Magnetic thin film, magnetic component that uses this magnetic thin film, manufacturing methods for the same, and a power conversion device

a technology of magnetic thin film and magnetic component, which is applied in the field of magnetic thin film, can solve the problems of difficult control of the film thickness of the magnetic thin film, difficult to obtain a good magnetic quality, and difficult to form a magnetic thin film on top of a semiconductor substrate, etc., and achieves the effect of soft magnetic qualities and easy manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

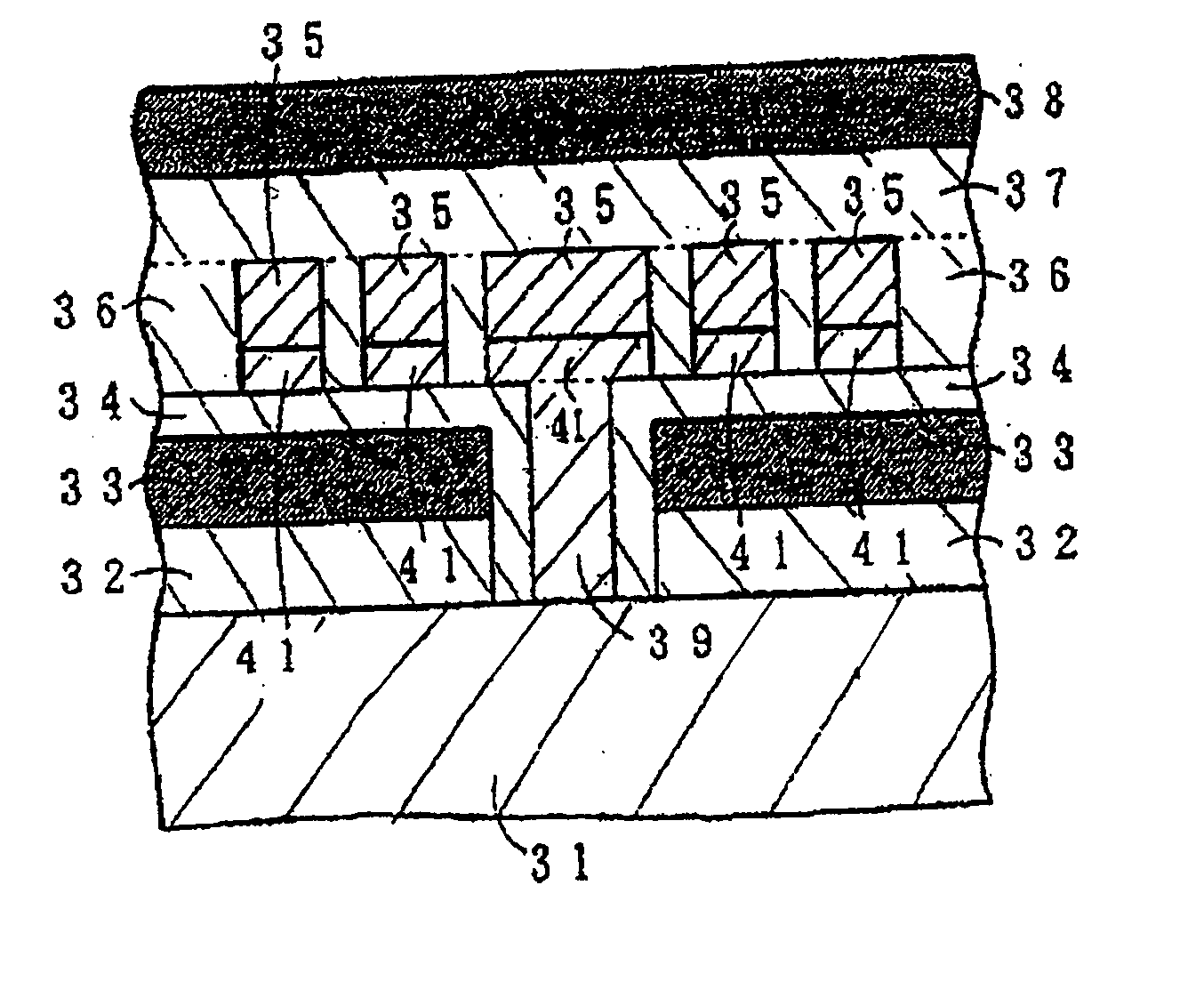

[0163] Referring to FIG. 1, there is a cross-section of the principal part of the magnetic thin film of the present invention. A magnetic particle 2 of size 20 nm is formed by surrounding Fe fine particles with a thin oxide film 3 of a thickness of several nm's. A magnetic thin film 4 has a structure in which magnetic particles 2 are scattered in a polyimide film 1 at approximately 100 nm intervals. Stated differently, magnetic thin film 4 has a structure wherein entities (the aforementioned cells) in which magnetic particles of 20 nm is surrounded by polyimide of approximately 100 nm thickness are placed approximately uniformly in polyimide. Furthermore, in terms of manufacturing the magnetic component, the practicable range for thickness W of magnetic thin film 4 is from several μm to several 10's of μm. If the thickness is less than several μm, it is difficult to achieve a magnetic flux density that is necessary for a magnetic component. As a magnetic component, adequate magnetic...

