Production method of cold cathode flat light source

A planar light source and manufacturing method technology, applied in cold cathode manufacturing, electrode system manufacturing, discharge tube/lamp manufacturing, etc., can solve the problems of light source damage, increase of non-luminous area, exhaust pipe rupture, etc., to improve the yield and production efficiency, improvement of luminance uniformity, and improvement of luminance uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

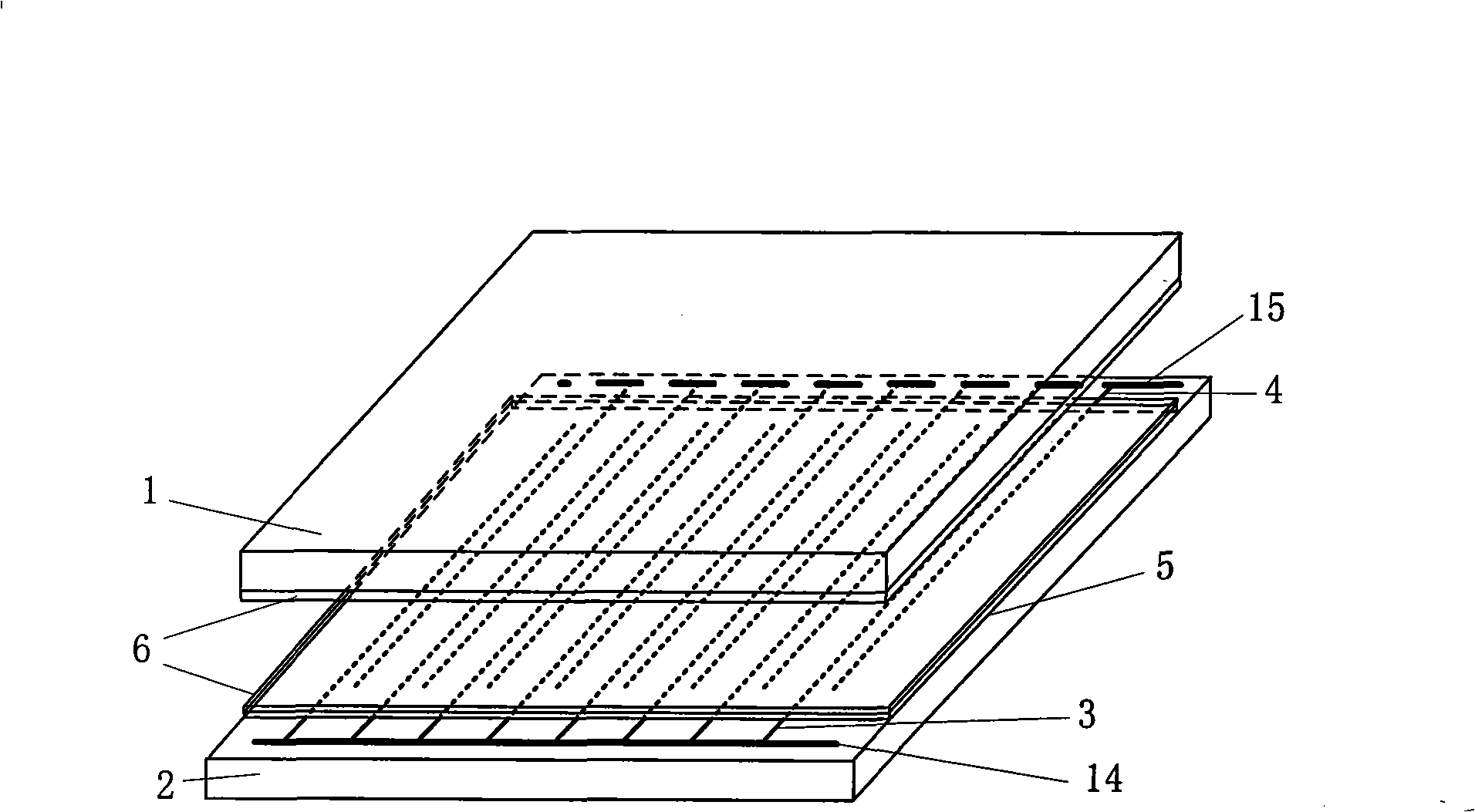

