Patents

Literature

95results about "Ultrathin/granular films" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

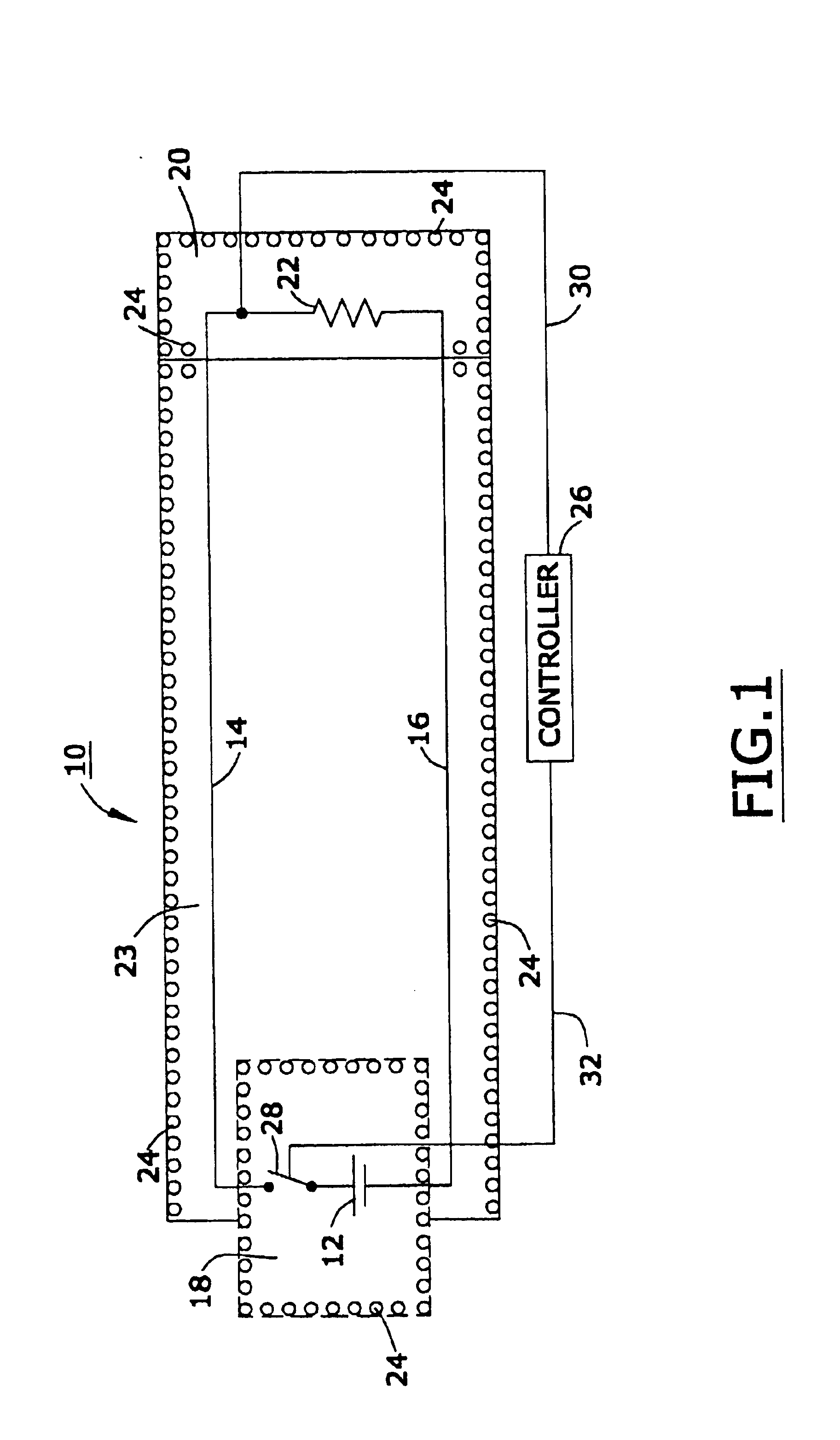

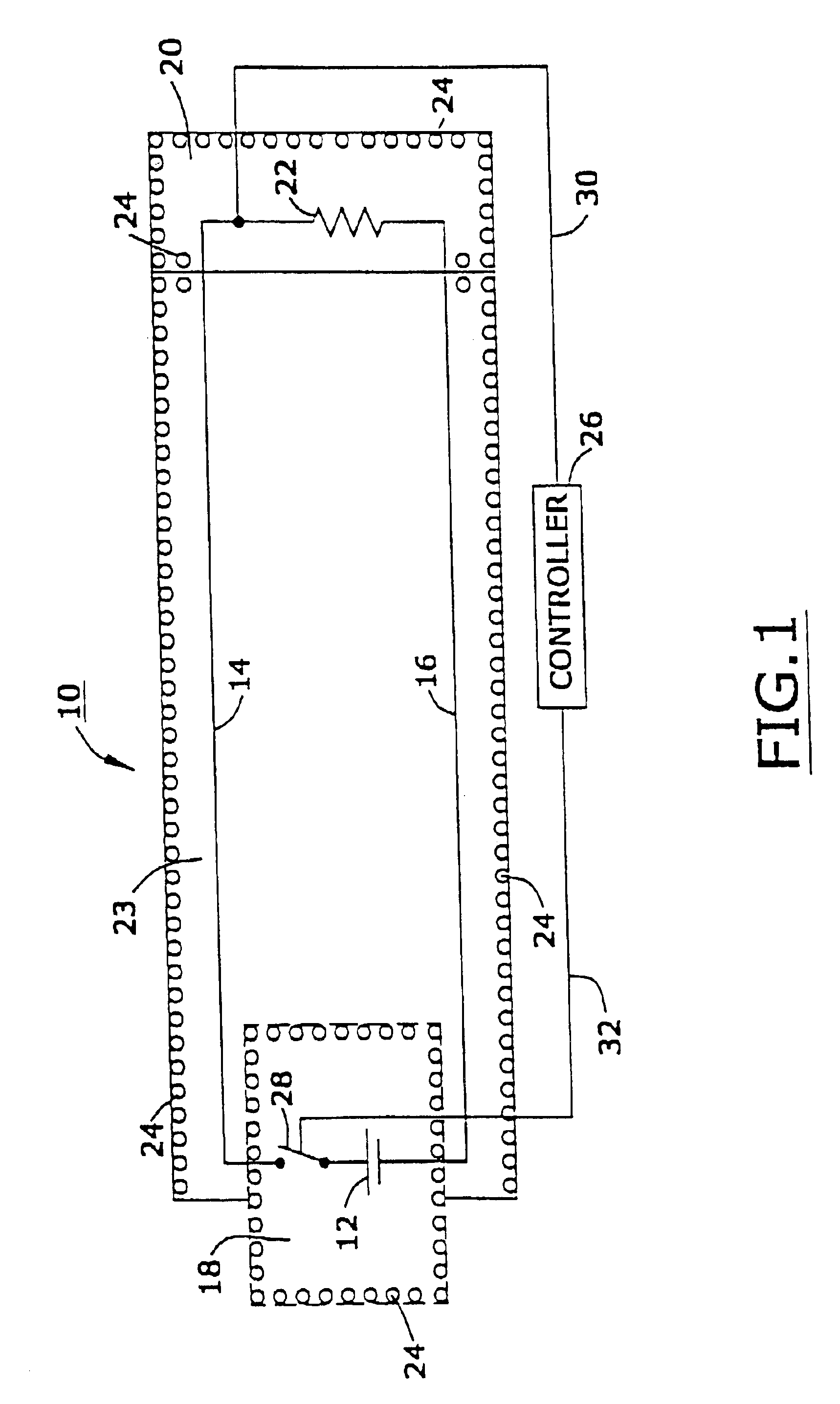

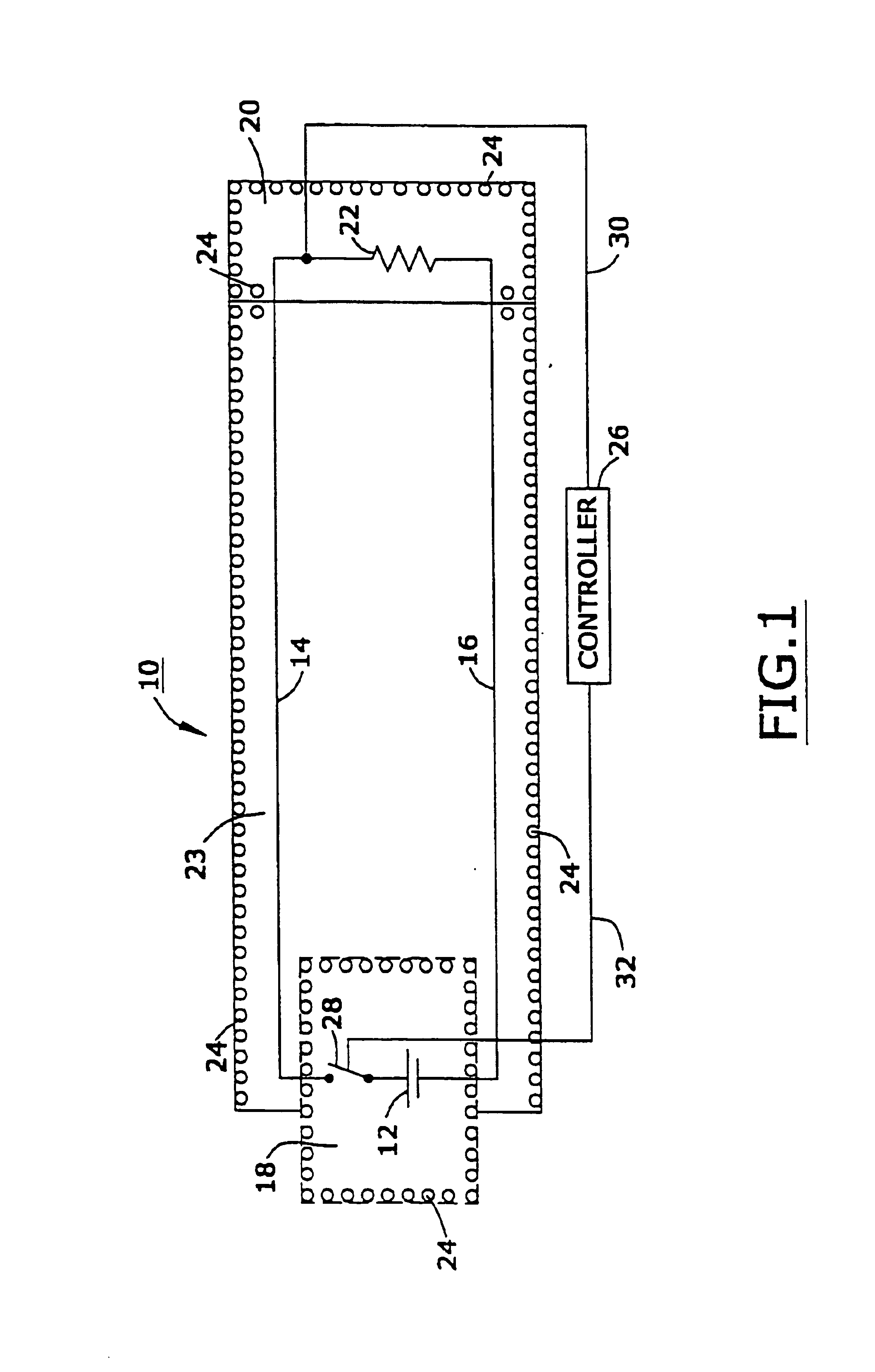

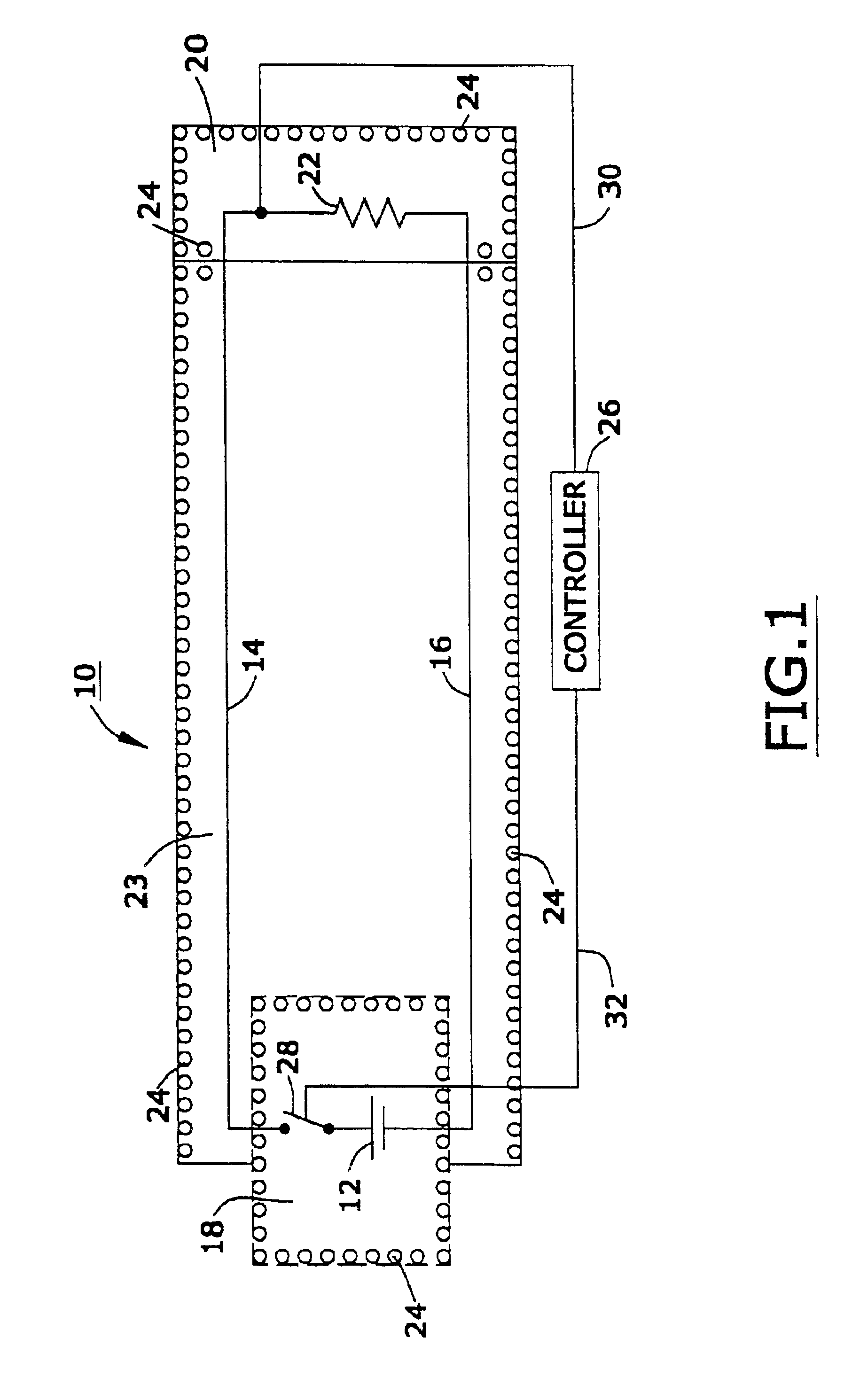

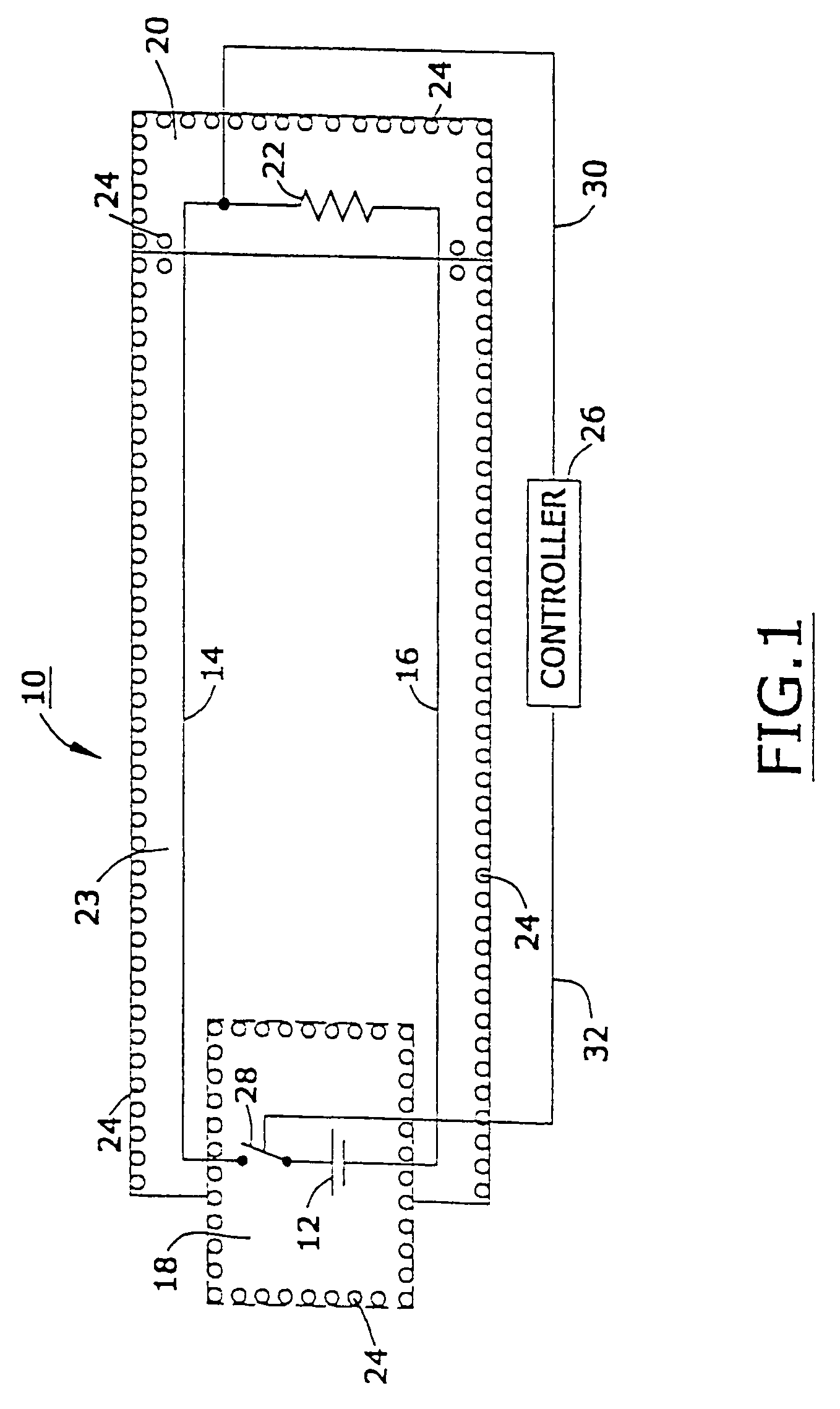

Protective assembly

An assembly for protecting biological tissue from the effects of heating. The assembly contains a conductor in contact with the biological tissue and forming an electrical circuit comprising the biological tissue. The assembly contains a device for modifying the impedance of the electrical circuit such that, at a frequency of from about 10 megahertz to about 150 megahertz, such impedance is at least about 0.5 ohms per centimeter of length of said conductor. The assembly also contains a device for limiting the flow of current through the biological tissue such that, when the assembly is exposed to an alternating current electromagnetic field at a frequency of 64 megahertz and a magnetic field strength of 1.5 Tesla for 15 minutes, the temperature of the biological tissue does not exceed 42 degrees Celsius.

