Wind turbine blade mold closing method

A technology for wind power blades and molds, which is applied in sustainable manufacturing/processing, climate sustainability, and other household appliances. It can solve the problems of increasing the blade mold cycle, low vacuum pass rate, and easy air leakage, etc., so as to reduce the number of employees The operation time, the probability of vacuum air leakage is small, and the effect of reducing the cycle time of the mold

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

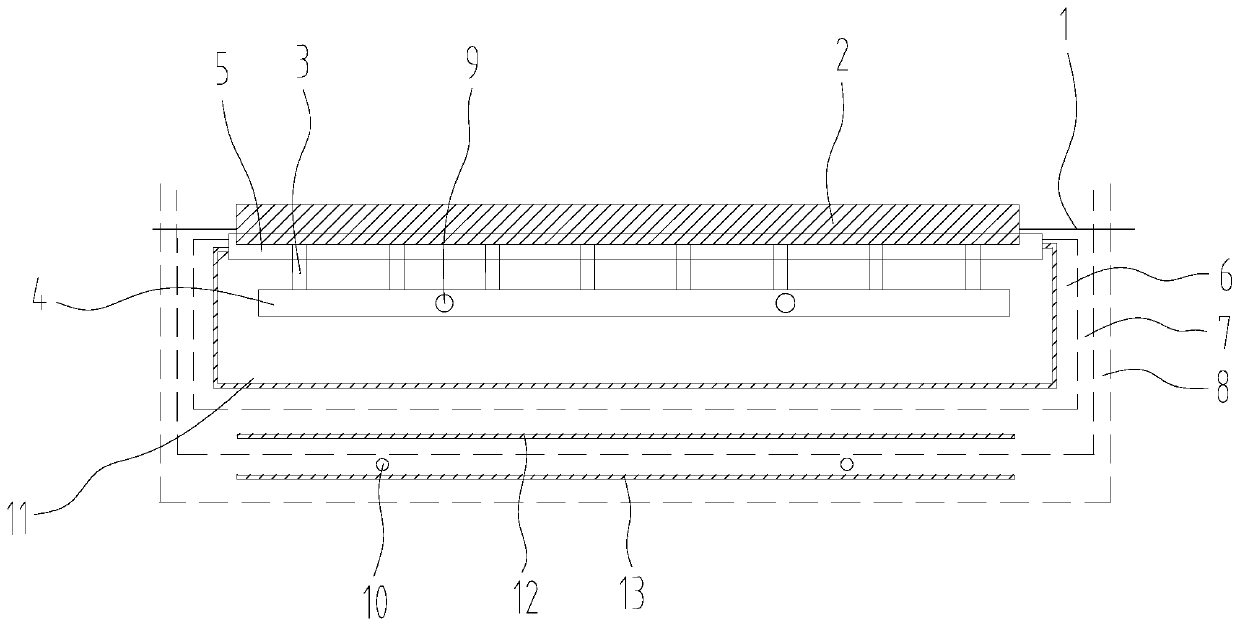

[0020] The invention provides a method for mold closing of wind power blades. Vacuum is required for mold clamping, that is, a vacuum is required in the bonding process of blade mold clamping. When the auxiliary materials are torn off in the bonding process, a vacuum film is reserved on the parting surface. Then reapply the vacuum tape on the outside of the mold edge, and seal the reserved vacuum film through the vacuum tape, so that the parting surface is in a negative pressure state, and the skin is tightly adsorbed on the mold, so that the skin can be together with the mold. Flip and close the mold.

[0021] Specific steps are as follows:

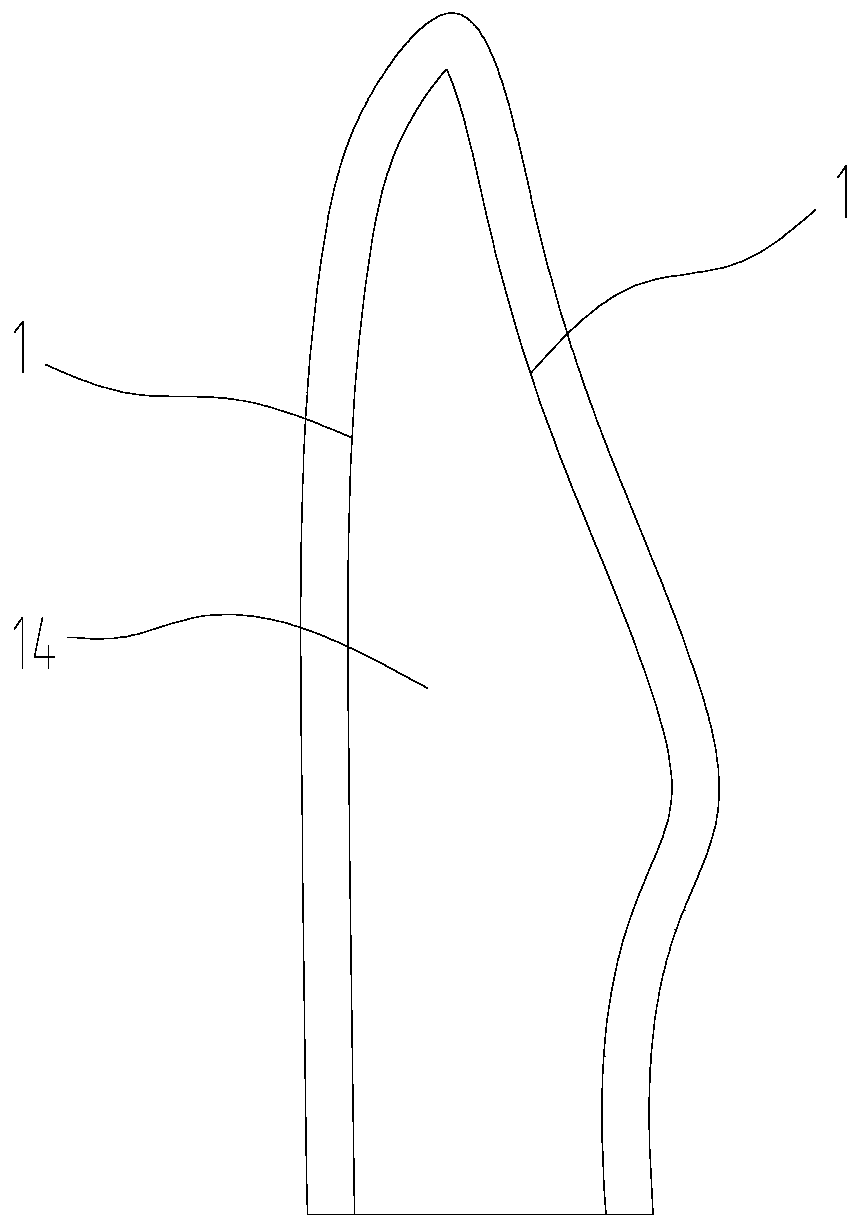

[0022] Step 1, laying the blade skin glass fiber cloth 2 in the main mold, and the glass fiber cloth 2 needs to cover the edge prism 1 of the main mold;

[0023] Step 2, prepare the first rubber-absorbi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com