Patents

Literature

37results about How to "Reduce duty cycle" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

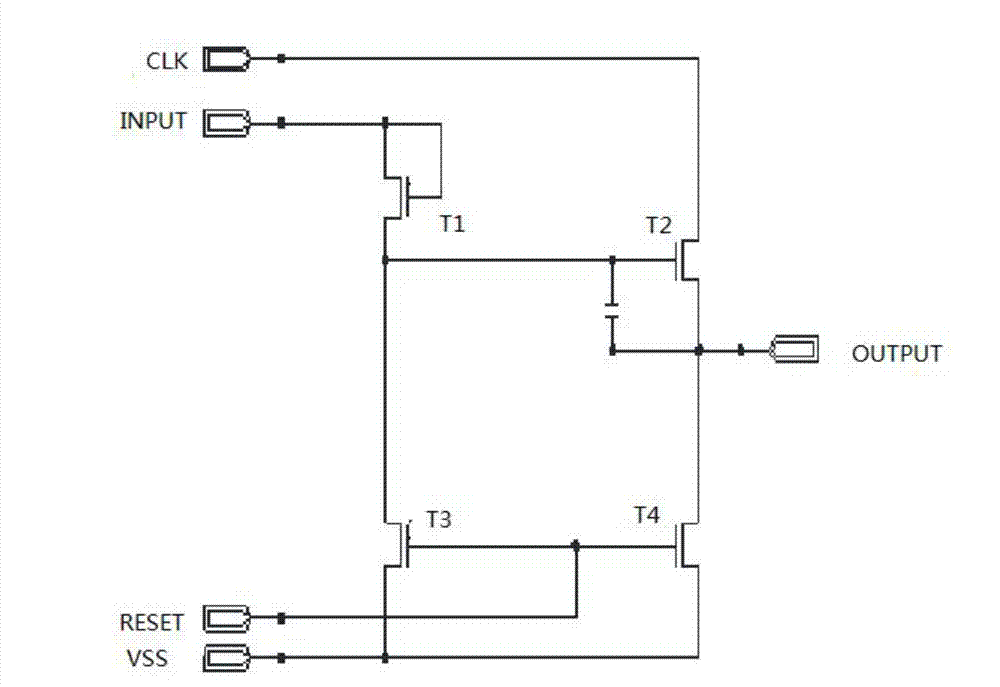

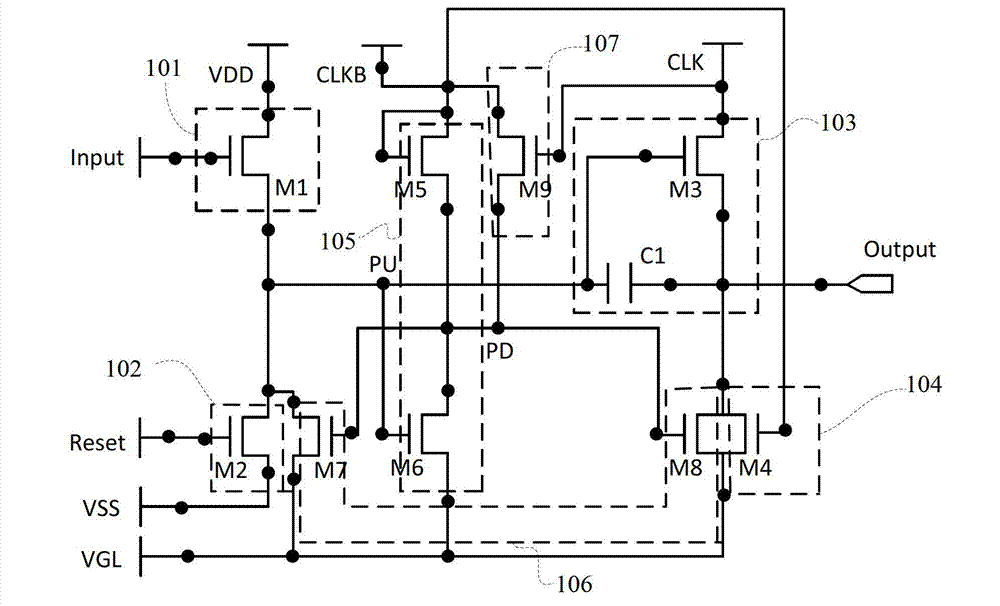

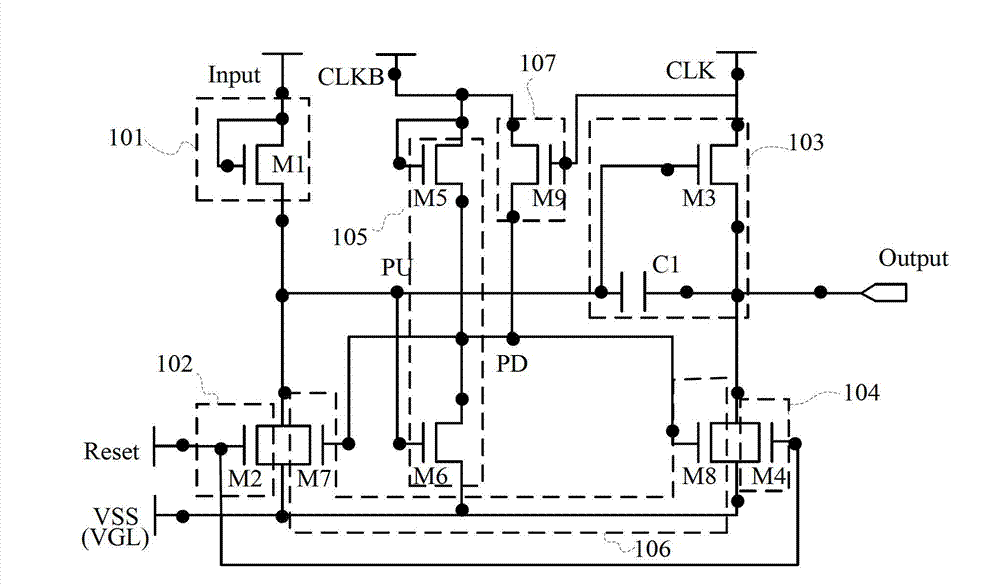

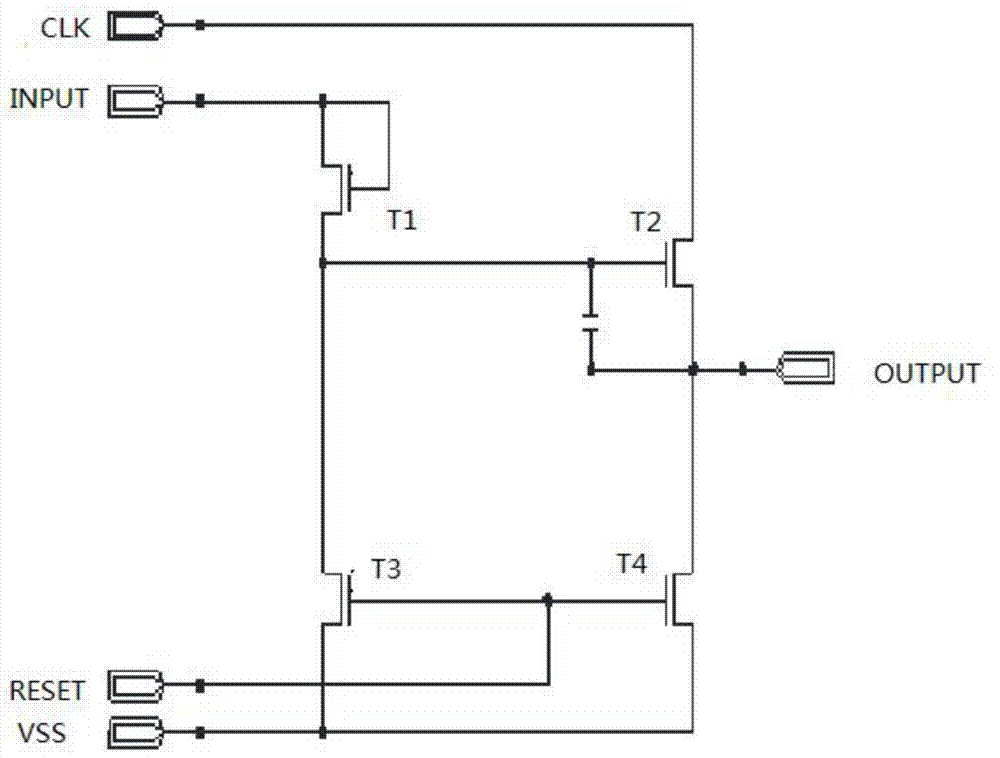

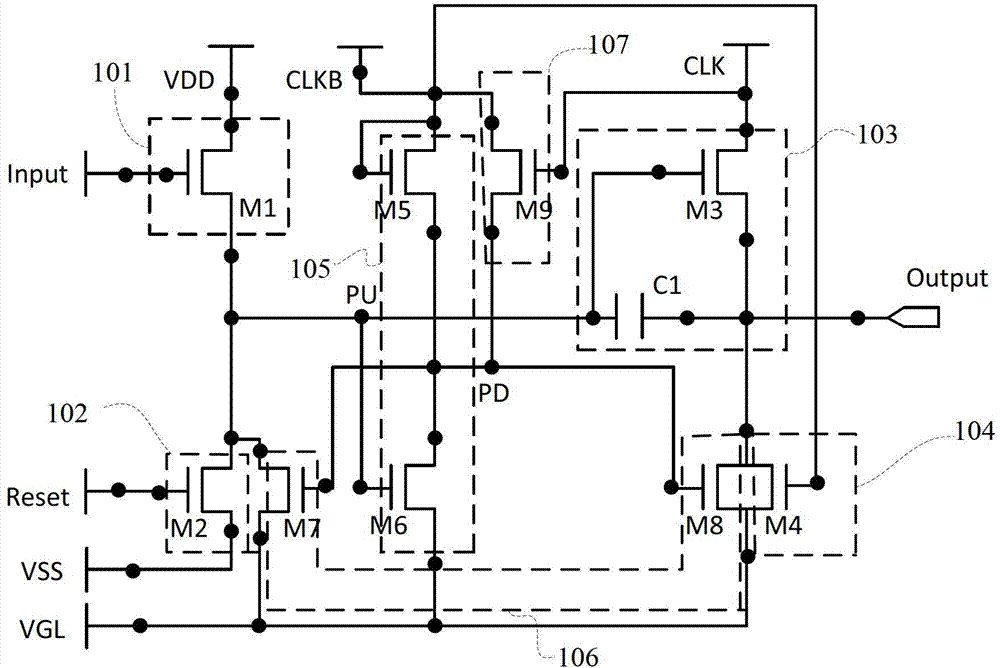

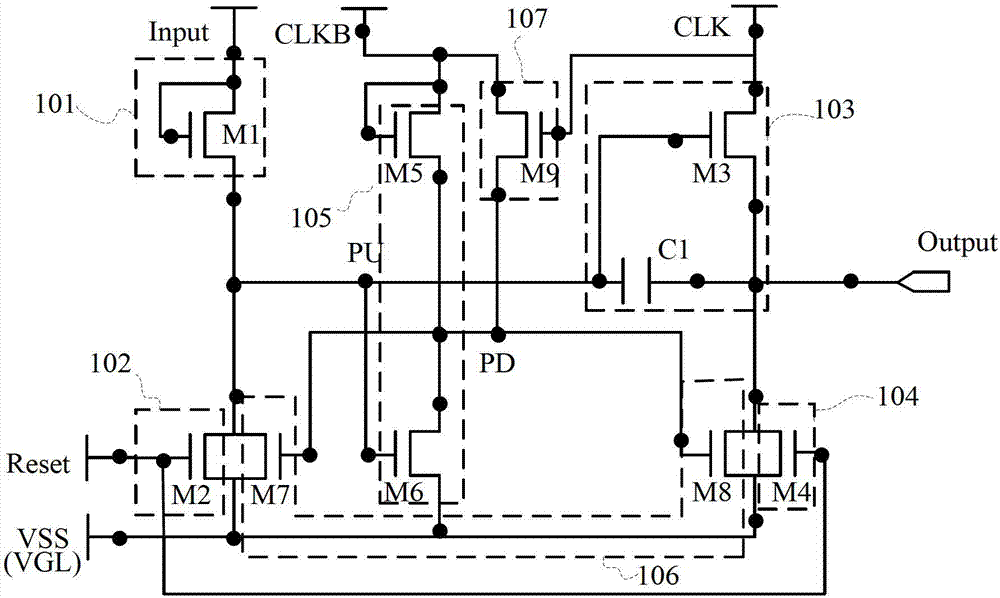

Shifting register unit and array substrate gird driving device

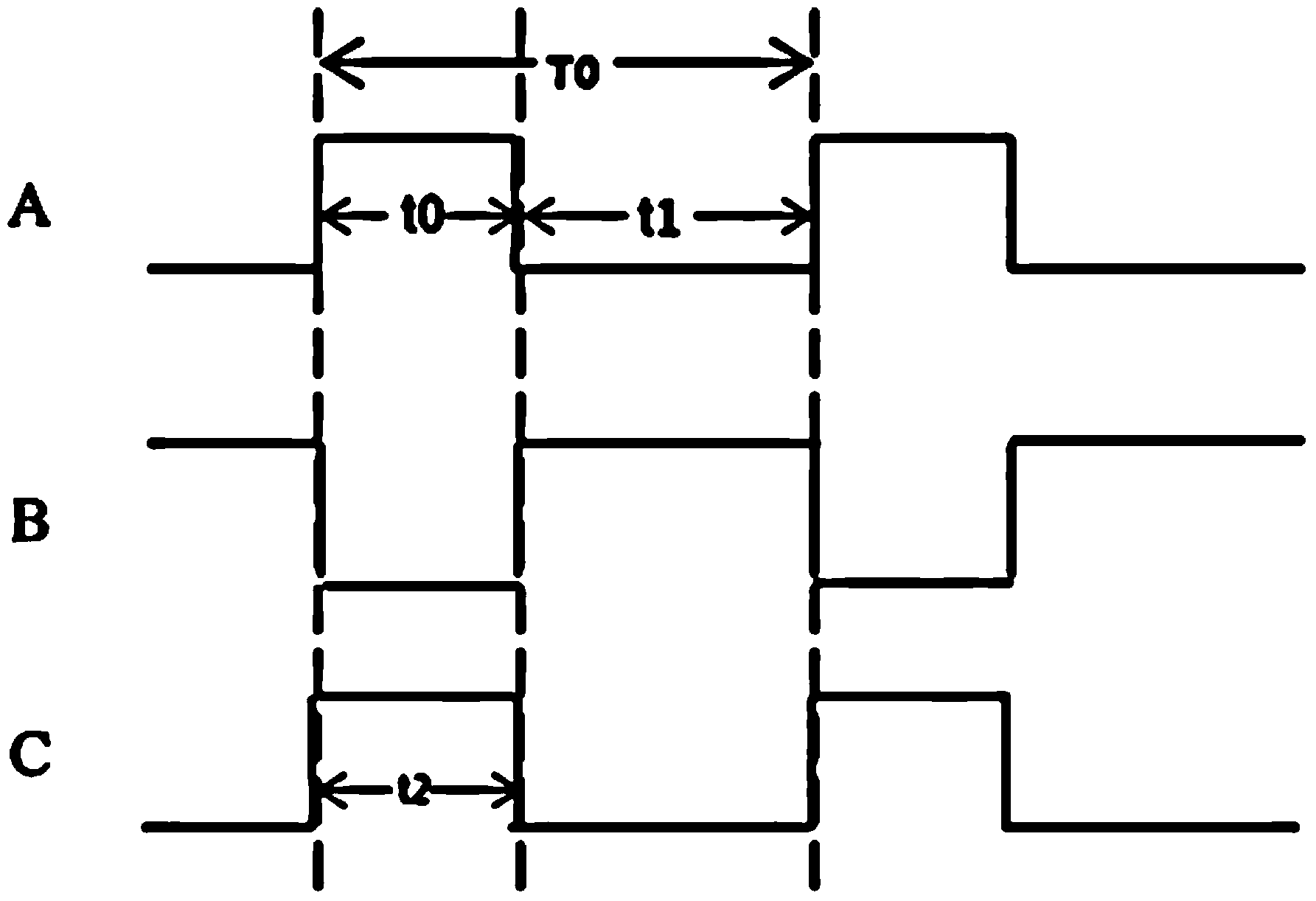

The invention discloses a shifting register unit and an array substrate gird driving device. With the adoption of the shifting register unit and the array substrate gird driving device, low-noise signals can be output by the shifting register unit and the shifting register unit can stably work for a long time period. The shifting register unit provided by the invention comprises an input module, a resetting module, a pull-upward module, a first pull-downward module, a first pull-downward control module, a second pull-downward module and a second pull-downward control module, wherein the input module is used for supplying a first working voltage to a pull-upward node of the pull-upward module; the resetting module is connected with the pull-upward node and is used for reducing the voltage of the pull-upward node to a second working voltage; the pull-upward module is connected with the pull-upward node, is used for storing the first working voltage and supplies a first clock signal to an output terminal; the first pull-downward module is used for supplying a third working voltage to the output terminal; the first pull-downward control module supplies a second clock signal to the pull-downward node, and supplies the third working voltage to the pull-downward node; the second pull-downward module is used for supplying the third working voltage to the pull-upward node and the output terminal; and the second pull-downward control module is used for inputting the second clock signal to the pull-downward node.