Owner:BIOPHAN TECH

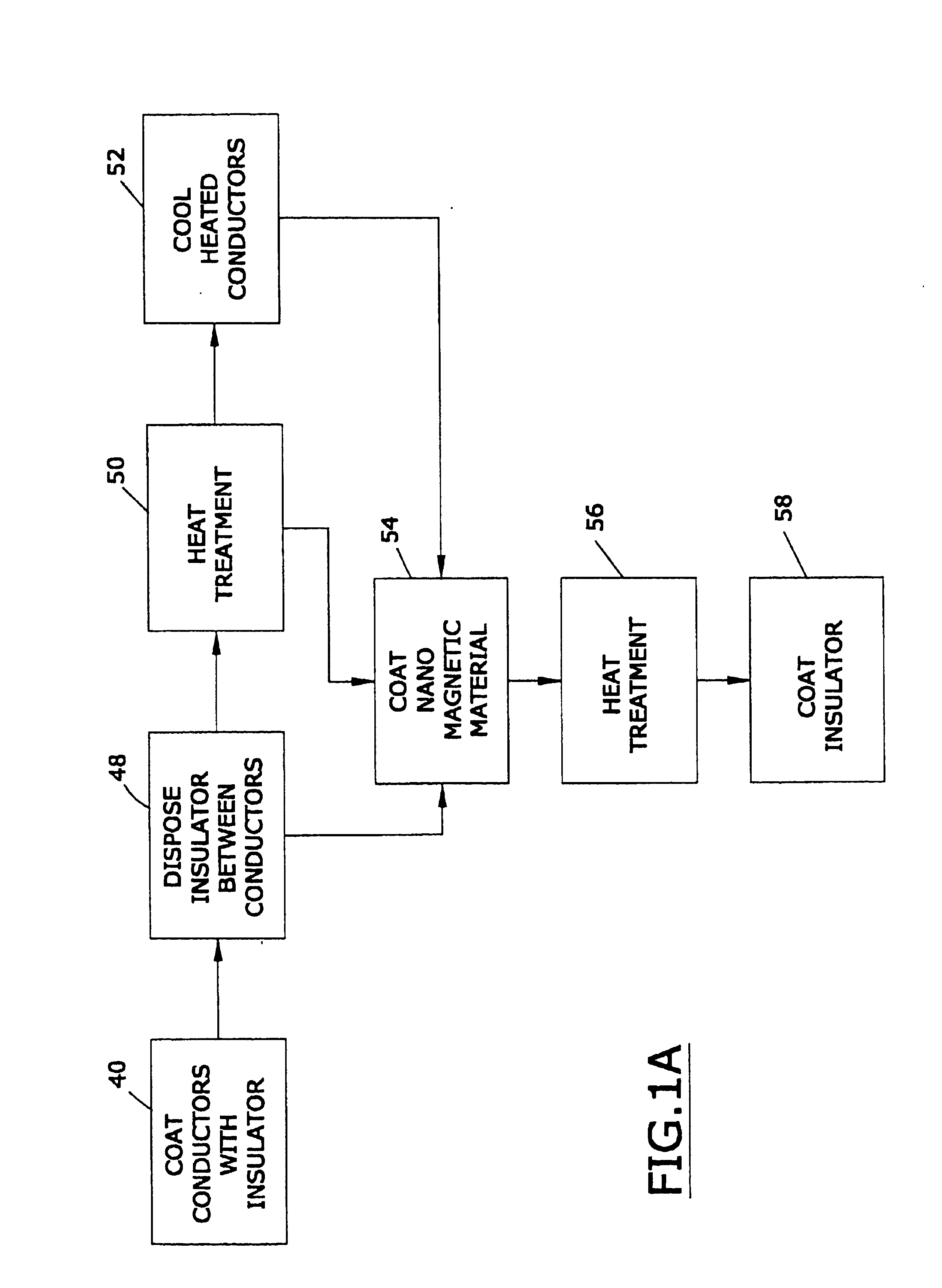

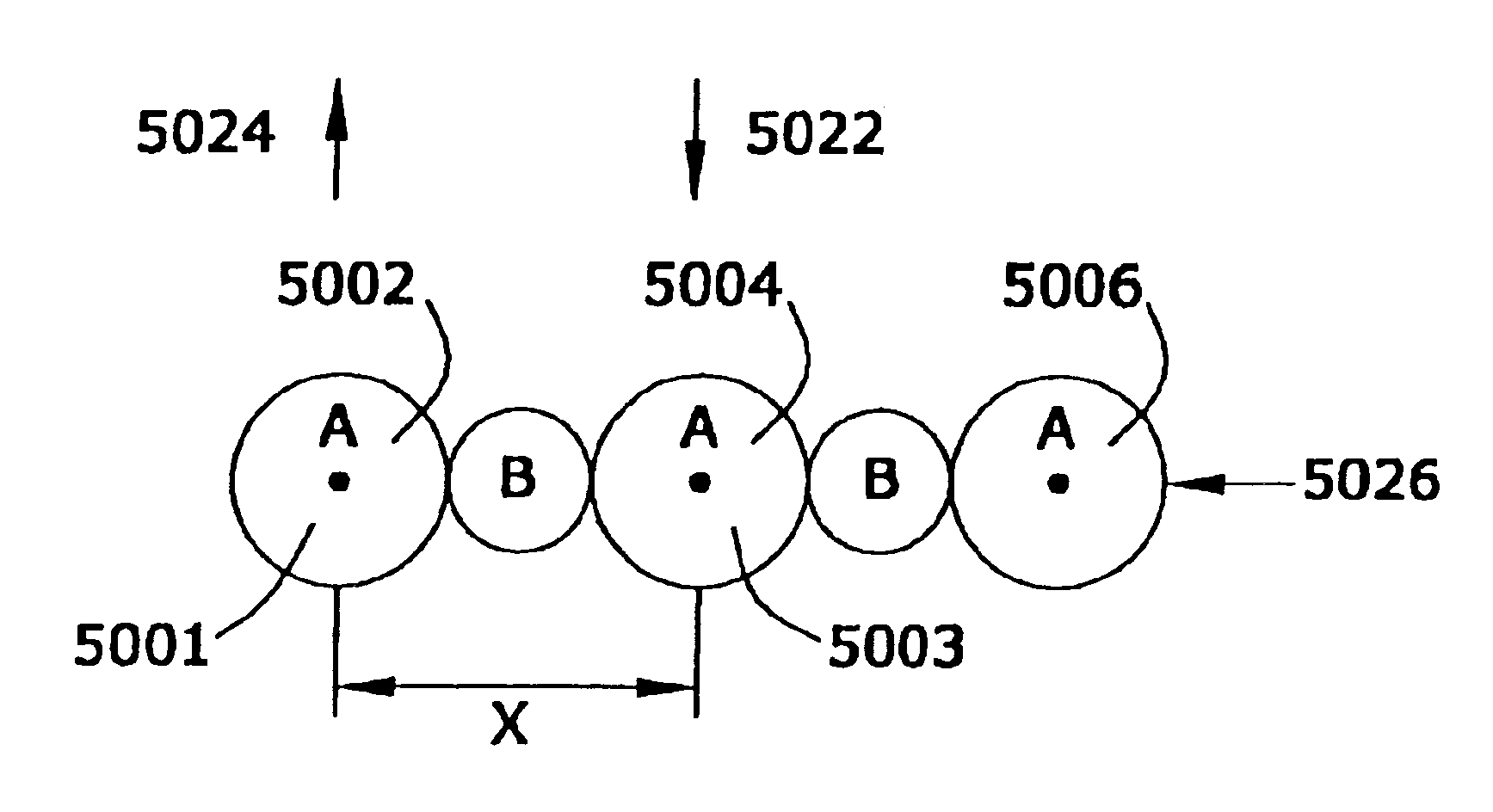

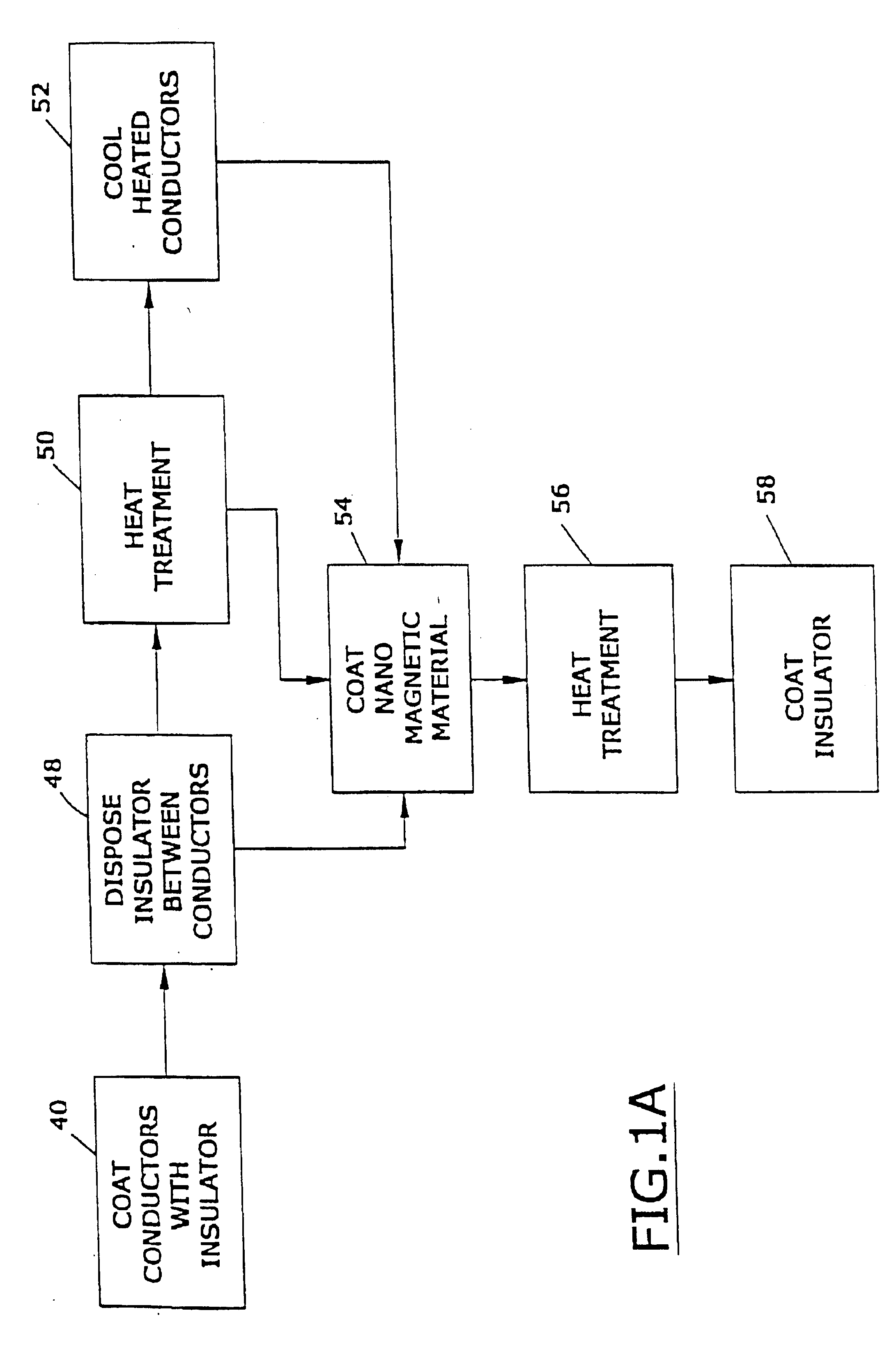

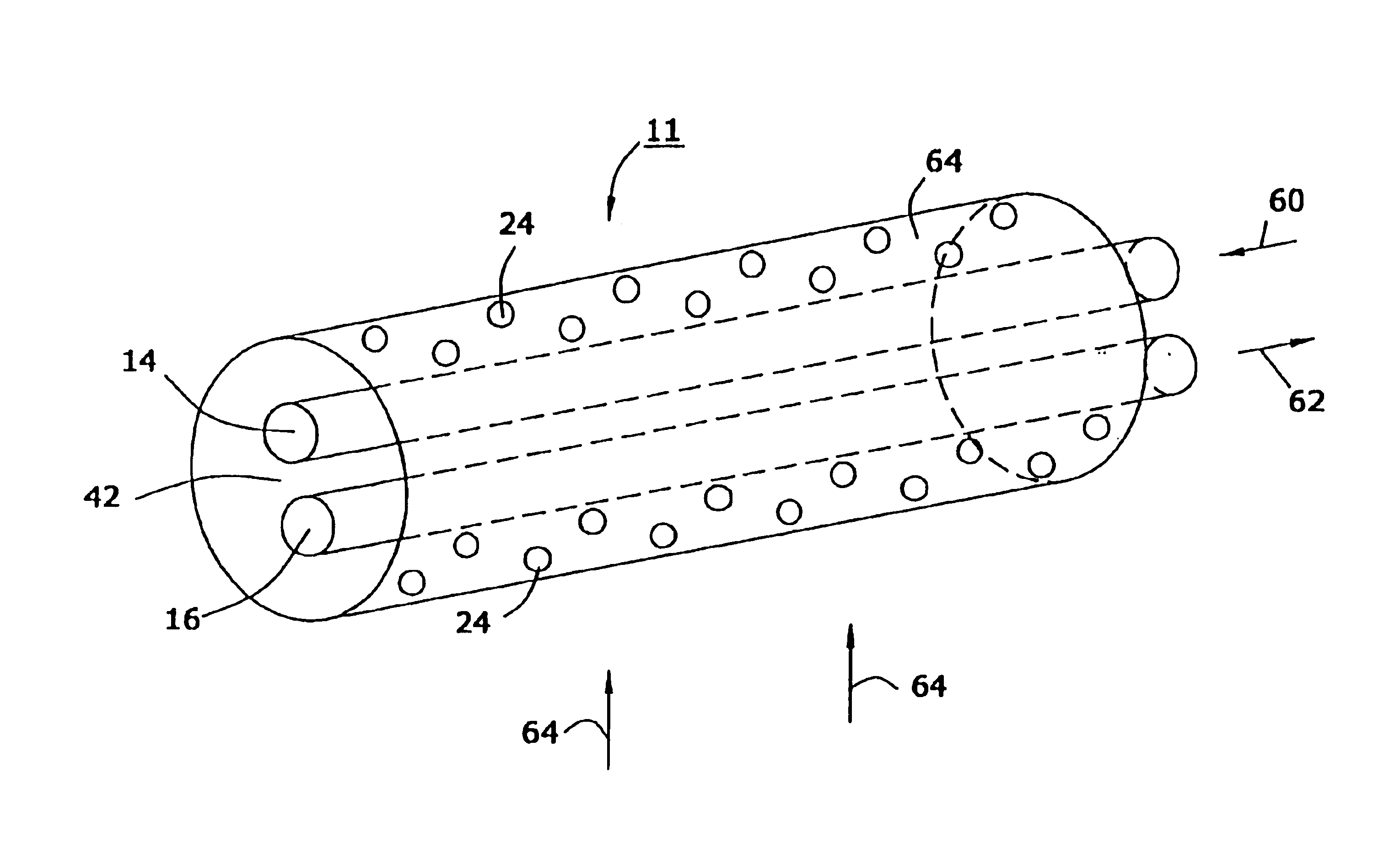

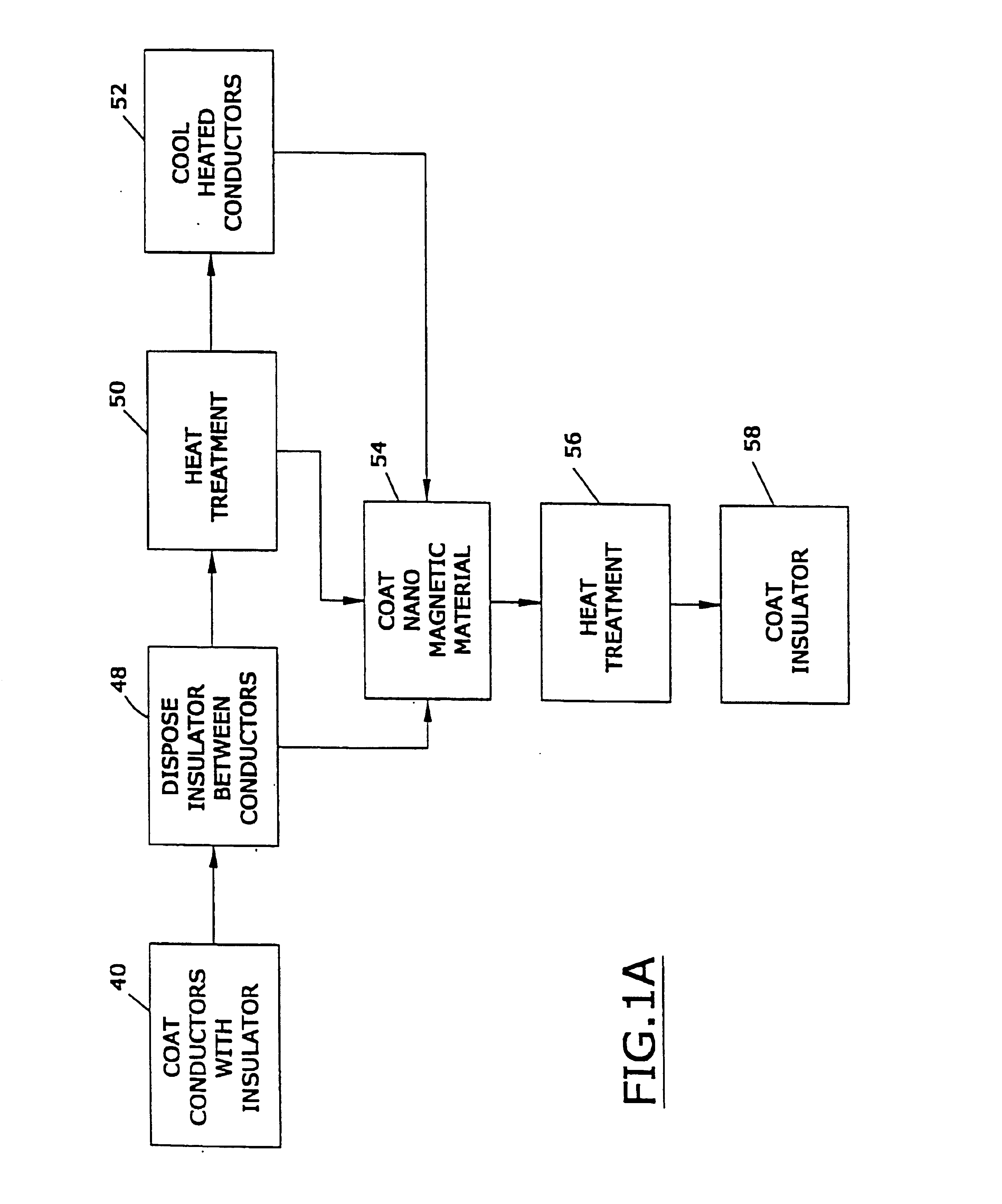

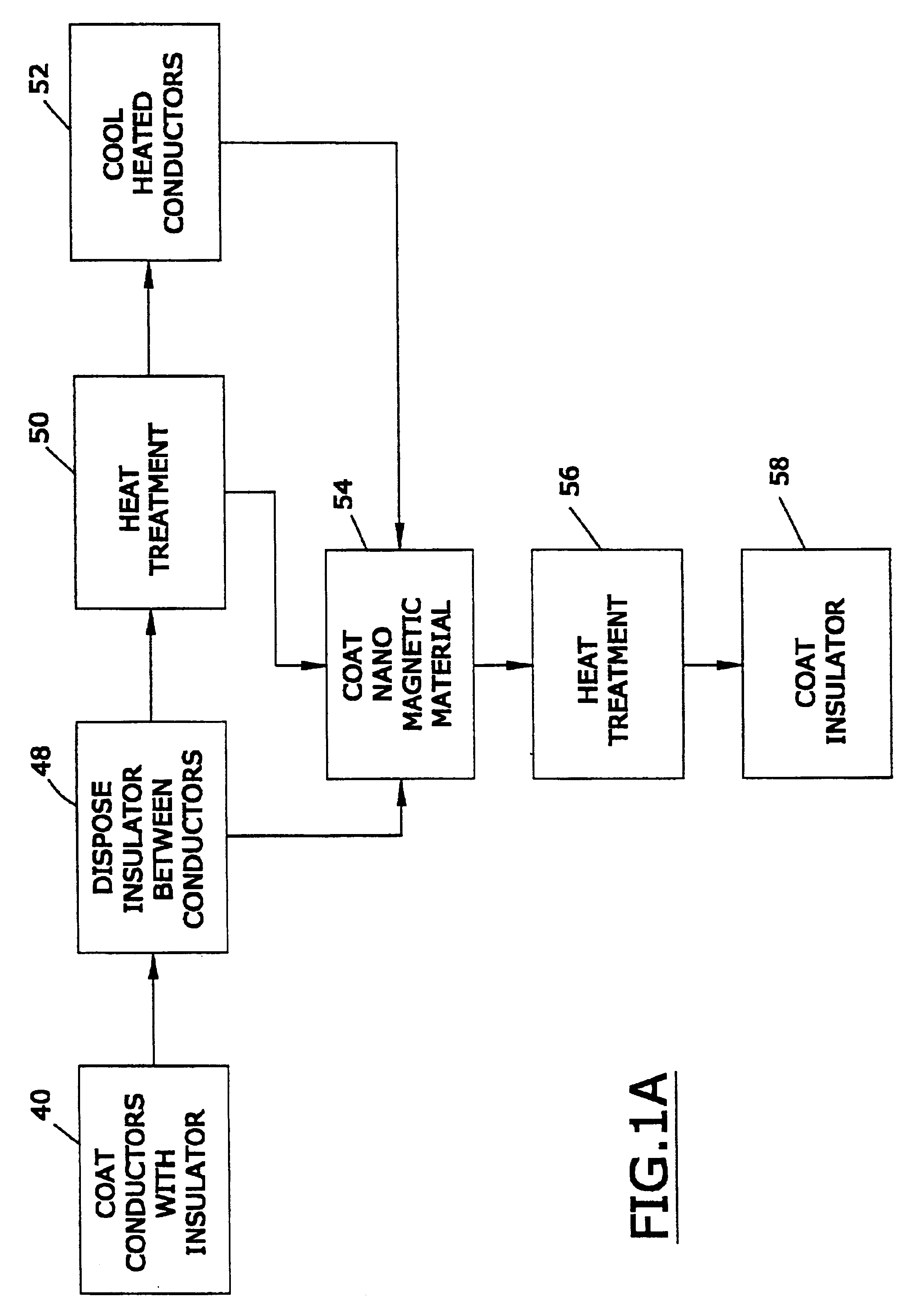

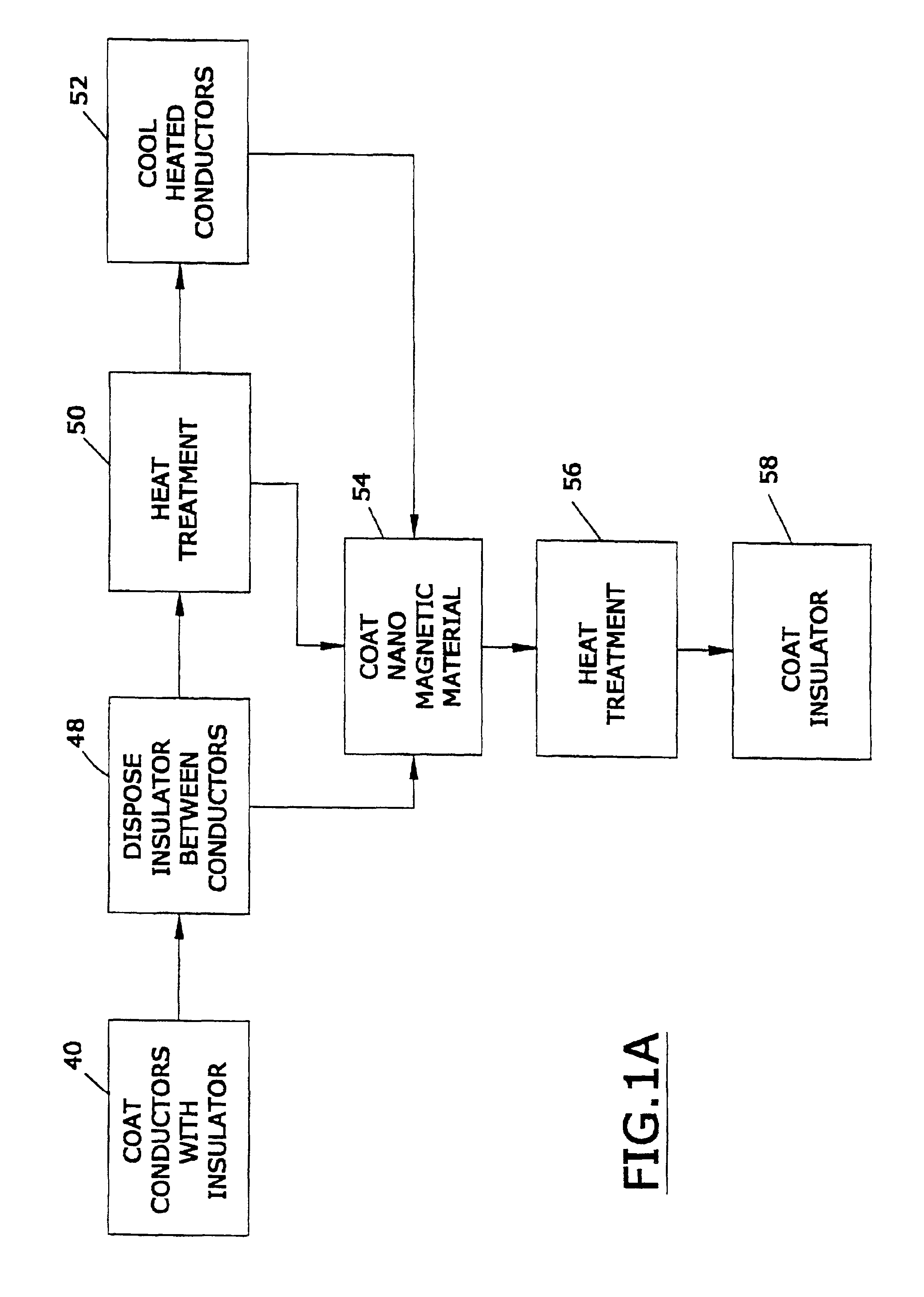

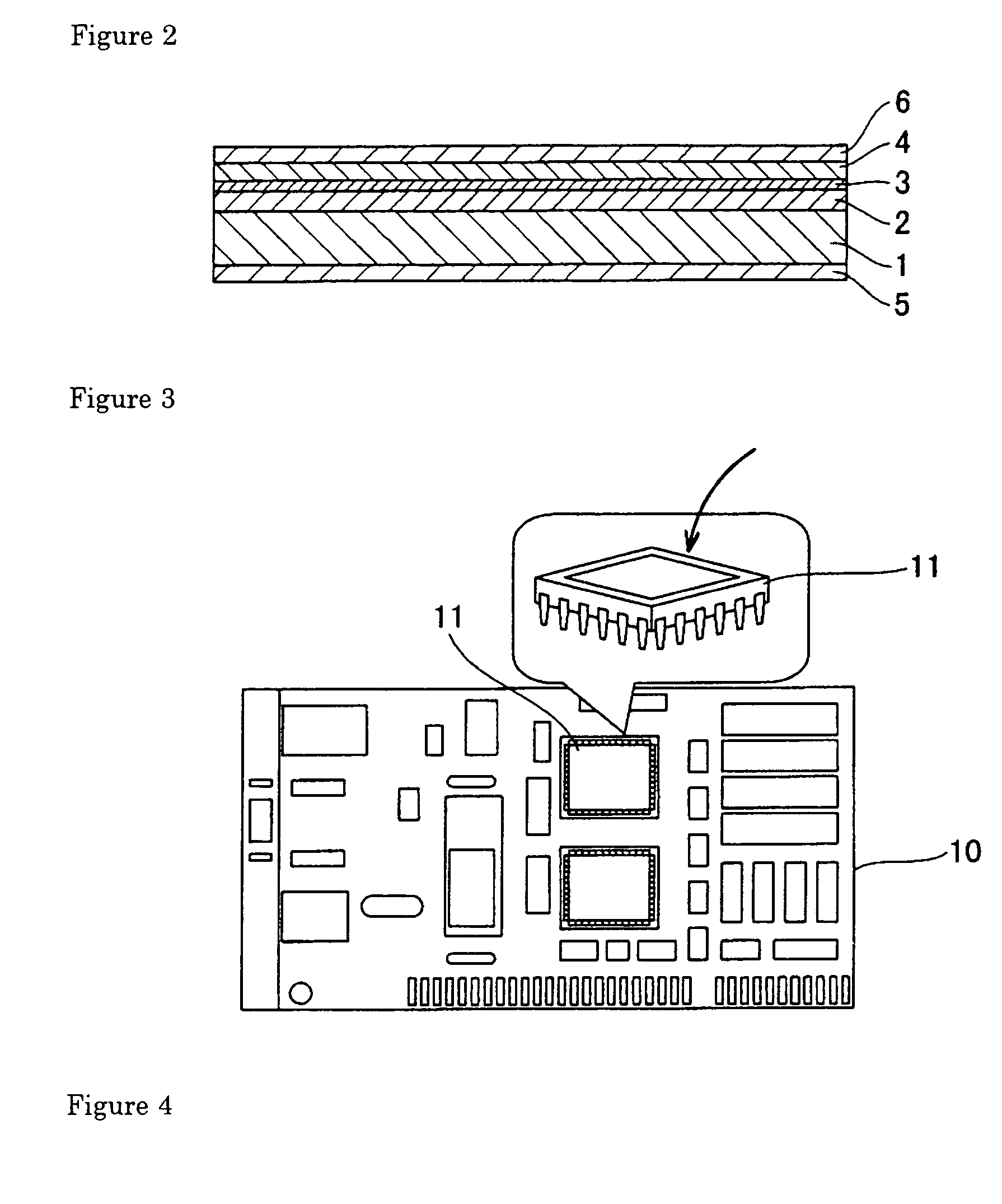

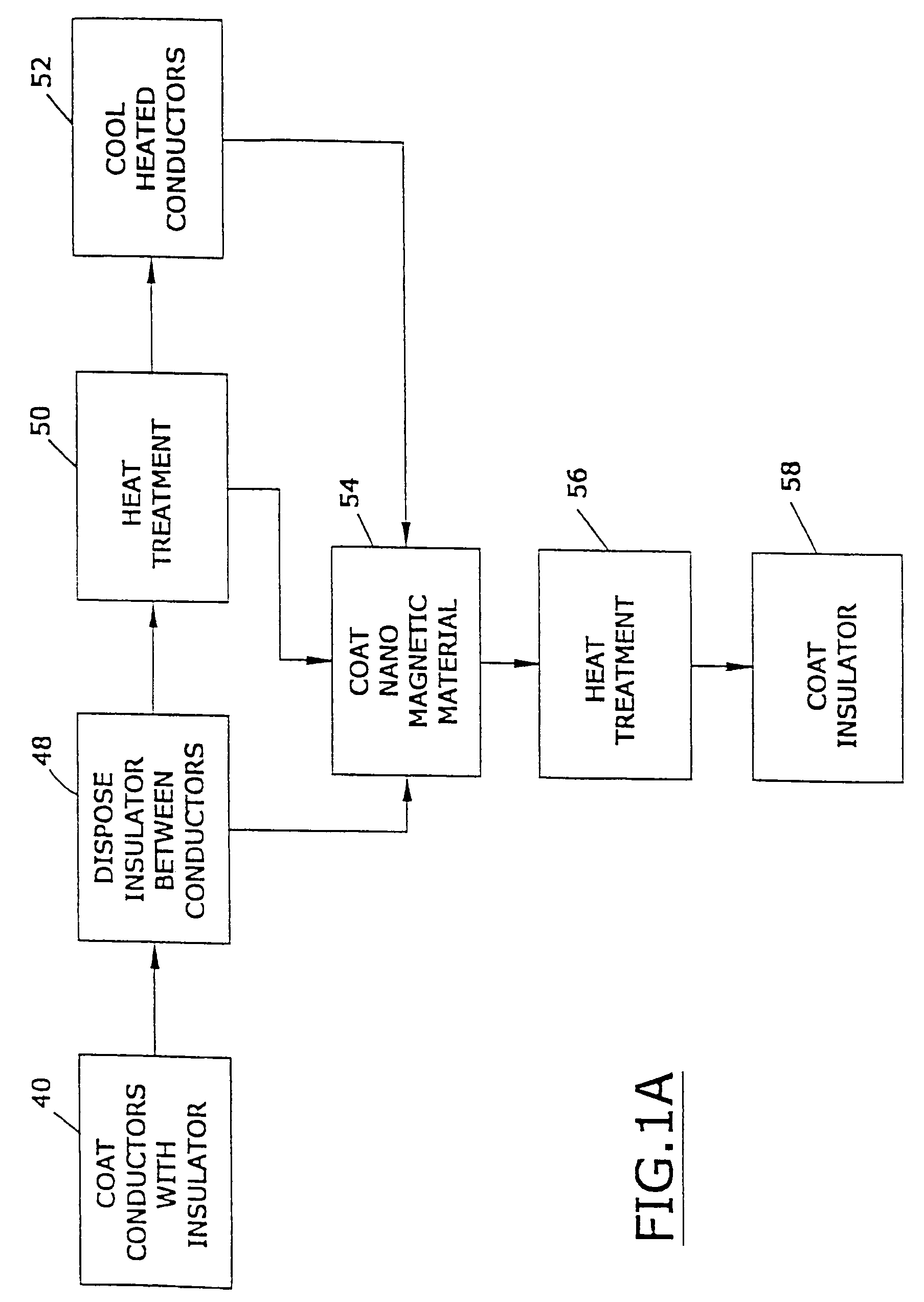

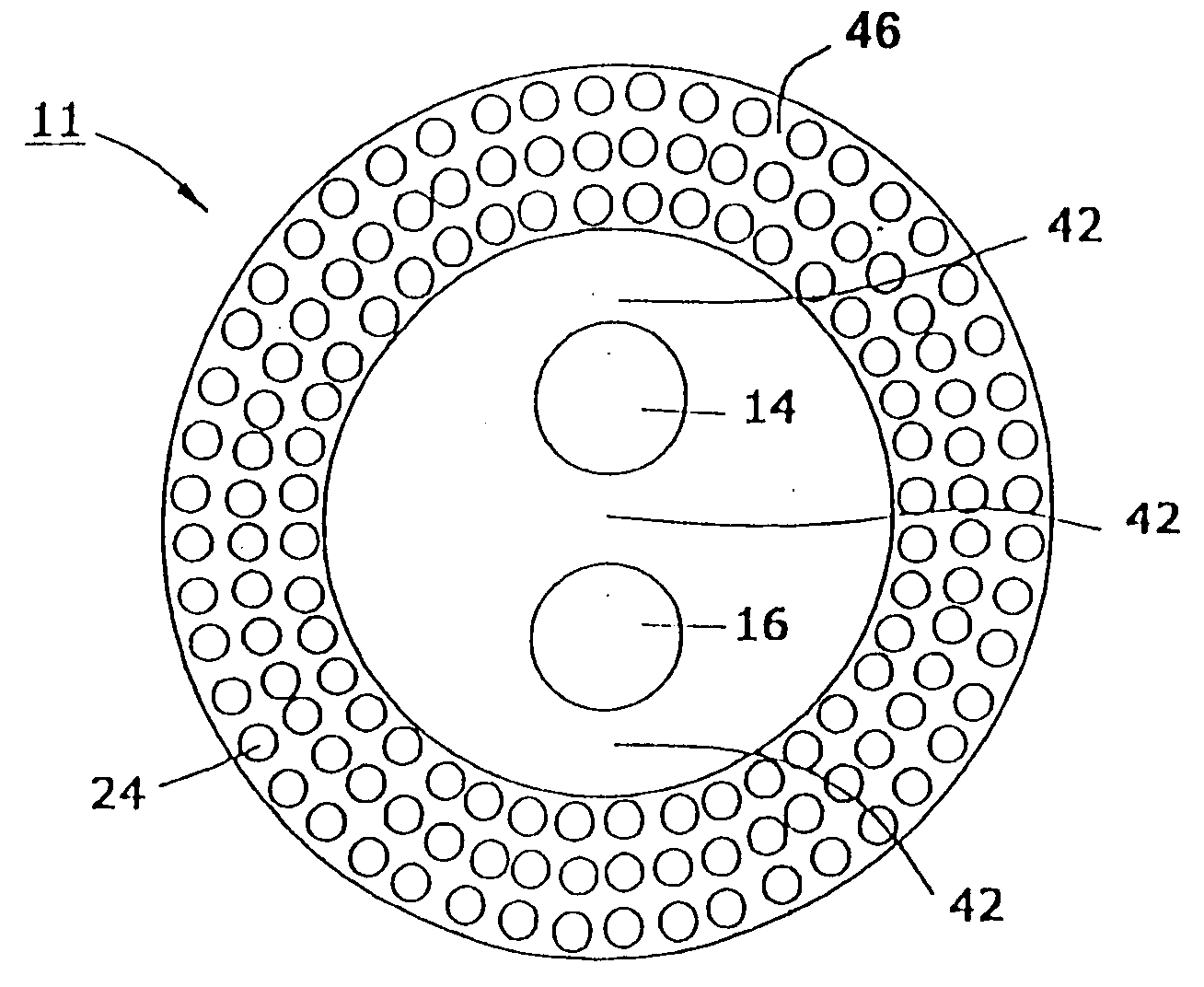

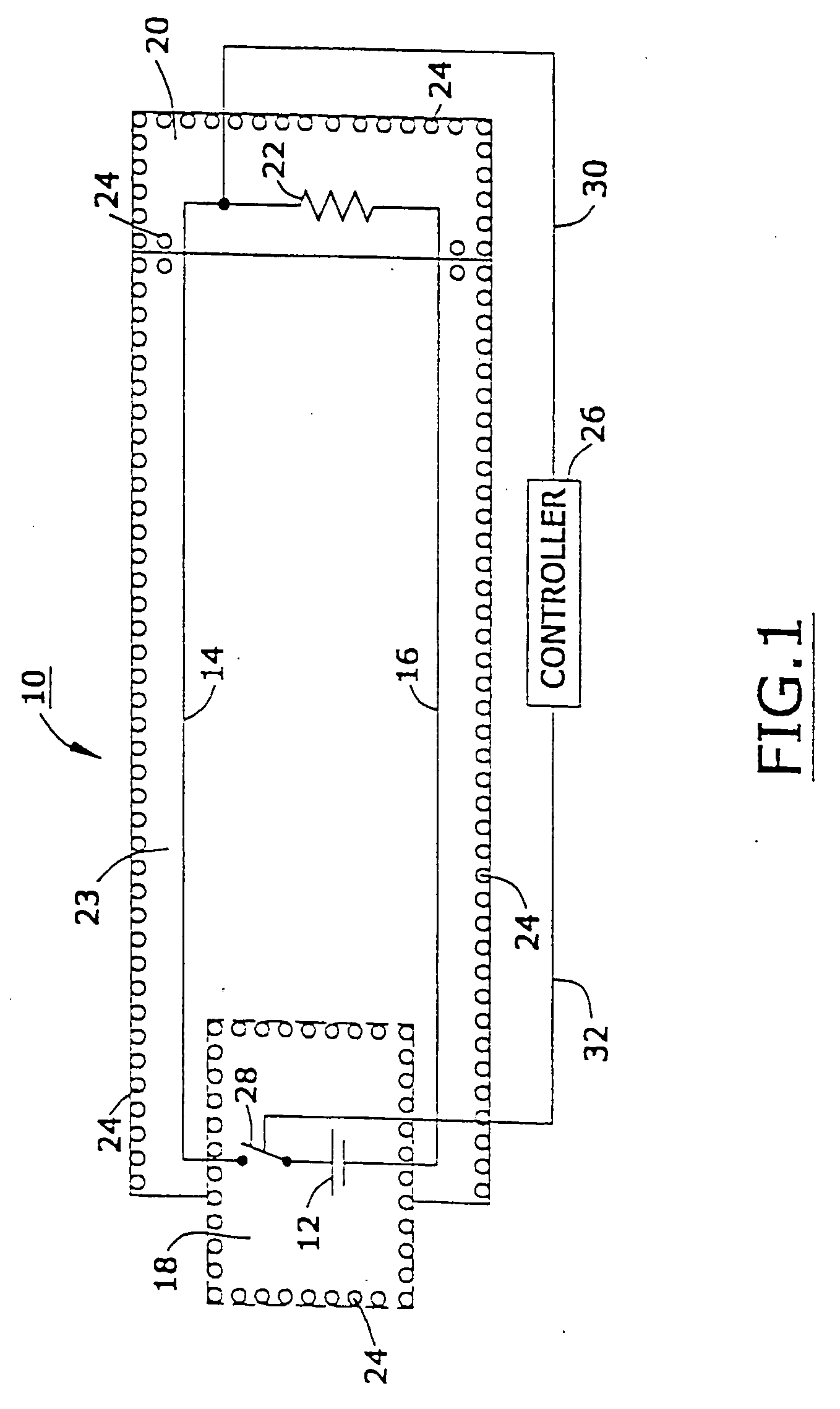

Magnetically shielded conductor

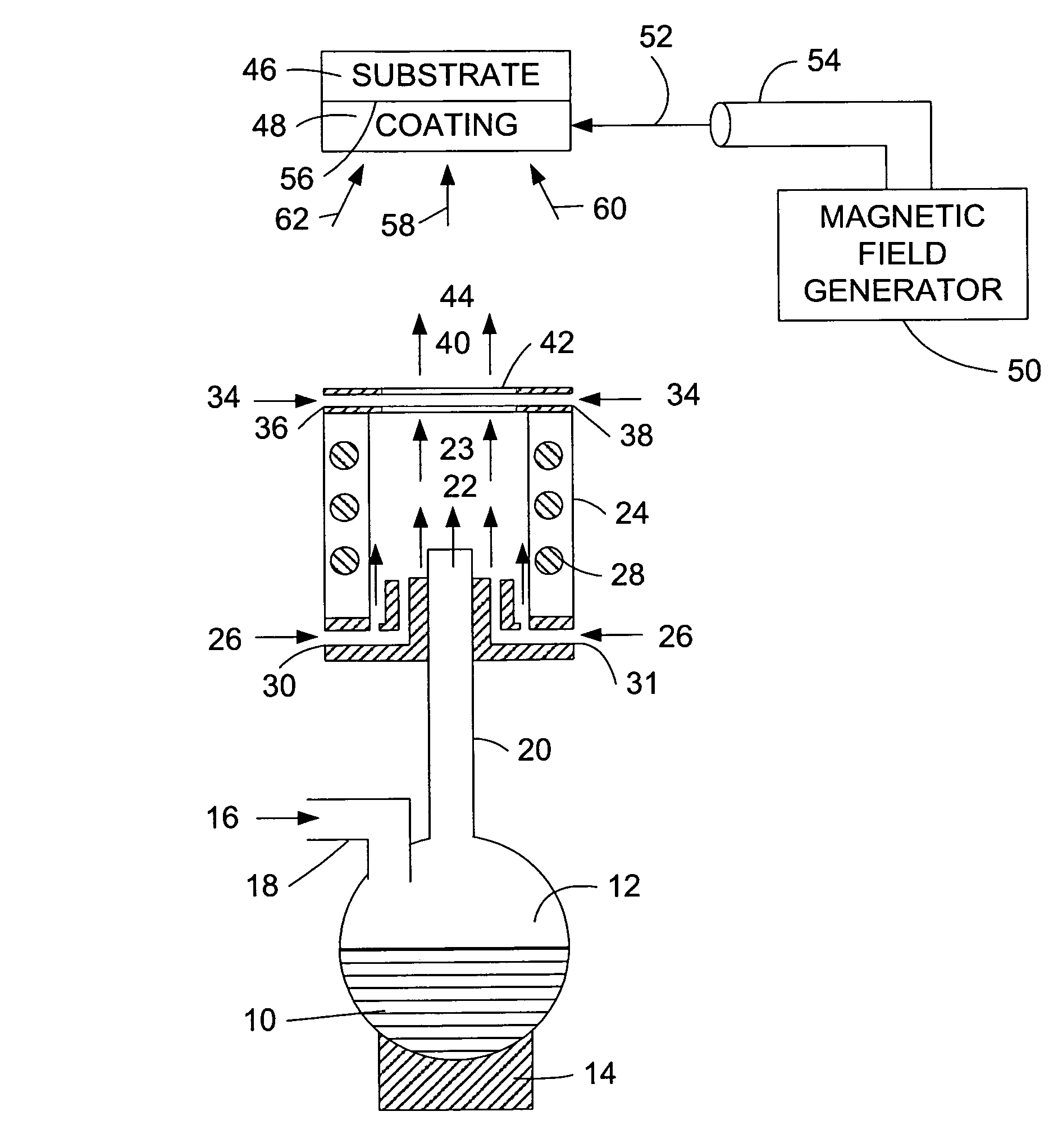

A magnetically shielded conductor assembly with a conductor device and a film of nanomagnetic material located above the conductor device. The conductor device has a resistivity of from about 1 to about 2,000 micro ohm-centimeters. The film of nanomagnetic material has a thickness of from about 100 nanometers to about 10 micrometers and a magnetic shielding factor of at least about 0.5. The nanomagnetic material has a mass density of at least about 0.01 grams per cubic centimeter, a saturation magnetization of from about 1 to about 36,000 Gauss, a coercive force of from about 0.01 to about 5,000 Oersteds, a relative magnetic permeability of from about 1 to about 500,000, and an average particle size of less than about 100 nanometers.

Owner:BIOPHAN TECH

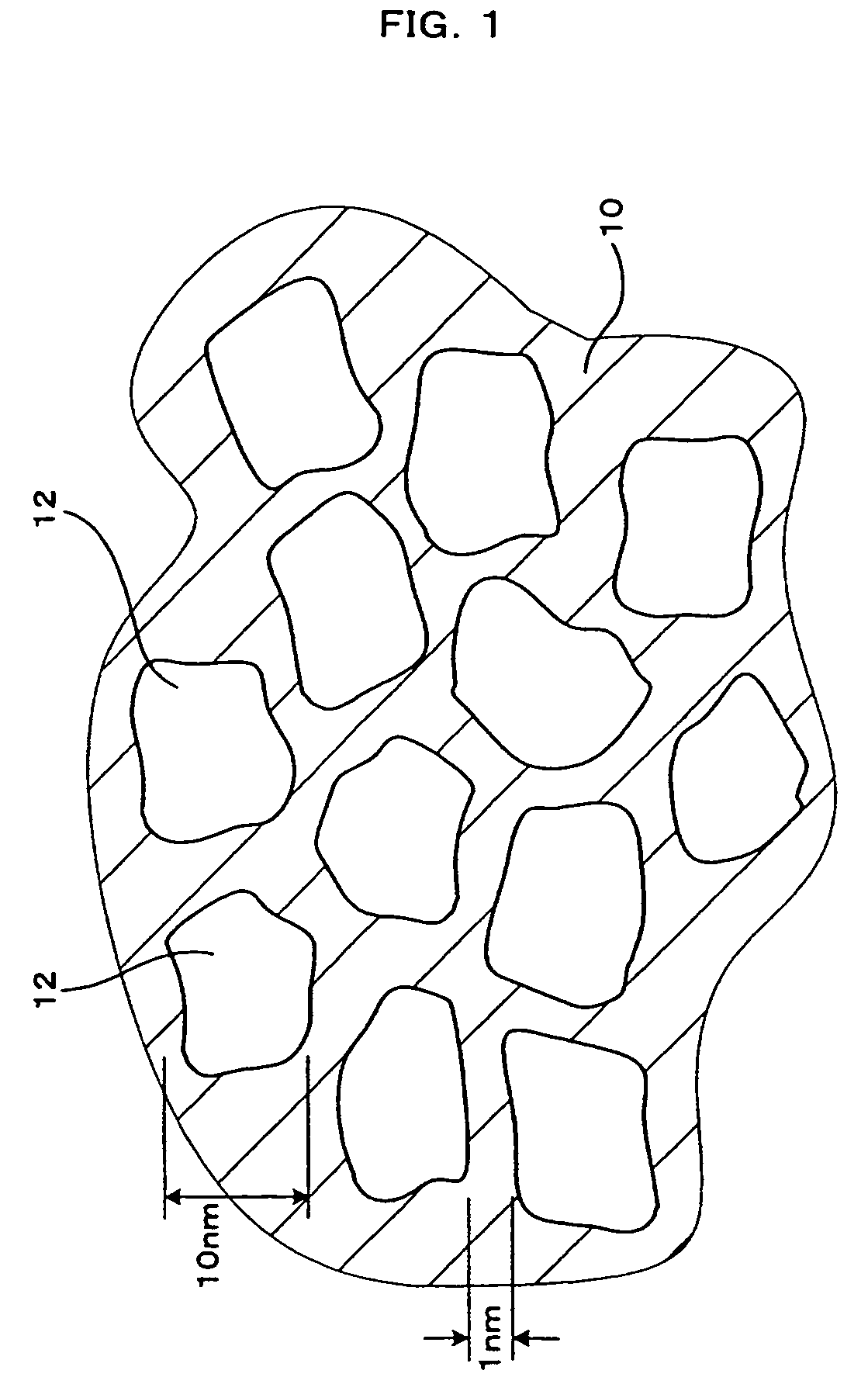

Nanomagnetically shielded substrate

A shielded substrate assembly that contains a magnetic shield with a layer of magnetic shielding material; the magnetic shield has a magnetic shielding factor of at least about 0.5. The magnetic shield contains nanomagnetic material nanomagnetic material with a mass density of at least about 0.01 grams per cubic centimeter, a saturation magnetization of from about 1 to about 36,000 Gauss, a coercive force of from about 0.01 to about 5,000 Oersteds, a relative magnetic permeability of from about 1 to about 500,000, and an average particle size of less than about 100 nanometers. The nanomagnetic material contains magnetic material with a coherence length of from about 0.1 to about 100 nanometers.

Owner:BIOPHAN TECH

Magnetically shielded assembly

A shielded assembly containing a substrate and a shield. The shield contains both nanomagnetic material and a material with an electrical resistivity of from about 1 microohm-centimeter to about 1×1025 microohm centimeters. The nanomagnetic material has a mass density of at least about 0.01 grams per cubic centimeter, a saturation magnetization of from about 1 to about 36,000 Gauss, a coercive force of from about 0.01 to about 5000 Oersteds, a relative magnetic permeability of from about 1 to about 500,000, and an average particle size of less than about 100 nanometers.

Owner:BIOPHAN TECH

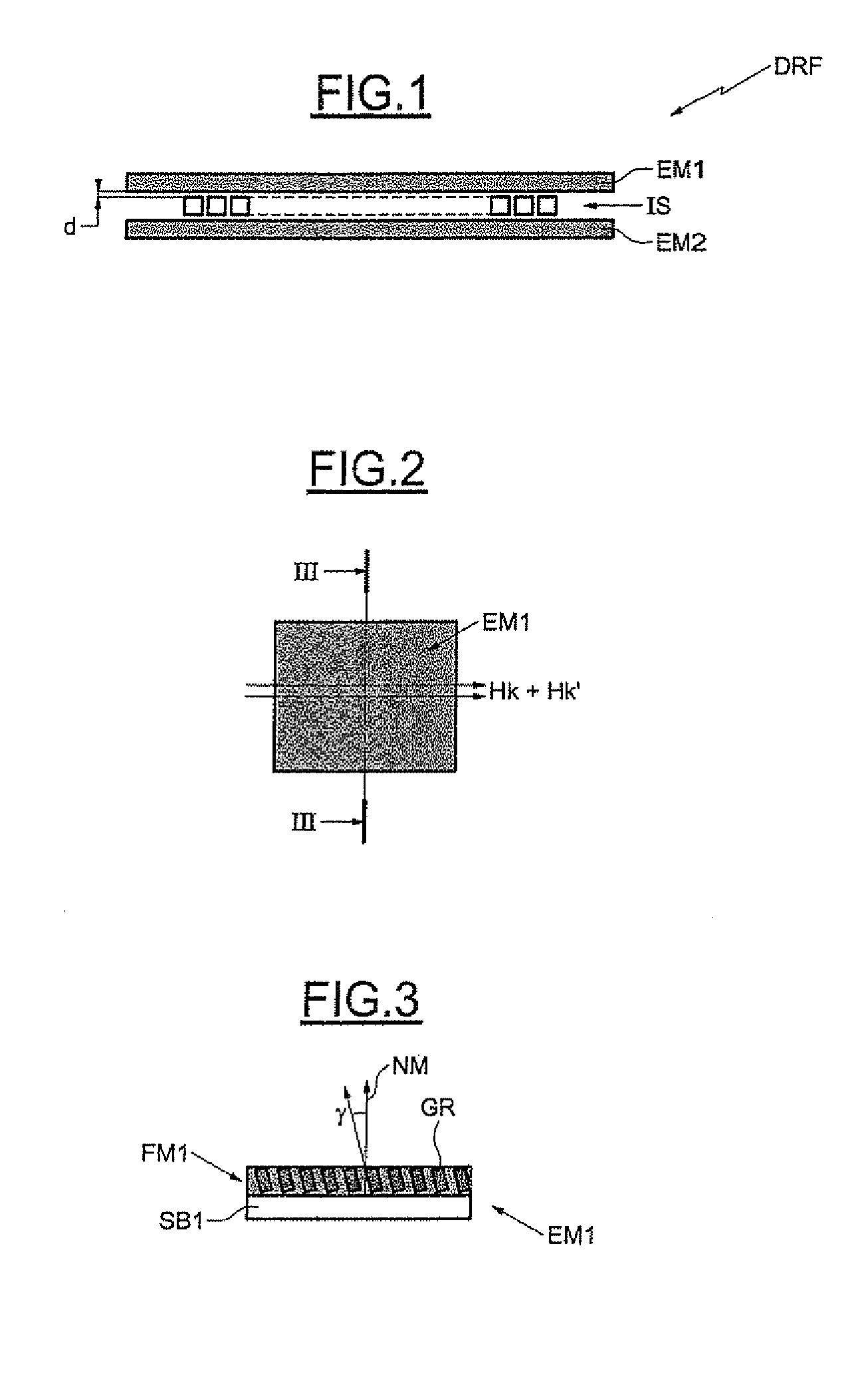

Radio Frequency Device with Magnetic Element, Method for Making Such a Magnetic Element

InactiveUS20080297292A1Easy to controlAdjustable angleNanomagnetismVacuum evaporation coatingRadio frequencyPhysics

Owner:STMICROELECTRONICS SRL +1

Magnetically shielded conductor

A conductor assembly that contains a flexible conductor and a layer of nanomagnetic material coated onto the conductor. The layer of nanomagnetic material has a tensile modulus of elasticity of at least about 15×106 pounds per square inch, an average particle size of less than 100 nanometers, a saturation magnetization of from about 200 to about 26,000 Gauss, and a thickness of less than about 2 microns.

