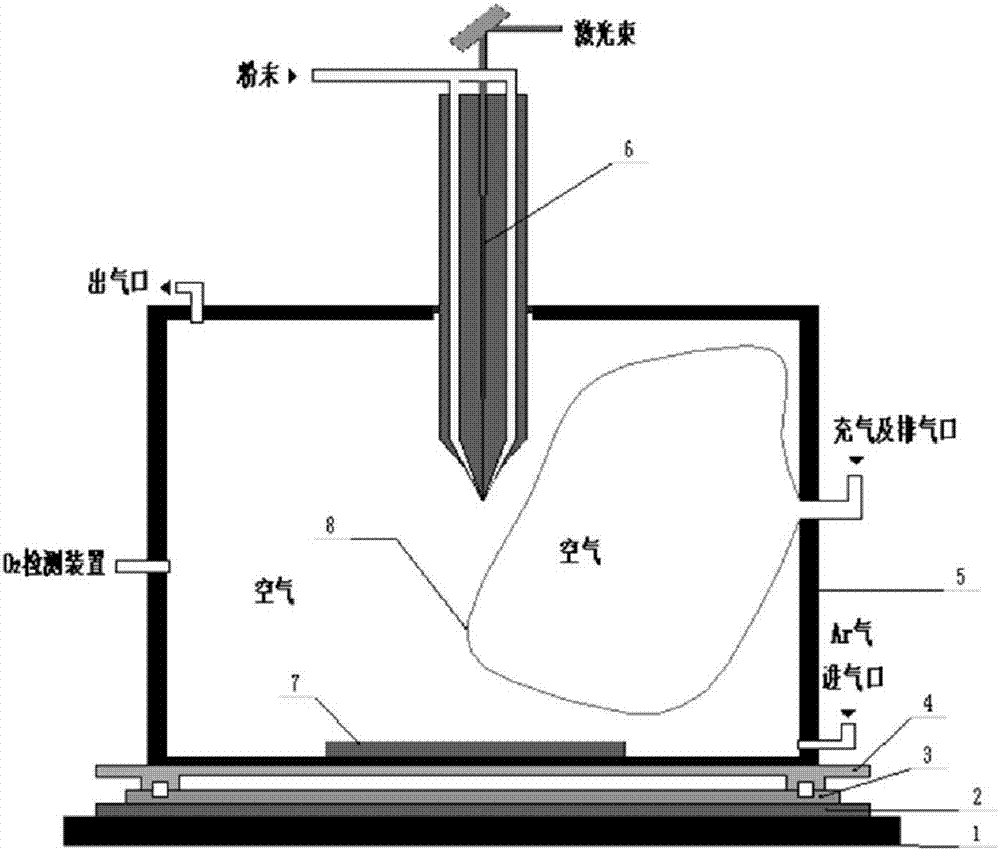

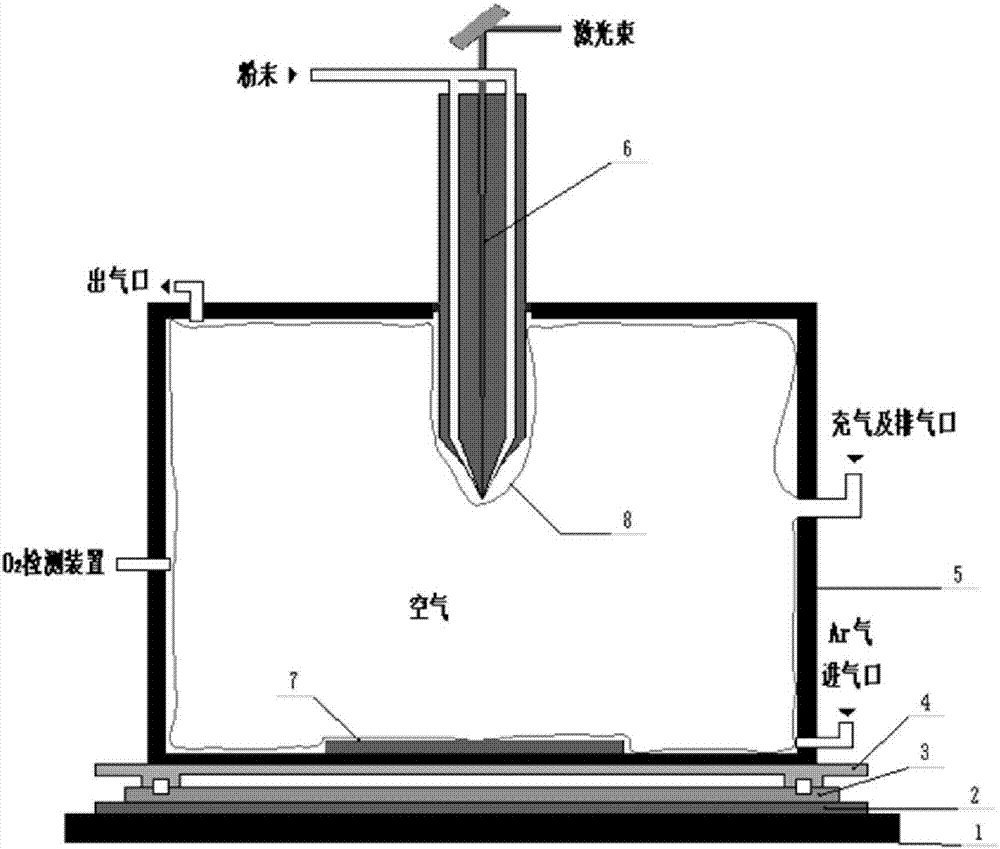

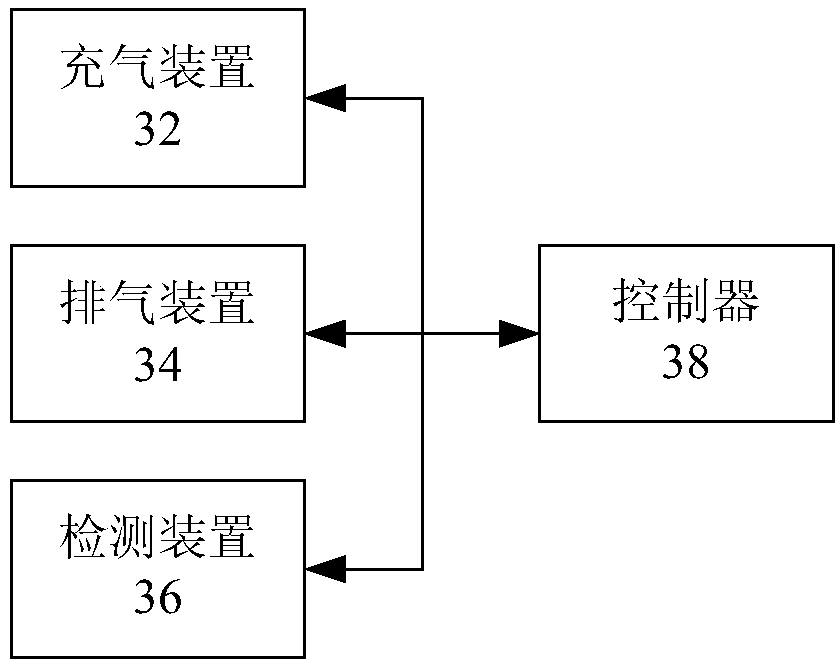

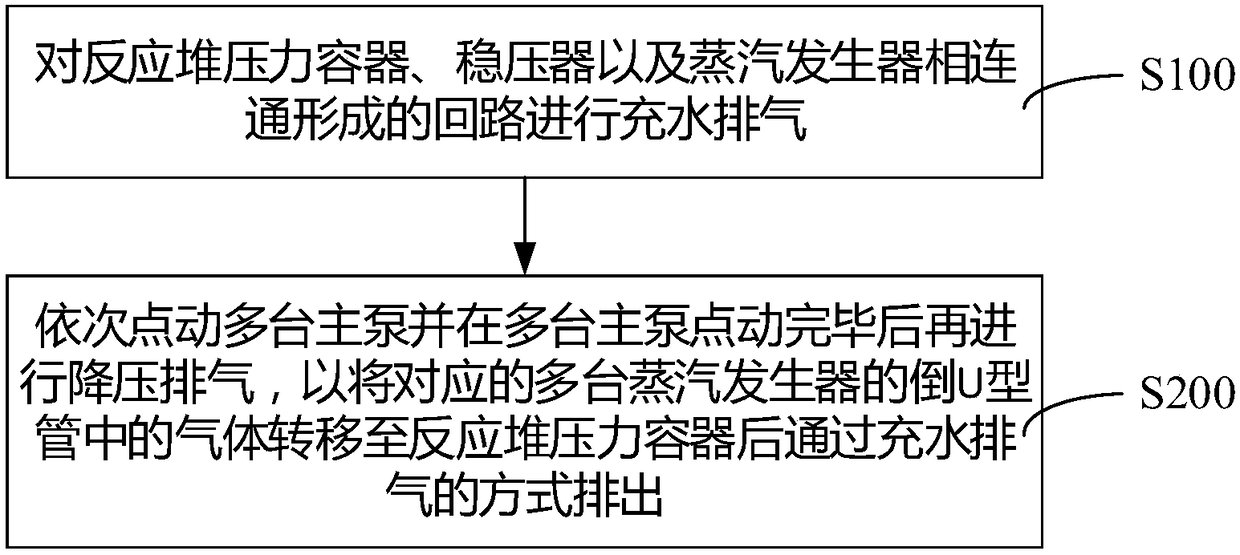

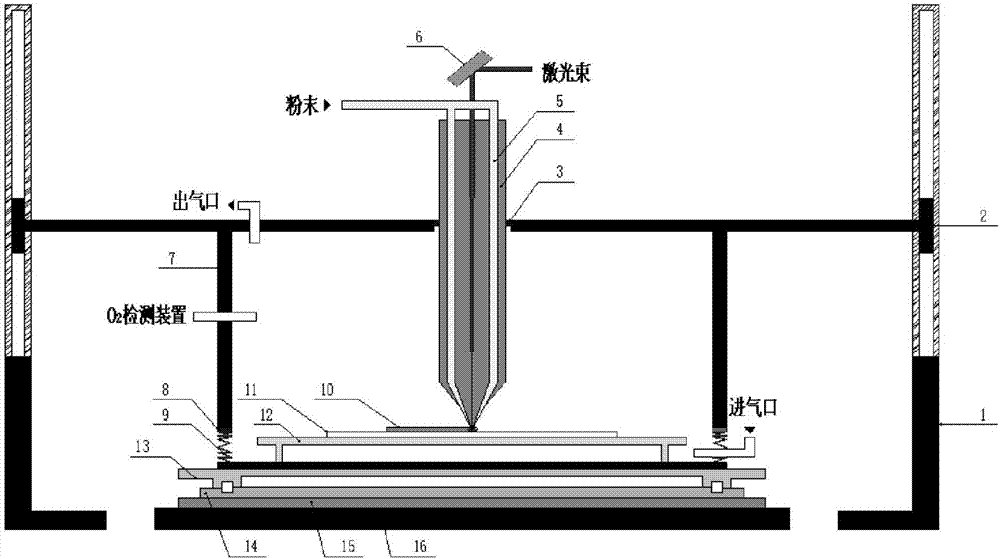

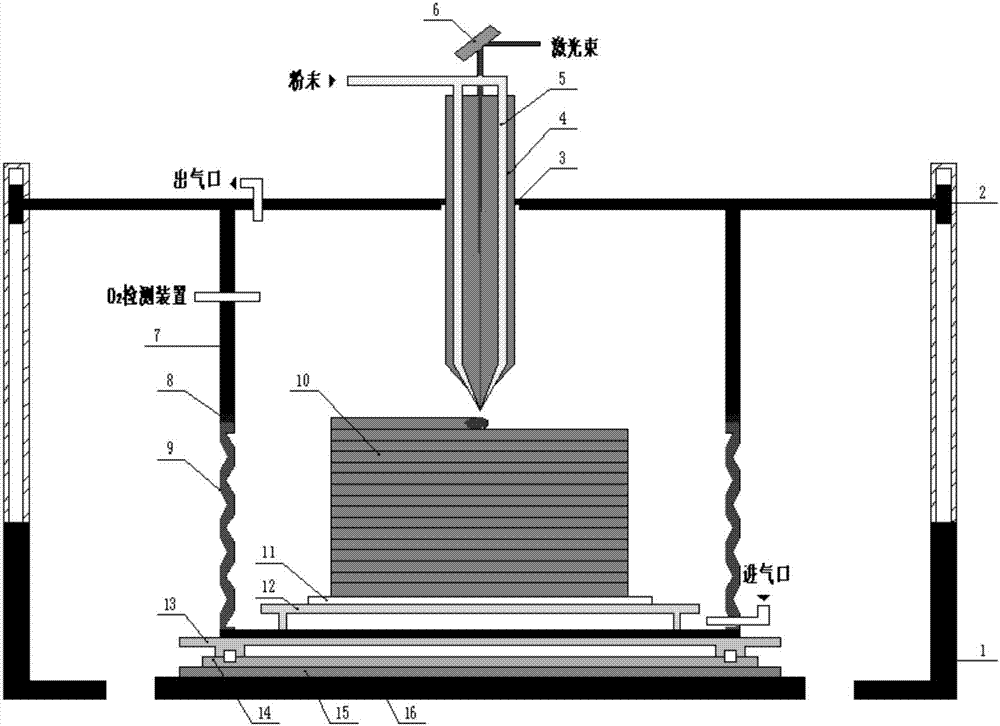

Air inflation and exhaust system, additive manufacturing equipment and air inflation and exhaust method

ActiveCN107952960AShorten inflation timeShorten exhaust timeAdditive manufacturing apparatusIncreasing energy efficiencyEngineeringMechanical engineering

The invention provides an air inflation and exhaust system. The system comprises a sealing device which forms a forming cavity and a flexible device used for keeping and releasing the gas, wherein thesealing device is provided with a gas outlet, a gas inlet, a first through hole and a second through hole, the gas outlet is used for allowing the gas in the forming cavity to be discharged out of the cavity, the gas inlet is used for enabling the inert gas to enter the forming cavity through the gas inlet, the first through hole is used for allowing a part of a access device to be accommodatedin the forming cavity of the sealing device in a sealing mode, and the main body part of the flexible device is arranged in the forming cavity of the sealing device in a sealing mode through the second through hole; and the flexible device is provided with a gas inflation port and a gas extraction port which are used for allowing the gas to be fed and allowing the gas to be extracted respectively,and the gas inflation port and the gas extraction port are positioned outside the sealing device. The invention further provides additive manufacturing equipment and an air inflation and exhaust method.