Owner:BEIJING BOE OPTOELECTRONCIS TECH CO LTD

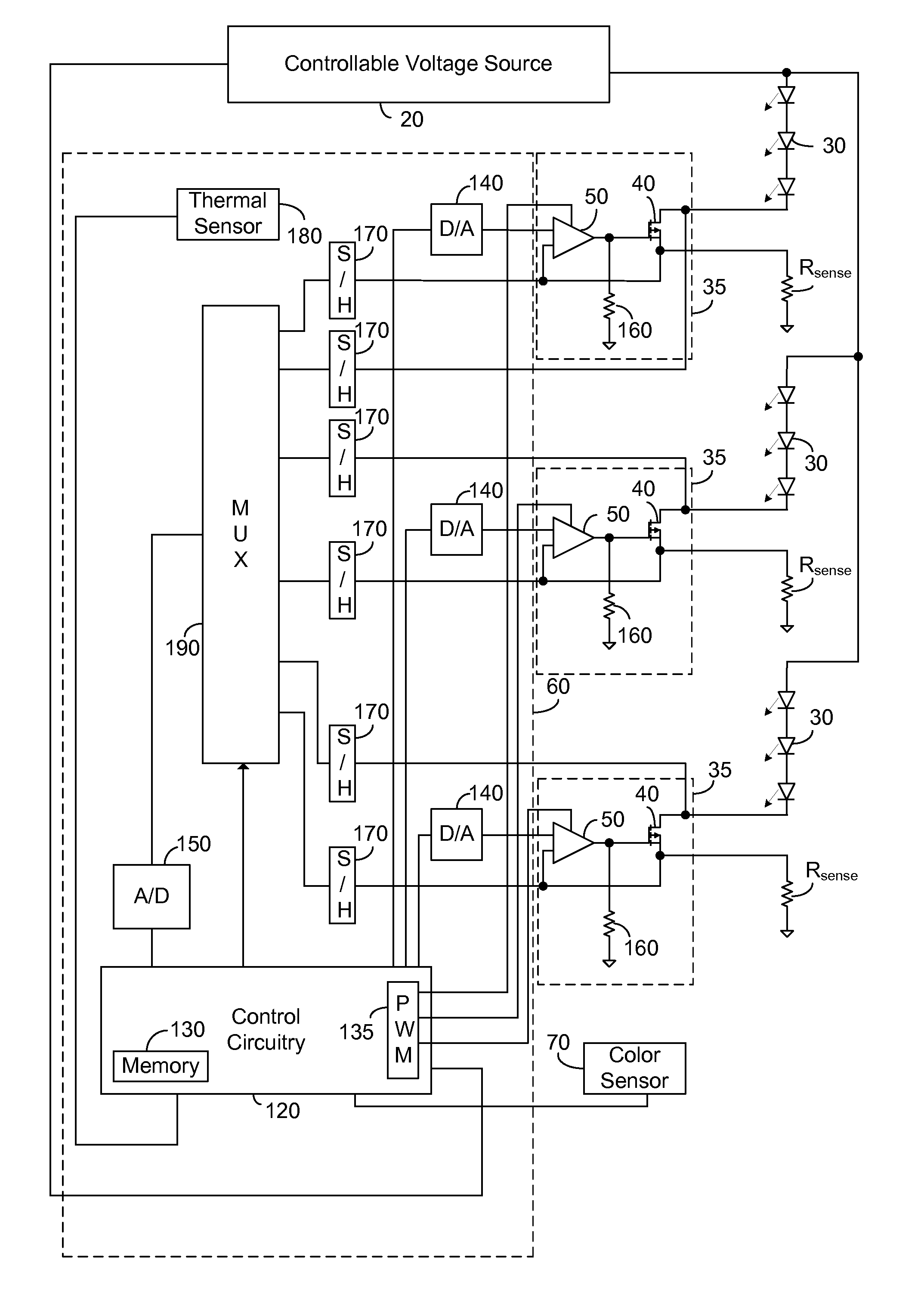

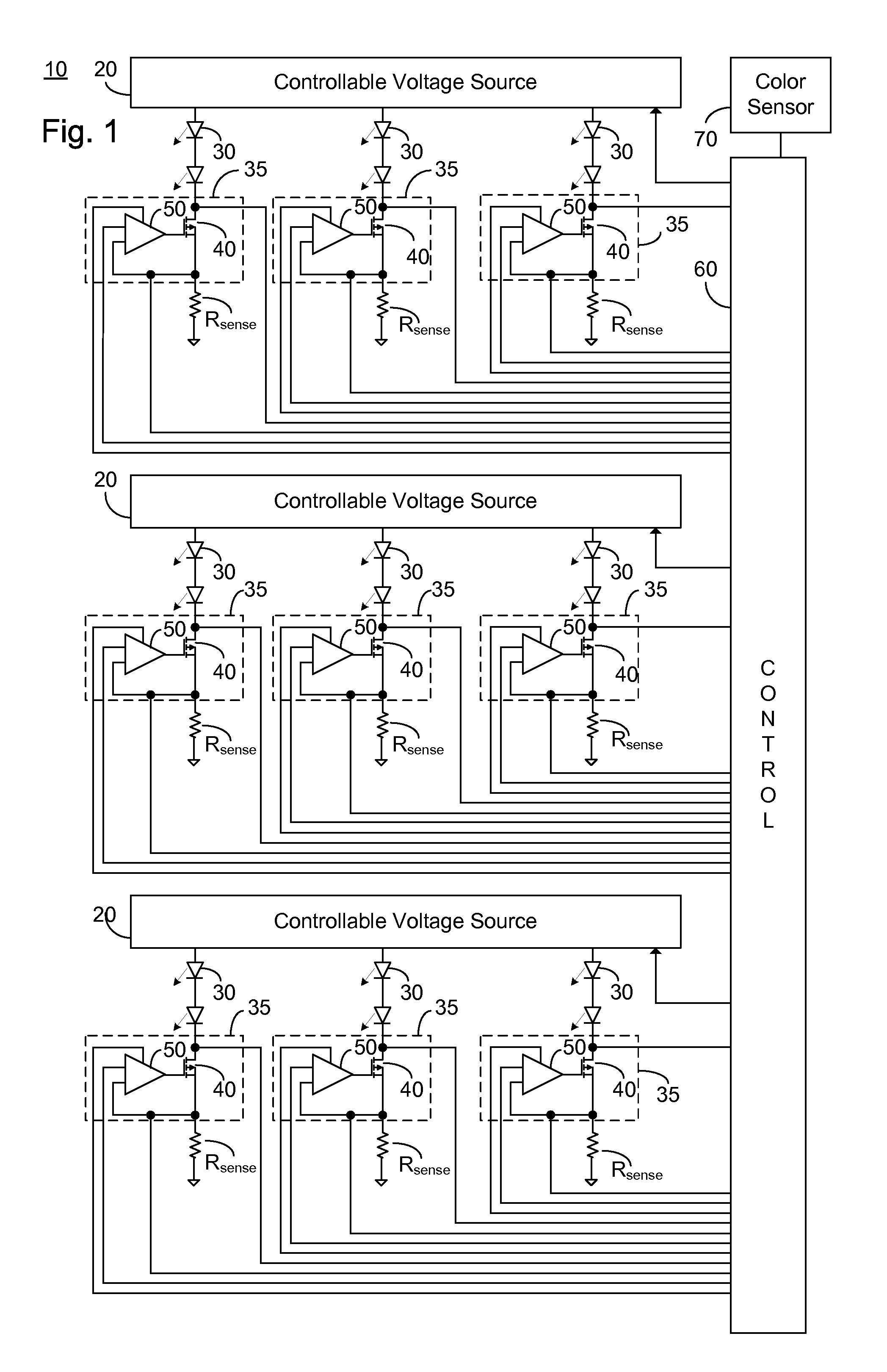

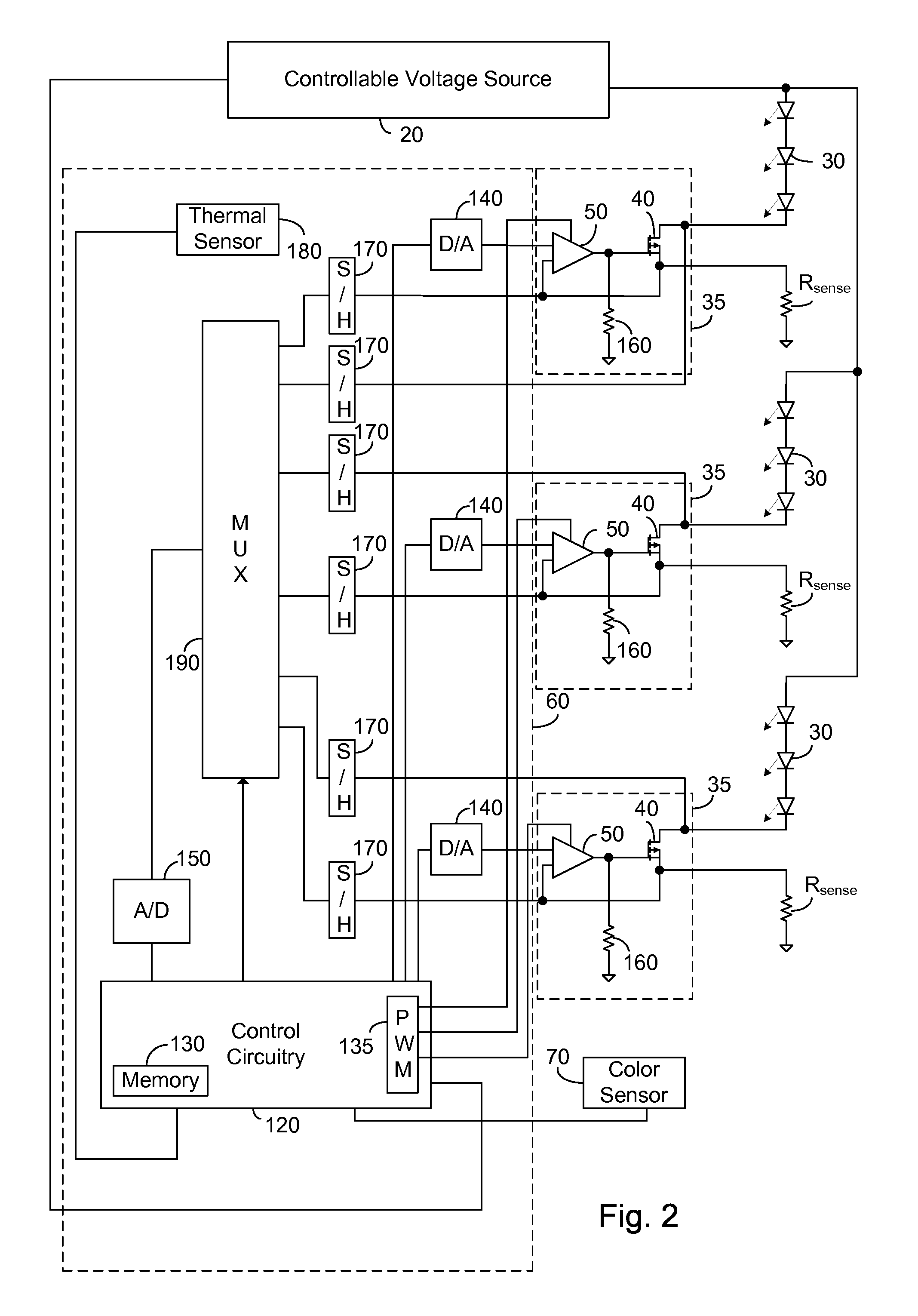

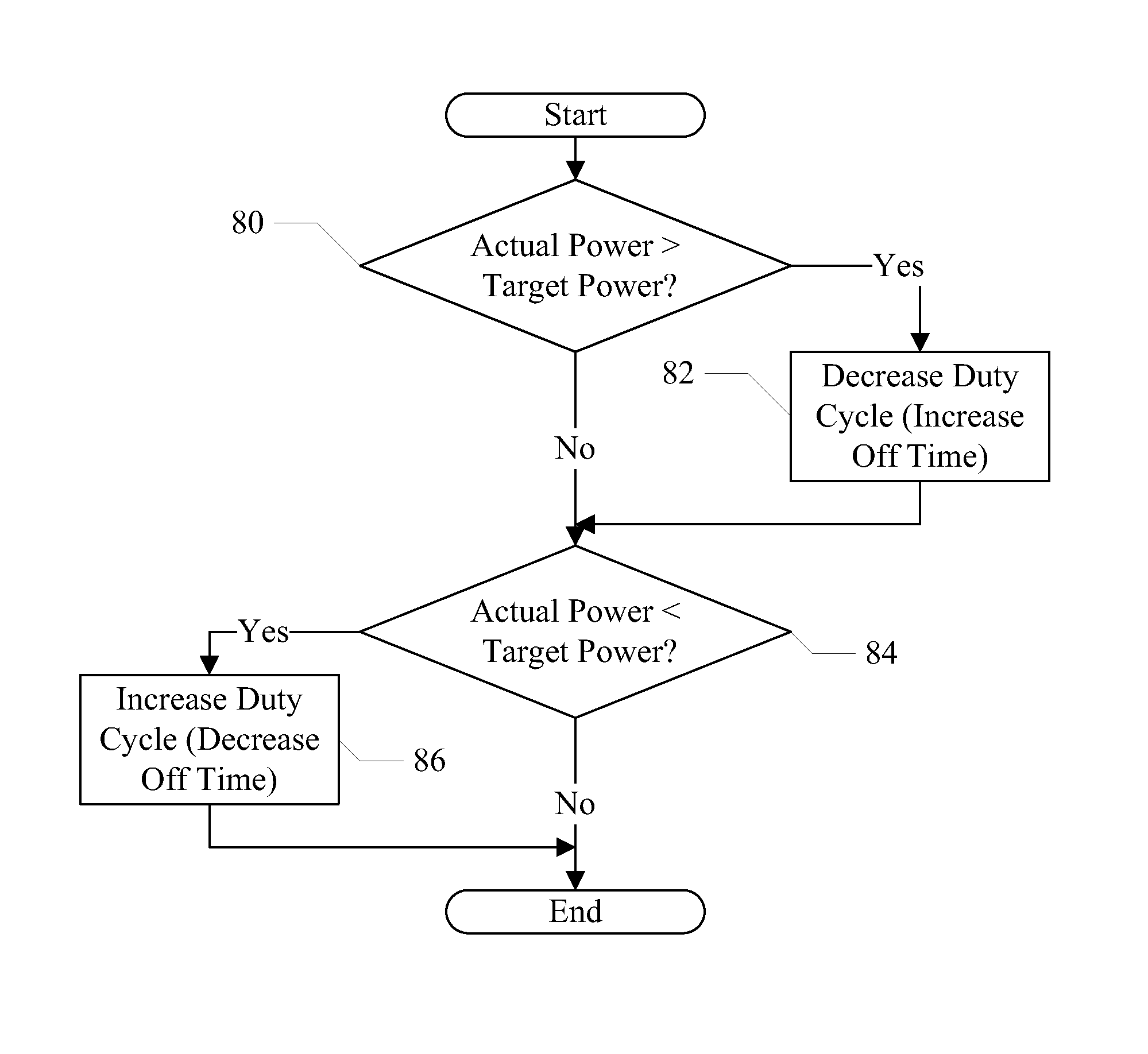

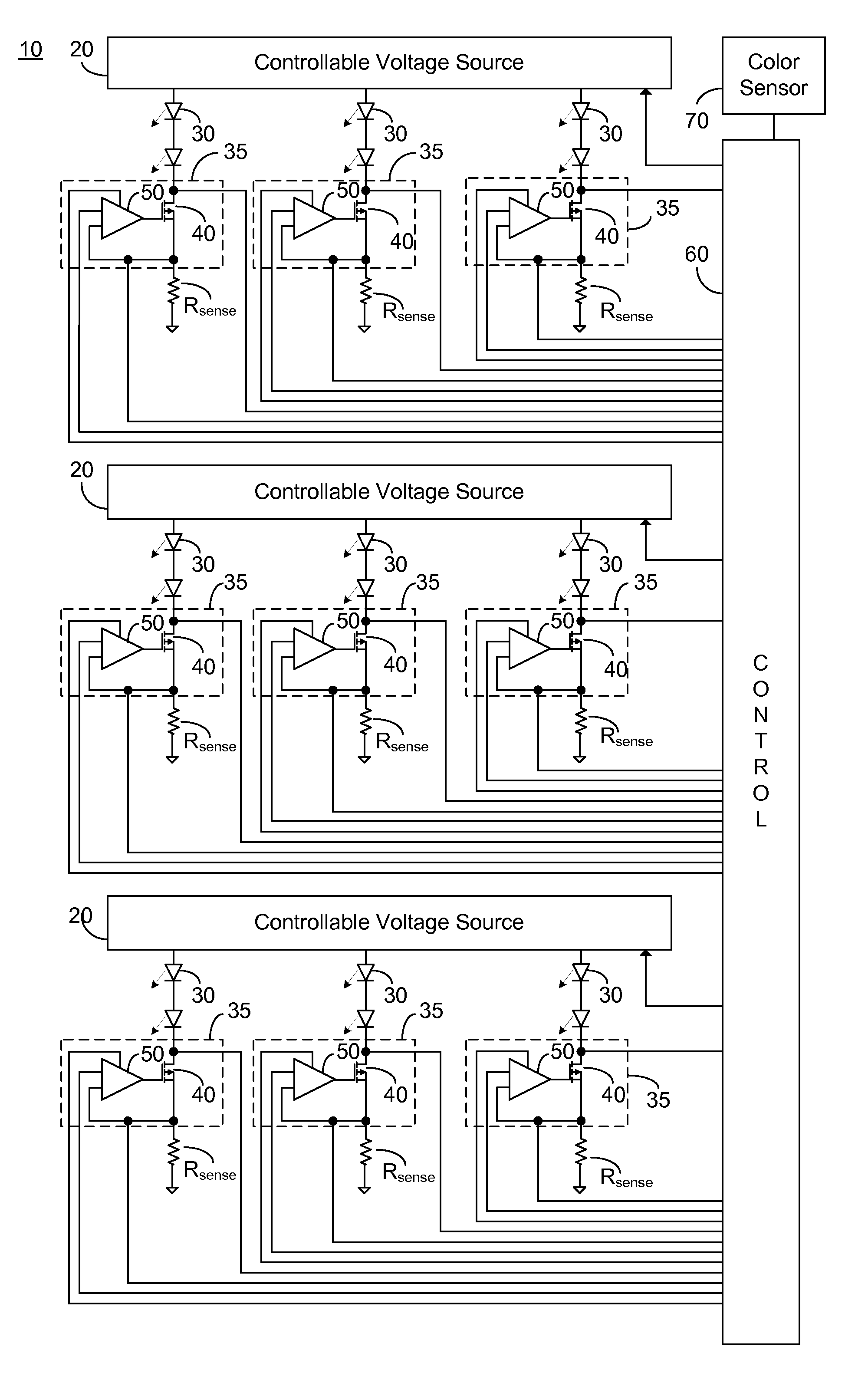

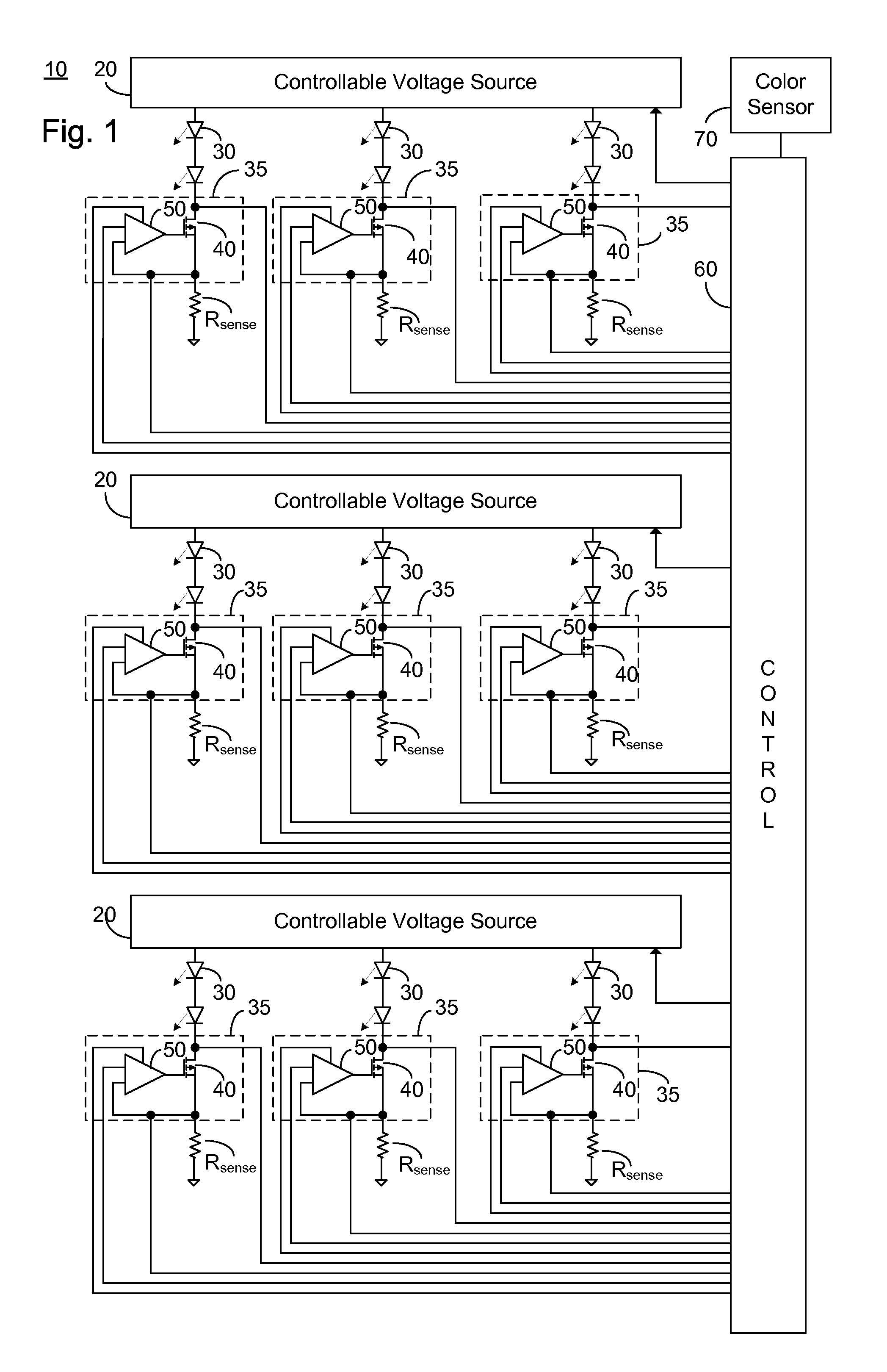

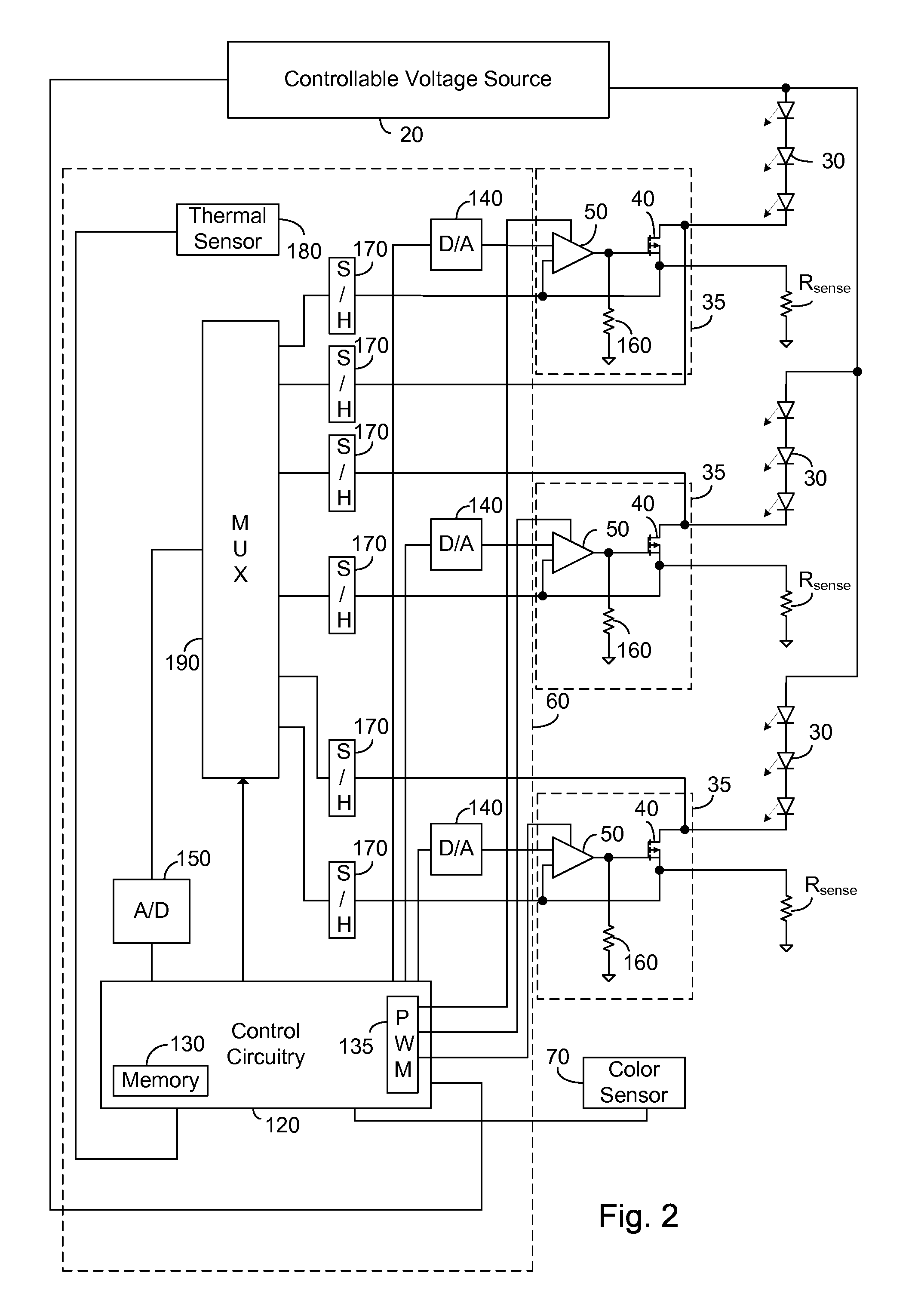

Thermal limited backlight driver

InactiveUS7791584B2Reduce thermal stressOvercome disadvantagesStatic indicating devicesElectroluminescent light sourcesEngineeringControl circuit

A system for powering and controlling an LED backlight, the system comprising: a control circuitry; a plurality of LED strings; a pulse width modulation functionality associated with the control circuitry and arranged to pulse width modulate a current flow through each of the plurality of LED strings; and a plurality of current limiters responsive to the control circuitry, each of the plurality of current limiters being associated with a particular one of the plurality of LED strings and operative to limit current flow of the pulse width modulated current there-through, the control circuitry being operative in the event of a thermal condition of one of the plurality of current limiters to reduce a duty cycle of the pulse width modulation functionality of the current flow through the one of the plurality of current limiters.

Owner:POLARIS POWERLED TECH LLC

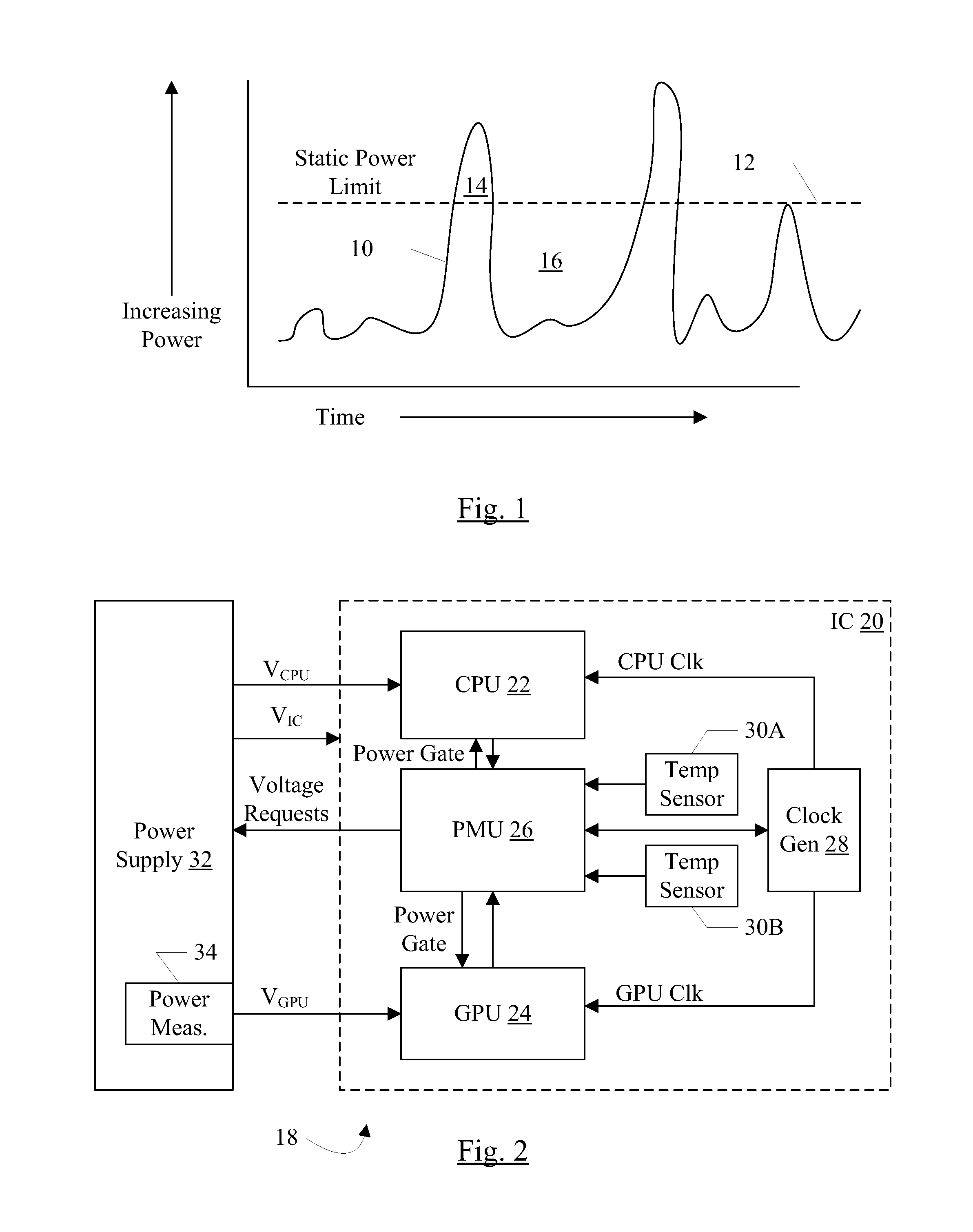

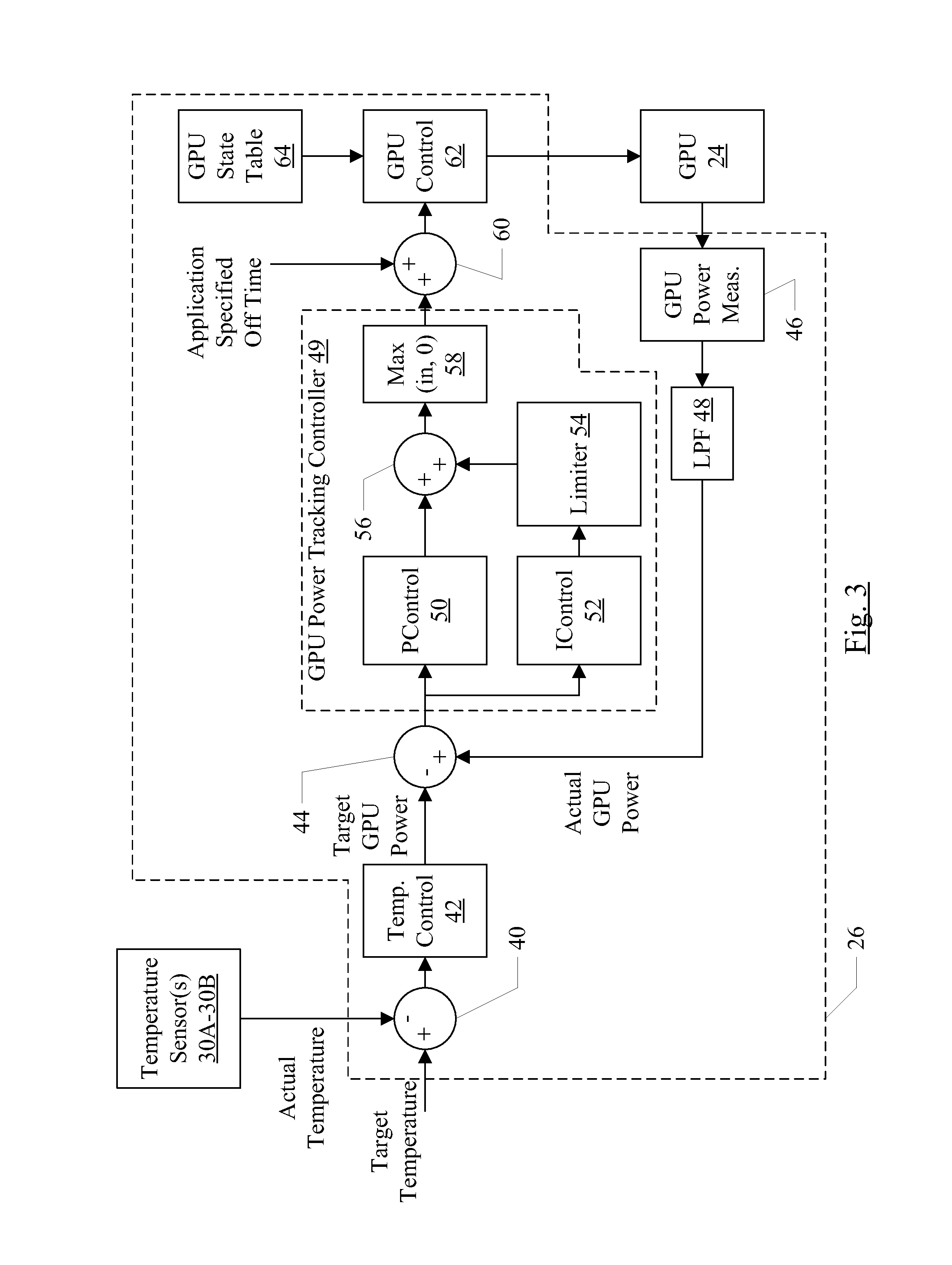

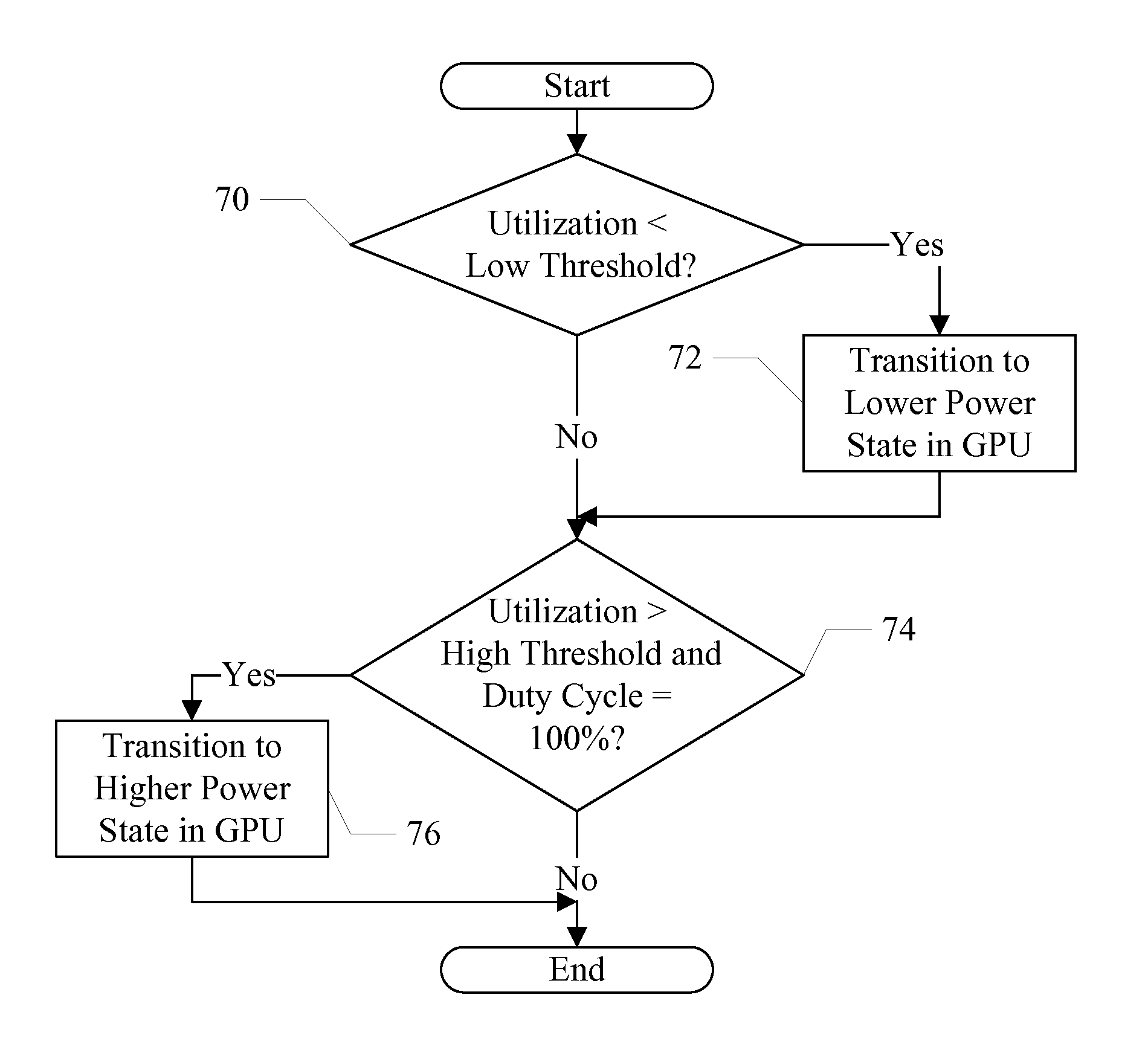

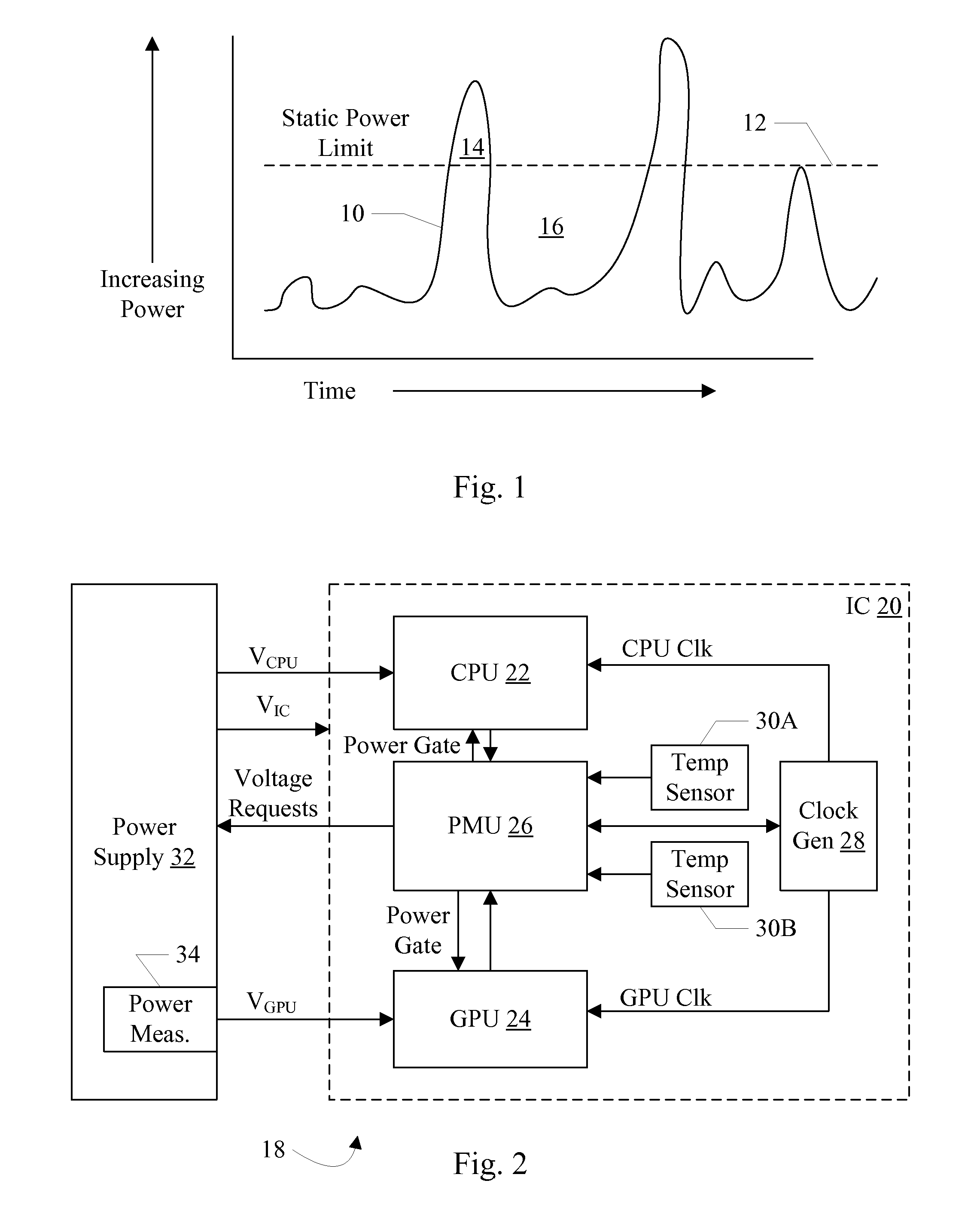

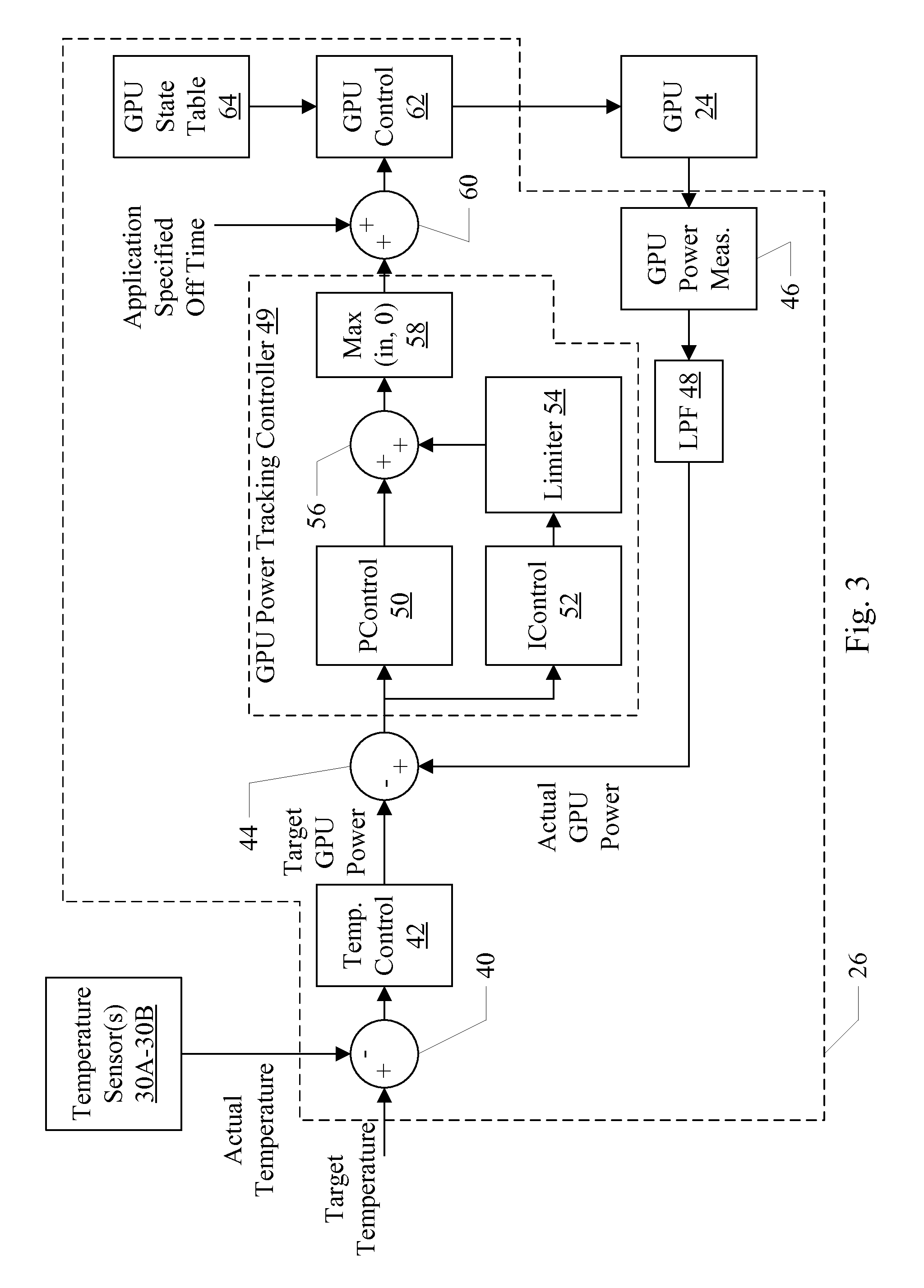

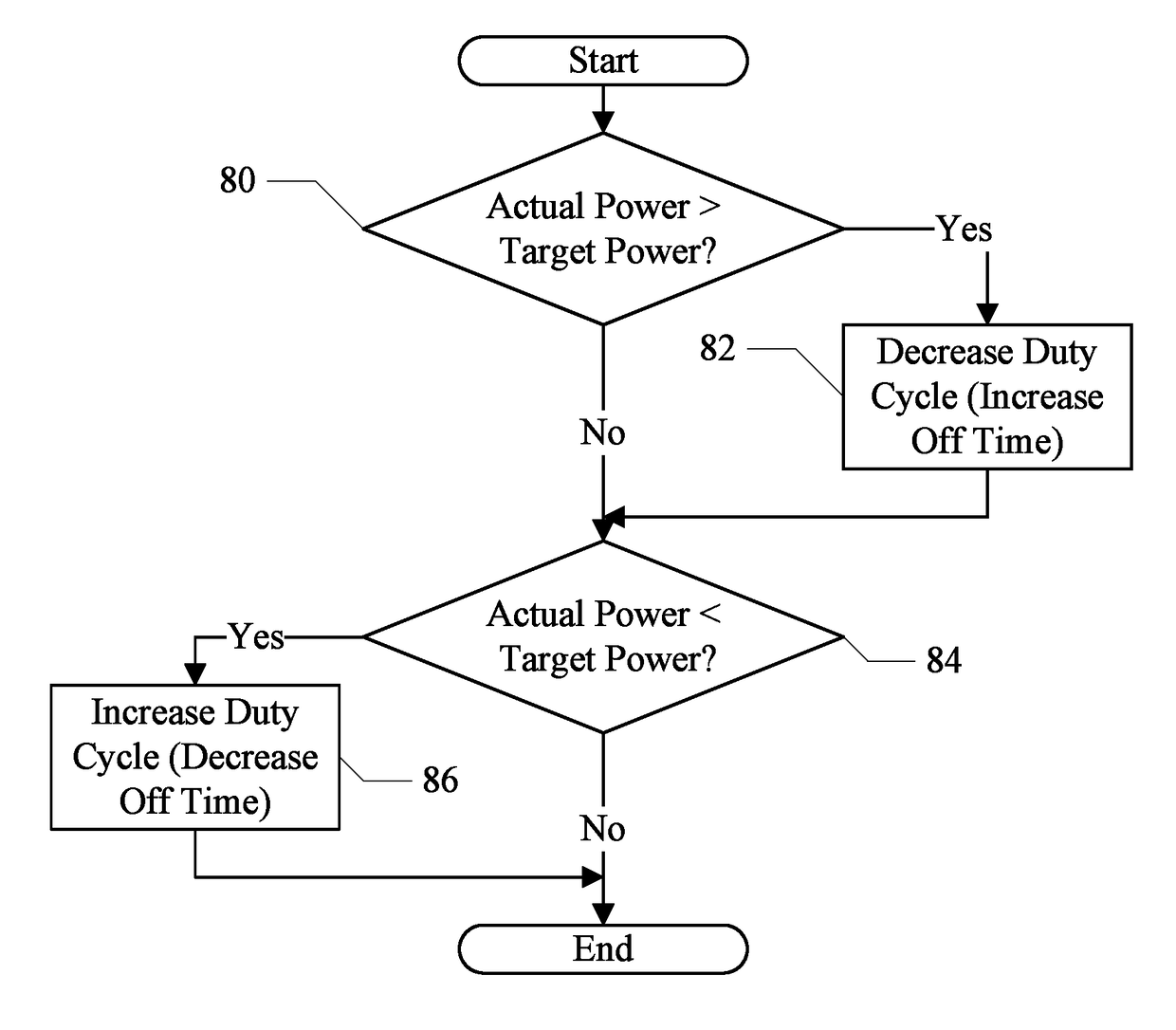

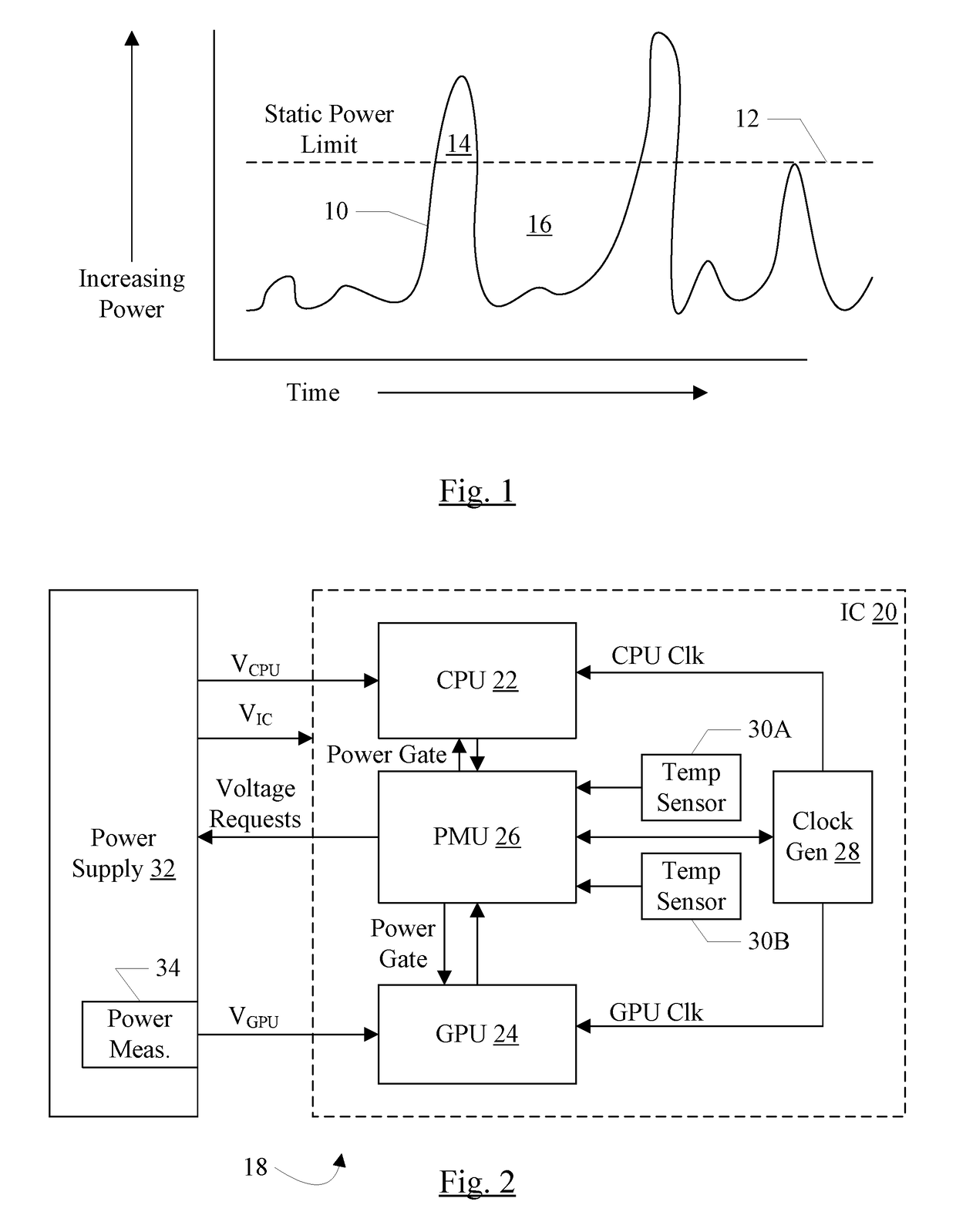

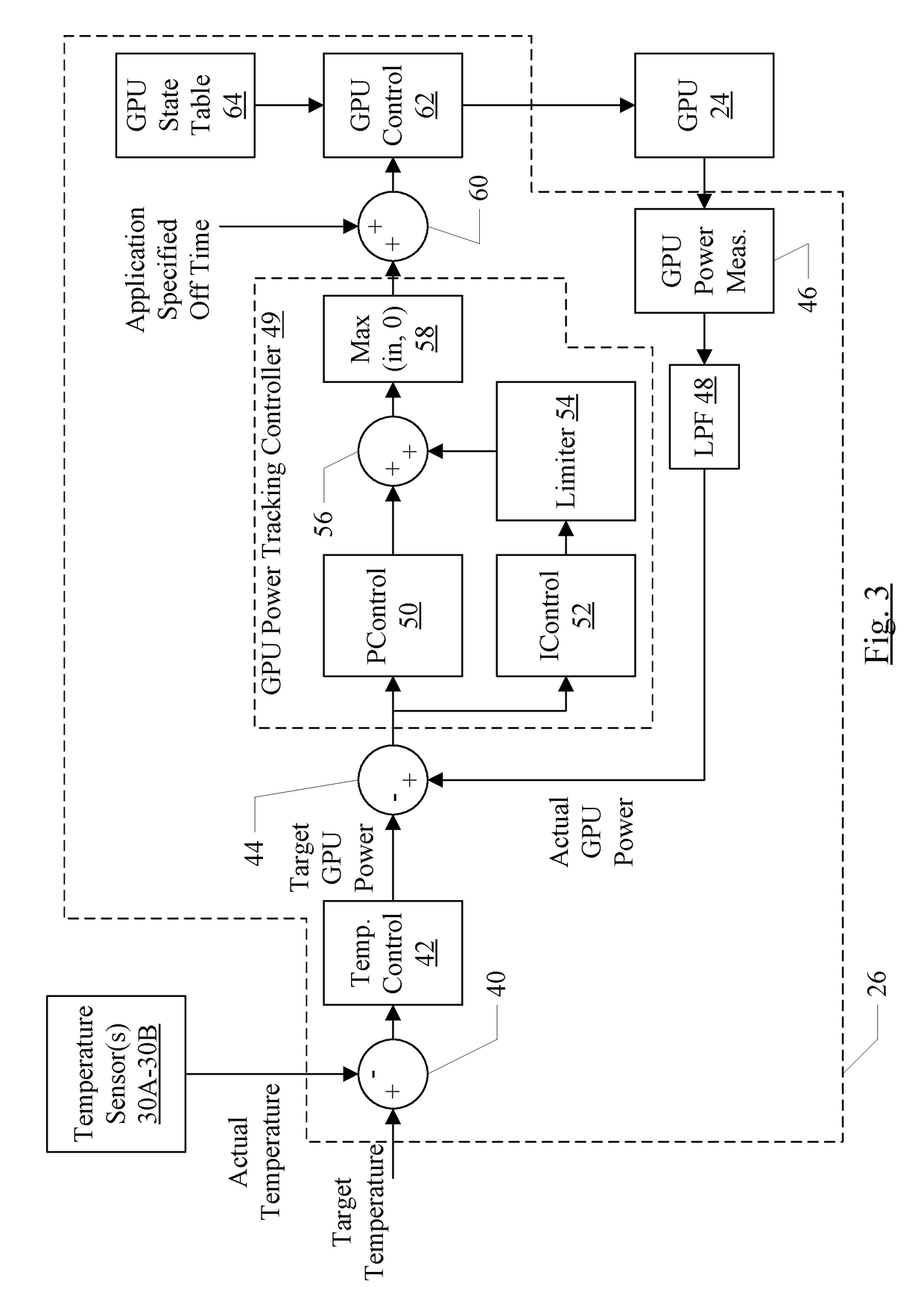

Power management for a graphics processing unit or other circuit

ActiveUS8924752B1Reduce duty cycleReduce utilizationDigital data processing detailsEnergy efficient computingElectricityGraphics

In one embodiment, a system includes power management control that controls a duty cycle of a processor to manage power. The duty cycle may be the amount of time that the processor is powered on as a percentage of the total time. By frequently powering up and powering down the processor during a period of time, the power consumption of the processor may be controlled while providing the perception that the processor is continuously available. For example, the processor may be a graphics processing unit (GPU), and the period of time over which the duty cycle is managed may be a frame to be displayed on the display screen viewed by a user of the system.