Owner:BIOPHAN TECH

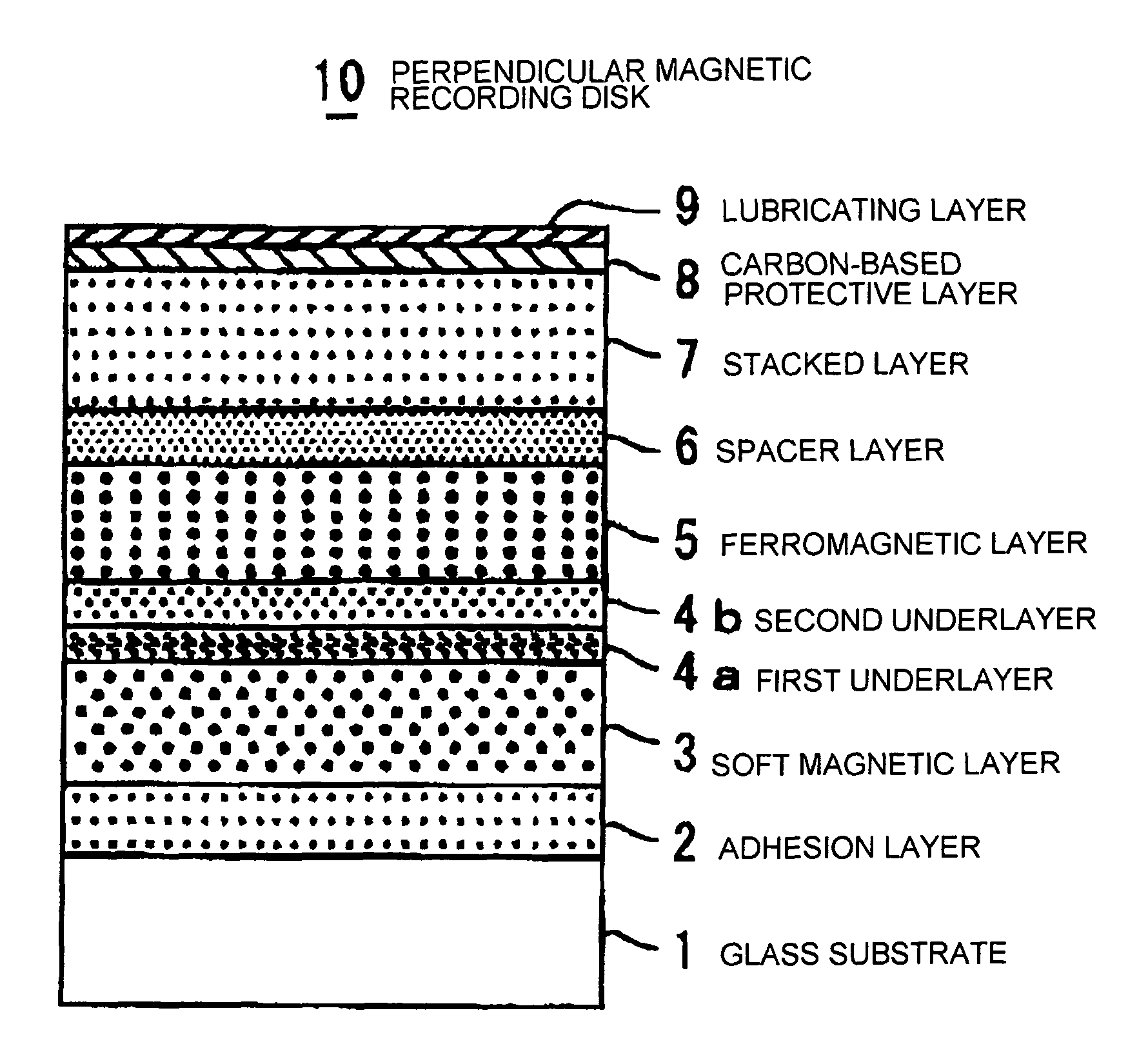

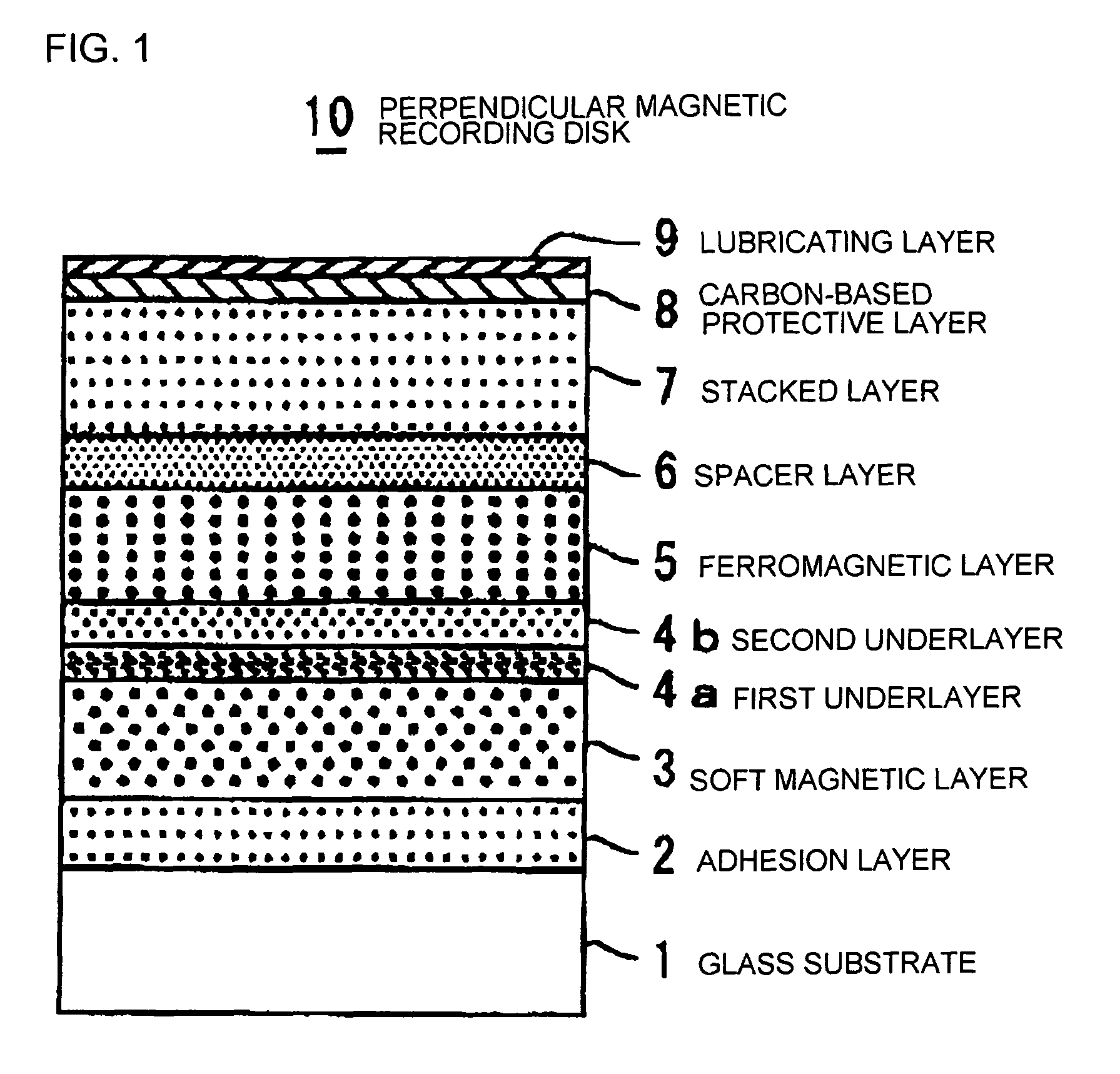

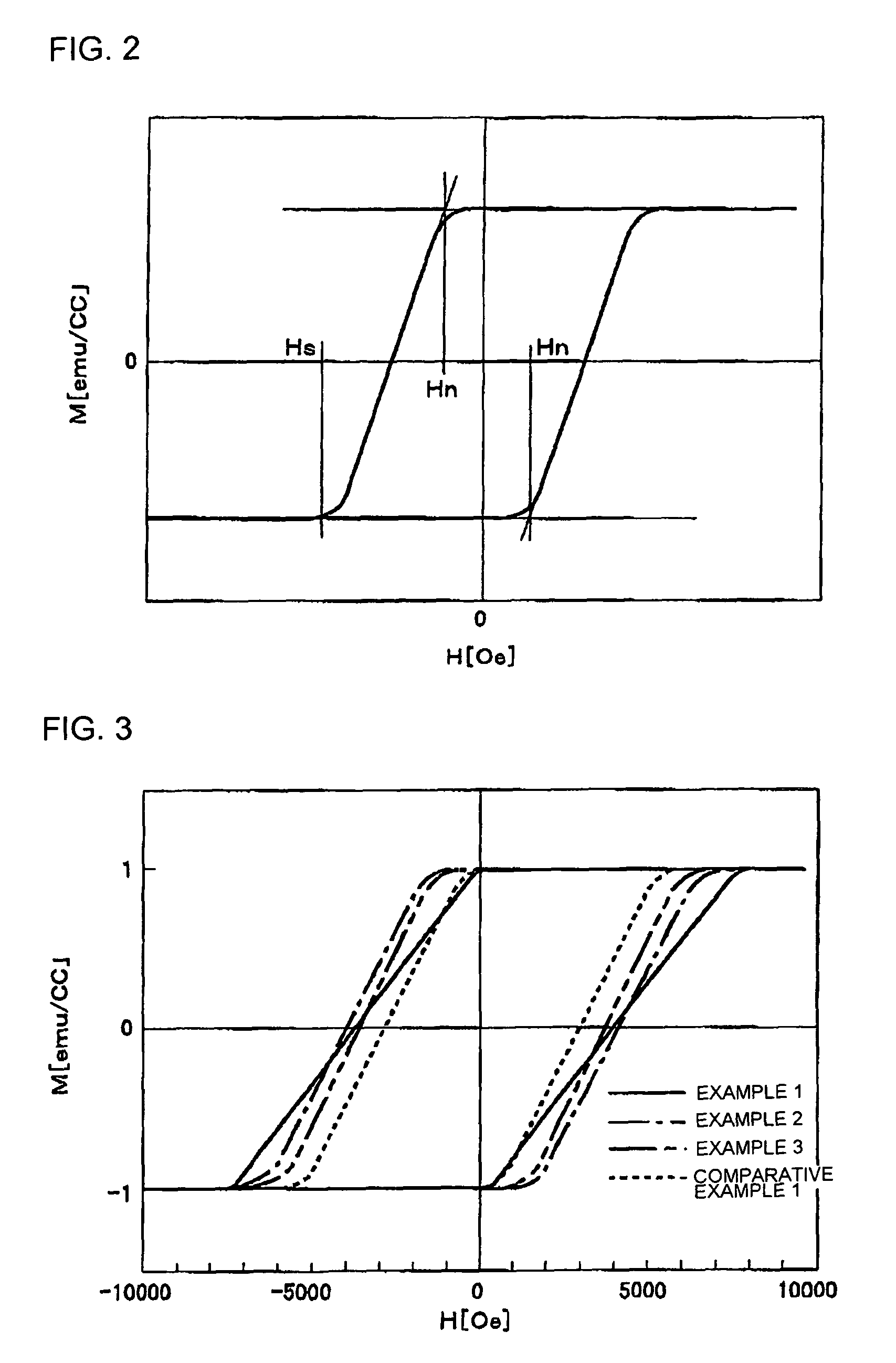

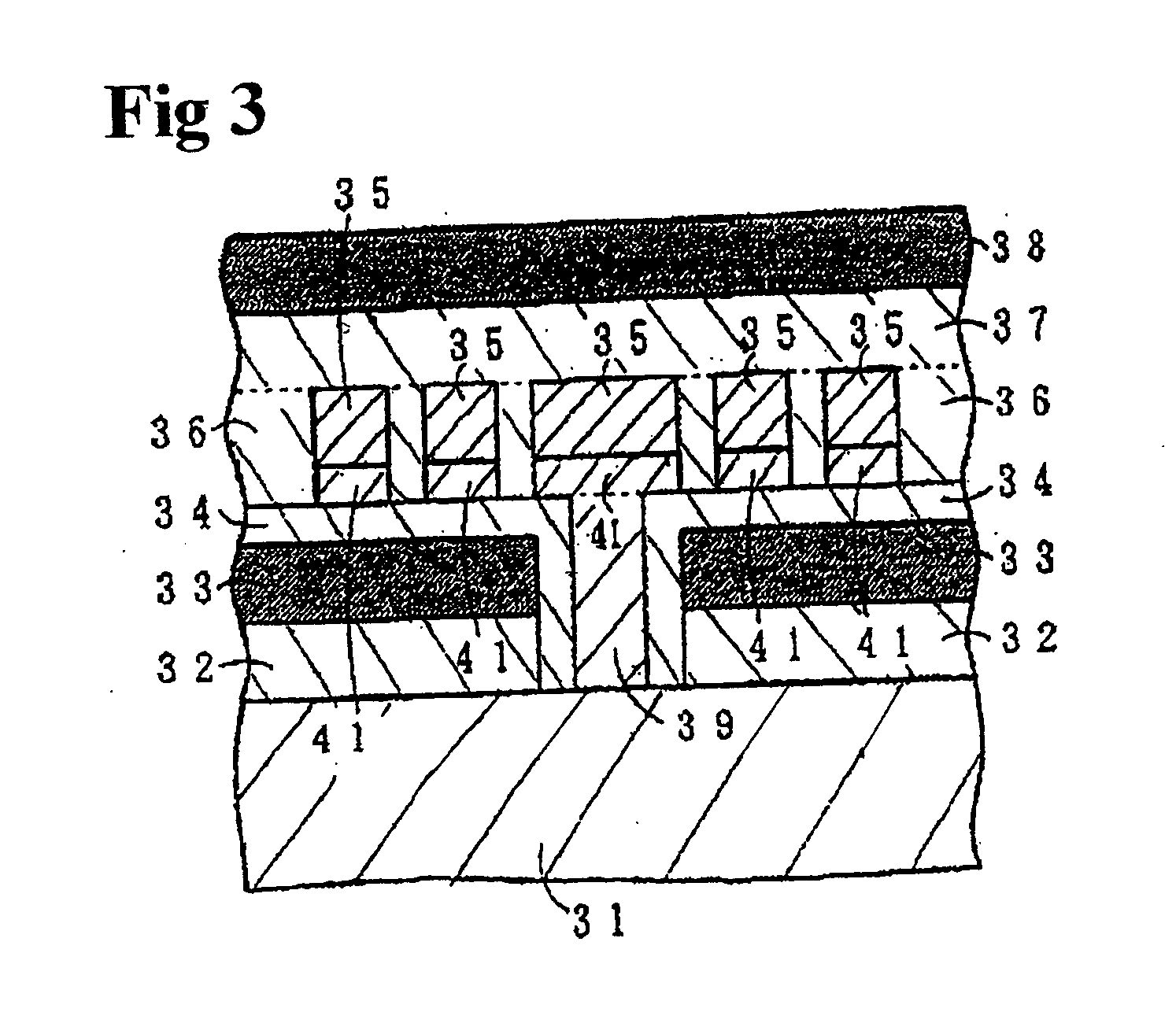

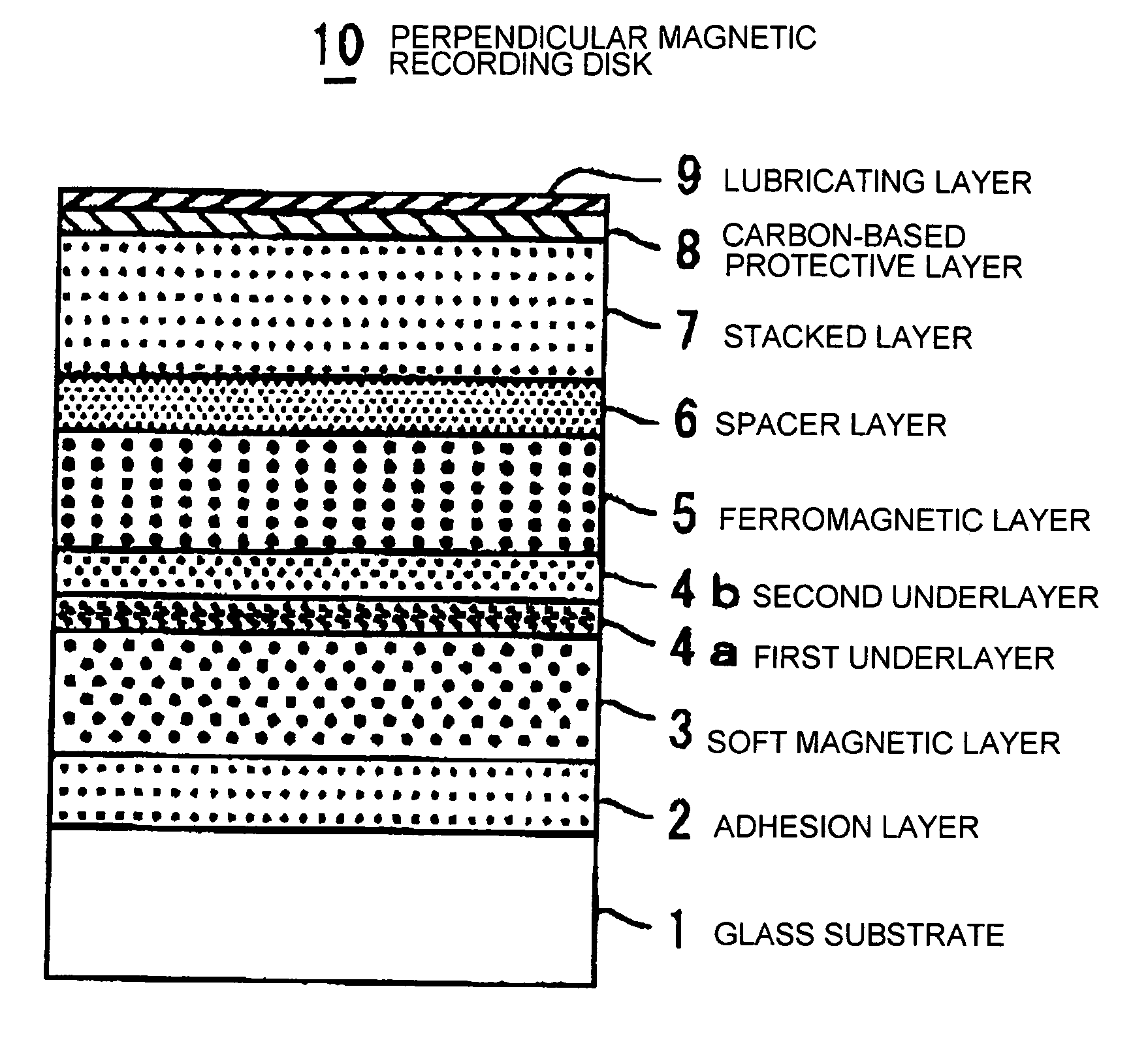

Perpendicular magnetic recording disk and manufacturing method thereof

ActiveUS8603650B2Improve noiseImprove recording densityNanomagnetismVacuum evaporation coatingAlloyRecording layer

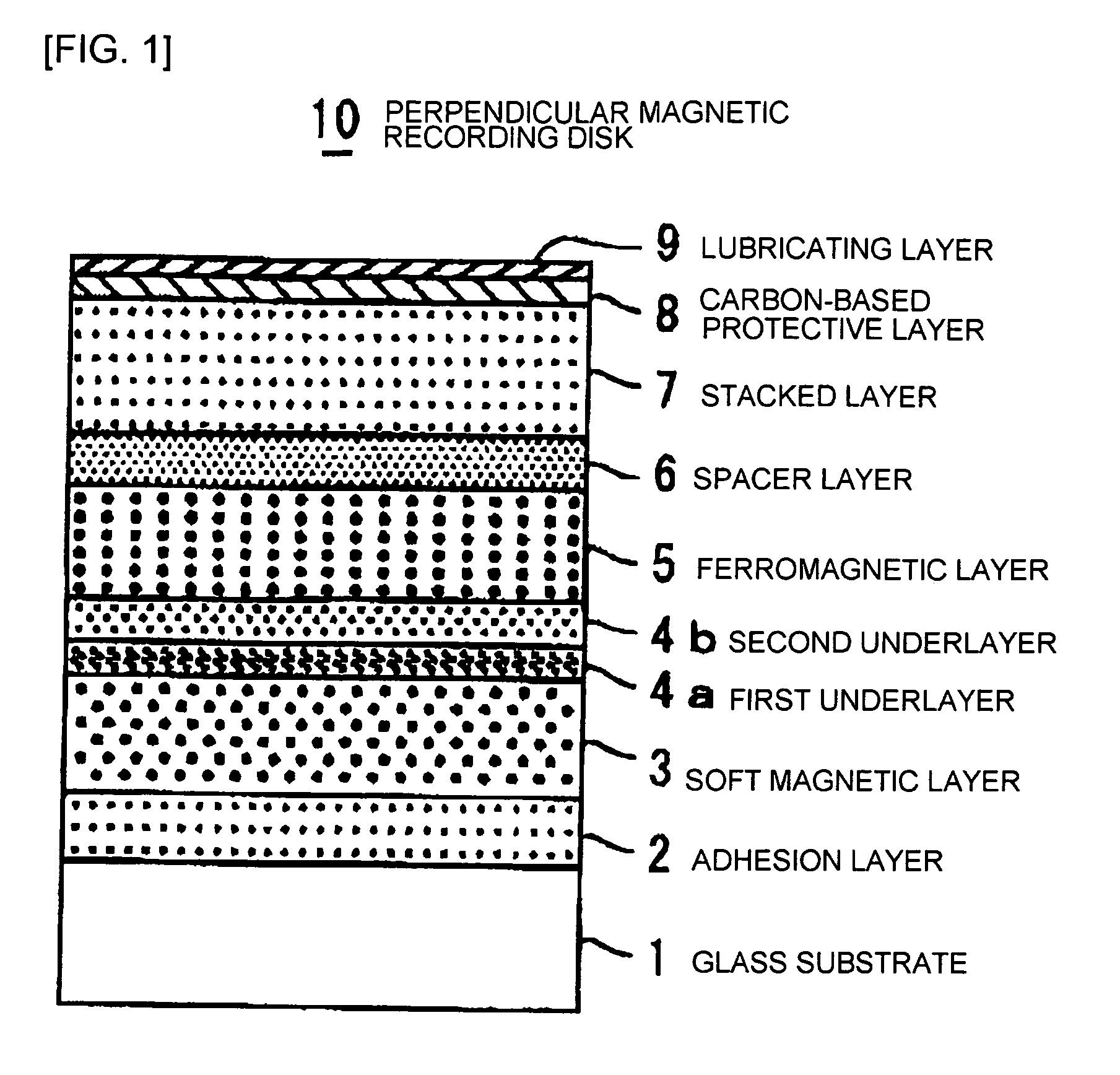

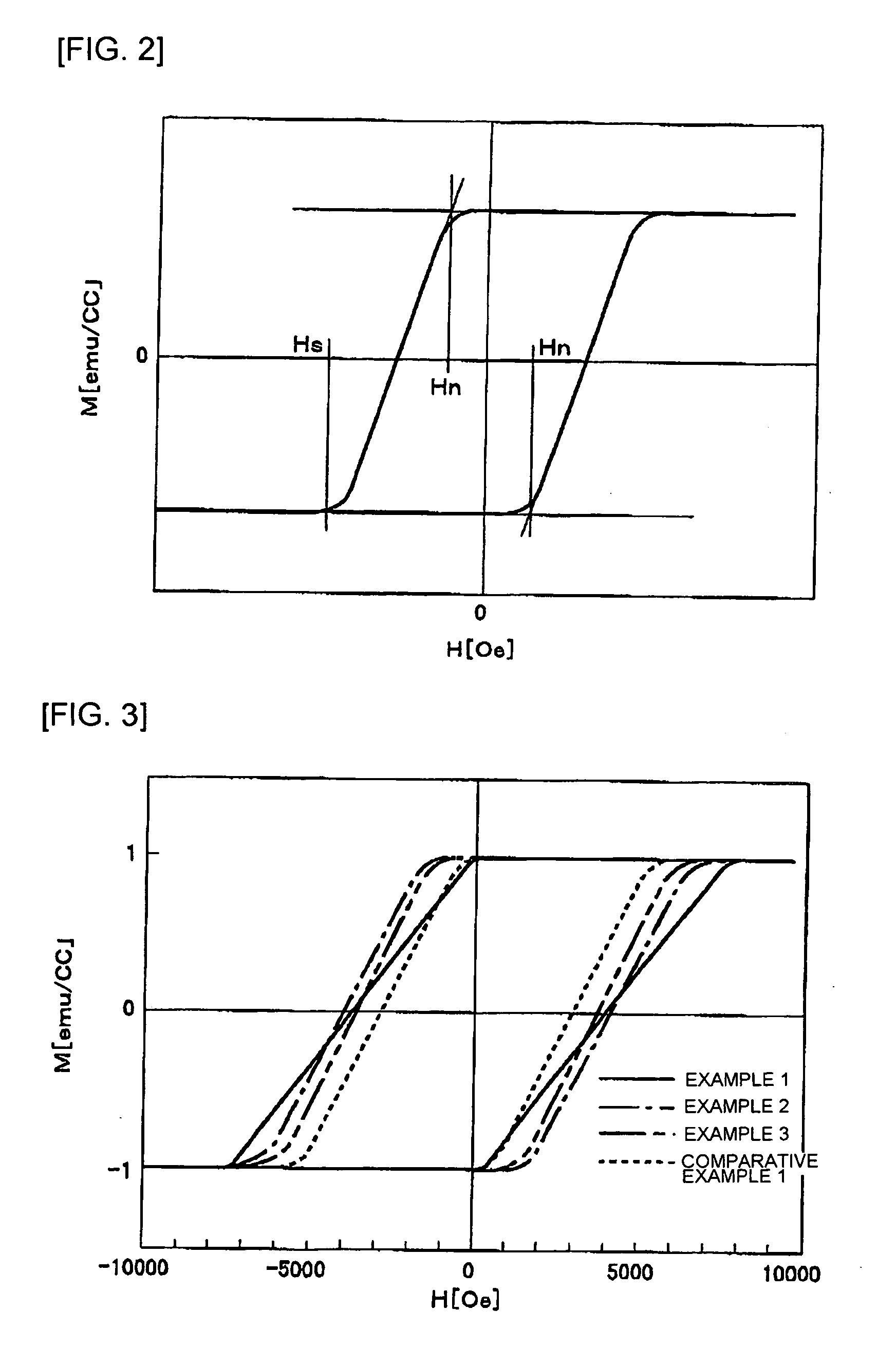

A magnetic disk 10 for use in perpendicular magnetic recording has at least a magnetic recording layer on a substrate 1. The magnetic recording layer is composed of a ferromagnetic layer 5 of a granular structure containing silicon (Si) or an oxide of silicon (Si) between crystal grains containing cobalt (Co), a stacked layer 7 having a first layer containing cobalt (Co) or a Co alloy and a second layer containing palladium (Pd) or platinum (Pt), and a spacer layer 6 interposed between the ferromagnetic layer 5 and the stacked layer 7. After forming the ferromagnetic layer 5 on the substrate 1 by sputtering in an argon gas atmosphere, the stacked layer 7 is formed by sputtering in the argon gas atmosphere at a gas pressure lower than that used when forming the ferromagnetic layer 5.

Owner:WESTERN DIGITAL TECH INC

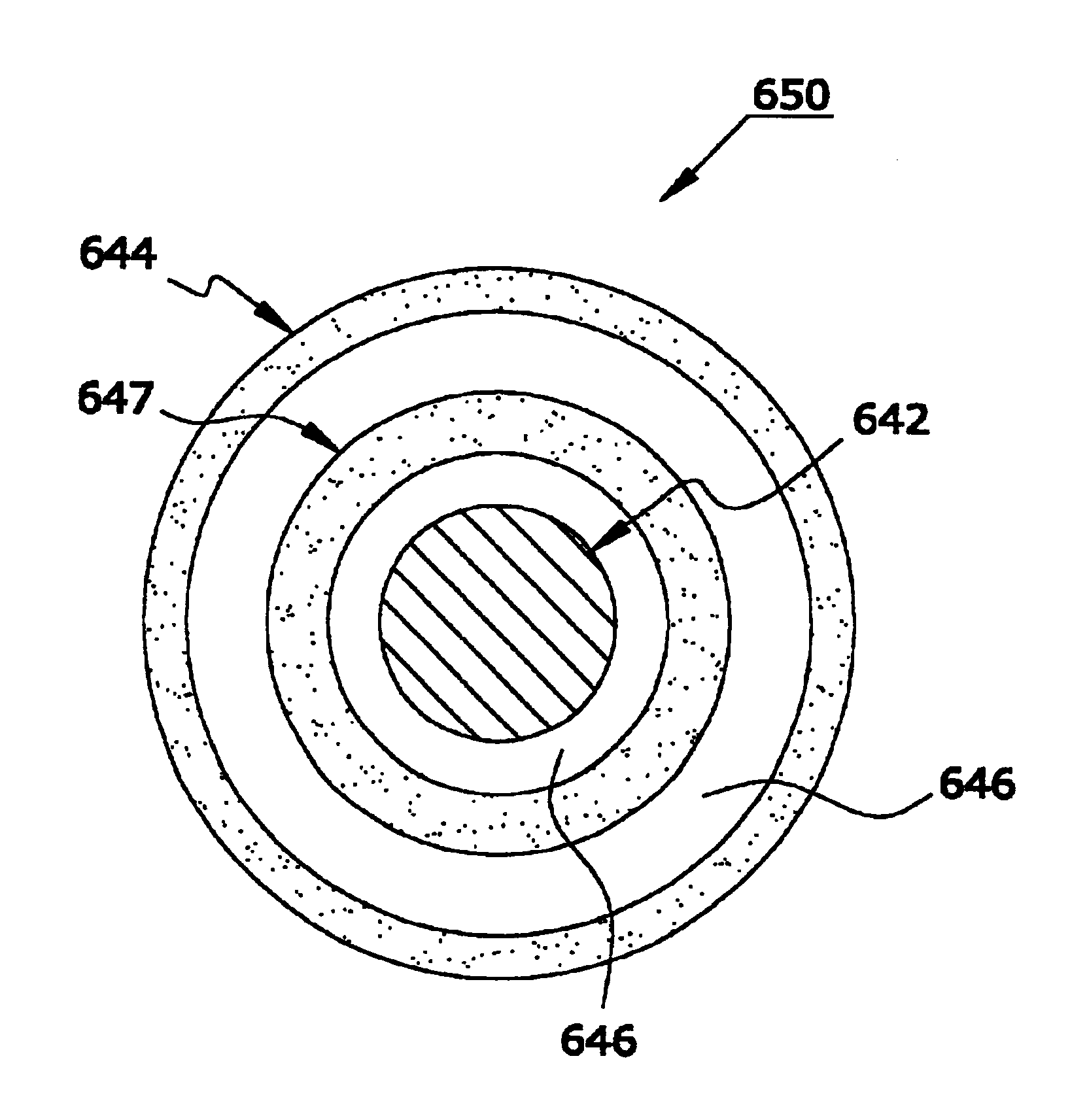

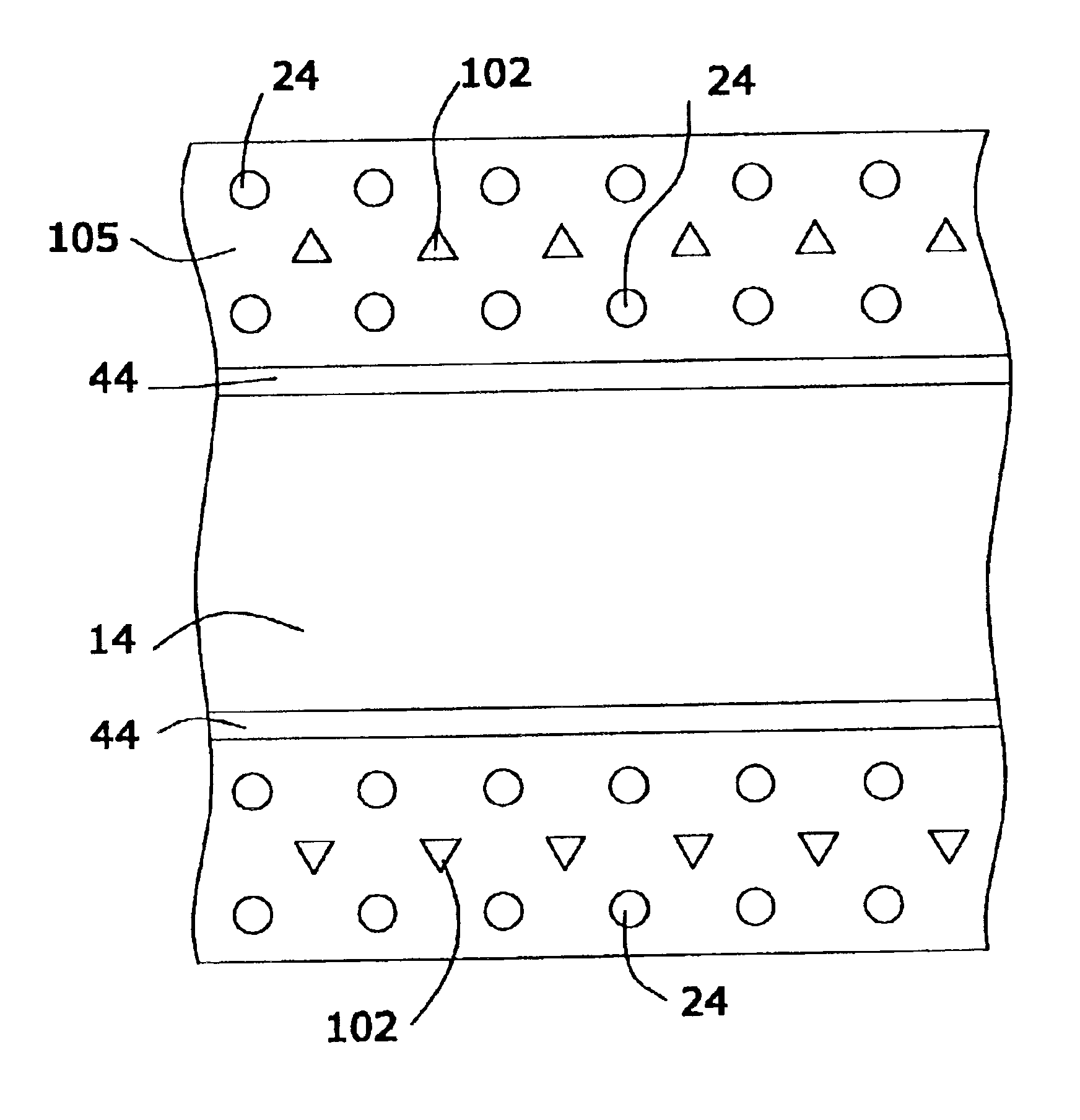

Magnetically shielded conductor

A magnetically shielded conductor assembly containing a conductor disposed within an insulating matrix, and nanomagentic material and nanoelectrical material disposed around the conductor. The conductor has a resistivity at 20 degrees Centigrade of from about 1 to about 100 microohm-centimeters. The insulating matrix is composed of nano-sized particles having a maximum dimension of from about 10 to about 100 nanometers. The insulating matrix has a resistivity of from about 1,000,000,000 to about 10,000,000,000,000 ohm-centimeter. The nanomagnetic material has an average particle size of less than about 100 nanometers. The nanomagnetic material has a saturation magnetization of from about 200 to about 26,000 Gauss. The magnetically shielded conductor assembly is flexible, having a bend radius of less than 2 centimeters.