Owner:北京煜鼎增材制造研究院股份有限公司

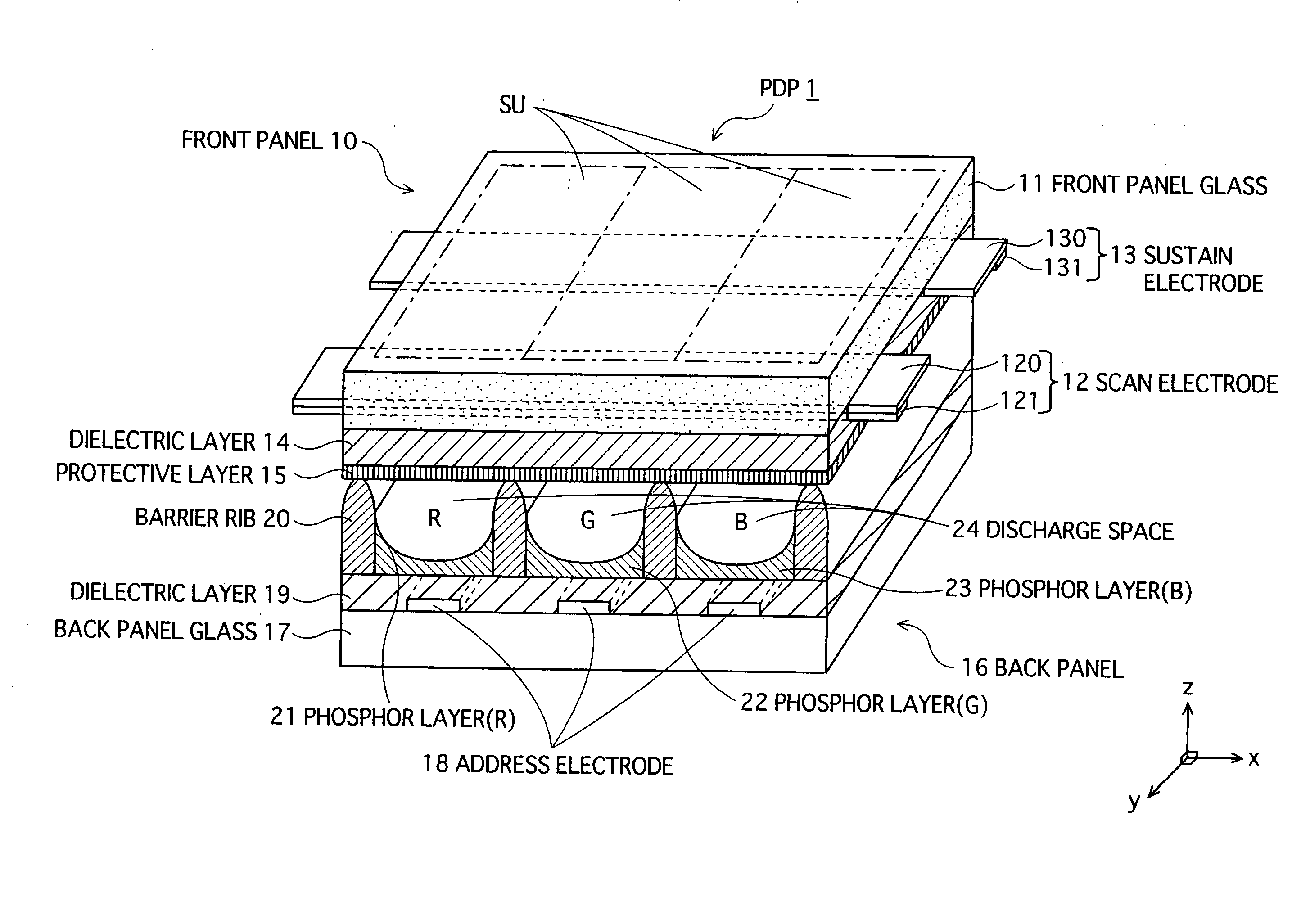

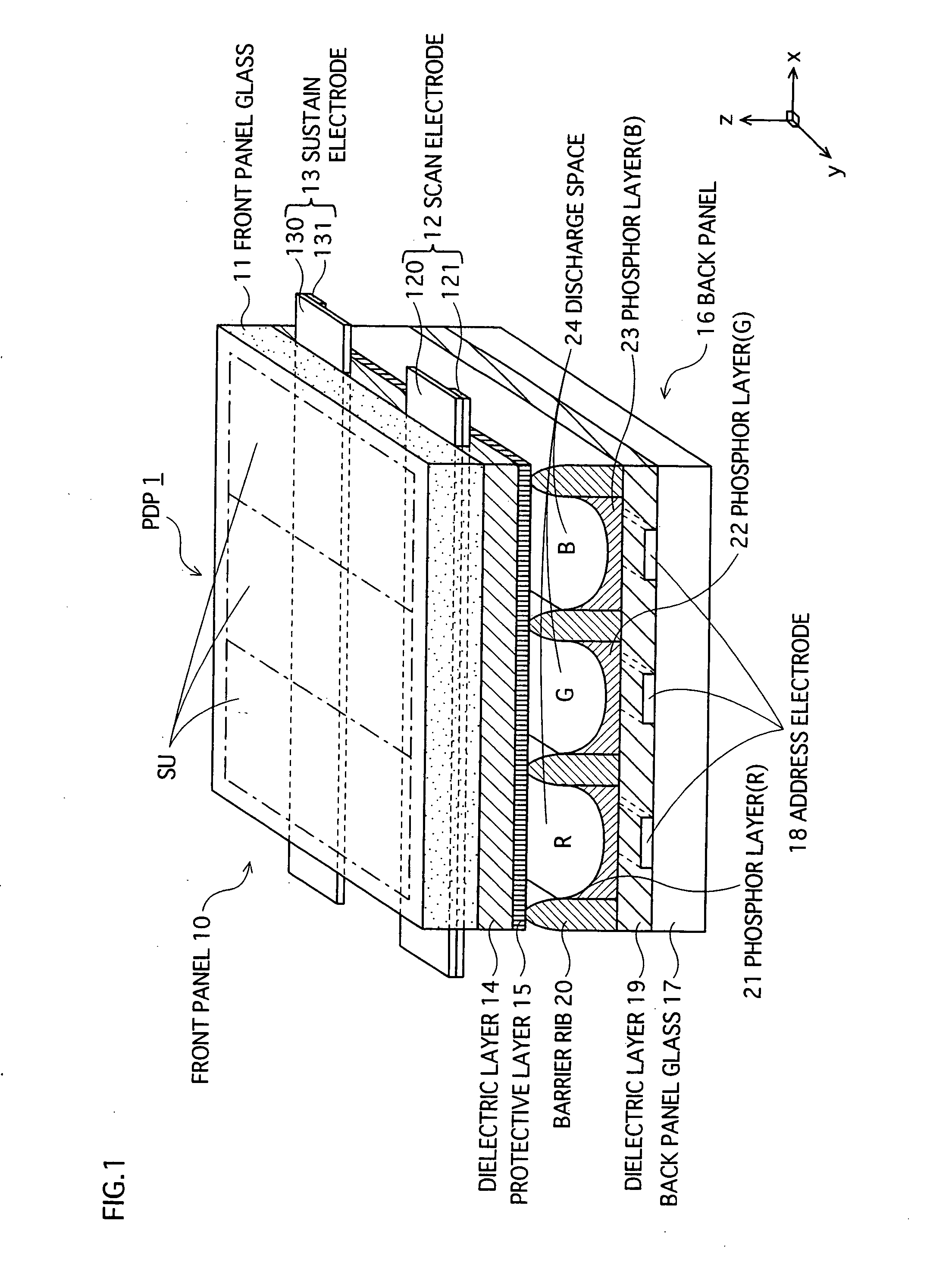

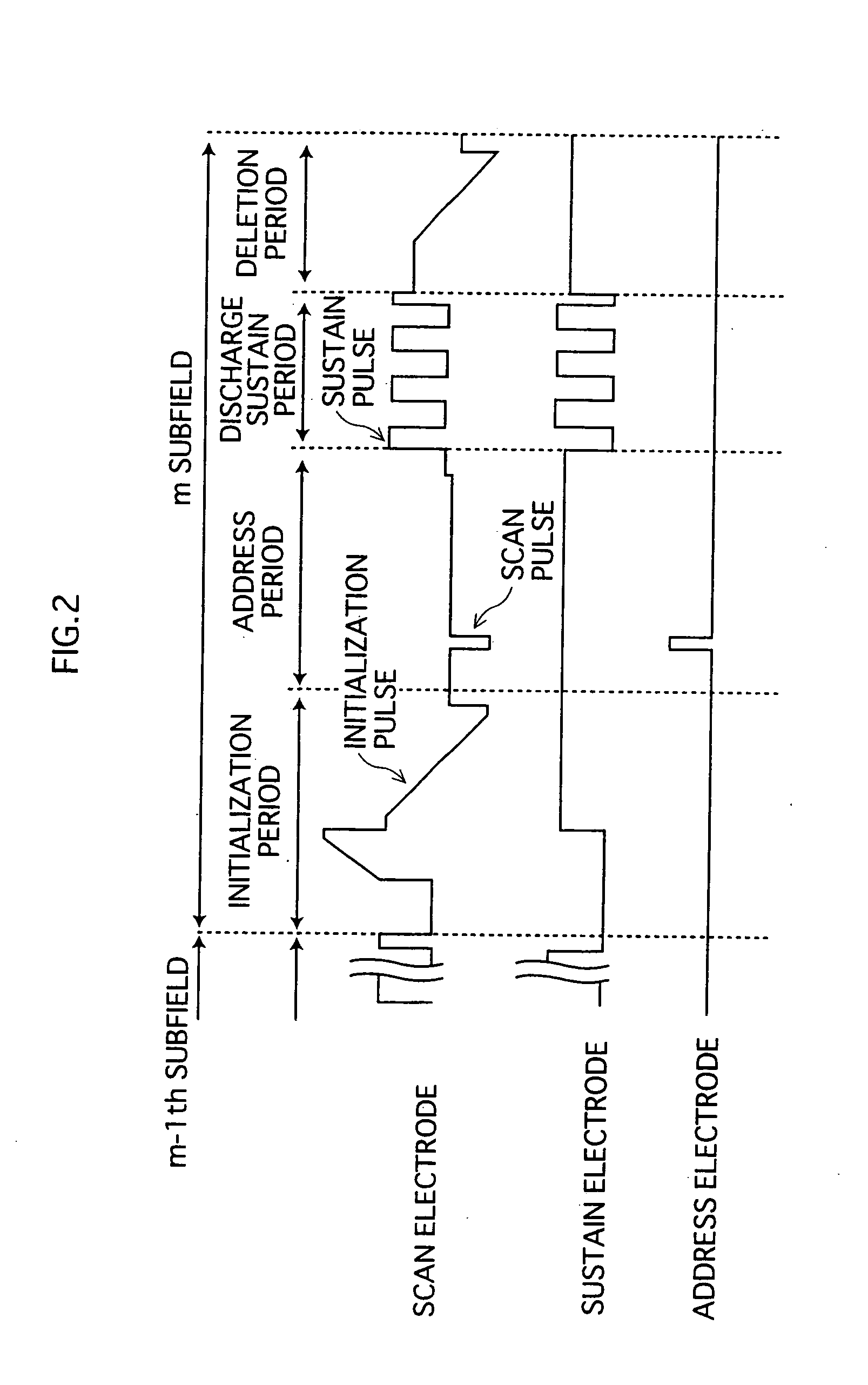

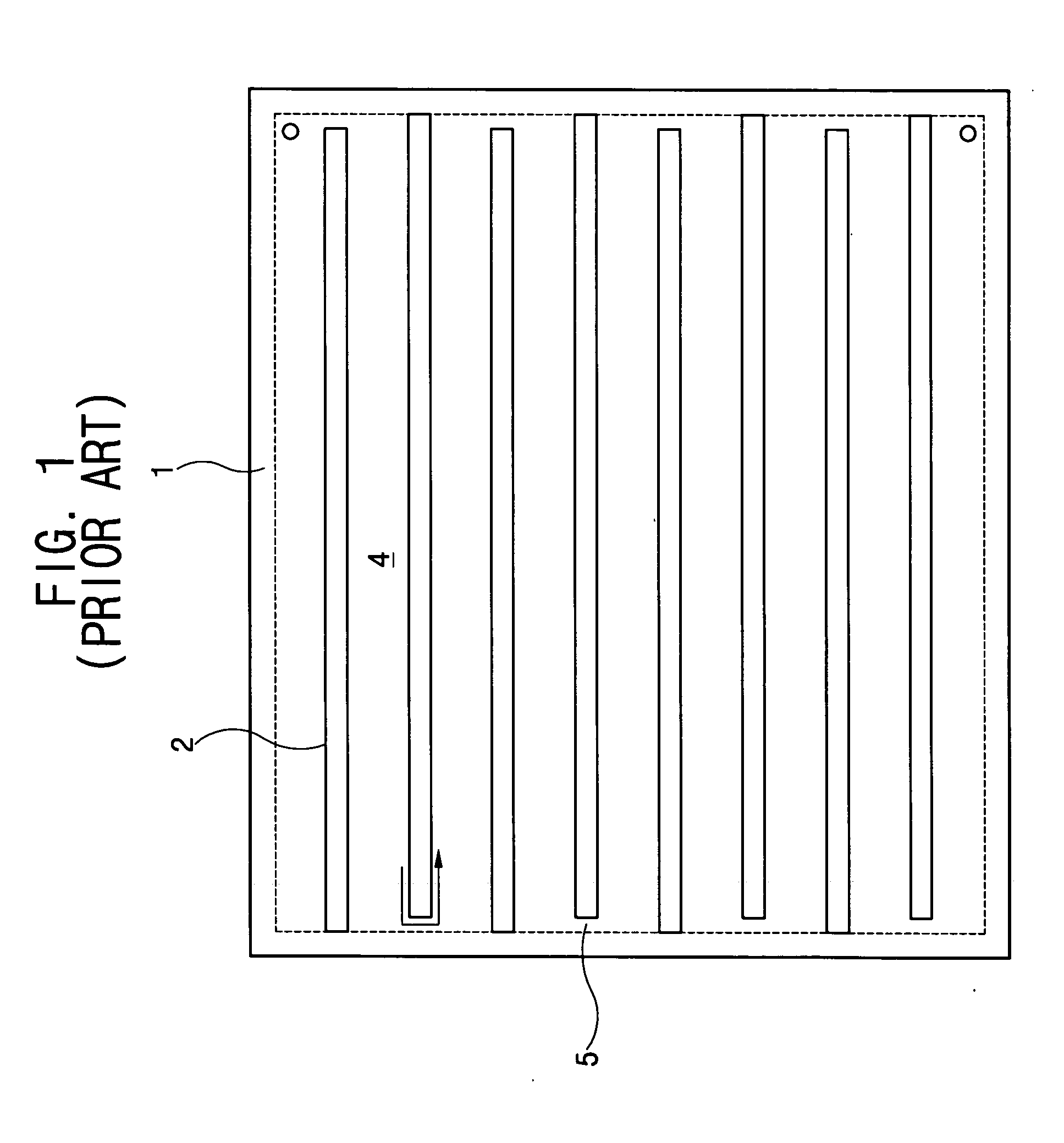

Gas Discharge Display Panel

InactiveUS20080278074A1More reliabilityReduce layeringVacuum evaporation coatingAlternating current plasma display panelsManufacturing cost reductionTectorial membrane

Provided is a gas discharge display panel that exhibits a favorable display performance by maintaining a wall charge retaining power, controlling discharge delay within a range adequate for optimal image display, and reducing the discharge starting voltage at comparatively low cost. Also provided is a PDP that exhibits more reliability with enhanced display quality by further improving the secondary electron emission factor γ compared to conventional cases and lowering the discharge starting voltage to widen the driving margin. Further provided is a manufacturing method of a gas discharge display panel, by which the manufacturing cost lowers by reduction of the exhaustion time in the sealing exhaustion process, and by which the driving circuit cost is reduced. In a gas discharge display panel of the present invention, a protective layer (15) has a first protective film (151) and a second protective film (152), the second protective film (152) is formed on at least part of a surface of the first protective film (151), and the first protective film (151) has a larger impurity content than the second protective film (152).

Owner:PANASONIC CORP

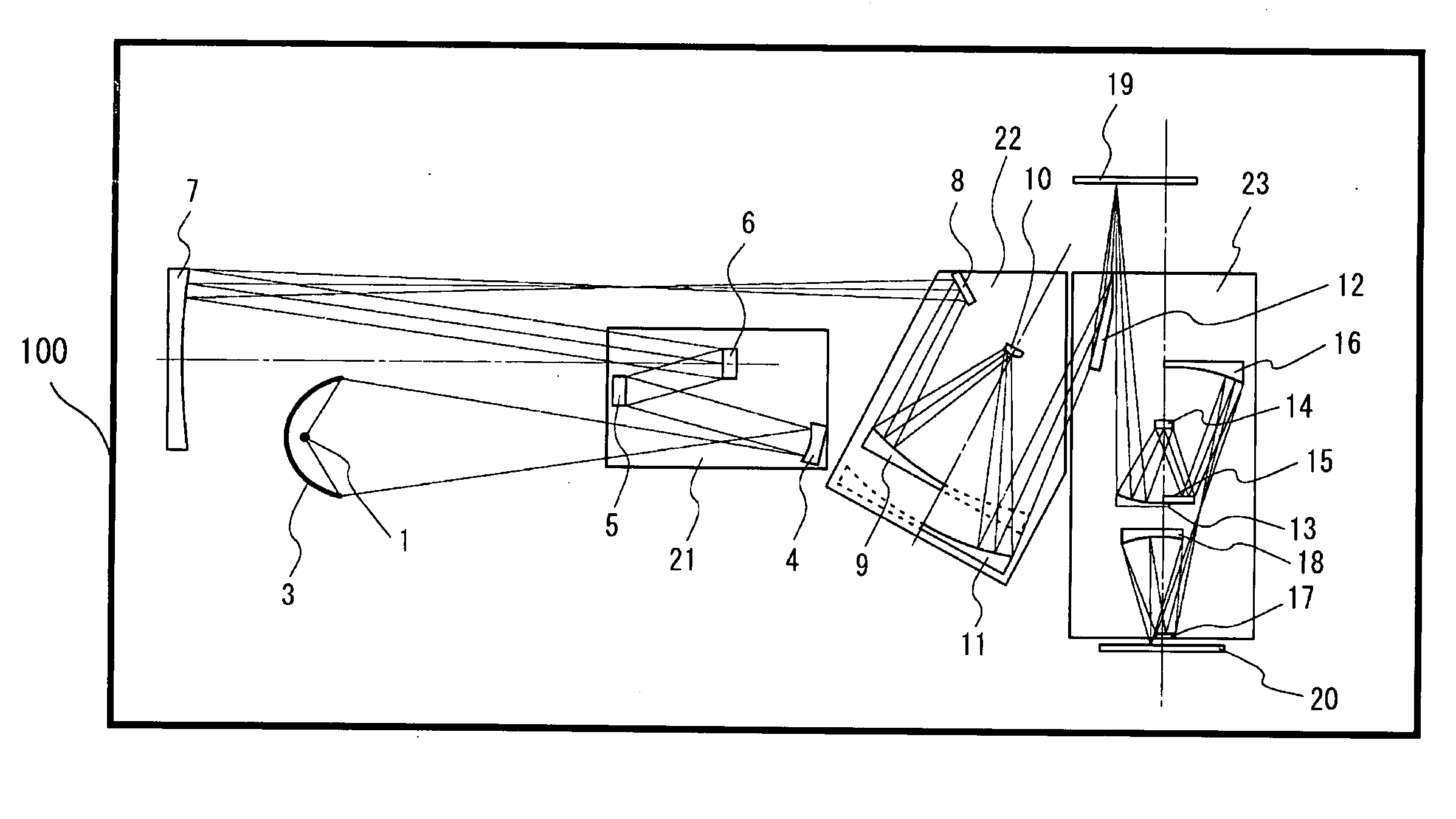

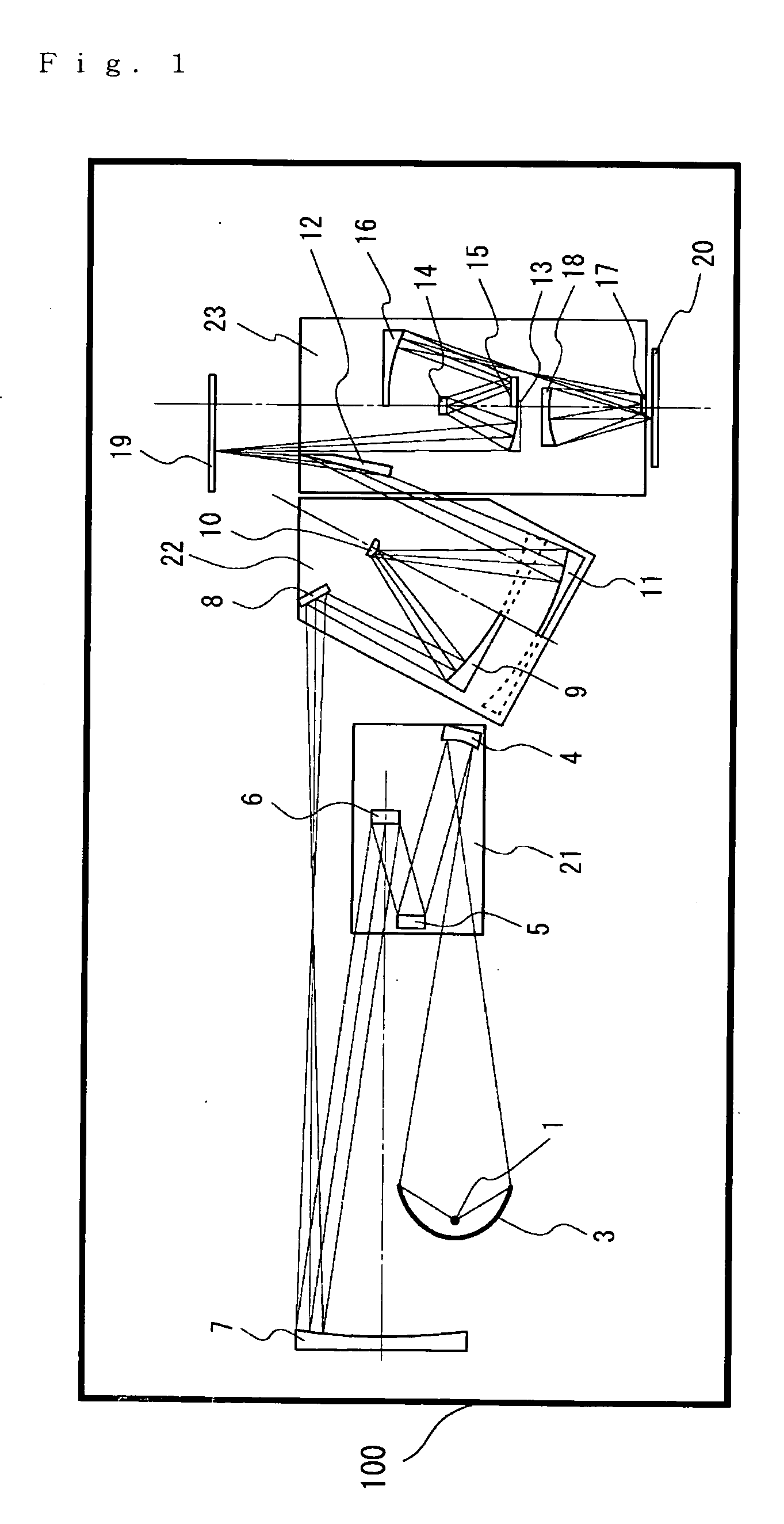

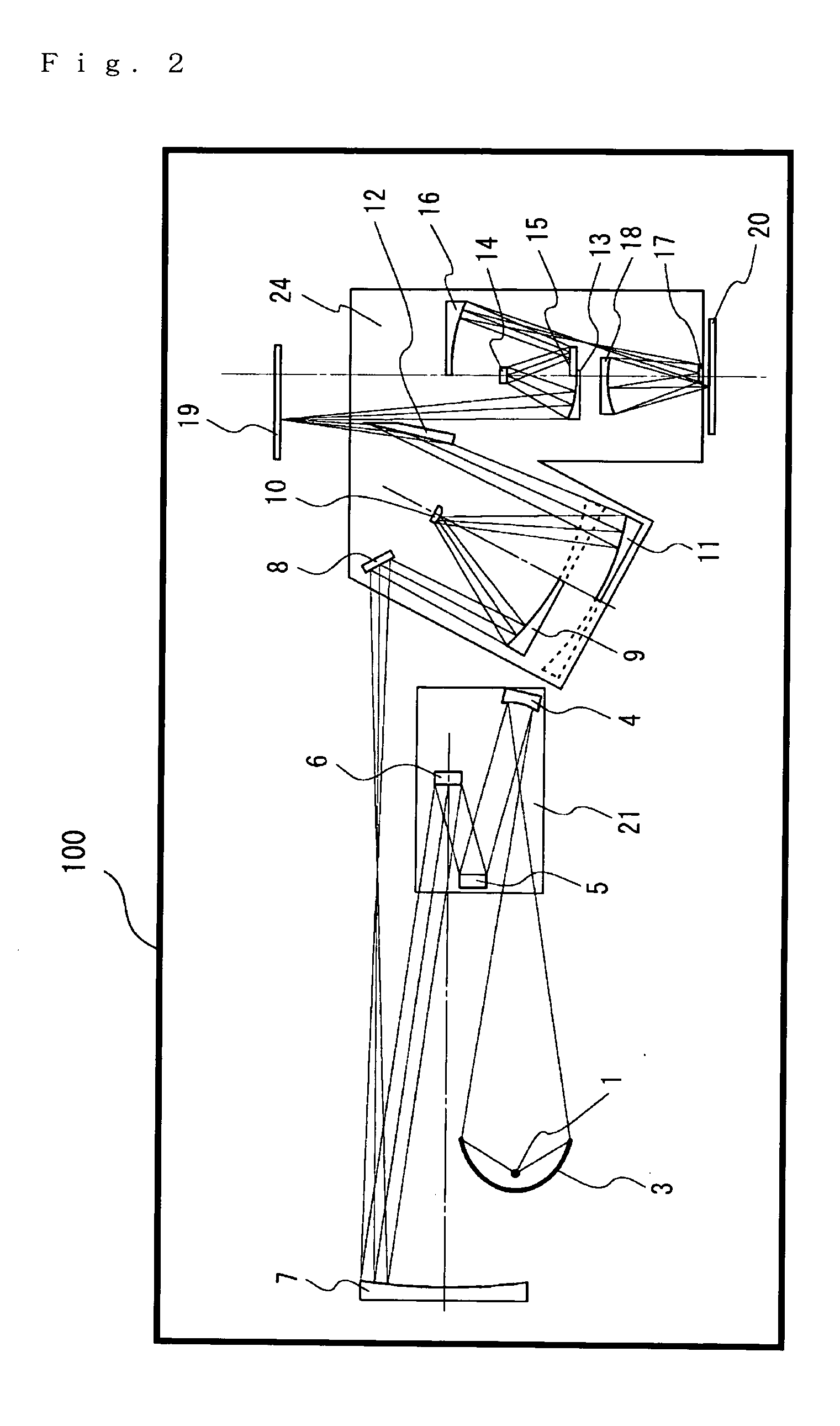

Extreme ultraviolet exposure apparatus and vacuum chamber

InactiveUS20050213069A1Extend the exhaust timeExtended leak timeNanoinformaticsPhotomechanical exposure apparatusUltravioletProjection system

An extreme ultraviolet exposure apparatus comprising a light source that emits extreme ultraviolet light, a plurality of illumination reflective mirrors that direct the extreme ultraviolet light emitted from the light source to a mask, a plurality of projection reflective mirrors that direct the extreme ultraviolet light reflected by the mask onto a sensitive substrate and that project and focus an image of the mask on this sensitive substrate, and a projection system optical housing that accommodates at least one of the projection reflective mirrors and at least one of the illumination reflective mirrors.