Owner:APPLE INC

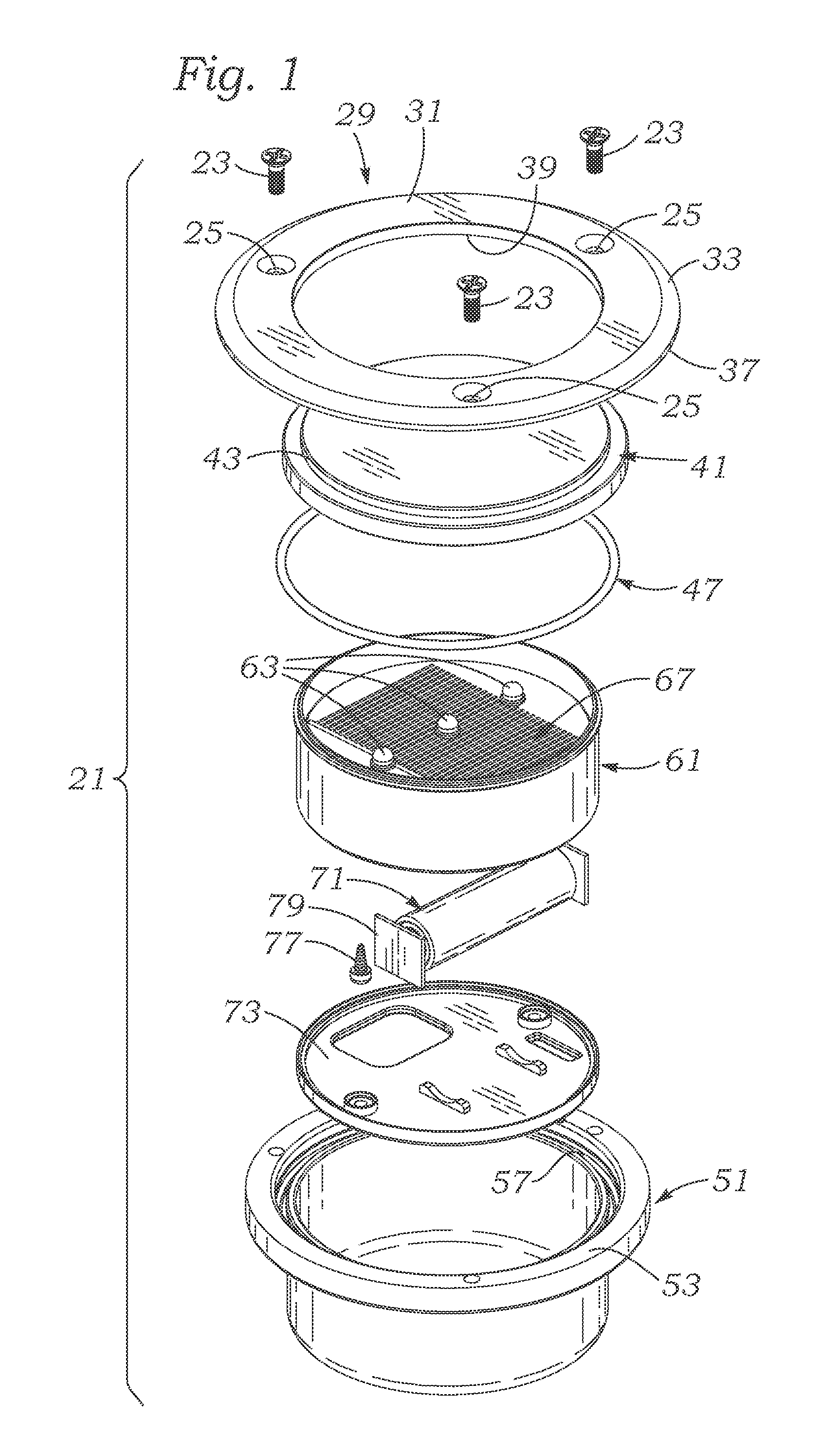

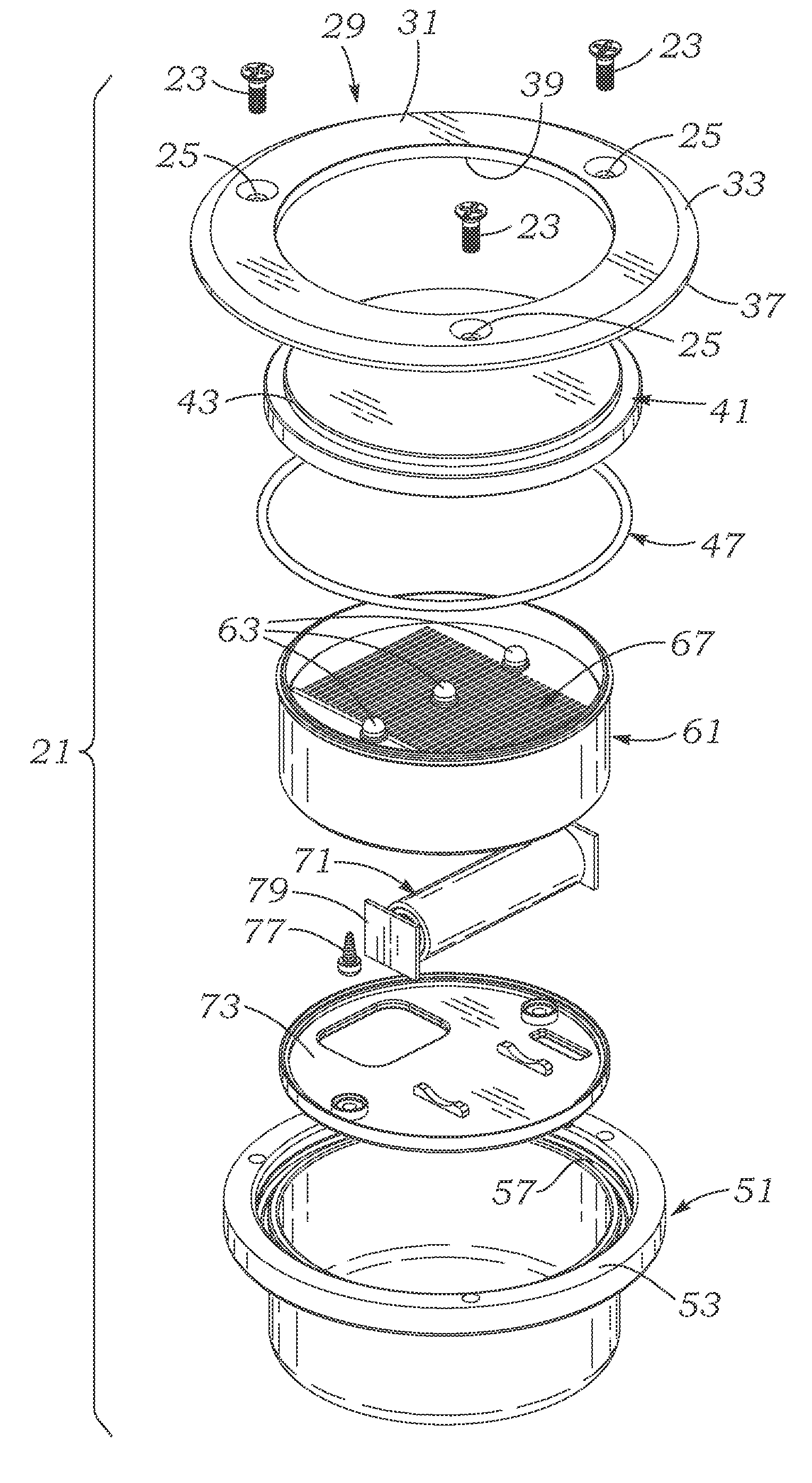

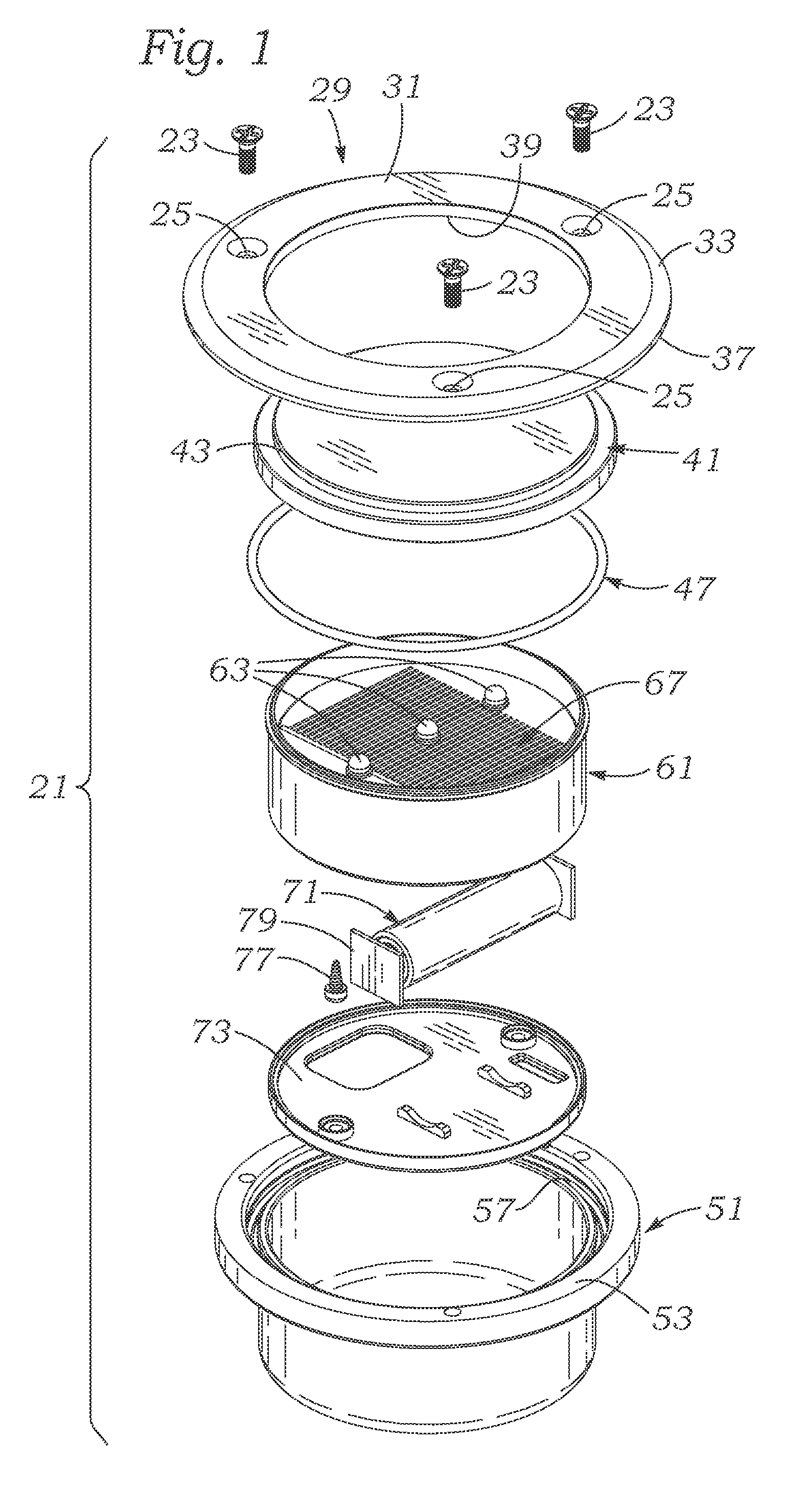

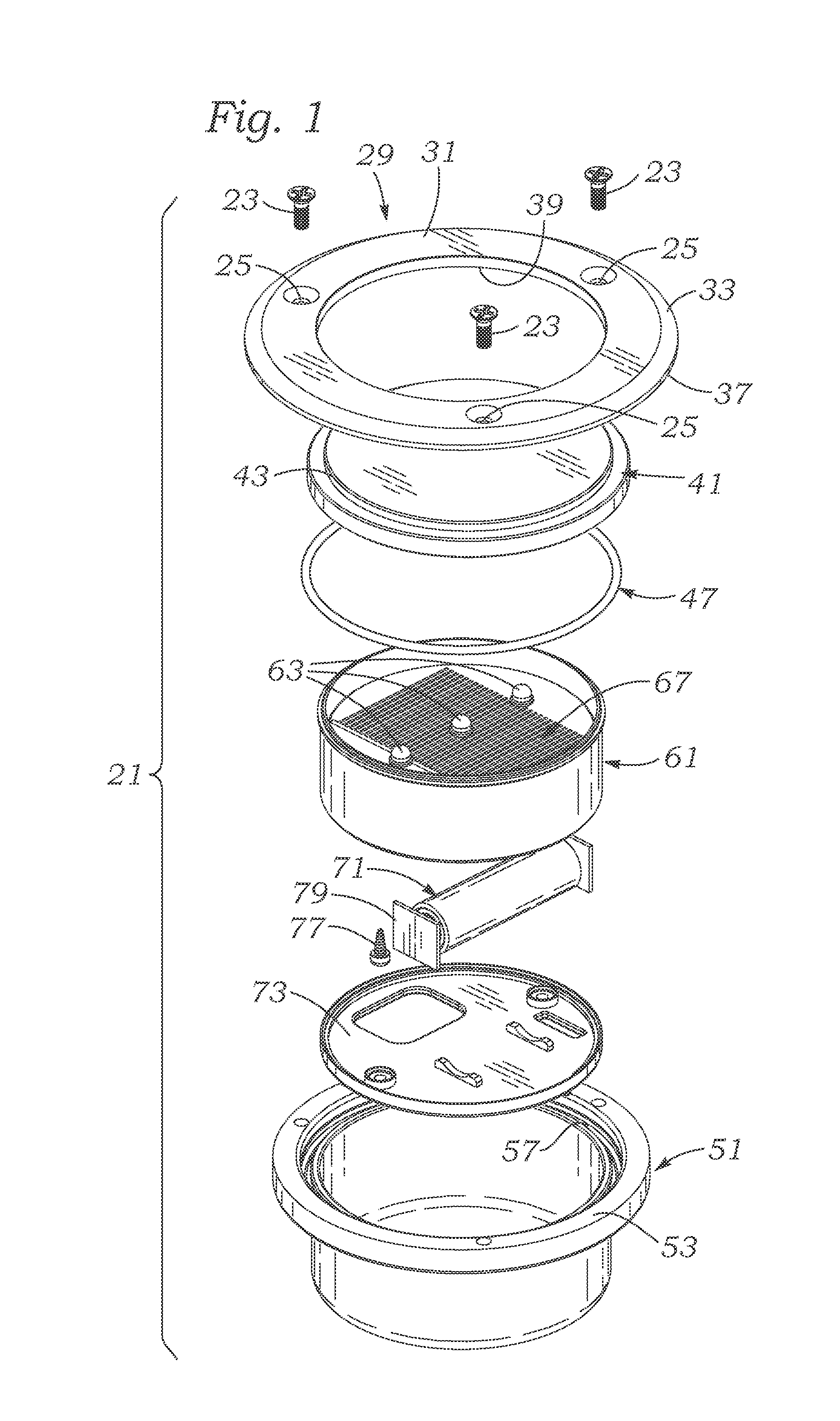

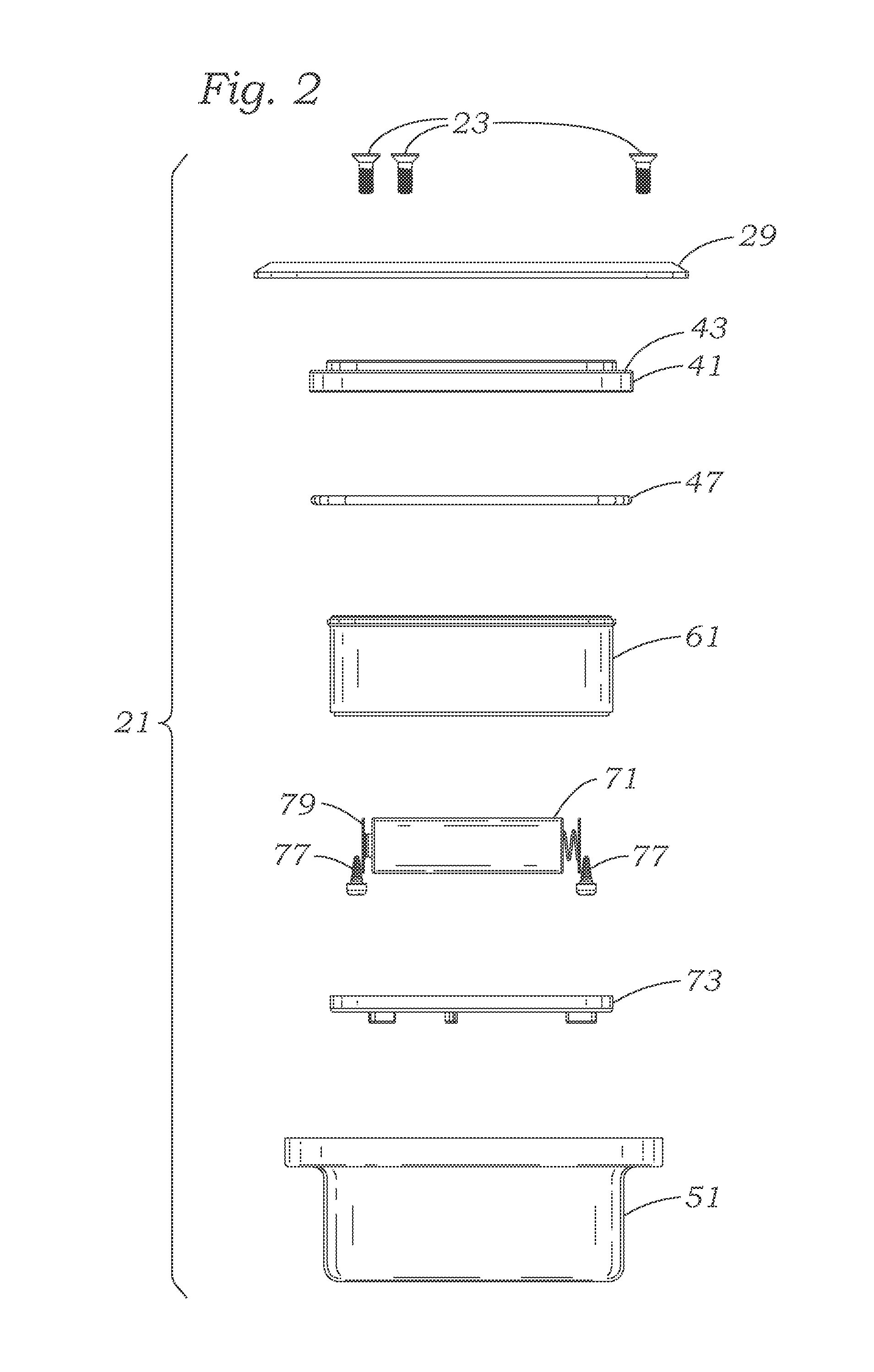

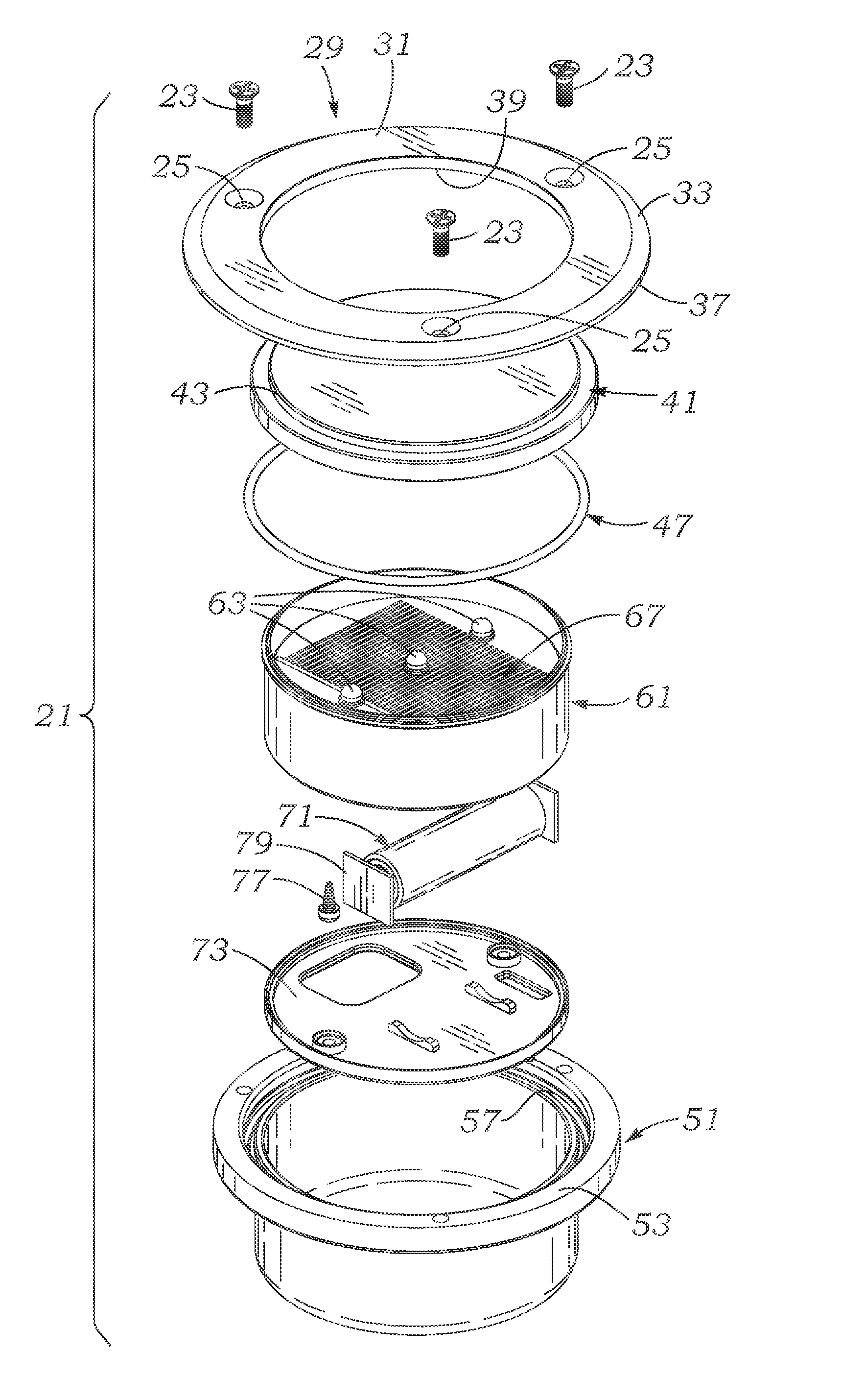

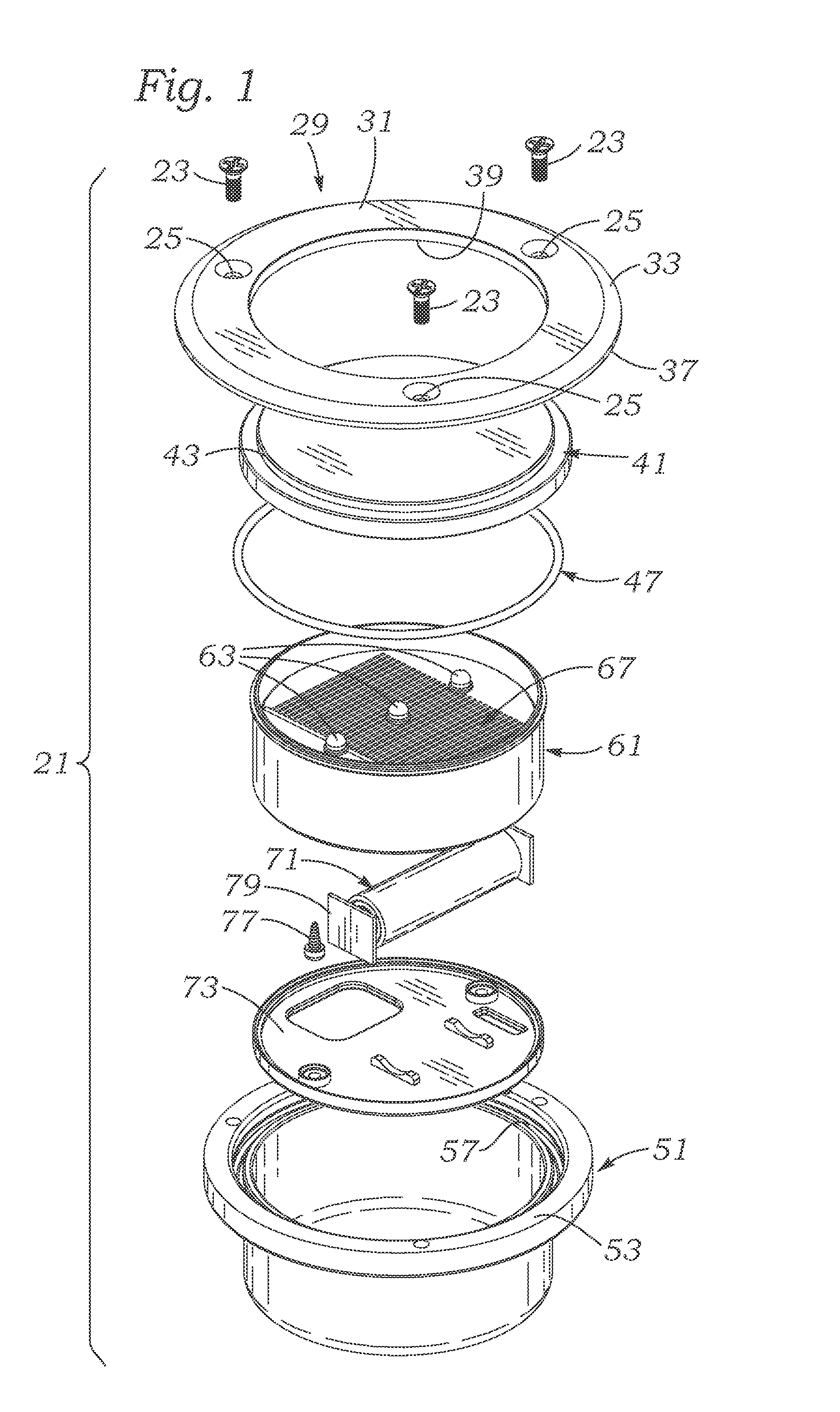

Solar Powered Ground Light

InactiveUS20140218900A1Easy to seeSure easyWith electric batteriesElectric lighting with built-in generatorsSynthetic materialsLow voltage

A solar powered ground lights is typically mounted in a walkway, pathway, pool deck, roadway, park pathway, either in cement, wood, synthetic materials, or otherwise, and are ideally suited for use in walls, ceilings, and pool or dock areas because they are readily mounted from the top, requiring only a cylindrical depression and possibly three screws for mounting and require no external wiring. The solar powered ground lights are also low voltage and safe. Illumination of the Solar powered ground lights is provided by a Solar Powered system utilizing Light Emitting Diodes (LEDs), or an electro-illuminescent Lighting system backed up with a solar powered circuit for the rechargeable battery. This provides for an illumination system capable if providing ease if view for pedestrians as well as illuminating roadways. The system may be fully IP68 waterproof rated.