Owner:BIOPHAN TECH

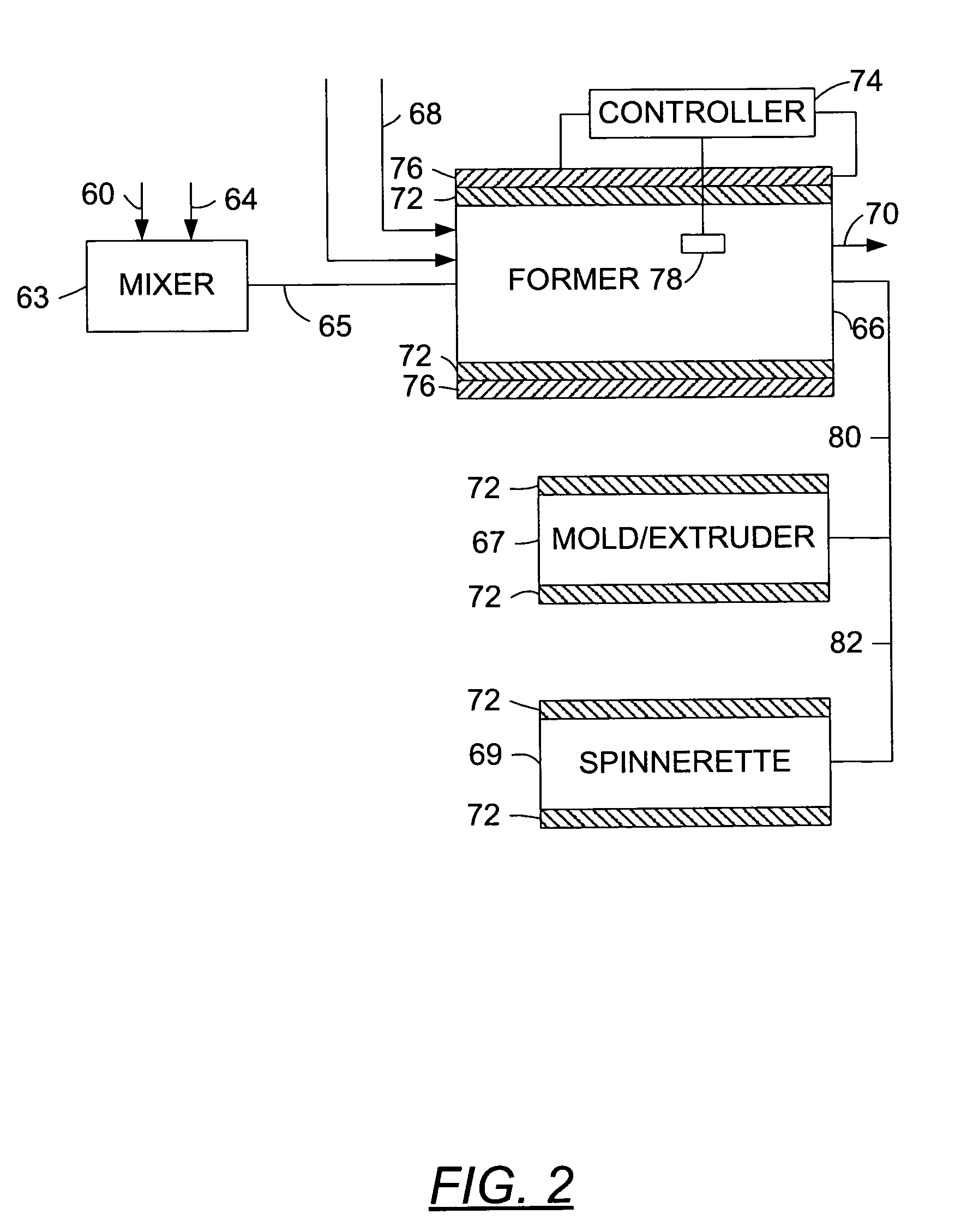

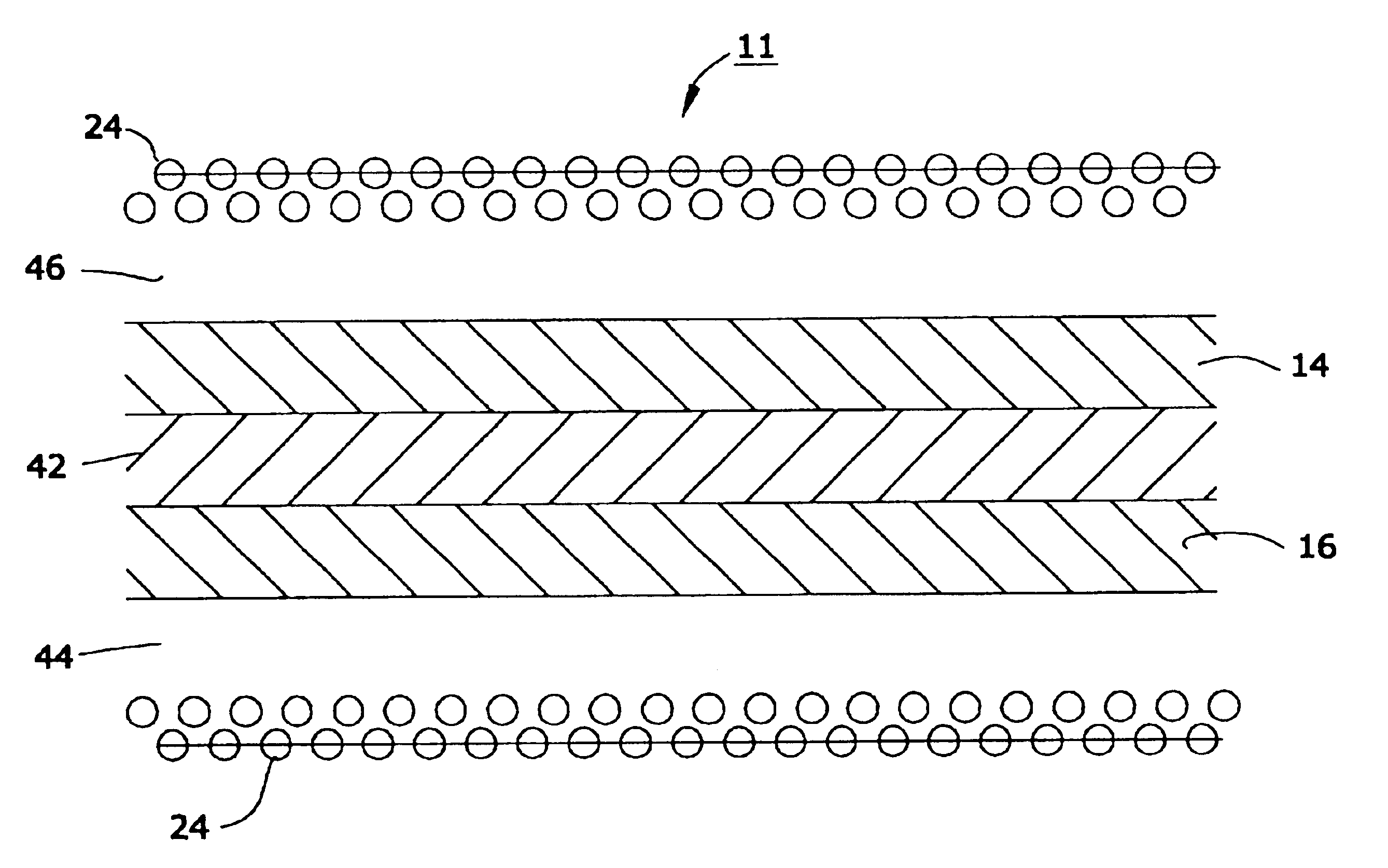

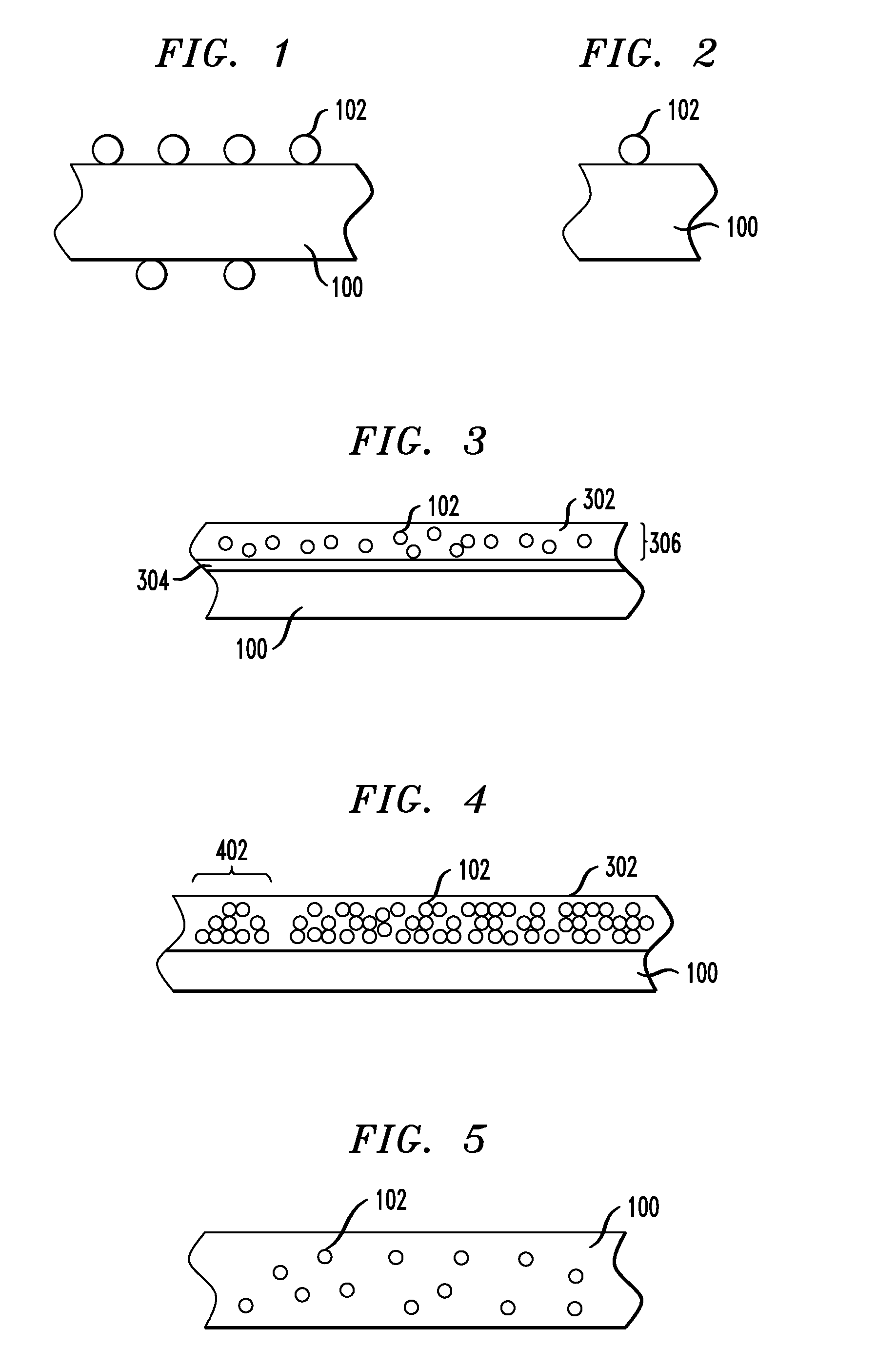

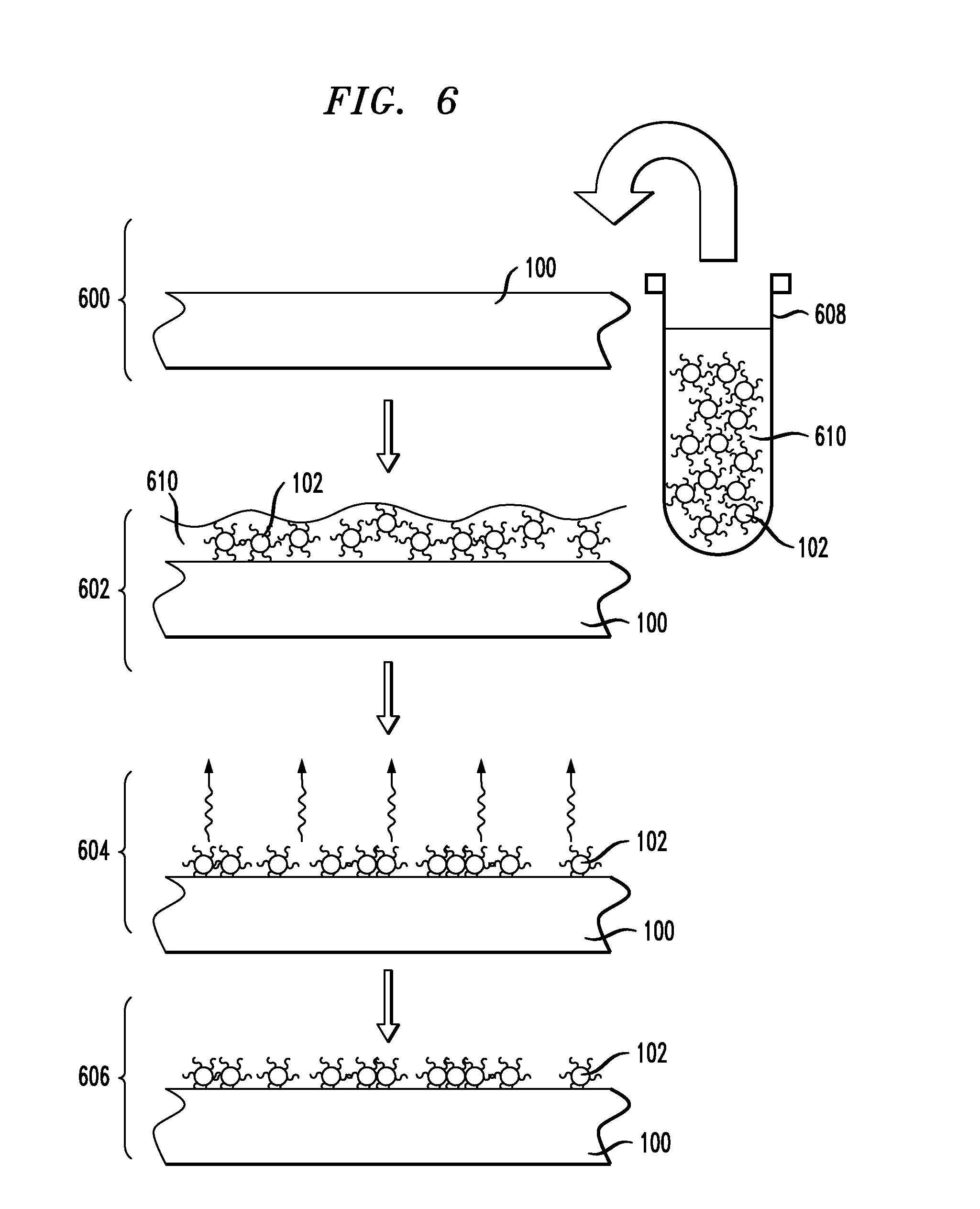

Method of preparing high orientation nanoparticle-containing sheets or films using ionic liquids, and the sheets or films produced thereby

InactiveUS7550520B2High magnetic anisotropyImprove signal-to-noise ratioNanostructure manufactureConductive materialNon solventMagnetite Nanoparticles

A method is provided for the preparation of nanomaterials, which involves the dissolution and / or suspension of a combination of (a) one or more resin substrate materials and (b) one or more magnetic nanoparticulate substances, in a medium made from one or more ionic liquids, to provide a mixture, and recovering the solid nanomaterial by combining the mixture with a non-solvent (solvent for the ionic liquids but not the other components), while also applying an electromagnetic field to the mixture during the recovering step to align the magnetic nanoparticulate substances, along with the use of the resulting nanomaterials to provide unique information storage media, particularly in the form of sheets or films.

Owner:UNIVERSITY OF ALABAMA +1

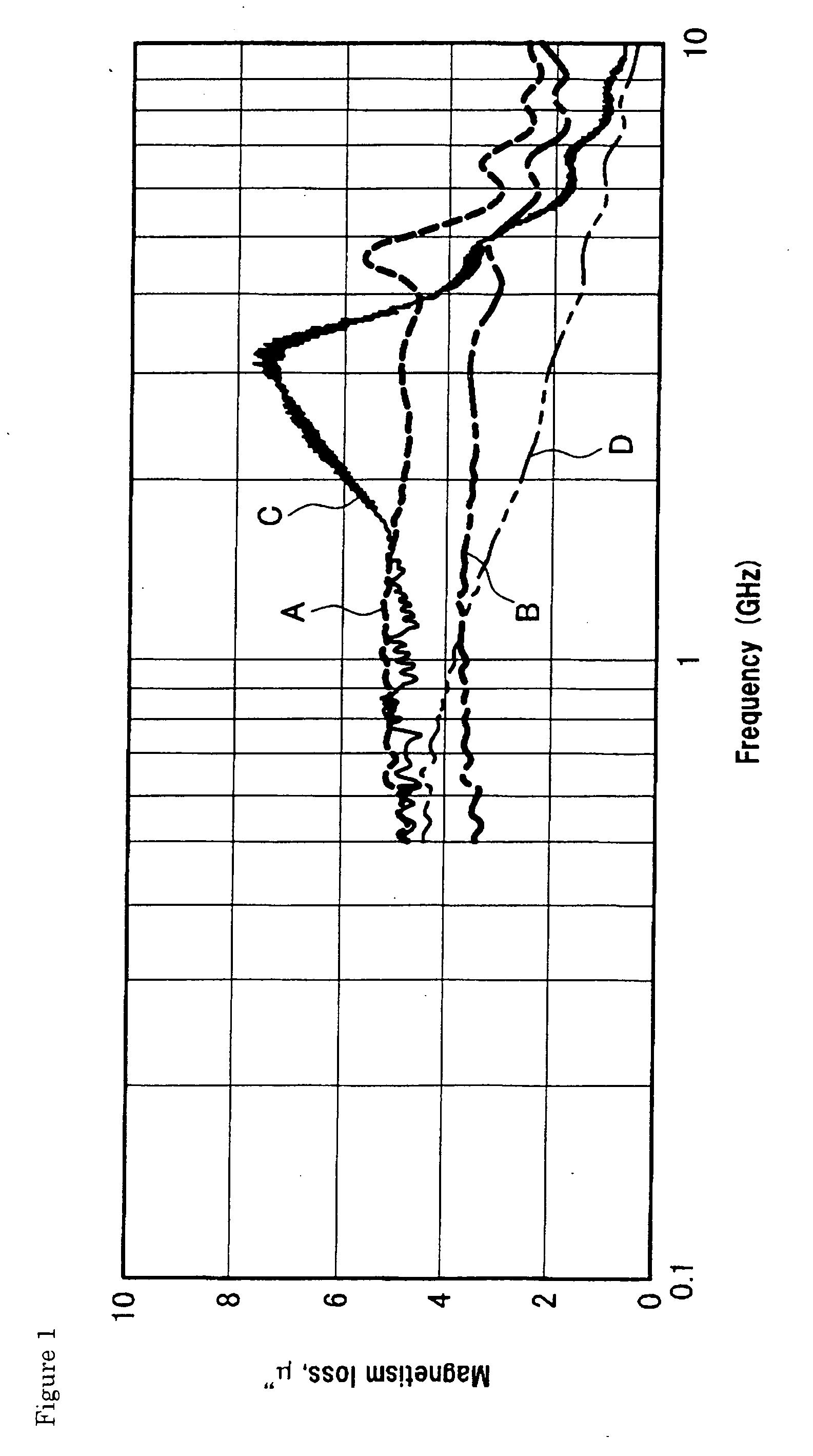

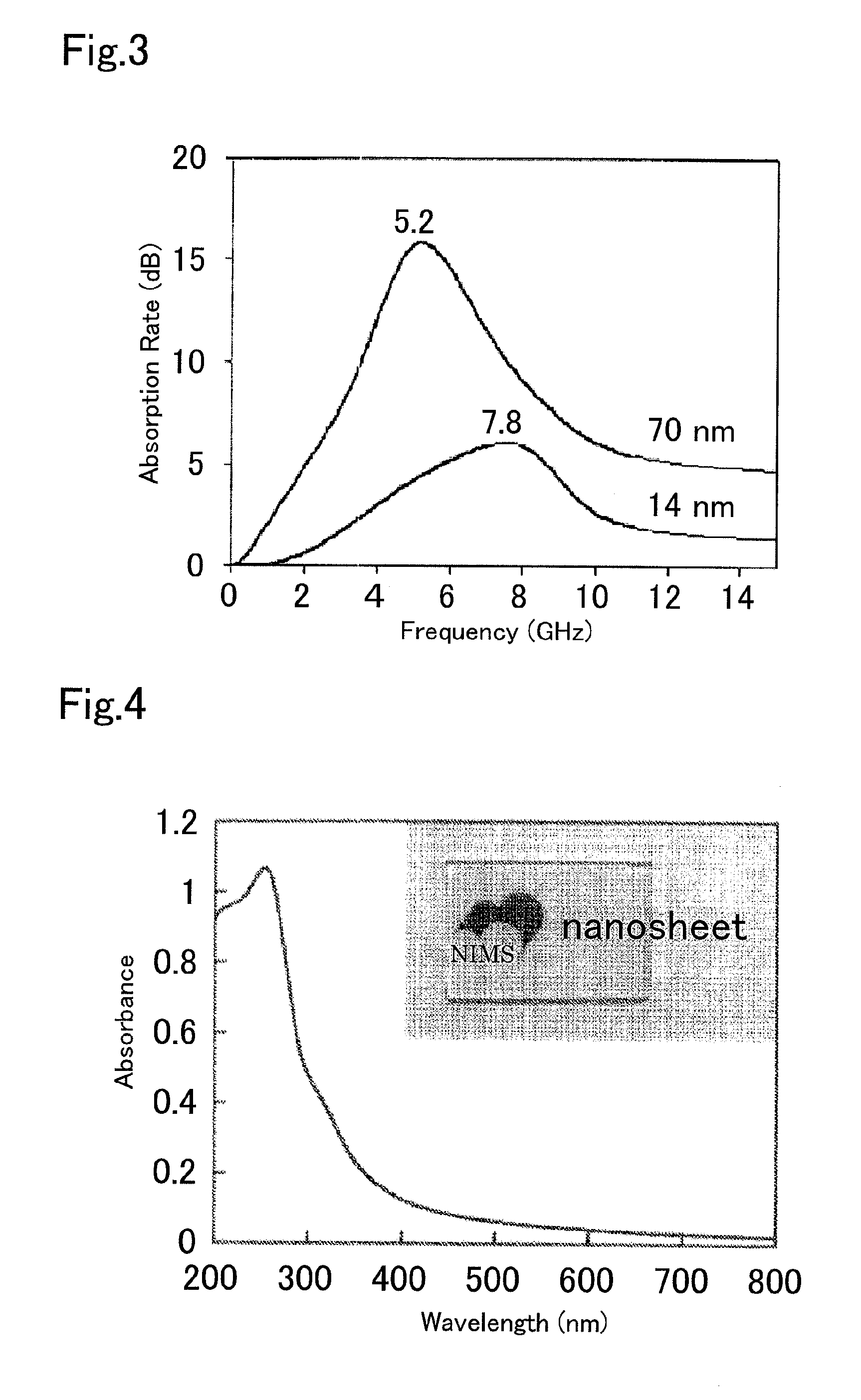

Electromagnetic wave absorber

InactiveUS20070196671A1Improve rendering capabilitiesImprove flame retardant performancePigmenting treatmentNanomagnetismHigh resistanceElectromagnetic wave absorber

Owner:GELTEC

Magnetic resonance imaging coated assembly

An assembly for shielding an implanted medical device from the effects of high-frequency radiation and for emitting magnetic resonance signals during magnetic resonance imaging. The assembly includes an implanted medical device and a magnetic shield comprised of nanomagnetic material disposed between the medical device and the high-frequency radiation. In one embodiment, the magnetic resonance signals are detected by a receiver, which is thus able to locate the implanted medical device within a biological organism.

Owner:BIOPHAN TECH

Magnetic resonance imaging coated assembly

An assembly for shielding an implanted medical device from the effects of high-frequency radiation and for emitting magnetic resonance signals during magnetic resonance imaging. The assembly includes an implanted medical device and a magnetic shield comprised of nanomagnetic material disposed between the medical device and the high-frequency radiation. In one embodiment, the magnetic resonance signals are detected by a receiver, which is thus able to locate the implanted medical device within a biological organism.

Owner:BIOPHAN TECH

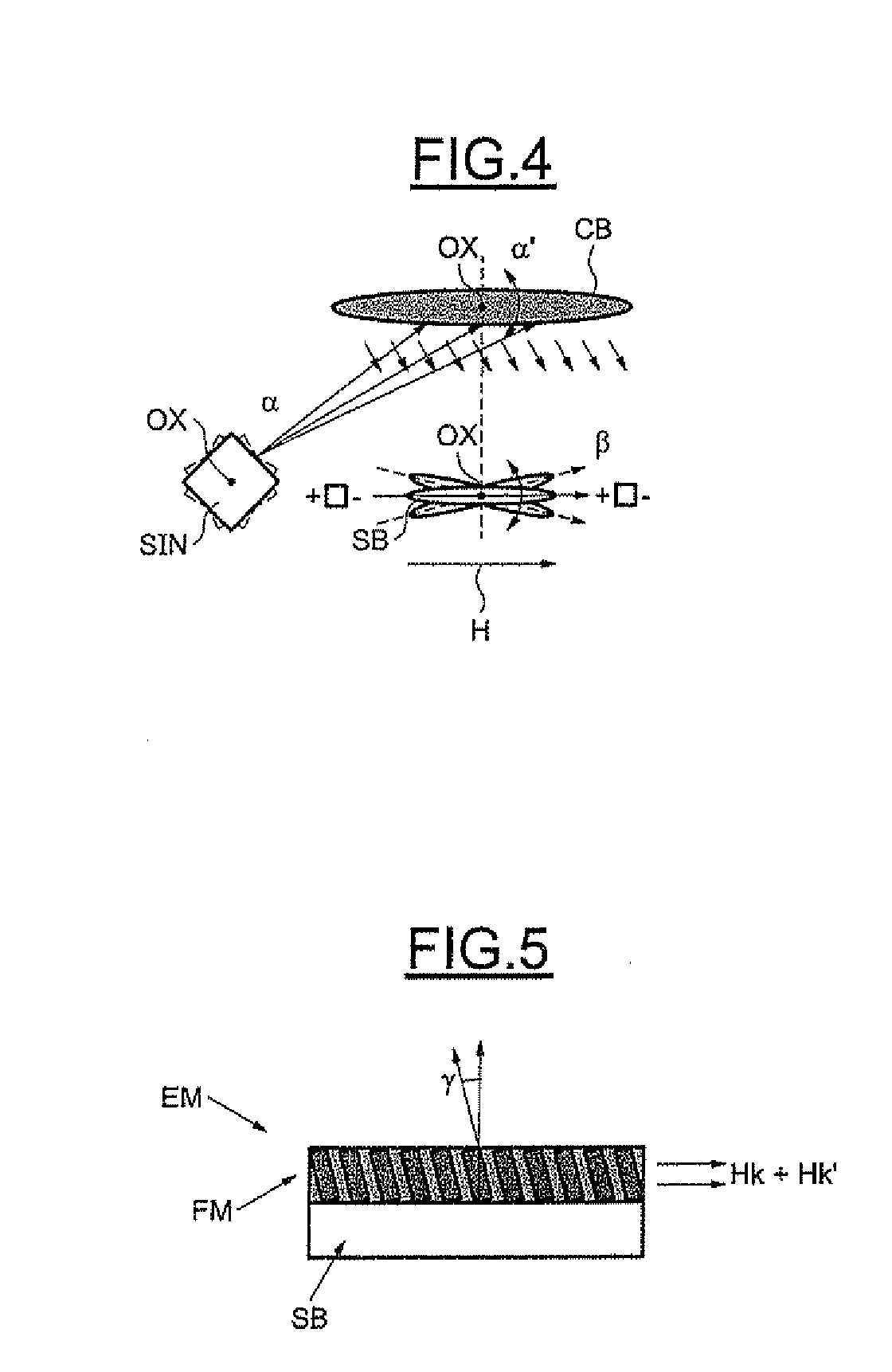

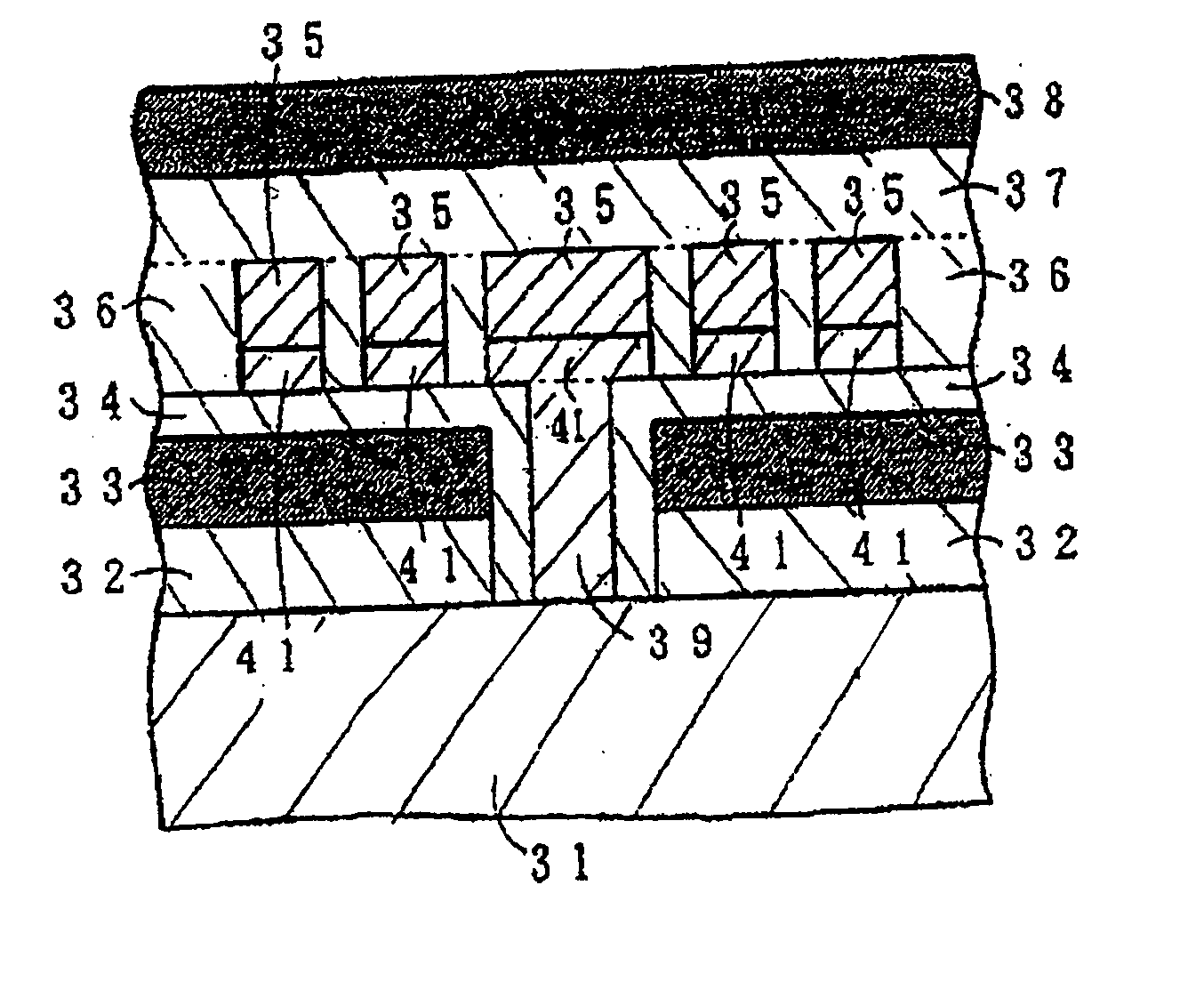

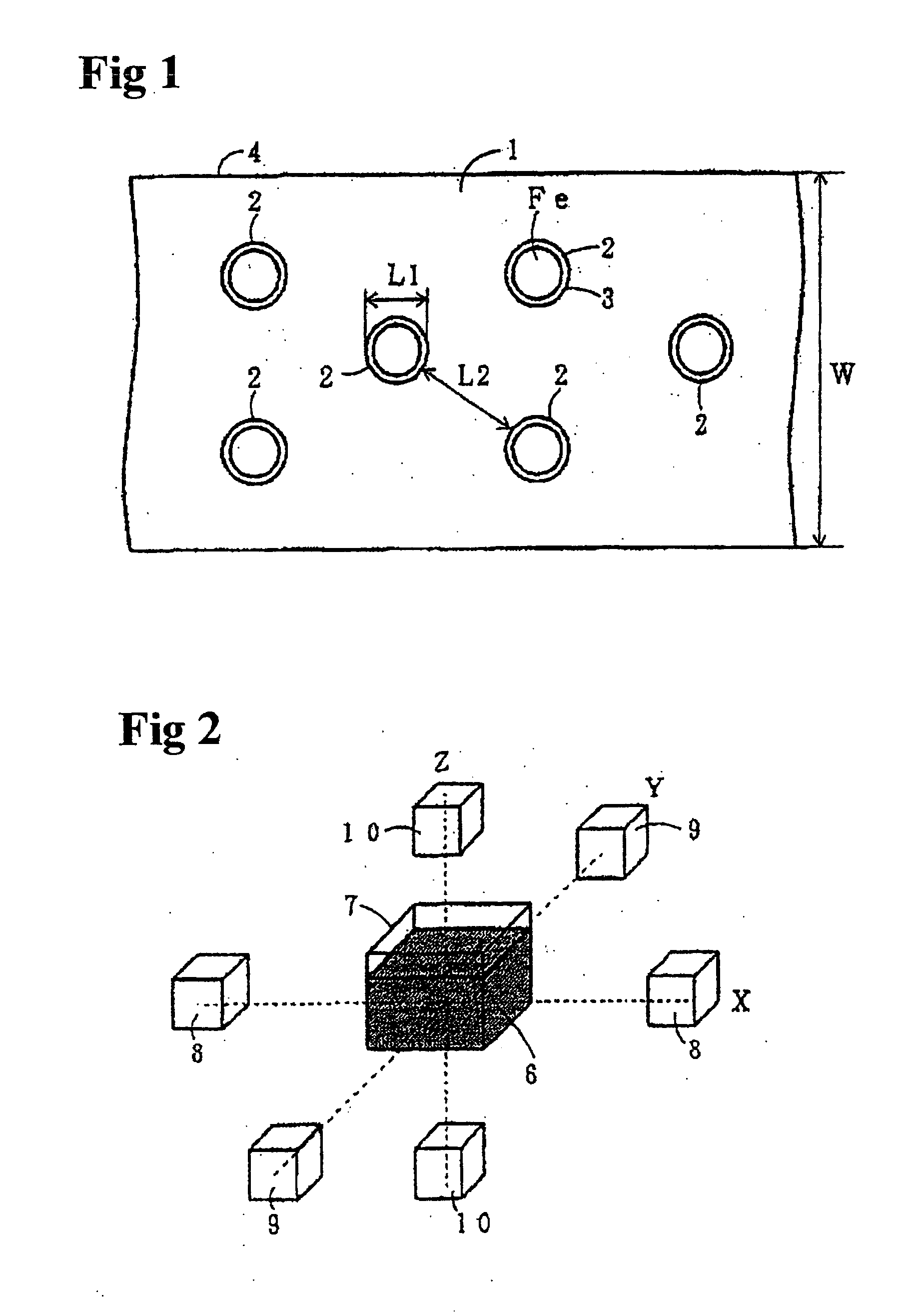

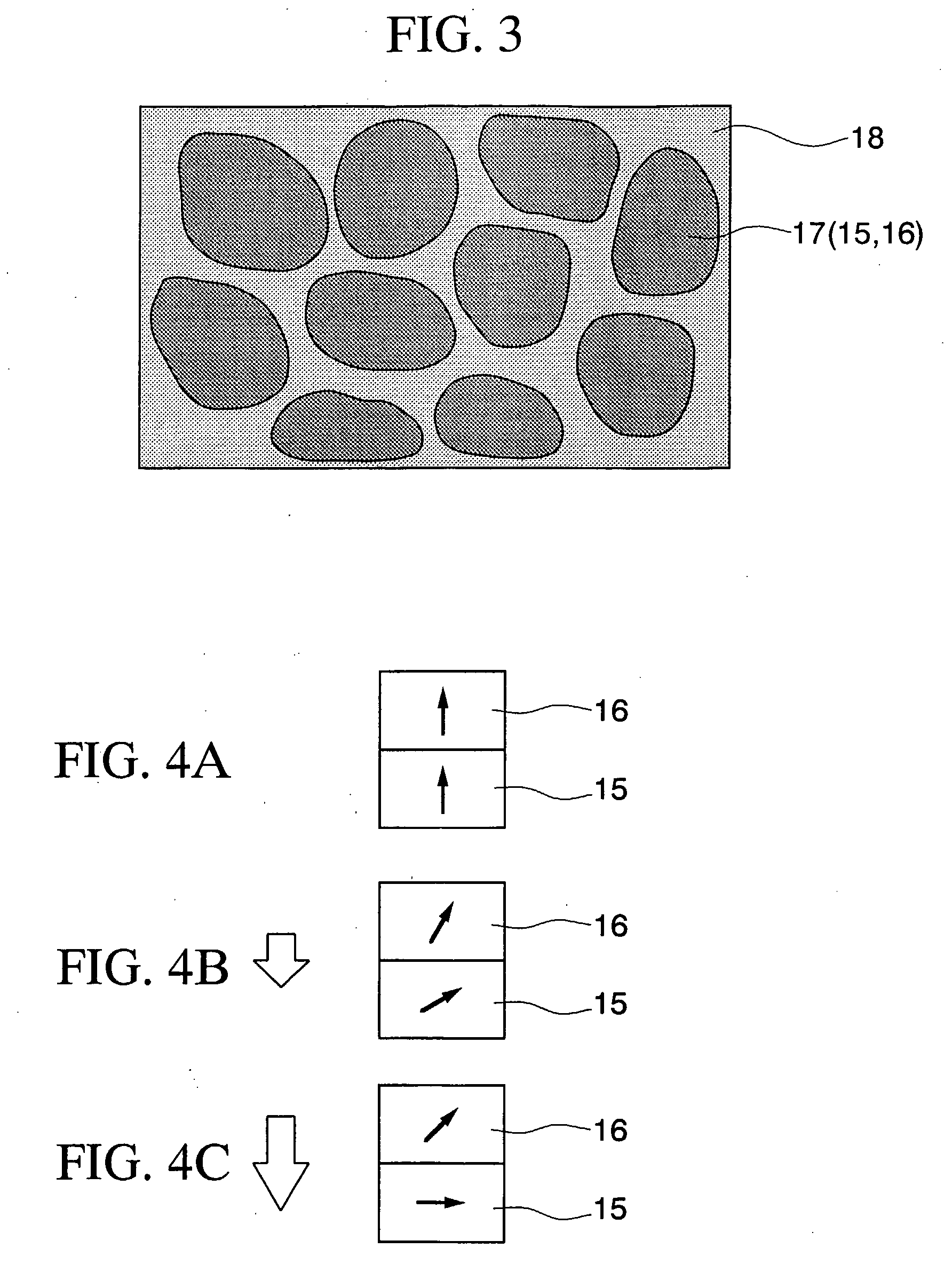

Granular thin film, perpendicular magnetic recording medium employing granular thin film and magnetic recording apparatus

InactiveUS20050214520A1Good crystalline orientationSmall granularityNanomagnetismBase layers for recording layersLow noiseVolumetric Mass Density

A perpendicular magnetic recording medium suitable for attaining a low noise high magnetic recording density is obtained. The medium has a small average magnetic grain diameter, a small magnetic grain diameter distribution, a high perpendicular crystallographic magnetic grain orientation and a high regularity magnetic grain arrangement. The perpendicular magnetic recording medium comprises a soft magnetic layer, a granular under-layer and a perpendicular magnetic recording layer on a substrate. The granular under-layer is formed on a metal under-layer. The metal grains in the granular layer are separated by nonmagnetic inter-grain material and are partially penetrated into the metal under-layer. The perpendicular magnetic recording layer is formed on the granular layer. Then a perpendicular magnetic recording medium shows high signal to noise ratio and excellent high-density recording characteristics.