Owner:NIKON CORP

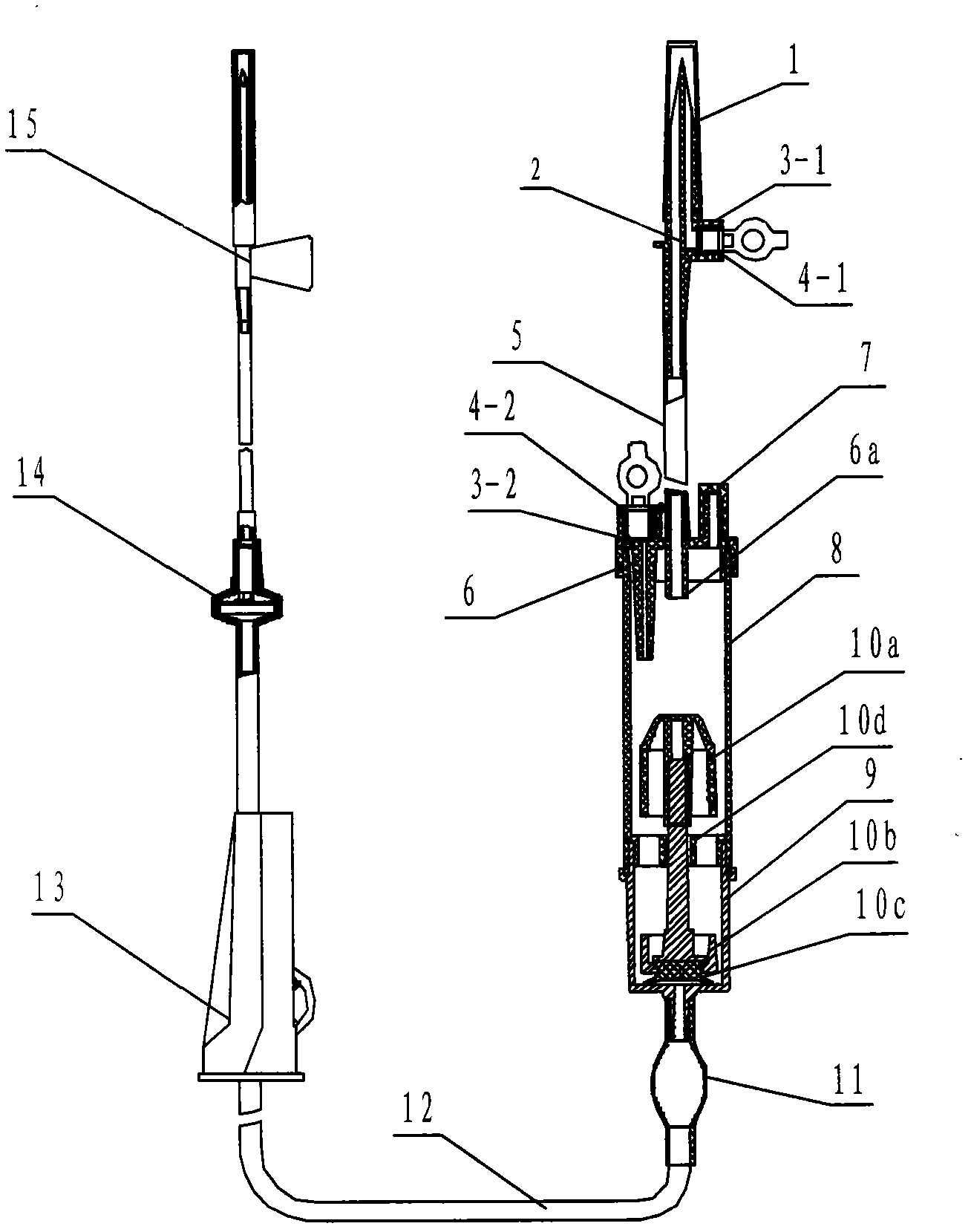

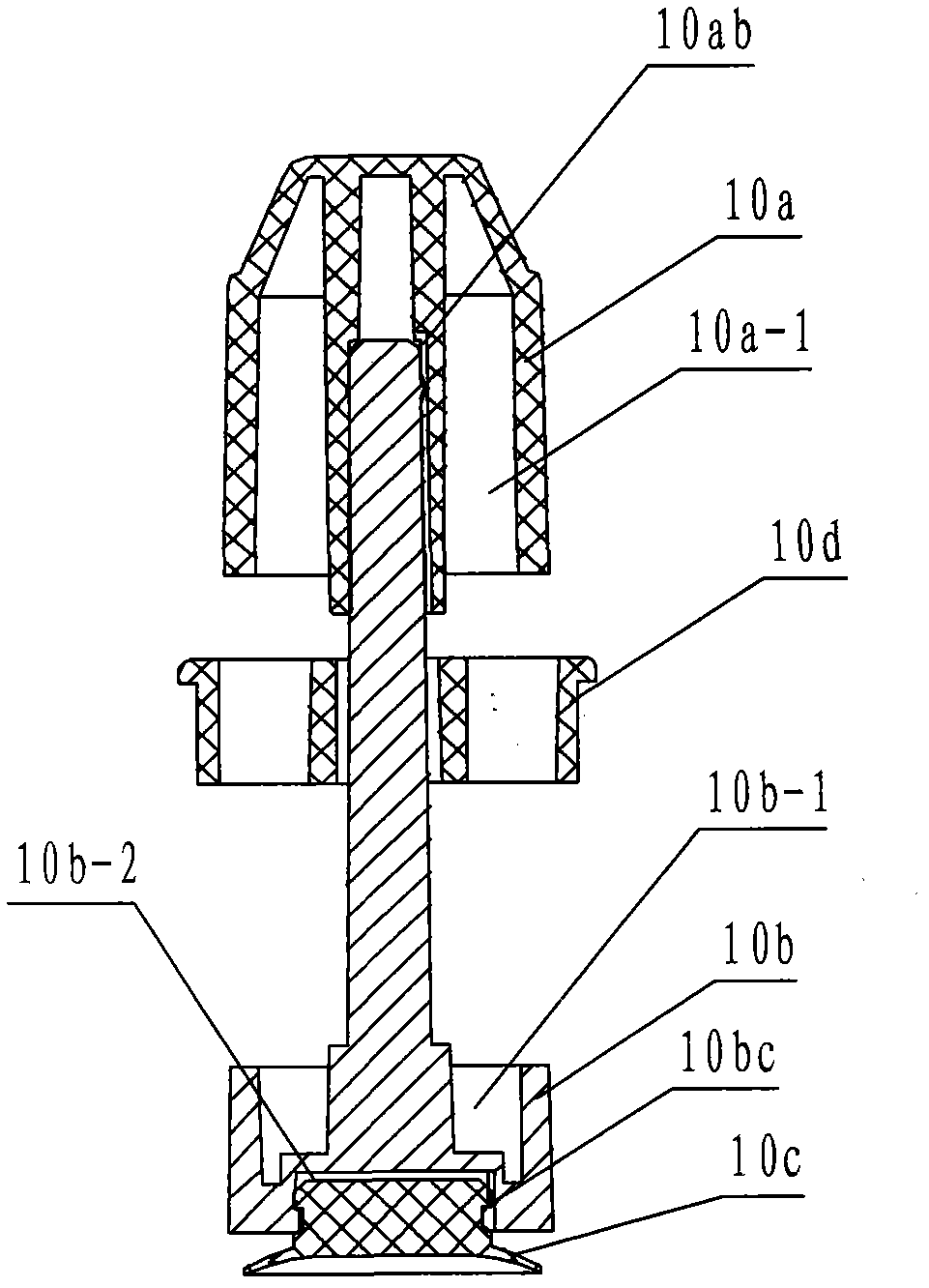

Disposable self-limiting and self-stopping transfusion system

The invention discloses a disposable self-limiting and self-stopping transfusion system, which comprises a bottle plug puncture unit protecting jacket, a bottle plug puncture unit, an air filtering membrane, an air plug, an upper flexible pipe, a dropping funnel cover, a latex cap, a self-limiting device, a self-stopping device, an upper dropping funnel, a lower dropping funnel, a pressurizing ball, a lower flexible pipe, a flow adjuster, a liquid medicine filter and an intravenous infusion needle, wherein the self-limiting device consists of the air plug, the air filtering membrane and an exhaust channel on the dropping funnel cover; the self-stopping device arranged inside the dropping funnel comprises a limiting shaft sleeve which is embedded into an opening section at the upper end of an inner cavity of the lower dropping funnel, and a liquid-stopping valve; the liquid-stopping valve consists of a floating cover, a floating shaft and a soft suction cup; the floating shaft is tightly matched with an inner sleeve of the floating cover through the centre of the limiting shaft sleeve; the upper part of the soft suction cup is embedded inside a concave part at the bottom of the floating shaft and limited by the limiting shaft sleeve; the floating cover and the soft suction cup are connected through the floating shaft and move up and down in the inner cavities of the upper dropping funnel and the lower dropping funnel. The transfusion system can quickly discharge liquid automatically, control the liquid level height inside the dropping funnel, and automatically discharge air in the dropping funnel after the bottle plug puncture unit is inserted into a large transfusion bottle plug; the liquid-stopping valve can automatically seal the pipeline to prevent the air from entering inside the lower flexible pipe to lead to blood return when no liquid medicine is in a medicine bottle or a little liquid medicine is in the dripping funnel in an infusion process.

Owner:HENAN SHUGUANG JIANSHI MEDICAL EQUIP GRP CO LTD

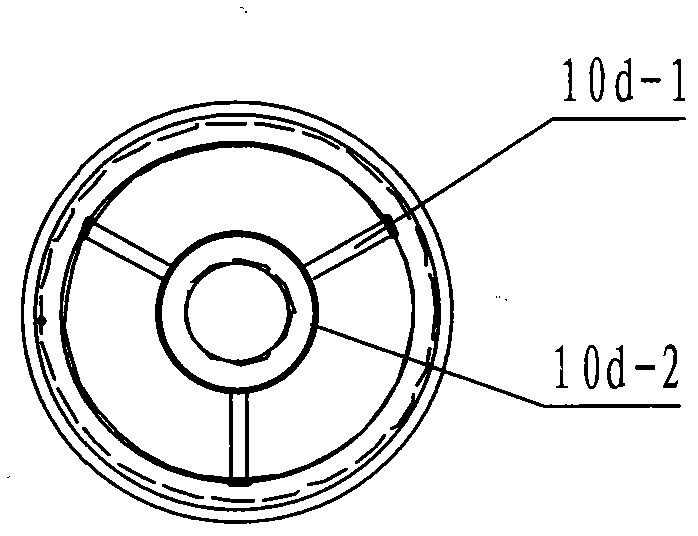

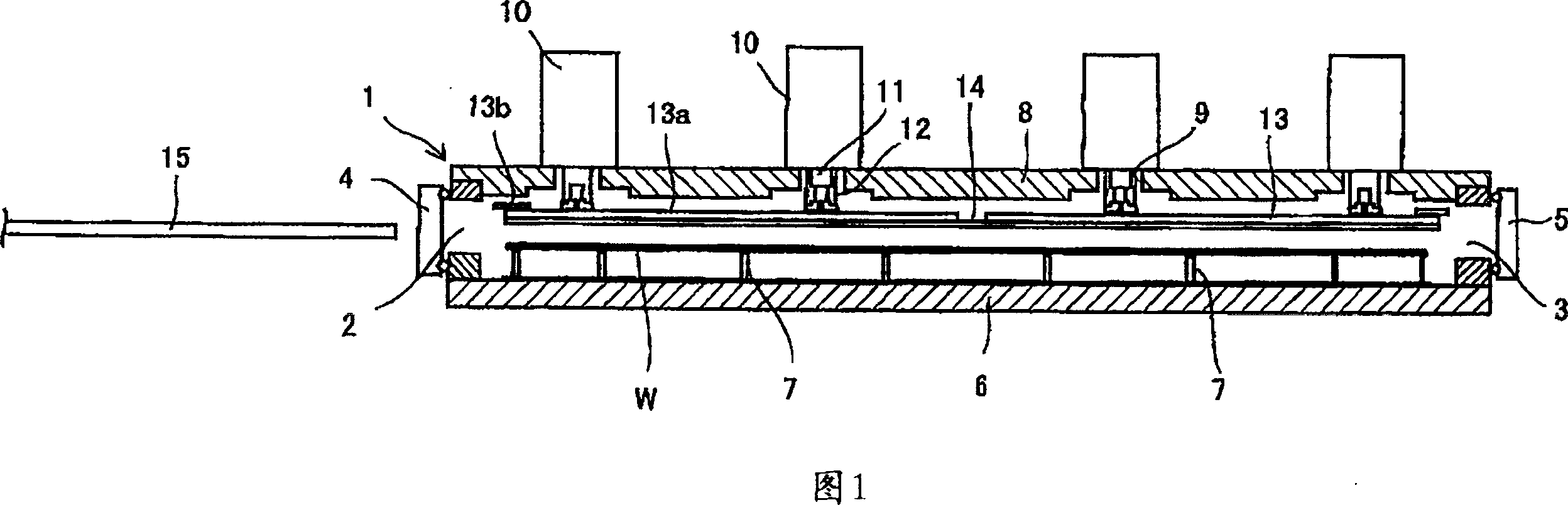

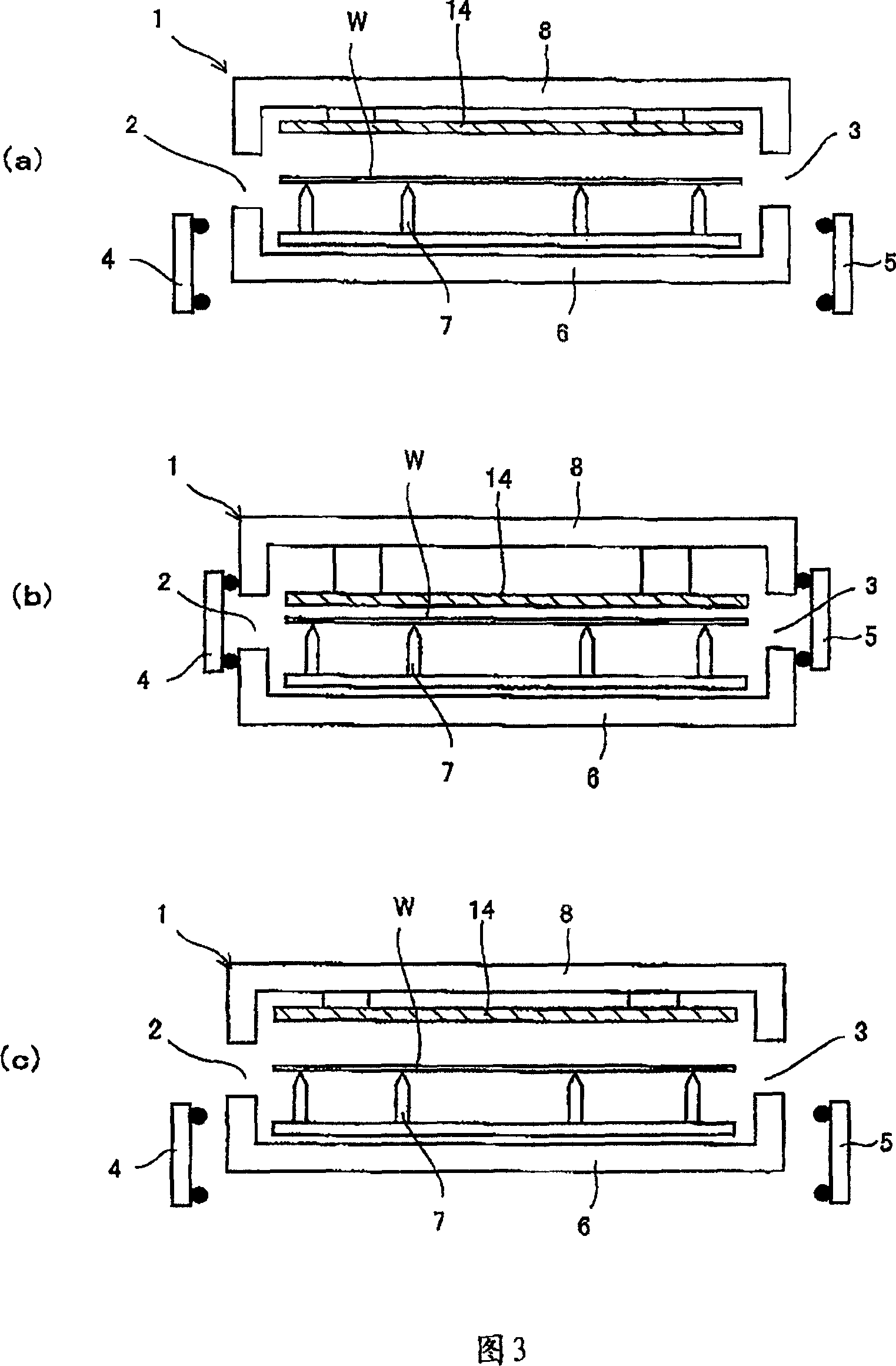

Decompression drying processing device

ActiveCN101013657AAvoid interferenceExtend the exhaust timeDrying solid materials without heatPretreated surfacesLarge sizeMechanical engineering

The present invention is to provide a decompress drying process device capable of processing large size substrate with high efficiency. Said subject is resolved with following method: a top plate (14) is installed across a reinforcing plate (13) on the bottom of a bar (11) of a cylinder unit (10). The size of the top plate (14) can be made to a size for covering the substrate (W) adequately. Its thickness is thinner than that of the reinforcing plate (13) such that light weight is achieved. In addition, the reinforcing plate (13) comprises four combination plate (13a) having an angle of 45 degree with said top plate (14) when overlook, and connection section (13b) for connecting these combination plates (13a). Thus each combination plate (13a) is connected to form rectangle shaped reinforcing plate (13), and the reinforcing plate (13) is arranged staggering with the top plate (14) by 45 degree, thus distortion of the top plate (14) because of torsion can be prevented.

Owner:艾美柯技术株式会社

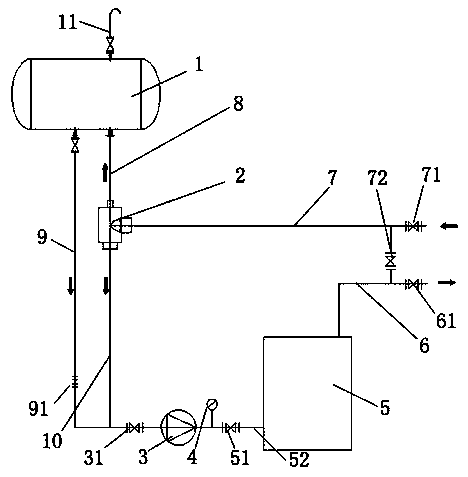

Heat conducting oil circulating device achieving fast exhausting

InactiveCN105509317AReduce cavitationShorten exhaust timeStorage heatersExpansion tankHeat conducting

The invention discloses a heat conducting oil circulating device achieving fast exhausting. The heat conducting oil circulating device comprises a heat conducting oil boiler, a circulating oil pump and a first oil return pipe. A first oil supply pipe is arranged between the heat conducting oil boiler and the circulating oil pump for connection. The heat conducting oil circulating device achieving fast exhausting further comprises an expansion tank, an oil-gas separator is arranged at the tail end of the first oil return pipe, the gas outlet end of the oil-gas separator and the gas inlet end of the expansion tank are directly provided with an expansion pipeline for connection, a second oil return pipe is arranged between the oil outlet end of the oil-gas separator and the oil inlet end of the circulating oil pump for connection, and a third oil return pipe is arranged between the oil outlet of the expansion tank and the oil inlet end of the circulating oil pump for connection. In this way, the heat conducting oil circulating device achieving fast exhausting supplies liquid to the circulating oil pump through the third oil return pipe, exhausting time is greatly shortened, the phenomenon that the circulating oil pump is unstable in pressure and large in air suction and vibration is eliminated, and system safety is guaranteed.