Owner:HERMAN N PHILHOWER AS TRUSTEE OF THE H N PHILHOWER FAMILY TRUST LAST DATED OCTOBER 31 2012

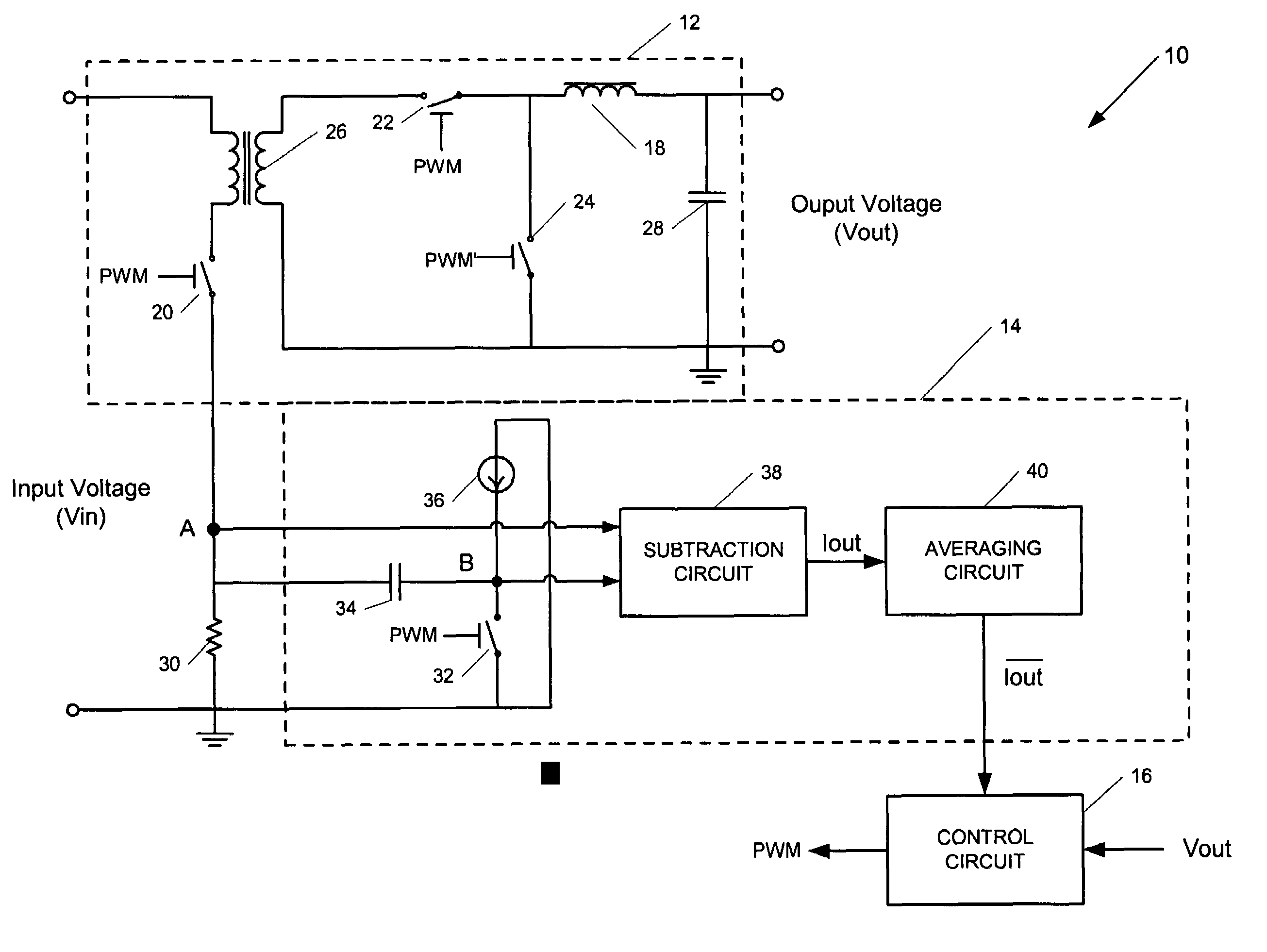

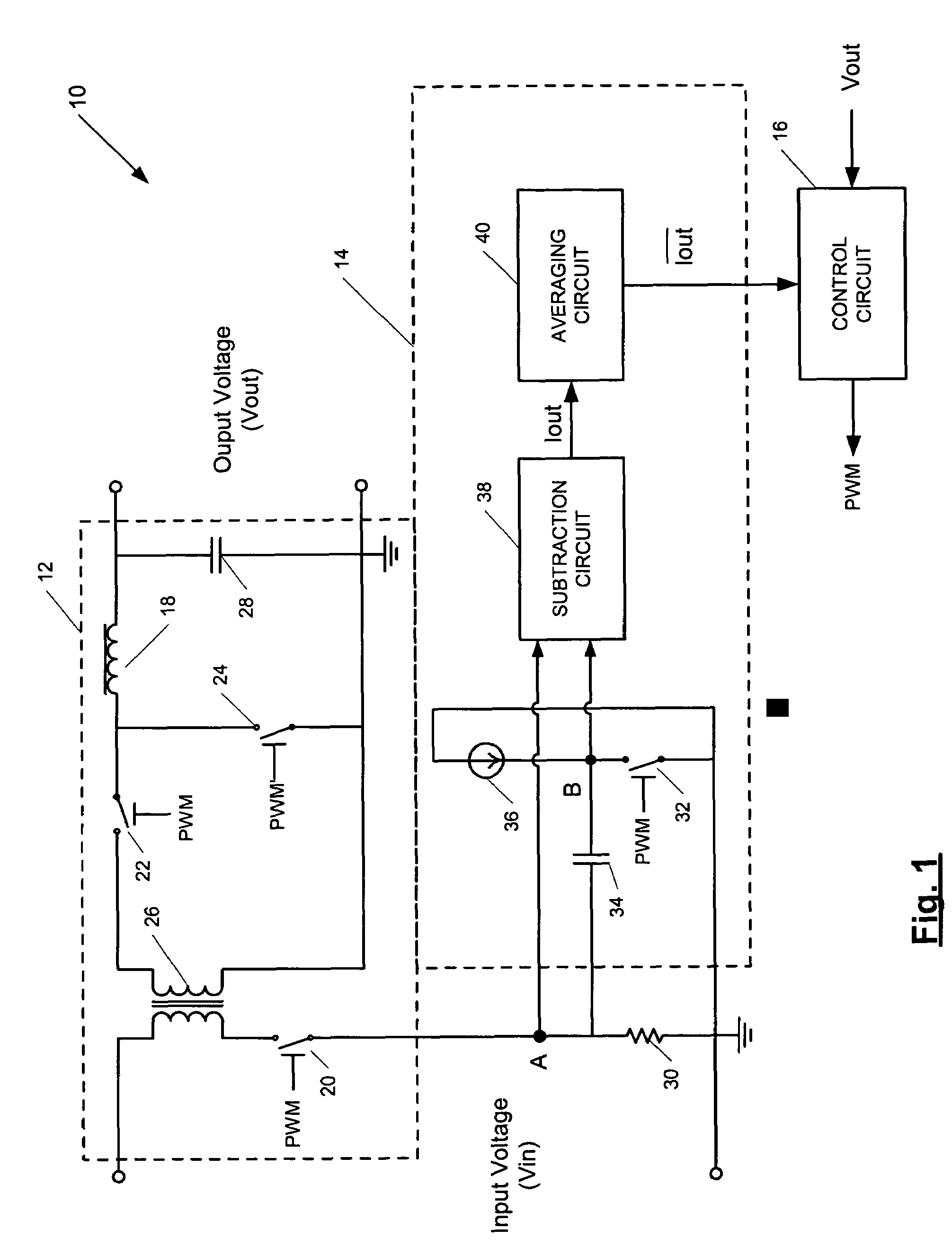

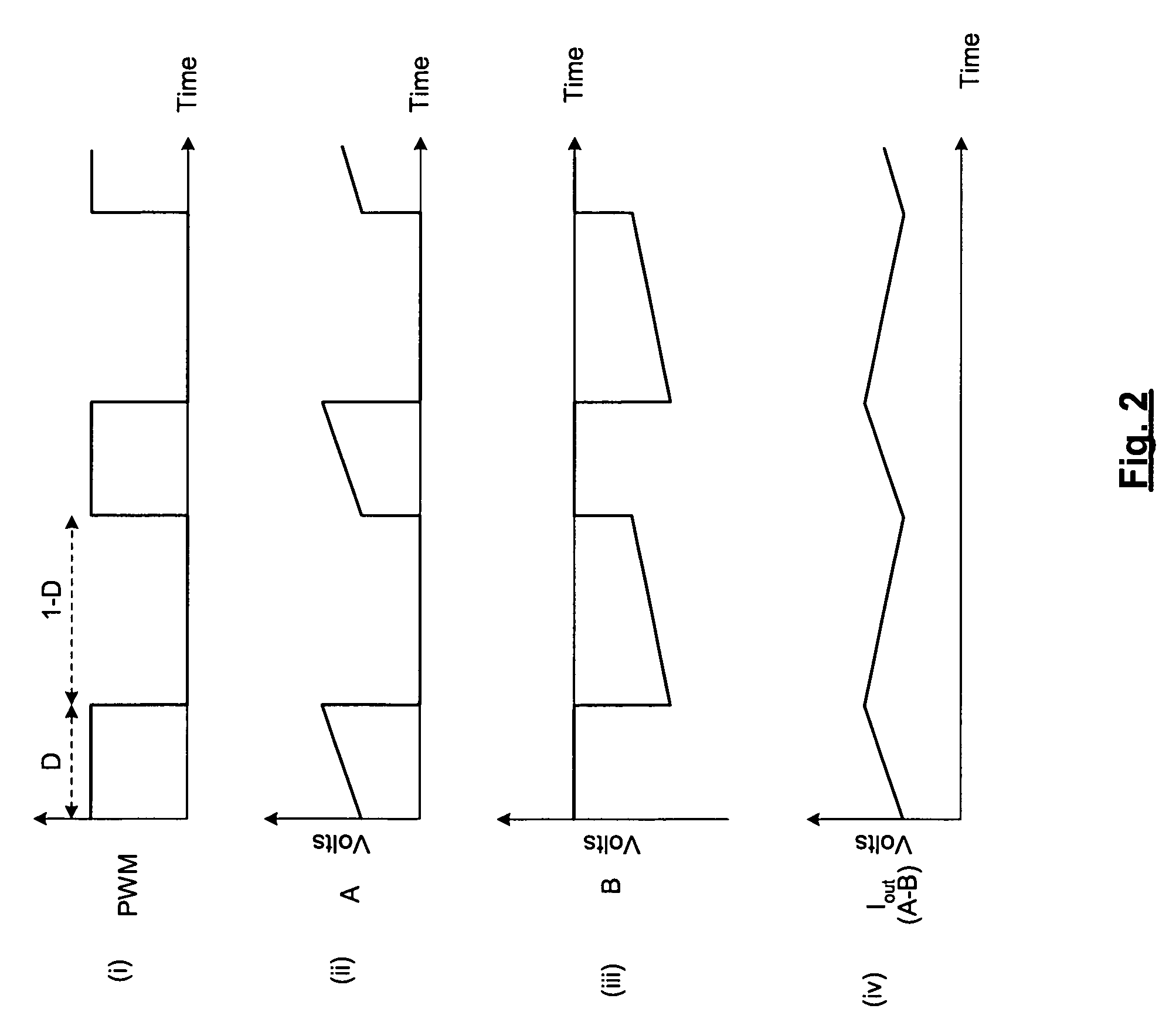

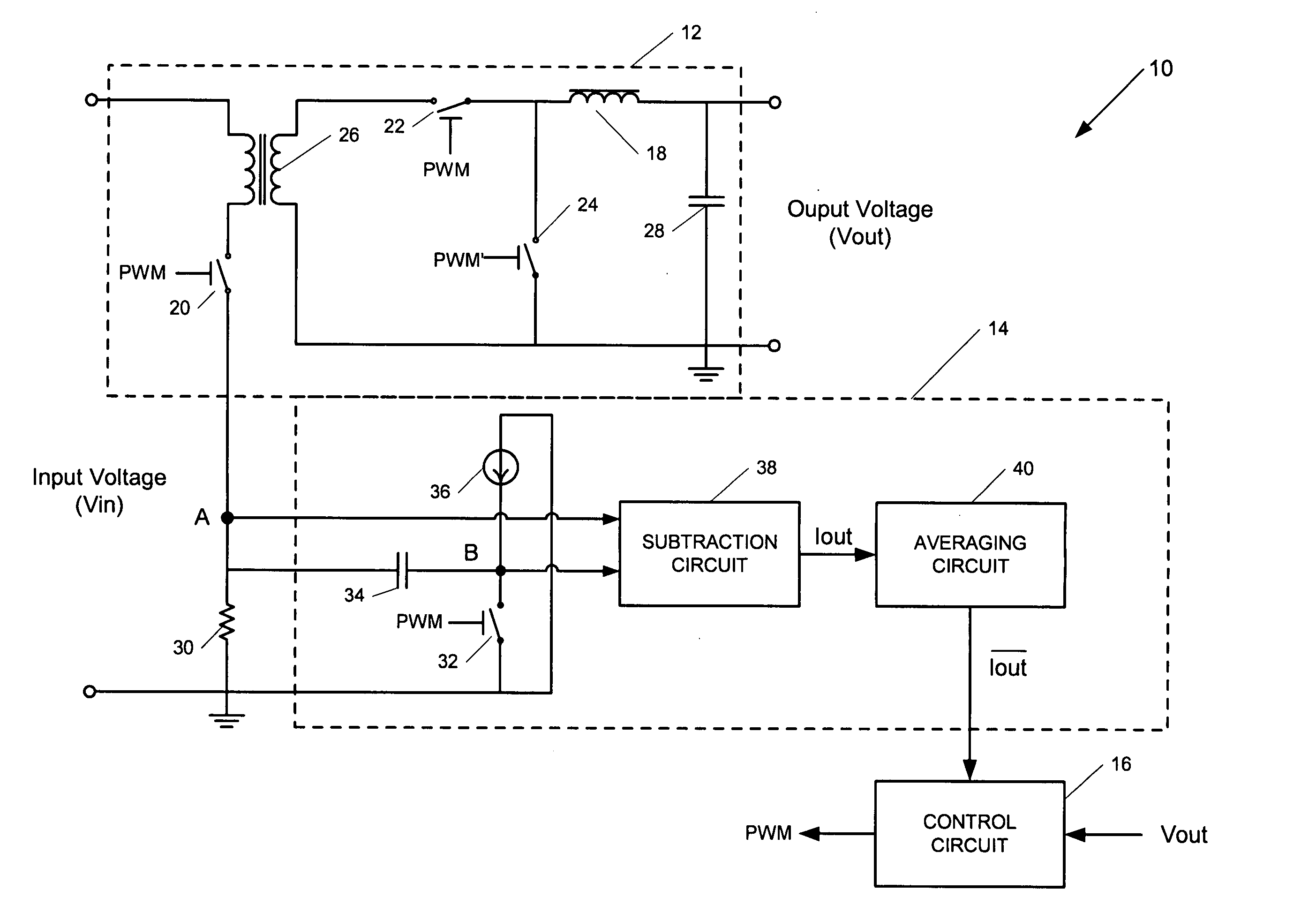

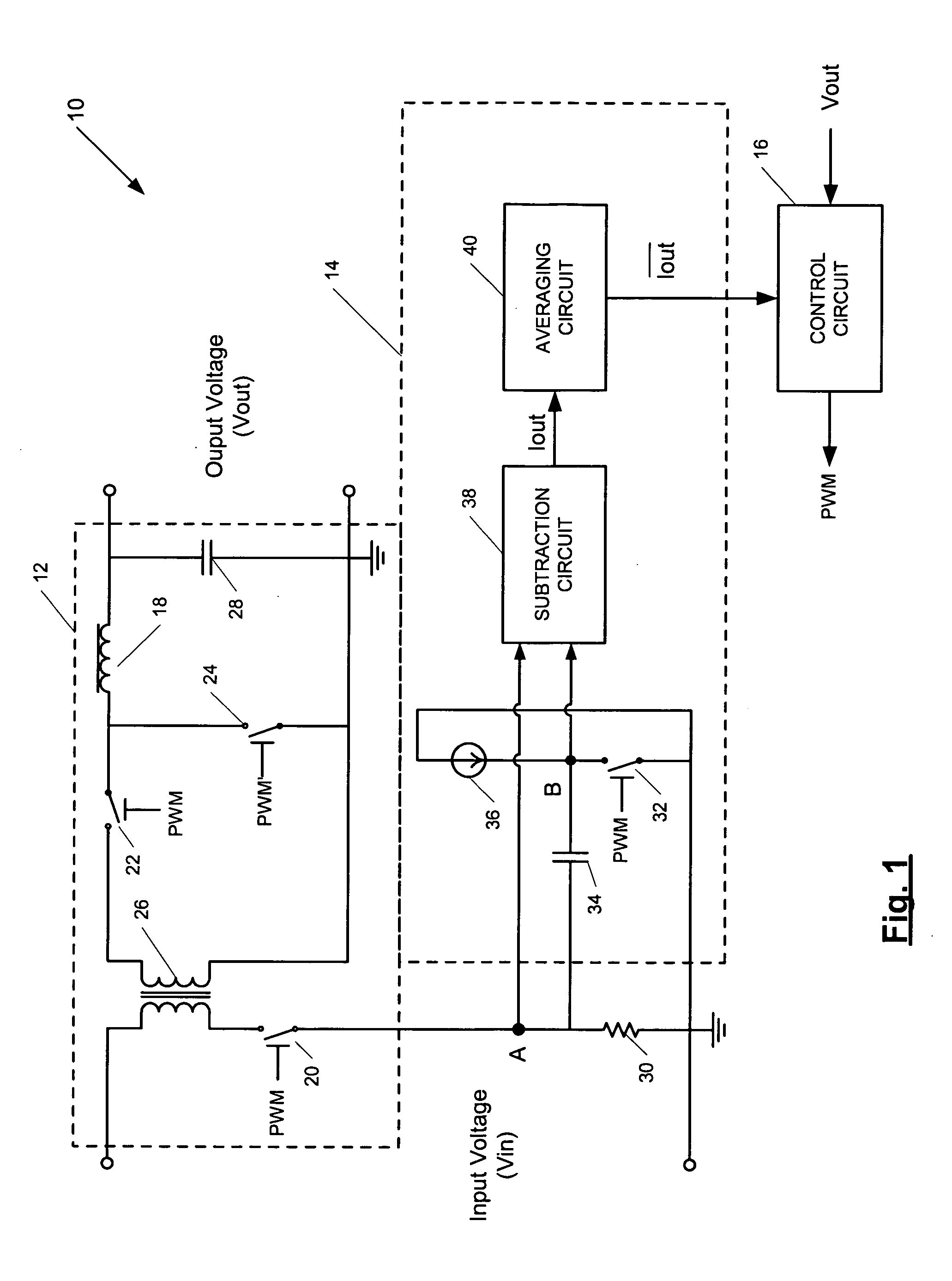

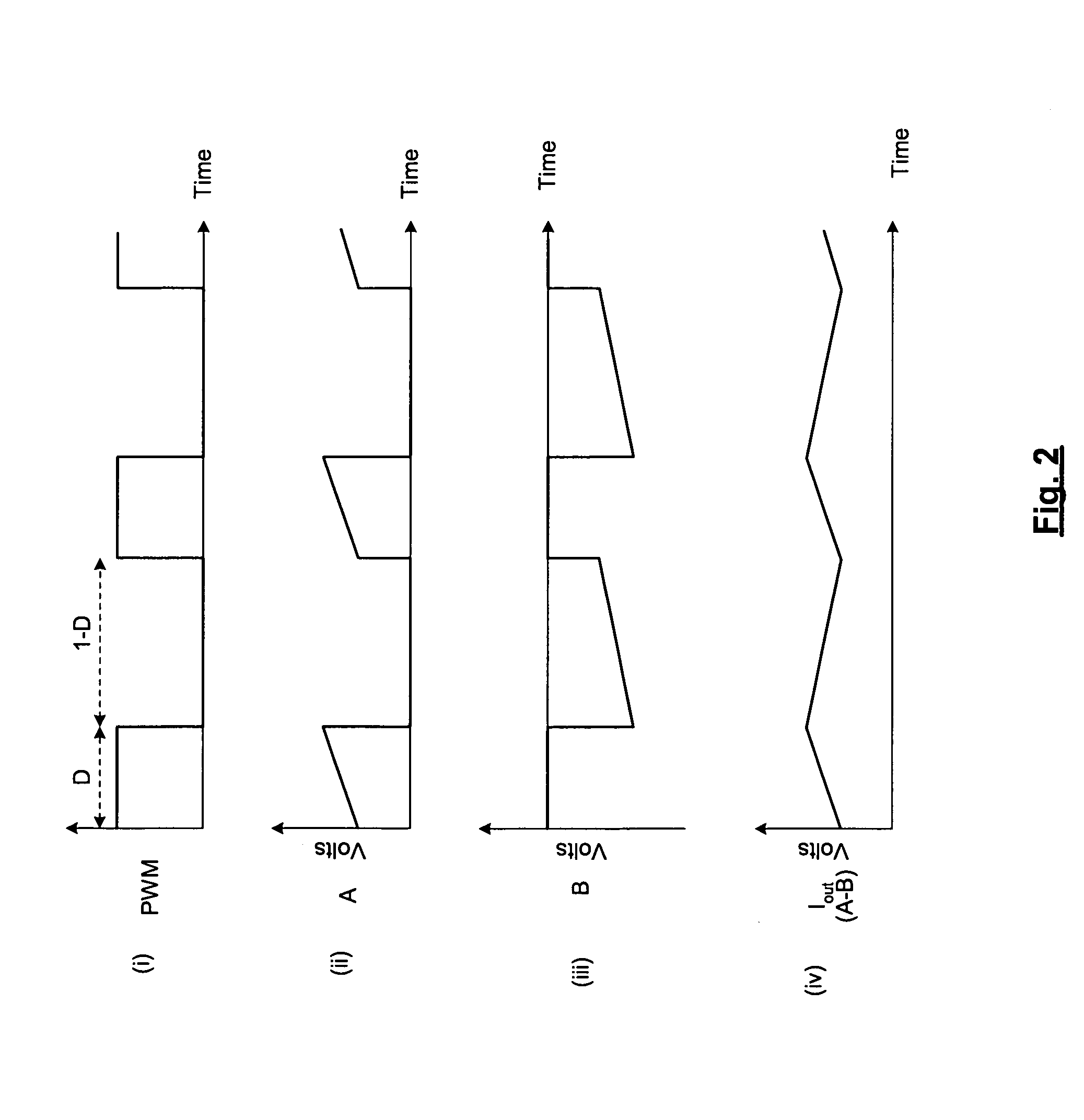

Current limit circuit and power supply including same

ActiveUS7254044B2Reduce duty cycleAc-dc conversion without reversalConversion with intermediate conversion to dcTime segmentControl signal

The present invention is directed generally to a power supply. According to various embodiments, the power supply includes at least one DC / DC converter. The converter includes a primary switch controlled by a pulse width modulated control signal such that the primary switch is on for a D time period of each switching cycle of the converter and is off for a 1-D time period of each switching cycle. Also, the power supply includes a current sensing element connected in series with the primary switch. In addition, the power supply includes a current limit circuit connected to the current sensing element. The current limit circuit includes a functional circuit having a first input responsive to a first signal whose voltage is proportional to the output current of the converter during the D time period of the switching cycle of the converter. A second input of the functional circuit is responsive to a second signal whose voltage is proportional to the output current of the converter during the 1-D time period of the switching cycle of the converter. In that way, the voltage of the output signal of the functional circuit is proportional to the output inductor current of the converter over both the energy storage phase (the D interval) and the energy deliver phase (the 1-D) interval of the converter.

Owner:ARTESYN TECH

Thermal Limited Backlight Driver

InactiveUS20070195024A1Reduce thermal stressOvercome disadvantagesStatic indicating devicesElectroluminescent light sourcesFault current limiterControl circuit

A system for powering and controlling an LED backlight, the system comprising: a control circuitry; a plurality of LED strings; a pulse width modulation functionality associated with the control circuitry and arranged to pulse width modulate a current flow through each of the plurality of LED strings; and a plurality of current limiters responsive to the control circuitry, each of the plurality of current limiters being associated with a particular one of the plurality of LED strings and operative to limit current flow of the pulse width modulated current there-through, the control circuitry being operative in the event of a thermal condition of one of the plurality of current limiters to reduce a duty cycle of the pulse width modulation functionality of the current flow through the one of the plurality of current limiters.

Owner:POLARIS POWERLED TECH LLC

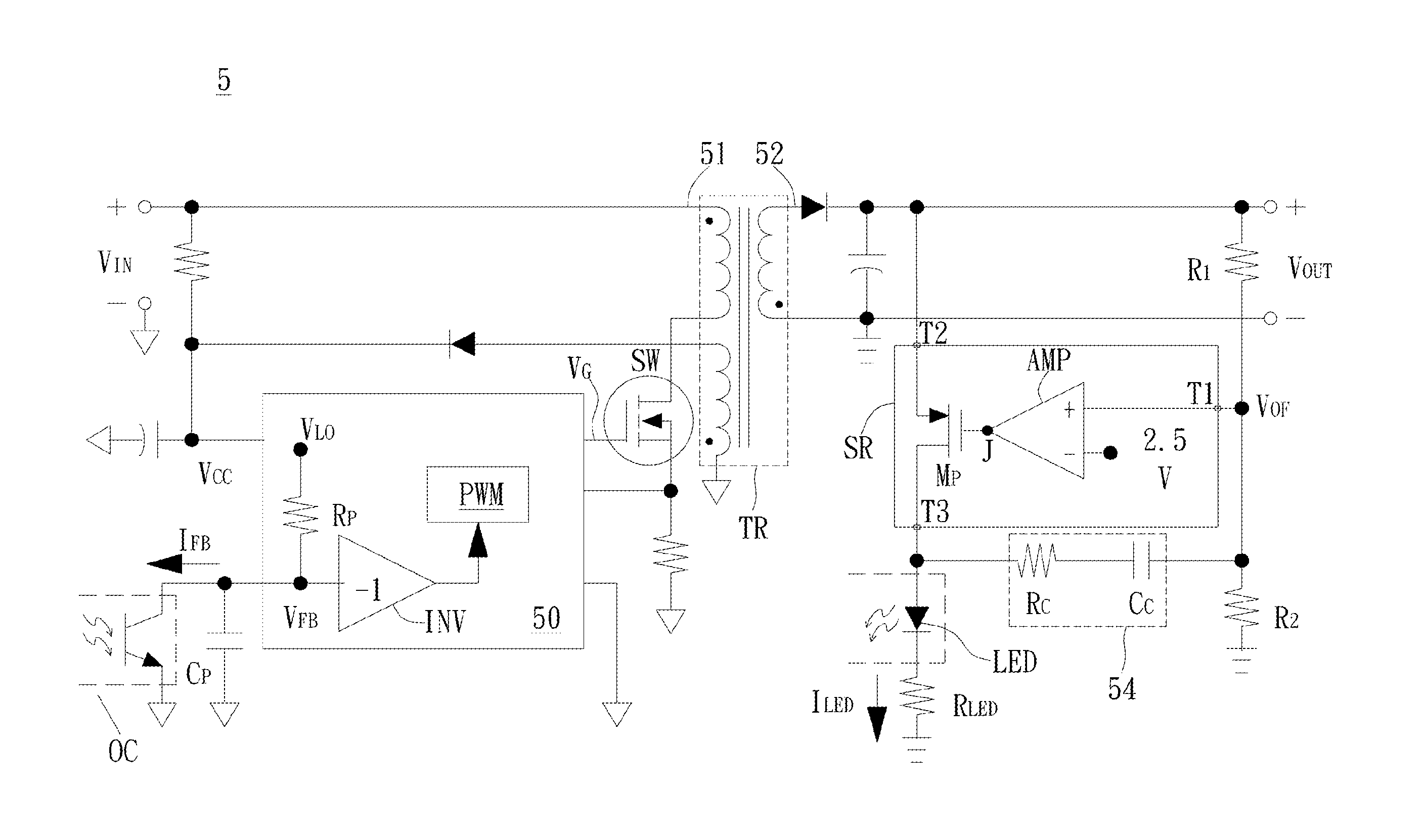

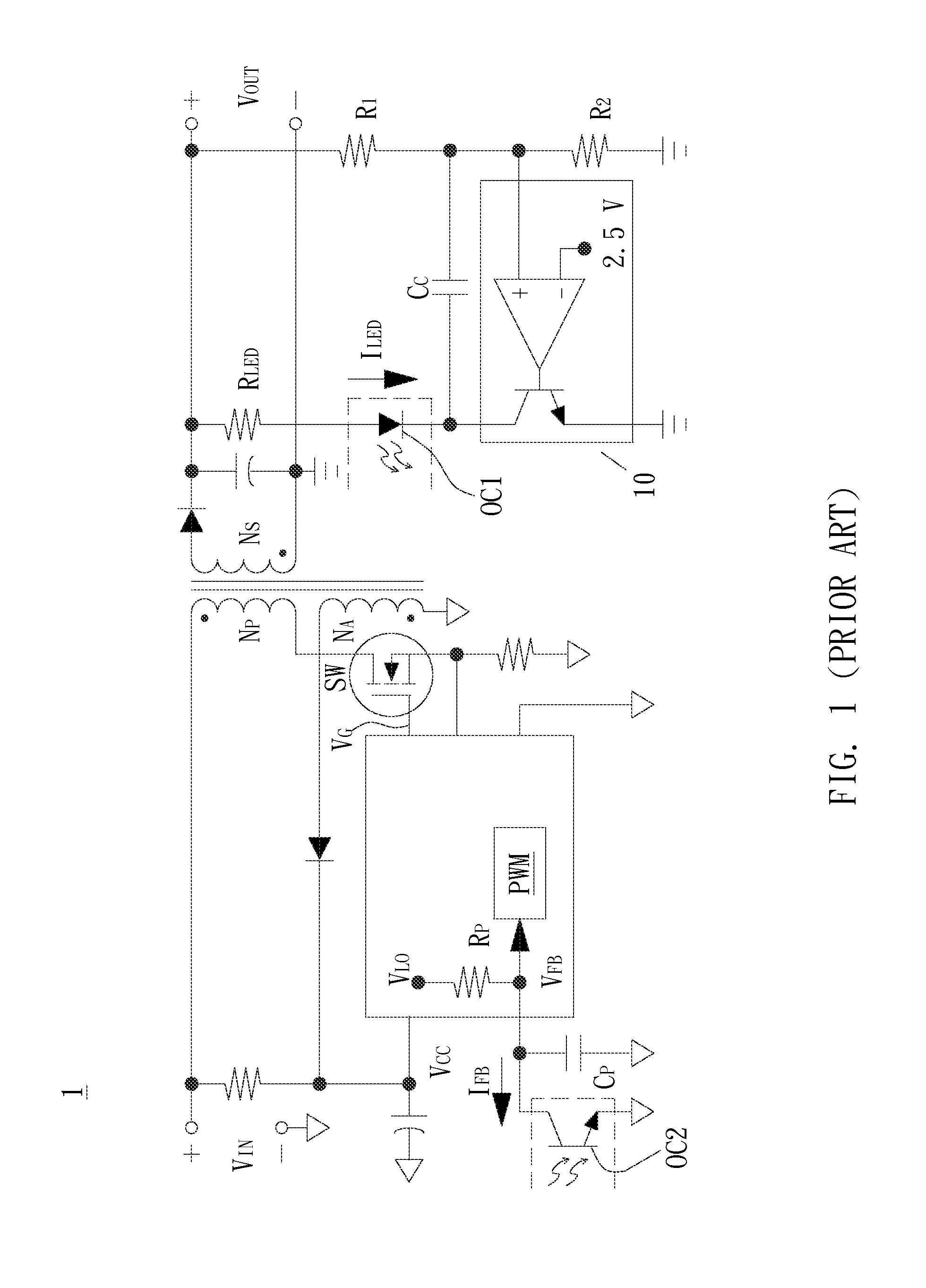

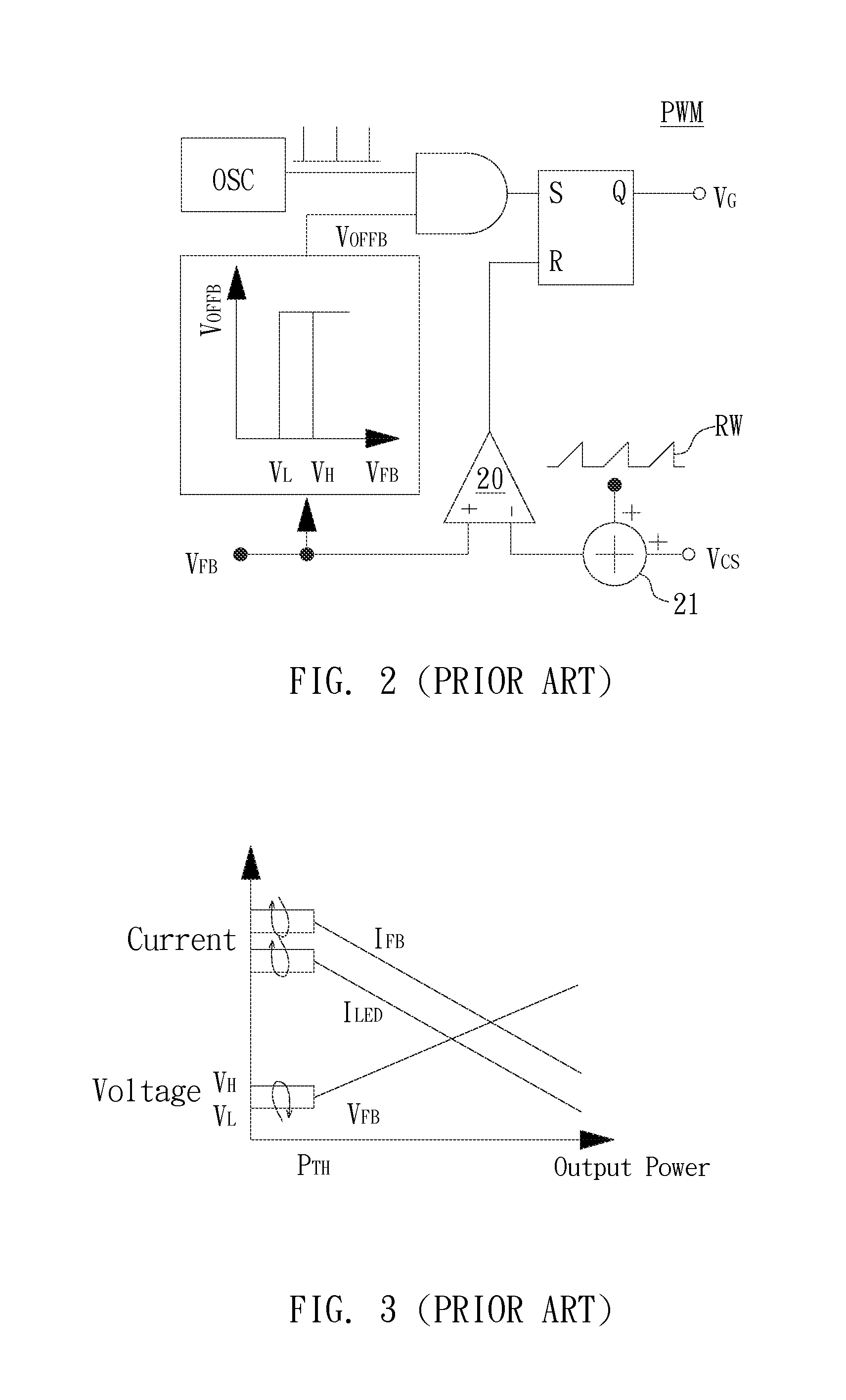

Isolated power converter, inverting type shunt regulator, and operating method thereof

InactiveUS20140140107A1Decreasing opto-coupling currentEnhanced feedback voltageEfficient power electronics conversionDc-dc conversionMOSFETPower flow

An isolated power converter, an inverting type shunt regulator, and an operating method thereof are disclosed. The isolated power converter includes a transformer, an inverting type shunt regulator, a controller, and an optocoupler. The inverting type shunt regulator is located on the secondary side of the transformer. The inverting type shunt regulator includes an error amplifier and a MOSFET. The controller is located on the primary side of the transformer. The controller includes an inverting unit cooperated with the MOSFET. The controller receives a feedback voltage. The optocoupler is coupled to the inverting type shunt regulator and the controller to provide an opto-coupling current to the controller.

Owner:NOVELTEK SEMICON CORP

Current limit circuit and power supply including same

ActiveUS20060152203A1Reduce duty cycleAc-dc conversion without reversalConversion with intermediate conversion to dcInductorSwitching cycle

The present invention is directed generally to a power supply. According to various embodiments, the power supply includes at least one DC / DC converter. The converter includes a primary switch controlled by a pulse width modulated control signal such that the primary switch is on for a D time period of each switching cycle of the converter and is off for a 1-D time period of each switching cycle. Also, the power supply includes a current sensing element connected in series with the primary switch. In addition, the power supply includes a current limit circuit connected to the current sensing element. The current limit circuit includes a functional circuit having a first input responsive to a first signal whose voltage is proportional to the output current of the converter during the D time period of the switching cycle of the converter. A second input of the functional circuit is responsive to a second signal whose voltage is proportional to the output current of the converter during the 1-D time period of the switching cycle of the converter. In that way, the voltage of the output signal of the functional circuit is proportional to the output inductor current of the converter over both the energy storage phase (the D interval) and the energy deliver phase (the 1-D) interval of the converter.