Owner:KK TOSHIBA

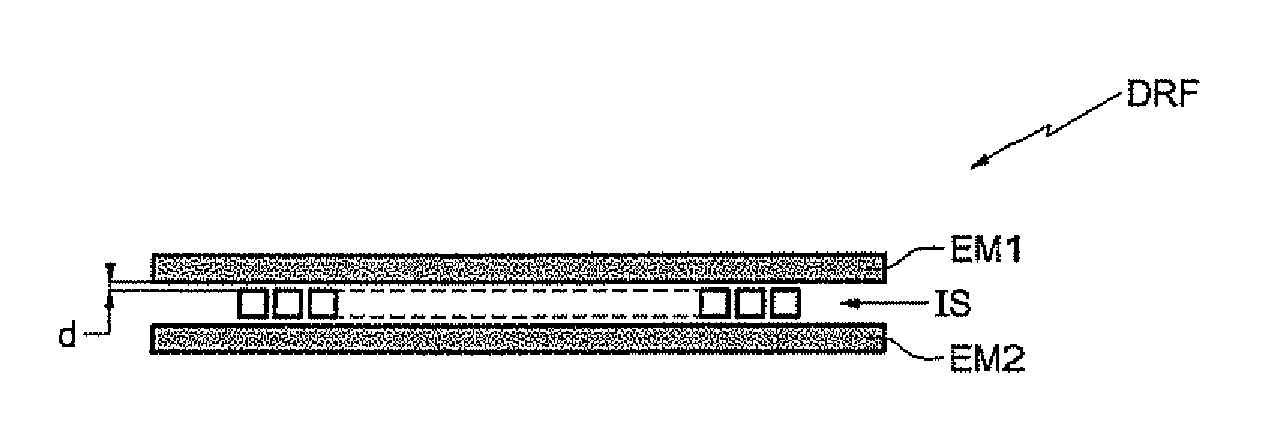

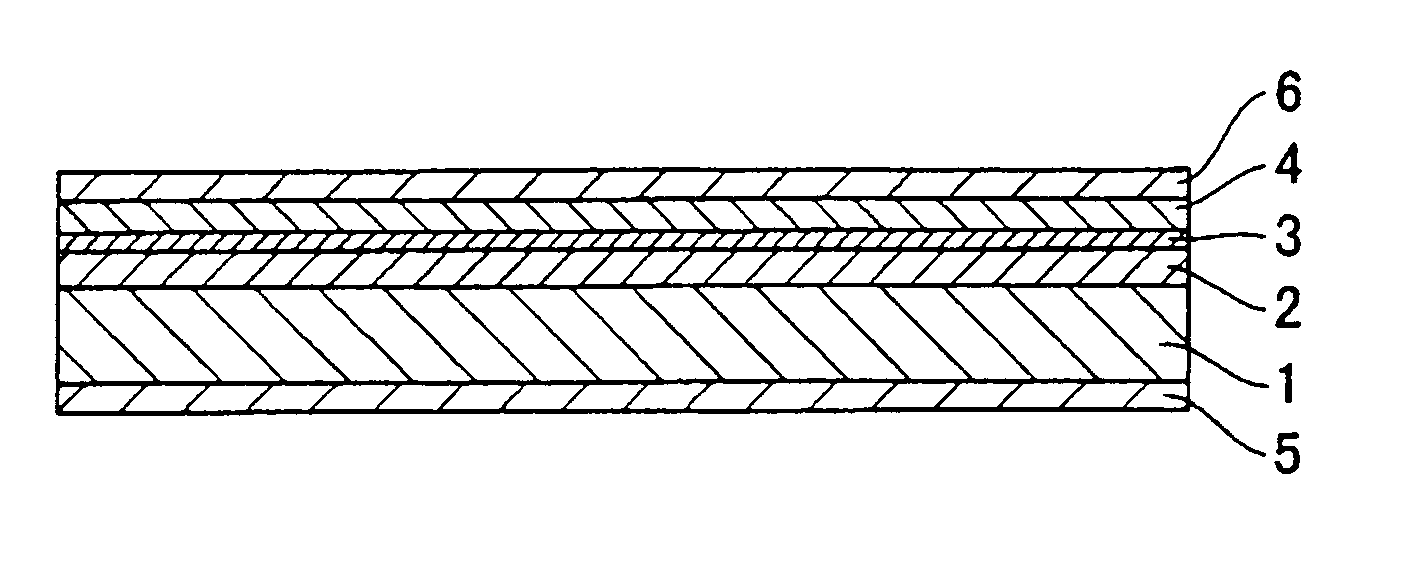

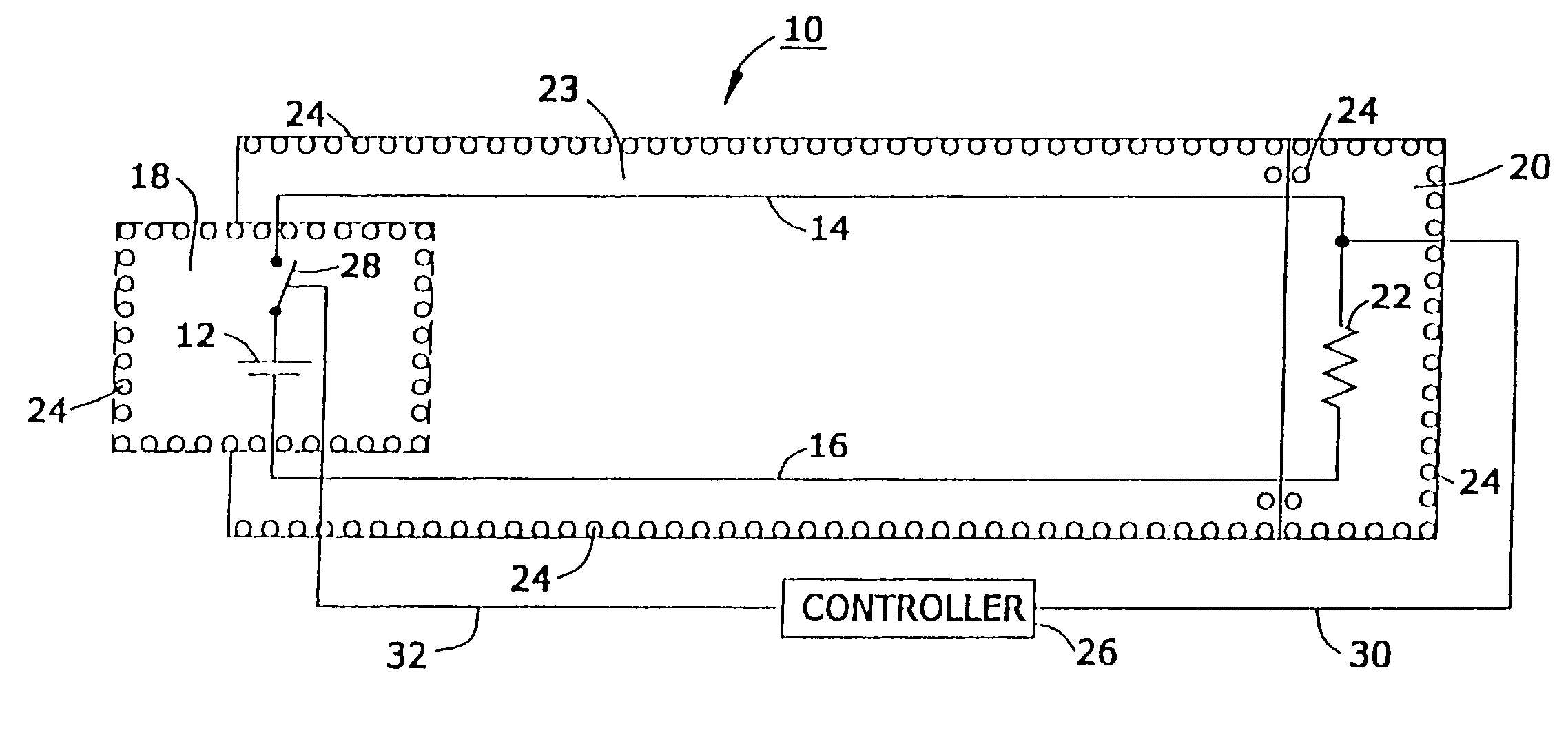

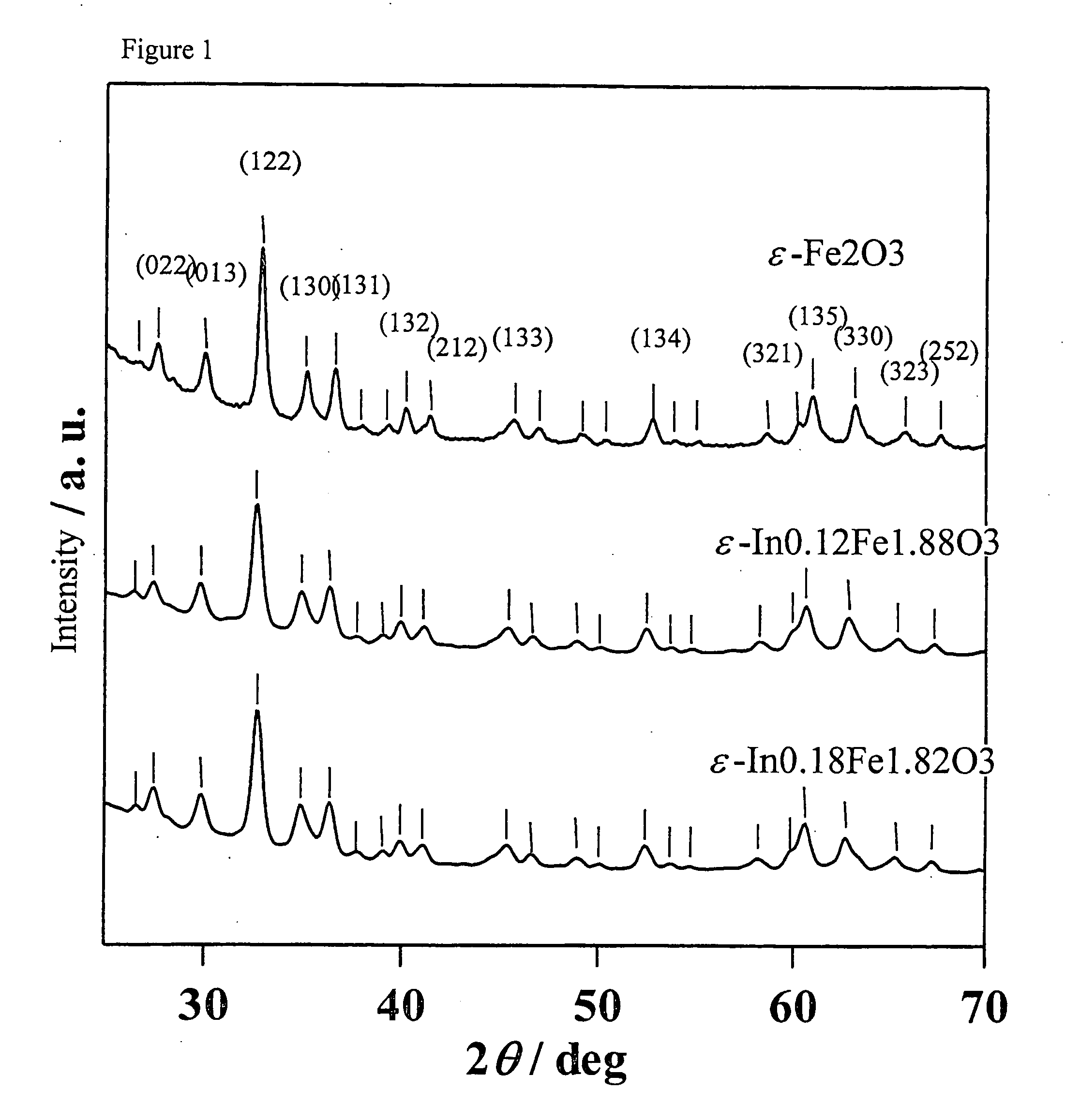

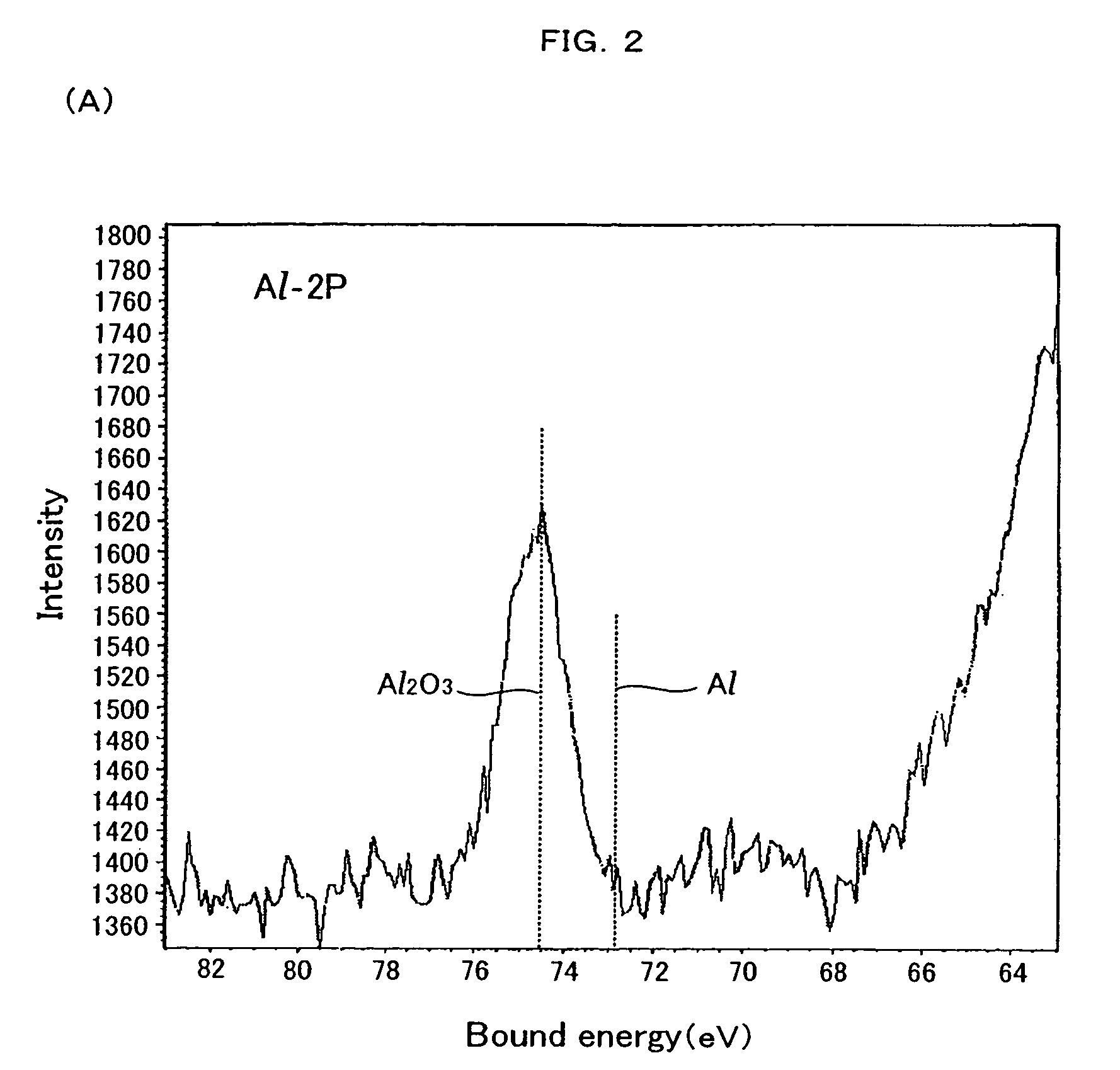

Magnetic thin film, magnetic component that uses this magnetic thin film, manufacturing methods for the same, and a power conversion device

InactiveUS20050094302A1Soft qualityEasy to manufactureNanomagnetismSemiconductor/solid-state device detailsElectric forceElectrical conductor

On top of a silicon substrate, a polyimide film with a thickness of 10 μm is formed. On top of this, a magnetic thin film that is a polyimide film containing Fe fine particles and that has a thickness of 20 μm is formed. On top of this magnetic thin film, a patterned Ti / Au film and a Ti / Au connection conductor are formed. On top of this, a polyimide film with a thickness of 10 μm, and a Cu coil with a height 35 μm, width 90 μm, space 25 μm, and a polyimide layer that fills the spaces in the Cu coil are formed. On top of this, via a polyimide film with a thickness of 10 μm, a magnetic thin film that is a polyimide film containing Fe particles and that has a thickness of 20 μm is formed. This thin film inductor has a small alternating current resistance. The present invention provides a magnetic thin film that is well suited for mass production, can be manufactured easily, can be made into a thick film, has soft magnetic qualities, and is inexpensive. The present invention also provides a magnetic component that uses this magnetic thin film, manufacturing methods for these, and a power conversion device.

Owner:FUJI ELECTRIC DEVICE TECH CO

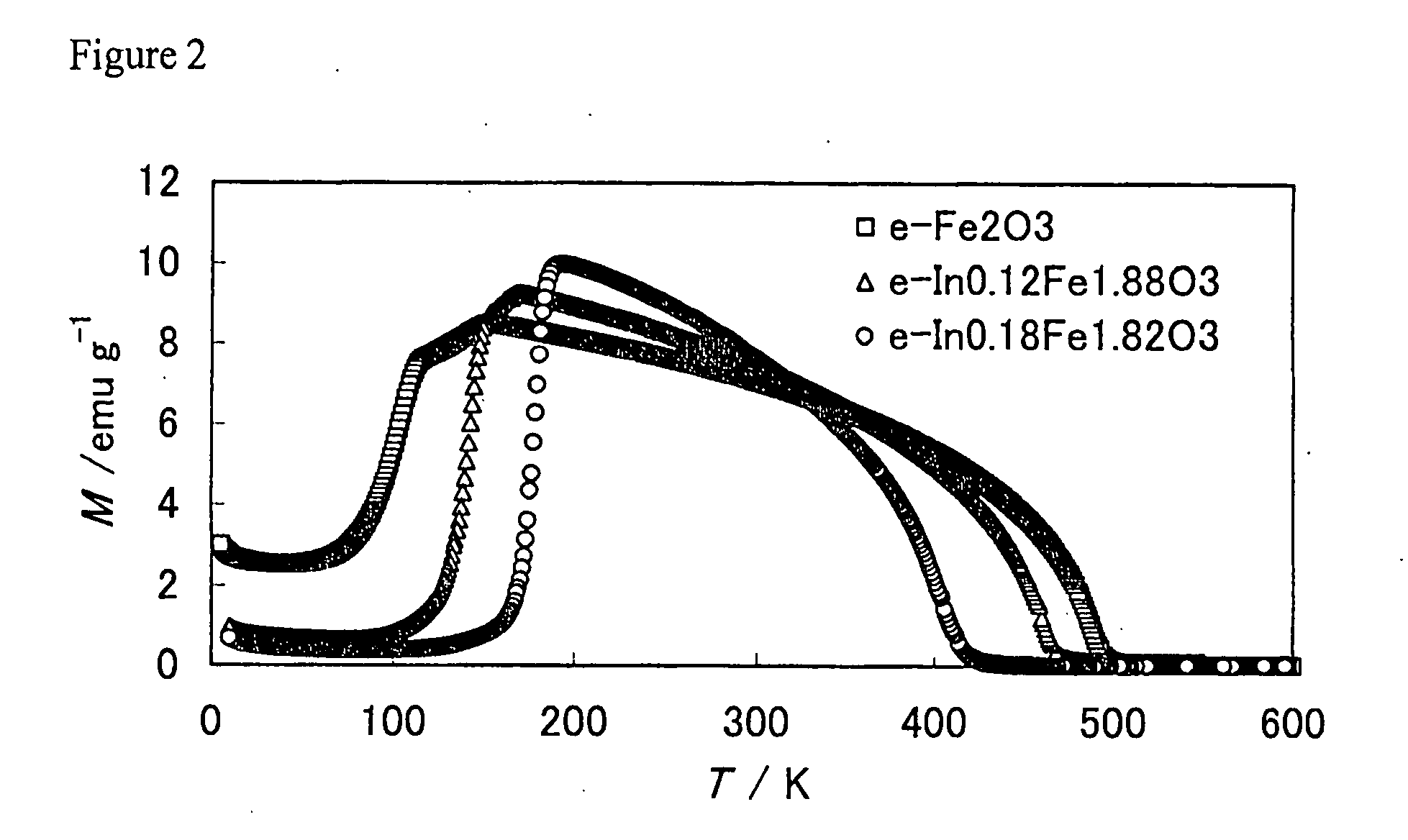

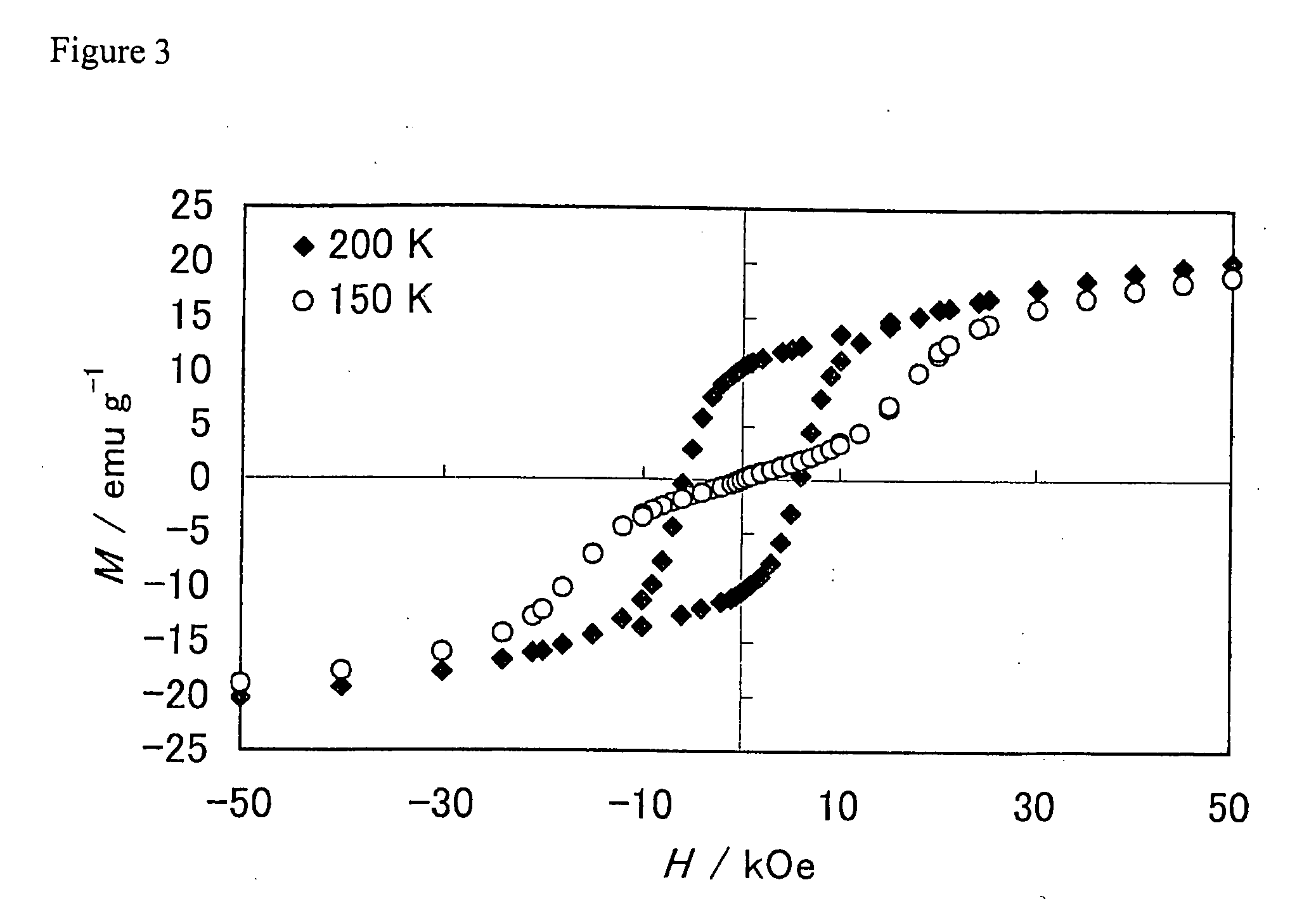

Magnetic material, and memory and sensor using same

ActiveUS20070218319A1Easy to ultimately obtainLarge coercive forceNanomagnetismThermometers using electric/magnetic elementsDielectricCrystal structure

A magnetic material composed of ε-InxFe2-xO3 (wherein 0<x≦0.30) crystal in which In is substituted for a portion of the Fe sites of the ε-Fe2O3 crystal. The crystal exhibits an X-ray diffraction pattern similar to that of an ε-Fe2O3 crystal structure and has the same space group as that of an ε-Fe2O3. The In content imparts to the magnetic material a magnetic phase transition temperature that is lower than that of the ε-Fe2O3 and a spin reorientation temperature that is higher than that of the ε-Fe2O3. The In content can also give the magnetic material a peak temperature of the imaginary part of the complex dielectric constant that is higher than that of the ε-Fe2O3.

Owner:THE UNIV OF TOKYO +1

Method of preparing high orientation nanoparticle-containing sheets or films using ionic liquids, and the sheets or films produced thereby

InactiveUS20060269695A1High magnetic anisotropyImprove signal-to-noise ratioNanostructure manufactureConductive materialNon solventMagnetite Nanoparticles

A method is provided for the preparation of nanomaterials, which involves the dissolution and / or suspension of a combination of (a) one or more resin substrate materials and (b) one or more magnetic nanoparticulate substances, in a medium made from one or more ionic liquids, to provide a mixture, and recovering the solid nanomaterial by combining the mixture with a non-solvent (solvent for the ionic liquids but not the other components), while also applying an electromagnetic field to the mixture during the recovering step to align the magnetic nanoparticulate substances, along with the use of the resulting nanomaterials to provide unique information storage media, particularly in the form of sheets or films.

