Ultrathin electromagnetic steel sheet

A kind of electromagnetic steel plate, ultra-thin technology, applied in the direction of thin material processing, inorganic material magnetism, ultra-thin film/granular film, etc., can solve the problems of difficult high-Si steel plate, processability deterioration, etc., to achieve stable magnetic properties and avoid magnetic properties effect of degradation and reduction of the duty cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

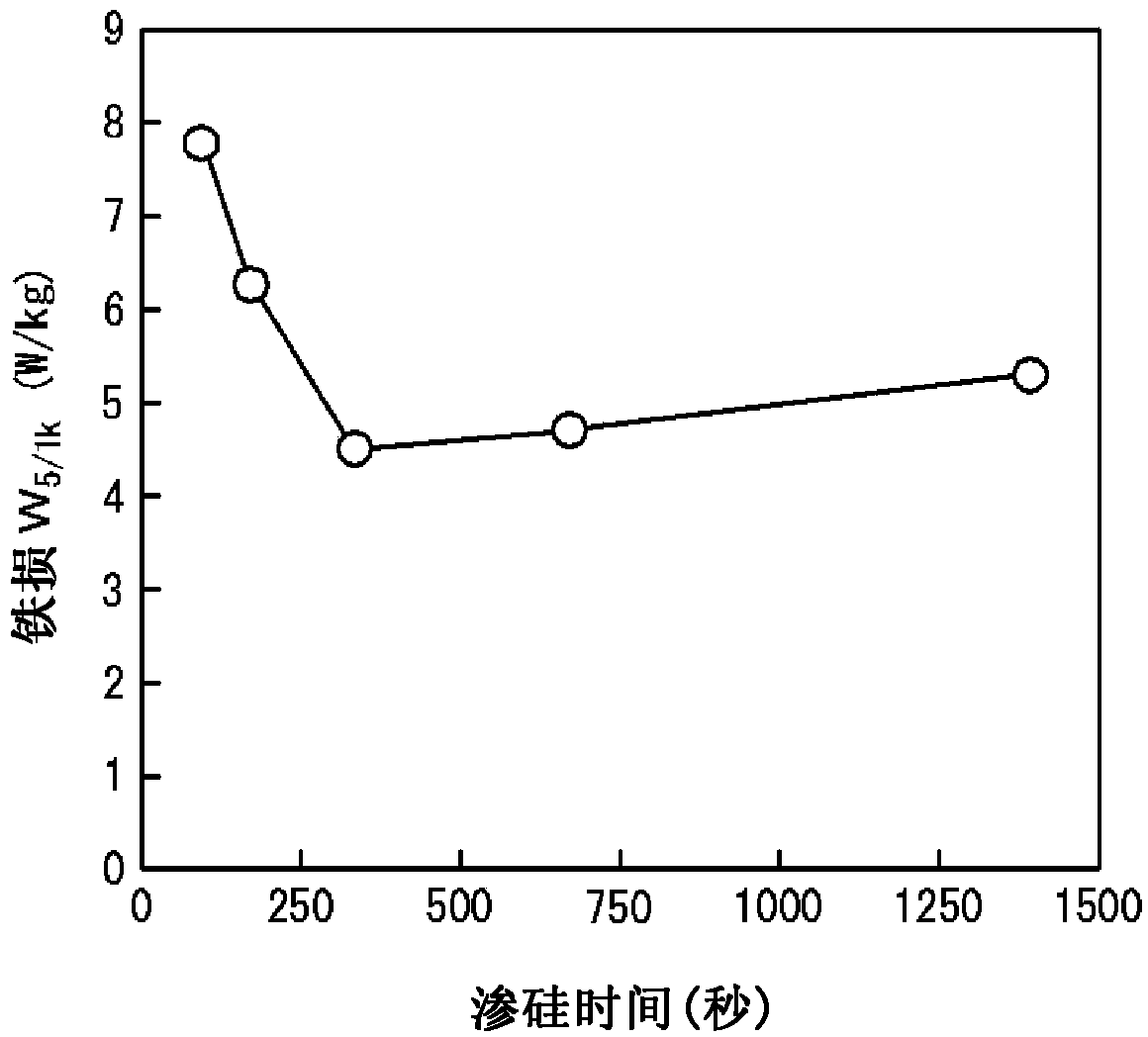

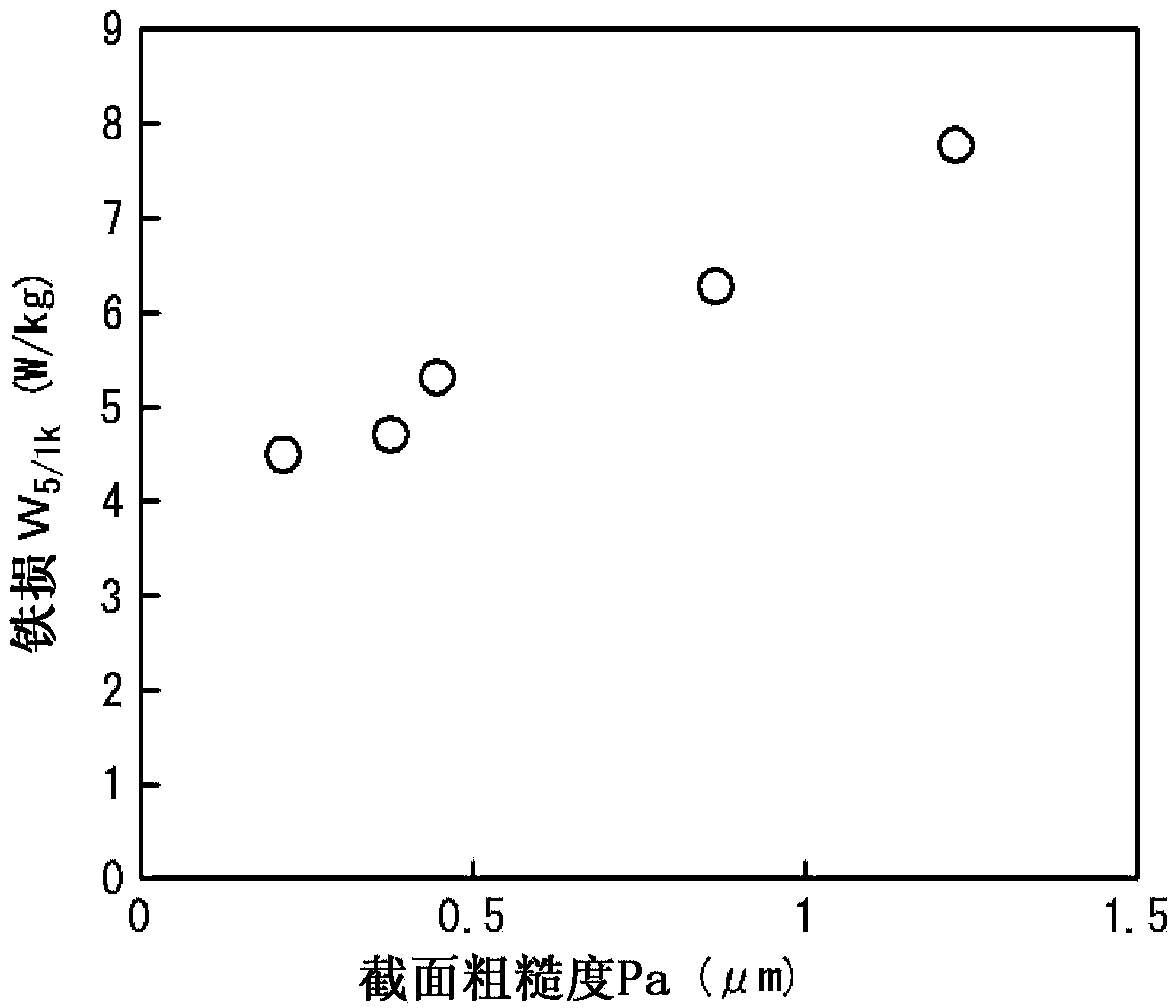

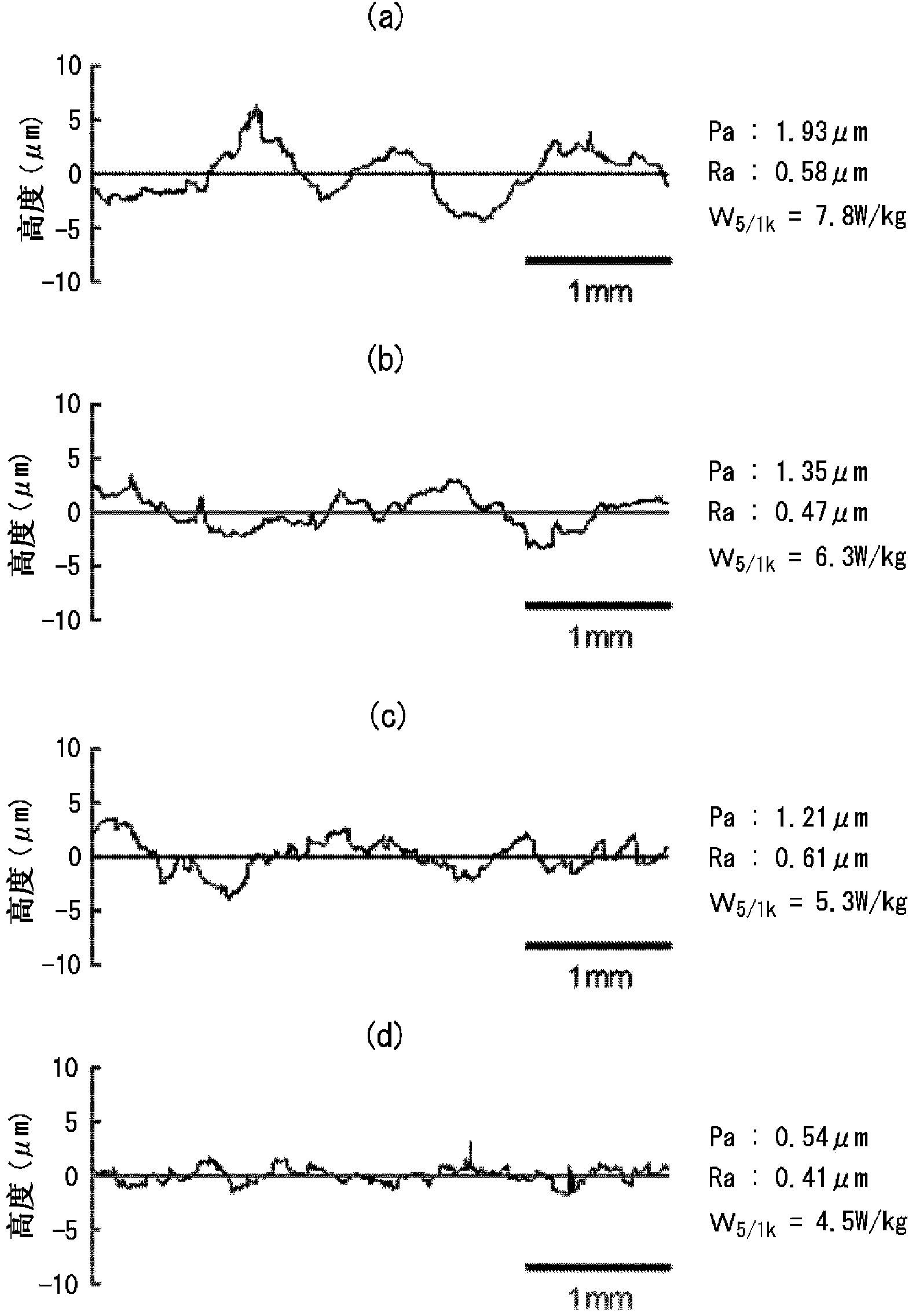

Embodiment 1

[0085] A steel billet containing C: 0.0031%, Si: 3.05%, and Mn: 0.15% is produced by continuous casting, and the balance is composed of Fe and unavoidable impurities. rolling plate. Next, the hot-rolled sheet was annealed at 1000° C. for 30 seconds, then cold-rolled