Owner:ARTESYN TECH

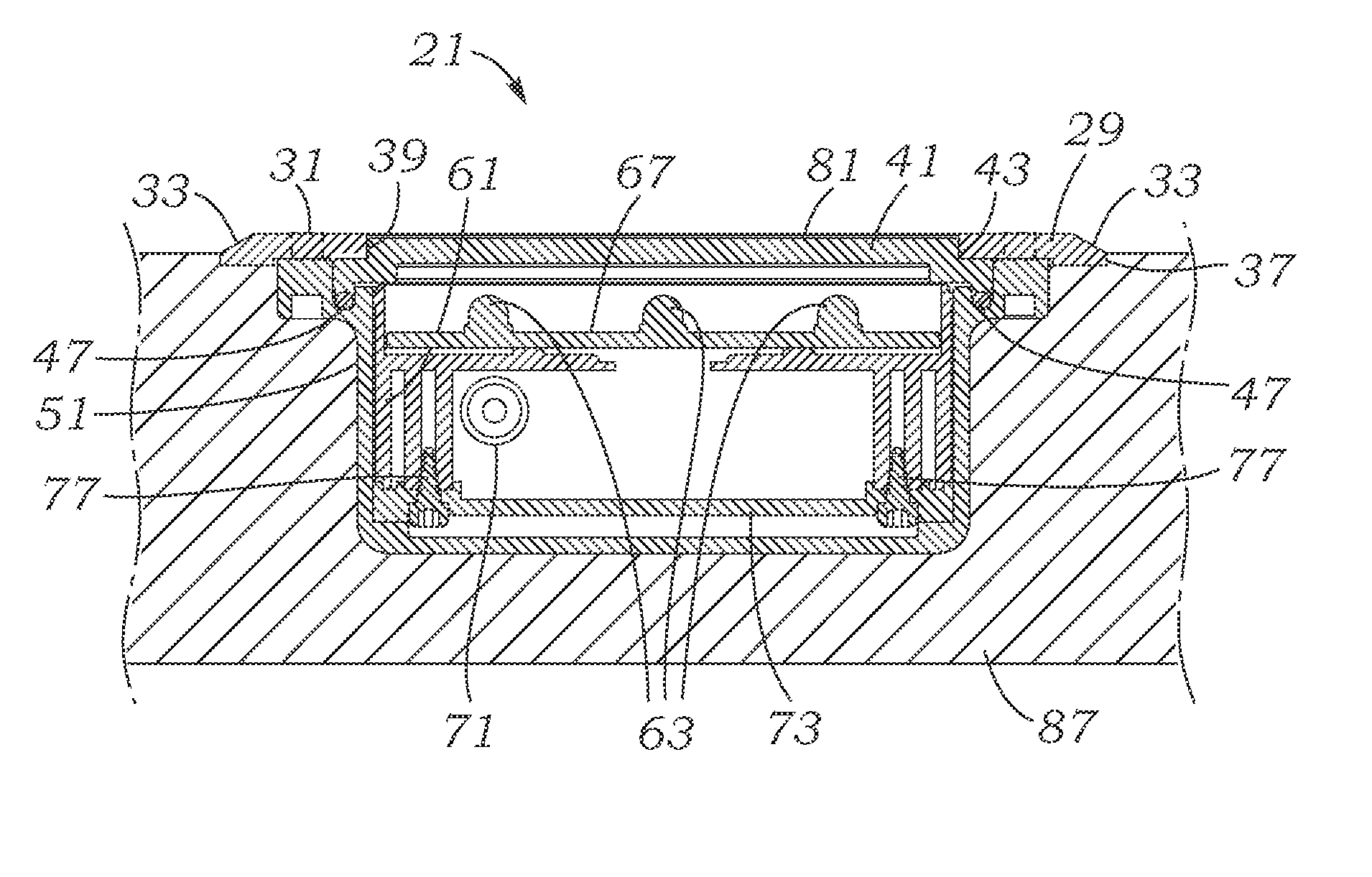

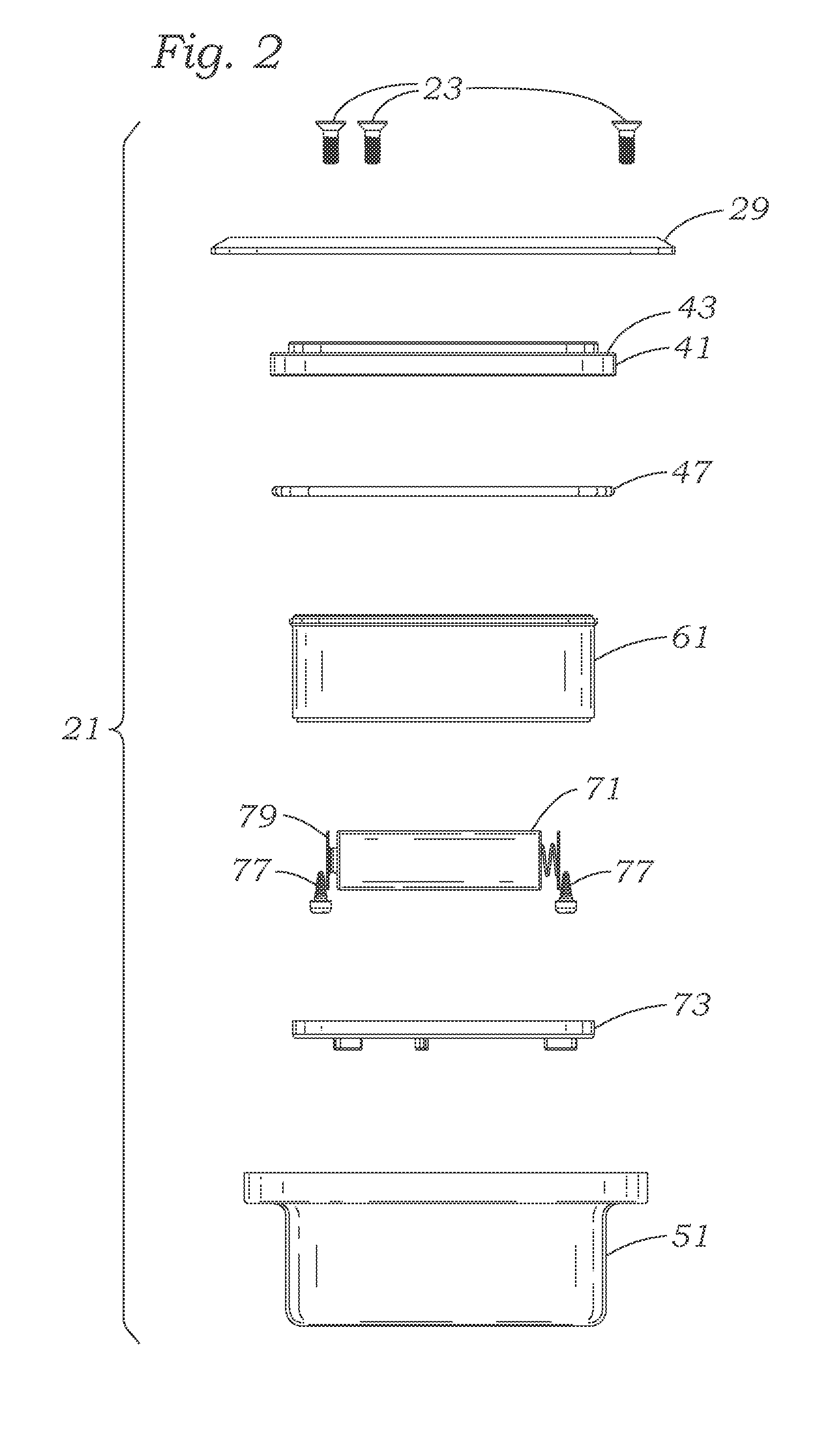

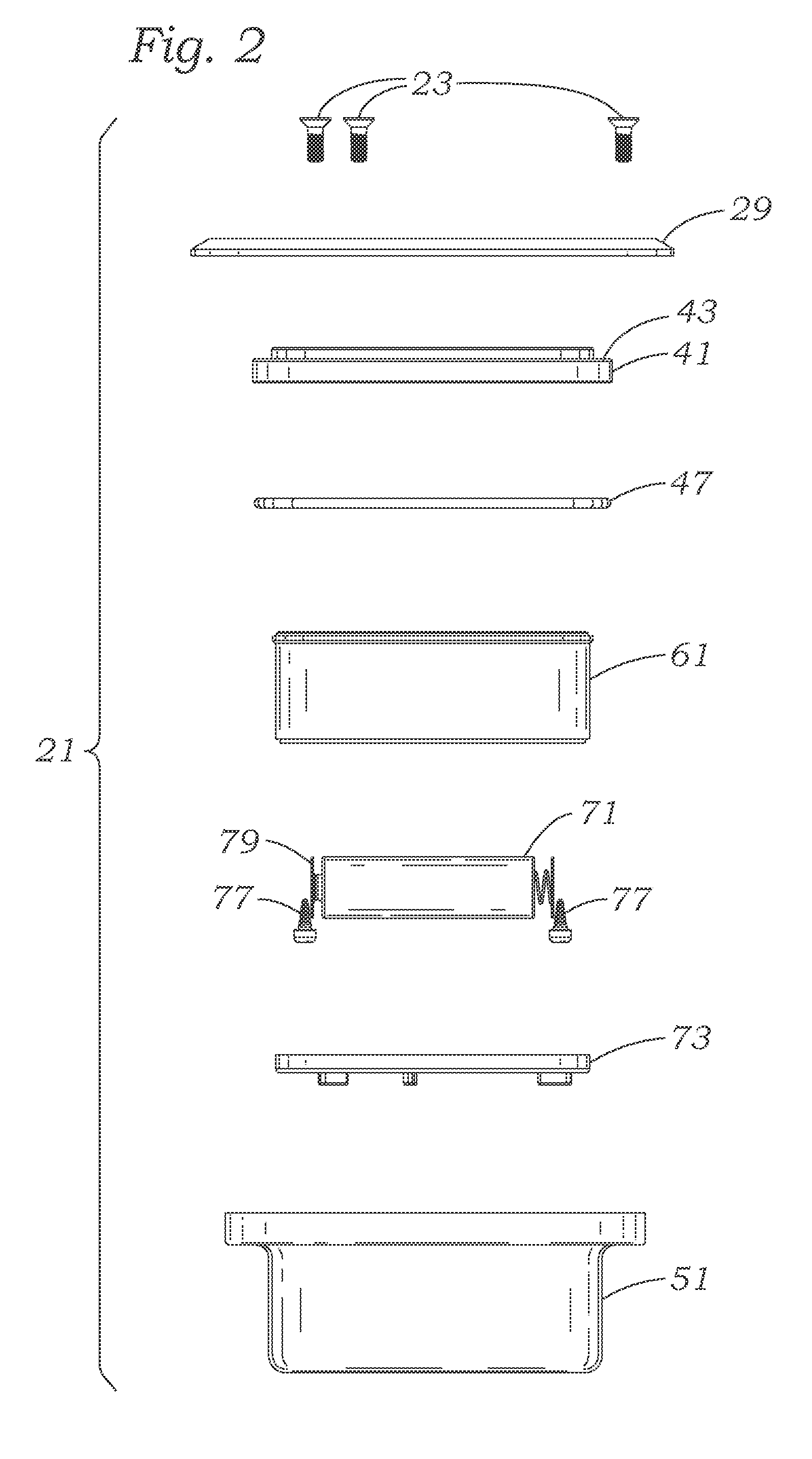

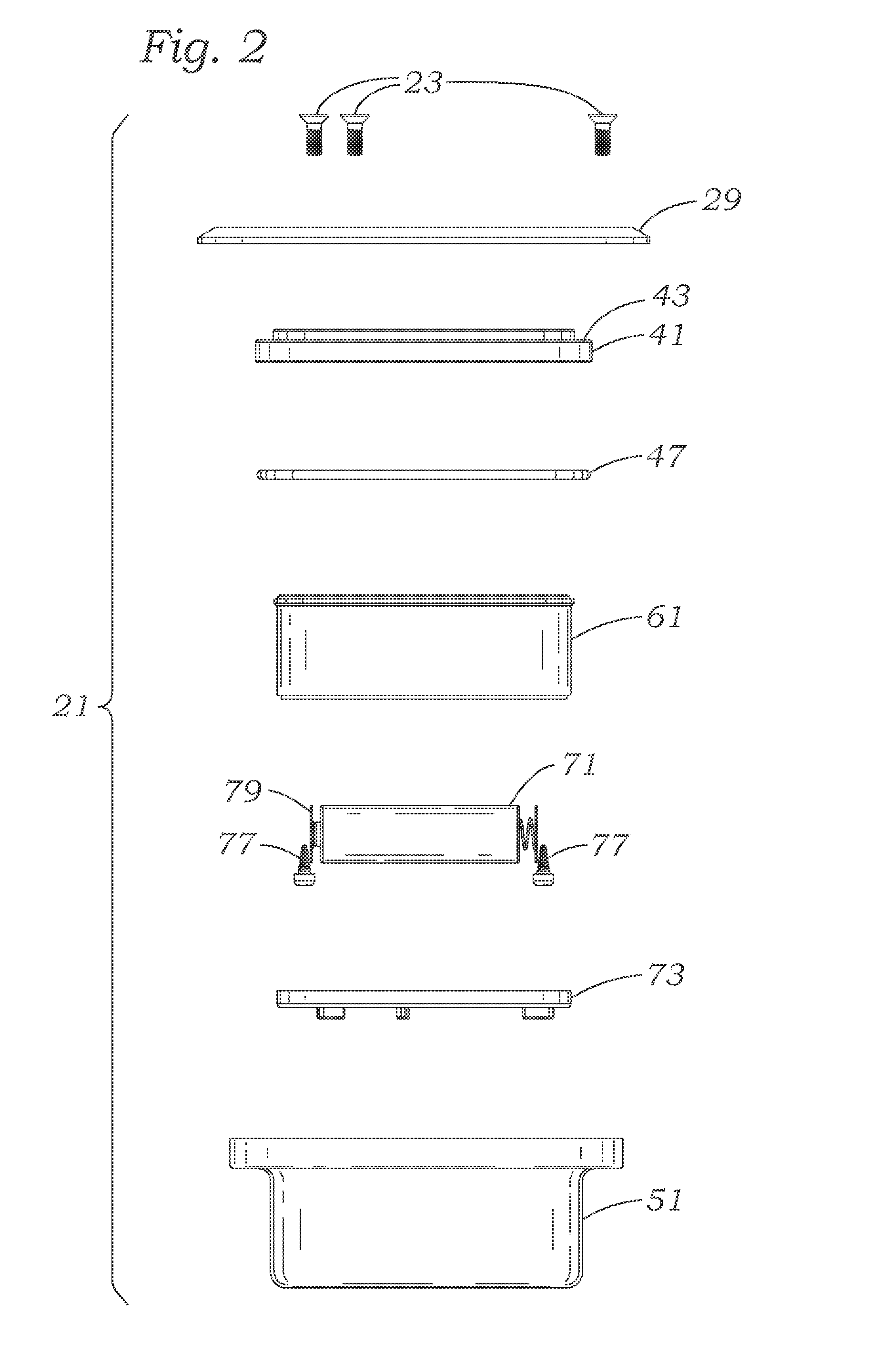

Solar powered ground light

InactiveUS9175821B2Readily mount flushReduce duty cycleElectric circuit arrangementsGas-tight/water-tight arrangementsSynthetic materialsLow voltage

A solar powered ground lights is typically mounted in a walkway, pathway, pool deck, roadway, park pathway, either in cement, wood, synthetic materials, or otherwise, and are ideally suited for use in walls, ceilings, and pool or dock areas because they are readily mounted from the top, requiring only a cylindrical depression and possibly three screws for mounting and require no external wiring. The solar powered ground lights are also low voltage and safe. Illumination of the Solar powered ground lights is provided by a Solar Powered system utilizing Light Emitting Diodes (LEDs), or an electro-illuminescent Lighting system backed up with a solar powered circuit for the rechargeable battery. This provides for an illumination system capable if providing ease if view for pedestrians as well as illuminating roadways. The system may be fully IP68 waterproof rated.

Owner:HERMAN N PHILHOWER AS TRUSTEE OF THE H N PHILHOWER FAMILY TRUST LAST DATED OCTOBER 31 2012

Solar powered ground light

InactiveUS9273841B2Easy to installReduce duty cycleElectric circuit arrangementsWith built-in powerLow voltageSynthetic materials

A solar powered ground lights is typically mounted in a walkway, pathway, pool deck, roadway, park pathway, either in cement, wood, synthetic materials, or otherwise, and are ideally suited for use in walkways, walls, ceilings, and pool or dock areas because they are readily mounted from the top, requiring only a cylindrical depression and possibly three screws for mounting and require no external wiring. The solar powered ground lights are LED or electro-illuminescent or similar type, supported close to a lens for a good low angle view factor and are low voltage and safe. A solar panel recharges the battery. The system may be fully IP68 waterproof rated.

Owner:HERMAN N PHILHOWER AS TRUSTEE OF THE H N PHILHOWER FAMILY TRUST LAST DATED OCTOBER 31 2012

Solar Powered Ground Light

InactiveUS20160025287A1Easy to installReduce duty cycleWith electric batteriesElectric lighting with built-in generatorsLow voltageSynthetic materials

A solar powered ground lights is typically mounted in a walkway, pathway, pool deck, roadway, park pathway, either in cement, wood, synthetic materials, or otherwise, and are ideally suited for use in walkways, walls, ceilings, and pool or dock areas because they are readily mounted from the top, requiring only a cylindrical depression and possibly three screws for mounting and require no external wiring. The solar powered ground lights are LED or electro-illuminescent or similar type, supported close to a lens for a good low angle view factor and are low voltage and safe. A solar panel recharges the battery. The system may be fully IP68 waterproof rated.

Owner:HERMAN N PHILHOWER AS TRUSTEE OF THE H N PHILHOWER FAMILY TRUST LAST DATED OCTOBER 31 2012

Power management for a graphics processing unit or other circuit

ActiveUS9494994B1Reduce duty cycleReduce utilizationPower supply for data processingEnergy efficient computingElectricityGraphics

In one embodiment, a system includes power management control that controls a duty cycle of a processor to manage power. The duty cycle may be the amount of time that the processor is powered on as a percentage of the total time. By frequently powering up and powering down the processor during a period of time, the power consumption of the processor may be controlled while providing the perception that the processor is continuously available. For example, the processor may be a graphics processing unit (GPU), and the period of time over which the duty cycle is managed may be a frame to be displayed on the display screen viewed by a user of the system.

Owner:APPLE INC

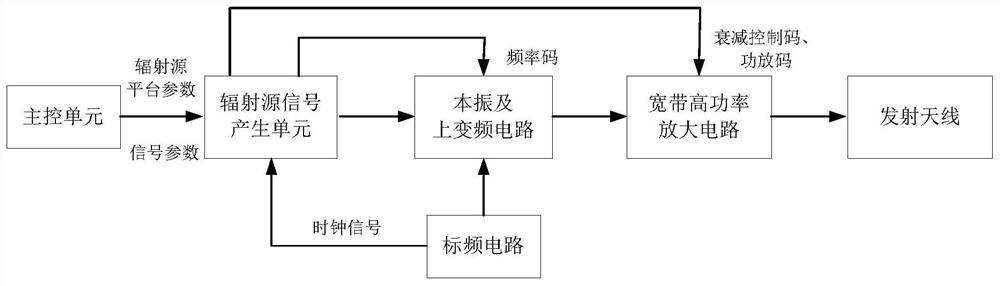

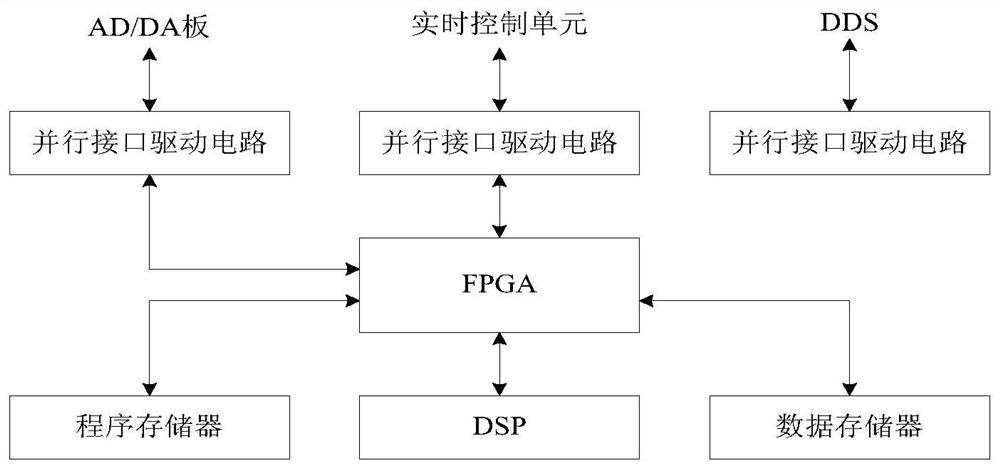

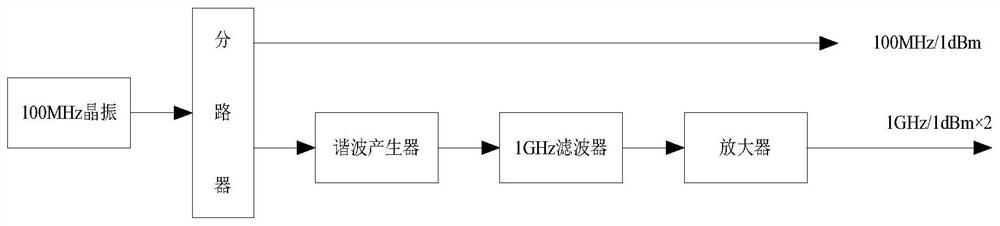

Radar radiation source signal simulation system capable of accurately controlling signal power

ActiveCN112379602AReduce duty cycleReduce power consumptionSimulator controlICT adaptationControl signalRadar radiation

The invention belongs to an electronic simulation technology, and relates to a radar radiation source signal simulation system capable of accurately controlling signal power, which can be used for programmably and quickly generating typical combat opponent airborne and missile-borne radar signals in real time. The method is used in semi-physical radiation source radar signal simulation, and vivid,controllable and adjustable airborne and missile terminal guidance threat signal environment simulation can be rapidly generated on line in real time.

Owner:PLA DALIAN NAVAL ACADEMY

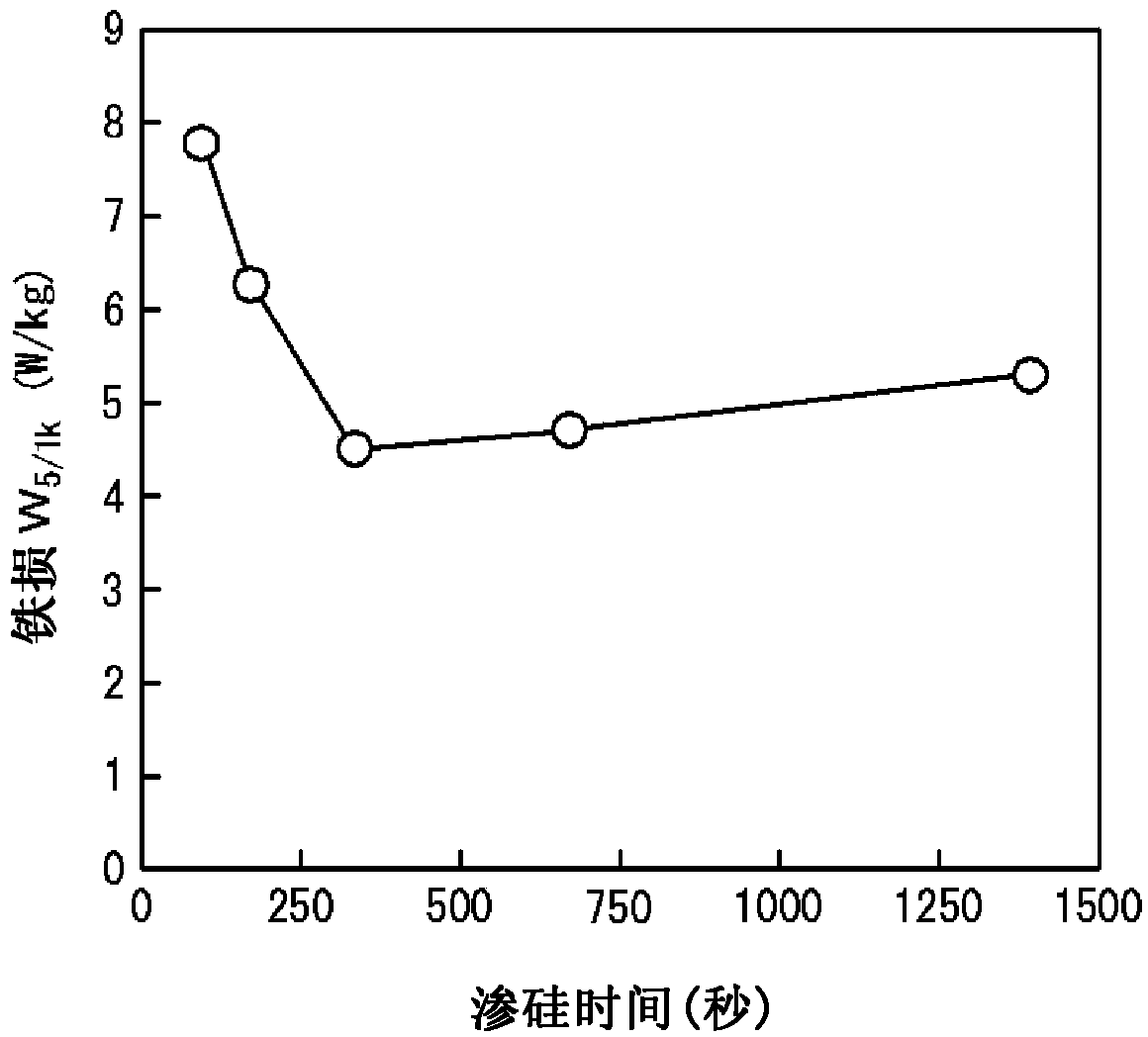

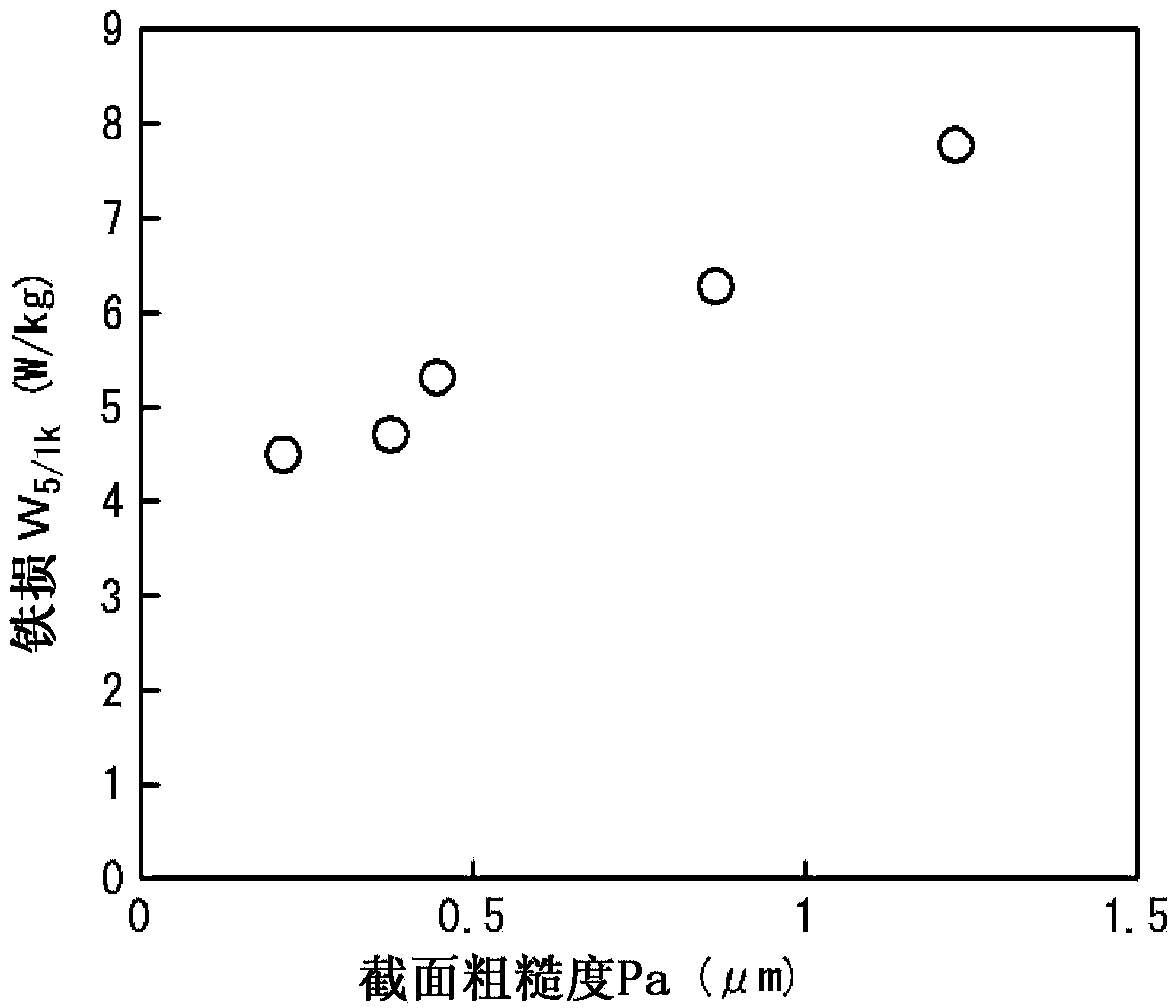

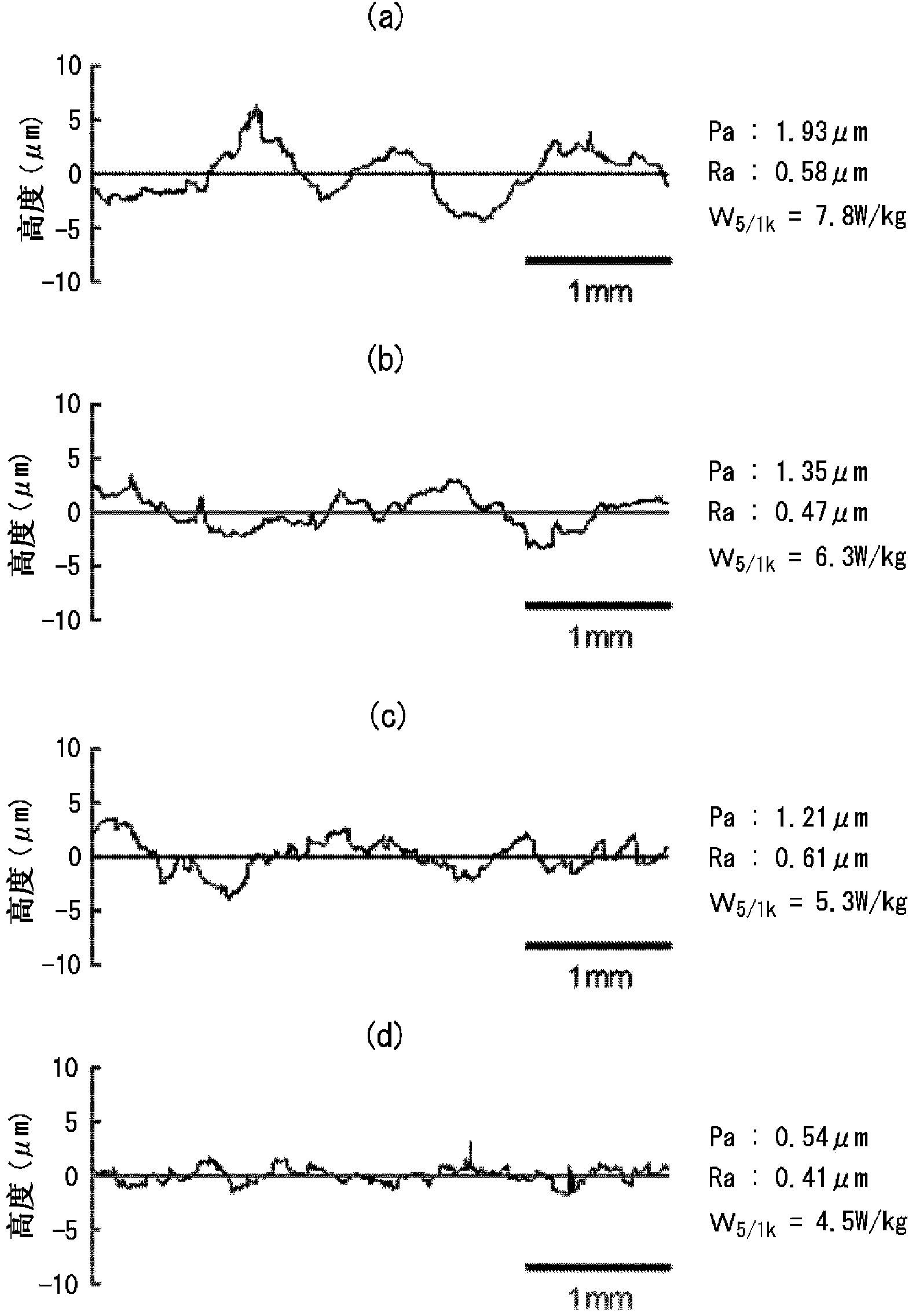

Ultrathin electromagnetic steel sheet

ActiveCN103930584AReduced characteristicsReduce duty cycleInorganic material magnetismSolid state diffusion coatingSheet steelImpurity

By producing a composition comprising, by mass%, 0.007% or less of C, 4 to 10% of Si, and 0.005 to 1.0% of Mn, with Fe and inevitable impurities as the balance, and by bringing the sheet thickness to between 0.01 and 0.10 mm and the cross section roughness Pa to 1.0 [mu]m or less, there is no degradation of magnetic properties and it is possible to realize iron loss properties such that degradation of the space factor is avoided, even when an electromagnetic steel sheet having a sheet thickness of 0.10 mm or less has been subjected to siliconizing in order to increase the Si content of the steel.