Owner:苏州泰盛新绿节能环保科技有限公司

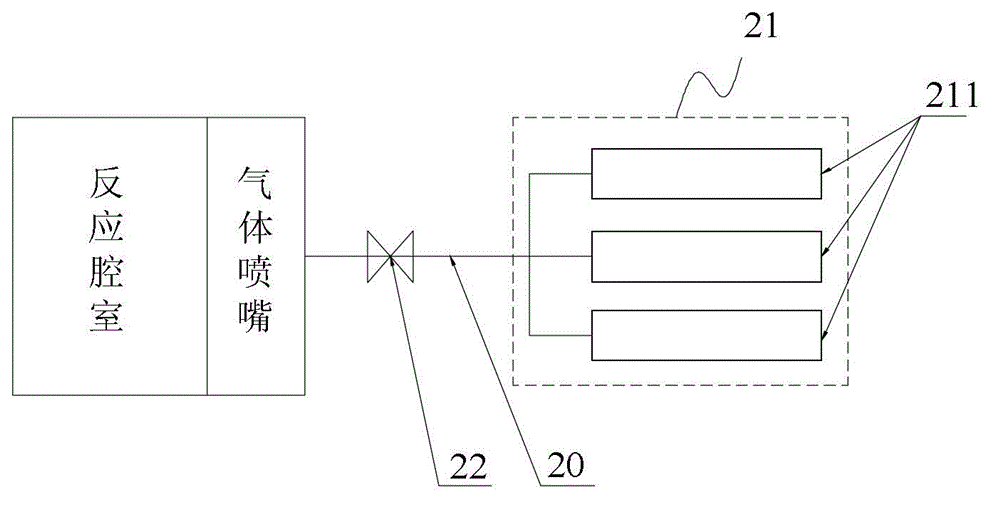

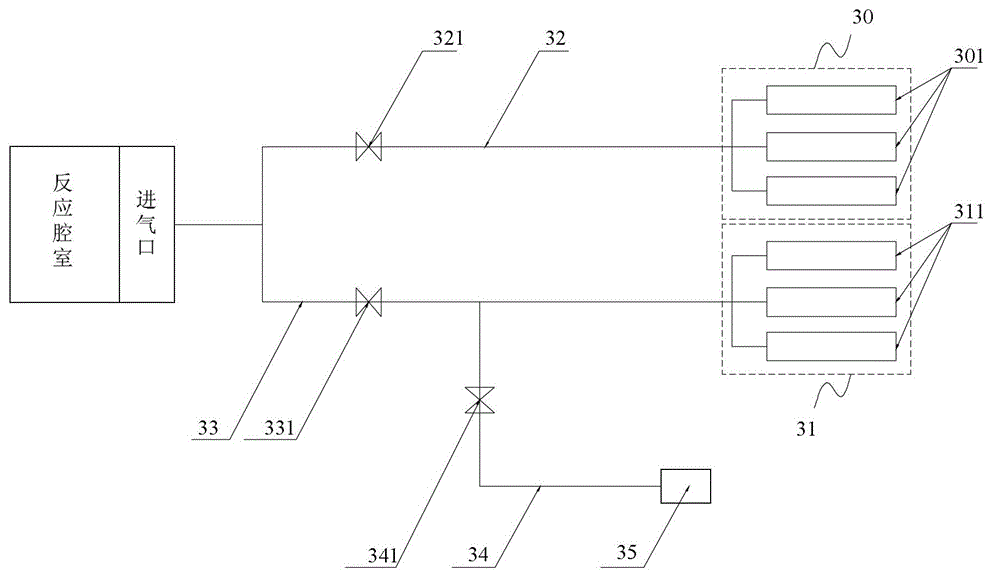

Gas intake system and substrate processing equipment

ActiveCN103943534AShorten exhaust timeImprove efficiencySemiconductor/solid-state device manufacturingChemical vapor deposition coatingProcess engineeringProduct gas

The invention provides a gas intake system and a set of substrate processing equipment. The gas intake system comprises a gas inlet communicated with a reaction cavity, a gas intake pipeline and at least one gas source, wherein different gas sources provide different types of gases. The gas intake pipeline comprises a main line, main line valves, branches and branch valves, wherein the main lines are connected between the gas inlet and all the gas sources and used for delivering gases output by the gas sources into the reaction cavity through the gas inlet; the main line valves are arranged on the main lines and used for connecting or disconnecting the main lines; one ends of the branches are connected into the main lines in series and located on the upstream of the main line valves, and the branches are used for discharging gases in the main lines when the main line valves are closed; the branch valves are arranged on the branches and used for connecting or disconnecting the branches. According to the gas intake system, the efficiency for switching the types of gases in the reaction cavity is high, and thus the technological efficiency can be improved.