to a sheet thickness of 0.075 mm, and then rolled in (10% SiCl 4 +90% Ar) atmosphere at 1100° C. for 600 seconds of siliconizing treatment. At this time, in the annealing furnace, such as Figure 4 As shown in (a), it is installed in such a way that intermittent siliconizing treatment can be performed. Two or more nozzles 1 for injecting raw material gas are arranged near both surfaces of the steel plate 2, and a pair of nozzles 1 for shielding raw material gas are arranged between the nozzles. The shielding plates 3 can be siliconized by raw material gas in the vicinity of the injection nozzle 1 without siliconizing between the shielding plates 3 . Moreover, for some samples, such as Figure 4 As shown in (b),...

Embodiment 2

[0093] Steel slabs having various compositions shown in Table 2 were produced by continuous casting, heated at 1200° C., and then hot-rolled into 2.7 mm hot-rolled sheets. Next, the hot-rolled sheet was annealed at 900° C. for 30 seconds, then cold-rolled to a sheet thickness of 0.050 mm, and then rolled in (15% SiCl 4 +85%N 2 ) in an atmosphere at 1200° C. for 100 seconds of siliconizing treatment. At this time, in the annealing furnace, such as Figure 4 As shown in (a), it is installed in such a way that intermittent siliconizing treatment can be performed. Two or more nozzles 1 for injecting raw material gas are arranged near both surfaces of the steel plate 2, and a pair of nozzles 1 for shielding raw material gas are arranged between the nozzles. The shielding plates 3 can be siliconized by raw material gas in the vicinity of the injection nozzle 1 without siliconizing between the shielding plates 3 . In addition, at this time, the line tension at the time of passing ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com