Owner:UNIVERSITY OF ALABAMA +1

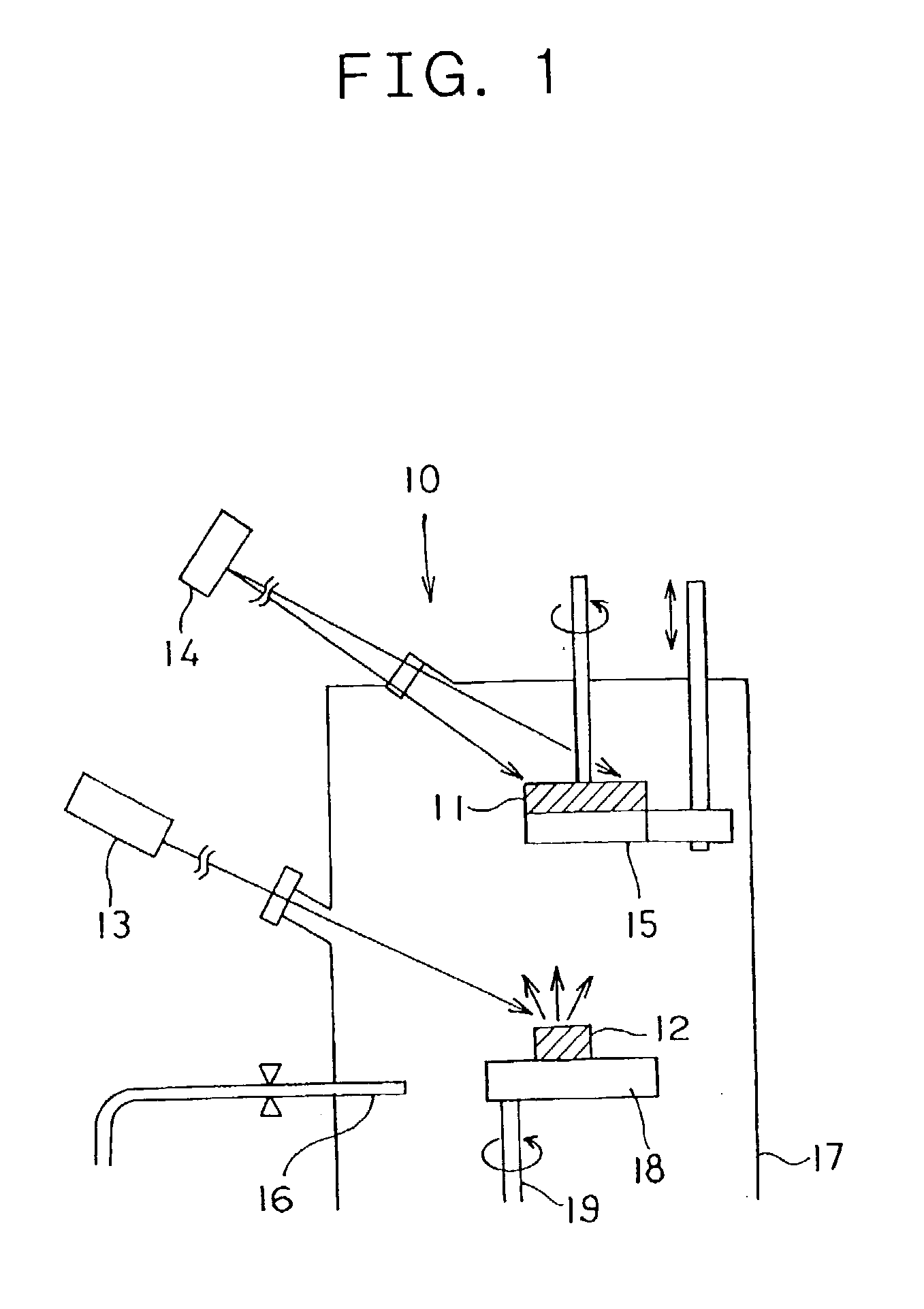

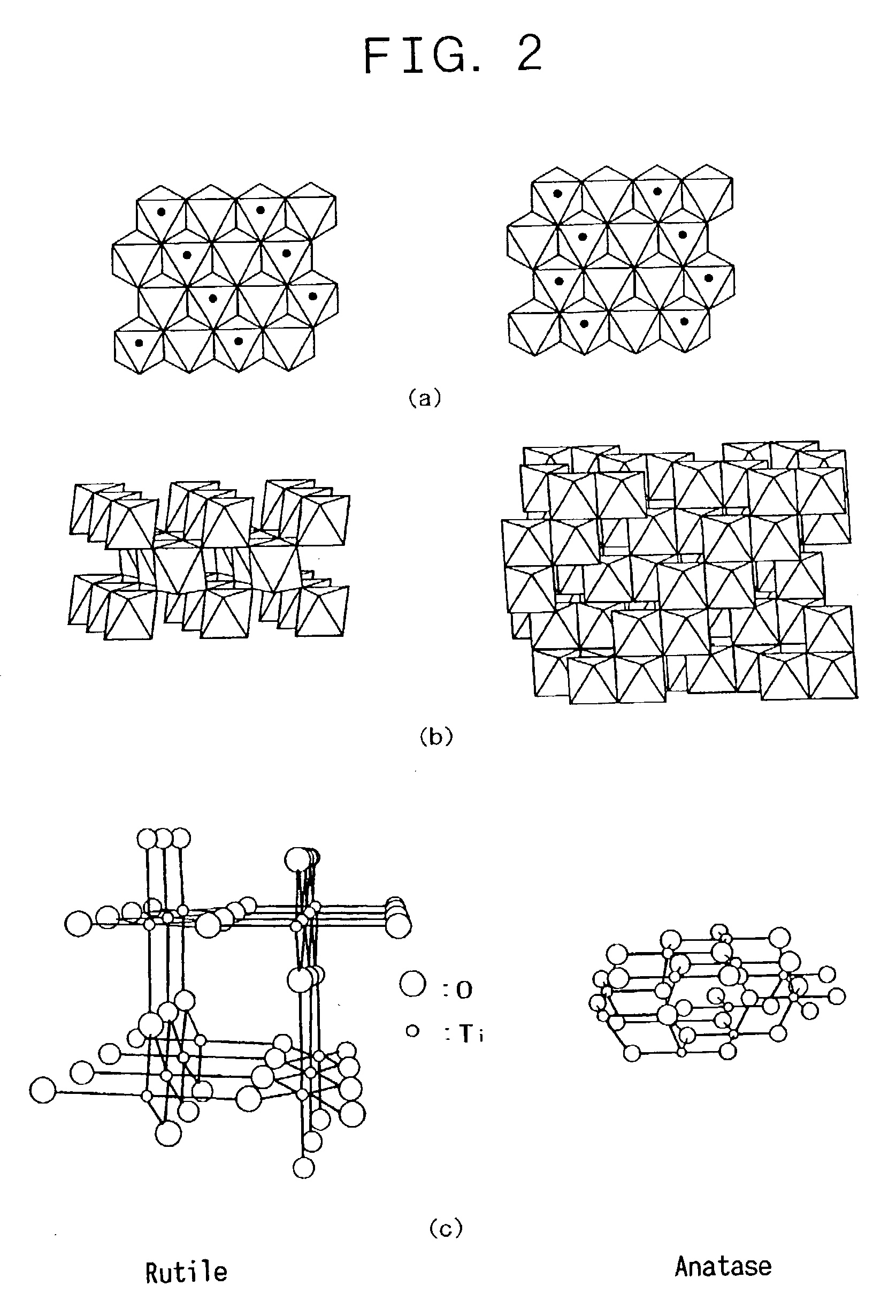

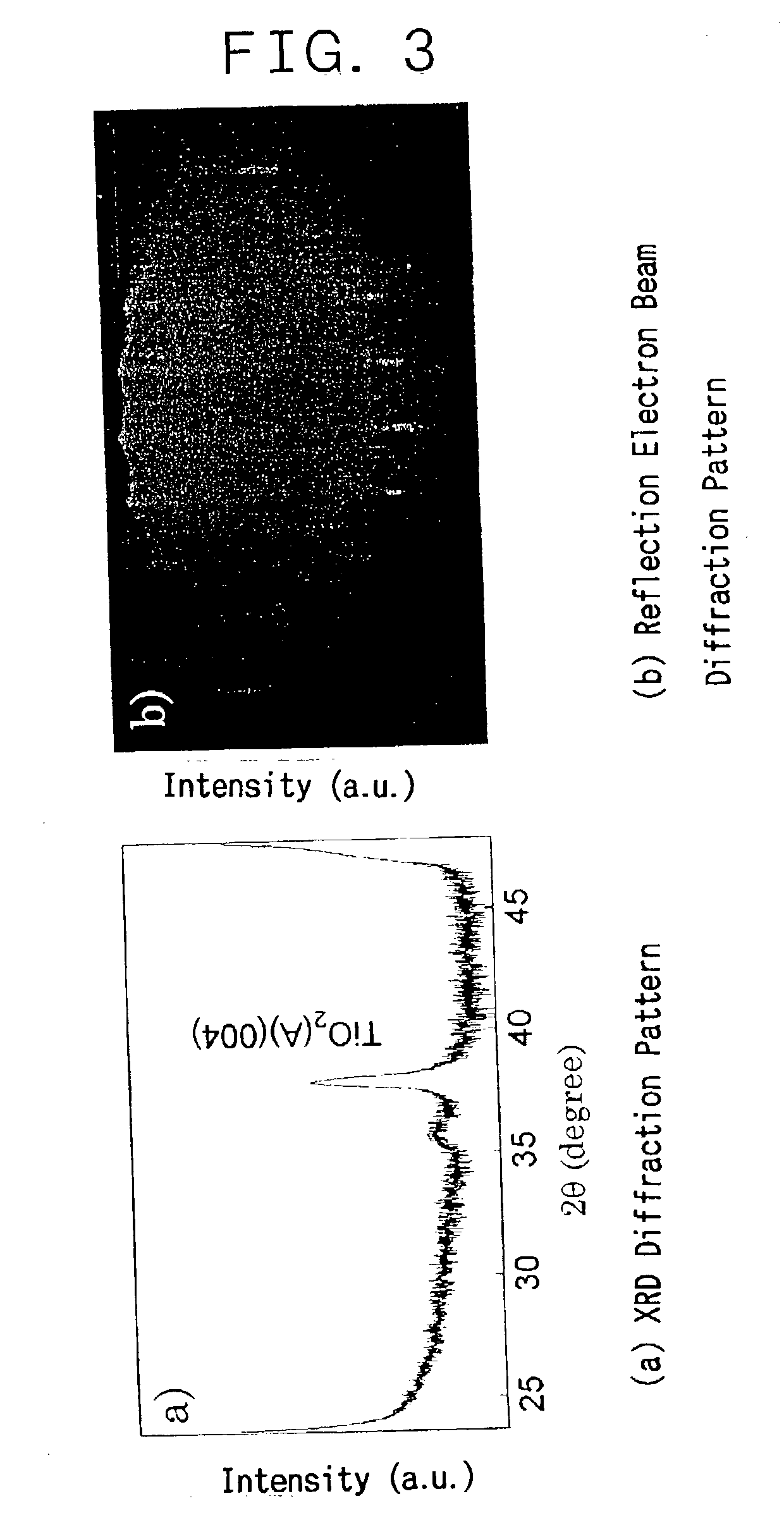

Titanium dioxide cobalt magnetic film and its manufacturing method

InactiveUS20030091500A1High catalytic activitySoldering apparatusVacuum evaporation coatingSemiconductor materialsMagnetization

A titanium dioxide.cobalt magnetic film is provided that is useful to make up a photocatalyst having high catalytic capability, a semiconductor material having an optical, an electrical and a magnetic function all in combination, and a transparent magnet. The titanium dioxide.cobalt magnetic film has a composition expressed by chemical formula: Ti1-xCoxO2 where 0<x<=0.3, wherein a Ti atom at its lattice position is replaced with a Co atom, and the magnetic film is a film epitaxially grown on a single crystal substrate. The magnetic film has either anatase or rutile crystalline structure, has its band gap energy varying in a range between 3.13 eV and 3.33 eV according to the concentration of Co atoms replaced for Ti atoms at their lattice positions, is capable of retaining its magnetization even at a temperature higher than a room temperature, and is also transparent to a visible light. I the manufacture of the titanium dioxide.cobalt magnetic film, a target having TiO2 and Co mixed together at a selected mixing ratio is prepared, placed in a vacuum chamber provided with an atmosphere with a selected oxygen pressure therein, and irradiated in the vacuum chamber with a selected laser light under selected irradiating conditions to cause TiO2 and Co to evaporate from the target and a layer of TiO2.Co to grow in a single crystal substrate that is heated in the vacuum chamber.

Owner:JAPAN SCI & TECH CORP

Magnetic recording medium and magnetic recording and reproducing apparatus

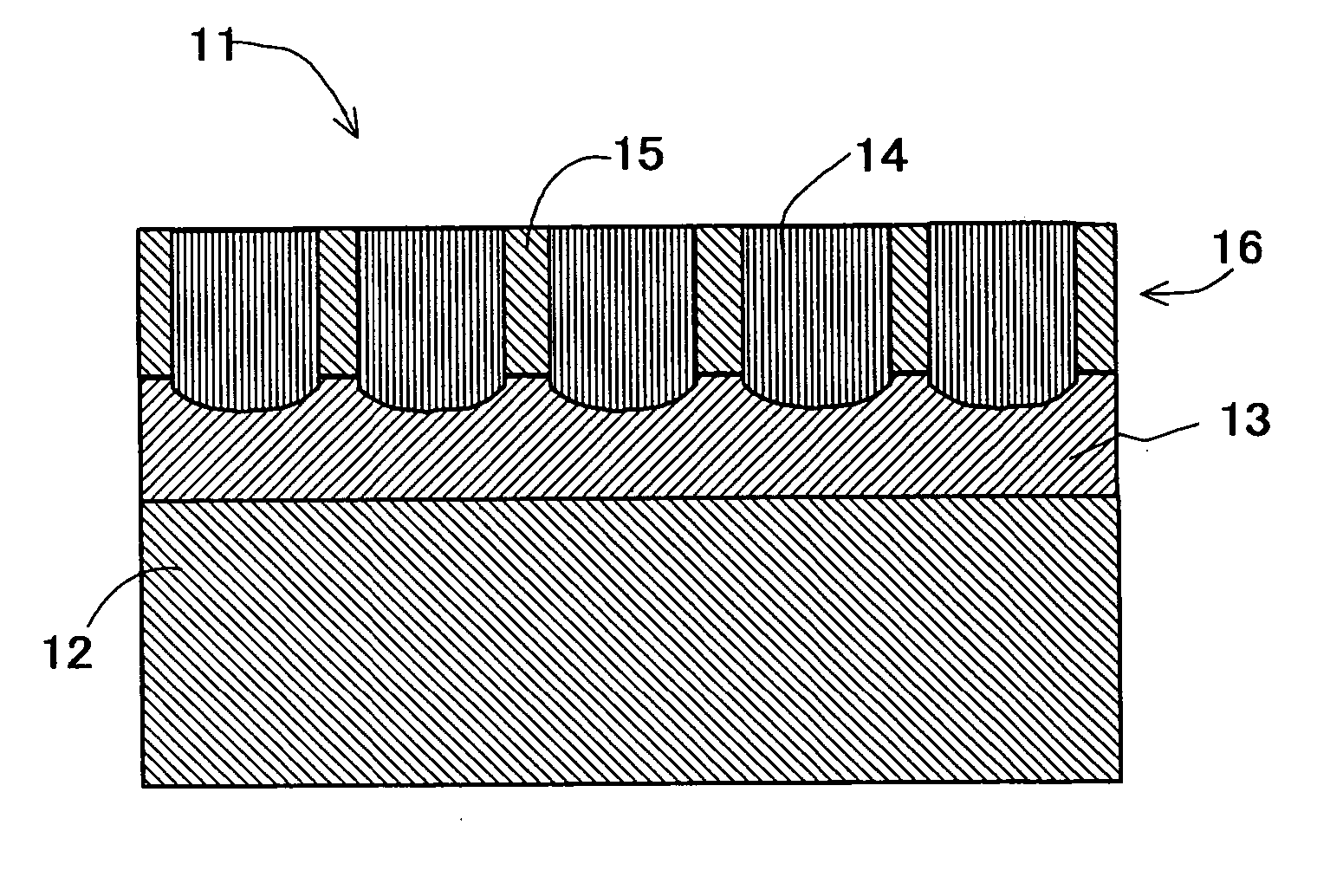

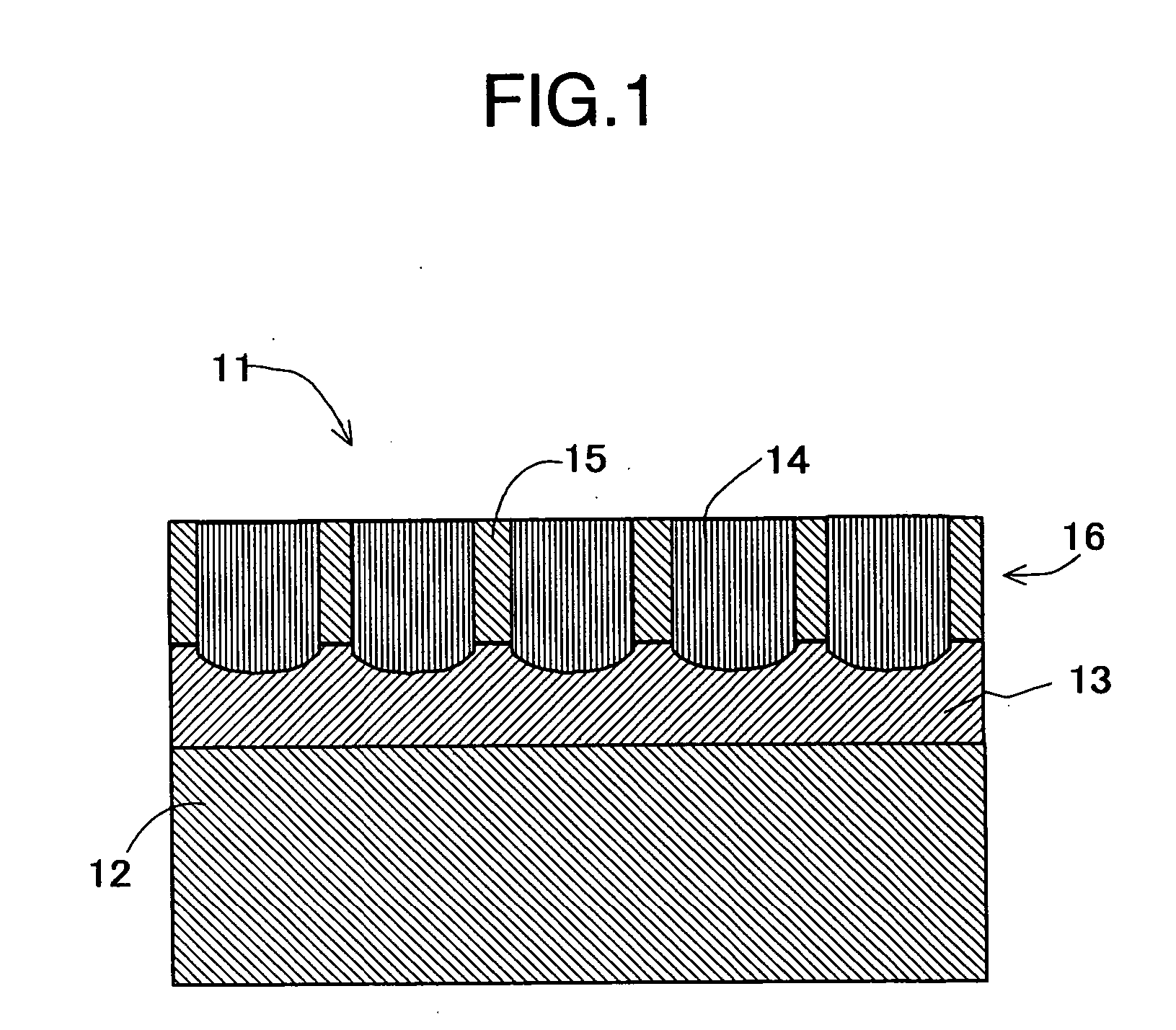

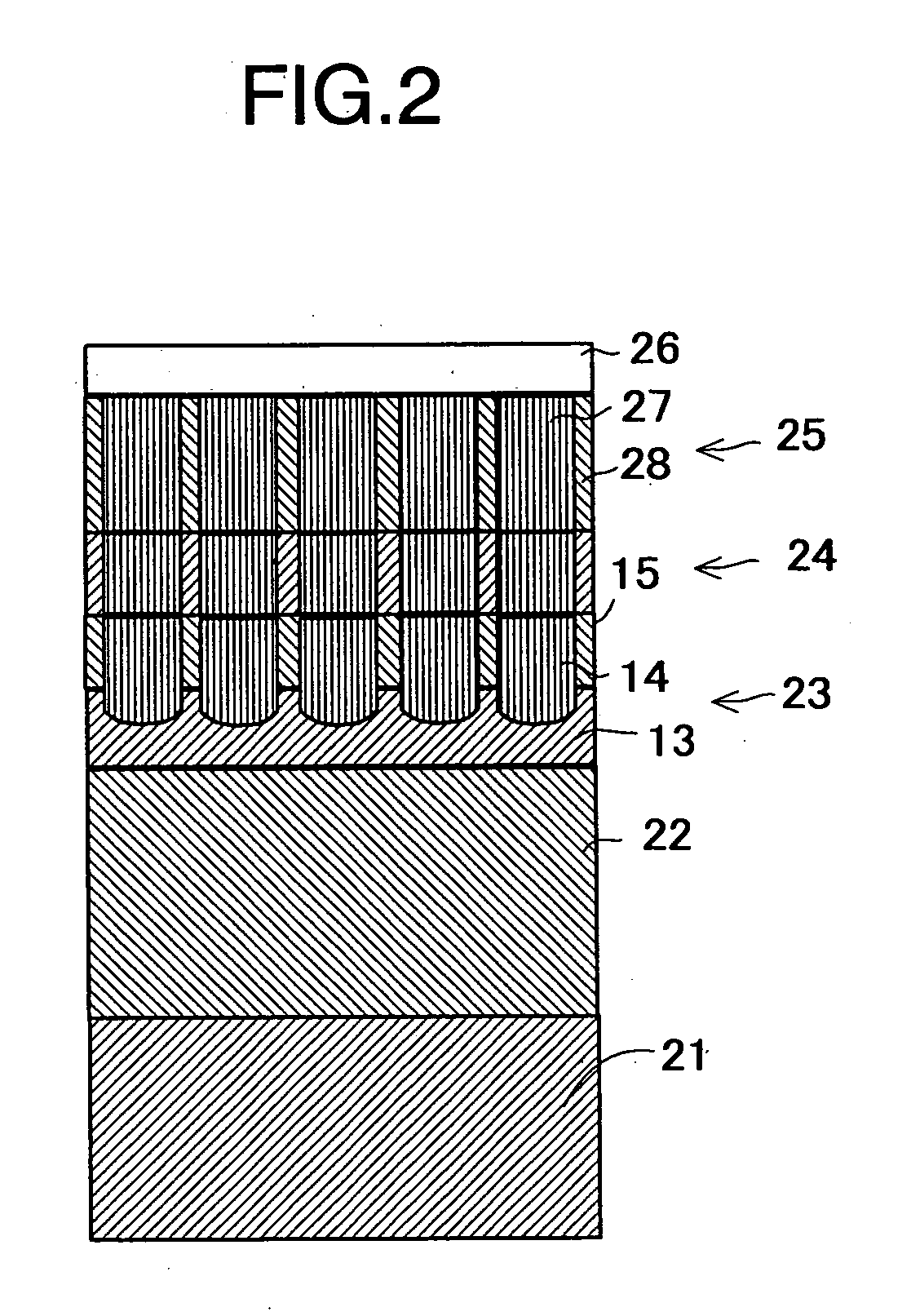

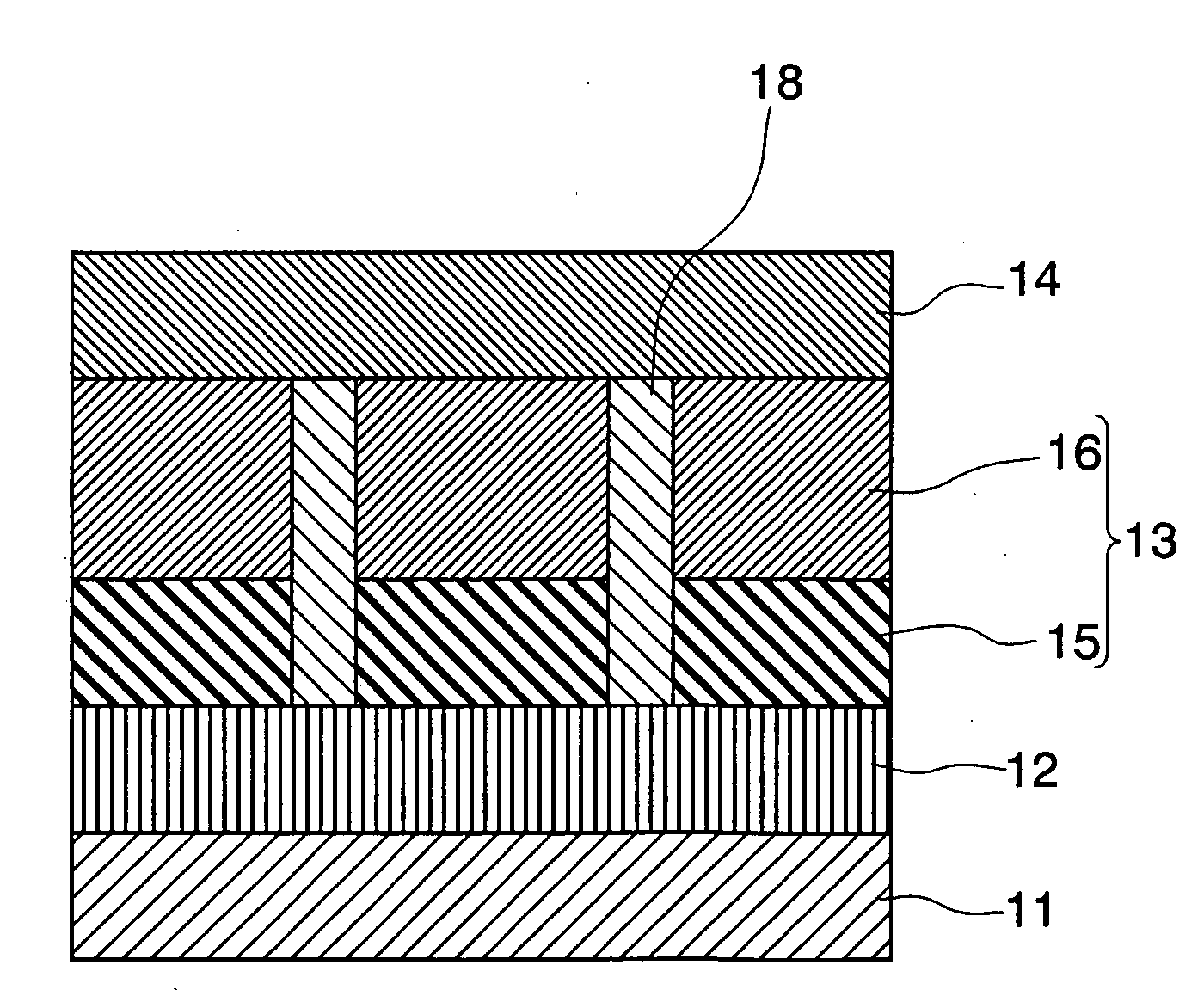

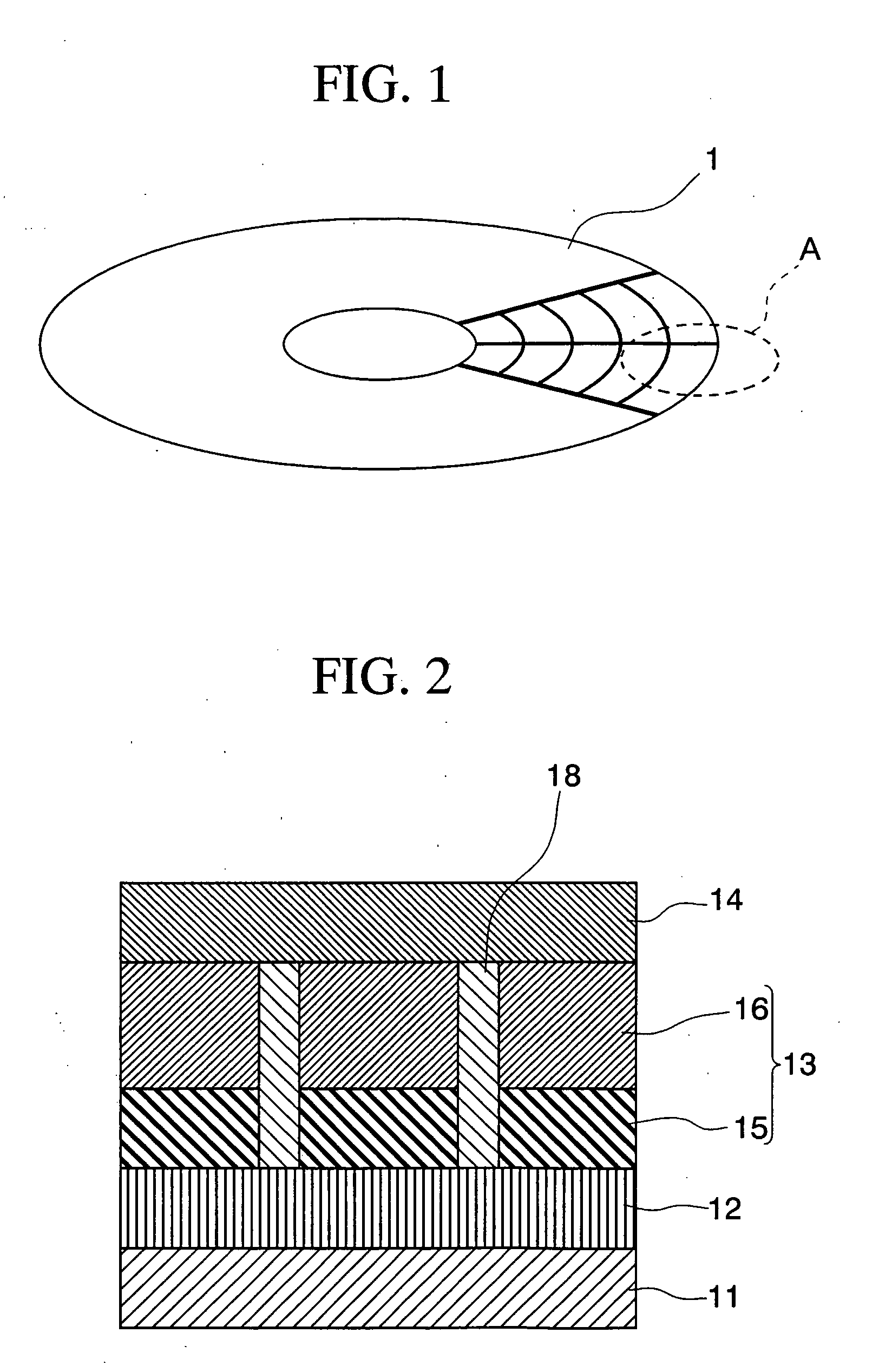

ActiveUS20090231755A1Easy to manufactureThe process is simple and convenientRecord information storageUltrathin/granular filmsRecording layerRecording media

The invention provides a magnetic recording medium, and a magnetic recording and reproducing apparatus. The magnetic recording medium includes a substrate 11, an under layer 12 formed on the substrate 11, a magnetic recording layer 13 formed on the under layer 12, and a protective layer 14 formed on the magnetic recording layer 13. The magnetic recording layer 13 is composed of a primary recording layer 14 and a secondary recording layer 15 which are mutually exchange-coupled. The primary recording layer 14 has magnetic grains and a nonmagnetic material that surrounds the magnetic grains, and has a perpendicular magnetic anisotropy. The secondary recording layer 15 is made of a material having a negative crystal magnetic anisotropy and its easy plane of the magnetization is a plane of the medium.