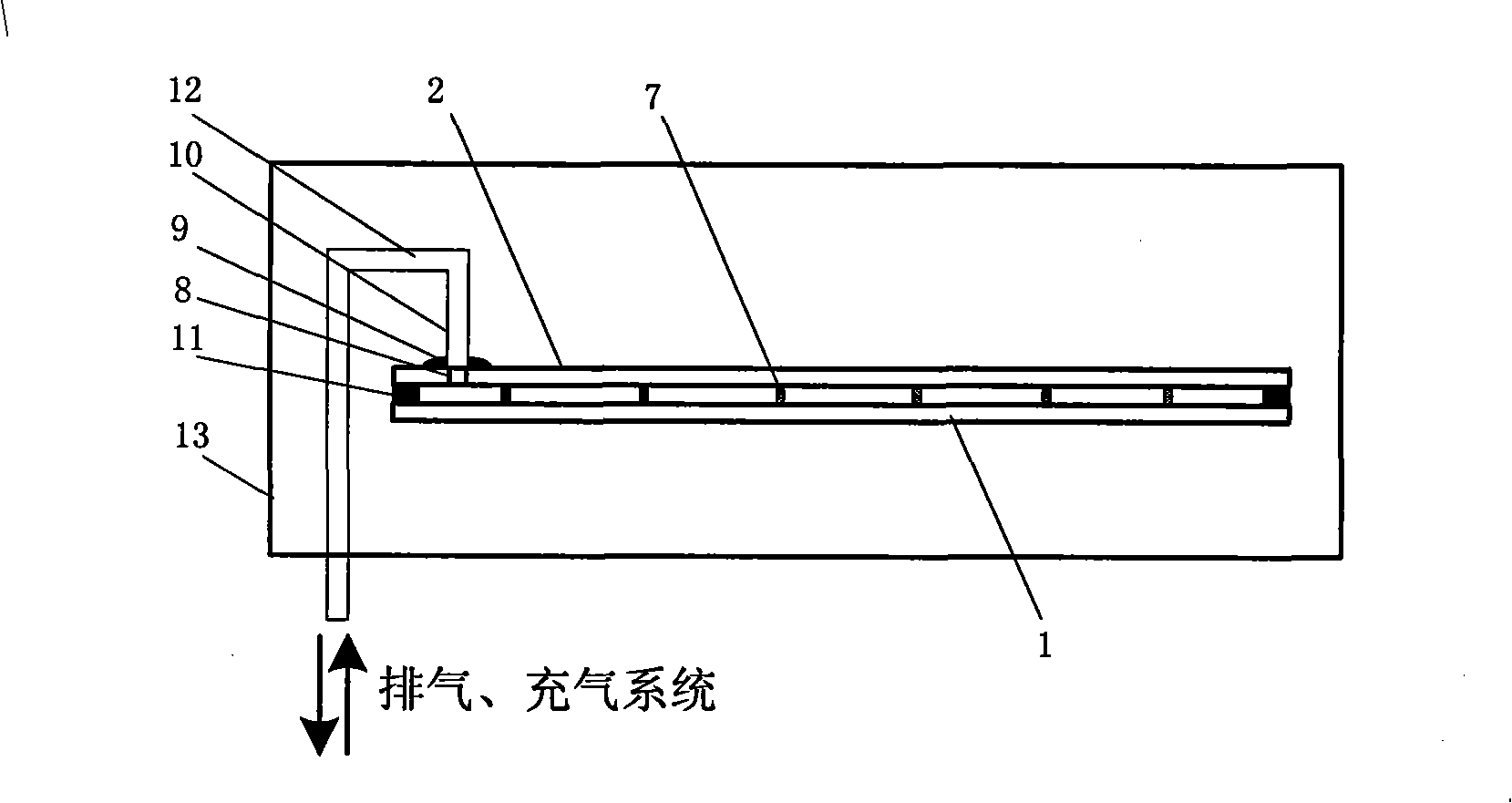

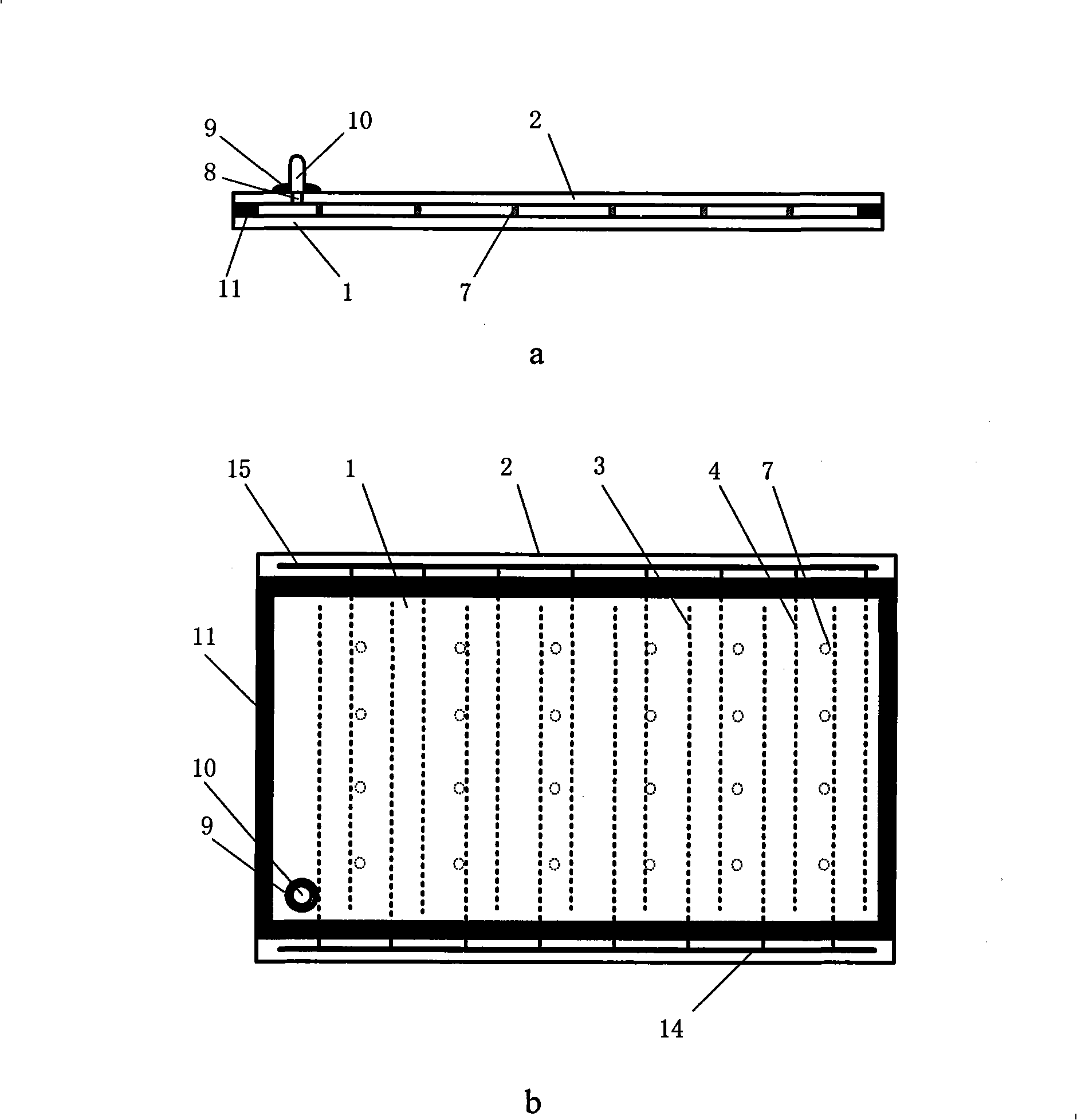

[0047] refer to figure 1 As shown, it consists of a front glass substrate 1 and a rear glass substrate 2. The inner surface of the front glass substrate 1 is equipped with a phosphor layer 6, and the inner surface of the rear glass substrate 2 is equipped with two sets of electrodes, namely X electrodes 3 and Y electrodes. 4. X electrodes 3 and Y electrodes 4 are covered with dielectric layer 5, and the surface of dielectric layer 5 is covered with phosphor layer 6. All X electrodes 3 are connected to lead electrodes 14, and all Y electrodes 4 are connected to lead electrodes 15. A certain distance is maintained between the glass substrate 1 and the rear glass substrate 2 by spacers, the interior is filled with discharge gas, and a certain voltage waveform is applied between the X electrode 3 and the Y electrode 4, a discharge will be generated between the electrodes, and the discharge generated Ultraviolet light excites the phosphor to emit visible light.

[0048] refer to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com