fourth embodiment

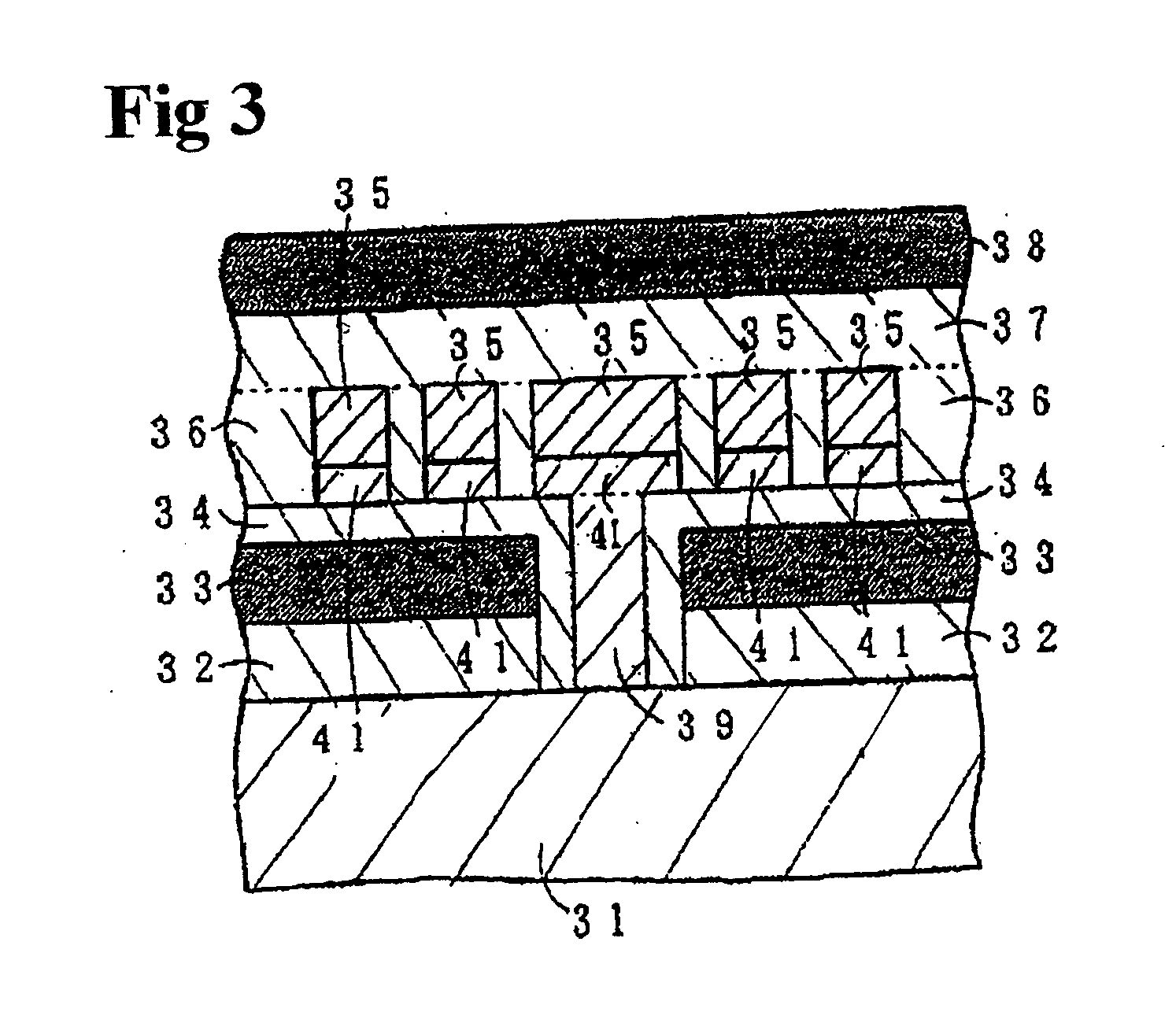

[0179] Polyimide film 62 is formed on top of silicon substrate 61 with a built-in semiconductor element. In the same manner as in the fourth embodiment, Fe particles that have their surfaces covered with an oxide and that have a particle size of 20 nm are dispersed in a non-photosensitive polyimide. This is rotation coated at a rotation frequency of 500 rpm and baked. Magnetic thin film 63 of thickness 20 μm is formed on top of polyimide film 62. On top of magnetic thin film 63, in the same manner as in the prior art, a plating electrode of Ti / Au film 64 and Ti / Au connection conductor 69 are formed (FIG. 6(a)). Next, photosensitive polyimide in which magnetic particles are dispersed is rotation coated at a rotation frequency of 200 rpm and baked. This is exposed to light and developed, and plating mask 65 with a thickness of 30 μm is formed. As with the prior art, Cu coil 66 with a thickness of 30 μm and a turn number of 16 is formed (FIG. 6(b)). Again, on top of this, non-photosens...

seventh embodiment

[0180] Referring to FIG. 7, a cross-section diagram of the principal parts of a thin film inductor of the present invention is shown.

[0181] A polyimide film 72 is formed on top of a silicon substrate 71 in which a semiconductor element is built in. On top of polyimide film 72, a magnetic thin film 73 with a thickness of 10 μm is formed. With magnetic thin film 73, Fe fine particles that are covered with an oxide film and that have an average particle size of 20 nm are aggregated as in FIG. 13. On top of magnetic thin film 73, a plating electrode of a Ti / Au film 74 and a connection conductor 79 which connects with silicon substrate 71 are formed. On top of this, a Cu coil 76 of thickness 30 μm and 16 turns is formed. A magnetic thin film 78 in which Fe fine particles are aggregated is formed between and above Cu coil 76, and the thin film inductor is completed. Compared with the third and fifth embodiments, the magnetic bonding is strong because there is no resin (however, because fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com