Owner:TOHOKU UNIV +2

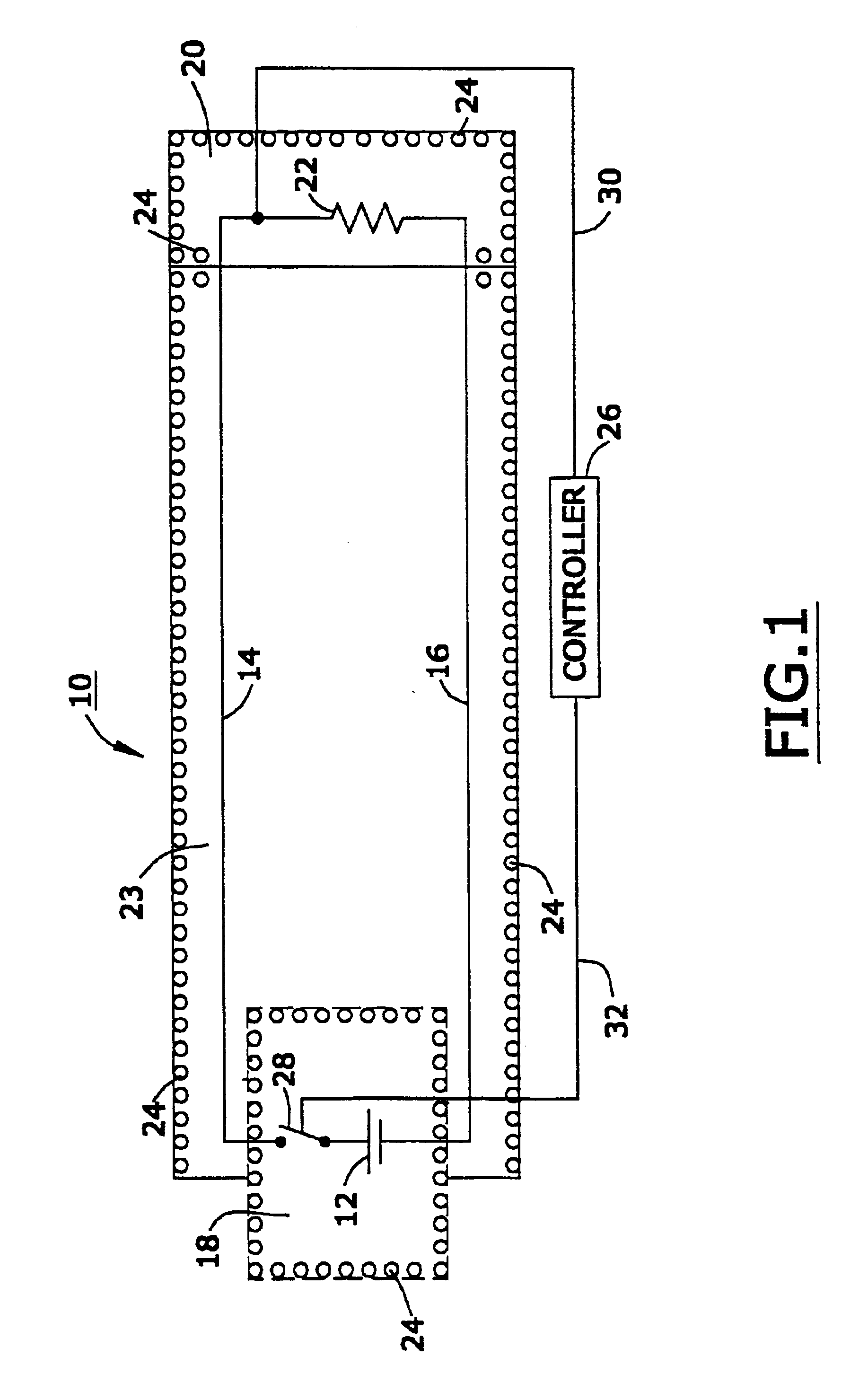

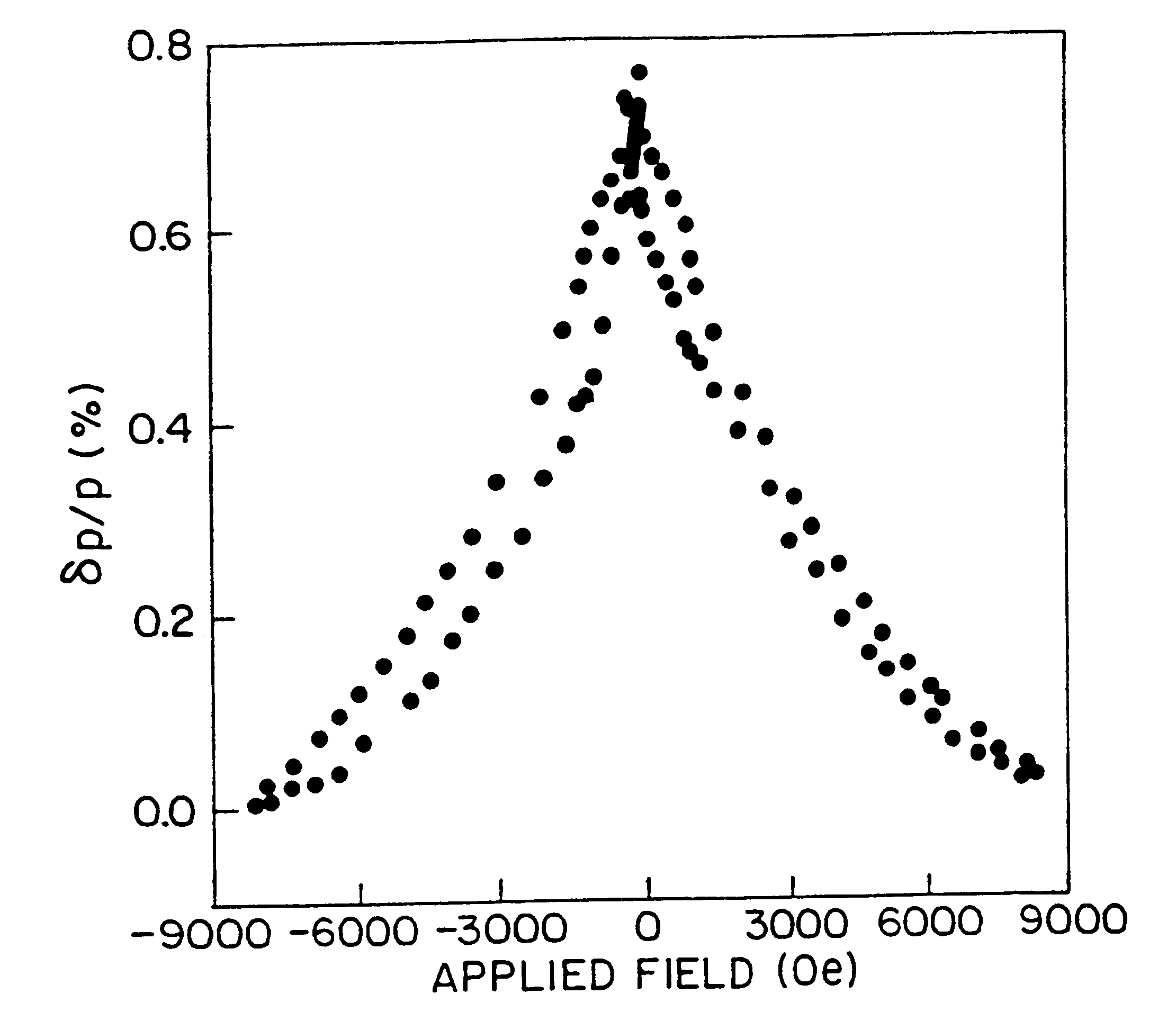

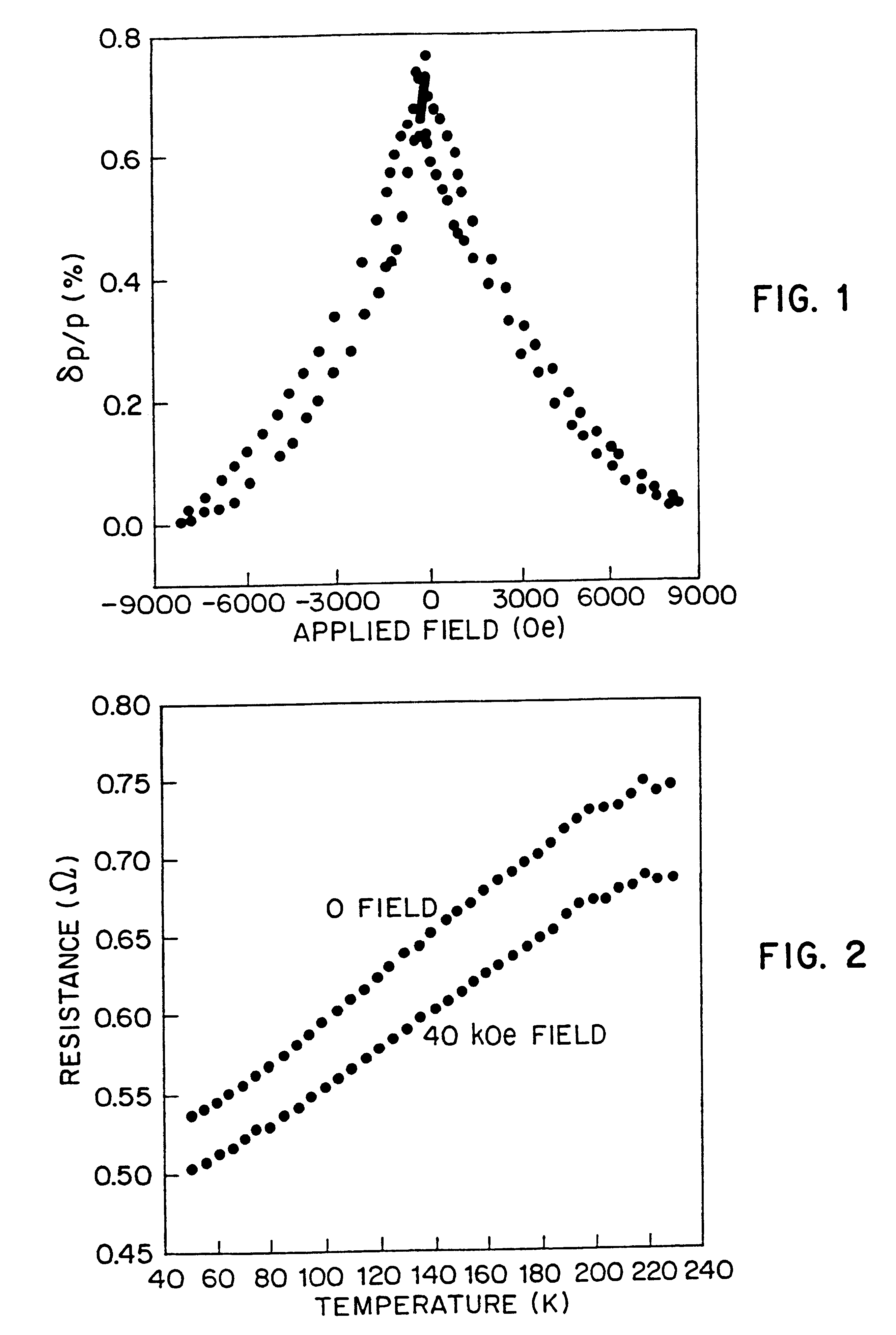

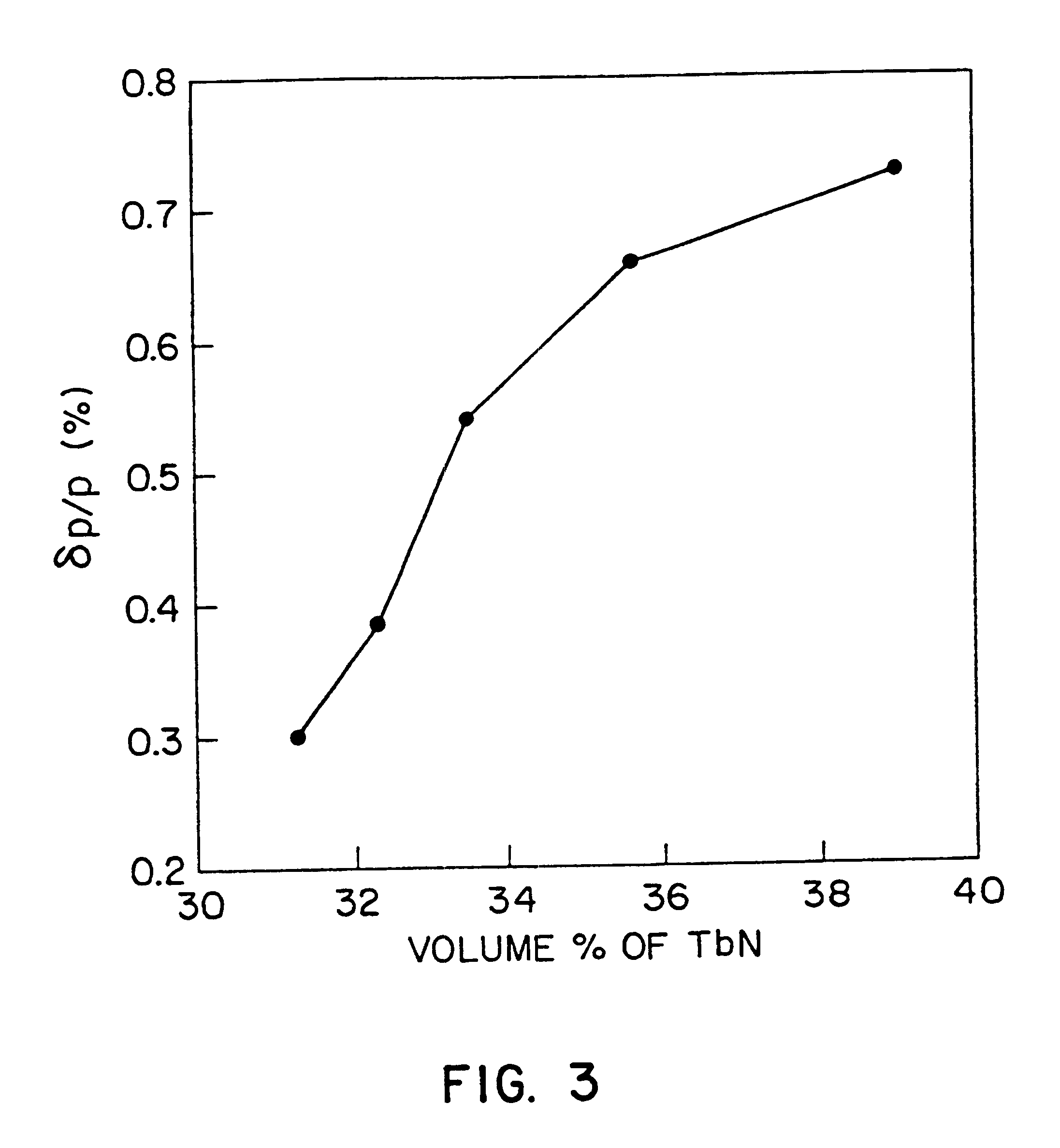

Magnetoresistive material with two metallic magnetic phases

A magnetoresistive material with two metallic magnetic phases. The material exhibits the giant magnetoresistance effect (GMR). A first phase of the material includes a matrix of an electrically conductive ferromagnetic transition metal or an alloy thereof. A second precipitate phase exhibits ferromagnetic behavior when precipitated into the matrix and is antiferromagnetically exchange coupled to the first phase. The second precipitate phase can be electrically conductive rare earth pnictide or can be a Heusler alloy. A method of manufacturing magnetoresistive materials according to the present invention employs facing targets magnetron sputtering. The invention also includes a method of detecting magnetic field strength by providing a read head including a portion of one of the magnetoresistive materials according to the invention, exposing the read head to the magnetic field of a magnetic recording medium, sensing electrical resistivity of the portion of material associated with the magnetic field of the magnetic recording medium, and converting the electrical resistivity into a signal which is indicative of the magnetic field strength of the magnetic field associated with the magnetic recording medium. A digital magnetic recording system, according to the present invention, is adapted for use with a magnetic recording medium having a characteristic coercive force and a plurality of stored bits thereon. The bits are stored by magnetic field strength levels of a magnetic field associated with the medium. The system can include a conventional write head and a controller. The system can also include a read head including a portion of magnetoresistive material according to the present invention which is located in proximity to the medium and a suitable resistivity sensor.

Owner:THE RES FOUND OF STATE UNIV OF NEW YORK

Process for manufacturing magnetic material, magnetic material and high density magnetic recording medium

InactiveUS20060204793A1High densityEfficiently obtainedNanomagnetismInorganic material magnetismHigh densityFerromagnetic order

A process for manufacturing a magnetic material, comprising: coating a nanoparticle dispersion containing alloy nanoparticles capable of forming a ferromagnetic ordered alloy phase, and a fusion inhibitor on a support to form a coated film of a nanoparticle magnetic layer, and heat-treating the coated film to ferromagnetize the alloy nanoparticles. Further, a magnetic material comprising a support and a nanoparticle magnetic layer of a nanoparticle dispersion coated thereon, wherein the nanoparticle dispersion comprises alloy nanoparticles capable of forming a ferromagnetic ordered alloy phase and a fusion inhibitor, is provided.

Owner:FUJIFILM HLDG CORP +1

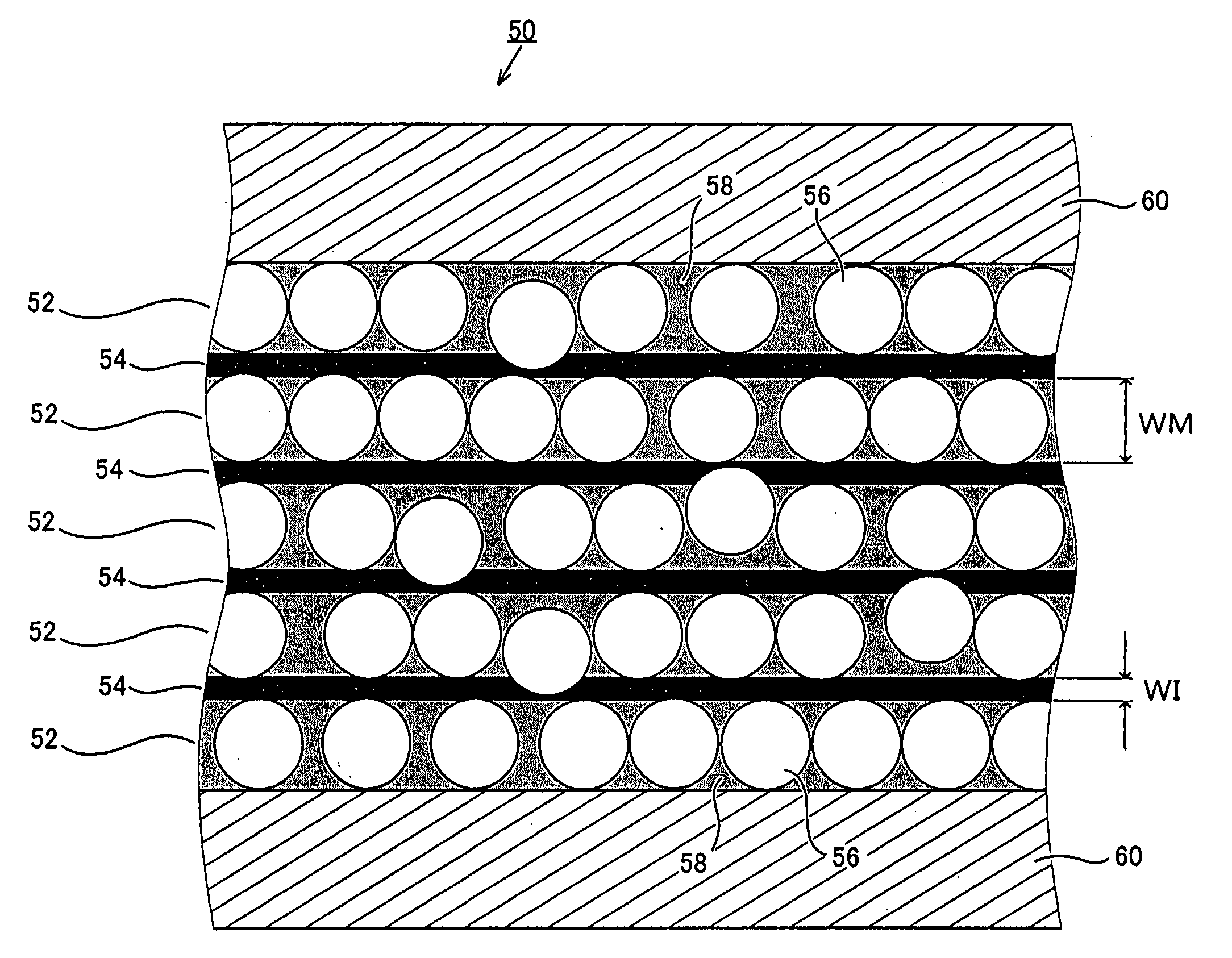

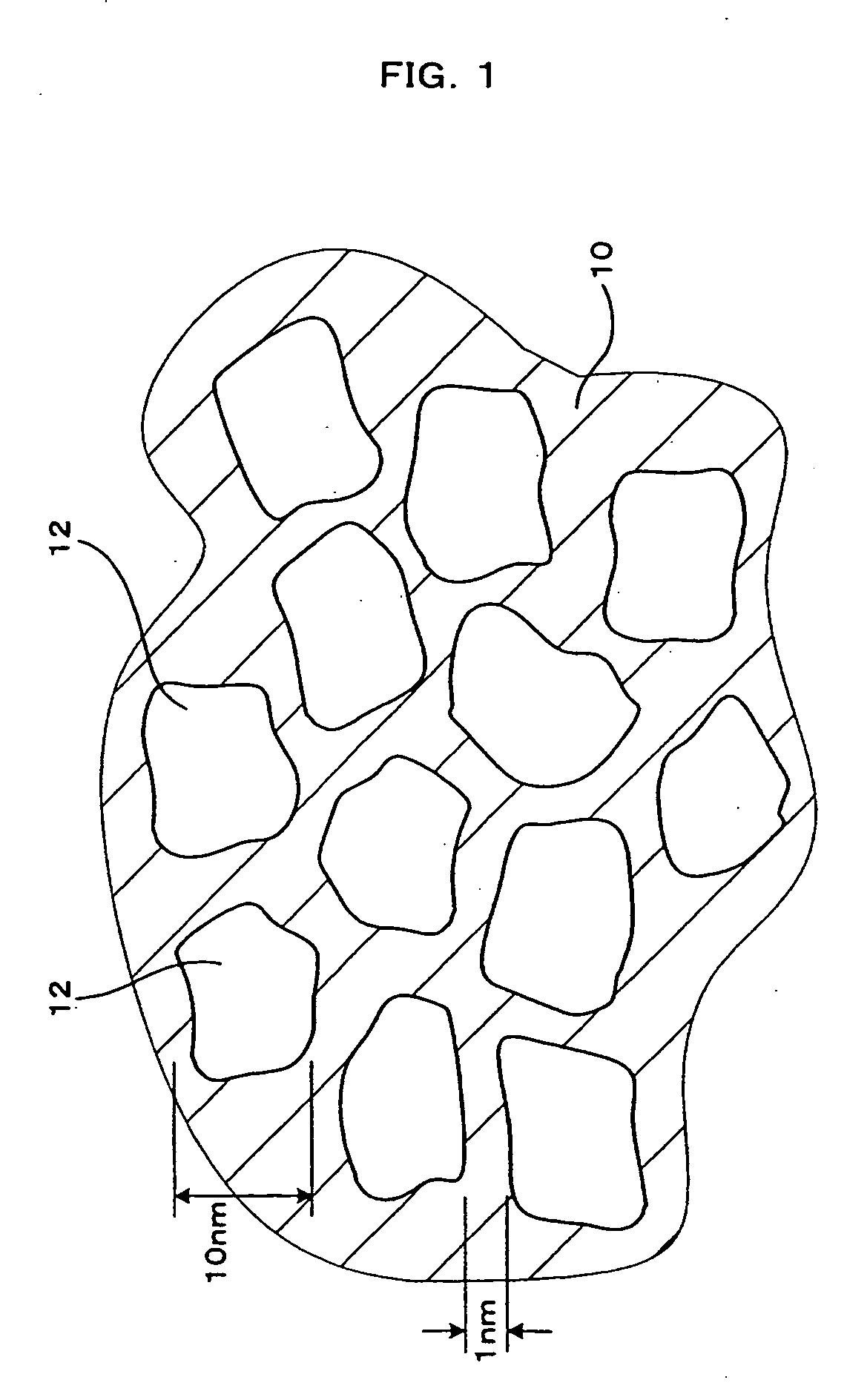

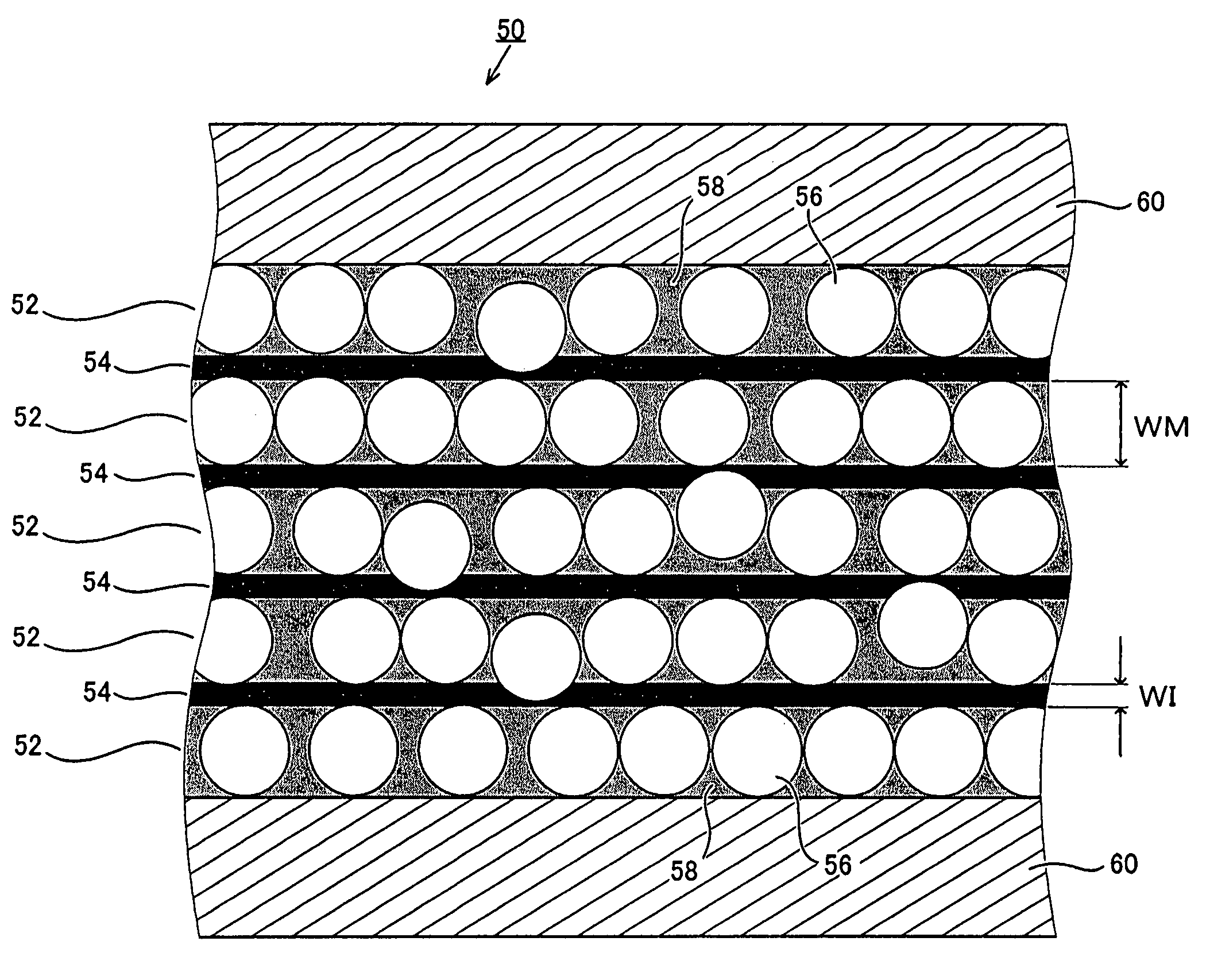

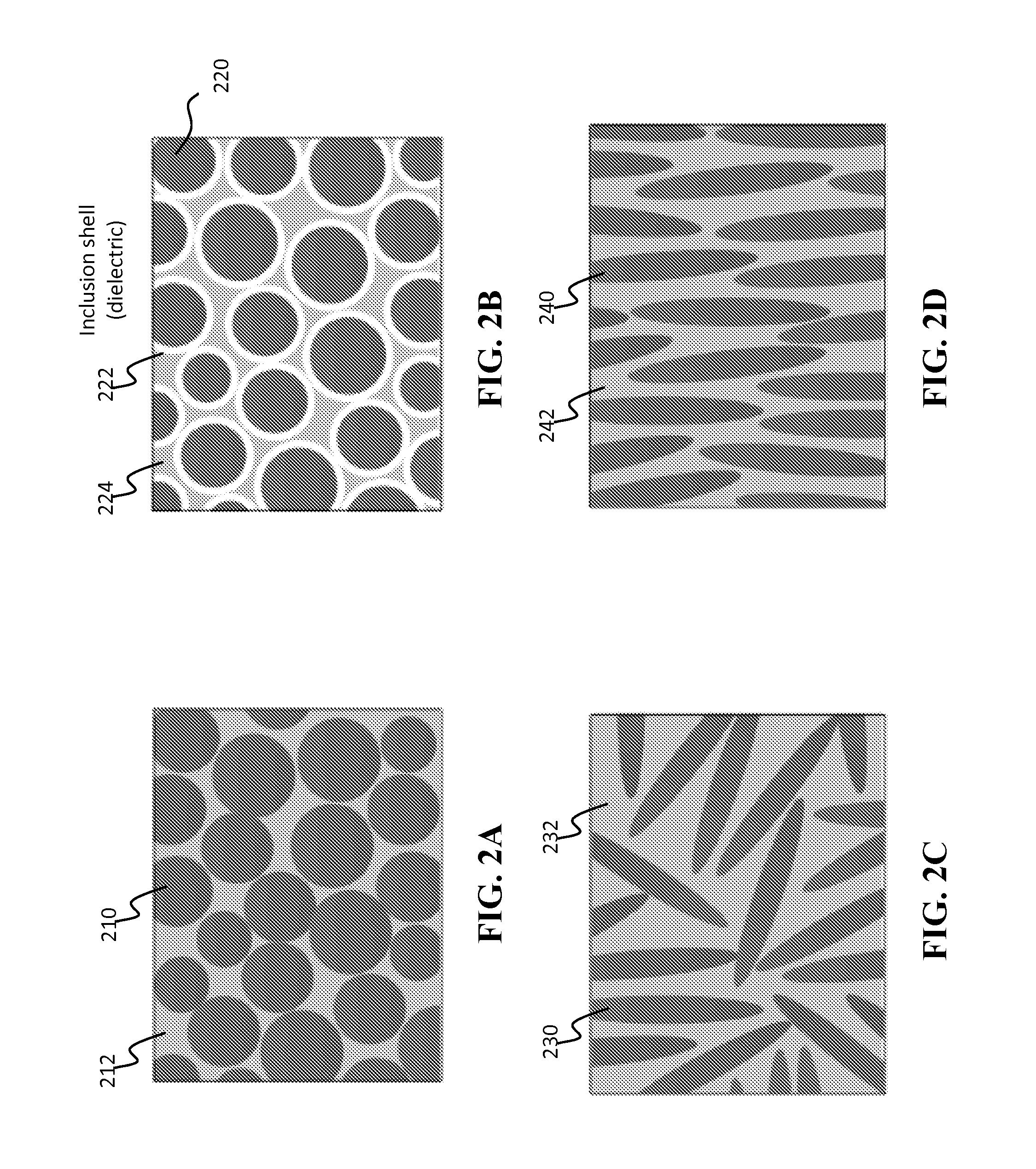

Granular magnetic thin film and method for making the same, multilayered magnetic film, magnetic components and electronic equipment

InactiveUS20040209098A1Improved high-frequency characteristicExcellent soft magnetic propertiesNanostructure applicationNanomagnetismHigh resistivityMaterials science

There are provided a magnetic thin film utilizing a granular film and having excellent high frequency characteristics and a method of manufacturing the same, and a multilayered magnetic film and magnetic components and electronic equipment utilizing the same. A nonreactive sputtering is performed so that there is no oxidation of a magnetic metal, and a saturation magnetization is increased to increase a resonant frequency of permeability. Also, a multi-target simultaneous sputtering is combined with the nonreactive sputtering so that in a granular structure including magnetic grains and an insulating layer a size of the magnetic grains and a thickness of the insulating layer are optimized thereby ensuring a proper magnitude for a crystalline magnetic anisotropy within the grains and excellent soft magnetic properties. Further, the optimization of the thickness of the insulating layer has the effect of improving a resistivity, decreasing an eddy current and improving an exchange interaction between the magnetic grains.

Owner:TAIYO YUDEN KK

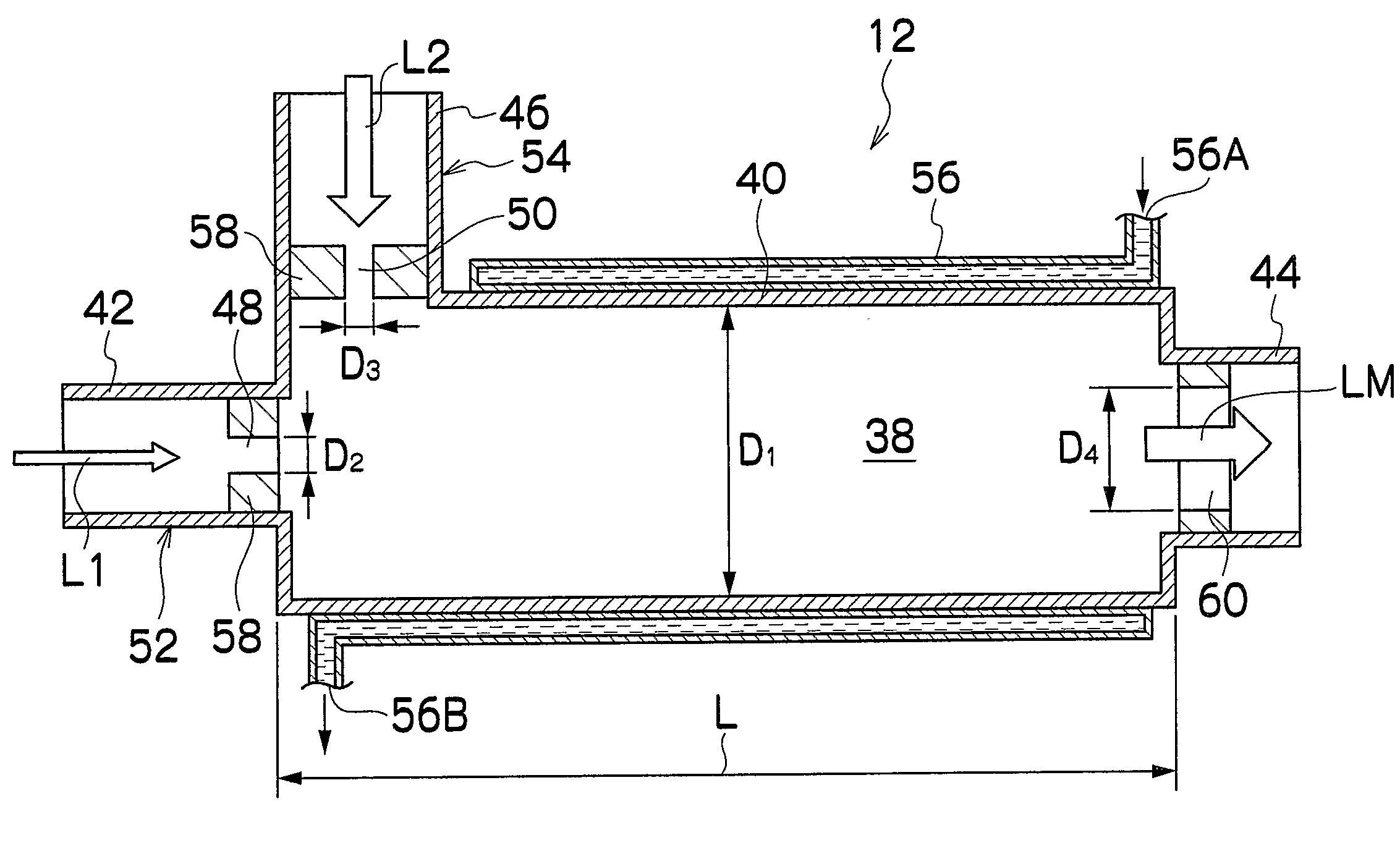

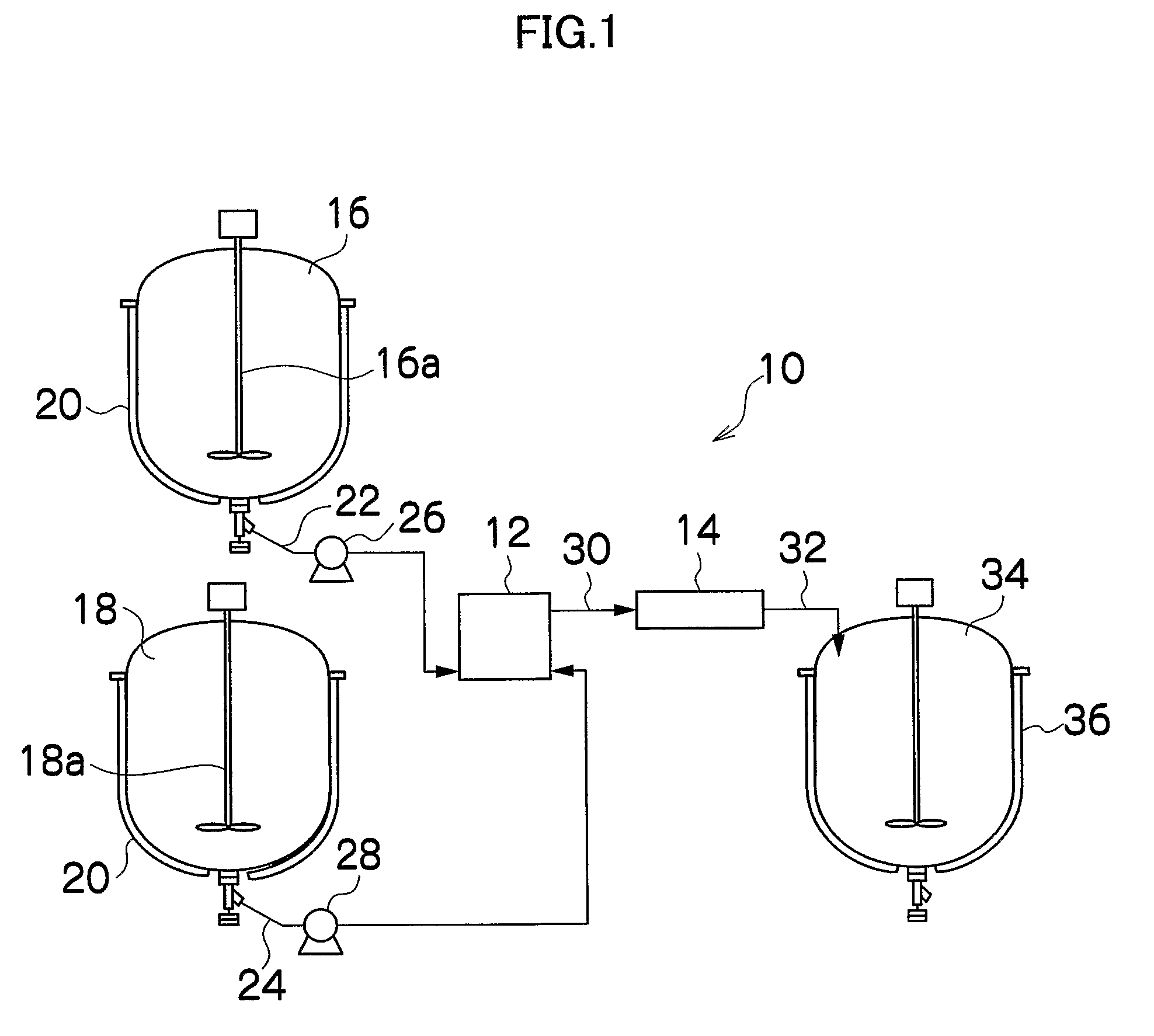

Reaction Method and Apparatus and Method and Apparatus for Manufacturing Chemical Substance Using the Same

InactiveUS20090087683A1Evenly and efficiently performSmooth responseNanomagnetismLiquid degasificationReaction systemAir bubble

The present invention provides a reaction method for a reaction system generating gas by a reaction, comprising the steps of: providing a sealed mixing section for mixing a plurality of liquids to start a reaction and a degassing section having a gas-liquid interface for removing, from a reaction liquid, gas bubbles generated from a mixed reaction liquid, separately; and feeding the reaction liquid mixed in the mixing section to the degassing section, without being interfered by gas bubbles even in a reaction system where gas is generated by a reaction, so that it is possible to stabilize a reaction at the start of the reaction and in the progress of the reaction and stably feed liquid to a subsequent process.