Owner:BEIJING NAURA MICROELECTRONICS EQUIP CO LTD

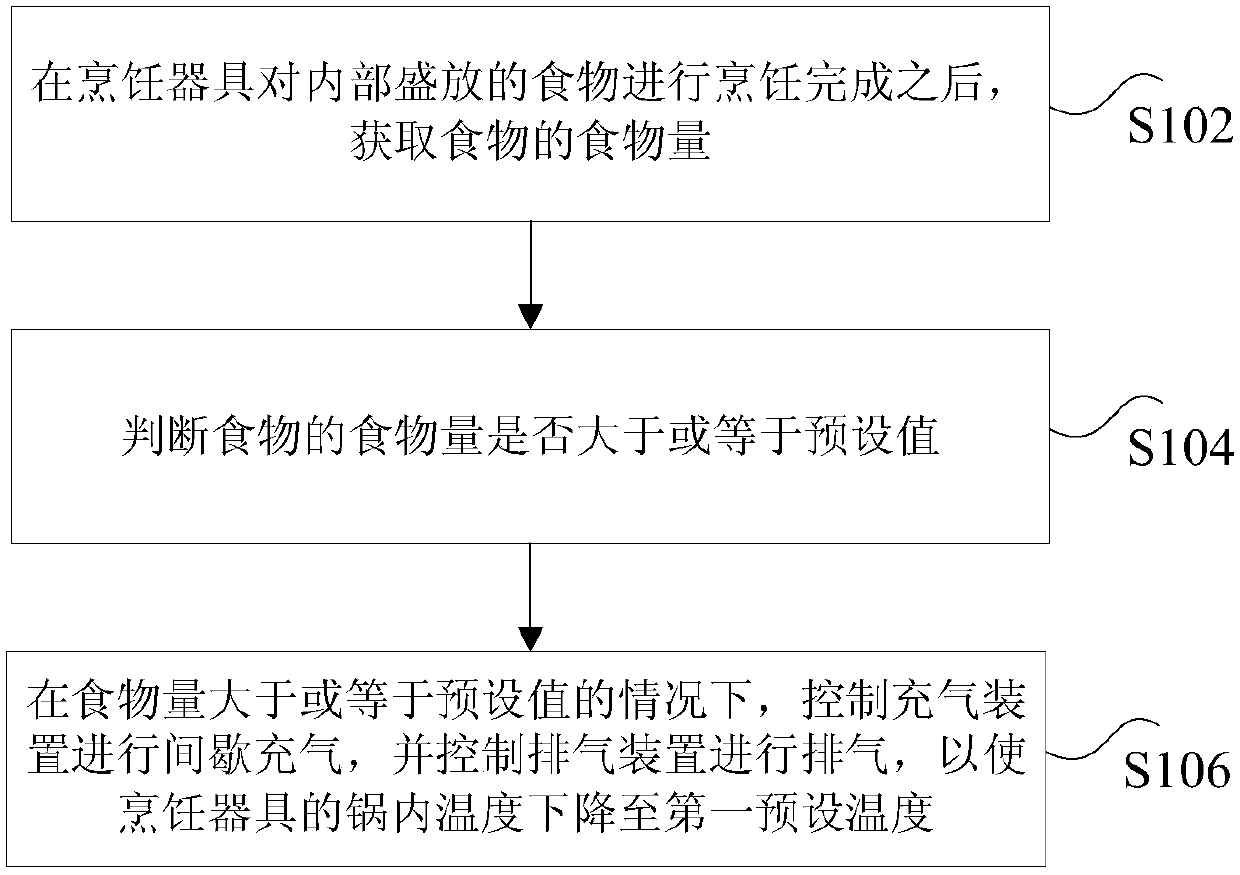

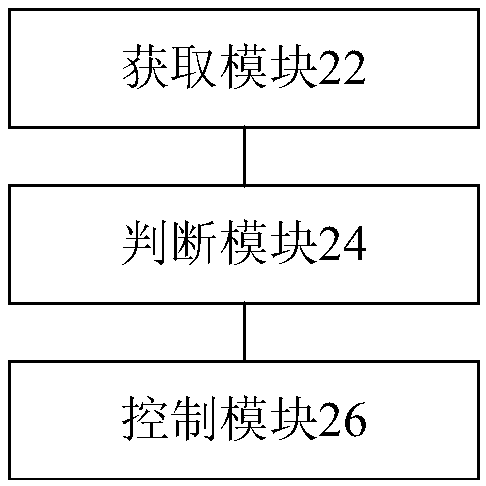

Cooking utensil, exhaust control method and exhaust control device thereof

Owner:ZHEJIANG SHAOXING SUPOR DOMESTIC ELECTRICAL APPLIANCE CO LTD

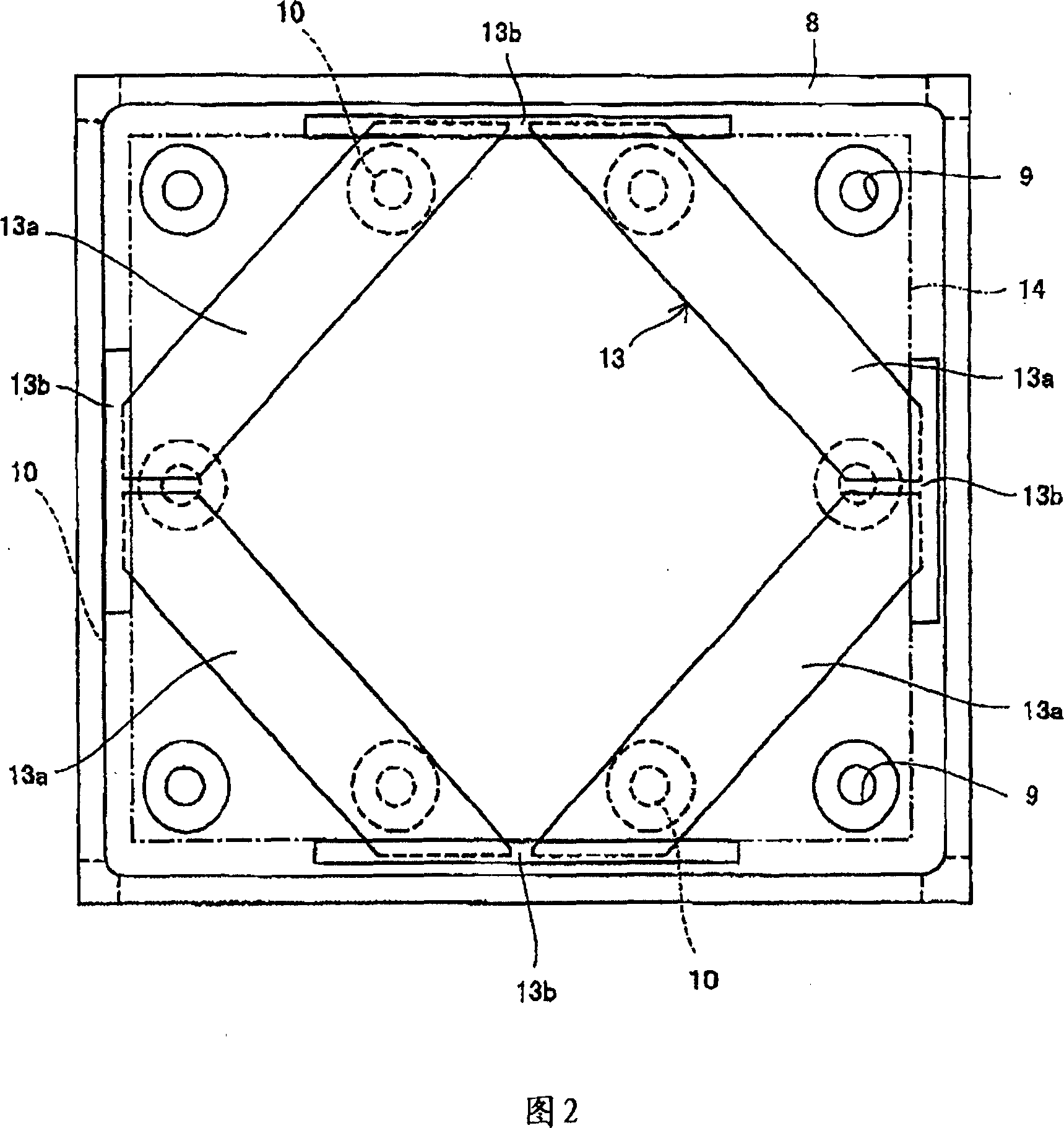

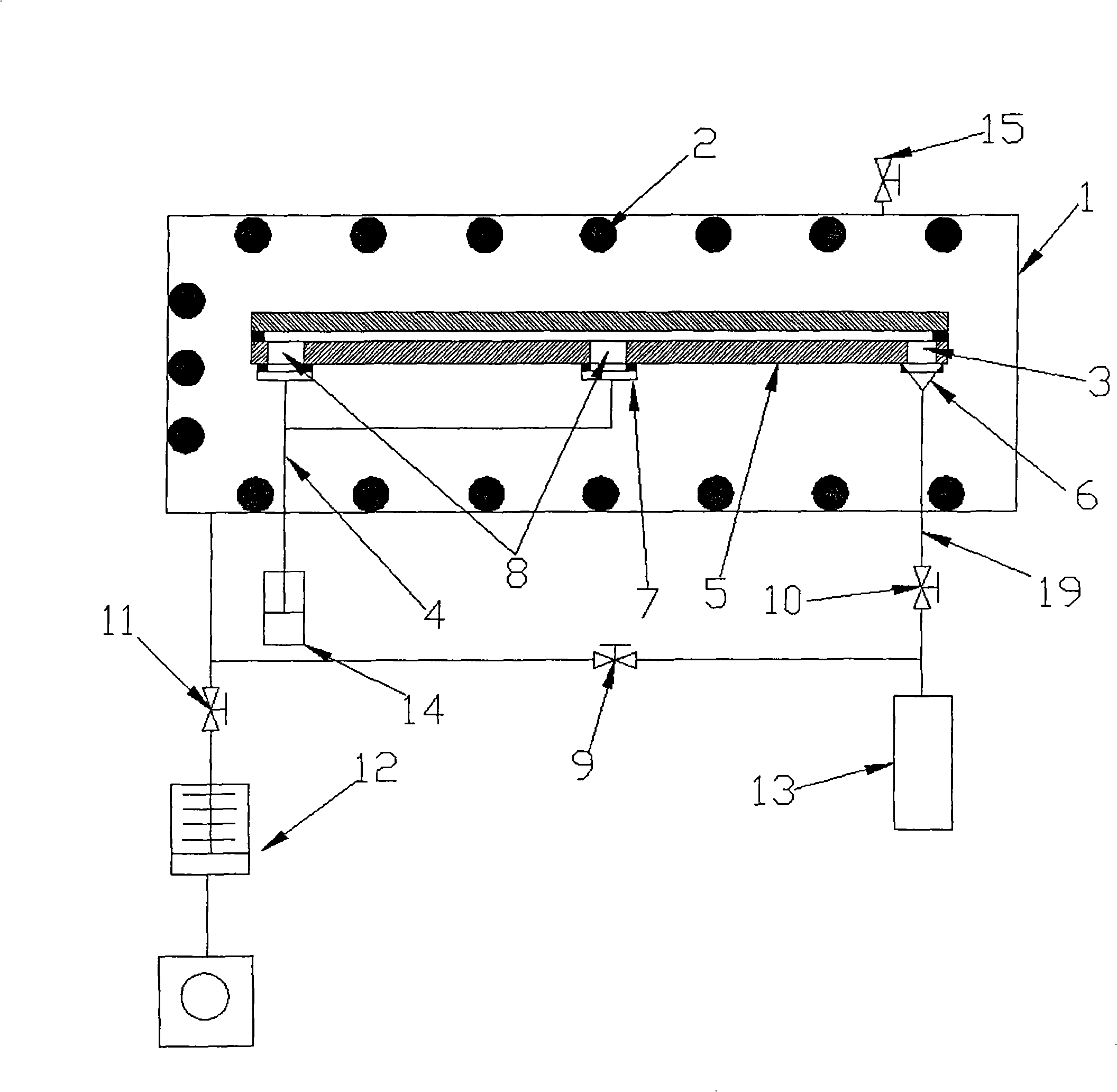

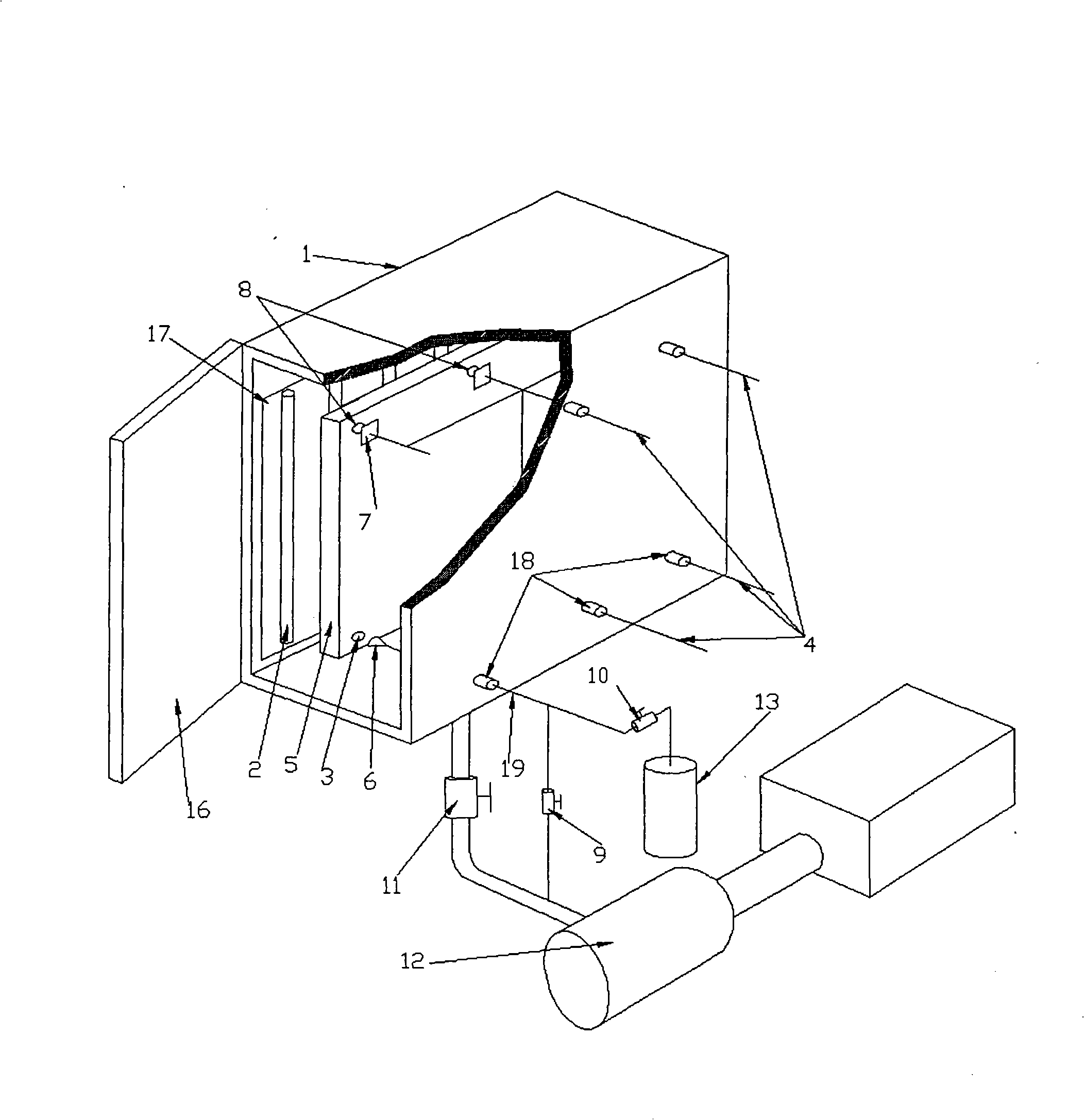

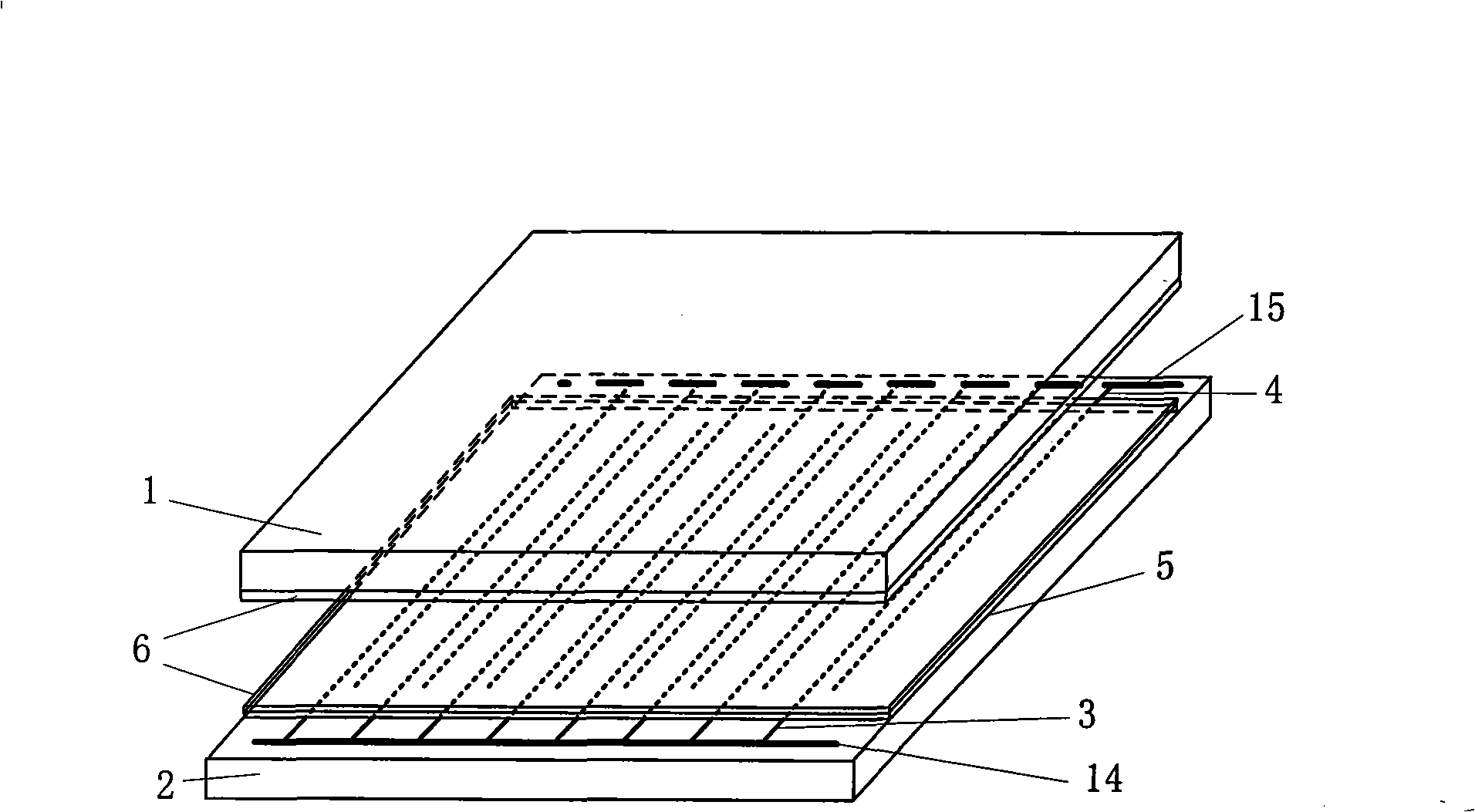

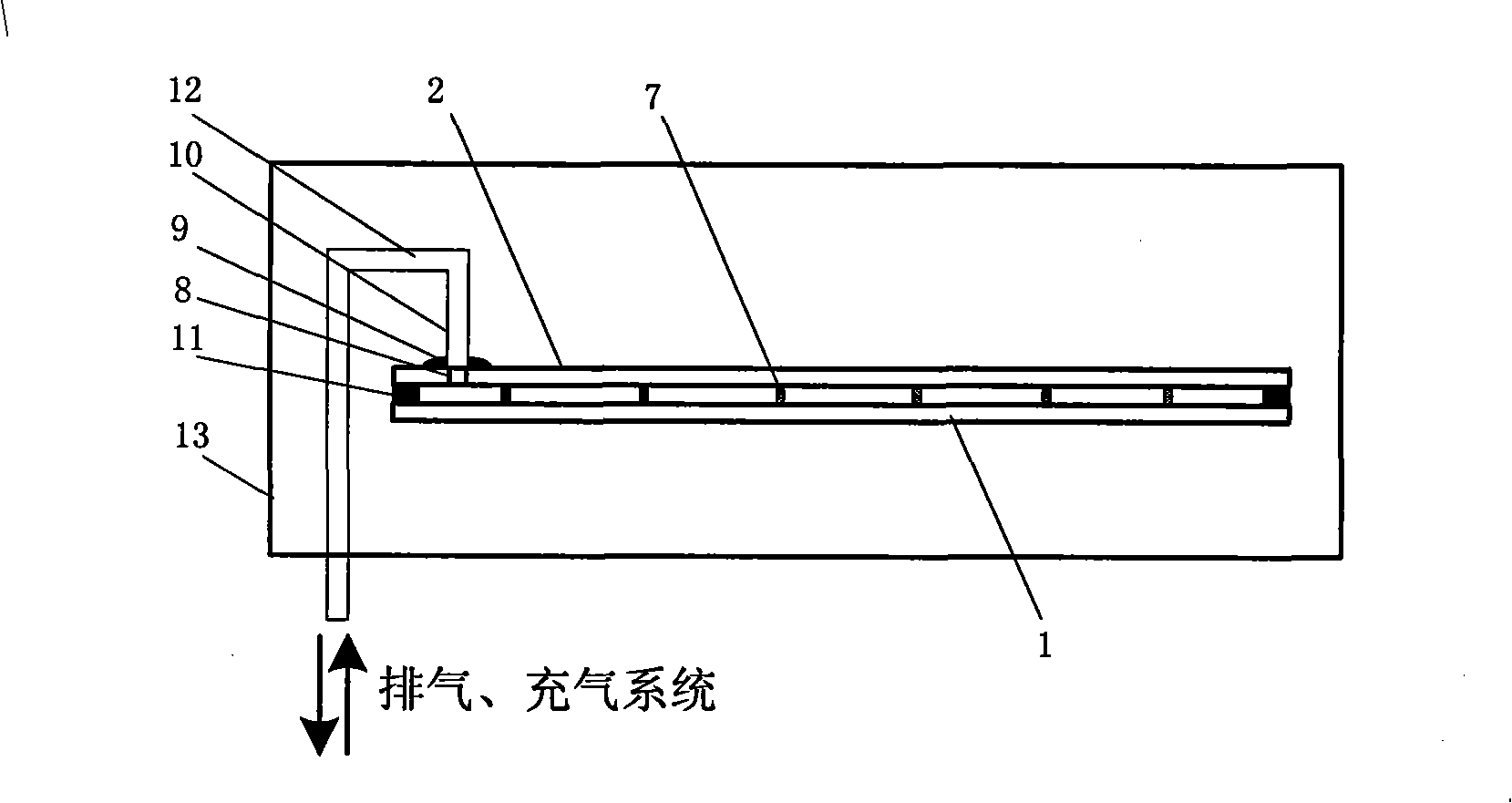

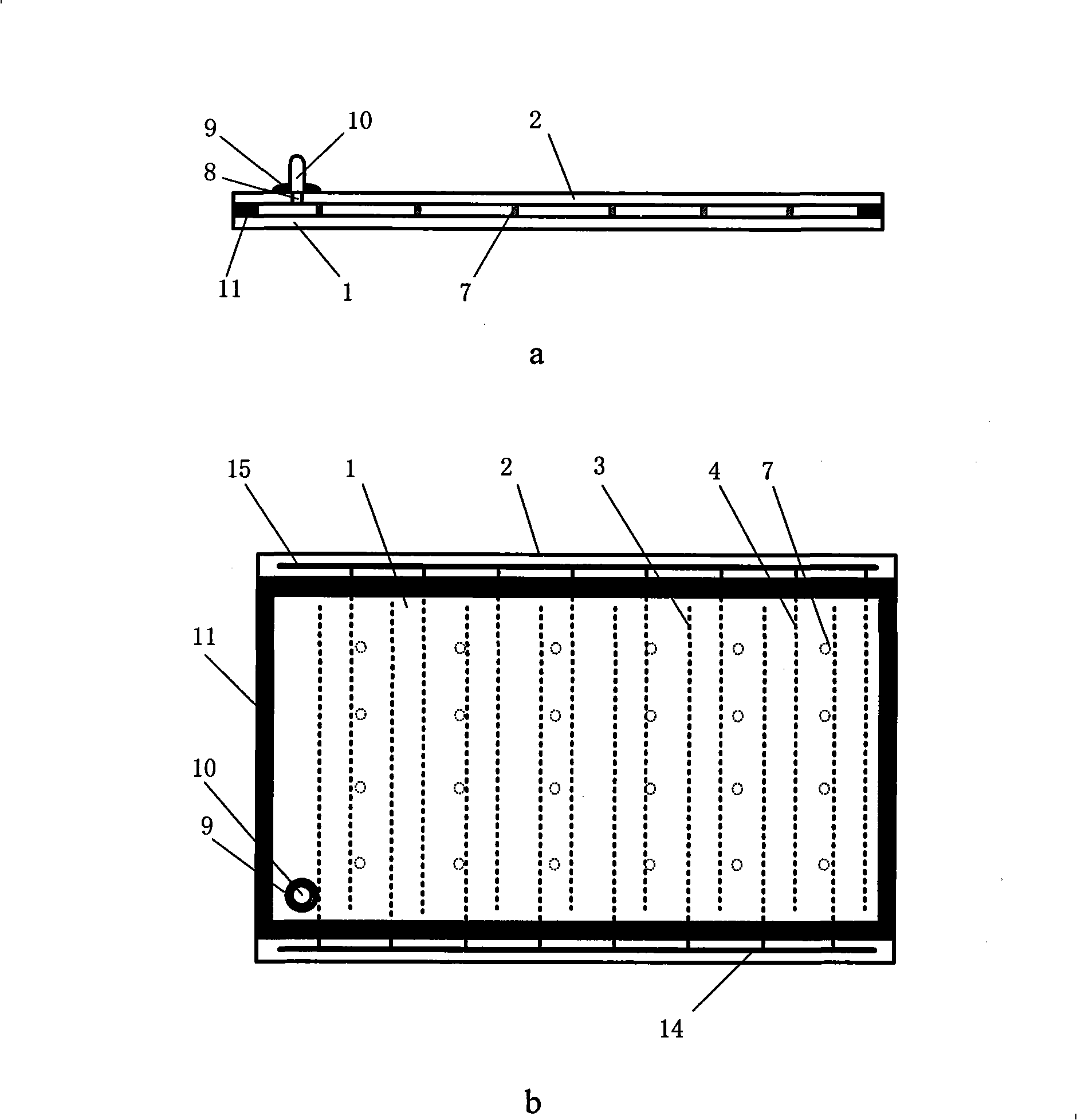

Method and apparatus for sealing and air exhaust of large size plasma display screen

InactiveCN101350277AEfficient sealing exhaustWithout compromising securityCold cathode manufactureGlass coverGas-filled tube

The invention relates to a device and a method of sealing and exhausting a large-scale type plasma display screen. The invention is characterized in that a plurality of vent holes (8) and an inflating / exhausting hole(3) are arranged on a rear base plate of the plasma display screen, heating a clamped front and a clamped rear glass base plates (5) through arranging the plates in a vacuum heating container (1), and simultaneously carrying out the vacuum exhausting to the vacuum heating container (1), after the temperature is increased and is kept for certain time, the temperature begins to reduce, glass cover plates (7) are used to seal the vent holes (8), and an inflation tube (6) is connected on the inflating / exhausting hole (3), when the temperature is reduced to the indoor temperature, the inflation tube (6) is pumped with working gas, and then the screen sealing process is completed after the inflation tube (6) is sealed. The invention has the advantages that the energy sources and the working gas are saved, and simultaneously, the safety of the plasma display screen can not be reduced.

Owner:NANJING HUAXIAN HIGH TECH CO LTD

Production method of cold cathode flat light source

InactiveCN101315854ASimple manufacturing processImprove brightness uniformityTube/lamp vessel fillingTube/lamp vessels exhaustionManufacturing cost reductionInternal pressure

The invention discloses a manufacturing method of a cold cathode planar light source, sealing materials are coated at the peripheries of a front substrate and a back substrate which are equipped with electrodes, dielectric layers and fluorescent powder layers, the space between the front substrate and the back substrate is not sealed, clamps are used for accurate contraposition of the two substrates, the front and back substrates are further arranged in a closed cavity, the heating and exhaust of the interior of the cavity are carried out, when the vacuum degree achieves 10 to 10 Pa, the exhaust is stopped, a discharge gas is filled in the cavity, the gas filling pressure is 80T / Tr to 101.3T / Tr kPa by selection, T is the temperature of the substrates during the gas filling, Tr is the room temperature, the sealing materials are melt under the high temperature, the temperature of the cavity is then decreased, the sealing materials are gradually cured, thus completely sealing the front and back substrates; when the temperature is decreased to the room temperature, the manufactured cold cathode planar light source is taken out from the cavity, and the internal pressure of the light source is 0.8 to 1 atmospheric pressure. The usage of the manufacturing method can simplify the manufacturing process of the cold cathode planar light source, reduce the manufacturing cost and reduce the thickness of the planar light source.

Owner:XI AN JIAOTONG UNIV

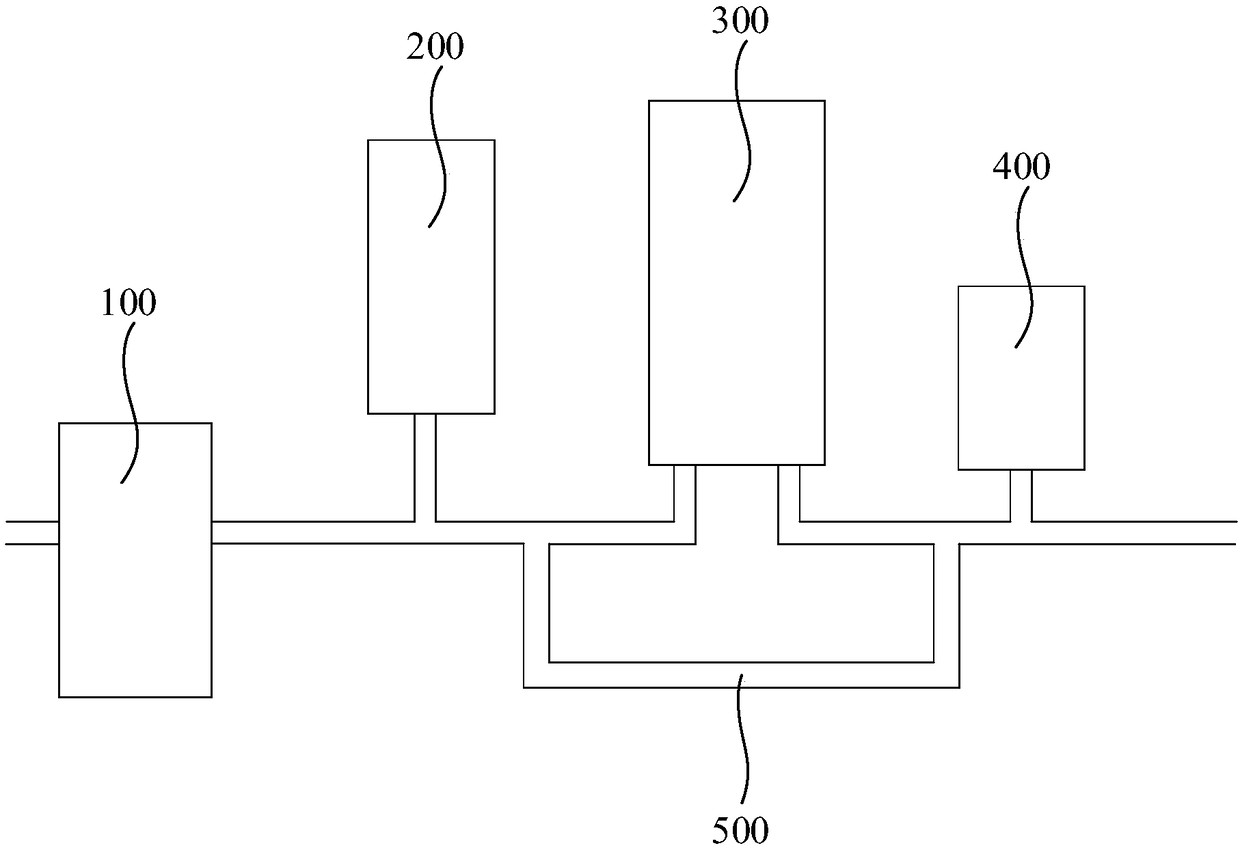

Exhaust optimizing method for primary circuit of million-kilowatt-level nuclear power station

ActiveCN108206063AShorten exhaust timeReduce wearNuclear energy generationCooling arrangementReactor pressure vesselNuclear power

The invention relates to an exhaust optimizing method for a primary circuit of a million-kilowatt-level nuclear power station. The primary circuit of the nuclear power station comprises a reactor pressure vessel, a pressure stabilizer, a plurality of steam generators and a plurality of main pumps sequentially communicating by a main pipeline, and the plurality of steam generators correspond to theplurality of main pumps one by one. The method comprises the steps: carrying out water filling and exhausting on a circuit formed by communicating the reactor pressure vessel, the pressure stabilizerand the steam generators; and sequentially joggling the plurality of main pumps, and reducing the pressure to exhaust after completing the joggling of the plurality of main pumps so as to transfer gases in inverted U-shaped pipes of the plurality of steam generators to the reactor pressure vessel and then exhaust the gases in a water filling and exhausting way. By using the exhaust optimizing method for the primary circuit of the million-kilowatt-level nuclear power station, the exhaust time of the primary circuit of the nuclear power station is greatly shortened, and the wear and damage risks of the main pumps are greatly reduced.

Owner:GUANGDONG NUCLEAR POWER JOINT VENTURE +4

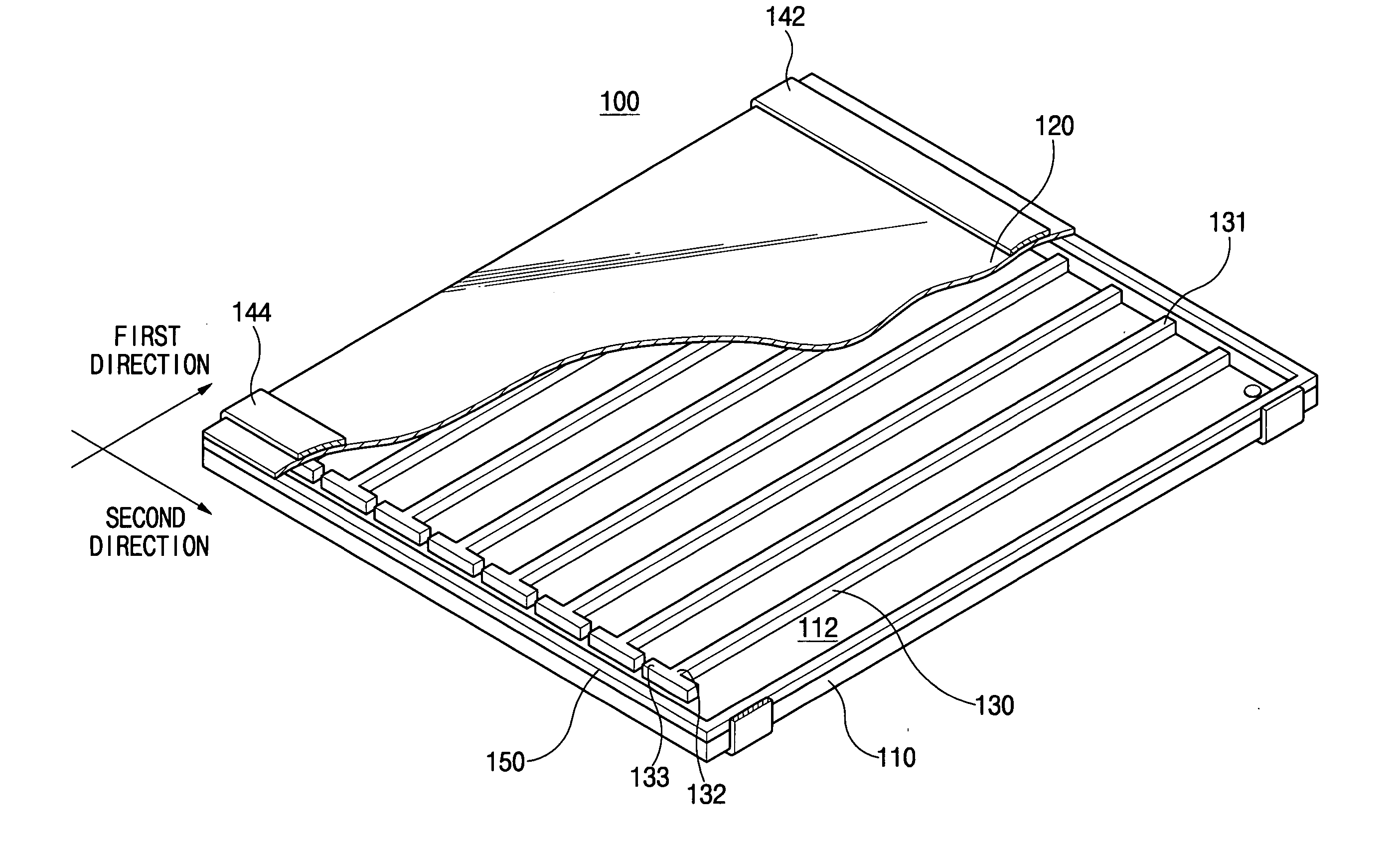

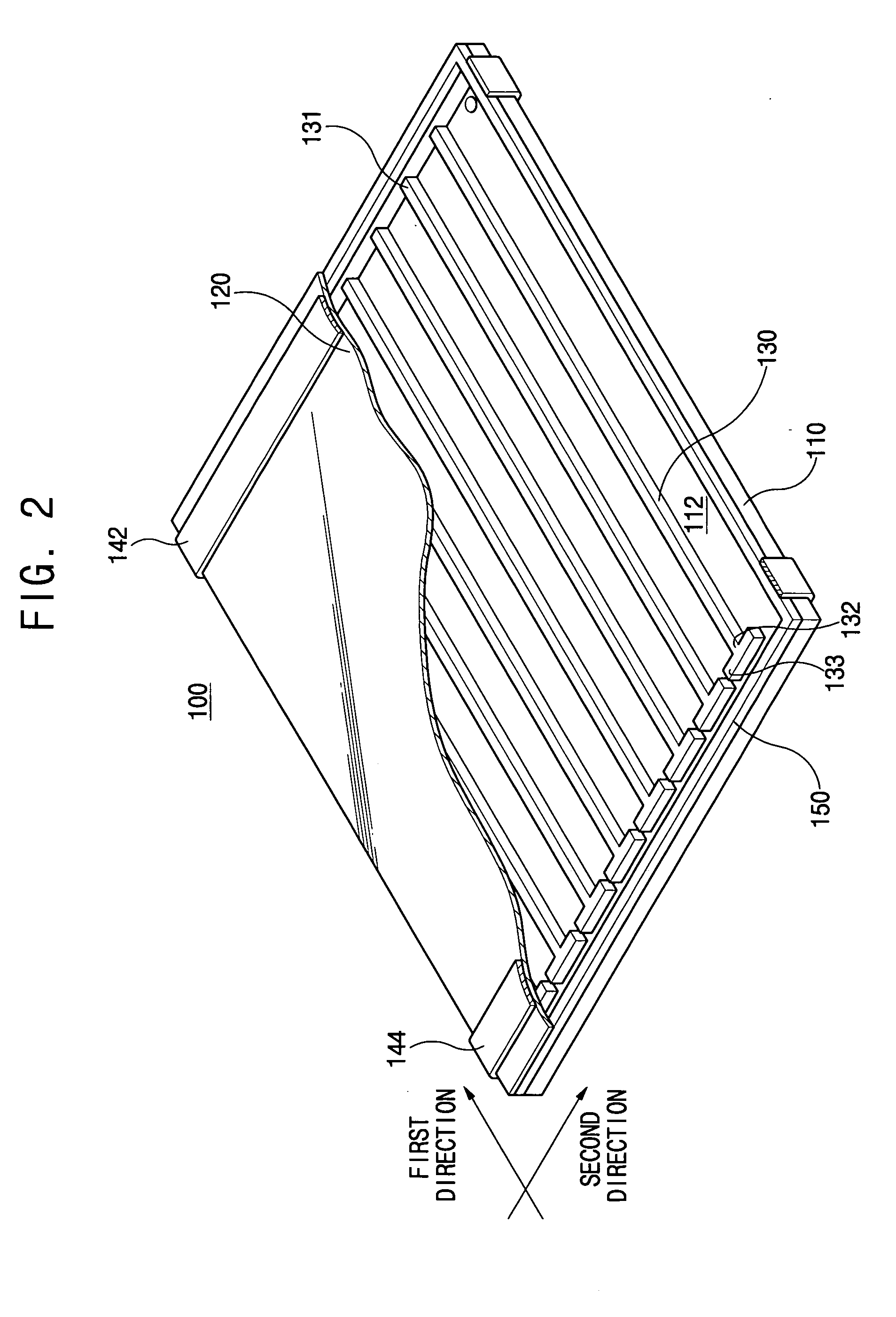

Planar-light source device and liquid crystal display apparatus having the same

InactiveUS20050083671A1Inhibit currentEffectively prevents or reduces drift currentMeasurement apparatus componentsMachines/enginesLiquid-crystal displayEngineering