Owner:JFE STEEL CORP

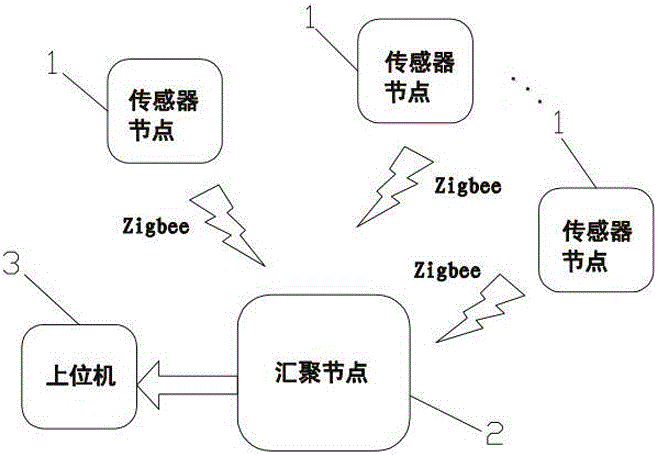

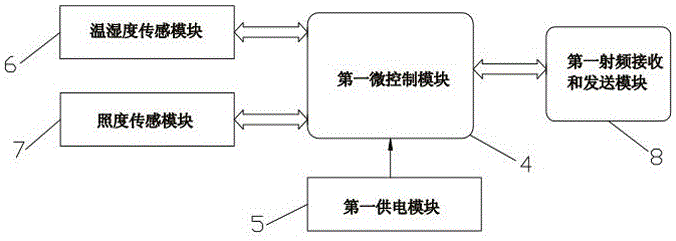

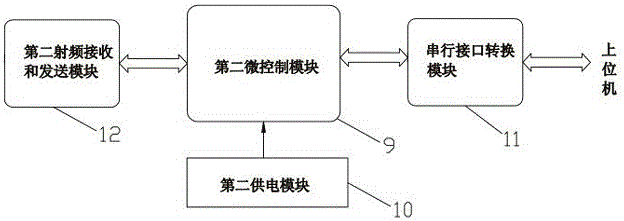

Spatial photometric distribution intelligent monitoring system based on Zigbee

InactiveCN106643872AGuaranteed stabilityOvercome monitoring difficultiesProgramme controlMeasurement devicesLine sensorData recording

The invention discloses a spatial photometric distribution intelligent monitoring system based on Zigbee, comprising: various sensor nodes in a Zigbee wireless sensing network, a converging node for transmitting the monitoring data and a host computer system to realize the functions of receiving, processing, saving and displaying data. Each sensor node comprises a first micro-control module, a first power supply module, a temperature and humidity sensing module to monitor the environment of the sensor node, a luminance sensing module to monitor the burning state of a to-be-detected lamp, and a first radio frequency receiving and sending module. The converging node comprises a second micro-control module, a second power supply module, a serial interface conversion module, and a second radio frequency receiving and sending module. According to the monitoring system of the invention, a low power consumption wireless sensing network technology is utilized to cooperate with a high precision temperature and humidity sensor and a luminescence sensor so that real time monitoring, temperature and humidity data recording and alarming over the allowed temperature could be possible for an entire photometric distribution testing system. At the same time, control over the burning state of a to-be-detected lamp can also be realized.

Owner:江门出入境检验检疫局检验检疫技术中心

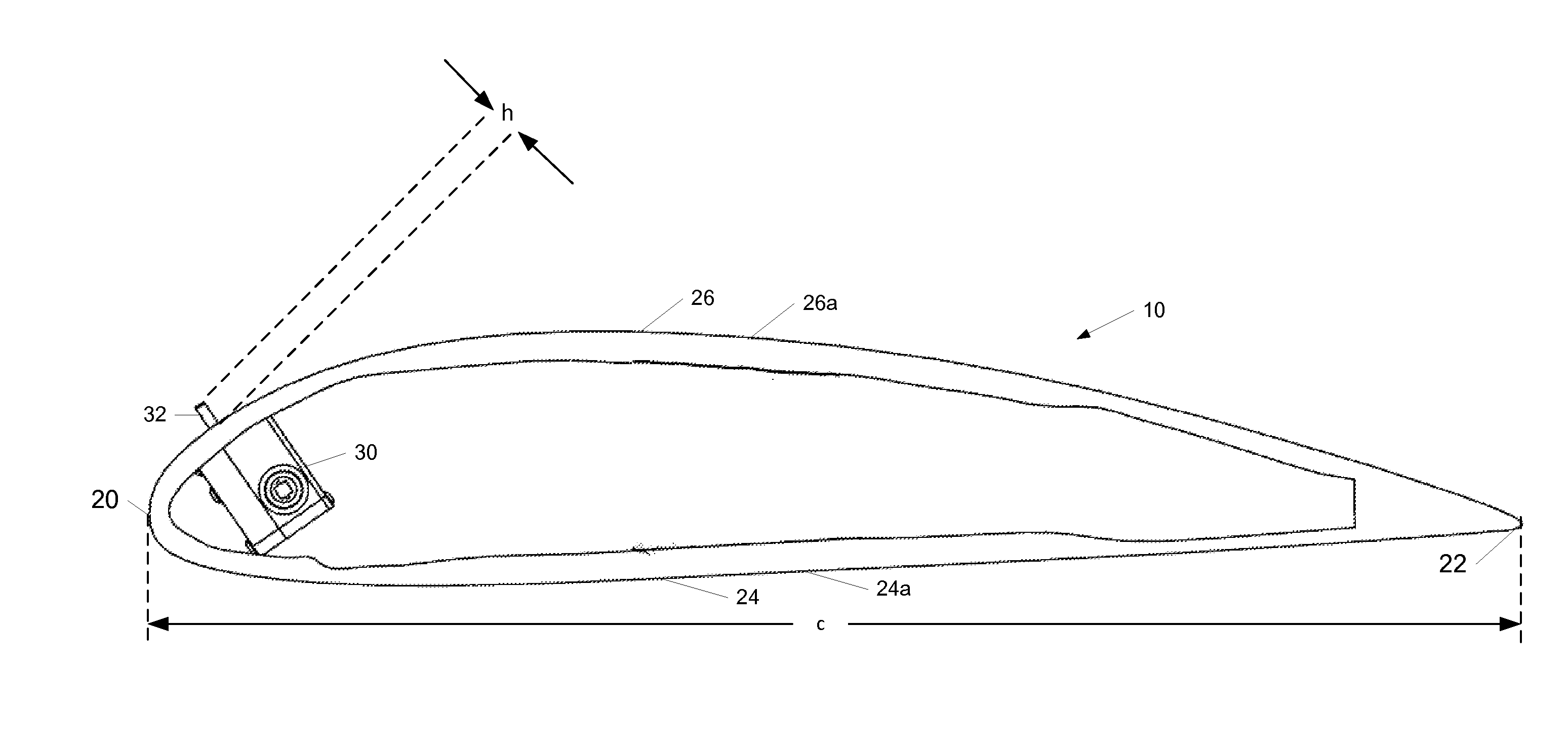

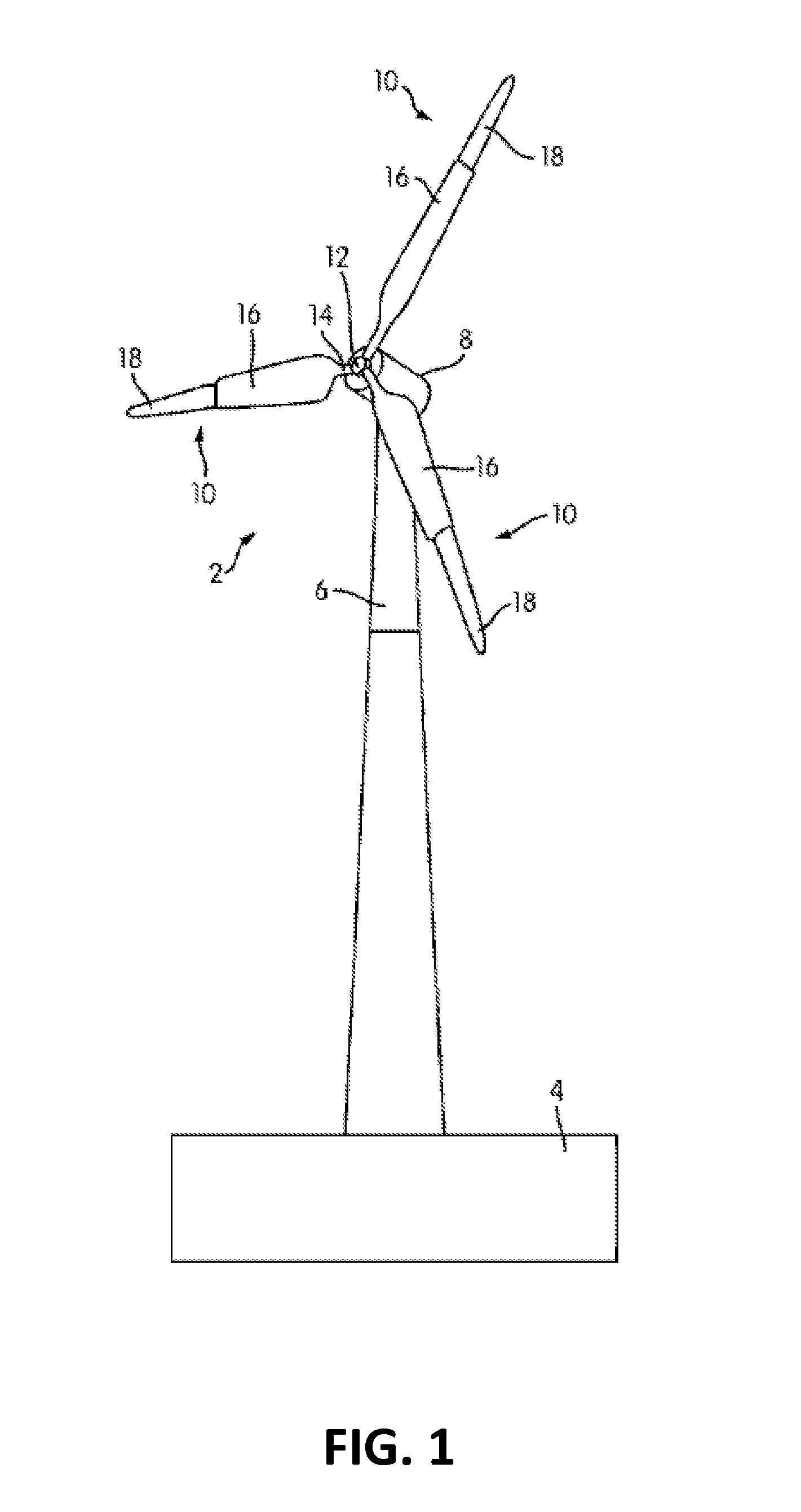

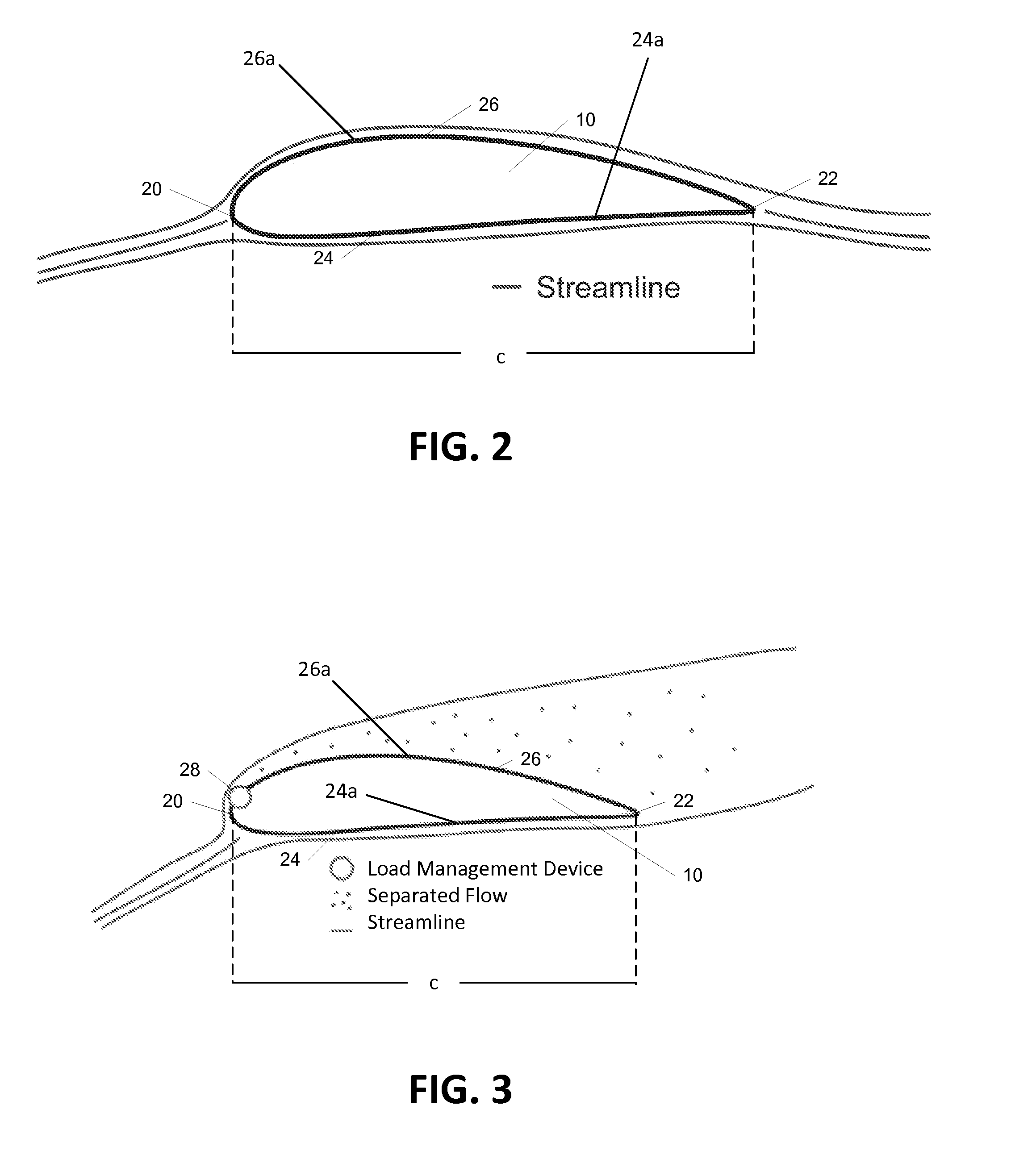

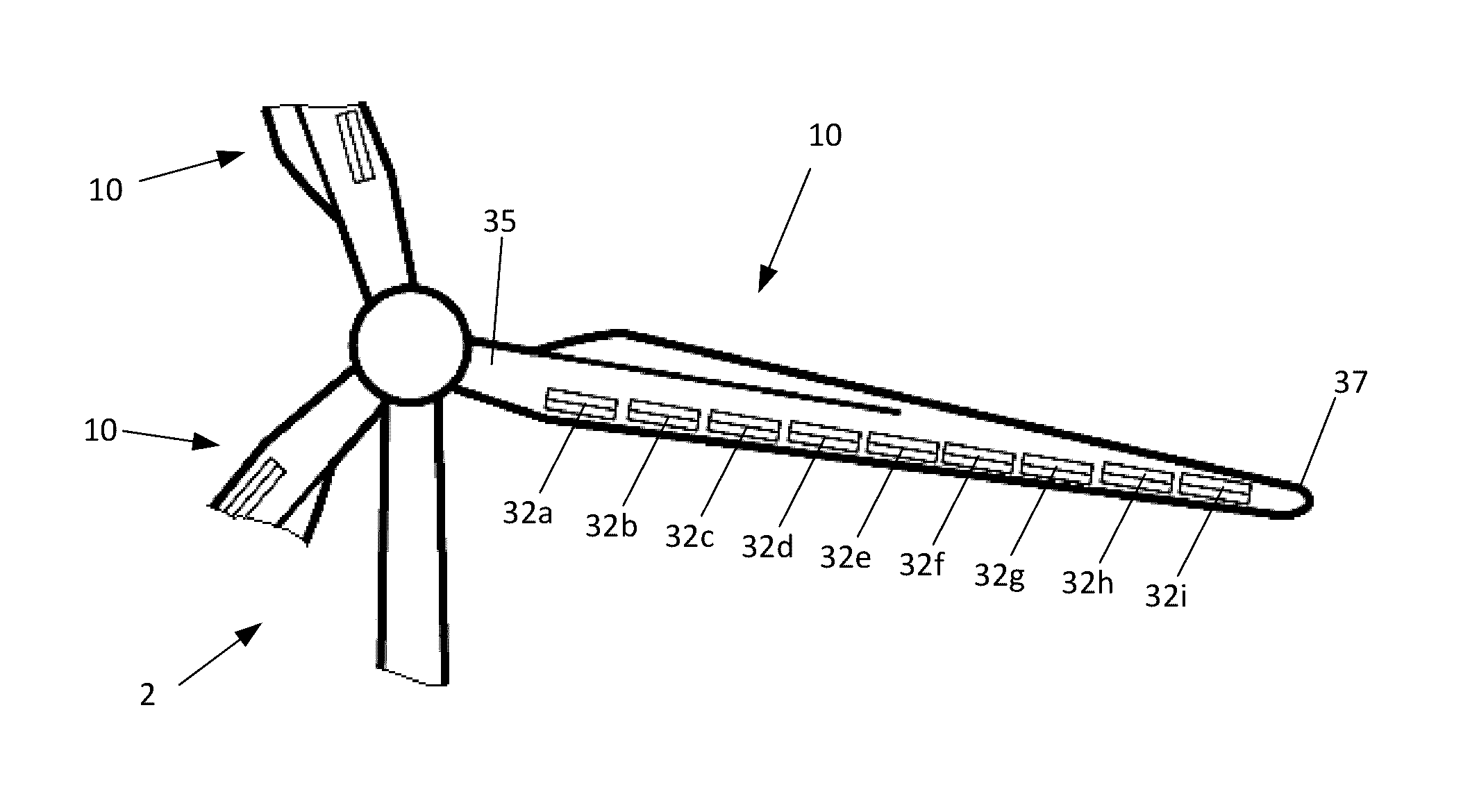

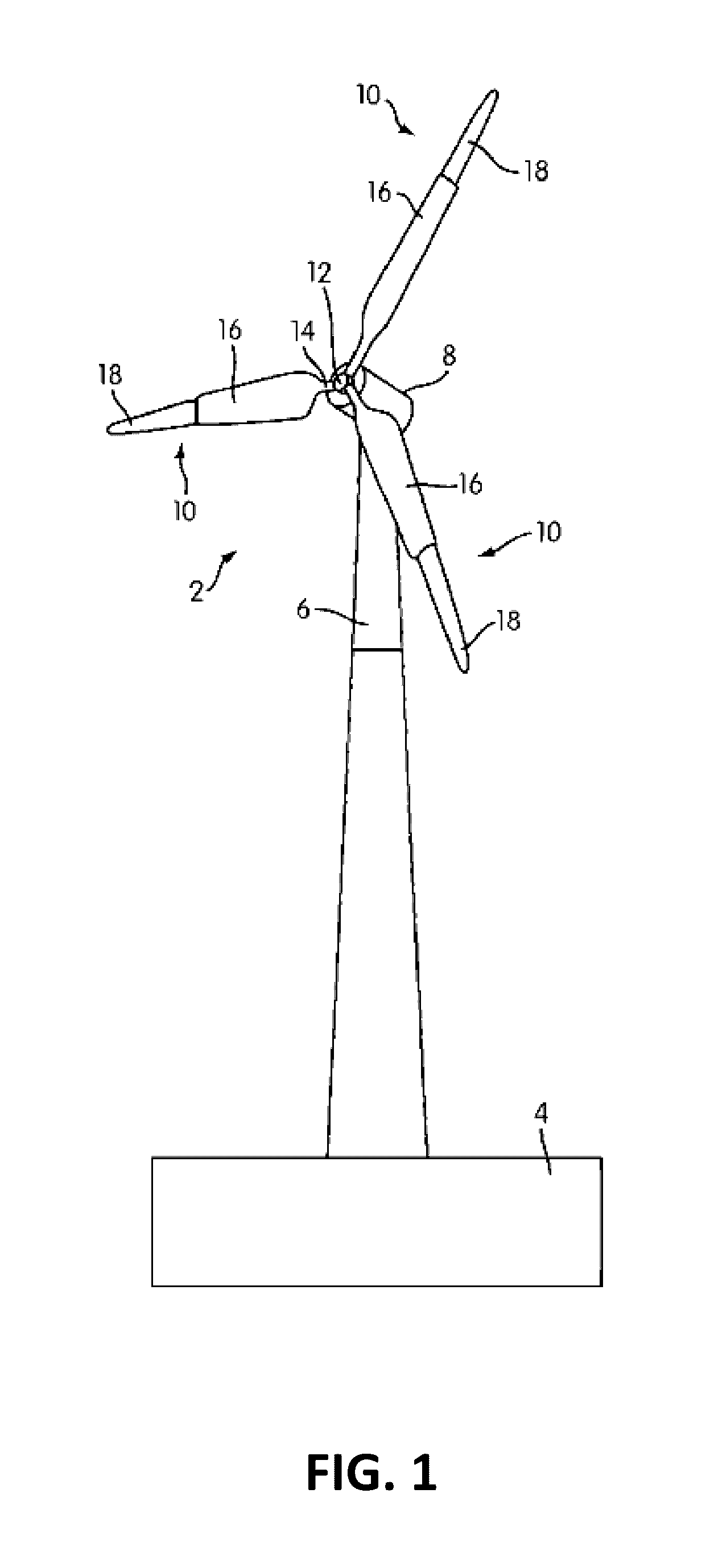

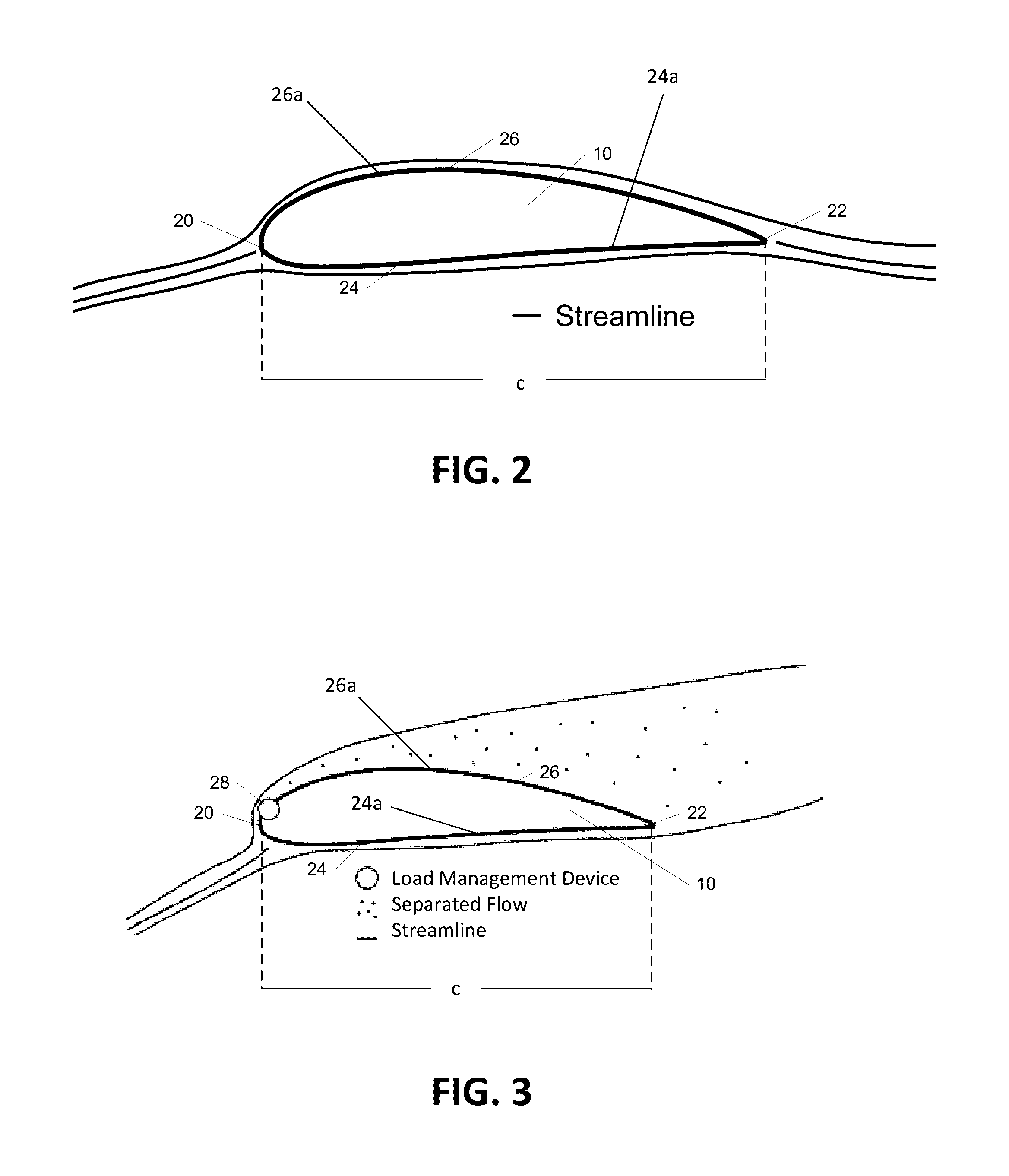

Actuation of distributed load management devices on aerodynamic blades

ActiveUS20140271184A1Increase powerOvercome limitationsPropellersWind motor controlTurbine bladeEngineering

Systems, apparatuses, and methods are provided for actuating less than all of a plurality of load management devices on a wind turbine and / or a wind turbine blade. In some embodiments, the actuation sequences may be a root-to-tip, tip-to root, maximum-distributed-load, random, and / or a cycle-count actuation sequence. Further, a combination of two or more actuation sequences may be utilized to achieve a desired result. The system may choose an appropriate blade-based and / or rotor-based actuation sequence according to operating conditions, may alternate actuation sequences, and / or may employ different actuation sequences among the plurality of blades of a wind turbine. The load management devices may be actuated to different maximum heights and / or may be configured to be actuated to variable heights. The load management devices may be included as part of a distributed management system providing a corresponding controller and / or sensor at each load management device.

Owner:GE INFRASTRUCTURE TECH INT LLC

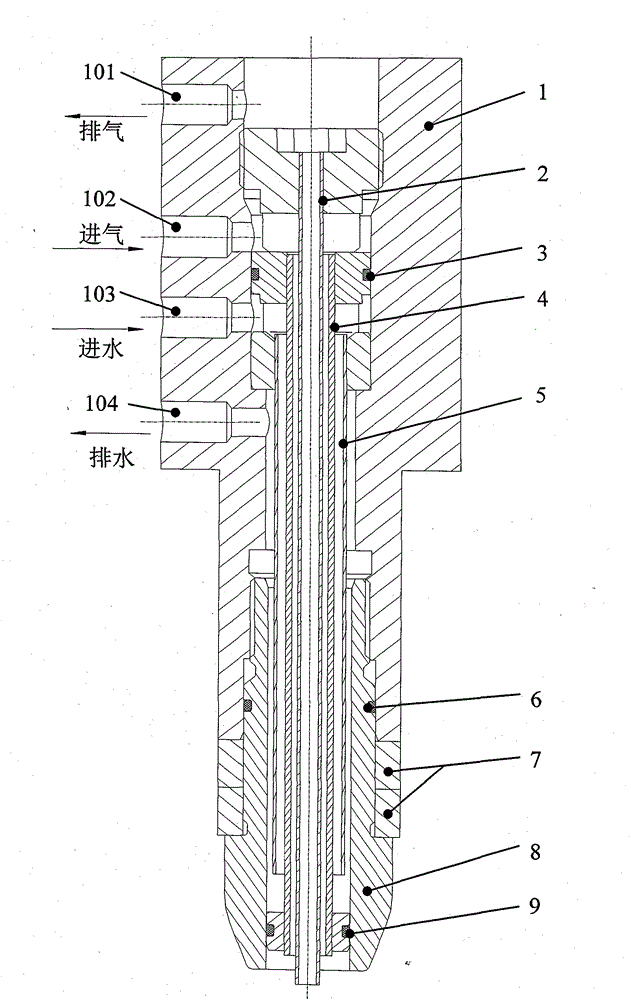

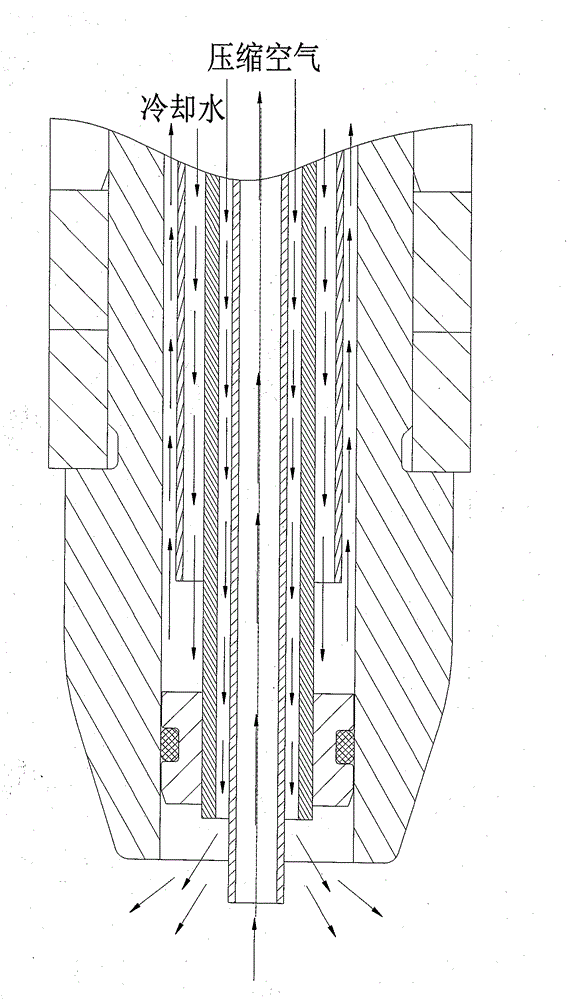

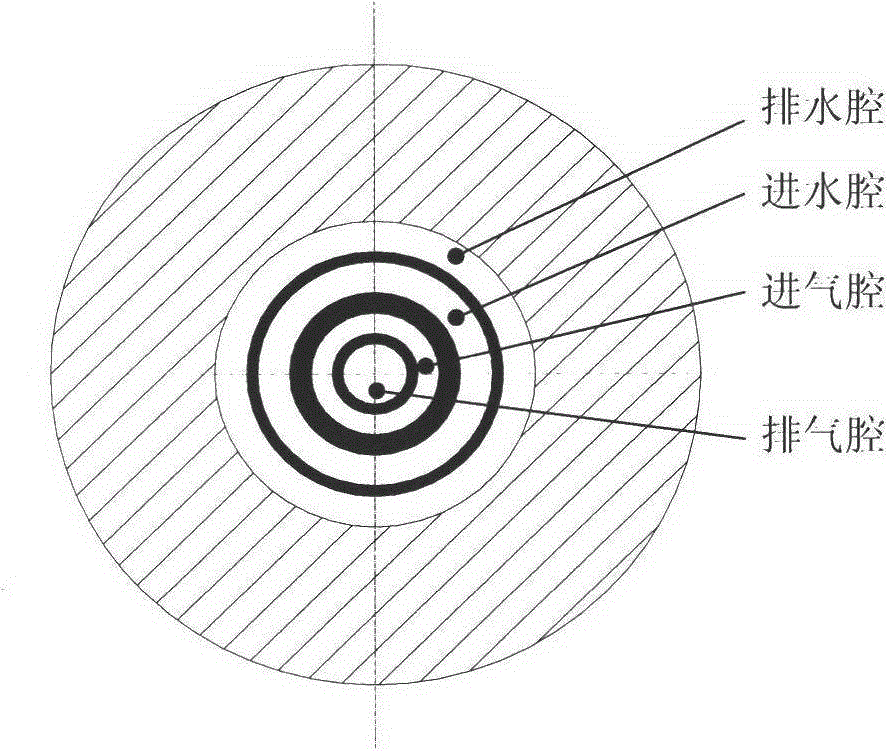

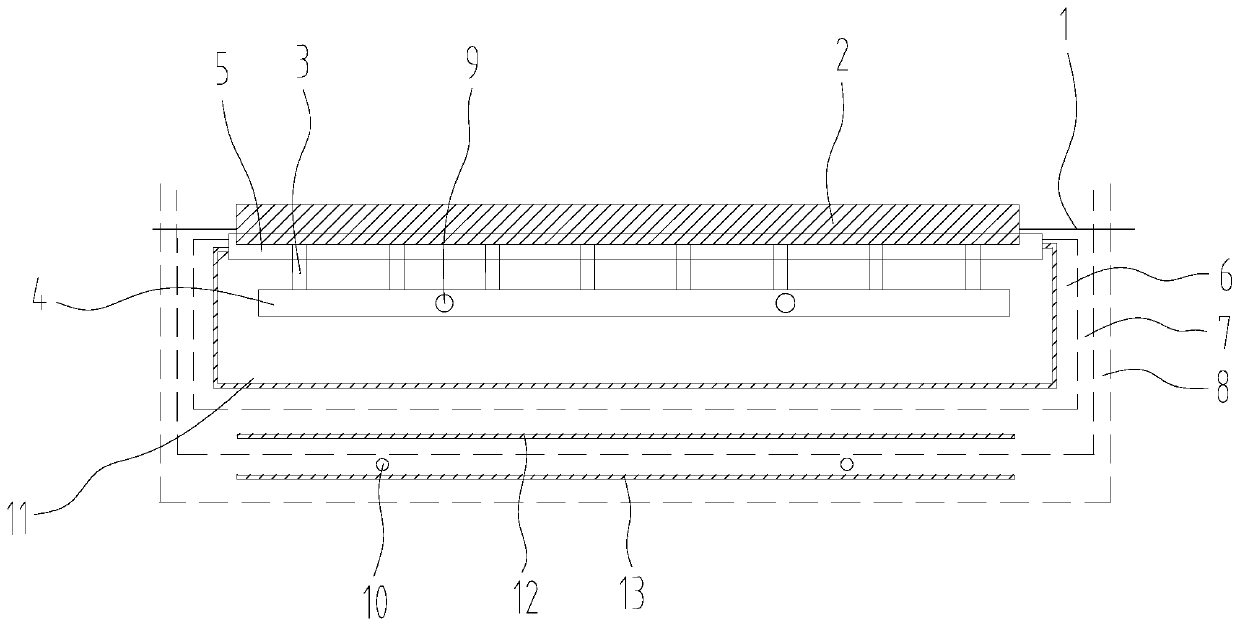

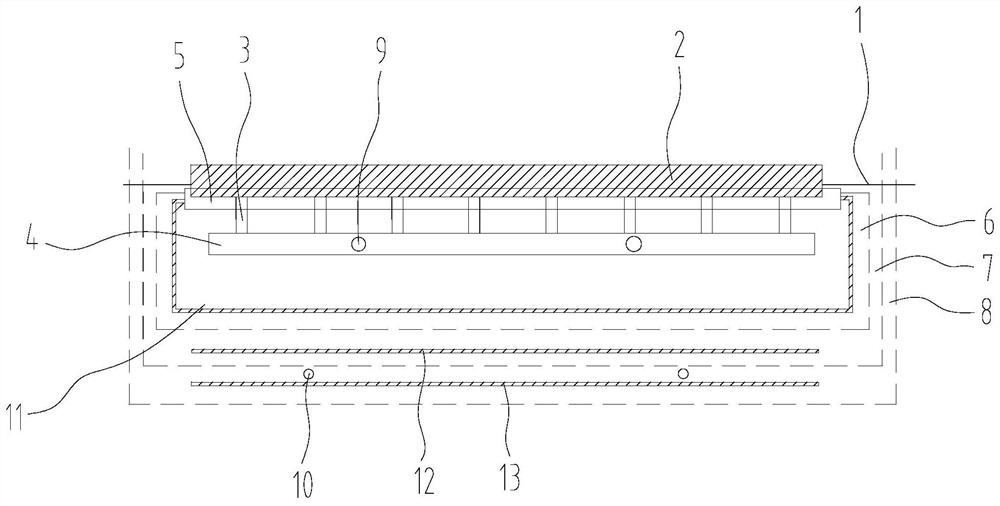

Bottle blowing machine blowing pin water cooled circulating device

The invention relates to a bottle blowing machine blowing pin water cooled circulating device. The device comprises a blowing pin body, wherein an exhaust pipe, an air inlet pipe, a cooling water pipe, a blowing pin cutter and a blowing pin head are mounted on the inner side of the blowing pin body; an air inlet, an air outlet, a water inlet and a water outlet are formed in the blowing pin body; the device is characterized in that the distance between the air inlet and the water inlet is 30 to 35 mm; the air inlet pipe is formed on the outer side of the exhaust pipe; a cooling water cavity comprising the cooling water pipe, the air inlet pipe, the blowing pin body and the blowing pin head is led to the blowing pin head, is sealed through an upper part O-shaped sealing ring, a middle O-shaped sealing ring and a lower part O-shaped sealing ring, and is isolated through an air cavity, the device can form a good cooling circuiting loop, and can keep a blowing pin at low temperature, thereby ensuring that the blowing pin and a bottle blank form large temperature difference, preventing the blowing pin from being adhered to a bottleneck, and further being capable of improving the production quality and the production efficiency of bottles.