Owner:FUJIFILM CORP

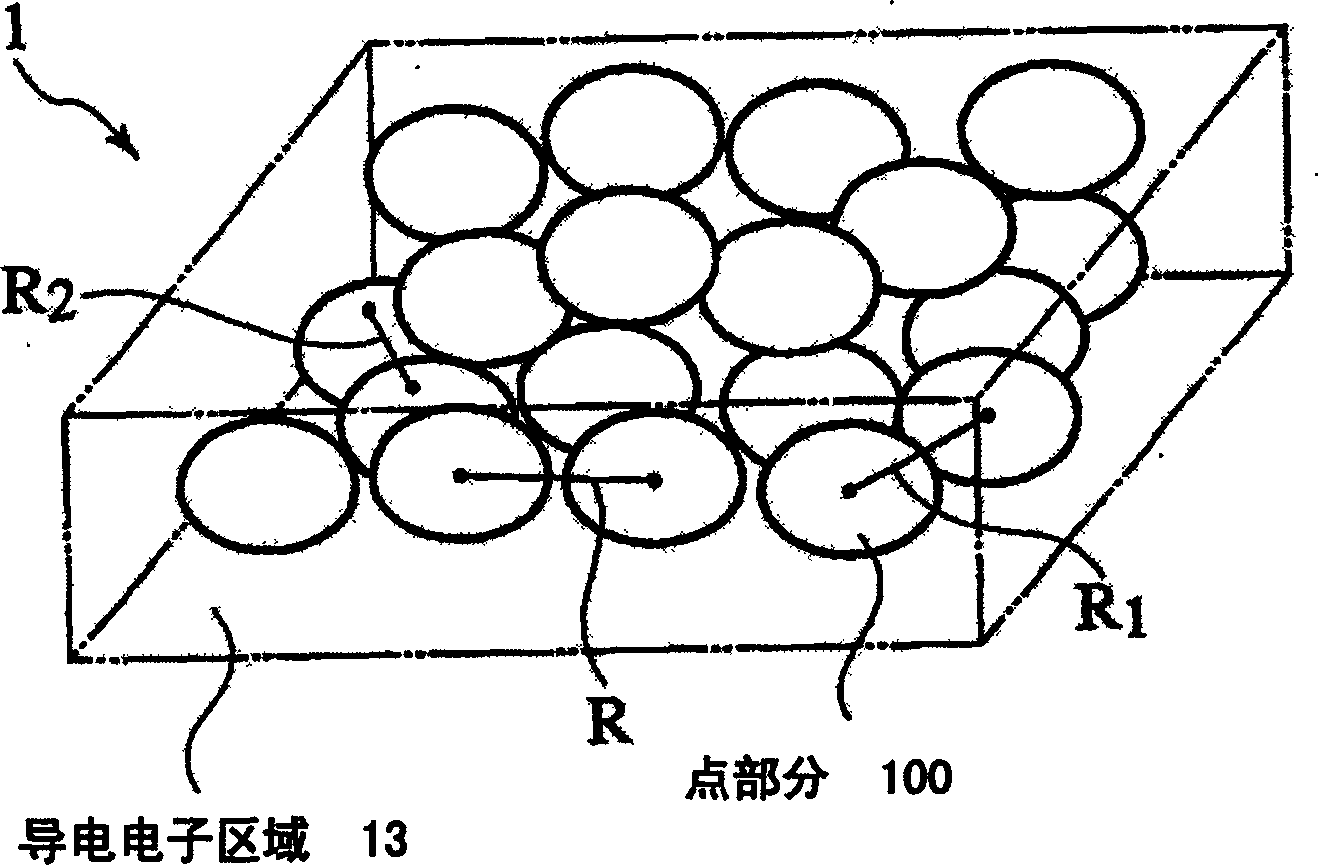

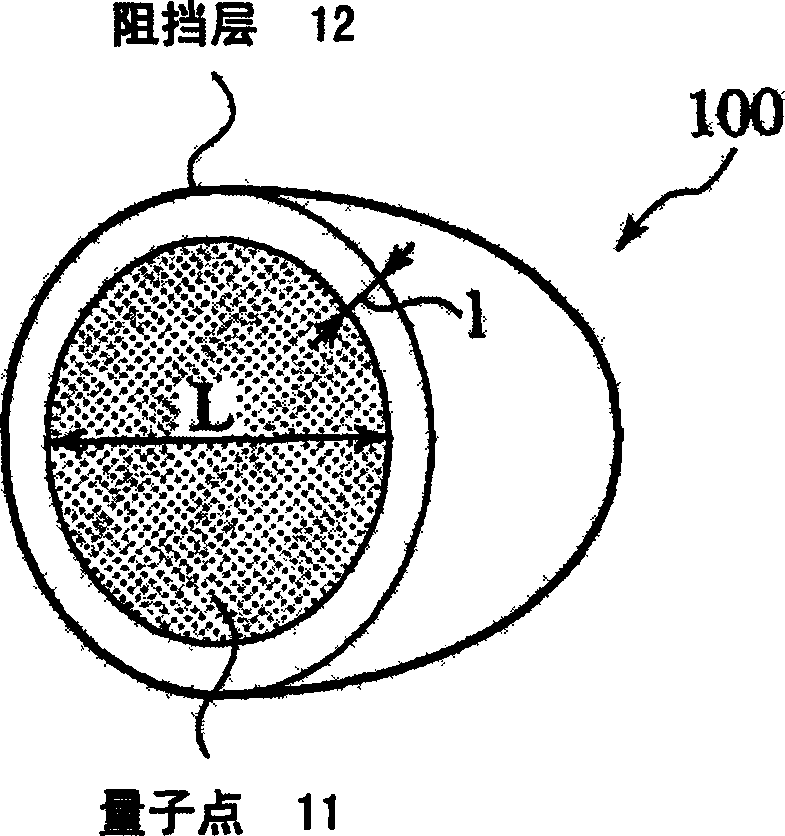

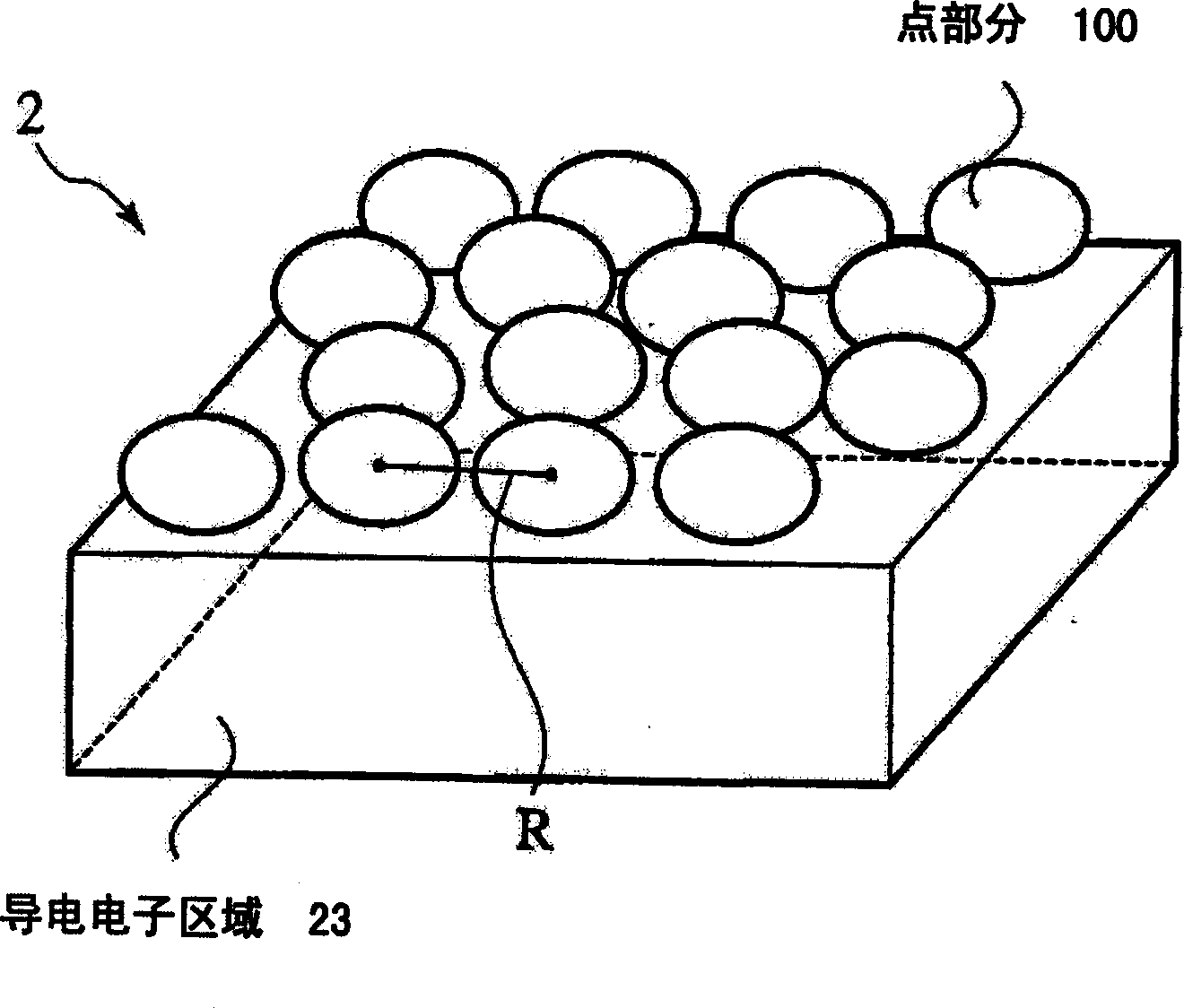

Magnetic body, apparatus using the same and its mfg. method

InactiveCN1494091AEasy to manufactureNanomagnetismInductances/transformers/magnets manufactureHigh energySpins

A magnetic body composed of non-magnetic material, includes a plurality of localized electron regions in each of which at least one electron is confined to form a localized spin, a barrier potential region having a higher energy than a Fermi energy of an electron in the localized electron region and permitting an electron to be confined in the respective localized electron regions, and a conductive electron region including a conductive electron system having a lower energy than an energy of the barrier potential region, wherein the respective localized electron regions are disposed separate from one another via the barrier potential region and the conductive electron region.

Owner:NIPPON TELEGRAPH & TELEPHONE CORP

Perpendicular magnetic recording disk and manufacturing method thereof

ActiveUS20070148499A1Improve recording densityImprove signal-to-noise ratioNanomagnetismVacuum evaporation coatingAlloyRecording layer

A magnetic disk 10 for use in perpendicular magnetic recording has at least a magnetic recording layer on a substrate 1. The magnetic recording layer is composed of a ferromagnetic layer 5 of a granular structure containing silicon (Si) or an oxide of silicon (Si) between crystal grains containing cobalt (Co), a stacked layer 7 having a first layer containing cobalt (Co) or a Co alloy and a second layer containing palladium (Pd) or platinum (Pt), and a spacer layer 6 interposed between the ferromagnetic layer 5 and the stacked layer 7. After forming the ferromagnetic layer 5 on the substrate 1 by sputtering in an argon gas atmosphere, the stacked layer 7 is formed by sputtering in the argon gas atmosphere at a gas pressure lower than that used when forming the ferromagnetic layer 5.

Owner:WESTERN DIGITAL TECH INC

Electromagnetic wave absorbent material

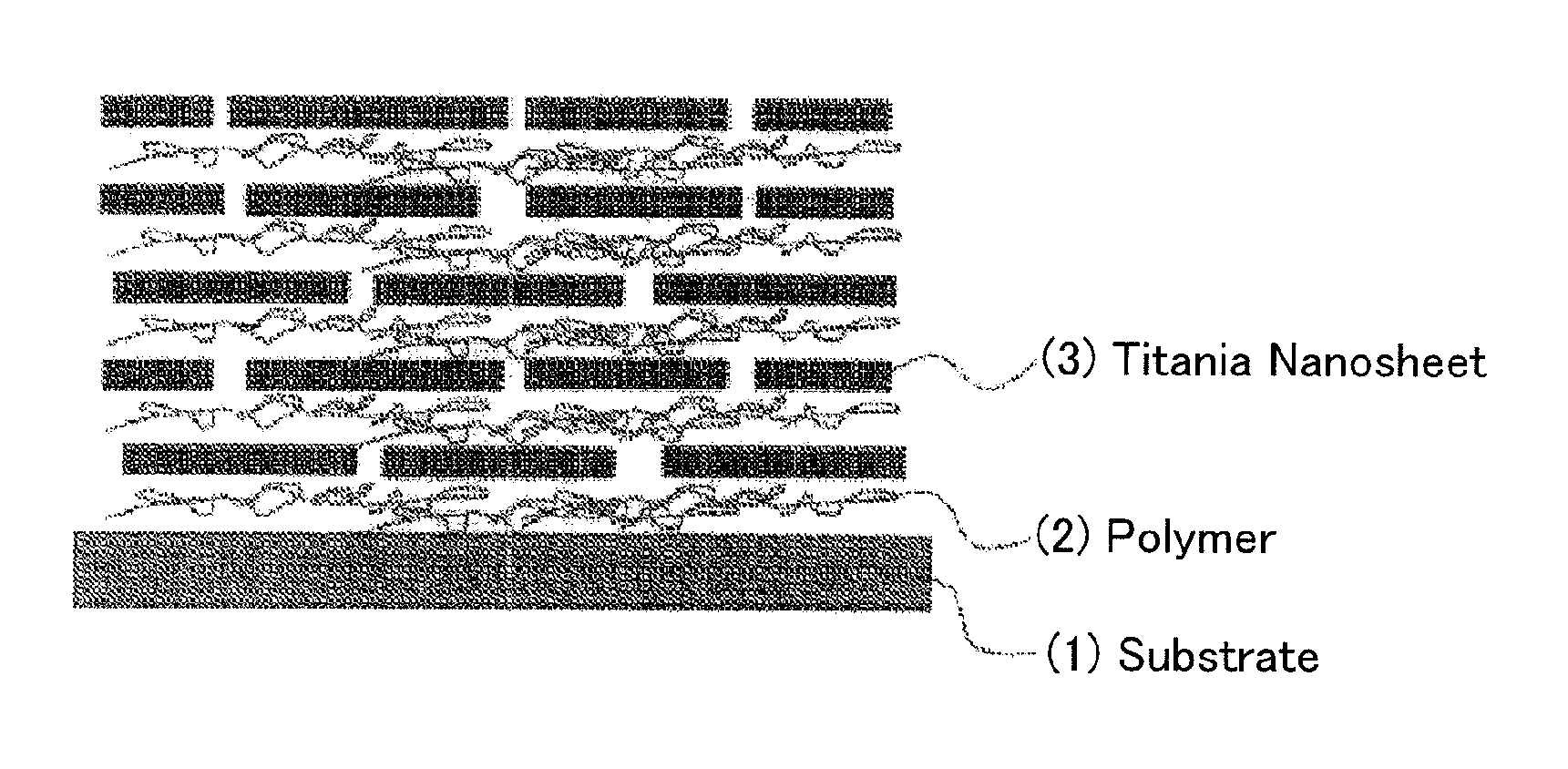

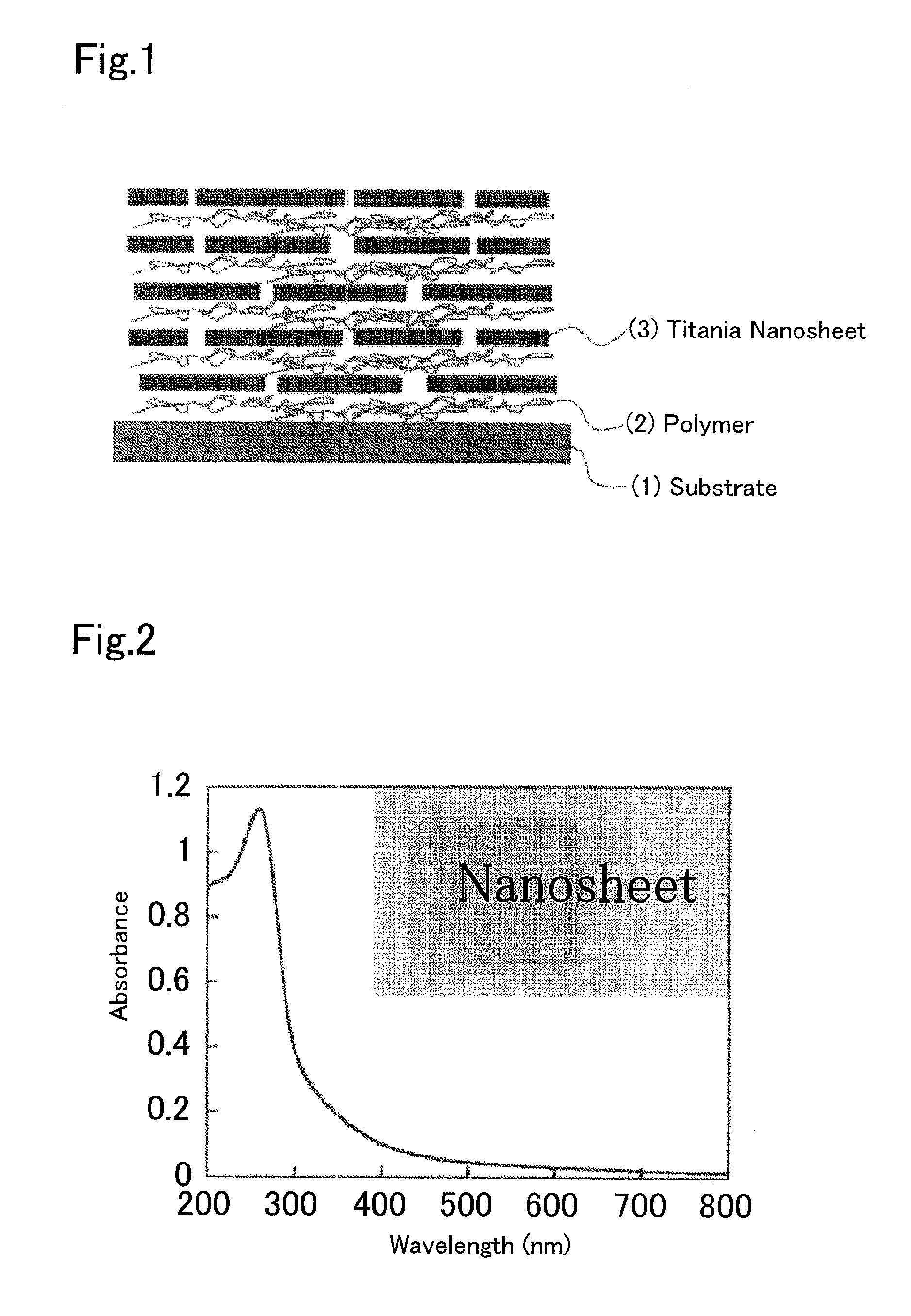

InactiveUS20110183133A1Low costEasy to controlAlkali titanatesNanomagnetismAbsorbent materialElectron

Provided is an electromagnetic wave absorbent material comprising a magnetic film as the main constituent thereof. The magnetic film comprises a titania nanosheet where a 3d magnetic metal element is substituted at the titanium lattice position. The electromagnetic wave absorbent material stably and continuously exhibits electromagnetic wave absorption performance in a range of from 1 to 15 GHz band and is useful as mobile telephones, wireless LANs and other mobile electronic instruments. The absorbent material can be fused with a transparent medium and is applicable to transparent electronic devices such as large-sized liquid crystal TVs, electronic papers, etc.

Owner:NAT INST FOR MATERIALS SCI

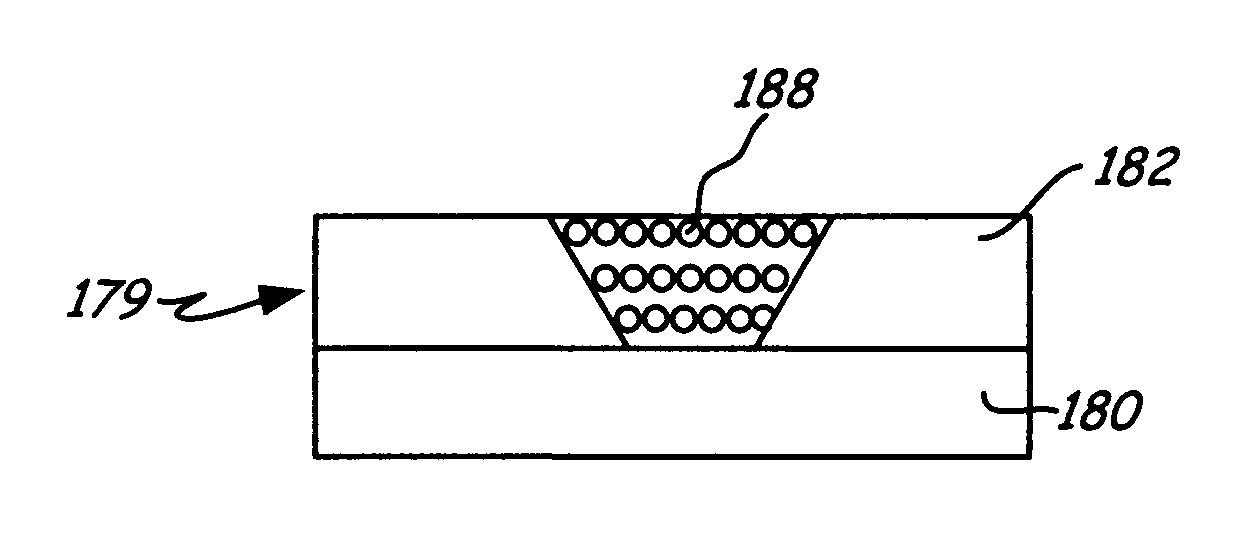

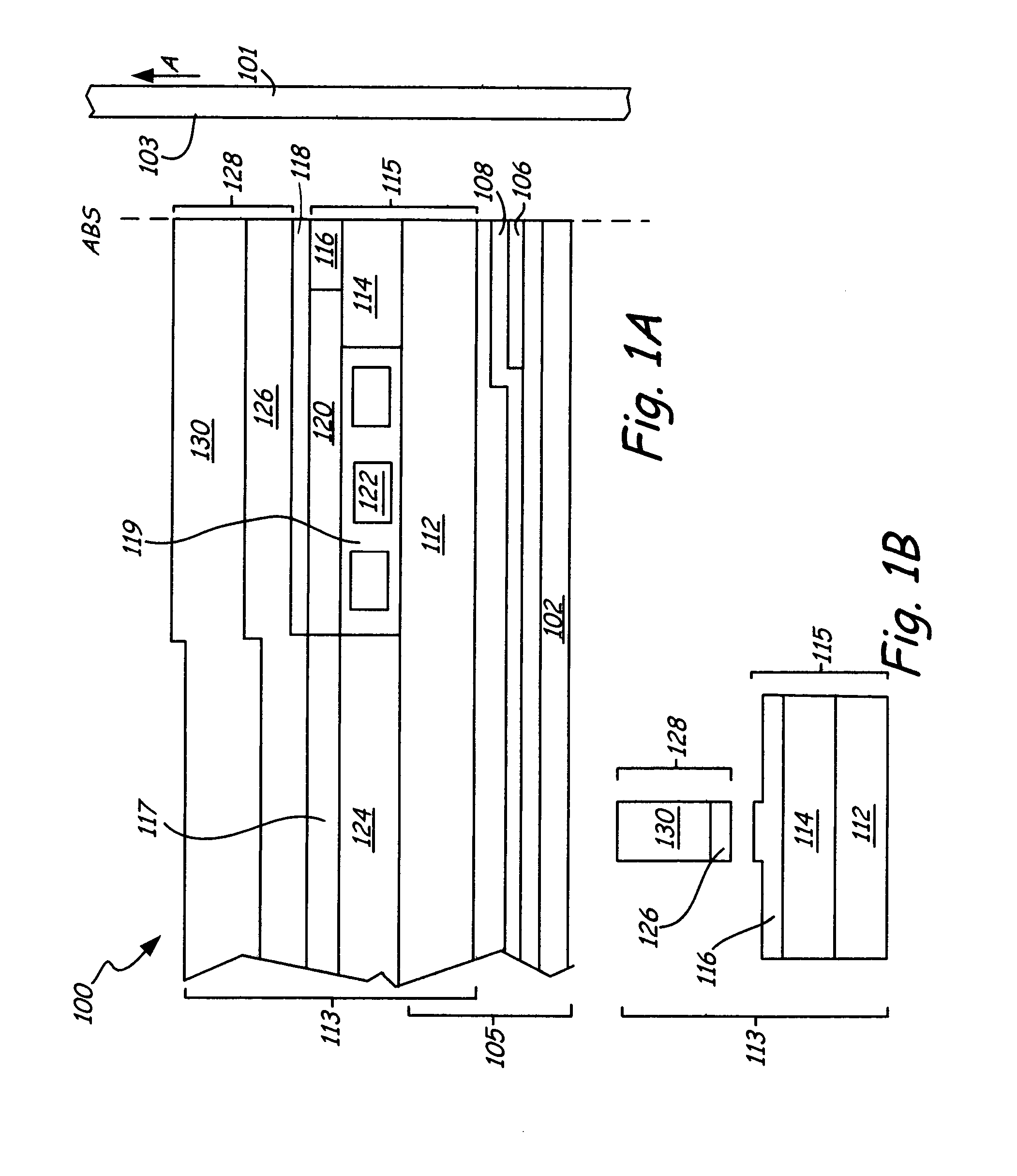

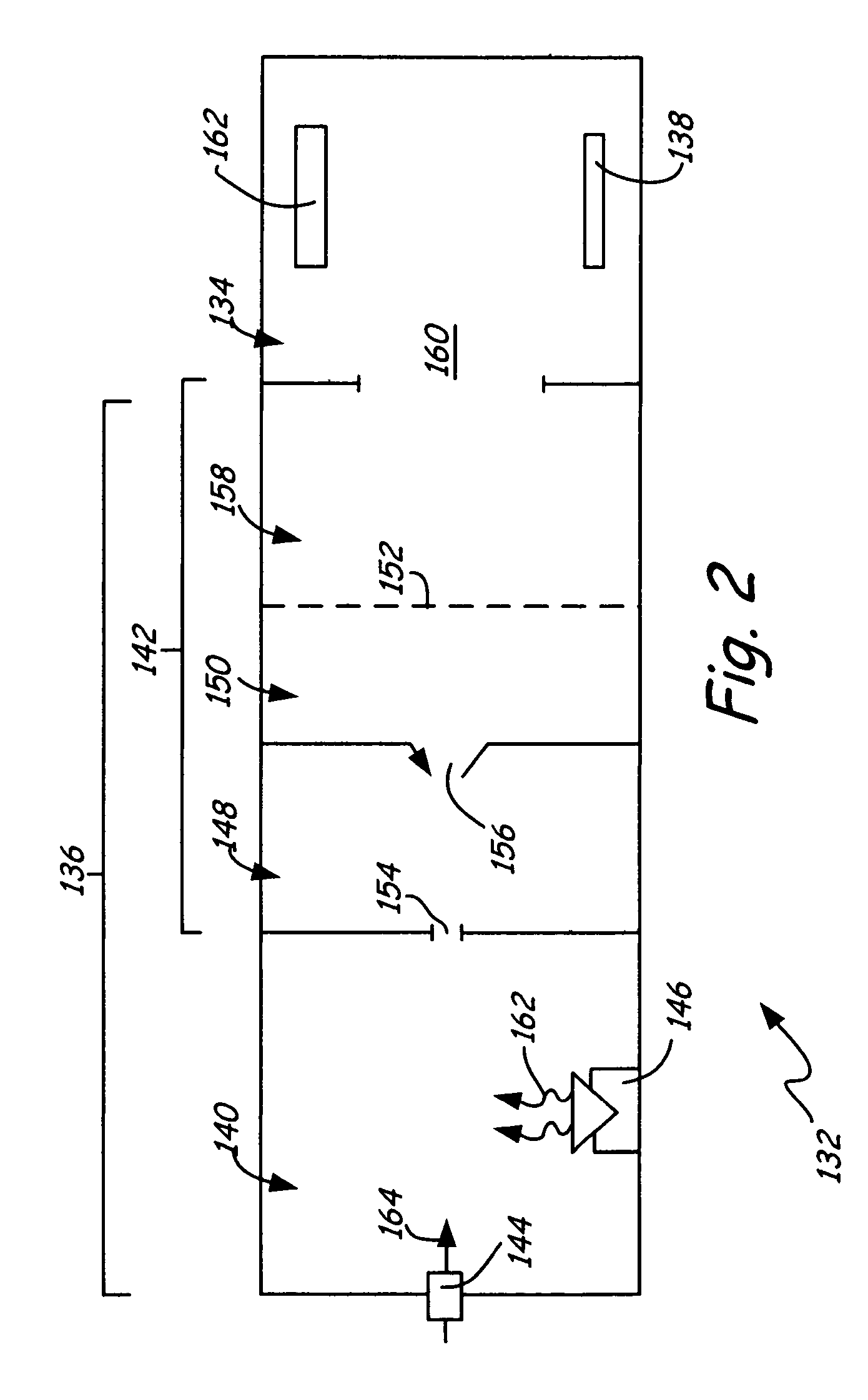

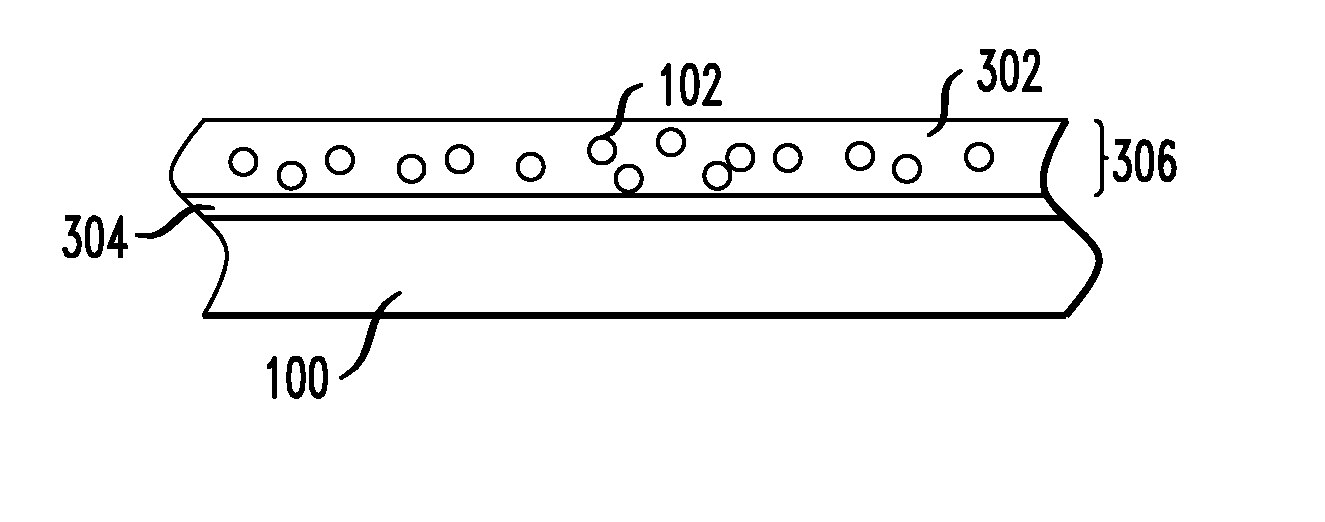

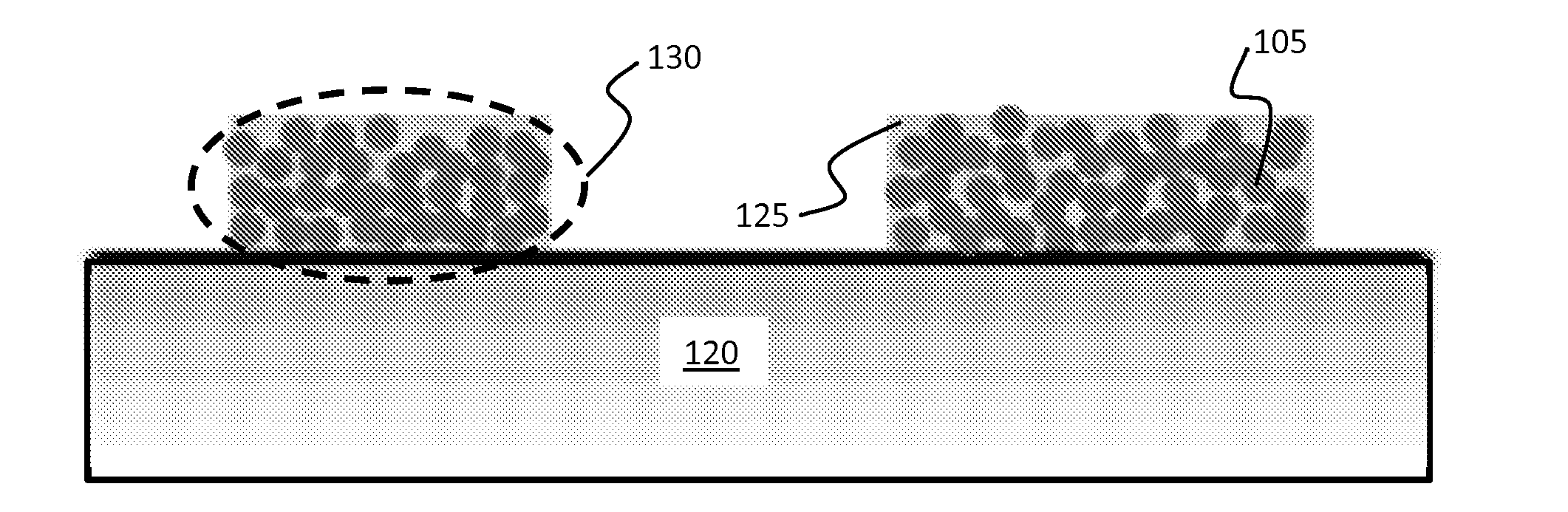

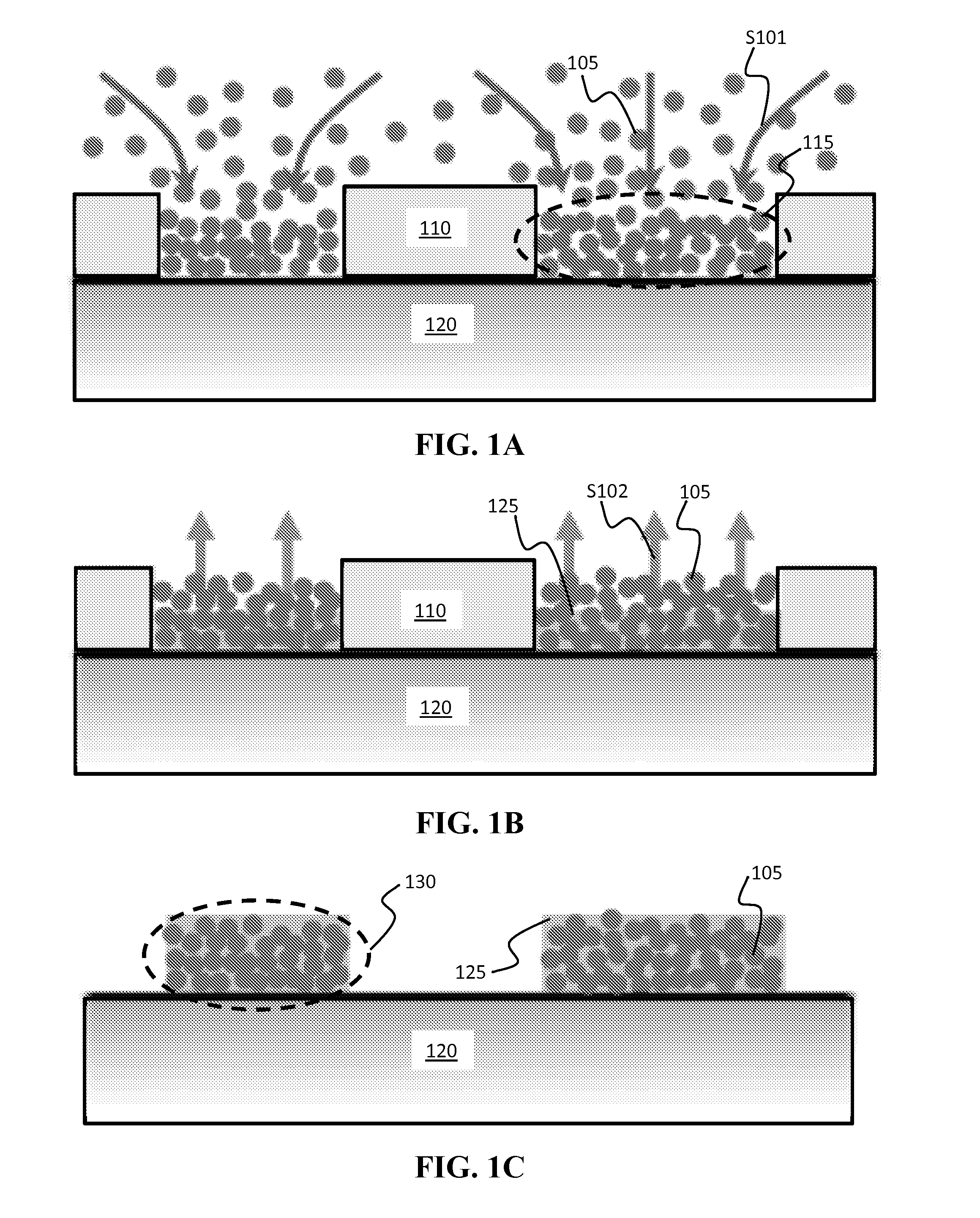

Nanoclustered magnetic materials for high moment write pole applications

The present invention includes magnetic write elements with portions formed a nanophase high magnetic moment material to enable further increases in areal density in magnetic recording. The nanophase deposited high magnetic moment material comprises coated nanoclusters and nanolaminated cluster films that are deposited to form nanophase high magnetic moment material portions of a write pole and SUL layer in perpendicular recording media. The nanophase write poles exhibit high magnetic moments and are generally compatible with conventional writer head fabrication techniques.

Owner:SEAGATE TECH LLC

Granular magnetic thin film and method for making the same, multilayered magnetic film, magnetic components and electronic equipment

InactiveUS7060374B2Enhanced magnetizationReduce in quantityNanostructure applicationNanomagnetismHigh resistivityElectron

Owner:TAIYO YUDEN KK

Magnetic materials having superparamagnetic particles

InactiveUS20070224454A1Increase dampingLow coercivityNanostructure applicationNanomagnetismHost materialSuperparamagnetism

Magnetic materials and uses thereof are provided. In one aspect, a magnetic film is provided. The magnetic film comprises superparamagnetic particles on at least one surface thereof. The magnetic film may be patterned and may comprise a ferromagnetic material. The superparamagnetic particles may be coated with a non-magnetic polymer and / or embedded in a non-magnetic host material. The magnetic film may have increased damping and / or decreased coercivity.

Owner:GLOBALFOUNDRIES INC

Ferromagnetic powder, and coating material and magnetic recording medium using same

InactiveUS20070059557A1Reduce noiseImprove carrier-to-noise ratioMaterials with cobaltSynthetic resin layered productsVolumetric Mass DensityMaterials science

A magnetic powder is provided composed of particles having a balanced shape and distribution, the particles having a small, uniform volume, making it possible to achieve improved density and reliability of a coating type magnetic recording medium. The magnetic powder has Fe as a main component, and is comprised of particles having a cross-section perpendicular to the particle major axis that is substantially round or elliptical, wherein a standard geometrical deviation indicating the variation in cross-sectional area thereof is within the range of 1.01 to 3.0. The invention is also directed to a magnetic powder in which the standard geometrical deviation indicating the variation in the particle volume is within the range of 1.01 to 4.0, and the standard geometrical deviation indicating variation in the flat acicularity is within 1.01 to 2.0.

Owner:DOWA ELECTRONICS MATERIALS CO LTD

Nanocomposite magnetic materials for magnetic devices and systems

Nanocomposite magnetic materials, methods of manufacturing nanocomposite magnetic materials, and magnetic devices and systems using these nanocomposite magnetic materials are described. A nanocomposite magnetic material can be formed using an electro-infiltration process where nanomaterials (synthesized with tailored size, shape, magnetic properties, and surface chemistries) are infiltrated by electroplated magnetic metals after consolidating the nanomaterials into porous microstructures on planar substrates. The nanomaterials may be considered the inclusion phase, and the magnetic metals may be considered the matrix phase of the multi-phase nanocomposite.

Owner:UNIV OF FLORIDA RES FOUNDATION INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com