A planar-light source device includes a light source body, partition members, a movement restriction member and an electrode. The light source body has a discharge space. The partition members are disposed in the discharge space to divide the discharge space into sub-spaces connected to each other. The movement restriction member is disposed at one of or both the side portions of the respective partition members to restrict plasma movement between the sub-spaces of the discharge space. The electrode surrounds the light source body, and is overlapped with the movement restriction member.

Owner:SAMSUNG ELECTRONICS CO LTD

Atmosphere protection system for laser additive manufacturing and laser additive manufacturing equipment

ActiveCN107952956AShorten access timeShorten exhaust timeAdditive manufacturing apparatusIncreasing energy efficiencyEngineeringAtmosphere

The invention provides an atmosphere protection system for laser additive manufacturing. The atmosphere protection system comprises a sealing device and sliding components fixedly connected with the outer wall of the sealing device; the sealing device is a forming cavity used for carrying out laser additive manufacturing, the sealing device comprises a rigid component and a flexible component, wherein the rigid component and the flexible component are used for defining the forming cavity in the vertical direction, and the flexible component is connected with the rigid component in the verticaldirection; the sliding components can slide on external guide rails in the vertical direction, the rigid component of the sealing device is driven in the vertical direction along with the sliding components sliding on the external guide rails in the vertical direction so that the flexible component can be driven by the rigid component to be compressed or stretched, and then the volume of the forming cavity can be reduced or increased. The invention further provides laser additive manufacturing equipment comprising the atmosphere protection system.