Owner:SUZHOU BESTAR BLOW MOLDING MASCH CO LTD

Actuation of distributed load management devices on aerodynamic blades

ActiveUS9506453B2Reduce duty cycleIncrease powerWind motor controlEfficient propulsion technologiesTurbine bladeEngineering

Systems, apparatuses, and methods are provided for actuating less than all of a plurality of load management devices on a wind turbine and / or a wind turbine blade. In some embodiments, the actuation sequences may be a root-to-tip, tip-to root, maximum-distributed-load, random, and / or a cycle-count actuation sequence. Further, a combination of two or more actuation sequences may be utilized to achieve a desired result. The system may choose an appropriate blade-based and / or rotor-based actuation sequence according to operating conditions, may alternate actuation sequences, and / or may employ different actuation sequences among the plurality of blades of a wind turbine. The load management devices may be actuated to different maximum heights and / or may be configured to be actuated to variable heights. The load management devices may be included as part of a distributed management system providing a corresponding controller and / or sensor at each load management device.

Owner:GE INFRASTRUCTURE TECH INT LLC

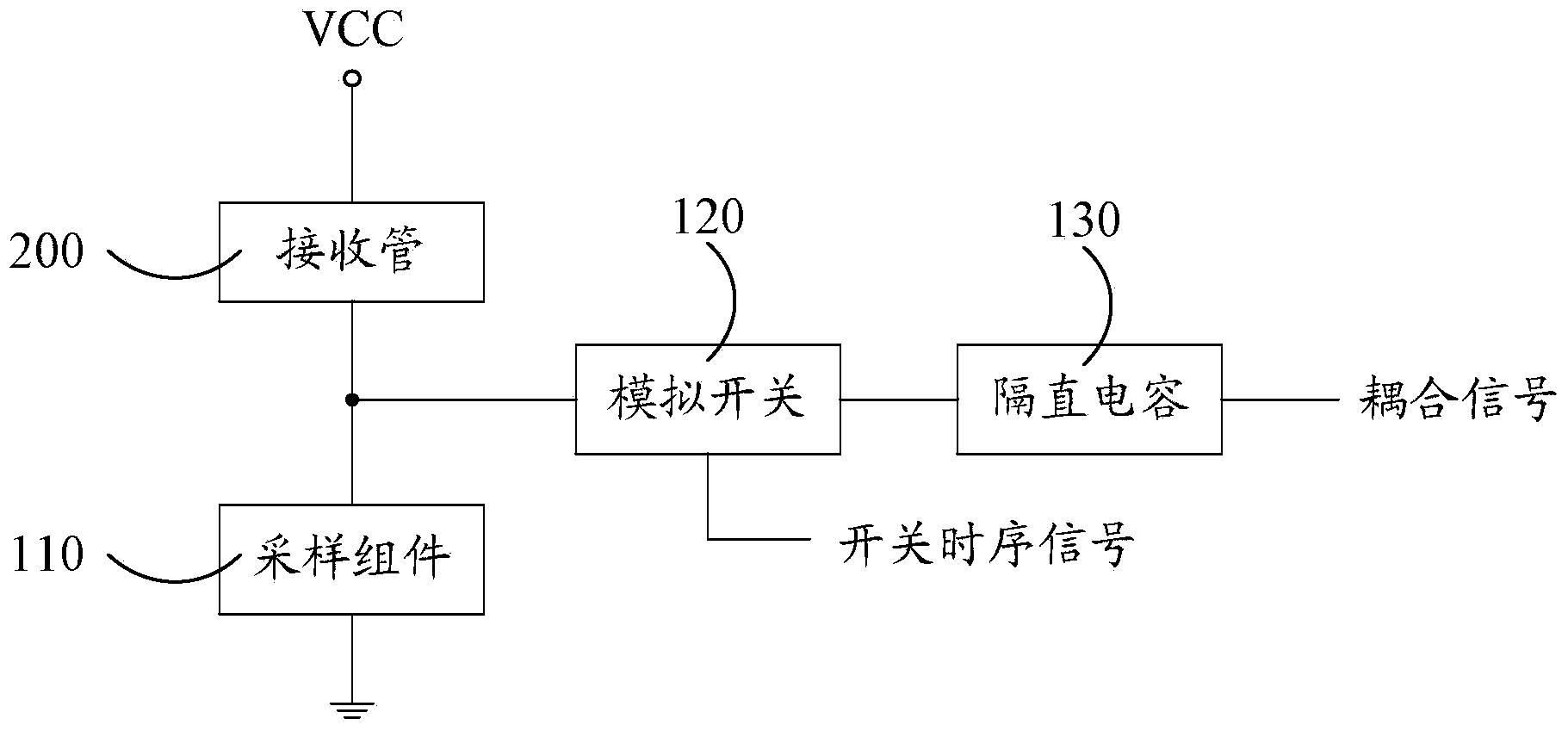

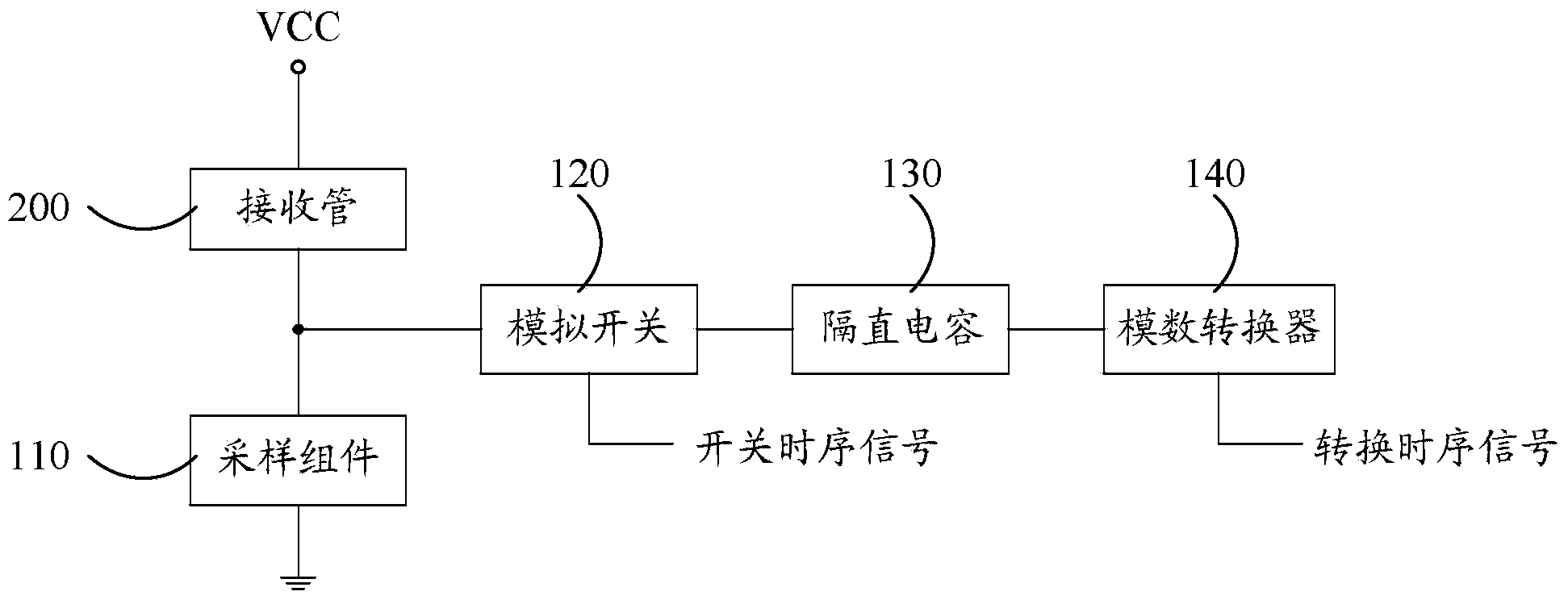

Signal receiving device of infrared touch frame

ActiveCN103631453AReduce power consumptionReduce duty cycleInput/output processes for data processingDigital conversionVIT signals

Provided is a signal receiving device of an infrared touch frame. A sampling assembly samples current signals output by a receiving tube, an analog switch receives switch sequence signals through a control end, the analog switch is switched on after a transmitting tube of the infrared touch frame emits light through control of the switch sequence signals, and the analog switch is switched off when the transmitting tube does not emit light. When switched on, the analog switch sends the signals sampled by the sampling assembly to a blocking capacitor, and the blocking capacitor couples and filters the signals received when the analog switch is switched on and then obtains and outputs the coupling signals for analog-digital conversion processing. Due to the facts that the analog switch is in a switched-off state when the transmitting tube does not emit light and charges stored by the blocking capacitor will not be released by the sampling assembly, when analog-digital conversion processing is carried out on the coupling signals output by the blocking capacitor, the transmitting tube does not emit light continuously, the working duty ratio of the transmitting tube is reduced, and the power consumption of the infrared touch frame is lowered.

Owner:GUANGZHOU SHIRUI ELECTRONICS

Power management for a graphics processing unit or other circuit

ActiveUS10114446B1Reduce duty cycleReduce utilizationPower supply for data processingEnergy efficient computingElectricityGraphics

Owner:APPLE INC

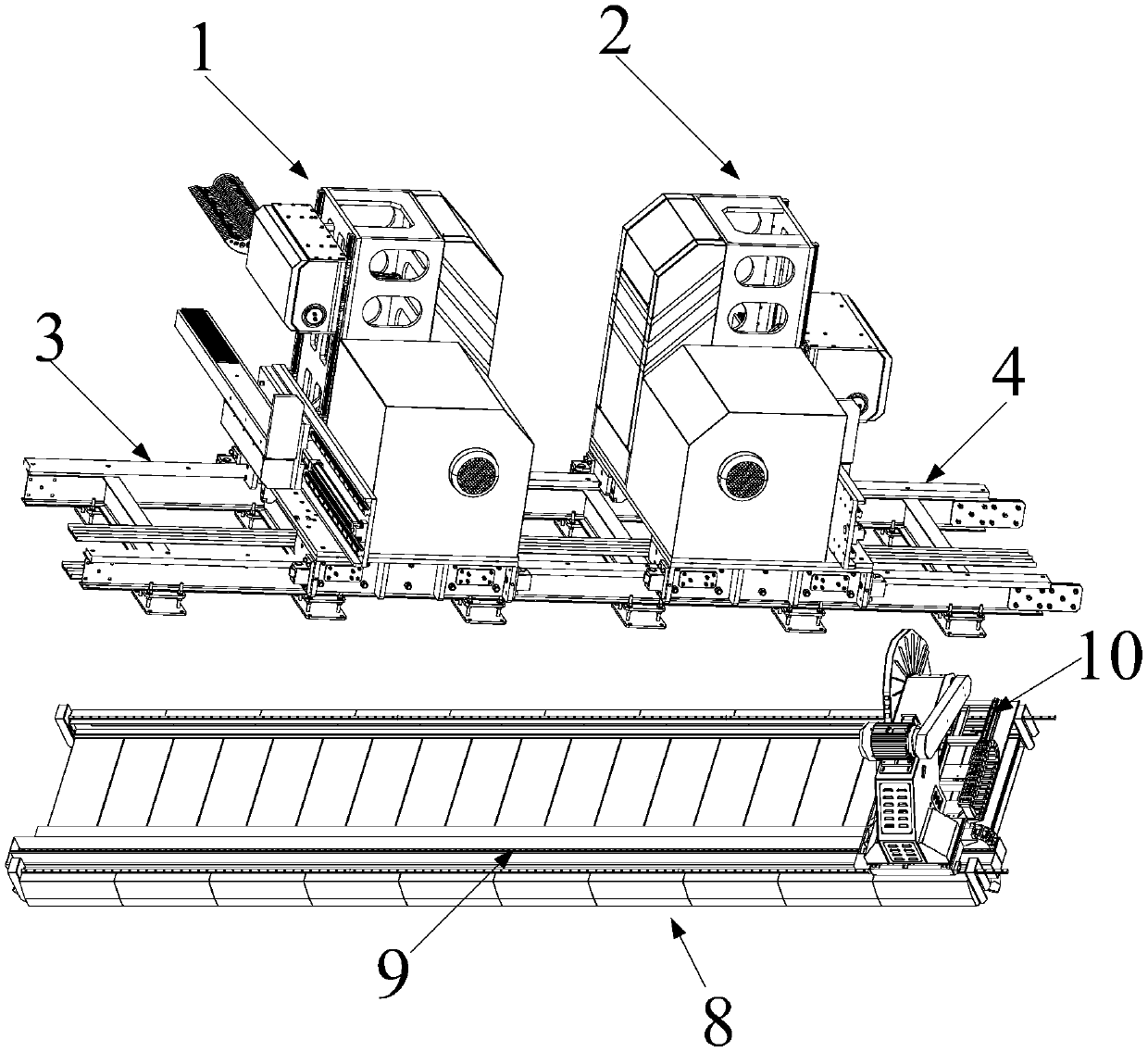

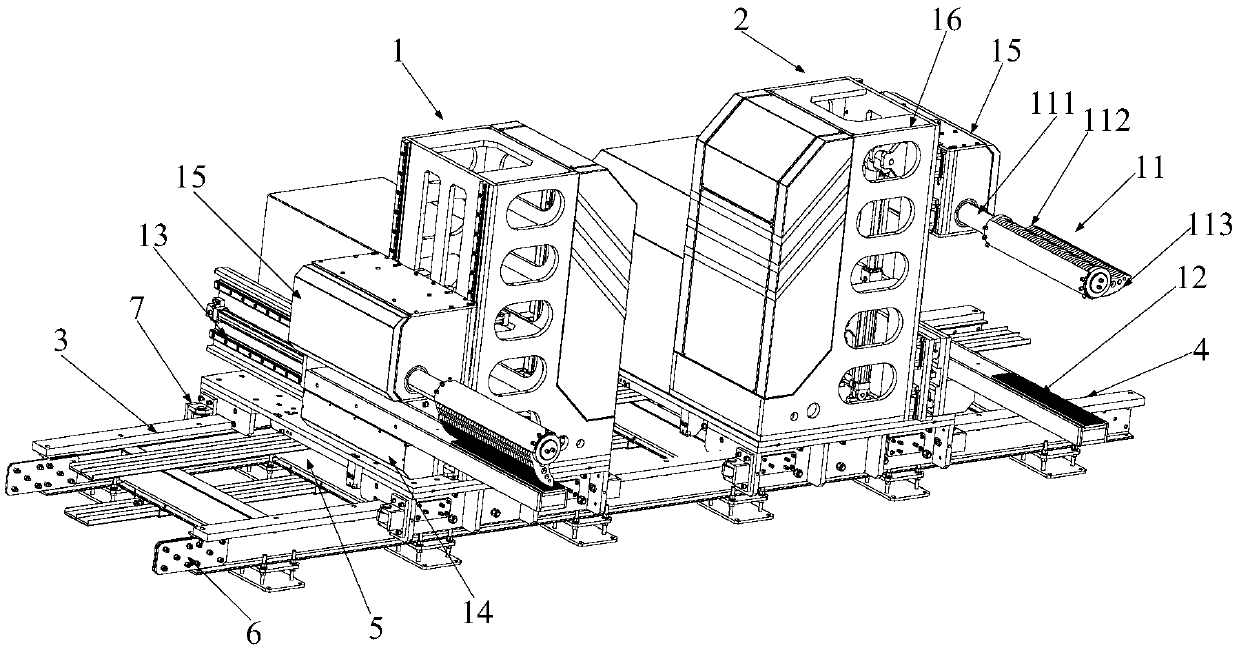

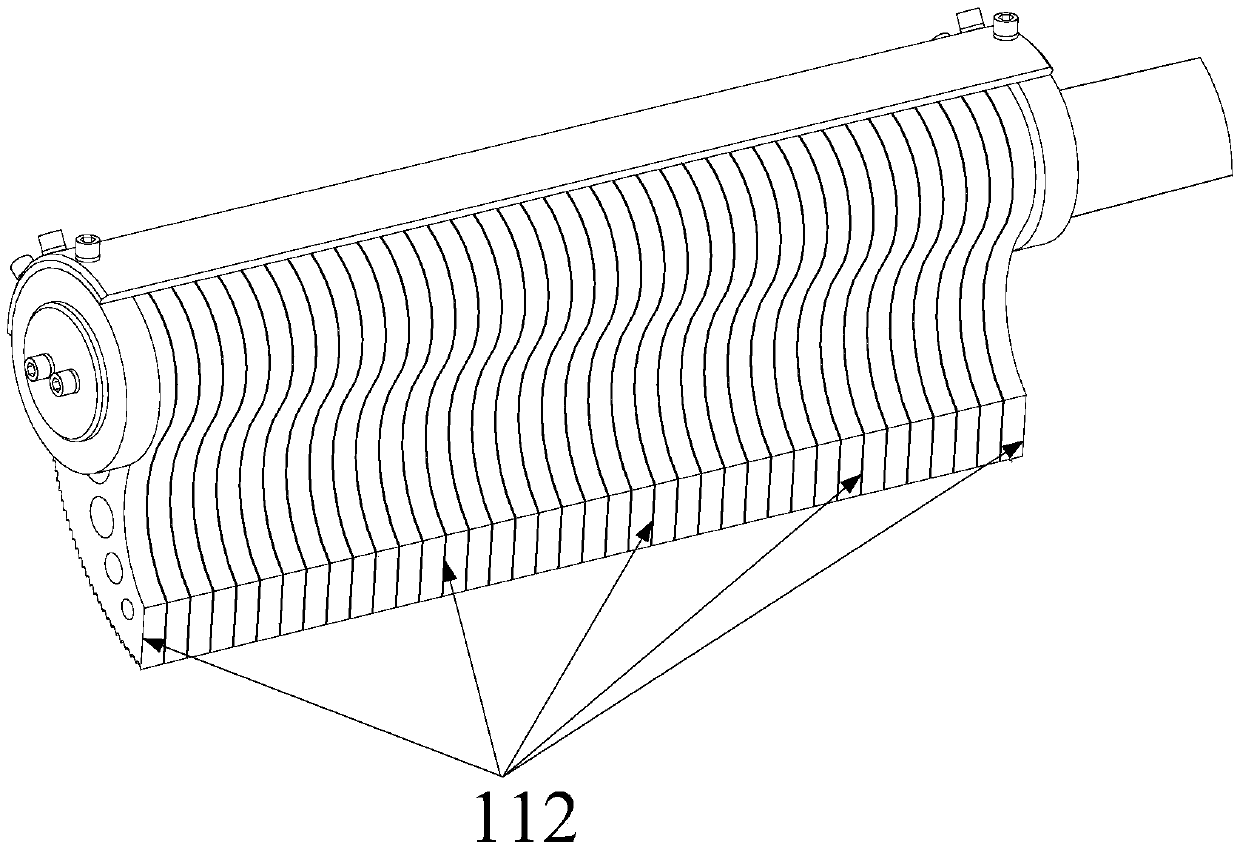

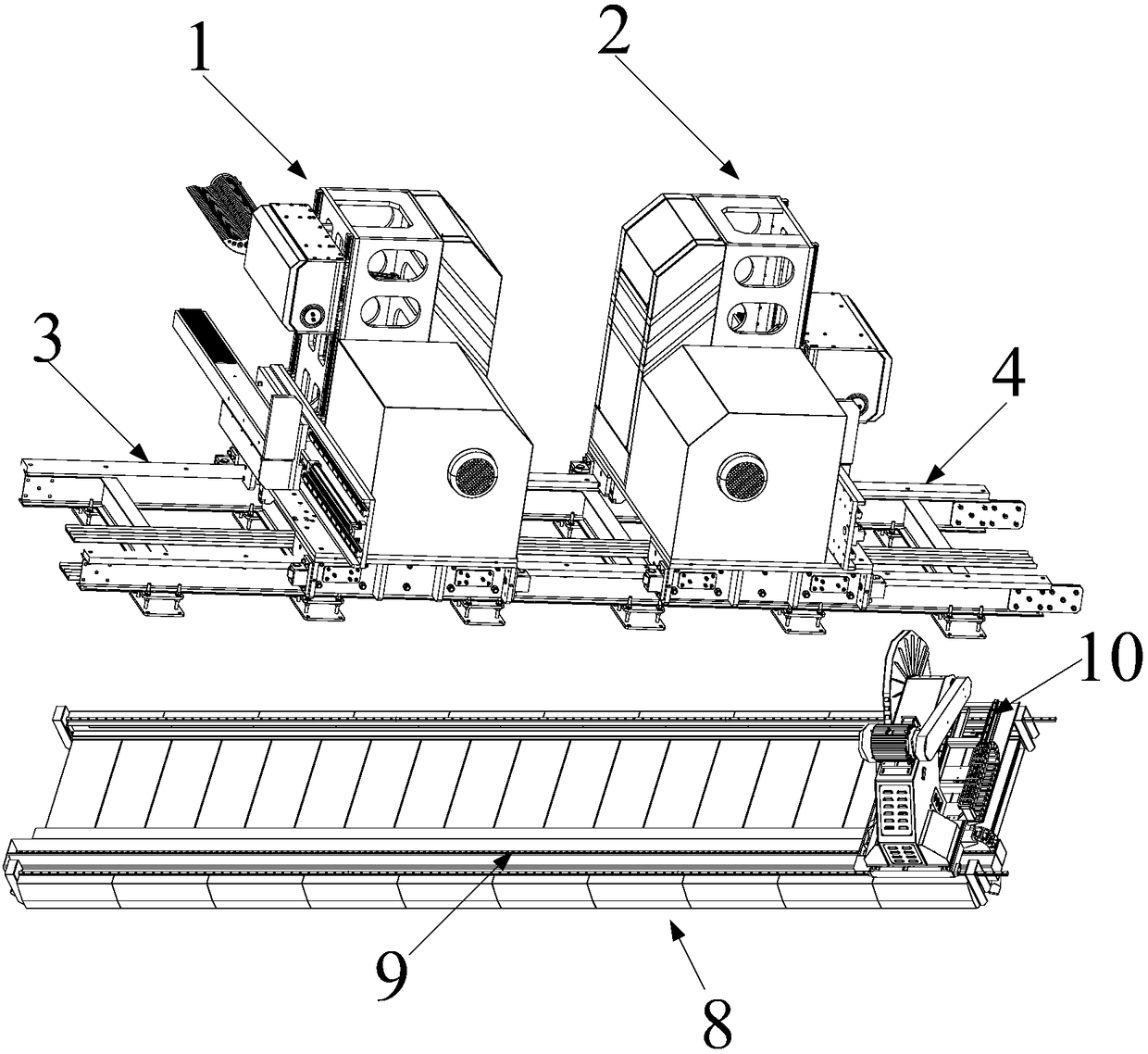

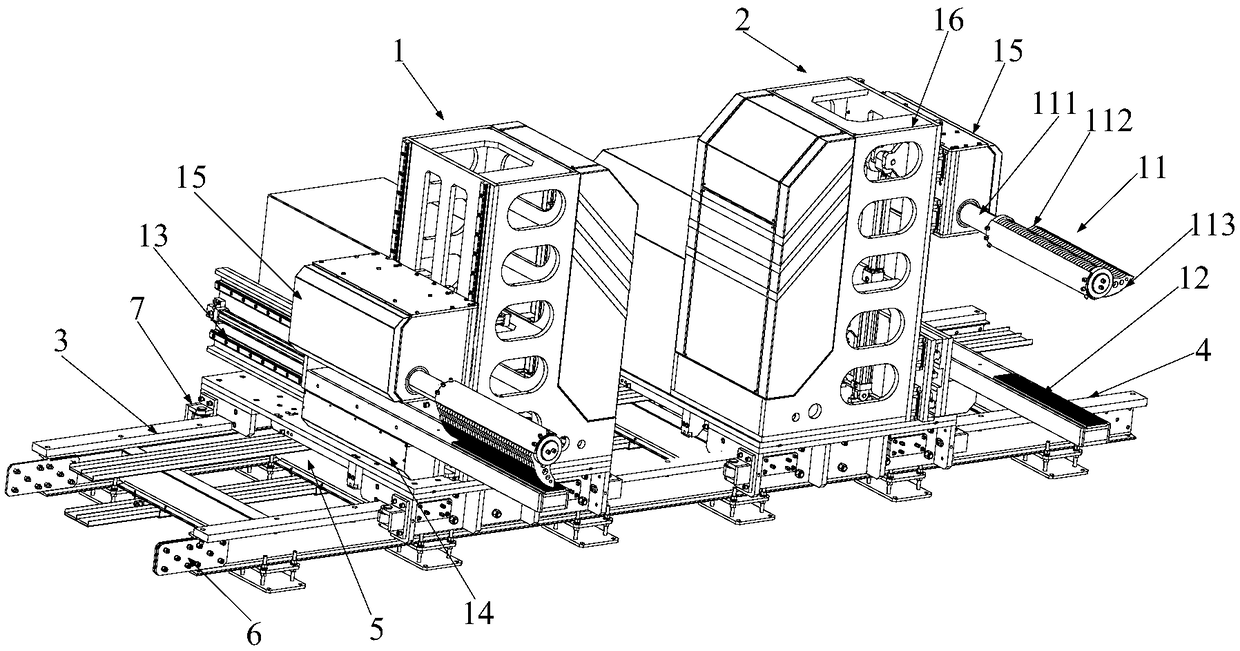

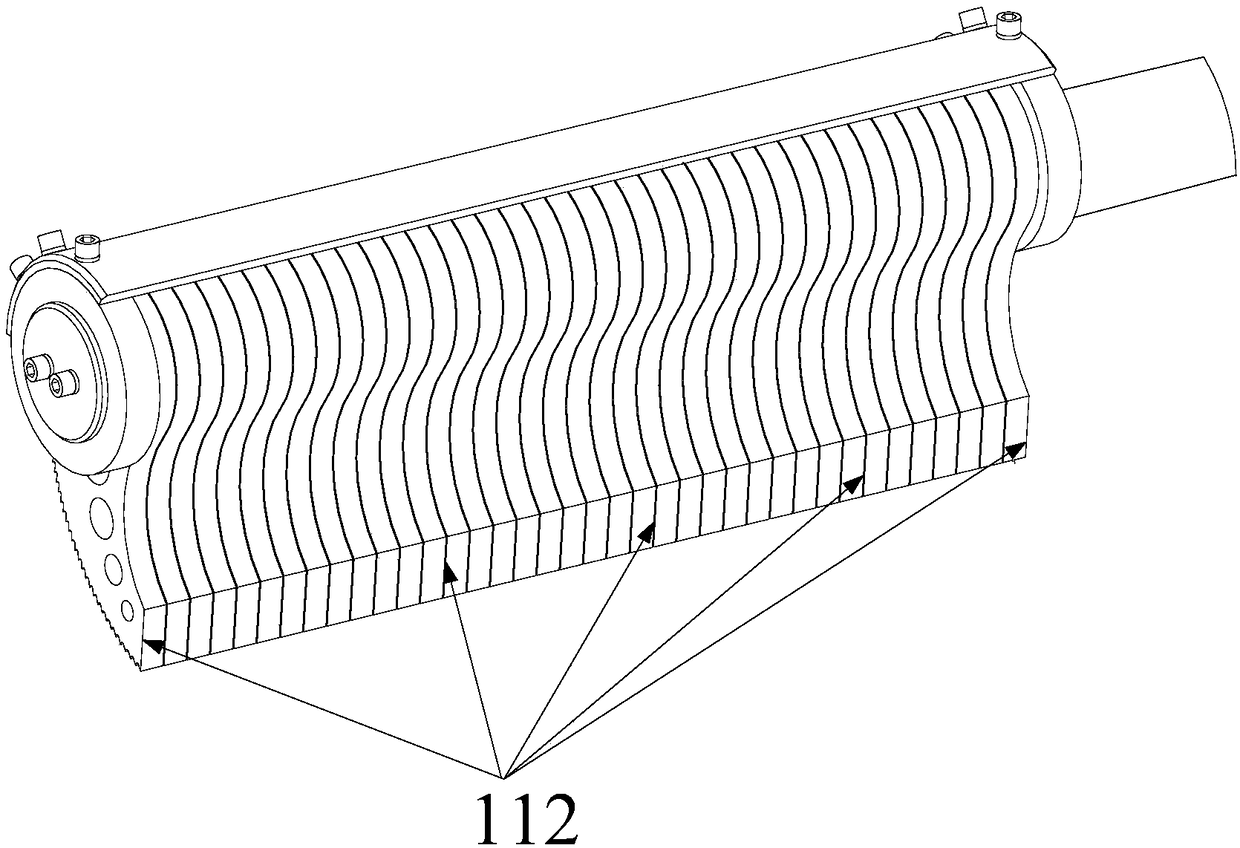

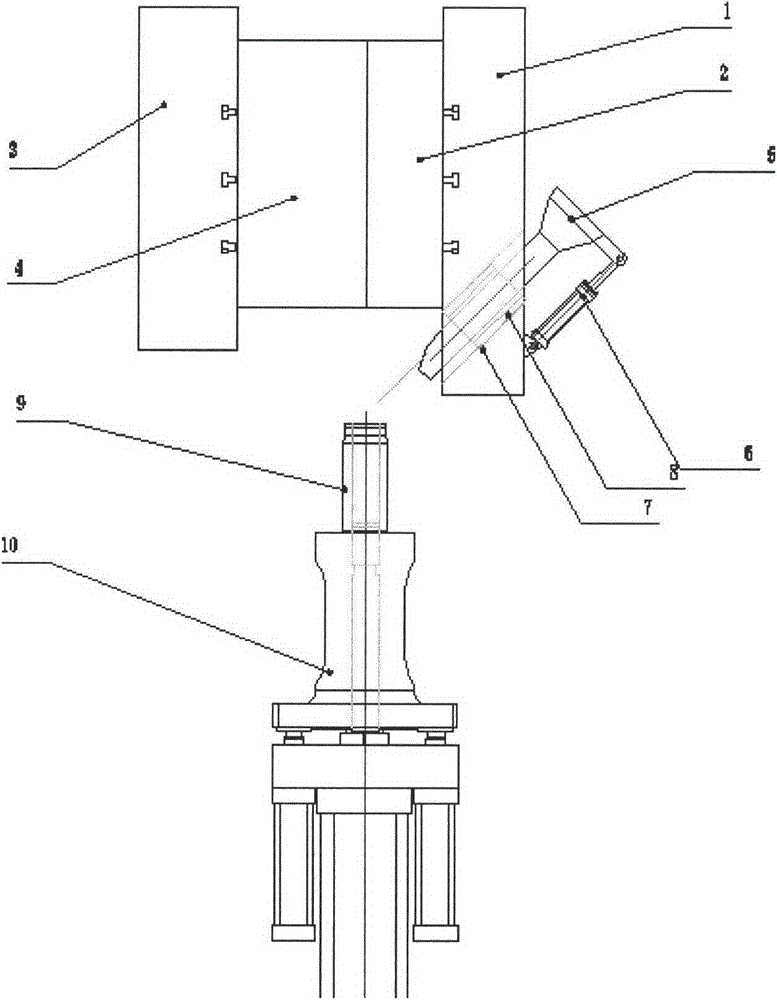

A Profile Traction Cutting Robot

The invention discloses a proximate matter traction cutting robot. According to the proximate matter traction cutting robot, the connection and the communication are achieved through double traction devices and a saw cutting device by means of a main control system, and the double traction devices and the saw cutting device all have own independent running orbits, so that the working cycle can begreatly shortened; when one traction device works, the other traction device returns to an original point at the low speed and awaits orders, so that the proximate matter traction cutting robot can beparticularly suitable for the situation that one rod needs to be sawed several times, and can break through the restriction that the highest return speed is always required for the single-orbit double traction process; the mechanical abrasion is greatly reduced; the higher safety is achieved; and the proximate matter traction cutting robot is durable and easy to maintain.

Owner:佛山市腾华自动化机械有限公司

Proximate matter traction cutting robot

ActiveCN108311753AReduce duty cycleReduce mechanical wearMetal sawing devicesProximateControl system

The invention discloses a proximate matter traction cutting robot. According to the proximate matter traction cutting robot, the connection and the communication are achieved through double traction devices and a saw cutting device by means of a main control system, and the double traction devices and the saw cutting device all have own independent running orbits, so that the working cycle can begreatly shortened; when one traction device works, the other traction device returns to an original point at the low speed and awaits orders, so that the proximate matter traction cutting robot can beparticularly suitable for the situation that one rod needs to be sawed several times, and can break through the restriction that the highest return speed is always required for the single-orbit double traction process; the mechanical abrasion is greatly reduced; the higher safety is achieved; and the proximate matter traction cutting robot is durable and easy to maintain.

Owner:佛山市腾华自动化机械有限公司

Shifting register unit and array substrate gird driving device

ActiveCN102956213BStable jobReduce noiseStatic indicating devicesDigital storageLow noiseShift register

The invention discloses a shifting register unit and an array substrate gird driving device. With the adoption of the shifting register unit and the array substrate gird driving device, low-noise signals can be output by the shifting register unit and the shifting register unit can stably work for a long time period. The shifting register unit provided by the invention comprises an input module, a resetting module, a pull-upward module, a first pull-downward module, a first pull-downward control module, a second pull-downward module and a second pull-downward control module, wherein the input module is used for supplying a first working voltage to a pull-upward node of the pull-upward module; the resetting module is connected with the pull-upward node and is used for reducing the voltage of the pull-upward node to a second working voltage; the pull-upward module is connected with the pull-upward node, is used for storing the first working voltage and supplies a first clock signal to an output terminal; the first pull-downward module is used for supplying a third working voltage to the output terminal; the first pull-downward control module supplies a second clock signal to the pull-downward node, and supplies the third working voltage to the pull-downward node; the second pull-downward module is used for supplying the third working voltage to the pull-upward node and the output terminal; and the second pull-downward control module is used for inputting the second clock signal to the pull-downward node.

