Bottle blowing machine blowing pin water cooled circulating device

A technology of water cooling cycle and blow molding machine, which is applied in the field of blowing needle cooling device, which can solve the problems that the cooling water cannot be guaranteed not to leak, seal isolation is not used, and the blowing speed of the parison is affected, so as to reduce the working cycle and reduce the cooling time. Time, efficiency improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

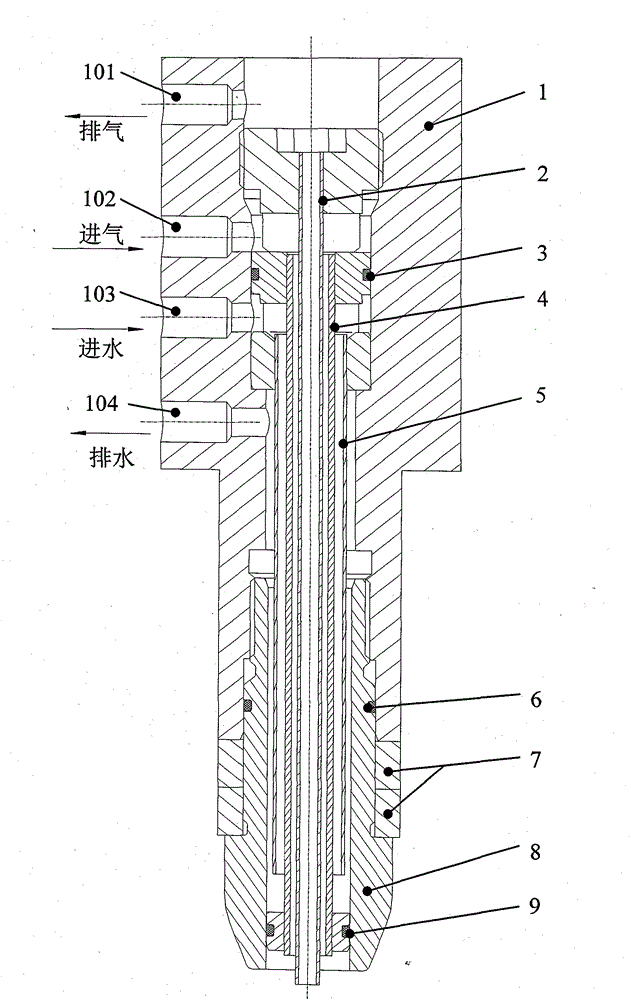

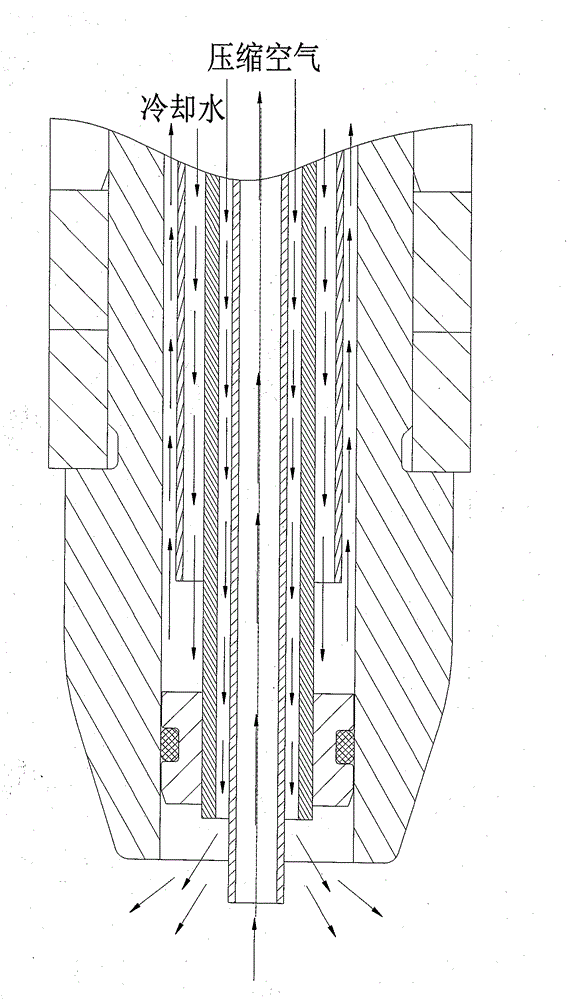

[0013] A kind of bottle blowing machine blowing needle water cooling circulation device provided by the present invention is described in detail below in conjunction with the accompanying drawings:

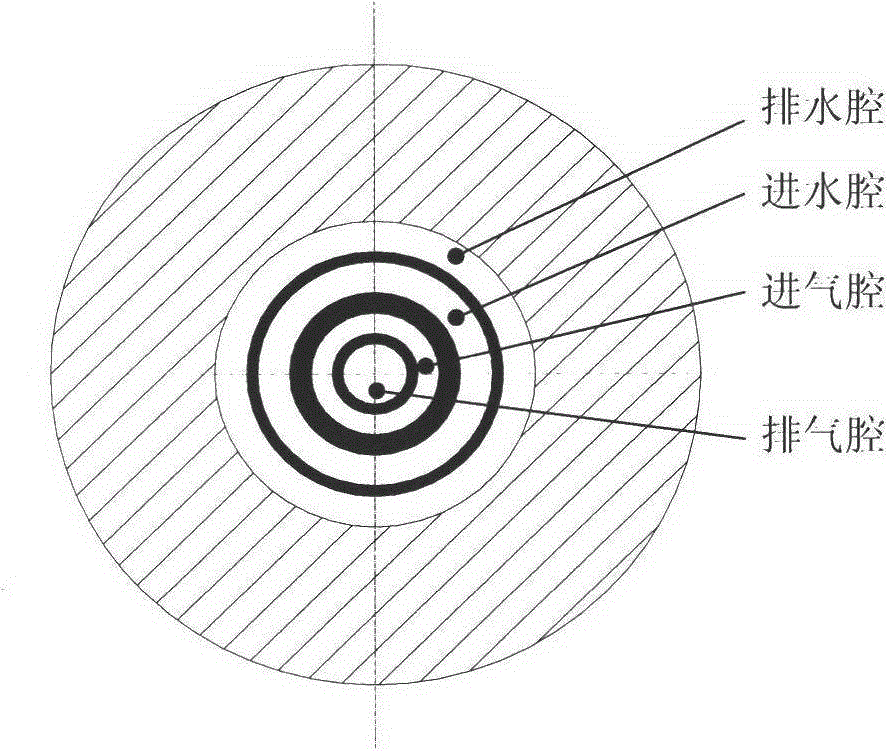

[0014] Such as Figure 1 ~ Figure 3 As shown, a blowing needle water cooling circulation device of a bottle blowing machine includes a blowing needle body 1, and an exhaust pipe 2, an air intake pipe 4, a cooling water pipe 5, a blowing needle cutter 7 and a blowing needle head 8 are installed on the inner side of the blowing needle body 1, The blowing needle body 1 is provided with an air inlet 102 , an air outlet 101 , a water inlet 103 and a water outlet 104 . The exhaust pipe 2, the air intake pipe 4 and the cooling water pipe 5 all adopt thin-walled seamless stainless steel pipes. The distance between the air inlet 102 and the water inlet 103 is 30-35mm. The intake pipe 4 is outside the exhaust pipe 2 . The cooling water cavity formed by the cooling water pipe 5, the air i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com