Owner:北京煜鼎增材制造研究院有限公司

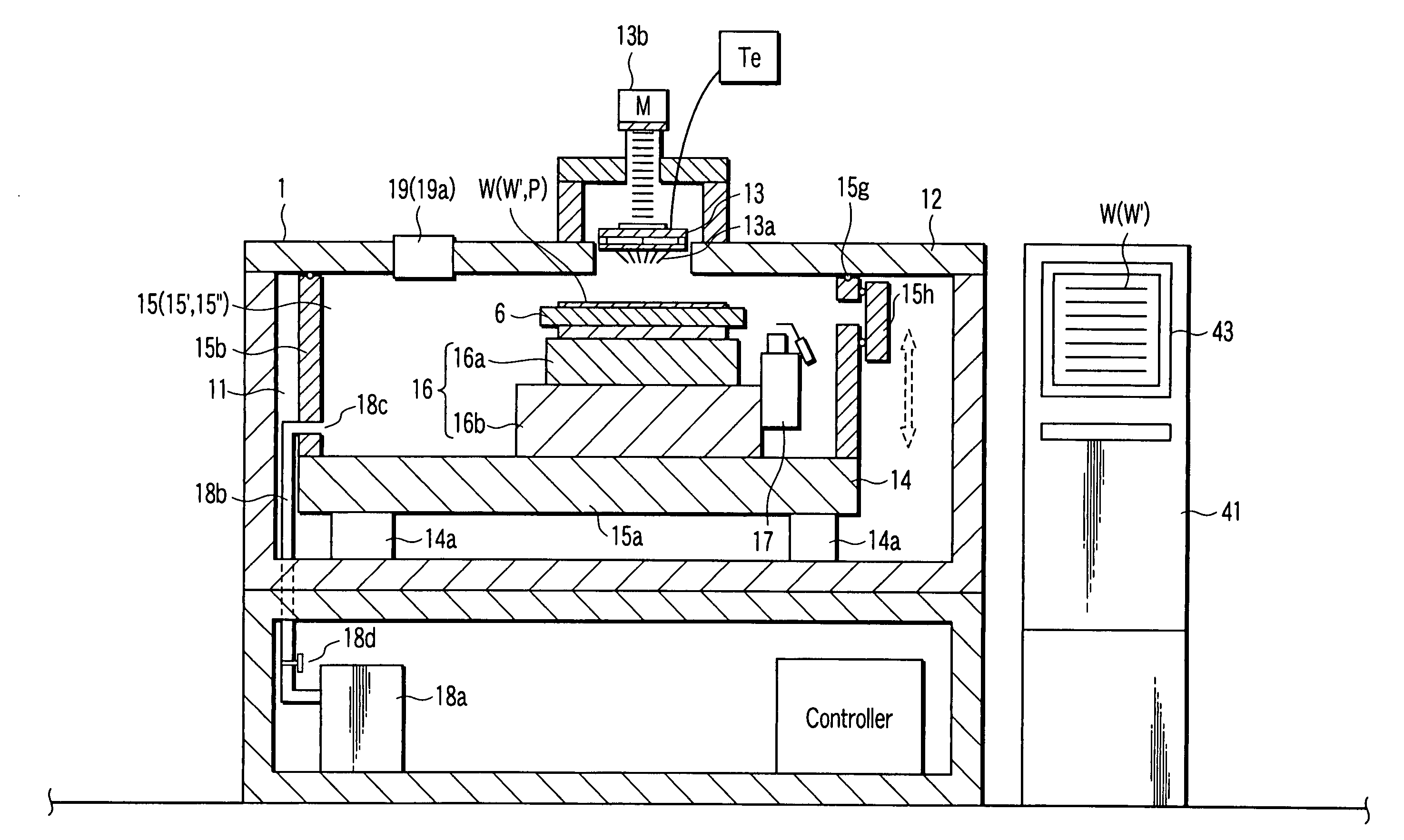

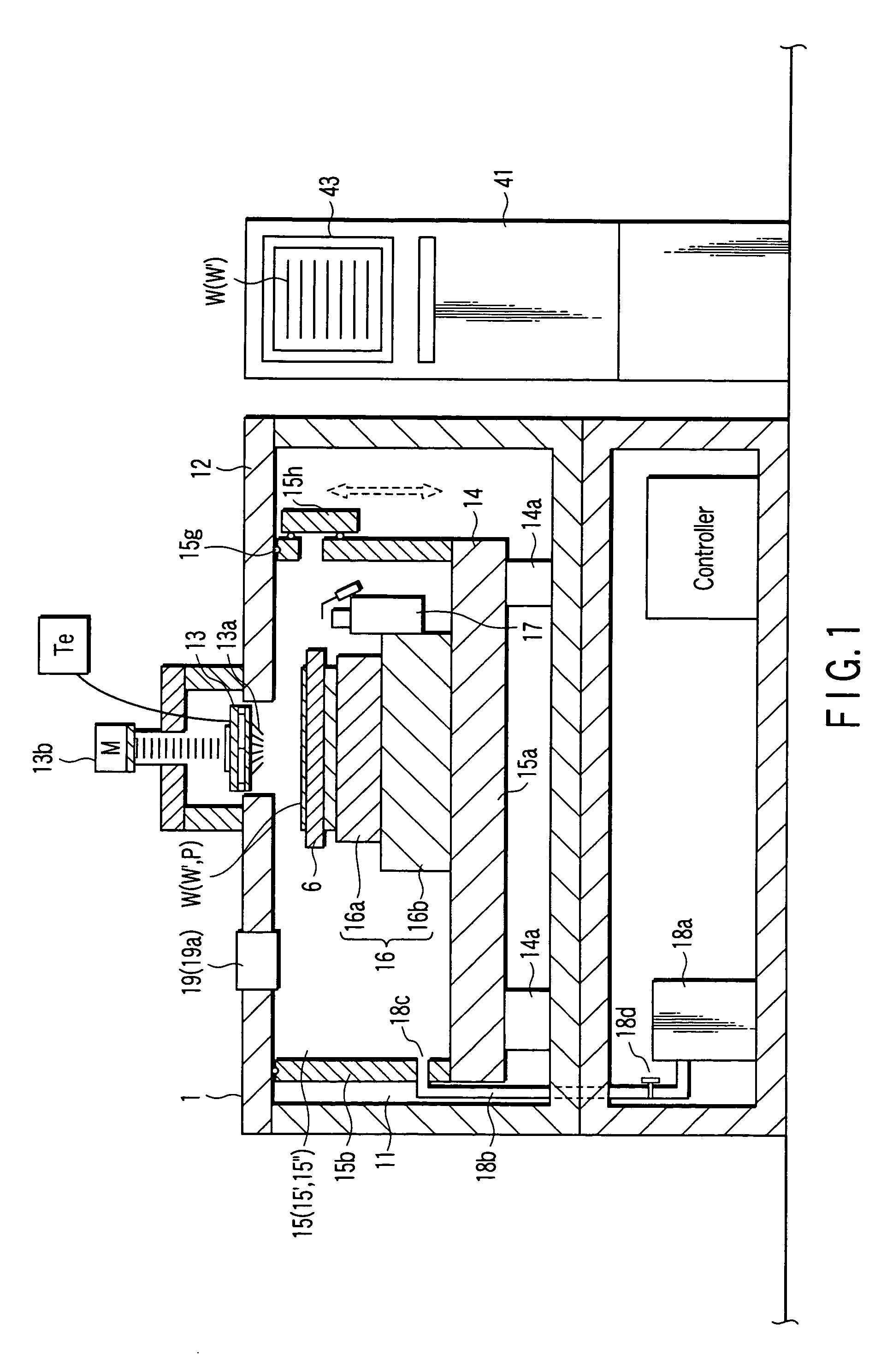

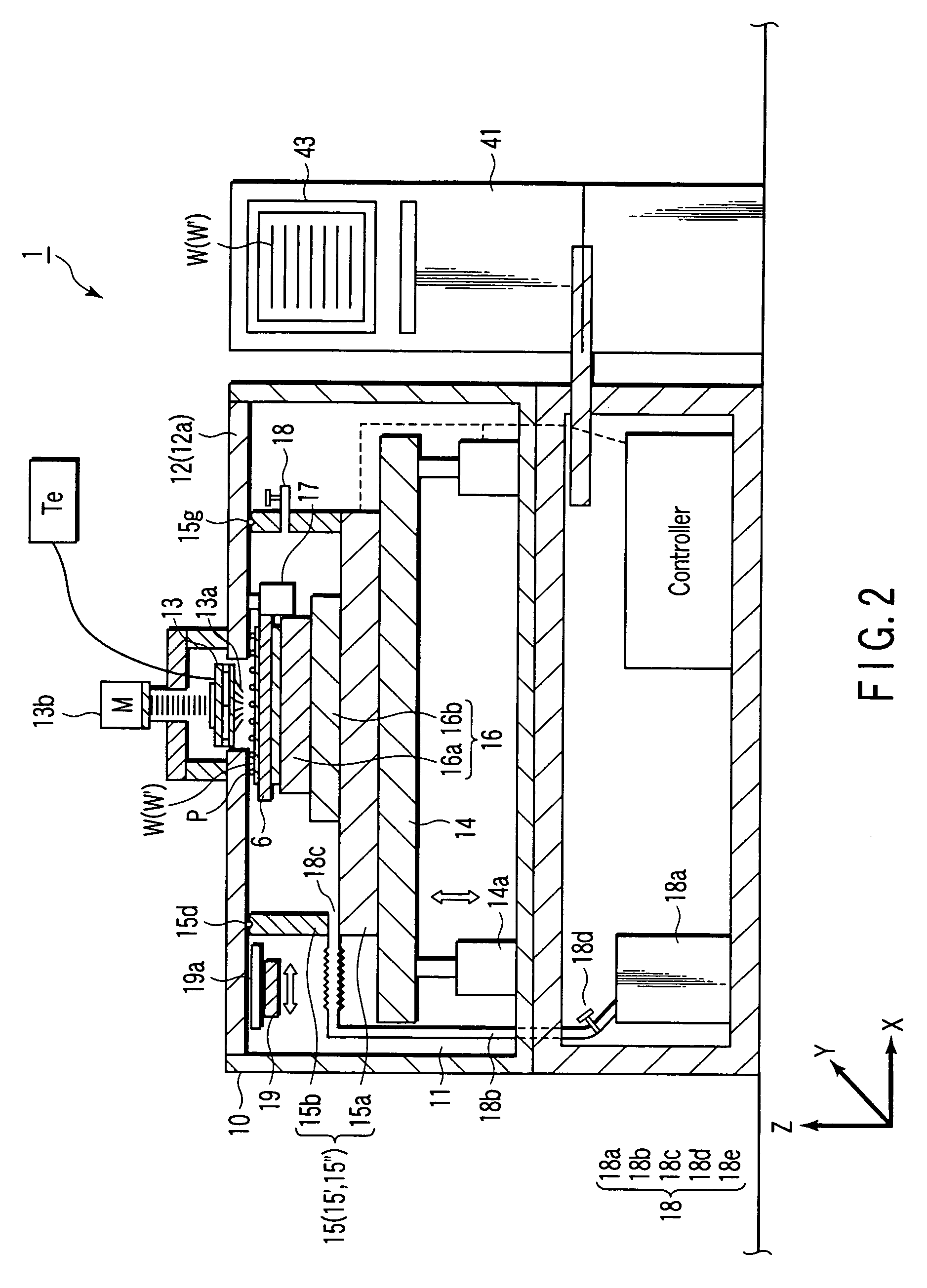

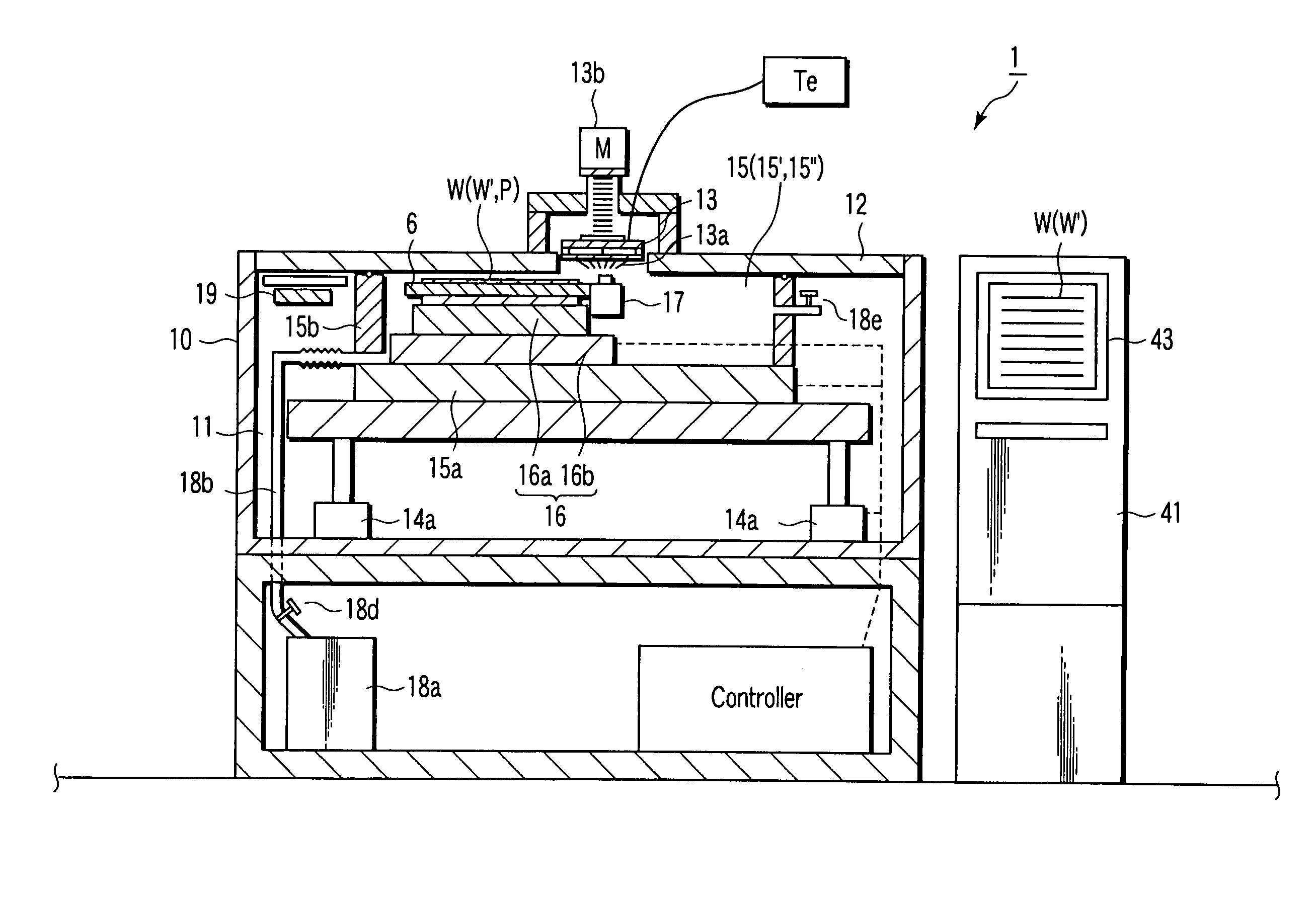

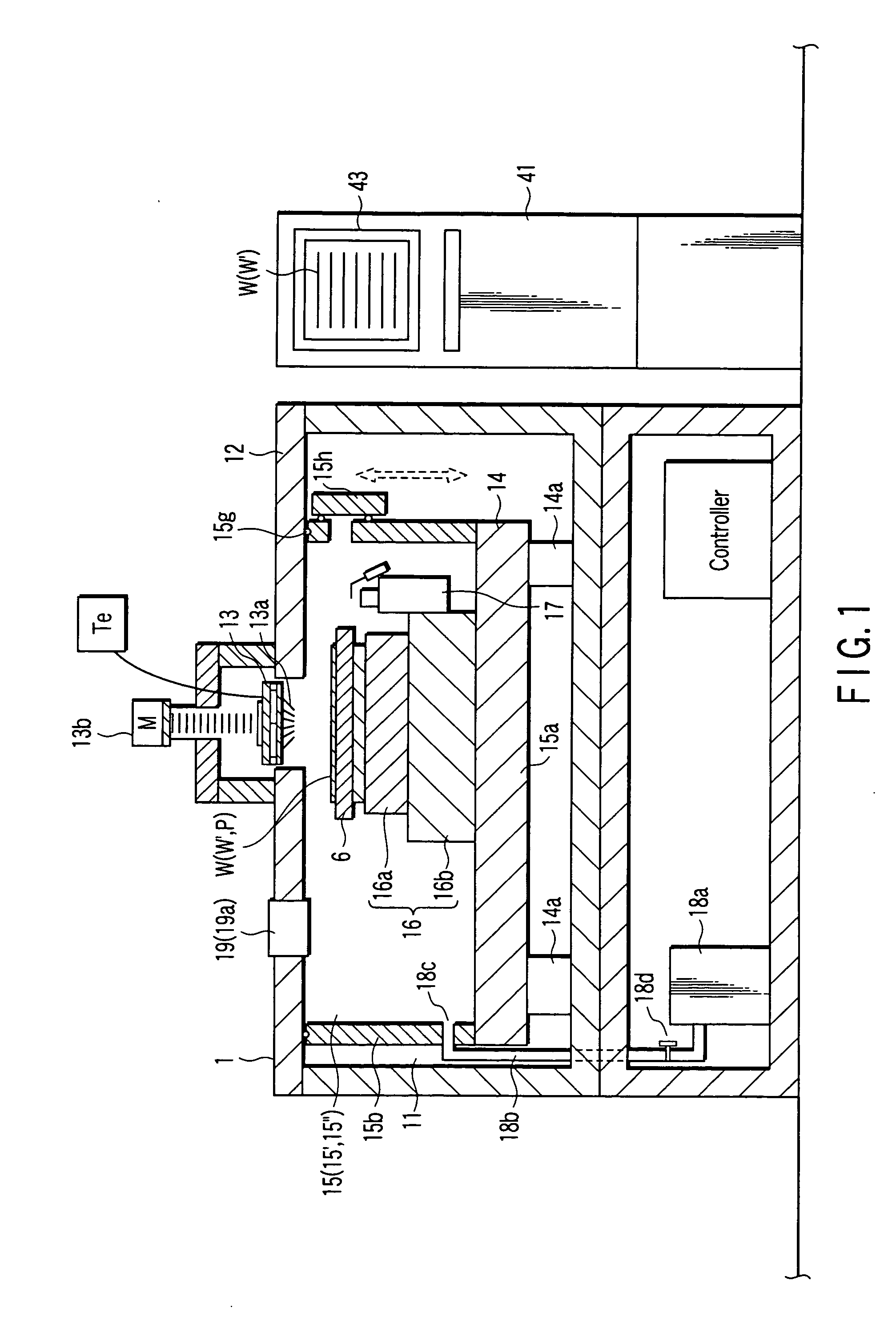

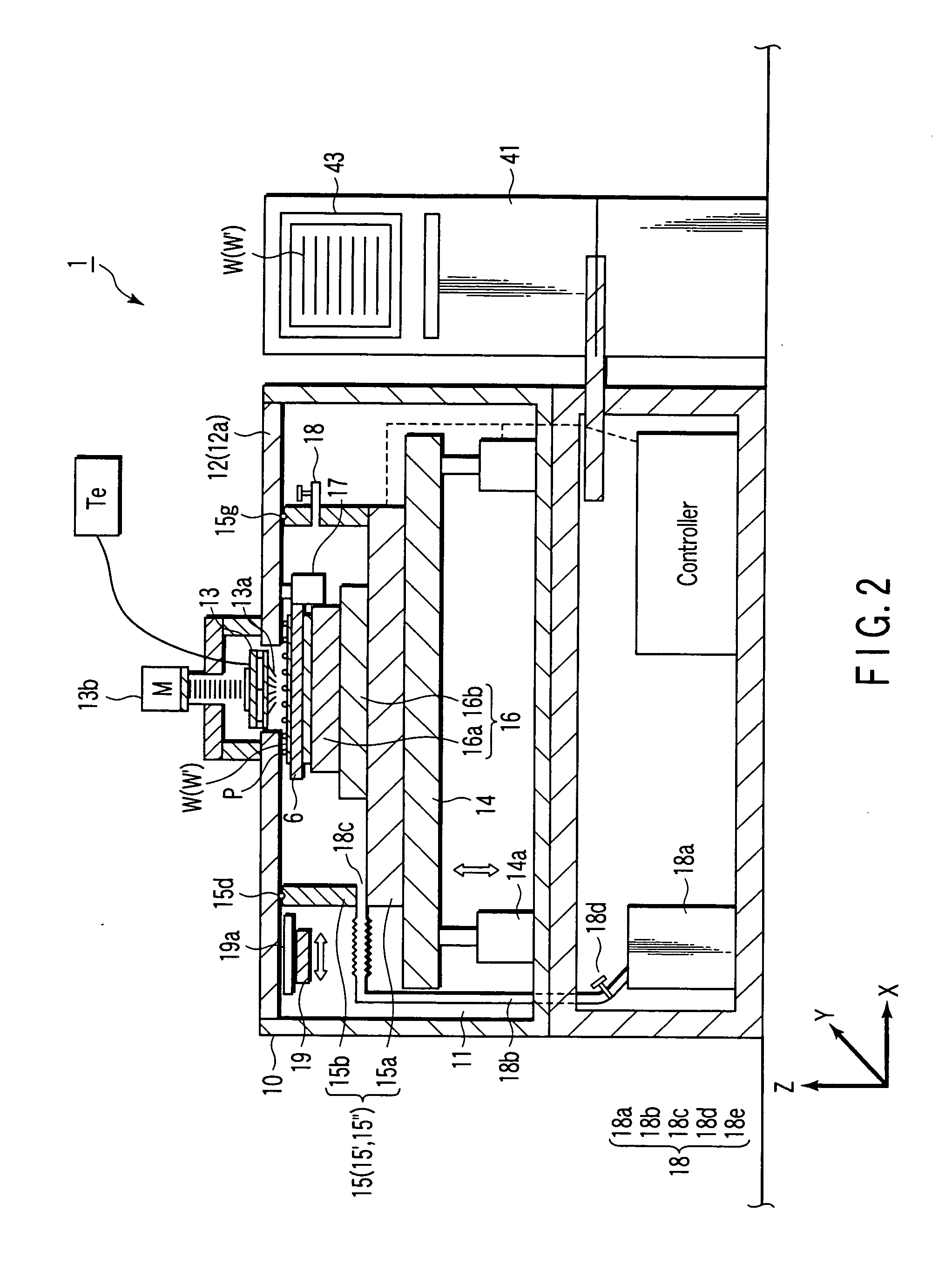

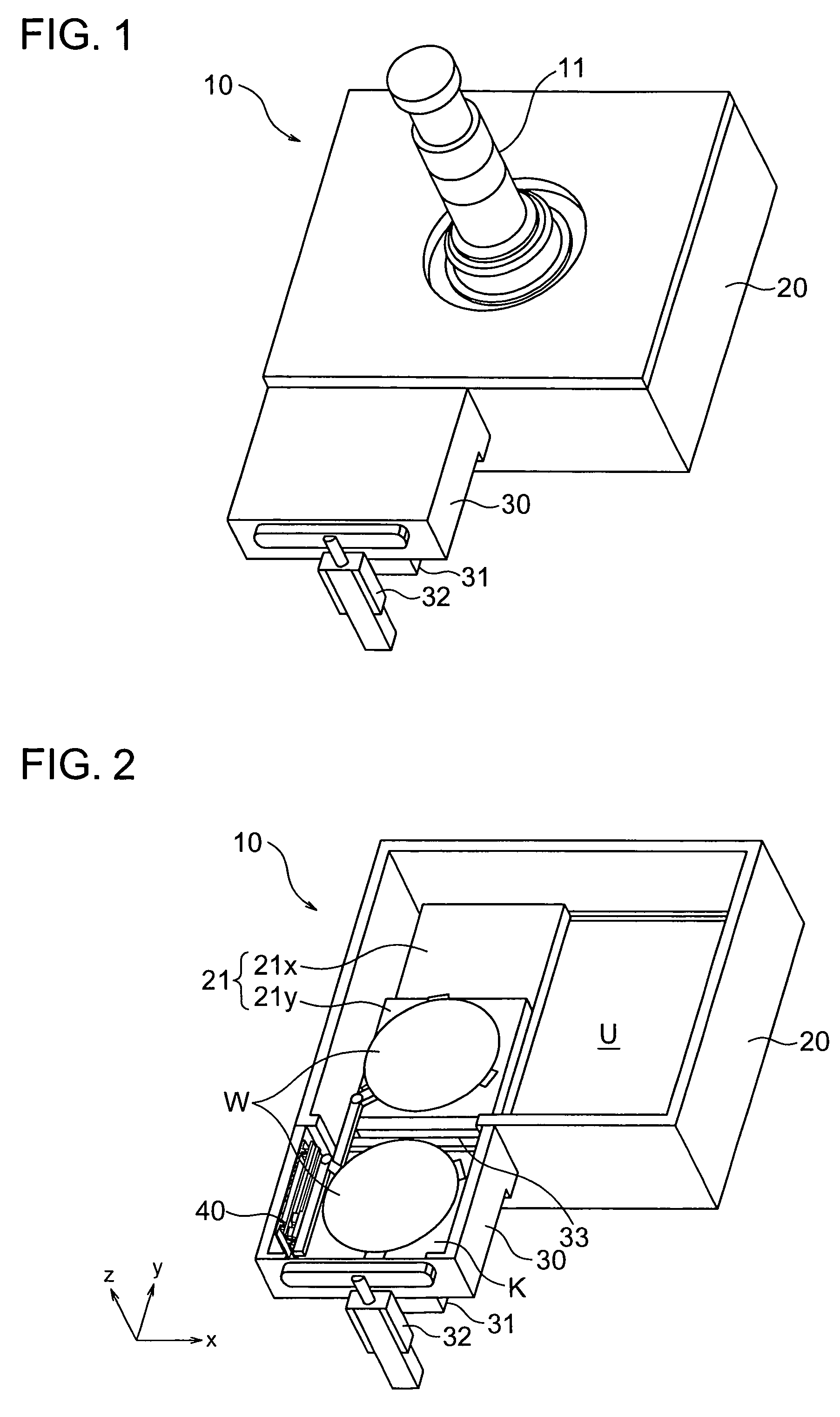

Vacuum prober and vacuum probe method

InactiveUS7221176B2Reduce capacityShorten exhaust timeConveyorsSemiconductor/solid-state device testing/measurementProbe cardEngineering

Owner:TOKYO ELECTRON LTD

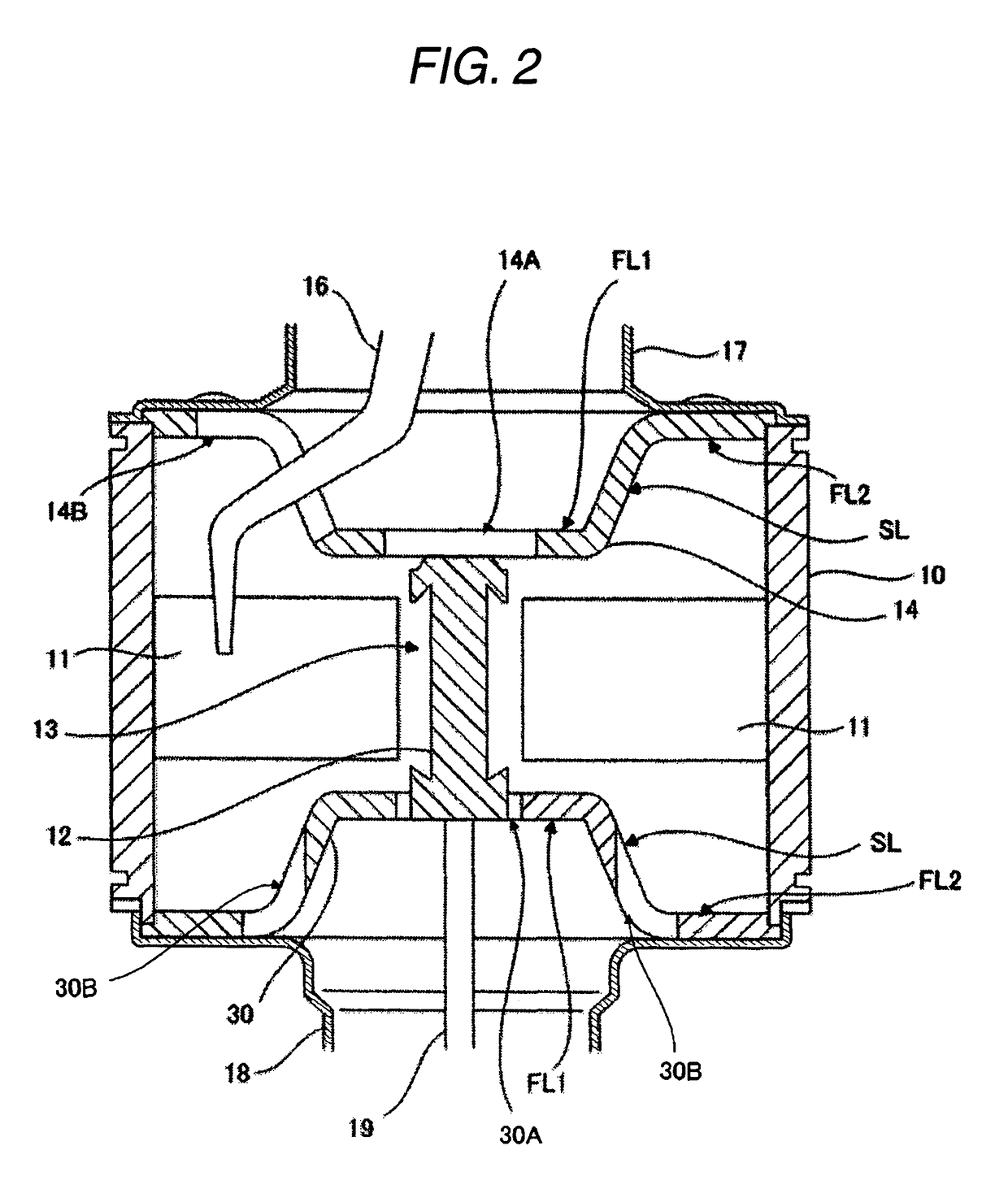

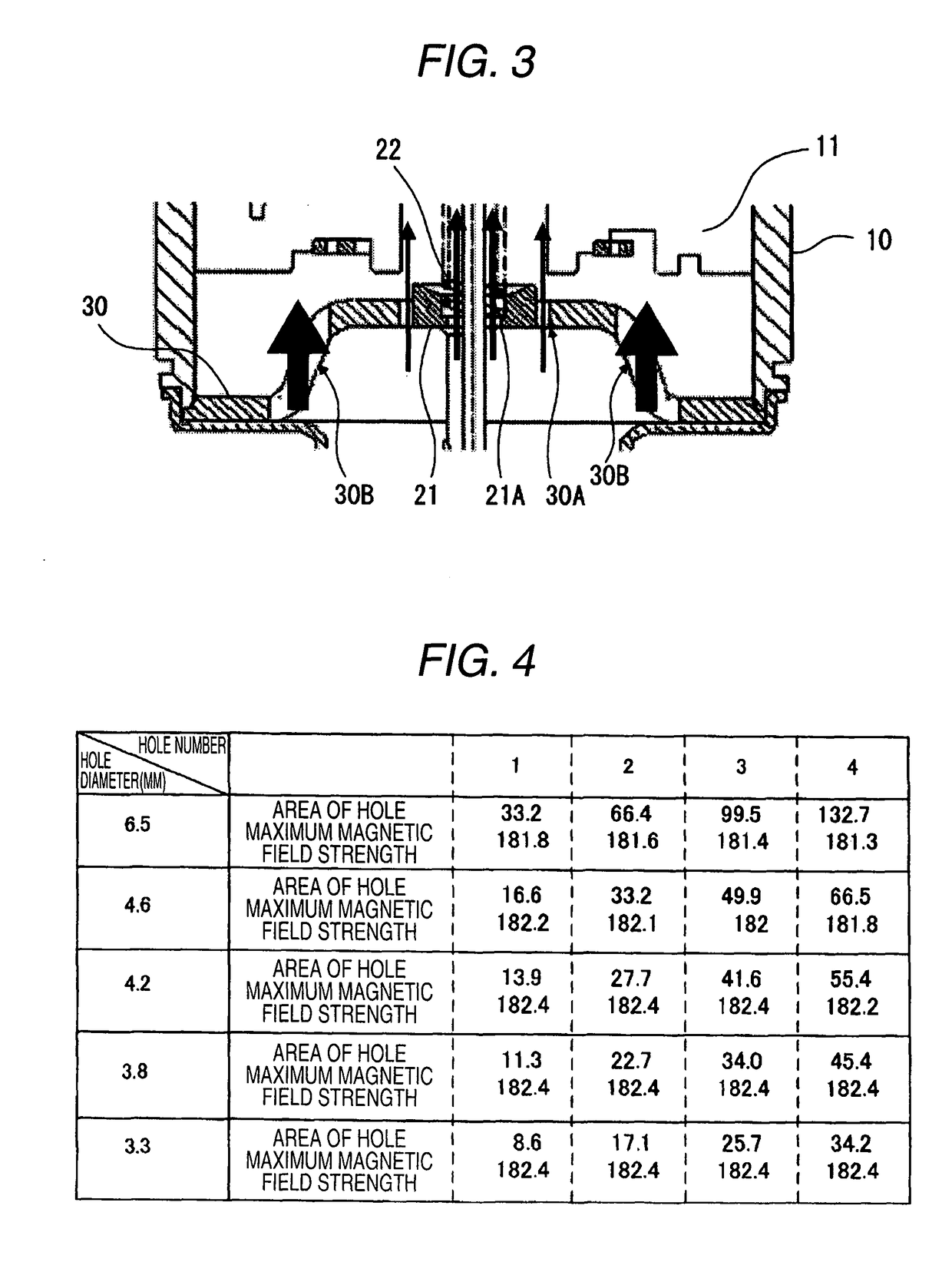

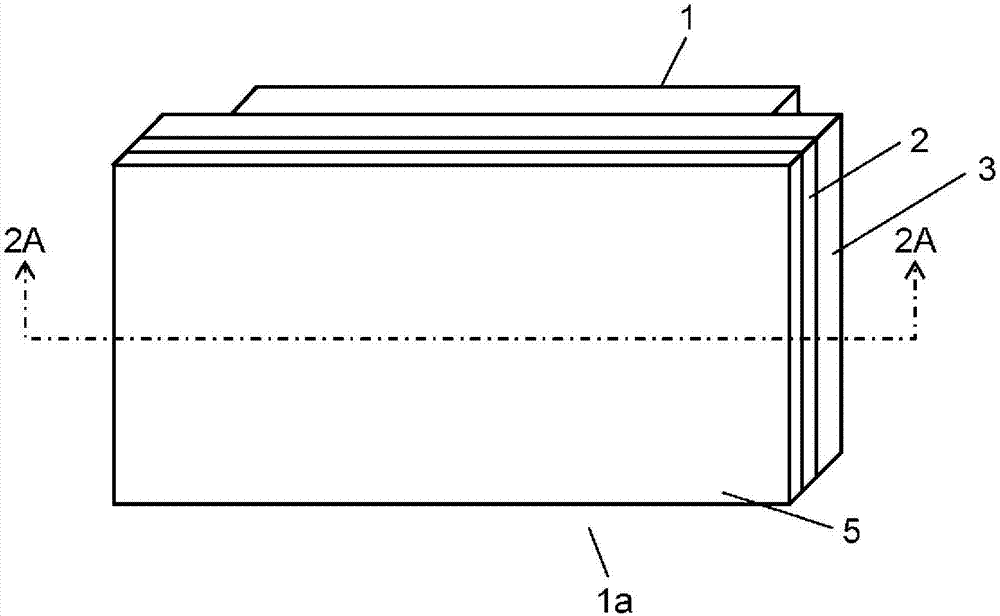

Magnetron

The magnetron includes: a cylindrical-shaped anode barrel member 10 having two openings respectively formed in the two end portions thereof; a cathode structure member 12 disposed on the center axis of the anode barrel member 10; more than one anode vane 11 disposed radially through an action space 13 in the periphery of the cathode structure member 12 and fixedly mounted on the inner wall surface of the anode barrel member 10; and, a pair of funnel-shaped pole pieces 14 and 30 respectively disposed in their associated ones of the two openings formed in the two end portions of the anode barrel member 10, each pole piece including a small-diameter flat portion FL1 having a penetration hole formed in the central portion thereof, a large-diameter flat portion FL2 having a diameter larger than the diameter of the small-diameter flat portion FL1, and a conical-shaped slanting portion SL for connecting the large-diameter flat portion FL2 and small-diameter flat portion FL1 to each other. Of the pair of pole pieces 14 and 30, the input side pole piece 30 includes, besides the penetration hole 30A formed in the central portion thereof, three or more, preferably, four penetration holes 30B respectively formed in the slanting portion SL thereof, each hole having an area of 16.6 mm2.