Owner:BEIJING BOE OPTOELECTRONCIS TECH CO LTD

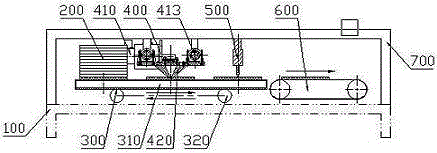

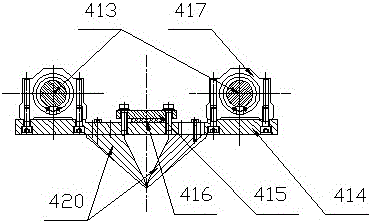

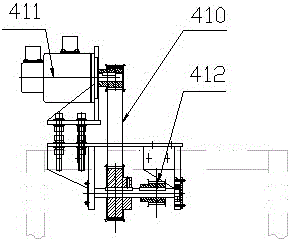

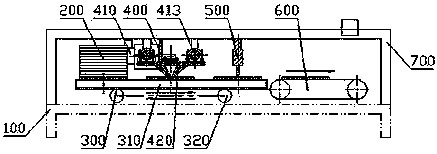

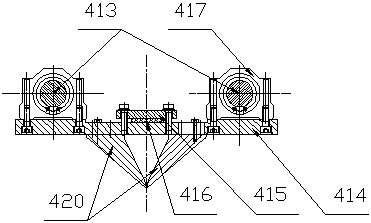

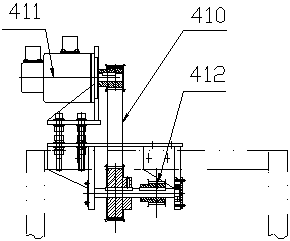

Grooving machine for bi-directional paperboard grooving and bi-directional paperboard grooving method

ActiveCN106079562AReduce duty cycleShorten the production cycleBox making operationsPaper-makingProduction linePaperboard

The invention provides a grooving machine for bi-directional paperboard grooving. The grooving machine comprises a workbench (100), a paperboard feeding device (200), a vacuum adsorption assembly (300), a movable cutter assembly (400), a fixed cutter (500), an output belt (600) and a rack (700), wherein the paperboard feeding device (200), the movable cutter assembly (400), the fixed cutter (500) and the output belt (600) are sequentially arranged on the workbench (100) and are used for achieving transportation and cutting grooving of paperboards; the paperboard feeding device (200) is positioned at the foremost end of a production line, and is used for placing and feeding the paperboards; the workbench (100) is positioned at the undermost part of the rack (700); the fixed cutter (500) is directly fixed to the rack (700), and is used for cutting the moving paperboards; and the output belt (600) is positioned at the rearmost end of the production line, and is used for outputting the cut paperboards. According to the grooving machine, the production efficiency of paperboard grooving is improved, the paperboards are located and processed at a time, the defective rate is decreased, raw materials are fully utilized, and the production cost is reduced.

Owner:江苏丰彩包装材料有限公司

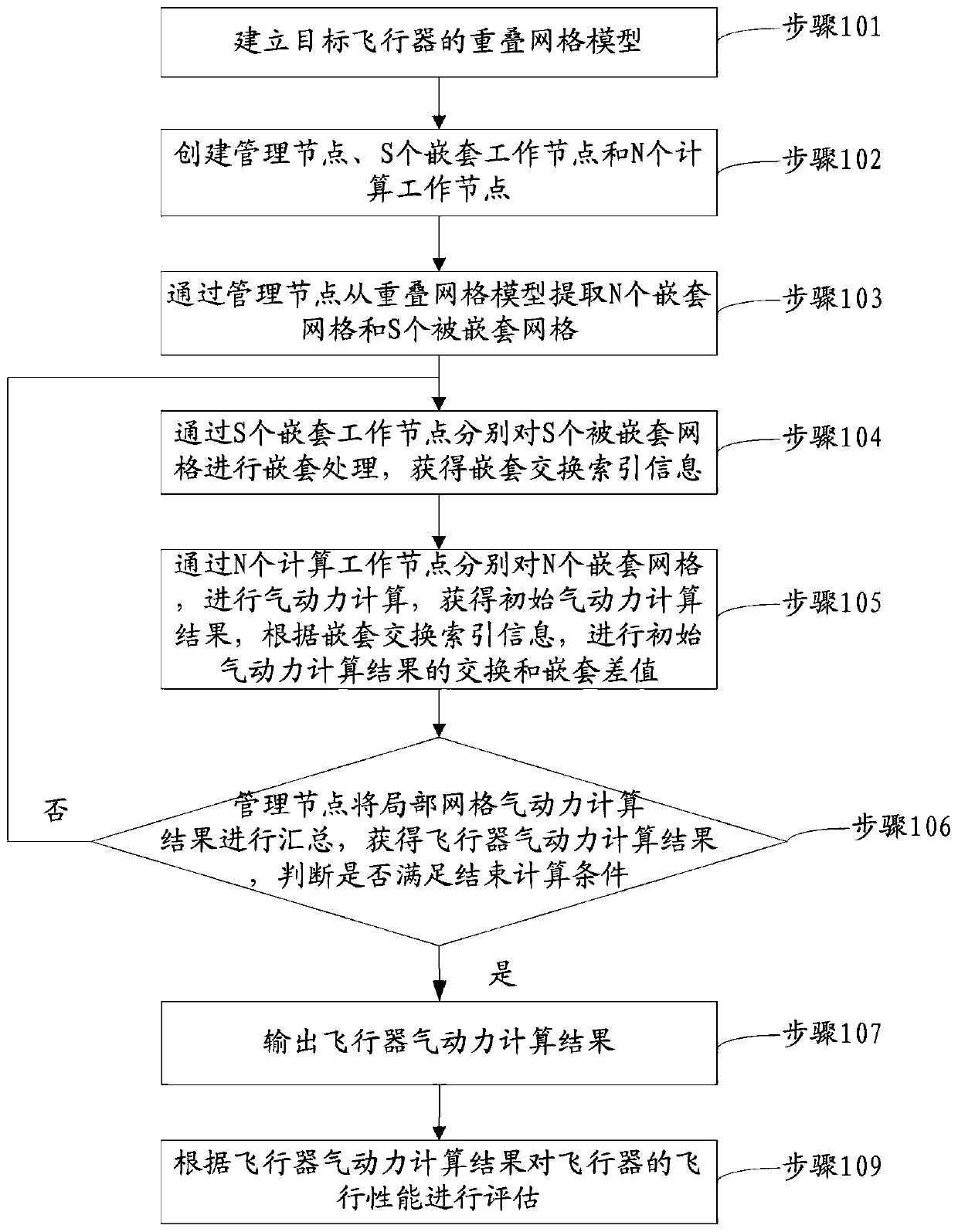

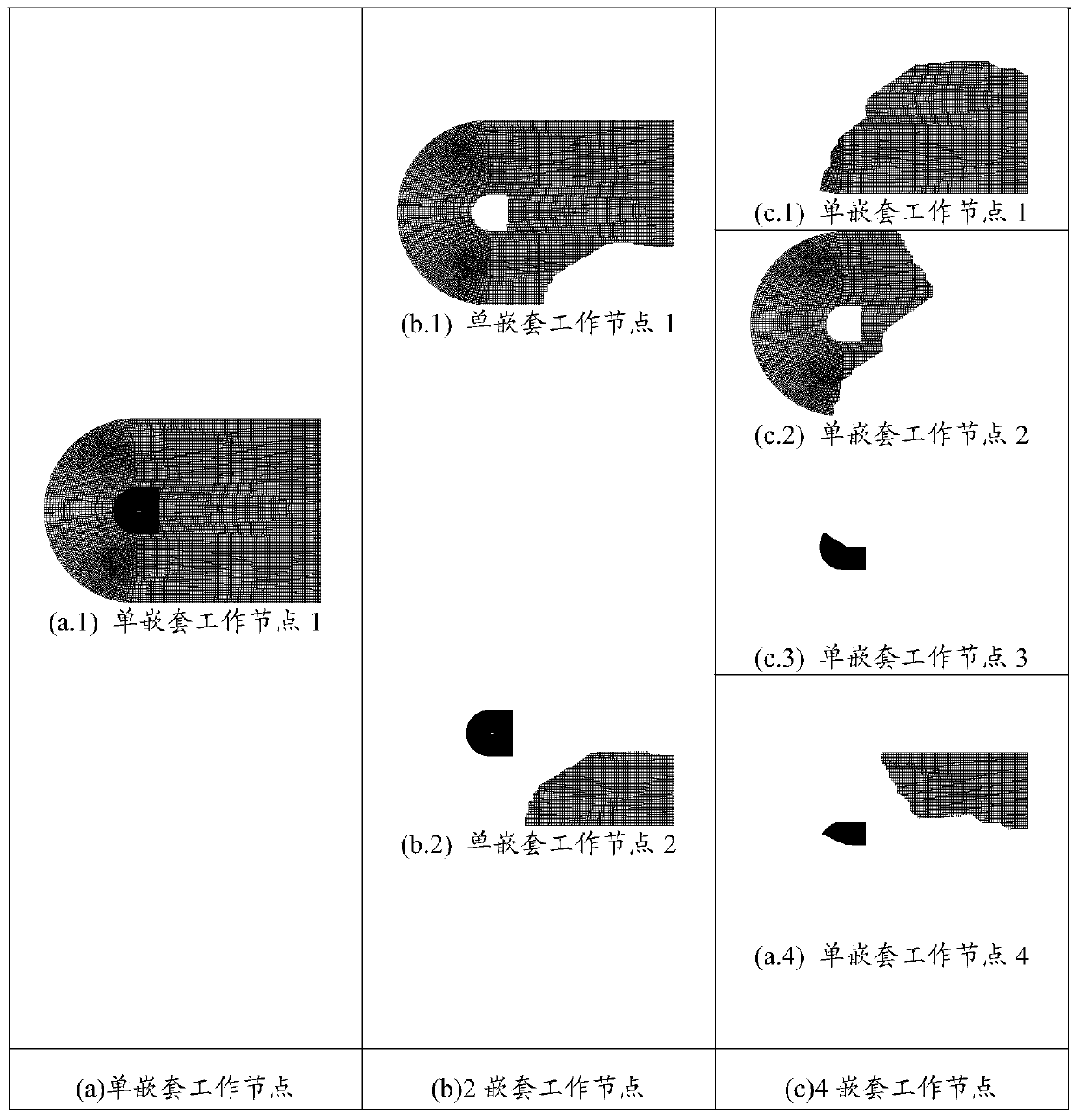

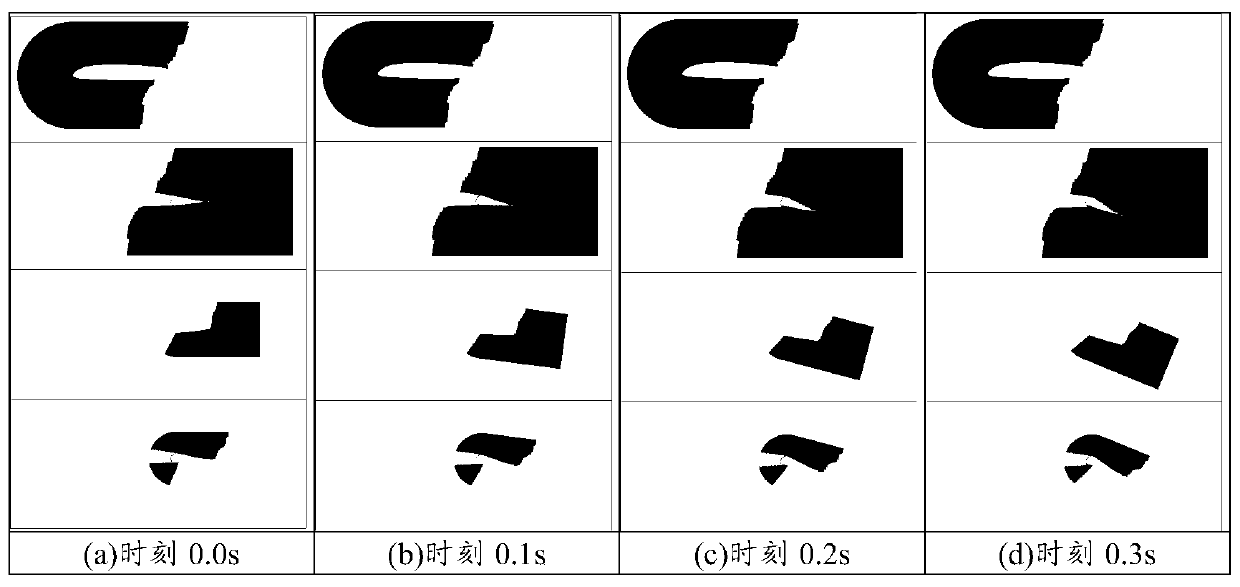

A performance evaluation method and system for an aircraft

ActiveCN109800506BReduce duty cycleIncreased speed of aerodynamic analysisGeometric CADSustainable transportationFlight vehicleSimulation

The invention discloses a method and a system for evaluating the performance of an aircraft. The evaluation method comprises the steps of establishing an overlapped grid model of a target aircraft; Creating a management node, S nested working nodes and N computing working nodes; Extracting N nested grids and S nested grids from the overlapped grid model through the management node; Respectively performing nesting processing on the S nesting grids through the S nesting working nodes; Respectively carrying out aerodynamic force calculation on the N nested grids through N calculation working nodes, and carrying out initial aerodynamic force calculation result exchange and a nested difference value according to nested exchange index information to obtain a local grid aerodynamic force calculation result; Summarizing the local grid aerodynamic force calculation results through the management nodes, judging whether calculation ending conditions are met or not, and outputting the aircraft aerodynamic force calculation results if the calculation ending conditions are met. According to the invention, the aerodynamic analysis speed of the aircraft is improved, and the performance evaluationspeed of the aircraft is further improved.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

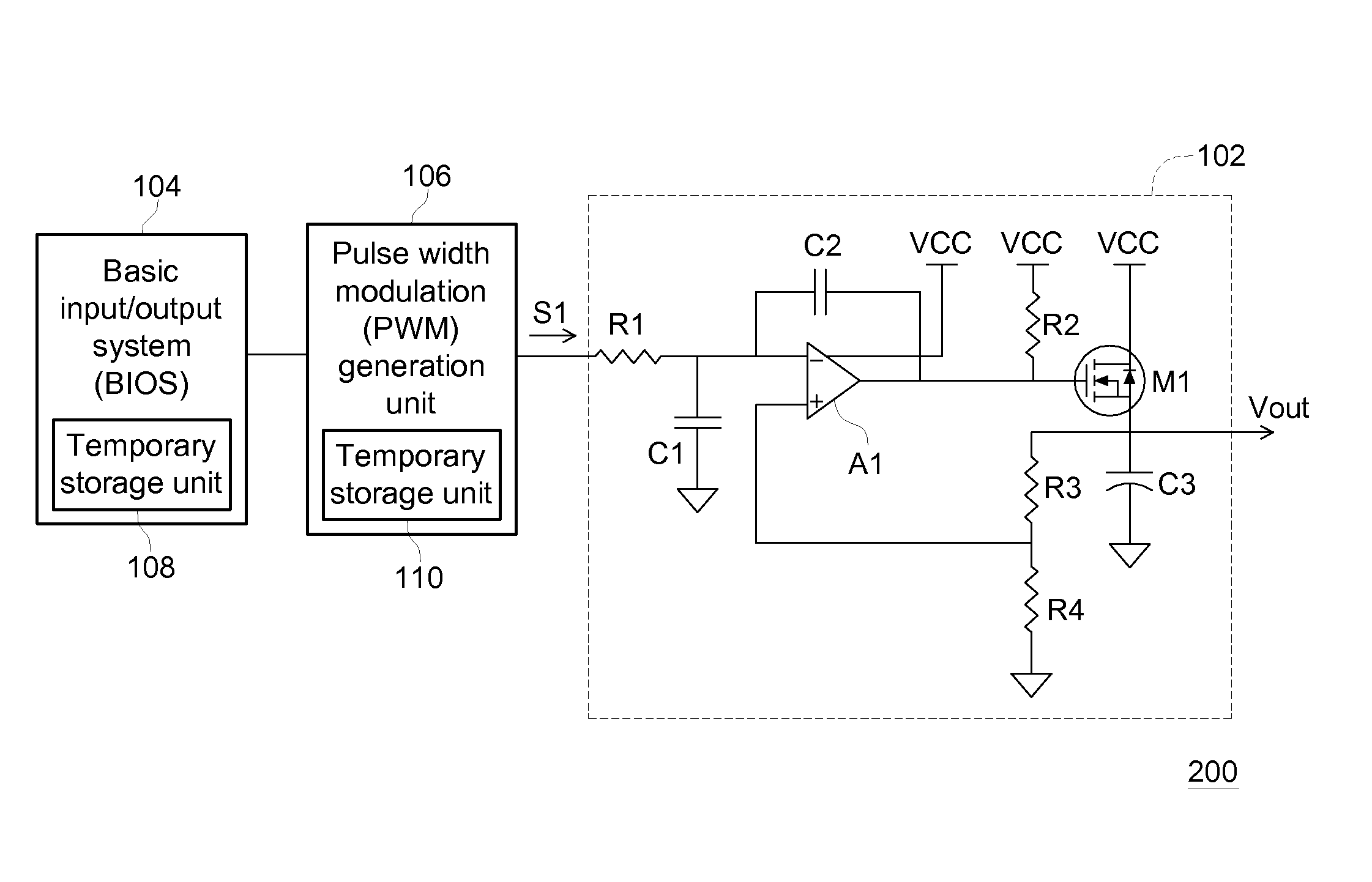

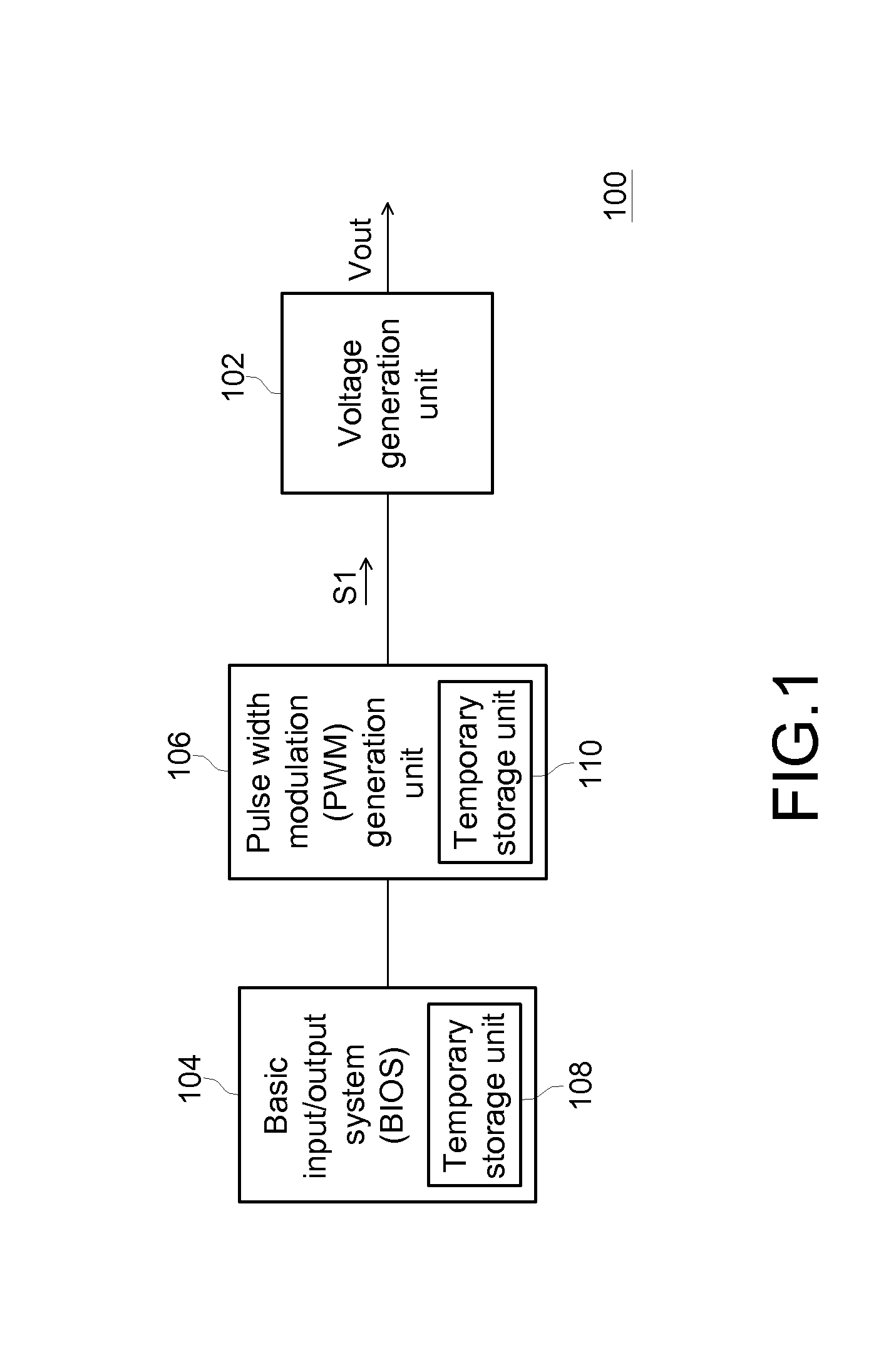

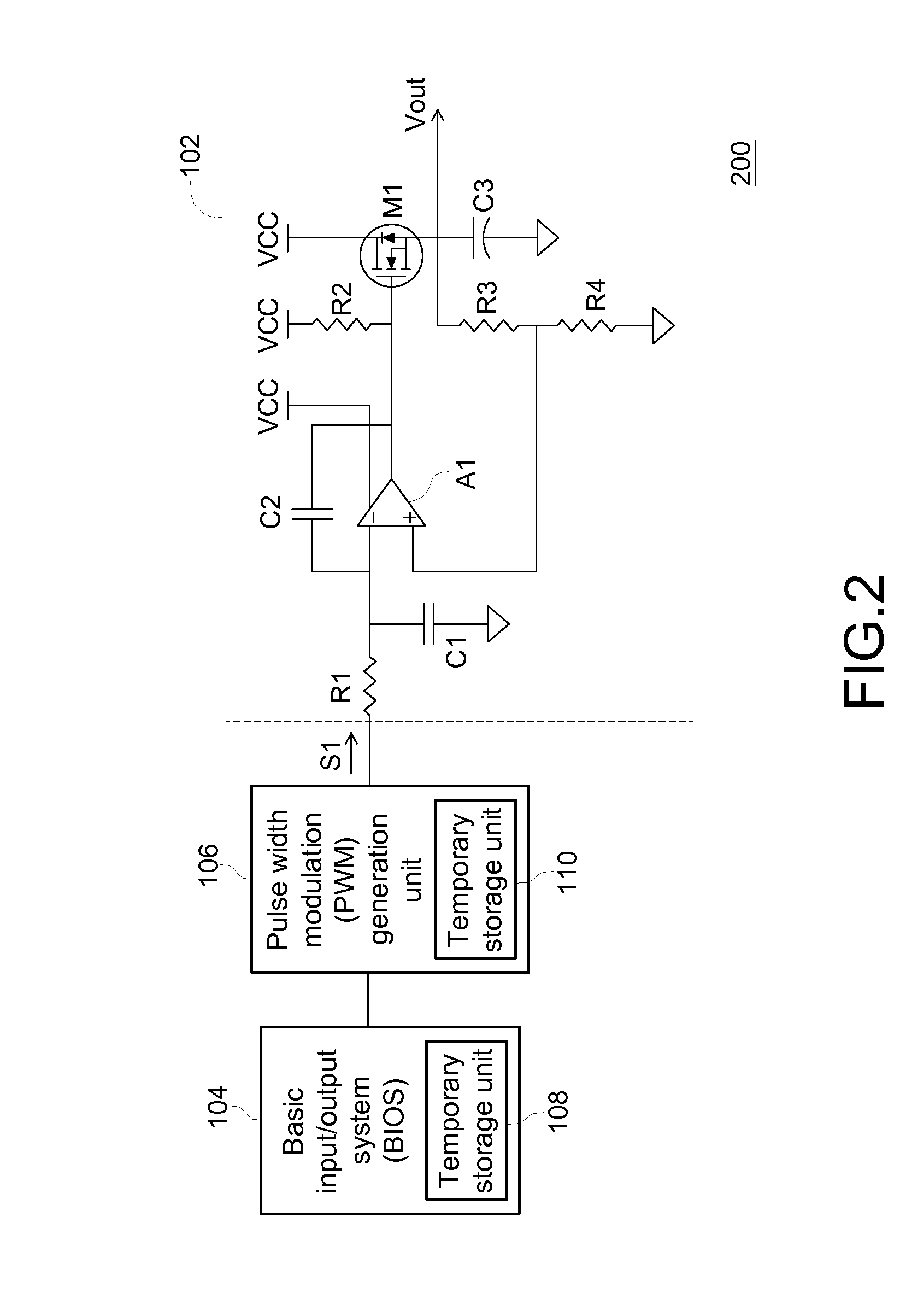

Adjustable voltage output device and adjustment method of operating voltage

InactiveUS20140285168A1Reduce duty cycleEasy to useDc-dc conversionElectric variable regulationEngineeringOutput device

This disclosure relates to an adjustable voltage output device and an adjustment method of an operating voltage, in which the adjustable voltage output device utilizes a basic input / output system for adjusting the duty cycle of the pulse width modulation (PWM) signal outputted by the PWM signal generation unit, so as to change the operating voltage outputted by the voltage generation unit.

Owner:INVENTEC PUDONG TECH CORPOARTION +1

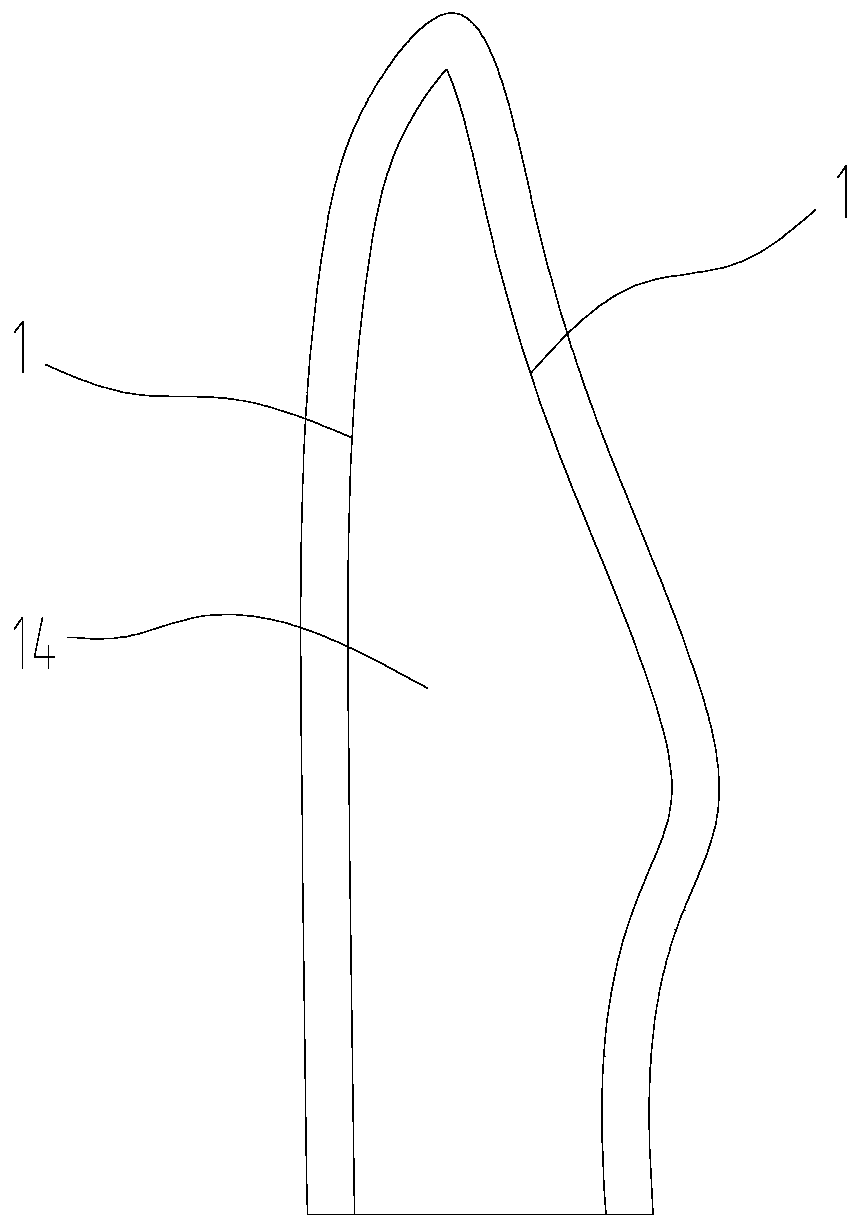

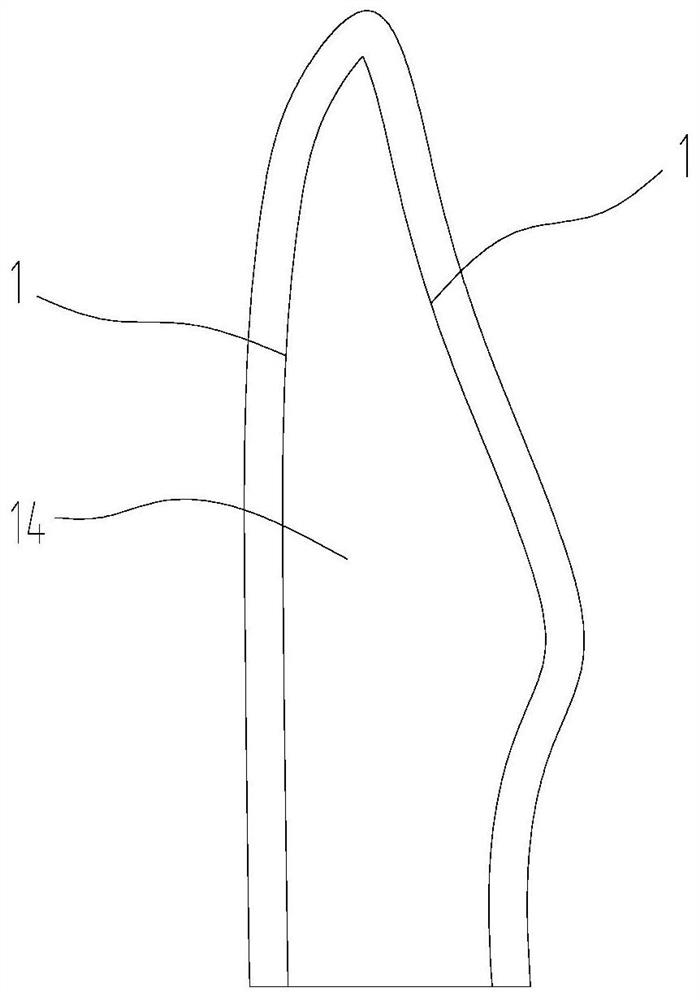

Wind turbine blade mold closing method

ActiveCN111186145ASave operating timeReduce duty cycleFinal product manufactureDomestic articlesTurbine bladeBonding process

The invention discloses a wind turbine blade mold closing method. In the method, by pre-laying a vacuum layer on a mold closing mold splitting surface, mold closing bonding can be directly performed after two vacuum layers are torn off after blade forming. By means of the method, the operation time of staff can be shortened, the mold occupation cycle of the bonding process can be shortened, it isavoided that on-site vacuum wrapping is preformed again in a traditional method, and the passing rate of vacuum inspection is significantly increased.

Owner:中材科技(萍乡)风电叶片有限公司

A slotting machine for bidirectional slotting of cardboard and method for bidirectional slotting of cardboard

ActiveCN106079562BReduce duty cycleShorten the production cycleBox making operationsPaper-makingProduction linePaperboard

The invention provides a grooving machine for bi-directional paperboard grooving. The grooving machine comprises a workbench (100), a paperboard feeding device (200), a vacuum adsorption assembly (300), a movable cutter assembly (400), a fixed cutter (500), an output belt (600) and a rack (700), wherein the paperboard feeding device (200), the movable cutter assembly (400), the fixed cutter (500) and the output belt (600) are sequentially arranged on the workbench (100) and are used for achieving transportation and cutting grooving of paperboards; the paperboard feeding device (200) is positioned at the foremost end of a production line, and is used for placing and feeding the paperboards; the workbench (100) is positioned at the undermost part of the rack (700); the fixed cutter (500) is directly fixed to the rack (700), and is used for cutting the moving paperboards; and the output belt (600) is positioned at the rearmost end of the production line, and is used for outputting the cut paperboards. According to the grooving machine, the production efficiency of paperboard grooving is improved, the paperboards are located and processed at a time, the defective rate is decreased, raw materials are fully utilized, and the production cost is reduced.

Owner:江苏丰彩包装材料有限公司

General casting machine feeding device

The invention relates to a general casting machine feeding device which comprises a fixed die plate, an inclined hole, a guiding barrel, a sliding rail and a traction device, wherein the inclined hole is formed in the middle part of the fixed die plate; a traction oil cylinder is used for pulling the guiding barrel to slide on the sliding rail, so that the positioning movement of materials supplied during the feeding is realized, the leftward and rightward inclined swing of the guiding barrel of the general casting machine is reduced, the working efficiency is improved, the complexity level of the equipment is simplified and the controllability and stability of the equipment are improved. By using the method of inclining the guiding barrel to drain, the accurate control of the feeding positioning is realized. Through replacing the inclining and straightening actions of the original inclining device, the efficiency is improved. The guiding barrel can be provided with connectors matched with various feeding machines. The general casting machine feeding device is used as a feeding device for metal forming machines and applied to the field of metal forming.

Owner:苏州盖成机械有限公司

A kind of wind power blade clamping method

ActiveCN111186145BSave operating timeReduce duty cycleFinal product manufactureDomestic articlesBonding processStructural engineering

The invention discloses a mold-closing method for wind power blades. A vacuum layer is pre-laid on the mold-closing and parting surfaces, and the two vacuum layers can be torn off after the blades are formed and can be directly mold-closed and bonded. The invention can reduce the operating time of employees, reduce the mold occupation cycle of the bonding process, avoid the traditional on-site vacuum repacking, and significantly improve the pass rate of the vacuum inspection.

Owner:中材科技(萍乡)风电叶片有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com