Owner:PANASONIC CORP

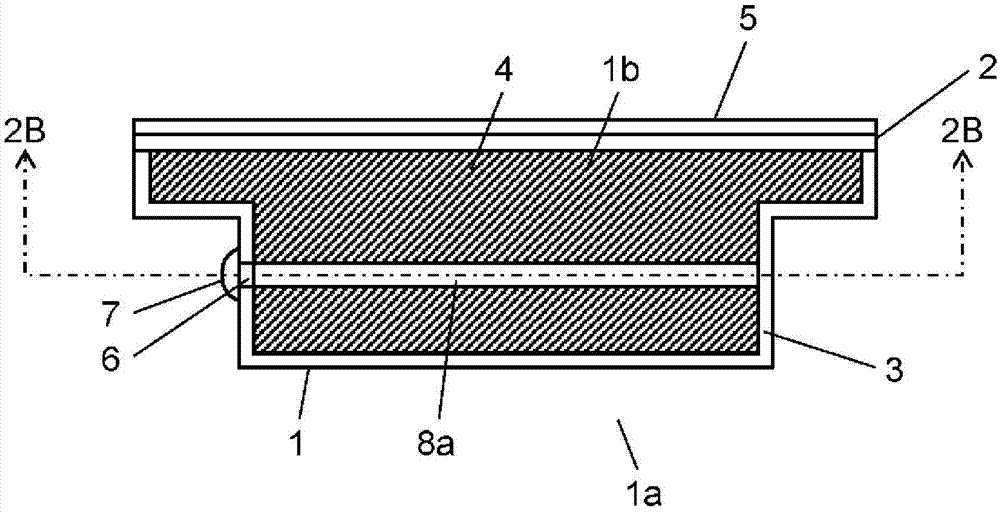

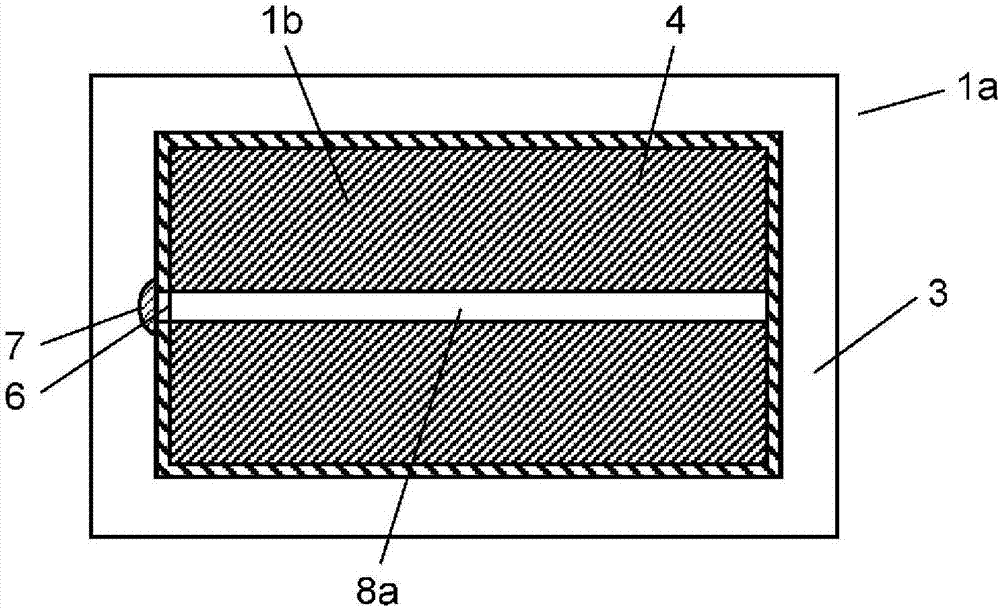

Vacuum heat insulation body

InactiveCN107250649AEfficient dischargeShorten exhaust timeThermal insulationInsulation for cooling apparatusThermal insulationEngineering

A vacuum heat insulation body is provided with: an outer case (2); an inner case (3); an open cell urethane foam (4) filling a space for heat insulation (1b) between the outer case (2) and the inner case (3); and a vacuum discharge port (6) which is provided to the outer case (2) or the inner case (3). The open cell urethane foam (4) is provided with a through passage (8a) that penetrates the open cell urethane foam (4) from the vacuum discharge port (6). The vacuum discharge port (6) is sealed after the space for heat insulation (1b), which is filled with the open cell urethane foam (4), is vacuum-evacuated.

Owner:PANASONIC INTPROP MANAGEMENT CO LTD

Vacuum prober and vacuum probe method

InactiveUS20050206396A1Reduce capacityShorten exhaust timeConveyorsSemiconductor/solid-state device testing/measurementProbe cardEngineering

In a vacuum prober, a head plate is arranged on a prober chamber. A stage, first moving mechanism, recessed chamber, and sealing member are provided in the prober chamber. The stage is arranged below a probe card. The first moving mechanism vertically moves the stage in at least the Z direction. The recessed chamber has a bottom portion and side portion. A lower camera, an upper camera, and the stage are operated to obtain data for alignment. When the upper end of the side portion of the recessed chamber comes into tight contact with the lower surface of the sealing member and a vacuum mechanism evacuates the recessed chamber, a vacuum chamber is formed. As the chamber has a small capacity, the time required for evacuation can be shortened.

Owner:TOKYO ELECTRON LTD

Method for repairing valve for filling nitrogen in manufacturing equipment of magnetron

A method for repairing nitrogen charging valve used on equipment for producing magnetron includes shearing damaged bellows in valve along vertical direction of its diameter , grinding two edges of corrugated sheet , applying high vacuum glue to bind two edges of said corrugated sheet and to let said glue fill full of seam of corrugated sheet , placing it in room temperature and drying it by air to let it be bound firmly , grinding it for ensuring evenness of vacuum glue to let it stretch out and draw back freely , setting repaired valve on leakage tester for checking whether repaired valve is on specification or not .

Owner:GUANGDONG WITOL VACUUM ELECTRONICS MFR

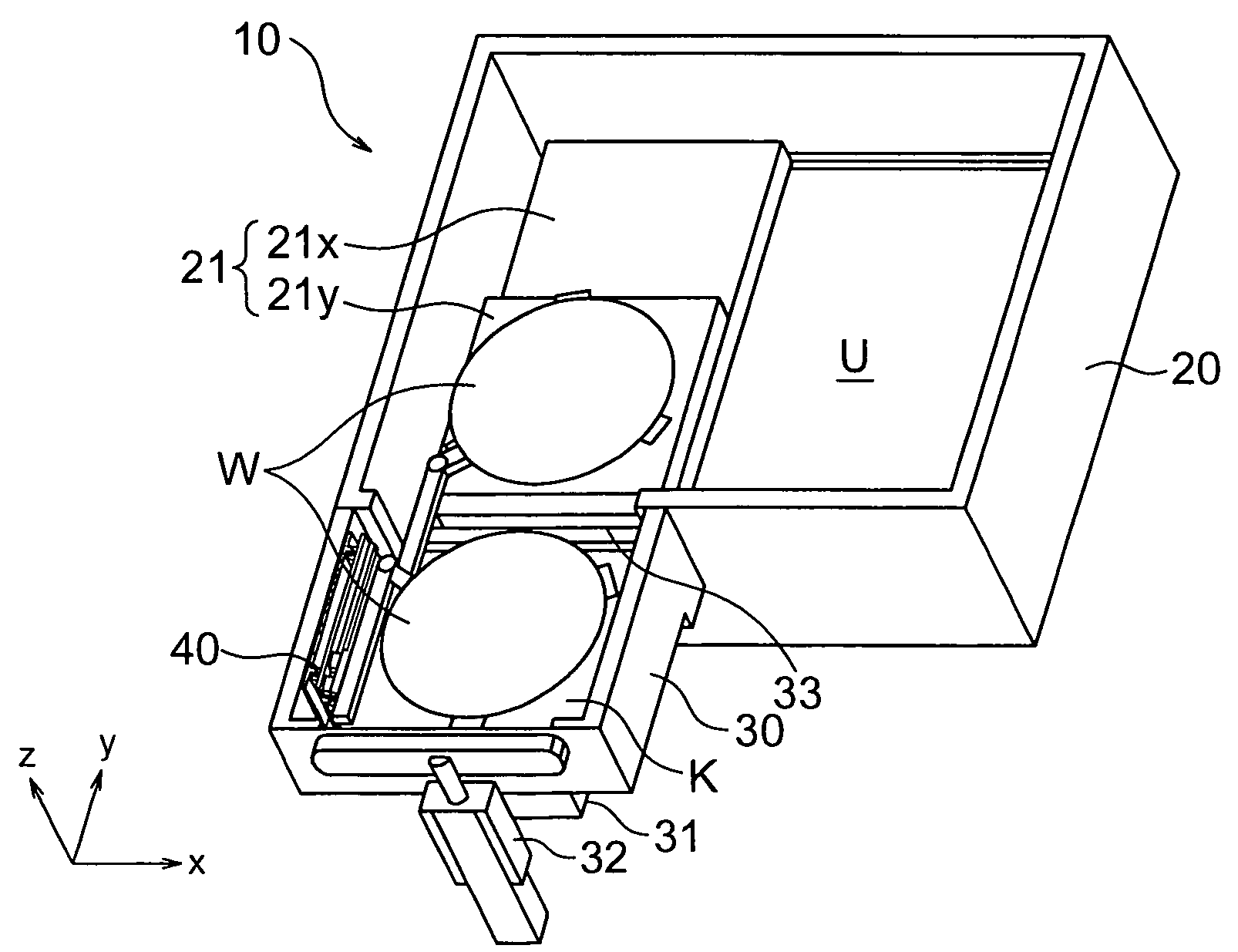

Vacuum conveying apparatus and charged particle beam equipment with the same

ActiveUS7531816B2Avoid it happening againSave footprintParticle separator tubesSemiconductor/solid-state device manufacturingReciprocating motionSemiconductor

A charged particle beam examination equipment for examining and measuring a semiconductor wafer, comprising a wafer exchange portion for exchanging an unexamined wafer and an examiner wafer with each other, which has a first arm longitudinally sliding for reciprocation, a first wafer gripping part provided to the distal end of the first arm, for gripping / releasing the wafer, a second arm longitudinally sliding for reciprocation, and a second wafer gripping part provided to the distal end of the second arm, for gripping / releasing the wafer. The apparatus may shorten the time required for exchange of the wafers so as to enhance the throughput during examination and measurement of the wafers.

Owner:HITACHI HIGH-TECH CORP

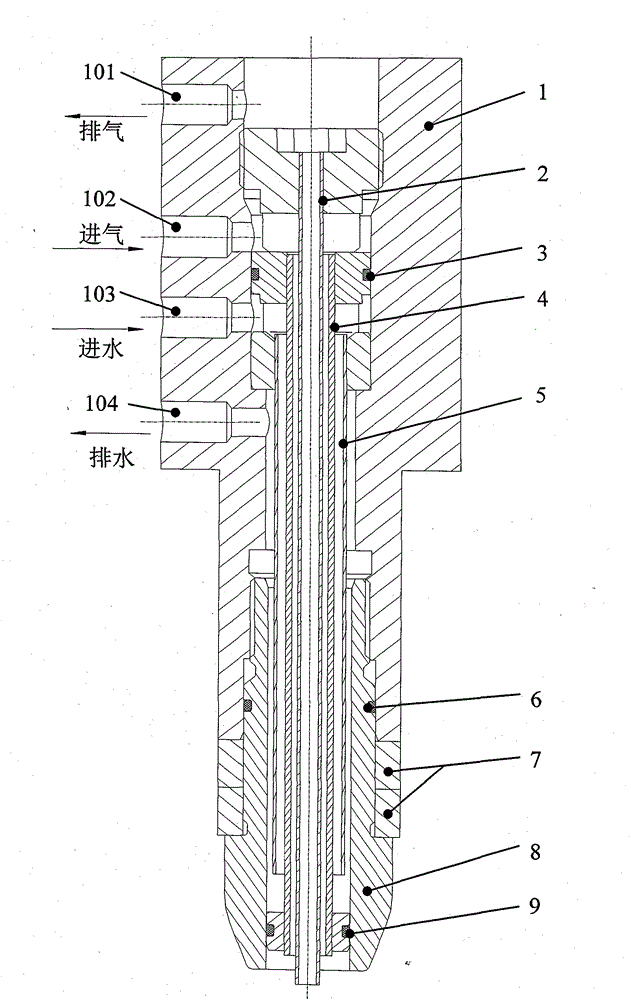

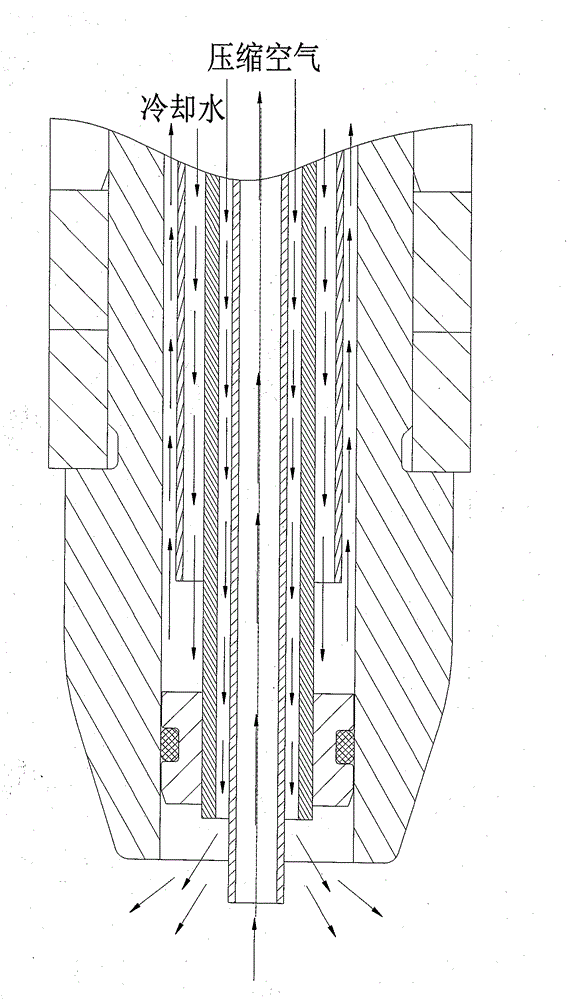

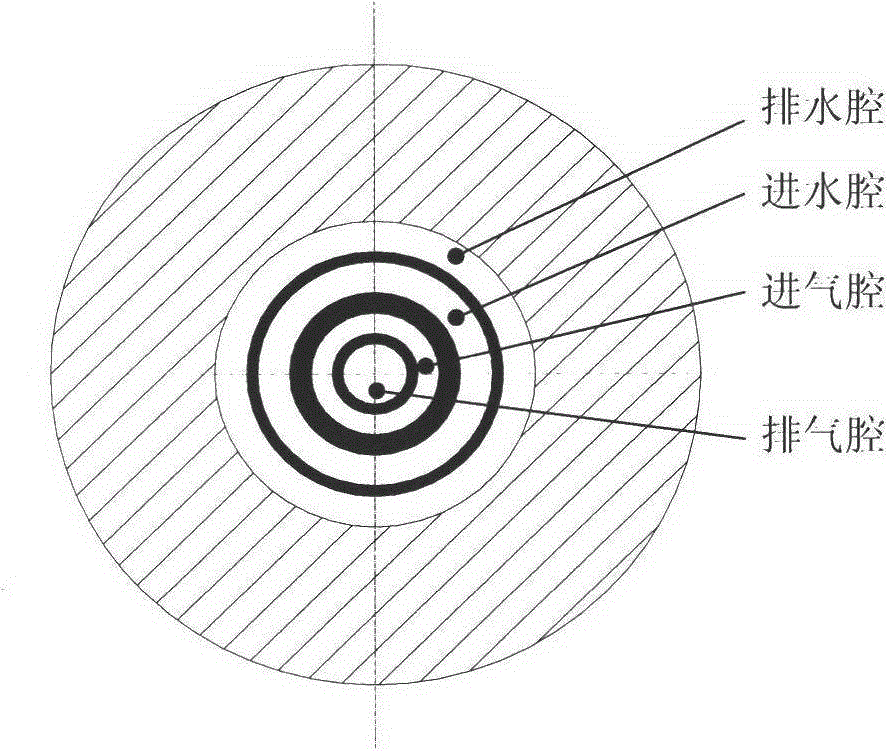

Bottle blowing machine blowing pin water cooled circulating device

The invention relates to a bottle blowing machine blowing pin water cooled circulating device. The device comprises a blowing pin body, wherein an exhaust pipe, an air inlet pipe, a cooling water pipe, a blowing pin cutter and a blowing pin head are mounted on the inner side of the blowing pin body; an air inlet, an air outlet, a water inlet and a water outlet are formed in the blowing pin body; the device is characterized in that the distance between the air inlet and the water inlet is 30 to 35 mm; the air inlet pipe is formed on the outer side of the exhaust pipe; a cooling water cavity comprising the cooling water pipe, the air inlet pipe, the blowing pin body and the blowing pin head is led to the blowing pin head, is sealed through an upper part O-shaped sealing ring, a middle O-shaped sealing ring and a lower part O-shaped sealing ring, and is isolated through an air cavity, the device can form a good cooling circuiting loop, and can keep a blowing pin at low temperature, thereby ensuring that the blowing pin and a bottle blank form large temperature difference, preventing the blowing pin from being adhered to a bottleneck, and further being capable of improving the production quality and the production efficiency of bottles.

Owner:SUZHOU BESTAR BLOW MOLDING MASCH CO LTD

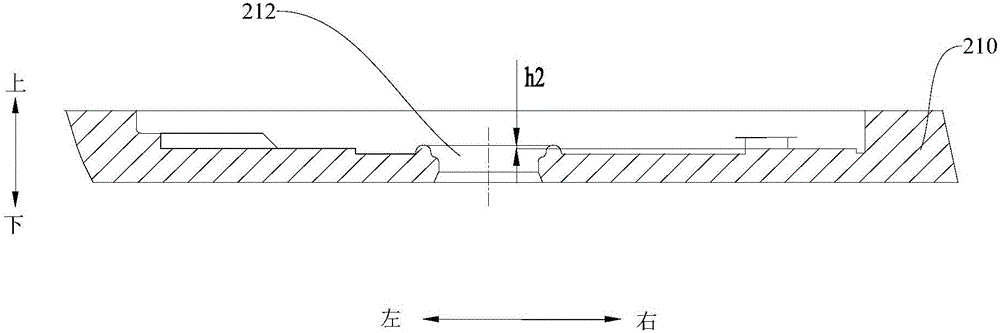

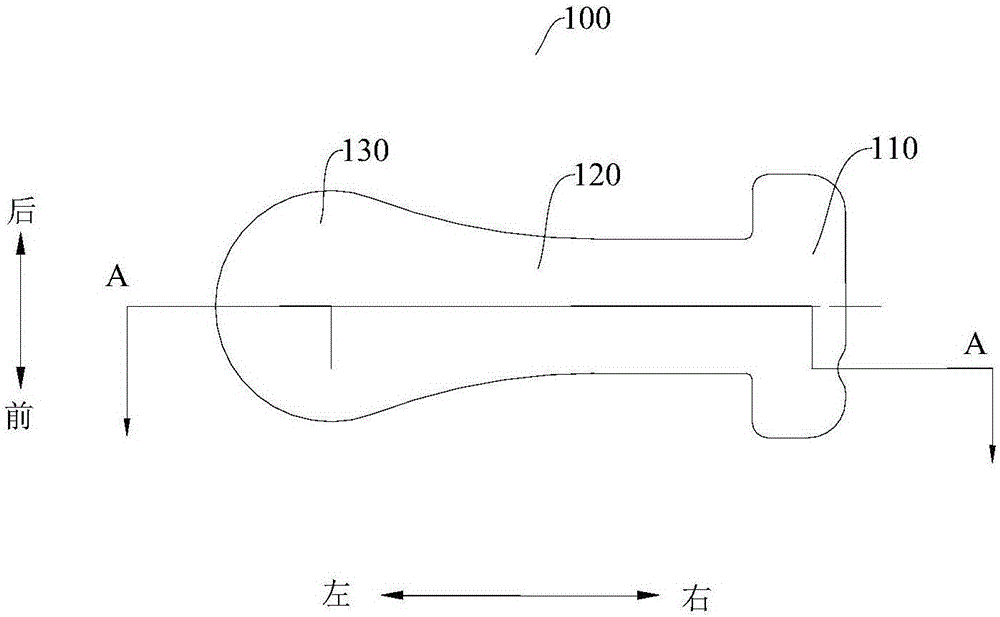

Exhaust valve plate for compressor, exhaust valve module and compressor

InactiveCN106593829AReduce leakageShorten exhaust timePositive displacement pump componentsPositive-displacement liquid enginesEngineeringExhaust valve

The invention discloses an exhaust valve plate for a compressor, an exhaust valve module and a compressor. The exhaust valve plate for the compressor is substantially strip-shaped with a length as S; S is smaller than 25 mm and bigger than 15 mm; at least one part of the exhaust valve plate is bent to one side of an exhaust valve port so as to form a height difference h1 between one end and the other end of the exhaust valve plate; and h1 is smaller than 0.5 mm and bigger than 0.03 mm. According to the exhaust valve plate for the compressor, one part of the exhaust valve plate is bent to one side of the exhaust valve port so as to warp the end part; the warping height of the end part of the exhaust valve plate is controlled to form lower pressure between the exhaust valve plate and the exhaust valve port; meanwhile, the compensation effect on the machining error of the exhaust valve port and the like can be achieved; the exhaust valve plate can be tightly bonded on the exhaust valve port to reduce the leakage; and the warping structure of one end of the exhaust valve plate can enable the exhaust valve plate to obtain higher resilience force, so that the exhaust time is shortened, and the exhaust efficiency is improved.

Owner:ANHUI MEIZHI COMPRESSOR +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com